A kind of modified non-woven lithium ion battery diaphragm and preparation method thereof

A technology of lithium ion battery and non-woven fabric is applied in the field of preparation of the battery separator, which can solve the problems of easy water absorption, low strength and poor heat resistance of the separator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

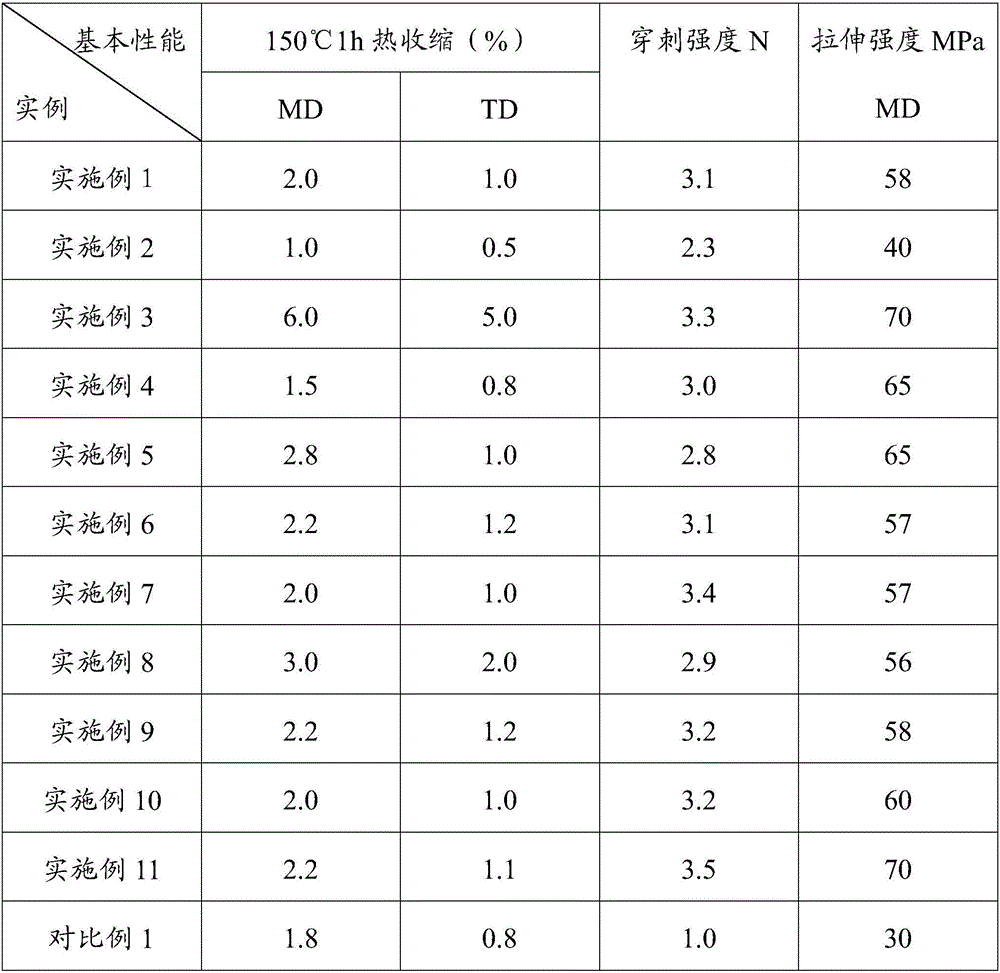

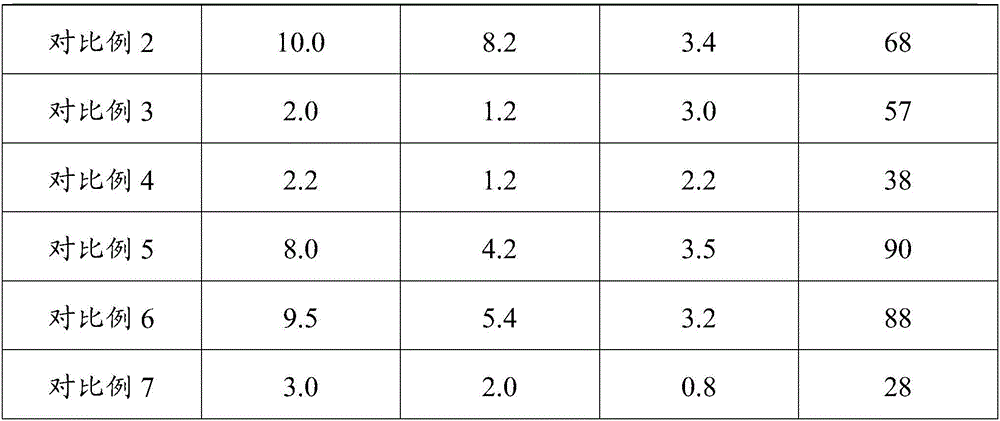

Examples

Embodiment 1

[0049] 95g of high-melting-point PET fibers with a melting point of 250°C and 5g of low-melting-point PET fibers with a melting point of 150°C were made into a non-woven fiber web layer by wet papermaking, and the non-woven fiber web layer was melted and crystallized at a temperature of 155 ℃, and then cooled to obtain a modified non-woven fabric substrate 1 with a porosity of 58%, an average pore diameter of 11um, a puncture strength of 3.0N, a heat shrinkage of 1% at 150℃ for 1h, and a thickness of 16um;

[0050] Get filler 2, said filler includes Al2O3, PVDF;

[0051] Dry the non-woven fabric treated by melt crystallization at a temperature of 90°C for 1 min, put 40g of aluminum oxide with a particle size of 250nm into an oven at a temperature of 100°C. The time is 4h.

[0052] Mix 20g of PVDF with a melting point of 165°C, 500g of acetone and 20g of ethanol, heat and stir, heat and stir at 60°C until clarified, add dried aluminum oxide, 0.5g of PVP and 1g of fluorosurfact...

Embodiment 2

[0056] The modified non-woven lithium-ion battery separator was prepared according to the method of Example 1, except that only 0.5 g of PET fibers with a melting point of 150 ° C and a low melting point were added to obtain a puncture strength of 2.2 N and a heat shrinkage of 0.5 at 150 ° C for 1 h. % of non-woven substrates.

Embodiment 3

[0058] Prepare the modified non-woven lithium-ion battery separator according to the method of Example 1, except that 16.8 g of low-melting PET fibers with a melting point of 150 ° C are added to obtain a puncture strength of 3.2 N and a heat shrinkage of 5% at 150 ° C for 1 hour non-woven substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com