Patents

Literature

44results about How to "Accurate whereabouts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

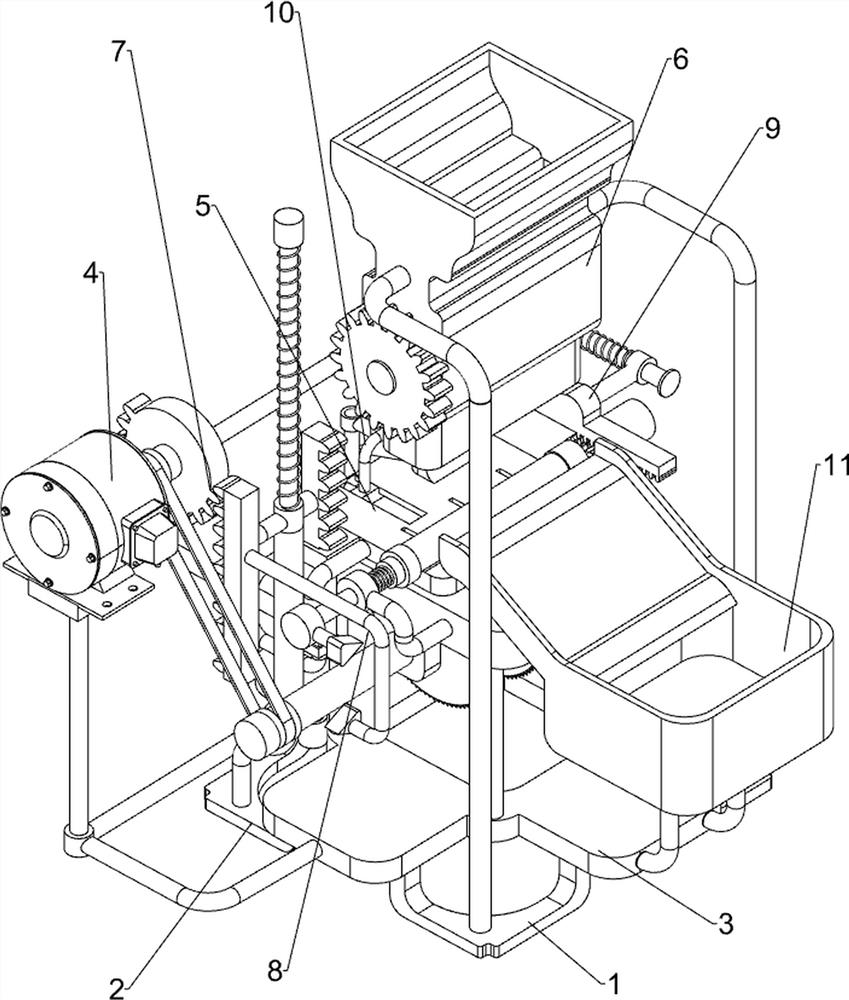

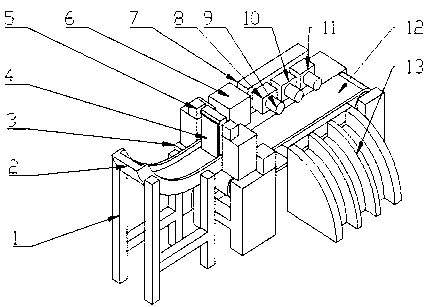

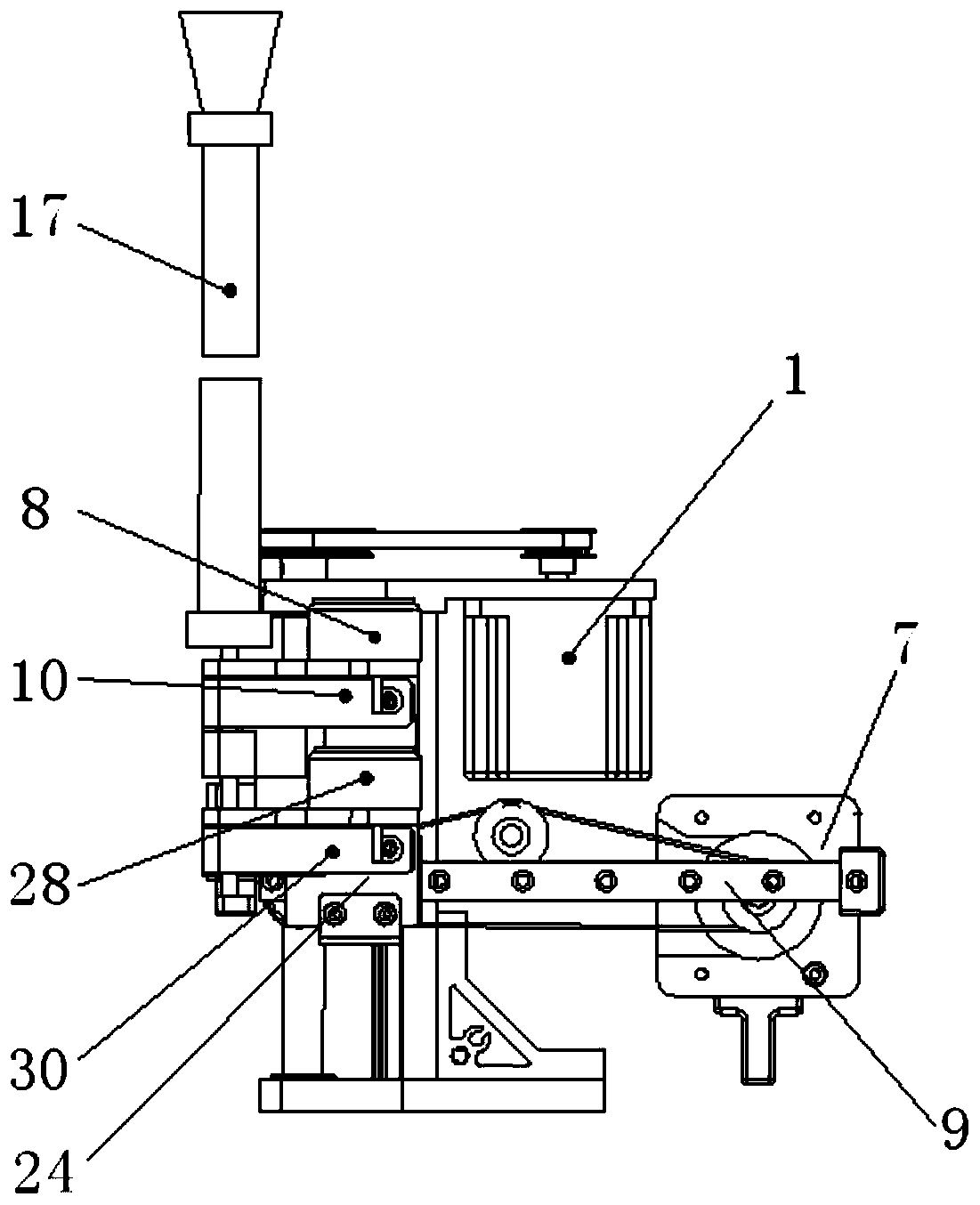

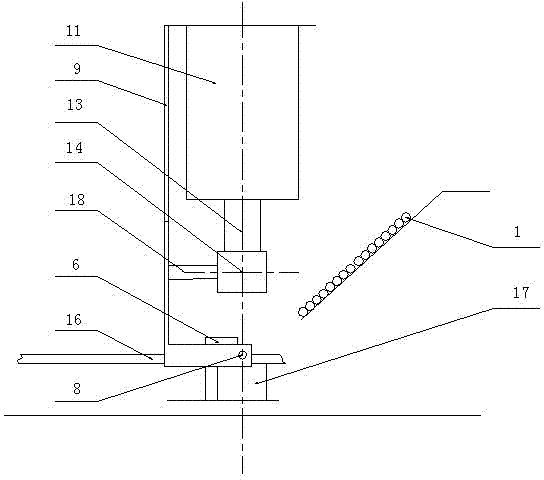

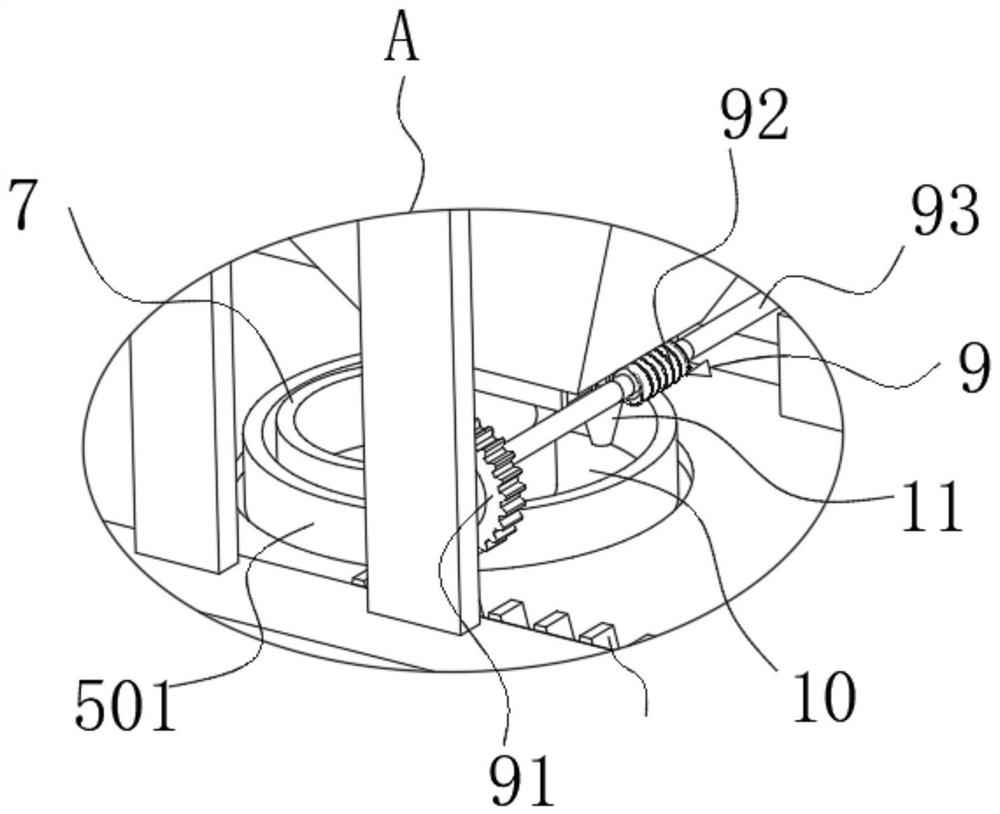

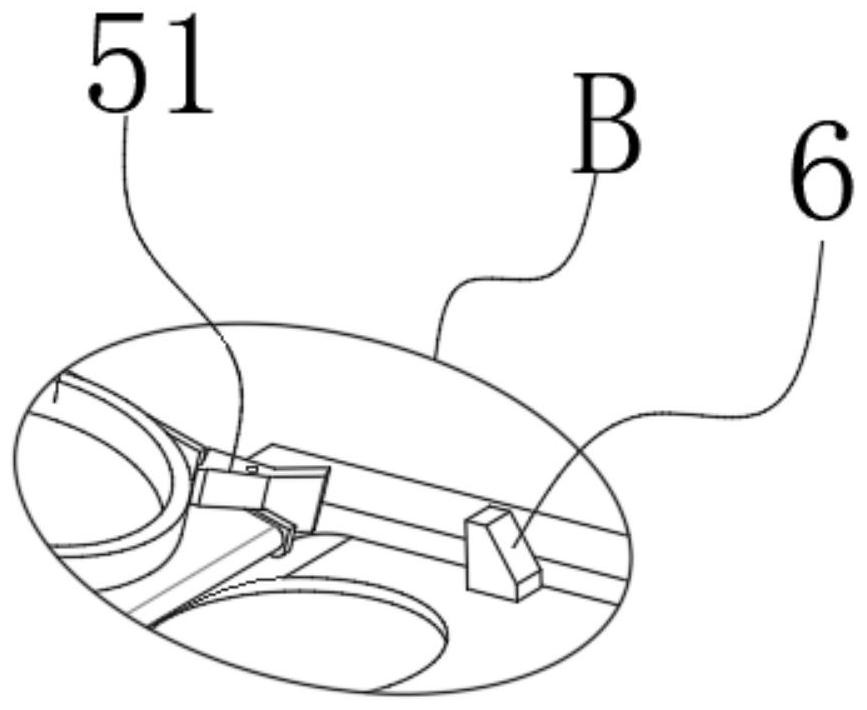

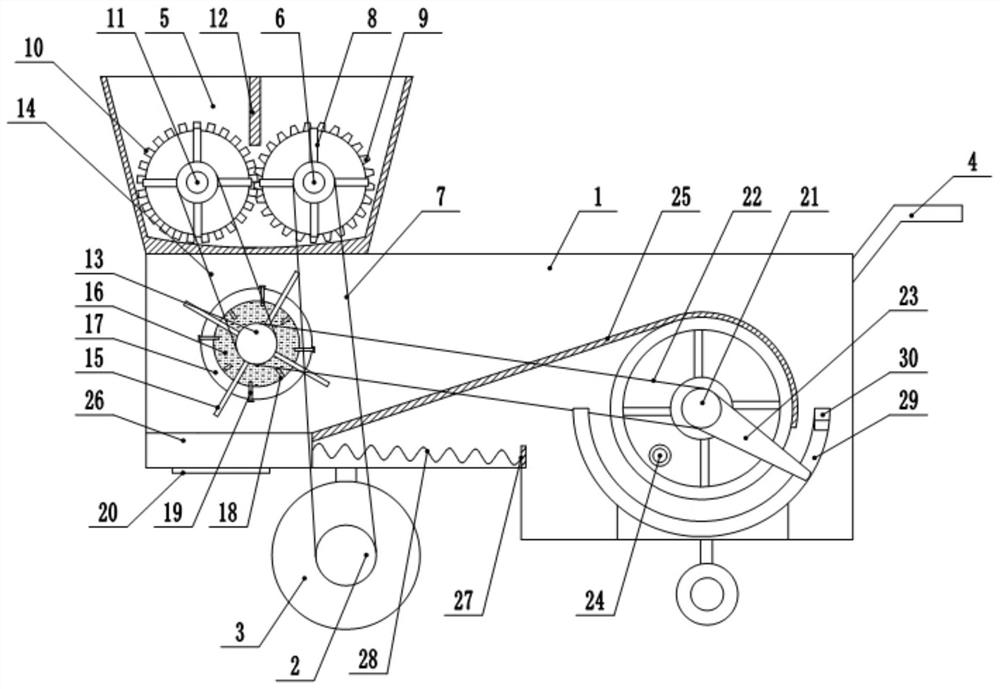

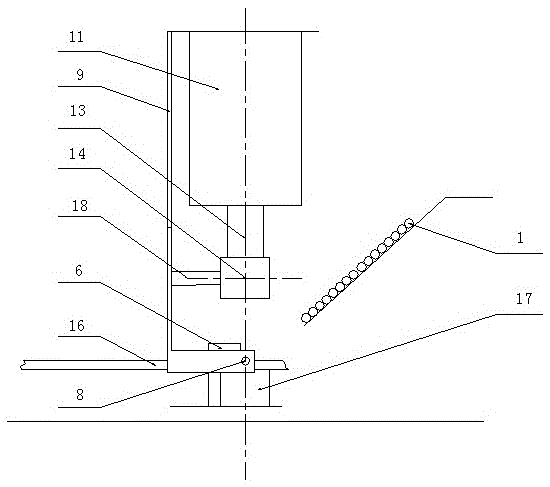

Automatic wood stick stripe cutting machine

PendingCN112476648ATo achieve the purpose of automatically cutting wooden sticksImprove work efficiencyProfiling/shaping machinesAgricultural engineeringSupport plane

The invention relates to a cutting machine, in particular to an automatic wood stick stripe cutting machine. The invention provides the automatic wood stick stripe cutting machine which not only can efficiently realize automatic discharging and automatic cutting, but also can collect cut materials in time. The automatic wood stick stripe cutting machine comprises first supporting frames and a supporting plate, wherein the first supporting frames are symmetrically arranged at the bottom of the supporting plate; second supporting frames symmetrically arranged at the bottom of the supporting plate; and a cutting mechanism arranged on the supporting plate. Through cooperation of a discharging, cutting and rolling mechanism and the cutting mechanism, the purpose of automatically cutting woodensticks is achieved; and through cooperation of an automatic pushing and rolling mechanism and an auxiliary clamping mechanism, the cut wood stick is pushed and rolled, and the purpose of cutting the surface of the wood stick is achieved.

Owner:黄国春

Adsorption-type quick film sticking device

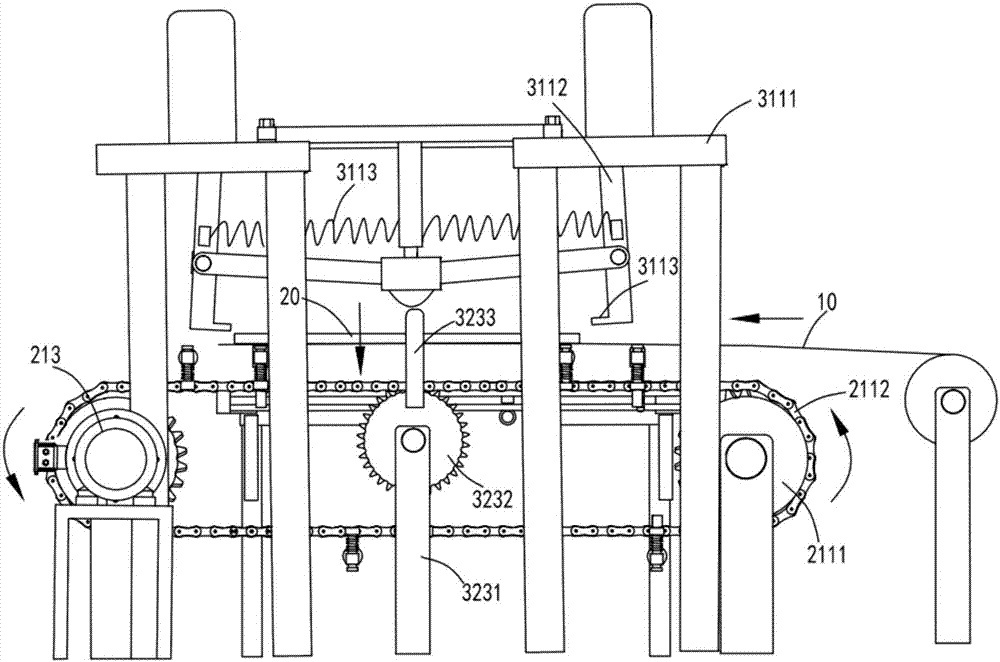

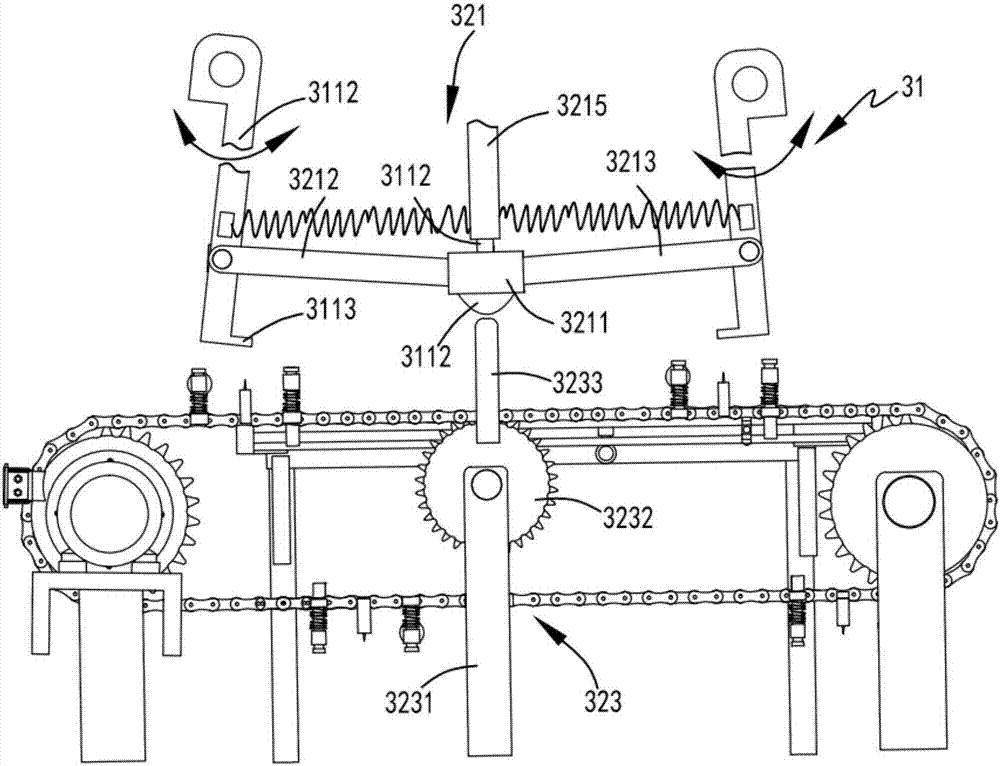

InactiveCN106965970AThe film pulling process is stableFilm PreciseWrapping material feeding apparatusEngineeringSheet material

The invention relates to an adsorption type fast film sticking device, which comprises a film unwinding part for conveying the film backward; a film pulling part for driving one end of the film to move backward to make the film unroll in a horizontal direction; a feeding part, the The feeding part is used to intermittently supply the sheet material to the film pulling part to make the sheet fit with the unfolded film; the film pulling part includes a rotating mechanism and several groups of supporting cutters which are arranged on the rotating mechanism and perform rotating motion under the driving of the rotating mechanism. A cutting mechanism and a negative pressure supply mechanism arranged on one side of the rotary mechanism; the feeding part includes a clamping mechanism for supporting the sheet material and a blanking material for controlling the sheet material in the clamping mechanism to fall intermittently with the rotation of the rotary mechanism Mechanism; the invention overcomes the problems of unstable film unfolding during the film sticking process, easy occurrence of wrinkles and inability to achieve continuous and efficient film sticking and complete film cutting while sticking the film.

Owner:浙江班萘特复合材料股份有限公司

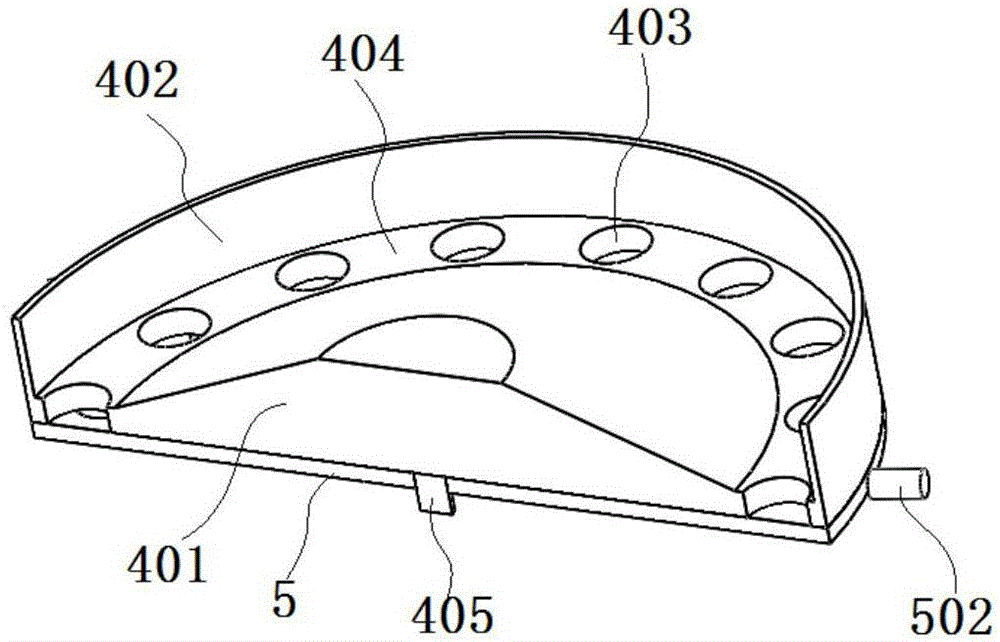

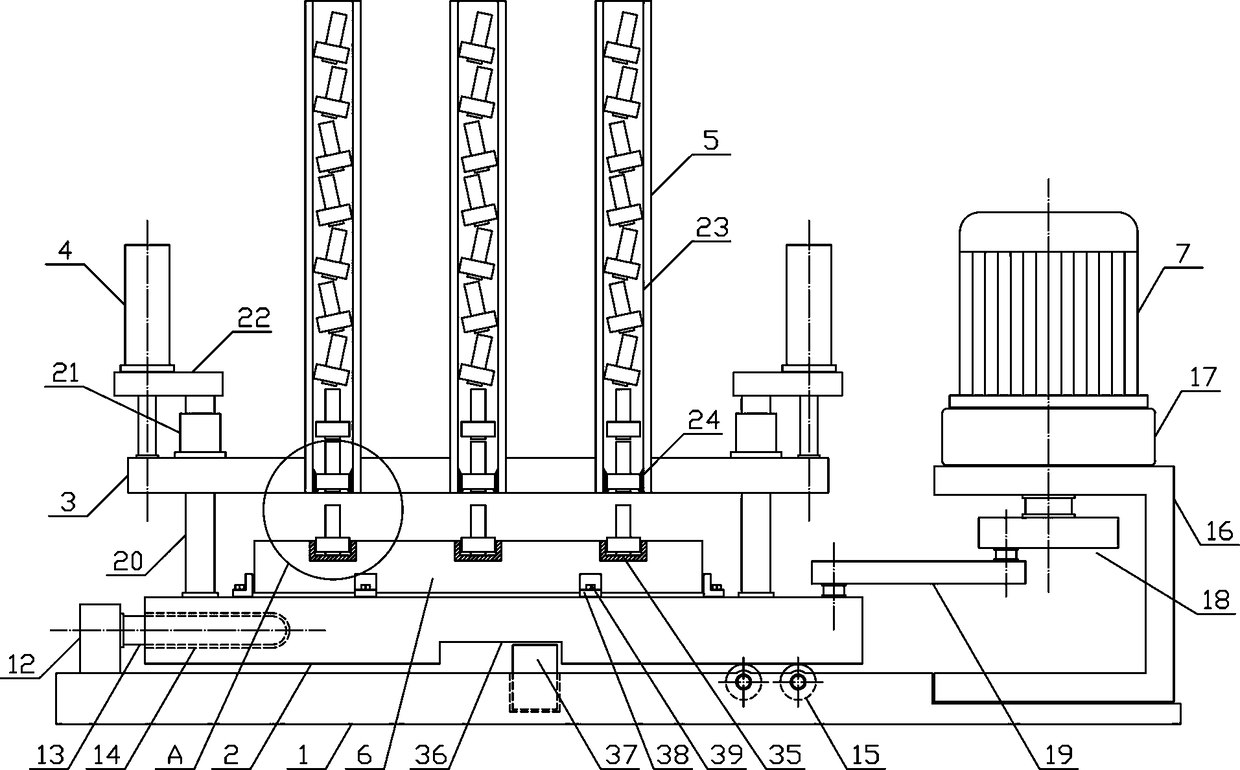

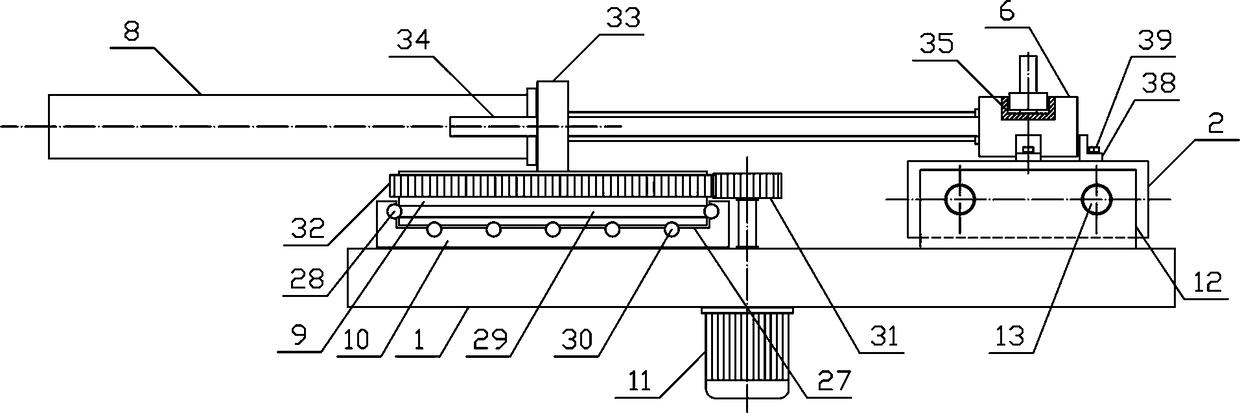

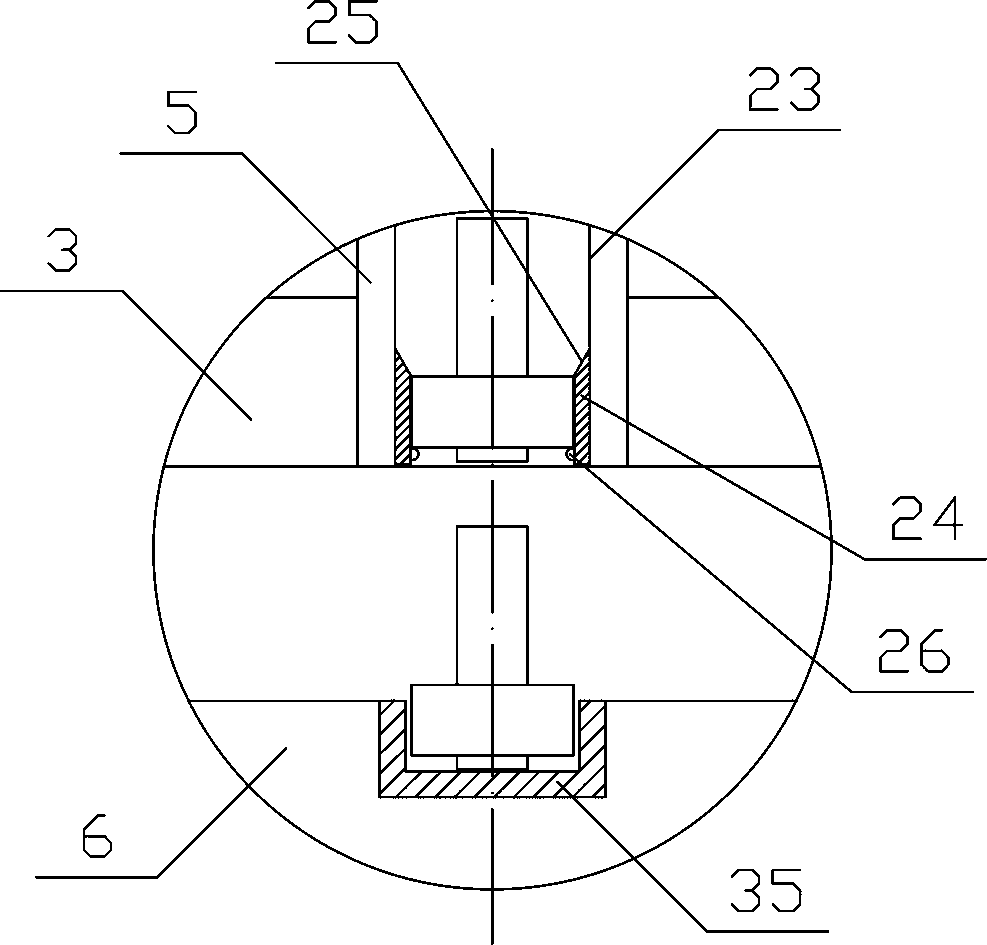

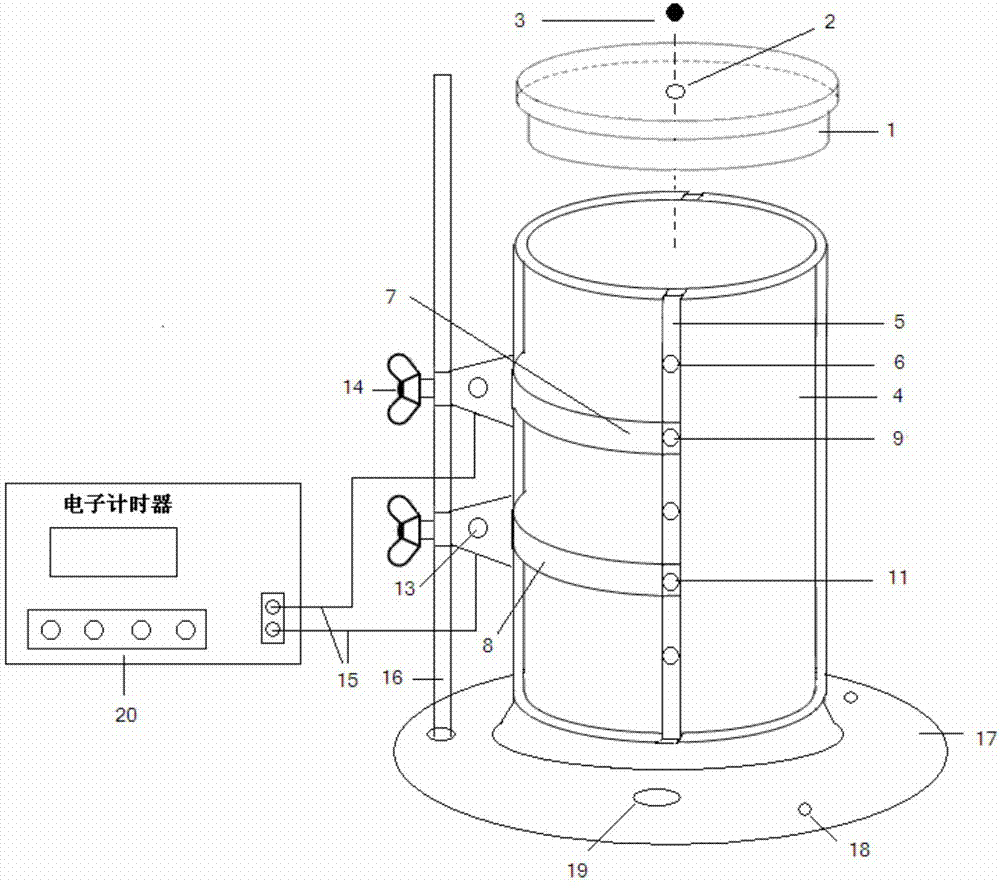

Method for detecting drop strength of green pellets under motion state

ActiveCN106644776ADrop Strength TestBreak down tech biasMaterial strength using repeated/pulsating forcesEngineeringDrive motor

The invention discloses a method for detecting drop strength of green pellets under a motion state and belongs to the technical field of iron mine pellets. The method comprises the following steps: 1) selecting the pellets, namely selecting M 10-18mm green pellets; 2) detecting the dropping of the pellets, switching on a motor control switch of a detection device, rotating a driving motor to drive a base plate to rotate, causing the green pellets fall onto the base plate from a pellet loading part of the detection device, recording the falling times as i, detecting the surfaces of the green pellets, recording the quantity of the green pellets with cracks on the surfaces at the No.i time as mi, and when Sigma mi is less than M, causing the green pellets without cracks fall onto the base plate from the pellet loading part till Sigma mi is equal to M; and 3) treating the drop strength with data, wherein the formula is as shown in the specification. According to the method disclosed by the invention, the simultaneous detection for a plurality of green pellets can be realized and the detection for the drop strength of green pellets under the motion state also can be realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

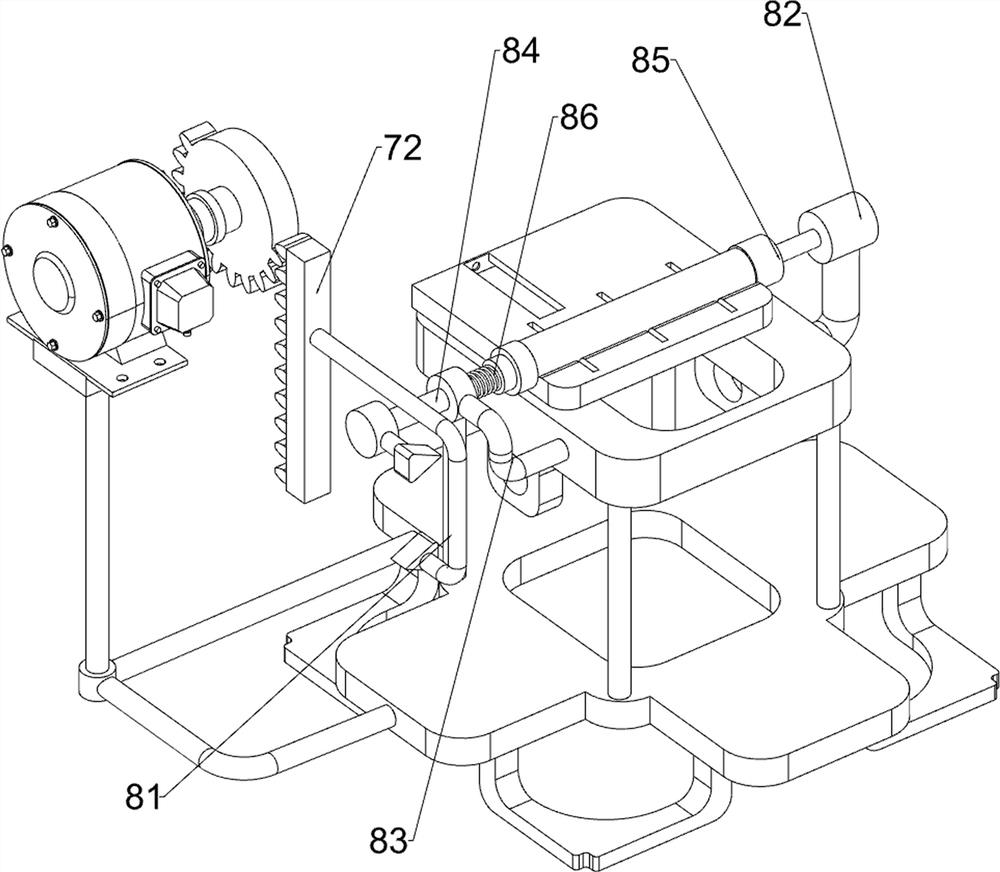

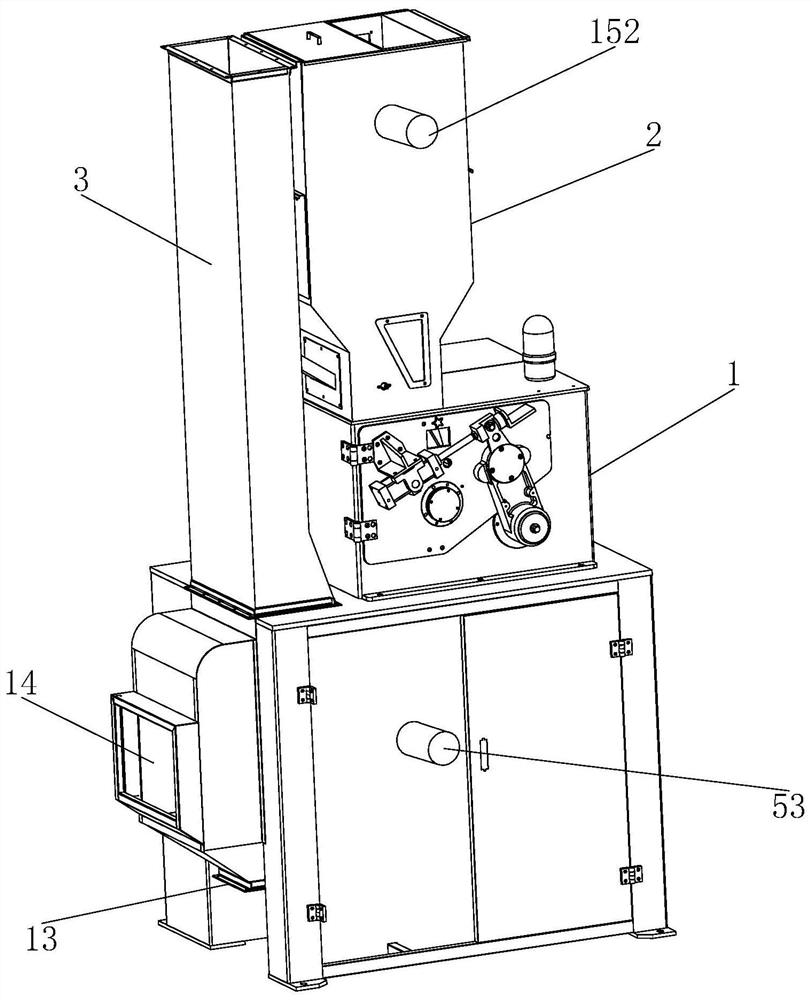

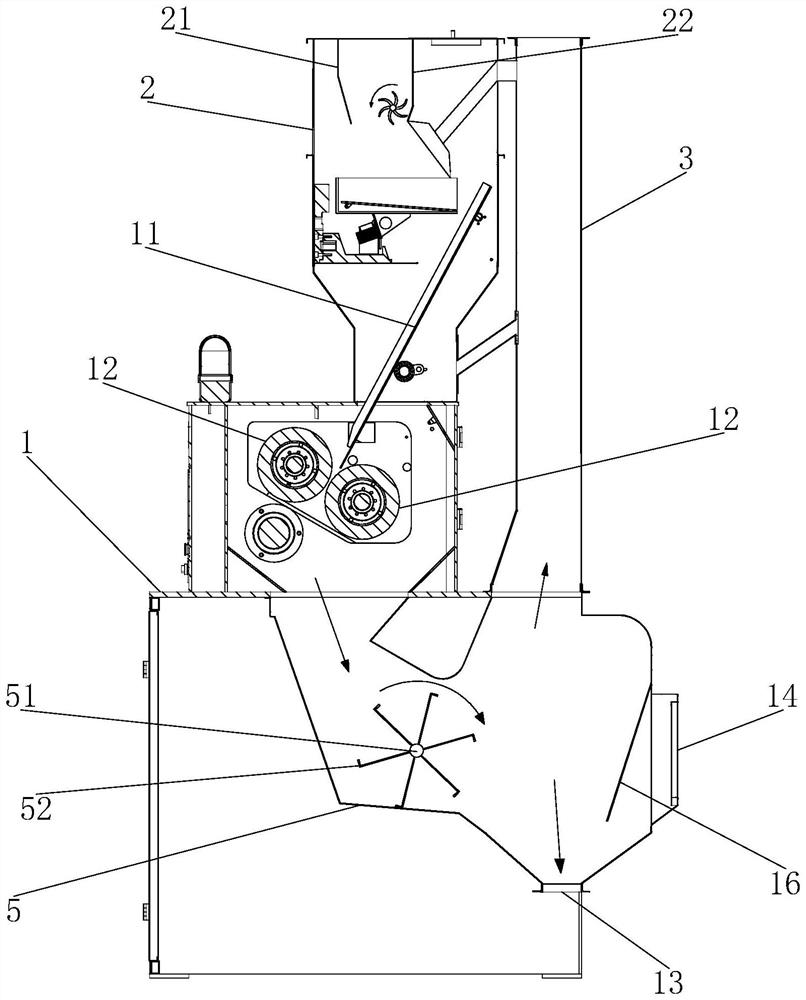

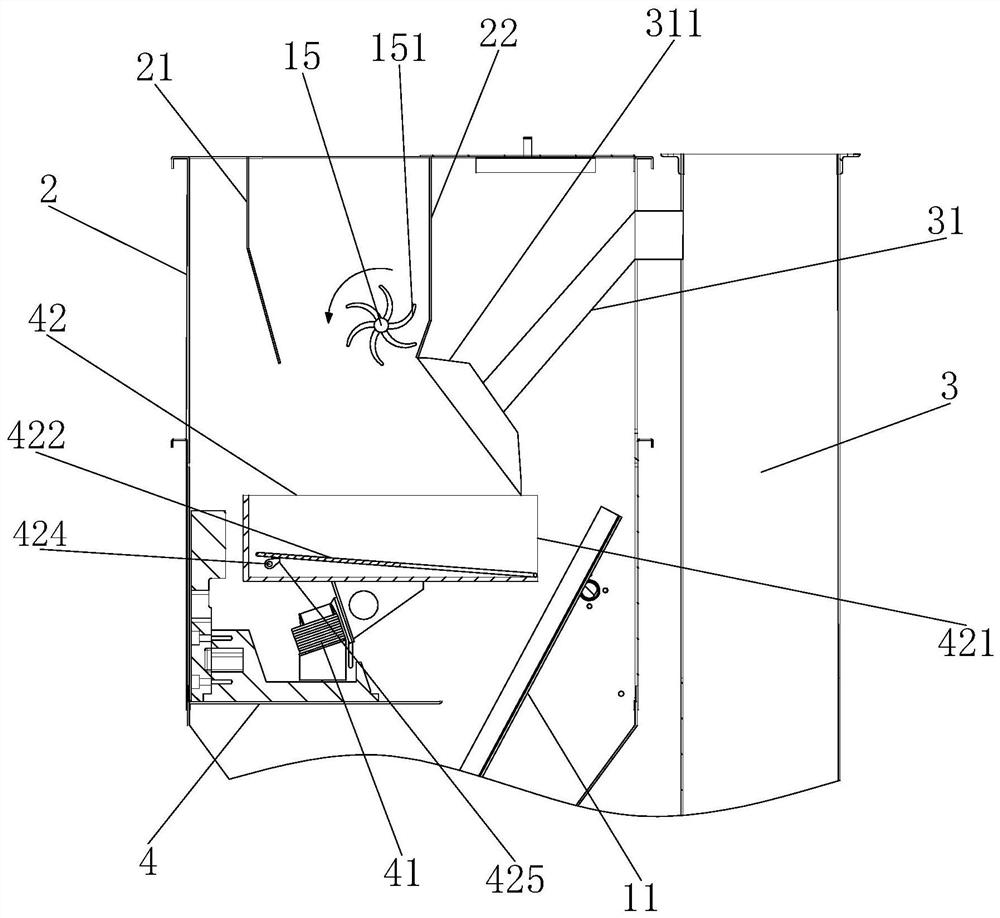

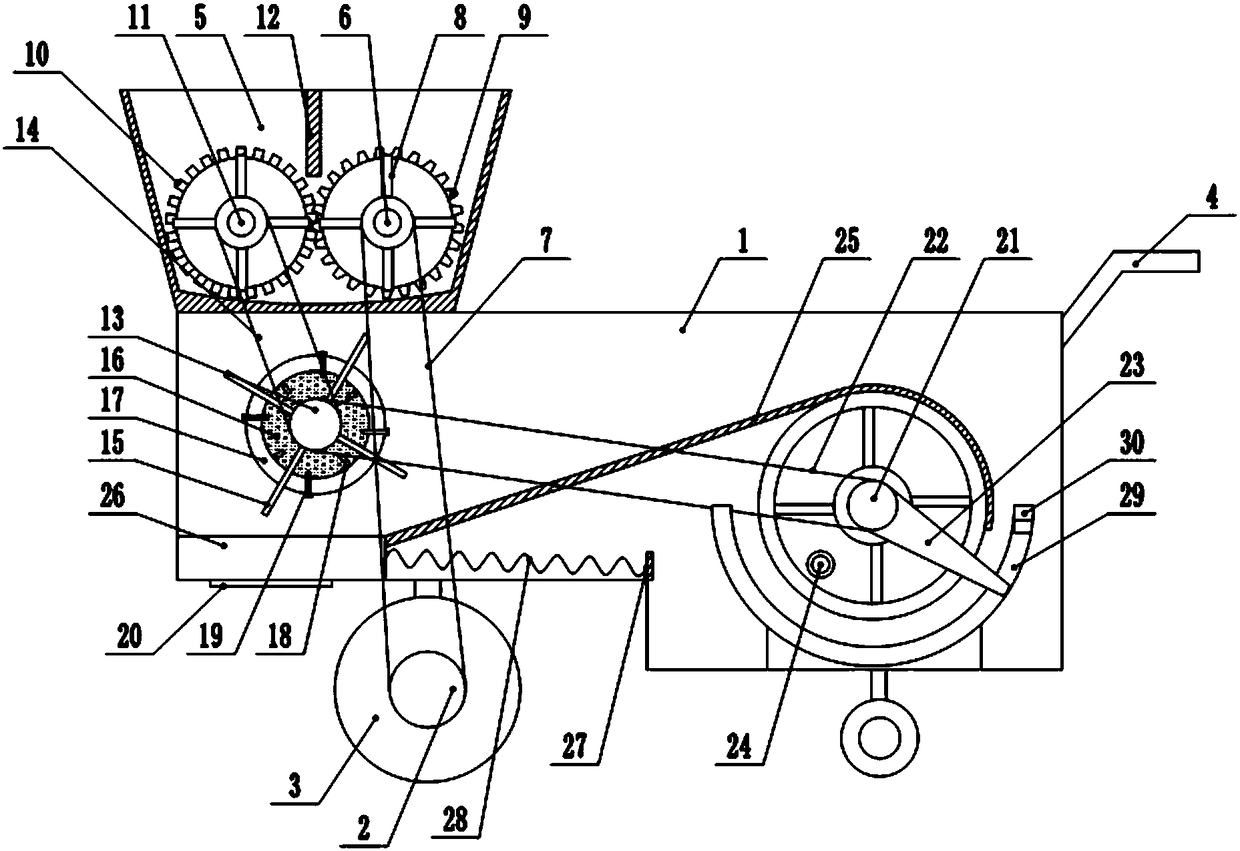

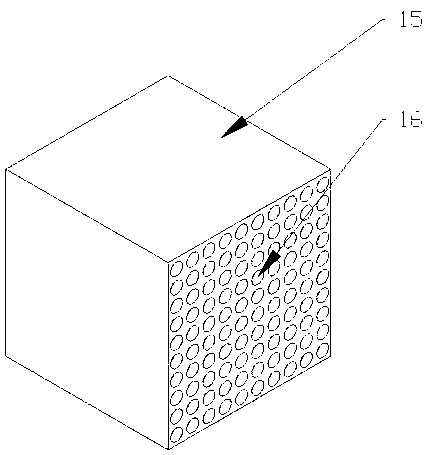

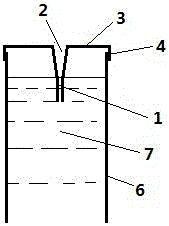

Rice huller with variable-frequency vibration feeding function

InactiveCN112774764AConvenient whereaboutsAccurate whereaboutsGrain huskingGrain polishingAnimal scienceElectric machinery

The invention relates to the technical field of rice huller design, and discloses a rice huller with a variable-frequency vibration feeding function. The rice huller comprises a machine body, a feeding hopper, a falling plate, two rubber rollers, a discharge port, an extraction pipe and an air inlet, a first guide plate is arranged at the upper end in the feeding hopper, and a second guide plate is further arranged at the position, located at one side of the first guide plate, in the feeding hopper. The lower end of the first guide plate inclines towards one side of the second guide plate, a rotating shaft is arranged at the position, located at the lower end of the second guide plate, in the machine body, feeding paddles are arranged at the peripheral side of the rotating shaft, and a driving motor used for being connected with the rotating shaft is arranged at the outer side of the feeding hopper. After rice enters the feeding hopper, the driving motor is used for driving the rotating shaft and the feeding paddles to rotate, and at the moment, the feeding paddles can turn over the rice between the first guide plate and the second guide plate and apply downward acting force to the rice, so that the possibility that the rice is blocked between the first guide plate and the second guide plate can be reduced.

Owner:浙江粮工机械科技有限公司

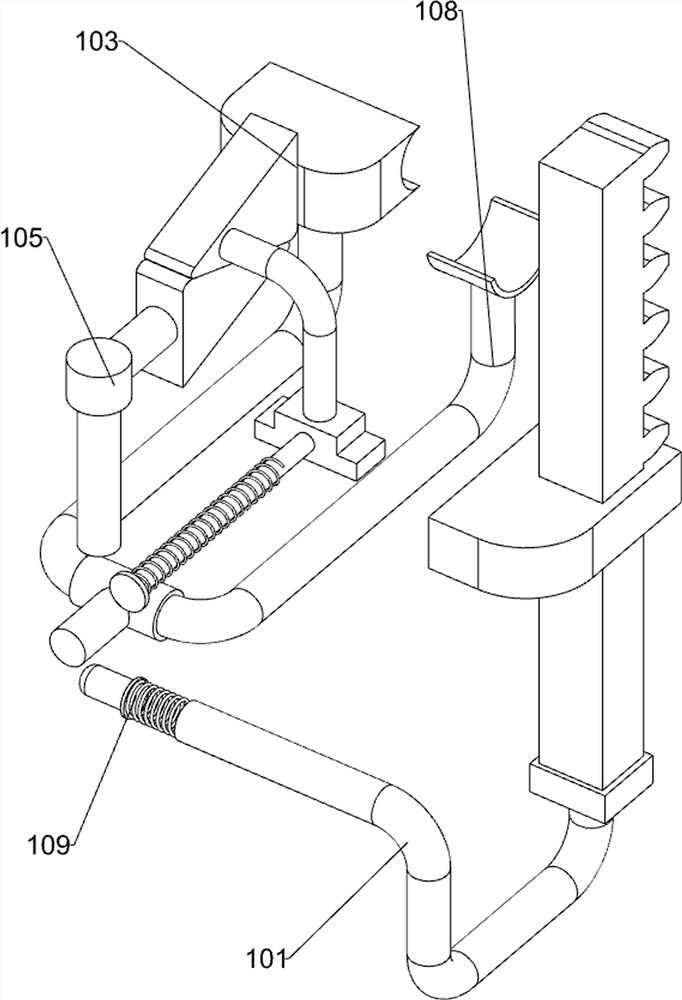

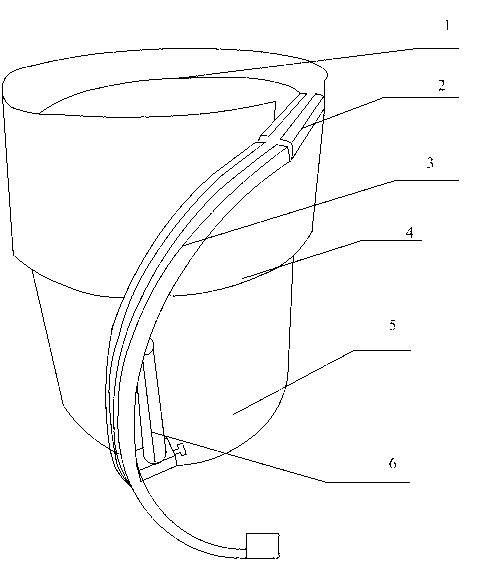

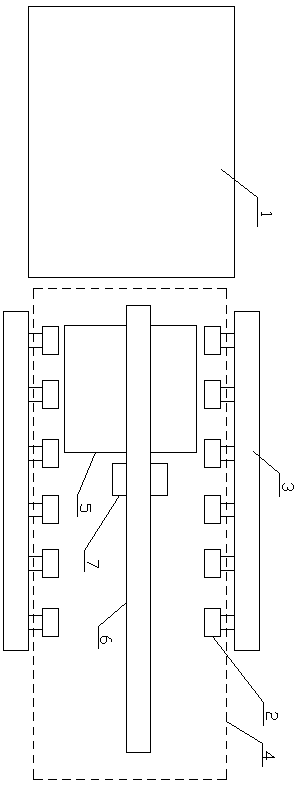

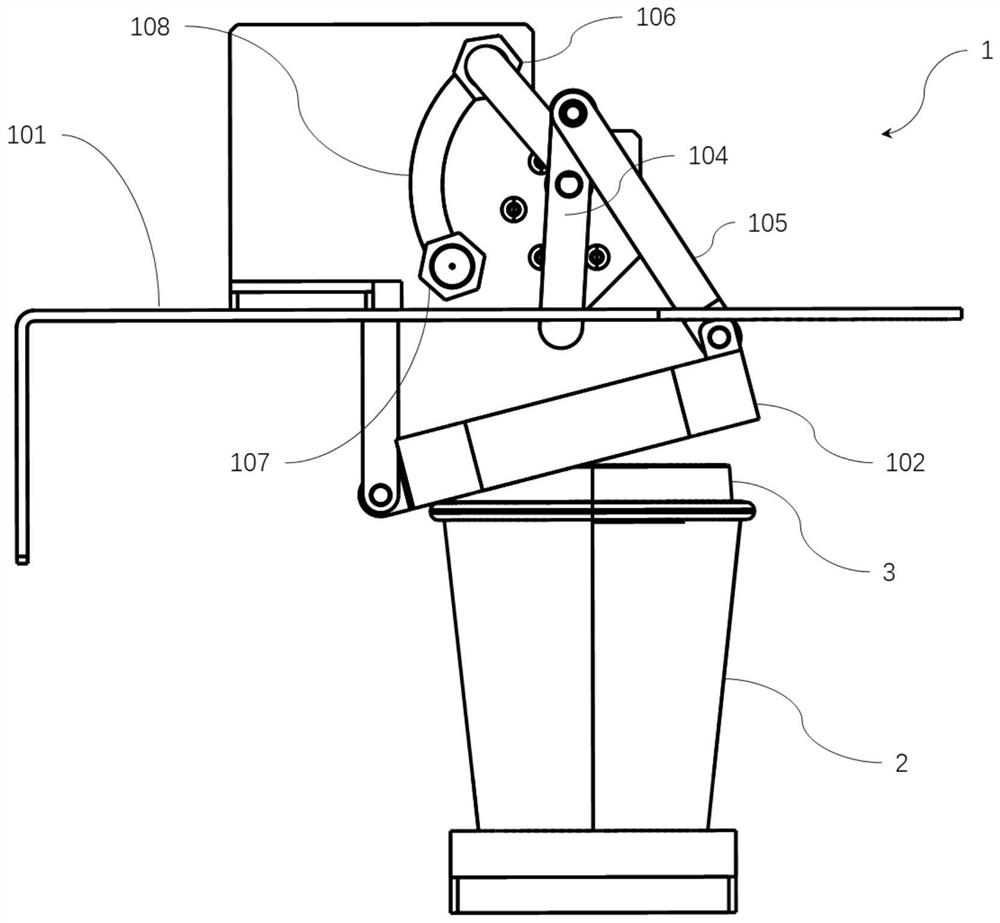

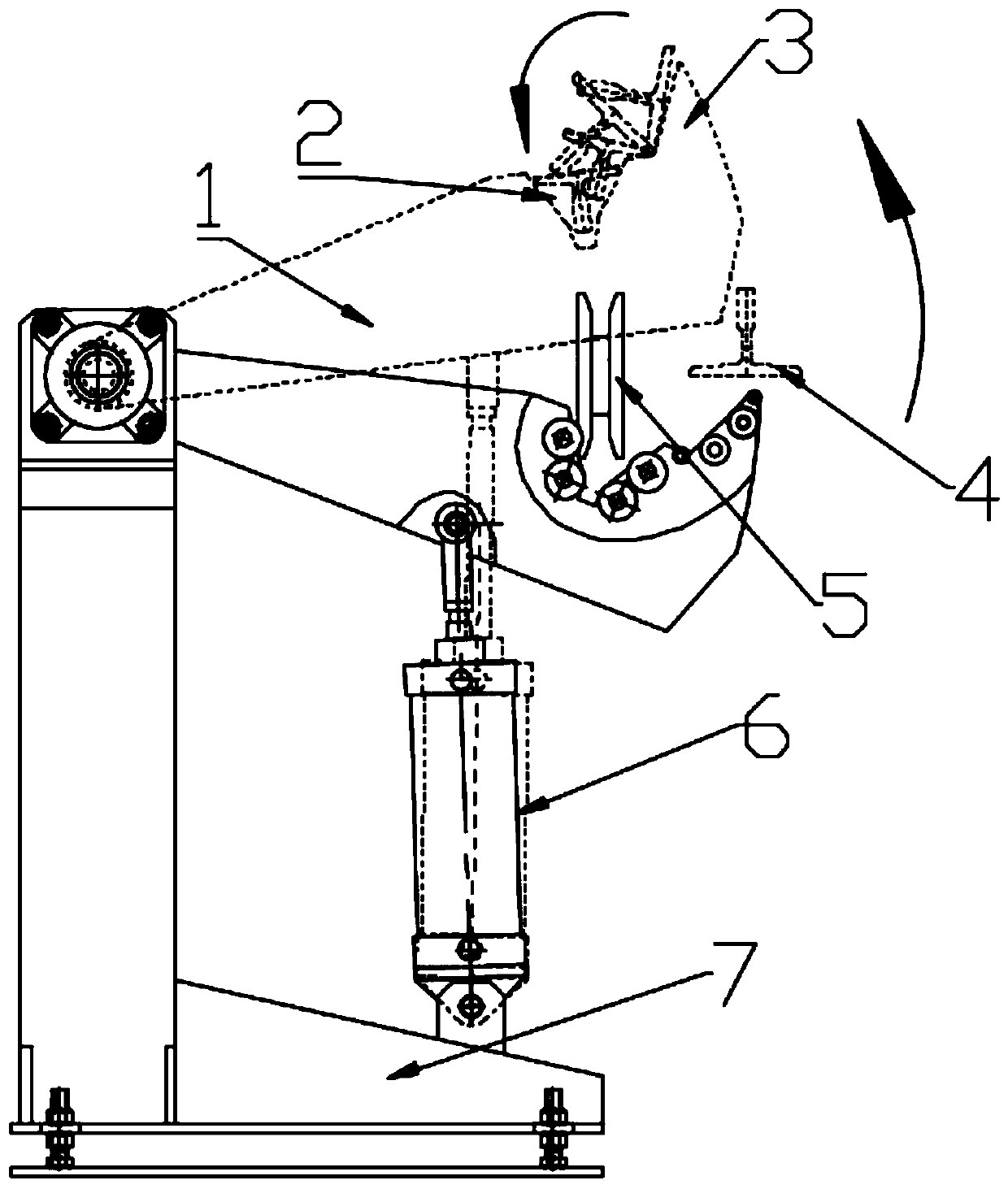

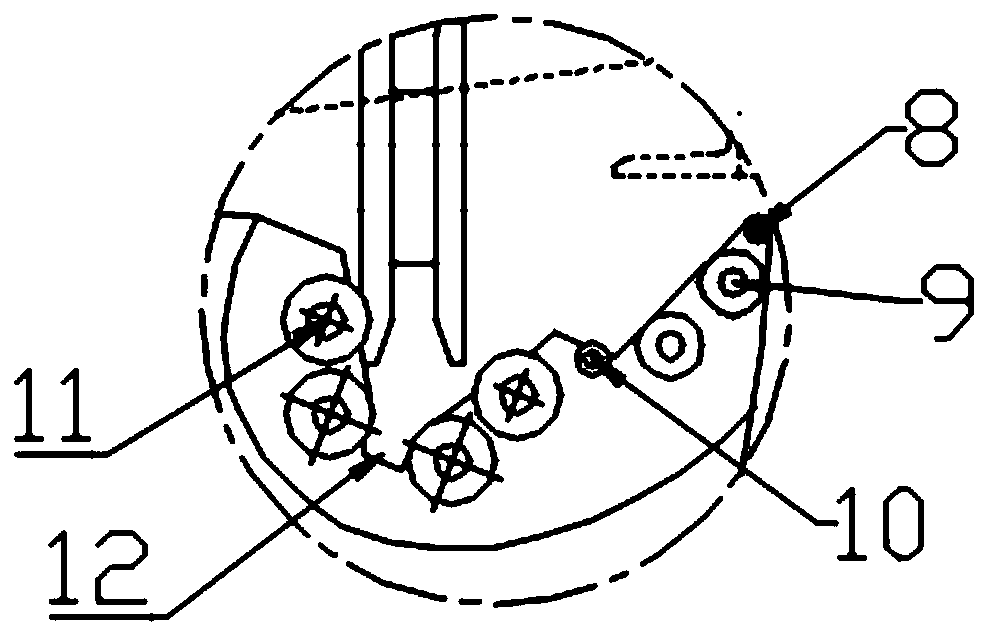

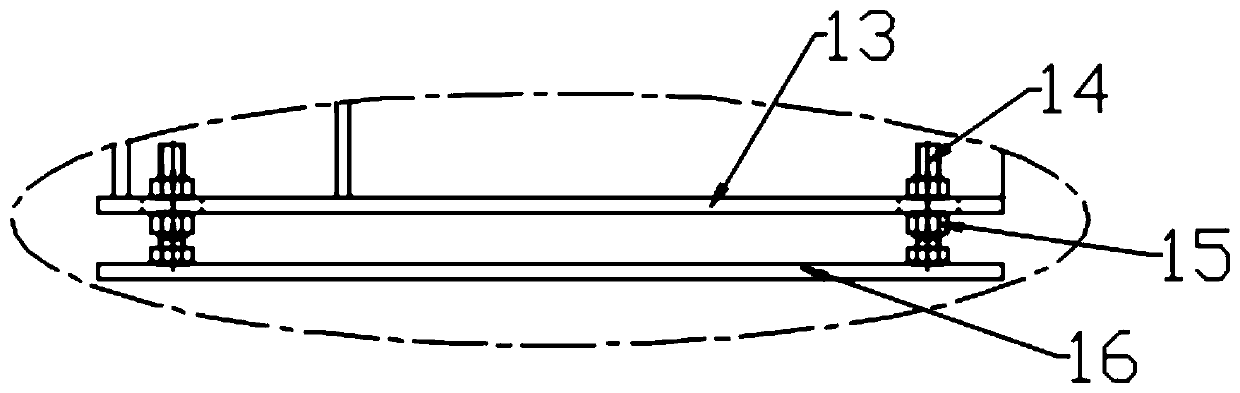

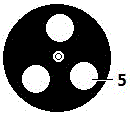

Poking and separating type automatic cup falling device

ActiveCN105775237AAccurate whereaboutsReasonable structurePackagingDe-stacking articlesEngineeringPiston rod

Disclosed is a poking and separating type automatic cup falling device. Rails are fixed to the edge of each through hole in a table board; a vertical face passing through the center line of each through hole is used as a center face; two sets of poking and separating mechanisms on the lower portion of the table board are symmetrically arranged along the center face; in each set of poking and separating mechanism, a first air cylinder is fixed to the upper side of the table board, and a second air cylinder and a third air cylinder are located on the lower portion of the table board and fixed together to an air cylinder rack; piston rods of the first air cylinders are connected with the corresponding air cylinder racks; pin columns are disposed on bases fixed to the lower side of the table board; the pin columns are connected with one group of upper poking forks; supports are connected to the upper poking forks; poking rods penetrating through the supports are connected with piston rods of the second air cylinders; the piston rods of the second air cylinders are connected with one group of middle poking forks; and piston rods of the third air cylinders are connected with one group of lower poking forks. The first air cylinders can control the air cylinder racks to move up and down; the second air cylinders can control the upper poking forks and the middle poking forks to be opened or closed; and the third air cylinders can control the lower poking forks to be opened or closed. All the air cylinders are controlled to act in sequence so that a pile of cups stacked up together in each group of rails can be poked and separated one by one.

Owner:BENGBU SAIYA MACHINERY

Conveying device applied to aluminum medicine bottle caps

InactiveCN103241694ASimple structureEasy to operateFlanged caps applicationJigging conveyorsMedicine bottle capEngineering

The invention discloses a conveying device applied to aluminum medicine bottle caps. The conveying device applied to aluminum medicine bottle caps comprises a bottle cap conveying track. The bottle cap conveying track comprises a spiral track, a straight-section track and a C-shaped track, wherein the spiral track, the straight-section track and the C-shaped track are connected in sequence. One end of the C-shaped track away from the straight-section track serves as the tail end of the bottle cap conveying track. The conveying device applied to aluminum medicine bottle caps further comprises a circular bottle cap containing bucket, the spiral track spirals down along the inner diameter surface of a circular bottle cap containing bucket until arriving at the bottom surface of the circular bottle cap containing bucket, and a downward-pressing retaining plate is arranged at the tail end of the C-shaped track. The conveying device applied to aluminum medicine bottle caps has the advantages of being simple in structure, easy to operate and low in construction cost.

Owner:CHINA CHENGDU ANIMAL HUSBANDRY IND BIOPHARM

Grape fertilization device

InactiveCN108496498AEasy to operateImprove synchronicityFertiliser distributersDrive wheelDrive shaft

The invention relates to a grape fertilization device which comprises a housing and a driving shaft, wherein the driving shaft is connected with a driving wheel; a feeding hopper is arranged at the upper part of the housing; a first rotating shaft is rotationally connected with the side wall of the feeding hopper; a first conveyer belt is connected between the first rotating shaft and the drivingshaft; a first baffle plate is fixedly connected with a first rotating shaft; a first gear is fixedly connected with the first rotating shaft coaxially; a first gear is meshed with a second gear; a second rotating shaft is fixedly connected with the second gear coaxially; a second baffle plate is fixedly connected with the second rotating shaft; a third rotating shaft is rotationally connected tothe interior of the housing; a second conveyer belt is connected between the third rotating shaft and the second rotating shaft; a storage cabin is fixedly connected with the third rotating shaft coaxially; baffle plates are arranged inside the storage cabin; an airbag is arranged between two adjacent baffle plates; the airbag is communicated with an air guide tube; a liquid outlet tube is connected inside the airbag; a fertilization hole is formed in the bottom of the housing; an intermittent discharge mechanism is connected to the fertilization hole in a sliding manner; a third conveyer beltis connected between the intermittent discharge mechanism and the third rotating shaft. By adopting the grape fertilization device, device feeding and device movement are carried out synchronously.

Owner:重庆龙佰绪生态农业开发集团有限公司

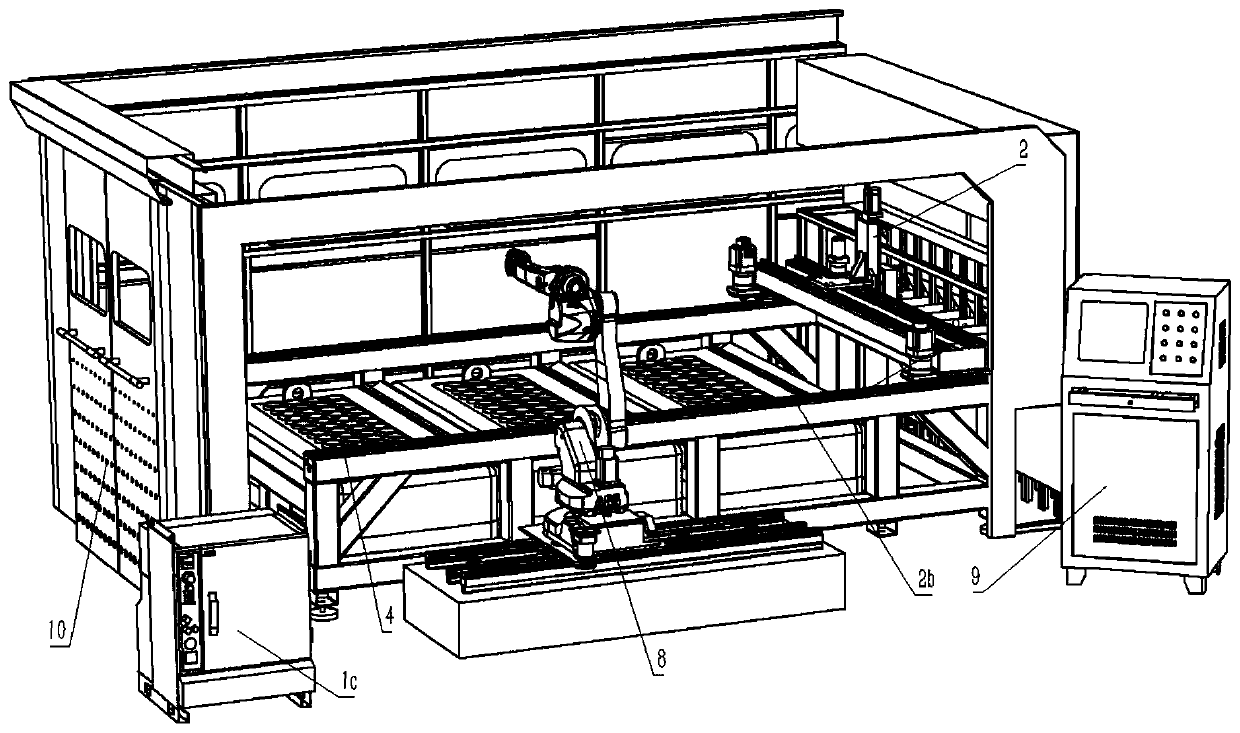

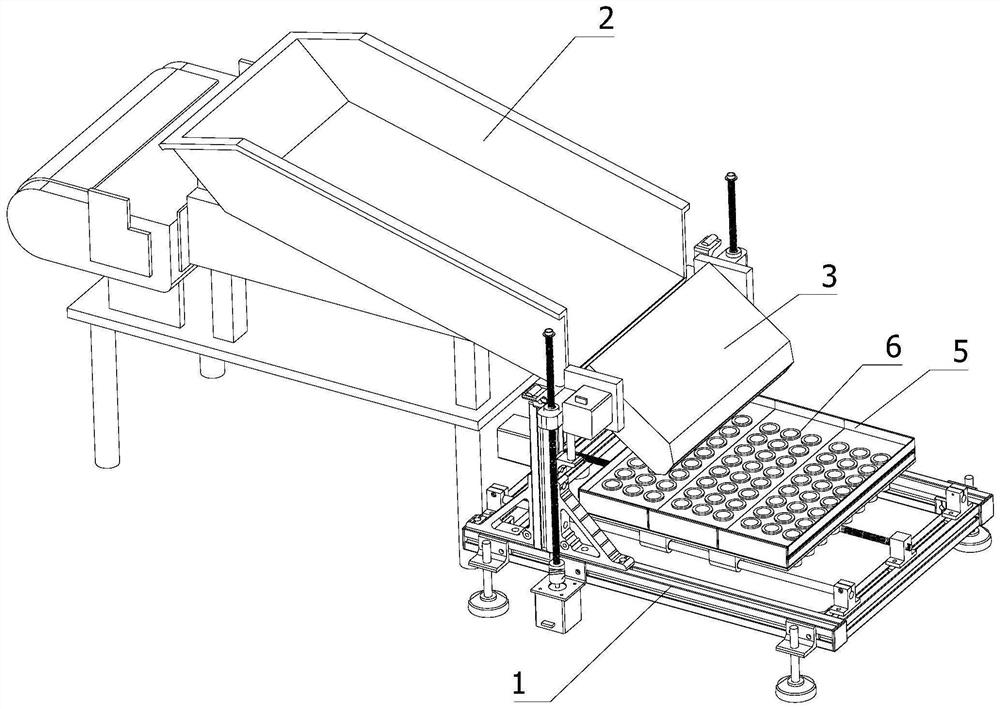

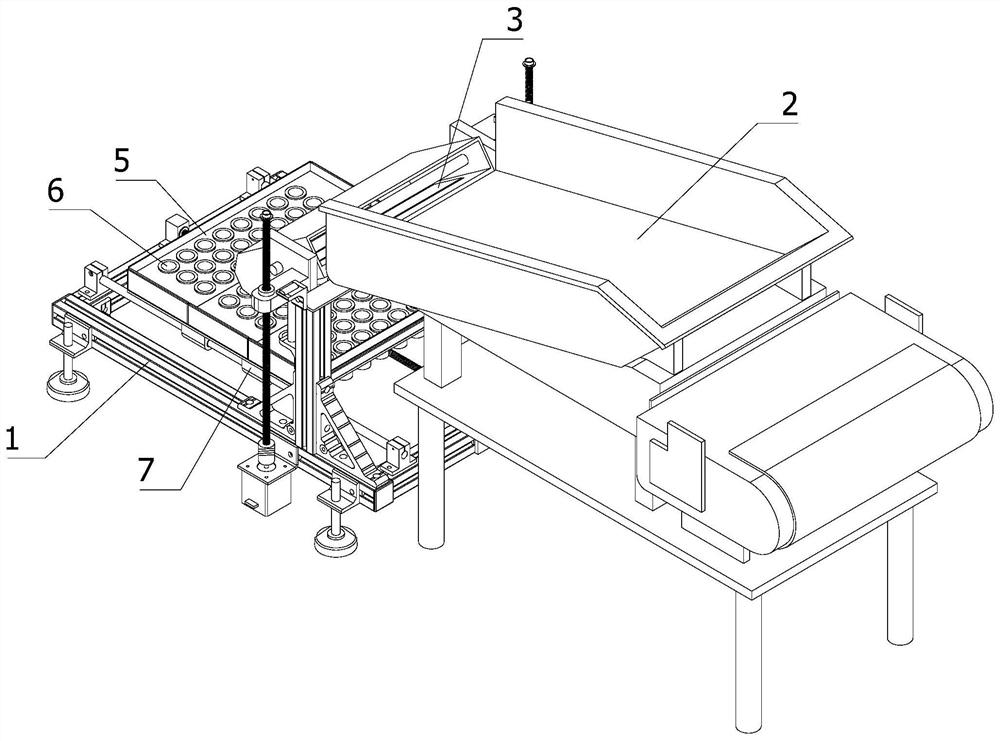

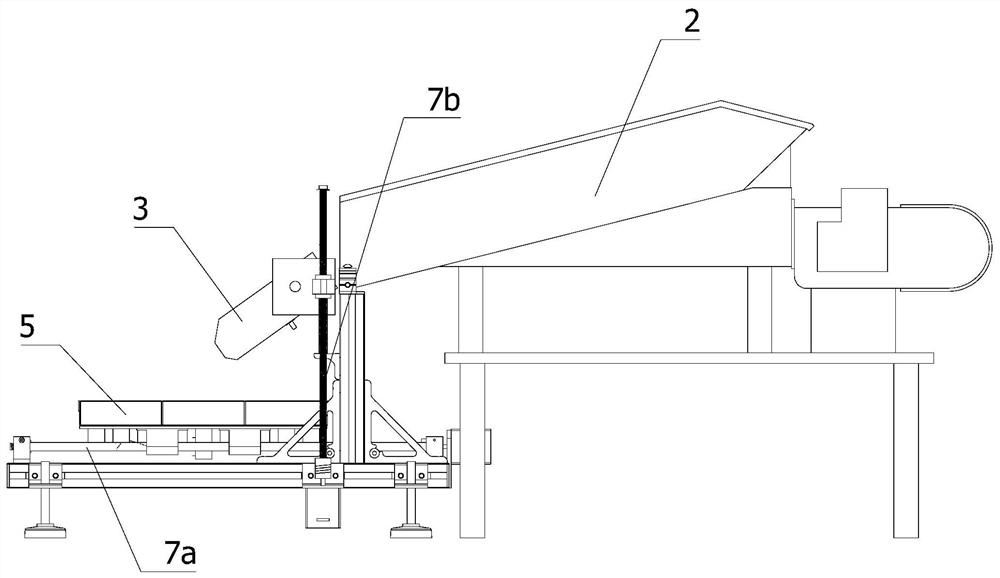

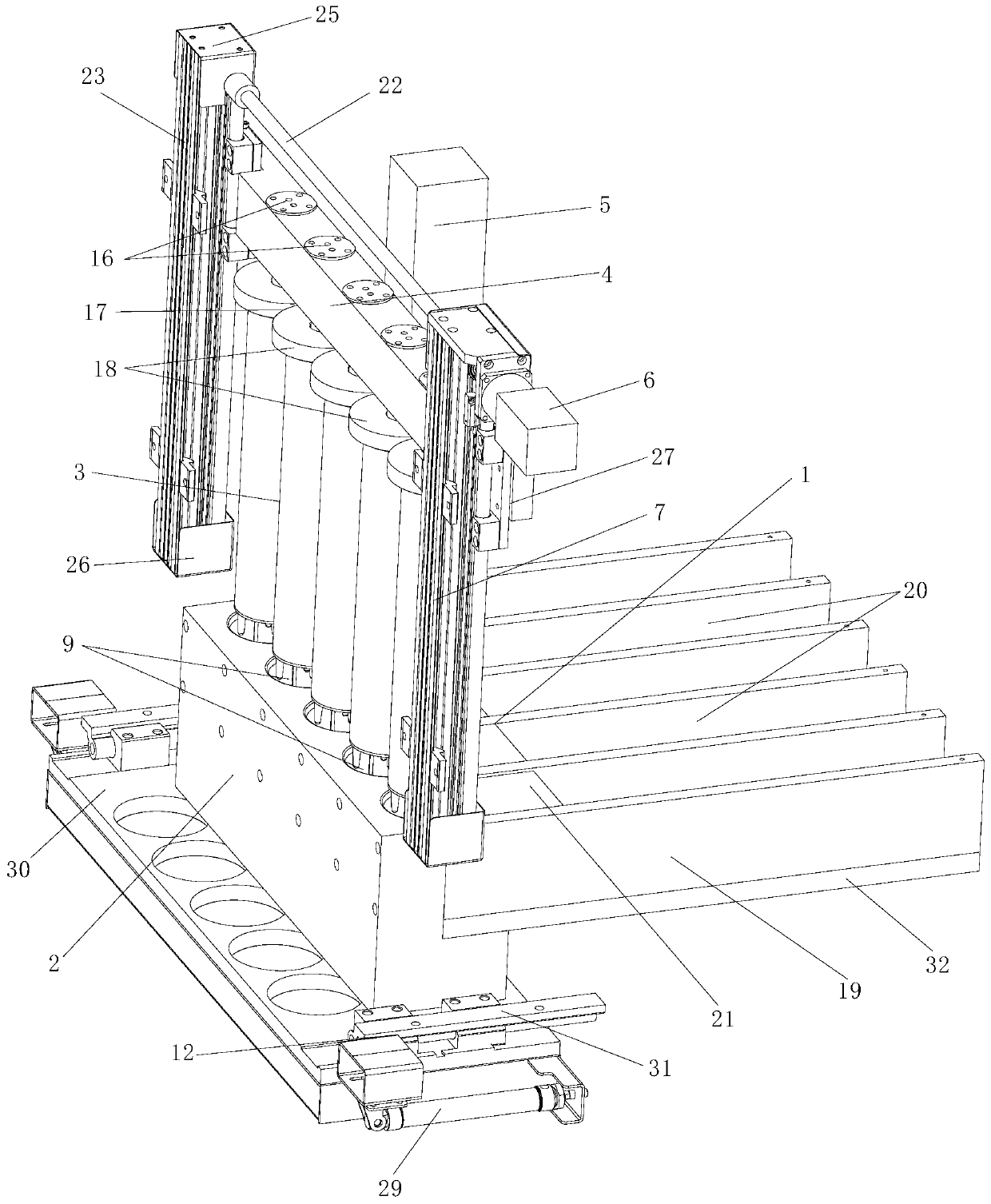

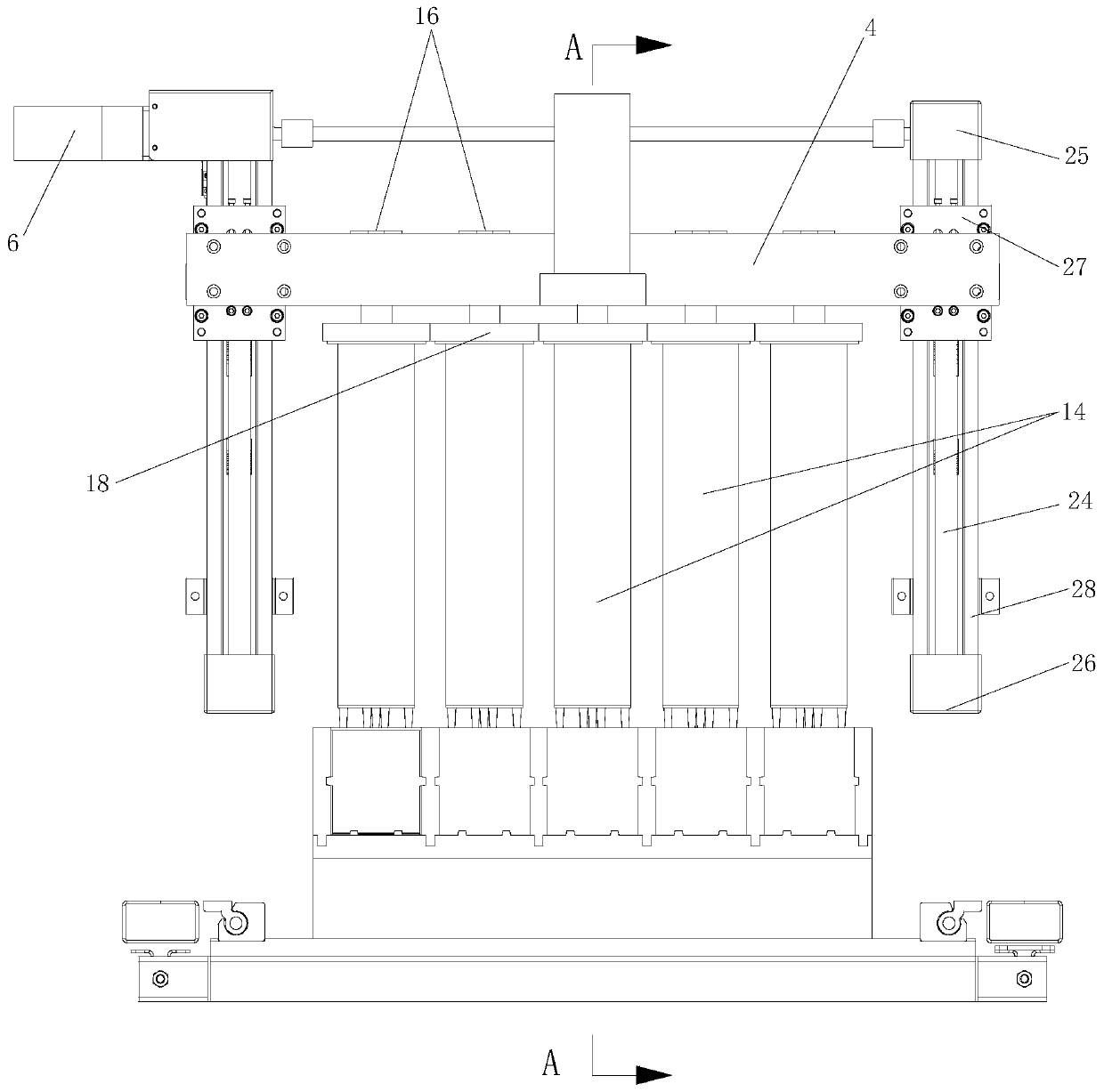

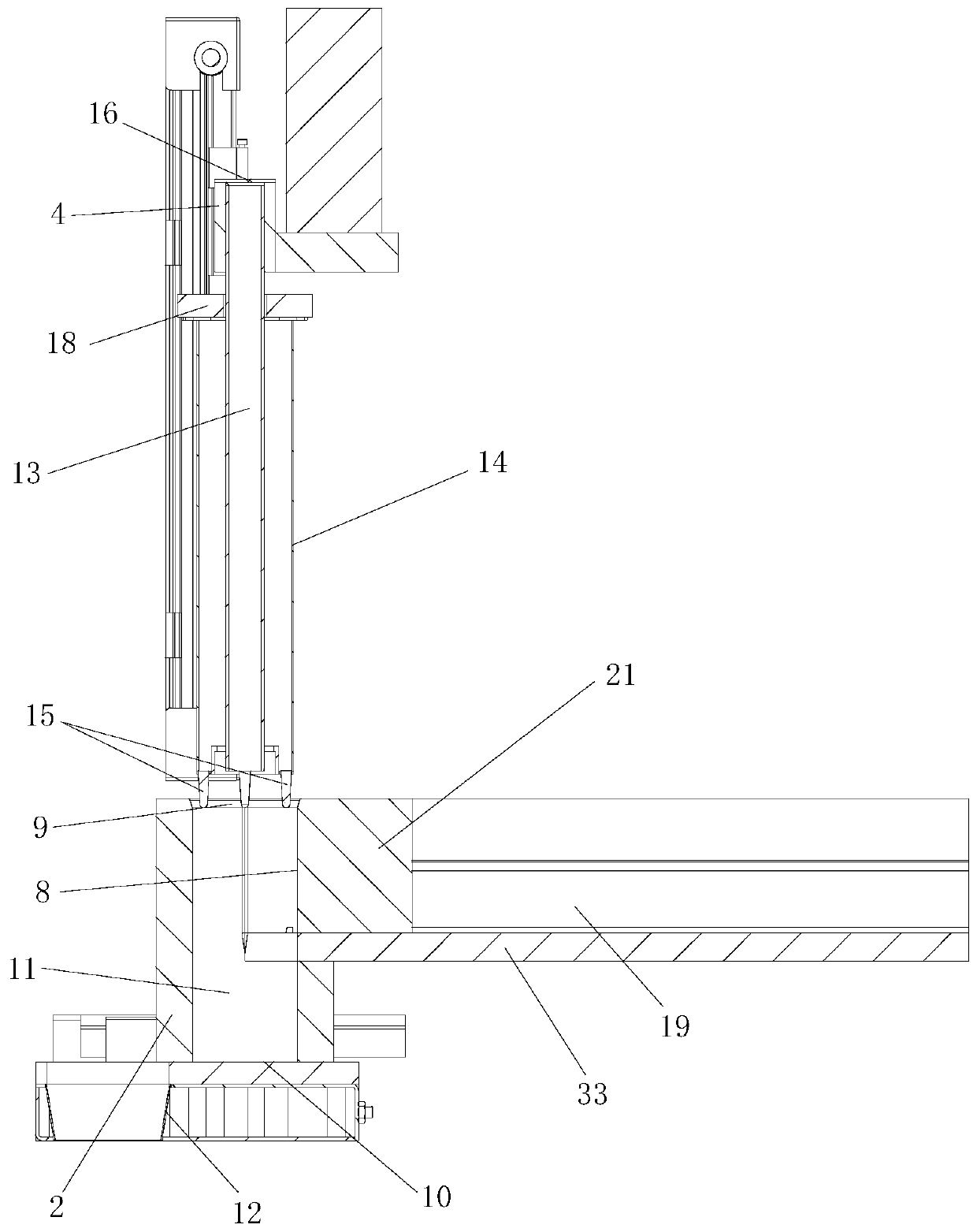

Equipment and method for preparing high-performance aluminum alloy material based on genome high-flux technology

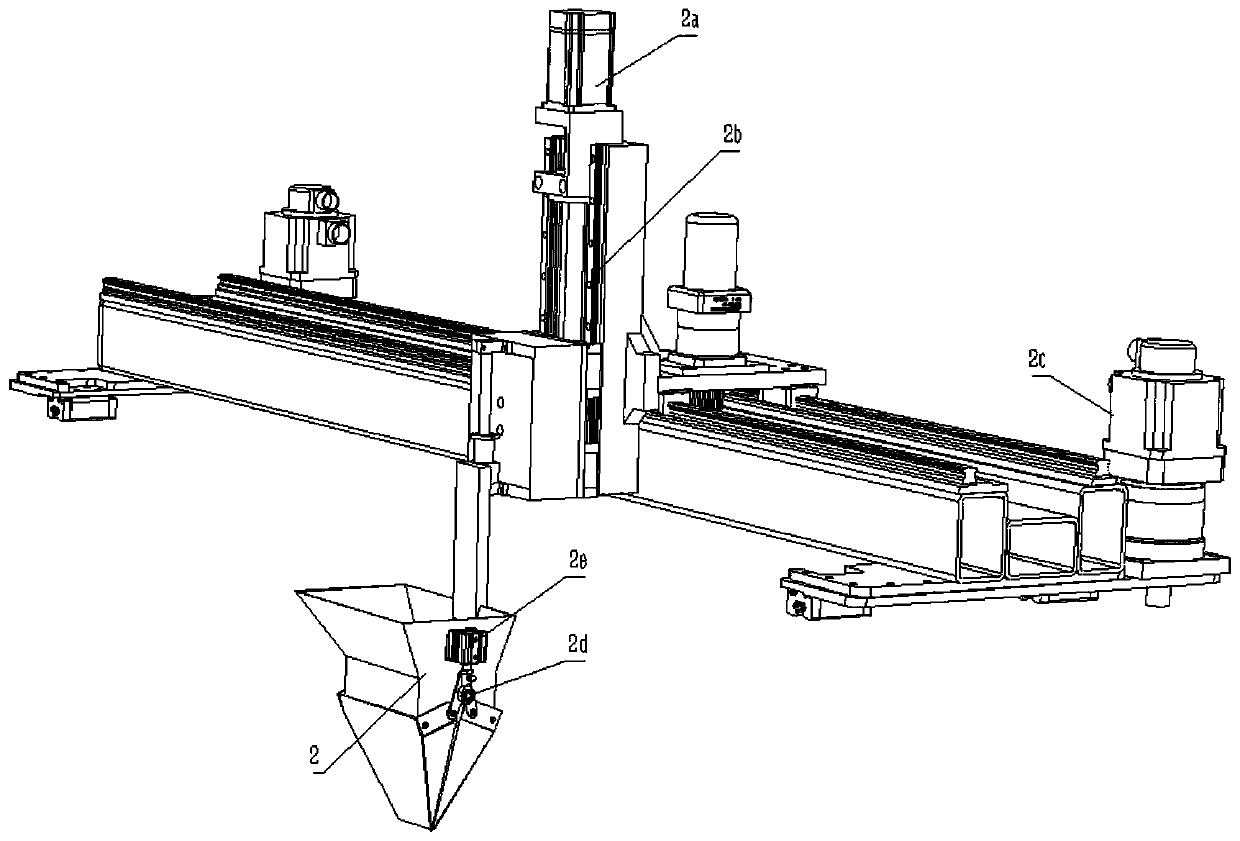

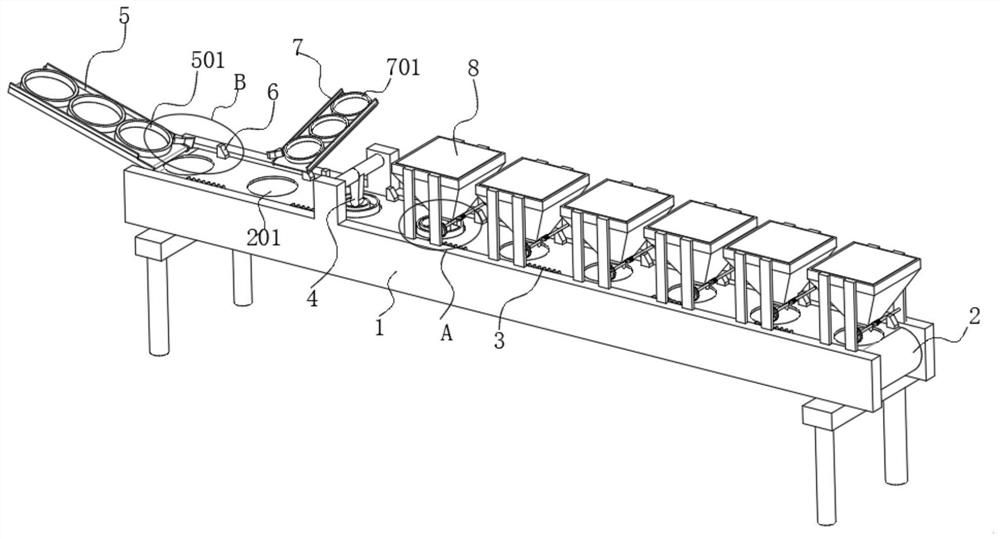

PendingCN111336809AGrain refinementImprove performanceStirring devicesCrucible furnacesHigh fluxMaterials science

The invention discloses equipment and a method for preparing a high-performance aluminum alloy material based on a genome high-flux technology. The equipment comprises an element box assembly, a feeding hopper mechanism and smelting devices, wherein the element box assembly is mounted at one end of the equipment, a funnel cooperating with the element box assembly and a moving device capable of moving horizontally and vertically are arranged on the feeding hopper mechanism, so that a plurality of horizontally arranged element boxes are placed into the smelting device of the next station throughvertical movement of the moving device after obtaining elements, at least one smelting device is horizontally arranged at the lower part of the equipment, and the smelting devices are composed of heating parts and stirring parts. By means of the equipment and method, multiple aluminum alloy material components made of different materials can be proportioned at a time, mechanical automation is completely achieved, and the characteristics of being high in proportioning precision and repeatability, high in smelting temperature field consistency and the like are achieved; and high-throughput preparation of the aluminum alloy can also be realized, and preparation of genome aluminum alloy samples of various batches can be carried out in various environments.

Owner:苏州慧金新材料科技有限公司

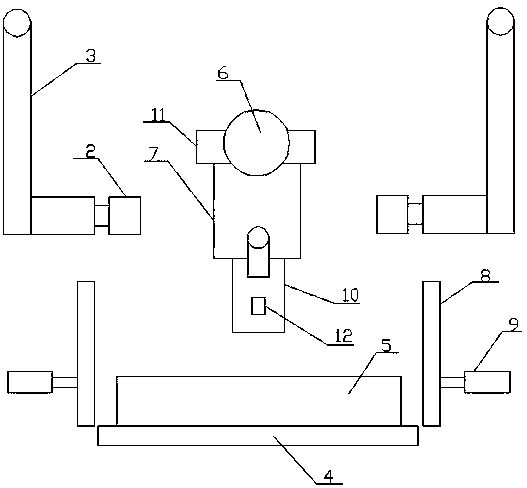

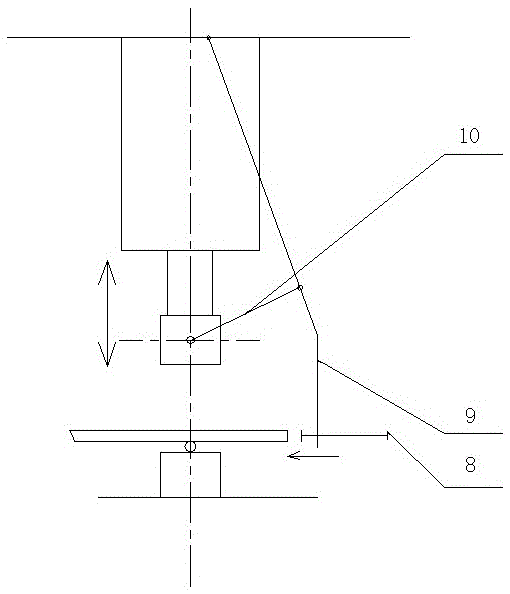

Workpiece arranging and feeding mechanism

InactiveCN108161384AAccurate and controllable reciprocating rangeReasonable structural designMetal working apparatusMechanical engineeringElectromagnet

The invention discloses a workpiece arranging and feeding mechanism and belongs to the field of workpiece assembling and machining machinery. A horizontal moving support of the workpiece arranging andfeeding mechanism is slidably arranged on the upper side of a fixing base in the horizontal direction. A horizontal moving connection rod is horizontally arranged between a rotating circular plate and the horizontal moving support. A lifting support is horizontally and slidably arranged on a lifting guide rod in the vertical direction. The output end of a lifting air cylinder is fixed to the upper side of the lifting support. The upper side of the lifting support is vertically and evenly provided with a plurality of material arranging cylinders. A feeding circular plate is horizontally and rotationally connected to a rotating base. The outer side of the upper portion of the feeding circular plate is horizontally and fixedly provided with a feeding rack which is matched with a rotating gear. The output end of a feeding air cylinder is horizontally and fixedly provided with a discharging support. The upper side of the discharging support is evenly provided with a plurality of annular electromagnets in the horizontal direction, and the annular electromagnets are matched with the material arranging cylinders. The workpiece arranging and feeding mechanism is reasonable in structural design, workpieces can be arranged to a needed feeding station through reciprocating vibration, synchronous feeding of multiple workpieces is achieved, and using demands are met.

Owner:TONGXIANG SHENGHUI PRECISION MACHINERY

Dual-time judgement electromagnetic propulsion type fruit grading device

The invention discloses a dual-time judgement electromagnetic propulsion type fruit grading device. The device comprises a fruit conveying rail. The fruit conveying rail is provided with an arc-shapeddownward sliding segment and a horizontal sliding rail segment. A stress sensor is vertically arranged on the end face of the tail end of the horizontal sliding rail segment. A blocking and pushing plate which is vertically arranged is connected with the back side of the stress sensor. Stepping motors are connected with both the two sides of the blocking and pushing plate, and are used for controlling the blocking and pushing plate to rotate for 360 degrees in the falling direction of fruits. A conveyer belt is arranged on one side of the blocking and pushing plate and corresponds to the horizontal sliding rail segment. A laser emission device and a laser receiving device are arranged on the two sides of the end face of the end, close to the blocking and pushing plate, of the conveyer belt. A plurality of electromagnetic propulsion devices are arranged on one side of the conveyer belt. Each electromagnetic propulsion device is provided with an electromagnetic propulsion block which ishorizontally arranged. Fruit separation sliding ways corresponding to the electromagnetic propulsion blocks are arranged on the other side of the conveyer belt. The dual-time judgement electromagnetic propulsion type fruit grading device carries out secondary grading according to the weight and sizes of fruits, achieves automatic recovery without damage, and is simple in structure and relativelyreasonable in cost.

Owner:HENAN UNIV OF SCI & TECH

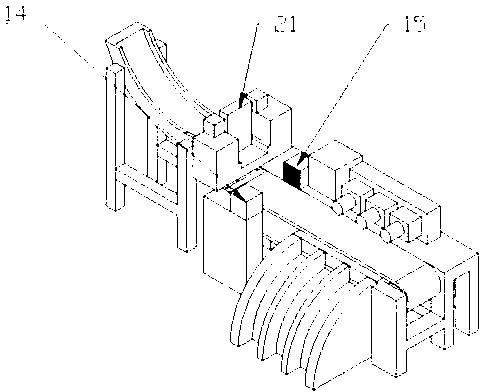

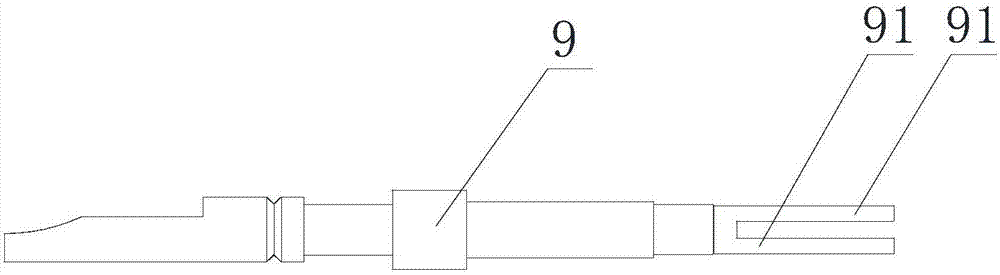

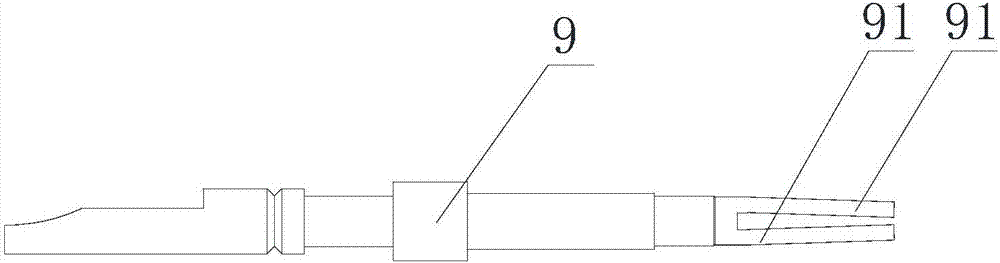

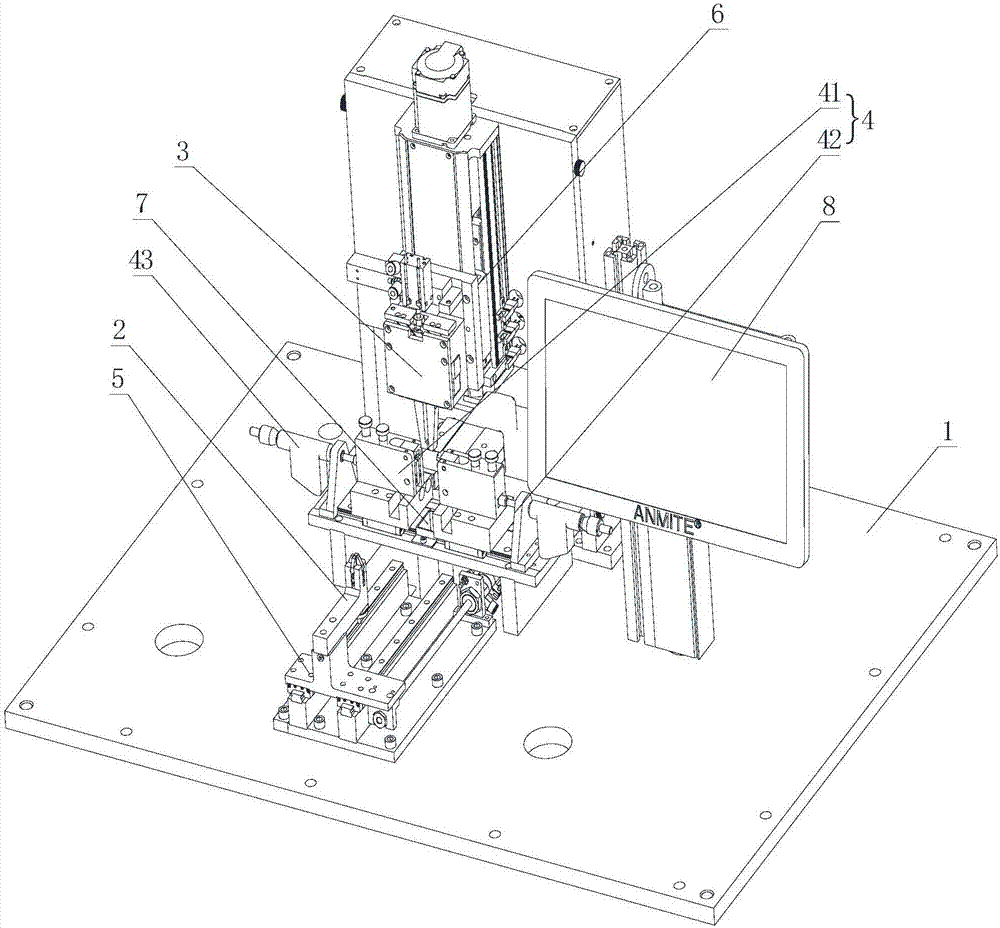

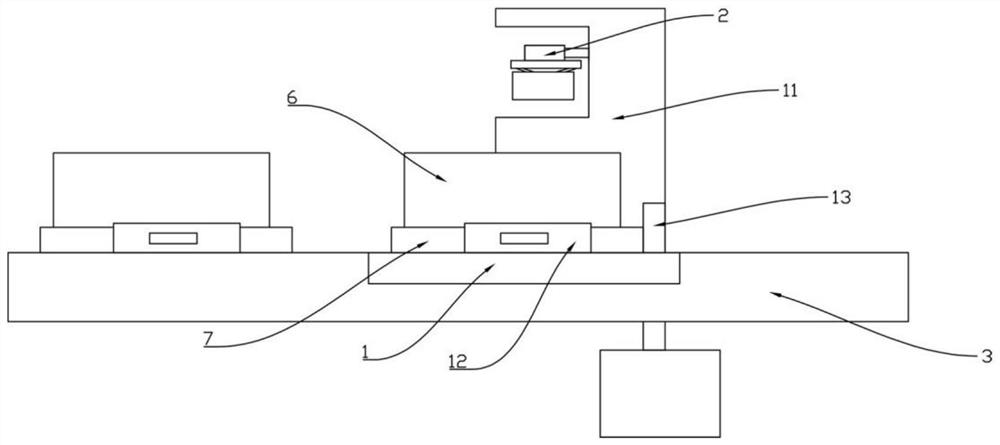

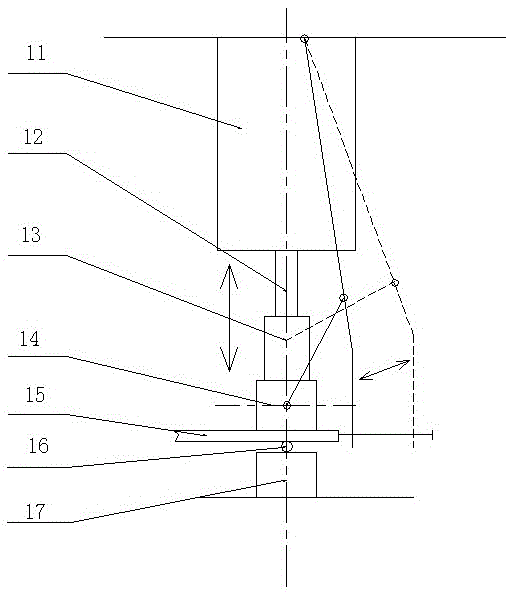

Automatic shell nosing device of adjustable connector jack

ActiveCN106981810AReduce misuseGuaranteed locking effectContact member manufacturingMotion parameterEngineering

The invention relates to an automatic shell nosing device of an adjustable connector jack. The automatic shell nosing device comprises a bottom plate, an adjustable feed mechanism, a clamping mechanism and an adjustable shell nosing mechanism, wherein the adjustable shell nosing mechanism comprises a left shell nosing assembly and a right shell nosing assembly, and the left shell nosing assembly and the right shell nosing assembly are respectively provided with an adjusting mechanism. The device is advantaged in that a jack clamped by the clamping mechanism can realize an automatic cylindrical open-slot jack shell nosing function through the shell nosing mechanism, flexible setting of shell nosing mechanical structure motion parameters can be realized, automatic shell nosing of the jack having an external diameter phi of 0.8-3mm can be realized without replacing the shell nosing mechanism, shell nosing efficiency is improved, jack reed bending angles of the left shell nosing assembly and the right shell nosing assembly are realized through the adjusting mechanism independently, independent control on the two jack reed bending angels is realized, and a problem of unstable plugging / unplugging force caused by humpback and single side defects after shell nosing because of a jack manufacturing error can be effectively avoided.

Owner:杭州航天电子技术有限公司

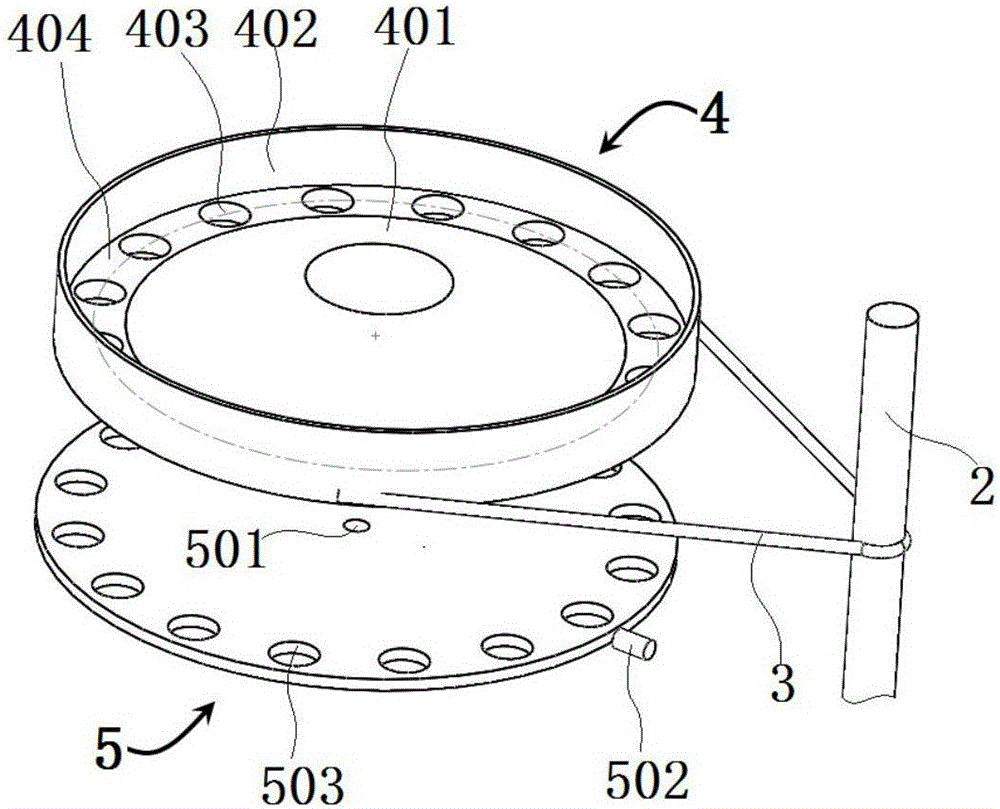

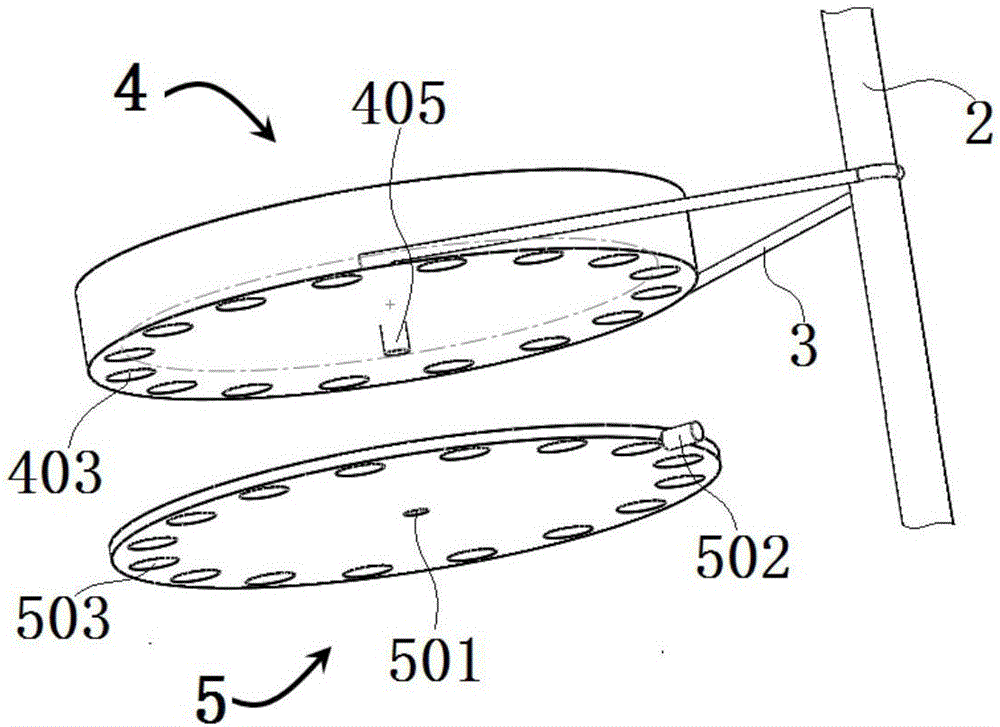

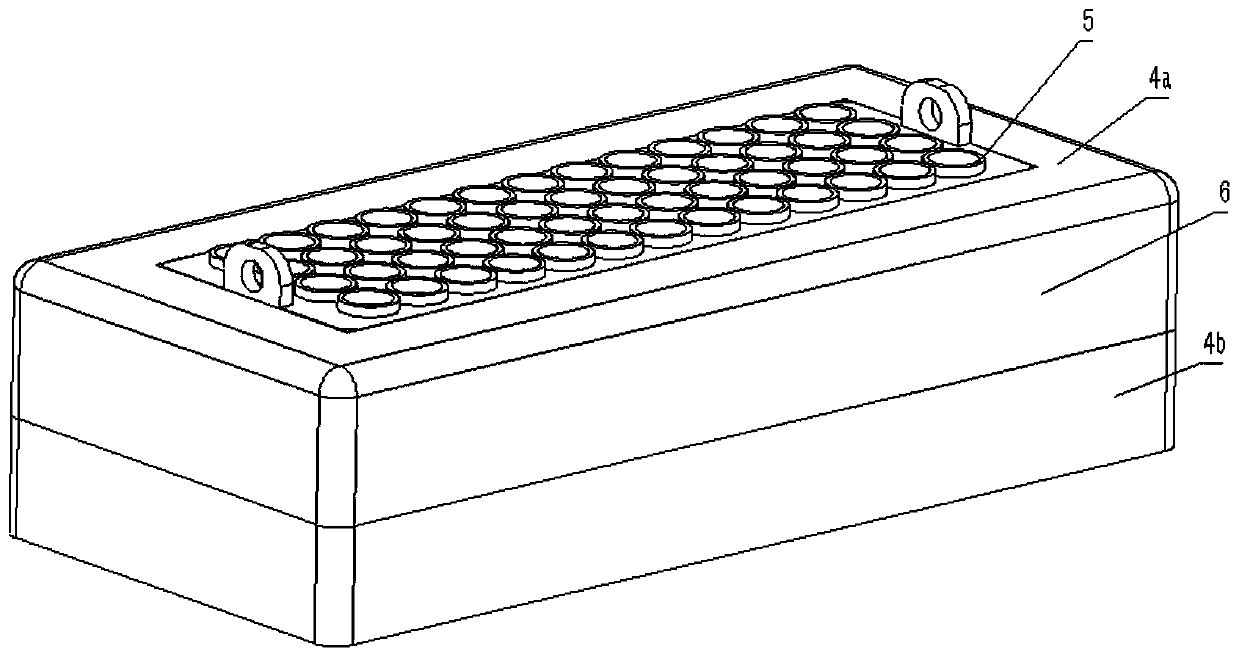

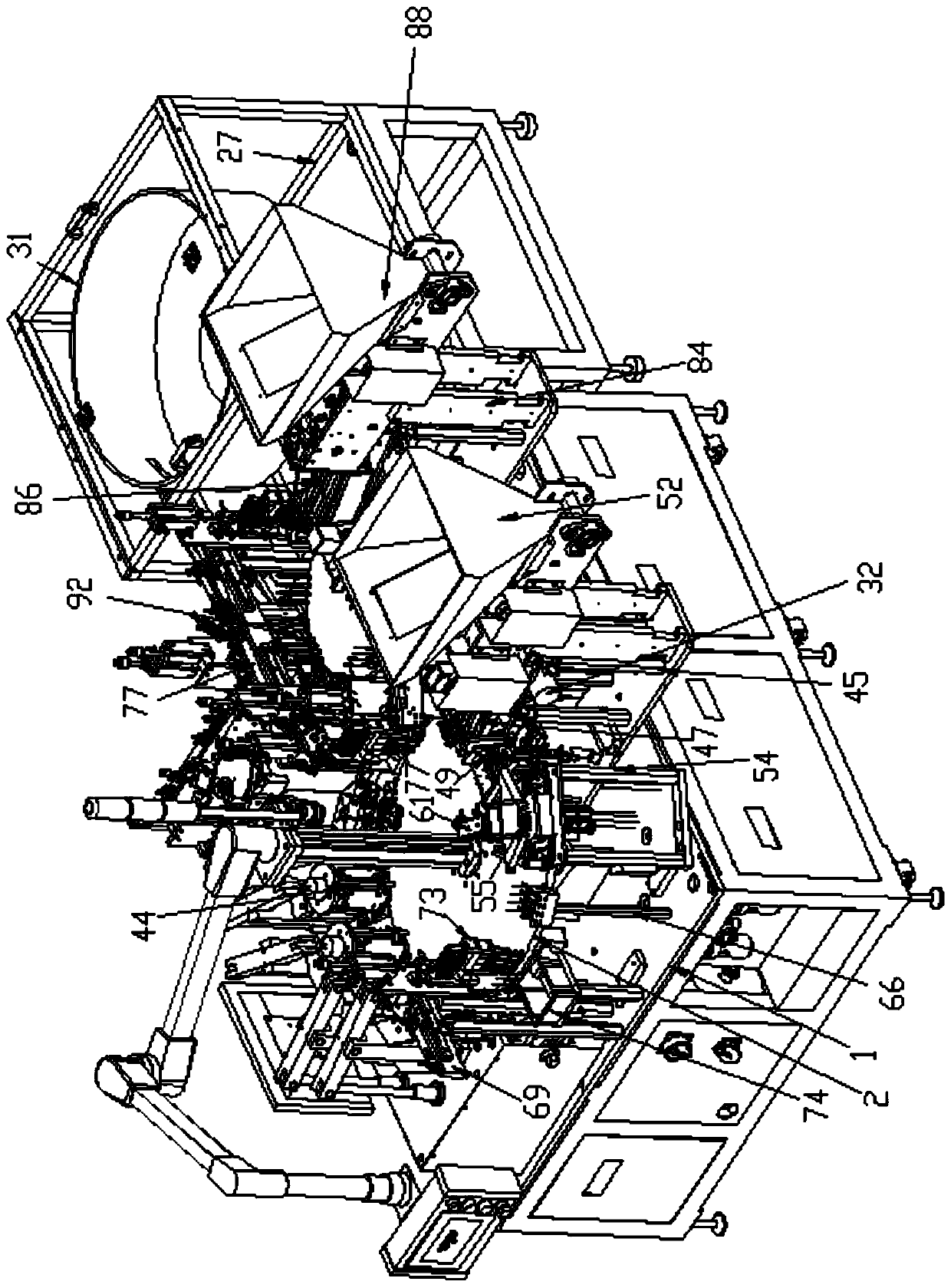

Automatic injection needle assembly machine and process for assembling injection needle by using automatic injection needle assembly machine

ActiveCN109702480AInhibit sheddingImprove the pressure effectAssembly machinesTransfer mechanismBiomedical engineering

The invention discloses an automatic injection needle assembly machine and a process for assembling an injection needle by using the automatic injection needle assembly machine. The automatic injection needle assembly machine comprises a needle feeding device, a protective sleeve feeding device and a protective cap feeding device; the needle feeding device comprises a first rotary disc in rotary connection with a table top of the automatic injection needle assembly machine, the first rotary disc is provided with a plurality of needle seat limiting molds, and a needle seat feeding mechanism, aneedle feeding mechanism, a first needle detecting mechanism, a seat removing mechanism, a needle riveting mechanism, an image detecting mechanism, a transferring mechanism and a waste removing mechanism are sequentially arranged in the rotating direction of the first rotary disc; the protective sleeve feeding device comprises a second rotary disc, the second rotary disc is provided with a plurality of needle seat limiting molds, and a needle seat receiving mechanism, a second needle detecting mechanism, a protective sleeve feeding mechanism, a protective sleeve pressing mechanism, a removingmechanism and a transfer turning mechanism are sequentially arranged in the rotating direction of the second rotary disc; and the protective cap feeding device comprises a third rotary disc, and the third rotary disc is provided with a protective sleeve needle receiving through hole group, and a protective sleeve needle receiving mechanism, an empty detecting mechanism, a protective cap feeding mechanism, a protective cap pressing mechanism and a finished product clamping mechanism are sequentially arranged in the rotating direction of the third rotary disc.

Owner:CAINA TECH CO LTD

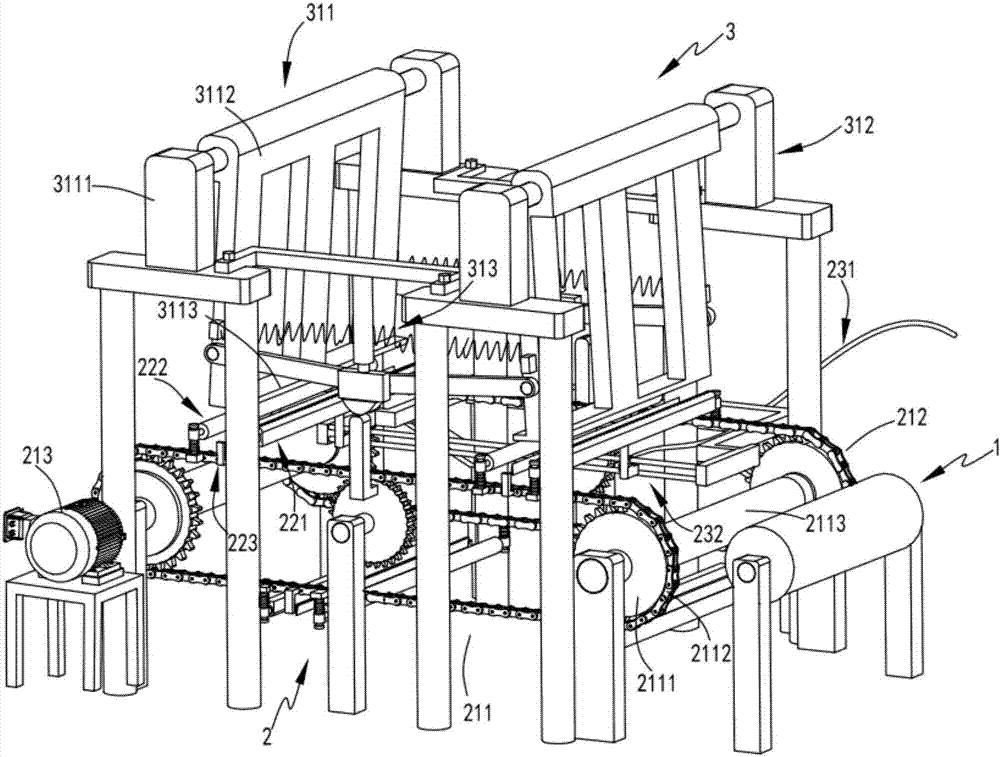

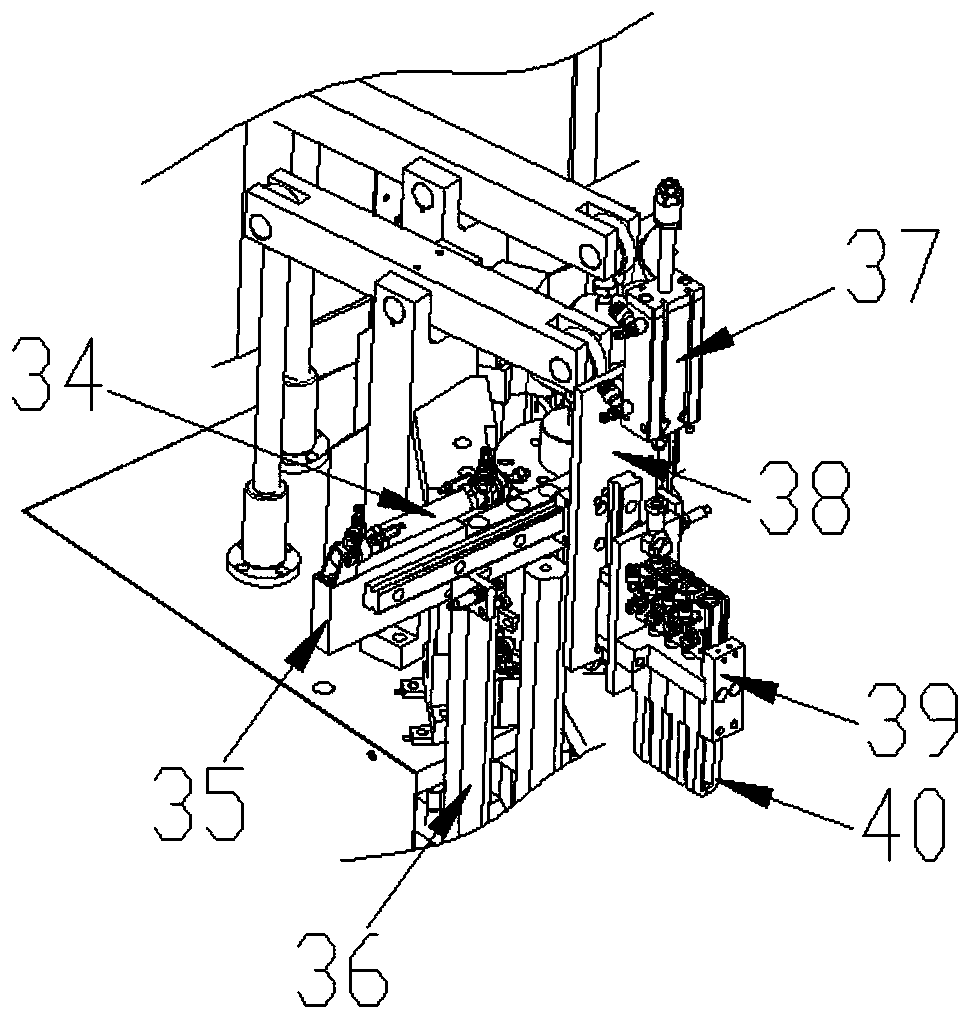

Plate stacking and automatic beating mechanism

PendingCN107902422AIncrease spacingAccurate whereaboutsConveyorsStacking articlesGround rollerEngineering

The invention discloses a plate stacking and automatic beating mechanism. The plate stacking and automatic beating mechanism comprises a transporting belt for moving plates, and the left side and theright side of the tail end of the transporting belt are both connected with roller shafts. The roller shafts are fixedly mounted on swinging frames, and the distance between the left roller shaft andthe right roller shaft is adjusted through swinging of the swinging frame. The roller shafts and the transporting belt are consistent in height, a rail is arranged on the ground between the left roller shaft and the right roller shaft, and a trolley is arranged on the rail. A supporting rod is arranged above the rail, and a vertically-downward baffle is arranged on the supporting rod. The plates falling on the trolley are slapped, and thus the plates on the trolley are tidy and orderly.

Owner:安徽戎发冲压机器人有限公司

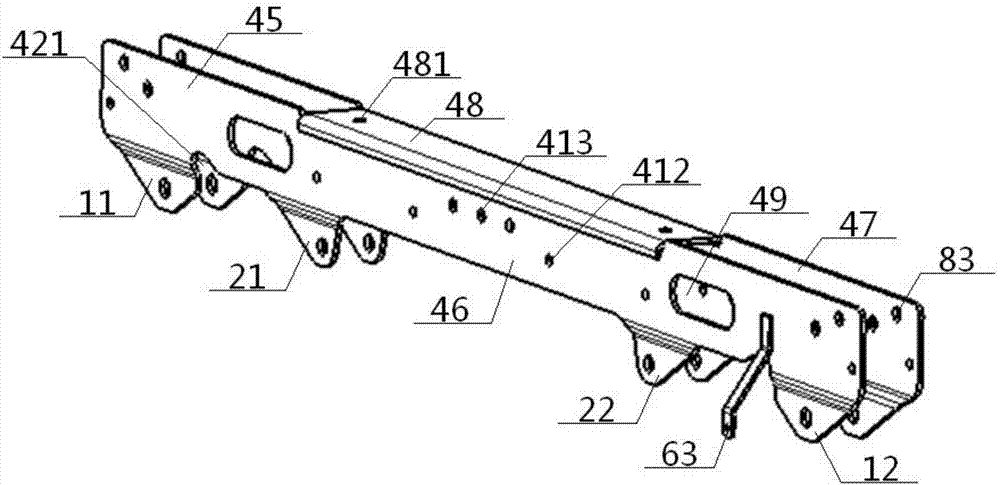

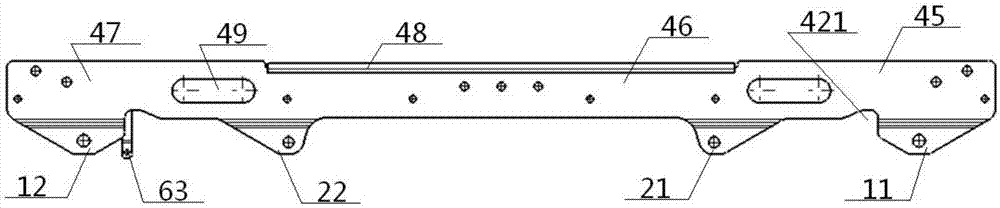

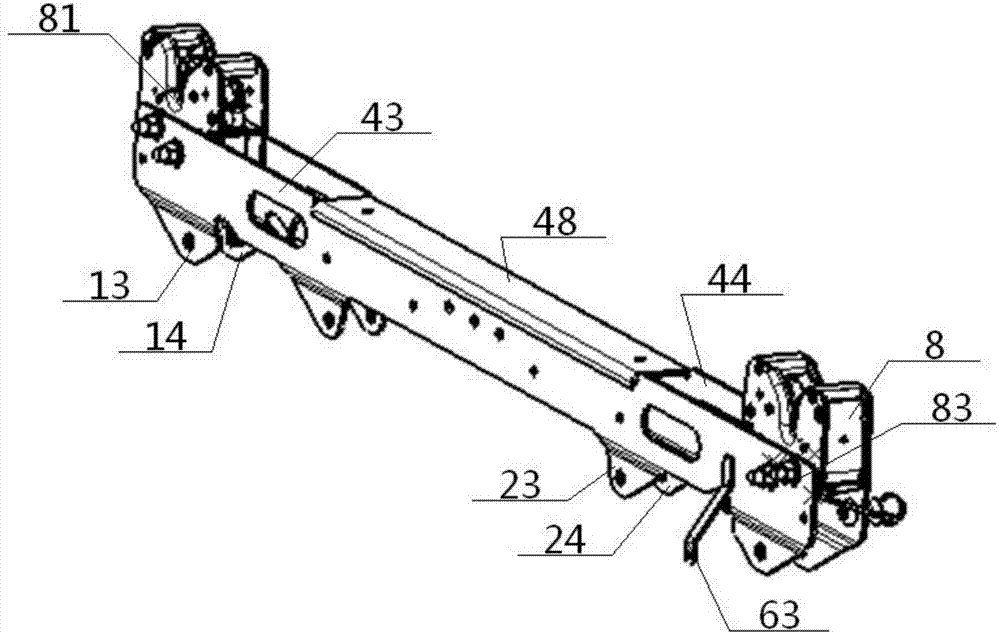

Suspension beam assembly for rear suspension

PendingCN107499396AStrong buffer functionEasy to fixLoading-carrying vehicle superstructuresClassical mechanicsStructural engineering

A suspension beam assembly for a rear suspension comprises a suspension beam body and a first left connecting portion, a second left connecting portion, a second right connecting portion and a first right connecting portion which are sequentially connected along the bottom of the suspension beam body. The suspension beam body is formed by clamping a front floating beam plate and a rear floating beam plate of the same structure, a hydraulic lock is clamped to portion between the left and right ends of the front floating beam plate, a hydraulic lock is clamped to the portion between the left and right ends of the rear floating beam plate, inward concave lock grooves are formed in the portions, located above the suspension beam body, of the hydraulic locks, lock hooks are arranged inside the lock grooves, and the front and rear floating beam plates each comprise a left panel, a middle panel and a right panel which are sequentially connected, wherein the widths of the left and right panels are larger than the width of the middle panel, and an overlay plate, a constraint hole, a pipeline gap, an oval through hole or a height valve adjusting rod support are arranged on the suspension beam body. The suspension beam assembly is good in stability, the falling fixing accuracy of a cab can be ensured, the manufacturing and installation costs are low, and functionality is high.

Owner:DONGFENG COMML VEHICLE CO LTD

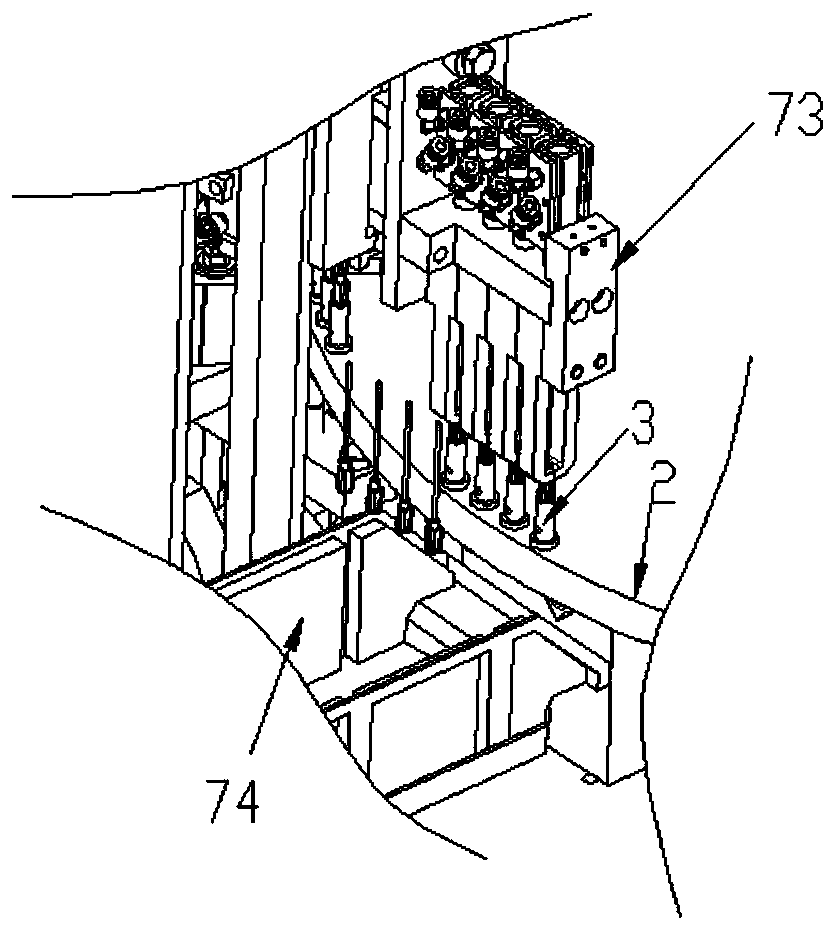

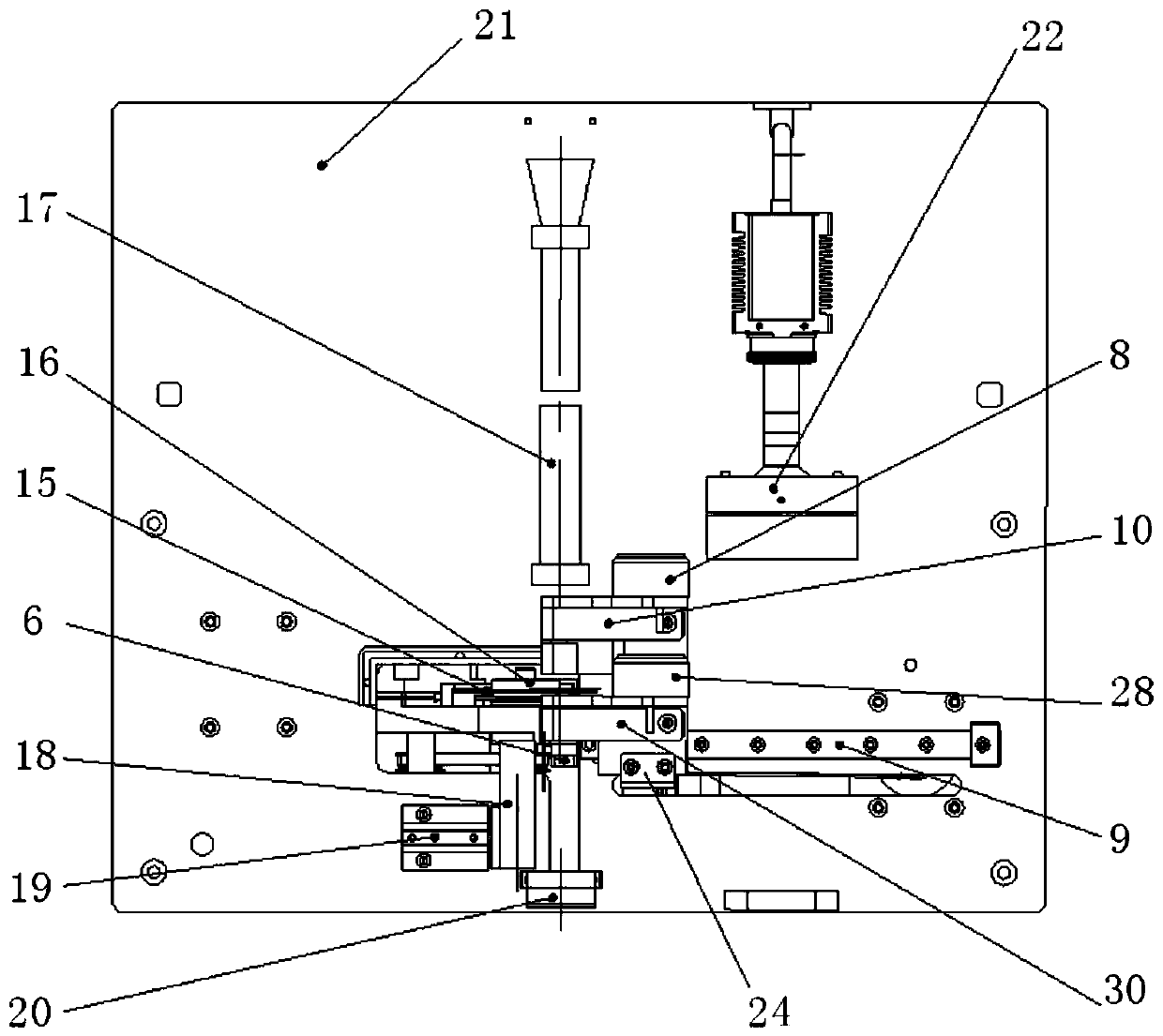

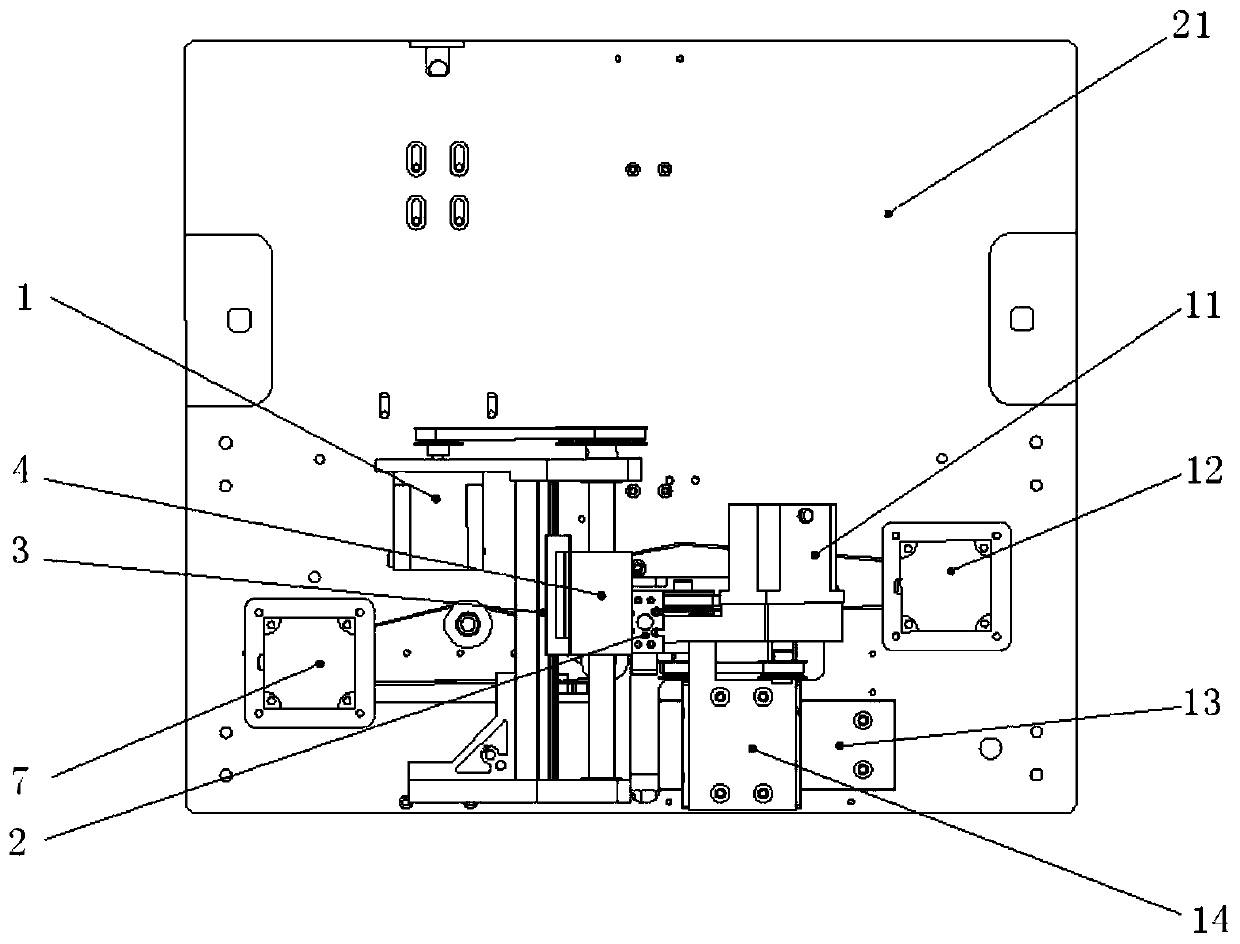

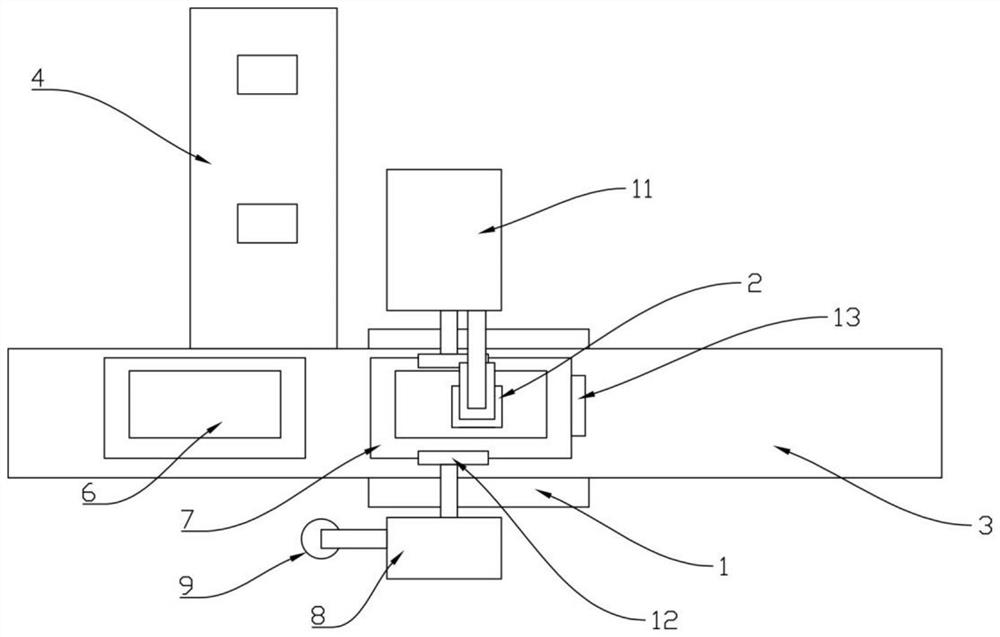

Filter stick cutting and section detecting device

PendingCN111280477AReasonable layoutCompact structureCigarette manufactureStructural engineeringControl theory

The invention discloses a filter stick cutting and section detecting device which comprises a fixed base plate, and a filter stick guide mechanism, a positioning mechanism, a clamping mechanism, a cutting mechanism and a section detecting mechanism which are arranged on the front side surface and the rear side surface of the fixed base plate. The filter stick guide mechanism comprises upper and lower guide pipes, the upper guide pipe is vertically fixed to the upper portion of the front side face of the base plate, and the lower guide pipe is arranged on the lower portion of the front side face of the base plate in a left-right moving mode. A positioning supporting plate of the positioning mechanism can be driven by a second power mechanism to move to the position below the upper guide pipe. The clamping mechanism comprises an upper clamping jaw and a lower clamping jaw, and the lower clamping jaw can be driven by a third power mechanism to move to the position below the image acquisition unit to achieve section detection. A blade of the cutting mechanism cuts the filter stick under the control of a fourth power mechanism. The section detection mechanism detects the section of thefilter stick clamped by the lower clamping jaw through the image acquisition unit. The mechanisms are arranged on the front side face and the rear side face of the base plate, accurate falling, positioning cutting and section detection of the filter stick can be achieved, layout is reasonable, and the structure is compact.

Owner:郑州润丰德科技有限公司

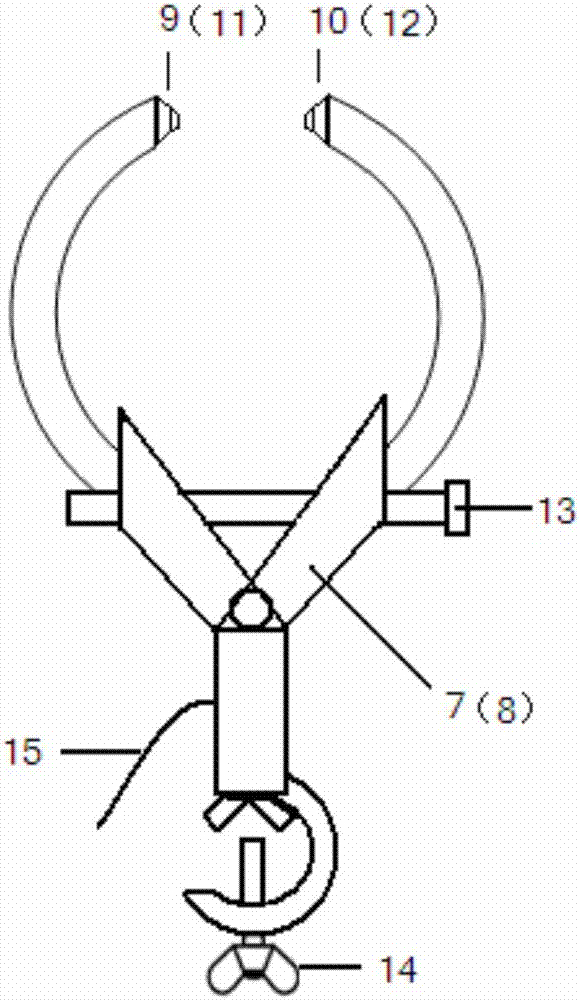

Experiment instrument for measuring liquid viscosity coefficient by pipe clamp photogates

ActiveCN107247009AAccurate whereaboutsReduce experimental errorFlow propertiesLaser transmitterGraduated cylinder

The invention relates to an experiment instrument for measuring liquid viscosity coefficient by pipe clamp photogates. The experiment instrument comprises a steel bead, a measuring cylinder, a measuring cylinder cover and at least two pipe clamp photogates; two grooves are formed in the two sides of the measuring cylinder oppositely; at least two pairs of conical grooves are formed in the grooves; each pipe clamp photogate comprises two clamping arms, a laser transmitter, a laser emergent head, a laser receiver, a laser receiving head, an adjusting screw and a fixing device; a laser emergent head and the laser receiving head are movably arranged at the free ends of the two clamping arms; the laser emergent head and the laser receiving head are circular truncated cone-shaped, so as to be matched with the conical grooves in shape. The experiment instrument avoids the tedious operation that the position of the receiver needs to be adjusted again after multiple-time refraction of laser, the laser emergent head and the laser receiving head are inserted into the conical grooves to realize automatic positioning, and the measuring precision and the efficiency are improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

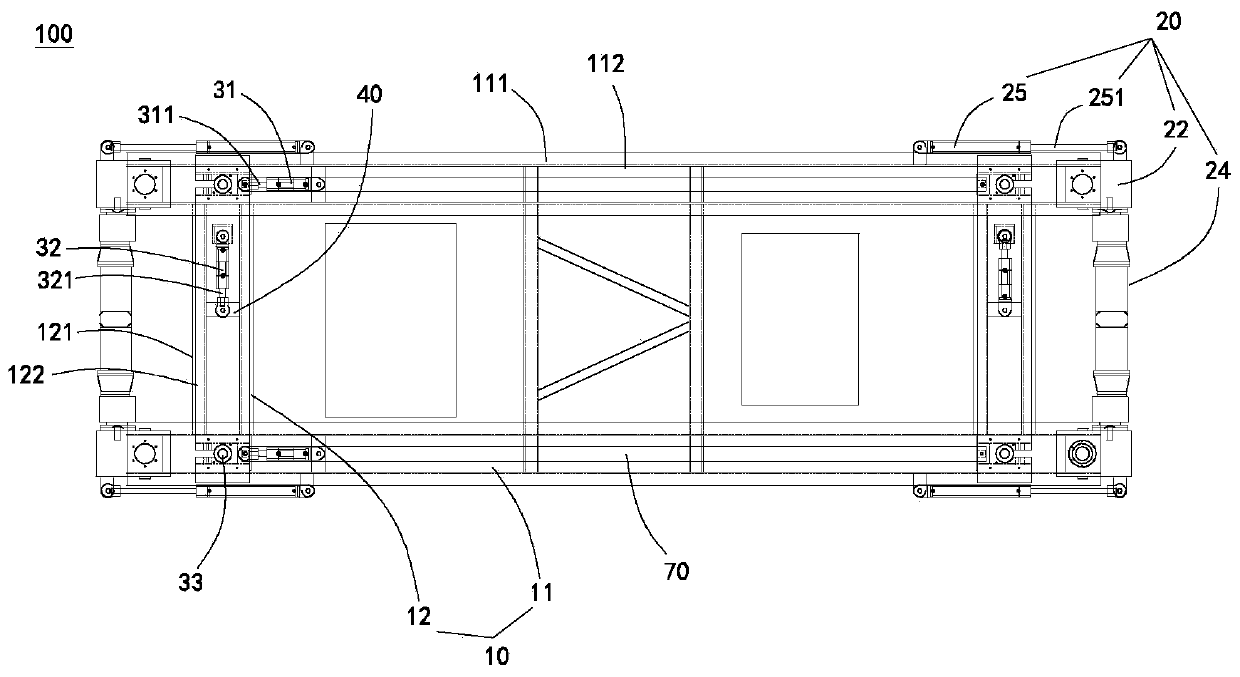

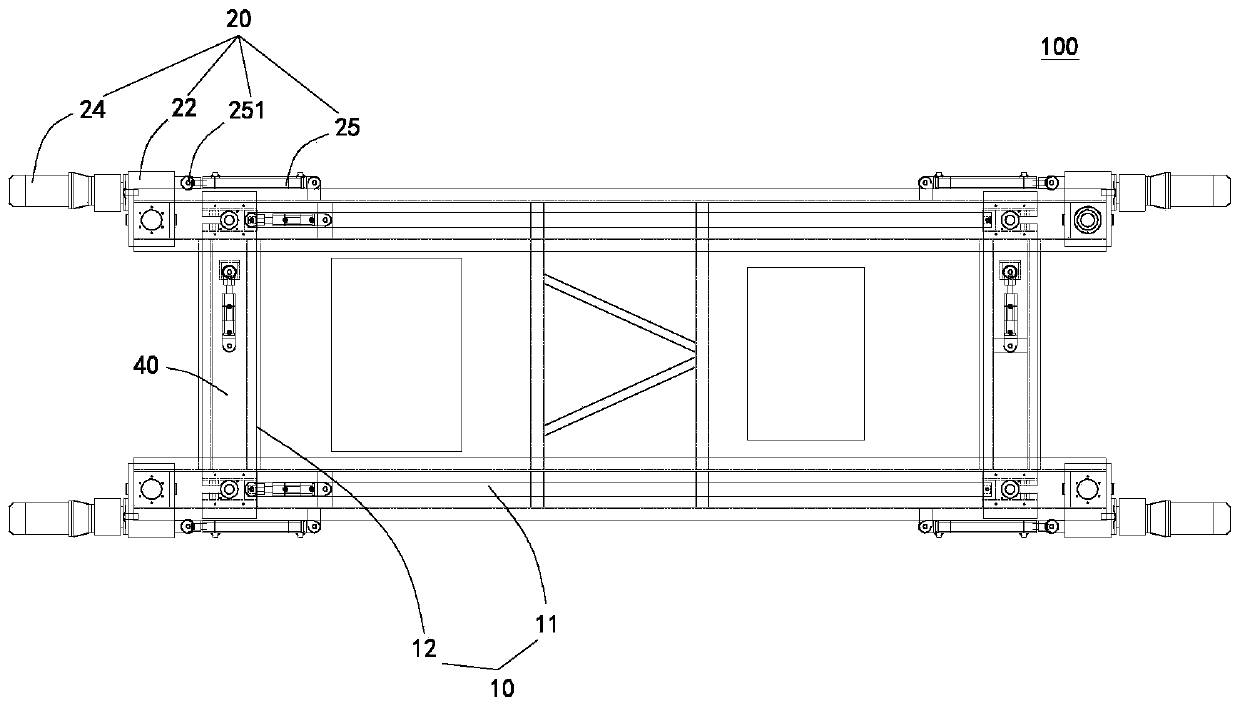

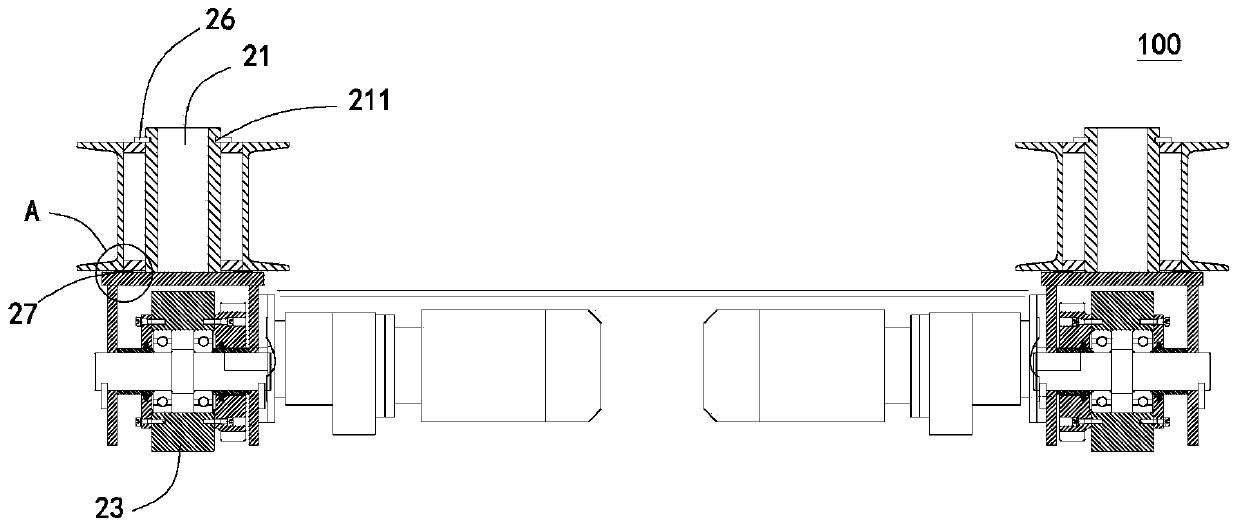

Box girder outer side mold plate loading and unloading trolley and mold plate loading and unloading method thereof

PendingCN111531689ASimple counterpointRealize vertical adjustmentDischarging arrangementMould separation apparatusVehicle frameArchitectural engineering

The invention discloses a box girder outer side mold plate loading and unloading trolley and a mold plate loading and unloading method thereof. The trolley comprises a trolley frame, a moving mechanism, a longitudinal hydraulic jack, a lateral hydraulic jack and a vertical hydraulic jack; bearing plates are arranged on two opposite sides of the top of the trolley frame and can make translation inthe horizontal direction; the moving mechanism is installed on the trolley frame and is for driving the trolley frame to move longitudinally and horizontally and turn; the longitudinal hydraulic jackis hinged on the trolley frame; the longitudinal hydraulic jack is connected with the bearing plates in a hinged mode for driving the bearing plates to make longitudinal translation; the lateral hydraulic jack is hinged on the trolley frame; the lateral hydraulic jack is connected with the bearing plates for driving the bearing plates to make lateral translation; and the vertical hydraulic jack ishinged on the bearing plates and can stretch along the direction perpendicular to the top of the bearing plates. According to the scheme, aligning installation of a box girder outer side mold plate is simple and easy, and a dilemma existing according to the prior art is practically solved.

Owner:THE SECOND ENG COMPANY OF CCCC FOURTH HARBOR ENG +1

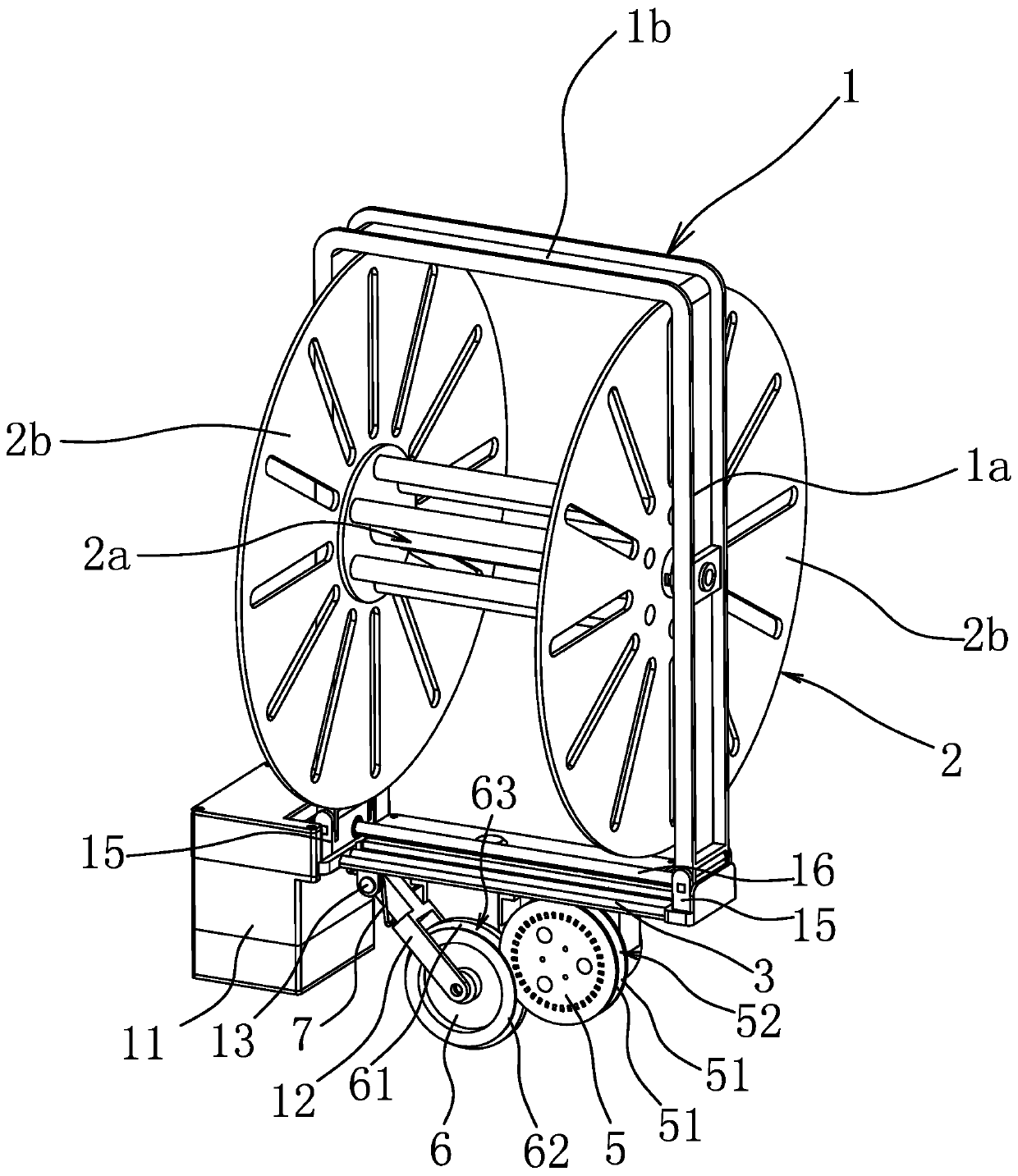

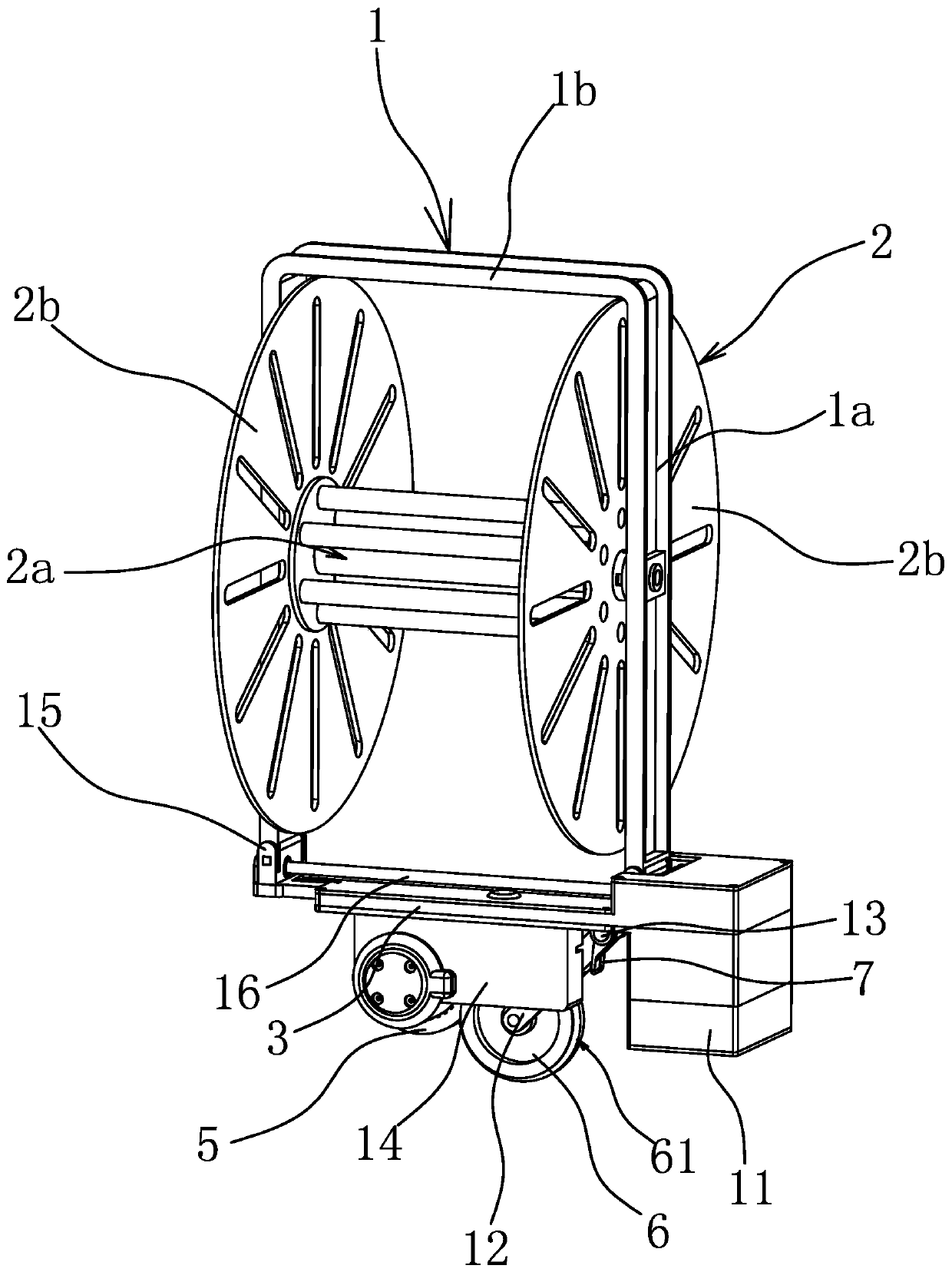

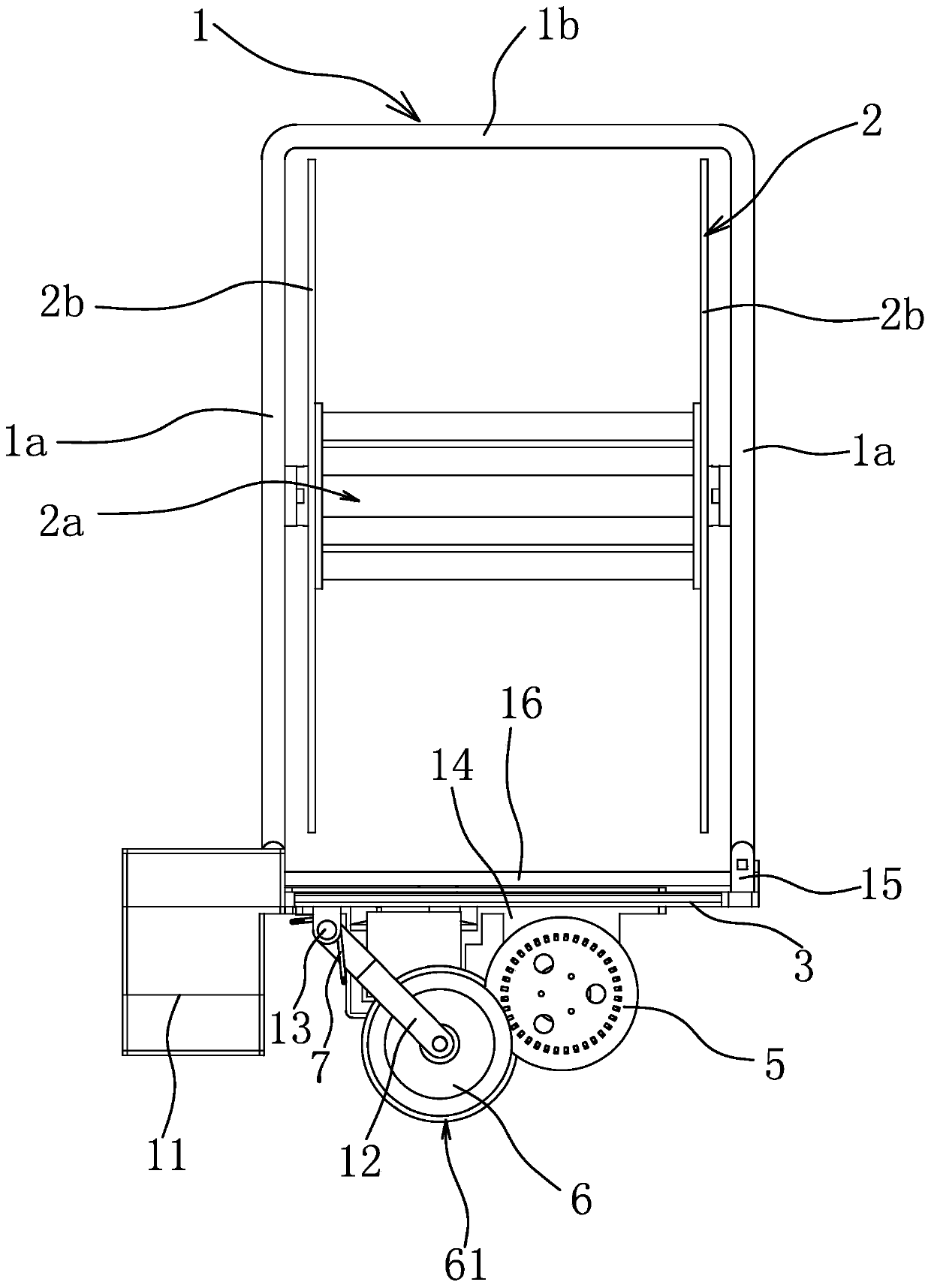

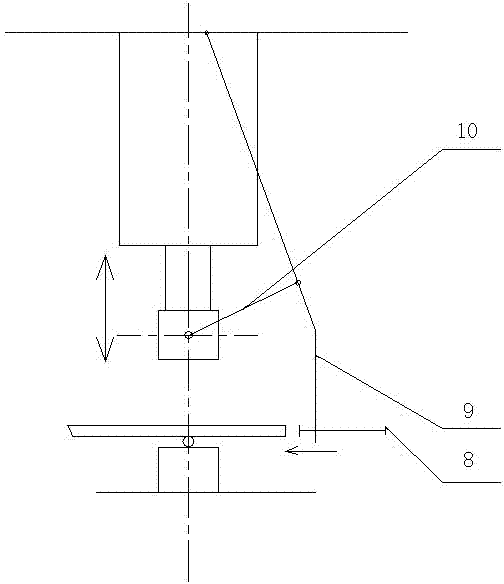

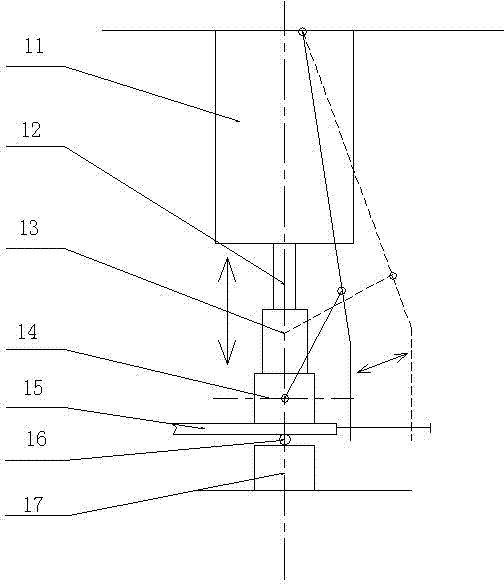

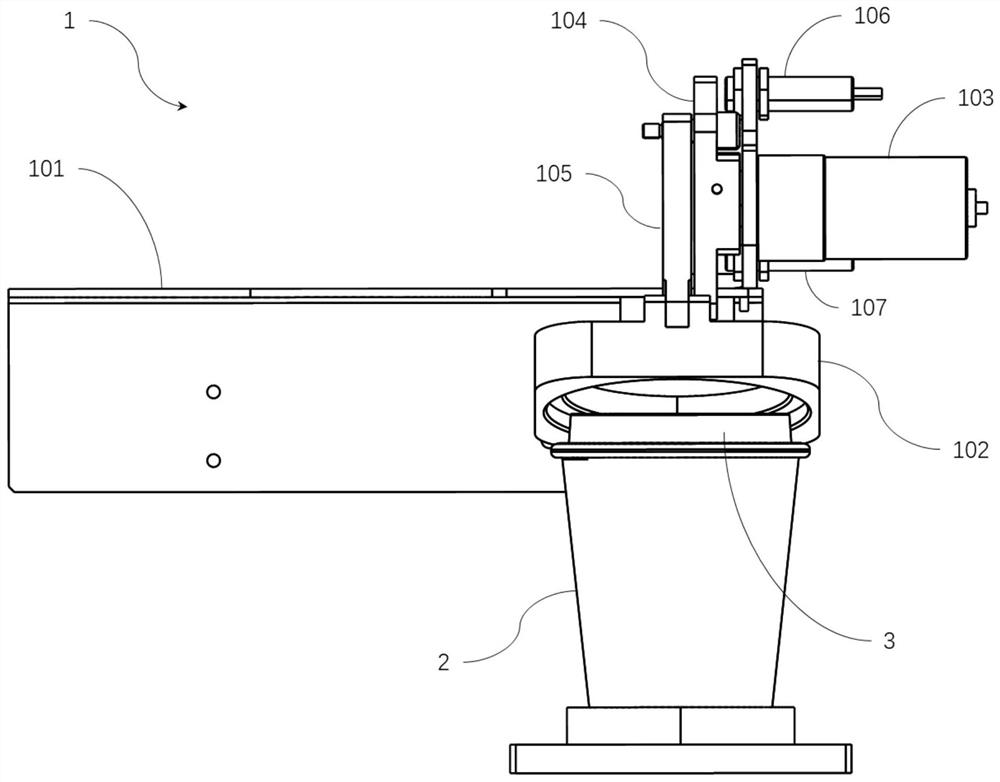

Rope releasing device for unmanned aerial vehicle

The invention provides a rope releasing device for an unmanned aerial vehicle, and belongs to the technical field of fire rescue equipment. The rope releasing device solves the problem that an existing rope releasing device for the unmanned aerial vehicle is difficult to smoothly and efficiently carry out high-rise pulling rope arrangement. The rope releasing device for the unmanned aerial vehiclecomprises a rope disc support used for being connected with the unmanned aerial vehicle, a rope disc used for winding a pulling rope is rotationally arranged on the rope disc support, a detachable throwing frame is further connected to the rope disc support, the throwing support is provided with a main rotating component and a rope releasing driving part used for driving the main rotating component to rotate, and a driven component used for pressing the pulling rope leading out of the rope disc against the main rotating component is rotationally arranged on the throwing frame. According to the rope releasing device for the unmanned aerial vehicle, the arrangement of the pulling rope in the high-rise fire-fighting rescue fire can be efficiently carried out, and the problem that due to thetrouble of the arrangement of the pulling rope and the waste of the time, the best fire-fighting time is missed is avoided.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

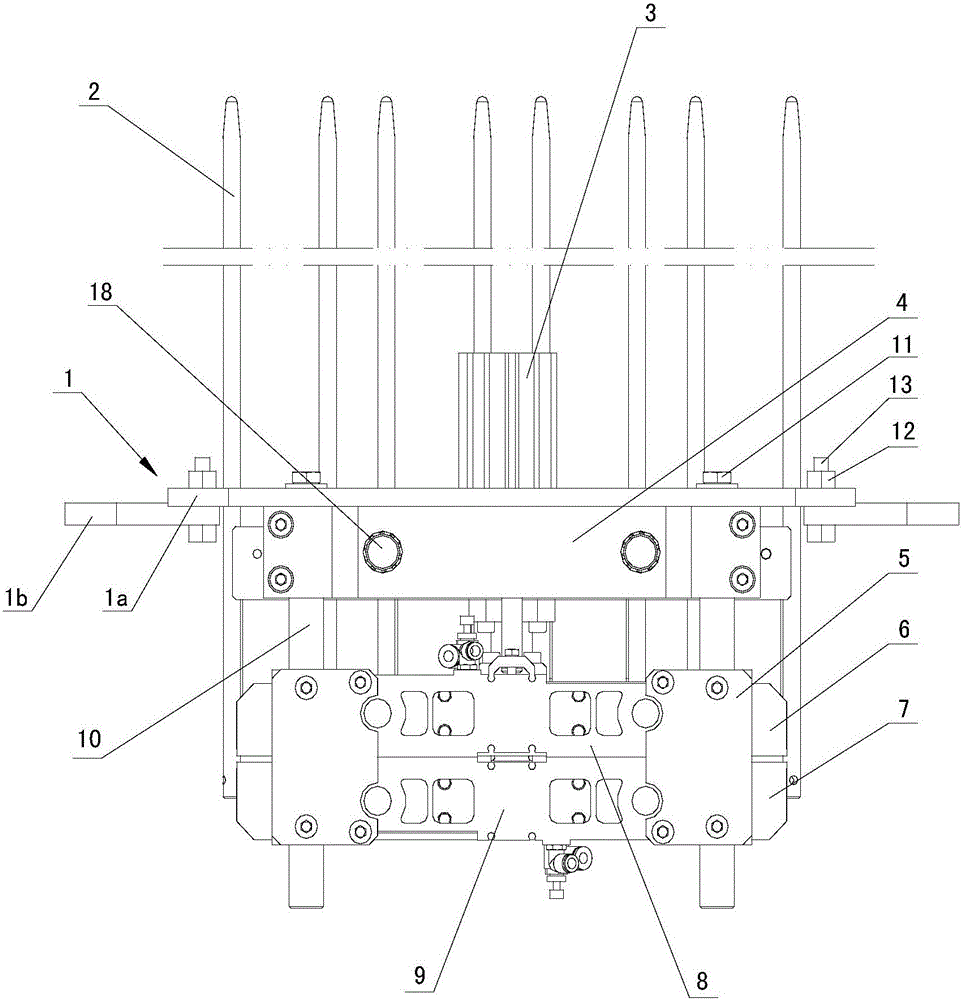

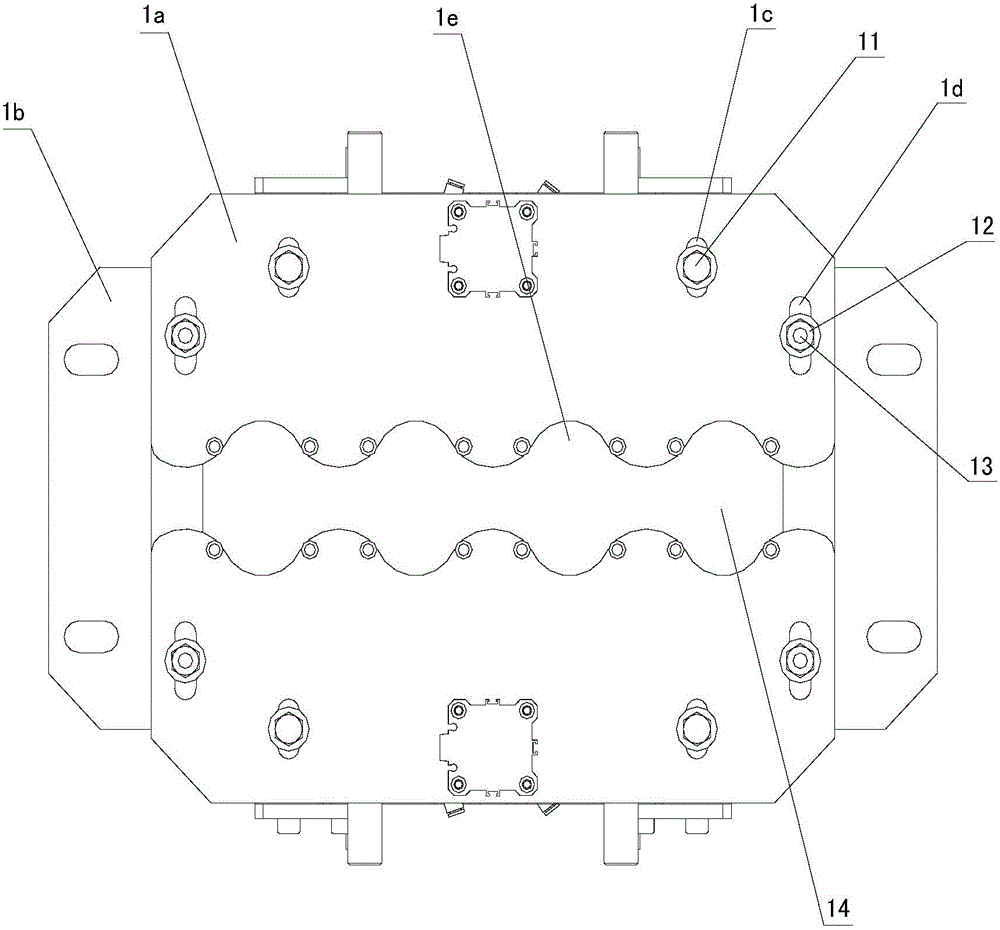

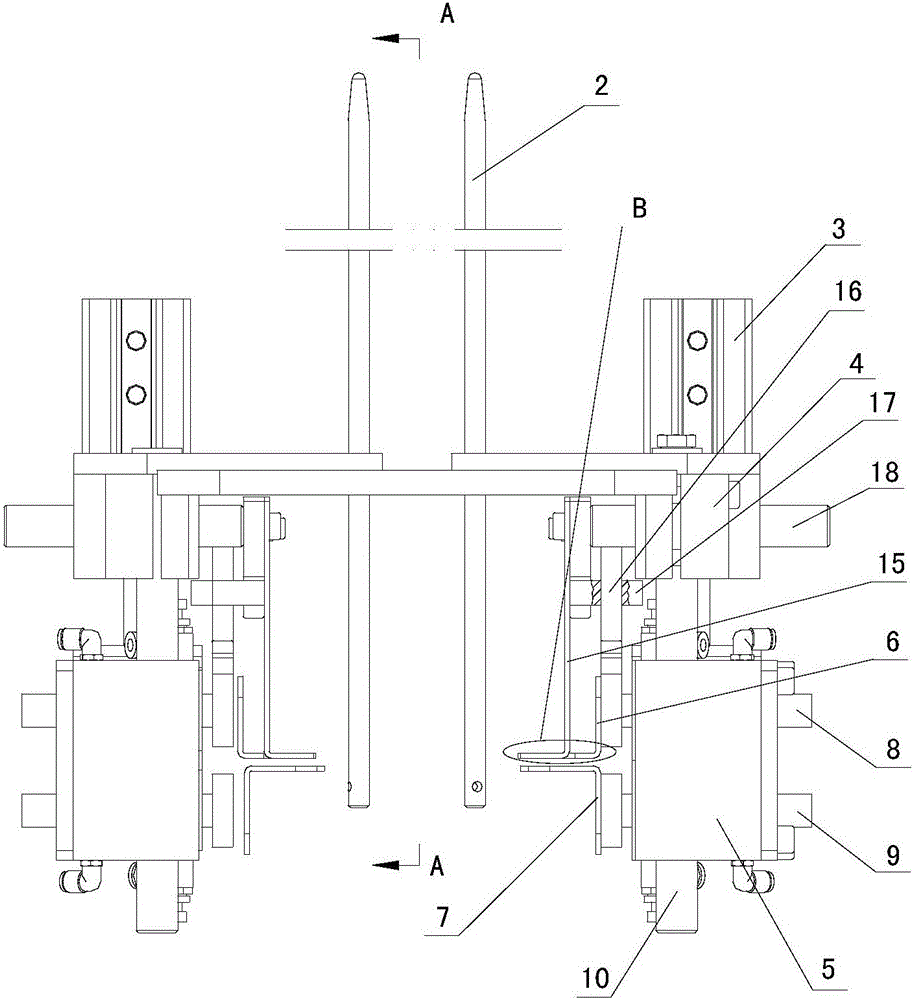

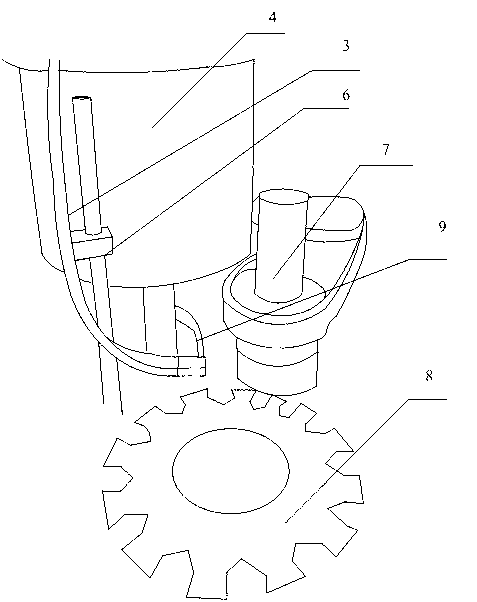

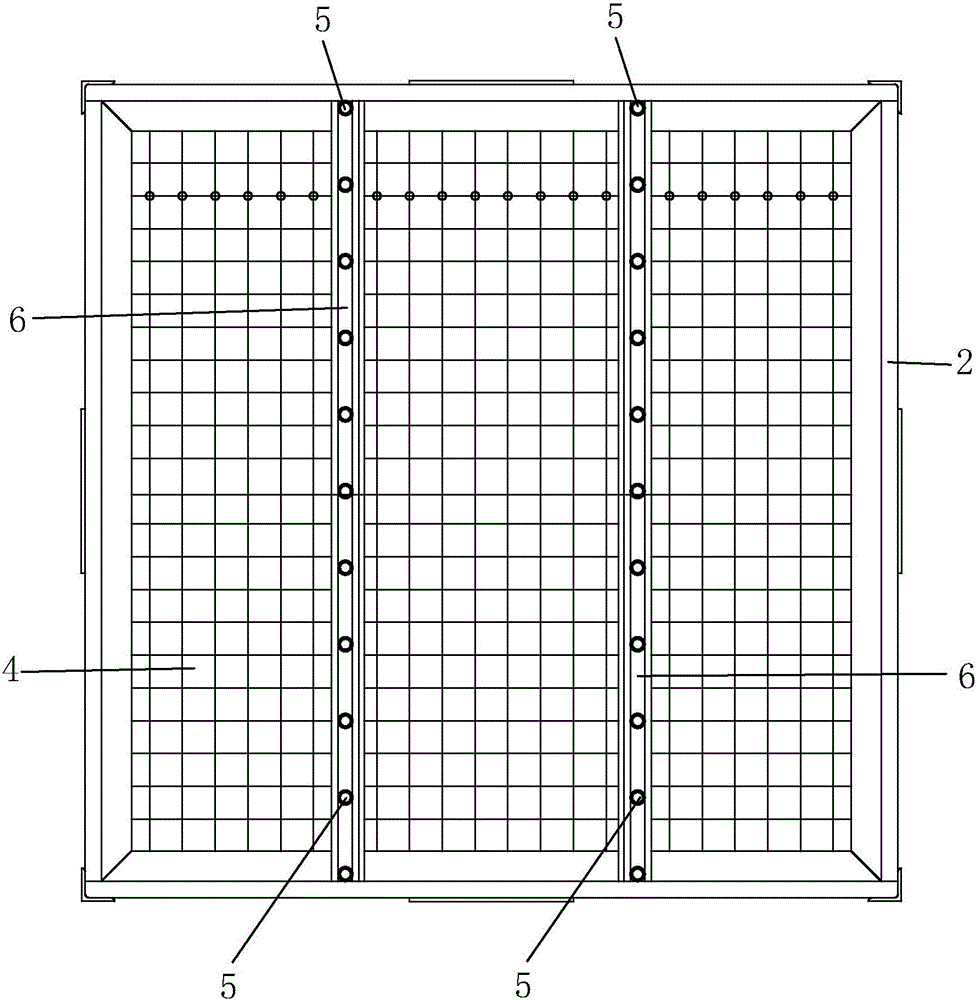

Weft wire locating device of steel bar welding mesh

ActiveCN103692080AAccurate whereaboutsGuarantee product qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRebar

The invention discloses a weft wire locating device of a steel bar welding mesh. The weft wire locating device comprises a fixing post, a connecting plate, an oscillating rod and a pushing plate, wherein the front end of the fixing post is connected to a welding mesh main machine, the rear end of the fixing post is hinged to the connecting plate which is horizontally arranged, the other end of the connecting plate is hinged to the oscillating rod, the upper end of the oscillating rod is connected to the welding mesh main machine, and the lower end of the oscillating rod is connected with the pushing plate. When the weft wire locating device works, welding weft wires can be fixed by a magnetic limiting plate after the welding weft wires freely fall from a weft wire storeroom, an upper electrode block is driven to move downwards to prepare for welding by an air cylinder rod, the weft wire locating device does corresponding motion during a falling process, the pushing plate is enabled to move and push the weft wires to be in position, and the welding can be carried out when the weft wires reach to needed positions. According to the weft wire locating device disclosed by the invention, accurate falling position of the weft wires can be ensured, thus the weft wires are flush with each other when the steel bar welding mesh is in welding, and the attractive appearance of a product is ensured while the quality of the product is ensured.

Owner:ANHUI BRC & MA STEEL WELDMESH +1

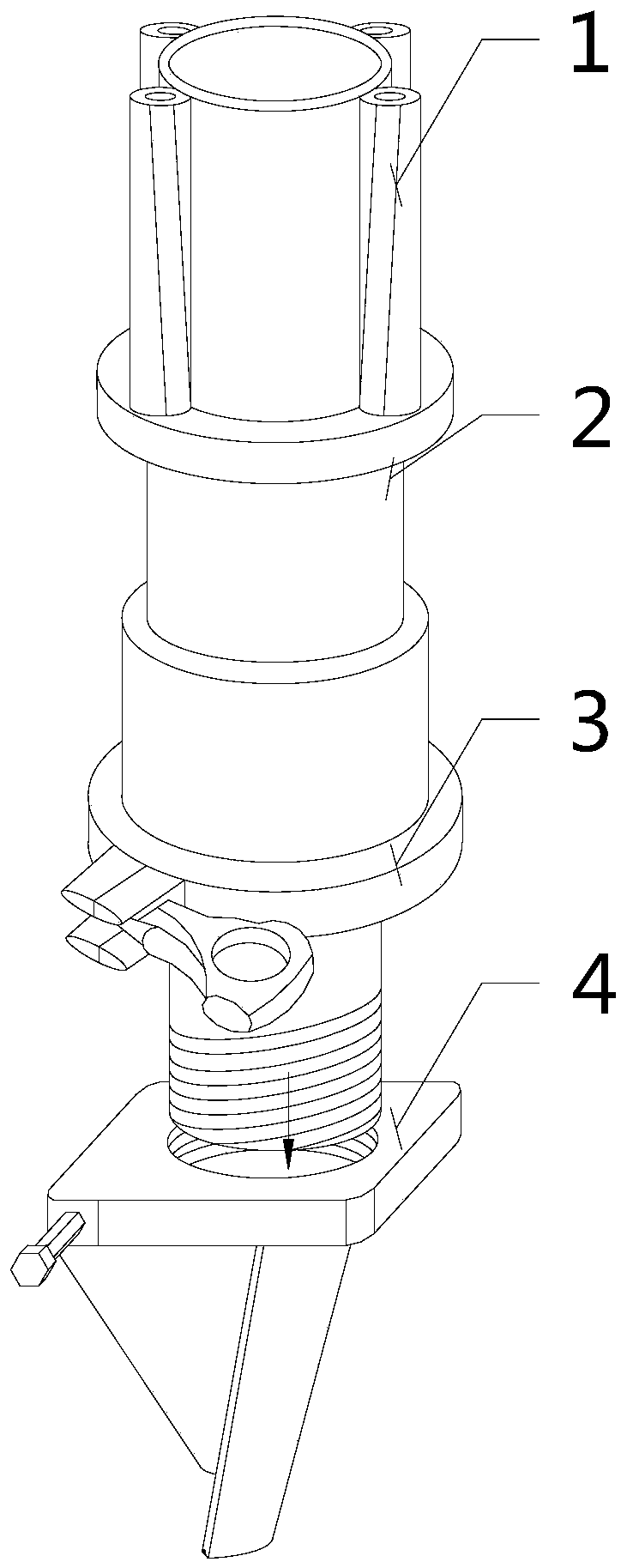

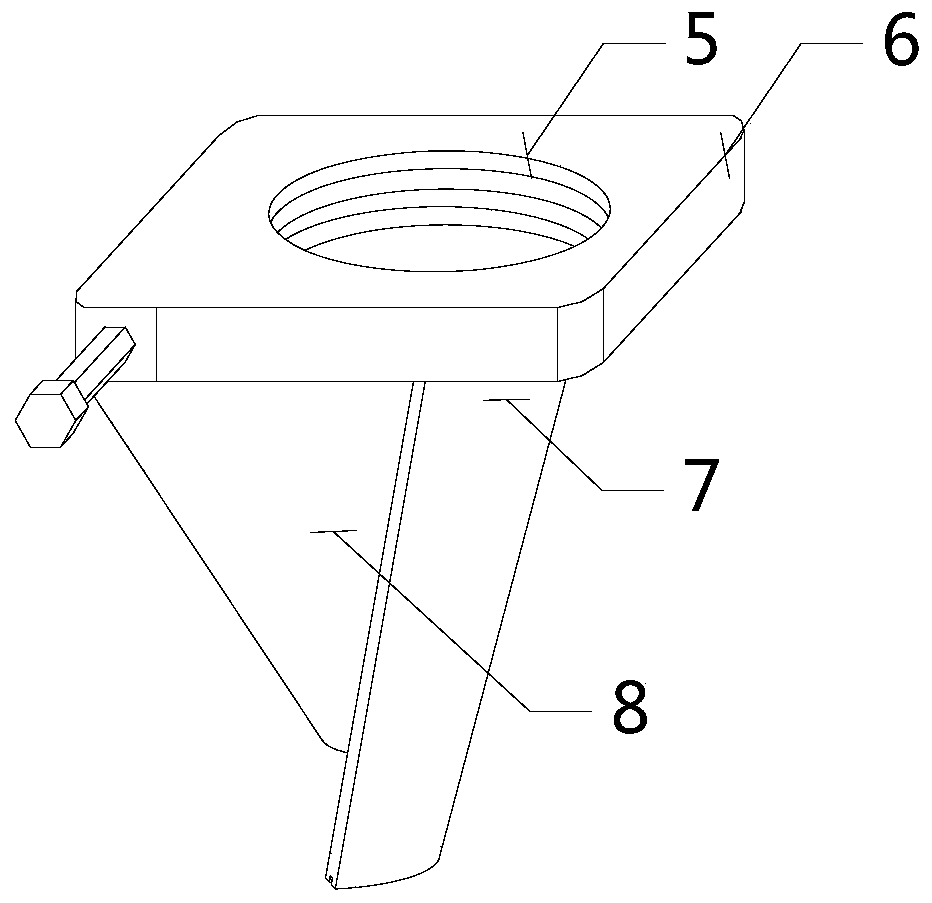

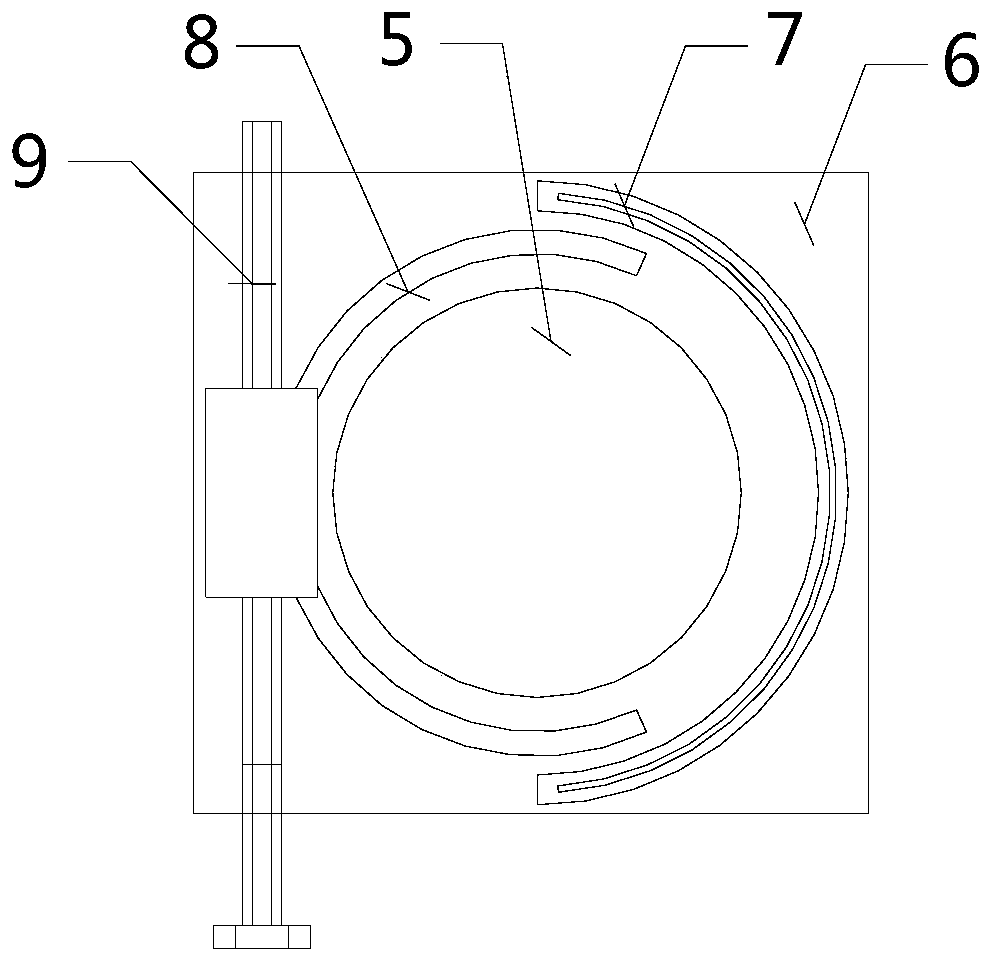

Culture medium filling device

The invention discloses a culture medium filling device. The device is composed of a material pipe, a filling head and the like, the filling head structurally comprises a connecting column, a connecting cylinder, a movable buckle and a guiding mechanism, the connecting column is installed at the top of the connecting cylinder, the other end of the connecting cylinder is in threaded connection withthe guiding mechanism, the movable buckle is installed in the middle of the connecting cylinder, the guiding mechanism is composed of a threaded opening, a leveling plate, a first arc plate and a second arc plate, and the threaded opening is formed in the middle of the leveling plate. According to the device, a mode that metal wires cooperate with screen cloth is adopted, when a culture medium isfilled, a net bag can be straightened due to the fact that the culture medium is contained, materials fall vertically, and along with gradual reduction of the filling content of the culture medium, the metal wires recover gradually to be in a semicircular bag shape to hold residual culture medium liquid drops to avoid continuous dripping.

Owner:常荣杰

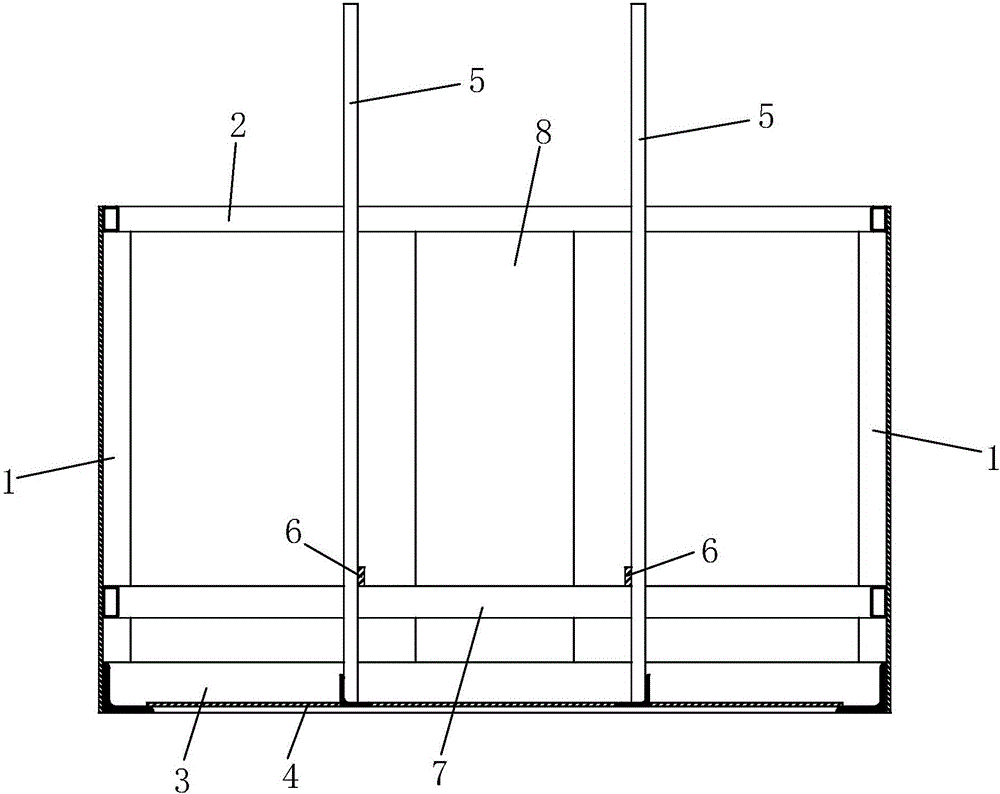

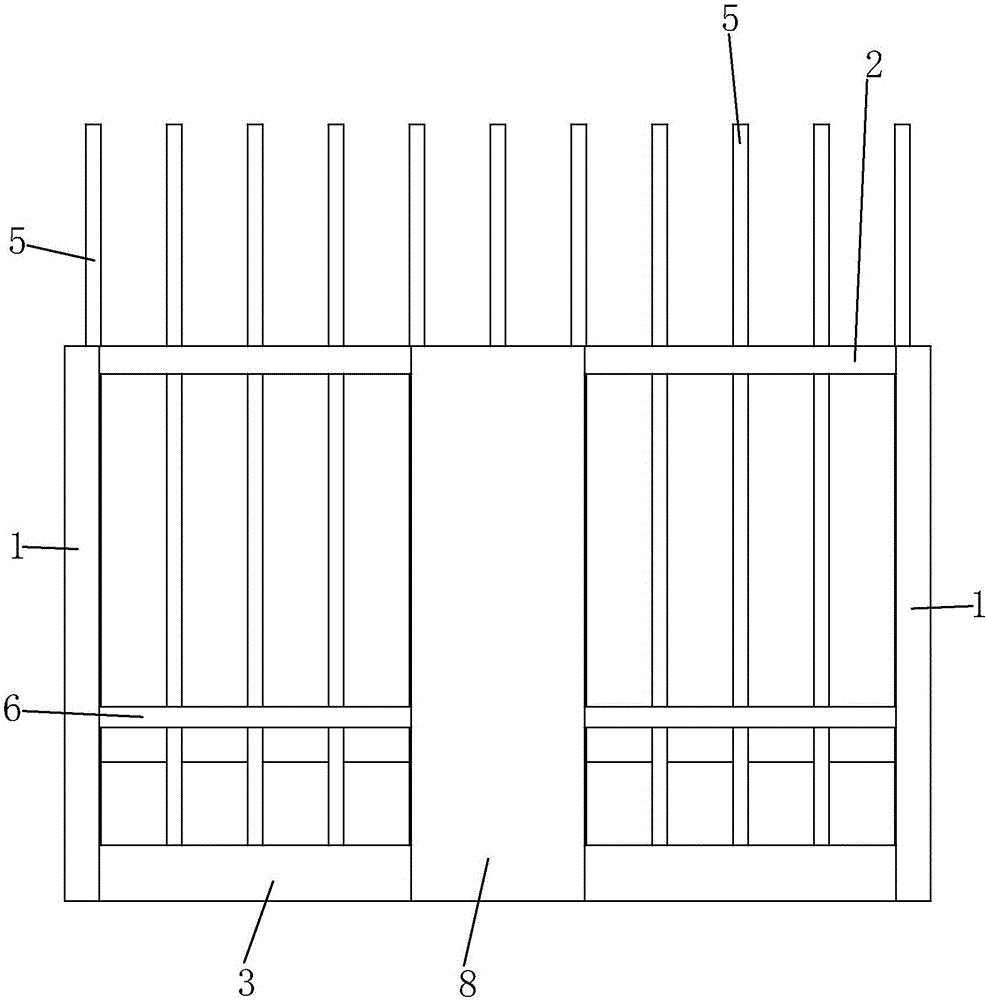

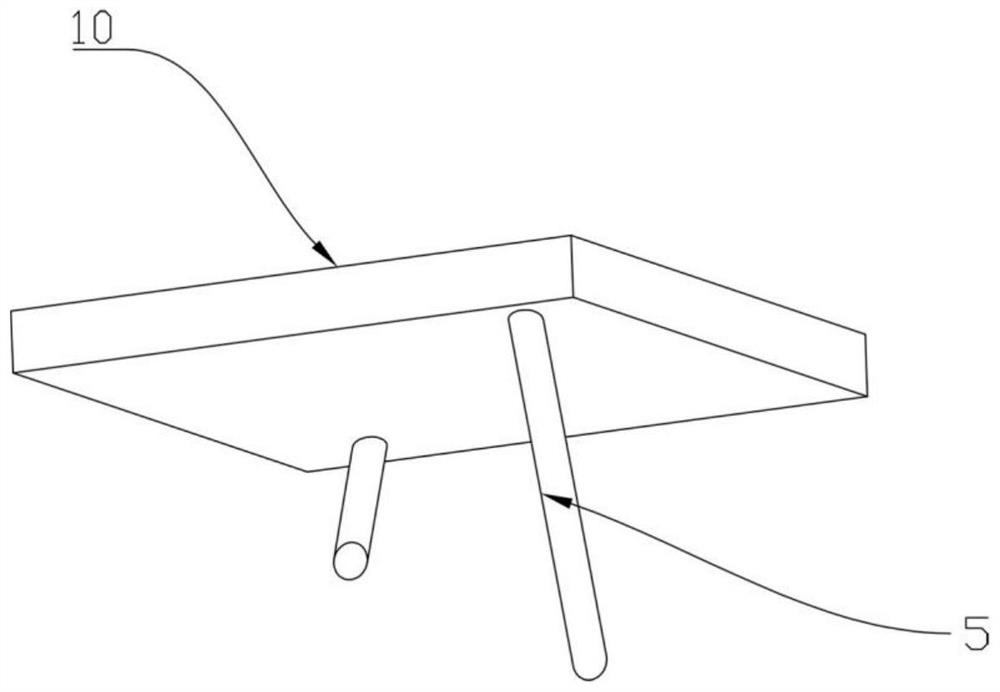

Drying frame of non-metallic mine molding filter cakes

ActiveCN106052376AAvoid chippingReduce the chance of fragmentationDrying chambers/containersDrying solid materialsProduction lineEngineering

The invention discloses a drying frame of non-metallic mine molding filter cakes. The drying frame is characterized in that a main body is a frame; the frame mainly consists of four stand columns, four upper edge frames, four lower edge frames and a baseplate; the stand columns are vertically arranged at four corners of the frame; the baseplate is fixedly connected to the four lower edge frames, and serves as a bottom support surface of the frame; the top of the frame is an opened opening structure; at least two rows of guide rods are vertically arranged in the frame; each row of guide rods consists of multiple guide rods; each row of the guide rods is the same in number of the guide rods; the distances between two adjacent guide rods in each row of guide rods are the same; the bottom ends of the guide rods are fixedly connected to the baseplate; the top ends of the guide rods extend out of the frame; and each row of guide rods is horizontally provided with a positioning cross bar in the arranging direction. The drying frame can load multiple filter cakes to adapt to the demands of an automatic drying production line of the non-metallic mine molding filter cakes, totally realizes mechanical carrying of the filter cakes, saves labors, and is high in working efficiency.

Owner:中国高岭土有限公司

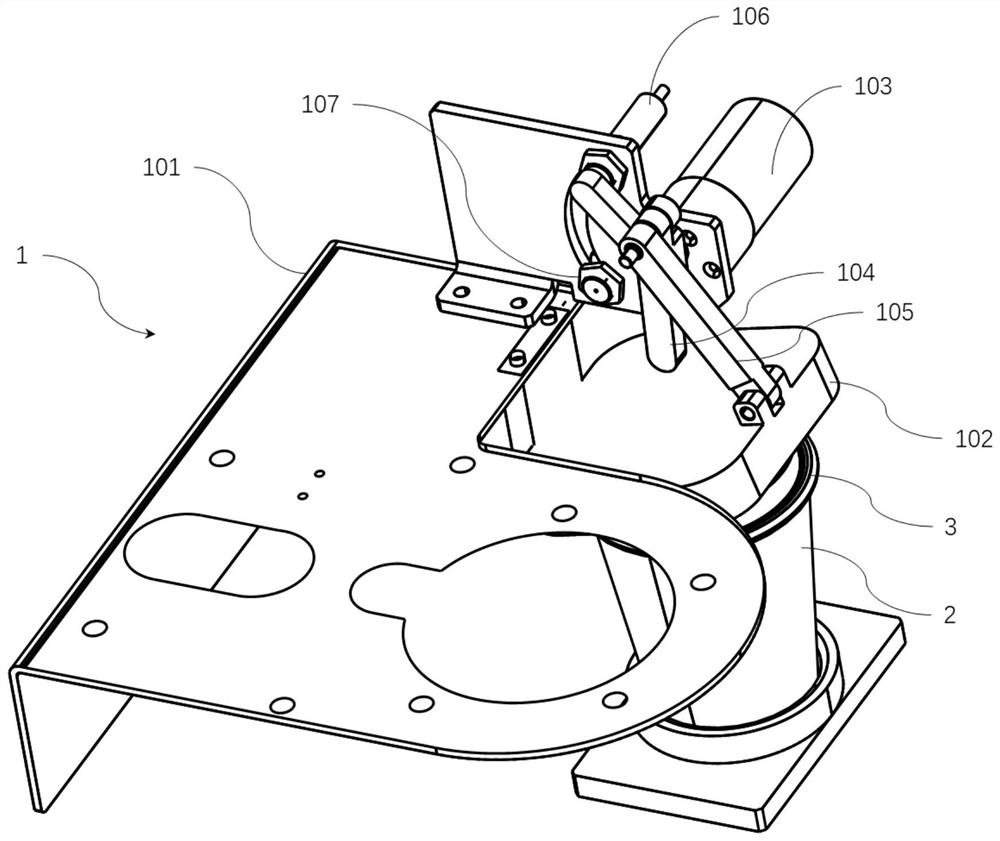

Cup cover pressing device and full-automatic cup covering machine

ActiveCN113538788APress firmlyThe pressing process is smooth and stableApparatus for dispensing fluids/granular materialsControl systemEngineering

The invention provides a cup cover pressing device and a full-automatic cup covering machine. The cup cover pressing device comprises a cover pressing piece which is provided with an initial position and a pressing position and used for pressing a cup cover to a cup; a first driving mechanism used for driving the cover pressing piece; a first bracket used for mounting the cover pressing piece and the first driving mechanism; wherein a first connecting end of the cover pressing piece is hinged to the first bracket, and a second connecting end is connected to the first driving mechanism; the first driving mechanism drives the cover pressing piece to rotate between the starting position and the pressing position around the first connecting end through the four-connecting-rod mechanism so as to press the cup cover. The full-automatic cup covering machine is provided with a cover falling station and a cover pressing station and comprises a cup cover storing and separating device used for stacking and storing cup covers and separating and falling single cup covers; a cup transferring device used for transferring the cup and the cup cover between the cover falling station and the cover pressing station; a cup cover pressing device arranged above the cover pressing station; and a control system and a housing. The cup covering machine is compact in structure, and accurate cap falling and reliable pressing can be guaranteed.

Owner:致籁(上海)机器人科技有限公司

Intelligent silkworm breeding equipment

ActiveCN113925027AAutomatically control the uniformity of blankingRealize the sterilization functionBio-organic fraction processingLoading/unloadingControl theoryMechanical engineering

The invention relates to the technical field of lime powder disinfection of silkworm nests, in particular to intelligent silkworm breeding equipment. The equipment comprises a machine frame, an electromagnetic vibration discharging machine, a discharging channel, an intelligent detection system, a mounting frame, silkworm nests and a displacement driving system, the electromagnetic vibration discharging machine is arranged beside the machine frame, the intelligent detection system is arranged in the discharging channel, and the mounting frame can be arranged on the machine frame in a sliding mode in the direction parallel to the conveying direction of the machine frame. The intelligent detection system comprises a controller and a pressure sensing mechanism, the displacement driving system comprises a horizontal displacement device, a vertical displacement device and a rotary driving device, and the controller is electrically connected with the pressure sensing mechanism, the horizontal displacement device, the vertical displacement device and the rotary driving device. The intelligent detection system in the equipment automatically controls the overall discharging speed and the lime powder discharging uniformity degree, the lime powder scattering amount in each silkworm nest is kept within a certain range, the intelligent degree of the equipment is improved, and the sterilization effect on the silkworm nests is improved.

Owner:那坡同益新丝绸科技实业有限公司

Inclined cross type grabbing device for steeping mud packaging production

The invention discloses an inclined cross type gripping device for steeping mud packaging production, which comprises a boxing platform, a mechanical gripper, a transfer conveying belt and a steeping mud conveying belt, the mechanical gripper is arranged above the boxing platform, the steeping mud conveying belt and the transfer conveying belt are arranged in a cross manner, and the mechanical gripper moves steeping mud blocks on the steeping mud conveying belt to the position above the boxing platform. The mechanical gripper is arranged on the boxing platform and can be conveniently conveyed away from the transfer conveying belt after boxing of the boxing platform, the mechanical gripper comprises two inserting rods which are obliquely arranged and intersect with each other, the two intersecting inserting rods do not make contact with each other, and the boxing platform is provided with a packaging carton used for bearing the foam blocks and a conveying tray used for carrying the packaging carton to move on the transfer conveying belt. And a horizontal positioning mechanism for limiting the position of the conveying tray is arranged on the boxing platform. In conclusion, the device has the advantages that the structure is simple, the foam blocks are convenient to transfer and not prone to falling off, the packaging carton is accurately placed, and the packaging carton is convenient to move.

Owner:河南斯普瑞斯智能装备有限公司

Turning units and devices for elevator guide rails

ActiveCN110371904BEasy flipAvoid scratchesLifting devicesHoisting equipmentsStructural engineeringControl theory

The invention provides a turn-over unit and device for an elevator guide rail. The turn-over unit comprises a swing arm for vertically swinging. A first groove for supporting the two sides of the horizontal end of a peripheral guide rail and a convex block for heeling the peripheral guide rail are sequentially arranged at one end of the swing arm. A step face is arranged between the first groove and the convex block, the two ends of the step face are connected with the upper side of the first groove and the lower side of the convex block correspondingly, or the two ends of the step face, the upper side of the first groove and the lower side of the convex block are integrally formed. The swing arm drives the first groove and the convex block at one end of the swing arm to ascend according to an arc-shaped path curve, and the guide rail with the horizontal end arranged downwards is placed above the convex block. The ascending convex block collides with the bottom of the outer side of theguide rail, the bottom of the guide rail bears external force, the outer side of the guide rail is jacked, and the guide rail inclines inwards. According to the technical scheme, the turn-over unit and device are simple in structure, small in occupied area, high in efficiency and low in cost, and has the characteristics of being fast and safe in turnover, and the production quality and productionefficiency are greatly improved.

Owner:广州塞维拉电梯轨道系统有限公司

Mechanical device for hardware machining

ActiveCN112576630AImprove placement efficiencyReduce labor costsBearing componentsConveyor partsEngineeringStructural engineering

The invention discloses a mechanical device for hardware machining. The mechanical device comprises a conveying frame, a conveying belt is arranged on the conveying frame, a plurality of feeding boxesused for containing steel balls are arranged above the conveying belt, worm wheels are rotationally connected to openings in the bottoms of the feeding boxes, lower baffles are fixedly installed at the bottoms of the feeding boxes, the worm wheels are located in the baffles, the lower baffles fixedly communicate with discharging nozzles, discharging assemblies are arranged below the feeding boxes, and the discharging assemblies can drive the discharging nozzles to conduct intermittent discharging in the continuous conveying process of the conveying belt. According to the mechanical device forhardware machining, through the discharging assemblies, power conveyed by the conveying belt is converted into intermittent power of the discharging boxes, that is, the steel balls in the dischargingboxes can be stably conveyed into a containing groove according to conveying of the conveying belt, the containing efficiency is high, manual containing is not needed, and the labor cost is greatly reduced.

Owner:HENAN POLYTECHNIC UNIV

A device for fertilizing grapes

InactiveCN108496498BEasy to operateImprove synchronicityFertiliser distributersDrive wheelDrive shaft

Owner:重庆龙佰绪生态农业开发集团有限公司

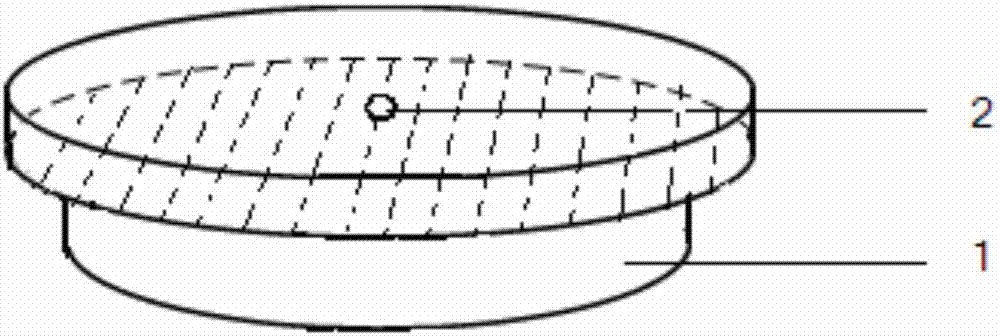

Small ball release accurate locating frame for liquid viscosity coefficient determination experiments

InactiveCN104990837AAccurate whereaboutsSatisfy the drop location requirementsFlow propertiesLiquid viscosityEngineering

The invention discloses a small ball release accurate locating frame for liquid viscosity coefficient determination experiments, and relates to the technical field of college physics experiment apparatuses. The locating frame comprises a guiding tube, a guiding tube V-shaped mouth, a panel, a lantern ring and a perspective hole, the internal surface of the guiding tube is a cylindrical surface, the internal surface of the guiding tube V-shaped mouth is a conical surface, the common axis of the guiding tube and the guiding tube V-shaped mouth is on the common axis center of the panel and the lantern ring, and the panel is provided with the round perspective hole. A small ball can accurately fall from the axis of a liquid column under the action of the guiding tube V-shaped mouth and the guiding tube in the experiment process, so requirements of an experiment principle on the falling position of the small ball are met, and the experiment precision is improved.

Owner:HUNAN CITY UNIV

Reinforcement Welded Mesh Weft Line Positioning Device

ActiveCN103692080BAccurate whereaboutsGuarantee product qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRebar

The invention discloses a weft wire locating device of a steel bar welding mesh. The weft wire locating device comprises a fixing post, a connecting plate, an oscillating rod and a pushing plate, wherein the front end of the fixing post is connected to a welding mesh main machine, the rear end of the fixing post is hinged to the connecting plate which is horizontally arranged, the other end of the connecting plate is hinged to the oscillating rod, the upper end of the oscillating rod is connected to the welding mesh main machine, and the lower end of the oscillating rod is connected with the pushing plate. When the weft wire locating device works, welding weft wires can be fixed by a magnetic limiting plate after the welding weft wires freely fall from a weft wire storeroom, an upper electrode block is driven to move downwards to prepare for welding by an air cylinder rod, the weft wire locating device does corresponding motion during a falling process, the pushing plate is enabled to move and push the weft wires to be in position, and the welding can be carried out when the weft wires reach to needed positions. According to the weft wire locating device disclosed by the invention, accurate falling position of the weft wires can be ensured, thus the weft wires are flush with each other when the steel bar welding mesh is in welding, and the attractive appearance of a product is ensured while the quality of the product is ensured.

Owner:ANHUI BRC & MA STEEL WELDMESH +1

Material shaping and discharging device

PendingCN110371402AAvoid scatterAccurate whereaboutsConveyorsPackagingEngineeringMechanical engineering

The invention discloses a material shaping and discharging device. The material shaping and discharging device mainly comprises a feeding mechanism, a compression blanking barrel, shaping mechanisms,a rotary motor, a compression motor and a lifting mechanism, wherein the side wall of the compression blanking barrel is provided with feeding openings; the upper end of the compression blanking barrel is provided with shaping ports; the lower end of the compression blanking barrel is provided with discharging openings; the shaping ports are communicated with the corresponding discharging openingsthrough shaping channels; one side of each shaping channel is communicated with the corresponding feeding opening; the feeding openings are connected with the feeding mechanism; a cross beam is arranged at the upper ends of the shaping mechanisms; the upper ends of the shaping mechanisms are connected with the rotary motor; the lower ends of the shaping mechanisms directly face the correspondingshaping ports; two ends of the cross beam are connected with the lifting mechanism; the lifting mechanism is connected with the compression motor; and a charging door mechanism for controlling openingand closing the discharging openings is arranged at the lower end of the compression blanking barrel. The material shaping and discharging device shapes in a rotating and pressing integrated mode, sothat space occupation is reduced, the shaping effect of materials is improved, and the shaped materials have complete and stable shape and can accurately fall into a drying box.

Owner:ACCUBAL INTELLIGENT MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com