Preparation method of cement-based shape-stabilized phase change material

A shape-setting phase change material and cement-based technology, which is applied in the fields of phase change material preparation, building energy saving, and thermal energy storage, can solve the problems of low encapsulation rate of phase change materials, fragile shell materials, and residual phase change materials. Achieve excellent physical properties, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

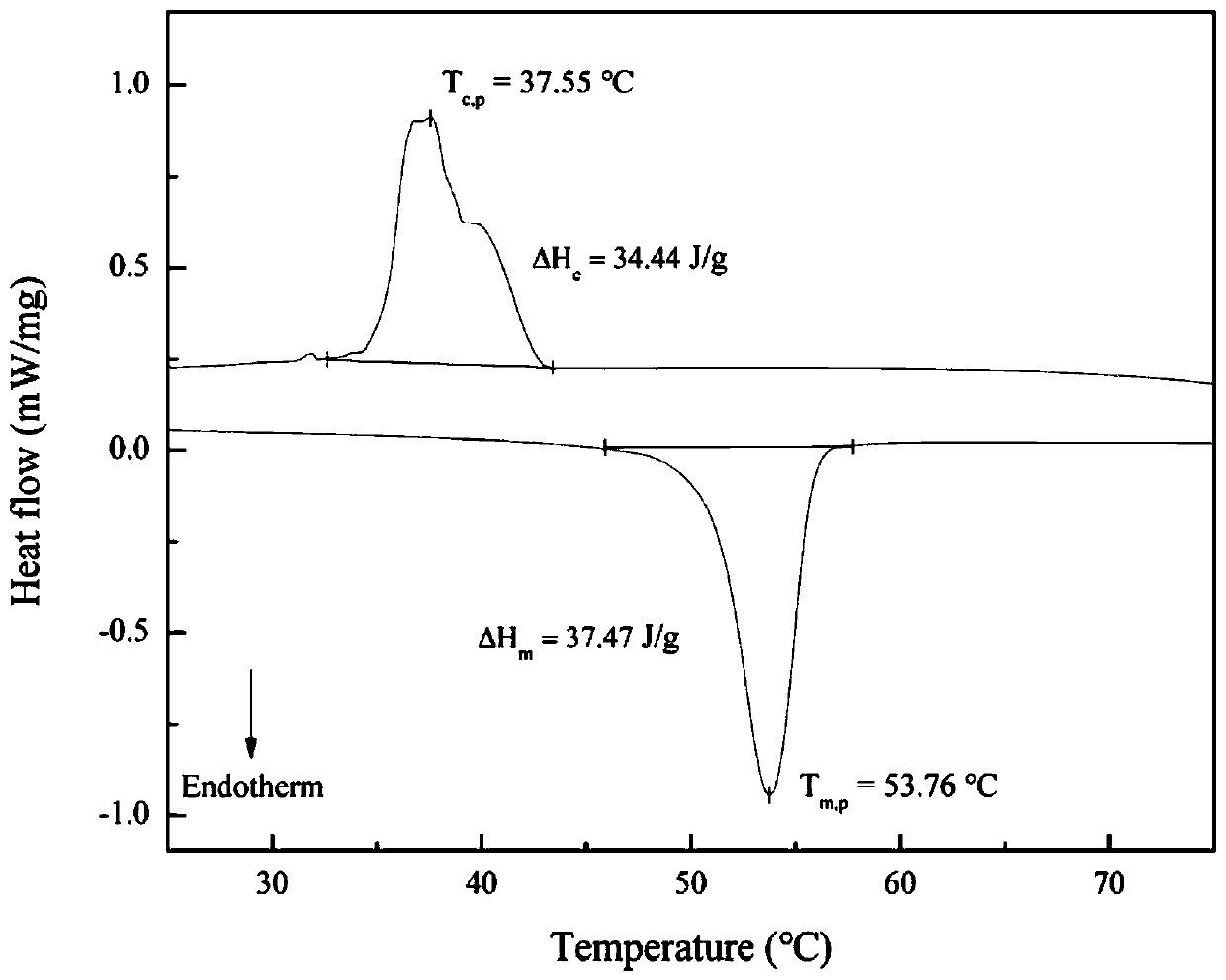

Embodiment 1

[0031] The raw material composition of the cement-based shape-setting phase-change material prepared in this example is as follows: the cement used is ordinary Portland cement, the phase-change material used is polyethylene glycol with a relative molecular mass of 2000, the mineral admixture used is silica fume, and the used The quick-setting agent is the Red Star Type I quick-setting agent belonging to the alumina clinker-carbonate system, the thickener used is polyacrylamide belonging to the propylene system, and the concentration of the polyethylene glycol aqueous solution is 70%. Concrete preparation steps are as follows:

[0032] S1. Add 70g polyethylene glycol 2000 into 30g water and stir at normal temperature to prepare 100g concentration of 70% polyethylene glycol aqueous solution;

[0033] S2. Weigh 100g of cement, 10g of silica fume, 5g of accelerator and 0.8g of thickener and put them into the mixing pot for dry mixing for 1 to 2 minutes;

[0034] S3. Slowly pour t...

Embodiment 2

[0041] The raw material composition of the cement-based shape-setting phase-change material prepared in this example is as follows: the cement used is sulfoaluminate cement, the phase-change material used is polyethylene glycol with a relative molecular mass of 4000, and the mineral admixture used is ultra-fine pulverized coal Ash, the quick-setting agent used is ART-SL12 non-alkali liquid quick-setting agent, the thickener used is cellulose ether belonging to the cellulose system, and the concentration of polyethylene glycol aqueous solution is 50%. Concrete preparation steps are as follows:

[0042] S1. Pour 50g polyethylene glycol 4000 into 50g water and stir at normal temperature to prepare 100g concentration of 50% polyethylene glycol aqueous solution;

[0043] S2. Weigh 100g of cement, 6g of superfine fly ash and 0.2g of thickener and put them into the mixing pot for dry mixing for 1 to 2 minutes;

[0044] S3. Slowly add the prepared 100g polyethylene glycol aqueous sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com