Patents

Literature

207results about How to "Guaranteed storage stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

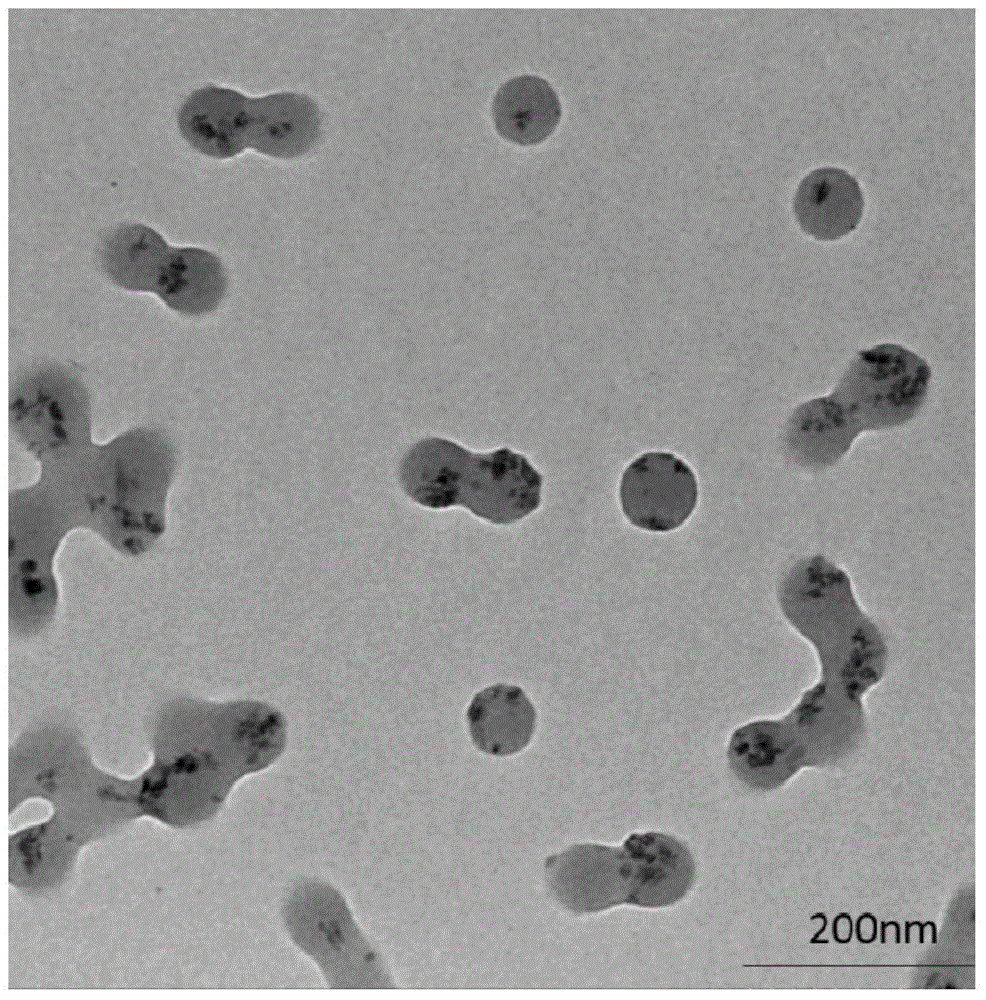

Nanometer titanium dioxide/acrylate polymer composite emulsion and preparation method thereof

The invention discloses a nanometer titanium dioxide / acrylate polymer composite emulsion and a preparation method thereof. The preparation method comprises: modifying nanometer titanium dioxide with a silane coupling agent; dispersing modified nanometer titanium dioxide into a liquid mixed from a monomer and a co-emulsifier; performing ultrasonic dispersion; adding the obtained liquid into an emulsifier aqueous solution; performing stirring; performing secondary ultrasonic dispersion; transferring the obtained liquid to a four-neck flask; elevating the temperate to 60-80 DEG C; adding an initiator; and performing heat preservation for 2-6 h to obtain the nanometer titanium dioxide / acrylate polymer composite emulsion. The nanometer titanium dioxide / acrylate polymer composite emulsion is of an emulsion particle structure, which is a core-shell structure by taking nanometer titanium dioxide as a core, and taking an acrylate polymer as a shell. The nanometer composite emulsion is good in storage stability; nanometer titanium dioxide is excellent in dispersibility and high in coating ratio in the acrylate polymer; and the nanometer composite emulsion is applicable to functional paint, such as ultraviolet-proof paint, self-cleaning paint, and anti-bacteria paint.

Owner:SOUTH CHINA UNIV OF TECH

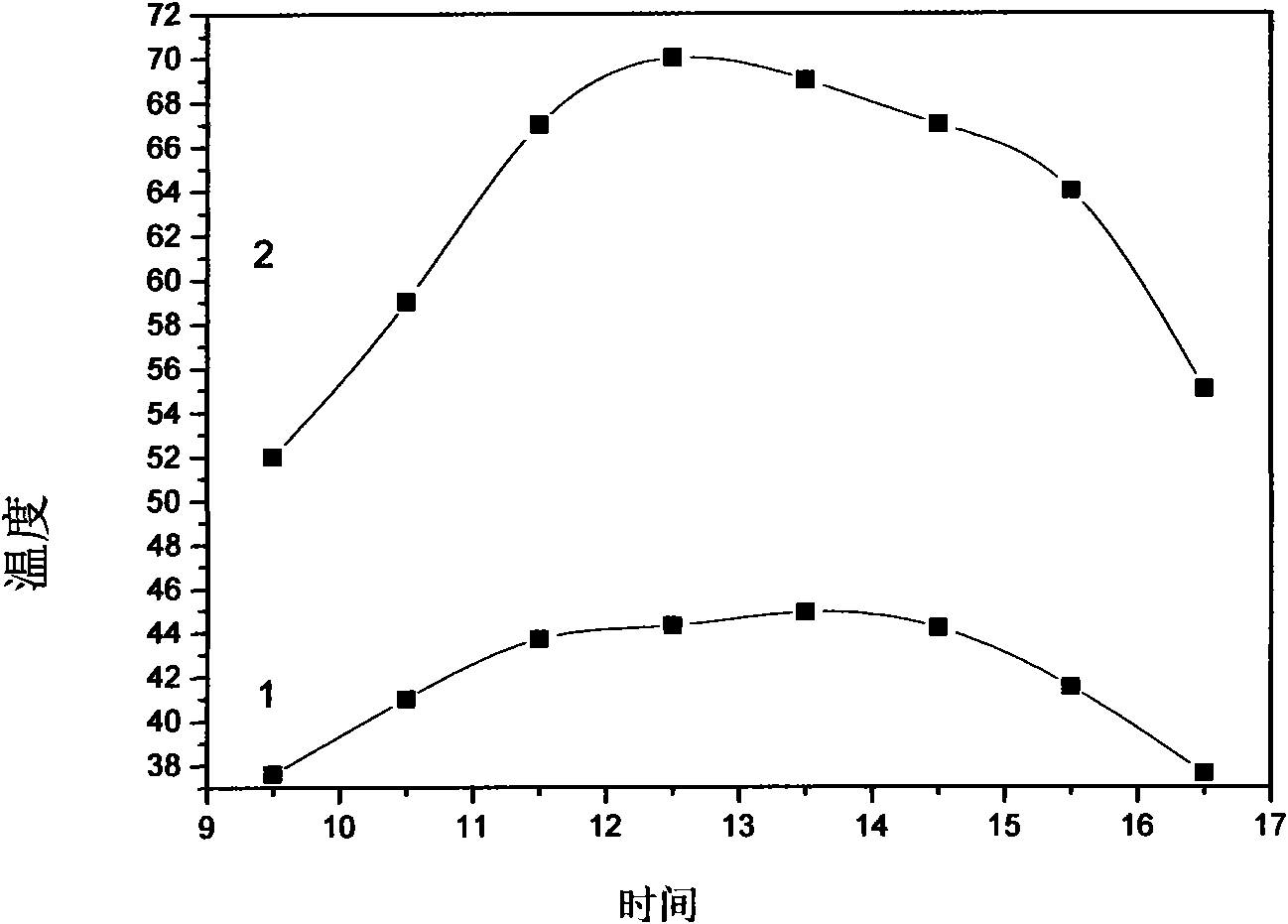

Reflecting thermal insulating paint

InactiveCN101818013AEasy constructionEffective reflectionReflecting/signal paintsWater basedEmulsion

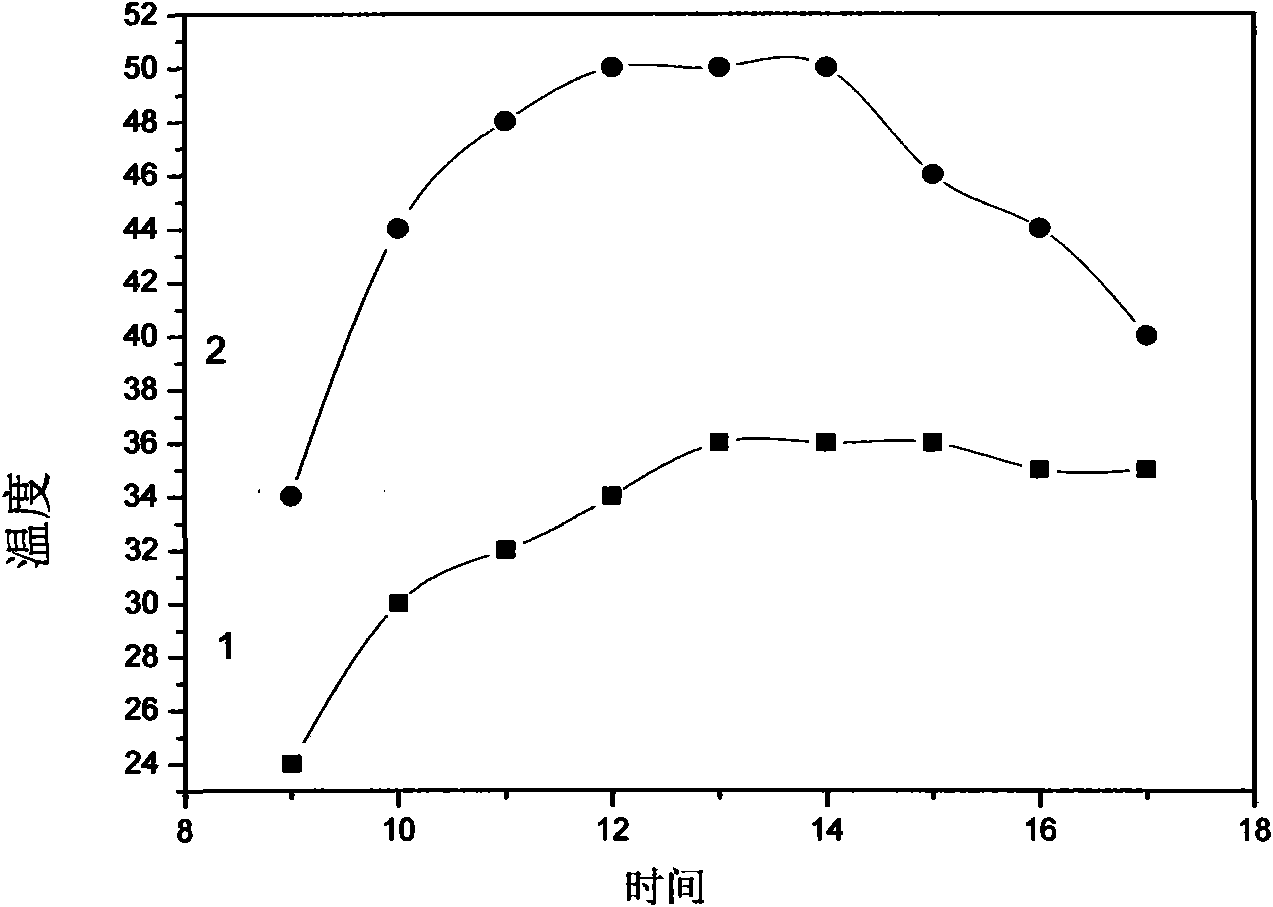

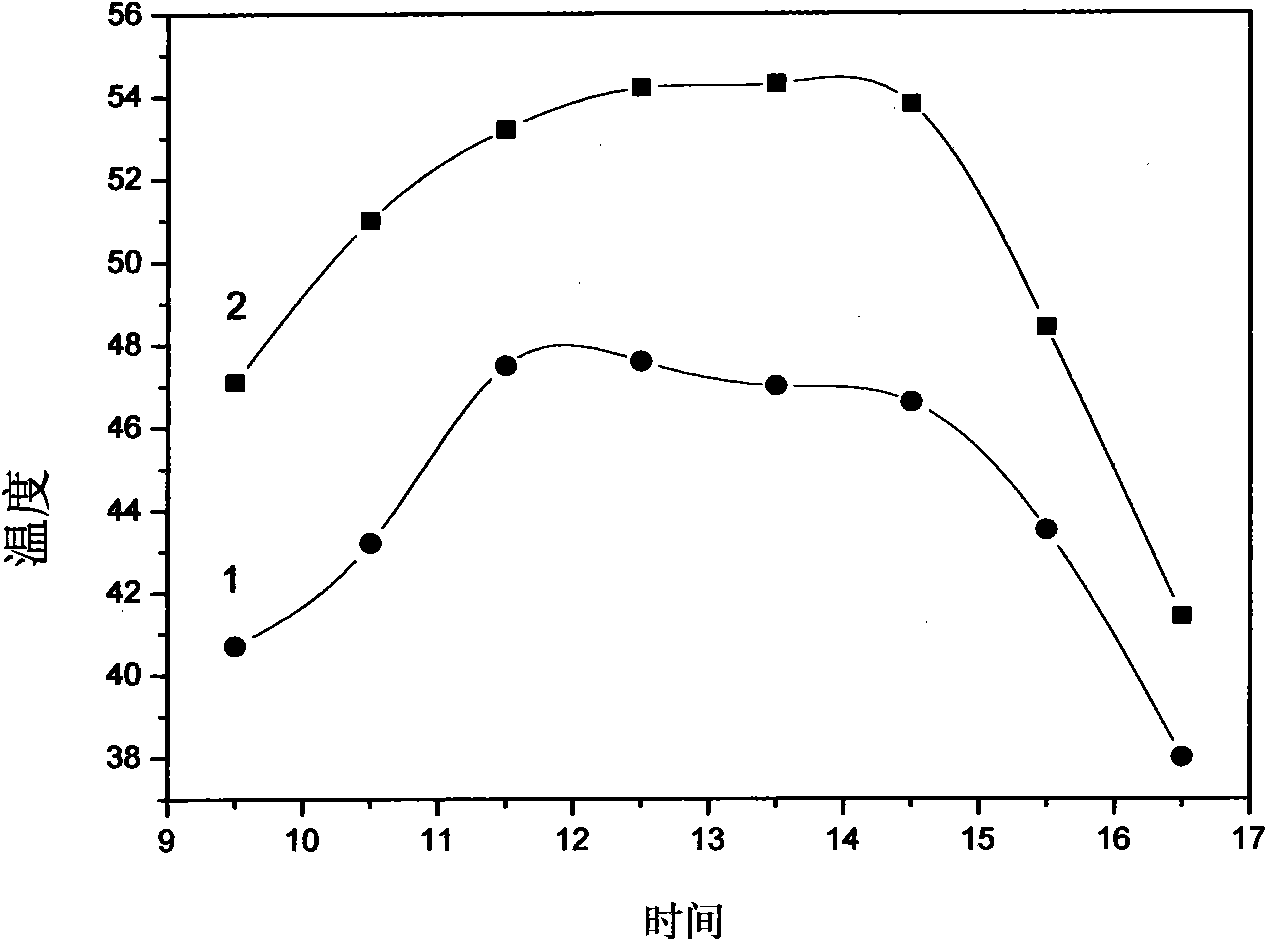

The invention discloses a reflecting thermal insulating paint which comprises the following components in parts by mass: 70 parts to 80 parts of water, 85 parts to 100 parts of rutile type titanium dioxide, 35 parts to 40 parts of cenosphere, 10 parts to 12 parts of far infrared ceramic powder, 6 parts to 10 parts of dispersing agent and 230 parts to 250 pars of pure elasticity acrylic emulsion. The invention also provides a preparation method of the reflecting thermal insulating paint. The reflecting thermal insulating paint belongs to water-based paints, has the advantages of safety and environment protection, has the thermal insulating temperature higher than 10 DEG C, has extensibility,crack resistance and wide application.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

Phosphorus-free film forming agent and preparation method thereof

ActiveCN101643898AImprove anti-corrosion performanceStrong adhesionMetallic material coating processesHydrofluoric acidAlcohol

The invention relates to a phosphorus-free film forming agent comprising the following components by weight percent: 0.5-4 percent of silane coupling agent, 0.5-2 percent of titanate coupling agent, 1-10 percent of fluozirconate or zircon salt, 3-5 percent of alcohol solvent, 0.5-2 percent of hydrofluoric acid or fluorid, 1-5 percent of hydrogen peroxide, 0.5-2 percent of notric acid or nitrate and the balance of deionized water or tap water. The phosphorus-free film forming agent is environment-friendly and can increase adhesive force and corrosion resistance.

Owner:CHANGZHOU JUNHE TECH

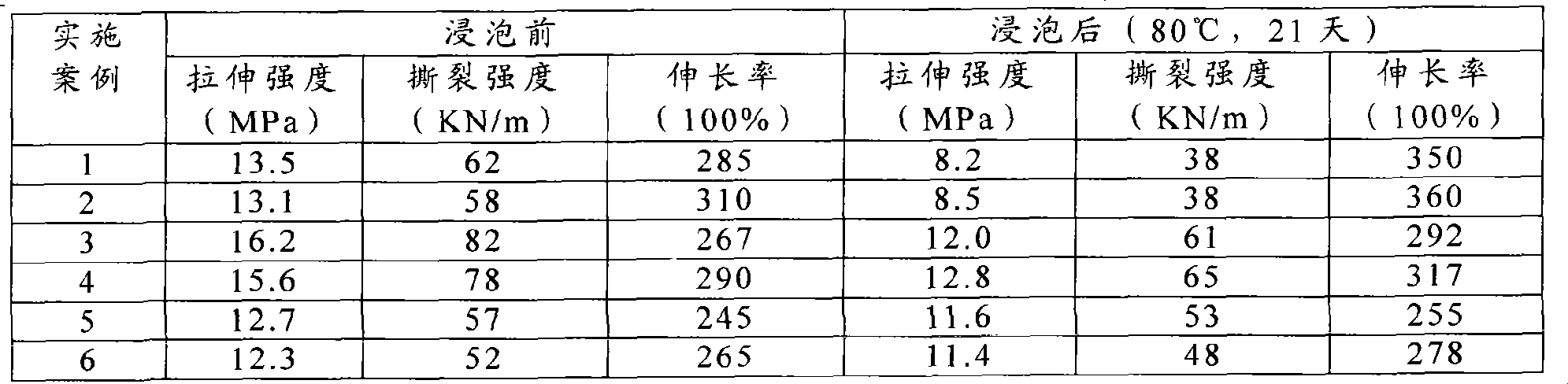

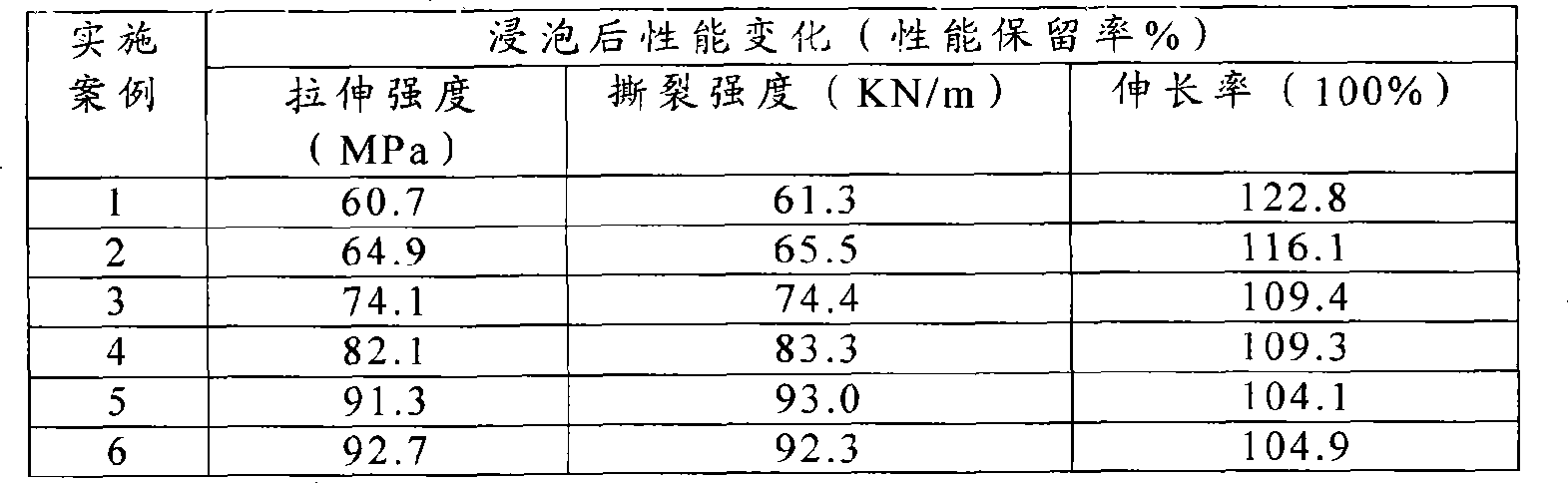

High-temperature resistant water spray coating polyurea flexible composition, preparation, construction method and uses thereof

InactiveCN101368062AGuaranteed storage stabilityGuaranteed viscosityPretreated surfacesAnti-corrosive paintsPrepolymerIsocyanate

The invention provides a high temperature resistant water spray polyurea elastic combination, a preparation and construction method and an applications thereof. The high temperature resistant water spray polyurea elastic combination solves the problem that the high temperature resistance and the water resistance of the prior art are poor, and the scope of application is limited. In the technical proposal, the high temperature resistant water spray polyurea elastic combination comprises a component A and a component R; the component A is a semi-prepolymer which is synthesized by using 35 to 65 portions of polyisocyanates and 35 to 65 portions of polyhydric alcohol; the component R comprises 20 to 50 portions of amine chain extenders and 45 to 80 portions of amine-terminated polyethers. The component A and the component R are used according to the isocyanate index of 1.1. By adopting the high temperature resistant water spray polyurea elastic combination, not only the high temperature resistance and the water resistance of the polyurea elastomer are improved; but also the miscibility and the mechanical property of the material are improved as a whole.

Owner:MARINE CHEM RES INST

Water-borne nano ultra-thin steel structure fire retardant coating and preparation method thereof

The invention discloses a water-borne nano ultra-thin steel structure fire retardant coating, which comprises a carbon source, an acid source, an air source and auxiliaries, and consists of the following components by weight percentage: 20-40% of acrylic ester emulsion, 10-30% of ammonium polyphosphate (APP), 5-15% of pentaerythritol, 1-10% of melamine, 1-10% of nanometer material, 0.001-5% of auxiliaries, and 10-30% of water. The invention also discloses a preparation method of the fire retardant coating. The prepared fire retardant coating has the characteristics of stable performance and good fire resistant performance, the thickness of the prepared fire retardant coating is no more than 2mm, and the fire reissuance duration of the prepared fire retardant coating is up to 120 minutes.

Owner:浙江川科防保材料发展有限公司

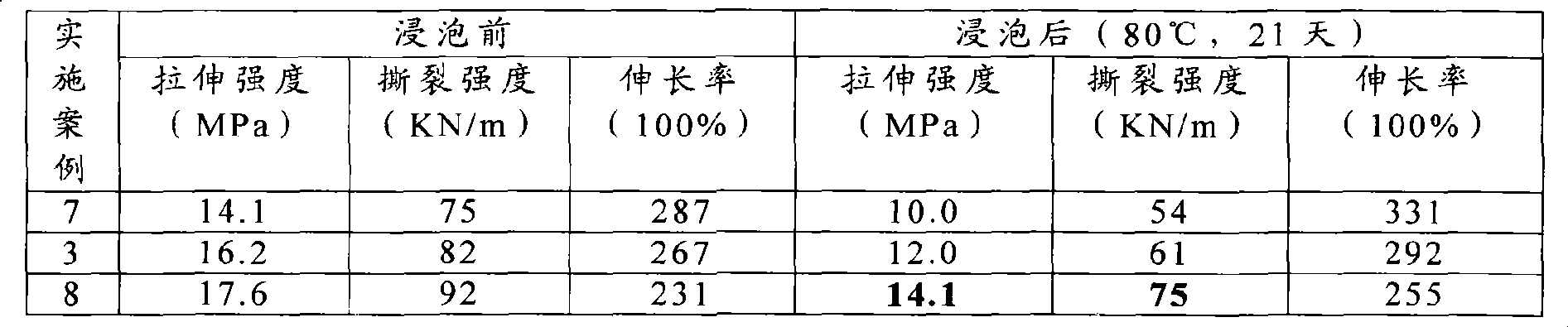

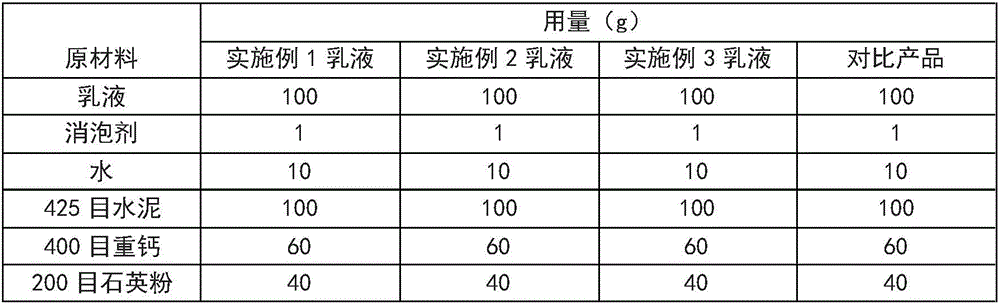

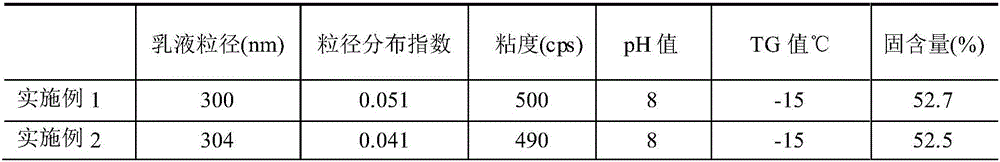

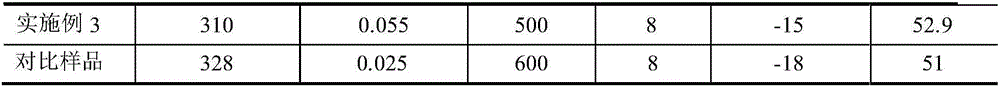

Amine-free waterproof emulsion, preparing method thereof and waterproof coating containing amine-free waterproof emulsion

ActiveCN105949381AHigh hardnessHigh tensile strengthCoatingsHydrophilic monomerPhosphoric Acid Esters

The invention discloses amine-free waterproof emulsion, and belongs to the technical field of waterproof coatings. The amine-free waterproof emulsion comprises, by weight, 40-50 parts of deionized water, 0.6-12.0 parts of emulsifying agent, 0.02-20 parts of phosphoric acid ester monomers, 0.05-40 parts of hydrophilic monomers, 0.05-60 parts of hydrophobic monomers, 0.05-20 parts of polymerization stabilizer, 0.02-5 parts of vinyl silicone, 0.02-5 parts of initiating agent, 0.02-5 parts of chain transfer agent, 0.02-5 parts of pH buffering agent, 0.02-5 parts of antifoaming agent, 0.02-5 parts of preservative and 0.02-5 parts of alkali liquid. The invention further provides a preparing method of the amine-free waterproof emulsion and a waterproof coating containing the amine-free waterproof emulsion. The waterproof emulsion and the waterproof coating are environmentally friendly and free of pollution, and pungent smells such as ammonia smells are not generated.

Owner:HENGSHUI XINGUANG CHEM +1

Rubber powder epoxy resin asphalt material as well as preparation method and using method thereof

ActiveCN103396673AProduction environmental protectionReduce energy consumptionIn situ pavingsBridge structural detailsEpoxyPolymer science

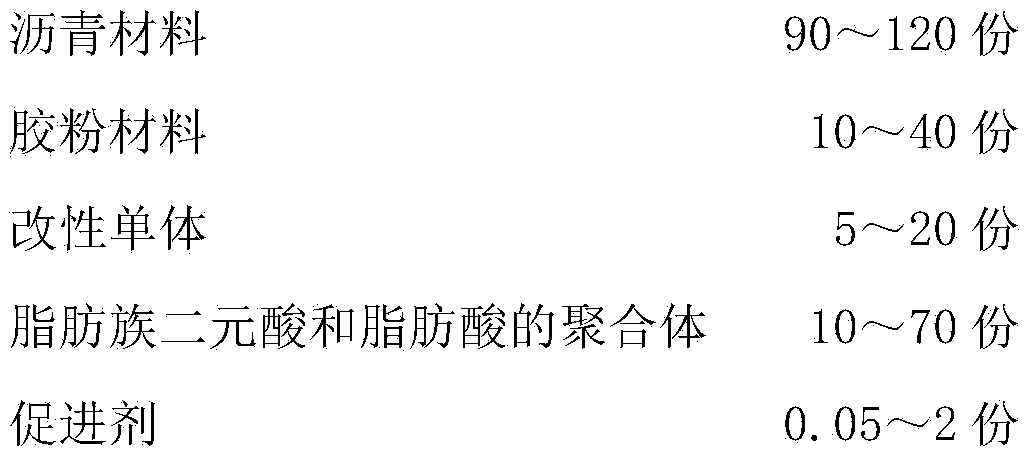

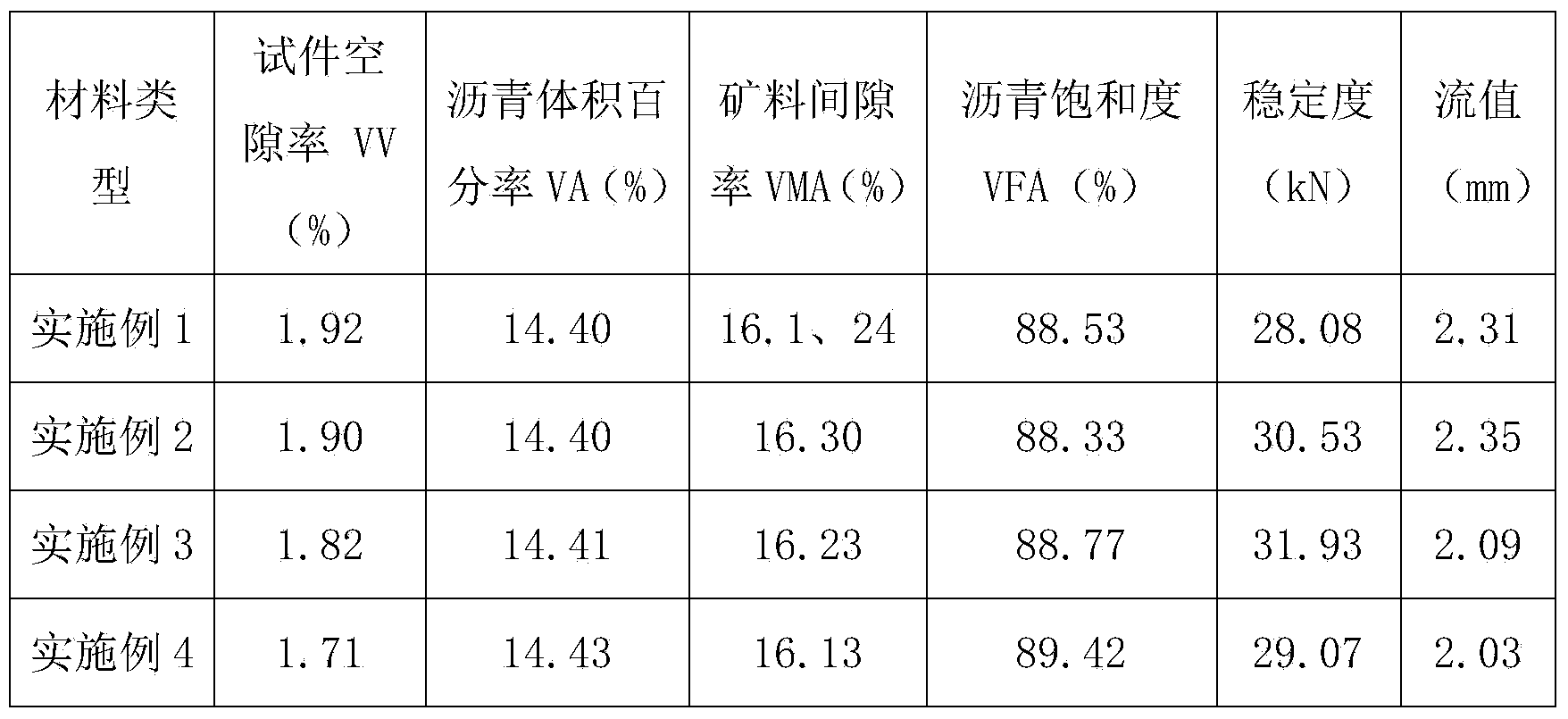

The invention discloses a rubber powder epoxy resin asphalt material, as well as a preparation method and a using method thereof. Modified asphalt comprises an A component and a B component, wherein a weight ratio of the A component to the B component is 1:(2-20); the A component comprises 100 parts of epoxy resin by weight; and the B component comprises 90-120 parts of asphalt material, 10-40 parts of rubber powder material, 5-20 parts of modified monomer, 10-70 parts of fatty group binary acid and fatty acid polymer and 0.05-2 parts of accelerant. According to the rubber powder epoxy resin asphalt material, the rubber powder material is adopted, so that the unit price of the epoxy resin asphalt material can be reduced, the low-temperature flexibility of the epoxy resin asphalt material can be improved, and waste rubber can be fully used; and the rubber powder epoxy resin asphalt material, the preparation method and the using method are energy-saving and environment-friendly. The rubber powder epoxy resin asphalt material can serve as a cementing material of a bonding layer and a waterproof layer of a deck and a pavement, asphalt concrete in road engineering, top dressing and the like, and can also be used for waterproofness and anticorrosion of a structure and a building.

Owner:黄卫 +1

Water-soluble coagulant for cement-based cementing material and preparation method of water-soluble coagulant

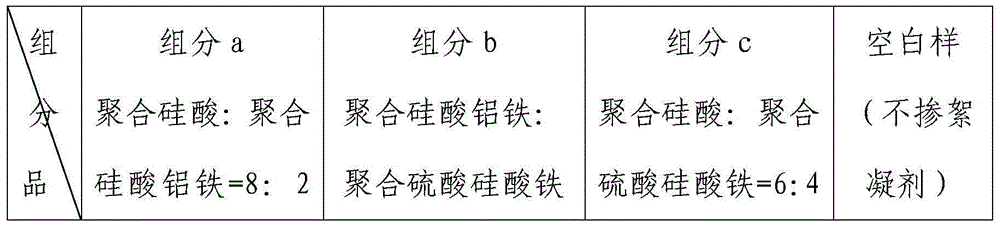

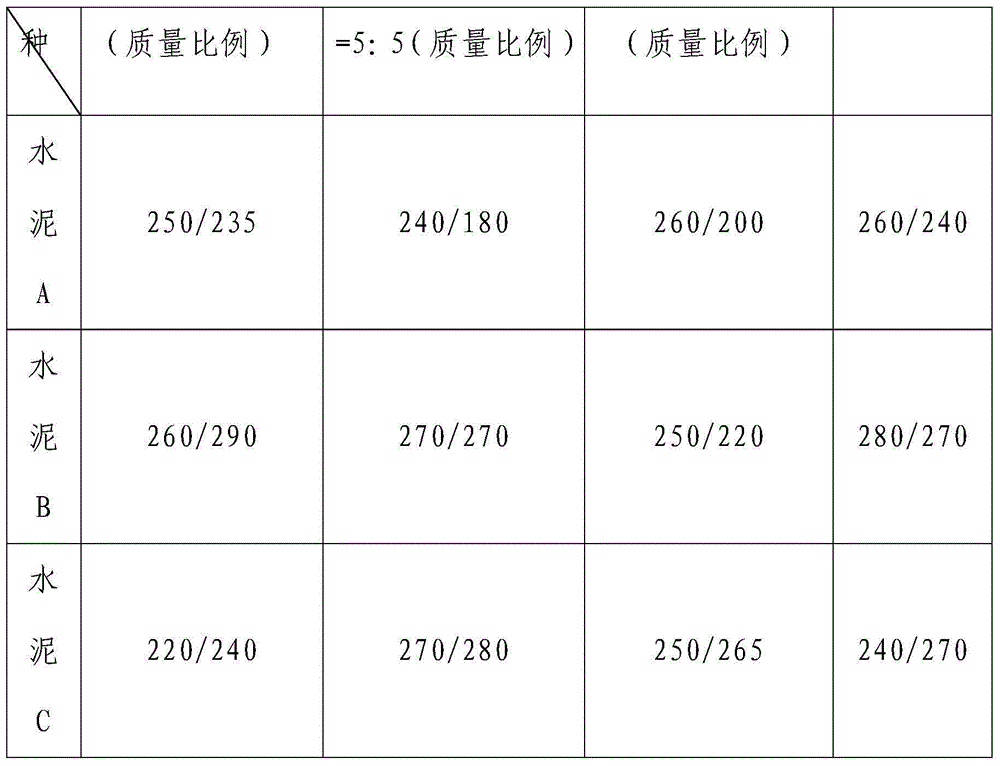

The invention provides a water-soluble coagulant for a cement-based cementing material and a preparation method. A solid solute part of the coagulant comprises raw materials in parts by weight as follows: 40-60 parts of a poly-silicic acid flocculating agent, 20-25 parts of an inorganic salt enhancer, 5-15 parts of a stabilizer and 1-5 parts of a dispersing agent. The prepared water-soluble coagulant is high in cost-performance ratio, and the actual engineering problem that the final coagulation time of the cement-based cementing material lags due to the lower temperature in winter and delayed coagulation of a polycarboxylate superplasticizer is solved on the basis of the theory and the nature of cement mineral hydration under the actual condition that the construction period is affected due to the fact that the concrete coagulation time is longer during construction in winter. Compared with like products on the market, the water-soluble coagulant has the advantages that the compatibility of the water-soluble coagulant with the polycarboxylate superplasticizer is higher, liquidity and slump retaining property indexes are not affected, and development of early strength of concrete and reduction of the cost of the superplasticizer are facilitated.

Owner:HUBEI UNIV OF TECH

Low temperature curable bottom filling adhesive with heat transfer function and preparation method thereof

InactiveCN106753143AGuaranteed reliabilityGuaranteed storage stabilityNon-macromolecular adhesive additivesHeat-exchange elementsPolymer scienceLow temperature curing

The invention relates to low temperature curable bottom filling adhesive with heat transfer function, comprising component A and component B; the component A is made from 100 parts of epoxy resin, 10-35 parts of modified epoxy resin, 0.5-5 parts of epoxy modified silicone oil, 5-15 parts of active diluent, 250-600 parts of heat transfer filler, 0.5-2 parts of a dispersant, 0.5-2 parts of a defoaming agent, and 0.2-4 parts of a rheological agent; the component B is made from 100 parts of liquid epoxy curing agent, 8-20 parts of a toughening agent, 250-600 parts of heat transfer filler, 0.5-5 parts of epoxy modified silicone oil, 0.5-2 parts of an adhesion promoter, 0.5-2 parts of a dispersant, 1-4 parts of a rheological agent, and 0.5-2 parts of a defoaming agent. The defects of low heat transfer coefficient, low temperature storage, high temperature curing and the like in existing filling adhesive can be overcome, and a chip packaged and cured by 3D MCP has high adhesive strength, good resistance to mechanical impact and good radiating performance.

Owner:NANJING NUOBANG NEW MATERIAL CO LTD

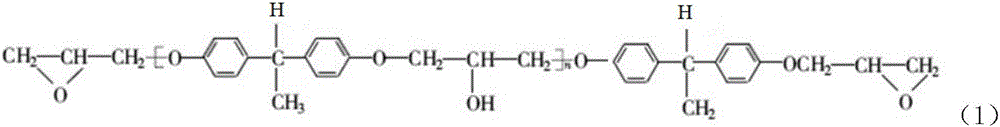

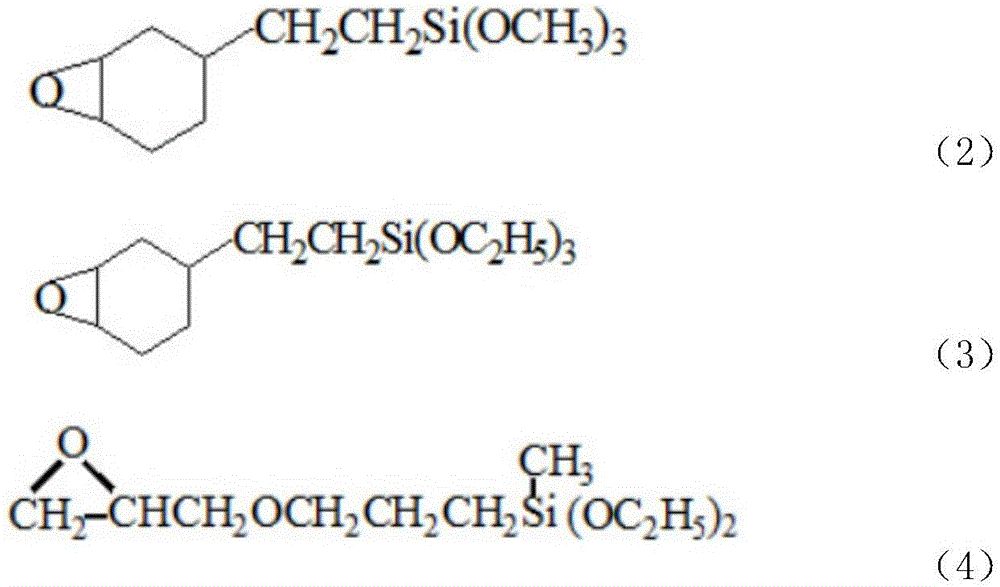

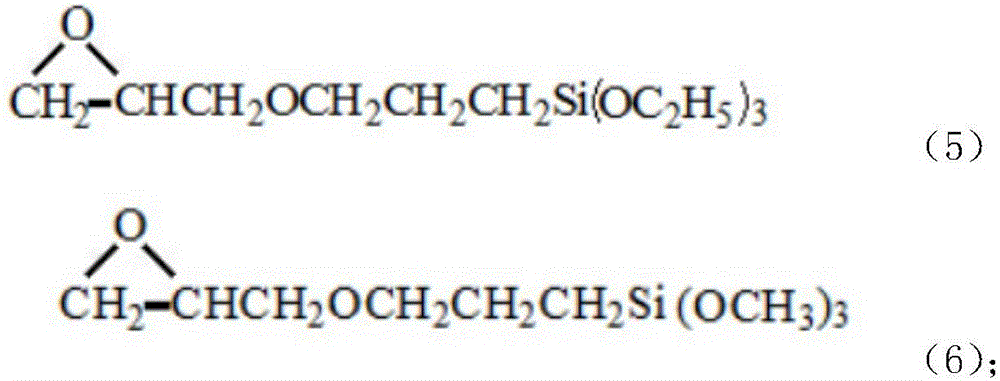

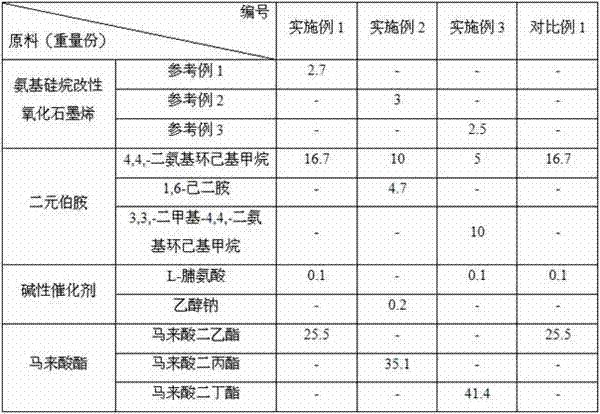

Polyaspartic acid ester resin, preparation method, and anticorrosive paint and preparation method thereof

InactiveCN107987274AGuaranteed storage stabilityImprove corrosion resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolyaspartic acidMolecular sieve

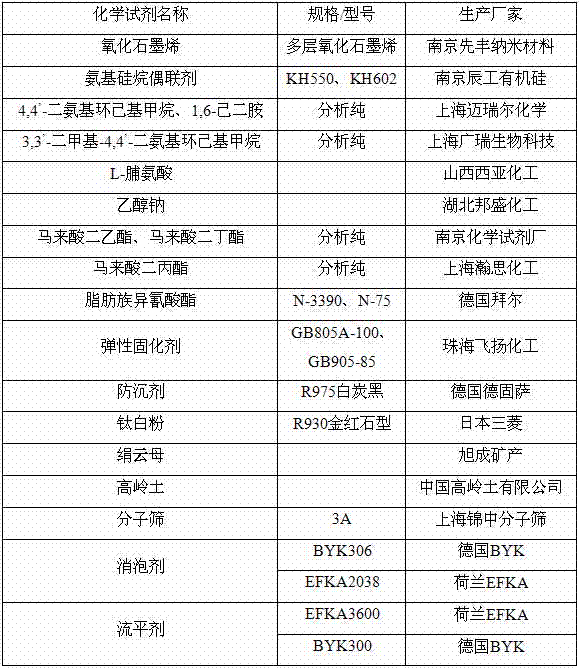

The invention discloses a polyaspartic acid ester resin, a preparation method, and an anticorrosive paint and preparation method thereof. The resin is mainly prepared from following raw materials in parts by weight: 2 to 5 parts of amino silane modified graphene oxide, 10 to 30 parts of binary primary amine, 0.1 to 0.3 part of alkaline catalyst, and 25 to 25 parts of maleate. The preparation method comprises the following steps: stirring amino silane modified graphene oxide, binary primary amine, and an alkaline catalyst, heating, dropwise adding maleate, heating, carrying out reactions at a constant temperature, and cooling. The anticorrosive paint is prepared by blending a component A and a component B, wherein the component A comprises aliphatic isocyanate and an elastic curing agent, and the component B comprises polyaspartic acid ester resin, an anti-settling agent, a pigment, a filling material, a molecular sieve, an antifoaming agent, a leveling agent, a dispersant, a hydroxyl acrylic resin, and an organic solvent. The invention also discloses a preparation method of the anticorrosive paint, which has the advantages of high solid content, good coating elasticity, good impactresistant performance, and excellent anticorrosive performance. The resin dispersibility is good.

Owner:CHANGSHA UNIVERSITY

Whole-oat hypolipidemic functional fine dried noodle and production method thereof

InactiveCN106858316AIncrease the amount addedImprove digestion and absorption rateFood preservationInorganic compound food ingredientsSecondary hyperlipidemiaGluten

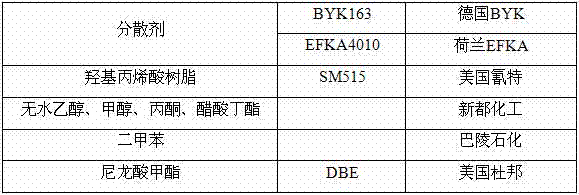

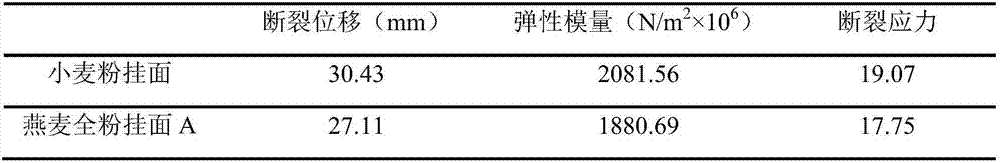

The invention provides a whole-oat hypolipidemic functional fine dried noodle and a production method thereof. According to the invention, the preprocessed whole oat flour is acquired according to the steps of preparing flour, stabilizing, pre-curing and finely smashing, and then the technologies, such as, formulation optimization, vacuum dough kneading and special rolling, are adopted for increasing the oat additive amount while guaranteeing the organoleptic quality of the fine dried noodle. The oat functional fine dried noodle is prepared from the following raw materials in parts by weight: 10-100 parts of preprocessed whole oat flour, 0-90 parts of wheat flour, 0-10 parts of high-activity gluten powder, 1-3 parts of salt, 0-3 parts of edible glue, 0-3 parts of soda and 0-3 parts of additional starch. According to the invention, under the condition of adding no any additives, 100% oat functional fine dried noodle product is produced, the quality is natural, the functional fine dried noodle belongs to dietary nutrition healthy food and has more obvious effects of reducing blood fat and restraining fat and an excellent staple food choice is supplied for the hyperlipidemia and obese patients.

Owner:KEMEN NOODLE MFG CO LTD

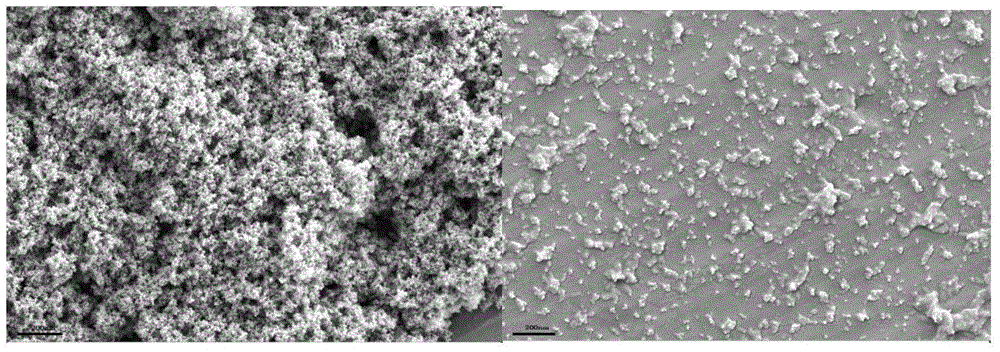

Modified nano titanium dioxide self-cleaning coating and preparation method thereof

ActiveCN106380981AHigh purityUniform particle sizeAntifouling/underwater paintsPaints with biocidesFiltrationUltrasonic dispersion

The invention belongs to the technical field of chemical coatings, and in particular, relates to a modified nano titanium dioxide self-cleaning coating and a preparation method thereof. The preparation method comprises the following steps: adding 1.5-3 parts of boron and nitrogen doped and coated nano titanium dioxide into an ethanol aqueous solution, stirring and dispersing, adding 0.5-2.5 parts of an organic silane coupling agent, carrying out stirring and heat preservation reaction, then carrying out suction filtration, drying and grinding to obtain silanized boron and nitrogen doped and coated nano titanium dioxide; dispersing 1.5-3 parts of the silanized boron and nitrogen doped and coated nano titanium dioxide into a mixed solution of 15-25 parts of an acrylate monomer and 0.5-2 parts of a co-emulsifier, stirring, carrying out ultrasonic dispersion, then adding 2-6 parts of an emulsifier and 50-90 parts of deionized water, stirring, carrying out ultrasonic dispersion, adding 0.3-0.6 part of an initiator, and carrying out heat preservation for 3-5 h, to obtain the modified nano titanium dioxide self-cleaning coating. The self-cleaning coating has the advantages of good dispersion of titanium dioxide and strong self-cleaning ability.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

Composite adhesive specially for heat insulating polystyrene outer-wall board

InactiveCN1403522AImprove adhesionImprove aging resistanceHydrocarbon polymer adhesivesPolymer scienceAdhesive

The composite adhesive is prepared with styrene and acrylic acid copolymer emulsion, which is inorganic silica gel and organosilicon modified and has low vitrification point and high adhesion, as main adhesive component and through adding quartzite, asbestos and other reinforcing material and some assistants. The composite adhesive has high adhesion effect, high adhesion strength, good antiaging performance, high hardness and high water resistance.

Owner:上海丰慧节能环保科技有限公司

Flux paste for high-bismuth content solder paste and preparation method thereof

InactiveCN102513735AGuaranteed storage stabilityMaintain wettabilityWelding/cutting media/materialsSoldering mediaSolder pasteElectronic industry

The invention belongs to the field of welding materials for an electronic industry, and provides flux paste for high-bismuth content solder paste and a preparation method thereof. The flux paste for the high-bismuth content solder paste comprises the following components in percentage by weight: 20 to 60 percent of resin, 20 to 50 percent of solvent, 2 to 8 percent of thixotropic agent, 2 to 10 percent of activating agent, 0.05 to 10 percent of corrosion inhibitor and 0.05 to 10 percent of antioxidant. According to the flux paste, by optimizing and selecting the activating agent in the flux paste, the high-bismuth content solder paste prepared from the flux paste does not generate black residues in the using process, and excellent performance such as the storage stability, wettability, impressionability and the like of the high-bismuth content solder paste is kept simultaneously, so that the problems in the prior art are solved effectively, the yield of products is improved, and the good benefit is obtained.

Owner:厦门市及时雨焊料有限公司

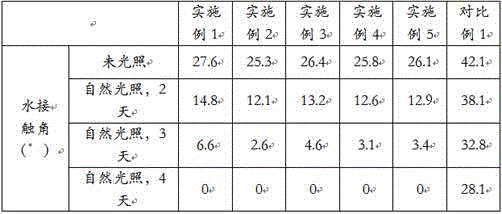

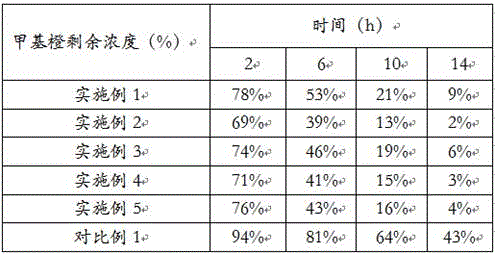

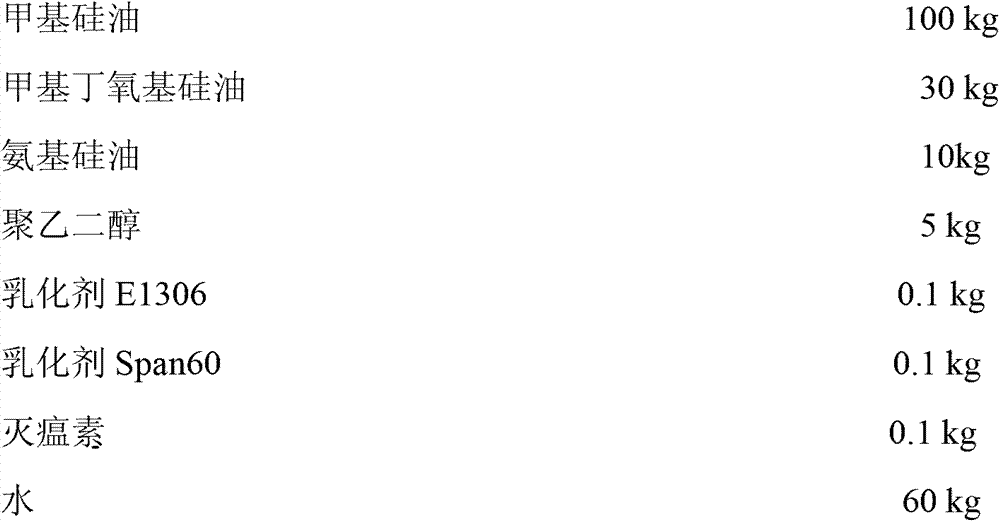

Application of organic silicone emulsion waterproof agent in outer wall rock wool heat insulating material waterproof agent

ActiveCN103043945AGuaranteed storage stabilityImprove waterproof performanceAdhesivePolyethylene glycol

The invention discloses application of an organic silicone emulsion waterproof agent in an outer wall rock wool heat insulating material waterproof agent. The waterproof agent is prepared from the following raw materials in percentage by mass: 100 parts of methyl silicone oil, 5-30 parts of methyl alkoxy silicone oil, 2-10 parts of amino silicone oil, 5-10 parts of polyethylene glycol, 0.2-1.0 part of an emulsifier, 0.1-1.0 part of a sterilizing agent and 6-100 parts of distilled water or deionized water. The preparation method comprises the following steps of: proportioning 20%-40% of water and the emulsifier, stirring the solution uniformly at 60-70 DEG C, adding methyl silicone oil, methyl alkoxy silicone oil, amino silicone oil and polyethylene glycol, pre-emulsifying the mixture for 1 hour, cooling to room temperature for later use, putting the pre-emulsifying liquid in a high-speed emulsifying machine of which the rotating speed is 5000-8000r / min, adding methyl silicone oil into the pre-emulsifying liquid for high-speed emulsification for 2-3 hours, adding the rest 60%-80% of water and the sterilizing agent, performing high-speed emulsification again for 1 hour, and then obtaining a waterproof organic silicone emulsion waterproof agent for an outer wall rock wool heat insulating material, wherein the organic silicone emulsion waterproof agent is white emulsion in appearance, pH value of the 10% of water solution is 6.5-7.0, solid content is 50%-70%, good centrifugation stability is achieved, the emulsion is not layered after being centrifuged at the rotating speed of 3000r / min for 30min, good thermal stability is achieved, and the emulsion is not layered after being maintained for 4 hours at 70+ / -2 DEG C. The organic silicone emulsion waterproof agent disclosed by the invention is used for soaking and spraying the outer wall rock wool heat insulating material or added into an adhesive for manufacturing rock wool heat insulating materials.

Owner:山东环绿康新材料科技有限公司

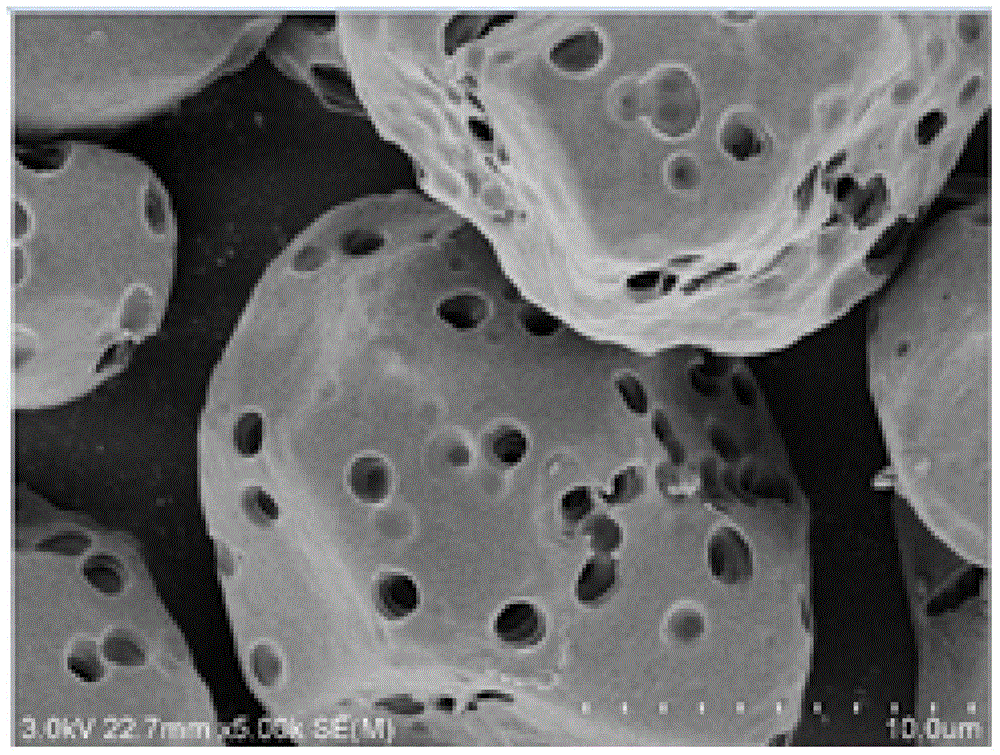

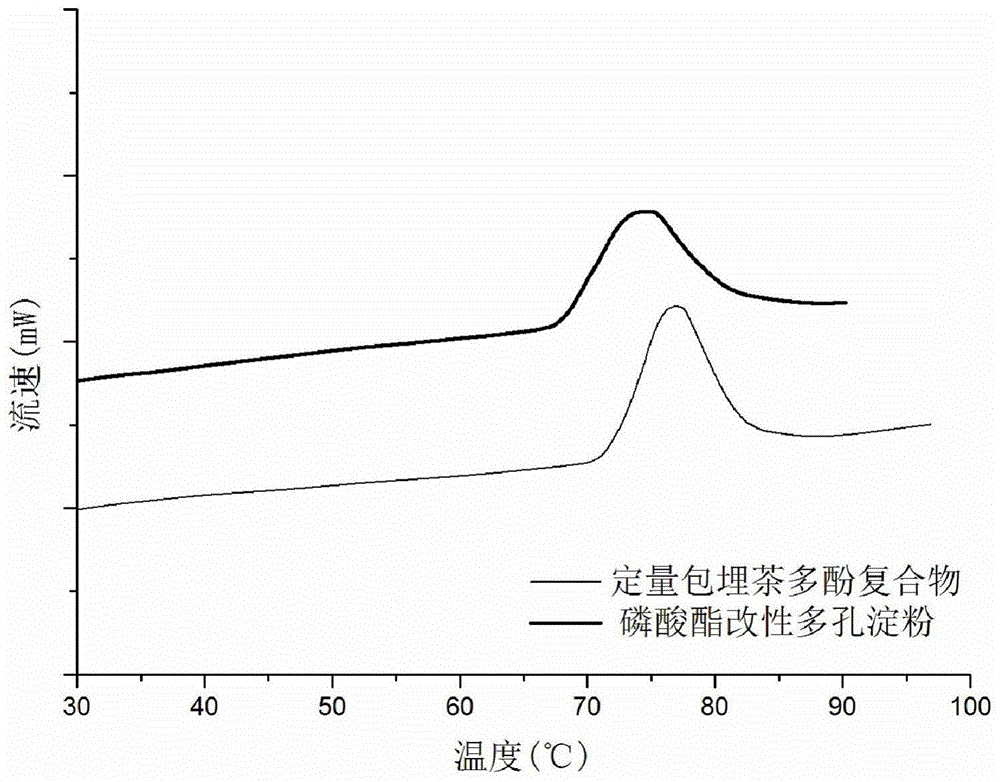

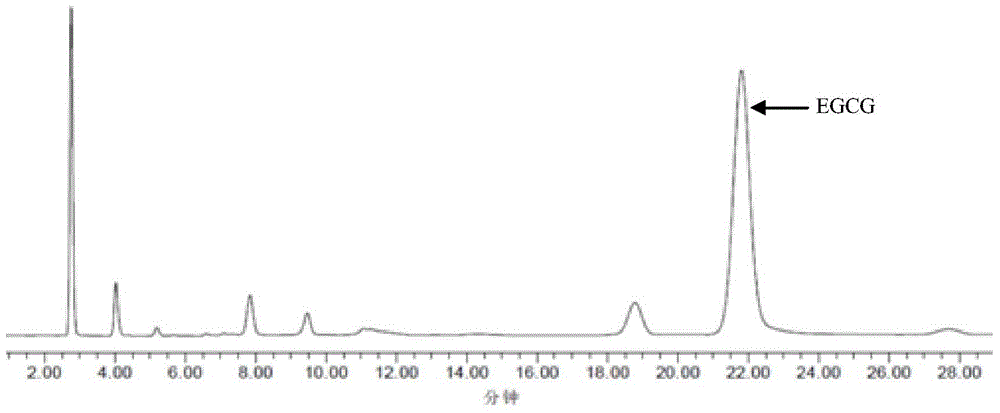

Phosphate-modified porous starch quantitative embedding tea polyphenol compound and preparation method and application thereof

InactiveCN105105335AReduce free radicalsExplain protection abilityTobacco smoke filtersPhosphatePorous starch

The invention discloses a phosphate-modified porous starch quantitative embedding tea polyphenol compound and a preparation method and application thereof. The phosphate-modified porous starch quantitative embedding tea polyphenol compound is a compound which is obtained in the way that porous starch absorption embedding tea polyphenol is modified by phosphate and then freezing and drying are carried out. The phosphate-modified porous starch quantitative embedding tea polyphenol can serve as a cigarette filter tip addition agent, and the dosage is 10 mg per cigarette. Through a manufactured binary combination filter tip, the solid-phase free radical and the gaseous-phase free radical in cigarette main stream smoke are lowered by 12.2% and 33.4% respectively, and after cigarettes are stored for one month at a normal temperature, the solid-phase free radical and the gaseous-phase free radical are lowered by 13.1% and 31.7% respectively.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Double-shell microcapsule and its preparation method and use

ActiveCN104888671AImprove mechanical propertiesImprove impact resistanceMacromolecular adhesive additivesCoatingsEmulsionMelamine formaldehyde

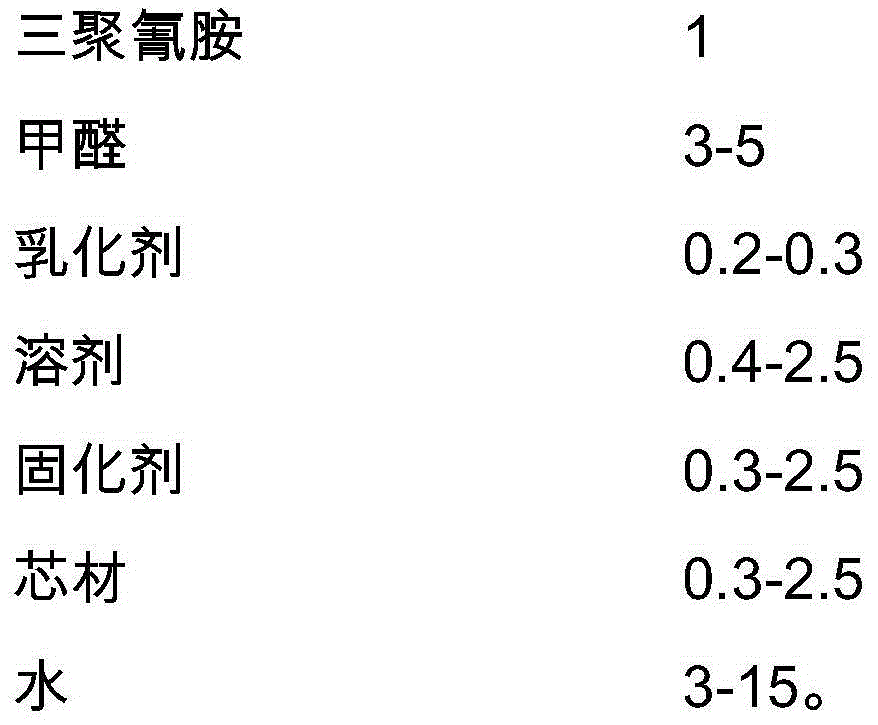

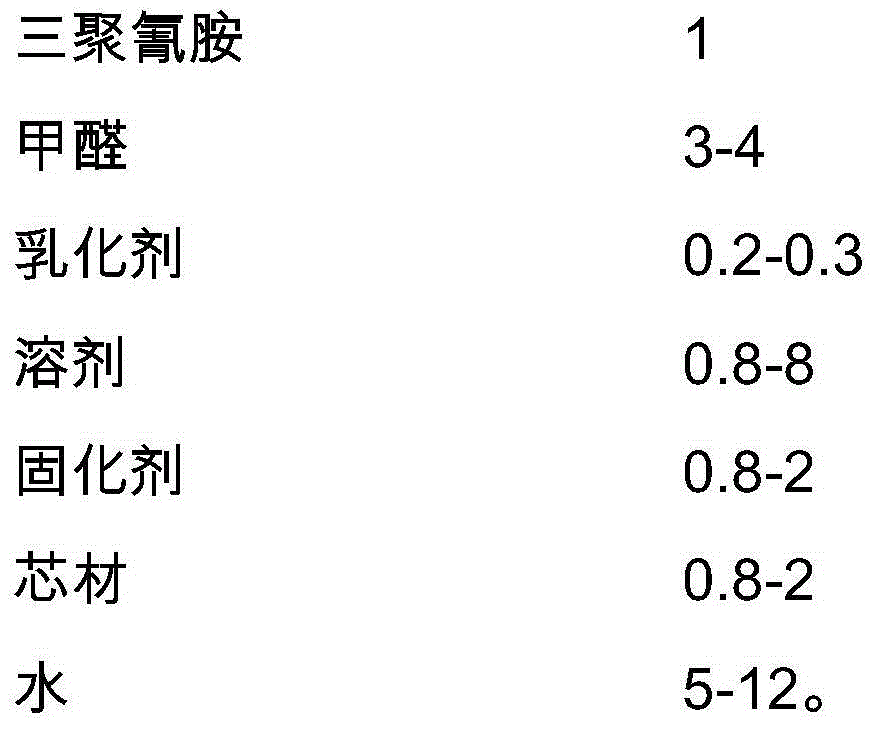

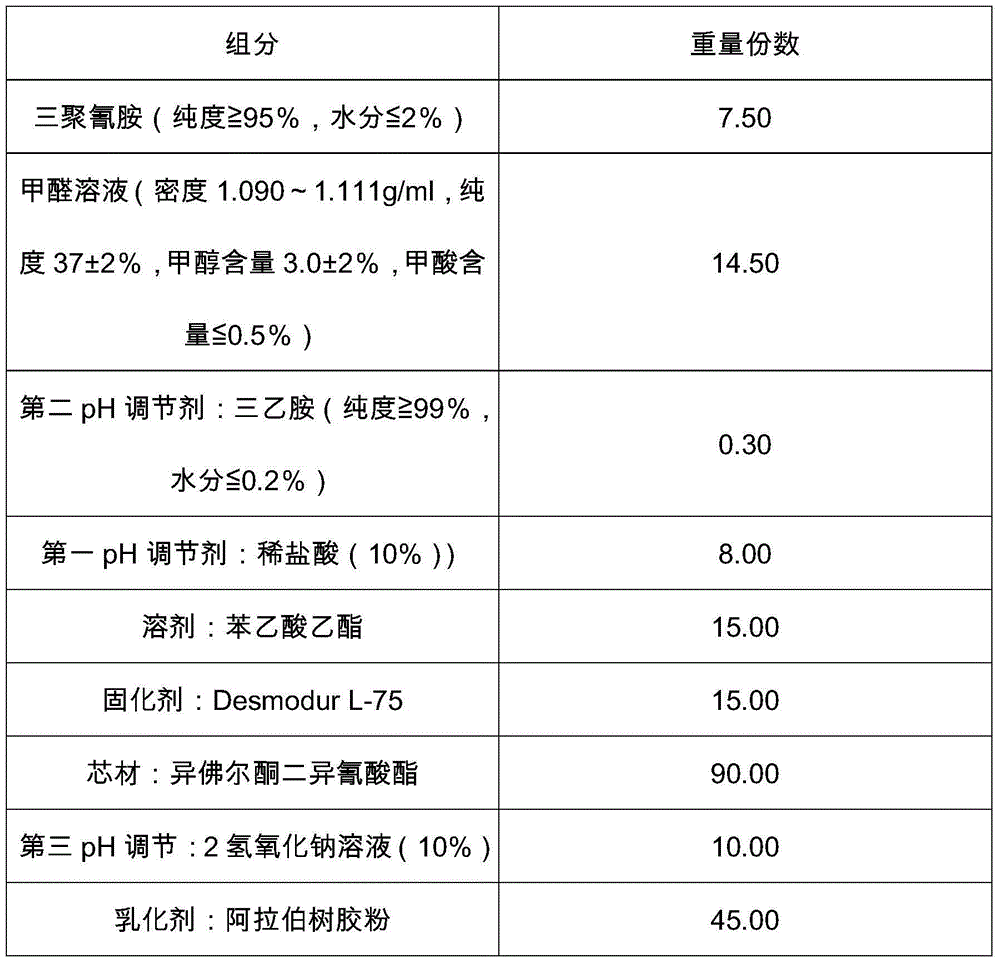

The invention discloses a double-shell microcapsule and its preparation method and use. The preparation method comprises orderly adding and mixing melamine and a formaldehyde solution according to a mole ratio of 1: 3-5, adding distilled water into the mixed solution to obtain a melamine-formaldehyde performed polymer, wherein the mass of the distilled water is 1-3 times that of the formaldehyde solution, adding the melamine-formaldehyde performed polymer and an emulsifier into a reactor according to a ratio of 100: 20-30, adjusting pH to 1-6, adding a solvent-curing agent-core material homogeneous mixture with a mass ratio of 1: 1: 3 to 1: 2: 12 into the reactor, wherein the total mass of the homogeneous mixture is 1-2.5 times that of the melamine-formaldehyde performed polymer, carrying out emulsification for 20-50min, heating the emulsion to more than 40 DEG C, carrying out a reaction process for 3-5h and adjusting pH to greater than or equal to 6. The double-shell microcapsule has good mechanical properties, guarantees product quality stability and storage stability and has a wide raw material source and a low shell raw material price. The preparation method has simple processes, can be used in the fields of foods, drugs and cosmetics, can be widely used in the field of functional materials and widens a microcapsule usage scope.

Owner:南雄市星隆化工有限公司

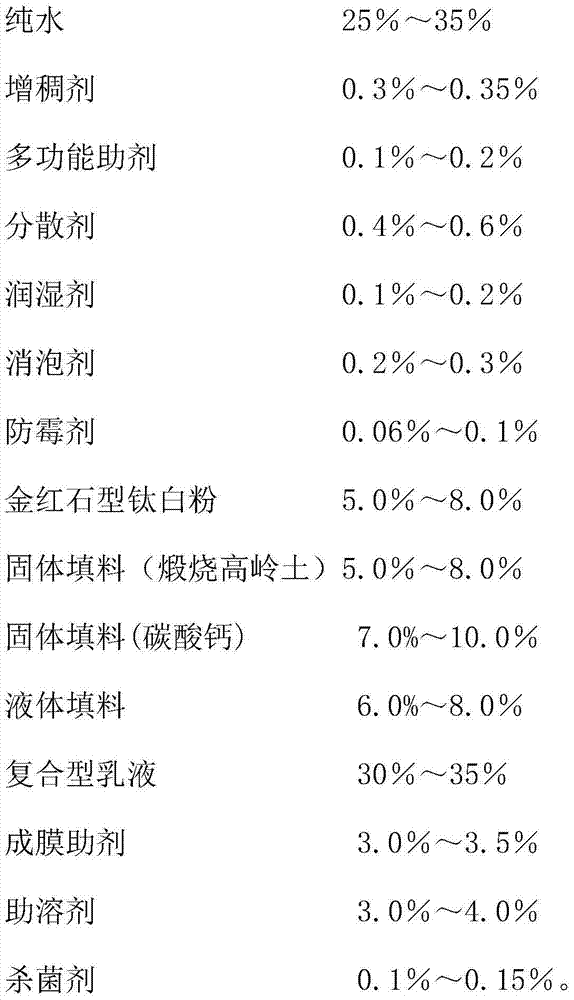

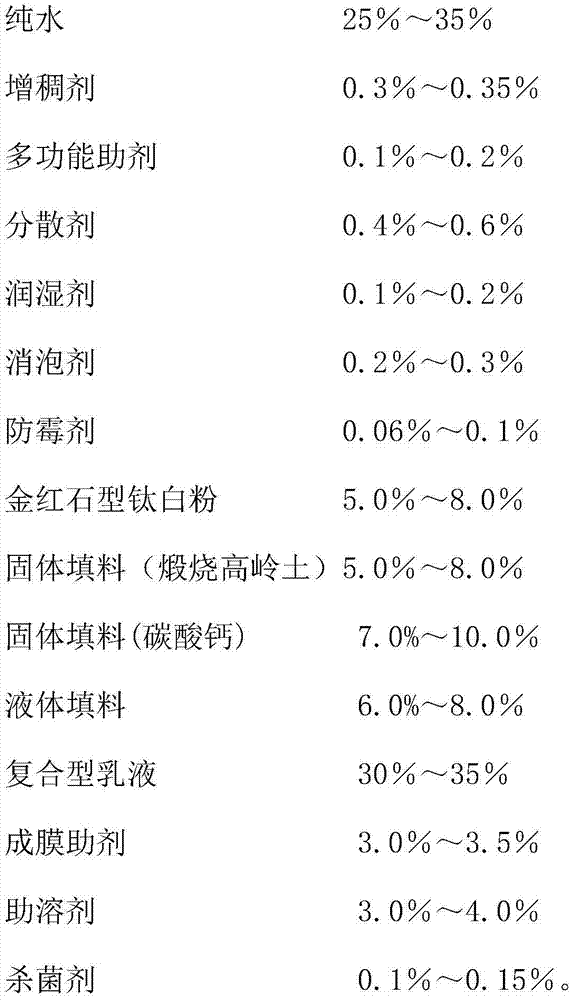

One coat paint prepared by organic and inorganic compound emulsion and preparation method thereof

The invention discloses a one coat paint prepared by an organic and inorganic compound emulsion and a preparation method thereof. The one coat paint is used for sealing and decorating an exterior wall. The one coat paint comprises the following components: pure water, a thickener, multifunctional additives, a dispersant, a wetting agent, a defoaming agent, a mildew-proof agent, rutile type titanium dioxide, a filler, a liquid filler, the compound emulsion, film-forming additives, a cosolvent and a fungicide. The one coat paint disclosed by the invention has the performances of a primer paint, namely excellent alkali burnout resistance and salting-out resistance; furthermore, all the performances are in line with the requirements of primer paint first-grade products for the exterior wall of buildings. The one coat paint further has the performances of a finish paint of the exterior wall: a paint film has excellent contrast ratio, scrub resistance, weatherability and stain resistance, and all the performances are in line with the requirements of high-grade products of latex paint for the exterior walls of the buildings.

Owner:NIPPON PAINT YASHILI

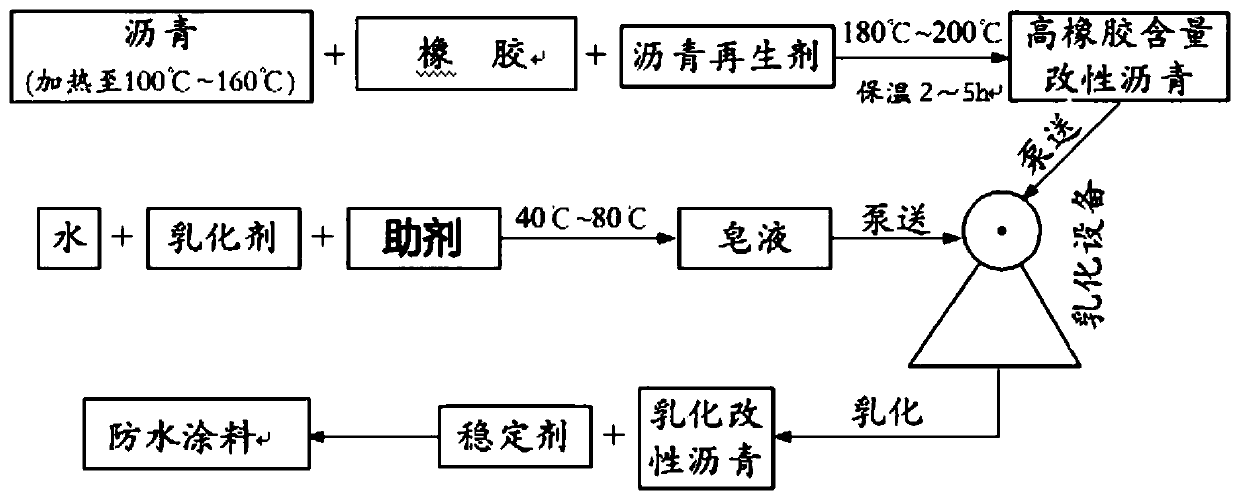

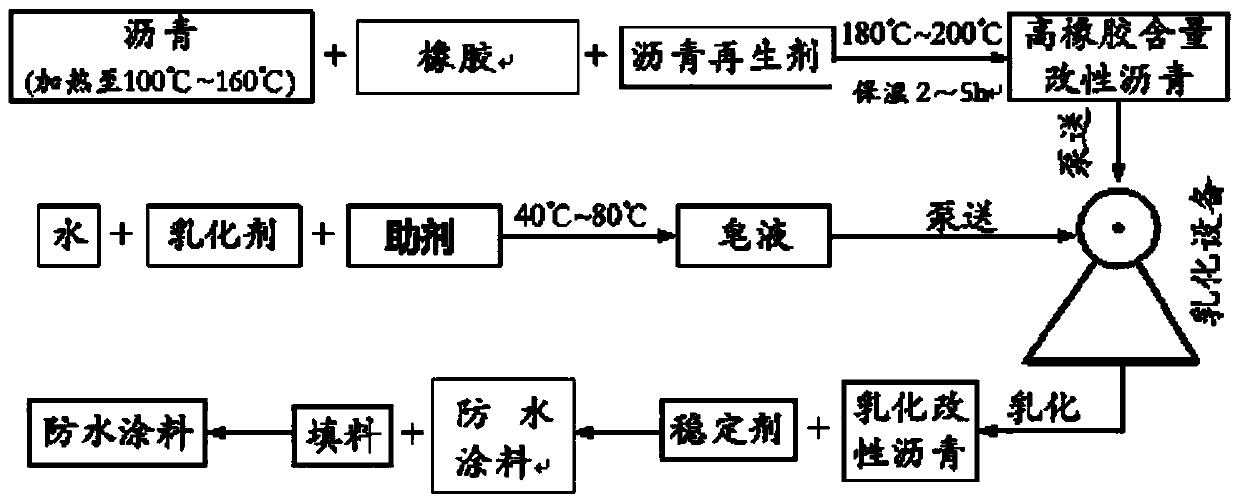

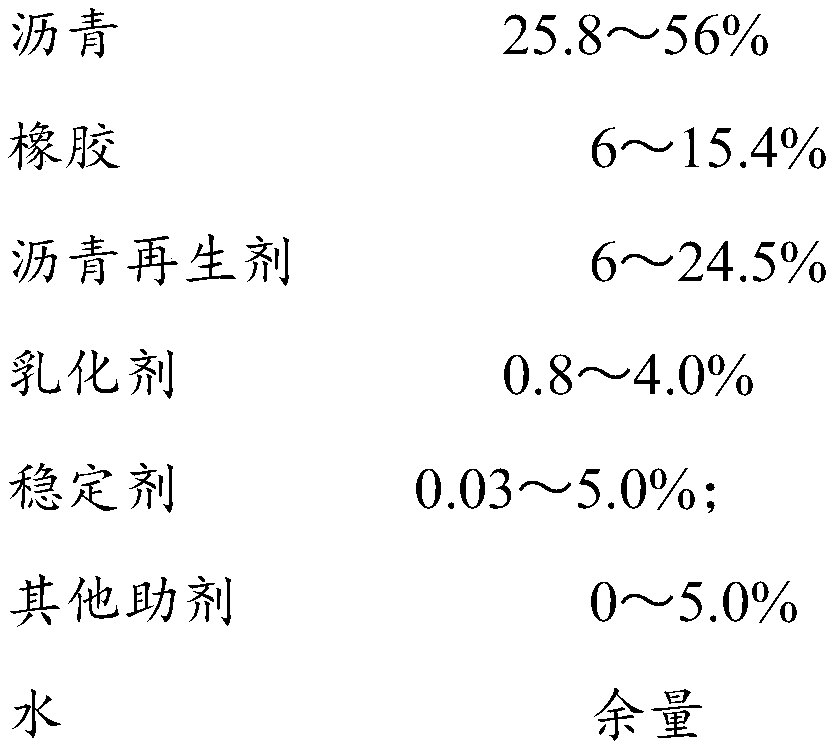

Rubber modified asphalt waterproof coating material, preparation method and uses thereof

InactiveCN110128945AReduce high temperature viscosityReduce the difficulty of emulsificationRoof covering using flexible materialsProtective foundationMaterials preparationPolymer science

The invention discloses a rubber modified asphalt waterproof coating material, which is prepared by mixing the following components: asphalt, rubber, an asphalt regenerant, an emulsifier, a stabilizer, water and other auxiliary agents. The invention further discloses a preparation method and applications of the rubber modified asphalt waterproof coating material. According to the present invention, in the rubber modified asphalt waterproof coating material preparation process, by using the asphalt regenerant, the added rubber can be fully fused with the asphalt, such that the modified asphaltwith high rubber content cannot segregate, and the asphalt regenerant can greatly reduce the high-temperature viscosity of the modified asphalt so as to reduce the emulsification difficulty of the modified asphalt with high rubber content; by using the preparation process comprising secondary pH value adjustment, the high solid content emulsified product can be prepared in the case of the low emulsifier adding amount; and by adding the stabilizer to the product of the invention, the occurrence of demulsification can be avoided so as to ensure the storage stability of the product at a later stage.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

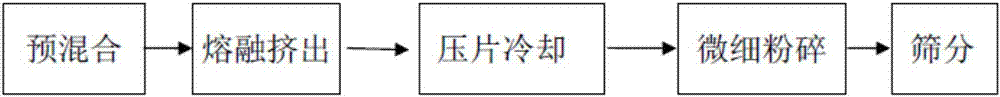

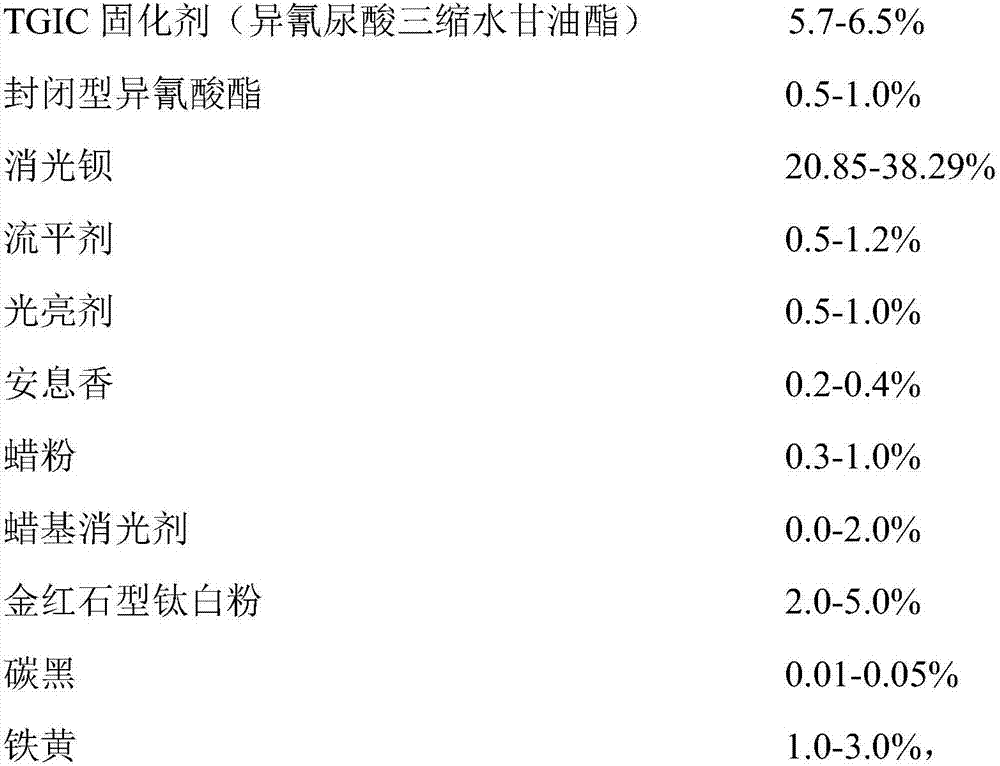

Low-gloss bending-resistant heat transfer printing powder coating used for section aluminum and a preparing method thereof

ActiveCN106867371AImprove storage stabilityReduce glossPowdery paintsPolyester coatingsWaxCarbon black

The invention relates to low-gloss bending-resistant heat transfer printing powder coating used for section aluminum and a preparing method thereof. The powder coating is prepared by mixing an A component and a B component. Raw materials of the A component include saturated carboxyl-ended polyester resin A, a TGIC curing agent, enclosed type isocyanate, extinction barium sulfate, a leveling agent, a brightening agent, benzoin, wax powder, a wax-based flatting agent, rutile type titanium dioxide, carbon black and iron oxide yellow. Raw materials of the B component include saturated carboxyl-ended polyester resin B, a TGIC curing agent, enclosed type isocyanate, extinction barium sulfate, a leveling agent, a brightening agent, benzoin, wax powder, rutile type titanium dioxide, carbon black and iron oxide yellow. Coating films of the powder coating have significant characteristics of extremely good storage stability, bending resistance and impact resistance, excellent whether resistance, high decoration performance, and the like.

Owner:广东华江粉末科技有限公司

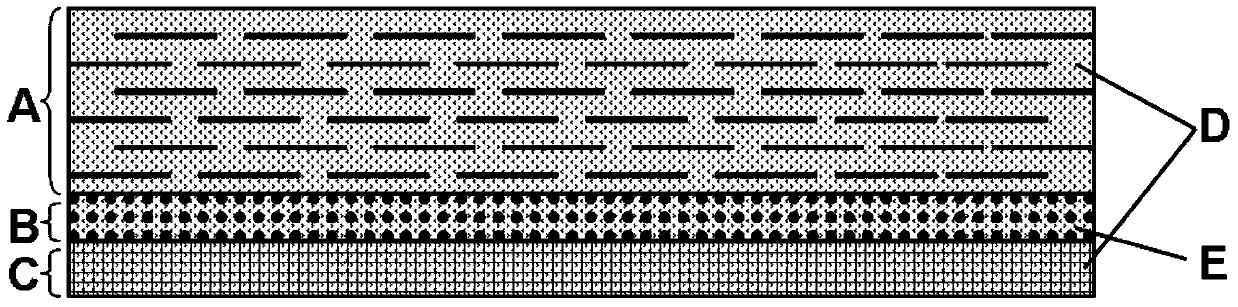

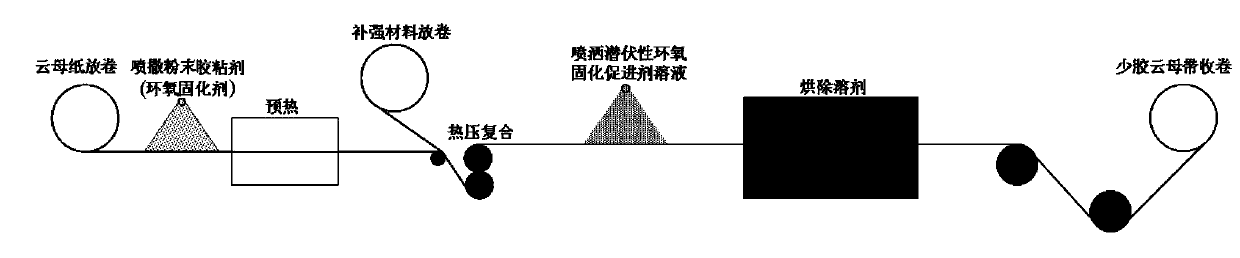

Mica tape, high in ventilation performance and with little glue, suitable for pure epoxy VPI insulating resin and preparation method thereof

The invention relates to mica tape, high in ventilation performance and with little glue, suitable for pure epoxy VPI insulating resin and a preparation method thereof. The mica tape comprises a mica paper layer, a reinforcing material layer, and an adhesive agent layer. The adhesive agent layer is composed of powder adhesion agents distributed, in a point shape, on the interface of the mica paper layer and the interface of the reinforcing layer. A large number of pore channels exist between powder adhesion agents distributed in the point shape. The powder adhesion agents are epoxy hardeners. The mica tape high in ventilation performance and with little glue further comprises latent epoxy curing accelerators distributed in the mica paper layer, the reinforcing material layer and the pore channels. No chemical reaction of the epoxy hardeners and the latent epoxy curing accelerators occurs under 110 DEG C, and the the epoxy hardeners and the latent epoxy curing accelerators can not dissolve and enter the pure epoxy VPI insulating resin in the VPI dipping paint process. The mica tape with little glue expands the utilization range of the epoxy resin as electric insulting materials, greatly reduces the requirements of the epoxy VPI insulation resin for dipping paint equipment and technologies, reduces energy consumption, and saves utilization cost.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

Emulsion-type accelerator special for sprayed concrete

The invention discloses an emulsion-type accelerator special for sprayed concrete, and belongs to the technical field of building materials. The developed accelerator is formed by activated sepiolite,polyethyleneimine, modified nano oxidized graphene and water. A preparation method comprises the following steps: in a preparation process, firstly weighing each component according to a raw materialcomposition, adding the activated sepiolite, the polyethyleneimine, the modified nano oxidized graphene and the water to a high-pressure reaction kettle, and continuously feeding a carbon dioxide gasto the reaction kettle, after a pressure is risen to 0.6-0.8 MPa, stopping feeding, stewing, after the pressure in the reaction kettle is reduced to 0.3-0.5 MPa, opening the reaction kettle, depressurizing until a normal pressure, and discharging, to obtain the emulsion-type accelerator special for the sprayed concrete. The obtained emulsion-type accelerator special for the sprayed concrete has excellent long-term strength and durability.

Owner:邹峰

Modified full acrylic ester emulsion

The acrylate emulsion modified with acrylic acid monomer containing amino ester and seed emulsion containing epoxy group has improved cohesion to base material and thus greatly raised water resistance and wash fastness. Using the anionic and non-ionic emulsifier with olefine group makes the emulsion possess greatly raised electrolyte stability and low temperature stability and further raised water resistance. Furthermore, the emulsion with raised flowability and low temperature stability makes it possible to reduce the amount of glycol, propylene glycol and other water soluble solvent and thus reduce VOC in preparing emulsion paint, and this is favorable to protecting environment and saving energy. The emulsion is used in emulsion paint for outer wall.

Owner:江苏日出化工有限公司

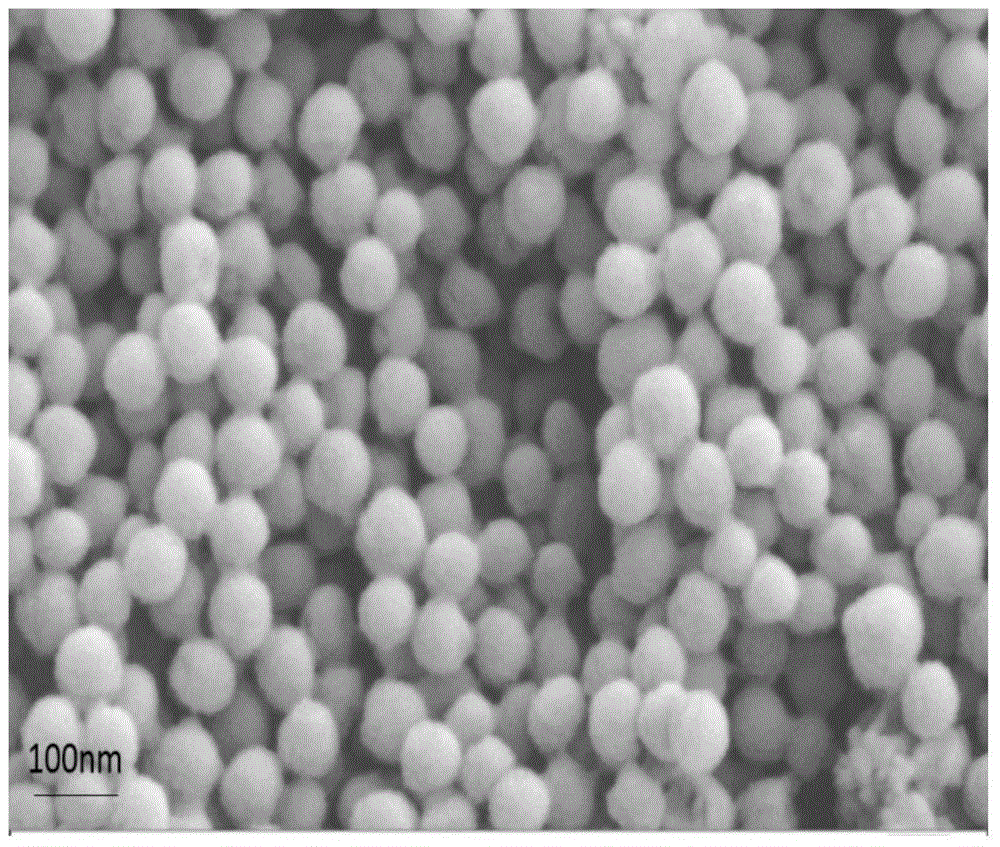

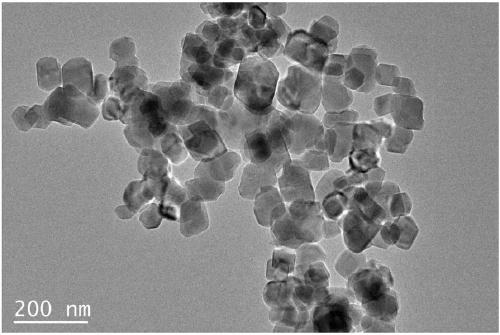

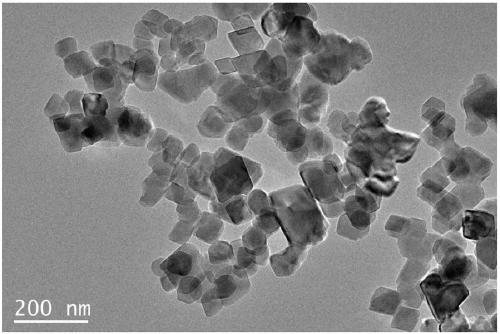

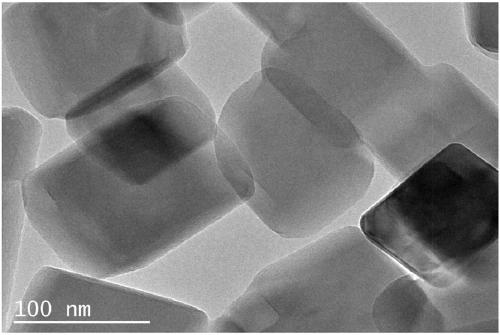

Preparation method of nano calcium carbonate for MS glue

InactiveCN109650431ADetermining performanceThe process steps are the sameCalcium/strontium/barium carbonatesNon-macromolecular adhesive additivesCarbonizationSlurry

The invention discloses a preparation method of nano calcium carbonate for MS glue, which comprises the following steps: removing impurities from calcium hydroxide (Ca (OH) 2) slurry obtained after the digestion reaction of quicklime (CaO) and water (H2O), preserving heat and aging, adding a crystal form control agent, performing primary carbonization synthesis reaction with the washed kiln gas containing carbon dioxide (CO2), adding a post-treatment agent, aging for a certain time, performing secondary carbonization synthesis reaction with the washed kiln gas containing carbon dioxide (CO2) to obtain calcium carbonate (CaCO3) cooked slurry, adding a modifier into the cooked slurry, performing filter pressing dehydration, drying, crushing and grading after the reaction is finished to obtain the nano calcium carbonate for MS glue. The nano calcium carbonate crystal prepared by the method is a standard cube, and the crystal is mono-disperse, and the average particle diameter is only 100-150nm, and the specific surface area is 16-18m <2 > / g, and the nano calcium carbonate crystal is used for MS glue, and the thixotropy is good, and the extrusion property is good, and the storage stability is good, and the surface finish after gluing is good, and the tensile strength is high, and the elongation is high and the bonding property is also good. The preparation method of nano calcium carbonate for MS glue has the advantages of simple and feasible process, low cost, low price and better economic benefit.

Owner:卢氏国嵩莱纳米科技有限公司

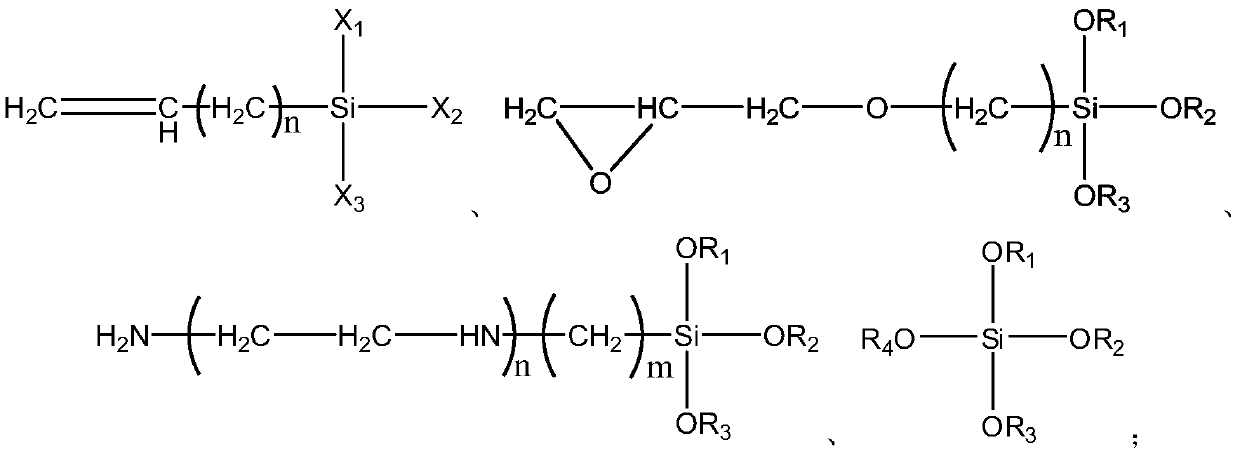

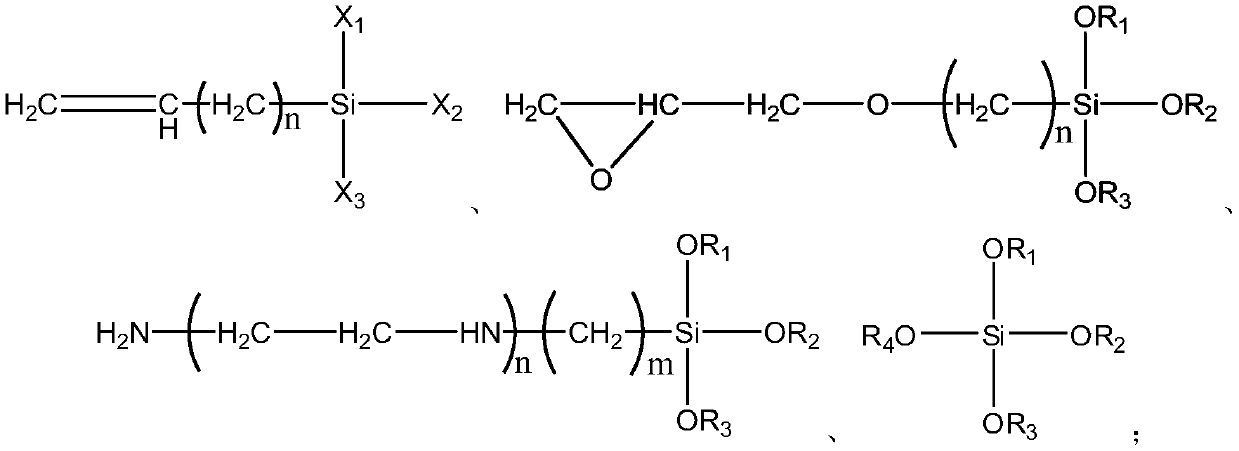

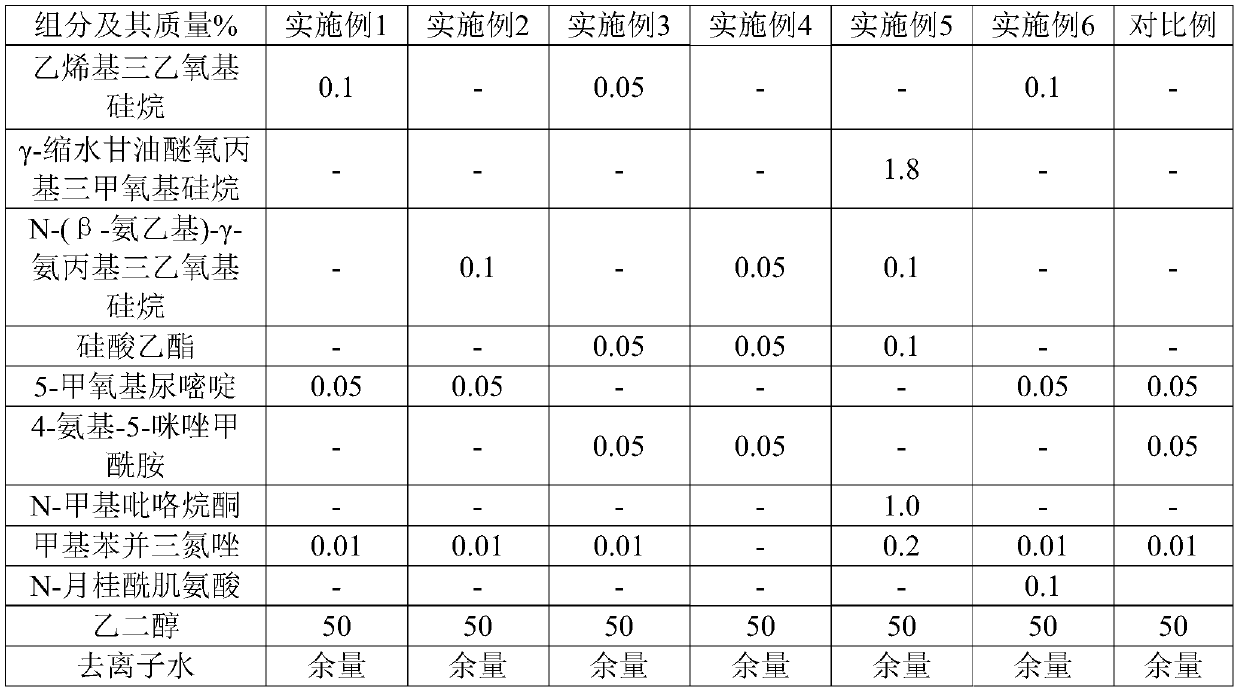

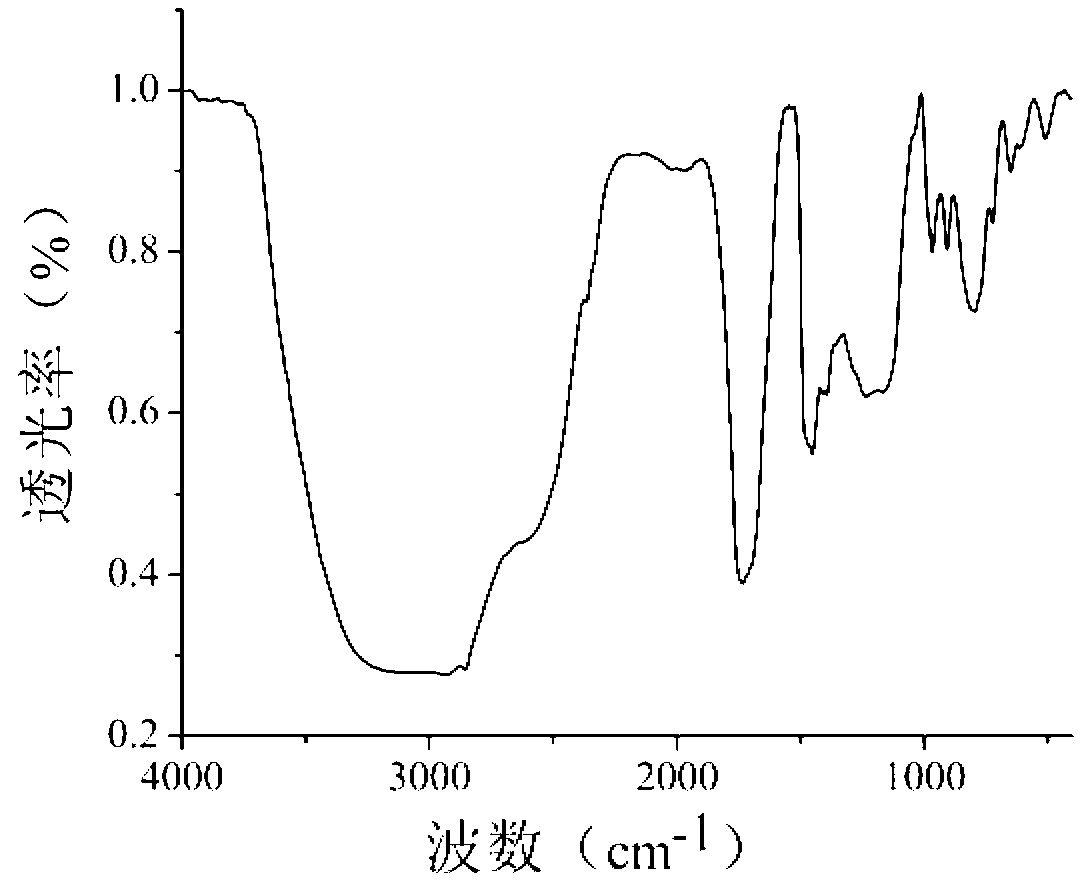

Low-conductivity cooling liquid and preparation method thereof

ActiveCN109762642AGuaranteed storage stabilityAvoid hydrolysisLubricant compositionCorrosionOrganosilicon

The invention relates to a low-conductivity cooling liquid and a preparation method thereof, and belongs to the field of chemical engineering. The total mass of each component in a cooling liquid formula is 100%, and the low-conductivity cooling liquid is prepared from the components in percentage by mass: 30-80% of dihydric alcohol, 0.05-5.0% of organosilicon compound, 0.01-2.0% of nitrogen-containing compound, 0-1.0% of azole-based compound and the balance of deionized water. The organosilicon compound, the nitrogen-containing compound and the azole-based compound are uniformly mixed and then added into the dihydric alcohol for normal temperature stirring for more than 20min, and finally the deionized water is added for uniform mixing to obtain the low-conductivity cooling liquid. The low-conductivity cooling liquid has good effect of corrosion inhibition on a multi-metal system, has better storage and using stability, and can be used for cooling and heat exchanging of fuel cells, electric automobile motors and wind power generators.

Owner:中国船舶集团有限公司第七一八研究所

Synthesis method of shell starch microsphere

This invention relates to a synthetic method of hud type starch microsphere. First carry out fully microwave dispersing to titanium dioxide, sodium silicate and de-ionized water, obtain TiO2 gel; blend soluble starch and de-ionized water, gain starch solution; intensive mixing cyclohexane, initiator, emulsifying agent, add TiO2 gel, then add cross-linking agent N, N -methylene bisacrylamide and starch solution, take reaction for 3 to 4 hours; finally stop whip, cooling, standing, by centrifugal to remove oil phase; use ethyl acetate, acetone, dehydrated alcohol in turns and abundantly to wash obtained precipitate, gain white go as far as yellowish product, vacuum drying.

Owner:XIAN MEDICAL UNIV +1

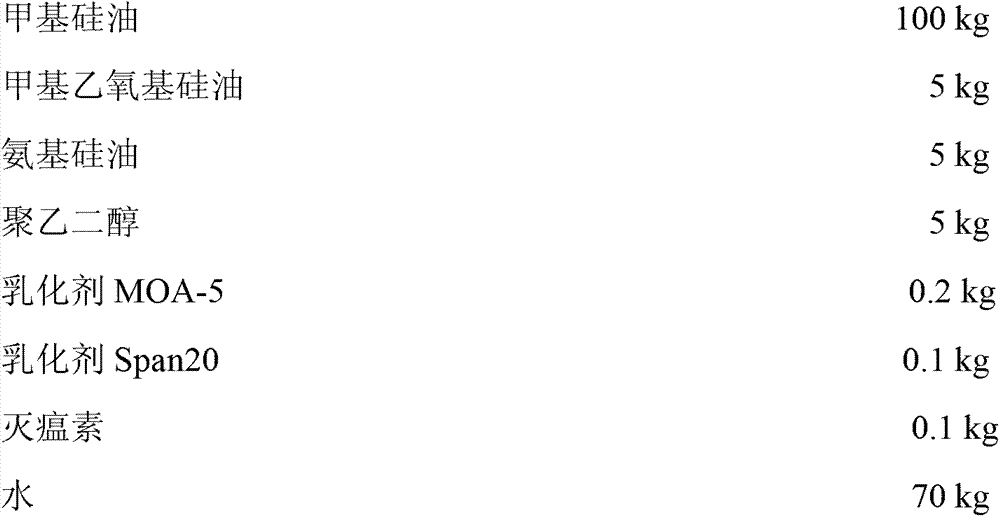

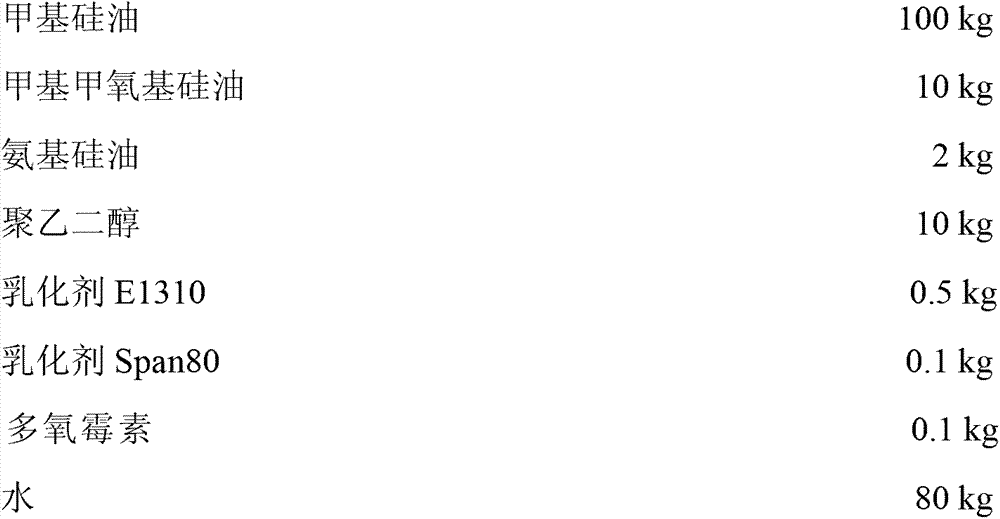

Method for preparing smoothing agent for fabric of organosilicon

InactiveCN1916271AGuaranteed storage stabilitySolve technical problems that are easy to layerFibre treatmentWaxEmulsion

The present invention relates to a preparation method of organosilicon fabric smooth agent. Sad preparation method includes the following steps: using hydroxyl-capped dimethyl silicone oil with ultrahigh viscosity and making it be mixed with low-viscosity dimethyl silicone oil so as to reduce viscosity, then making said mixture be mixed with emulsifying agent to make emulsification, then using high-speed shear emulsifying machine to make emulsification and prepare organosilicone smooth agent emulsion, then adding smooth synergistic agent nano oxypolyethylene wax emulsion and preparing organosilicone fabric smooth agent.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +1

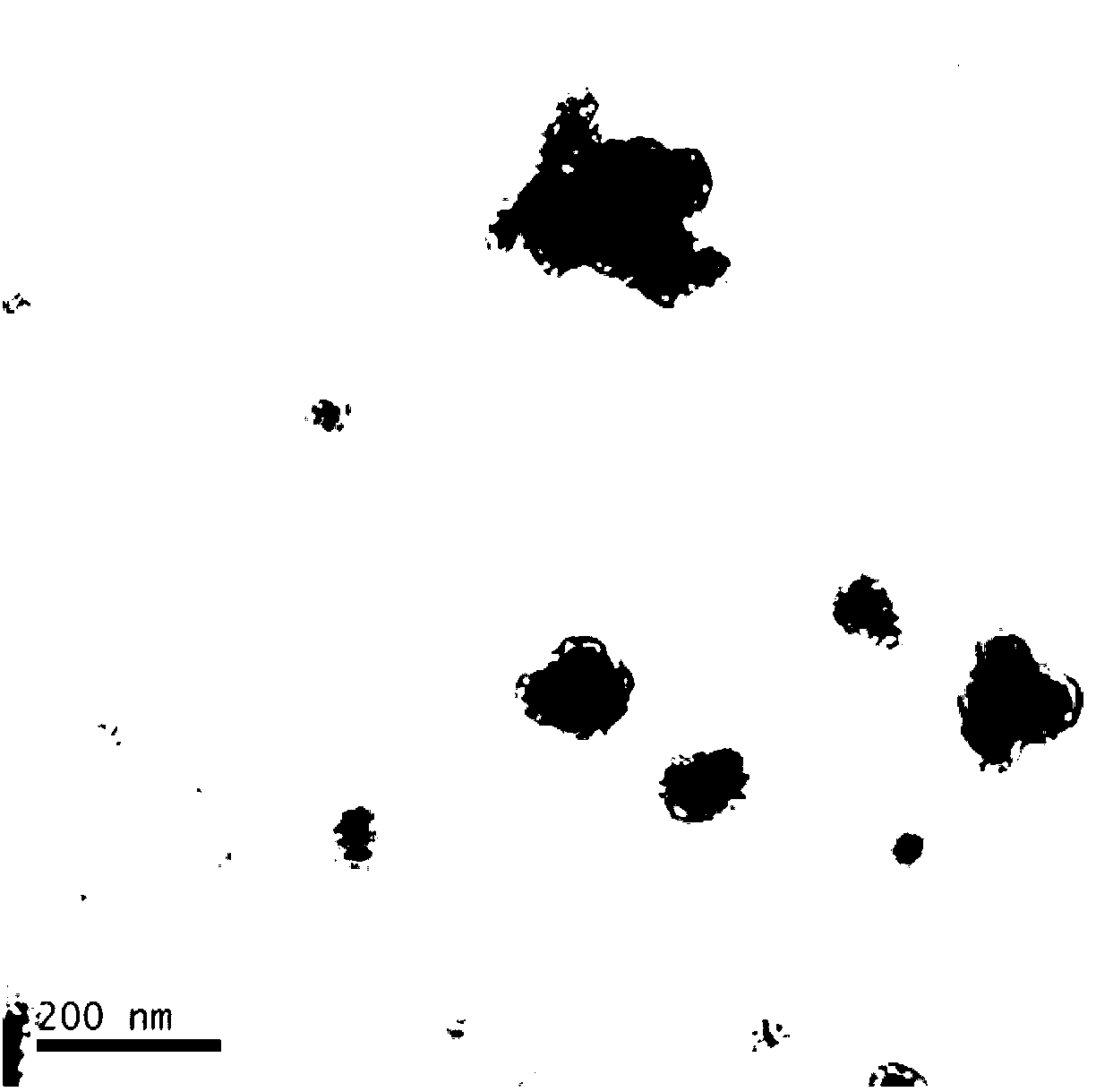

Method for preparing nano titanium dioxide/polyacrylate compound emulsion

The invention discloses a method for preparing a nano titanium dioxide / polyacrylate compound emulsion. The method comprises the steps as follows: at a room temperature, mixing 4-10 parts of hexadecyl trimethyl ammonium bromide, 6-14 parts of acrylic acid and 10-30 parts of an acrylate monomer in parts by mass uniformly and then dropwise adding deionized water until the system becomes clear; adding 2-6 parts of butyl titanate and 1-4 parts of a silane coupling agent, then adding 30-50 parts of deionized water, and performing ultrasonic dispersion; and adding deionized water and hexadecyl trimethyl ammonium bromide, raising the temperature, stirring, and dropwise adding a mixed solution of an initiator and deionized water, performing thermal reaction, raising the temperature to 80-90 DEG C, performing thermal reaction for 0.5-3h continuously, and lowering the temperature to the room temperature to obtain the nano titanium dioxide / polyacrylate compound emulsion. The method is simple in process, and avoids a problem of 'secondary agglomeration' of conventional nano titanium dioxide in a polymerization process of the emulsion effectively, so that a polymerization reaction can proceed smoothly. The prepared nano titanium dioxide / polyacrylate compound emulsion has good stability.

Owner:SOUTH CHINA UNIV OF TECH

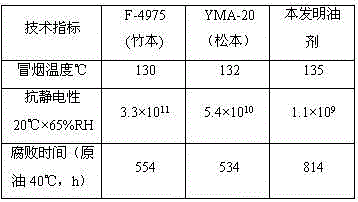

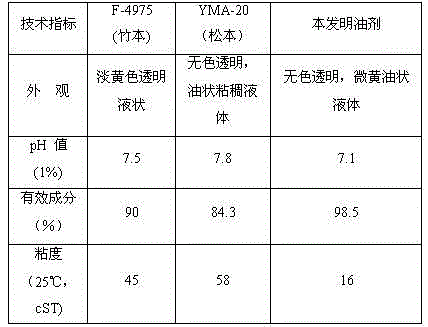

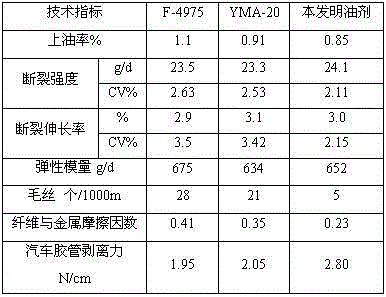

Aramid fiber oiling agent

The invention provides an aramid fiber oiling agent. The aramid fiber oiling agent comprises, by weight, 92-82% of a lubricating agent, 3-10% of a bundling agent, 5-8% of a composite antistatic agent, and the balance is an annexing agent. The lubricating agent is fatty acid sebacate. The aramid fiber oiling agent has the good antistatic property in various humidity conditions, corrosion is not likely to happen, the requirements for reducing of fiber corrosion and enhancing of composite performance of fibers and rubber of aramid fibers with various standards in the spinning procuding or secondary processing process can be met, the aramid fiber quality can be effectively improved, and continuous processing quality can be effectively improved.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

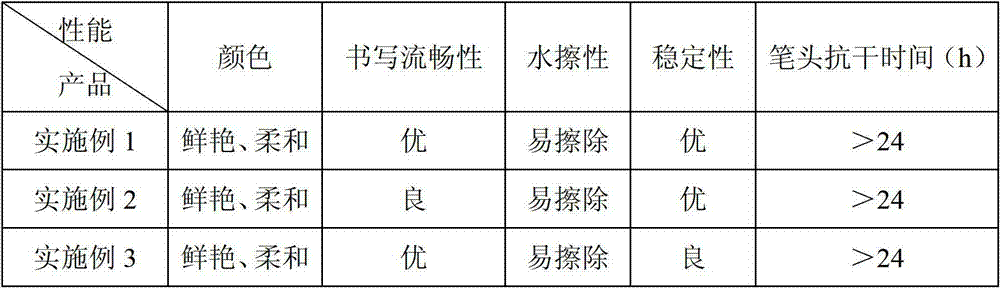

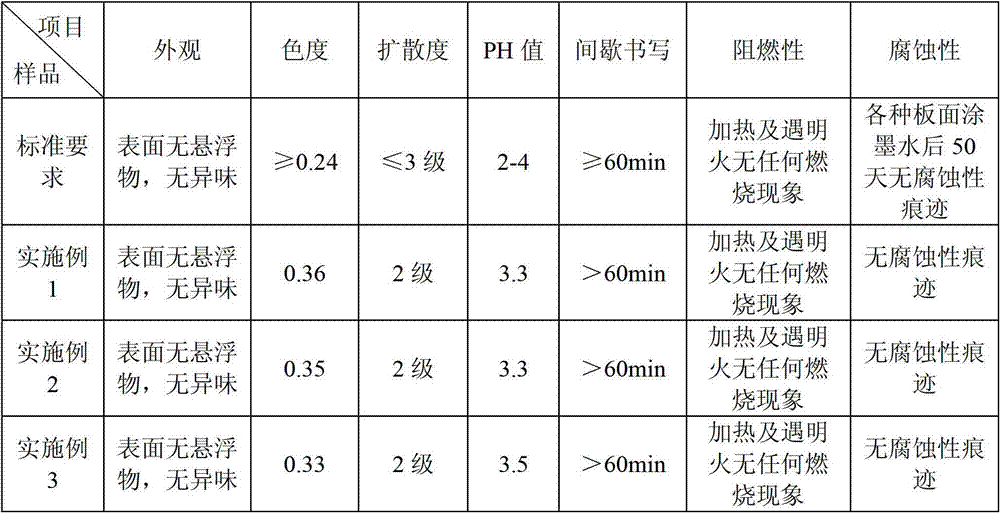

Environmental-friendly writing ink for white board pen

The invention discloses an environmental-friendly writing ink for a white board pen. The writing ink is made from the following materials in part by weight: 4-8 parts of plant pigments, 6-10 parts of emulsifying agents, 2-5 parts of castor oil, 3-7 parts of palygouskite, 15-25 parts of ethanol and 30-80 parts of deionized water. The ink has the advantages of environment protection, safety, stable long-placed performance, bright and soft color and smoothness in writing, can be quickly erased by water and is particularly applicable to the teaching white board pen.

Owner:SHANDONG LANBEISITE EDUCATIONAL EQUIP GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com