Patents

Literature

57 results about "Cem cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gelatinization material gypsum-cement and producing method thereof

The invention relates to a gypsum-cement binding material and a production method thereof. The material contains gypsum binding material, active admixture, alkaline excitant, oagulation accelerator, lime, water-reducing agent, early-strength agent and gypsum hemihydrate. The weight proportions of the components are as follows: 40%-80% of gypsum binding material, 10%-45% of active admixture, 4%-15% of alkaline excitant, 0-6% of coagulation accelerator, 0-1% of early-strength agent, 0-1% of water-reducing agent, 0-5% of lime and 0-10% of gypsum hemihydrate. The production method comprises the following steps: weighing raw materials at the given ratio, mixing all raw materials, and packaging. The inventive gypsum-cement material has high strength, good water resistance and good volume stability; and can be used as masonry cement, cement mortar, gypsum plaster, jointing gypsum and heat-insulating mortar.

Owner:长沙归一新材料科技股份有限公司

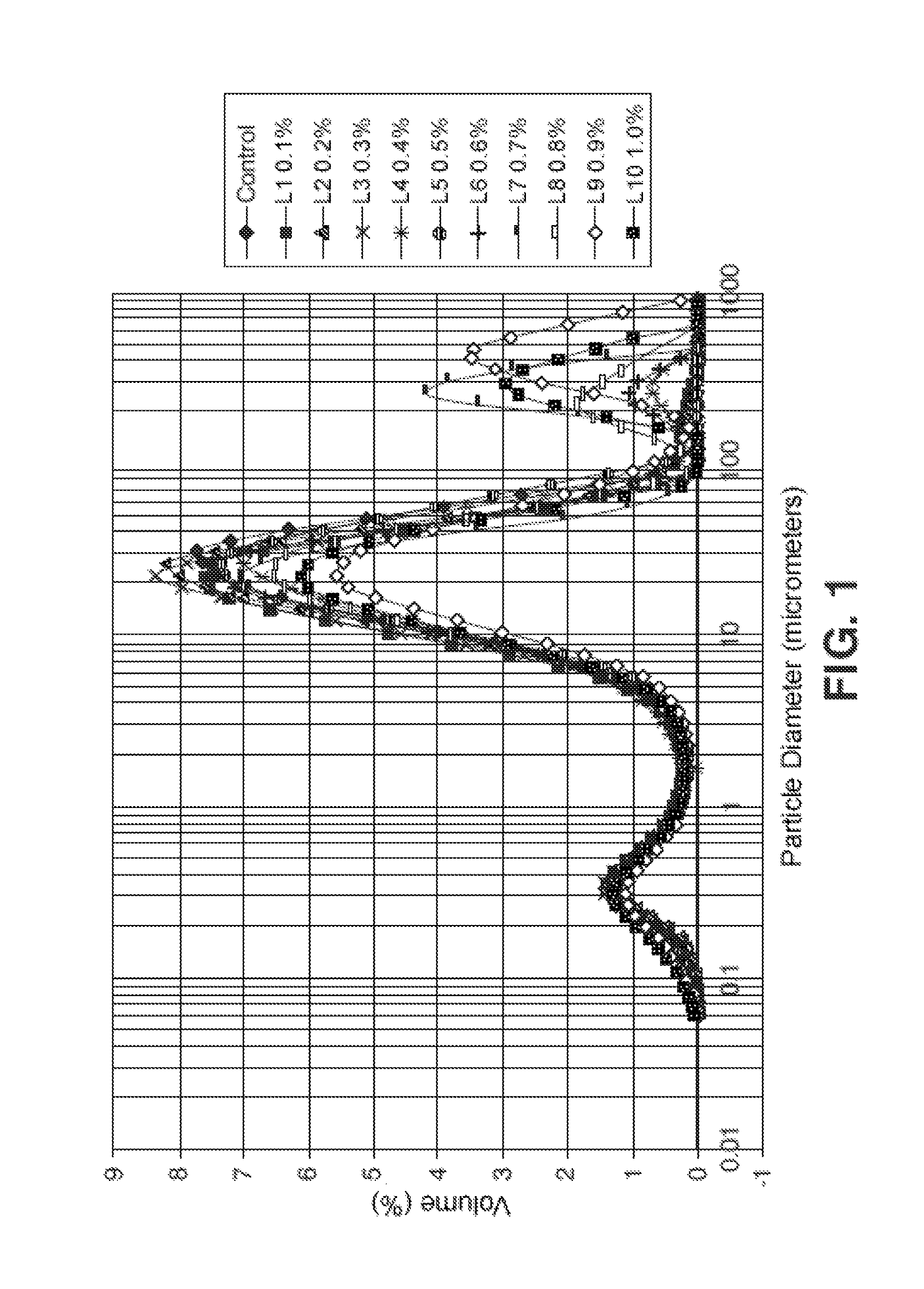

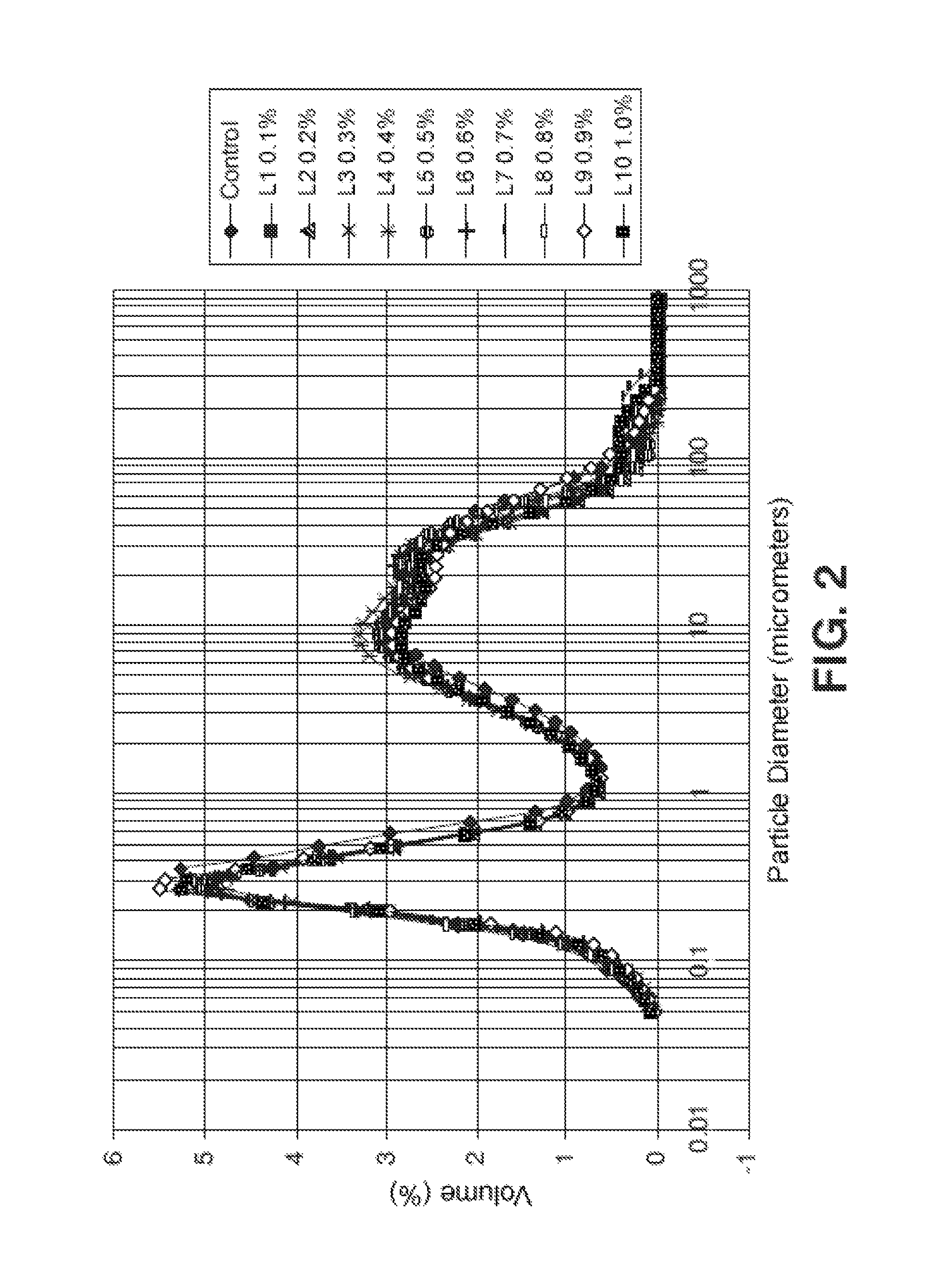

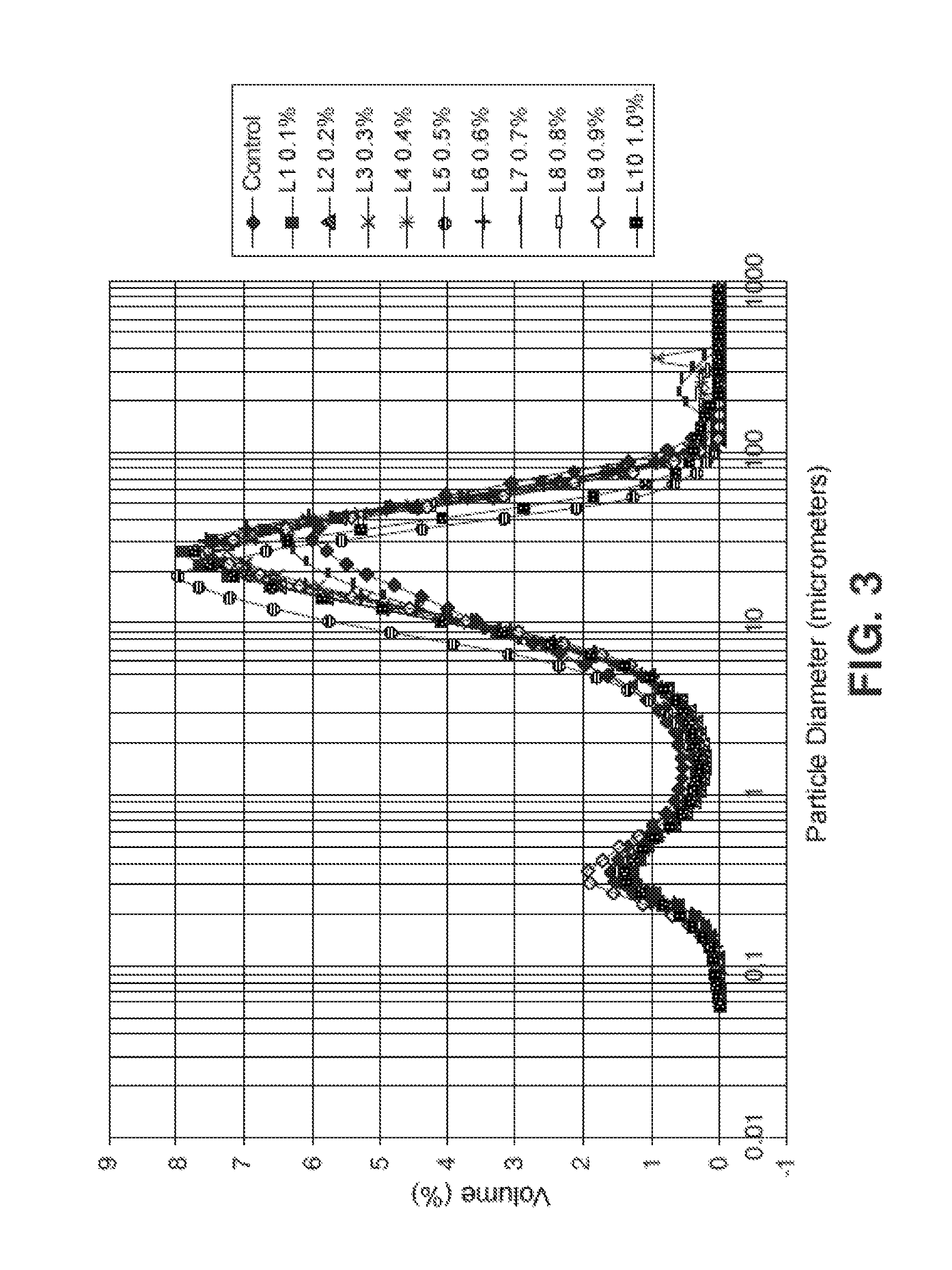

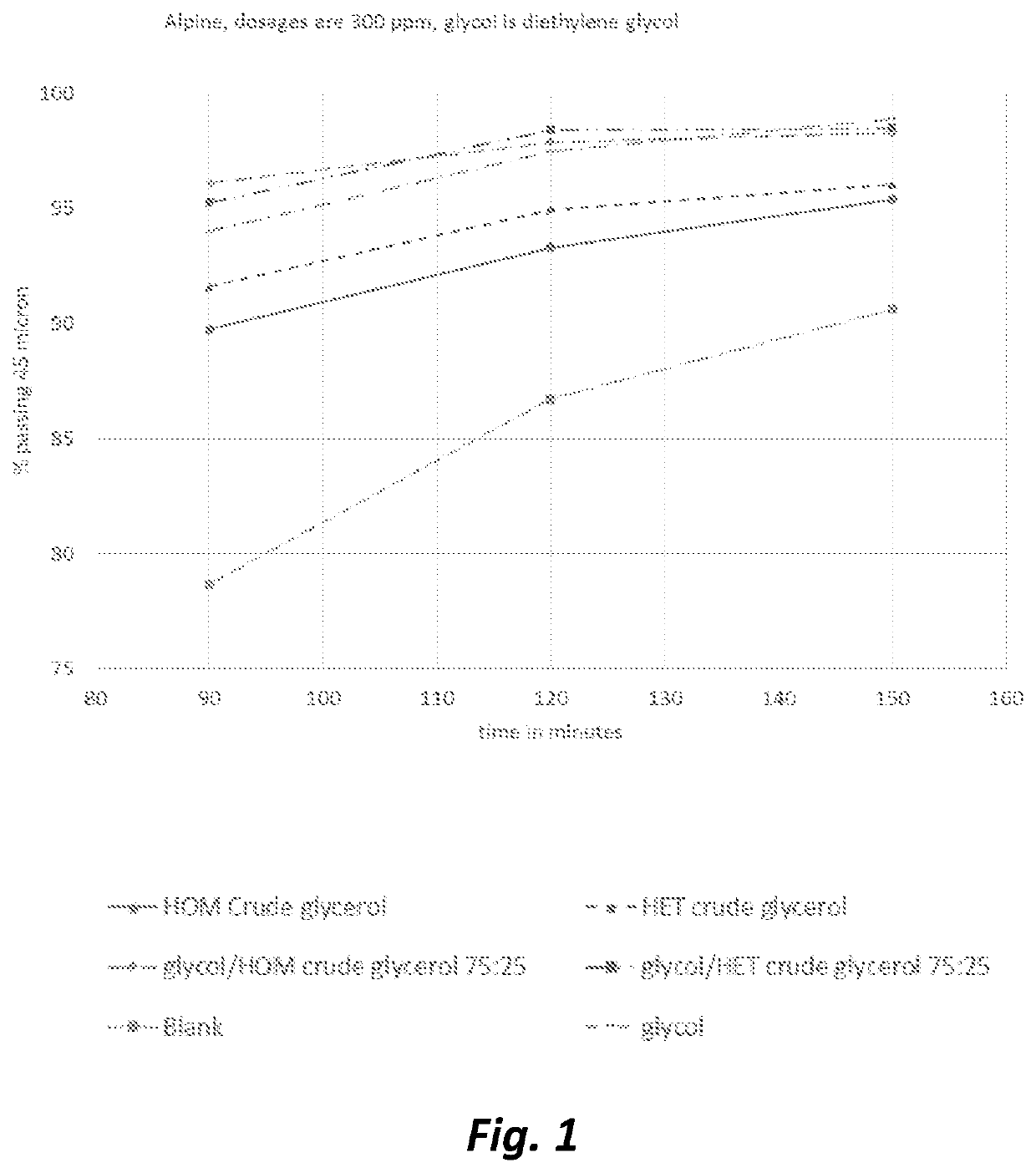

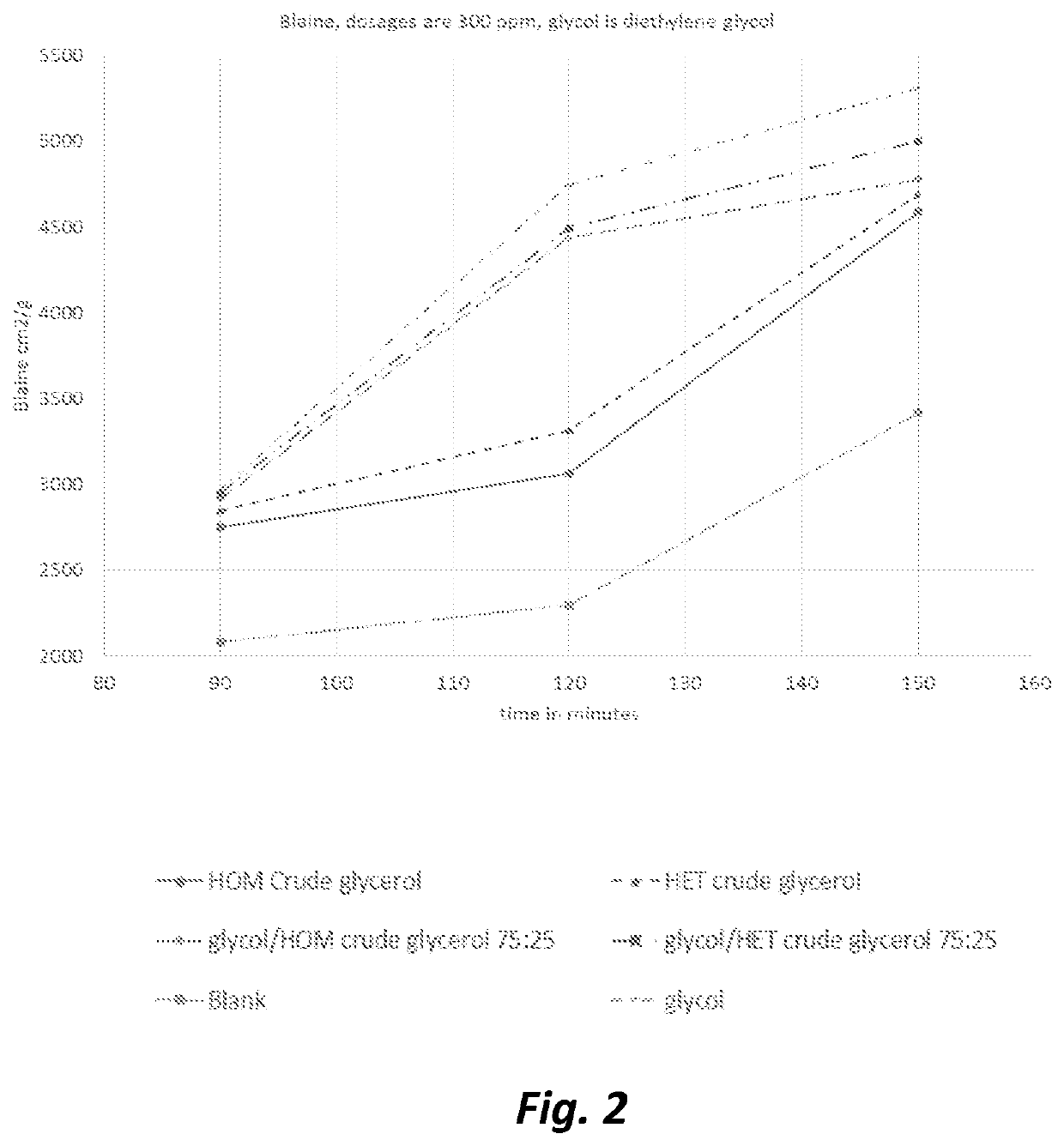

Biomass-derived grinding aids

Compositions and methods for increasing grinding efficiency of cement, cement clinker, raw materials for cement, and other inorganic particles. Use of biomass-derived polyols such as diols, triols, or mixtures thereof, optionally with a conventional grinding aid, cement quality improver, and / or hexavalent chromium reducer, are believed to provide less risk of sludging when compared to glycerides obtained from fossil fuel sources.

Owner:GCP APPL TECH INC

Preparation and application of cement material self-repairing molecular self-assembled microspheres

InactiveCN102049230ARealize controllable operationIntelligent self-healing functionMicroballoon preparationMicrocapsule preparationCross-linkBreaking strength

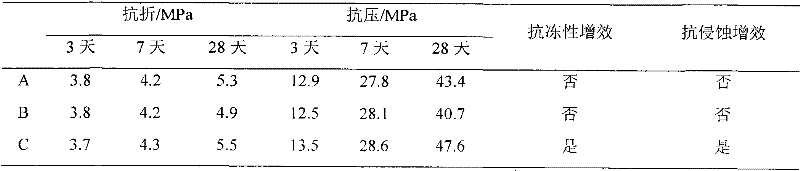

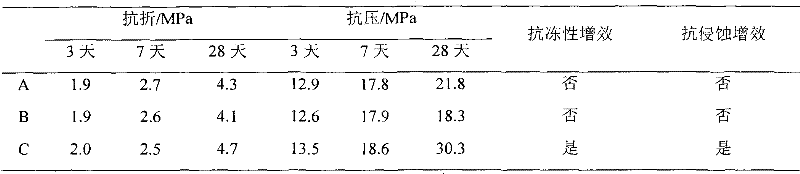

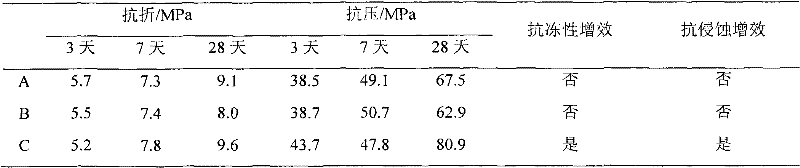

The invention discloses preparation of cement material self-repairing microspheres and application of the self-repairing microspheres in cement concrete. The microsphere preparation comprises the following steps: selecting repairing liquid with good repairing performance for cement and concrete; designing and screening self-repairing microsphere functional monomers; selecting cross-linking agent and porogen, and polymerizing the obtained functional monomers and the repairing liquid into microspheres with self-repairing function under proper conditions by using a molecular self-assembly technology; preparing self-repairing microspheres from the repairing liquid, the monomers, initiator, cross-linking agent, porogen and emulsifier under certain conditions in a certain proportion; and mixing the prepared cement material self-repairing microspheres in the cement and cement concrete to repair the material. By mixing the self-repairing microspheres, the breaking strength and compression strength of the cement concrete which cracks under stress are quickly recovered; and since the microspheres is added, the freezing resistance and erosion resistance of the cement concrete are remarkably improved.

Owner:UNIV OF JINAN

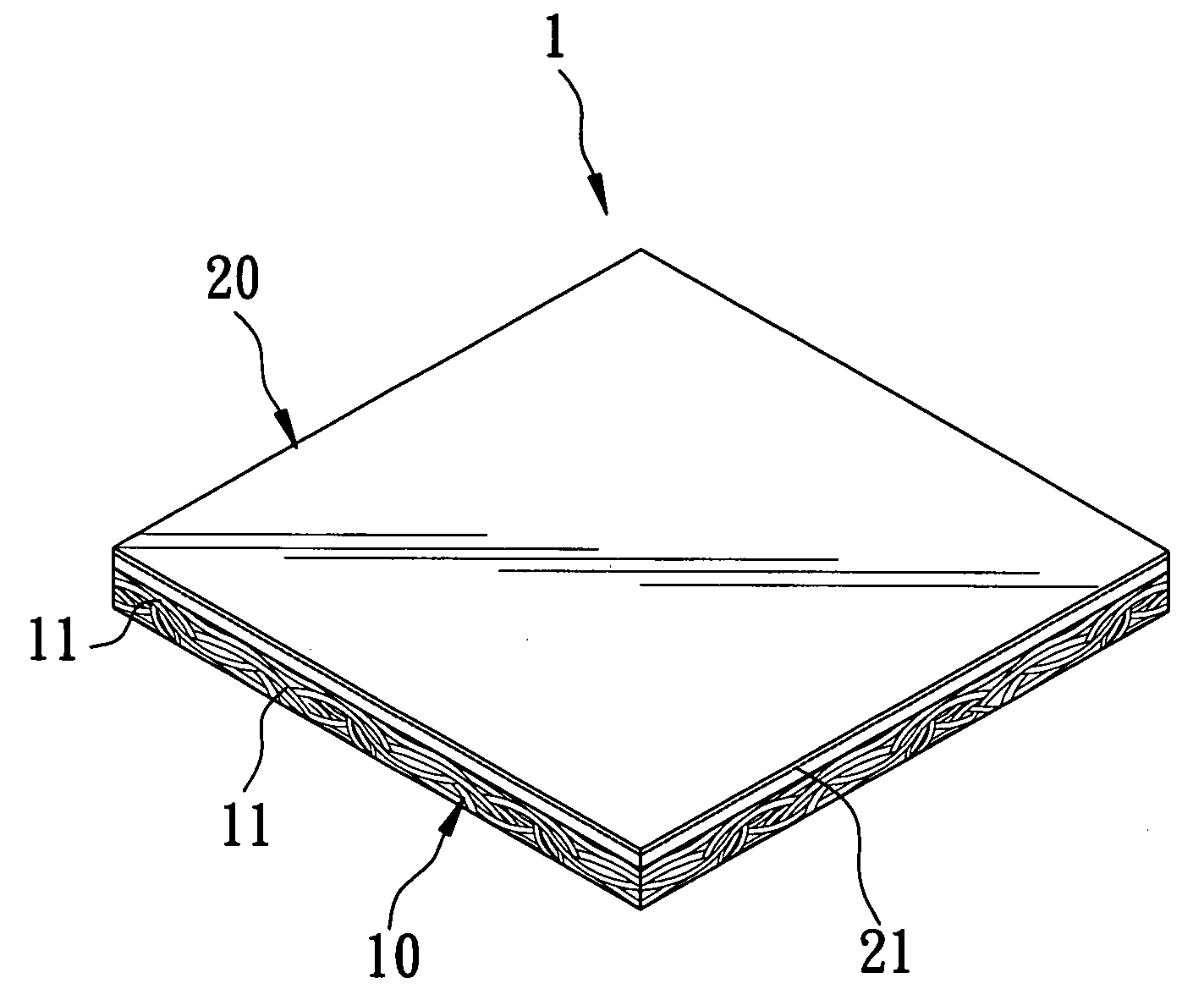

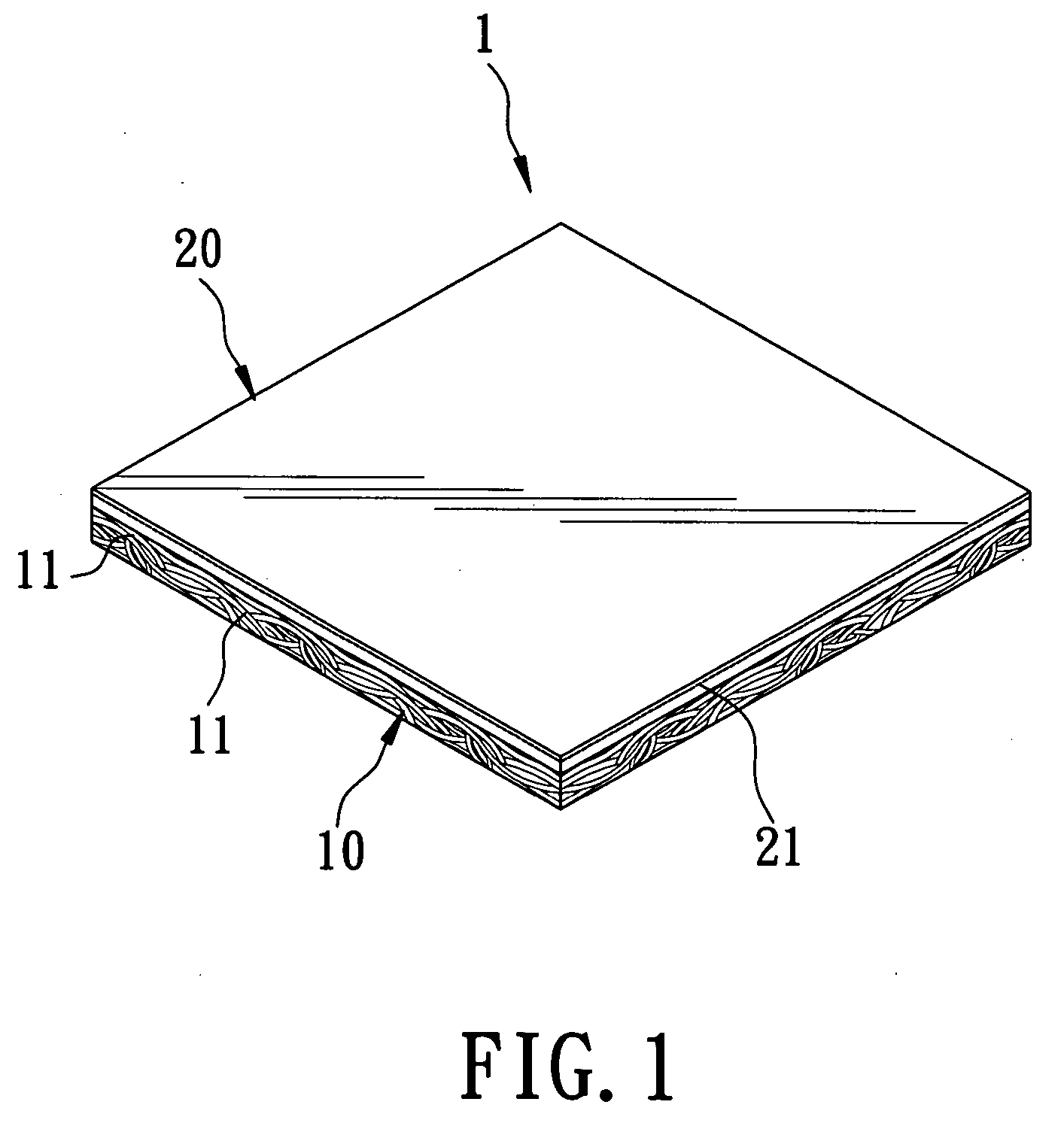

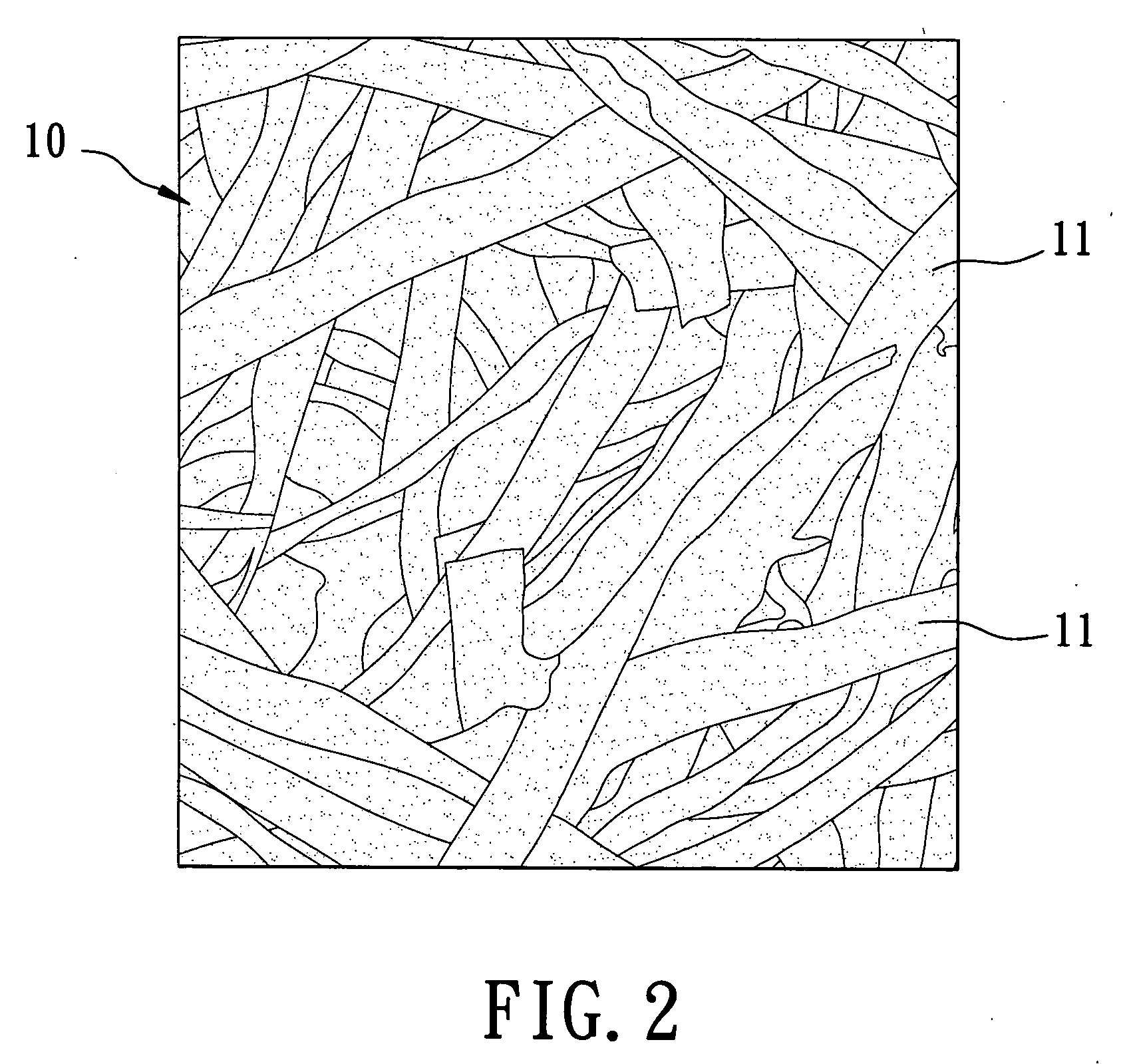

Composite panel and method of making the same

InactiveUS20060188740A1Easy constructionSolid waste managementCeramic shaping apparatusFiberChloride

Owner:KUAN YI CHE

Self-leveling cement mix for filling up and sealing diggings of channels, trenches, sewages and the like and for building works in general

A self-leveling cement mix employed for filling up and sealing excavations of channels, trenches, sewages and the like and for building works of various kinds. The cement mix includes large-sized sand of various kind having a mediangrain size of 3 mm, fine-sized sand of various kind having a median grain size of 1.5 mm, volatile ash as a remnant product of coal combustion, conventional type cement, cement aerating agent, fluidifying agent, and water.

Owner:KAPPA 6

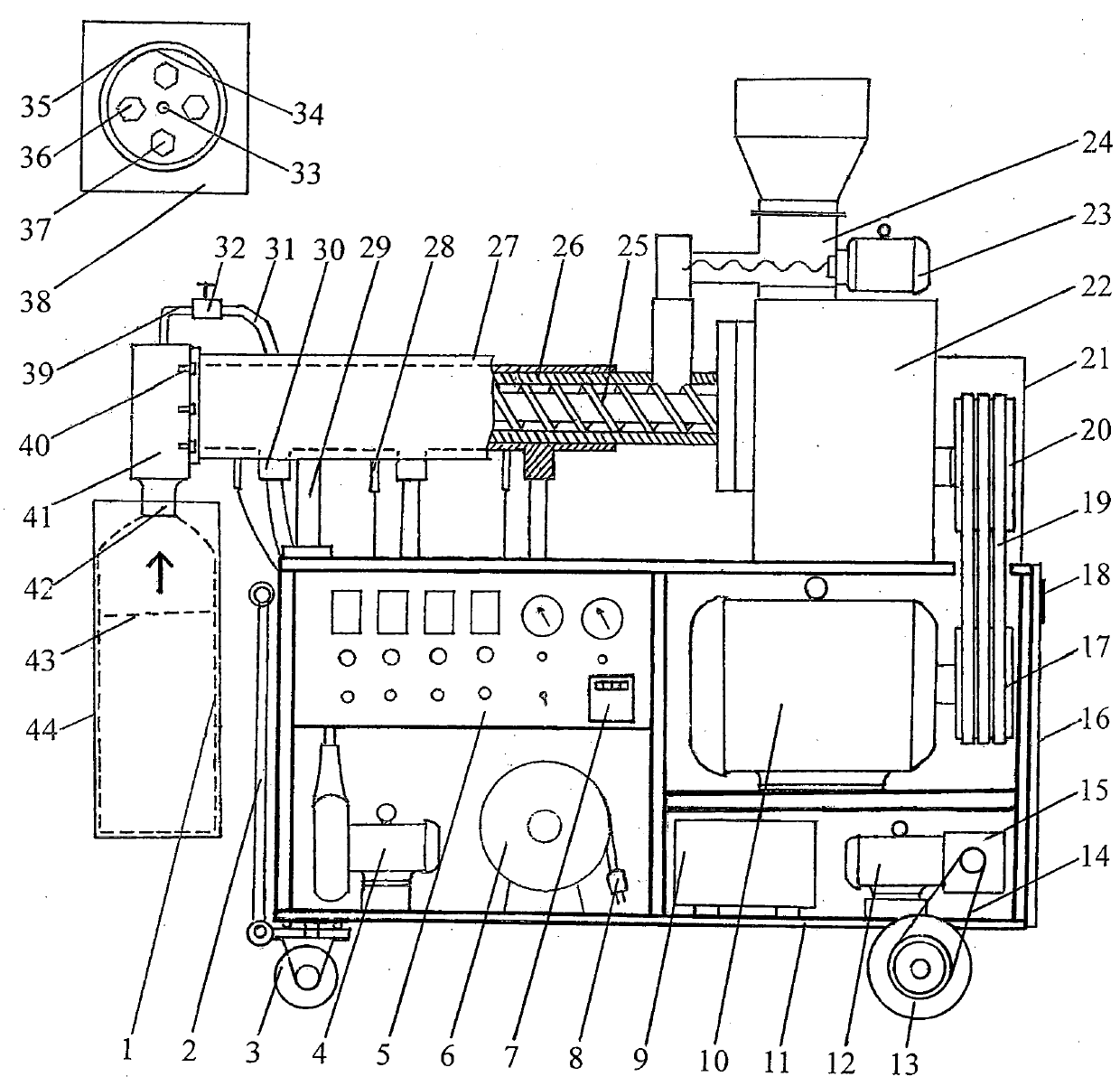

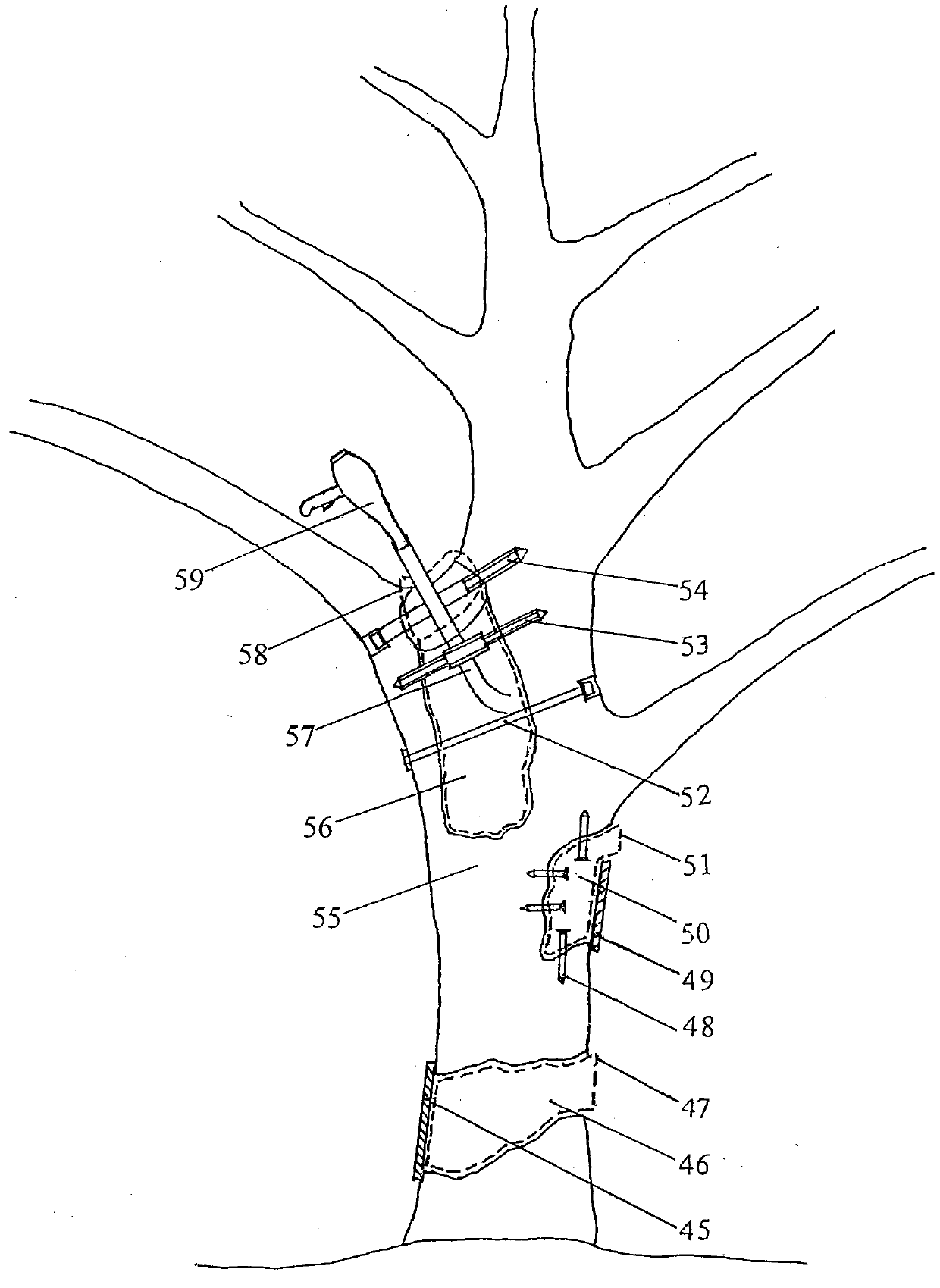

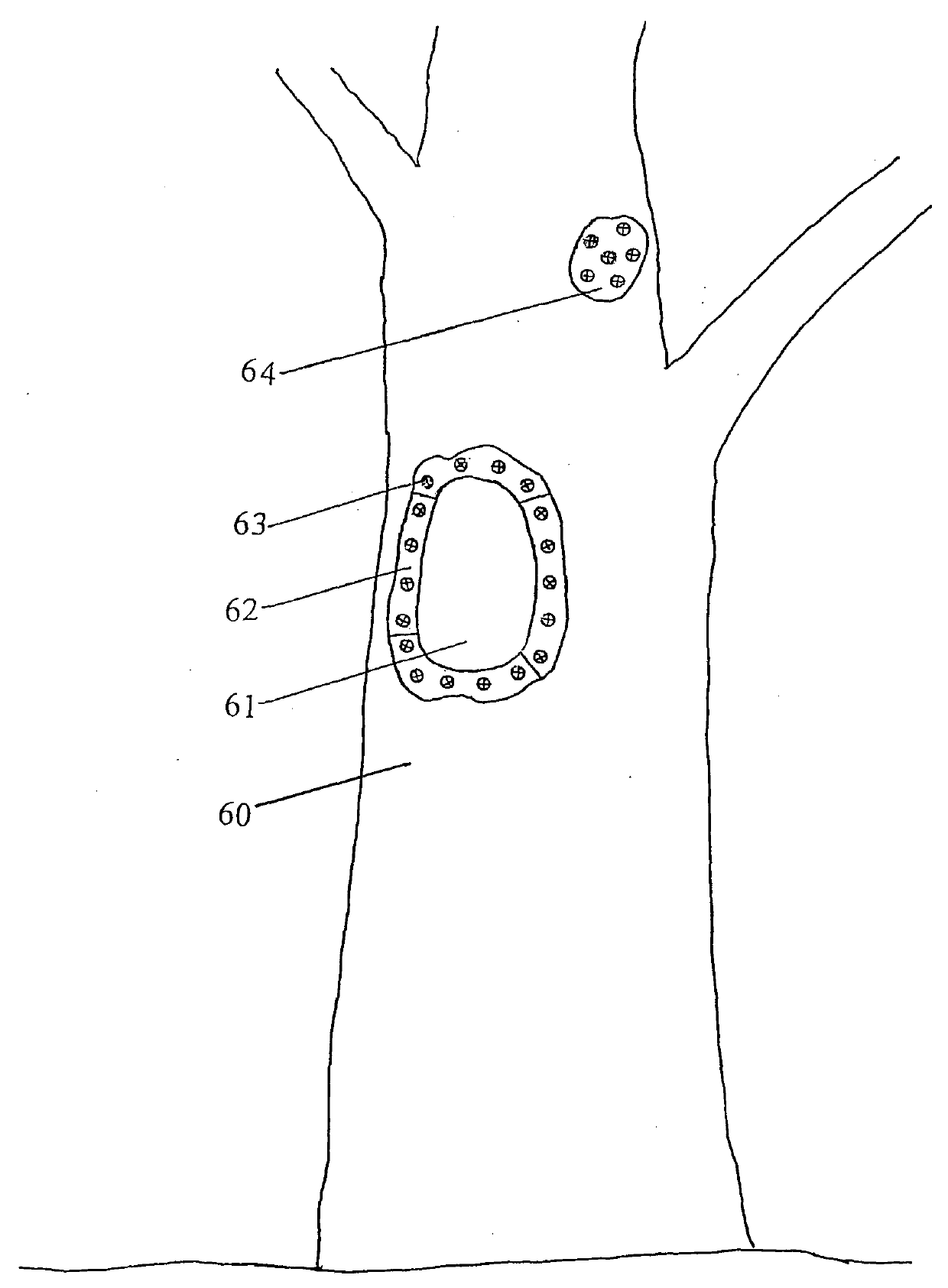

Method for repairing tree hole by manufacturing plastic thermal expansion bucket through moving type extruder and pouring cement

PendingCN107053627AGrowth does not affectWon't rotDomestic articlesHorticulture methodsChemical reactionThermal expansion

Disclosed is a method for repairing a tree hole by manufacturing a plastic thermal expansion bucket through a moving type extruder and pouring cement. The extruder is moved to a site, and the manufactured plastic thermal expansion bucket is put into the tree hole immediately; the wall of the thermal expansion bucket is blown to be heated through a hot air gun while the thermal expansion bucket is hot; the bucket wall expands when heated so as to be closely attached to the hole wall of the tree hole; metal tie bars and fixing screws are arranged in the cracked tree hole; the cement is poured in the bucket; after the cement is dried, a bucket opening is covered by a plastic plate; the hot air gun is used to blow the bucket edge and the plastic plate to melt and laminate the bucket edge and the plastic plate together; the cement plays a role in repairing and supporting; the tie bars tighten a circle of a trunk to be together to enable the trunk to be a whole trunk; plastic covers the cement so that the cement cannot absorb and evaporate water and conduct chemical reaction, and accordingly the tree hole is repaired by the cement; the plastic bucket wall does not affect growing of a tree; and wood pieces are additionally pasted on the opening-sealed plastic plate, the wood pieces are beneficial for growing and healing of bark, and finally the bark covers the plastic thermal expansion bucket and cement in a tree core to enable the big tree to be integral and grow normally.

Owner:王黔平

High-strength cement adhesive

The invention discloses a high-strength cement adhesive which is prepared from the following components in percentage by weight: 45%-60% of cement, 28%-35% of high-strength artificial sands special for a cement gel, 1.5%-2% of a water reducer and the balance of water. A preparation method comprises the following steps: firstly, uniformly mixing the cement with the high strength artificial sands special for the cement gel, adding water and the water reducer, and then further stirring for 4 minutes-8 minutes to prepare the adhesive; and then, after moulding an adhesive specimen, putting the adhesive specimen in a maintenance box at 50 DEG C-60 DEG C to evaporate, wherein the humidity is not less than 95%, demoulding for 4 hours-6 hours, and putting a demoulded specimen in hot water at 45 DEG C-70 DEG C to be maintained for 48 hours-96 hours. The high strength cement adhesive disclosed by the invention has excellent performances of simple components, stable performance and high strength. The adhesive is suitable for electric porcelain products of various high strength suspended porcelain insulators, so that the percent of pass of the insulators is remarkably improved and the production cost of the insulators is further lowered.

Owner:张耀辰

Concrete utilizing industrial solid waste and preparation method thereof

InactiveCN112608085AOvercome the defect of floatingEvenly distributedSolid waste managementCompressive resistanceThermal insulation

The invention relates to the field of concrete, and particularly discloses concrete utilizing industrial solid waste and a preparation method of the concrete, and the concrete utilizing the industrial solid waste is prepared from the following raw materials in parts by weight: 260-270 parts of cement; 45-55 parts of fly ash; 35-45 parts of mineral powder; 710-720 parts of fine sand; 990-1000 parts of broken stone; 10-12 parts of a water reducing agent; 140-160 parts of water; and 100-150 parts of modified waste polyurethane particles; wherein the modified waste polyurethane particles are obtained by coating the surfaces of waste polyurethane particles with modified slurry and curing, and the modified slurry is prepared from cement, a cement accelerator, plant fibers and water. The concrete has the advantage that the thermal insulation property and compressive strength of the concrete are improved.

Owner:陕西天皓万业混凝土工程有限责任公司

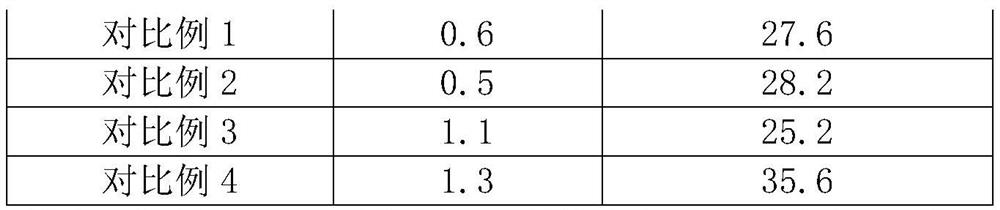

High-performance polymer repair mortar

The invention discloses high-performance polymer repair mortar which is prepared from the following raw materials in weight percent: 34 to 36% of dual-quick anti-cracking sulfur-aluminum cement, 4 to6% of cement, 0.14 to 0.16% of poly element acid, 2.4 to 2.6% of wacker rubber powder, 0.09 to 0.11% of cellulose mud, 0.24 to 0.26% of lithium carbonate coagulant, 0.29 to 0.31% of silicon-magnesiumlubricant, 0.06 to 0.08% of sodium citrate, 39 to 41% of washed-out sand and the balance of quartz sand. The prepared repair mortar disclosed by the invention has the advantages of good construction workability, strong binding force with concrete members, no drooping in trowel wiping, wide application to flat surfaces, vertical surfaces and top surfaces of the concrete members, no crack after being hardened, no shrinkage, high strength, very good frost thawing resistance, salt frost resistance, fluorinion permeability resistance and durability.

Owner:刘世新

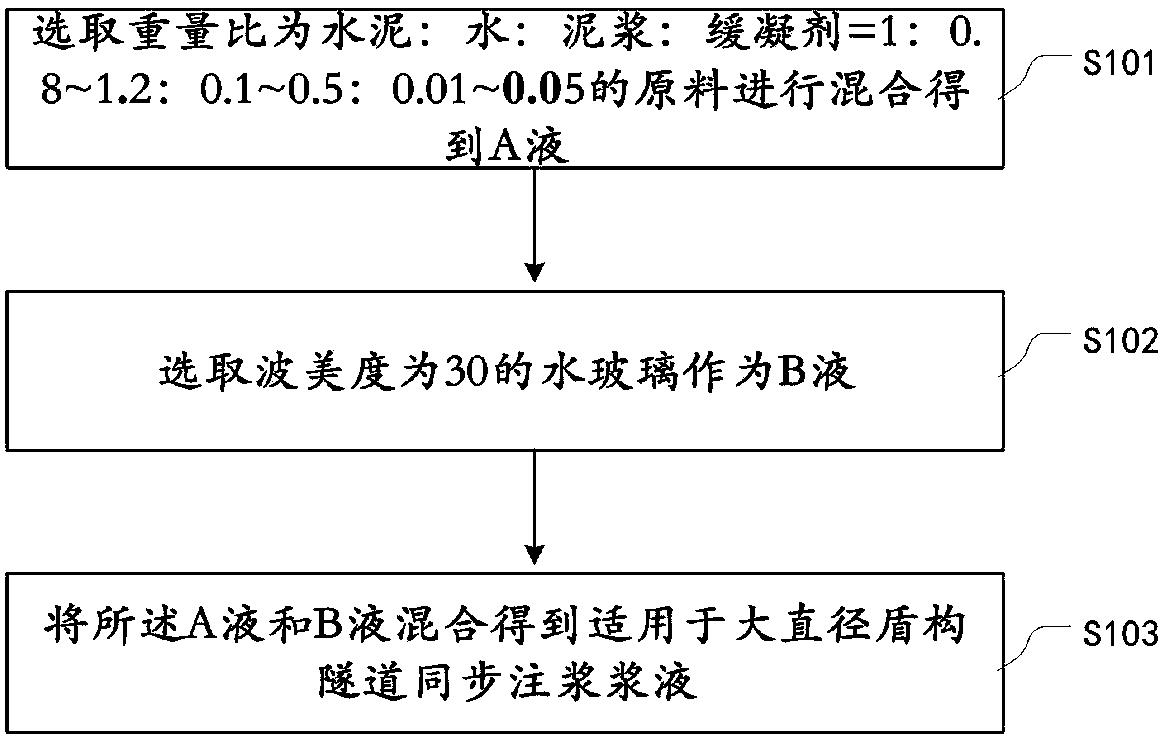

Slurry suitable for large-diameter shield tunnel synchronous grouting

InactiveCN108442932AThe preparation method is simple and easyQuality controllableUnderground chambersTunnel liningSocial benefitsAdditive ingredient

The invention relates to slurry suitable for large-diameter shield tunnel synchronous grouting. The slurry is composed of liquid A and liquid B, wherein the usage volume ratio of the liquid A to the liquid B is 10:1, the weight ratio of raw materials of cement to water to mud to a retarder in the liquid A is 1: (0.8-1.2): (0.1-0.5): (0.01-0.05), the liquid B is water glass with Baume degree of 30,and the liquid A and the liquid B are mixed to obtain the slurry. A preparation method of the slurry is simple, the mass of the slurry is easy to control, the cost of the ingredients is low, and goodeconomic and social benefits are achieved. The setting time of the slurry is short and is between 15s-20s, the early strength increases rapidly, and the later strength is high, the slurry has the advantages of being not prone to segregating and blocking pipes, and has a good effect on settlement control of large-diameter shield tunnels.

Owner:BEIJING JIAOTONG UNIV

Anti-seepage and anti-corrosion concrete and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to anti-seepage and anti-corrosion concrete and a preparation method thereof. The concrete product developed by the method comprises cement and graphene oxide of which the mass is 10-15% of that of the cement, a polymer is deposited between the graphene oxide layers; the molecular structure of the polymerhas an amidine group; and the amidine group is positioned on the side chain of the polymer molecular chain. The polymer is formed by in-situ polymerization of a monomer between the graphene oxide layers; in addition, the concrete also comprises a chelating agent; and the chelating agent is deposited between the graphene oxide layers. In the actual use process, the obtained product has excellent anti-seepage and anti-corrosion performance, and the service life of concrete can be effectively prolonged.

Owner:陈永霞

Solid fuel product

A solid fuel product can include a carbon based solid fuel, a cementitious material, and a plastic material. The carbon based solid fuel can include coal, petroleum coke, wood and / or other carbon products. The cementitious material can include Portland cement, lime, calcium aluminate cement, natural cement, slag cement, blended cement, cement kiln dust, lime kiln dust, and / or fly ash. The plastic material can include a thermoplastic material and / or a thermoset material. The solid fuel product can include about 45% by weight to about 98% by weight of the carbon based solid fuel and about 1% by weight to about 50% by weight of the plastic material.

Owner:Z DUST GRP INC

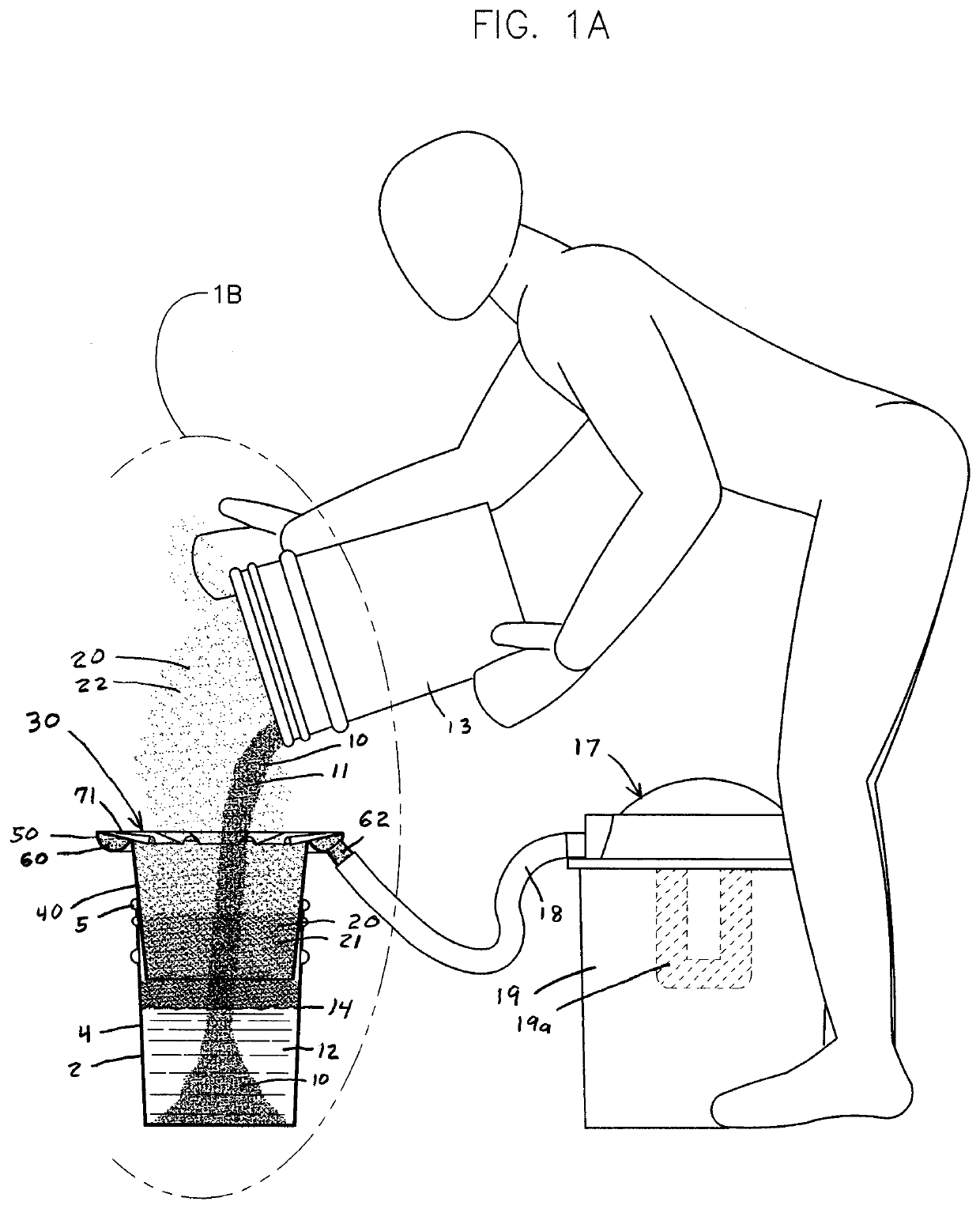

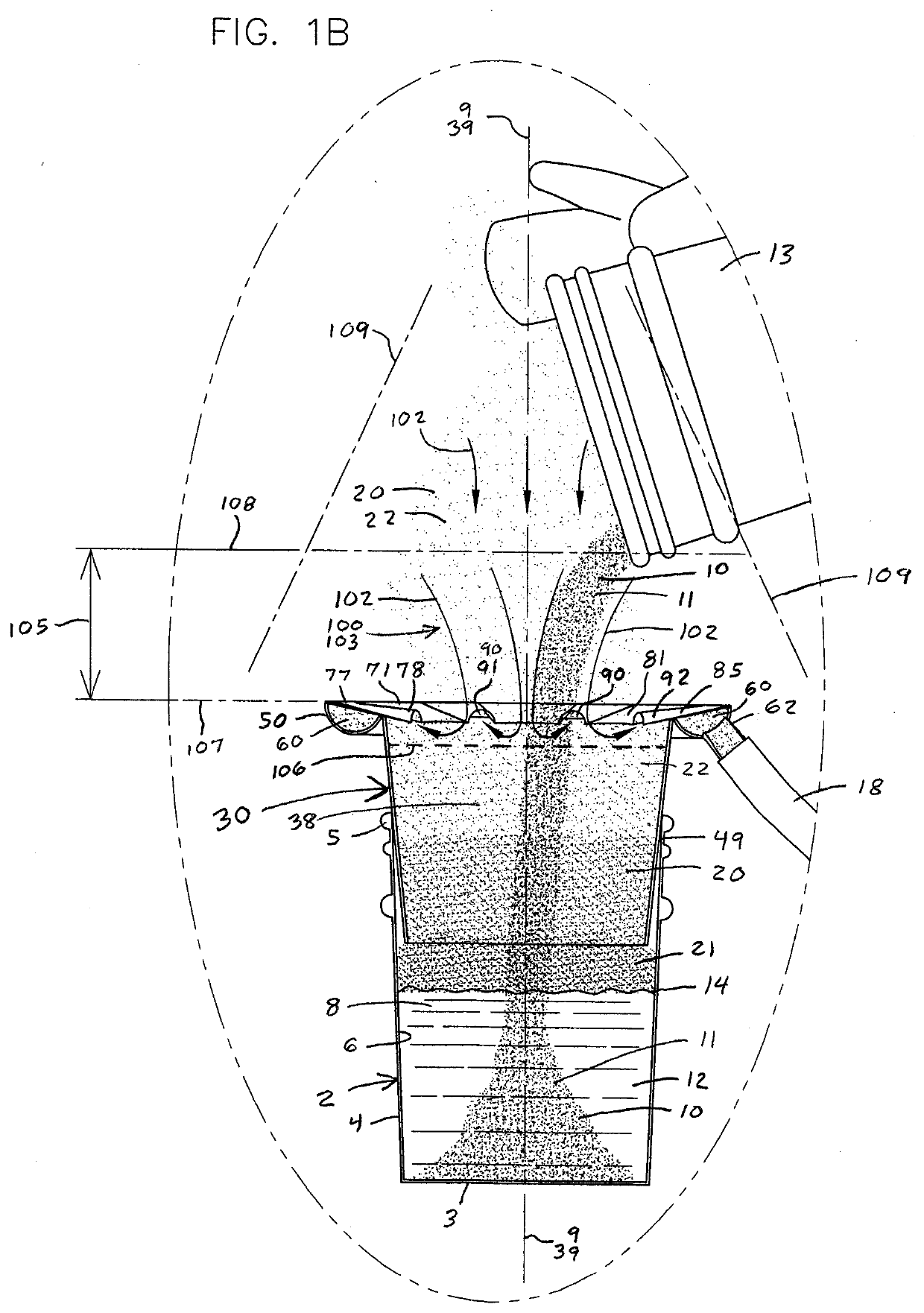

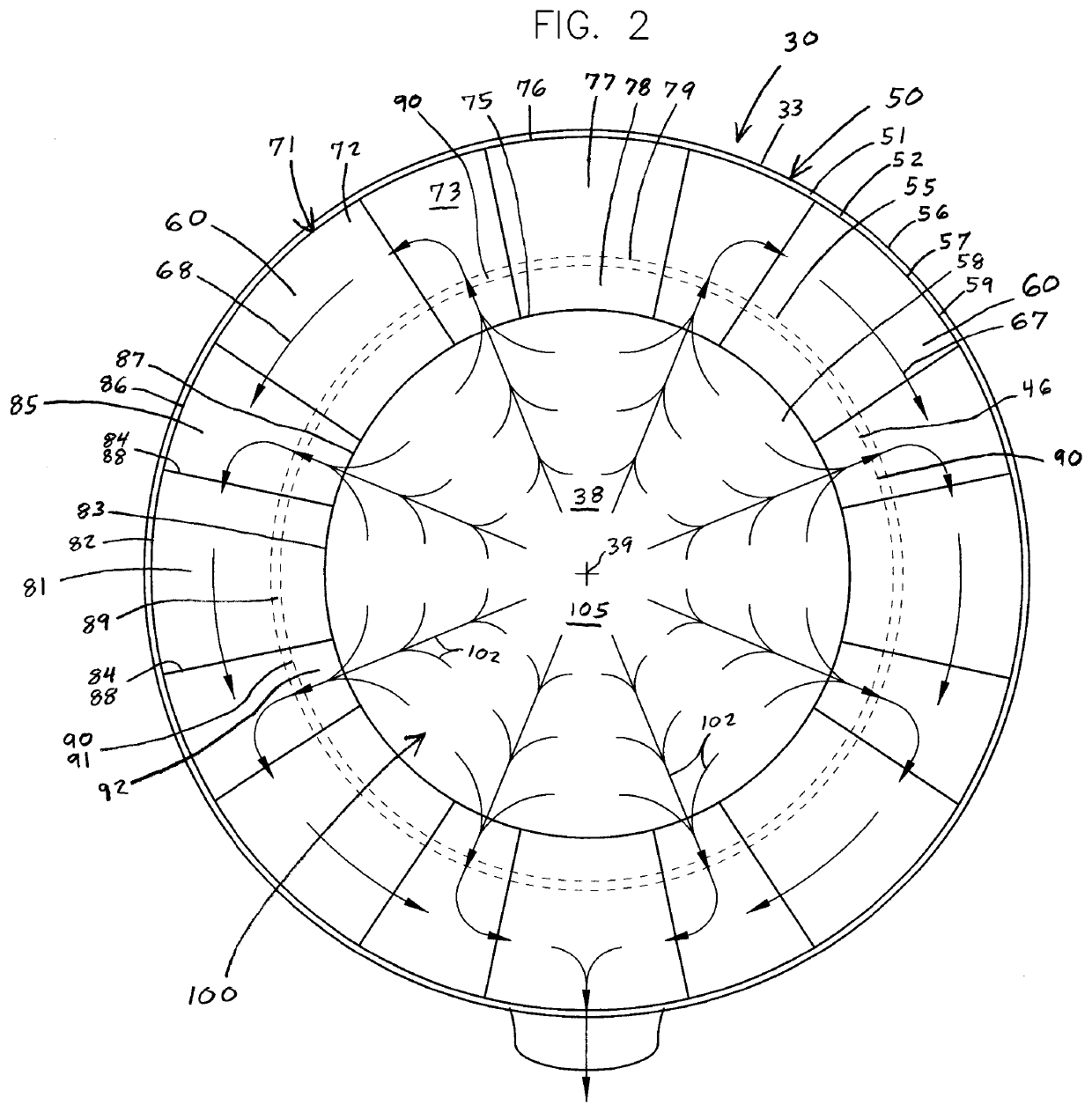

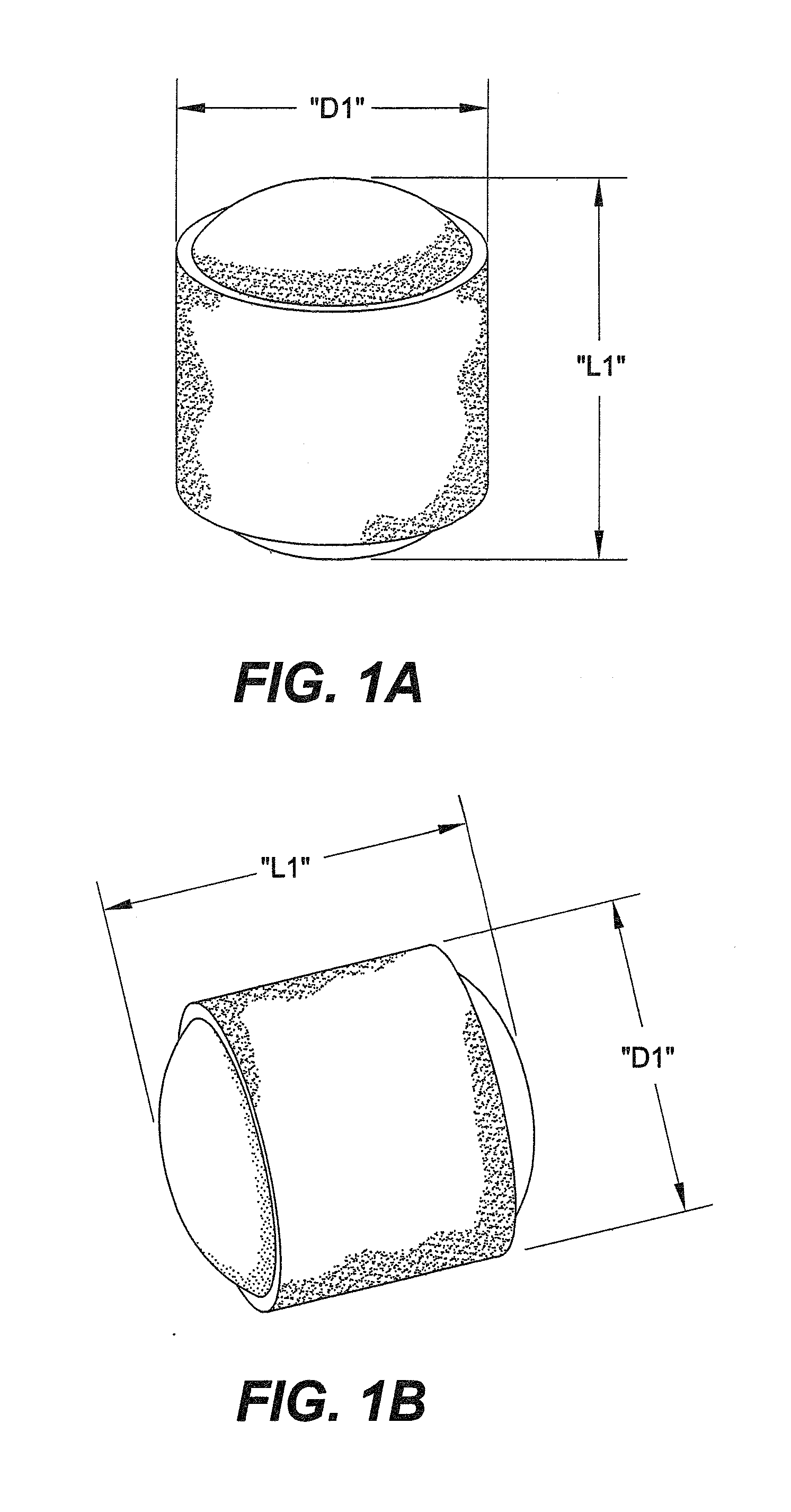

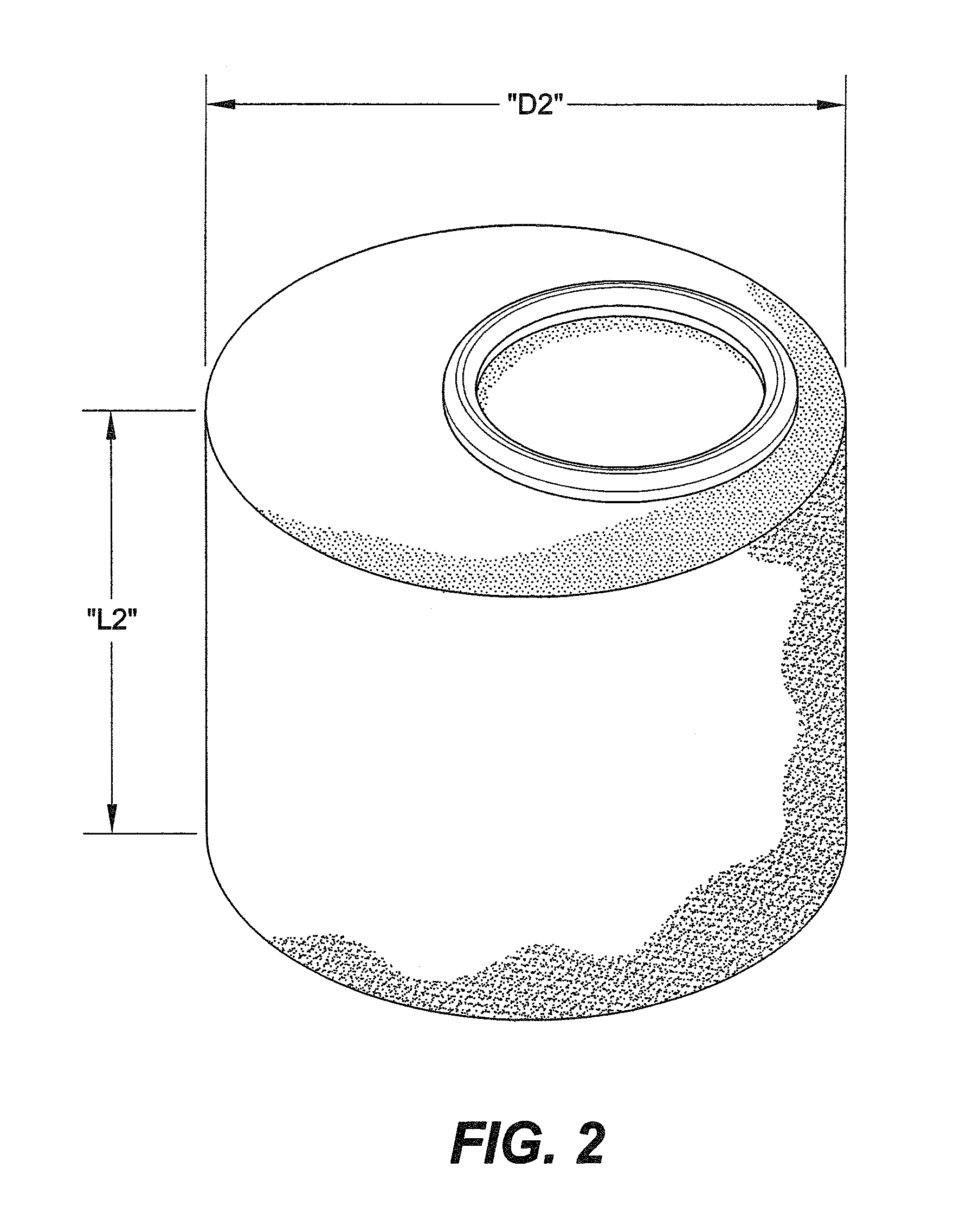

Dust Shield Device

ActiveUS20200222869A1Material is retainedImprove worker safetyRotary stirring mixersTransportation and packagingMining engineeringAir filter

The present invention is a dust shield device that secures over a mixing pail. Powdery material, such as plaster, cement, grout or the like, is poured through the device, and mixed with water inside the pail. The device includes a mounting sleeve, a radial manifold housing and a funnel shaped lid. The manifold housing and lid form a radial pneumatic channel with a circumferentially disbursed air intake that generates a radially uniform airflow that draws in airborne dust that would otherwise escape to the surrounding air. The manifold is connected to a vacuum with an air filter, and generates a dust shield zone air intake zone above the device. The manifold lid forms a radial guard to prevent downward flows of material and water from entering the manifold, and forms a splash guard to retain upwardly projected splashes of material and water inside the pail.

Owner:COONER CHARLES C

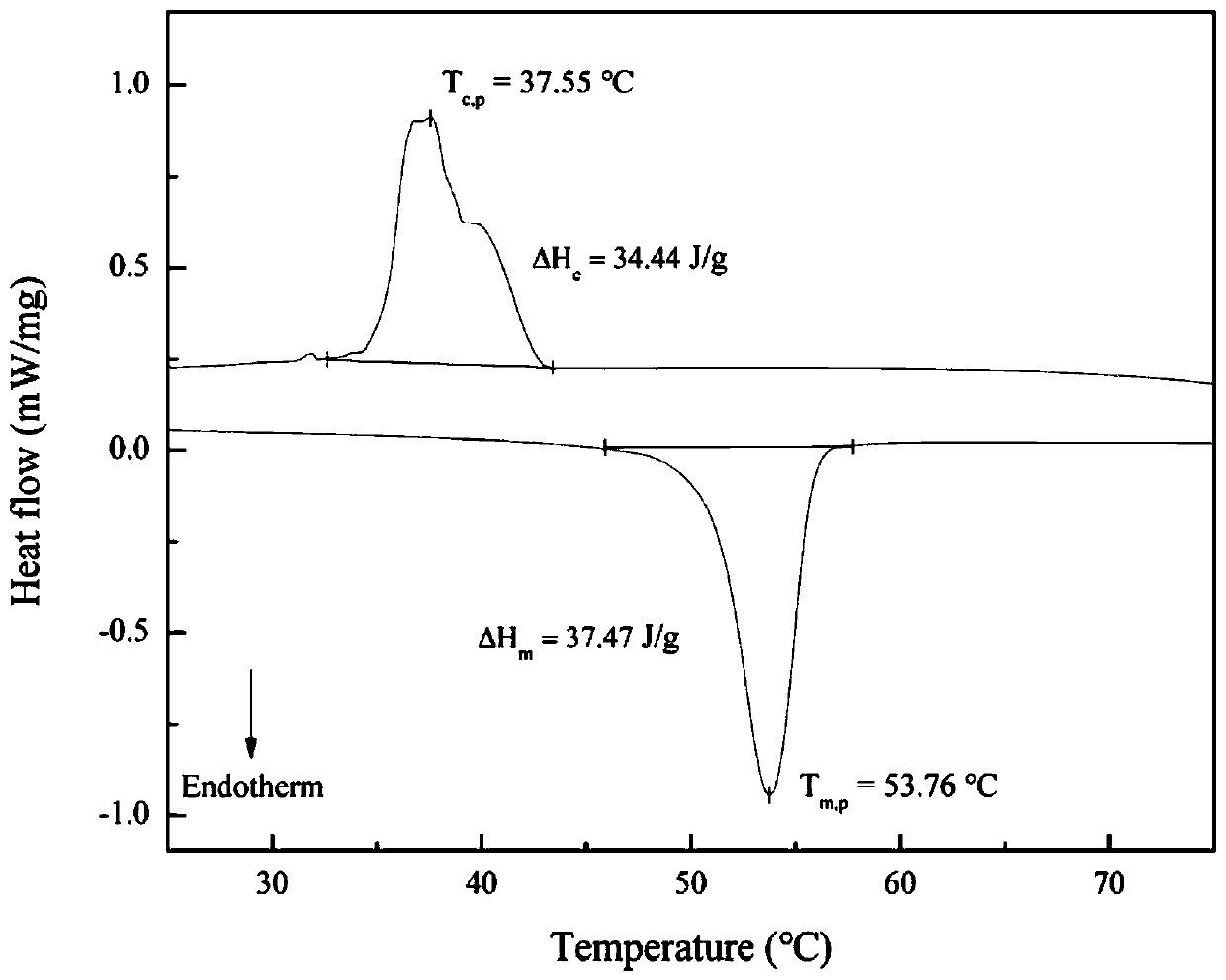

Preparation method of cement-based shape-stabilized phase change material

ActiveCN110776282AHigh encapsulation rateImprove stabilityHeat-exchange elementsHydration reactionPolymer science

The invention discloses a preparation method of a cement-based shape-stabilized phase change material, belonging to the technical field of preparation of phase-change materials. According to the invention, the cementitious characteristic of cement and the water solubility of a phase-change material polyethylene glycol are utilized; the cement is blended with an aqueous polyethylene glycol solutionand undergoes a hydration reaction with water in the solution, and the polyethylene glycol is gradually crystallized and separated out due to supersaturation and is wrapped by a generated hydration product; and when the cement is finally hydrated, the polyethylene glycol is firmly packaged by the hydration product. The cement-based shape-stabilized phase change material disclosed by the inventionhas the advantages of high phase change material encapsulation rate, good stability, simple preparation process, low cost and the like, and can be widely applied to the fields of heat energy storage,building energy conservation and the like. The hydration of the cement and the crystallization and precipitation of the polyethylene glycol are carried out at the same time, so the hydration productand a polyethylene glycol chain segment are intertwined; and thus, a stable packaging system is formed, and the prepared cement-based shape-stabilized phase change material is prevented from leaking when phase change occurs.

Owner:CENT SOUTH UNIV +1

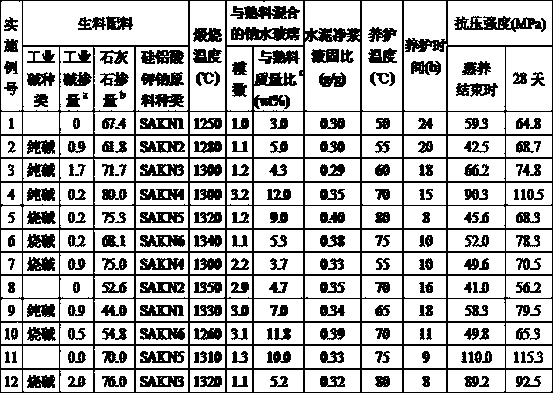

Preparation and using method of steam-curing alkali-activated cement

The invention discloses a preparation and using method of steam-curing alkali-activated cement. A small amount of industrial alkali and potassium sodium aluminosilicate and limestone are mixed and ground to be calcinated under the temperature of 1,250-1,300 DEG C and quenched to obtain a clinker, the clinker is ground into powder and evenly mixed into 3.0-12.0% of sodium silicate with the modulusbeing 1.0-3.2 to obtain cement, the cement is steamed and cured under the temperature of 50-80 DEG C for 8-24 h after being mixed with water to be uniform, and a high-intensity hardening body is obtained. The prepared cement has the advantages that hardening is rapid, the strength is high, raw materials are wide, the cost is low, consumption is low, low-carbon emission is achieved, and the performance is stable and easy to control, and the method is particularly suitable for preparing prefabricated parts.

Owner:湖南湘楚先路环保科技有限责任公司

Solid fuel product

A solid fuel product can include a carbon based solid fuel, a cementitious material, and a plastic material. The carbon based solid fuel can include coal, petroleum coke, wood and / or other carbon products. The cementitious material can include Portland cement, lime, calcium aluminate cement, natural cement, slag cement, blended cement, cement kiln dust, lime kiln dust, and / or fly ash. The plastic material can include a thermoplastic material and / or a thermoset material. The solid fuel product can include about 45% by weight to about 98% by weight of the carbon based solid fuel and about 1% by weight to about 50% by weight of the plastic material.

Owner:FORMULATED FUELS LLC

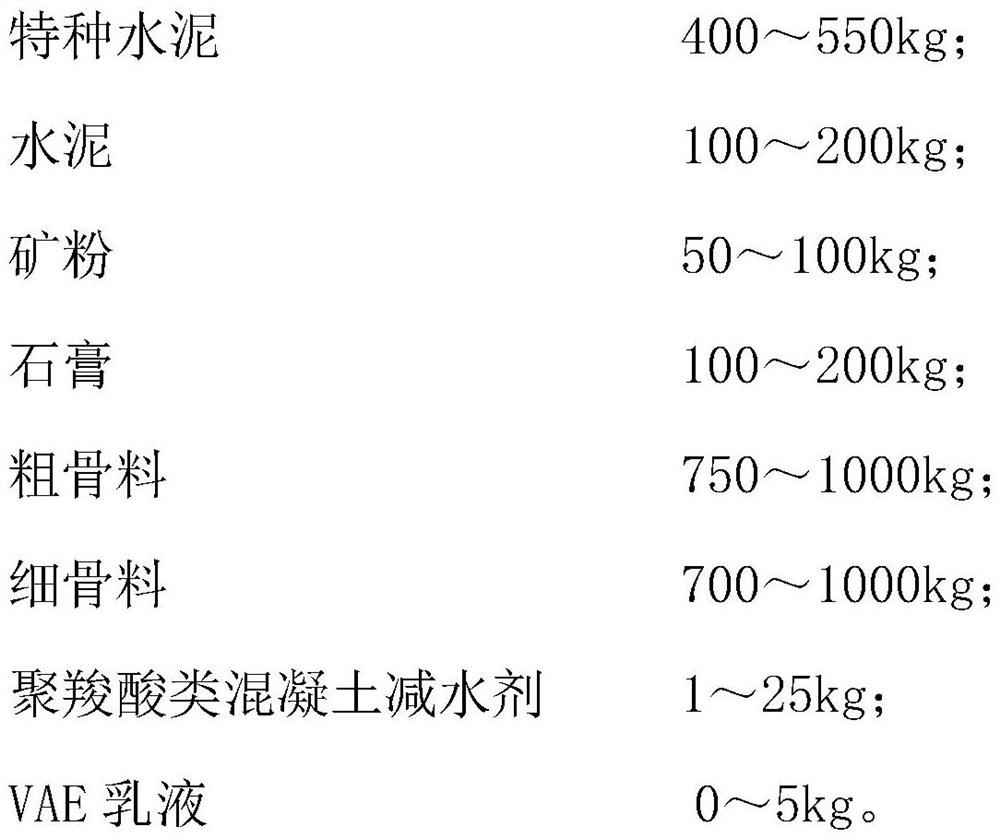

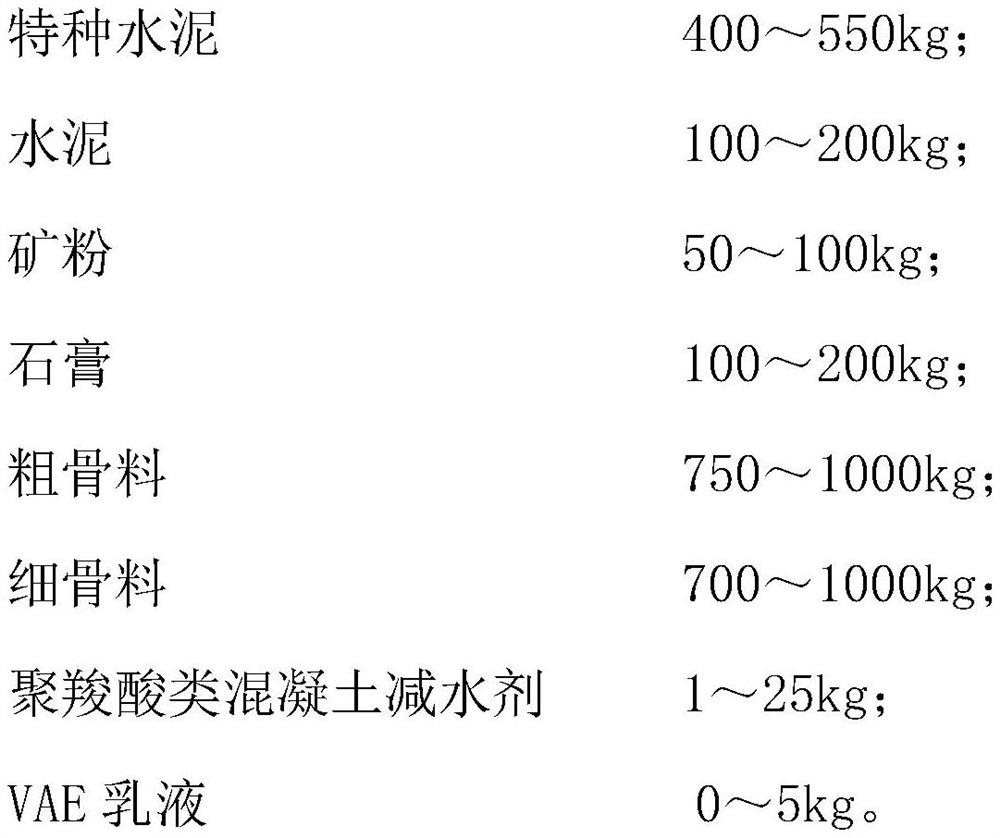

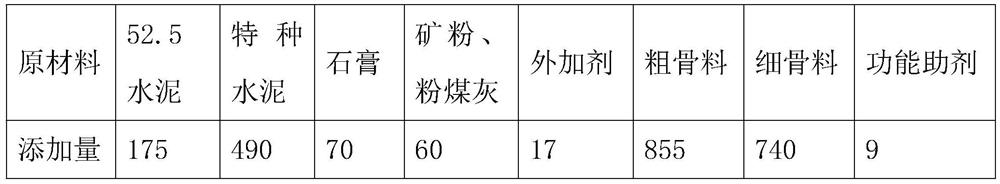

High-performance self-compacting concrete for rapid repair as well as preparation method and application thereof

The invention discloses a high-performance self-compacting concrete for rapid repair as well as a preparation method and application thereof, and belongs to the field of concrete materials. The high-performance self-compacting concrete is prepared by mixing and homogenizing special cement, cement, fly ash, mineral powder, gypsum, coarse aggregate, fine aggregate, a polycarboxylic acid concrete water reducer and VAE emulsion. The concrete is used as bridge expansion joint concrete, section thickening concrete or concrete under the conditions of narrow space and dynamic load, has the characteristics of super early strength, no shrinkage, high wear resistance, high adhesion, high toughness, high impact resistance, high durability and high workability, and effectively fills up the blank of theconcrete raw material industry.

Owner:SHANGHAI MEICHUANG ARCHITECTURAL MATERIALS +1

Use of carboxymethyl chitosans as additives in agglomerating compositions

The present invention belongs to the field of binder compositions for construction, more specifically it relates to the use of carboxymethylchitosan as flocculating additive and setting accelerator in binder compositions of the cement, cement mortar, concrete, grout, stucco and similar type. The invention also relates to binder compositions comprising carboxymethylchitosan, as well as to the method for their preparation.

Owner:UNIV DE NAVARRA

Preparation method of mortar with efficient water-resisting, moisture-resisting expanding, crack-resisting and seepage preventing functions

The invention discloses a preparation method of mortar with efficient water-resisting, moisture-resisting expanding, crack-resisting and seepage preventing functions. The preparation method is characterized by comprising the following steps: weighing raw materials cement, a cement compound additive, sands, polypropylene fibers and a naphthalene water reducer; putting the raw materials in a cone-shaped double helix stirrer in proportion, uniformly stirring for 50 minutes and stirring to obtain the mortar. The mortar disclosed by the invention has the efficient water-resisting, moisture-resisting, expanding, crack-resisting and seepage preventing functions and is free of corrosive action to reinforcing steel bars.

Owner:广州市盈坚建材科技发展有限公司

A kind of nanoscale cement preparation method

The invention discloses a method for preparing nanoscale cement. The method includes the following steps that firstly, moisture is controlled; secondly, ball hamming type ball milling grinding is conducted, wherein cement in the first step serves as raw materials, the ratio of grinding balls to the raw materials is 2 to 1, the grinding balls and the raw materials are placed into a hanging spring type double-barrel liquid cooling micro-nano ball mill grinding tank for high-energy ball hamming type sealed ball milling, and ball materials are separated and packaged through a 100-mesh screen. In the first step, two methods are adopted for controlling the moisture, firstly, cement needing to be prepared are selected and dried for 4 hours in a 120-DEG C electrothermal drying device; secondly, co-milling cement containing high polymers or fibers is prepared, additive is added to the cement, the added additive accounts for 0.25% to 2% of the cement, the cement is dehumidified for 6 hours in a sealed environment, and through the two methods, the moisture content of the cement is smaller than 3%. The method has the following advantages that the nanoscale cement can enter a hypotonic stratum with gaps with the diameter below the micrometer scale or concrete gaps; compressive strength is improved by 3 times; a microstructure with gas phase permeability lower than one or more times fundamentally changes.

Owner:重庆子易新材料科技有限公司

Sulfate-corrosion-resistant cement and cement mortar in marine environment as well as preparation method and application thereof

ActiveCN111675499AProlong the erosion timeWide variety of sourcesCement productionBulkheads/pilesPhysical chemistryBall clay

The invention relates to sulfate-corrosion-resistant cement and cement mortar in a marine environment as well as a preparation method and application thereof. The cement is prepared from the followingraw material components in parts by weight: 25-35 parts of shell lime powder, 15-20 parts of anhydrite and 40-50 parts of calcined ball clay, wherein the calcined ball clay is ball clay subjected tocalcination treatment. The preparation method comprises the following steps: calcining shells, grinding anhydrite and ball clay, calcining the ball clay, and mixing the calcined ball clay with anhydrite and shell lime powder. The problem that in the prior art, a high-pressure jet grouting pile is severely corroded by sulfate in the marine environment, and consequently the foundation reinforcing effect is poor is solved.

Owner:山东恒泰工程集团有限公司 +1

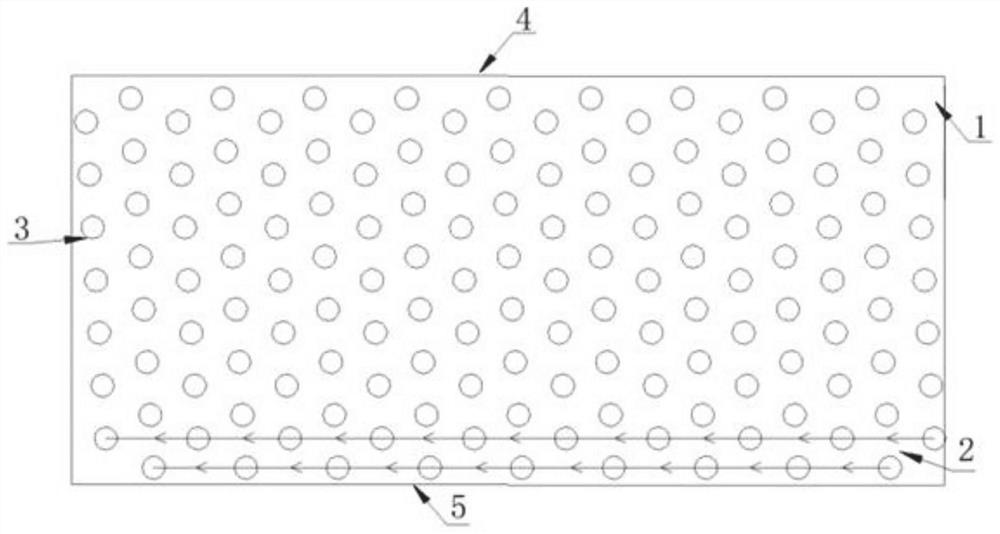

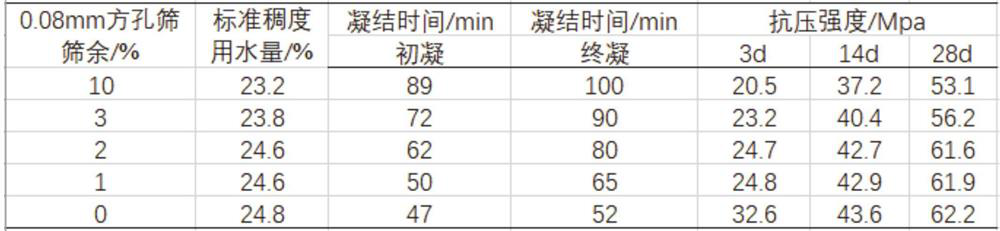

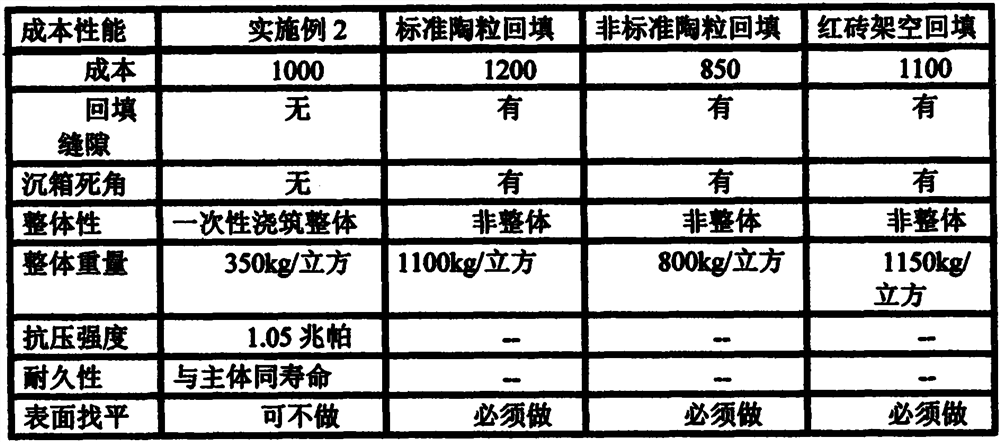

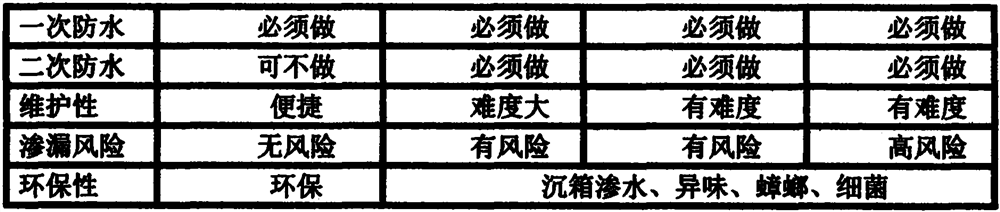

Backfill leveling material and using method thereof

The invention discloses a backfill leveling material and a using method thereof, and aims to solve the problem that a large amount of river sand is required when the conventional backfill leveling material is used. The product comprises the following raw materials in percentage by mass: 0.8-1.2% of a foaming agent, 0.4-0.65% of a reinforcing agent, 0.38-0.59% of an anti-cracking filler and the balance of cement. The cement comprises a mixture of ordinary Portland cement and sulphoaluminate cement, and the weight ratio of the ordinary Portland cement to the sulphoaluminate cement is (8-12): 1.The product is wide in raw material source, simple and convenient to use, high in foaming speed, good in pressure resistance, fluidity, light weight, water resistance, smoothness, environment-friendliness, heat insulation and durability, suitable for toilet backfilling and ground leveling and wide in application prospect.

Owner:韩超

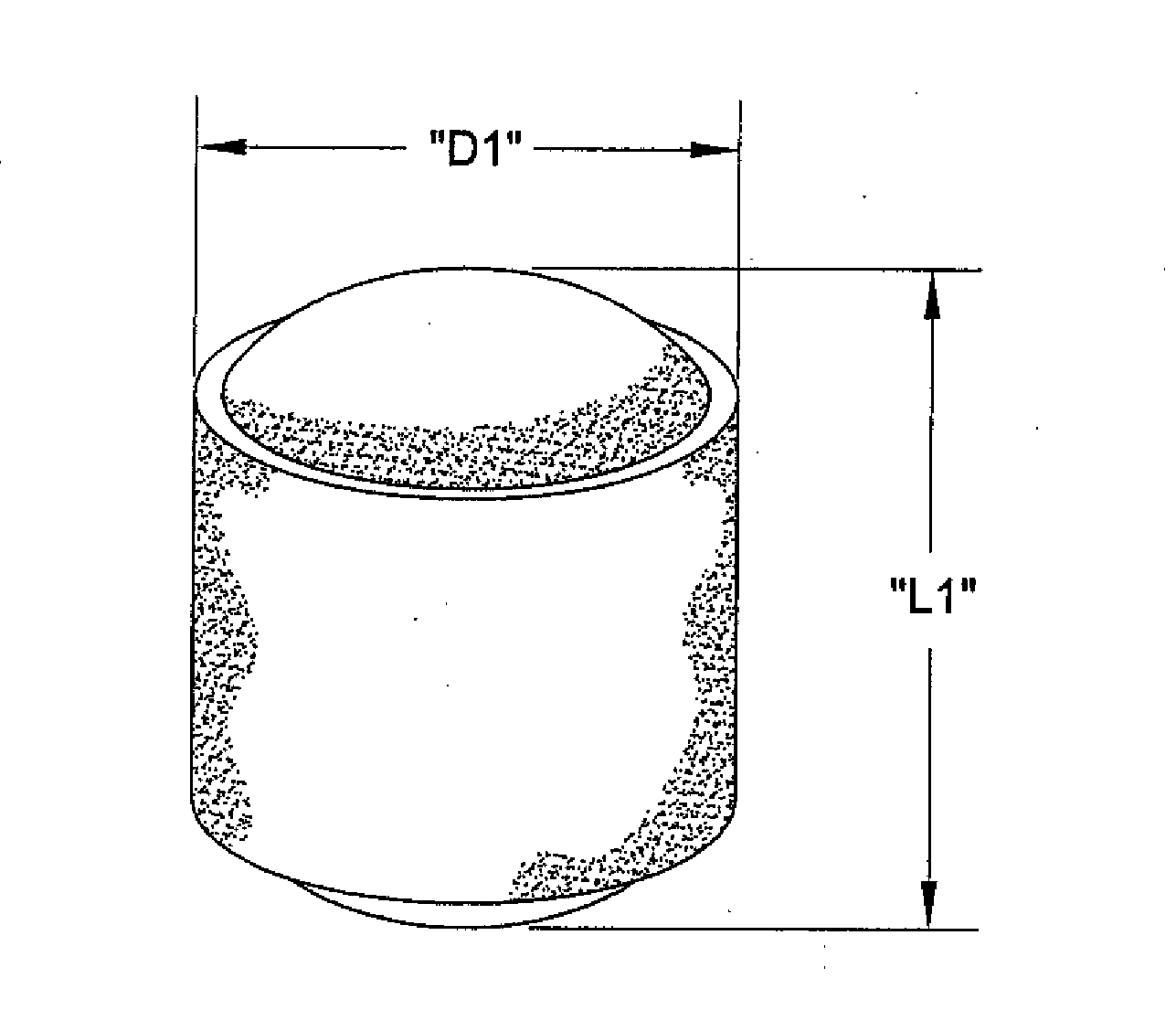

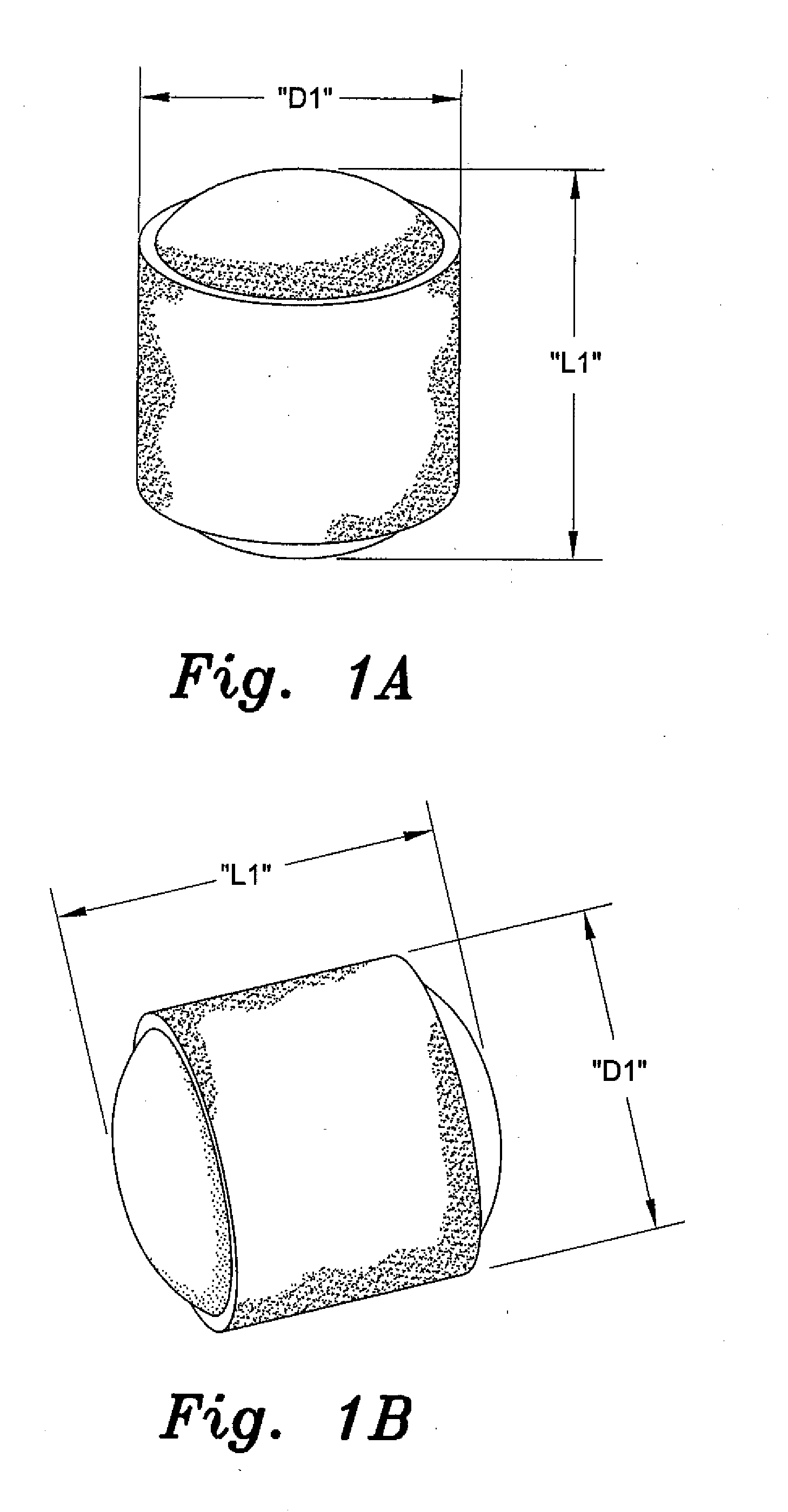

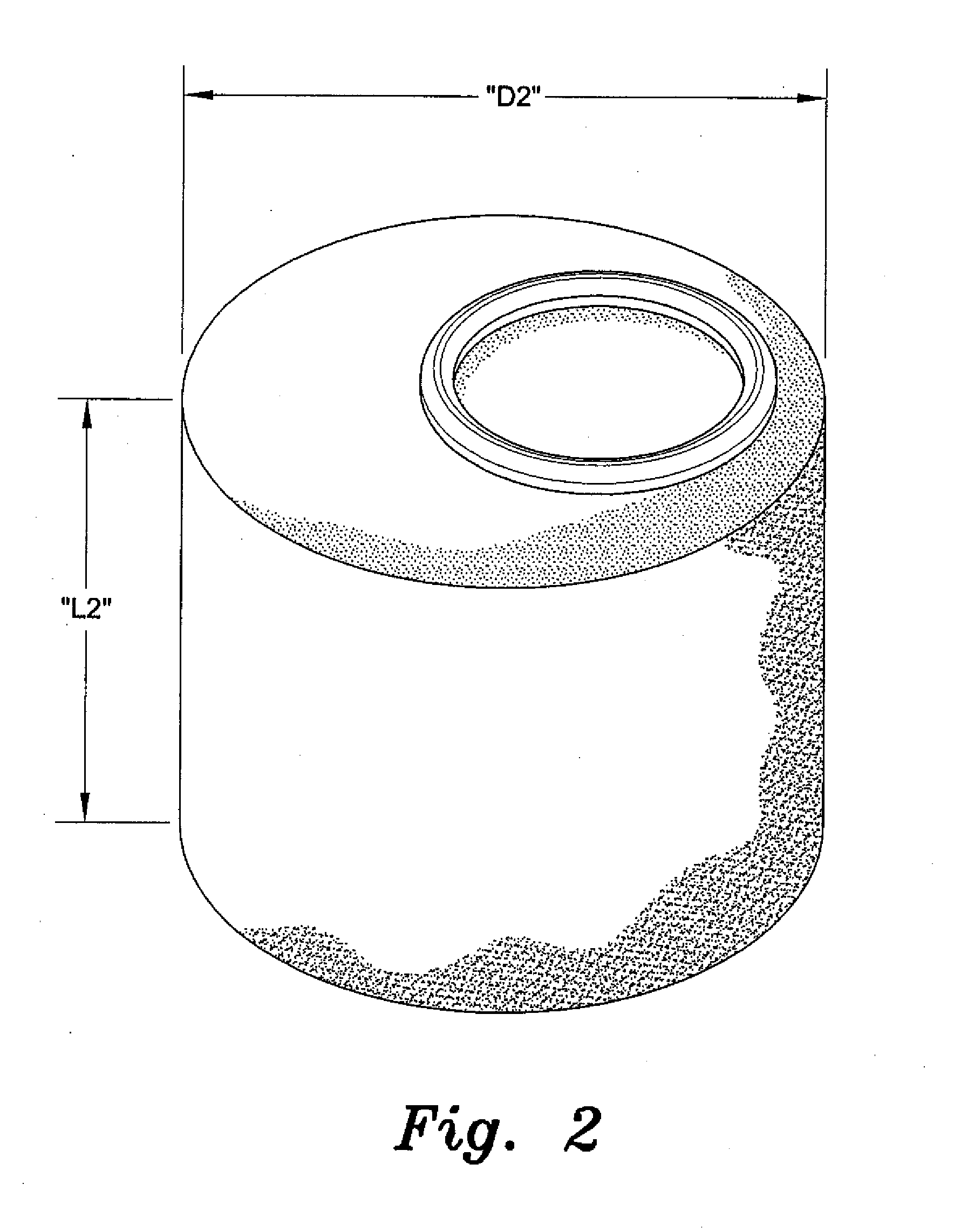

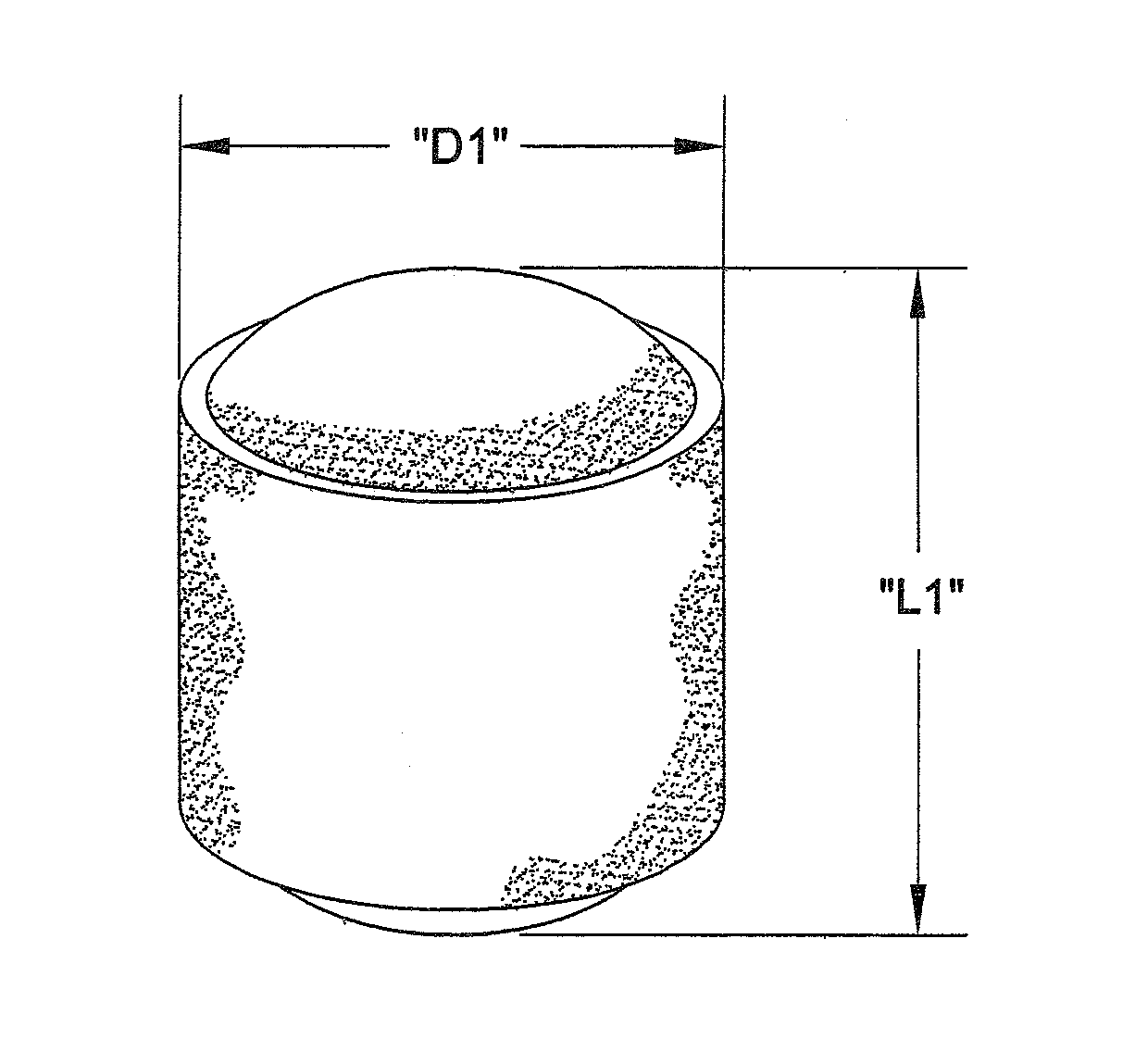

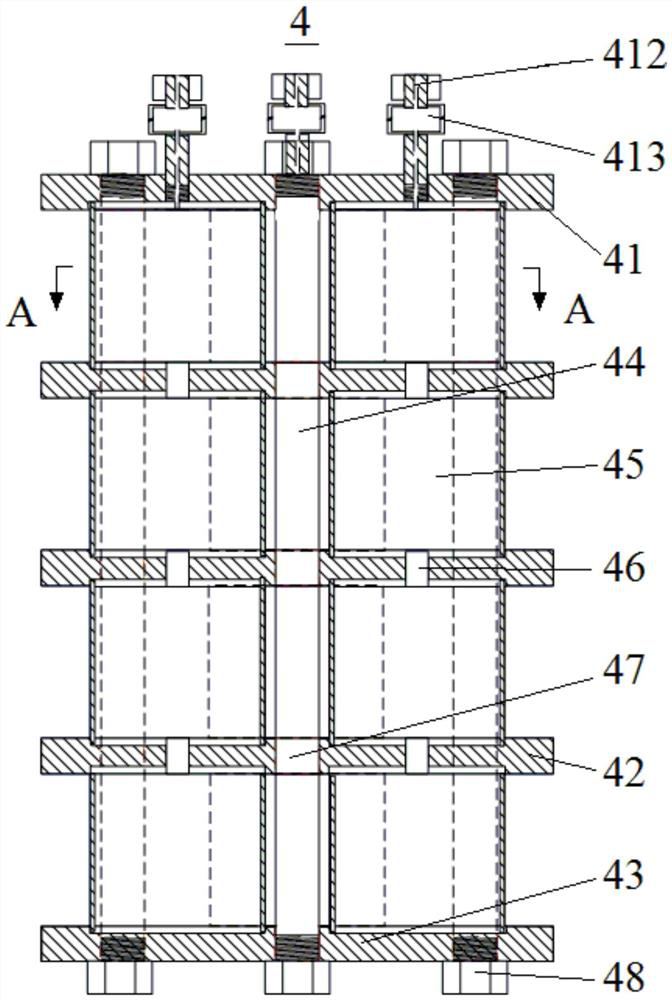

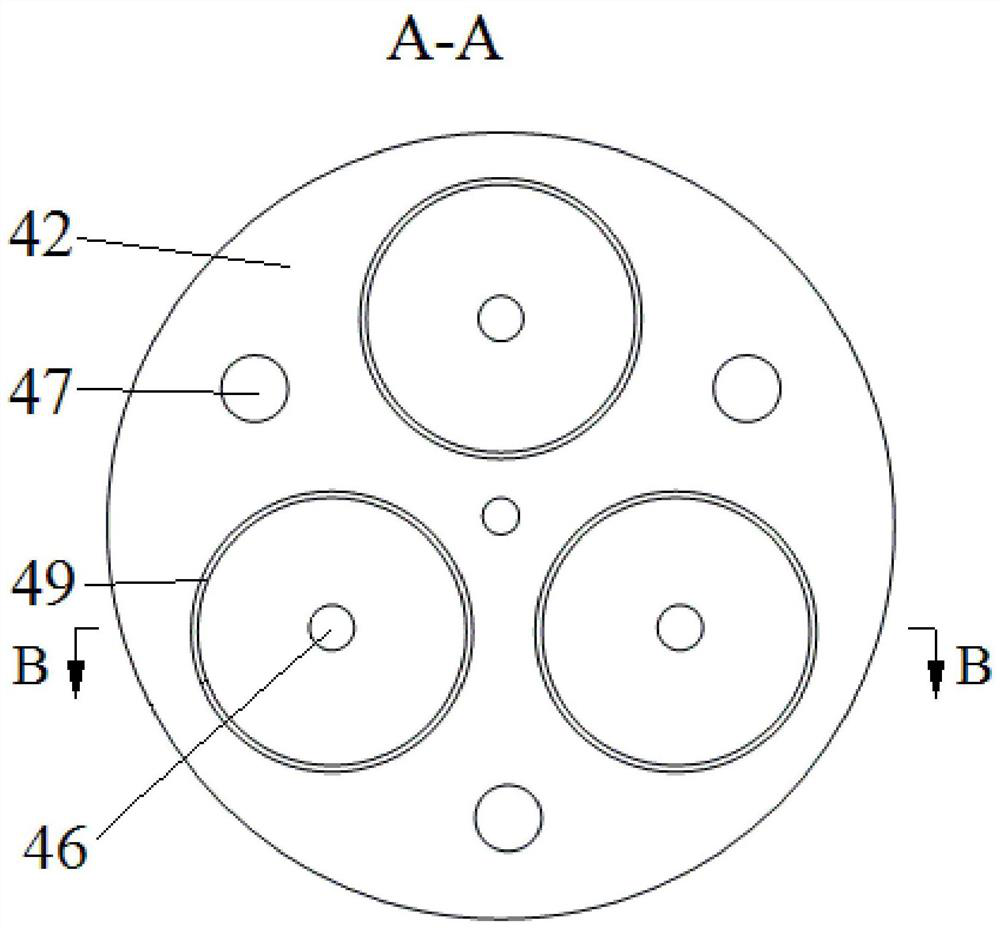

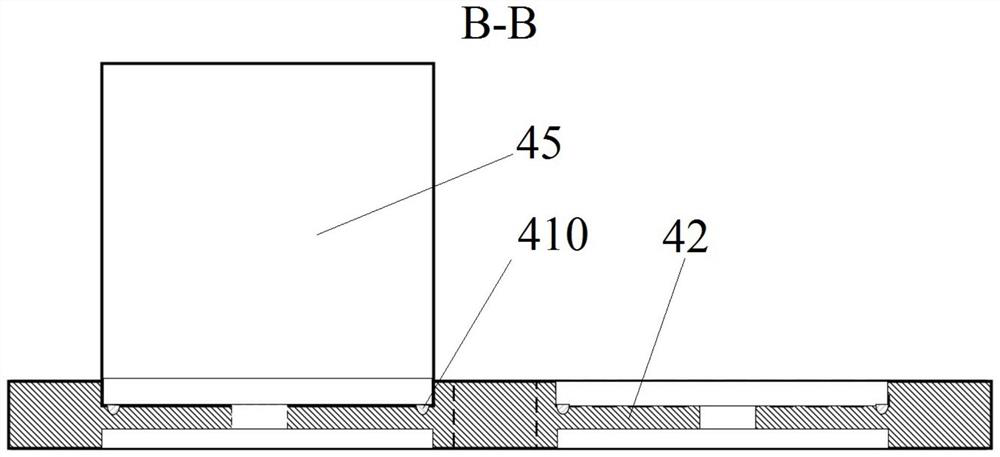

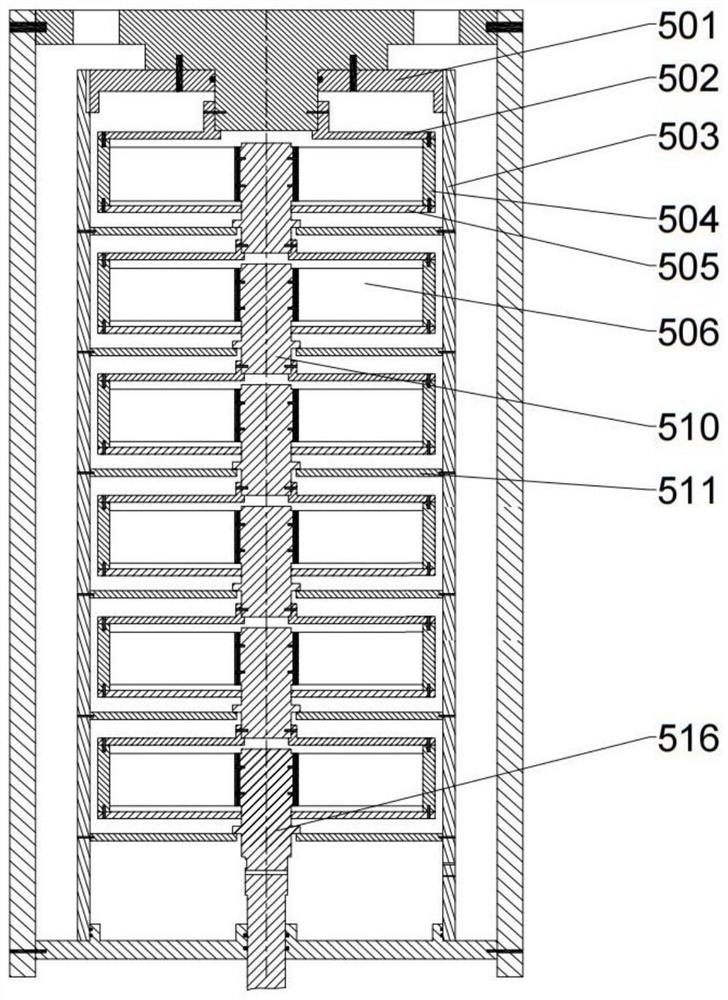

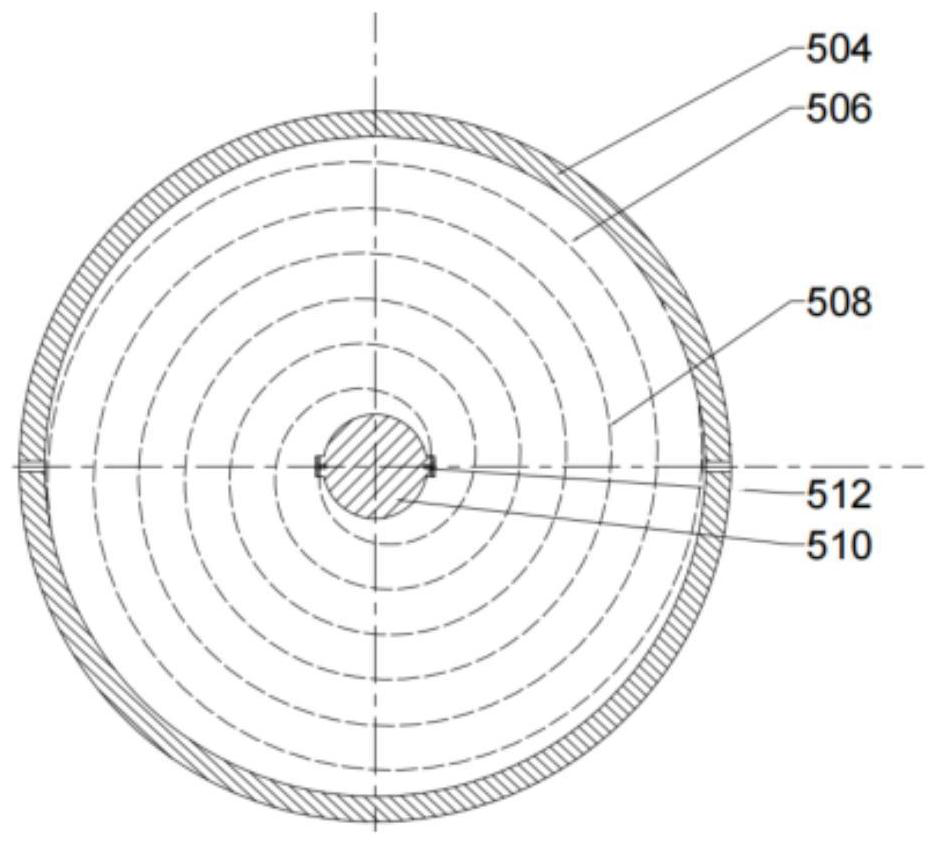

Set cement curing mold and dynamic gas corrosion experiment device

ActiveCN111896339AGuaranteed tightnessImprove practicalityWeather/light/corrosion resistanceMouldsCem cementCement paste

The invention provides a set cement curing mold. The set cement curing mold comprises a top plate, a plurality of partition plates, a bottom plate, connecting rods and a curing cylinder. A curing cylinder is clamped between every two of the top plate, the plurality of partition plates and the bottom plate; the grouting holes in the two corresponding plates are communicated with the curing barrel;when set cement curing is carried out, cement is poured from the grouting holes in the top plate, all the curing cylinders in the whole mold can be filled with the cement, then all the plates can be tightly pressed and locked through the connecting rods so that the sealing performance of cement forming can be guaranteed, the connecting rods are detached after cement curing forming, the top plate and all the partition plates are knocked out in sequence, and set cement with the complete structure can be obtained. The dynamic gas corrosion experiment device comprises a curing kettle, a rotary base, a heater and the set cement curing mold, set cement with a complete structure is tested in the dynamic gas corrosion experiment device, and the corrosion condition and the service life of well cementation cement paste injected into an actual stratum can be reflected more truly.

Owner:YANGTZE UNIVERSITY +1

Special concrete material and preparation method and application thereof

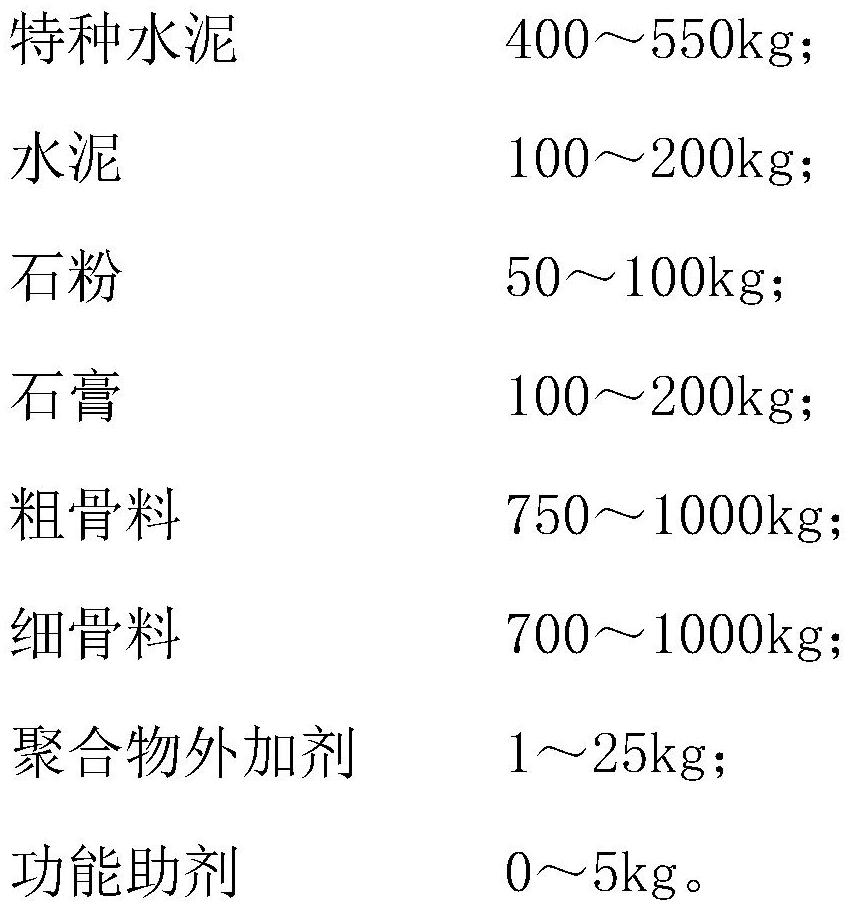

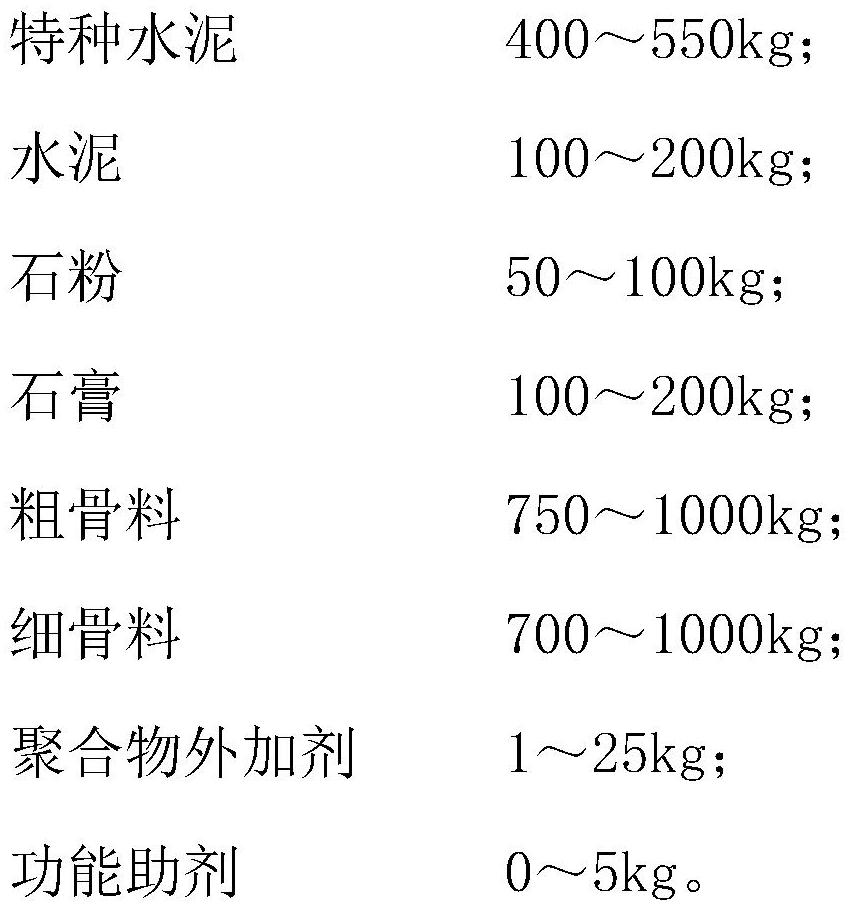

The invention discloses a special concrete material and a preparation method and application thereof and belongs to the field of concrete materials. The special concrete material is prepared by mixingand homogenizing special cement, cement, fly ash, mineral powder, gypsum, coarse aggregate, fine aggregate, a polymer additive and a functional additive. The special concrete material is used as bridge expansion joint concrete, section thickened concrete or concrete under the conditions of narrow space and dynamic load, has the characteristics of super early strength, no shrinkage, high wear resistance, high adhesion, high toughness, high impact resistance, high durability and high workability, and effectively fills up the blank of the concrete raw material industry.

Owner:SHANGHAI MEICHUANG ARCHITECTURAL MATERIALS

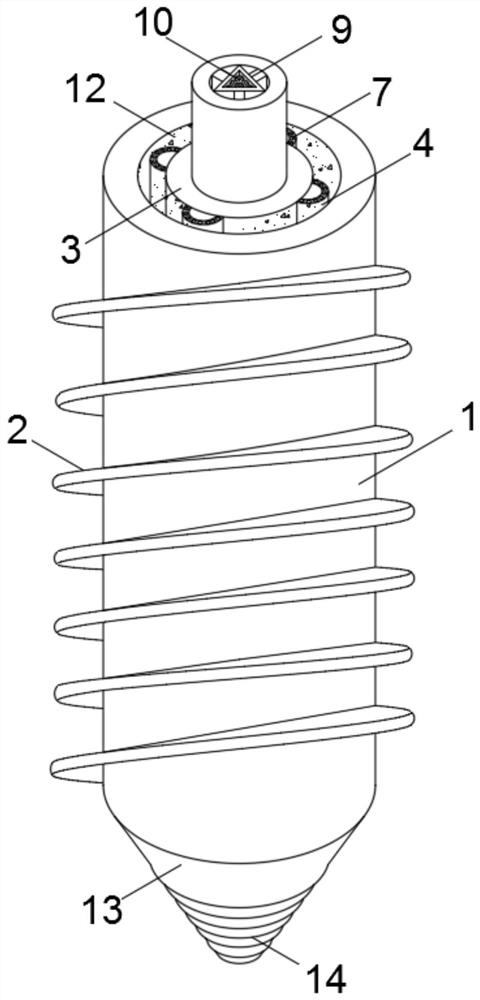

Reinforced building pile foundation

InactiveCN113585246AImprove entry efficiencyWon't moveBulkheads/pilesArchitectural engineeringCem cement

The invention discloses a reinforced building pile foundation in the field of building pile foundations, and the reinforced building pile foundation comprises an outer pile, a spiral piece is mounted on the outer wall of the outer pile, a drill bit is mounted at the bottom end of the outer pile, a thread is arranged on the outer wall of the drill bit, and a second cavity is formed in the outer pile. The outer pile driving efficiency is improved through the spiral piece and the drill bit, the spiral piece forms tension to the ground, the outer pile cannot move, and the pile foundation strength and the shock resistance and pressure resistance are effectively improved; a plurality of clamping blocks are arranged on the outer wall of an inner pile, a plurality of steel bars are arranged in the clamping blocks, fixing blocks are arranged between the clamping blocks, and reinforcing columns are arranged in the fixing blocks, so that the strength of the inner pile is enhanced, cement is poured into the inner pile through cement pipes in connecting columns, the cement is input into a first cavity and a second cavity through holes in the outer wall of the inner pile, and the inner pile and an outer pile are fixed; the strength of the inner pile and the outer pile and the pile foundation stability are effectively improved.

Owner:陈万里

Magnesium aluminate cement material containing C7A5M mineral

ActiveCN112645617AOutstanding early hardening and fast hardening performanceLower firing temperaturePhysical chemistryCem cement

The invention provides a magnesium aluminate cement material containing a C7A5M mineral, the weight percentage of a magnesium pentacalcium aluminate mineral in cement clinker is 40-60%, and the magnesium pentacalcium aluminate is 7CaO. 5Al2O3. MgO. And the cement clinker also contains monocalcium aluminate and magnesium aluminate. The aluminate cement material containing the C7A5M mineral has outstanding early strength and rapid hardening performance, and is low in firing temperature, good in hydration performance and energy-saving. The compressive strength of the cement mortar is 30-50 MPa in 3d and 60-80 MPa in 28d, the middle and later strength of the cement is remarkably improved, and the strength loss caused by air shrinkage is made up.

Owner:UNIV OF JINAN

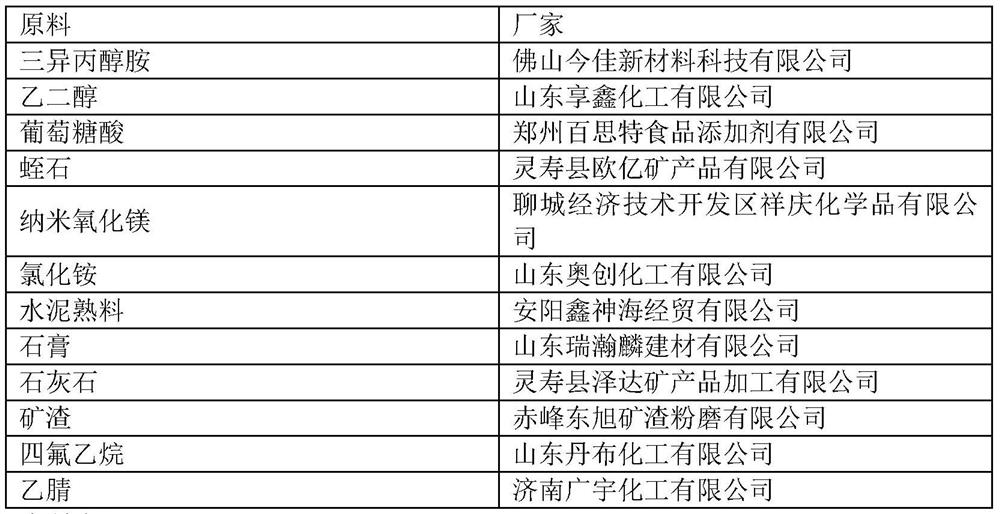

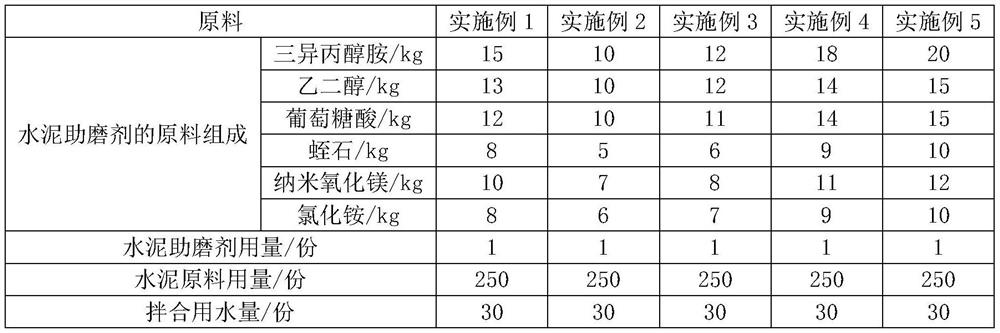

Cement grinding aid and cement using cement grinding aid

The invention relates to the field of cement admixtures, and particularly discloses a cement grinding aid and cement using the cement grinding aid, and the cement grinding aid is prepared by stirring and mixing the following raw materials in parts by mass: 10-20 parts of triisopropanolamine, 10-15 parts of ethylene glycol and 10-15 parts of gluconic acid. The preparation method of the cement grinding aid comprises the following steps: putting the cement grinding aid and cement raw materials into a ball mill according to the mass ratio of 1: 250, and grinding for 30 minutes to obtain cement, the cement grinding aid can be used for cement production, and has the advantage of improving the strength of cement.

Owner:唐山冀东水泥外加剂有限责任公司 +1

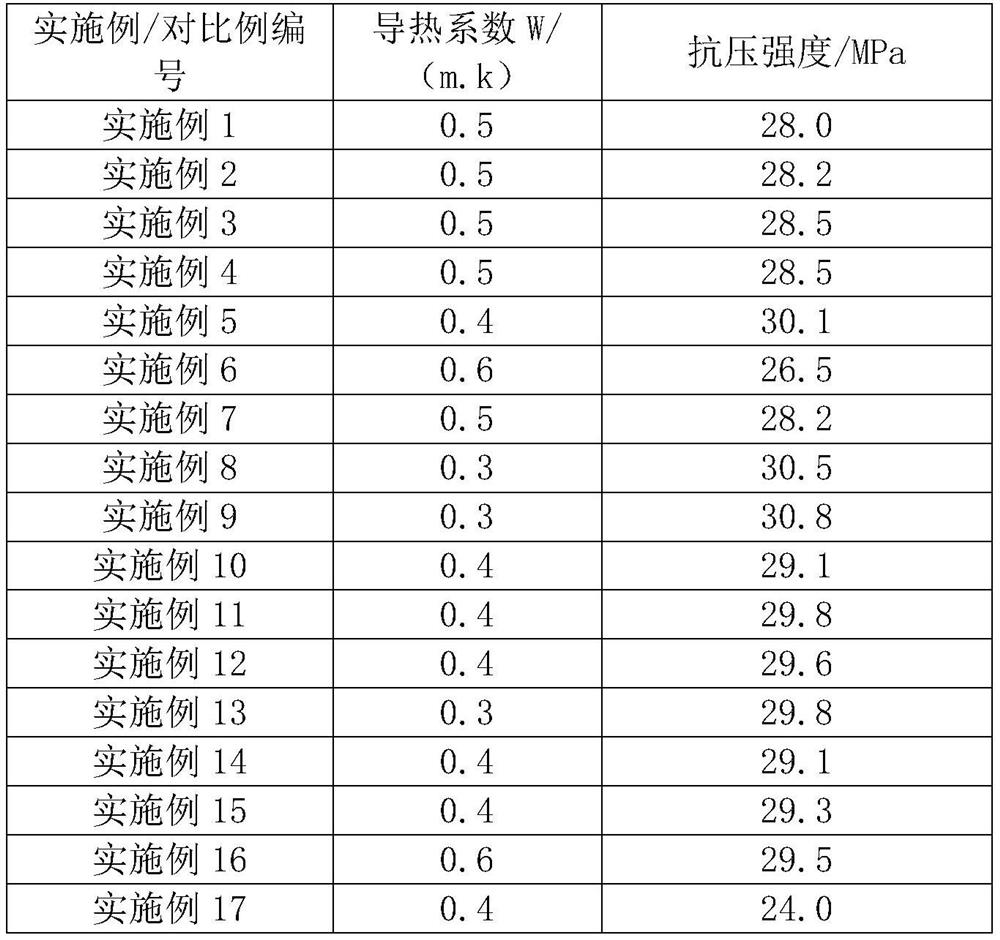

Method for preparing wall thermal insulation material from industrial solid waste

PendingCN112521179ATo achieve impurity removalNo pollution in the processSolid waste managementCeramic shaping apparatusThermal insulationActive agent

The invention discloses a method for preparing a wall thermal insulation material from industrial solid waste. The method comprises the following steps: respectively drying, grinding and screening copper slag, fly ash and phosphogypsum to 80-100 meshes; proportioning according to a certain proportion and a certain adding sequence; selecting quick lime as an exciting agent, and selecting a mixtureof alpha-olefin sodium sulfonate, sodium dodecyl benzene sulfonate and sodium alcohol ether sulphate as a foaming agent; and sequentially mixing quick lime, a small amount of water, phosphogypsum andauxiliary materials, cement and a cement foaming agent to prepare slurry, molding by casting, naturally standing and drying for 24 hours, and heating and drying in a thermostat for 24 hours to obtainthe building wall thermal insulation material. The method has the advantages that the solid waste phosphogypsum is not subjected to desulfurization treatment, the copper slag is directly utilized, andother auxiliary raw materials are added to react with substances in the copper slag, so that an impurity removal effect is achieved; three anionic surfactants with less research are selected as the cement foaming agent; and the process is simple and easy to implement, and the prepared thermal insulation material is natural, pollution-free and excellent in performance.

Owner:KUNMING UNIV OF SCI & TECH

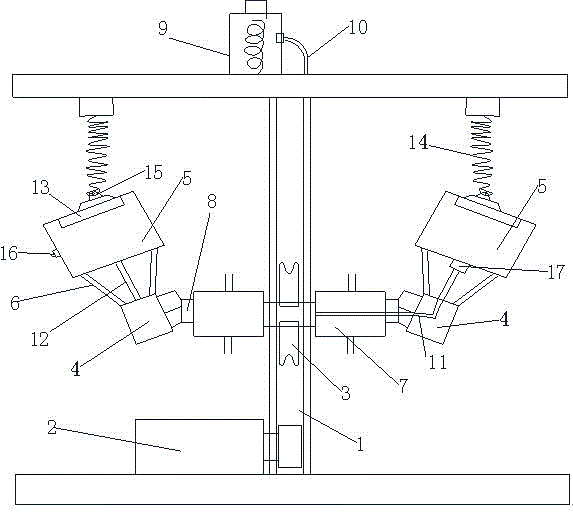

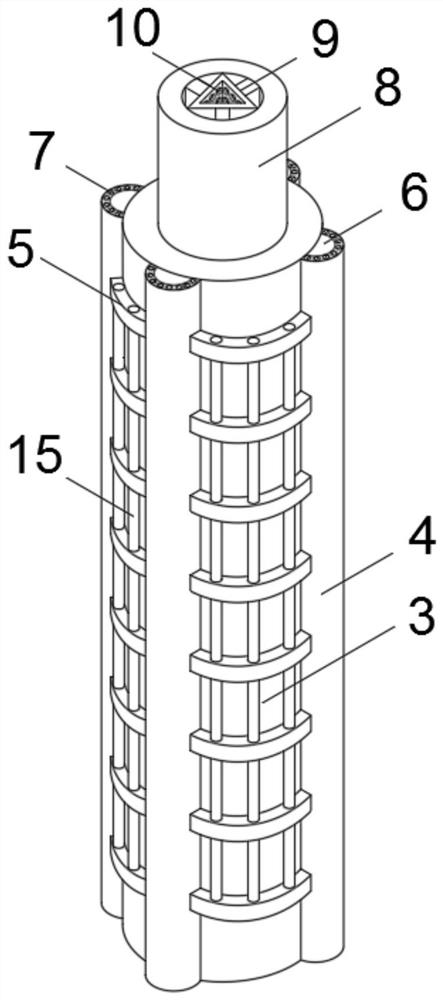

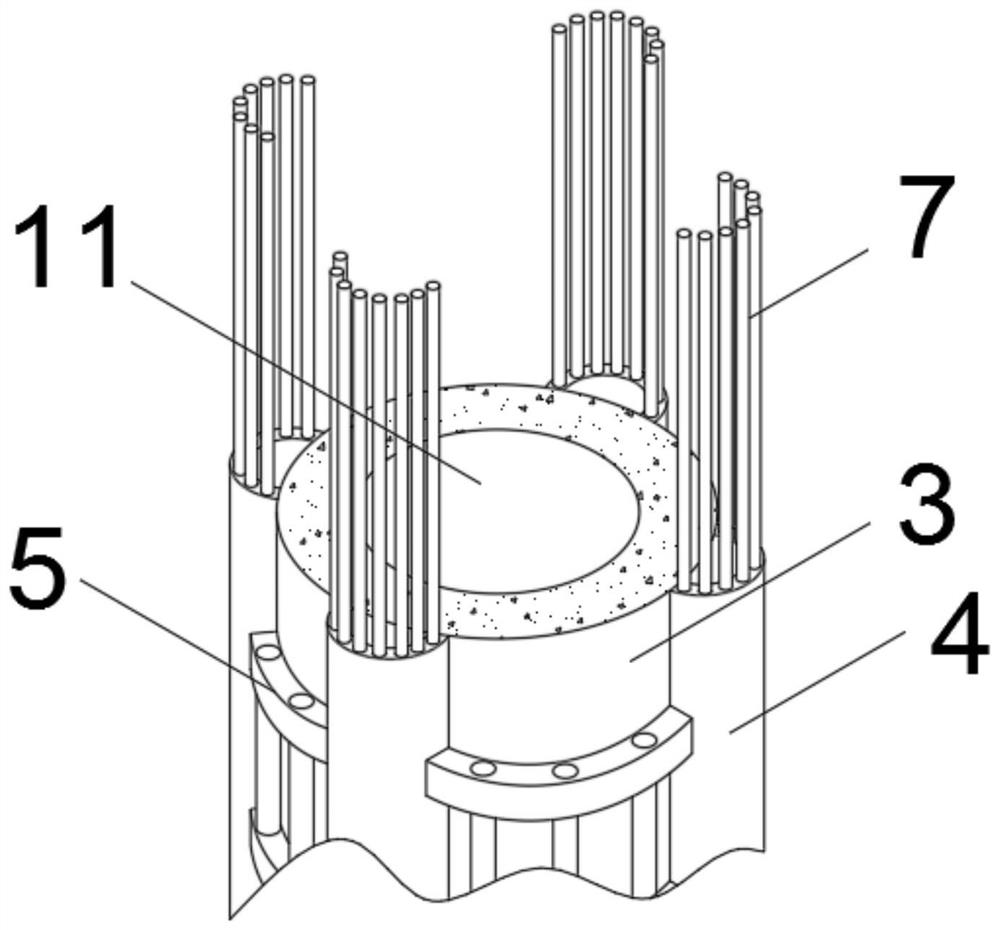

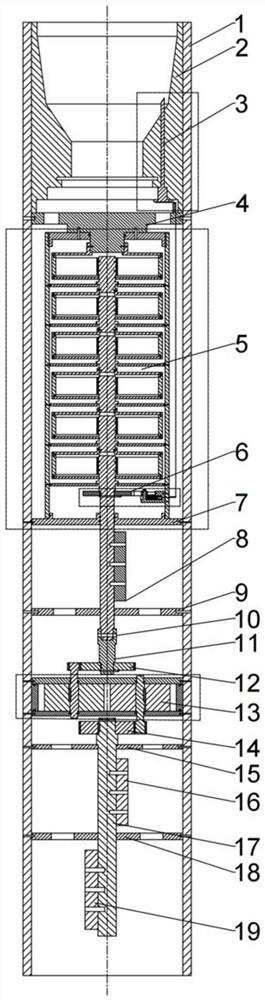

Vibration well cementation device with mechanical energy storage function and using method and testing device of vibration well cementation device

ActiveCN114251069AImprove compactnessImprove uniformityVibration devicesSealing/packingElectric power equipmentWell cementing

The invention provides a mechanical energy storage vibration well cementation device and a using method and a testing device thereof, the vibration well cementation device comprises an energy conversion device, an energy storage device, a vibration shaft, an overload protection device and an energy release triggering device, the energy conversion device is used for converting fluid kinetic energy into kinetic energy of the shaft and driving the vibration shaft to rotate to generate vibration; the energy storage device is used for converting kinetic energy of the shaft into elastic potential energy and storing the elastic potential energy; the overload protection device has an overload protection effect on the energy storage device; and during cement setting waiting, the mechanical potential energy stored by the energy storage device is released through the energy release triggering device to generate radial vibration, so that vibration in the whole process of cement injection, cement paste replacement and cement setting waiting is realized. According to the device, fluid kinetic energy is converted into mechanical potential energy to be stored and eccentric vibration is generated in the cementing and cement paste displacement process, the compactness and uniformity of the cement paste are further improved, the well cementation technology does not need to be changed, underground power equipment does not need to be changed, the design is simple, and the cost is low.

Owner:CHINA AGRI UNIV

Efficient Formulation Stable Crude Glycerine Grinding Additive

InactiveUS20200048148A1Overall design flexibilityImprove efficiencyGrain treatmentsBiodieselPtru catalyst

Compositions and methods for grinding inorganic particles, such as cement, cement clinker, limestone, or other inorganic particles, involving a grinding efficiency enhancing additive comprising a crude glycerin byproduct, obtained through the use of heterogeneous catalyst processes in biodiesel fuel production. The molecules generated through the use of such heterogeneous catalytic processes result in a crude glycerin that confers good additive formulation stability, while avoiding or minimizing large quantities of undesirable compounds such as fatty acids, fatty acid esters, and salts.

Owner:GCP APPL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com