Patents

Literature

949results about How to "Won't move" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

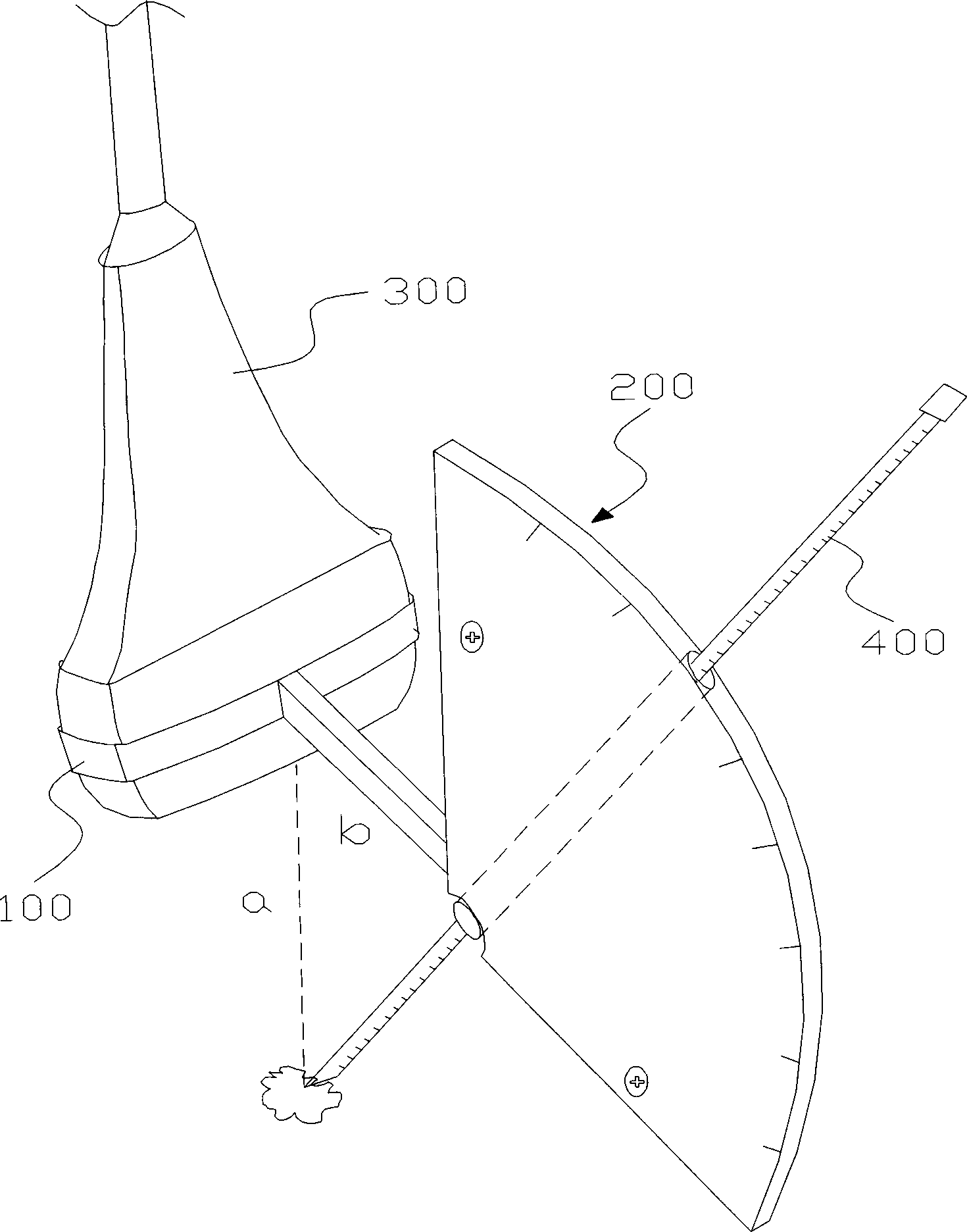

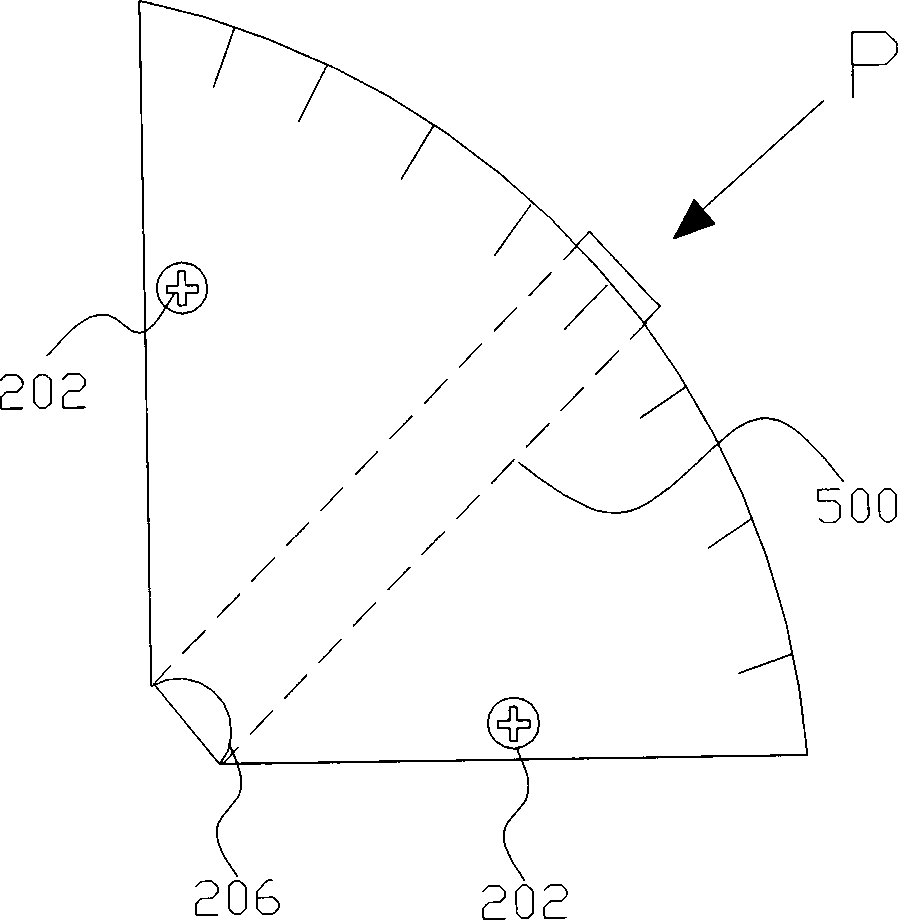

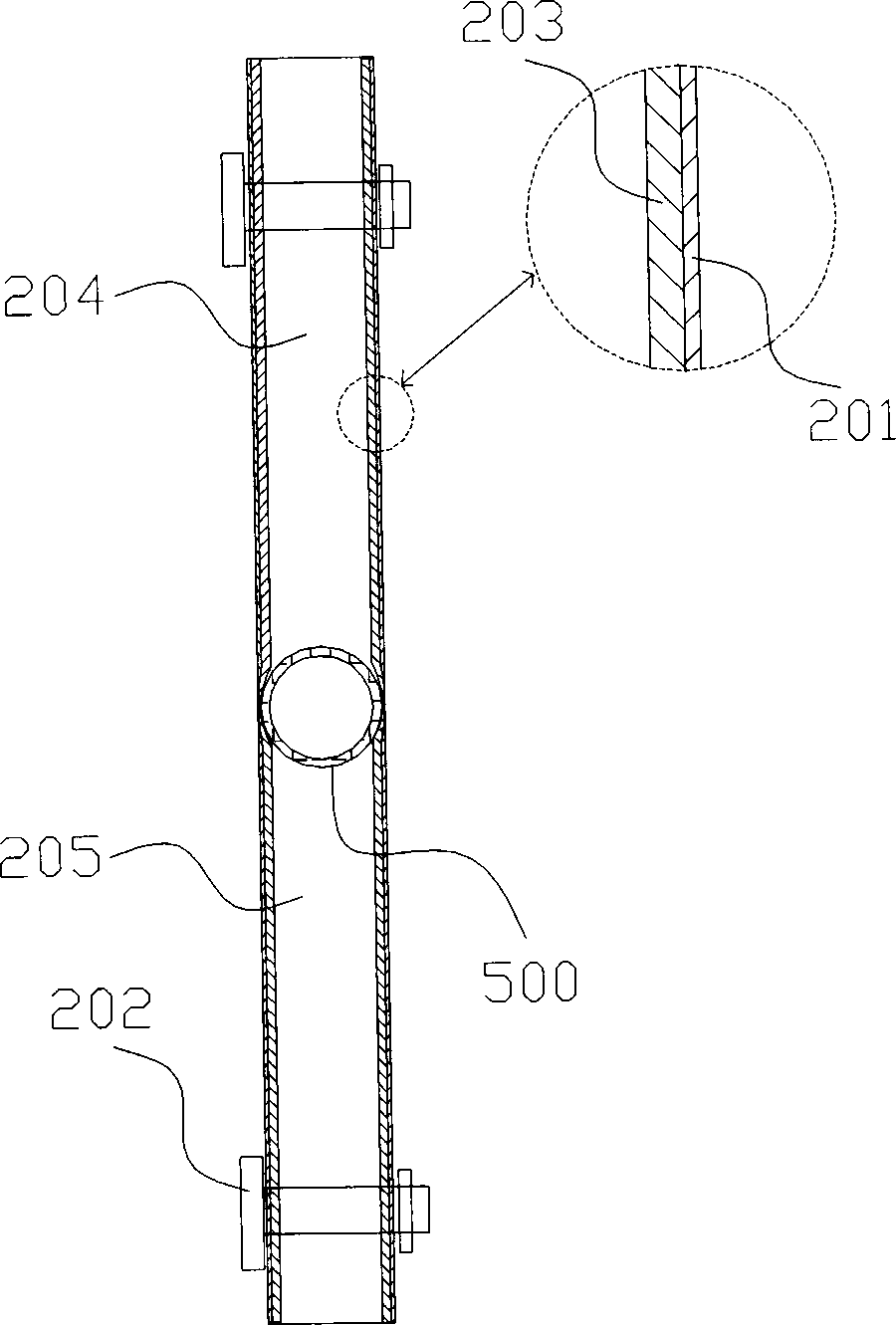

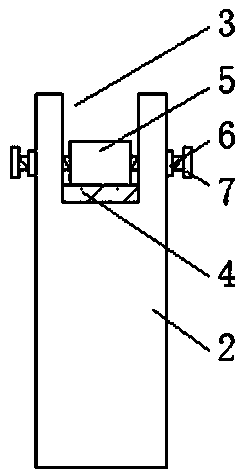

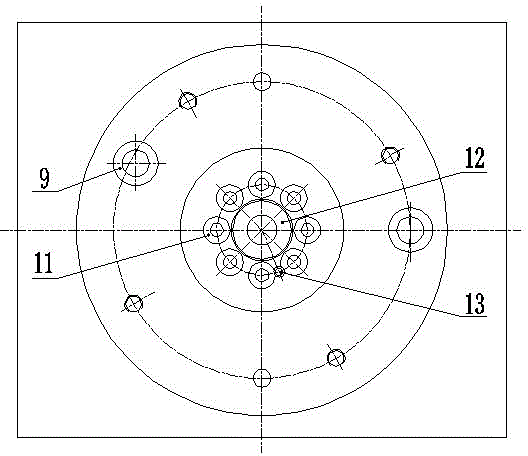

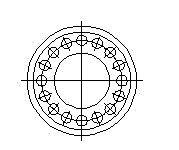

Ultrasound-guided out-of-plane puncture adapter, ultrasound-guided puncture device with same, and corresponding method

InactiveCN103222897AAchieve fixed positionNo angular shiftDiagnosticsSurgical needlesEngineeringOut of plane

The invention relates to the technical field of out-of-plane puncture, and discloses an ultrasound-guided out-of-plane puncture adapter which is mounted on an ultrasonic probe. The adapter comprises a first fixing device mounted on the ultrasonic probe and a second fixing device used for fixing a puncture needle and connected with the first fixing device, wherein the second fixing device corresponds to a center short shaft of the ultrasonic probe and comprises two opposite right-angle fan-shaped clamping pieces and a locking device used for locking the former two; a movable sleeve is arranged between the two right-angle fan-shaped clamping pieces; the puncture needle is arranged in the movable sleeve; and one end of the movable sleeve is arranged at the right-angled vertices of the right-angle fan-shaped clamping pieces, and the other end thereof moves along the circular arcs of the right-angle fan-shaped clamping pieces. The invention further discloses an ultrasound-guided out-of-plane puncture device and a puncture method thereof. According to the invention, the problem that the corresponding puncture adapter is not available in an ultrasound-guided out-of-plane puncture technology is solved, and the application of the ultrasound-guided out-of-plane puncture technology in the clinical medical field is greatly promoted.

Owner:SUZHOU SCI&TECH TOWN HOSPITAL

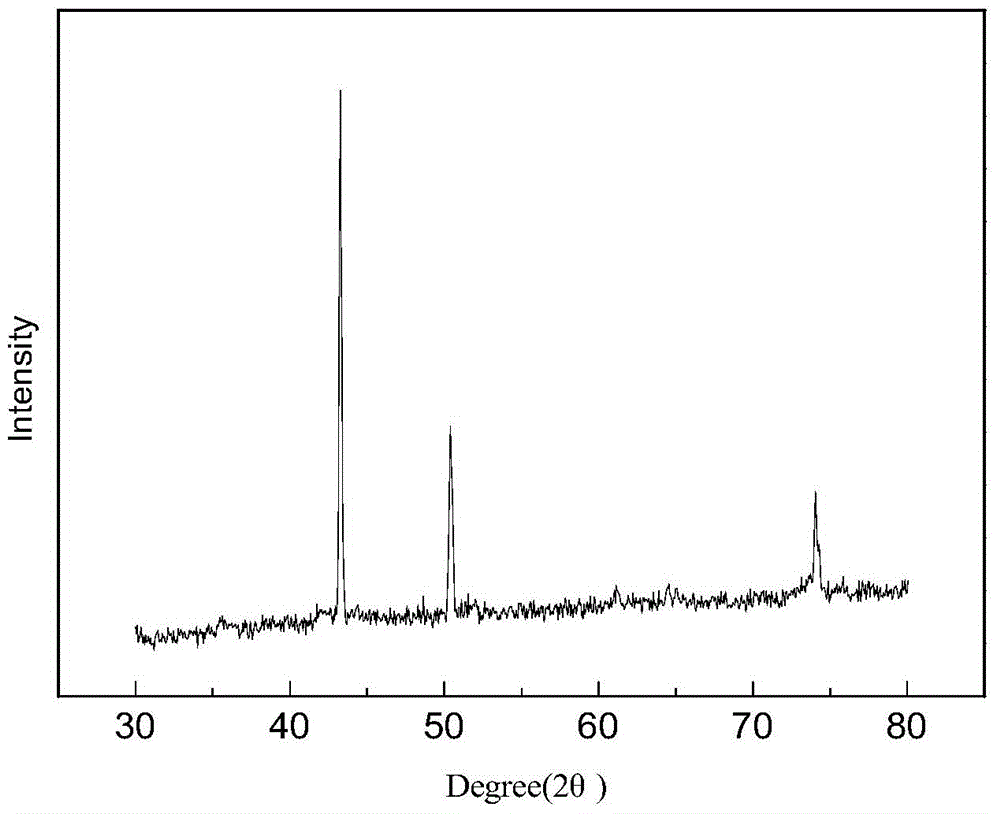

Method for preparing high-entropy alloy coating

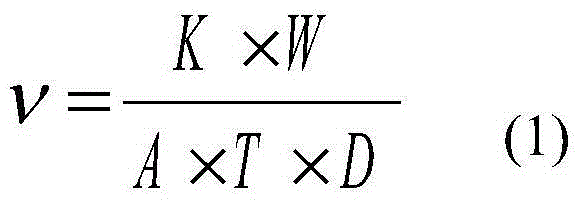

InactiveCN103556146AHigh hardnessImprove wear resistanceArc welding apparatusMetallic material coating processesHigh entropy alloysGas tungsten arc welding

The invention relates to the field of multi-principal element high-entropy alloy materials and in particular relates to a method for preparing a high-entropy alloy coating, belonging to the field of coating preparation. The method for preparing the high-entropy alloy coating comprises the following steps: pretreating a substrate, so that the surface of the substrate is clean and flat; preparing high-entropy alloy powder, uniformly mixing, and adding 3-6wt% of organic solution in the alloy powder; uniformly mixing the organic solution and the high-entropy alloy powder, and preparing into paste; uniformly coating the pasty alloy powder on the treated substrate, wherein the thickness of the coating layer is 0.3-6mm; baking the treated coating layer and substrate in an oven at the temperature of 55-80 DEG C for 20-30 hours; cladding the coating layer on the surface of the substrate through gas tungsten arc welding. According to the method for preparing the high-entropy alloy coating, the high-entropy alloy coating with the thickness of 0.3-6mm can be prepared, a heat affected zone to the substrate in the preparation process is small, and the coating is uniform in distribution and firmly bound to the base material.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

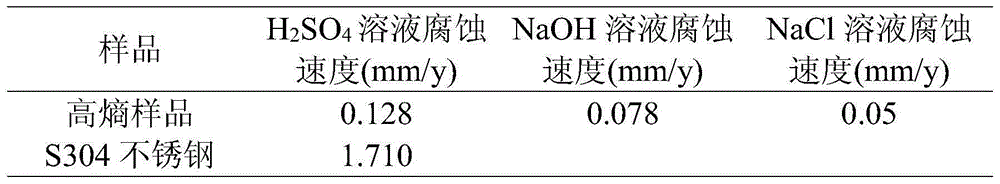

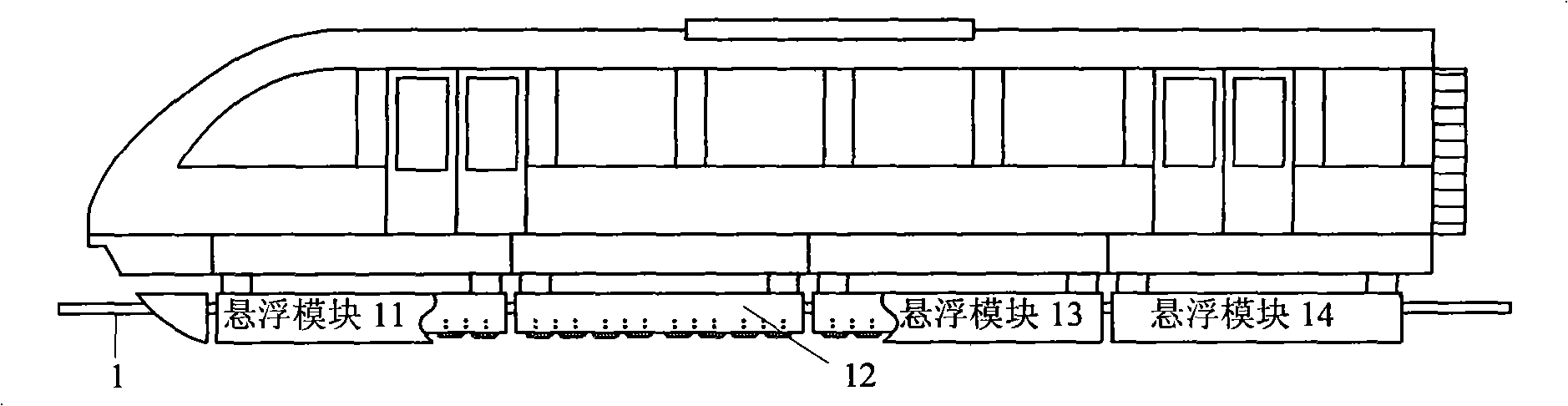

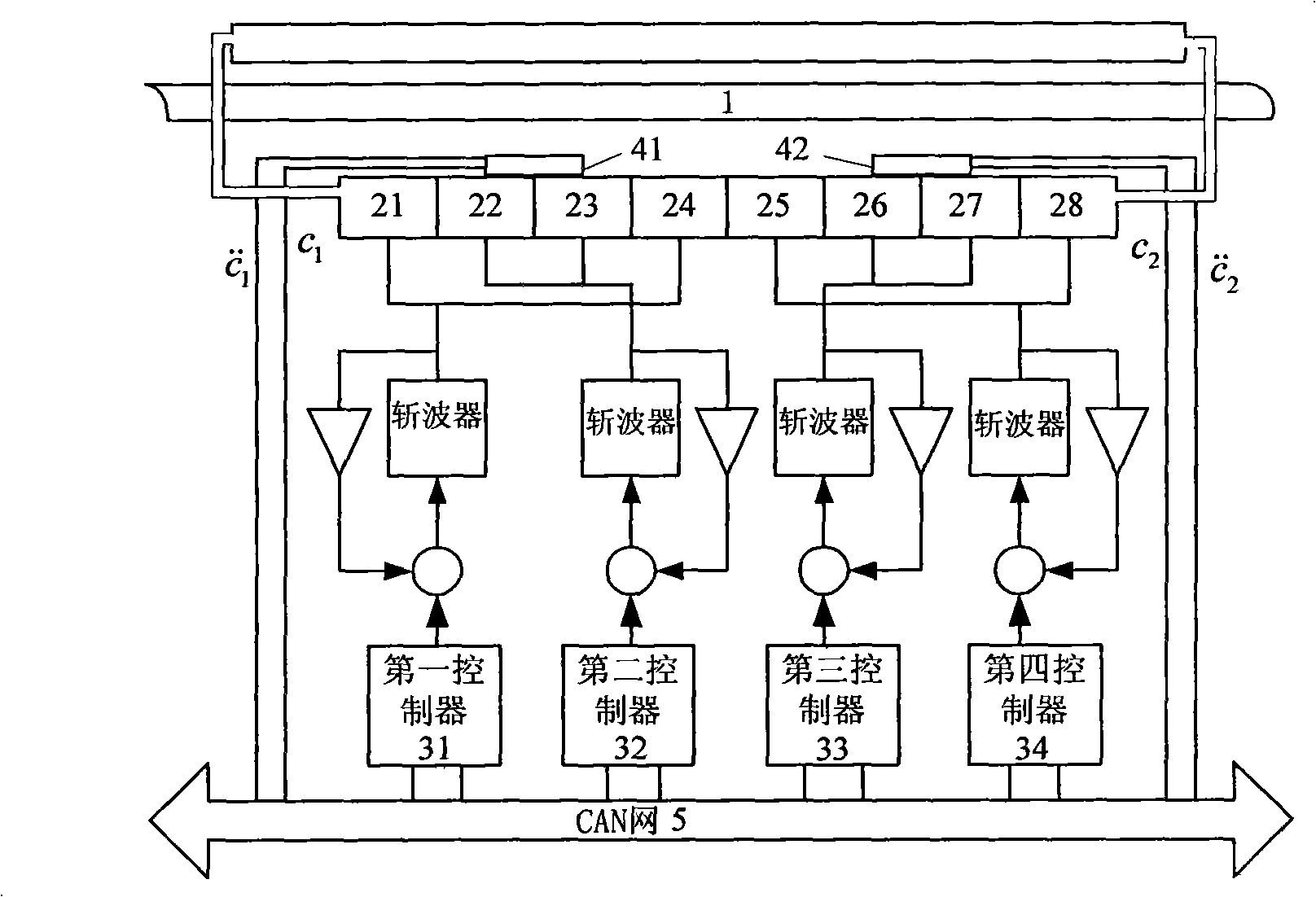

Distributed active fault tolerant control system of electromagnetic type magnetic floating train suspending module

ActiveCN101327747ASuspension stabilityReduce deviationElectric propulsionActive faultMonitoring system

The present invention relates to a distributed active fault-tolerant control system of suspension module of electromagnetic maglev train. The control system comprises 8 electromagnets which are arranged on the suspension module, 4 independent suspension controllers, a first sensor group and a second sensor group; the 8 electromagnets are divided into 4 electromagnet groups; each electromagnet group comprises two electromagnets which are connected in series; each suspension controller is connected with an electromagnet group through a chopper; the first sensor group and the second sensor group are respectively arranged at two ends of the suspension module; the suspension controller, the first sensor group and the second sensor group are connected through a CAN bus; the suspension controller is connected with the vehicle monitoring system of the maglev train. The distributed active fault-tolerant control system of the suspension module of the electromagnetic maglev train can tolerate failures of the controller, the sensor and the actuator in the suspension system, and thus greatly improve the reliability, stability and security.

Owner:NAT UNIV OF DEFENSE TECH

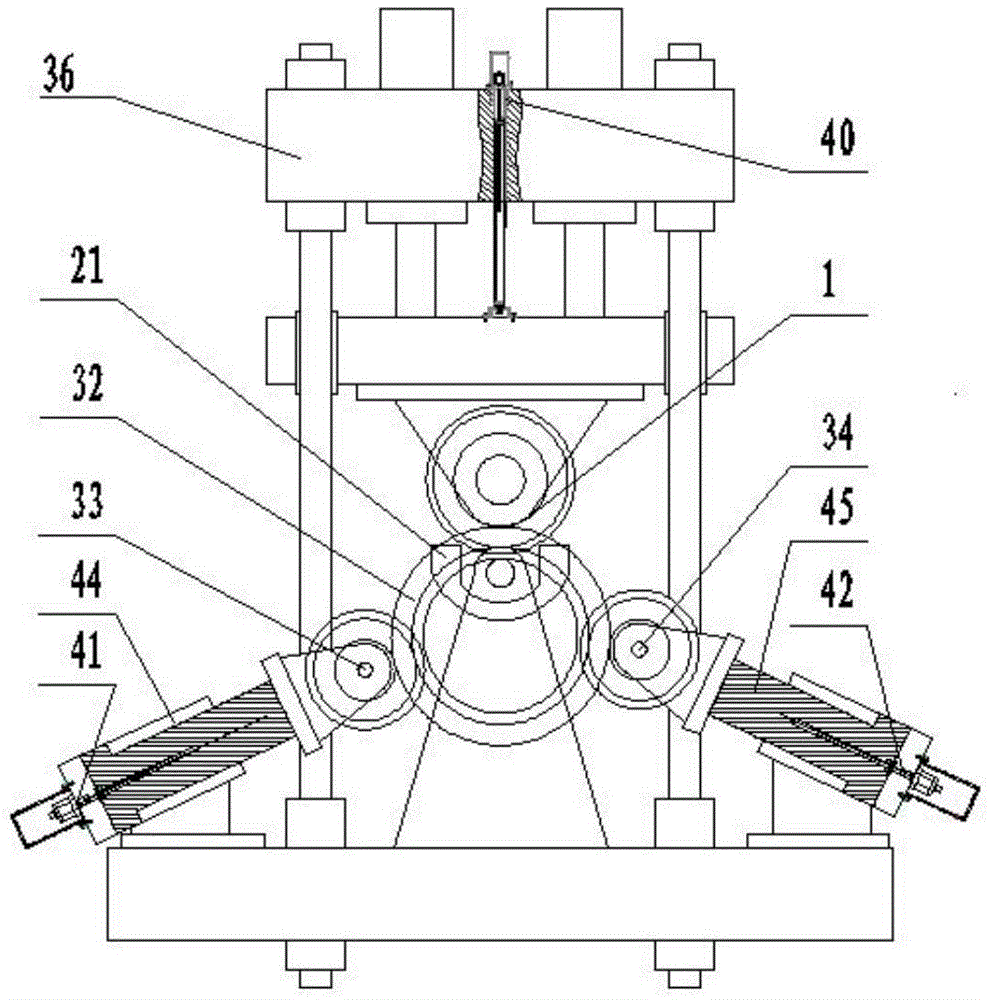

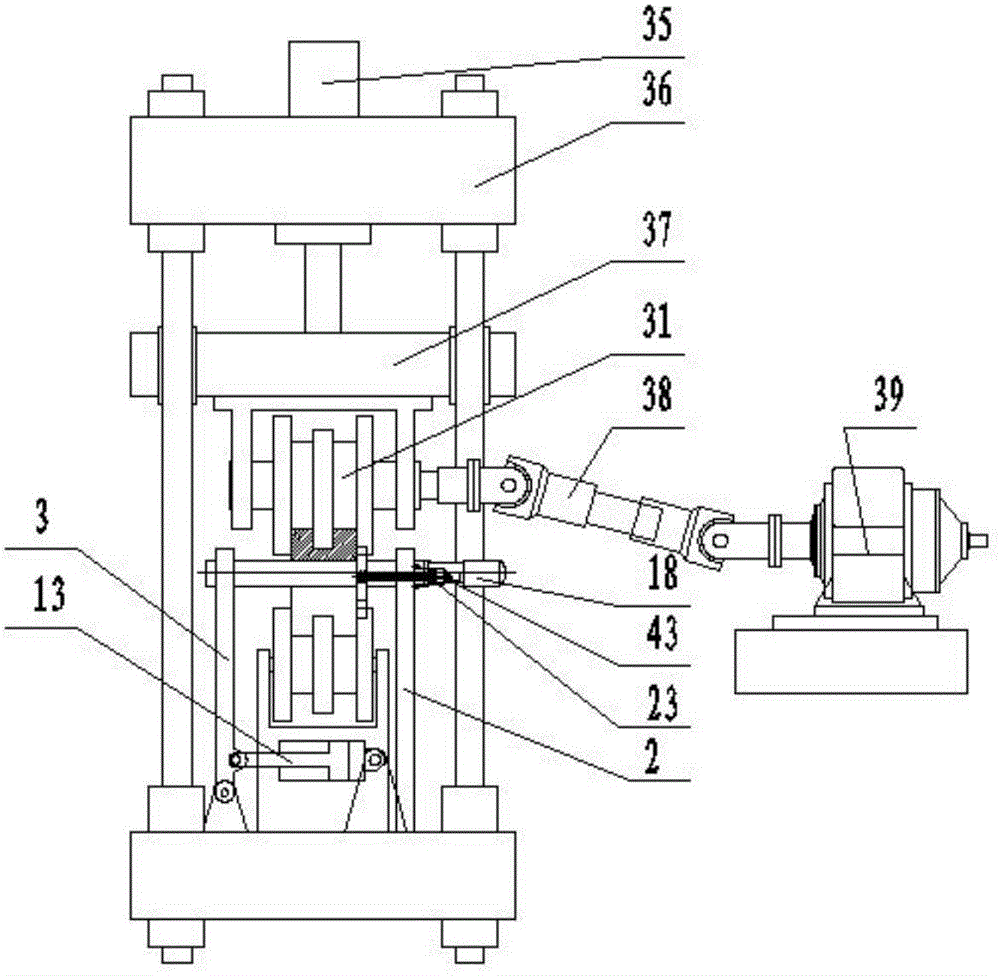

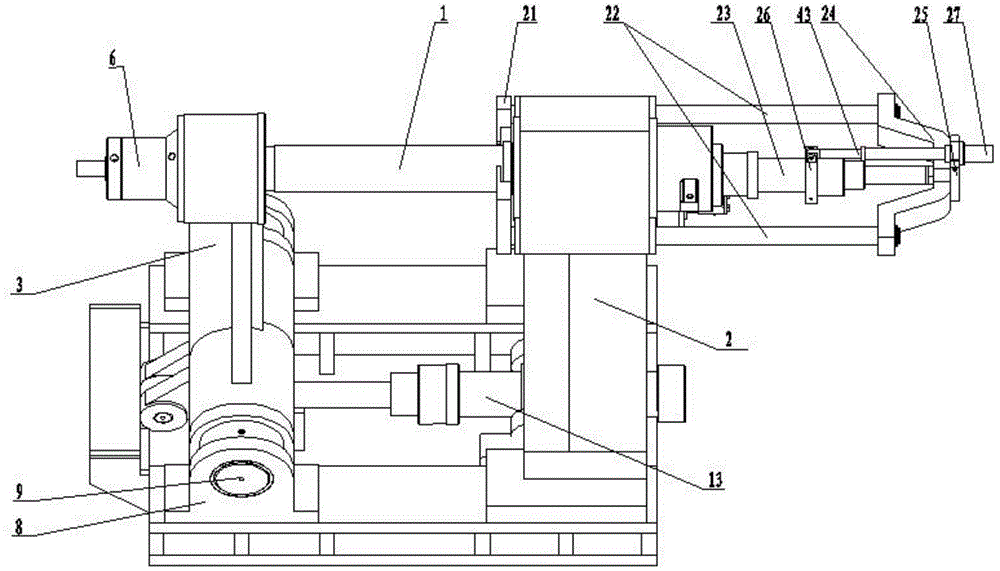

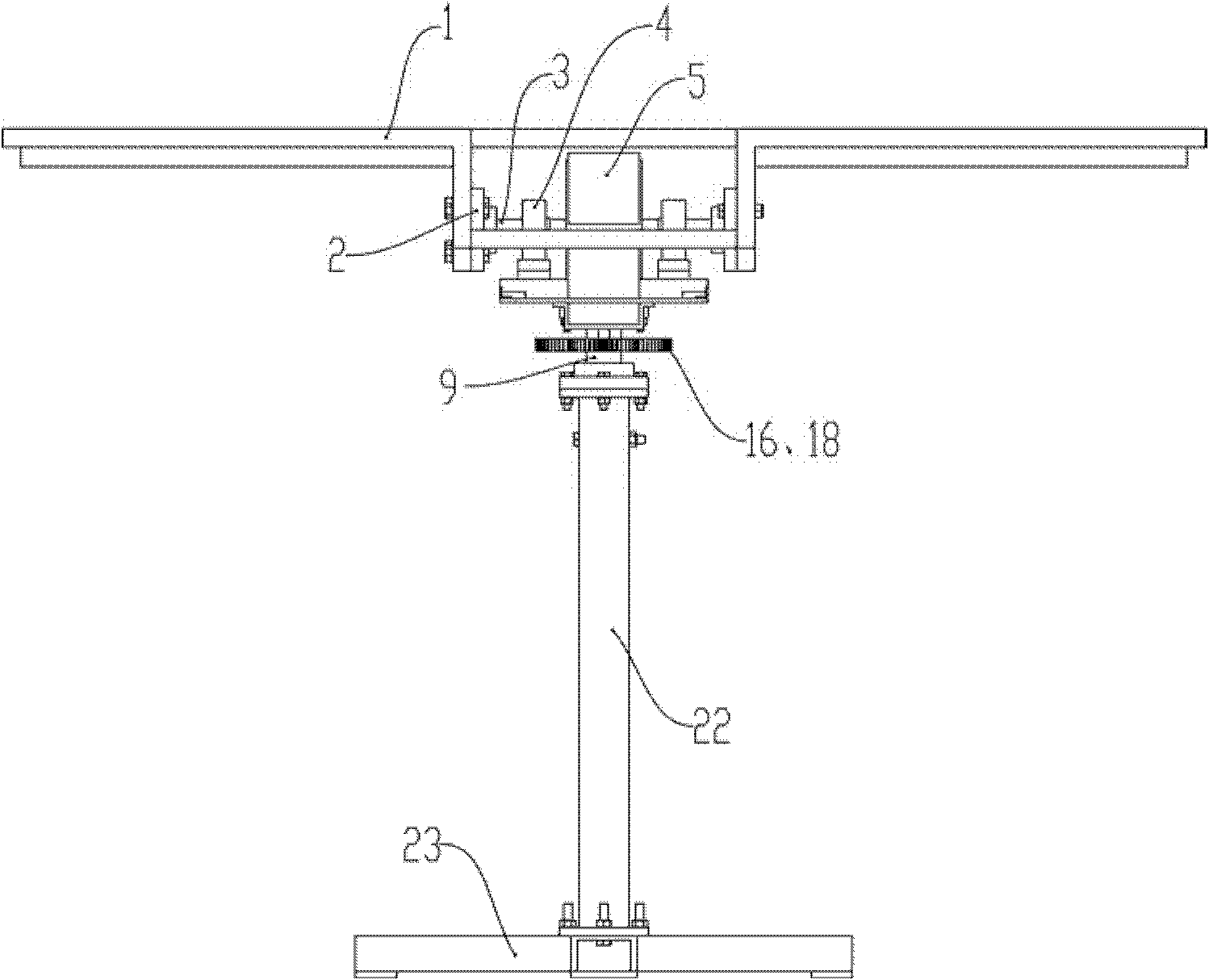

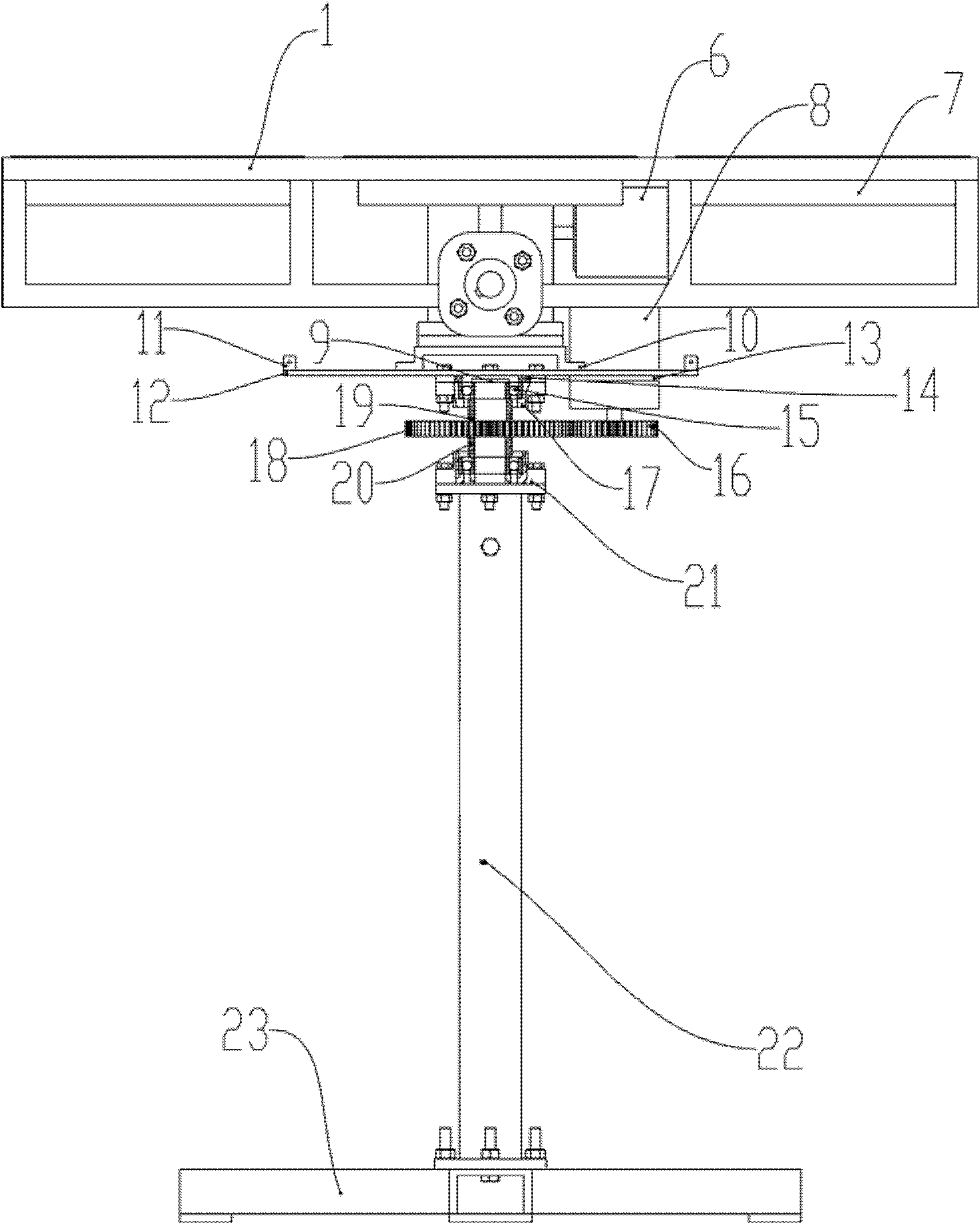

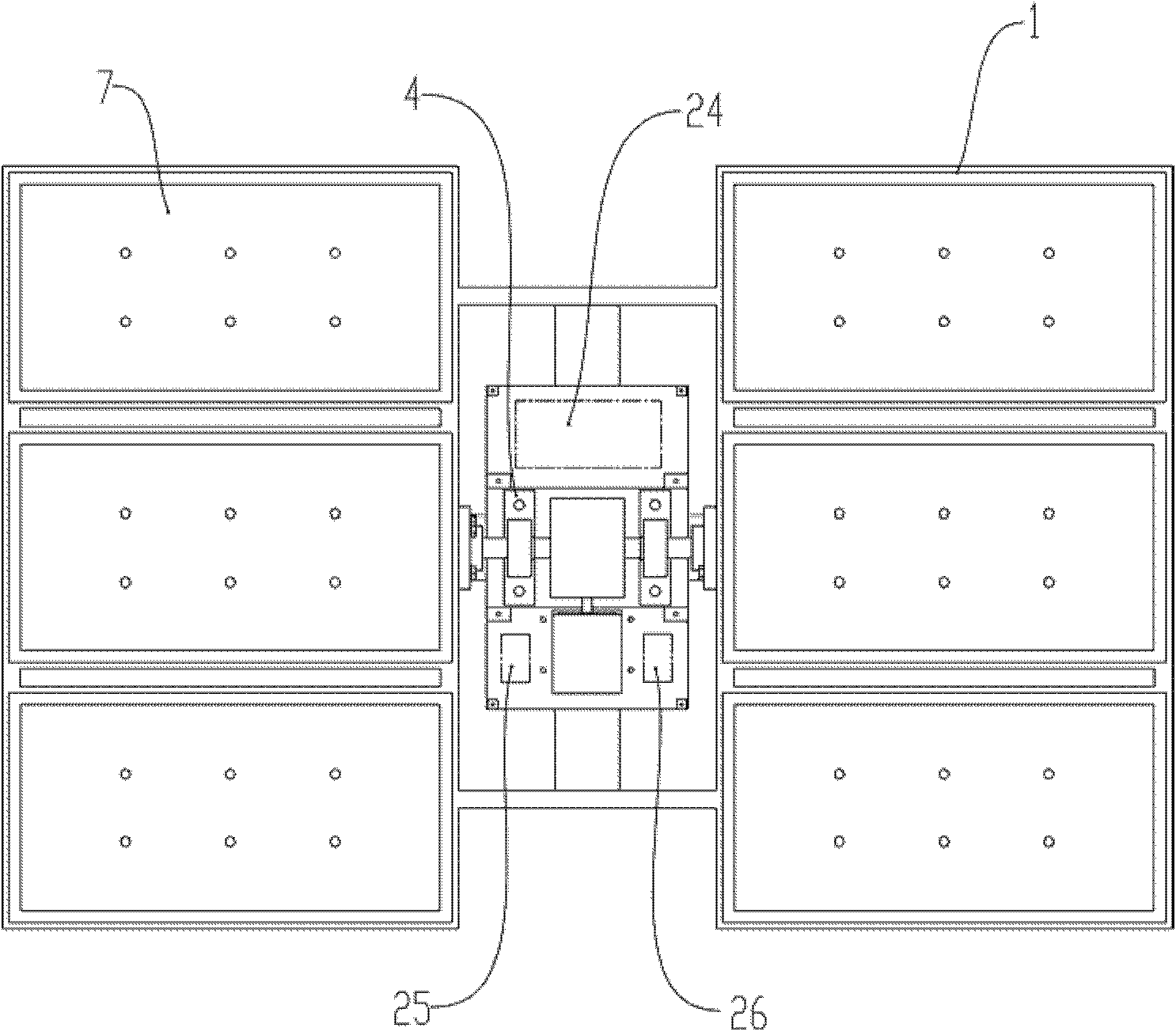

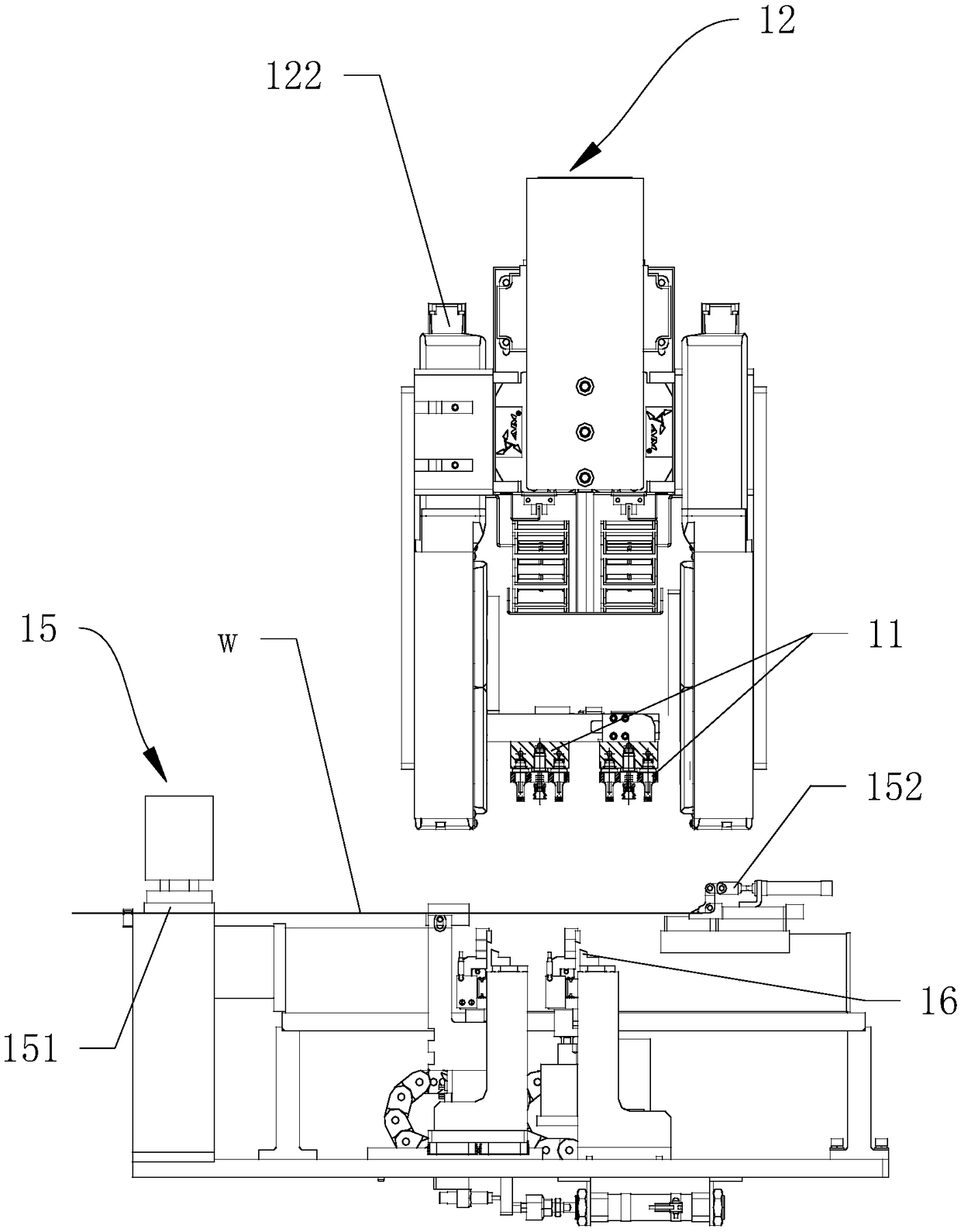

Large vertical type composite ring rolling mill and control method

ActiveCN104438990AHigh precisionImprove mechanical propertiesRoll force/gap control deviceMetal rolling arrangementsThick wallRoll forming

The invention provides a large vertical type composite ring rolling mill and a control method. The large vertical type composite ring rolling mill comprises a frame, a roller mechanism, a left sub roller mechanism, a right sub roller mechanism, a core roller mechanism and a control device. The control device is used for controlling operation of the roller mechanism, the left sub roller mechanism, the right sub roller mechanism and the core roller mechanism. The core roller mechanism comprises a core roller, a fixed support, a movable support, a core roller base and a lifting drive device, the lower end of the movable support is connected with the lifting drive device to enable the movable support to move up and down, the outer side of the fixed support is connected with a rotary drive device which can drive the core roller to rotate, the outer side of the rotary drive device is connected with a locating baffle mechanism, and precise locating of a baffle is achieved through displacement sensors. The large vertical type composite ring rolling mill can be used for automatic composite roll forming of large complex thick-wall deep-groove rings, and a mill user can obtain remarkable economic benefits.

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS +1

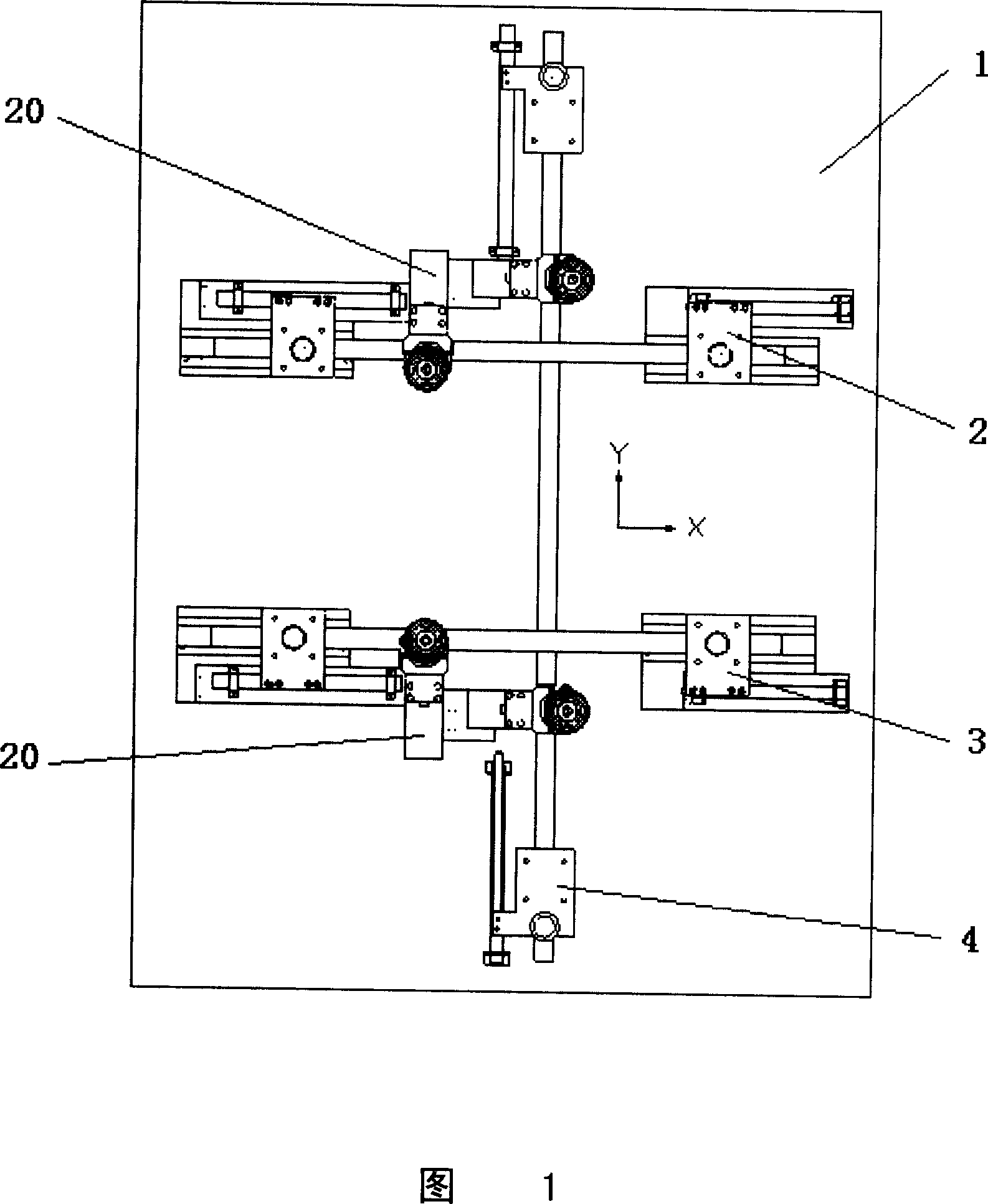

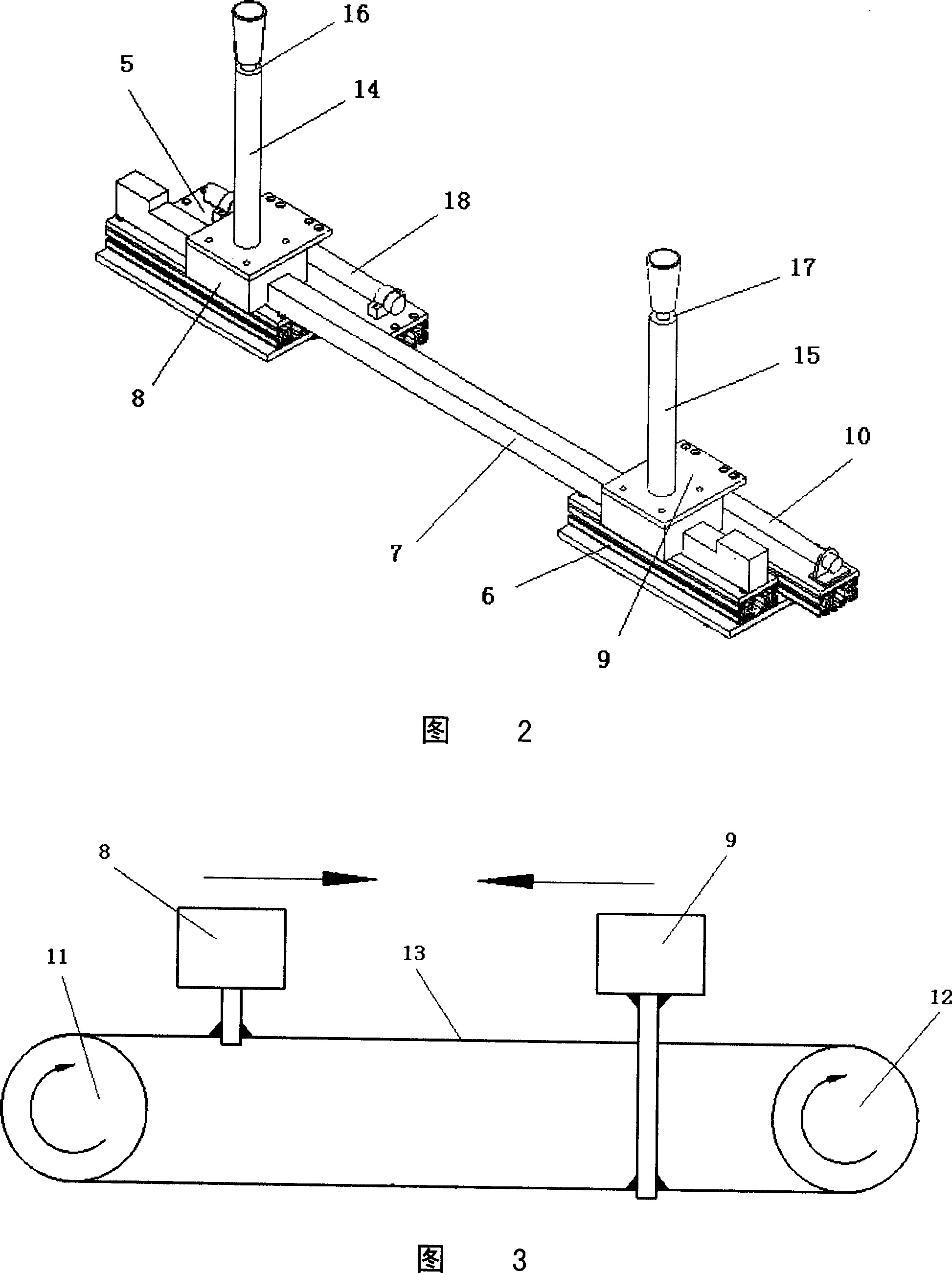

Glue spreading and positioning system of robot

ActiveCN101091942APrecise positioningWon't moveLiquid surface applicatorsSpraying apparatusEngineeringLinear displacement

The invention relates to a rubberizing-positioning system which is worked by robots, it includes a pair of middle- stages, two groups of X directions to the unit, a group of Y direction to the unit and two groups of sucker units, the characteristic of it is that: Each group to the unit has two foundations, a chute which has two slides on it; a slide connects with an air cylinder, and another with a linear displacement sensor relatively, the head of the two slides has a pair of sticks, and joining a connection ambulacrum relatively, each group of sucker units includes two moldings, the long molding fixes together to the stage, and the short molding installs on the long molding. At the head of the two moldings establishments a adjustment board which extends to X direction and the Y direction, the adjustment board nose connects a sucker module separately; each sucker module has a sucker junction panel, a U support whose two extending terminal through a knuckle bearing pin connects at both sides of the sucker bracket, the base of the sucker bracket connects an air cylinder which brings along the sucker. The invention can carry on the pinpointing orientation to the glass in X, Y and Z directions, and distinguishes the glass model, and enable robots to control the gelatinizing procedure automatically.

Owner:廊坊智通机器人系统有限公司

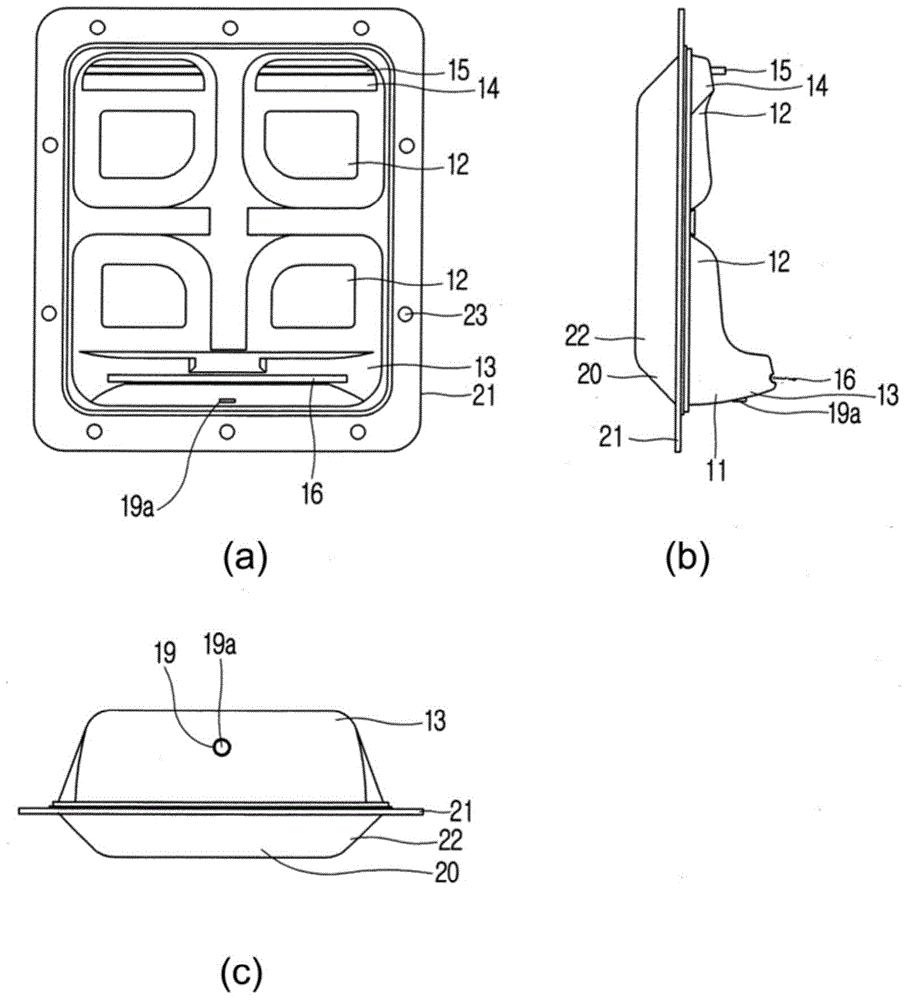

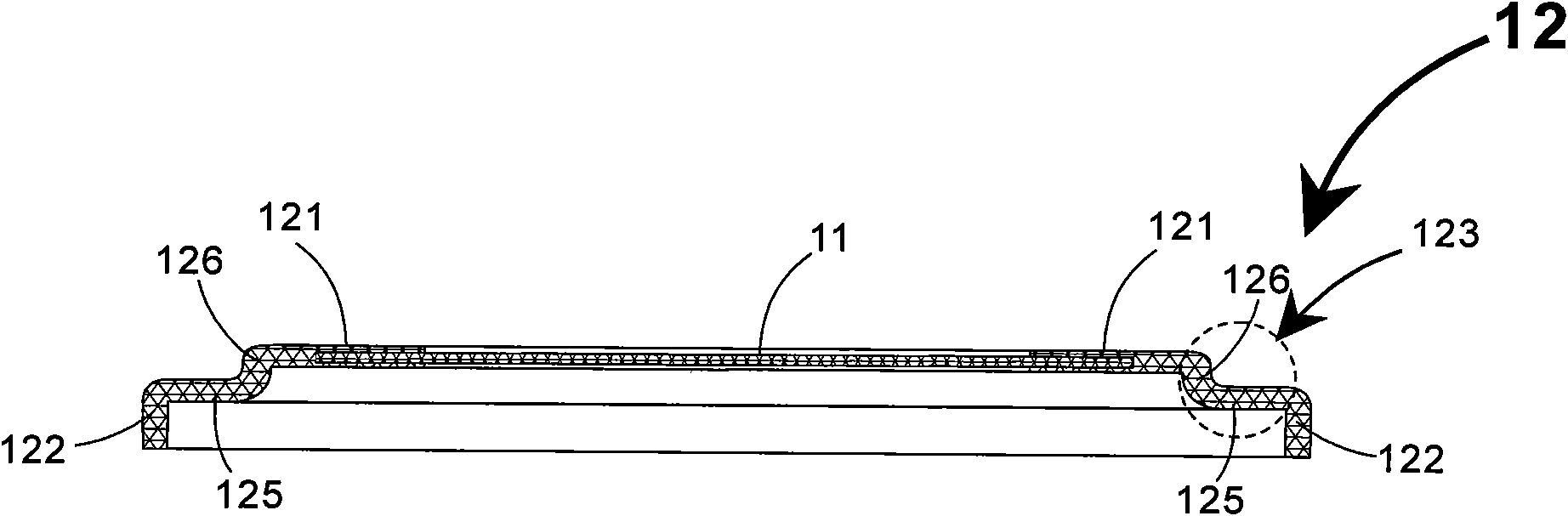

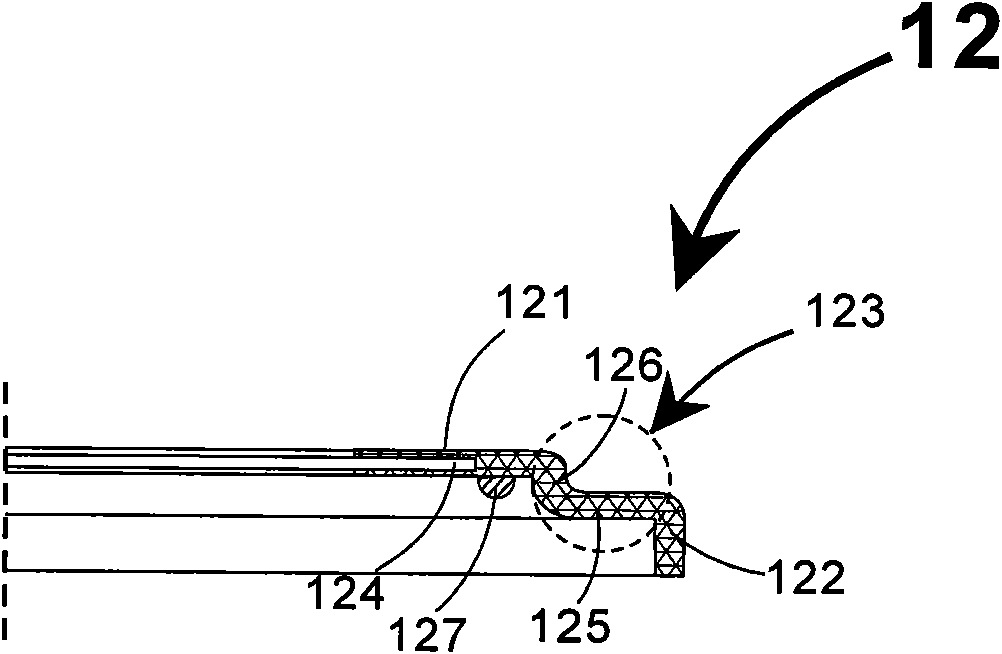

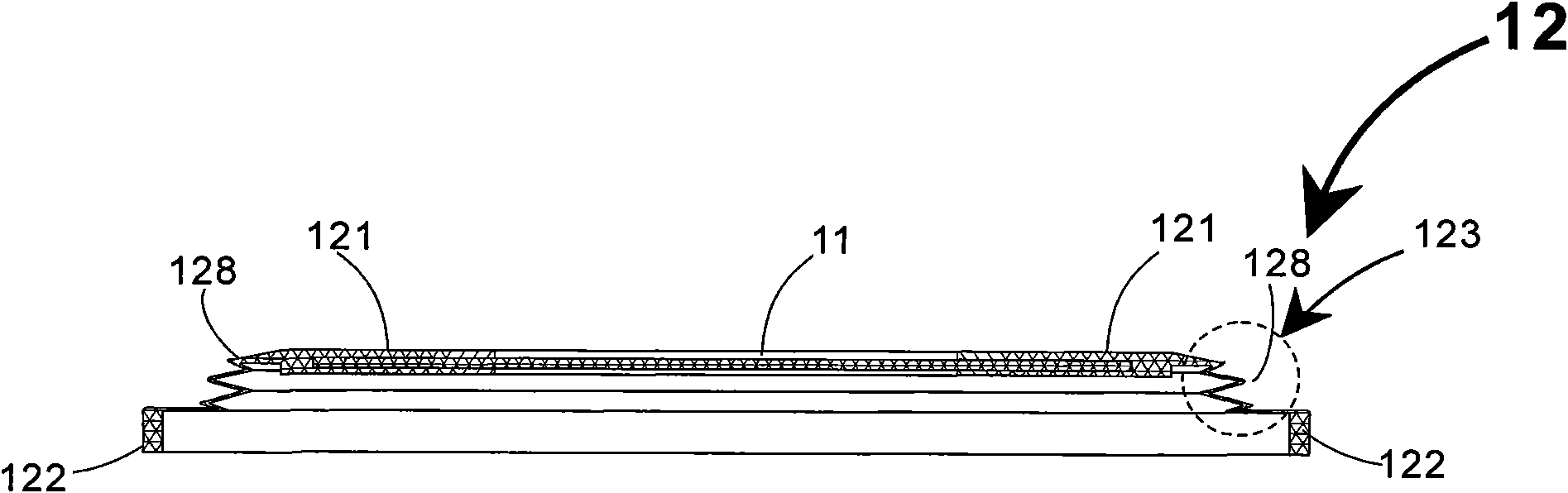

Supporting device for solar panel

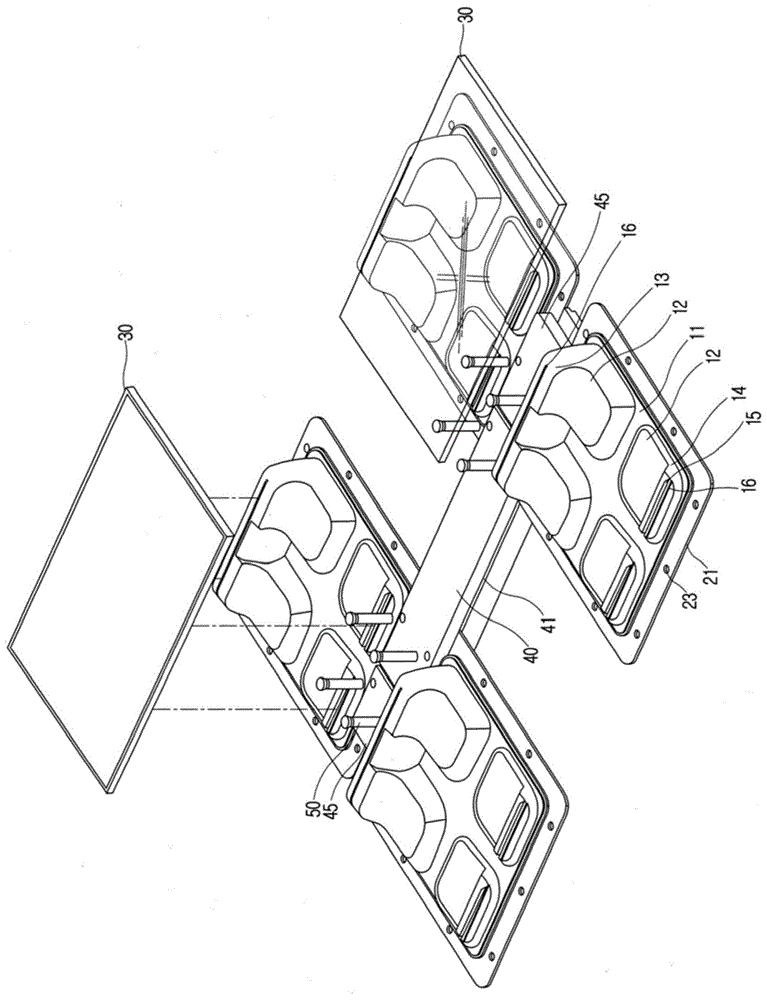

InactiveCN104702200AWon't moveMaintain stabilityPhotovoltaic supportsSolar heating energyEngineeringPhotovoltaic system

The present disclosure relates to a photovoltaic system and, more particularly, to a supporting device for a solar panel employed in a photovoltaic system. A supporting device for a solar panel includes a buoyant member (10) including an upper body (11) in which a plurality of protrusions (12) are formed upwardly and first (13) and second (14) props are formed on the protrusions (12) to prop a solar panel (30), respectively, and a lower body (20) in which a wing part (21) is formed to be protruded from the side thereof and a lower surface (22) is formed to be protruded downwardly, and a connector (40) formed to have a box shape and connecting the buoyant member (10) to another buoyant member (10) in a vertical direction or horizontal direction, wherein the buoyant member (10) is coupled to the connector (40) when the wing parts (21) are coupled to the connector (40).

Owner:LSIS CO LTD

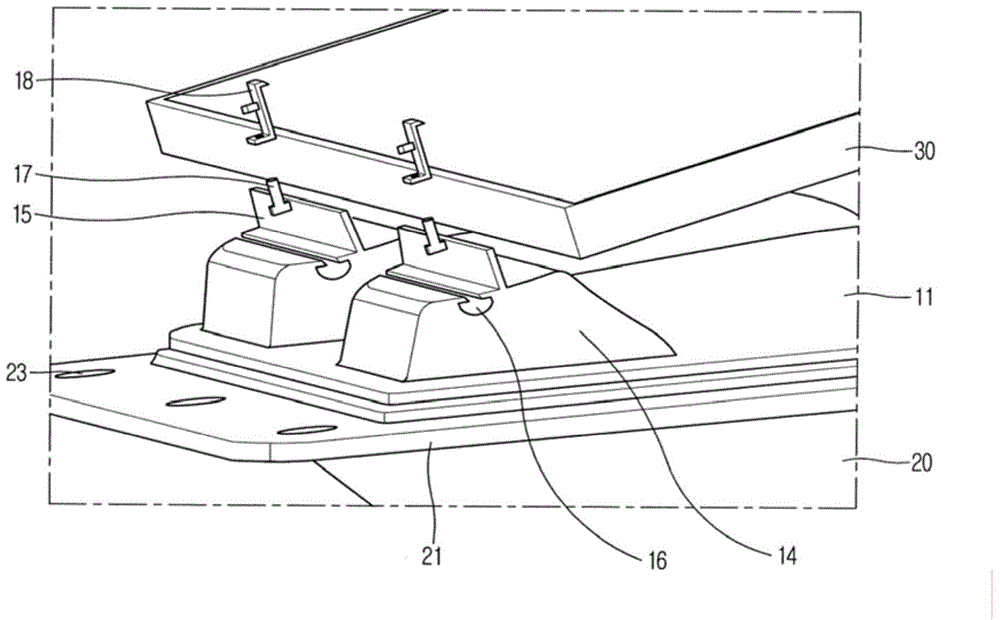

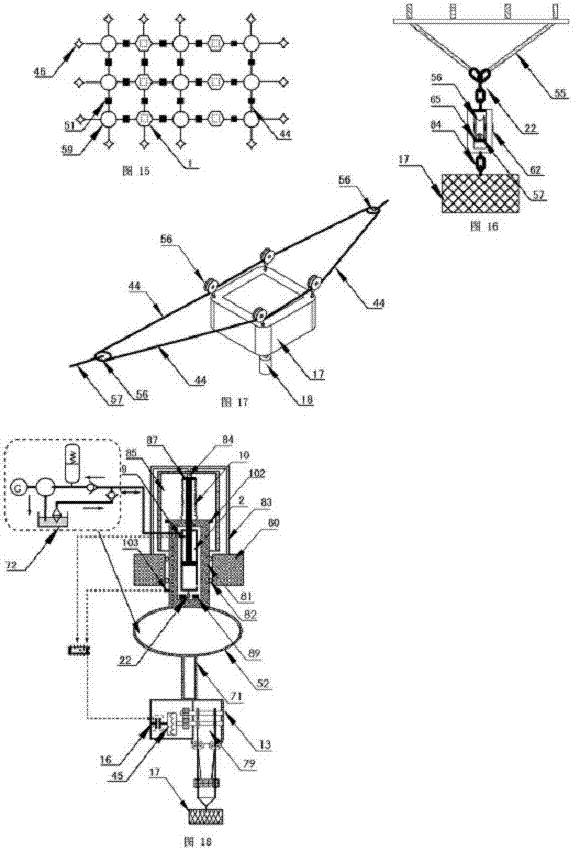

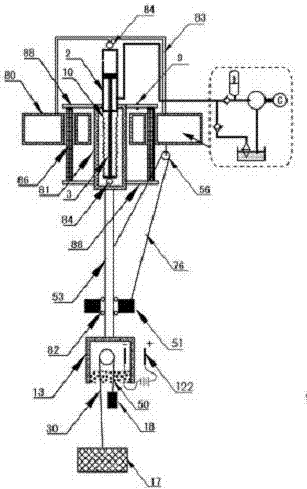

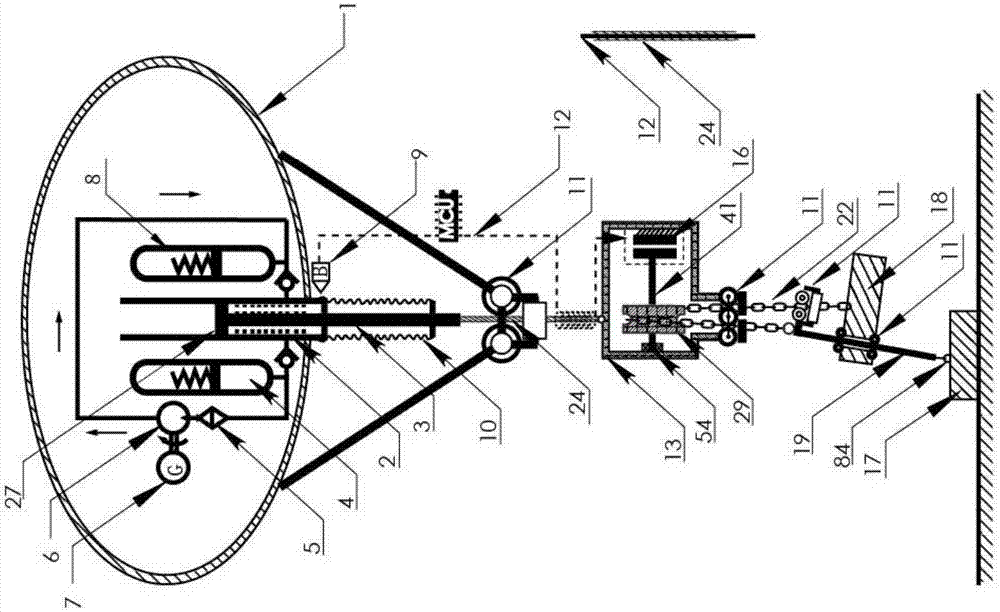

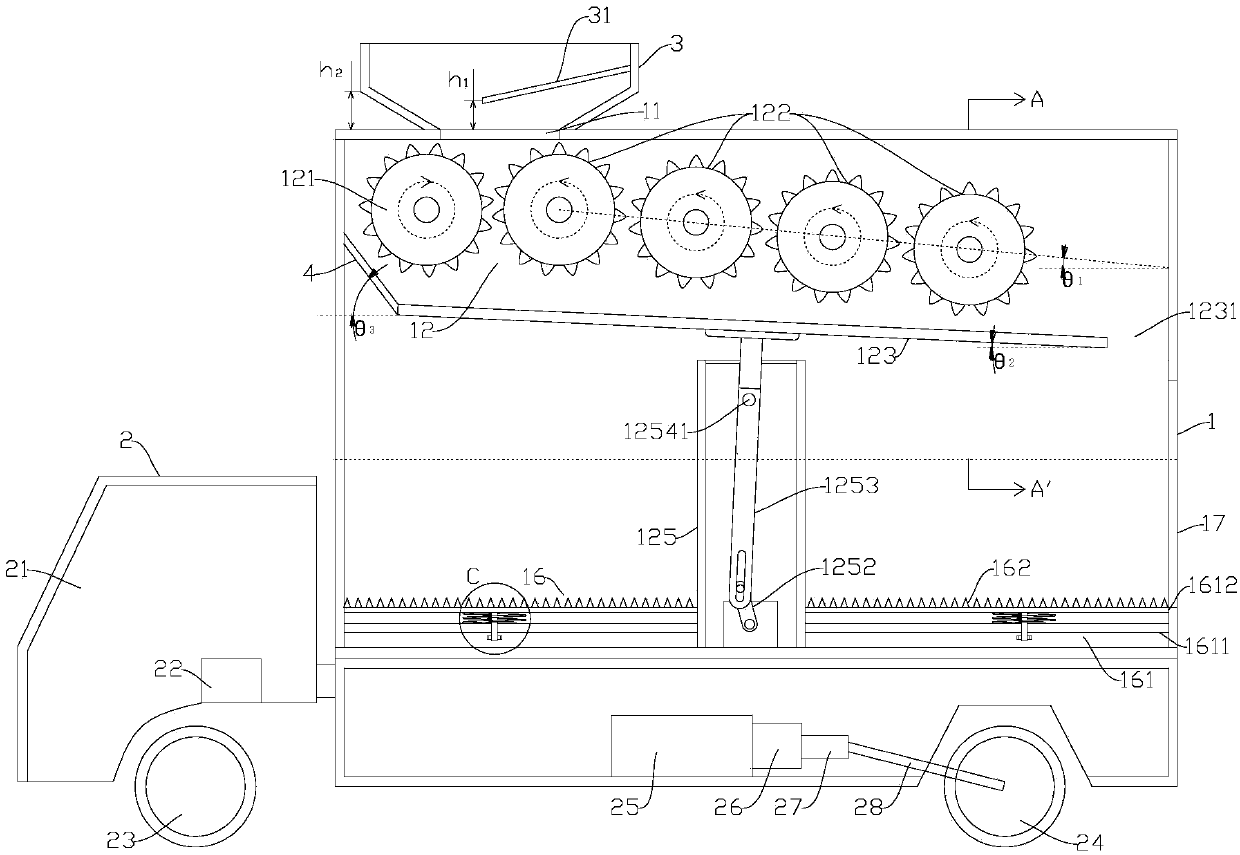

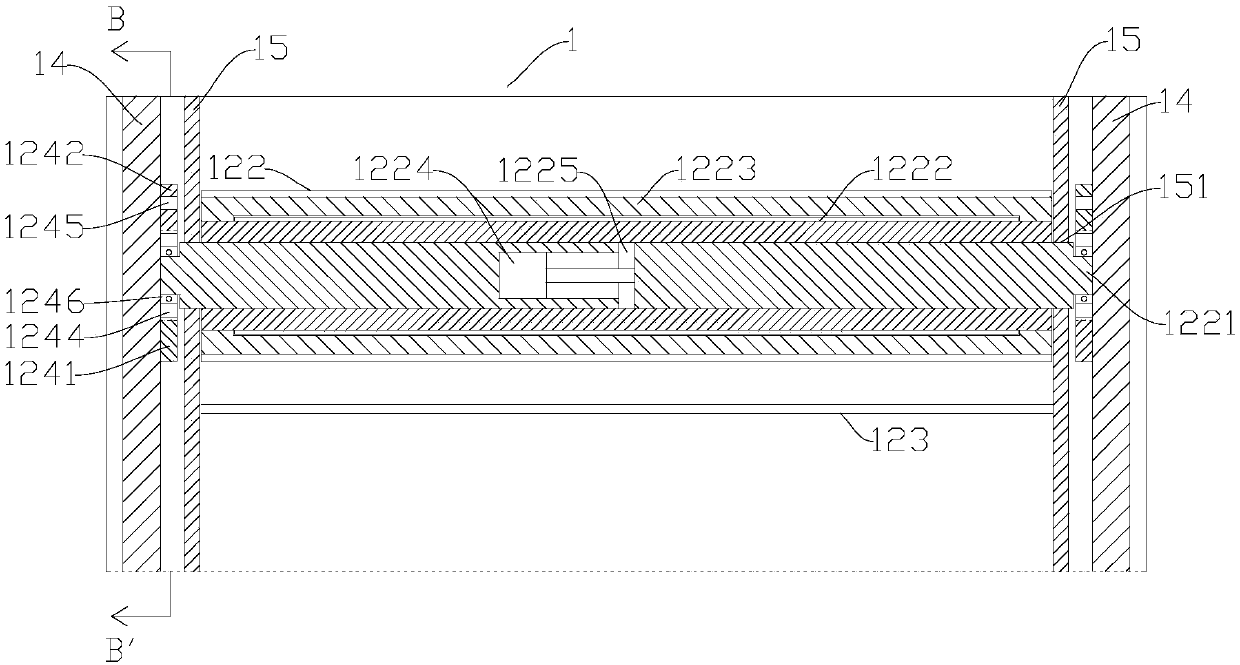

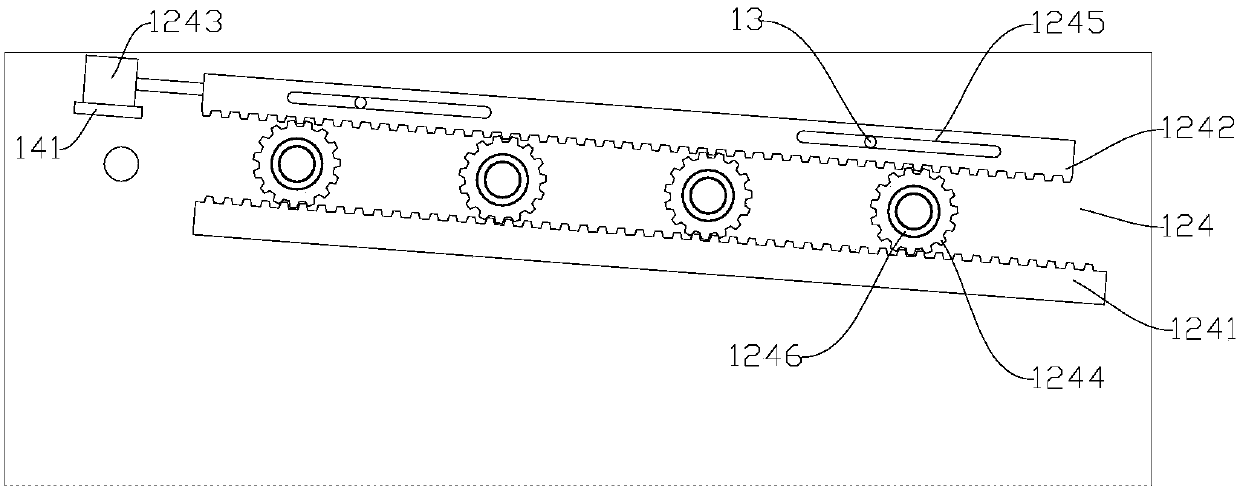

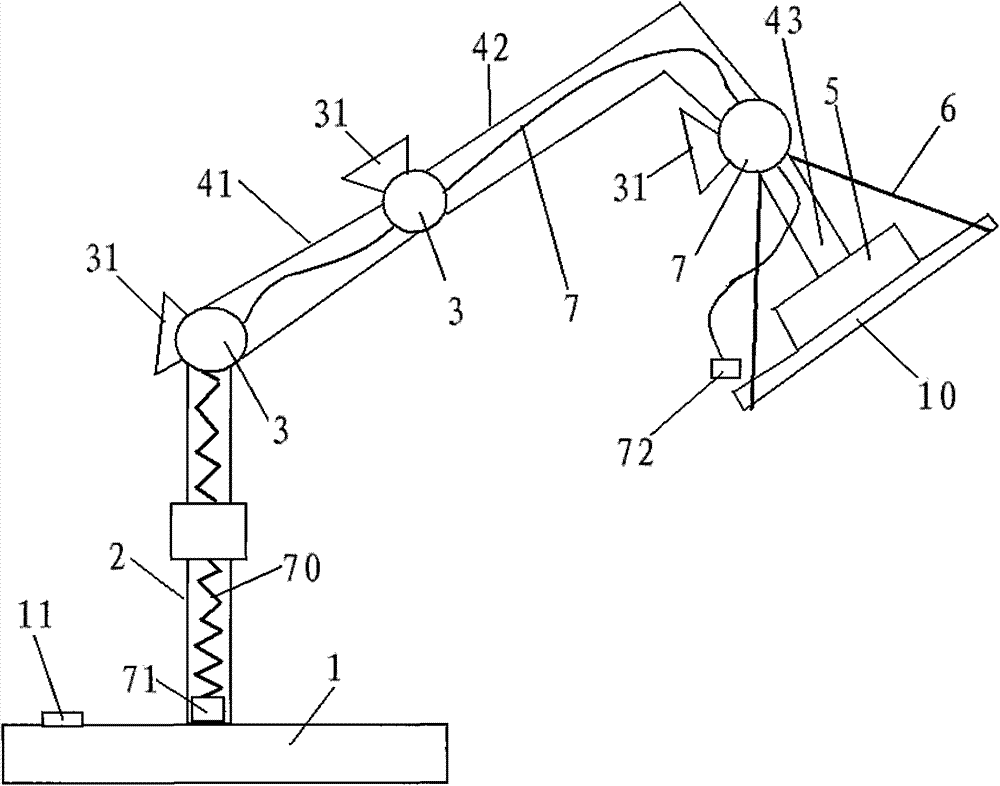

Wave-activated generator with line-operated hydraulic cylinder

PendingCN107255060AReduce distanceStable distanceMachines/enginesEngine componentsHydraulic cylinderHydraulic motor

The invention relates to a wave-activated generator with a line-operated hydraulic cylinder. The generator comprises a wave energy absorption and transformation portion, a line controlling device, and a gravity anchor, wherein the wave energy absorption and transformation portion comprises a floating body and a hydraulic system. A hydraulic oilcircular path of the hydraulic system comprises a single-acting cylinder, an exit one-way valve, a high pressure accumulator, a hydraulic motor, a low pressure accumulator / an opening oil box, an oil filter, and an admission one-way valve. A cylinder body of the single-acting cylinder is connected with the floating body, and a lower end of a piston rod of the single-acting cylinder is connected through a rope or a chain with a upper end of a rack of an actuating mechanism of the line controlling device which is under the floating body. The rope controlled by the line controlling device extends downwards to be connected with the gravity anchor. According to the system, the hydraulic cylinder which has limited range can adapts to big wave and tidal changes, the effect of rope coiling is good, and the efficiency of rope coiling is high.

Owner:曲言明

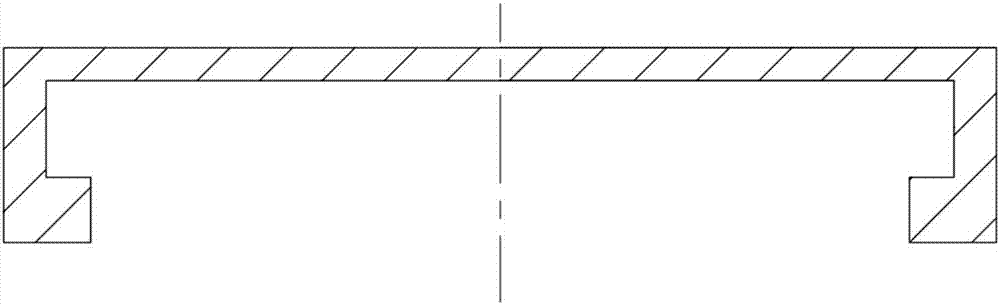

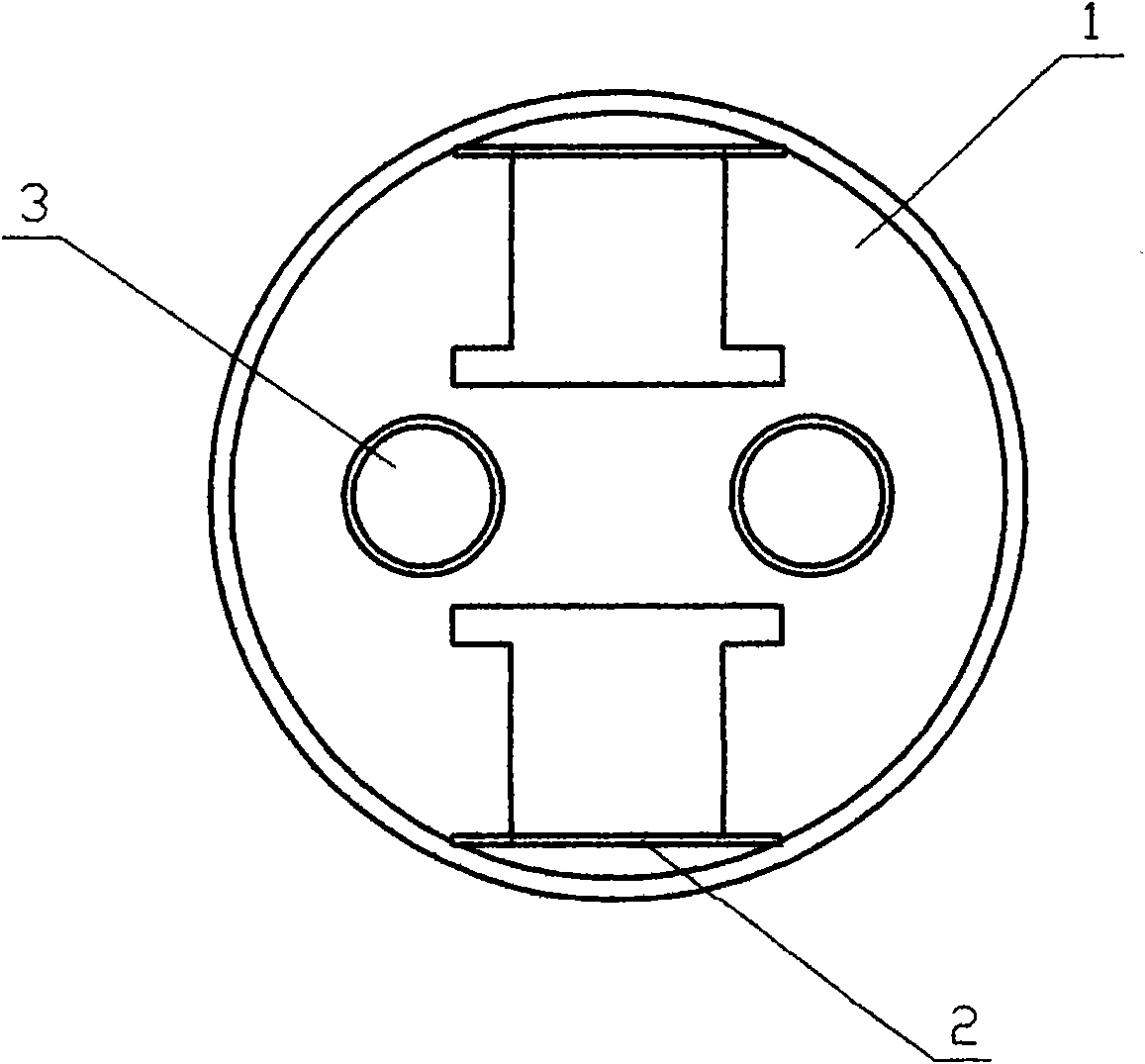

Combined membrane, stethoscope head matched with same as well as matching component of both

ActiveCN101647712AImprove recovery effectPrecise positioningStethoscopeSound producing devicesSTETHOSCOPE HEADEngineering

The invention relates to a medical instrument accessory, in particular to a stethophone accessory. The invention discloses a combined membrane which comprises a round membrane and a fixer. The fixer comprises three parts including a big ring, a small ring and a connecting part, wherein the big ring is arranged below the connecting part, the small ring is arranged above the connecting part and radially provided with a ring slot, and the outer edge of the round membrane is positioned in the ring slot. The invention also provides a stethoscope head which comprises a stethoscope head body and a cylinder, wherein the cylinder and the stethoscope head body are integrated into a whole, the end surface of the cylinder is provided with an axial ring slot and a sound collecting surface; and a soundguide hole and a fixing hole are arranged on the sound collecting surface. The membrane has the advantages of good restoration and accurate positioning; the stethoscope head is easy to install and hasstrong tightness; and users can acutely acquire a matching structure of multitone only by changing force applied on the stethoscope head body.

Owner:单希杰

Seedling raising device capable of regulating intensity and angle of received light

ActiveCN102405796AConvenient lightingUniform light receivingGreenhouse cultivationCultivating equipmentsElectric machineryEngineering

The invention relates to technical field of energy and particularly discloses a seedling raising device capable of regulating intensity and angle of received light. The device comprises a supporting frame, a control box, and an upright post, wherein culture box cases for raising seedlings are arranged on the supporting frame; the control box is arranged on the supporting frame, and a horizontal motor which controls the horizontal rotation of the supporting frame, an axial motor which controls the vertical rotation of the supporting frame, two motor drivers which are connected with the horizontal motor and the vertical motor respectively and a controller which is connected with the two motor drivers are arranged in the control box; the control box can be connected with a computer for controlling the rotation rate and pitch swing angle of the supporting frame; and the upright post is arranged below the control box for supporting the supporting frame and the control box. In the device, the top layer is kept under optimal illumination all the time because of the automatic light tracing function of the device; and through the rotation and pitch swing of the device, leaves in different directions and different parts of the same leaf receive the same light, so the optimal photosynthesis is realized.

Owner:NONGXIN TECH BEIJING CO LTD

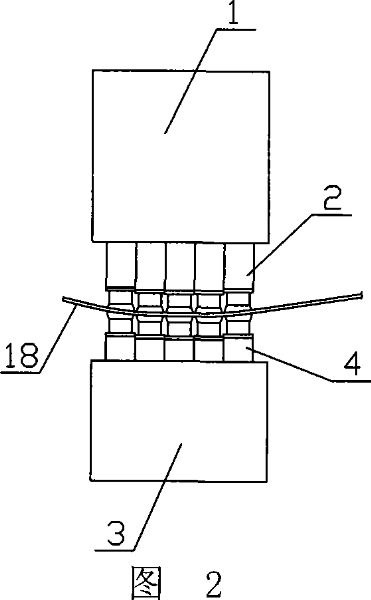

Huoluo hemisphere type pressure head base body of multi-pressure-head sheet forming device

Owner:WUHAN UNIV OF TECH

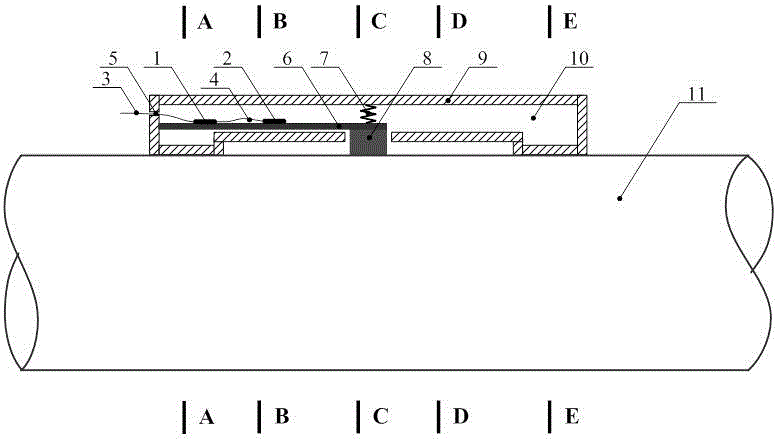

Temperature compensation optical fiber grating steel bar corrosion sensor and temperature compensation method thereof

PendingCN106501165AReduce volumeHighly integratedWeather/light/corrosion resistanceThermometers using physical/chemical changesGratingReinforced concrete

The invention provides a temperature compensation optical fiber grating steel bar corrosion sensor and a temperature compensation method thereof. The temperature compensation optical fiber grating steel bar corrosion sensor comprises a cantilever beam arranged in a case, optical fiber gratings and a probe. The cantilever beam is provided with a fixed end and a free end, wherein the fixed end is fixedly connected with the case; the probe is mounted on the free end; the optical fiber gratings are adhered to the cantilever beam; the case is provided with a steel bar contact unit and a suspension unit; the probe penetrates out of the suspension unit. The compensation method comprises sensing the central wavelength shift of the optical fiber grating caused by temperature change and steel bar corrosion through the two bare optical fiber gratings simultaneously; according to differences of the shift, achieving temperature compensation to steel bar corrosion measurement results and meanwhile obtaining the corrosion rate as well as the temperature change of the steel bars at a measured point. The temperature compensation method can greatly reduce the size of sensors based on the optical fiber grating sensing principles and improve the integration degree of the sensors. The temperature compensation optical fiber grating steel bar corrosion sensor has the advantages of being high in precision, small in size, good in duration, anti-electromagnetic and the like and can bring huge convenience to reinforced concrete structure testing.

Owner:HOHAI UNIV

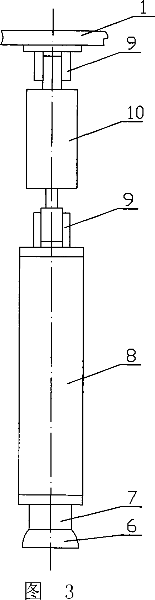

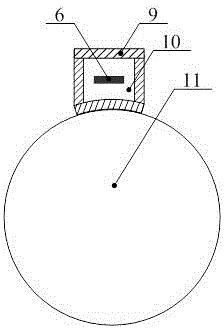

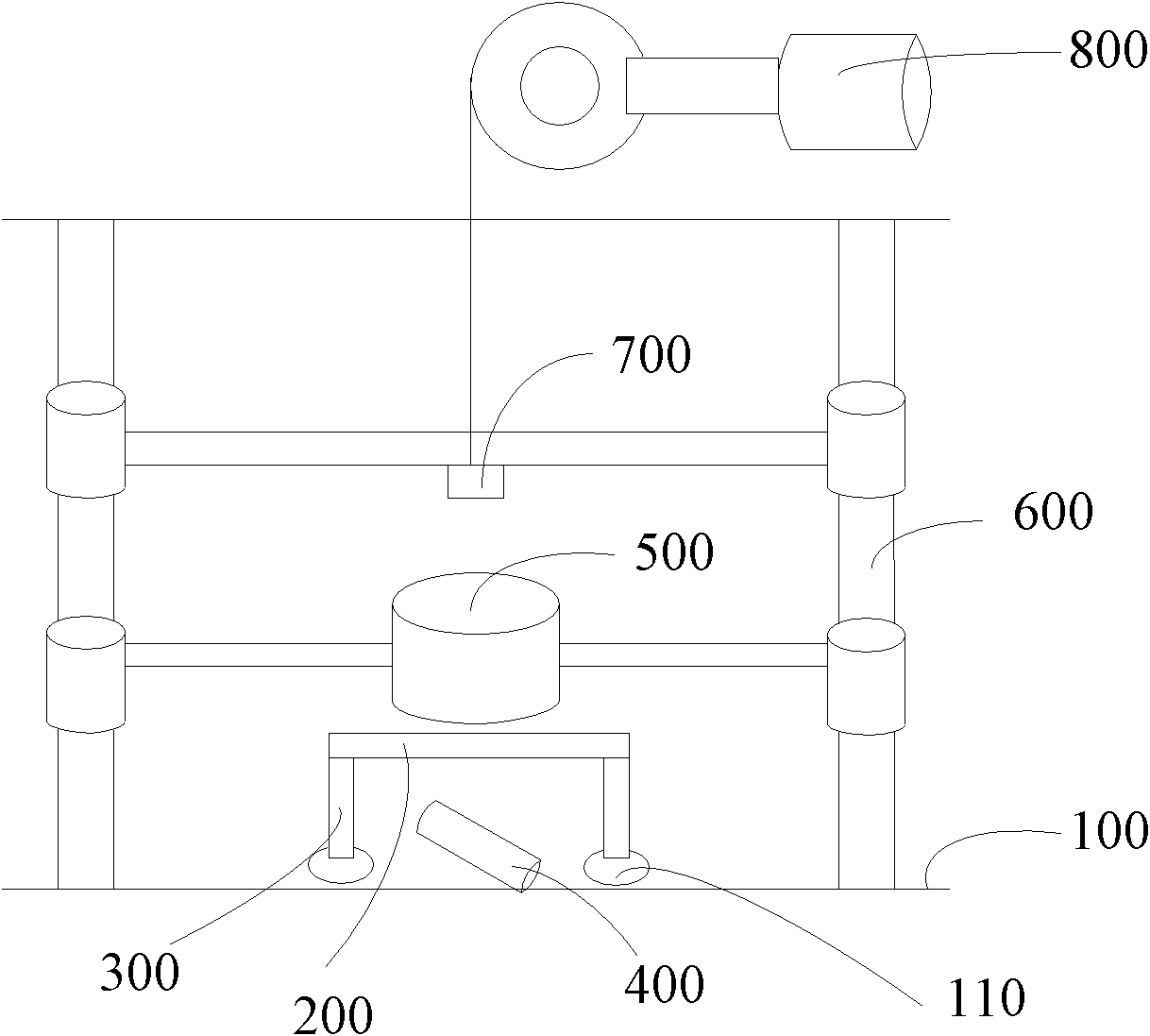

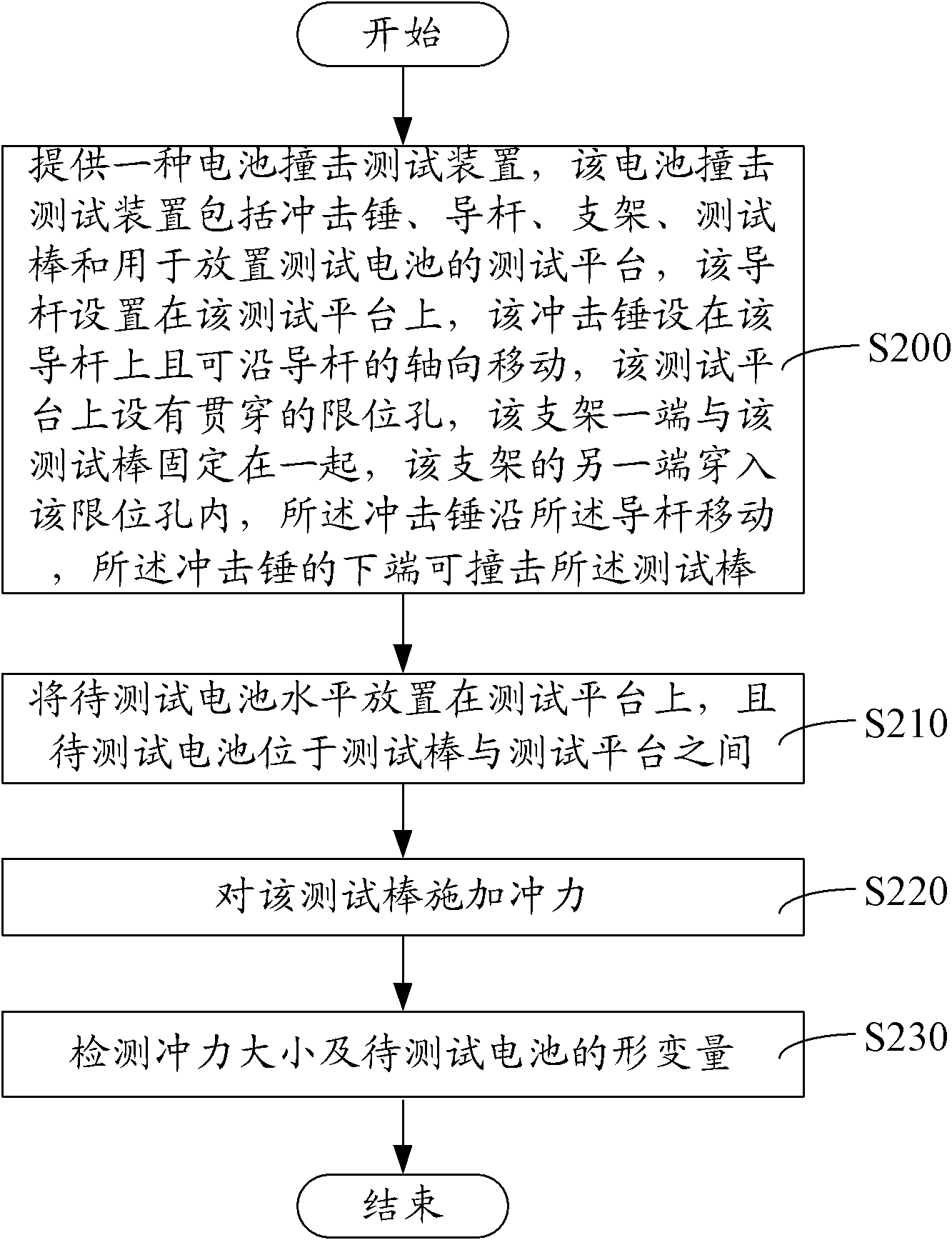

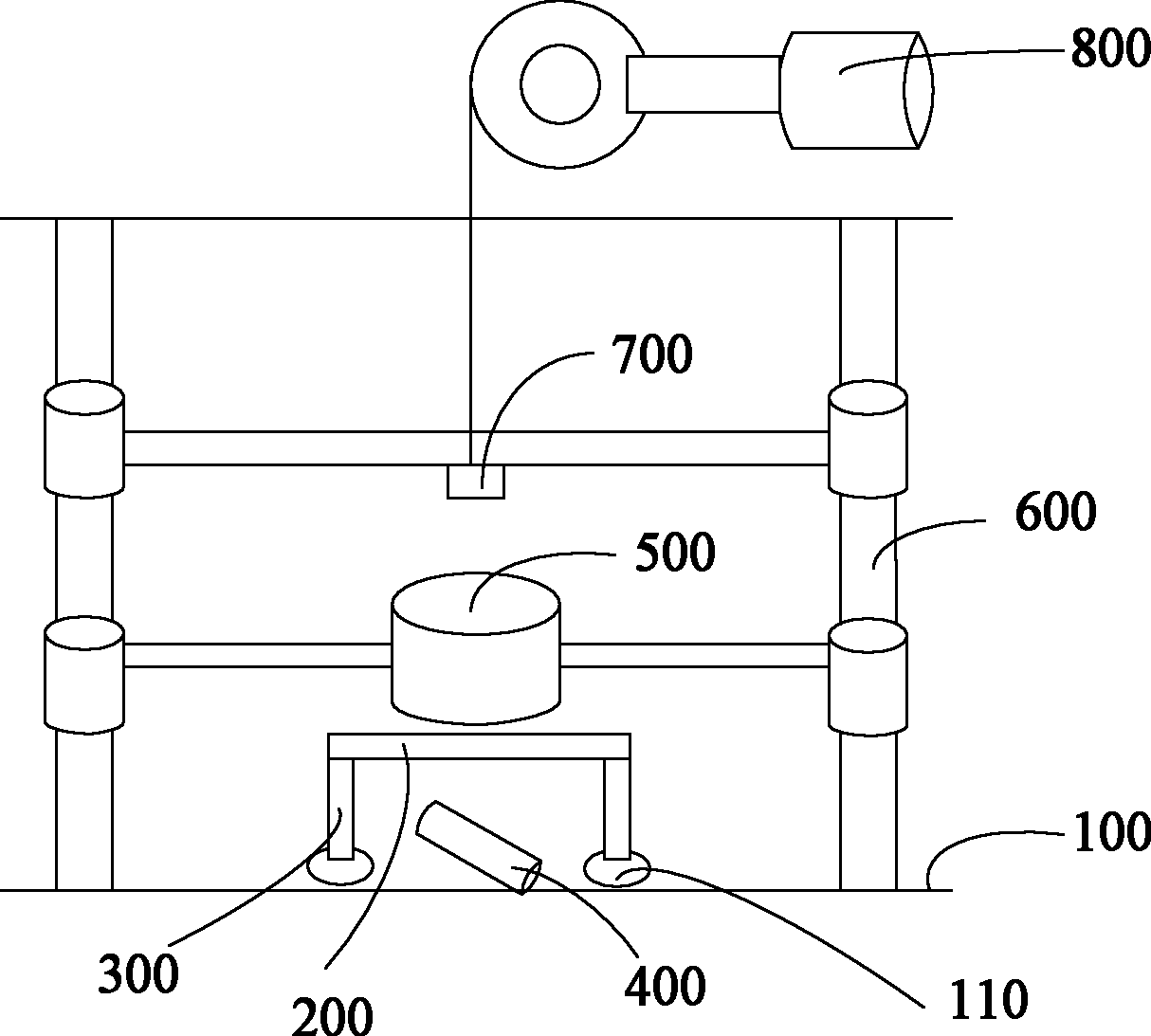

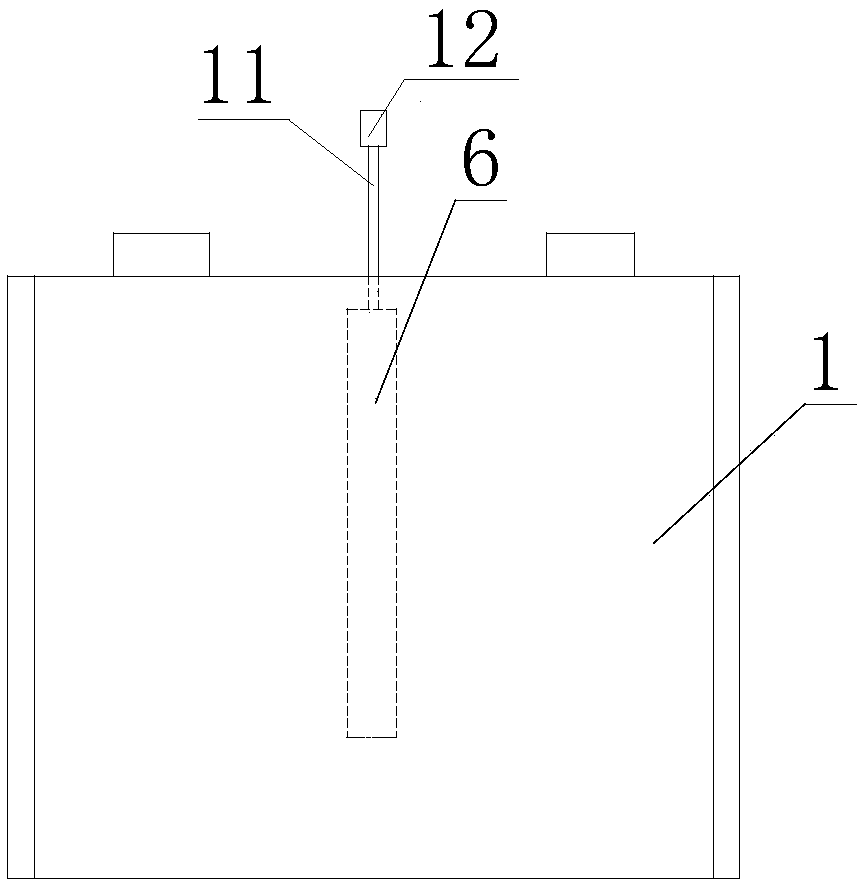

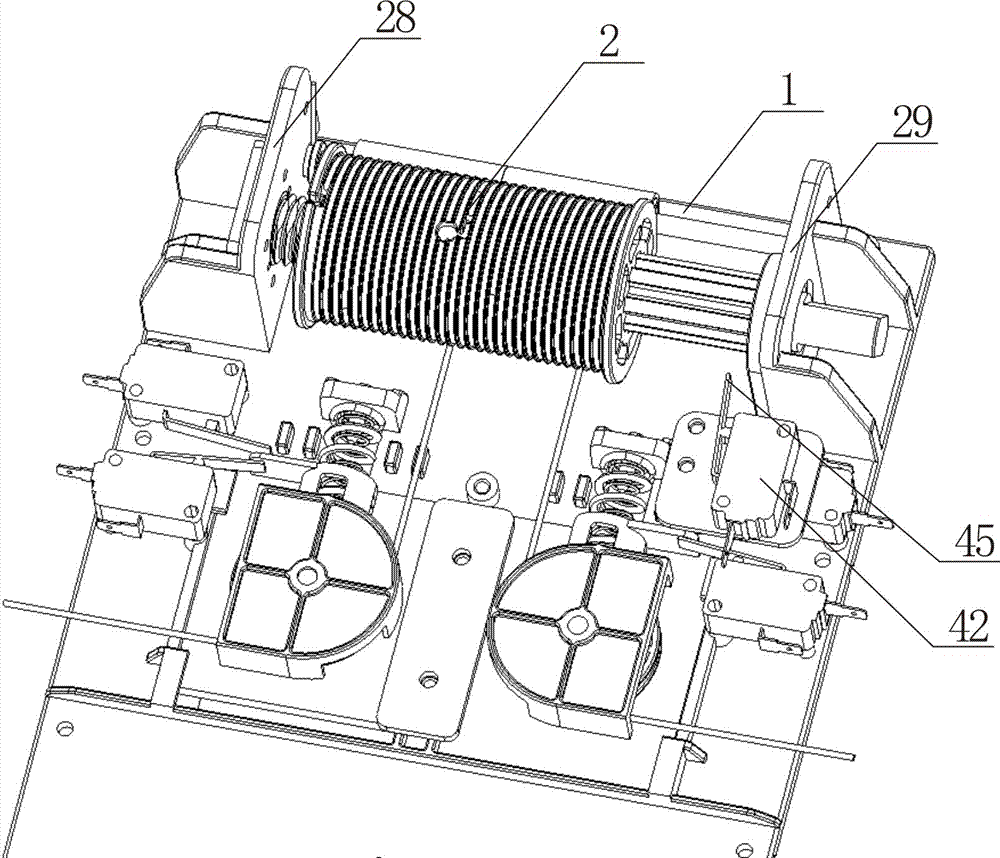

Testing device and testing method for battery impact

The invention relates to a testing device and a testing method for battery impact. The device comprises an impact hammer, a guide bar, a testing rod and a testing platform which is used for holding a test battery, wherein the guide bar is arranged on the testing platform; the impact hammer is arranged at the guide bar and can move along the axial direction of the guide bar.. The device also comprises a bracket, wherein a through spacing hole is formed on the testing platform; one end of the bracket and the testing rod are fixed together and the other end of the bracket penetrates through the spacing hole; and the impact hammer moves along the guide bar and the lower end of the impact hammer can impact the testing rod. According to the testing device and the testing method for the battery impact, the testing rod does not move during a battery impact test by fixing the bracket and the testing rod and limiting the bracket in the spacing hole of the testing platform, so that testing is convenient and the test results are accurate; and the testing rod does not move, so that the testing rod does not need to be adjusted, and the testing efficiency is improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

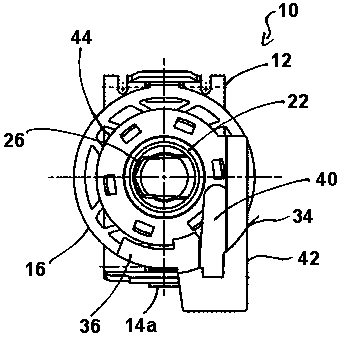

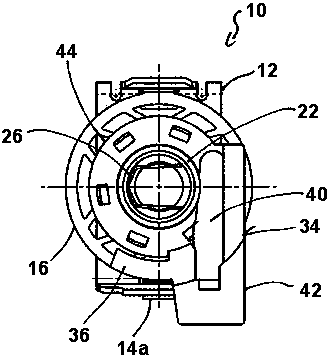

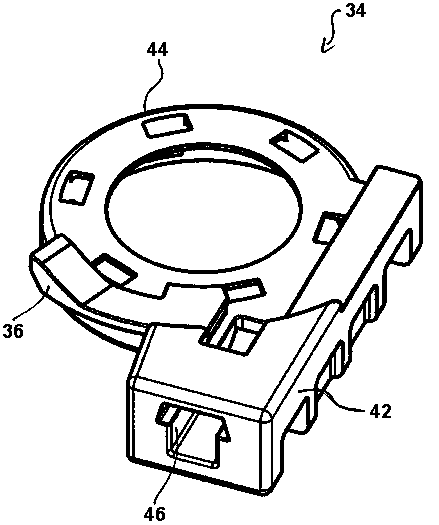

Tolerance compensation apparatus

ActiveCN103994131ACompensation element movementWon't moveWashersNutsClassical mechanicsControl theory

Owner:WITTE AUTOMOTIVE GMBH

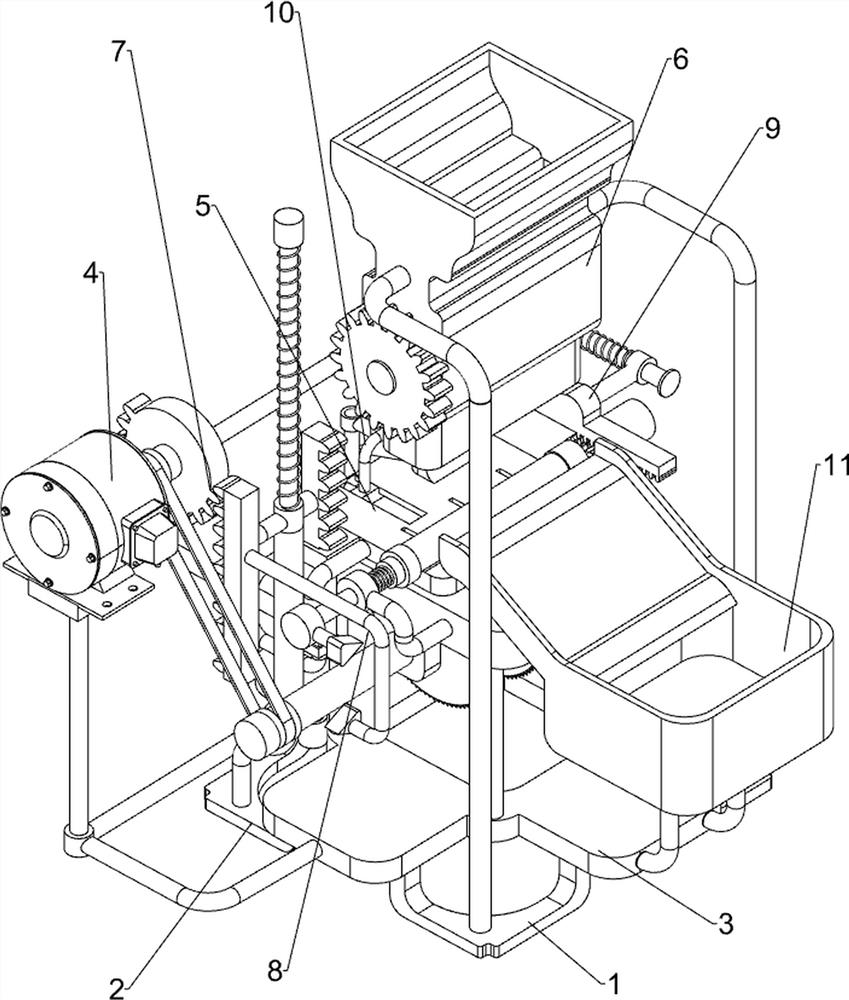

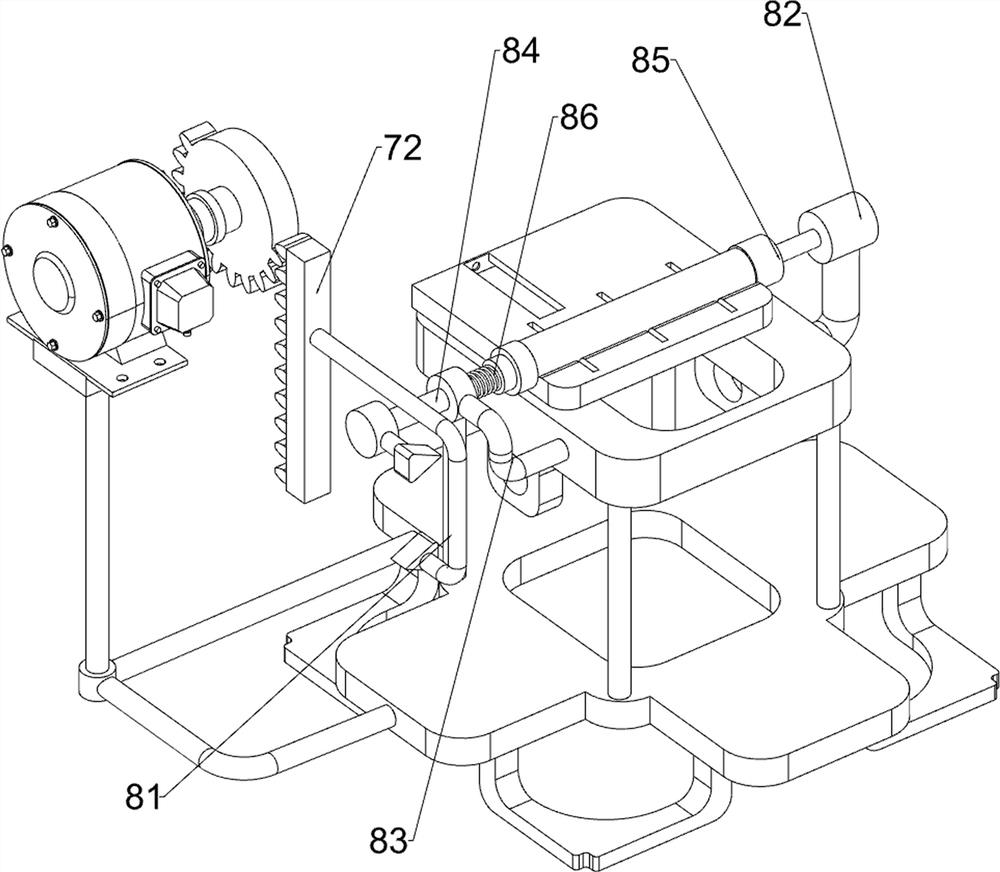

Automatic wood stick stripe cutting machine

PendingCN112476648ATo achieve the purpose of automatically cutting wooden sticksImprove work efficiencyProfiling/shaping machinesAgricultural engineeringSupport plane

The invention relates to a cutting machine, in particular to an automatic wood stick stripe cutting machine. The invention provides the automatic wood stick stripe cutting machine which not only can efficiently realize automatic discharging and automatic cutting, but also can collect cut materials in time. The automatic wood stick stripe cutting machine comprises first supporting frames and a supporting plate, wherein the first supporting frames are symmetrically arranged at the bottom of the supporting plate; second supporting frames symmetrically arranged at the bottom of the supporting plate; and a cutting mechanism arranged on the supporting plate. Through cooperation of a discharging, cutting and rolling mechanism and the cutting mechanism, the purpose of automatically cutting woodensticks is achieved; and through cooperation of an automatic pushing and rolling mechanism and an auxiliary clamping mechanism, the cut wood stick is pushed and rolled, and the purpose of cutting the surface of the wood stick is achieved.

Owner:黄国春

Polishing device for aluminium alloy door and window support notch

InactiveCN108942461ALess hurtful thingsImprove work efficiencyEdge grinding machinesGrinding carriagesEngineeringAluminium alloy

The invention discloses a polishing device for an aluminium alloy door and window support notch, and relates to the technical field of aluminium profile machining. The polishing device comprises a working table, a clamping plate is fixedly connected to the middle portion of the upper surface of the working table, an object containing hole is formed in the top of the side face of the clamping plate, an elastic mat is fixedly connected to the lower surface of the inner wall of the object containing hole, and the upper surface of the elastic mat and the lower surface of an aluminium plate are inlap joint. According to the polishing device for the aluminium alloy door and window support notch, when polishing discs are in contact with the notch of the aluminium plate, polishing work can be done on the notch, a large quantity of flying chippings can be generated in the polishing process of the polishing discs, the flying chippings are limited into a protection cover under the effect of theprotection cover and then flows out through a drain outlet, the condition that the flying chippings hurt people can be effectively reduced, the two polishing discs can polish the two side faces of thealuminium plate at the same time, and therefore the working efficiency of a worker can be improved.

Owner:黄山市强峰铝业有限公司

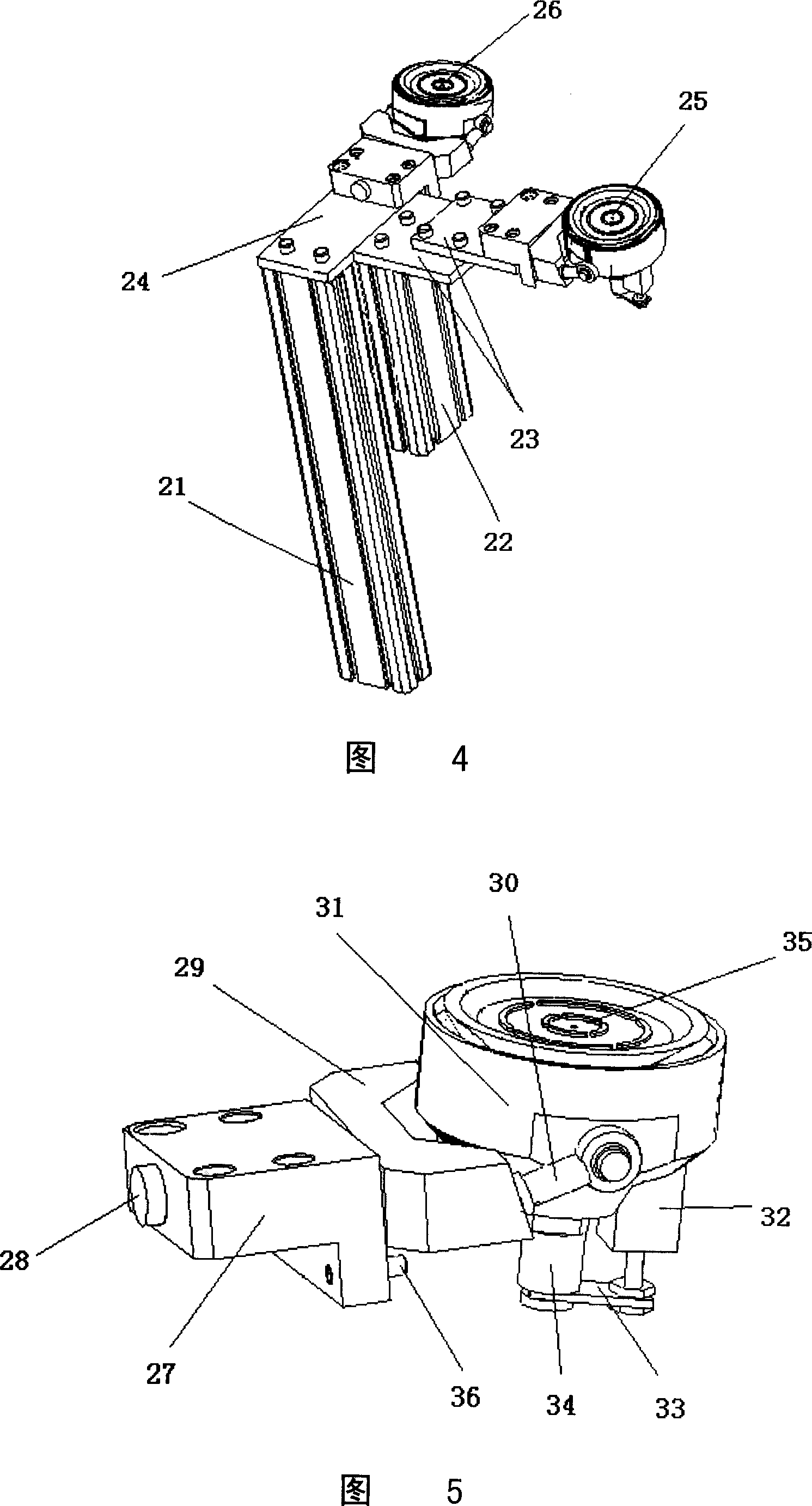

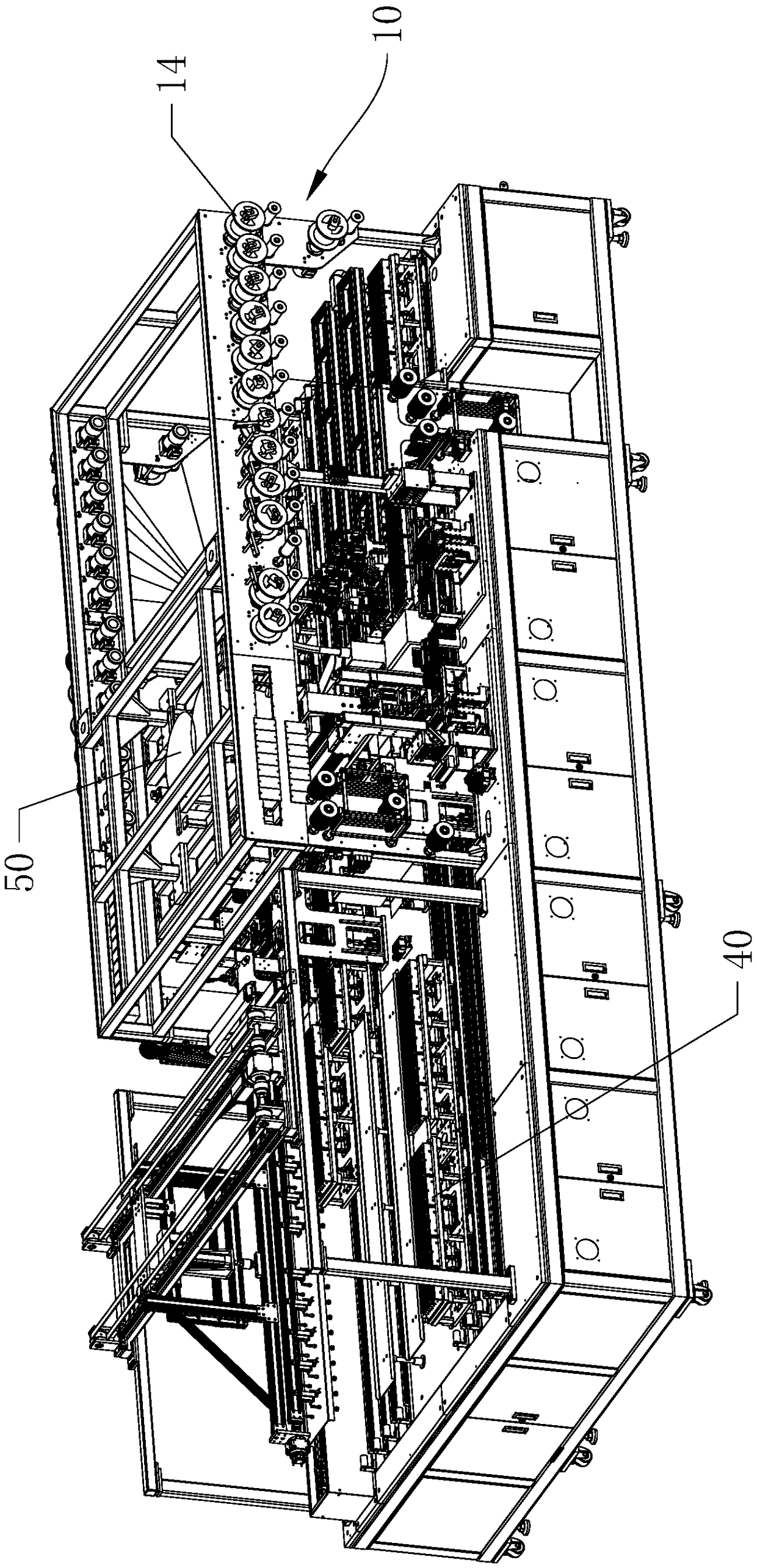

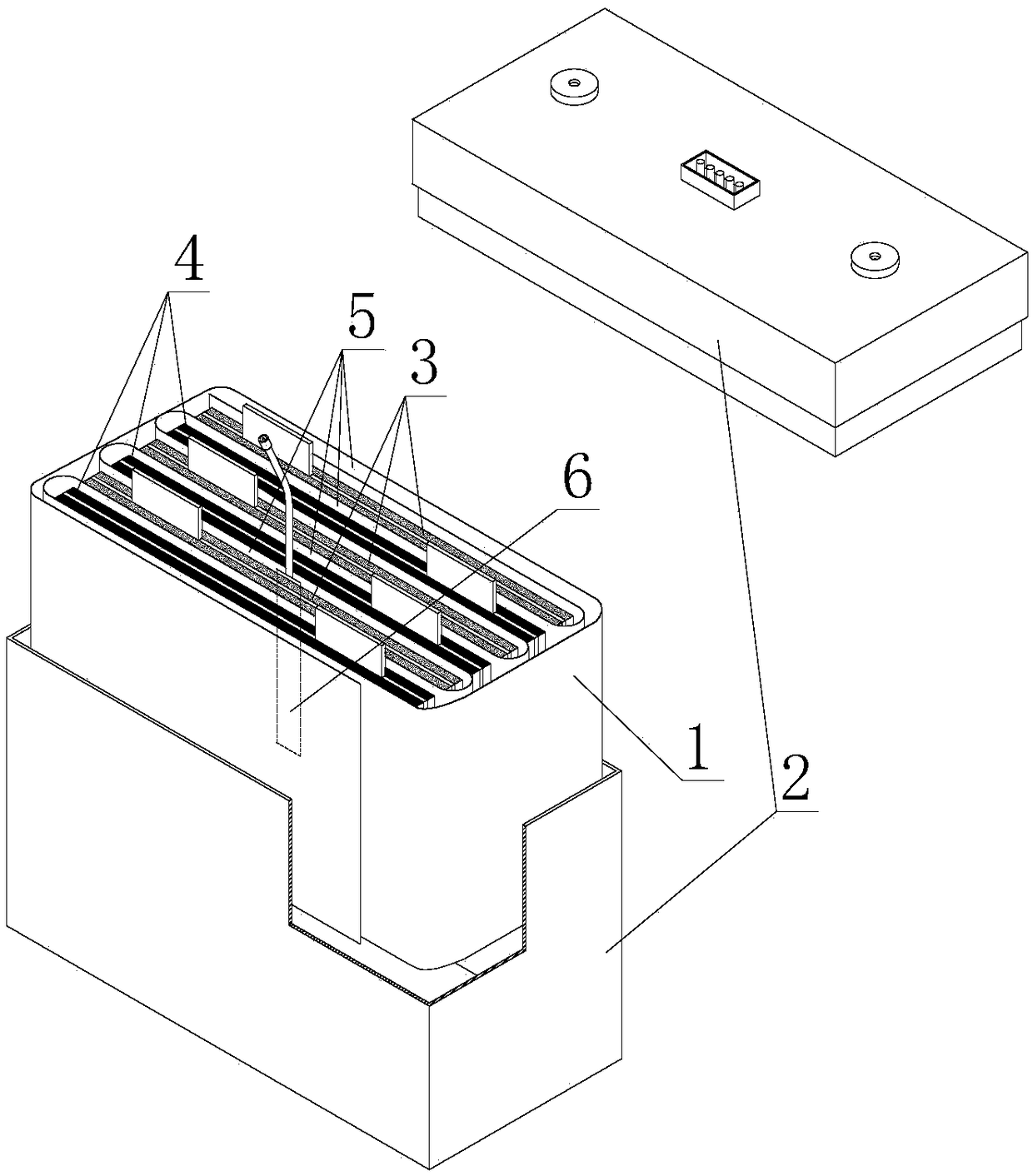

Solar cell series welding system

ActiveCN109128551AWon't moveWon't flipFinal product manufactureWelding/cutting auxillary devicesSolar cellWelding

The invention provides a solar cell series welding system. The solar cell series welding system comprises a flat welding strip feeding device, a solar cell feeding device, a special-shaped welding strip feeding device, a welding platform and a heating device. The special-shaped welding strip feeding device comprises a first moving module and tongs installed on the first moving module. The tongs comprise grabbing pieces with first positioning grooves and first pressing pins. The welding platform comprises a body with second positioning grooves and first adsorption air holes. After special-shaped welding strips are put into the first positioning grooves of the tongs, the first pressing pins press the special-shaped welding strips, the first moving module drives the tongs to move and carry the special-shaped welding strips to the second positioning grooves of the body, and second adsorption air holes in the bottoms of the second positioning grooves adsorb the special-shaped welding strips. Solar cells are carried to the body and are adsorbed by the first adsorption air holes, and the special-shaped welding strips are aligned to interconnected electrodes on one faces of the solar cells. Flat welding strips are carried to the solar cells and are aligned to interconnected electrodes on the other faces of the solar cells.

Owner:HANGZHOU JOY ENERGY TECH CO LTD

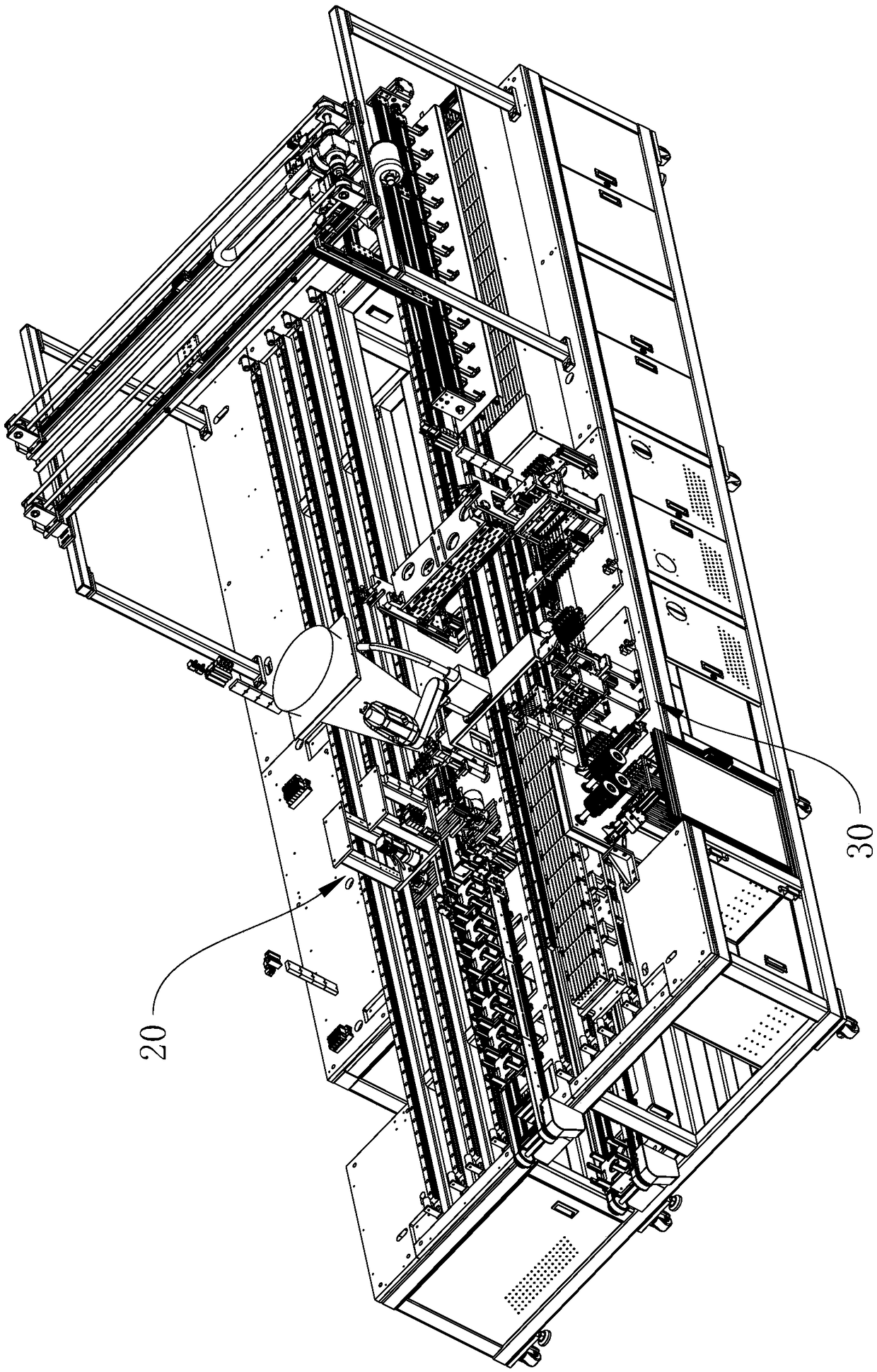

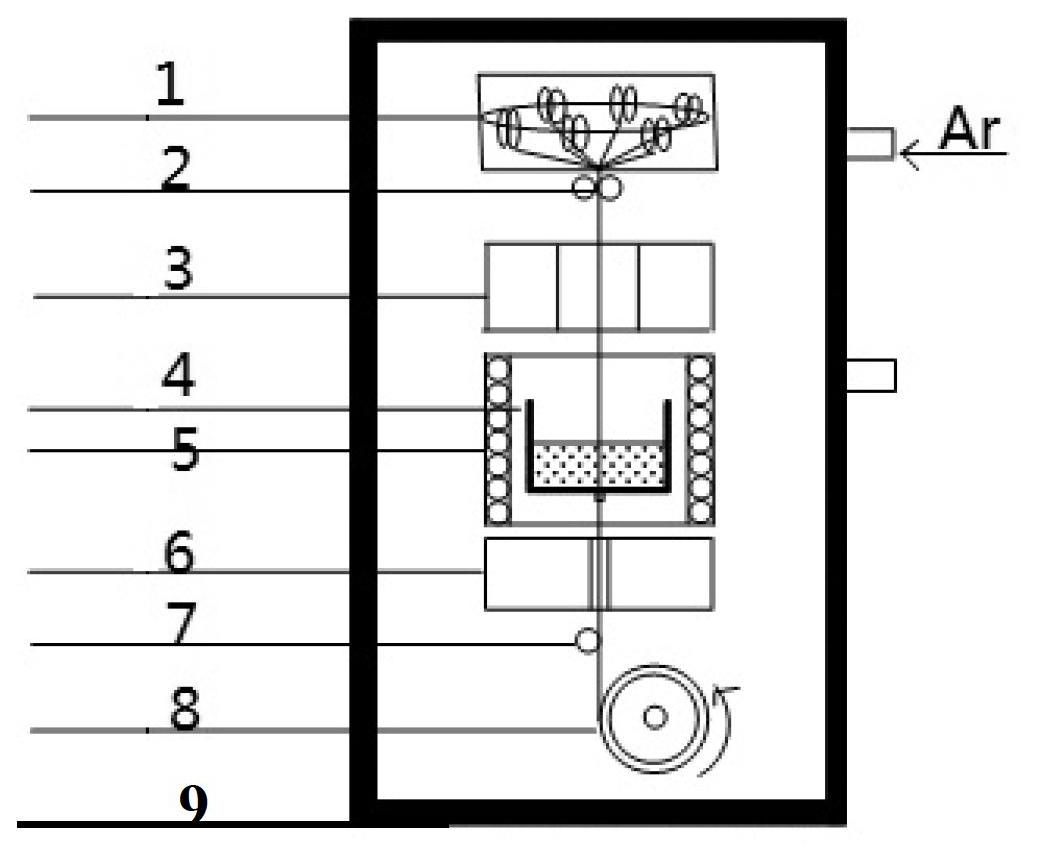

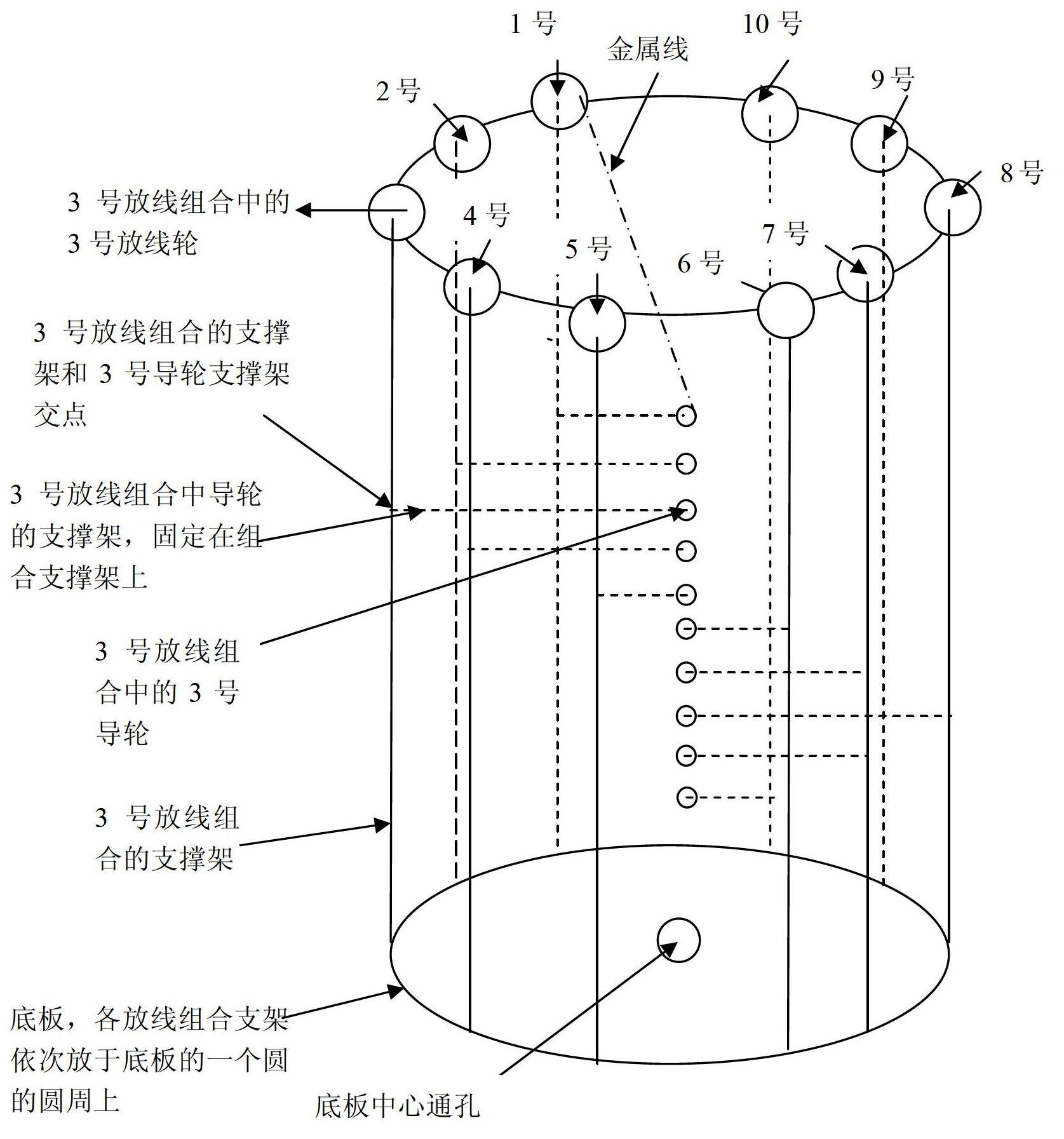

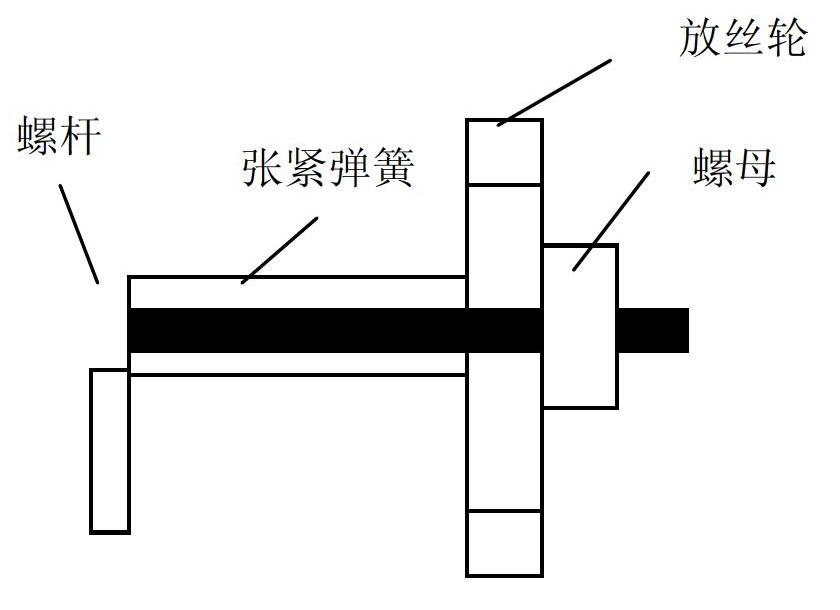

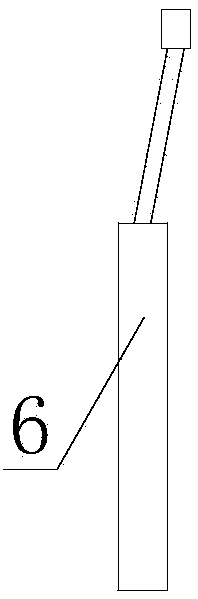

Continuous preparation equipment and process for fiber-reinforced metal glass composite filament

The invention provides continuous preparation equipment and a process for a fiber-reinforced metal glass composite filament, and belongs to the field of amorphous alloy (metallic glass). The continuous preparation equipment is composed of a vacuum system, a pay-off wheel set, a heating system, a cooling device and a dragging mechanism. A heating carrier is placed in the high vacuum system so as to obtain a composite interface with good bonding property, no blends and complete cleaning performance. By adopting the method for paying off, a double-guide-wheel device is used, the two guide wheels are tangent in the two guide wheels, and the lower guide wheel is connected with a motor so as to directly wind the prepared filament, thus realizing the continuous and large-scale production and achieving the purposes of short procedures and energy conservation and consumption reduction. The continuous preparation equipment and process are applied to preparation of armour piercing materials and other uses.

Owner:UNIV OF SCI & TECH BEIJING

Lithium battery

PendingCN108511829AReal-time monitoring of deformationTimely reflection of work heat expansionSecondary cellsInternal pressureElectrochemical response

The invention provides a lithium battery. The lithium battery comprises an electrical core and a shell, wherein the electrical core is arranged in the shell, comprises a positive plate, a negative plate and a diaphragm, and is characterized in that a pressure transducer is arranged between the positive plate or / and negative plate and the diaphragm. Various pressure transducers for monitoring pressure changes are available; however, transducer for detecting the inner pressure of the battery should have a tiny size; and in measurement of high-fidelity transfer pressure, the pressure transducer is tightly pasted with the pole plates in the battery and has no influence on electrochemical reactions in the battery.

Owner:长沙聚能充新能源有限公司

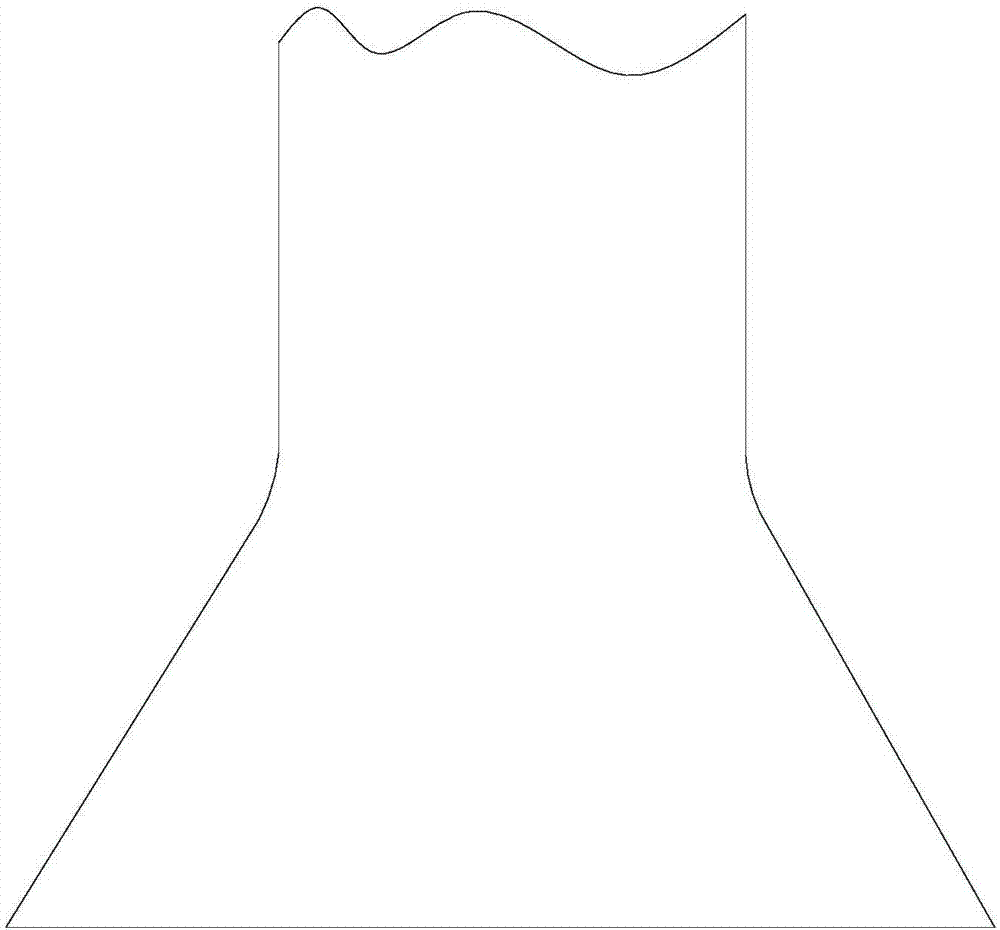

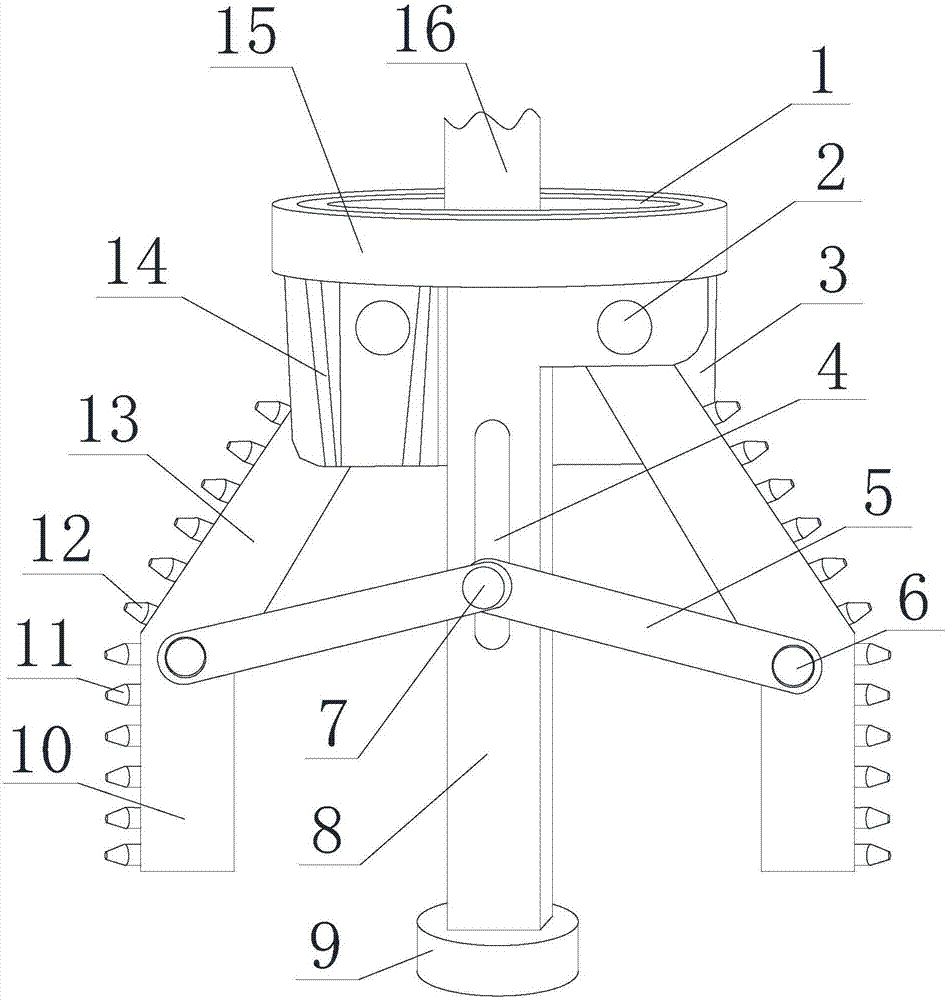

Chambering method of chambering equipment on construction site

InactiveCN106869797AImprove stabilityReduce the reducing rangeDrill bitsDrilling without earth removalEngineeringChamber method

The invention discloses a hole reaming method for hole reaming equipment on a construction site. A connecting rod is gradually lowered under the action of a power mechanism, the connecting arm rotates around the pin shaft 2 and the pin shaft 1, and the scraping mechanism rotates around the connecting pin, so that The connecting arm is horizontal, and the reaming equipment rotates around its axis, so that the scraping teeth scrape the wall of the original pile hole. After the scraping mechanism is expanded to the maximum state, the hole formed by scraping is formed; the connecting rod is gradually raised by the action of the power mechanism. The connecting arm rotates around pin 2 and pin 1, and the scraping mechanism rotates around the connecting pin, so that the connecting arm tilts from the horizontal state, and the scraping mechanism shrinks to the minimum state; the reaming equipment is pulled out along the original pile hole to the hole outside. The diameter of the hole expanded by this reaming method is high in longitudinal depth, and the diameter reduction range at the bottom of the hole and the original diameter of the pile hole is reduced, so that the bearing force after grouting is increased, the stability of the upper building can be maintained, and the reaming efficiency is high. And it can protect the security of the equipment.

Owner:CHINA MCC5 GROUP CORP

Ore extraction and transfer device

ActiveCN107670768AAvoid the problem of impact and easy damage to the boxAvoid the problem of fragile cabinetsGrain treatmentsEngineering

Owner:湖北省华建石材股份有限公司

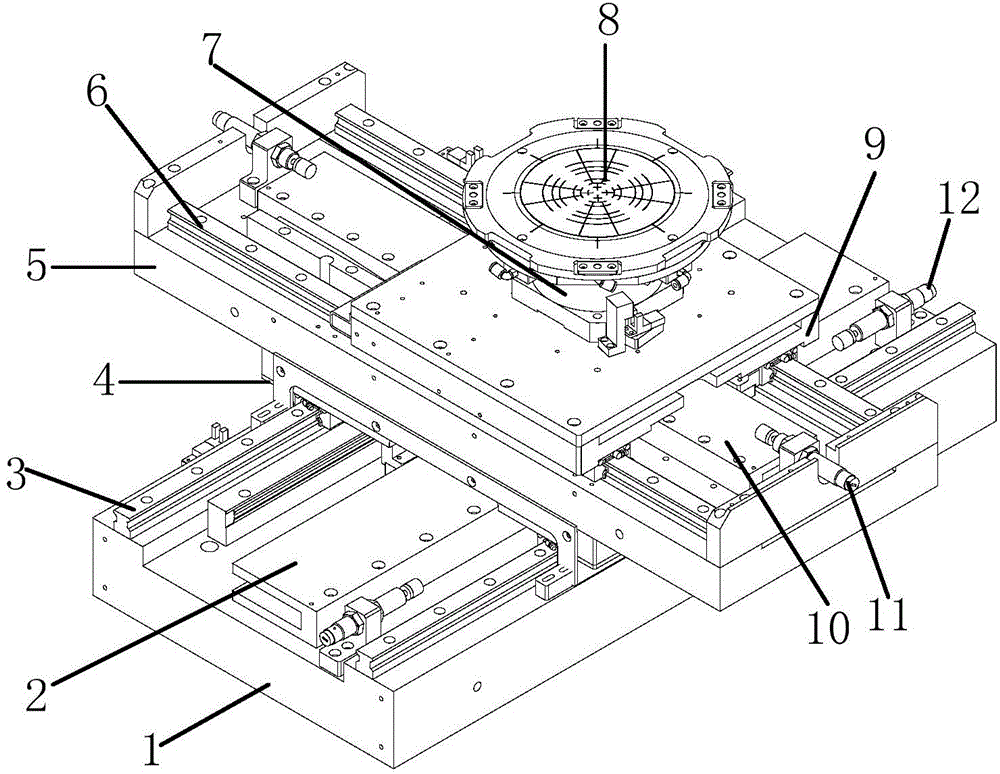

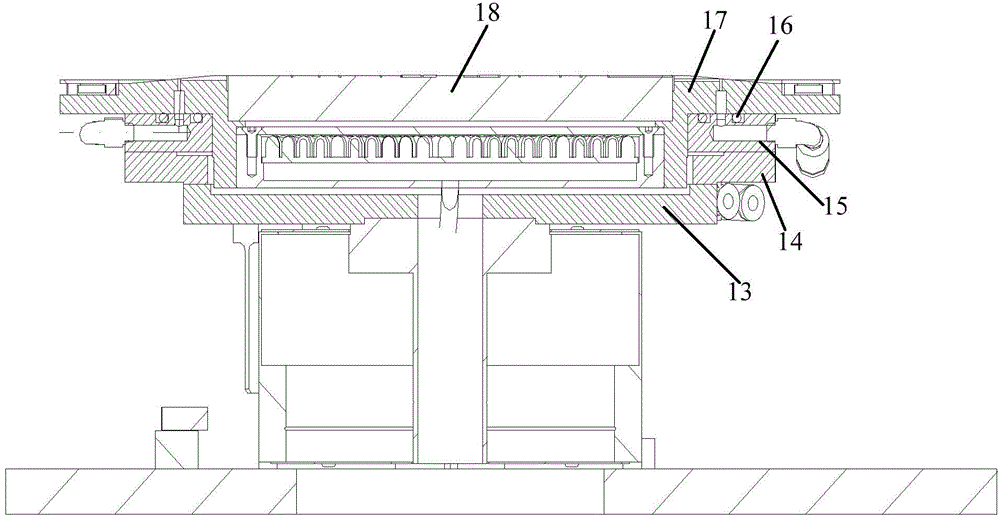

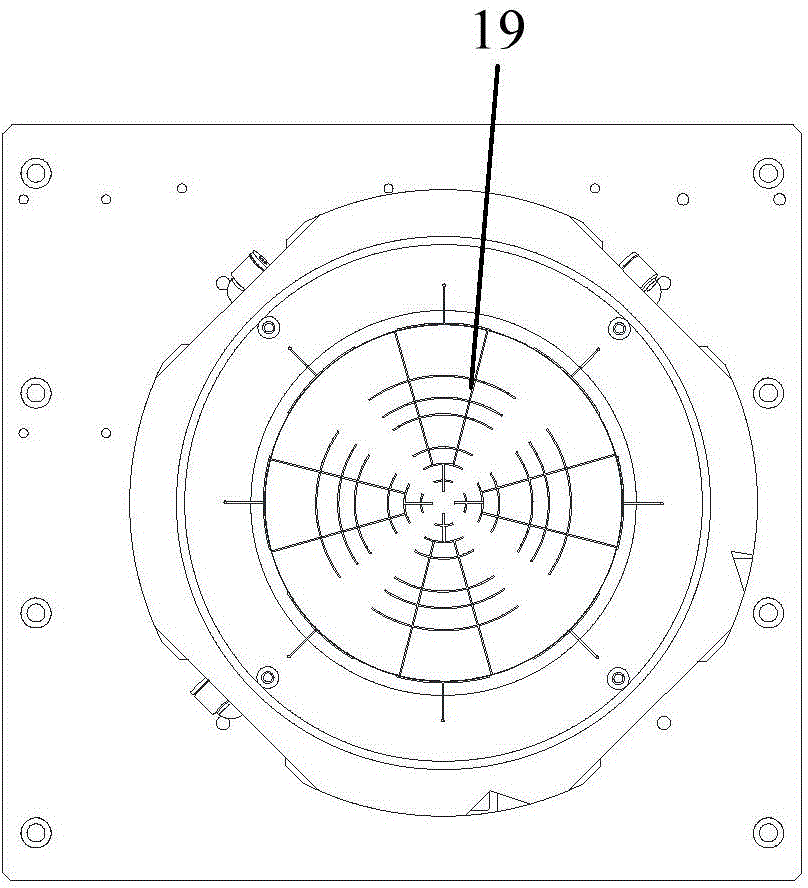

Marble high-precision movement platform

ActiveCN104362228AGuaranteed stabilityReduce shockSemiconductor/solid-state device manufacturingSemiconductor devicesModular designEngineering

The invention relates to a marble high-precision movement platform. An X-axis linear guide rail and an X-axis linear motor are arranged on an X-axis marble base, an X-axis connecting plate is arranged on the X-axis linear guide rail, the X-axis linear motor and the X-axis connecting plate are in driving connection, and the X-axis connecting plate is controlled to move along the X-axis linear guide rail. A Y-axis linear guide rail and a Y-axis linear motor are arranged on a Y-axis marble base, a Y-axis connecting plate is arranged on the Y-axis linear guide rail, the Y-axis linear motor and the Y-axis connecting plate are in driving connection, and the Y-axis connecting plate is controlled to move along the Y-axis linear guide rail. The Y-axis marble base is connected with the X-axis connecting plate, and an included angle of 90 degrees is formed between the Y-axis linear guide rail and the X-axis linear guide rail. A quartz carrying table is arranged on a rotary DD motor, and the rotary DD motor is arranged on the Y-axis connecting plate. Movement is quiet, noise is low, an X-axis platform and a Y-axis platform can be dismounted, matching is convenient, and the modular design requirement is met.

Owner:SUZHOU DELPHI LASER +1

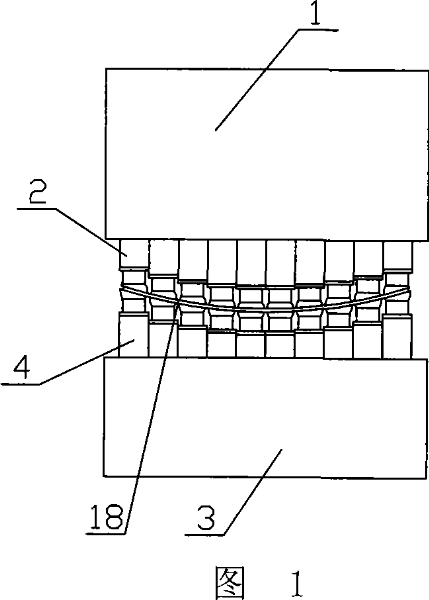

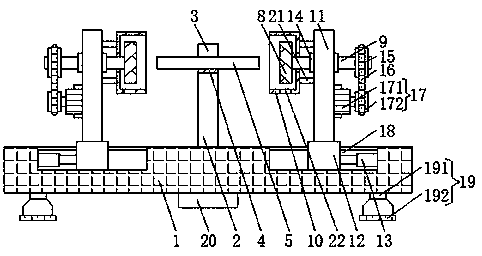

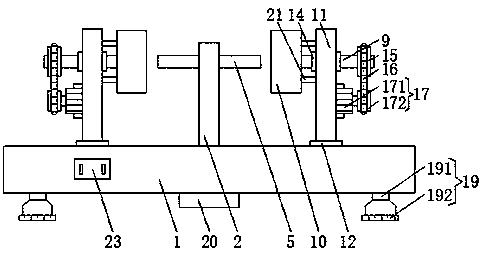

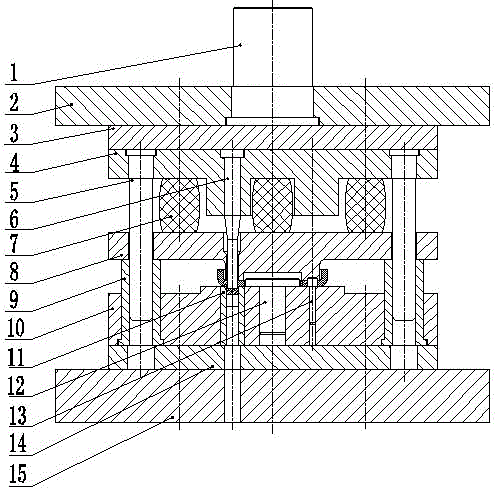

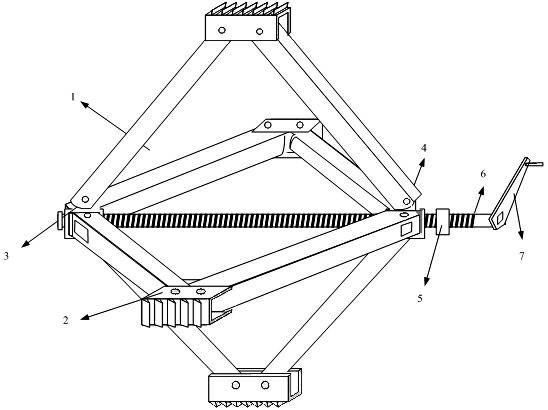

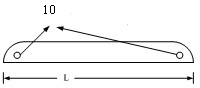

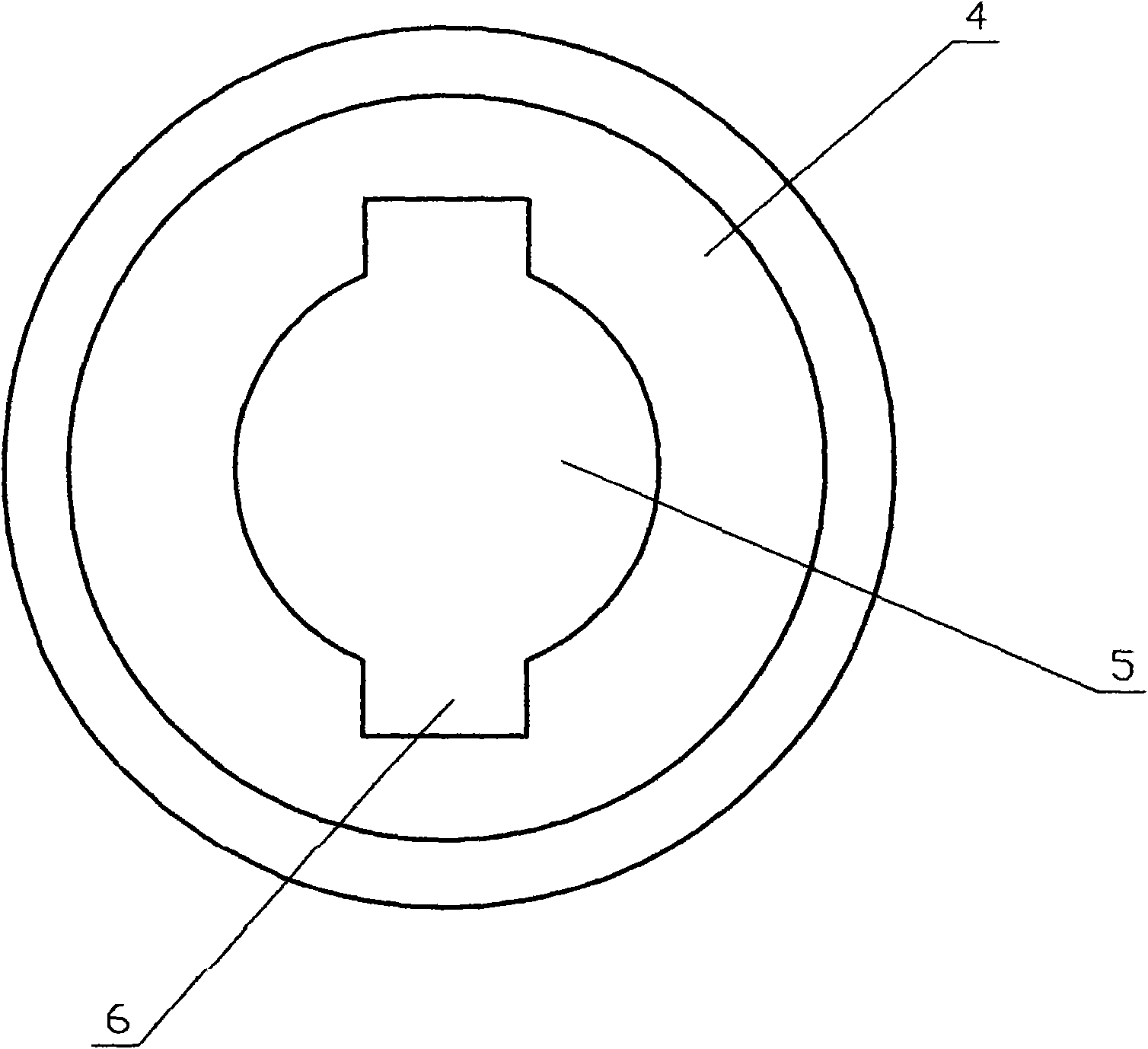

Rear axle regulating nut punching die and punching process

The invention discloses a rear axle regulating nut punching die and a punching process. The die is divided into both upper and lower parts; the top half part of the die comprises an upper die plate (2), a male die fixing plate (4), a guide pillar (5) and a punching male die (6); and the bottom half part of the die comprises a guide sleeve (9), a female die fixing plate (10), a punching female die (11) and a lower die plate (15). The rear axle regulating nut punching die is characterized in that a guide plate (8) is arranged between the male die fixing plate (4) and the female die fixing plate (10); the guide plate (8) is provided with an upper die guide hole in sliding connection with the guide pillar (5); the guide plate (8) is provided with a male die guide hole in sliding connection with the punching male die (6); the upper part of the guide plate (8) is connected with the male die fixing plate (4) by a discharging eraser (7); and a regulating nut positioning end face is arranged below the guide plate (8). According to the invention, the guide plate structure is adopted; the same punching die can be used for punching 16 holes on a regulating nut in two steps; a gap between the punching male die (6) and the punching female die (11) is ensured to be uniform; product quality and service life of the die are improved and prolonged; and the rear axle regulating nut punching die has high production efficiency and low production cost.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

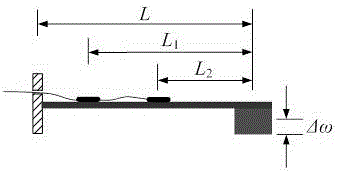

Pipe inner wall support positioning device

InactiveCN102279278AAccurate measurementStrong concealmentSpeed/acceleration/shock instrument detailsVolume meteringMeasurement deviceEngineering

The invention relates to a support and positioning device for the inner wall of a pipeline, which includes a vertical support frame and a horizontal support frame. The supporting feet are connected flexibly, and the inner end is respectively connected to the fixed joint and the movable joint. The fixed joint and the movable joint are connected by a screw. A movable handle is installed at the end, and a positioning nut is screwed on the screw rod between the movable joint and the movable handle. The invention can be used to build the internal support of the pipeline, and the flow velocity measuring device can be mounted on the platform, which can directly measure the parameters inside the pipeline, and has accurate measurement, strong concealment, and is not easy to be washed away. It is widely used in environmental monitoring, water conservancy, oil transportation and other fields.

Owner:SHANGHAI INST OF TECH

Hollowing-resistant construction process of polished brick

The invention discloses a hollowing-resistant construction process of a polished brick. The hollowing-resistant construction process of the polished brick disclosed by the invention comprises the following steps of: (1), processing a basic layer: cleaning the surface of the basic layer; (2), snapping a control line; (3), brushing an interface agent: brushing an interface processing agent at the back of the polished brick, and naturally airing: (4), paving cement gum: uniformly smearing modified mortar or cement gum special for the polished brick on the surface of the basic layer so as to form an adhesive layer; (5), paving the brick: kneading the processed polished brick on the adhesive layer, and beating the surface of the polished brick by using a rubber hammer from top to bottom, so that the polished brick is stuck with the adhesive layer to the most extent; (6), adjusting, pointing and cleaning; and (7), maintaining: maintaining by watering after paving the polished brick for 24 h. According to the invention, the adhesive strength among various layers of materials can be increased; and the problems, such as hollowing and falling off of the surface layer, can be avoided.

Owner:ZHEJIANG SHENMEI DECORATION ENG

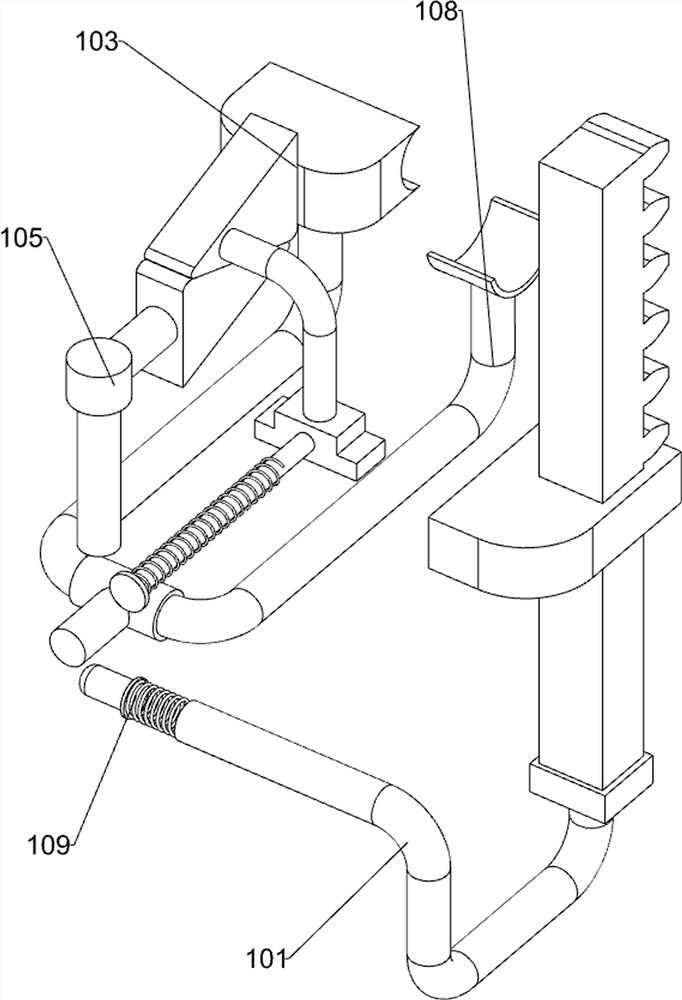

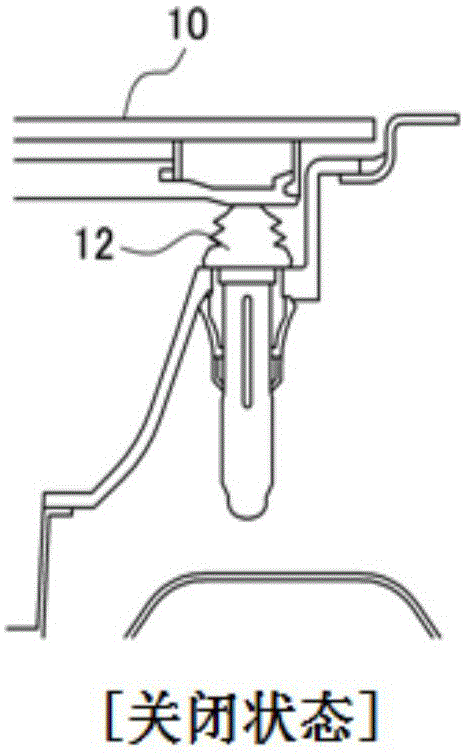

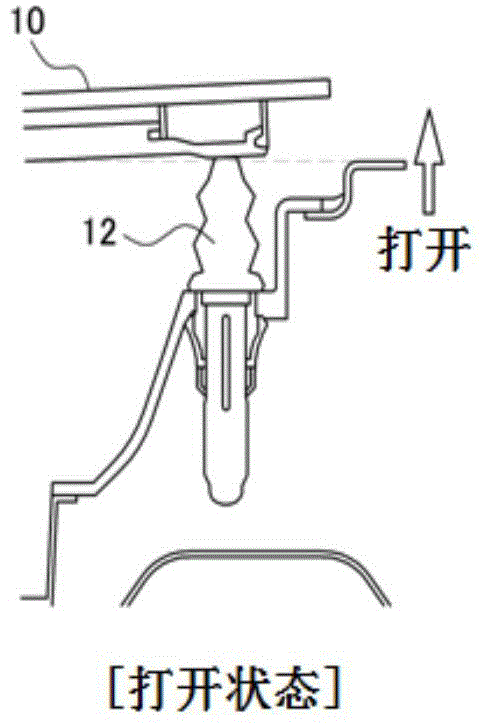

Device for opening and closing push open type fuel door for vehicle

InactiveCN105082986AReduce in quantityImprove assembly processabilityPower transmission/actuator featuresElectrical locking actuatorsEngineeringElectric motor

Owner:HYUNDAI MOTOR CO LTD +2

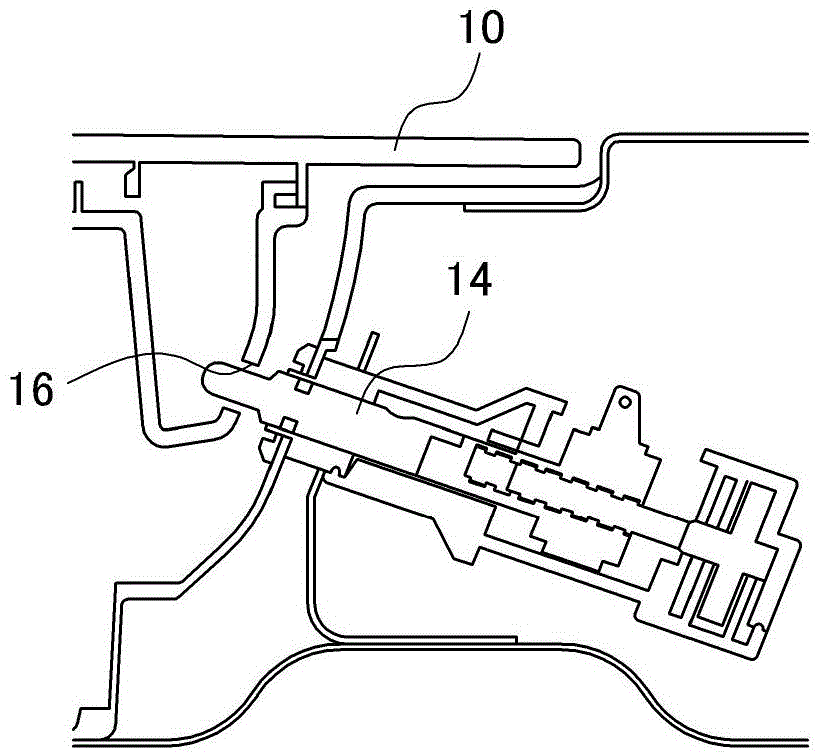

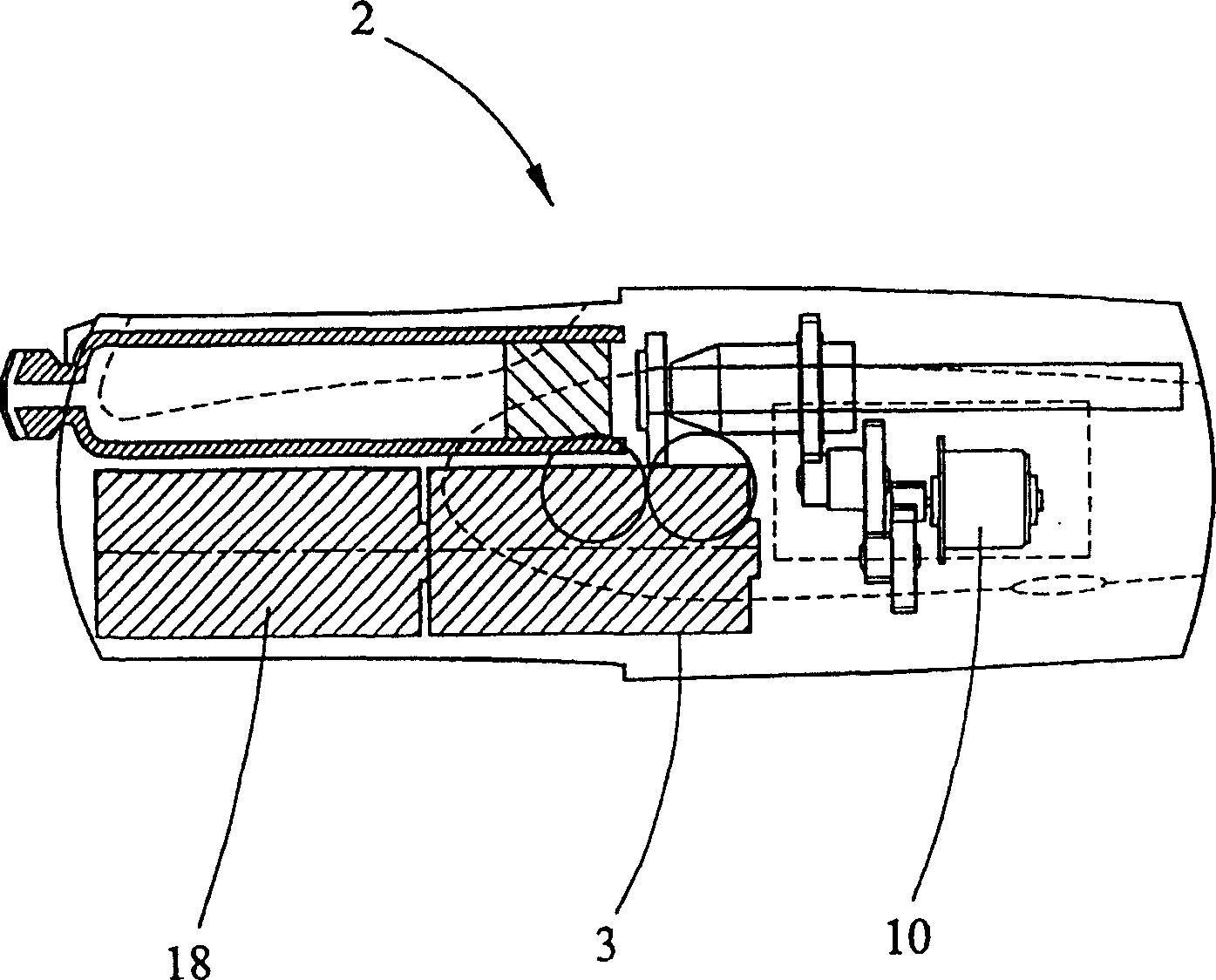

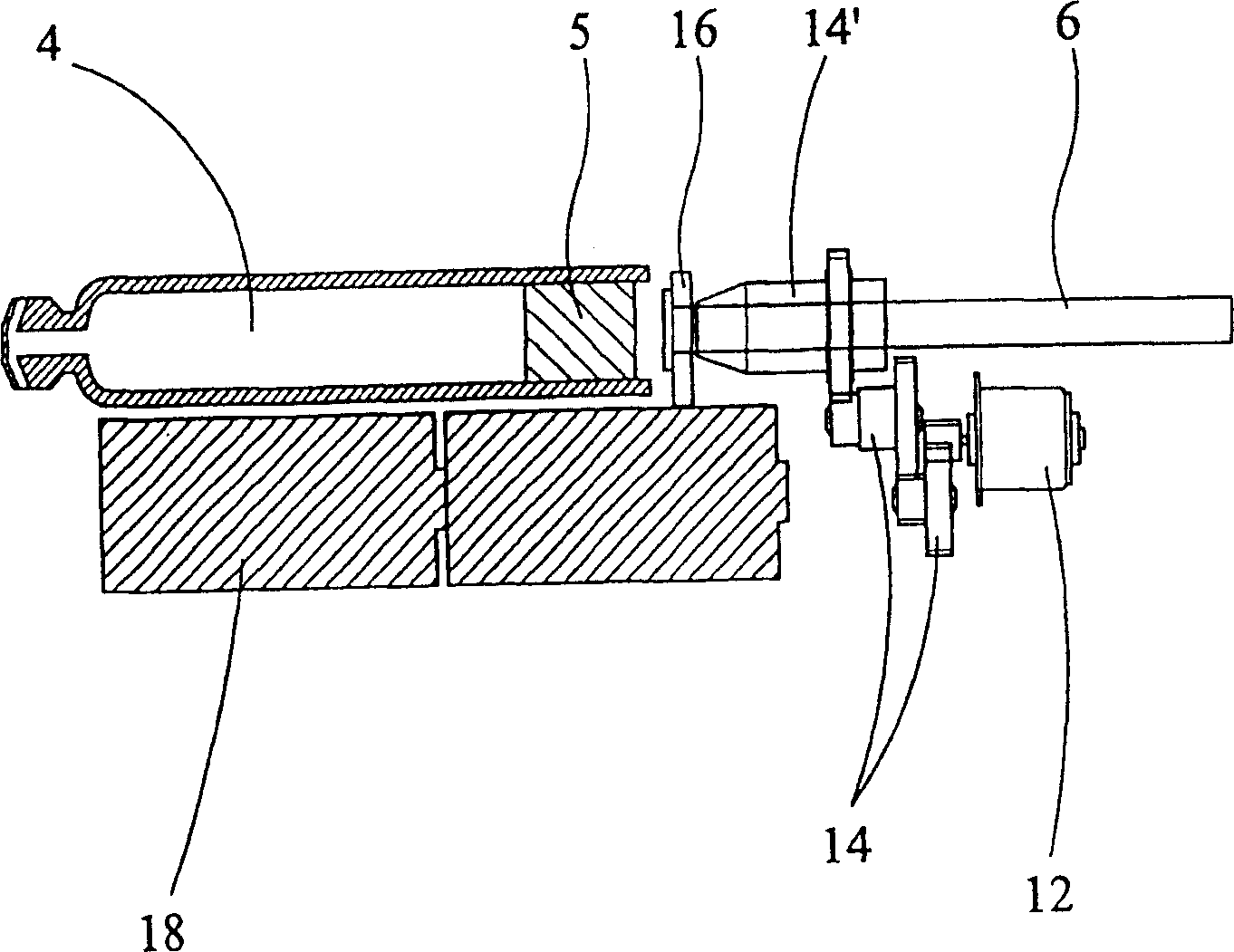

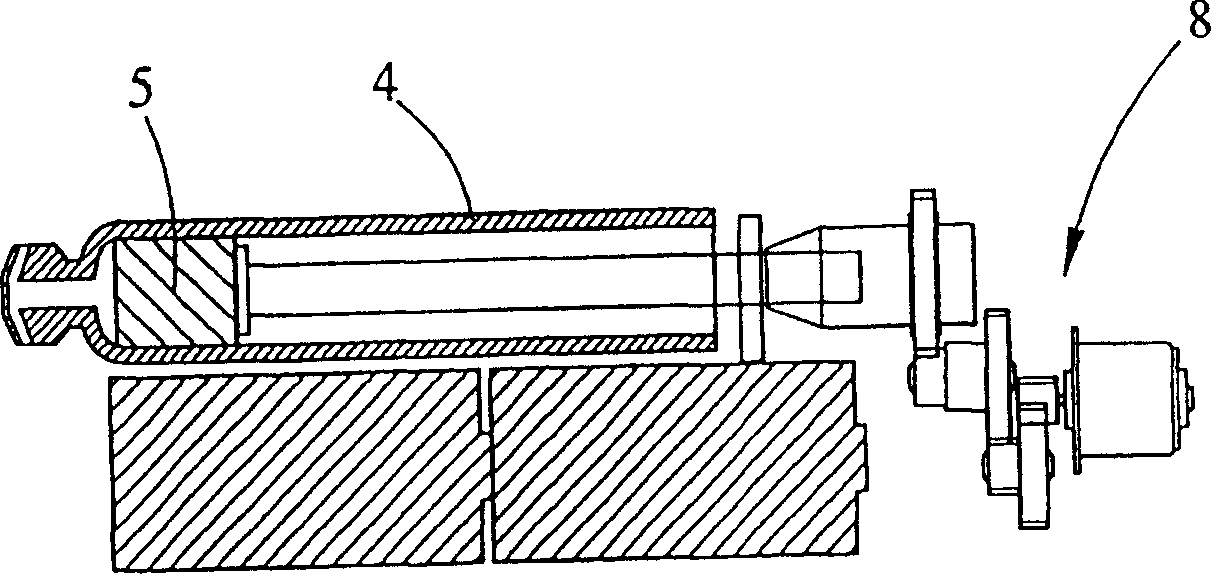

Medicament injection devive with axially displaceable lead screw

The present invention relates to a drug delivery device in which the drug to be delivered is stored in a cartridge having a movable piston inside it. The movable piston is driven by a lead screw (6) to expel the drug, which lead screw (6) is advanced and retracted by suitable drive means (14). Provide a guide slot (16) through which the lead screw can pass. However, in known devices the guide slots are held in place by other parts of the device. Such devices are complex to manufacture. Additionally, they may need to be disassembled and reassembled when changing cartridges. This is disadvantageous if the user, usually diabetic, is weak or has poor eyesight. The drug delivery device disclosed in the present invention includes a main housing (3), a threaded lead screw (6) with opposite flat surfaces, a rotary drive (14) and a guide sleeve (16), the rotary drive has a corresponding On the inner wall surface of the relatively flat surface of the lead screw, the guide sleeve has a hole for receiving the threaded lead screw, wherein the guide sleeve is permanently fixed to the main housing.

Owner:DCA DESIGN INTERNATIONAL LTD

Multifunctional support

InactiveCN103697300AEnsure stabilityPrecise positioningPoint-like light sourceLighting elementsUniversal jointPersonal computer

The invention discloses a multifunctional support. The multifunctional support is characterized by comprising a gravity base, a telescopic rod, a ball universal joint, a front-end aluminum-alloy pipe, a middle-section aluminum-alloy pipe, a tail-end aluminum-alloy pipe, a powerful vacuum sucking disc, an annular elastic anti-loosening rope, a USB power supply input interface with a rubber dust-proof cover, a multifunctional USB power supply interface and a power line. The multifunctional support is greatly better than an existing tablet personal computer support in the market in stability, practicability and convenience and can be sucked onto other small tablet electric appliances through the powerful vacuum sucking disc to achieve function expansion.

Owner:严虹桥

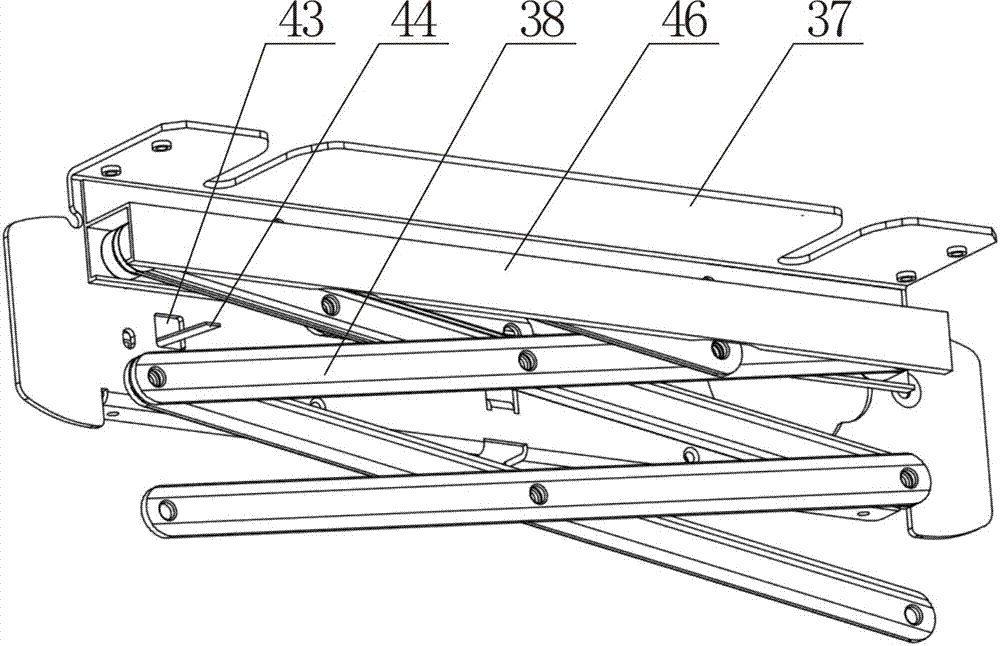

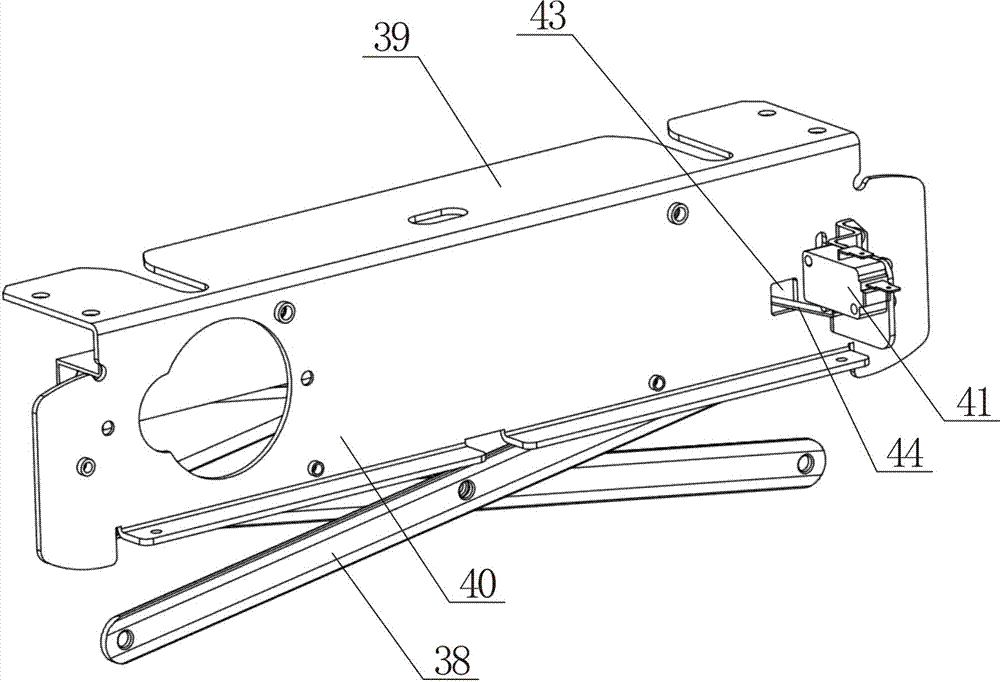

Movable limiting type clothes drying machine

InactiveCN107034640AEven strengthReduce frictionOther drying apparatusTextiles and paperLower limitEngineering

The invention discloses a mobile position-limiting clothes dryer, which comprises a transmission support plate, a wire reel, an L-shaped mounting plate and a scissor-type telescopic frame. The L-shaped mounting plate includes a top panel and a side panel, and a scissor-type telescopic frame. The upper end of the upper end is installed in the slide rail on the side panel, and also includes an upper and lower limit travel switch, and the upper and lower limit travel switch includes an up limit travel switch and a down limit travel switch, and the side panel in the L-shaped mounting plate There is a hole on the top, the switch shrapnel in the upward limit travel switch passes through the hole, the clothes rail goes up, and when the scissor-type telescopic frame shrinks, the scissors in the scissor-type telescopic frame touch the switch of the upward limit travel switch The shrapnel triggers the upward limit travel switch to control the driving motor of the wire reel to stop running, thereby improving the stability and reliability of the wire reel mechanism.

Owner:曾琼

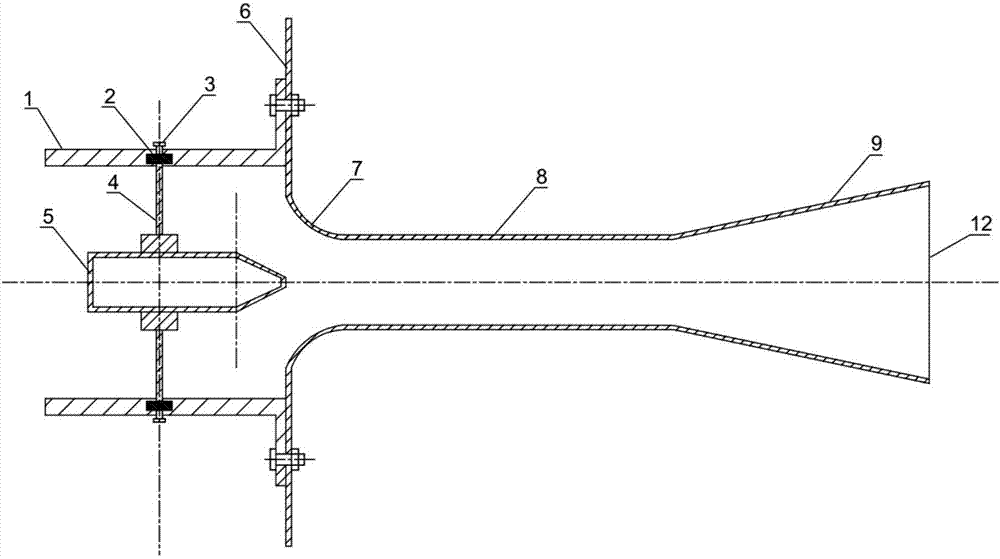

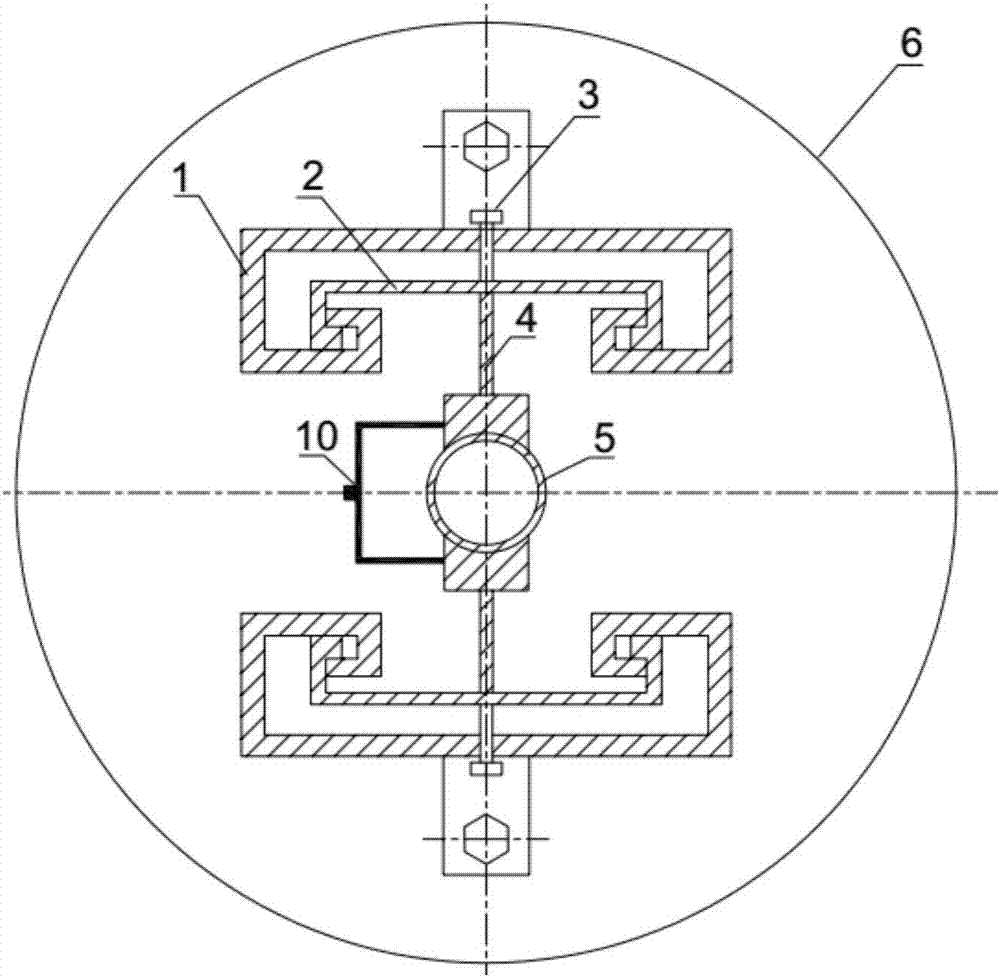

Ejector device with movable working nozzle

ActiveCN107255087AImprove work performanceTake advantage ofJet pumpsMachines/enginesWork performanceEngineering

The invention discloses an ejector device with a movable working nozzle, and belongs to the field of ejectors. The working nozzle is connected with a shrinking pipe of an ejector main body through a connecting piece, so that the working nozzle can move in the central axis direction of the ejector main body. The distance between the exit port of the nozzle and the throat part of the ejector can be changed to reach an optimal value, so that ejection capacity of the ejector for lower pressure gas is improved, the ejection ratio is increased, working performance of the ejector is improved. The ejector device with the movable working nozzle is not affected by kinds of the ejector, the design of the ejector device with the movable working nozzle can be used for all different ejectors, the distance between the exit port of the working nozzle and the throat part of the ejector is adjusted, the ejection ratio is increased, and the ejection performance of the ejector is improved.

Owner:XI AN JIAOTONG UNIV

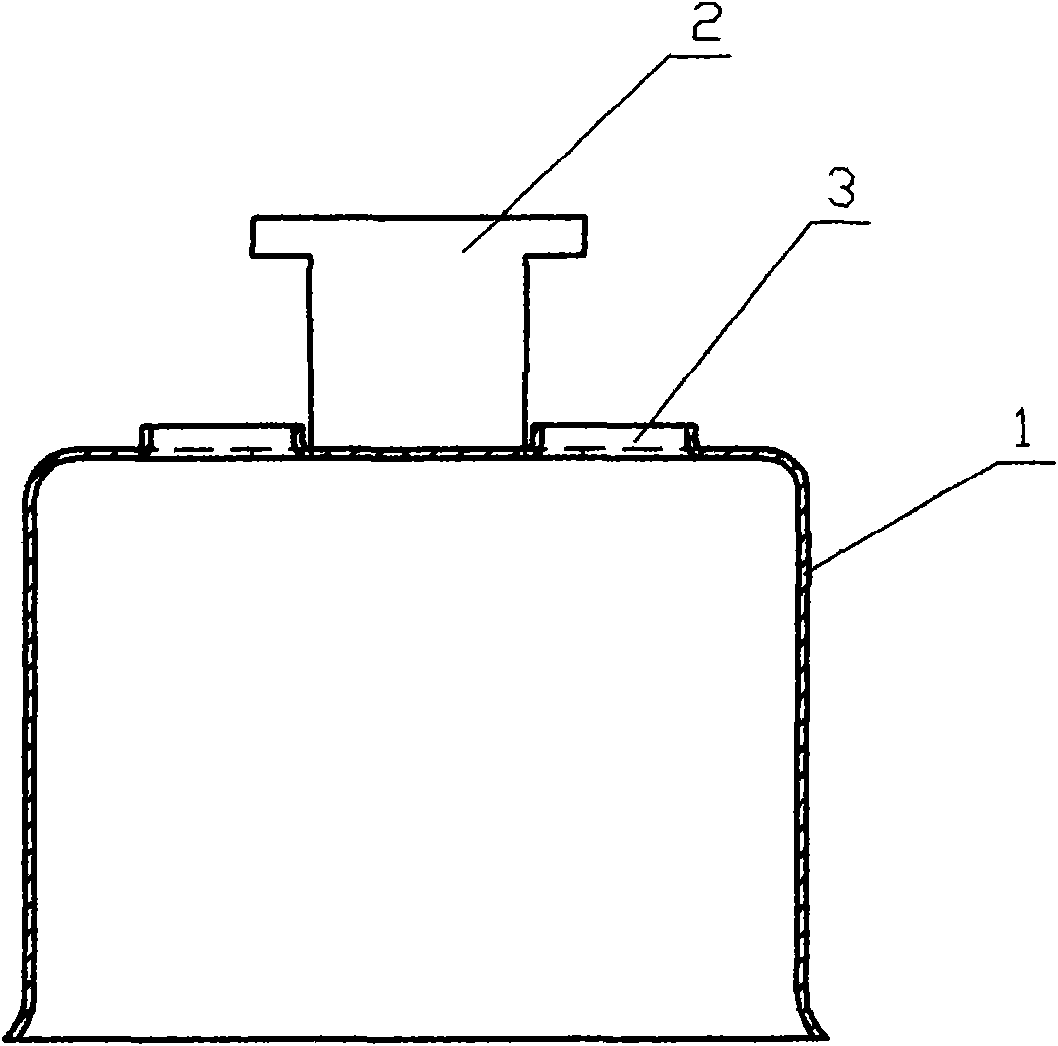

Mounting method for temperature transmitter thermosensors of electric cooker

InactiveCN101536868APrecise positioningImprove versatilityThermometer detailsCooking vesselsTemperature controlHeat sensitive

The invention relates to a mounting method for temperature sensor thermosensors of an electric cooker. The mounting method comprises the following steps: providing an inner shell (1) with a bottom punched with two T-shaped guide feet and a turnup hole for positioning and fixing extracted leads (11); providing an outer shell (4) with a bottom punched with a round hole and two guide grooves in the round hole; mounting a temperature control element (10) in a groove of tablettings (7), penetrating the leads (11) wrapped by a sleeve out of the turnup holes at the bottom of the inner shell (1) to be tightly matched with and fixed on the turnup holes; arranging the tablettings (7) between the inner shell (1) and an aluminum cover (13) to be riveted and compacted and using the tablettings (7) to compact temperature control element (10); supporting the inner shell (1) in the outer shell (4) by springs (12), penetrating the leads (11) wrapped by the sleeve out of the round hole of the outer shell (4), and penetrating the T-shaped guide feet of the inner shell (1) out of the round hole of the outer shell (4) to be bent in the guide grooves of the outer shell (4). The mounting method for the temperature sensor thermosensors of the electric cooker can reduce materials, decrease the cost, improve the qualified rate and ensure the product to be more reliable in the working process.

Owner:信宜市福尔电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com