Anti-reflection and anti-explosion protective film of mobile phone glass view-window protective screen and preparation method of anti-reflection and anti-explosion protective film

A technology for glass windows and protective screens, which is applied in the field of protective films for glass windows of mobile phones and their preparation, can solve the problems such as the light transmission performance and the explosion-proof function need to be improved, and achieves the improvement of the overall light transmission performance, the simple preparation process, and the improved use. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

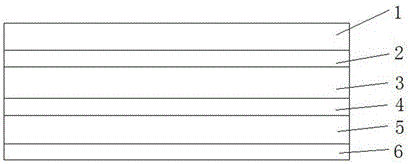

[0015] Specific implementation mode one: the anti-reflection explosion-proof protective film of the mobile phone glass window protection screen in this embodiment is a multi-layer film structure, including a polyethylene plastic base layer 1, multiple adhesive layers, a glass film layer 3 and an explosion-proof layer 5, wherein the The polyethylene plastic base layer 1 described above is formed by blown film, and the multilayer film structure from top to bottom is the plastic base layer 1, the first adhesive layer 2, the tempered glass film layer 3, the second adhesive layer 4, the explosion-proof layer 5 and the second Three adhesive layers6.

[0016] The raw materials in the polyethylene plastic base layer described in this embodiment include 30-60 parts of low-density polyethylene (LDPE), 25-45 parts of linear low-density polyethylene (LLDPE) and 20-40 parts of metallocene medium-density polyethylene ( m-MDPE), which can be blown to form a single-layer film, or a three-laye...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment is different from Embodiment 1 in that one side of the third adhesive layer 6 is glued to the explosion-proof layer 5 , and the other side of the third adhesive layer 6 is glued to the release film.

[0018] In this embodiment, the thickness of the release film is 50-200 μm, and the material of the release film is PET film.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that a hard coat layer or an oleophobic layer is provided on the surface of the polyethylene plastic base layer 1 .

[0020] The hard coat layer in this embodiment can be pasted on the (upper) surface of the plastic base layer by means of gluing, vapor deposition or sputtering. The hard coat layer is a hardened anti-scratch coating, such as polyurethane resin, and the thickness of the hard coat layer or oleophobic layer is 20-150 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com