Environmental-friendly writing ink for white board pen

A whiteboard pen, an environmentally friendly technology, applied in the field of ink, can solve problems such as poor writing, poor storage stability, and unfavorable human health, and achieve the effects of smooth writing, stable product performance, and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take cyanine pigment 10g, hydroxypropyl methylcellulose 12g, sodium dodecylbenzenesulfonate 8g, castor oil 10g, attapulgite (90% purity) 10g, ethanol (mass content 95%) 40g, remove 160g of ionized water.

[0019] The preparation method is:

[0020] (1) Pulverize the attapulgite to the nanometer level, that is, the particle size is less than 100nm;

[0021] (2) Add the cyanine pigment to 5 times the weight of deionized water, heat to 45°C and stir until the cyanine pigment is completely dissolved;

[0022] (3) Add step (1) nano-scale attapulgite, step (2) cyanine pigment aqueous solution, hydroxypropyl methylcellulose, sodium dodecylbenzenesulfonate, castor oil and ethanol to the remaining deionized water , stir for 30-60 minutes, mix well;

[0023] (4) Stand still for 2 hours to get dark blue ink.

Embodiment 2

[0025] Take magenta pigment (natural pigment extracted from the female body of tropical insect cochineal, generally classified as plant pigment) 8g, hydroxypropyl methylcellulose 6g, sodium dodecylbenzenesulfonate 6g, castor oil 4g, attapulgite Soil (90% purity) 6g, ethanol (95% mass content) 30g, deionized water 100g.

[0026] The preparation method is:

[0027] (1) Pulverize the attapulgite to the nanometer level, that is, the particle size is less than 100nm;

[0028] (2) Add the magenta pigment to 5 times the weight of deionized water, heat to 40°C and stir until the magenta pigment is completely dissolved;

[0029] (3) Add step (1) nano-scale attapulgite, step (2) aqueous solution of magenta pigment, hydroxypropyl methylcellulose, sodium dodecylbenzenesulfonate, castor oil and ethanol to the remaining deionized water, Stir for 30-60 minutes, mix well;

[0030] (4) Leave it to stand for 2 hours to get pink ink.

Embodiment 3

[0032] Take rouge pigment 16g, hydroxypropyl methylcellulose 8g, sodium dodecylbenzenesulfonate 8g, castor oil 6g, attapulgite (90% purity) 14g, ethanol (mass content 95%) 50g, deionized 120g of water.

[0033] The preparation method is:

[0034] (1) Pulverize the attapulgite to the nanometer level, that is, the particle size is less than 100nm;

[0035] (2) Add the rouge pigment to 4 times the weight of deionized water, heat to 40°C and stir until the rouge pigment is completely dissolved;

[0036] (3) Add step (1) nano-scale attapulgite, step (2) rouge pigment aqueous solution, hydroxypropyl methylcellulose, sodium dodecylbenzenesulfonate, castor oil and ethanol to the remaining deionized water, Stir for 30-60 minutes, mix well;

[0037] (4) Stand still for 2 hours to get dark red ink.

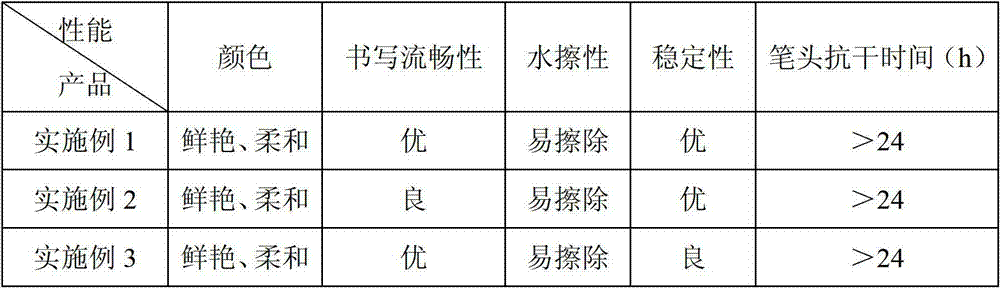

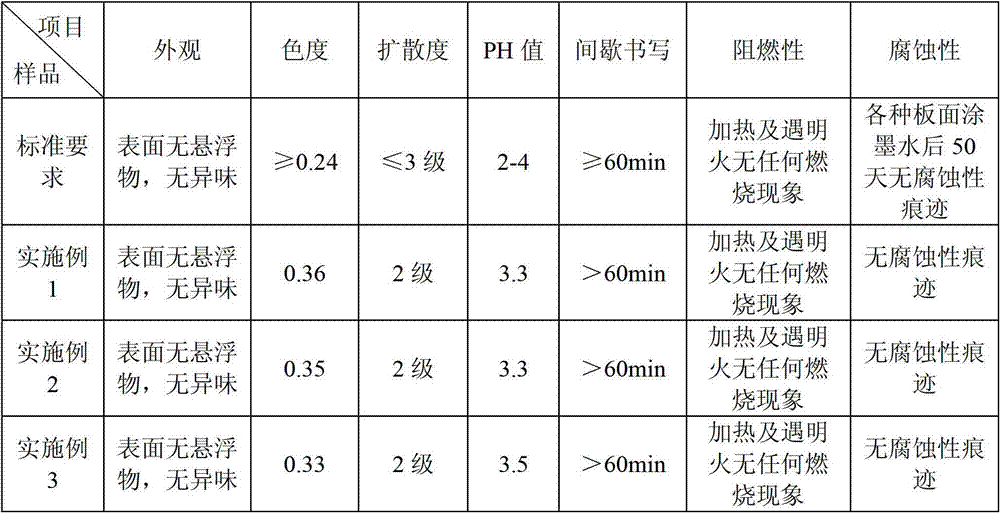

[0038] The inks prepared in Example 1, Example 2 and Example 3 are packed into whiteboard markers respectively, write on the blackboard, observe its color and writing fluency; then wipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com