Nanometer titanium dioxide/acrylate polymer composite emulsion and preparation method thereof

A technology of nano-titanium dioxide and acrylate, which is applied in the field of nano-titanium dioxide/acrylate polymer composite emulsion and its preparation, can solve the problems of low coating rate of composite emulsion nano-titanium dioxide, affecting the performance of latex film, complex nucleation mechanism, etc., to achieve Improved compatibility, guaranteed stability, and excellent dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In terms of parts by mass, its raw materials include the following components:

[0037] Modified nano titanium dioxide 3.2 parts

[0038] Acrylate monomer methyl methacrylate 40 parts

[0039] Co-emulsifier hexadecane 1.8 parts

[0040] Emulsifier Sodium Lauryl Sulfate and Tween 80 1.8 parts

[0041] Initiator potassium persulfate 0.4 part

[0042] 80 parts of deionized water

[0043] Prepare nano-titanium dioxide / acrylate polymer composite emulsion as follows:

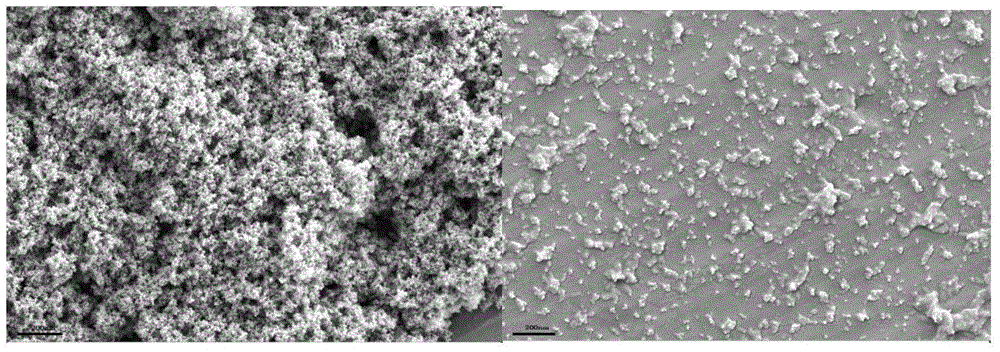

[0044] (1) Preparation of modified nano titanium dioxide

[0045] In terms of parts by mass, mix 3.2 parts of nano-titanium dioxide with 150 parts of isopropanol, disperse with 400W ultrasonic for 20 minutes, add 1.2 parts of vinyltrimethoxysilane, react at 70°C for 3.5h, centrifuge, wash with absolute ethanol, and centrifuge 1. Washing was repeated 3 times, and baked at 50° C. for 24 hours to obtain modified nano-titanium dioxide.

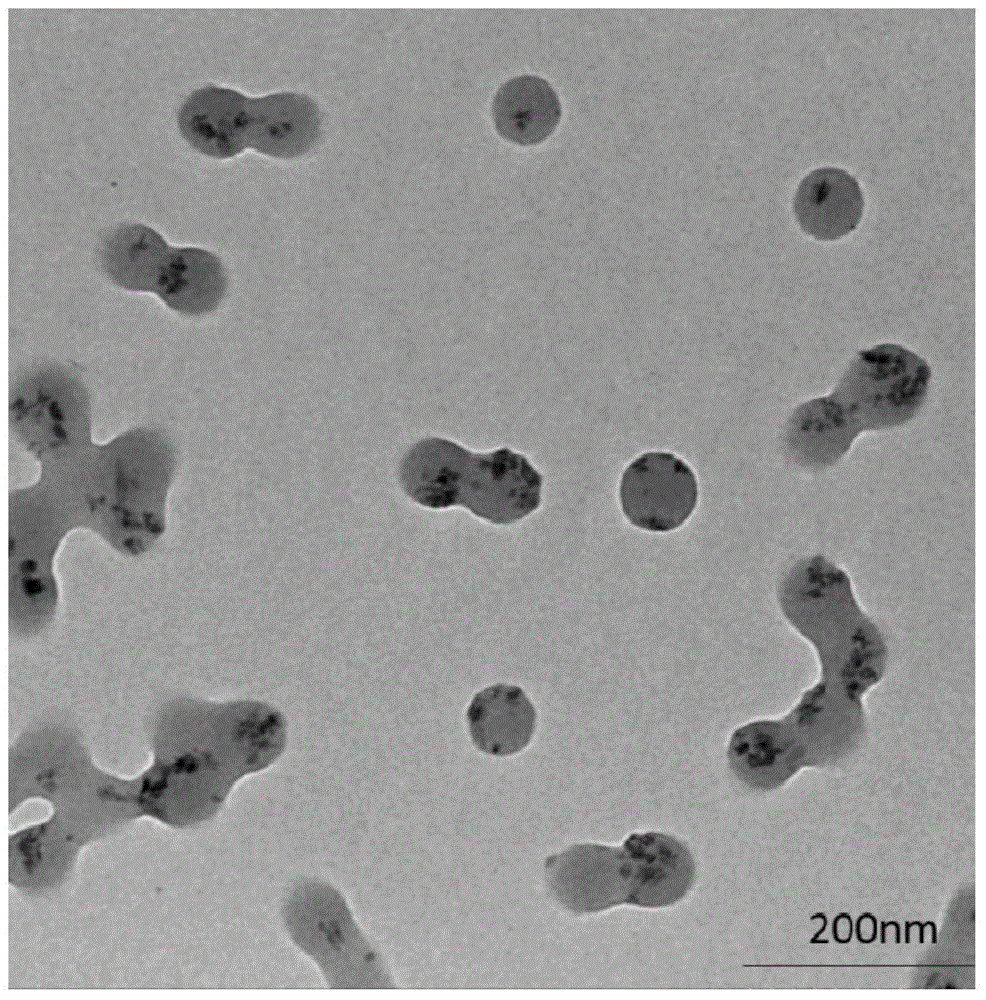

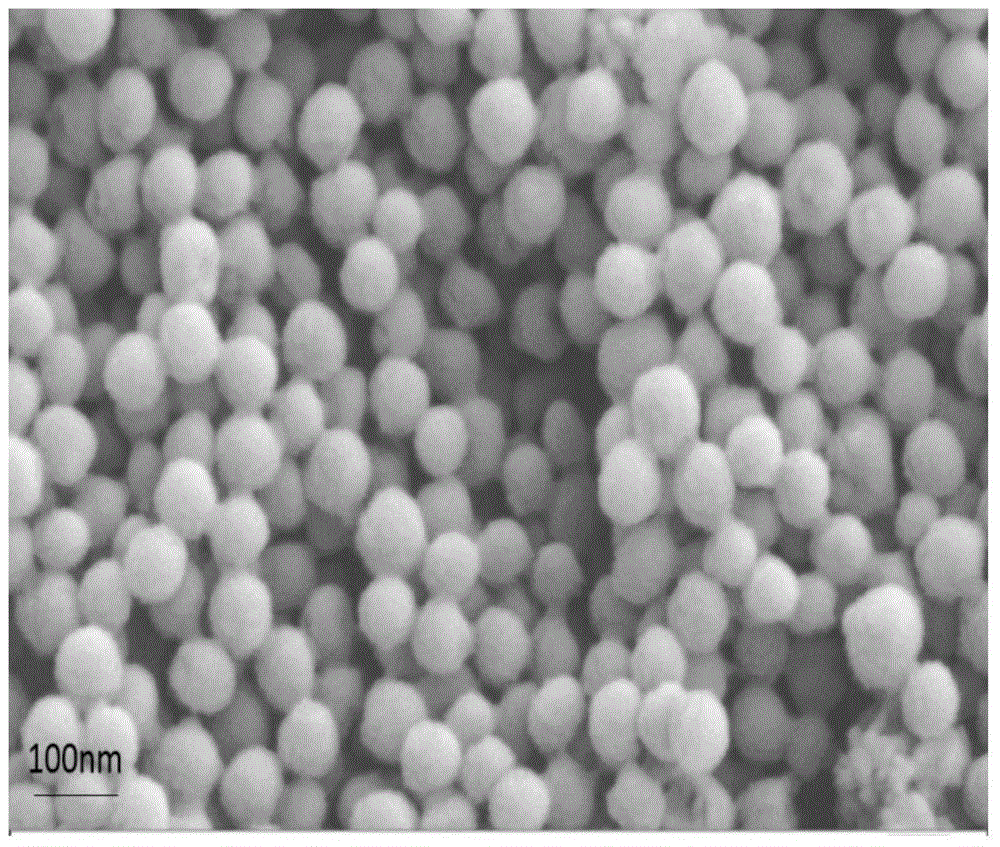

[0046](2) Preparation of Nano Titanium Dioxide / Acrylic Ester Polymer Co...

Embodiment 2

[0049] In terms of parts by mass, its raw materials include the following components:

[0050] Modified Nano Titanium Dioxide 5

[0051] Acrylic monomer acrylamide and butyl acrylate 50 parts

[0052] Co-emulsifier cetyl alcohol 2 parts

[0053] Emulsifier sodium oleate and Tween 80 2 parts

[0054] Initiator ammonium persulfate 0.5

[0055] Deionized water 80

[0056] Prepare nano-titanium dioxide / acrylate polymer composite emulsion as follows:

[0057] (1) Preparation of modified nano titanium dioxide

[0058] In terms of parts by mass, mix 5 parts of nano-titanium dioxide with 200 parts of ethanol, 800W ultrasonic dispersion for 35 minutes, add 5 parts of vinyltriethoxysilane, react at 80°C for 6 hours, centrifuge, wash with absolute ethanol, centrifuge and wash Repeat 3 times, and bake at 100° C. for 12 hours to obtain modified nano-titanium dioxide.

[0059] (2) Preparation of Nano Titanium Dioxide / Acrylic Ester Polymer Composite Emulsion

[0060] In terms of part...

Embodiment 3

[0062] In terms of parts by mass, its raw materials include the following components:

[0063] Modified Nano Titanium Dioxide 2.25

[0064] Acrylic monomers acrylate, tert-butyl methacrylate and acrylic acid 35 parts

[0065] Co-emulsifier n-pentanol 1.25 parts

[0066] Emulsifier sodium oleate 1.25 parts

[0067] Initiator hydrogen peroxide 0.3 part

[0068] Deionized water 70

[0069] Prepare nano-titanium dioxide / acrylate polymer composite emulsion as follows:

[0070] (1) Preparation of modified nano titanium dioxide

[0071] In terms of parts by mass, mix 2.25 parts of nano-titanium dioxide with 110 parts of methanol, 600W ultrasonic dispersion for 10 minutes, add 2.25 parts of γ-methacryloxypropyltrimethoxysilane, react at 60°C for 3.5h, centrifuge, and use Washing with absolute ethanol, centrifugation and washing were repeated 3 times, and drying at 75° C. for 18 hours to obtain modified nano titanium dioxide.

[0072] (2) Preparation of Nano Titanium Dioxide / Acr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com