Cement grinding aid and cement using cement grinding aid

A technology of cement grinding aid and heat absorbing agent, applied in the field of cement admixtures, can solve problems such as low cement strength, and achieve the effects of improving cement strength and inhibiting volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

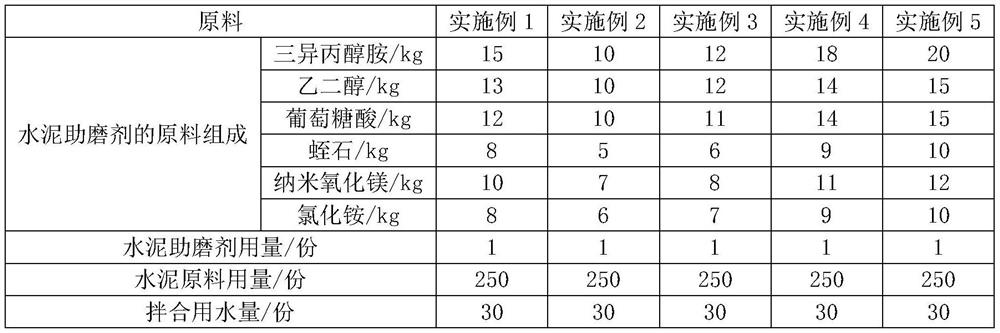

Embodiment 1

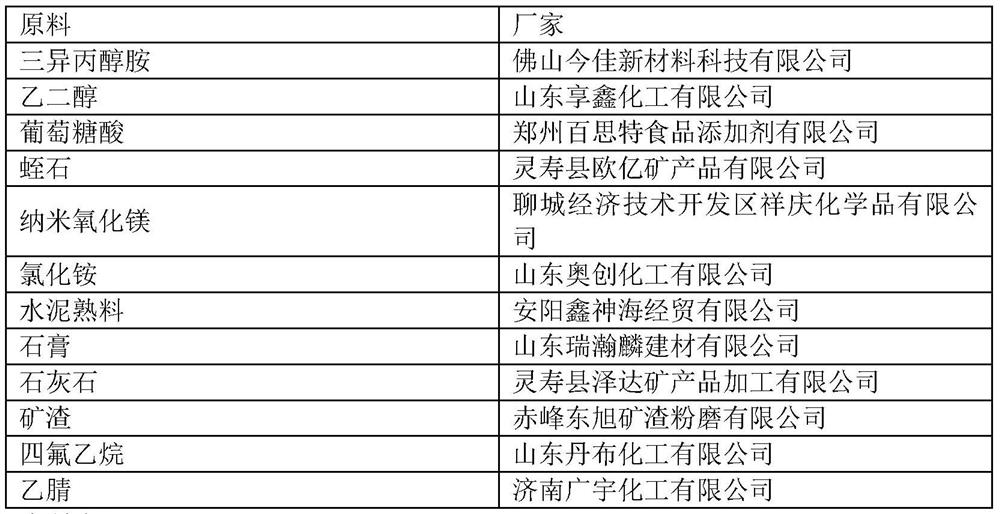

[0036] A cement grinding aid is prepared by stirring and mixing the following raw materials in parts by mass:

[0037] Triisopropanolamine 15kg,

[0038] Ethylene glycol 13kg,

[0039] Gluconic acid 12kg,

[0040] Vermiculite 8kg, the particle size of vermiculite is 15 microns,

[0041] Nano magnesium oxide 10kg, the particle diameter of nano magnesium oxide is 12 nanometers,

[0042] Endothermic agent 8kg, endothermic agent is ammonium chloride.

[0043] A cement using a cement grinding aid, which is prepared by including the above cement grinding aid, and the preparation steps are as follows, S1: Put the above cement grinding aid and cement raw materials in a ball mill at a mass ratio of 1:250 for grinding , and the grinding time is 30min to obtain cement.

[0044] The cement raw material is obtained by mixing cement clinker, gypsum, limestone and slag into powder according to the mass ratio of 10:1:1:4.

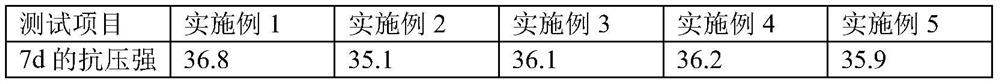

[0045] Carry out a kind of cement production that uses cement g...

Embodiment 6

[0060] A cement grinding aid, based on the basis of Example 1, the difference is that no vermiculite is added to the grinding aid, and the rest of the operating steps and parameters are the same as in Example 1.

Embodiment 7

[0062] A cement grinding aid, based on Example 1, the difference is that the particle size of the vermiculite is 10 microns, and the rest of the operating steps and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com