Crystalline silicon solar cell string splicing method and module

A technology of crystalline silicon solar cells and solar cells, applied in electrical components, circuits, photovoltaic power generation, etc., to achieve the effects of improving conversion efficiency, reducing hidden cracks, and reducing welding stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

[0031] A method for splicing crystalline silicon solar cell strings, comprising the following steps:

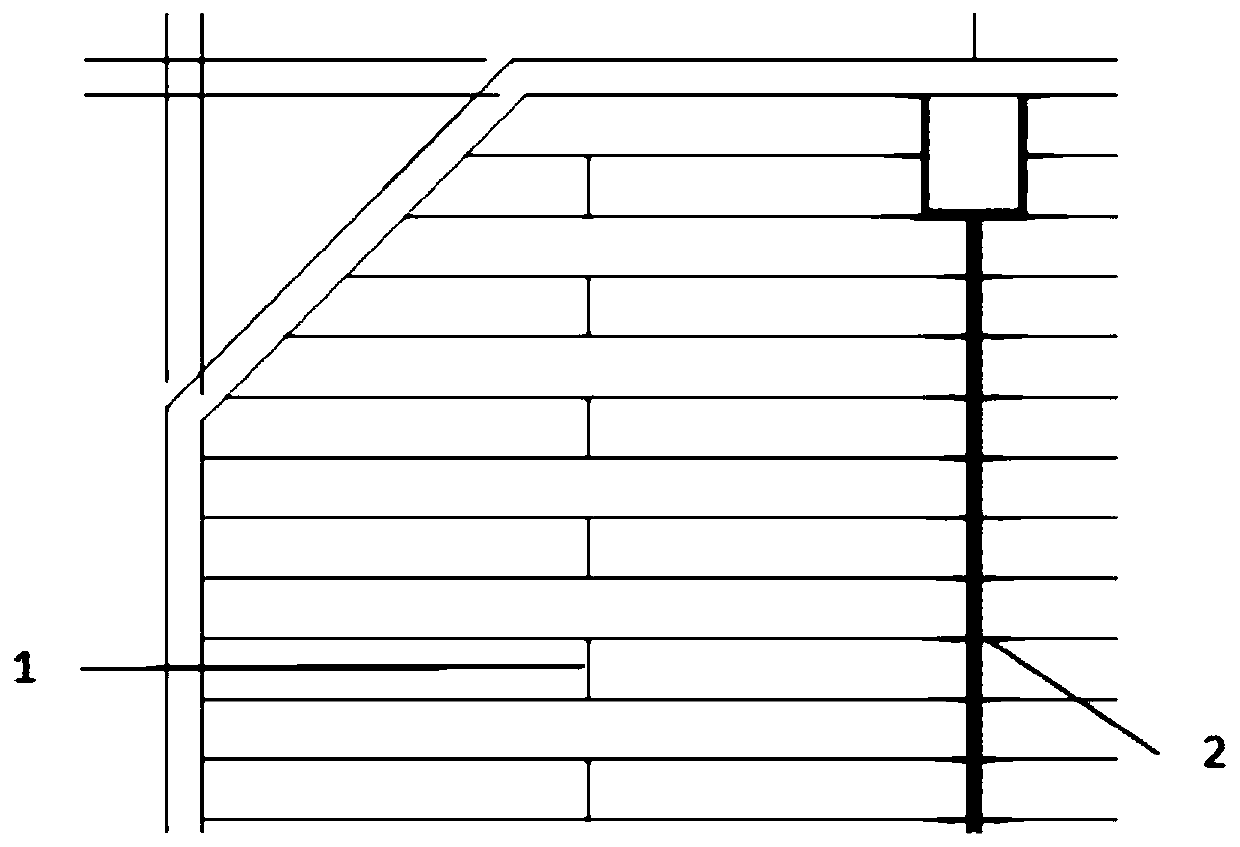

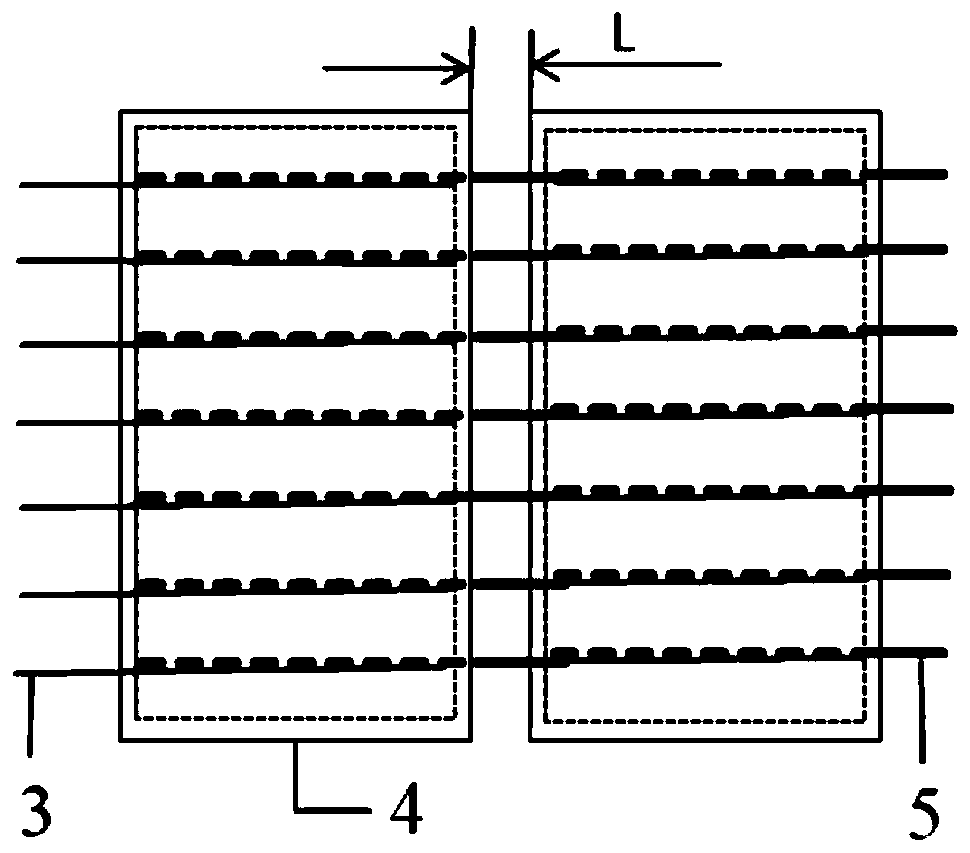

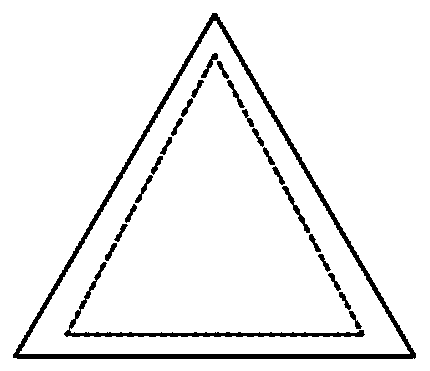

[0032] Such as figure 1 As shown, the crystalline silicon solar cells are first prepared according to the crystalline silicon solar cell printing graphics scheme; the crystalline silicon solar cell string welding parameters are set on the operation interface of the automatic stringer, and the various systems on the stringer are started to start welding. First place the front conductive material of the first two crystalline silicon solar cells 3 (i.e., the triangular ribbon) on the soldering platform, and then place the first crystalline silicon solar cell 3 on the triangular ribbon face down to ensure that the crystalline silicon solar cell Align the main grid of 3 with the position of the triangular ribbon, then place the condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com