Nanometer silver collosol, preparation method and application thereof

A nano-silver sol, sol technology, applied in the field of fiber textiles, can solve problems such as uncontrolled, and achieve the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Example 1 : Preparation of nano-silver sol with a concentration of 100ppm

[0099] The preparation steps are as follows:

[0100] First, in a reactor with a cover, 1 part of glycogen, 40 parts of ethanol and 59 parts of ethylene glycol were dissolved in parts by weight to prepare the mixed and dispersed reducing agent solution.

[0101] Then, silver acetate is dissolved in ethanol to make a concentration of 0.017% by weight silver salt ethanol solution, and then under stirring, dark and airtight conditions, the silver salt ethanol solution is added to the mixed dispersion obtained above. In the reducing agent solution, wherein the weight of the silver salt is 50 g, and the weight of the mixed and dispersed reducing agent solution is 50 g, and then react at a temperature of 60° C. for 10 hours to obtain the nano silver sol.

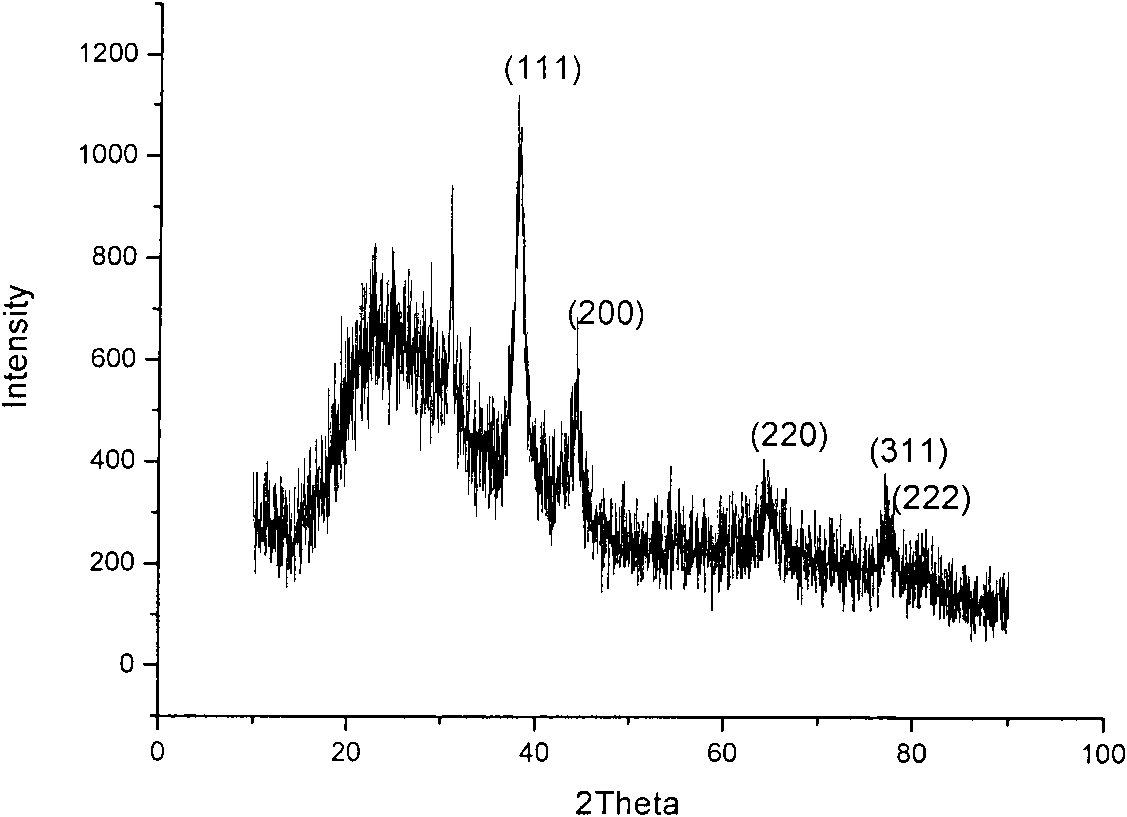

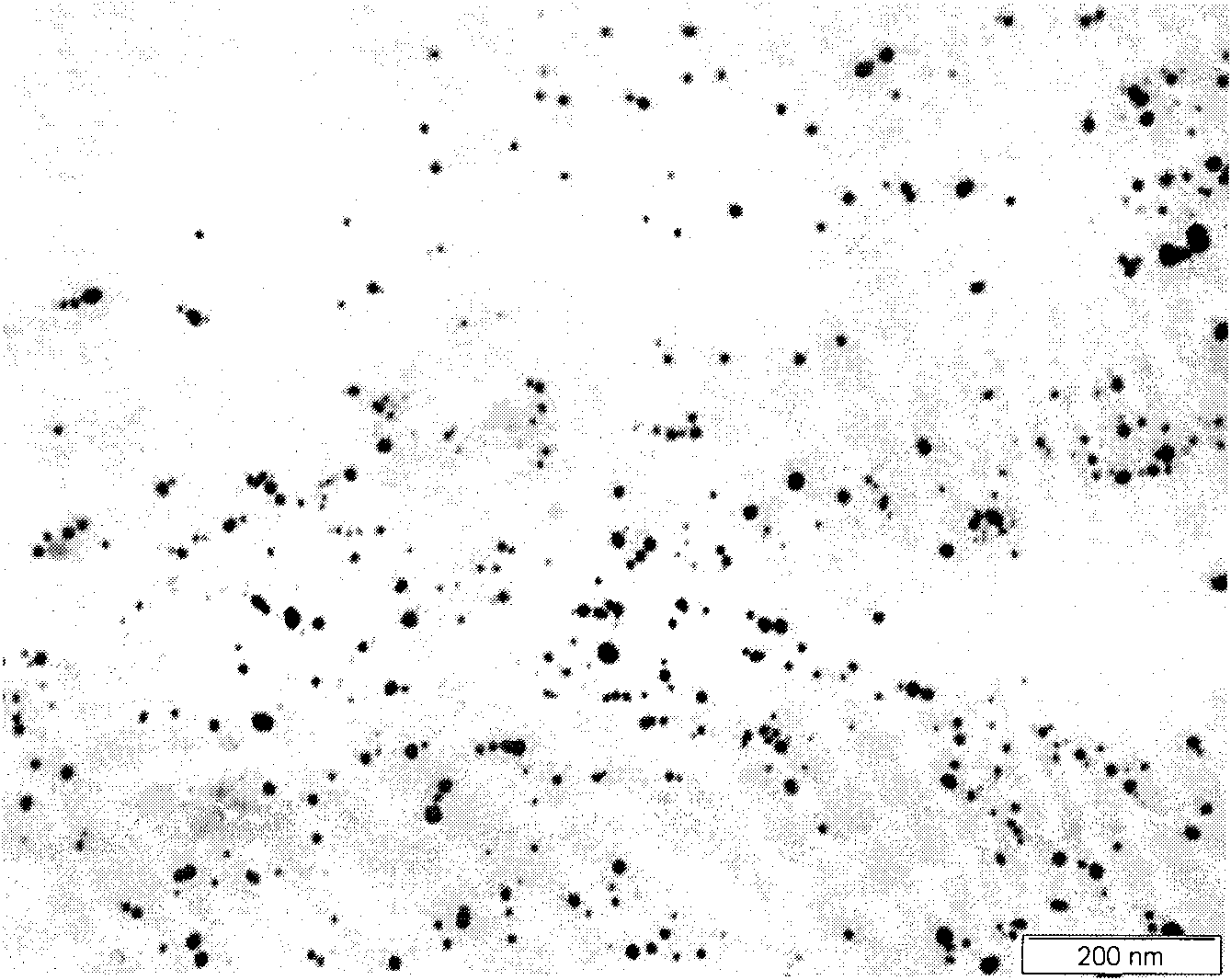

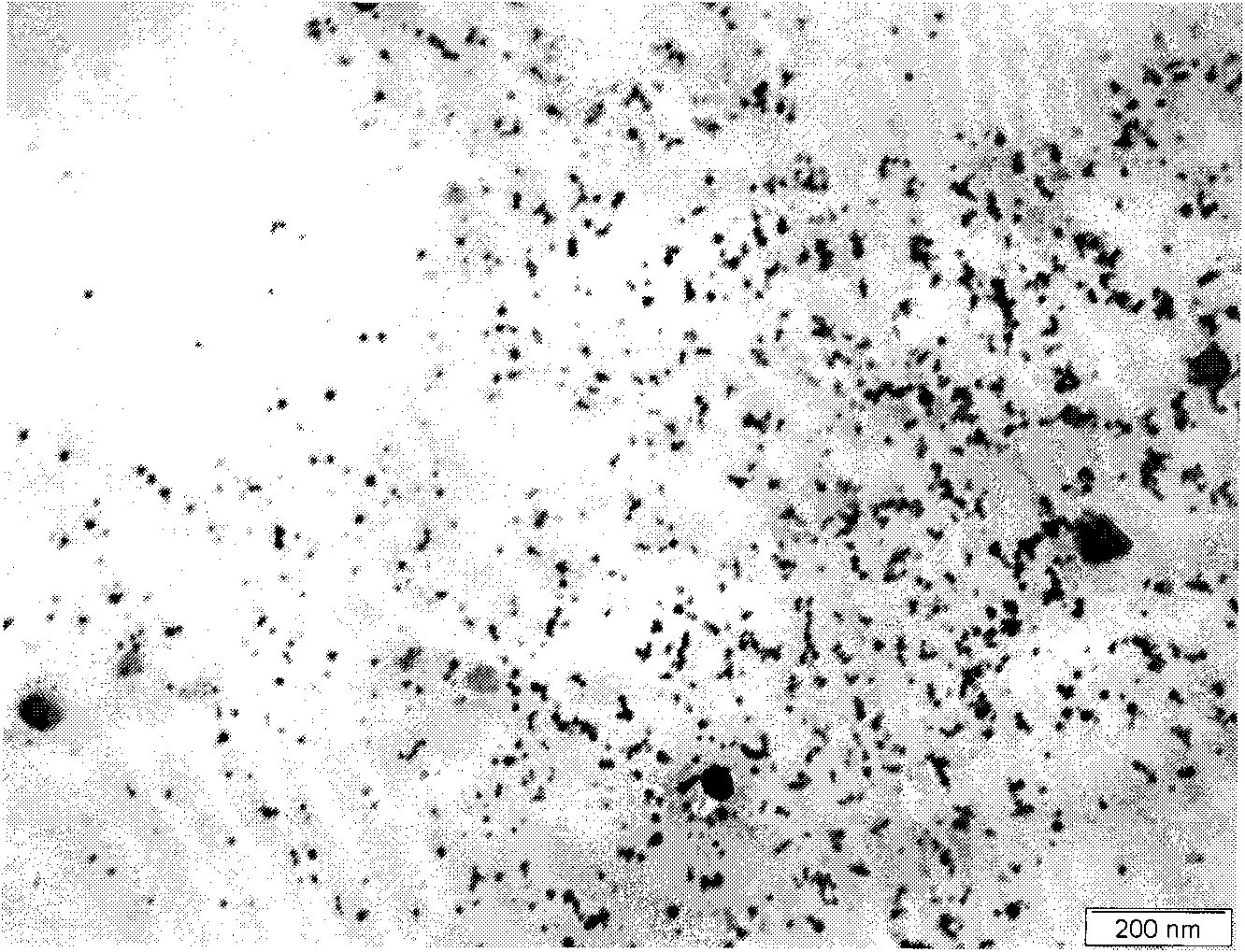

[0102] Obtained by X-ray diffraction method described in this specification figure 1 The results shown show that the colloidal particles in the...

Embodiment 2

[0104] Example 2 : Preparation of nano-silver sol with a concentration of 50ppm

[0105] The preparation steps are as follows:

[0106] The implementation of this example is the same as in Example 1, but using 0.1 parts of glucose, 75 parts of ethanol and 24.9 parts of ethylene glycol;

[0107] Then, silver nitrate is dissolved in ethanol to make a concentration of 0.0085% by weight silver nitrate ethanol solution, then under stirring, dark and airtight conditions, the silver nitrate ethanol solution is added to the mixed dispersion obtained in front In the reducing agent solution, wherein the weight of the silver nitrate is 50 g, and the weight of the mixed and dispersed reducing agent solution is 50 g, and then react at a temperature of 50° C. for 12 hours to obtain the nano-silver sol.

[0108] Adopt same detection method to detect, and its result is identical with the result that embodiment 1 obtains.

[0109] Using the method described in this manual to detect, after ...

Embodiment 3

[0110] Example 3 : Preparation of nano-silver sol with a concentration of 200ppm

[0111] The preparation steps are as follows:

[0112] The implementation of this example is the same as that of Example 1, but uses 5 parts by weight of polyvinylpyrrolidone, 55 parts by weight of ethanol, and 40 parts by weight of glycerol.

[0113] Then, silver acetate is dissolved in ethanol to make a concentration of 0.034% by weight silver nitrate ethanol solution, then under stirring, dark and airtight conditions, the silver acetate ethanol solution is added to the mixed dispersion obtained in front In the reducing agent solution, wherein the weight of the silver acetate is 50 g, and the weight of the mixed and dispersed reducing agent solution is 50 g, and then react at a temperature of 50° C. for 25 hours to obtain the nano-silver sol.

[0114] Adopt same detection method to detect, and its result is identical with the result that embodiment 1 obtains.

[0115] Using the method descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com