Novel modified non-woven fabric lithium-ion battery diaphragm and preparation method thereof

A technology of lithium-ion batteries and non-woven fabrics, applied in the field of preparation of the battery diaphragm, can solve the problems of poor heat resistance, easy water absorption of the diaphragm, and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

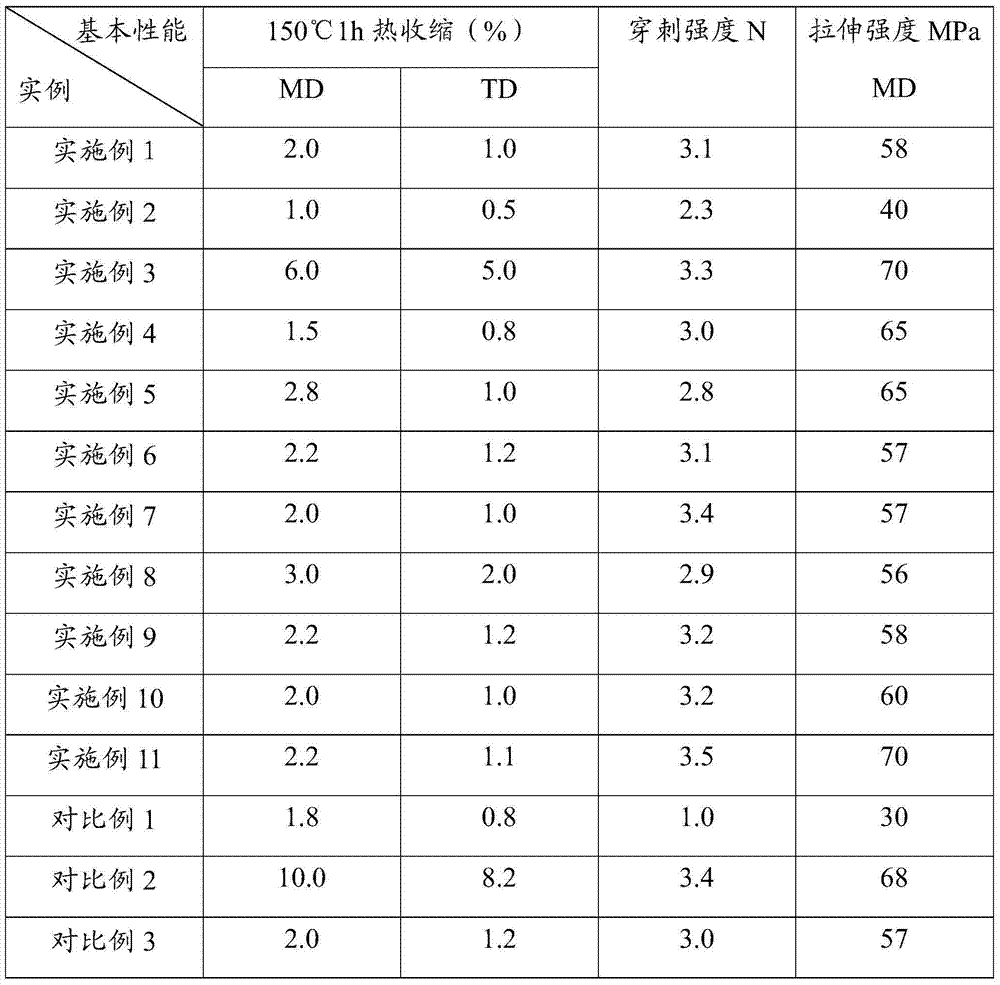

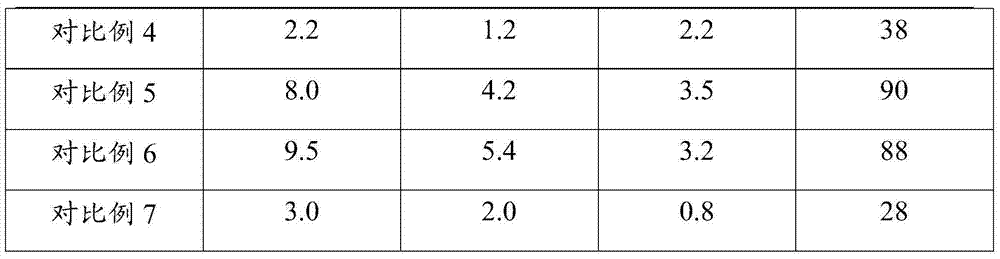

Examples

Embodiment 1

[0049] 95g of high-melting-point PET fibers with a melting point of 250°C and 5g of low-melting-point PET fibers with a melting point of 150°C were made into a non-woven fiber web layer by wet papermaking, and the non-woven fiber web layer was melted and crystallized at a temperature of 155 ℃, and then cooled to obtain a modified non-woven fabric substrate 1 with a porosity of 58%, an average pore diameter of 11um, a puncture strength of 3.0N, a heat shrinkage of 1% at 150°C for 1h, and a thickness of 16um;

[0050] Get filler 2, said filler includes Al2O3, PVDF;

[0051] Dry the non-woven fabric treated by melt crystallization at a temperature of 90°C for 1 min, put 40g of aluminum oxide with a particle size of 250nm into an oven at a temperature of 100°C. The time is 4h.

[0052] Mix 20g of PVDF with a melting point of 165°C, 500g of acetone and 20g of ethanol, heat and stir, heat and stir at 60°C until clarified, add dried aluminum oxide, 0.5g of PVP and 1g of fluorosurfac...

Embodiment 2

[0056] The modified non-woven lithium-ion battery separator was prepared according to the method of Example 1, except that only 0.5 g of PET fibers with a melting point of 150 ° C and a low melting point were added to obtain a puncture strength of 2.2 N and a heat shrinkage of 0.5 at 150 ° C for 1 h. % of non-woven fabric substrates.

Embodiment 3

[0058] Prepare the modified non-woven lithium-ion battery separator according to the method of Example 1, except that 16.8g of low-melting PET fibers with a melting point of 150°C are added to obtain a puncture strength of 3.2N and a heat shrinkage of 5% at 150°C for 1h. non-woven substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com