Patents

Literature

111results about How to "Reduce the chance of fragmentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

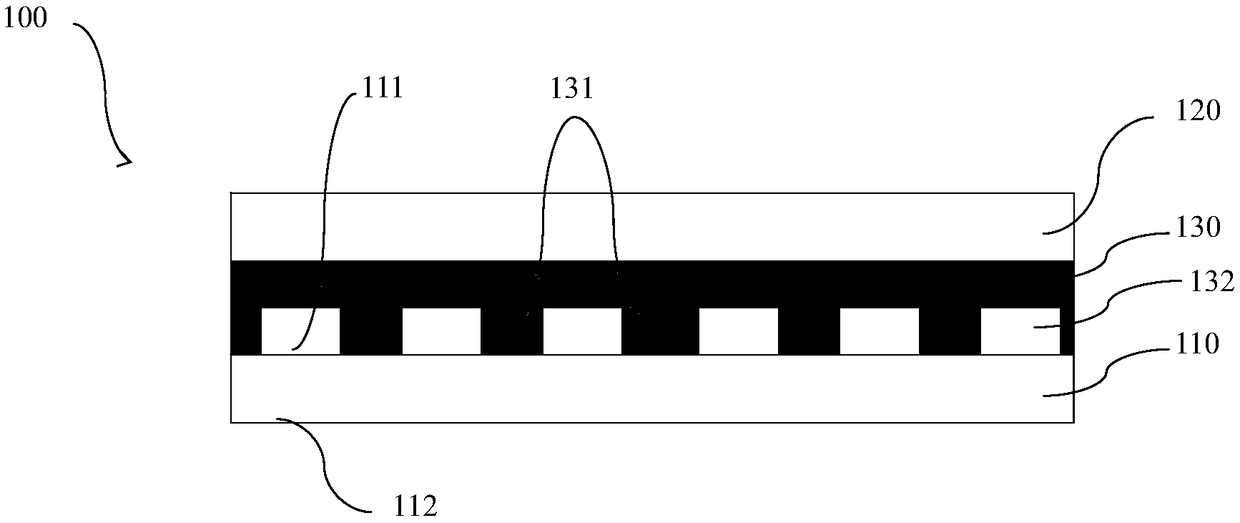

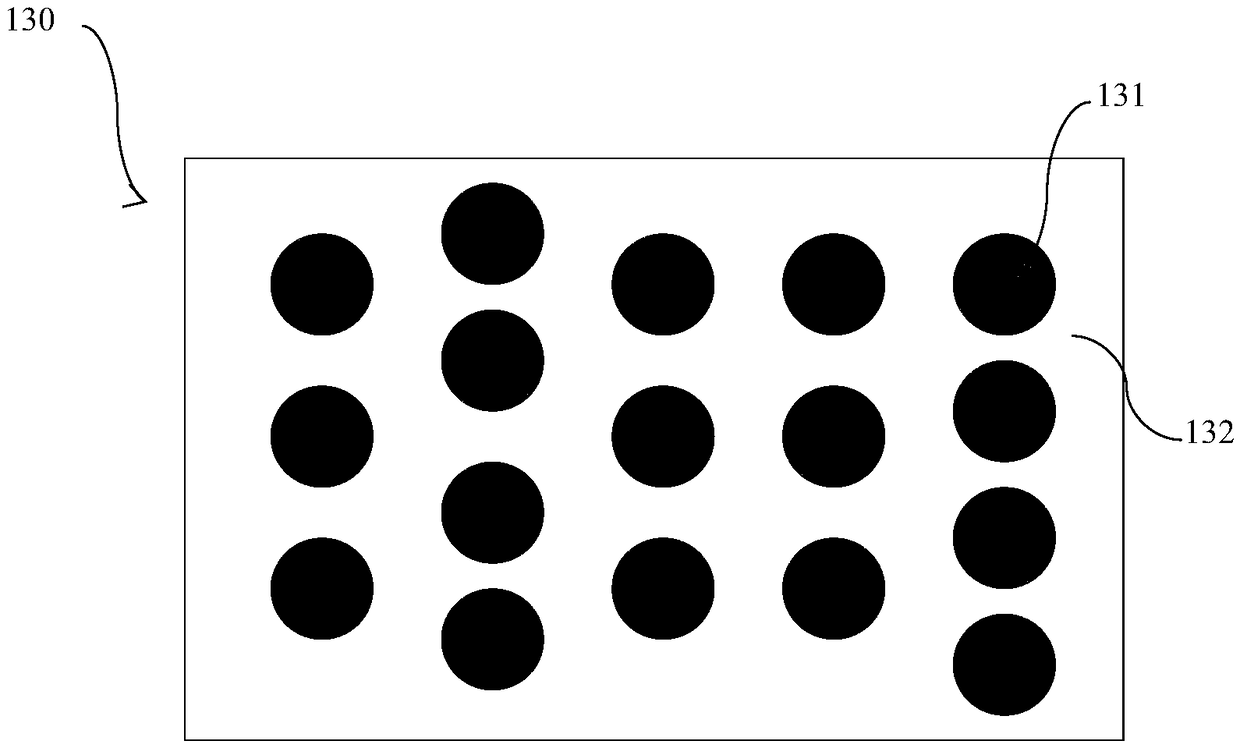

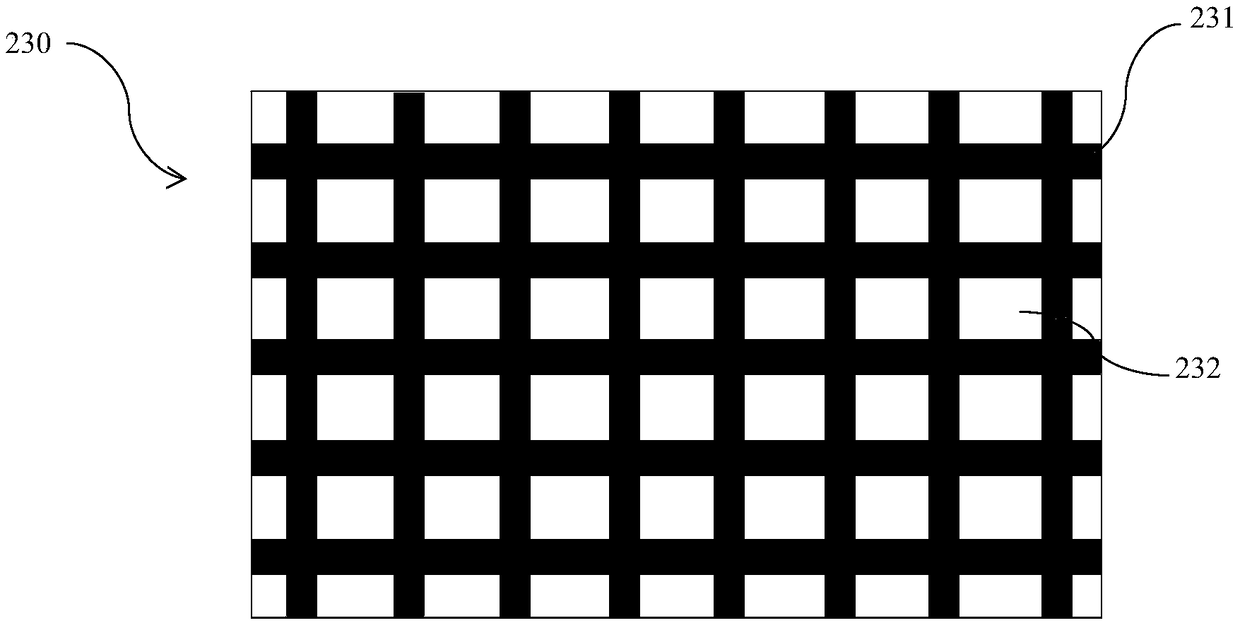

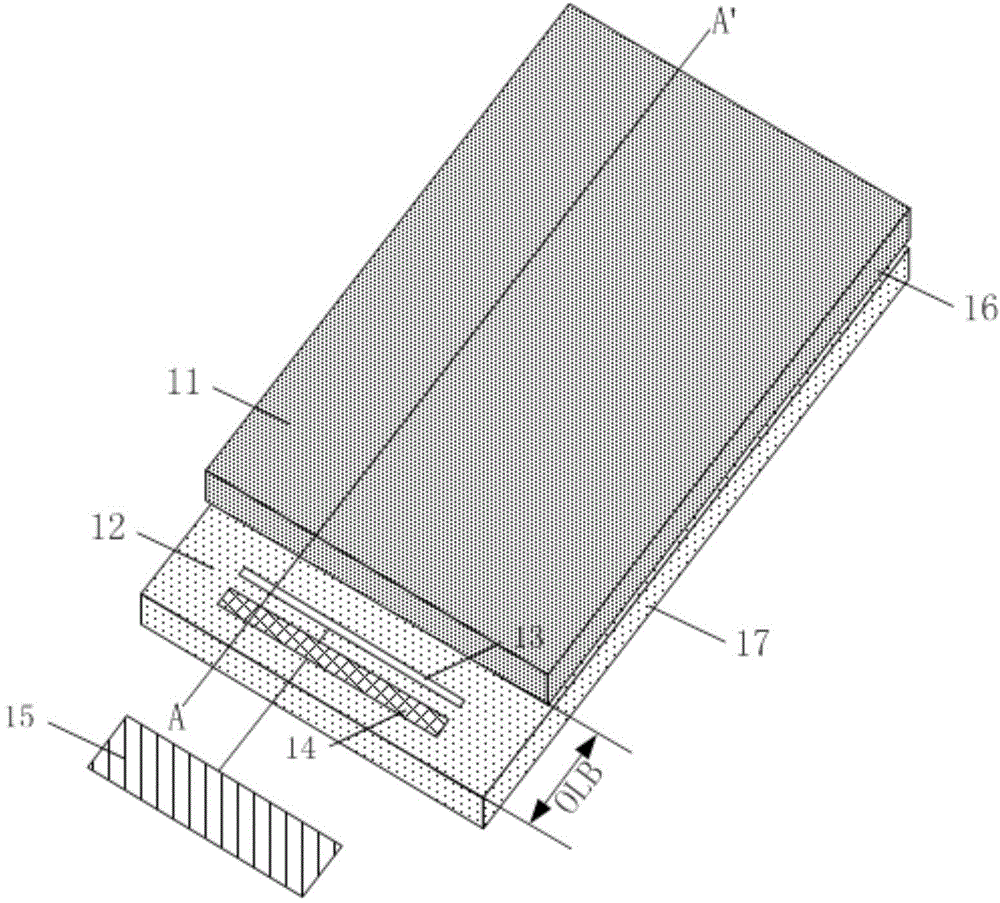

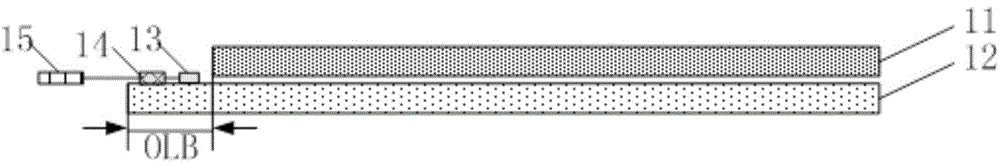

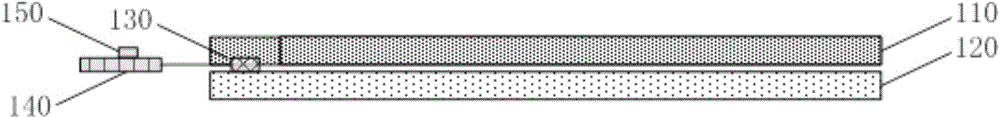

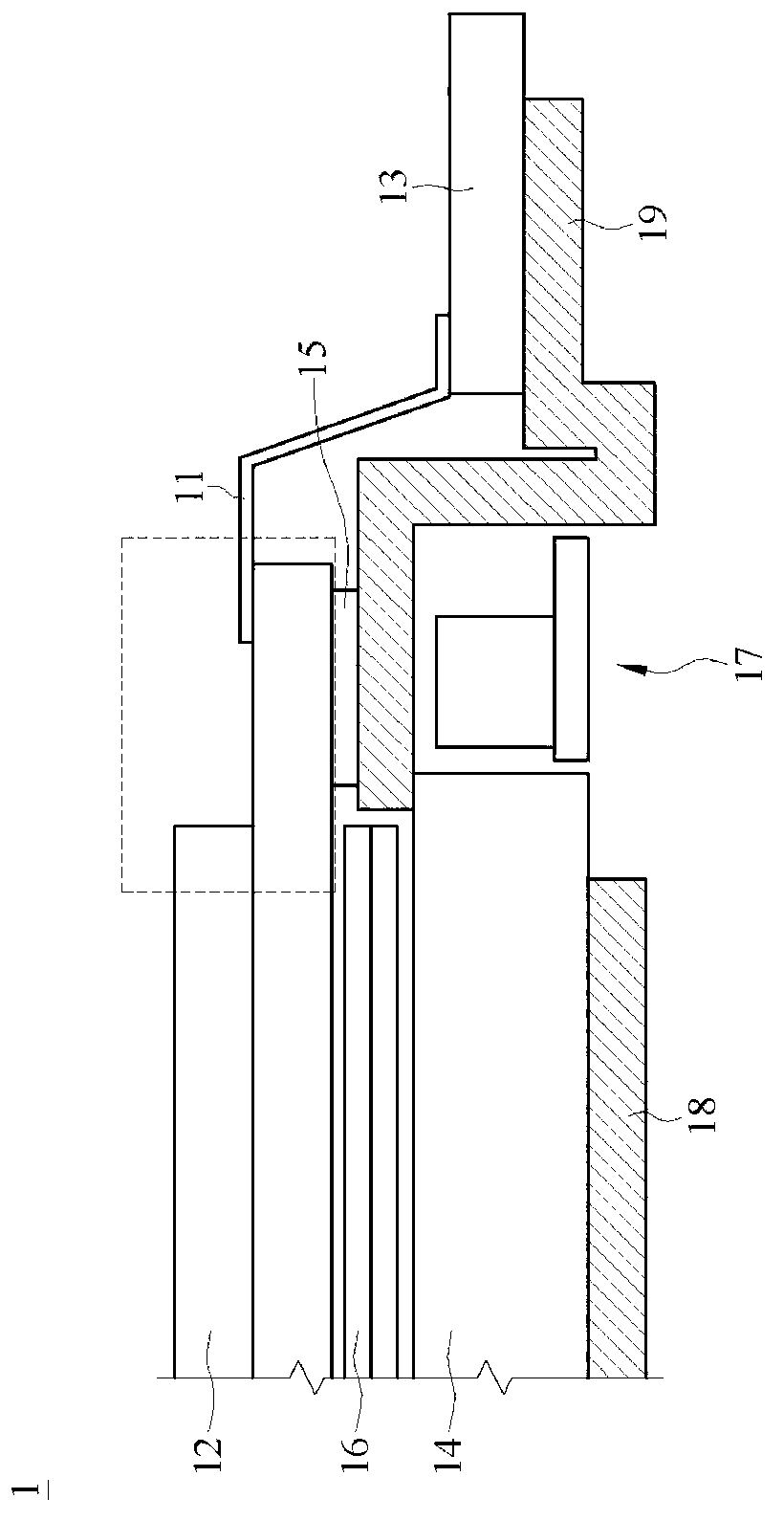

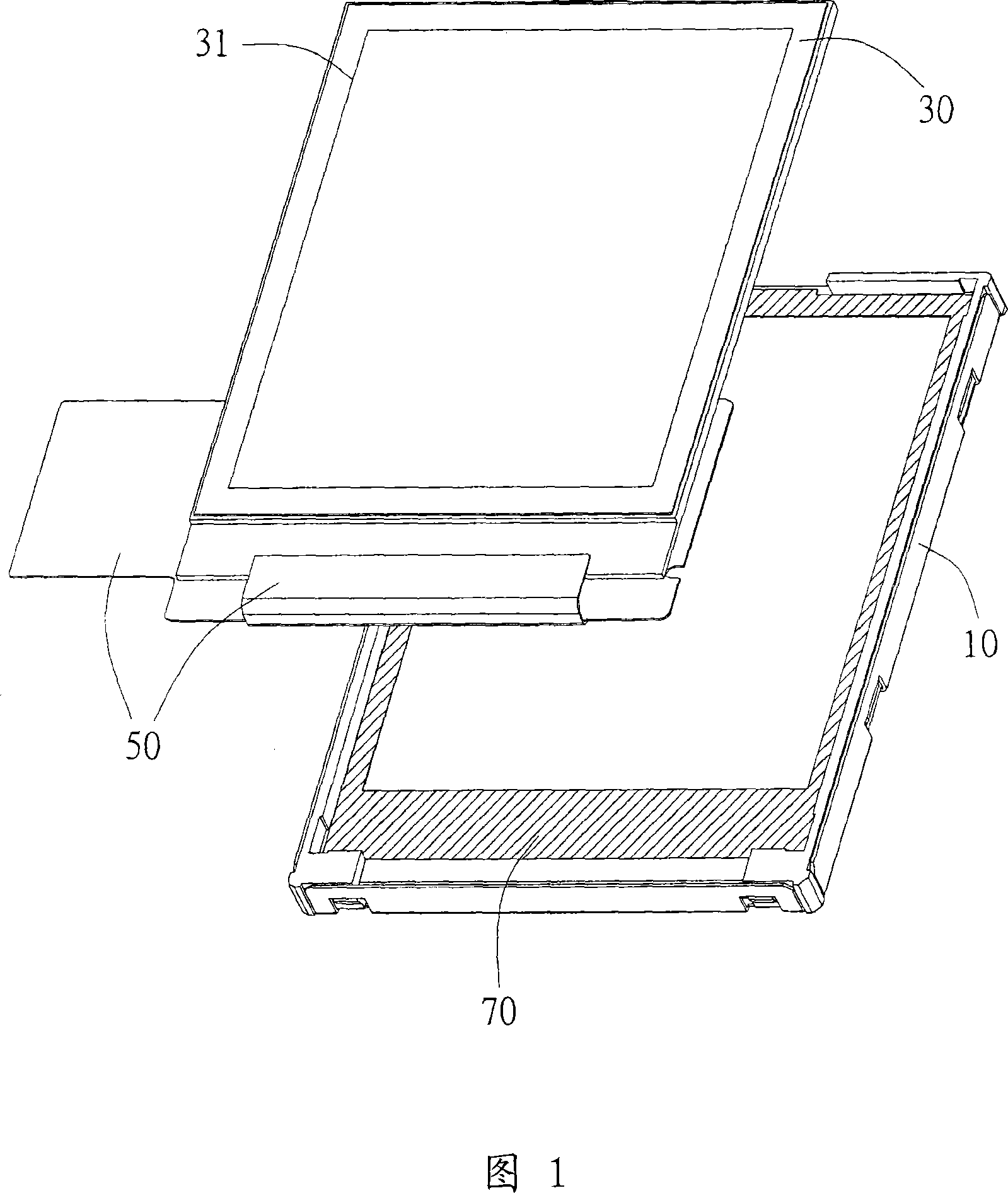

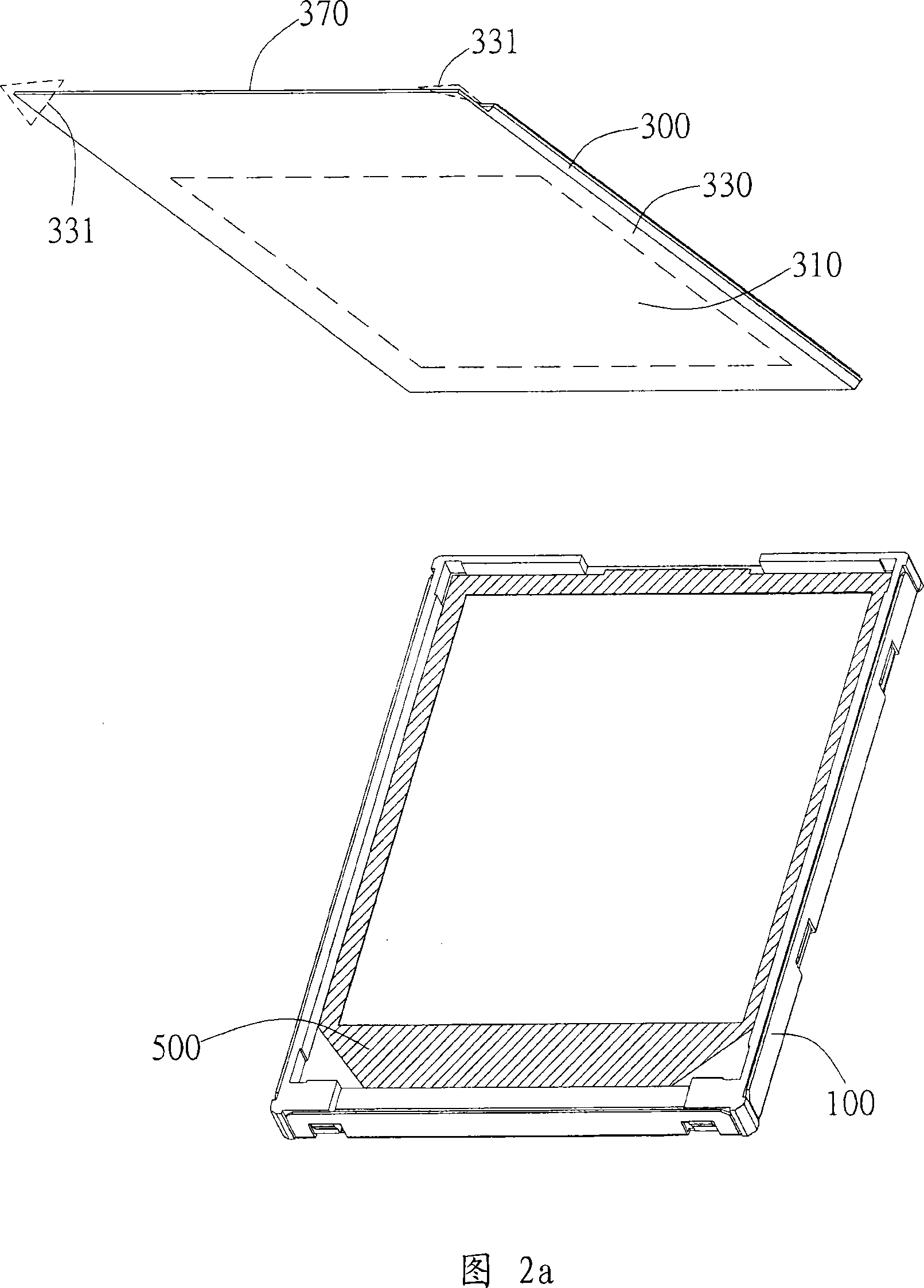

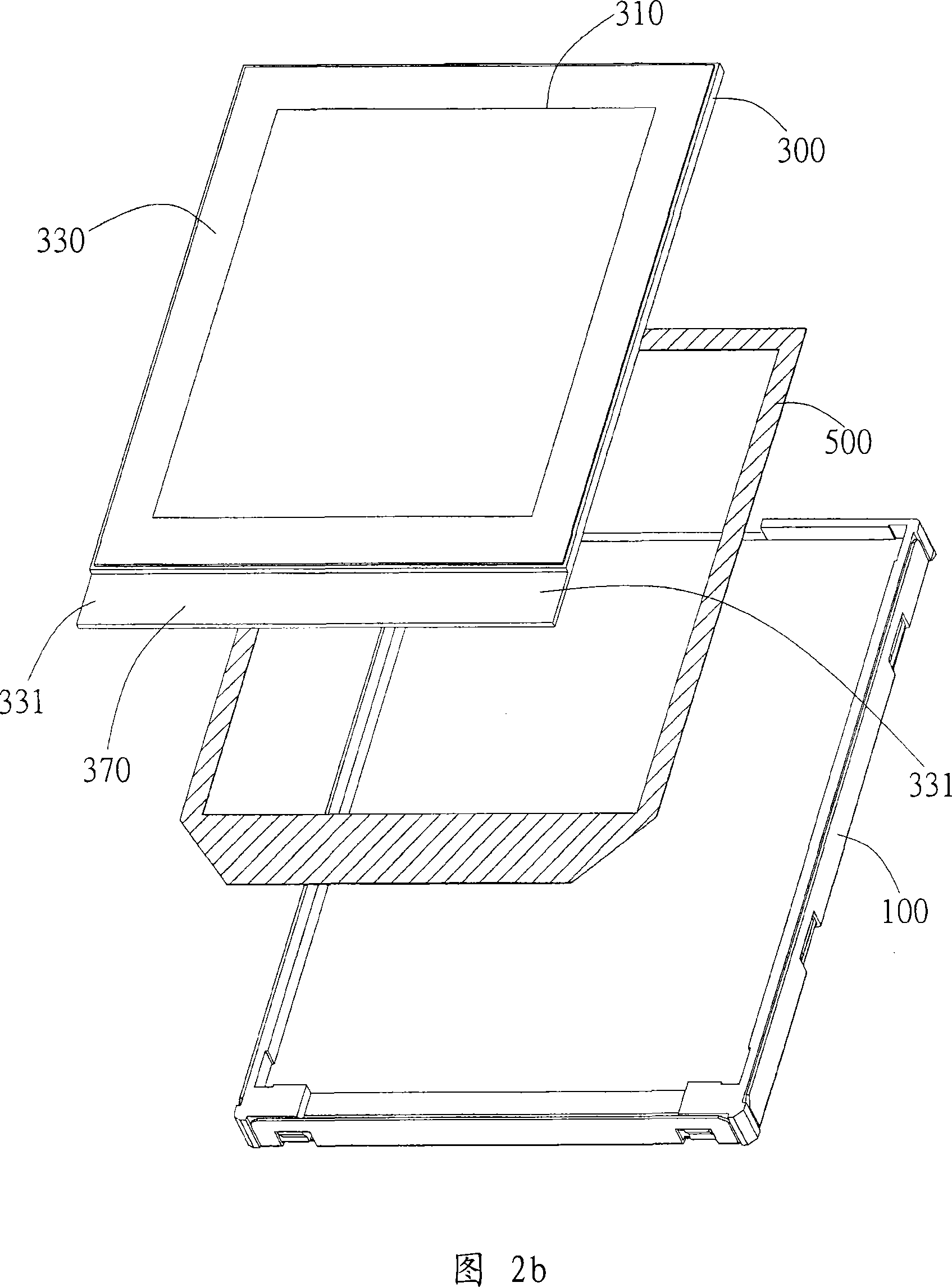

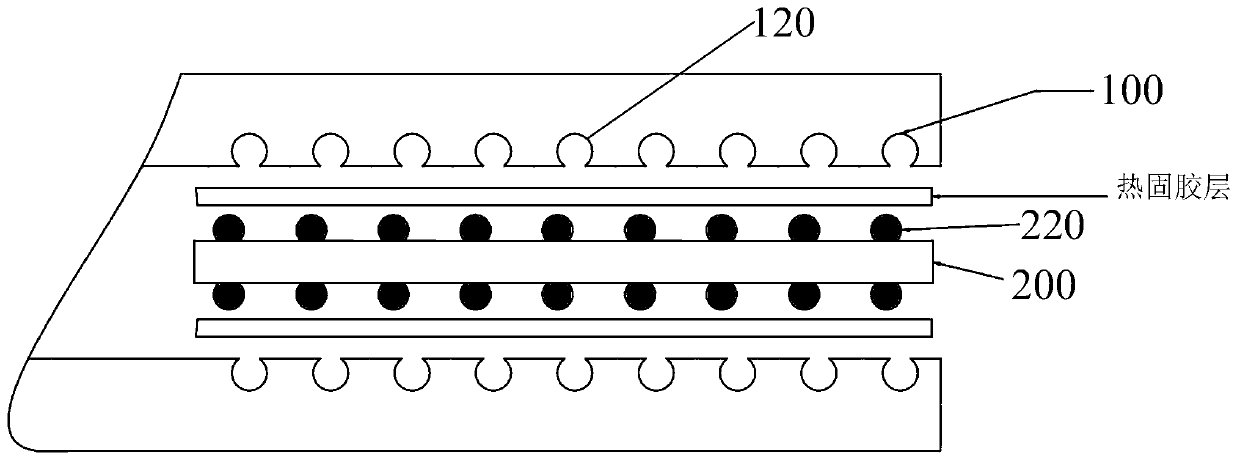

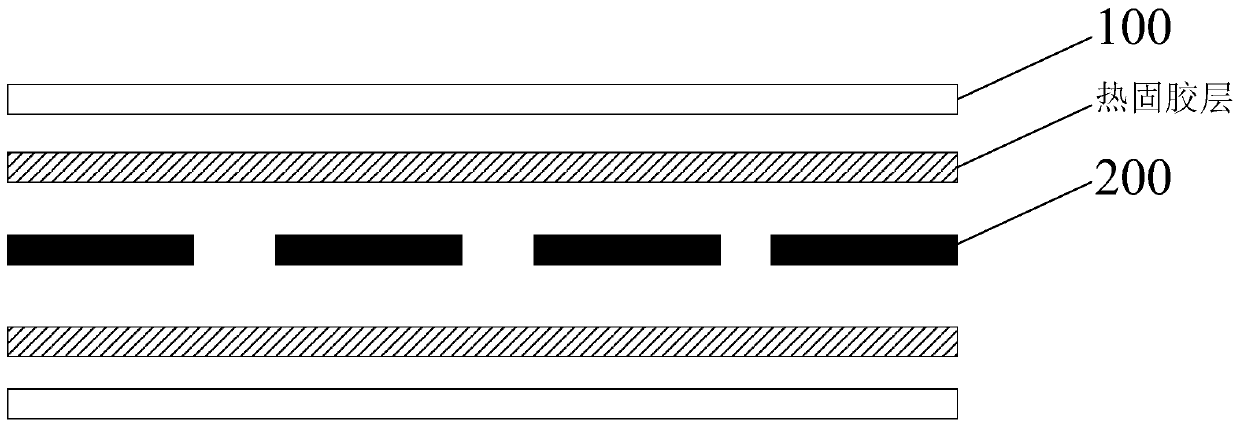

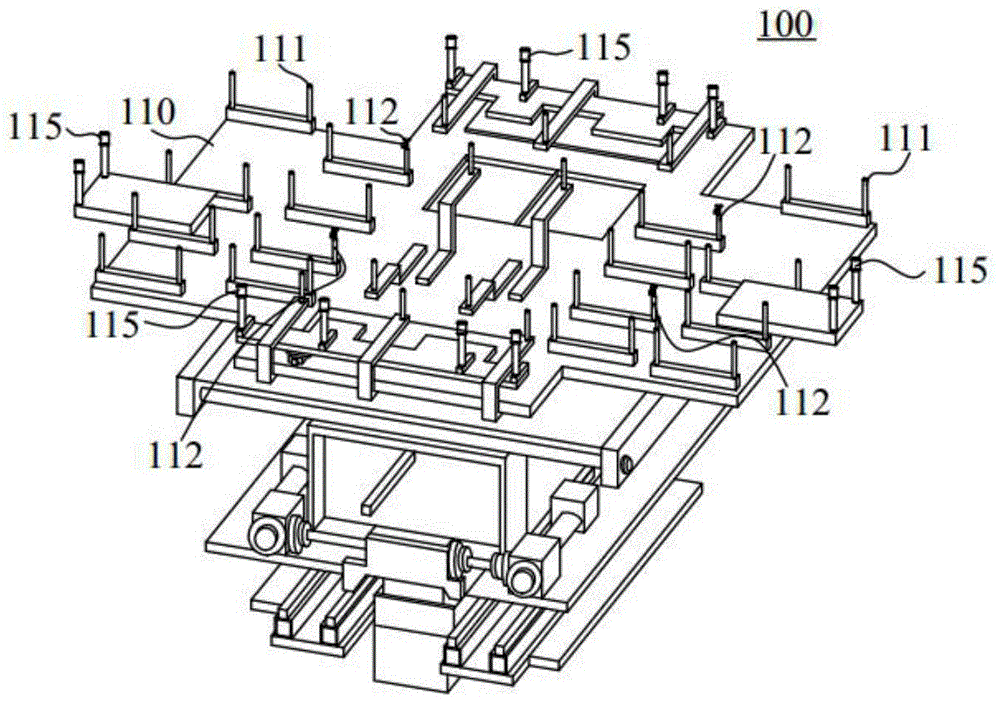

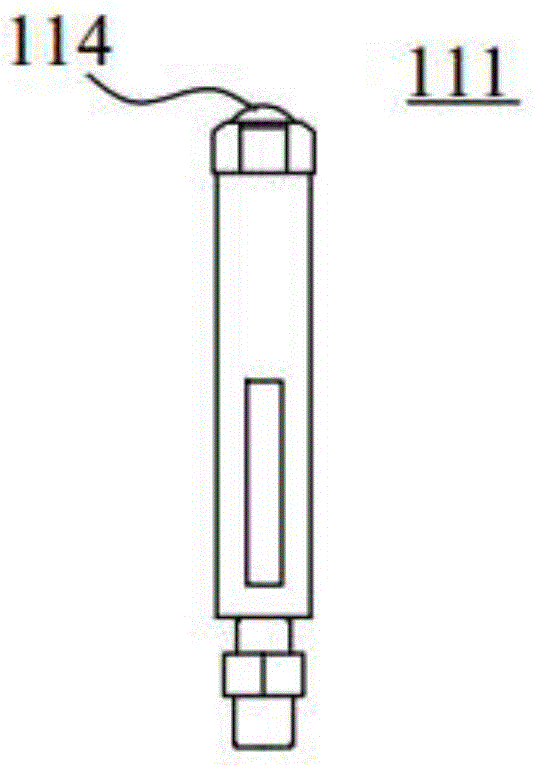

Cover plate and manufacturing method thereof, flexible display module and electronic equipment

ActiveCN109326220AImprove shear resistanceImprove chip resistanceInput/output processes for data processingIdentification meansEngineeringFlexible display

The invention provides a cover plate for a flexible screen and a manufacturing method thereof, a flexible display module and electronic equipment, wherein, the cover plate comprises: a base plate; a first cladding layer covering the first surface of the base plate; a first adhesive layer which adheres the first cladding layer with the base plate and forms a hollow structure between the base plateand the first cladding layer through at least one first bulge arranged on the first surface of the first adhesive layer. The invented cover plate effectively improves the anti-cracking intensity through the buffering action and the stress dispersing action of the bulges.

Owner:BEIJING VISIONOX TECH

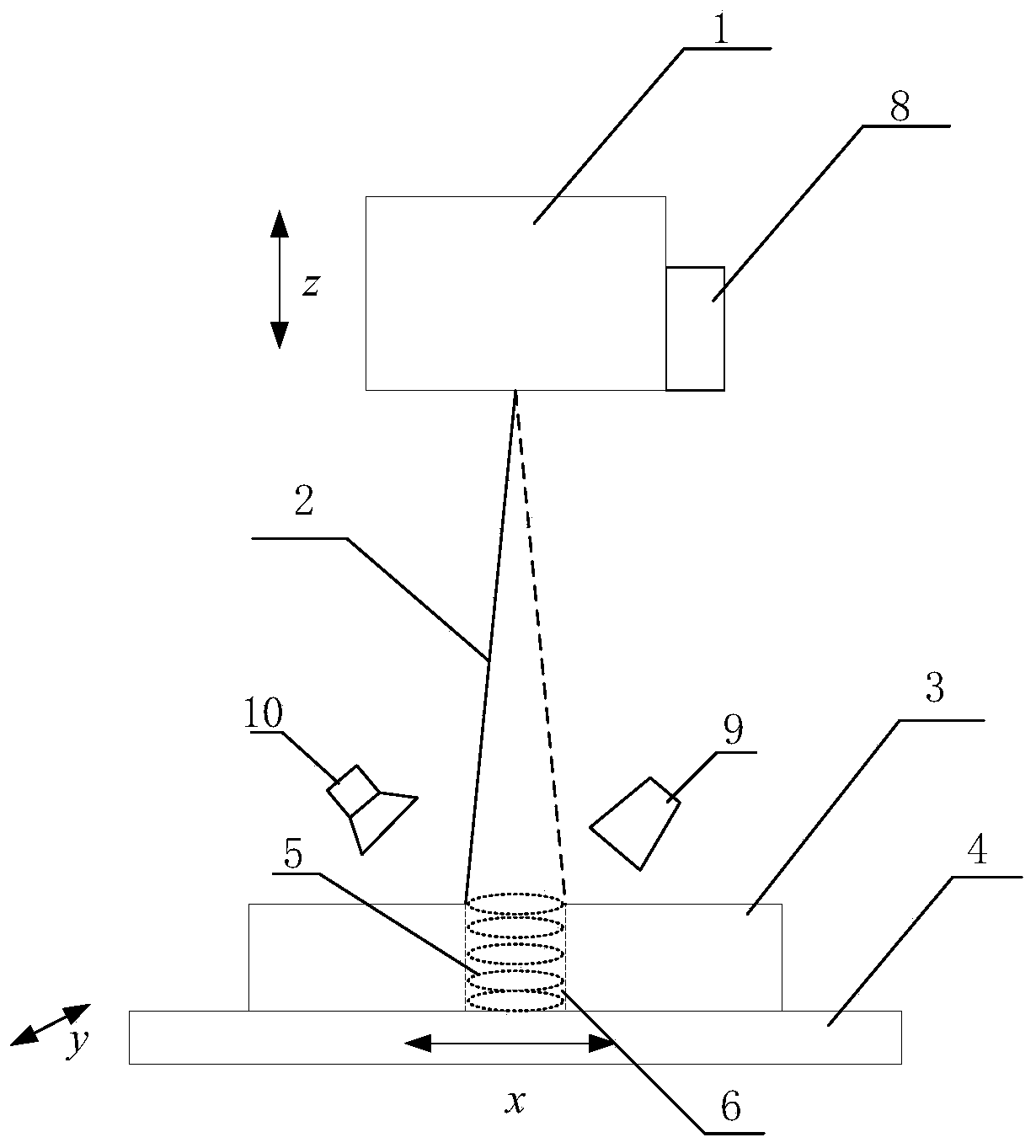

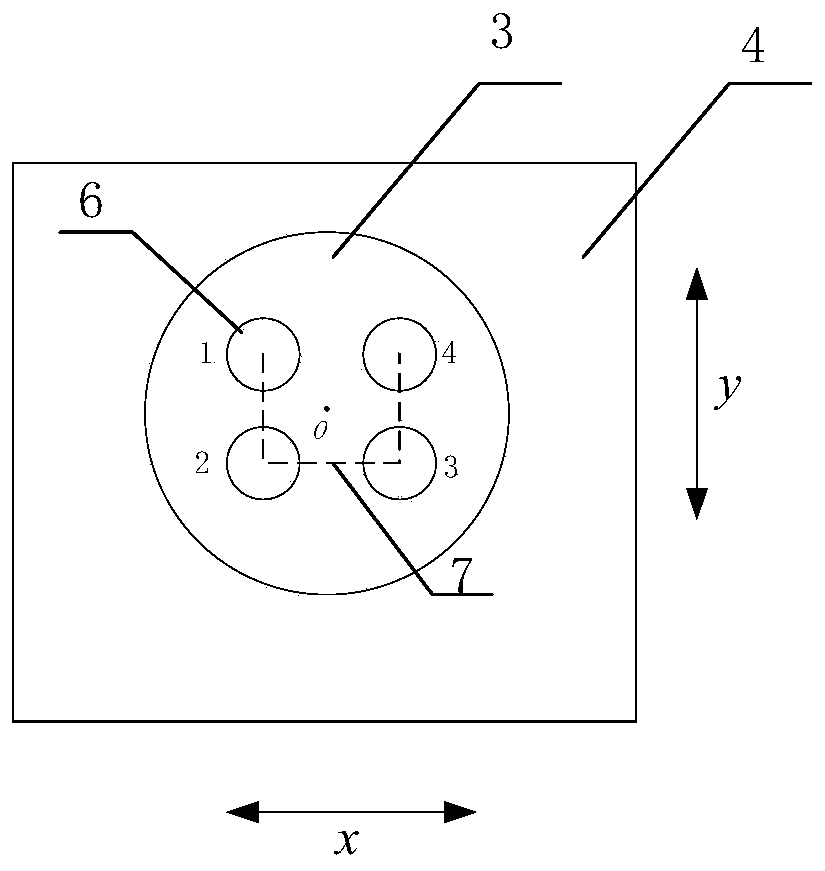

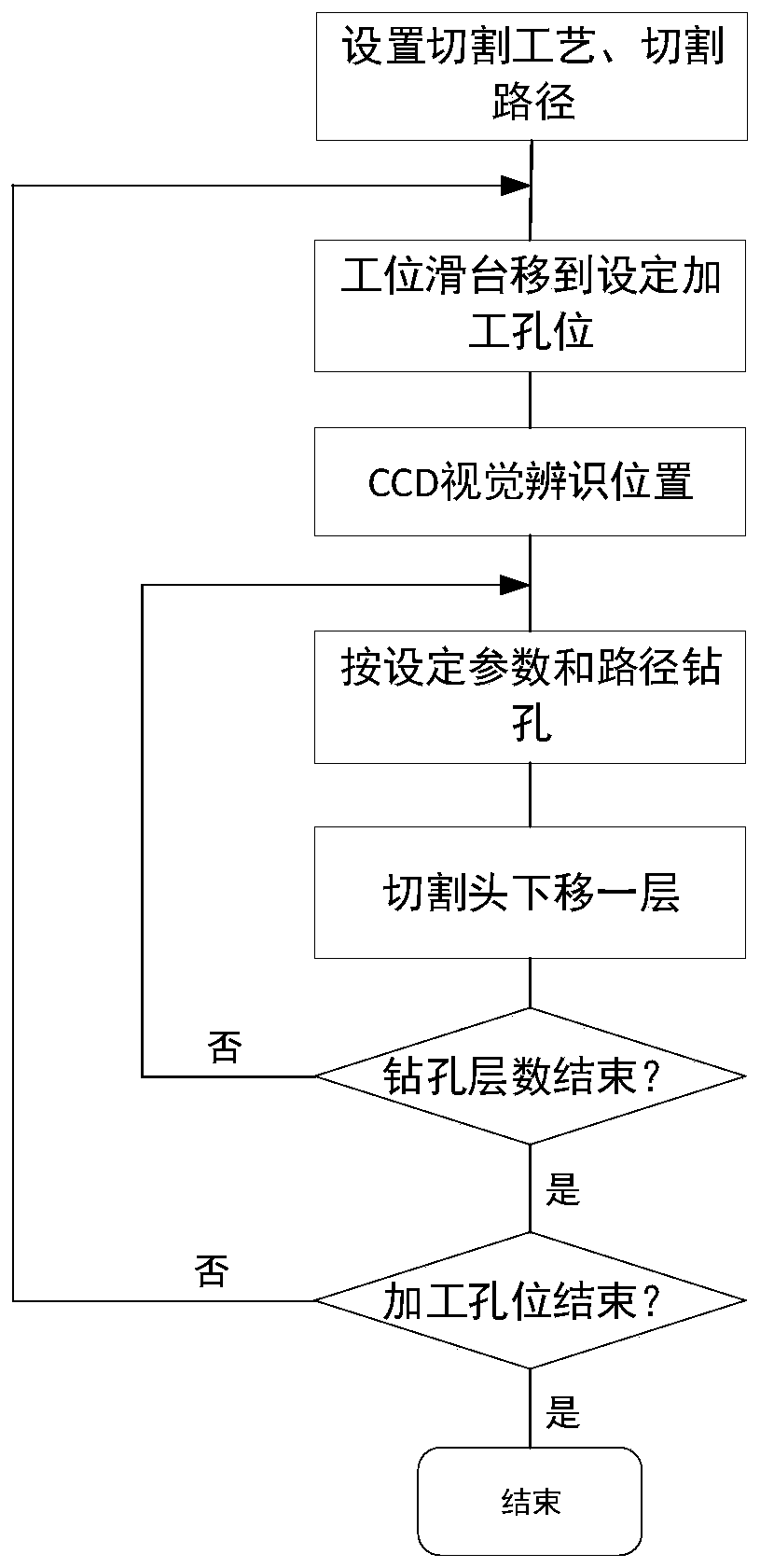

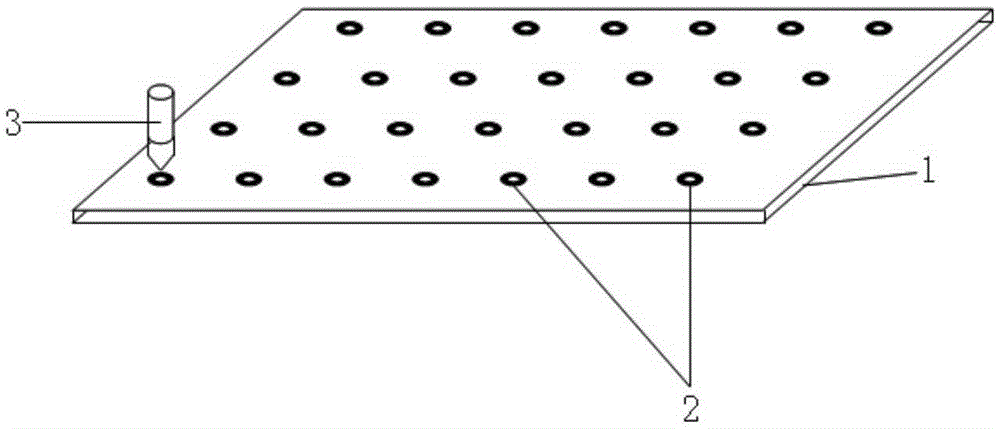

Ceramic substrate porous array picosecond laser galvanometer scanning drilling system and method

InactiveCN111590197ANo damageSmooth edgesLaser beam welding apparatusPicosecond laserHeat-affected zone

The invention provides a ceramic substrate porous array picosecond laser galvanometer scanning drilling system and method. The method comprises the steps that firstly a laser drilling route and a laser drilling technological parameter are arranged, during drilling, a station sliding table moves a hole to be drilled of a ceramic substrate to a drilling position, CCD vision identifies and positionsthe drilling position, and a galvanometer laser beam precisely drills the ceramic substrate layer by layer; meanwhile, smoke suction and protective gas are started, a cutting head automatically movesdown one layer of machining thickness for each layer machining until all the layers are machined; and then the station sliding table moves a workpiece to the next drilling position, repetition is carried out until all the holes in the ceramic substrate are drilled. According to the ceramic substrate porous array picosecond laser galvanometer scanning drilling system and method, cutting edges of the ceramic substrate are smooth, the roundness is good, the taper is small, the fragmentation probability is low, nearly no heat affected zone exists, the edges are not yellowed, nearly no damage is caused to the ceramic substrate, and the yield is greatly improved.

Owner:苏州优快激光科技有限公司

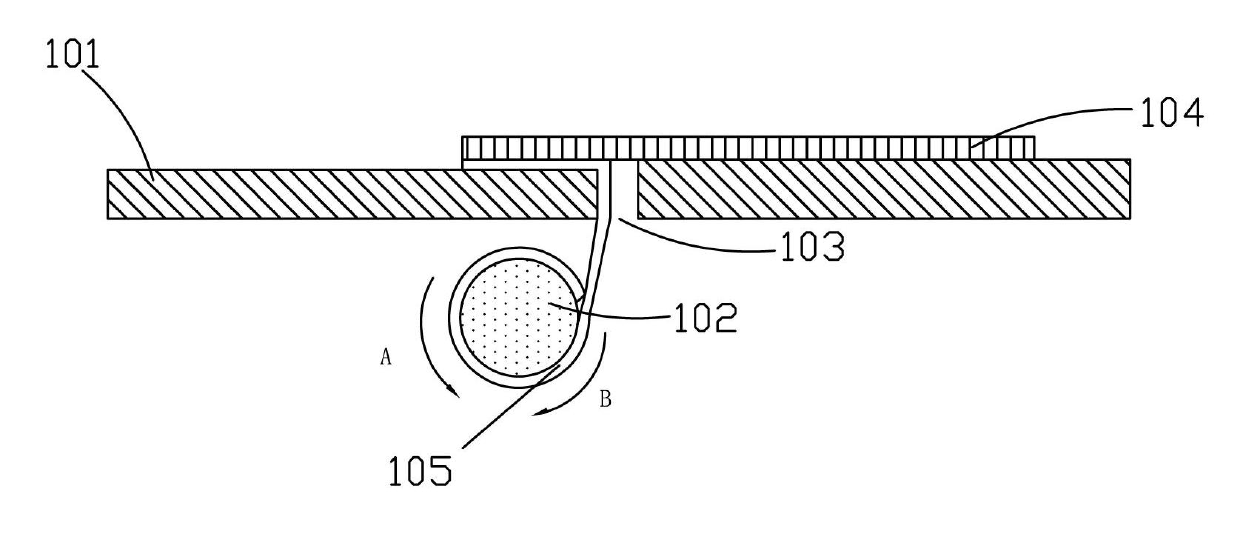

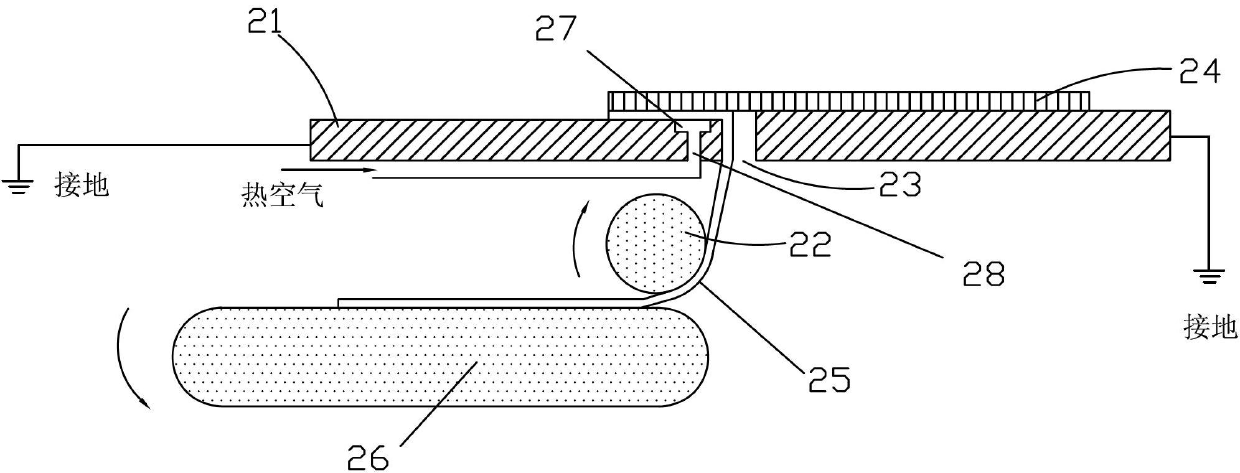

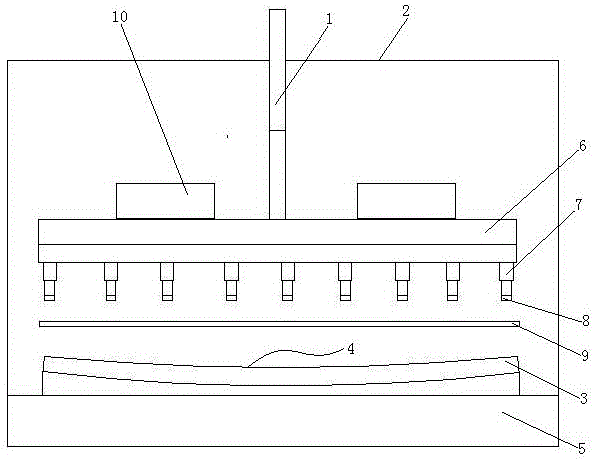

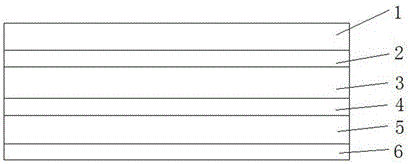

Polaroid stripping machine and method for stripping polaroid

ActiveCN102632685AEliminate hazardsLow peel strengthLamination ancillary operationsLaminationEngineeringUltimate tensile strength

The invention relates to a polaroid stripping machine and a method for stripping a polaroid. The polaroid stripping machine comprises an operation platform and a conveying device with a translatable surface, wherein the operation platform is provided with a gap which is used as a polaroid stripping position; the translatable surface of the conveying device is located below the gap; when the polaroid is stripped, a glass substrate with the polaroid to be stripped slides through the gap along the upper surface of the operation platform; and the stripped polaroid downwards extends and is paved on the translatable surface of the conveying device by the gap, and horizontally moves along with the translatable surface of the conveying device. The polaroid stripping machine and the method for stripping the polaroid, disclosed by invention, change the polaroid stripping operation into a continuous process, can eliminate the damages of static electricity accumulation in the polaroid stripping process to a panel and an operator, can heat the polaroid, and reduce the stripping strength and the fragmenting possibility.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

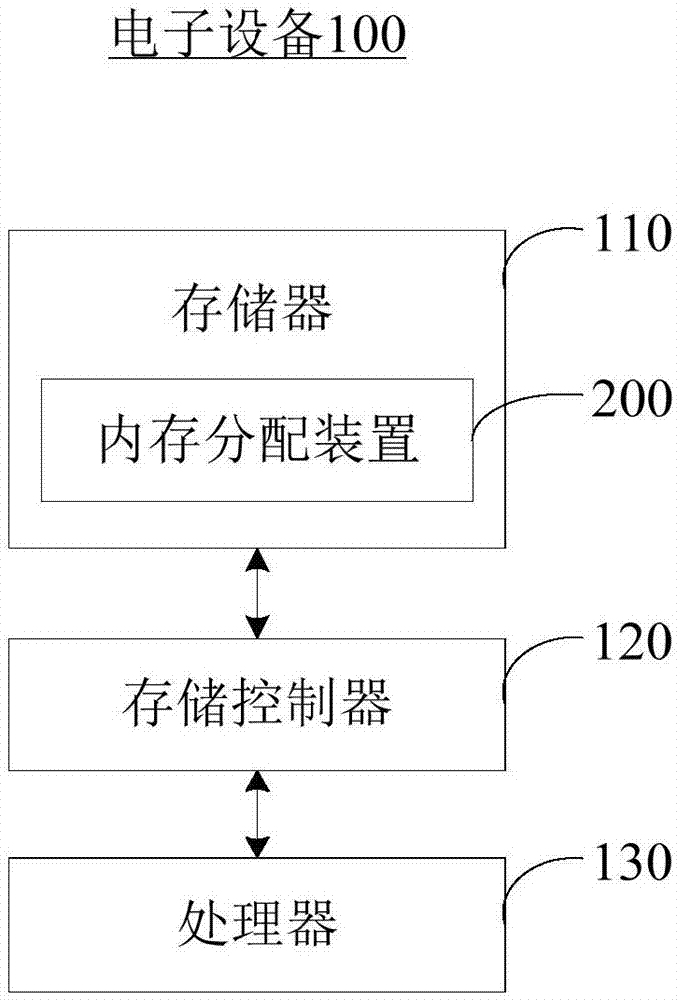

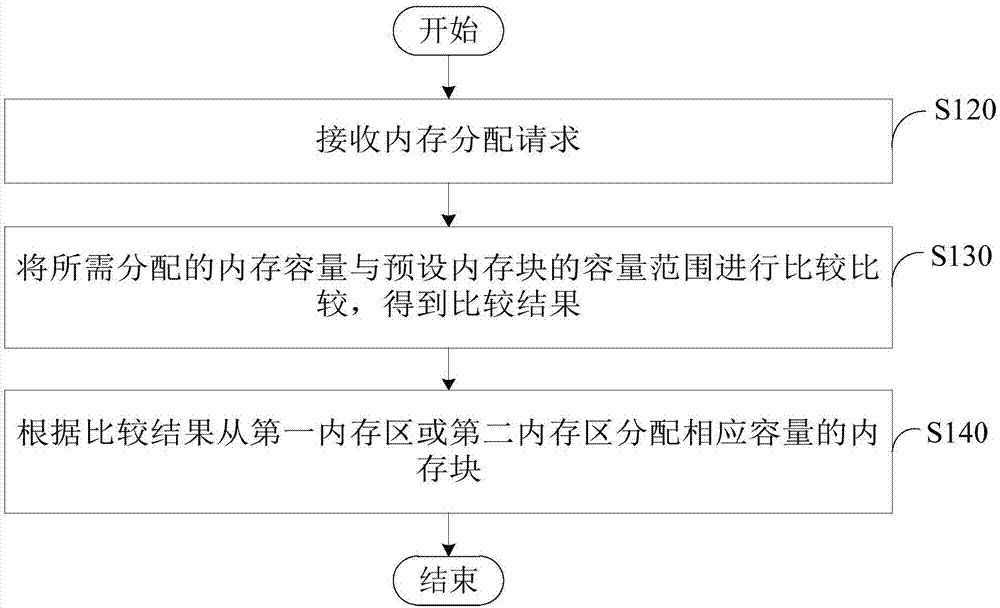

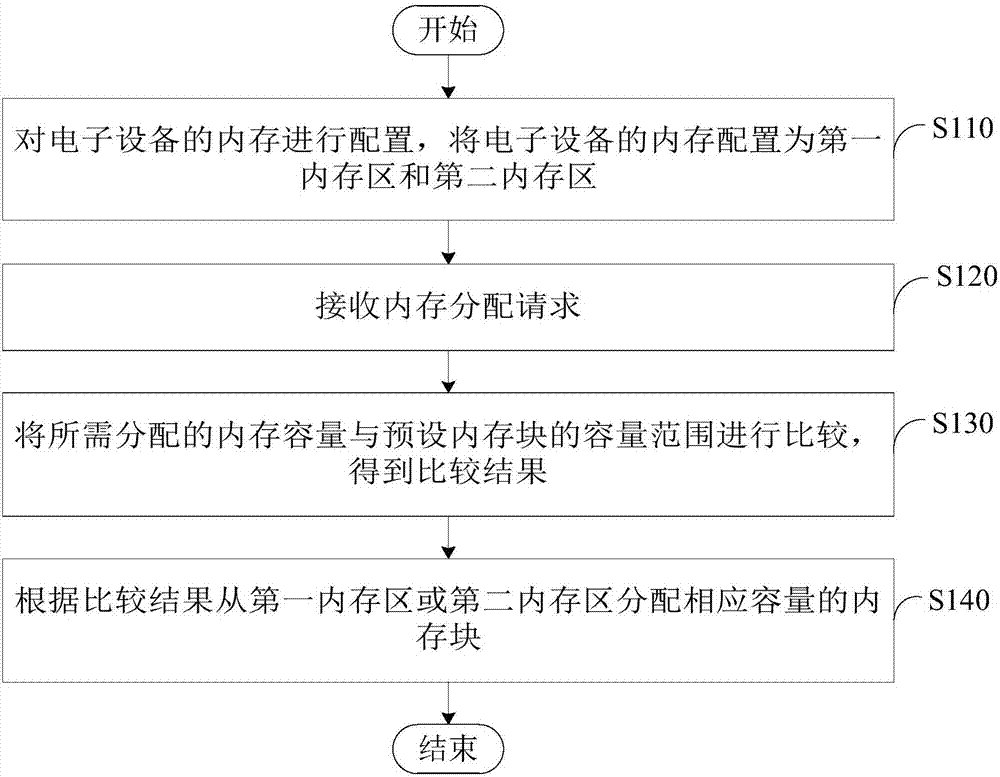

Memory allocation method and device, electronic device and readable storage medium

InactiveCN107203477AReduce chance of fragmentationBest practiceMemory architecture accessing/allocationMemory adressing/allocation/relocationDistribution methodComputer science

The invention provides a memory allocation method and device, an electronic device and a readable storage medium. A memory of the electronic device comprises a first memory area and a second memory area. The method comprises the steps of receiving a memory allocation request which comprises memory capacity needing to be allocated; comparing the memory capacity needing to be allocated with a capacity range of a preset memory block, and obtaining a comparison result; and allocating memory blocks of a corresponding capacity from a first memory area to a second memory area according to the comparison result. According to the method, by allocating the memory blocks in different memory areas, the memory blocks with different sizes are separated to be managed, memory fragmentization caused by mixed use of the memory blocks with different sizes is avoided, and thus the fragmentization occurrence probability is reduced.

Owner:ONEPLUS TECH SHENZHEN

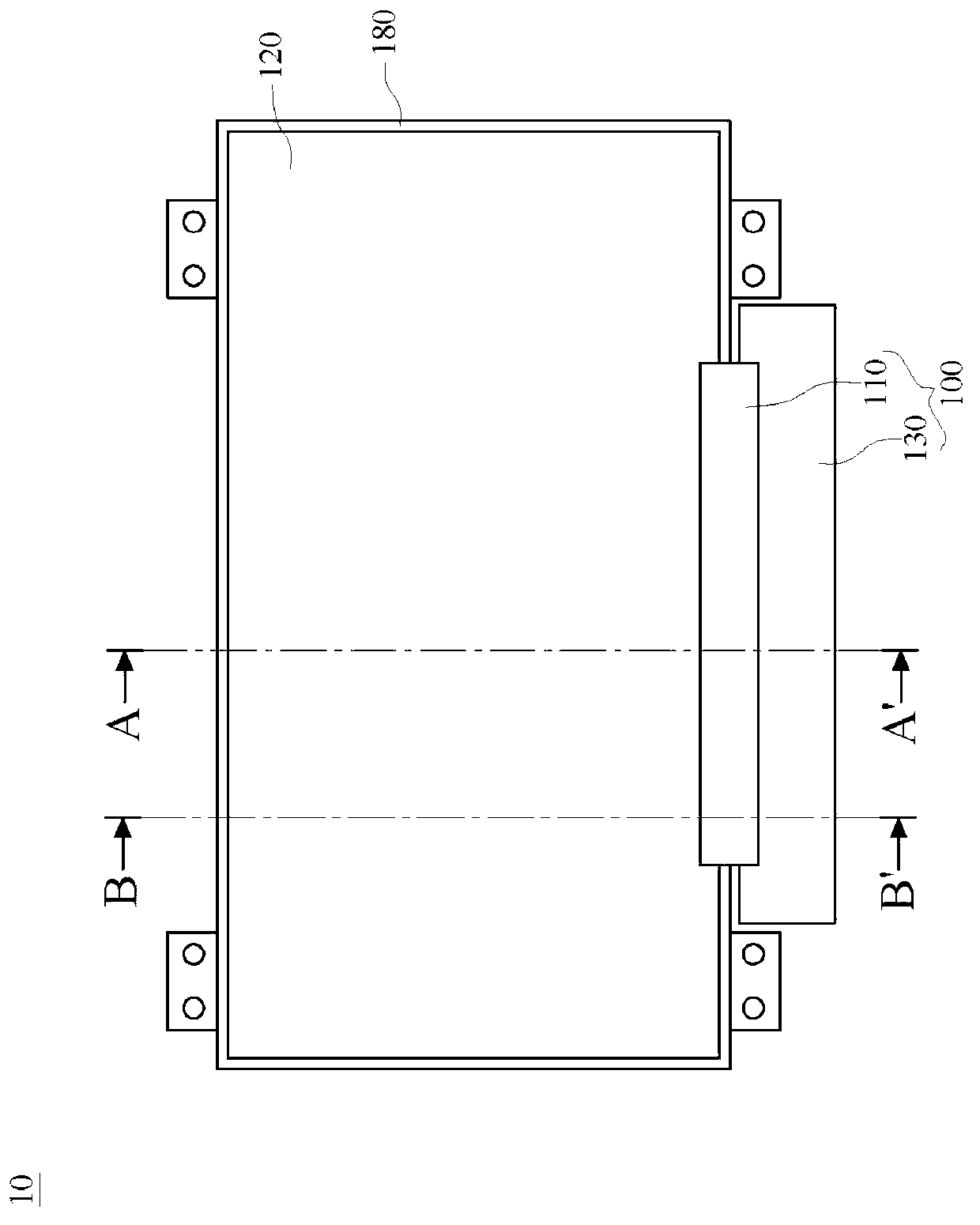

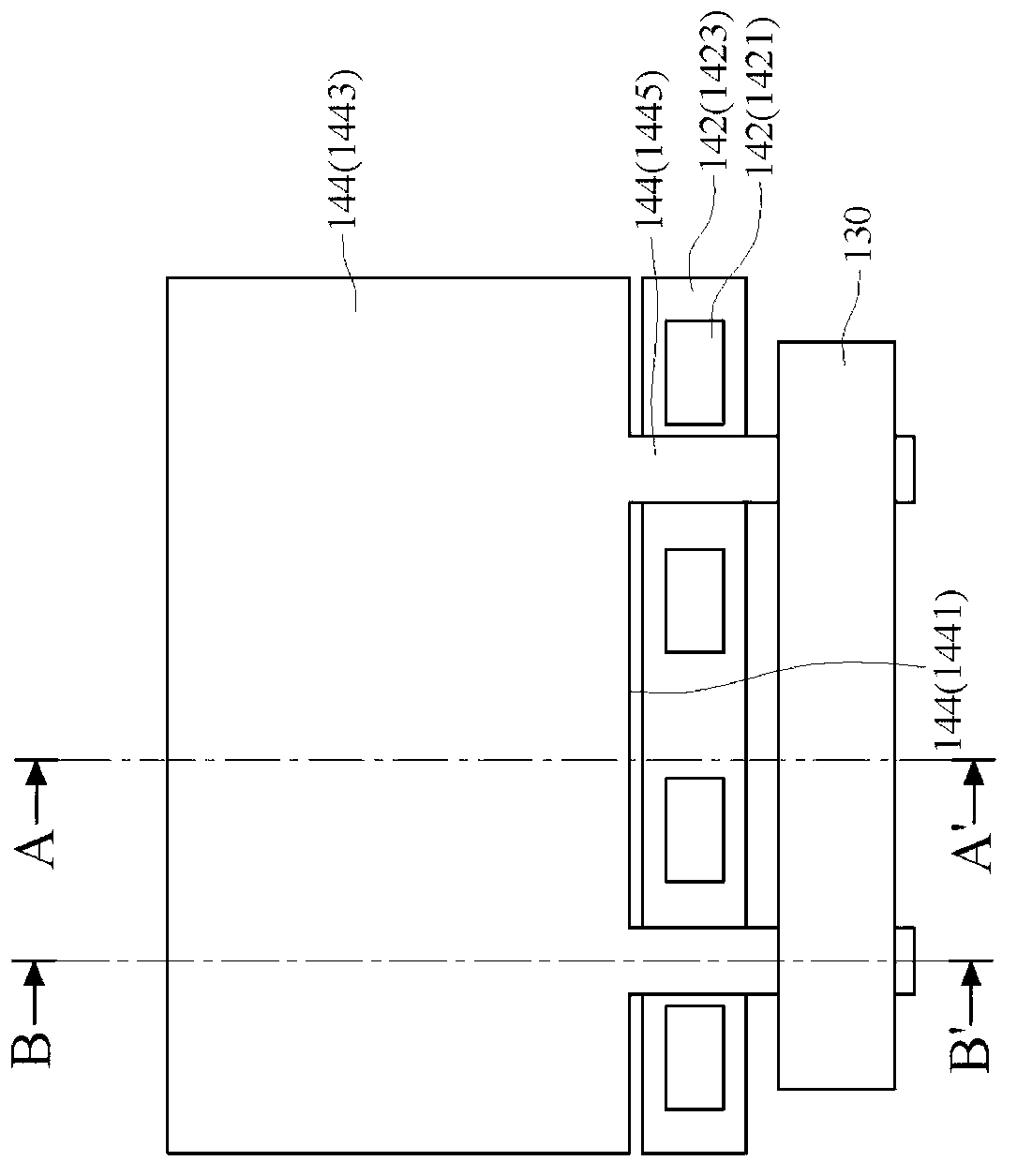

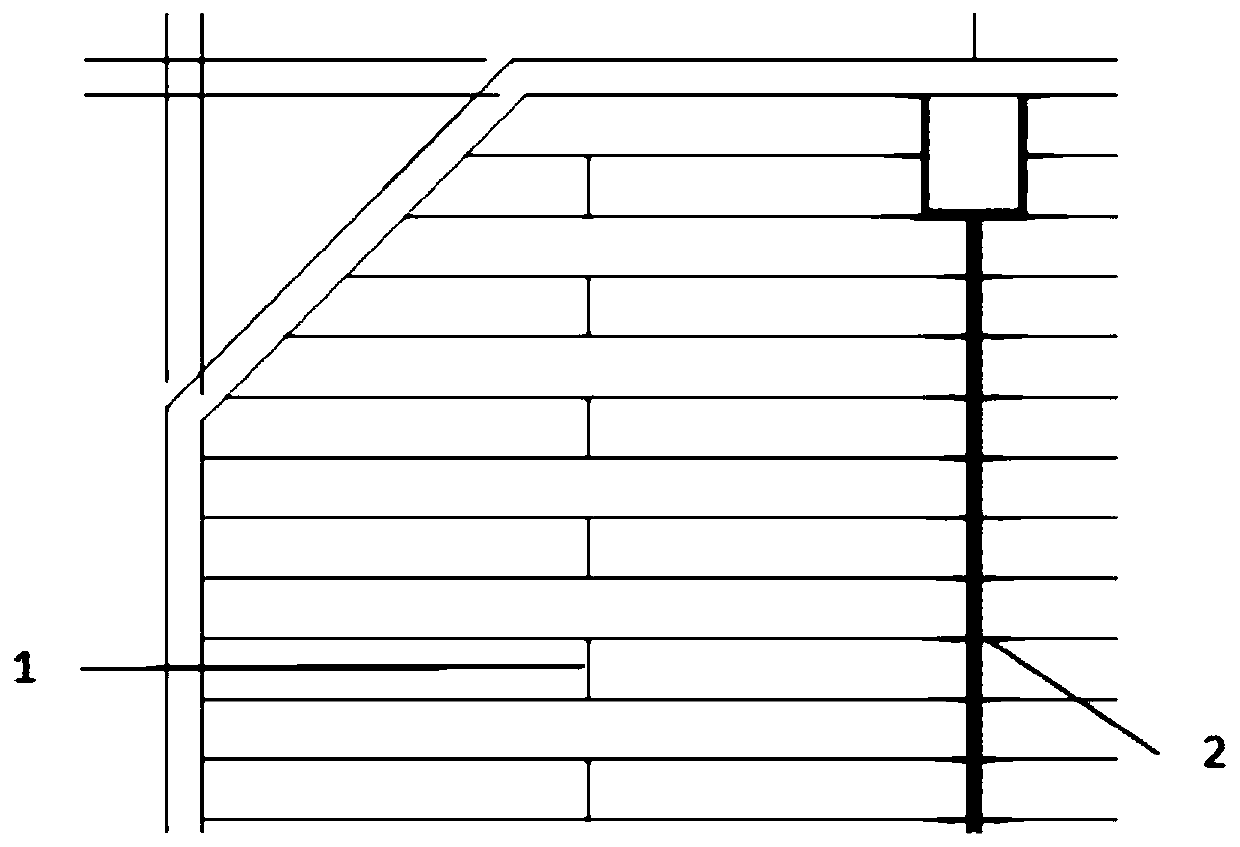

Display panel, display device and manufacturing method of display panel

InactiveCN104460092AReduce the chance of fragmentationImprove stress concentrationSolid-state devicesNon-linear opticsStress concentrationDisplay device

The invention discloses a display panel, a display device and a manufacturing method of the display panel. The display panel comprises a first substrate and a second substrate, the first substrate and the second substrate are opposite, the first substrate comprises multiple first side edges and at least one second side edge, and the second substrate comprises multiple third side edges and at least one fourth side edge. The first side edges correspond to the third side edges and are flush with the third side edges. The second side edges correspond to the fourth side edges. At least one notch is formed in the second side edges, and the length of each notch is smaller than that of the corresponding second side edge. According to the display panel, the positions of the side edge of the first substrate and the side edge of the second substrate correspond to each other, the notches are formed in the second side edges of the first substrate, the probability of breaking of the display panel when the display panel falls down or is impacted is lowered, the stress concentration problem of the display panel is solved, and the strength of the display panel is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

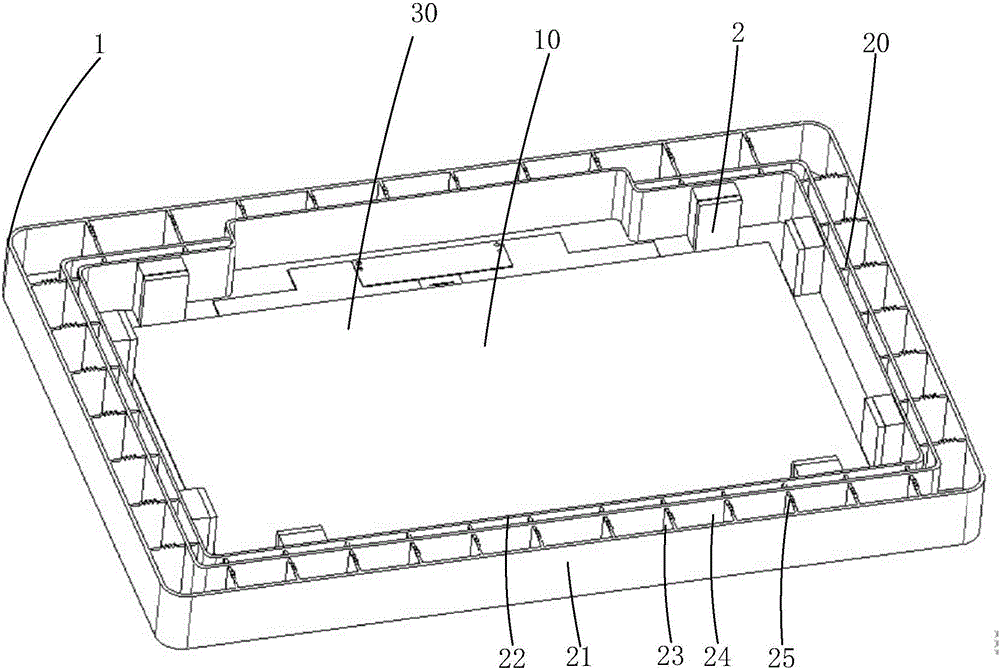

Stackable packaging box

ActiveCN105883140AAvoid horizontal shakingReduced chance of fragmentationRigid containersDamagable goods packagingLiquid-crystal displayLiquid crystal

The invention provides a stackable packaging box. Mutually-meshed micro-structures are respectively arranged at the bottom surface of a base plate of a box body and the top surface of the sidewall of the box body, so that when the packaging box is stacked, the base plate of the box body at the upper layer and the sidewall of the box body at the lower layer form close position limitation under the effect of gravity, the stacked packaging box, especially a plastic packaging box is prevented from horizontal jitter generated in a transportation process; therefore, the possibility of damage of a liquid crystal panel inside the packaging box is reduced; meanwhile, the possibility of eversion and reversion of the sidewall of the packaging box can be reduced as well.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

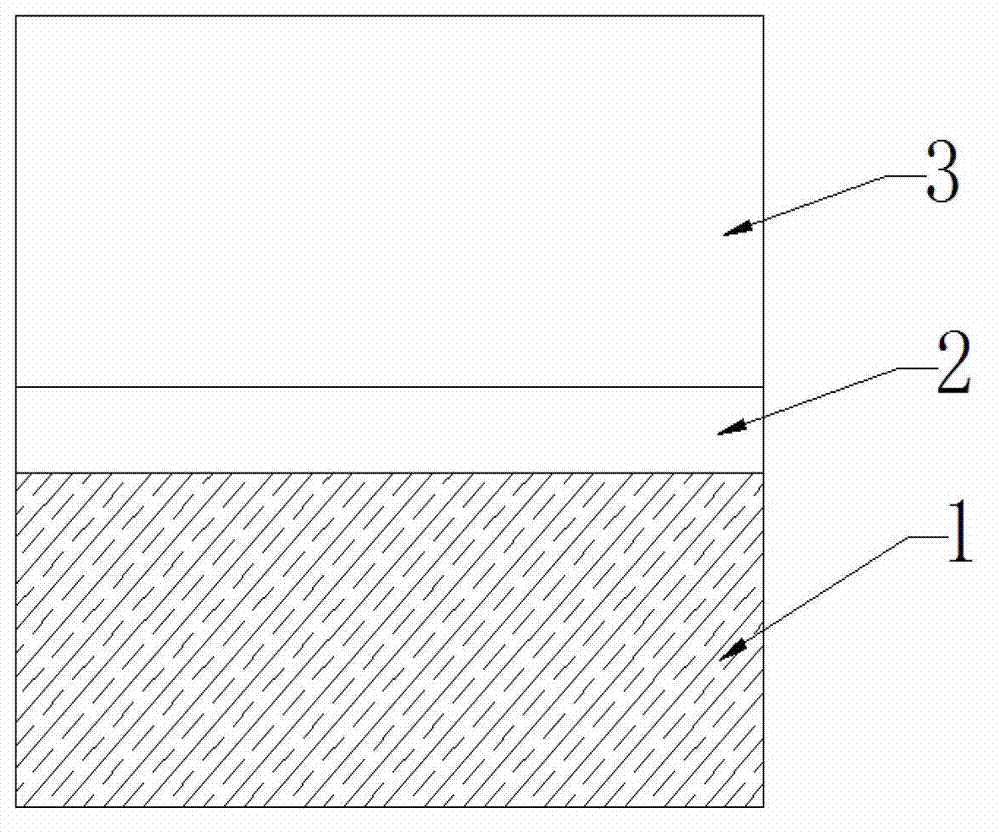

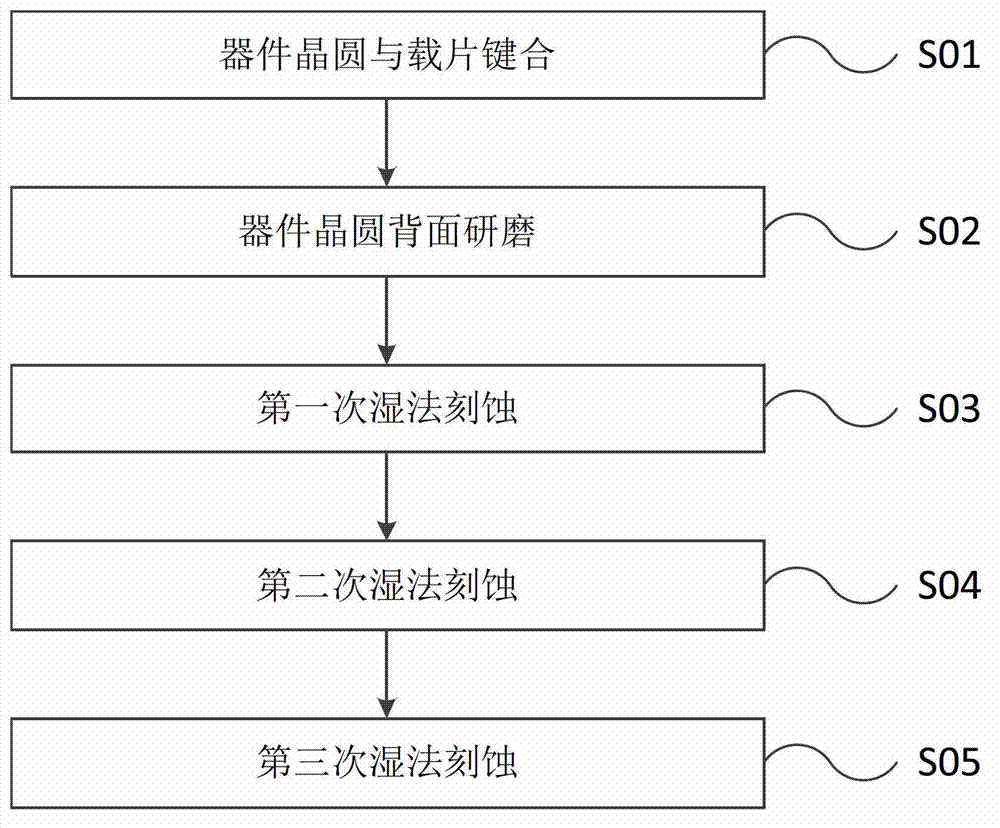

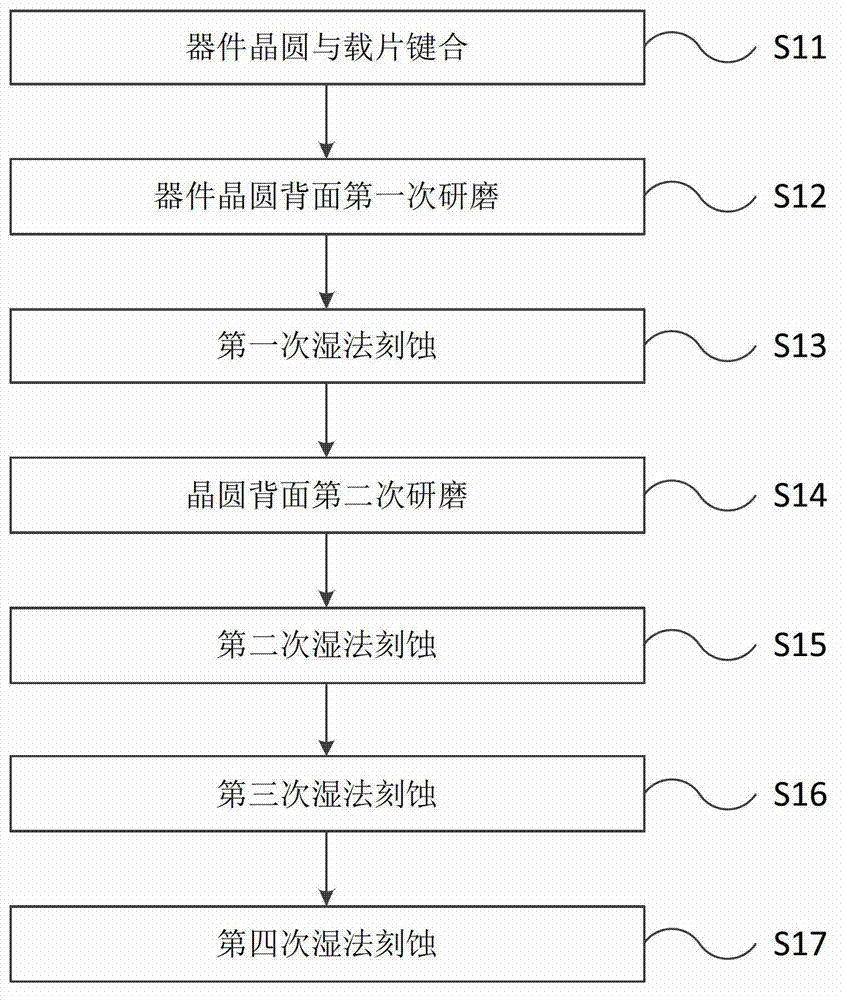

Wafer back face thinning method

InactiveCN103117218AReduce internal stressReduce the chance of fragmentationSemiconductor/solid-state device manufacturingAgricultural engineeringThinning

The invention relates to the field of semiconductors, in particular to a wafer back face thinning method. The wafer back face thinning method comprises the following steps: bonding a component wafer with a ground slide; conducting firs-time grinding on the back face of the component wafer; conducting first-time wet method etching on the component wafer; conducting second-time grinding on the back face of the component wafer; conducting second-time wet method etching on the component wafer; conducting third-time wet method etching on the component wafer; and conducting fourth-time wet method etching on the component wafer. Consequently, the component wafer is thinned to the required thickness. The wafer back face thinning method has the advantages of repeating grinding the back face of the component wafer and wet method etching in the original technological process, effectively reducing inner stress produced in the process of thinning the wafer after optimizing the technology through multi-step grinding and wet method etching, reducing fragment possibilities, and increasing the rate of finished products.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

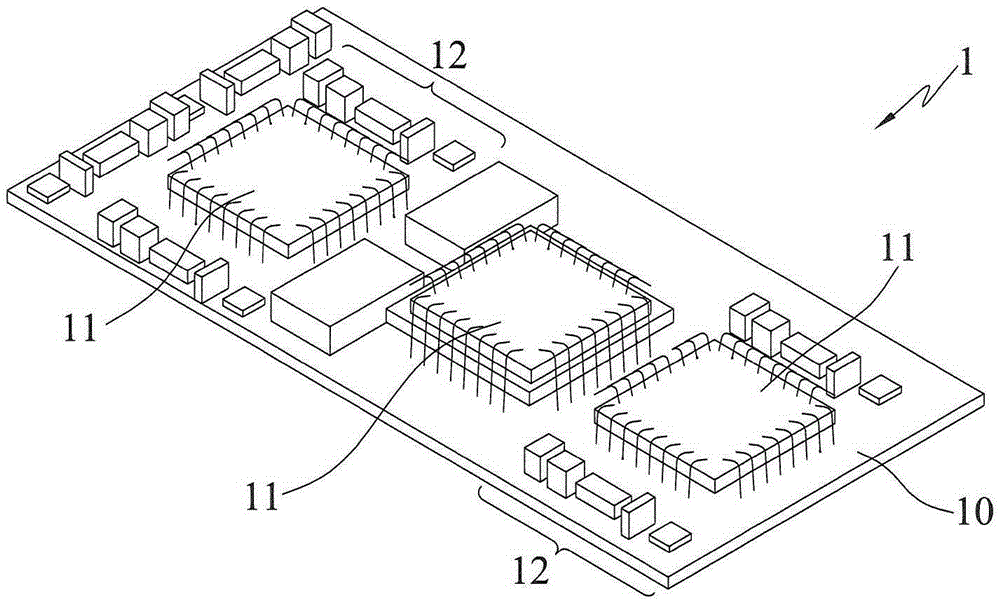

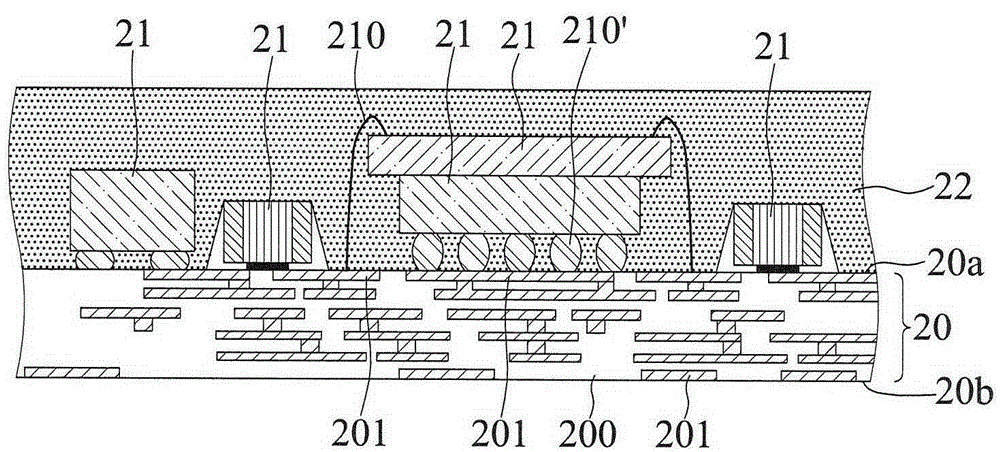

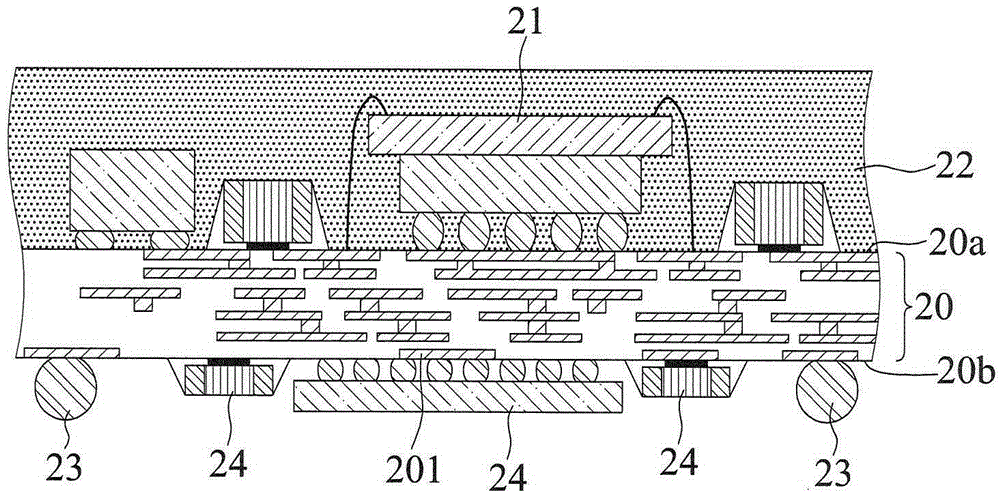

Electronic package and fabrication method thereof

InactiveCN106409780AOverall small sizePrevent moistureSemiconductor/solid-state device detailsSolid-state devicesMiniaturizationEngineering

An electronic package is provided, including: a substrate having opposite first and second surfaces; at least a first electronic element disposed on the first surface of the substrate; a first encapsulant encapsulating the first electronic element; at least a second electronic element and a frame disposed on the second surface of the substrate; and a second encapsulant encapsulating the second electronic element. By disposing the first and second electronic elements on the first and second surfaces of the substrate, respectively, the invention allows a required number of electronic elements to be mounted on the substrate without the need to increase the surface area of the substrate. Since the volume of the electronic package does not increase, the electronic package meets the miniaturization requirement.

Owner:SILICONWARE PRECISION IND CO LTD

Display device

ActiveCN103137021AReduced opening designHigh mechanical strengthIdentification meansDisplay deviceOpen design

Disclosed is a display device, comprising a display module, an electric circuit unit, and a backlight module, wherein the electric circuit is electrically connected with the display module. The backlight module is provided with a support part, and the circuit unit is arranged at the support part. The display device provided by the invention is characterized in that a second electric circuit board is supported through the support part arranged by virtue of the backlight module, so that opening design of a bottom part of a frame body can be reduced, mechanical strength of the frame body can be increased, and fragmentation probability of the display module can be reduced. Moreover, by virtue of the support part which is formed by extending the backlight module, additional components for supporting the second circuit plate can be saved.

Owner:AU OPTRONICS CORP

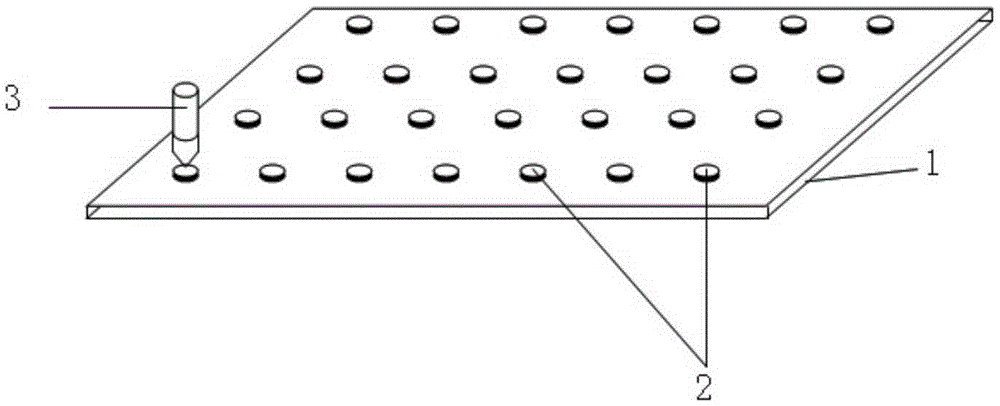

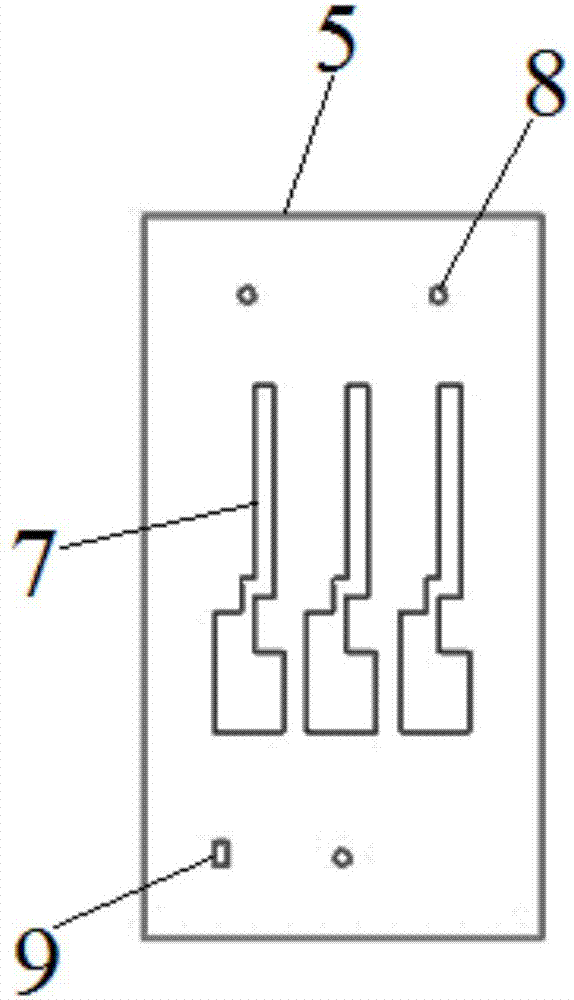

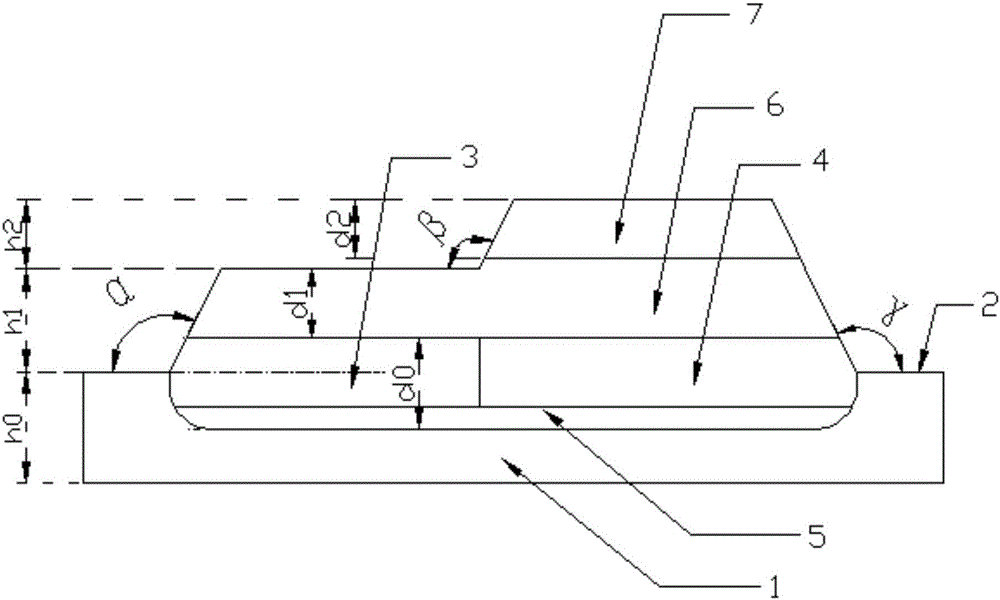

Preparation and distribution method of vacuum glass and supporter thereof

The invention discloses a preparation and distribution method of a vacuum glass and a supporter thereof. The preparation and distribution method of the supporter of vacuum glass comprises the following steps: drawing the three dimensional figure of the supporter and the three dimensional figure of a supporter assignment mode by using drawing software; arranging a glass flake on the printing tablet of a 3D printer, and filling the feeding chamber of the 3D printer with a bonding material; heating and fusing the bonding material, and printing the fused bonding material on glass in a preset position layer by layer according to the drawn three dimensional figure of the supporter under the control of the drawing software, and solidifying the bonding material to form the vacuum glass supporter; and completing printing and distribution of all the supporter on a glass panel under the control of the drawing software. The method improves the dimension and the distribution position precision of the vacuum glass supporter.

Owner:BEIJING HANGBO NEW MATERIAL TECH

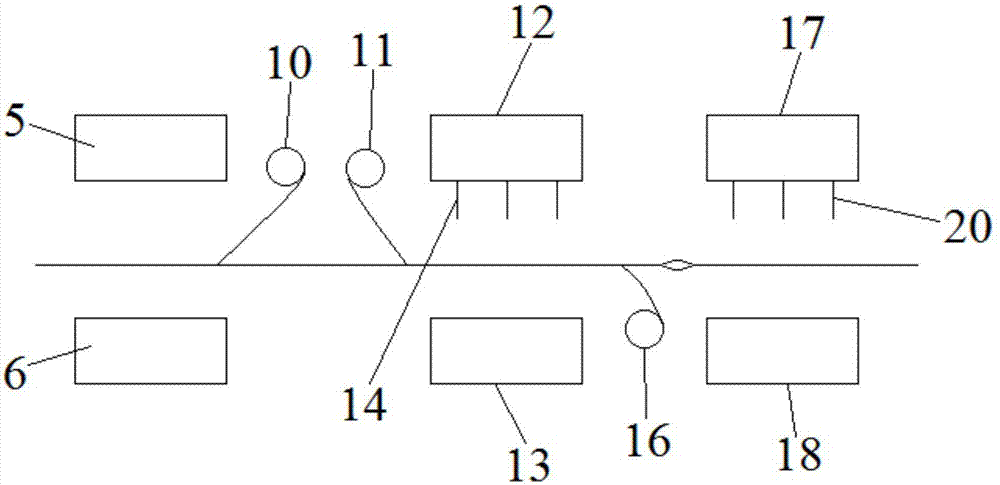

Model cutting device for mobile phone heat dissipating graphite sheet

PendingCN107984632AReduce Fragmentation RateReduce difficultyWorking accessoriesStone-like material working toolsAdhesiveEngineering

The invention relates to a model cutting device for a mobile phone heat dissipating graphite sheet. The device comprises a first model cutting unit, a first waste discharging unit, a double-face adhesive tape laminating unit, a second model cutting unit, a single-face adhesive tape separating unit and a third model cutting unit which are sequentially arranged in the moving direction of a materialbelt. The graphite sheet laminated on single-face adhesive tape is formed in a model cutting manner in the first model cutting unit. After outer frame waste materials of the graphite sheet are discharged through the first waste discharging unit, in the double-face adhesive tape laminating unit, double-face adhesive tape with a release film and the graphite sheet are laminated, locating and punching are carried out in the second model cutting unit, and after single-face adhesive tape is discharged through the single-face adhesive tape separating unit, the third model cutting unit carries out punching on the double-face adhesive tape. Compared with the prior art, at first, the single-face adhesive tape serves as a material belt carrier, model cutting forming of the graphite sheet is achieved, then the release film serves as the material belt carrier, model cutting forming of the double-face adhesive tape is achieved, the fragmentation rate and the machining difficulty of the graphite sheet are reduced greatly, and the quality and the production efficiency of finished products are improved.

Owner:昊佰电子科技(上海)有限公司

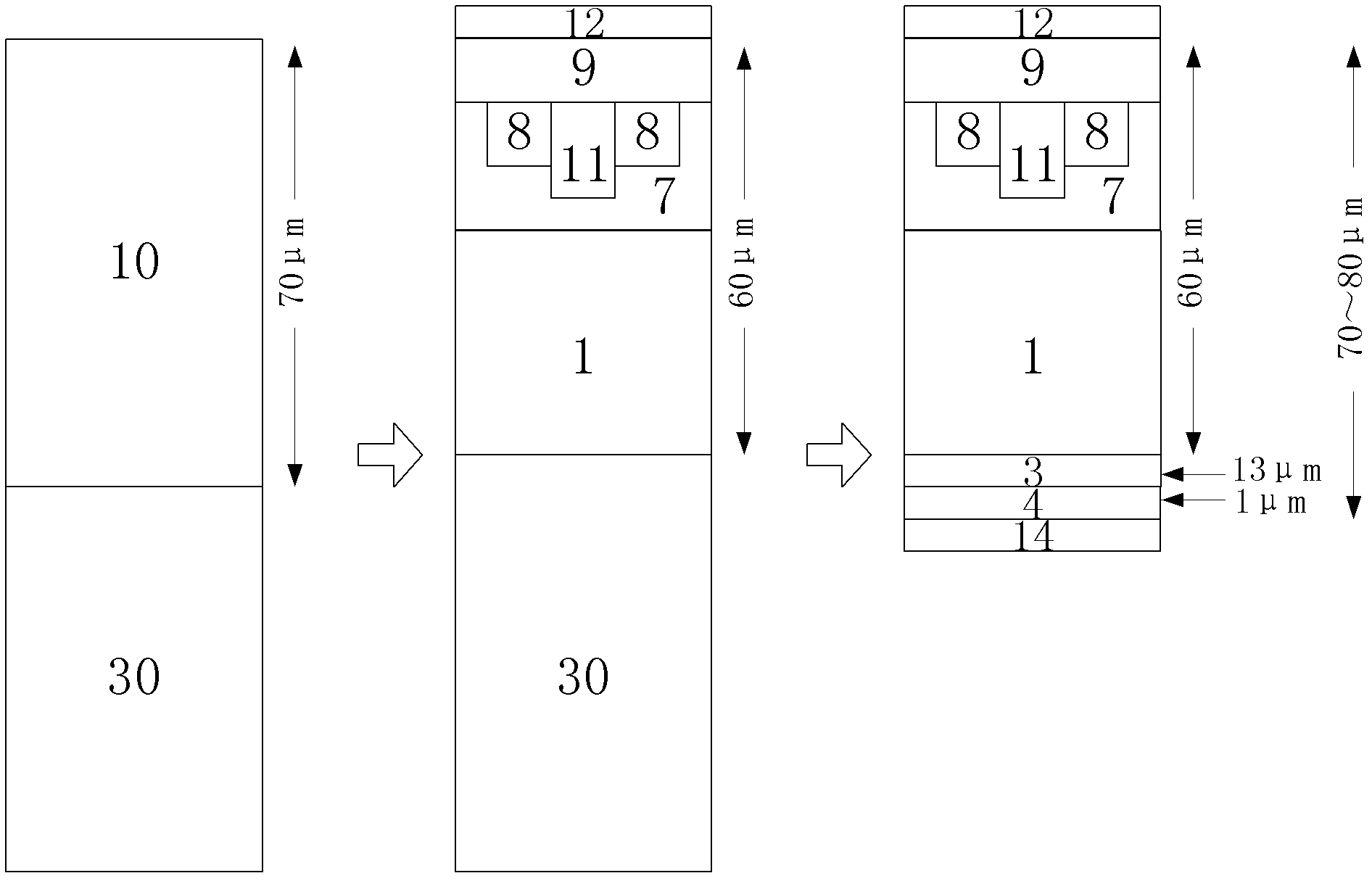

Method of manufacturing field termination type insulated gate bipolar translator (IGBT) component with substrate provided with outward-extending layer

ActiveCN103137473AReduce the chance of fragmentationHuge cost savingsSemiconductor/solid-state device manufacturingEngineeringIon implantation

The invention discloses a method of manufacturing a field termination type insulated gate bipolar translator (IGBT) component with a substrate provided with an outward-extending layer. The method comprises the steps of selecting the substrate provided with the outward-extending layer, and manufacturing a front face structure of the IGBT component on the front face of outward-extending layer until depositing front face metal as an emission electrode; thinning the silicon base from the back face, forming a p-shaped heavy doping field blocking-up zone on the back face of the silicon base through technology of injecting ions, and depositing metal on the back face of the p-shaped heavy doping field blocking-up zone to form a collector. The method of manufacturing the IGBT component with the substrate provided with the outward-extending layer does not need production technology for extremely thin slices with thickness less than 70 nanometers, thereby effectively reducing the slice breaking rate of slice technology, and saving enormous cost of purchasing new machines and equipment.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

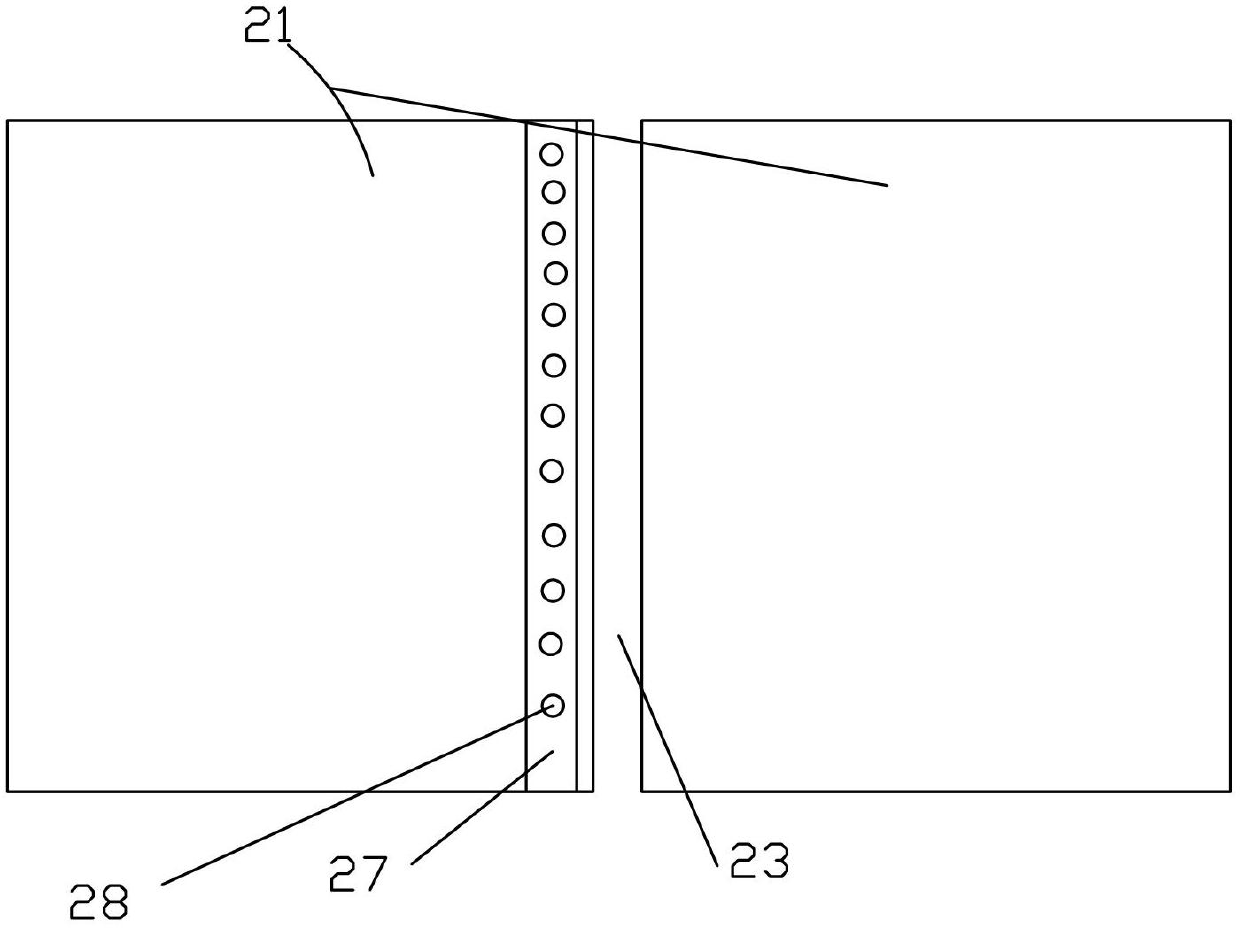

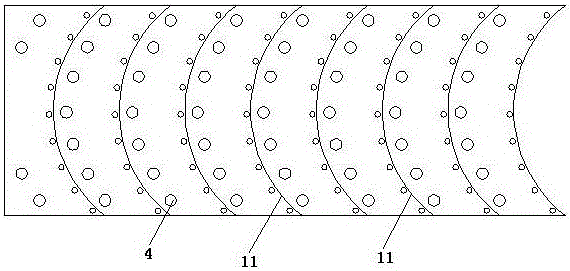

Gradual cracking device for strip-shaped optical glass

ActiveCN105837021AReduce the impactGood release controllabilityGlass severing apparatusOptical glassLine structure

The invention relates to a gradual cracking device for strip-shaped optical glass. The gradual cracking device comprises pillar plates which are oppositely arranged, and a lower supporting plate, wherein the pillar plates are arranged above; the lower supporting plate is arranged below; sucking disc pillars are arranged on the pillar plates; the pillar plates are arranged on a horizontal track; the gradual cracking device is characterized in that two rows of arch pillars are configured on the pillar plates; diameters of one row of arch pillars are greater than those of the other row of arch pillars; each row of arch pillars is configured in a line structure and consists of a plurality of arch pillars; the arch pillars are arranged in through holes of the pillar plates and are connected with driving devices; the driving devices are capable of driving the arch pillars to move towards the lower supporting plate; a cooling jacket is arranged on a bottom surface of the lower supporting plate.

Owner:明光康诚伟业机电设备有限公司

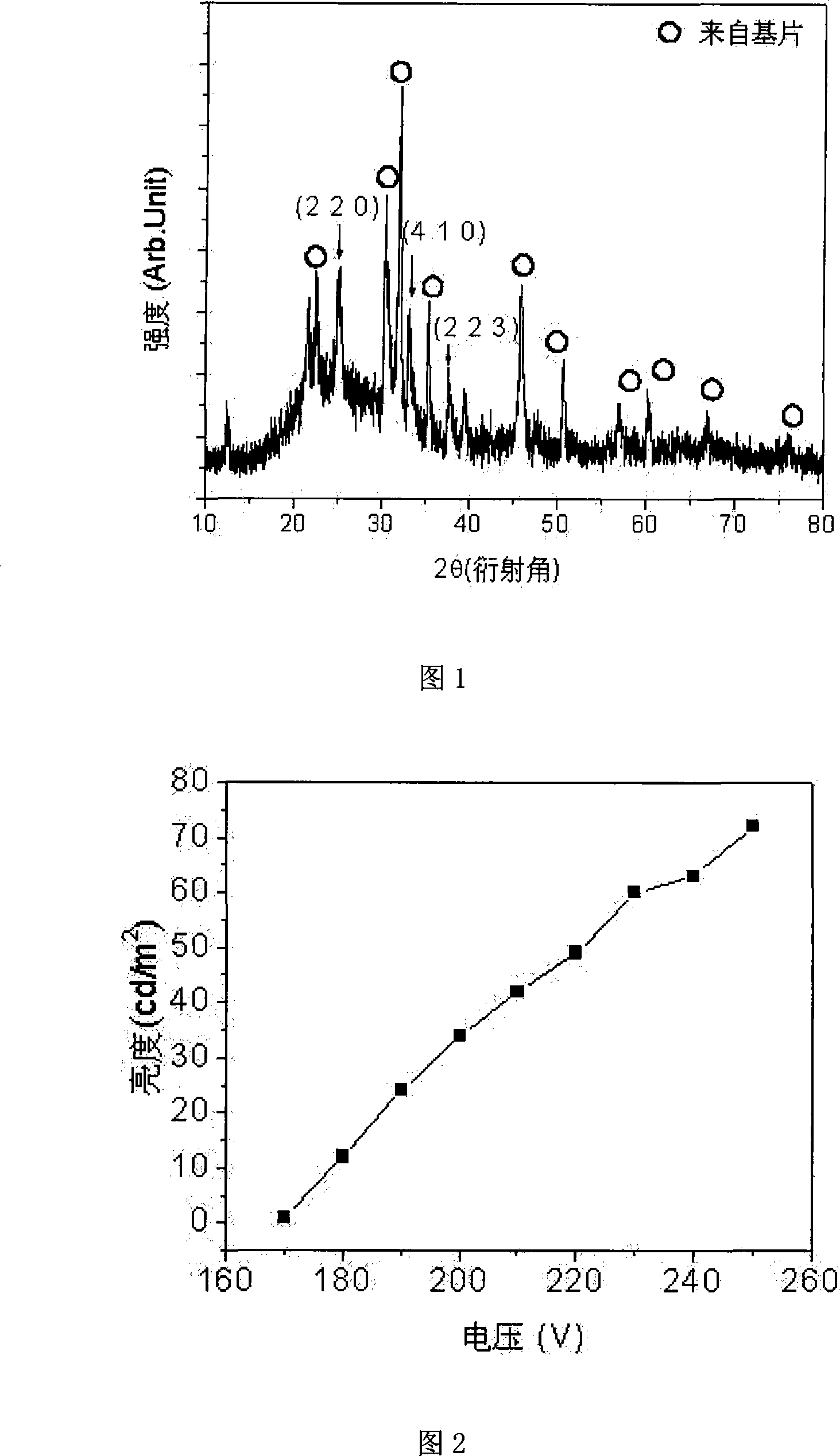

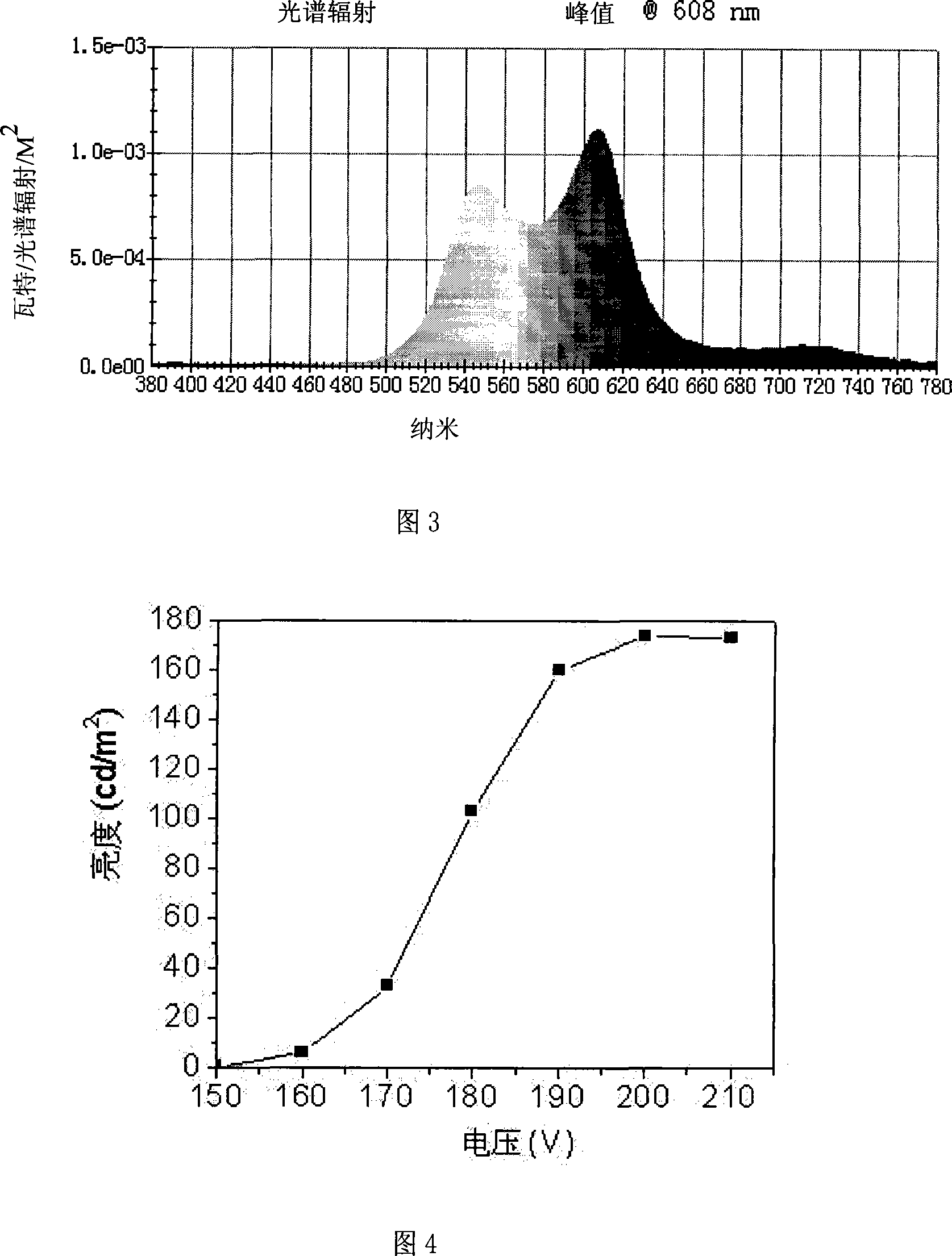

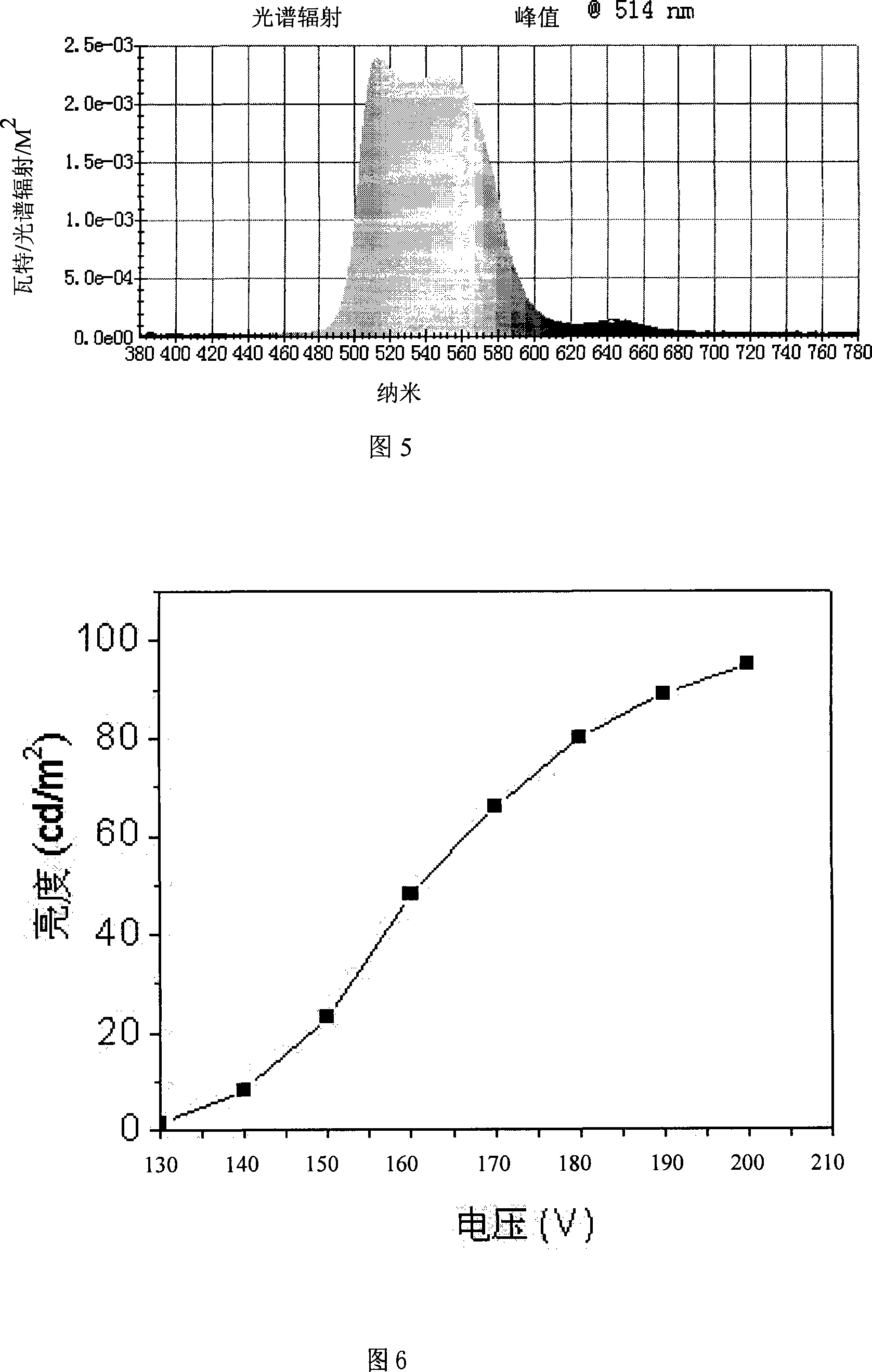

Production method for oxide luminescent layer in inorganic electroluminescence display device

InactiveCN101175347AAvoid fragileImprove cooling effectElectrical apparatusElectroluminescent light sourcesManufacturing technologyAlternating current

The present invention discloses the production method of the oxide luminous layer in a non-organic electroluminescent display, which belongs to the manufacturing technical field of the non-organic electroluminescent display driven by alternating current. The method of the present invention is that the corresponding oxide powder is directly sprayed and coated on a metal backboard to make a ceramic target. The ceramic target is sputtered on a plating film to form an oxide luminous layer film, which is applied to the non-organic electroluminescent display. With the present invention, the production cost of a large-size target used for sputtering and aggrading a large-area oxide luminous film; the crack in the ceramic target production agglutinating process is avoided; the probability of the crack in the target using process is reduced; the target component is much easier to be adjusted; and the research and development and the production costs of the display are reduced.

Owner:INESA ELECTRON

Wafer thinning method

InactiveCN109346403AReduce internal stressAvoid pollutionSemiconductor/solid-state device manufacturingBreakage probabilityEtching

The invention discloses a wafer thinning method. The wafer thinning method is characterized by comprising the steps of providing a wafer to be thinned, trimming a wafer edge by laser, and removing a part of material at a round angle to form an arc chamfer angle; preparing a coating liquid, uniformly coating the coating liquid on a front surface of the wafer and the chamfer angle of the edge, baking and hardening to form a coverage layer, and fixing the front surface of the wafer and a substrate; performing first-time grinding on a back surface of the wafer, and performing first-time wet etching on the back surface of the wafer; performing second-time grinding on the back surface of the wafer; and performing second-time wet etching on the back surface of the wafer, making the wafer and thesubstrate separated, removing the coverage layer of the wafer, thereby obtaining the thinned wafer. The wafer thinning method employs a special protection process, the internal stress of the device generated during the wafer thinning process can be reduced, the front surface of the wafer can be prevented from being polluted by a mixture of particle generated during the wafer thinning process and cooling wafer, the breakage probability is reduced, the finished rate is improved, and the production cost is reduced.

Owner:广西桂芯半导体科技有限公司

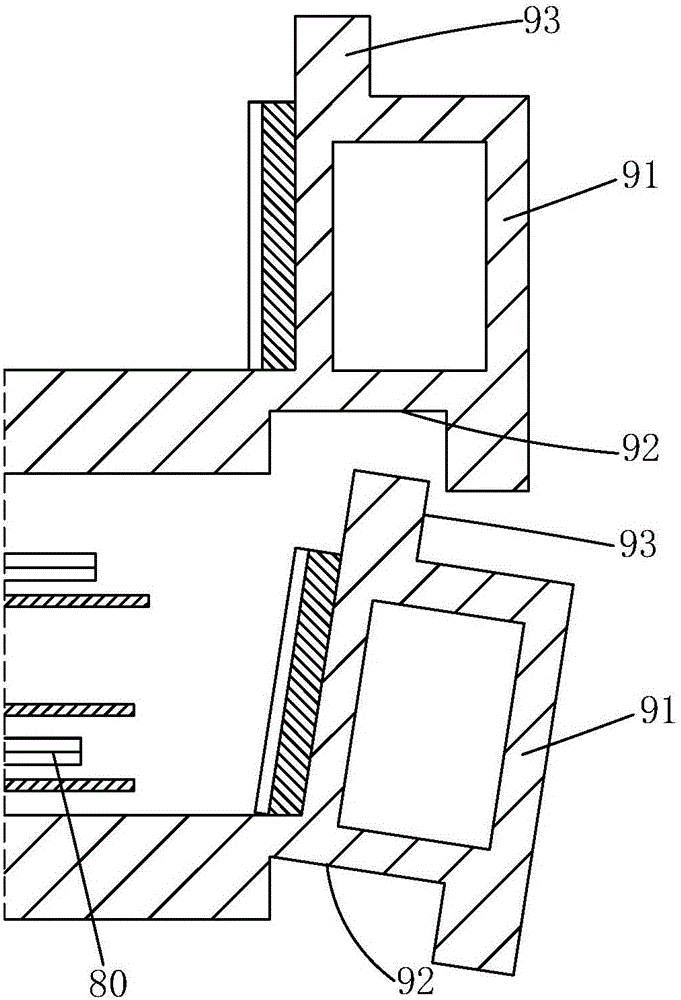

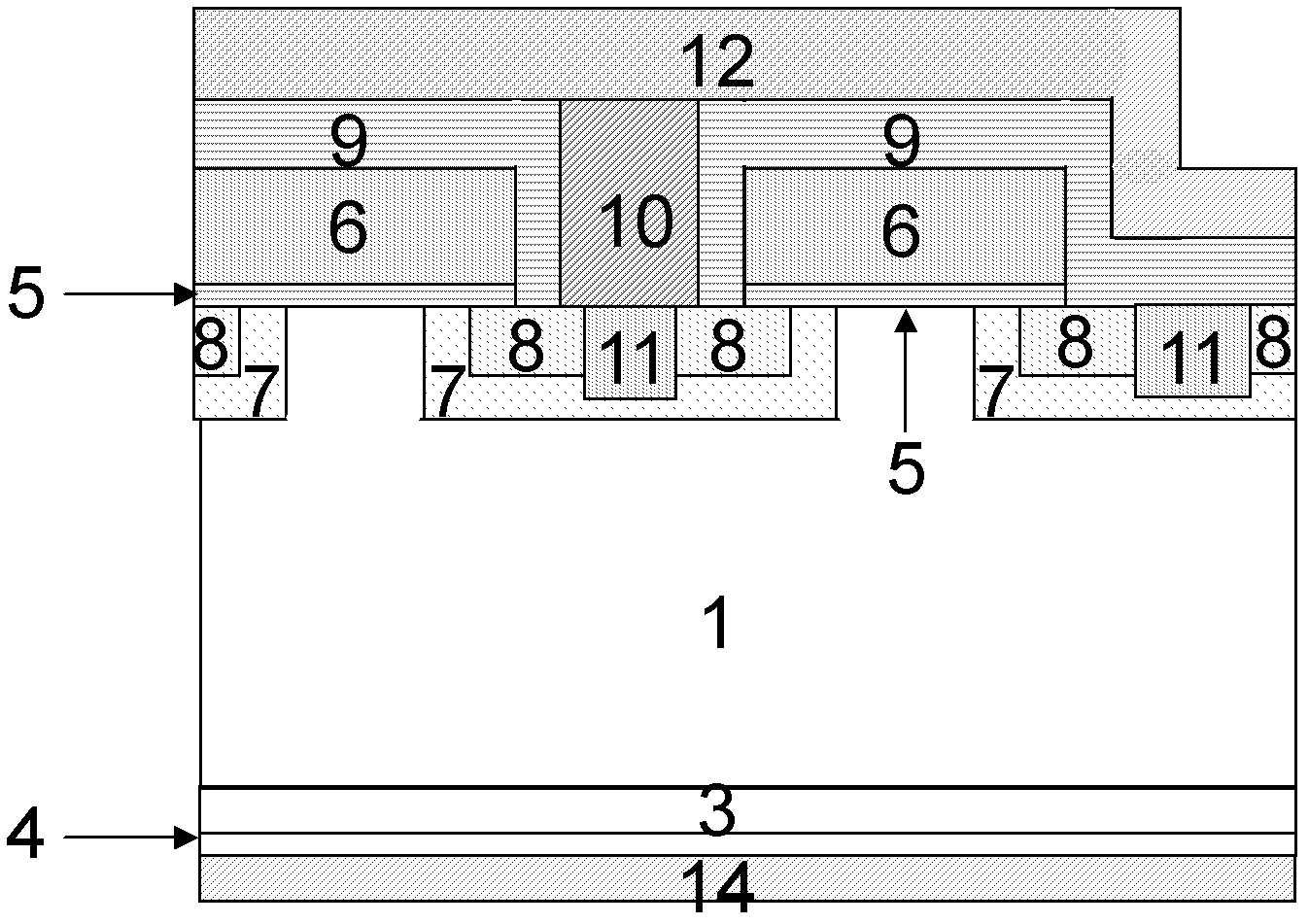

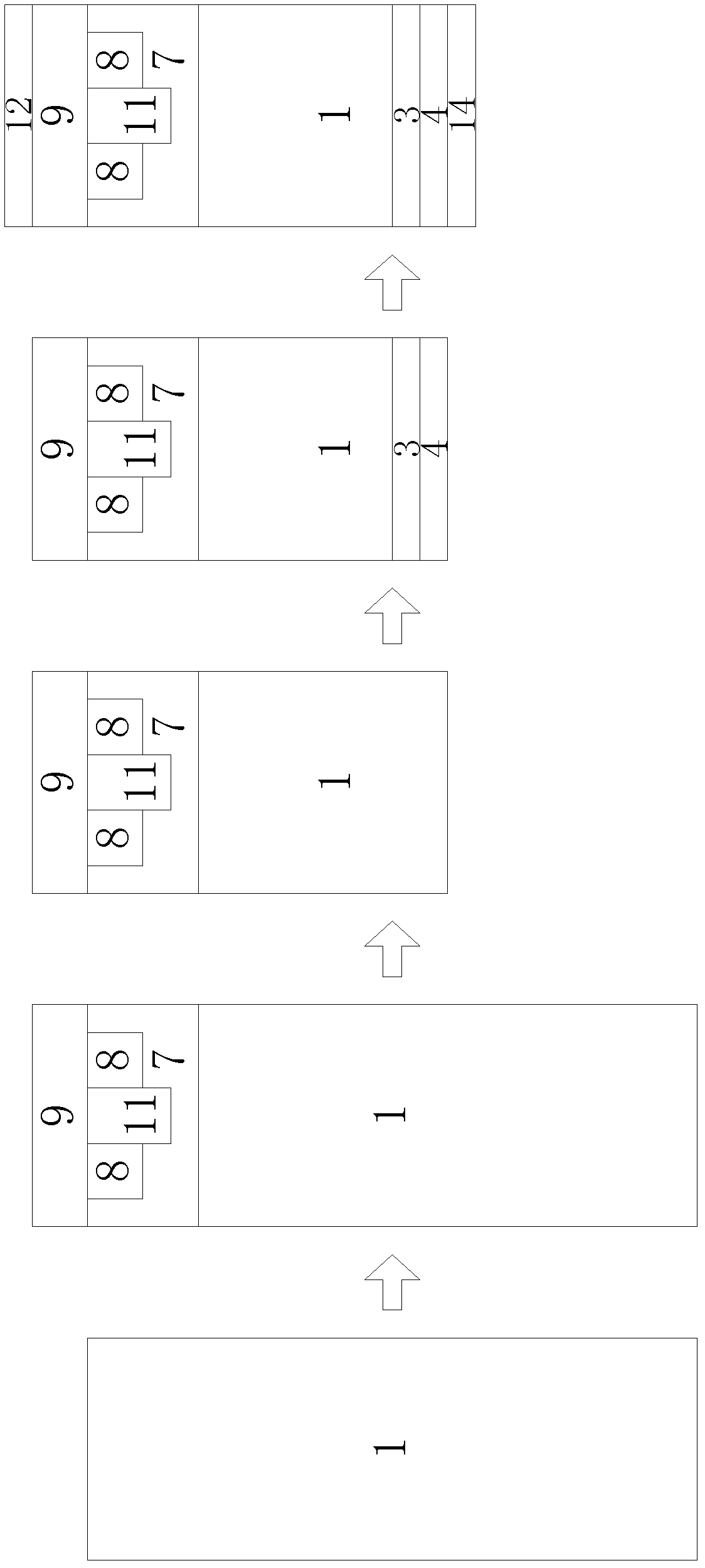

Back structure of electron multiplying charge-coupled device (EMCCD) and production method of back structure

PendingCN106847852ANot easy to breakUniform removalSolid-state devicesRadiation controlled devicesElectron multiplicationPhysical chemistry

The invention relates to a back structure of an electron multiplying charge-coupled device (EMCCD) and a production method of the back structure. The back structure comprises an EMCCD chip, electrode extracting regions, a photosensitive region, a storage grain region, ion implanting regions, an antireflection film and a metal shielding layer, wherein the electrode extracting regions are arranged on two sides of the back side of the EMCCD chip; bonding graphs are arranged on the electrode extracting regions at intervals; the photosensitive region and the storage grain region on the back side of the EMCCD chip are positioned between the electrode extracting regions; the ion implanting regions formed by implanting low-energy ions are separately formed inside the photosensitive region and the storage grain region; by using the antireflection film on the surface of the photosensitive region, a standing wave effect can be reduced, and reflected light rays are reduced; by using the metal shielding layer on the surface of the storage grain region, transmission of incident light on the surface of the storage grain region can be prevented. The back structure disclosed by the invention can be used for improving the photoelectric conversion efficiency of the EMCCD; meanwhile, the manufacturing cost of the device also can be reduced, and the rate of finished products is improved.

Owner:NORTH ELECTRON RES INST ANHUI CO LTD

Display apparatus having shading glue film

InactiveCN101082720AAvoid stress concentrationAvoid damageStatic indicating devicesScreening apparatusDisplay deviceComputer science

The invention discloses a display device, which comprises the following parts: chassis, display panel and black gel layer, wherein the display panel is set on the chassis; the display panel has display area and rim area around the display area; the rim area has at least one corner part; the black gel layer is set between the chassis and display panel, which is distributed at the rim area of display panel; the distributing area of black gel layer doesn't reach the corner part of rim area and between corner part of chassis neither, which exposes the corner part to face the chassis directly.

Owner:AU OPTRONICS CORP

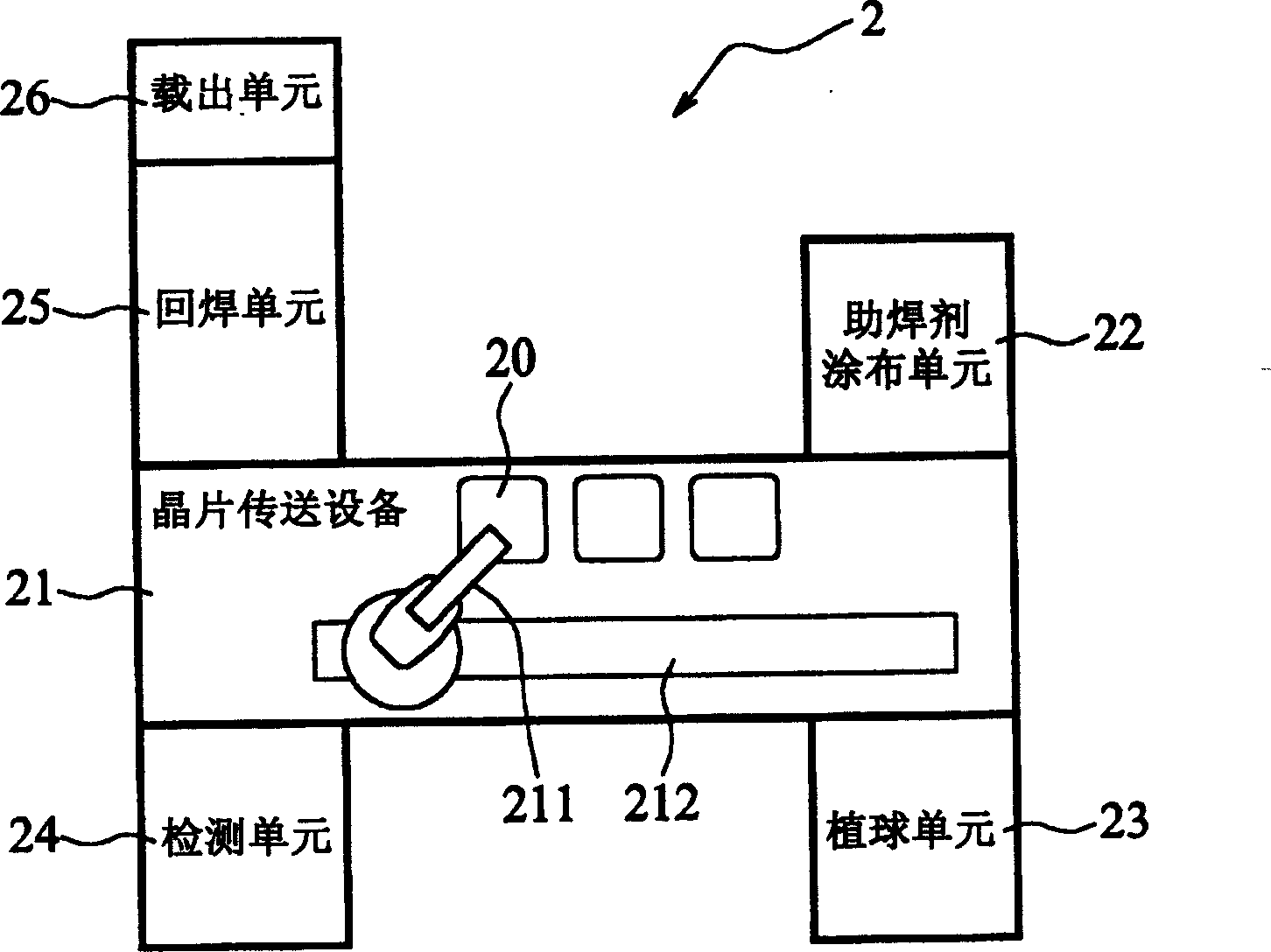

Wafer transferring equipment

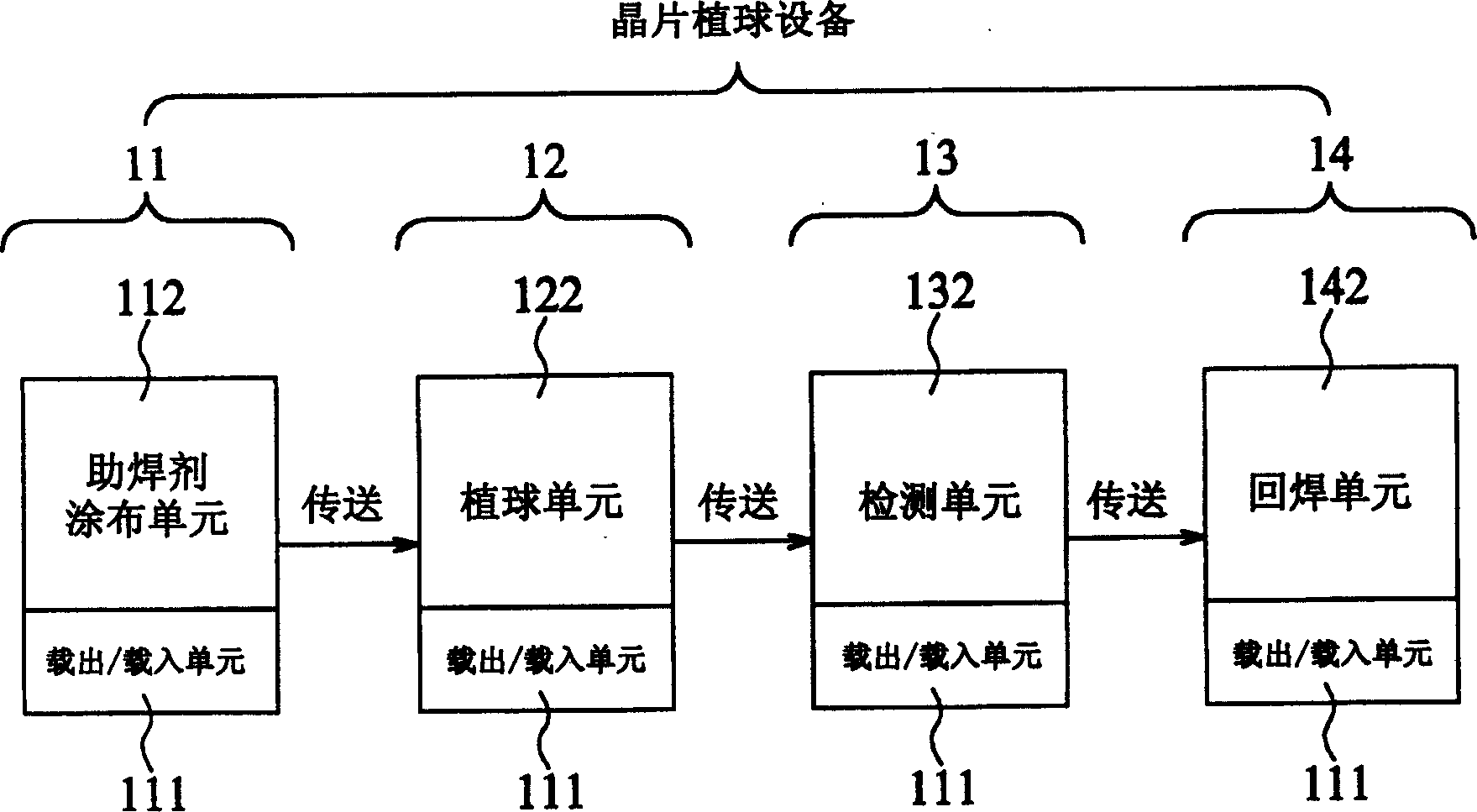

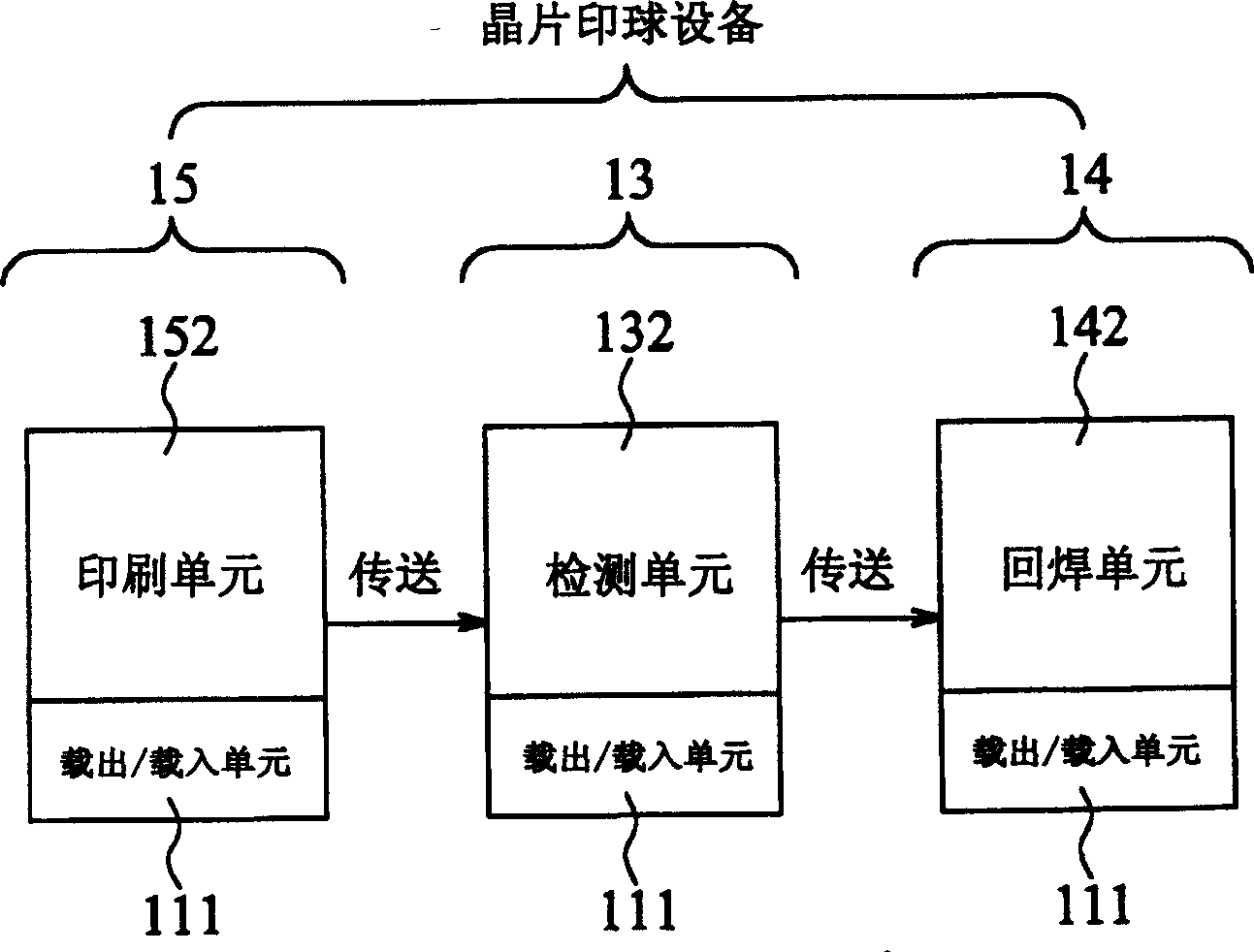

InactiveCN1515479AReduce processing timeSave spaceCharge manipulationConveyor partsElectrical and Electronics engineeringCoating

The present invention discloses a wafer transfer equipment. It can be used in the wafer ball-planting equipment having at least one crystal boat box, soldering flux coating unit, ball-planting unit, reflow soldering unit and carryover unit or used in the wafer ball-printing equipment having at least one crystal boat box, printing equipment, reflox soldering unit and carryover. The wafer transfer equipment includes a mechanical arm which is used for taking out wafer from at least crystal boat box and for transferring the wafer into any of crystal boad, soldering flux coating unit, ball-planting unit or printing equipment and reflow soldering unit or transferring the wafer out from any of them. The wafer transfer equipment also has a carrying table for loading mechanical arm.

Owner:D TEK TECHNOLOGY CO LTD

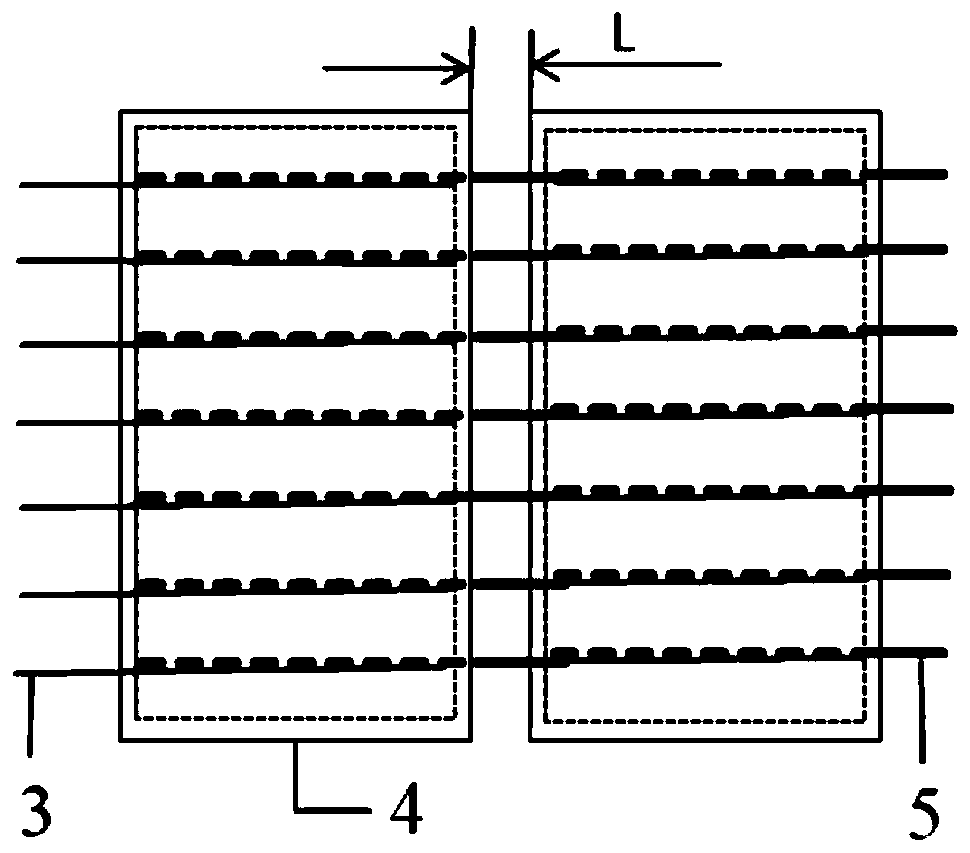

Crystalline silicon solar cell string splicing method and module

PendingCN110676345AReduce crackingReduce the chance of fragmentationFinal product manufacturePhotovoltaic energy generationThermodynamicsEngineering

Owner:YELLOW RIVER PHOTOVOLTAIC IND TECH CO LTD +2

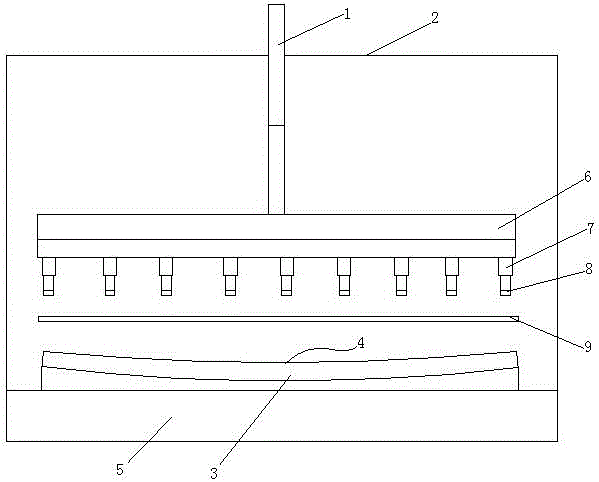

Ultrasonic processing device for optical glass

InactiveCN105837018AReduce ambient temperatureReduce breakageGlass severing apparatusGlass productionTemperature controlEngineering

The invention relates to an ultrasonic processing device for optical glass. The ultrasonic processing device comprises a stud plate, a deformation plate with an arc-shaped surface, and a temperature control device, wherein the stud plate and the deformation plate are oppositely arranged; the temperature control device can reduce the temperature of an environment where the stud plate and the arc-shaped surface are placed; a plurality of studs are arrayed on one surface of the stud plate and are vertically in threaded connection with the stud plate; an ultrasonic device is arranged on the deformation plate; the arc-shaped surface of the deformation plate is opposite to the surface, with the studs, of the stud plate; the length of each stud extending out of the stud plate can be adjusted in a rotatable manner through a thread; the surface, without the studs, of the stud plate is connected with a driving arm; the driving arm can drive the stud plate to get close to the deformation plate; a rubber suction disk is arranged at the free end of each stud; a buffer rubber layer is arranged on the arc-shaped surface.

Owner:SUZHOU WEIMI OPTICS TECH CO LTD

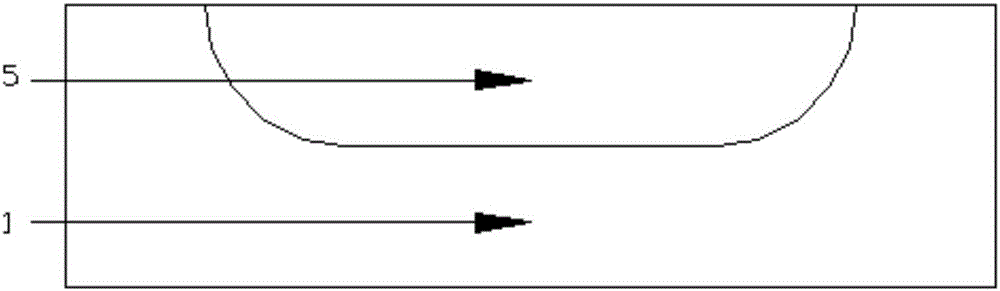

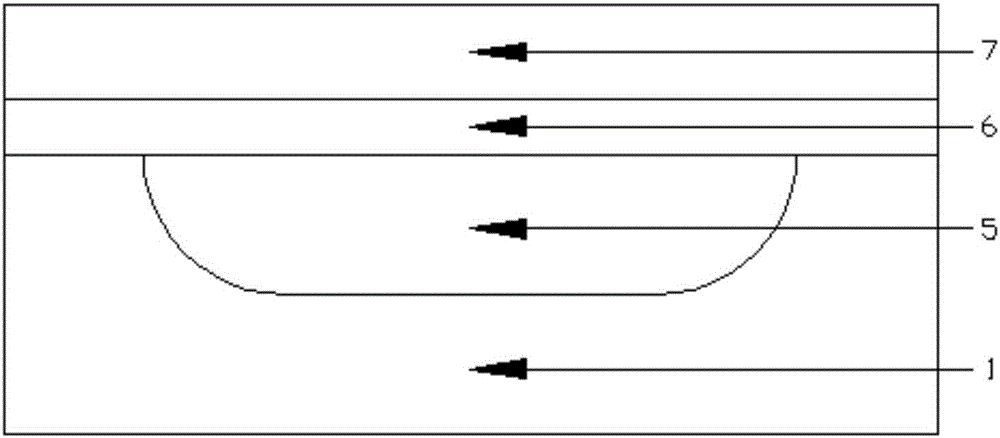

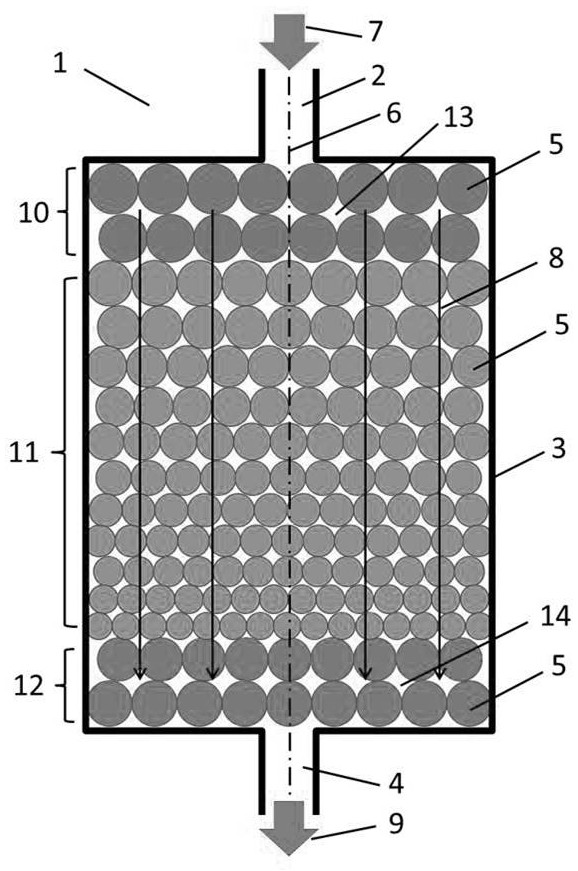

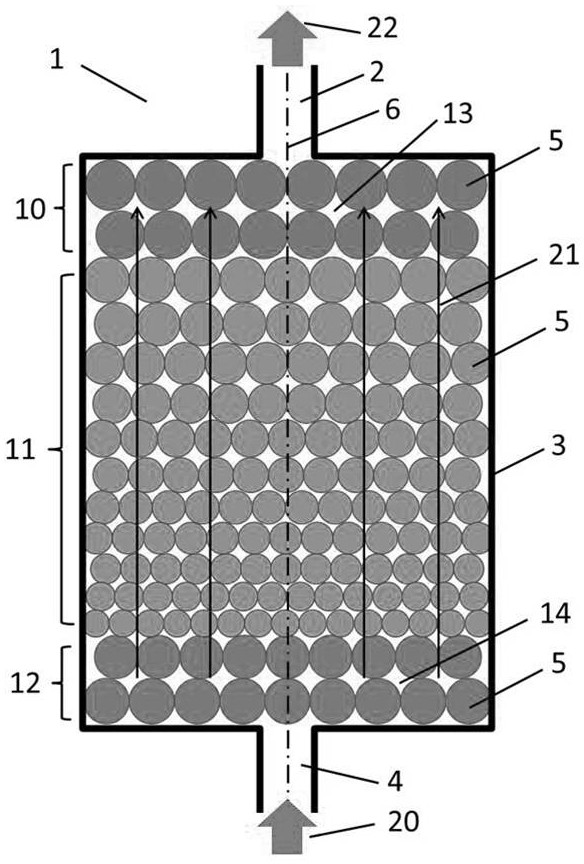

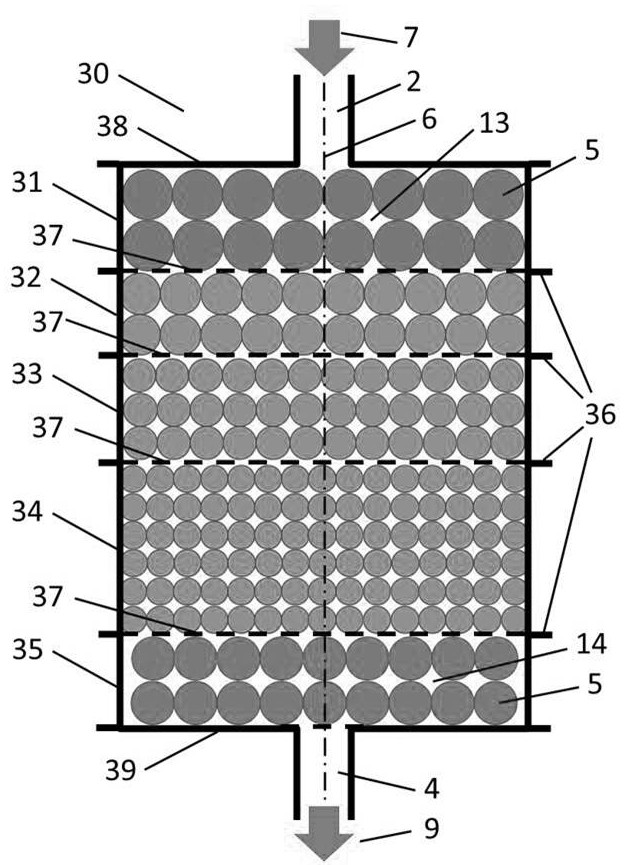

High-efficiency, long-life, low-coking and low-blocking regenerator

PendingCN111854494AReduce the chance of fragmentationExtended service lifeHeat storage plantsIndirect carbon-dioxide mitigationThermodynamicsFlue gas

The invention belongs to the technical field of regenerators, in particular to a high-efficiency, long-life, low-coking and low-blocking regenerator. The high-efficiency, long-life, low-coking and low-blocking regenerator comprise a flue gas inlet pipeline, a regenerator wall and a flue gas outlet pipeline, and the flue gas inlet pipeline, the regenerator wall and the flue gas outlet pipeline arearranged in the same direction, wherein a container formed by the regenerator wall contains a large number of heat storage balls, the flue gas inlet area and the flue gas exhaust outlet area use the large-size heat storage balls, and the particle sizes of the heat storage balls in the middle of the regenerator gradually decrease in the flue gas flow direction. The design scheme that the particle sizes of the heat storage balls gradually decrease in the flue gas flow direction is adopted in the middle of the regenerator, the breaking probability of the heat storage balls caused by thermal stress can be greatly reduced, the service life of the heat storage balls is significantly prolonged, the cycle for replacing the heat storage balls during use of the regenerator is prolonged, the flue gas inlet pipeline, the regenerator wall and the flue gas outlet pipeline are arranged in the same direction, the restricted vertical staggering of the air intake and exhaust is not required in the technical scheme, and the high-efficiency, long-life, low-coking and low-blocking regenerator is more convenient for the staff to operate and use .

Owner:SUZHOU NORETA NEW MATERIAL TECH

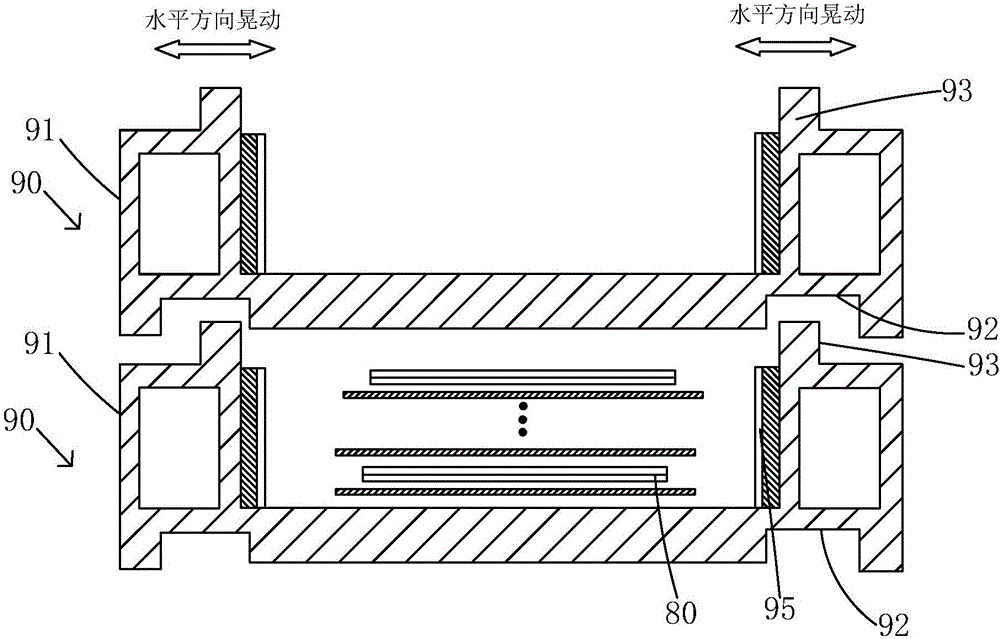

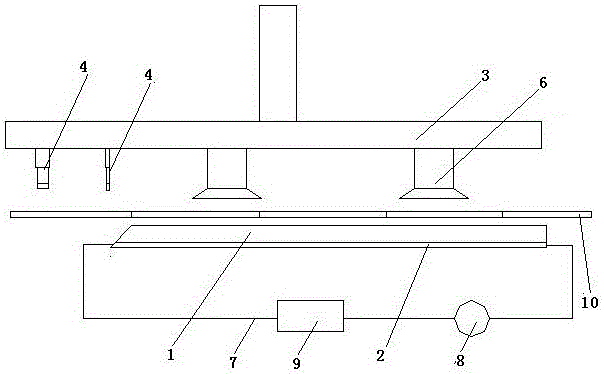

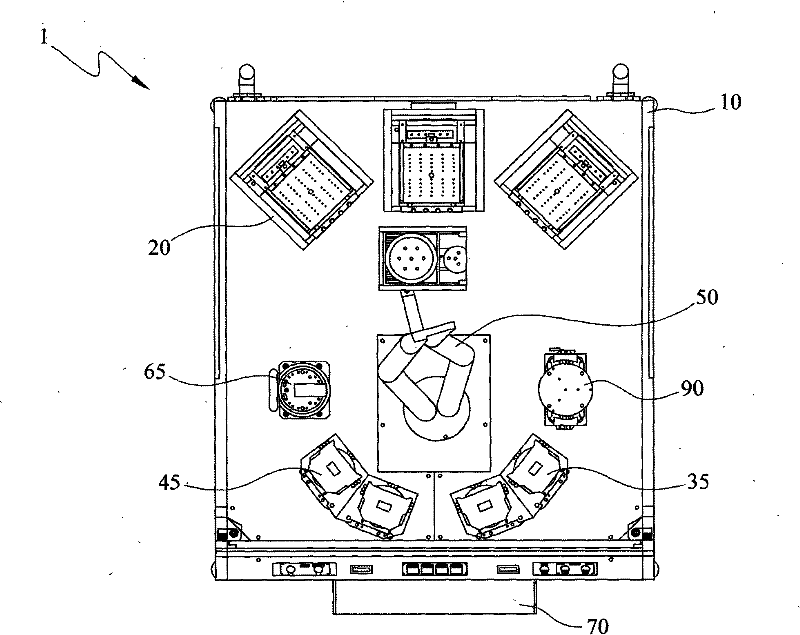

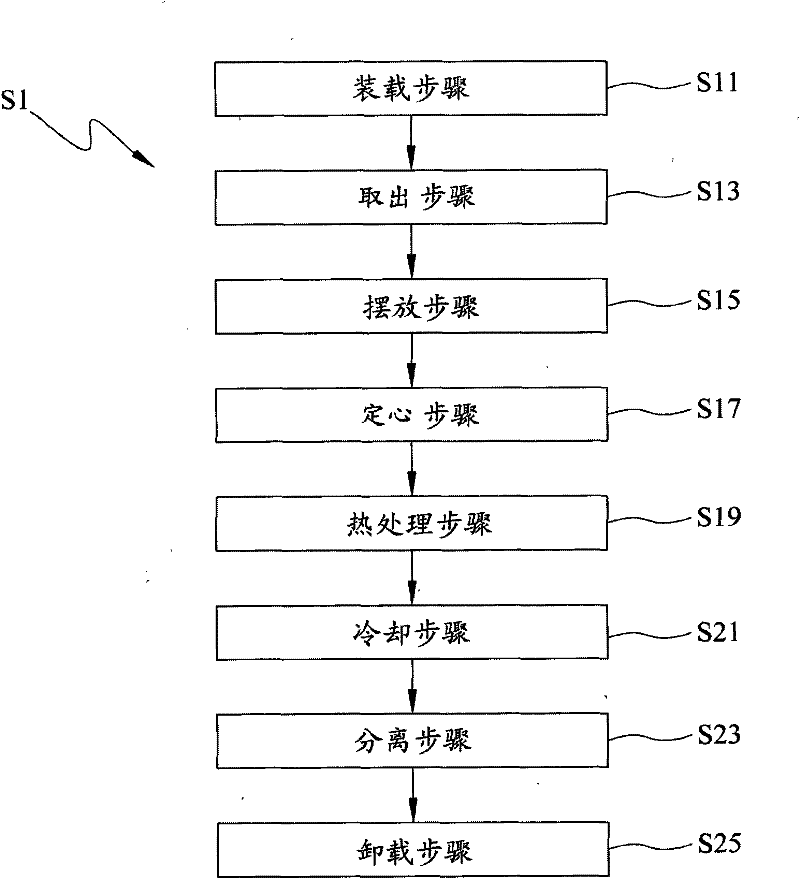

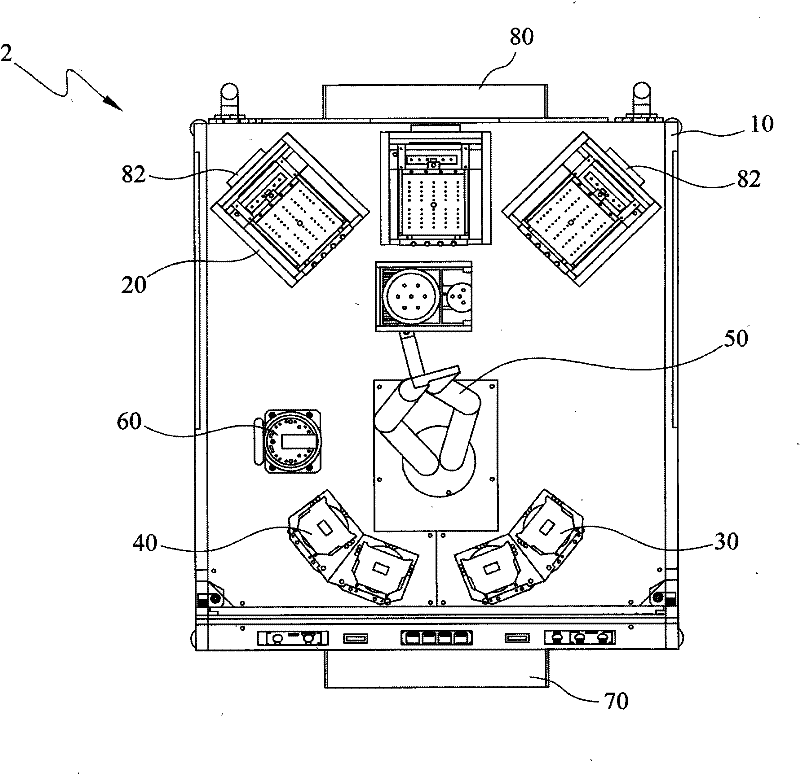

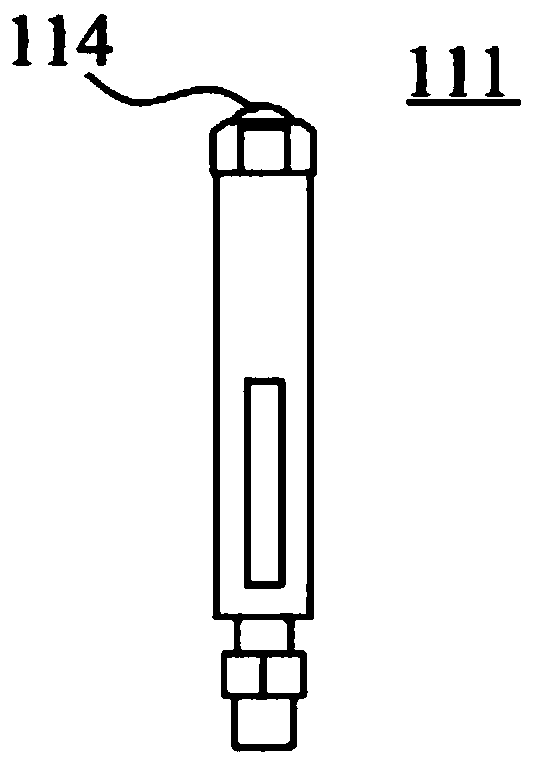

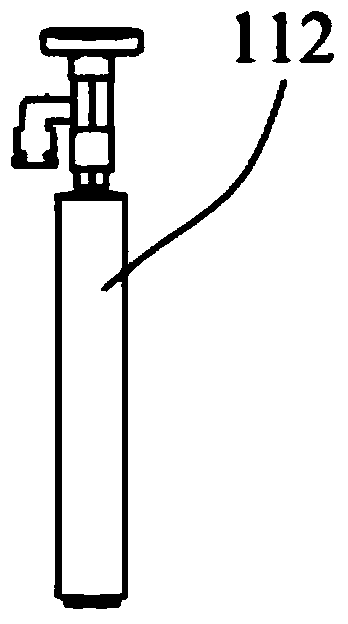

Equipment and operation method for improving rapid thermal processing productivity of wafers

ActiveCN102651328AReduce the chance of fragmentationIncrease production capacitySemiconductor/solid-state device manufacturingRobotic armEngineering

The invention discloses equipment and an operation method for improving the rapid thermal processing productivity of wafers. The equipment includes at least one processing procedure module, a base body, a front end control interface and a rear end control interface, wherein each processing procedure module includes at least one processing procedure cavity, a loading end, an unloading end, a mechanical arm and a cooling device; the loading end and the unloading end are combined-type cassettes used for accommodating multiple-piece graphite bearing plates in a layered manner; and the multiple-piece graphite bearing plates are provided with carving grooves, so as to load wafers of various sizes. The cassettes are designed to be the multiple-piece graphite bearing plates capable of accommodating and loading wafers, so that operation of the mechanical arm during the processing procedure is reduced, and rapid thermal processing for a plurality of wafers can be performed at the same time, the productivity in unit time can be greatly improved, the flexibility of the processing procedure and the compatibility of the equipment are improved, the time for processing procedure is saved, and the fragment probability of wafers is reduced.

Owner:PREMTEK INT

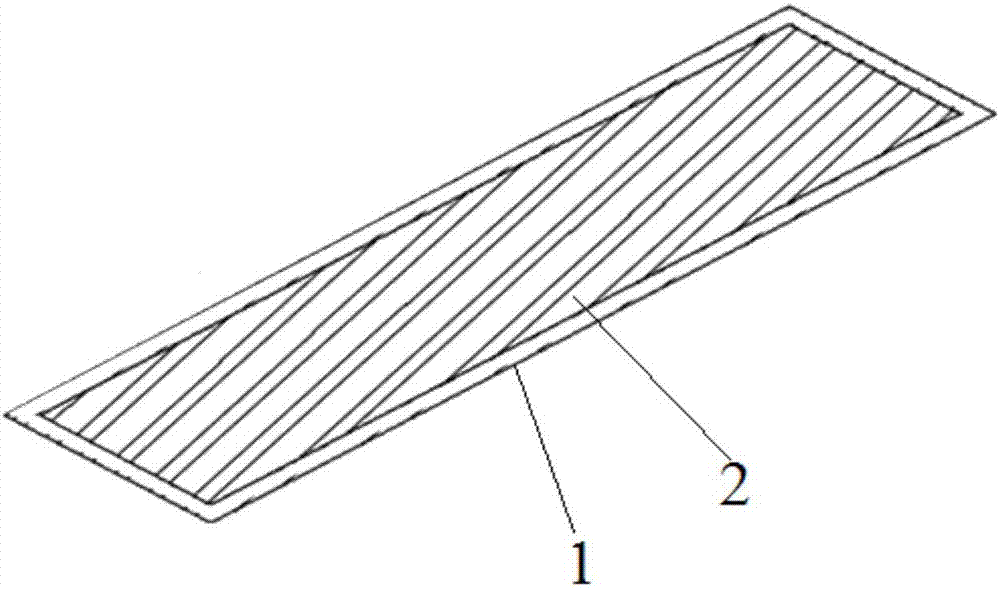

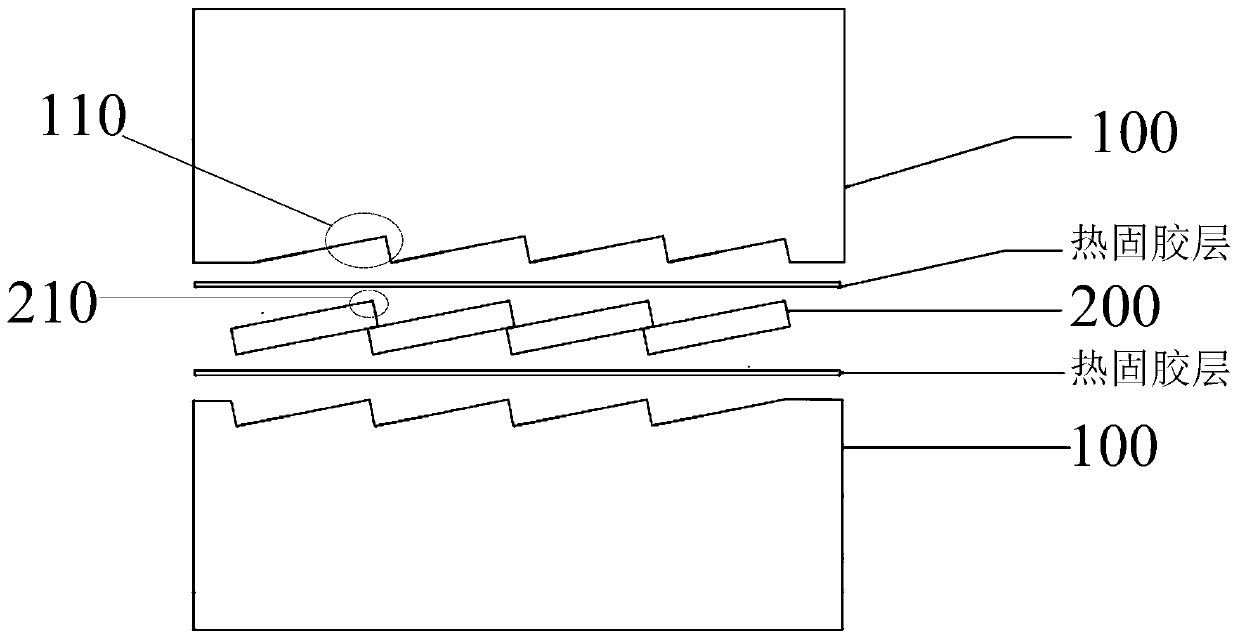

Photovoltaic cover plate and photovoltaic assembly

PendingCN111370517AReduce crackingReduce the chance of fragmentationPhotovoltaic energy generationSemiconductor devicesEngineeringSolar battery

The invention discloses a photovoltaic cover plate. The photovoltaic cover plate is a cover plate for packaging a laminated solar cell module of a photovoltaic module; a battery piece accommodating groove is formed in the first surface of the photovoltaic cover plate, and the battery piece accommodating groove is a groove for accommodating a convex part of the laminated solar cell module; the first surface is the surface, close to the laminated solar cell module, of the photovoltaic cover plate. According to the invention, the surface of the photovoltaic cover plate is provided with the cell accommodating groove matched with the laminated solar cell module; therefore, the photovoltaic cover plate is in full contact with the laminated solar cell module. The stress in the welding or laminating process is uniformly distributed on the surface of the whole laminated solar cell, so that the possibility of hidden cracks or fragments of the laminated solar cell is greatly reduced, and meanwhile, the invention also provides a photovoltaic module with the beneficial effects.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

Revolving working bench and display panel detection apparatus

Owner:SUZHOU JINGLAI OPTO CO LTD

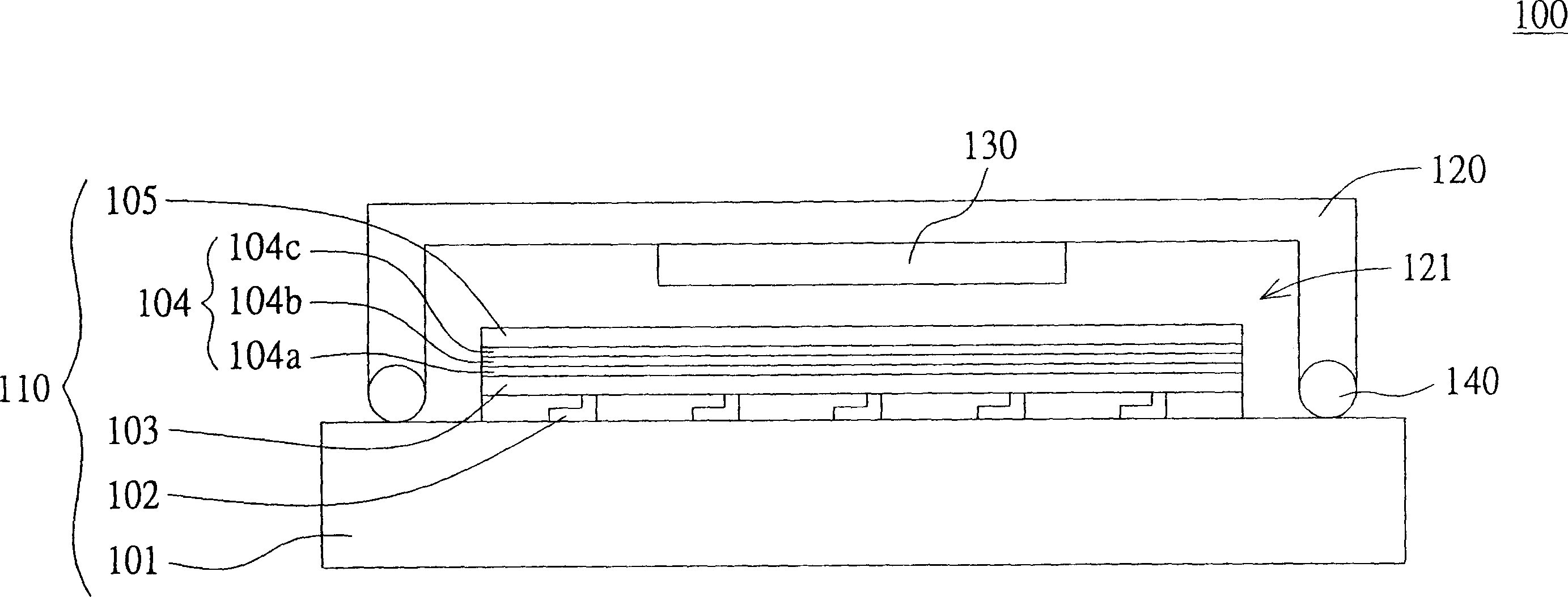

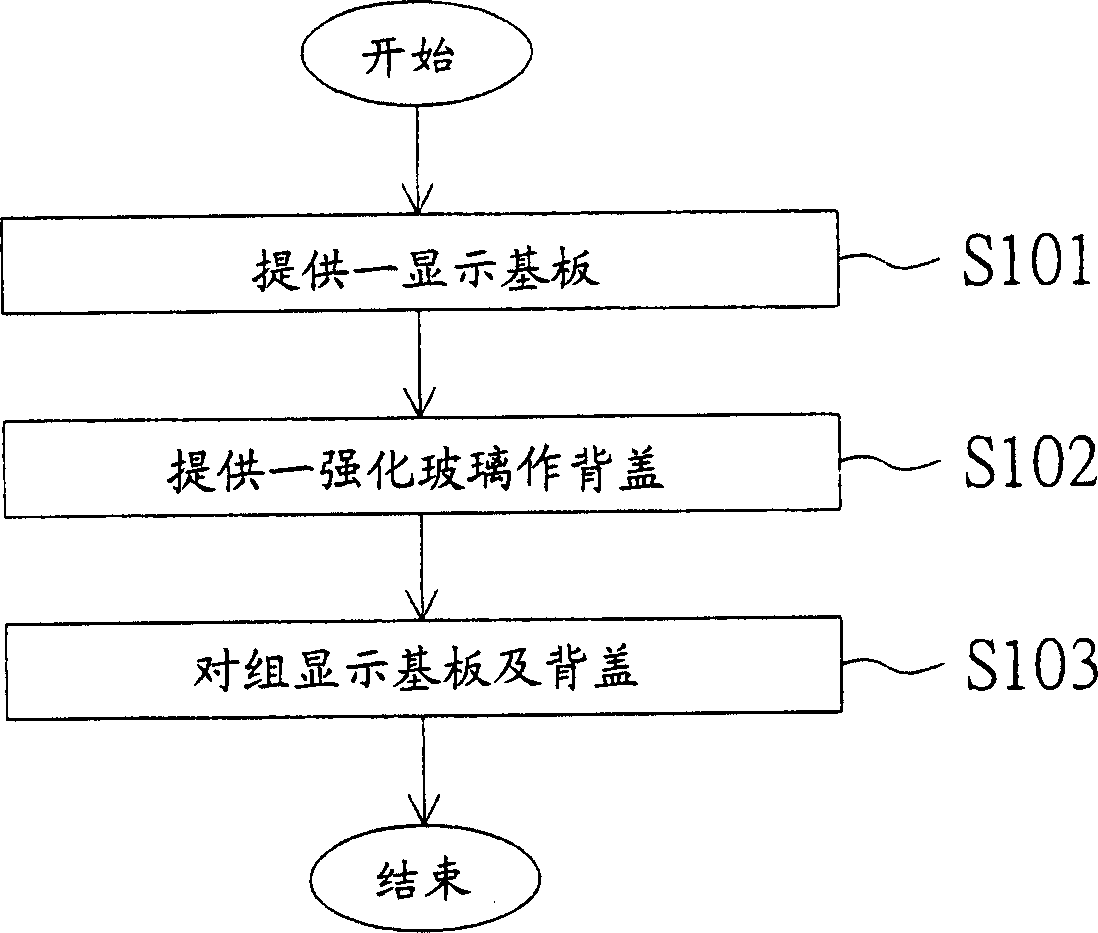

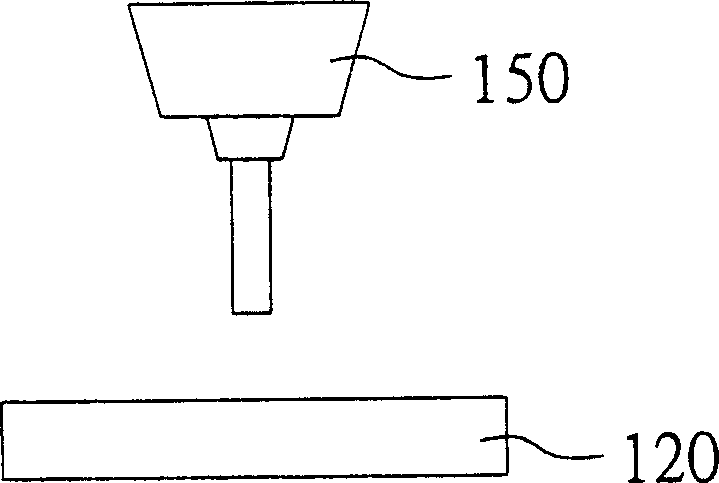

Organic electroluminescent display and packaging method thereof

ActiveCN1668146AHigh strengthReduce the chance of fragmentationElectrical apparatusElectroluminescent light sourcesOrganic electroluminescenceComputer engineering

An organic electroluminance display includes a display base plate and a back cover-an intensified glass assembled in side display plate. The content of K ions in the back cover is larger than 1%, that is 3%~10%. A package method includes: providing a display base plate, and an intensified glass as the back cover, which is back-to-back with the display base plate.

Owner:XIAMEN TIANMA DISPLAY TECH CO LTD

Anti-reflection and anti-explosion protective film of mobile phone glass view-window protective screen and preparation method of anti-reflection and anti-explosion protective film

InactiveCN106564262AImprove the safety of useSimple preparation processSynthetic resin layered productsGlass/slag layered productsTectorial membraneTransmittance

The invention discloses an anti-reflection and anti-explosion protective film of a mobile phone glass view-window protective screen and a preparation method of the anti-reflection and anti-explosion protective film, relates to a protective film of the mobile phone glass view-window protective screen and a preparation method of the protective film, and aims to solve the problem that the light transmittance performance and the anti-explosion function of the anti-reflection and anti-explosion protective film of the mobile phone glass view-window protective screen are needed to be improved. The anti-reflection and anti-explosion protective film comprises a plastic basic layer, a first plastic layer, a reinforced glass film layer, a second plastic layer, an anti-explosion layer and a third plastic layer in sequence, wherein the polyethylene plastic basic layer is formed by film blowing and is prepared from low density polyethylene, linear low density polyethylene and metallocene medium density polyethylene. The high-light-transmittance-performance plastic basic layer is prepared by film blowing, so that the structure of the protective film is optimized, and the light transmittance rate of the anti-reflection and anti-explosion protective film can be up to 90 percent or above; and furthermore, when the reinforced glass film layer is broken, the reinforced glass film layer is only cracked instead of generating sputtering broken blocks, so that the use safety is improved.

Owner:萍乡星弛光电科技有限公司

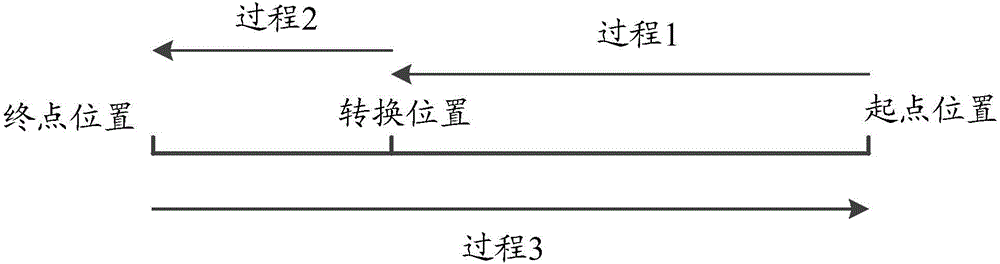

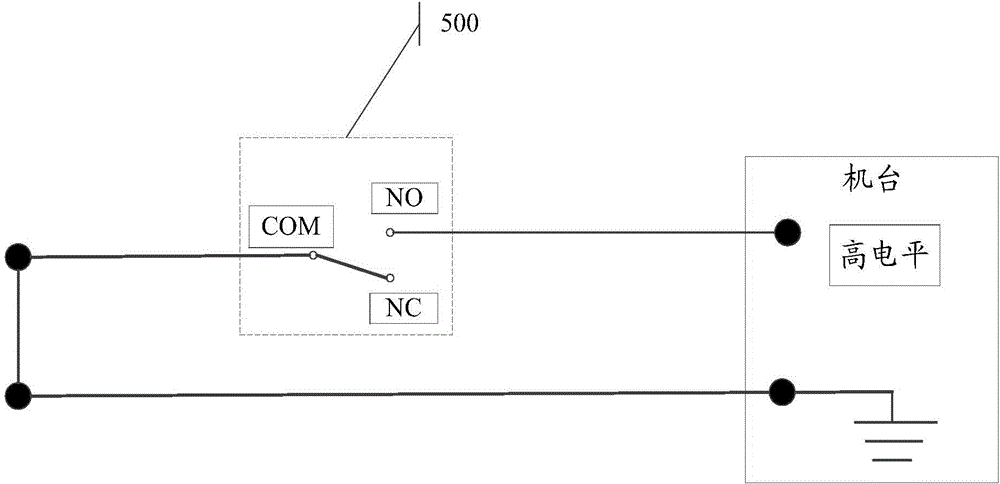

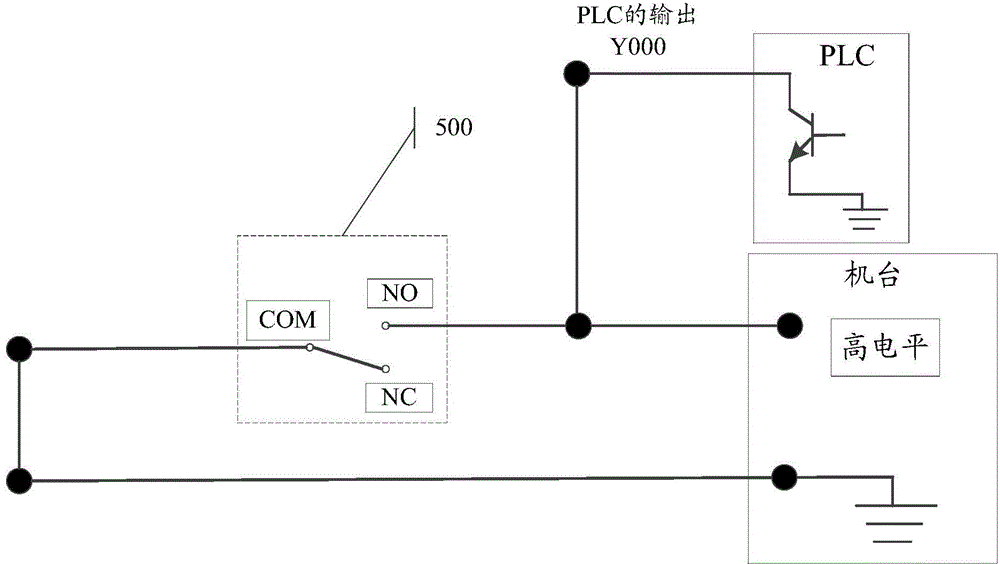

Monitoring system and method

ActiveCN105204448AFix broken tech issuesReduce the chance of fragmentationTotal factory controlProgramme total factory controlControl signalMonitoring system

The application discloses a monitoring system and a method. The system comprises a first detection device, a second detection device, and a control unit, the first detection device is arranged on a film-drawing device of a laminator and a place which the film-drawing device passes through in the moving direction and used for detecting and obtaining a first optocoupling signal for representing the film-drawing starting position of the film-drawing device and a second optocoupling signal for representing the final position of the film-drawing device, the second detection device is used for detecting and obtaining a first detection signal for representing the film-drawing process of the film-drawing device from the starting position to the final position, and the control unit is connected with the first detection device and the second detection device and used for receiving the first optocoupling signal and / or the second optocoupling signal, and the first detection signal and generating and outputting a first control signal based on the first optocoupling signal and / or the second optocoupling signal, and the first detection signal so that the laminator is controlled to be in the stopping state.

Owner:FOUNDER MICROELECTRONICS INT

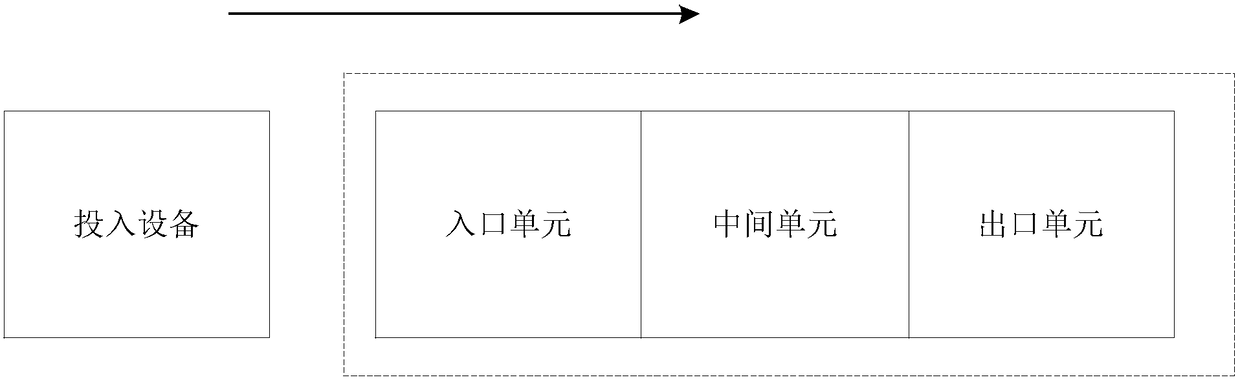

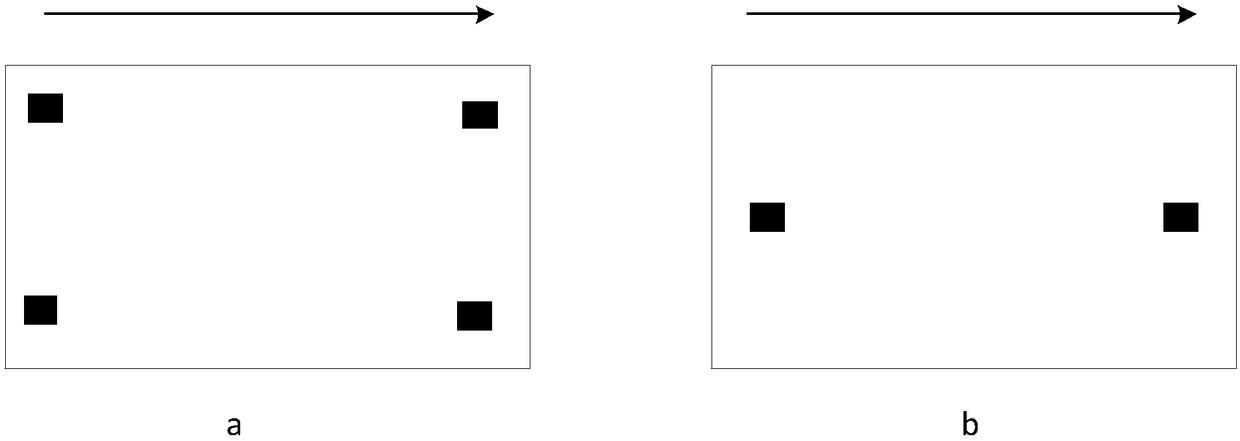

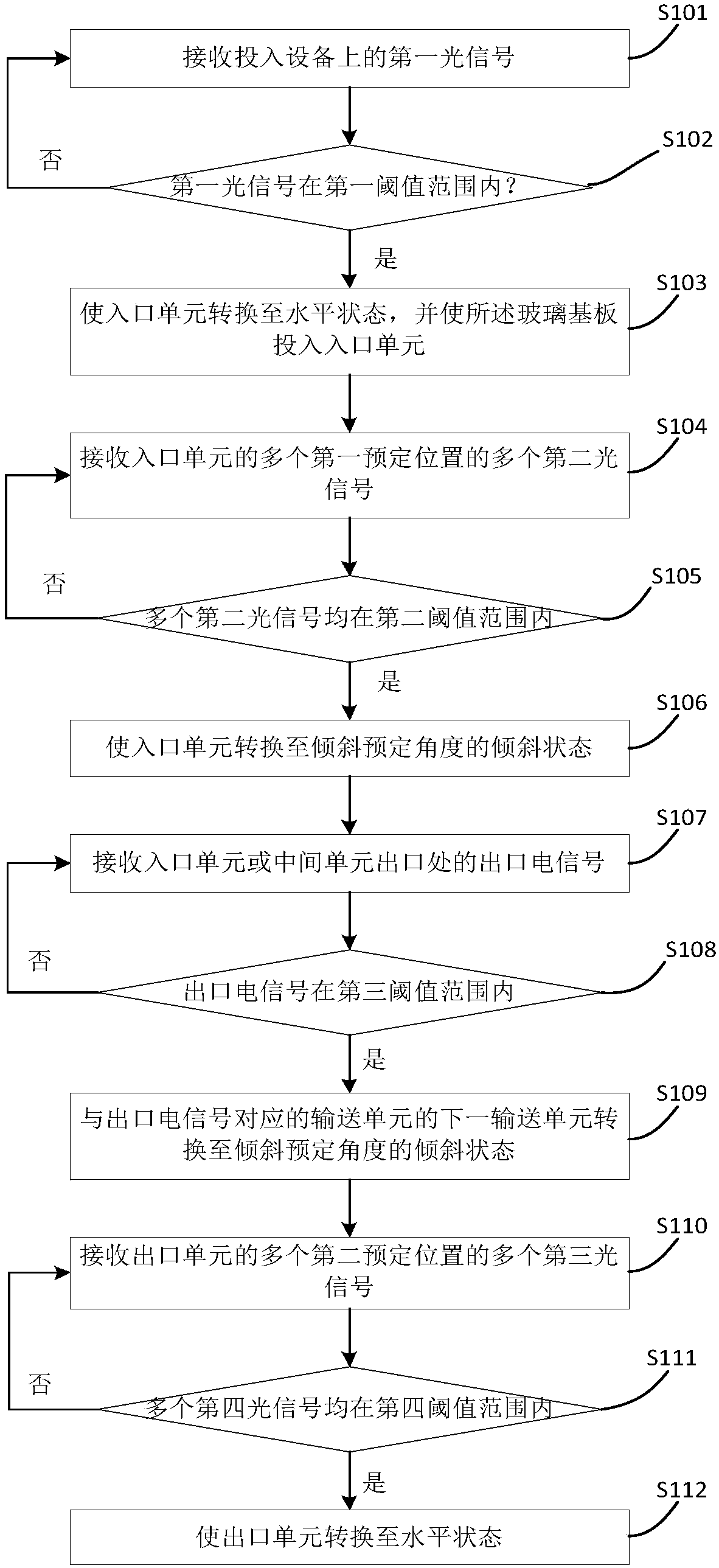

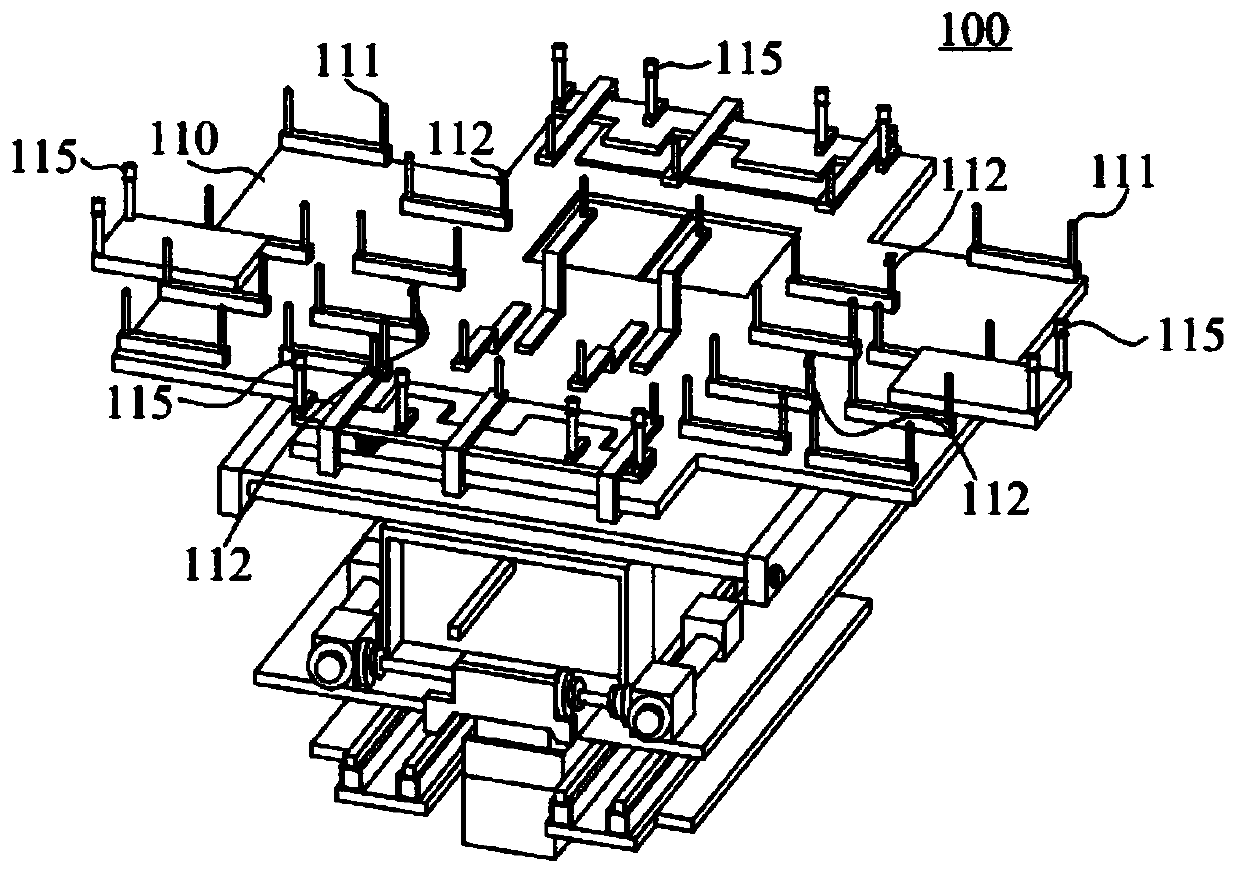

Method and device for conveying plastic substrate

ActiveCN108147130AReduce the chance of fragmentationImprove yield rateCharge manipulationConveyor partsElectric signal

The embodiment of the invention provides a method and a device for conveying a plastic substrate and belongs to the field of industrial control. The method comprises the following steps that when a first optical signal of throwing equipment is in a first threshold range, an inlet unit is switched into a horizontal state, and a plastic substrate is thrown into the inlet unit; when a plurality of second optical signals of the inlet unit are all in a second threshold range, the inlet unit is switched into an inclined state with a preset inclined angle; an outlet electric signal at an outlet of the inlet unit or a middle unit is received, and when the outlet electric signal is in a third threshold range, a next conveying unit of a conveying unit, corresponding to the outlet electric signal, isswitched into the inclined state with a preset inclined angle; and a plurality of third optical signals of a plurality of second preset positions of the outlet unit are received, and when a pluralityof fourth optical signals are all in a fourth threshold range, the outlet unit is switched into the horizontal state. The method and the device can enable the plastic substrate to be successfully conveyed in production equipment, so that the plastic substrate can be avoided from being broken, and the rate of good products is increased.

Owner:深圳市格睿尔科技有限公司

Rotary table and display panel detection device

Owner:SUZHOU JINGLAI OPTO CO LTD

Initial processing device for optical glass

InactiveCN105837012AReduce the temperatureReduce the impactGlass severing apparatusGlass productionTemperature controlRefrigeration compressor

The invention relates to a preliminary processing device for optical glass, comprising: a stud plate oppositely arranged and a deformable plate with an arc-shaped surface, characterized in that several studs are arranged on one side of the stud plate, The studs are vertically connected to the stud plate by threads, and the side of the deformed plate with a curved surface is opposite to the side of the stud plate with studs, and each stud can pass through Thread rotation adjusts the length of the protruding stud plate. The side of the stud rod without a stud is connected to the driving arm, and the driving arm can drive the stud plate close to the deformation plate; it also includes a temperature control box, the deformation The plate and the stud plate can be arranged in the temperature control box, and the temperature control box includes a refrigeration compressor arranged in the refrigeration seat and a thermal insulation cover that can cover the refrigeration seat to form a closed space.

Owner:SUZHOU WEIMI OPTICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com