Automatic wood stick stripe cutting machine

A cutting machine and cutting mechanism technology, used in wood processing appliances, forming/shaping machines, special forming/shaping machines, etc., can solve the problems of easy to hurt hands, low efficiency, inconvenience, etc., to reduce workload, improve Accuracy, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

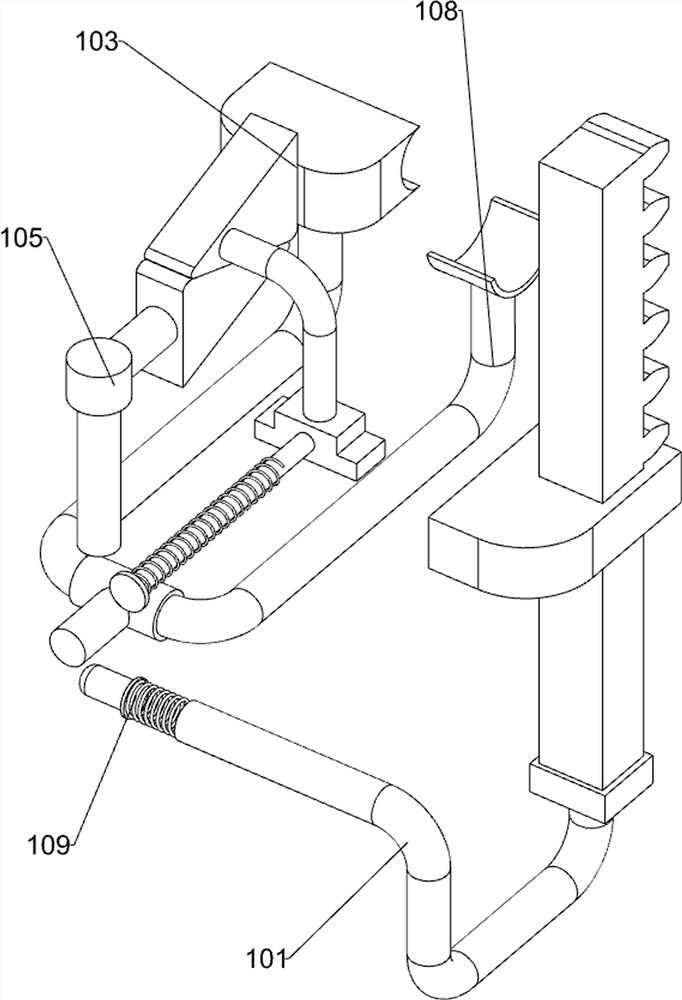

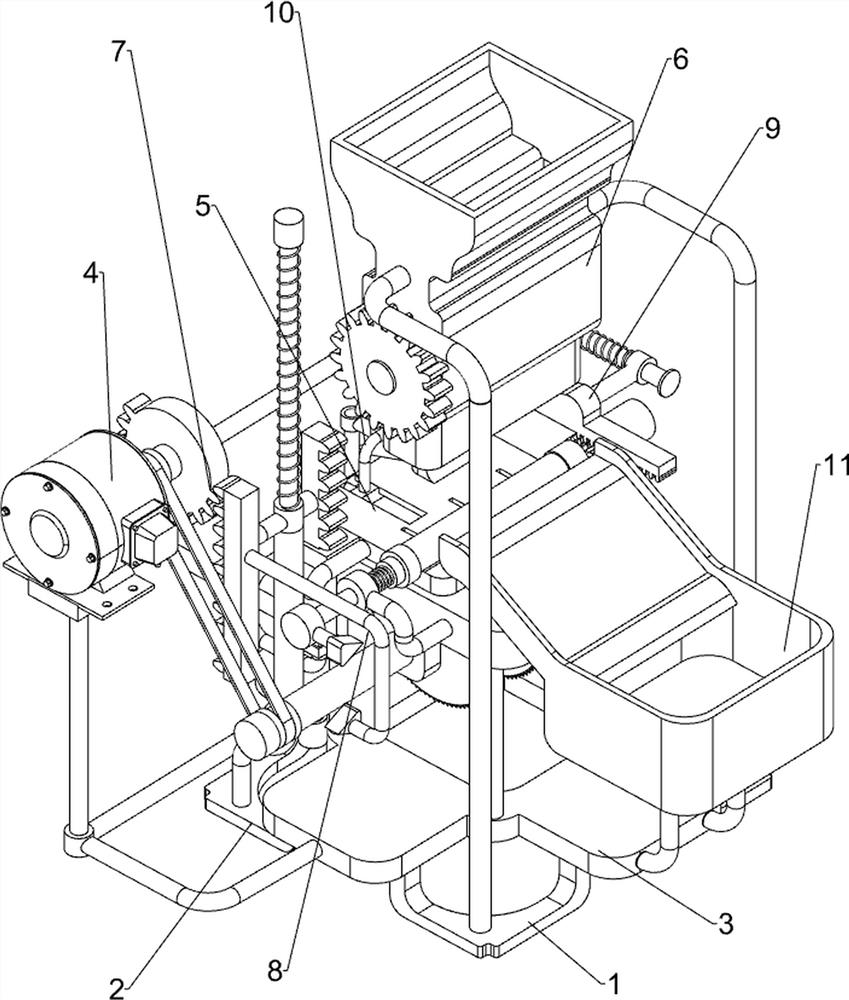

[0088] An automatic cutting machine for wood stick stripes, such as figure 1 As shown, it includes a first support frame 1, a second support frame 2, a support plate 3, a cutting mechanism 4 and a feeding cutting and rolling mechanism 5, and the front side of the bottom of the support plate 3 is symmetrically provided with the first support frame 1 and the support plate 3. A second support frame 2 is arranged symmetrically on the left and right sides of the bottom, and a cutting mechanism 4 is provided on the support plate 3. The second support frame 2 on the left side is provided with a discharging cutting rolling mechanism 5, a discharging cutting rolling mechanism 5 and a cutting mechanism. 4 connections.

[0089] When it is necessary to perform striped cutting on the surface of the wooden stick, people first place the wooden stick on the feeding and cutting rolling mechanism 5, then start the cutting mechanism 4, and at the same time, people rotate the wooden stick, and th...

Embodiment 2

[0091] On the basis of Example 1, such as figure 2 and image 3 As shown, the cutting mechanism 4 includes a connecting support frame 41, a first rotating shaft 42, a cutting knife 43, a supporting column 44, a motor 45, a second rotating shaft 46 and a transmission assembly 47, and the middle side of the supporting plate 3 is provided with a connecting supporting frame 41 The upper part of the connecting support frame 41 is rotatably provided with a first rotating shaft 42, the right part of the first rotating shaft 42 is evenly provided with a cutting knife 43, the cutting knife 43 is located in the connecting supporting frame 41, and the left side of the supporting plate 3 is provided with a supporting column 44, supporting A motor 45 is installed on the upper part of the column 44 , a second rotating shaft 46 is arranged on the output shaft of the motor 45 , and a transmission assembly 47 is arranged between the left part of the second rotating shaft 46 and the left part ...

Embodiment 3

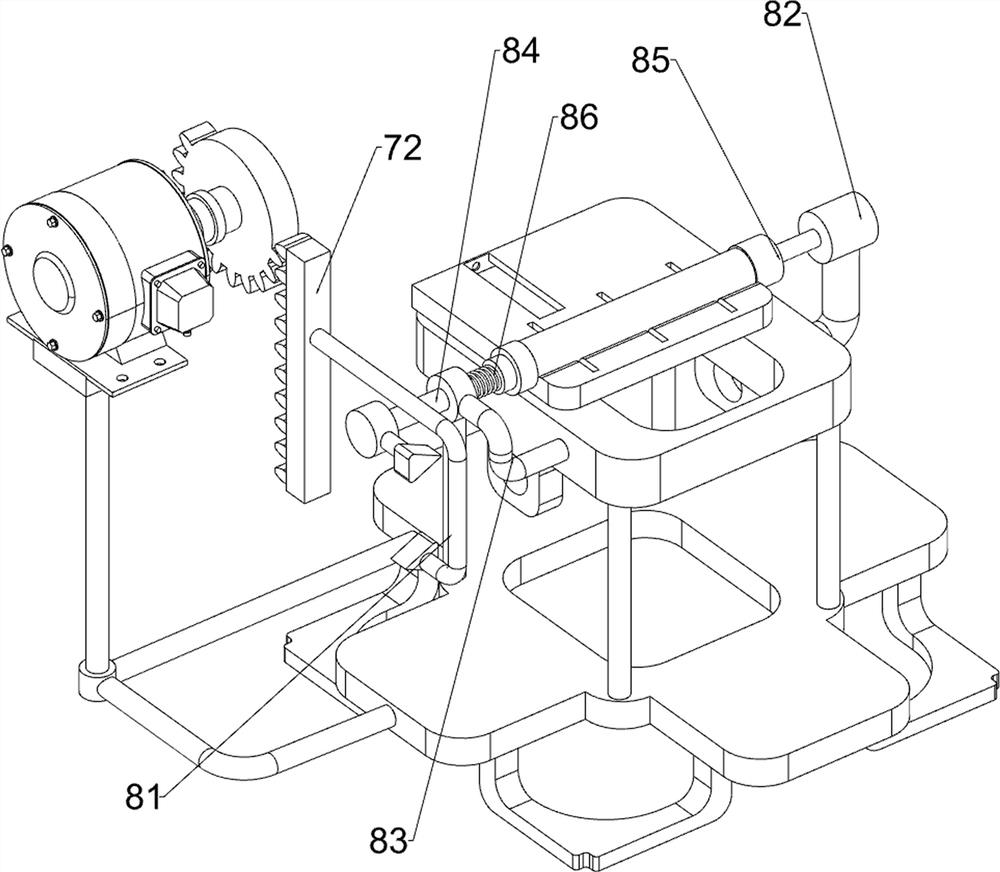

[0096] On the basis of Example 2, such as figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, it also includes an intermittent discharge mechanism 6, an automatic intermittent unloading mechanism 7, an auxiliary clamping mechanism 8, an automatic push and roll mechanism 9, an automatic push mechanism 10 and a collection device 11. The first support frame 1 is provided with intermittent The discharge mechanism 6, the second rotating shaft 46, the first sliding sleeve 52, the material plate 53 and the intermittent discharge mechanism 6 are provided with an automatic intermittent blanking mechanism 7, and the automatic intermittent blanking mechanism 7 and the connecting support frame 41 are provided with The auxiliary clamping mechanism 8, the first sliding sleeve 52, the connecting support frame 41 and the auxiliary clamping mechanism 8 are provided with an automatic push rolling mechanism 9, and the automatic intermit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com