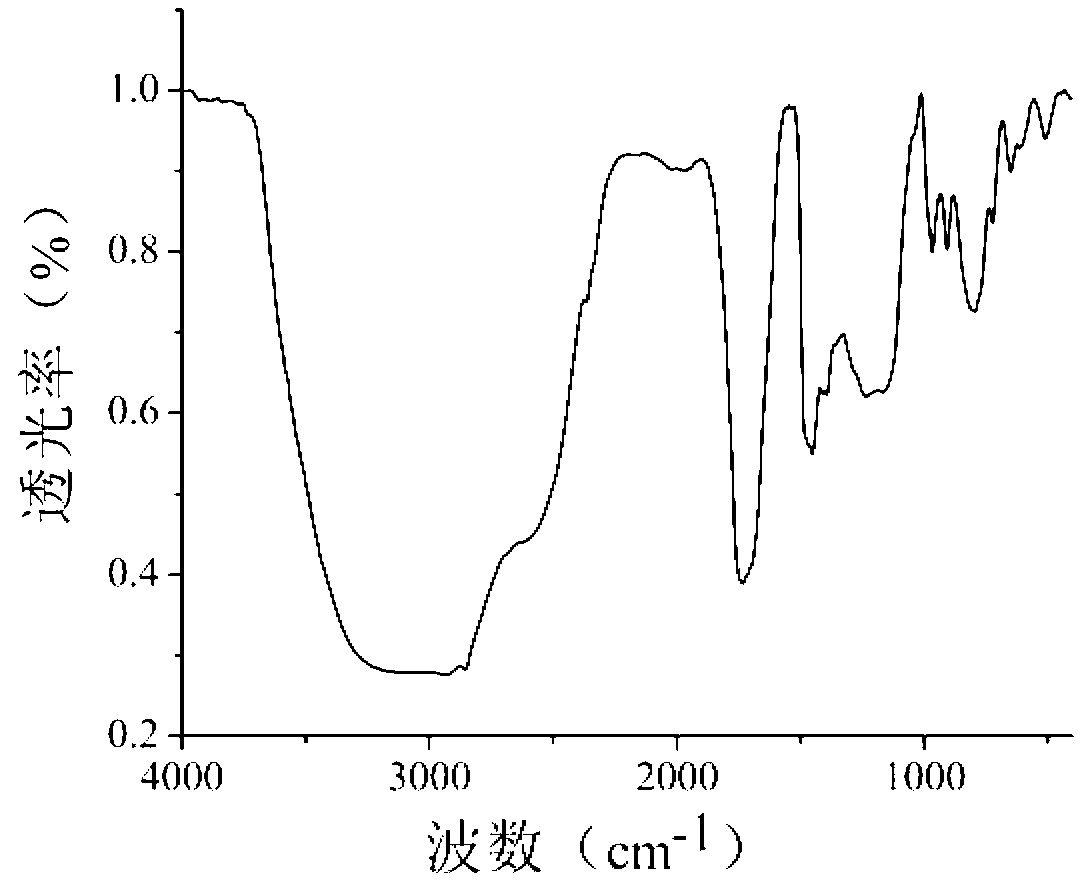

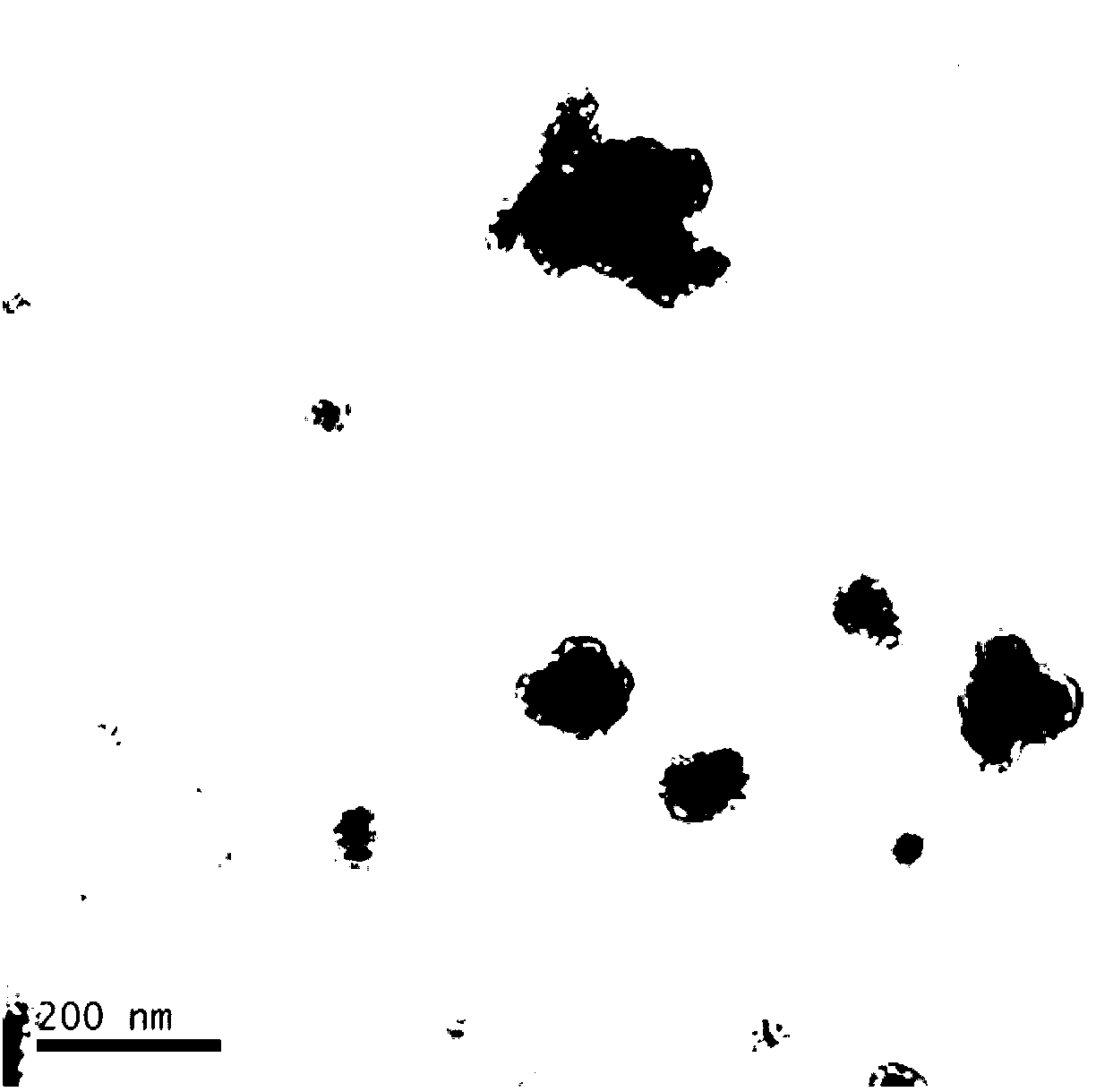

Method for preparing nano titanium dioxide/polyacrylate compound emulsion

A technology of nano-titanium dioxide and polyacrylate, which is applied in the field of composite emulsion, can solve the problems of complicated process and easy agglomeration of nano-titanium dioxide, and achieve the effects of simplifying the process, improving compatibility and avoiding secondary agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] At room temperature, mix 4g of cetyltrimethylammonium bromide (CTAB), 6g of acrylic acid (AA) and 10g of methyl methacrylate (MMA) evenly, and slowly add 14g of deionized water dropwise until the system becomes Clarification; add 2g of butyl titanate and 1g of γ-methacryloxypropyltrimethoxysilane (A-174), control the addition rate to 0.4-0.6g / min, and then stir at room temperature for 24h to obtain Organic nano titanium dioxide system. Add 30g of deionized water to the organic nano-titanium dioxide system, disperse at a speed of 1500rpm / min for 15min, and continue to ultrasonically disperse in an ultrasonic cell disruptor for 10min; In the mixed liquid reactor, heat up to 75°C, stir at a speed of 100rpm / min for 30min, drop the mixed liquid containing 0.1g potassium persulfate and 5g deionized water within 2h, keep warm for 2h, then heat up to 80°C , continue the heat preservation reaction for 1 hour, and finally lower to room temperature to obtain nano-titanium dioxide...

Embodiment 2

[0022] At room temperature, mix 6g of cetyltrimethylammonium bromide (CTAB), 8g of acrylic acid (AA), 10g of methyl methacrylate, and 10g of butyl acrylate, and then slowly drop 15g of deionized water into the system Become clear; add 2.5g butyl titanate and 1.5g vinyltrimethoxysilane (A-171), control the addition rate to 0.4-0.6g / min, then stir at room temperature for 12h to prepare organic nano-titanium dioxide system. Add 40g of deionized water to the organic nano-titanium dioxide system, disperse at a speed of 2500rpm / min for 10min, and continue to ultrasonically disperse in an ultrasonic cell disruptor for 30min; In a liquid reactor, heat up to 70°C and stir for 40min at a speed of 120rpm / min, add dropwise a mixed solution containing 0.5g potassium persulfate and 10g deionized water within 1h, keep warm for 3h, heat up to 90°C, continue Insulate and react for 2 hours, and finally cool down to room temperature to obtain nano-titanium dioxide / polyacrylate composite emulsio...

Embodiment 3

[0024] At room temperature, mix 7g of cetyltrimethylammonium bromide (CTAB), 7g of acrylic acid (AA) and 25g of butyl acrylate, and then slowly add 12g of deionized water until the system becomes clear; add 3g of titanium Acrylic acid butyl ester and 1.5g γ-methacryloyloxypropyltrimethoxysilane (A-174), control the addition rate to 0.4-0.6g / min, and then stir at room temperature for 6h to prepare organic nano-titanium dioxide system. Add 35g of deionized water to the organic nano-titanium dioxide system, disperse at a speed of 800rpm / min for 60min, and continue to ultrasonically disperse in an ultrasonic cell disruptor for 10min; In the liquid reactor, heat up to 65°C and stir for 40min at a speed of 120rpm / min, add dropwise a mixture containing 1g ammonium persulfate and 12g deionized water within 2h, keep warm for 2h, heat up to 85°C, and continue to keep warm React for 2 hours, and finally lower to room temperature to obtain nano-titanium dioxide / polyacrylate composite emu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com