Patents

Literature

38results about How to "Reduce internal resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphite-Carbon composite electrode for supercapacitors

ActiveUS20090059474A1Conductivity lowerReduce internal resistanceLiquid electrolytic capacitorsBaby linensElectrochemical capacitanceMaterials science

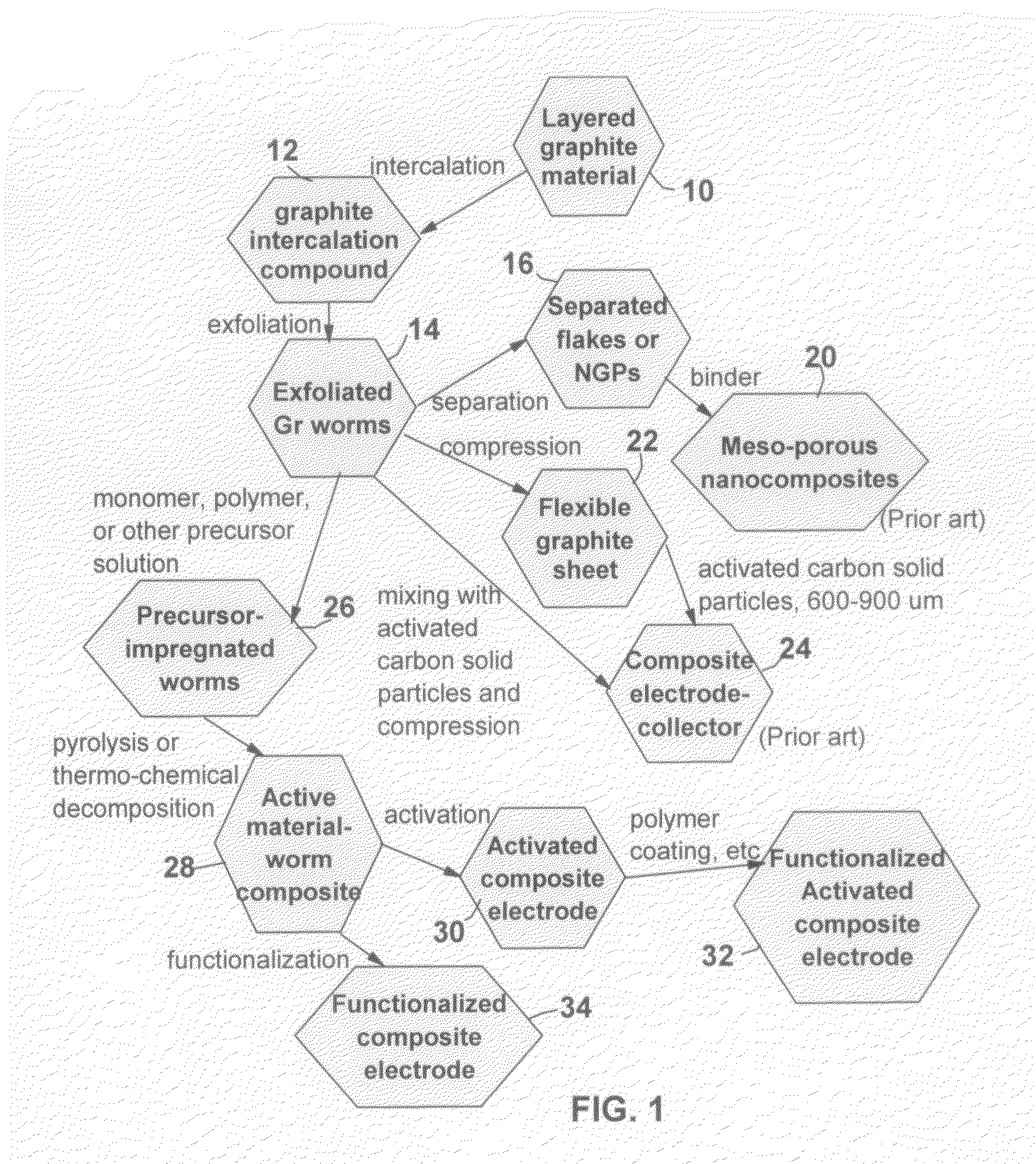

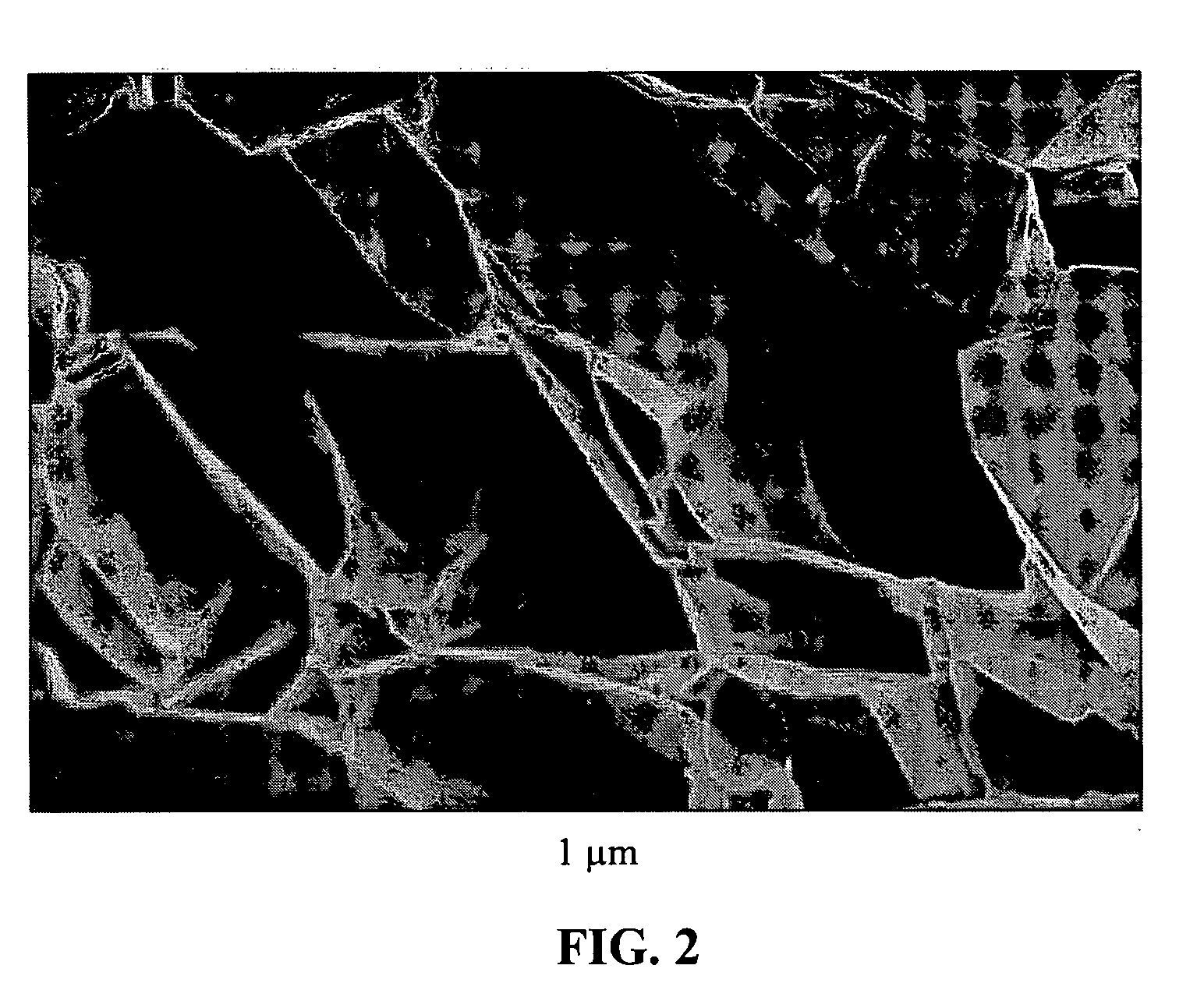

A composite composition for use in an electrode for electrochemical capacitors, comprising: (a) an electrochemically active material; and (b) exfoliated graphite flakes that are substantially interconnected to form a porous, conductive graphite network comprising pores, wherein at least a portion of the active material resides in a pore of the network. The composite composition is characterized by having liquid accessible pores which provide a surface area greater than about 200 m2 / gm, preferably greater than 500 m2 / gm, more preferably greater than 1000 m2 / gm, and most preferably greater than 1000 m2 / gm. Also disclosed is a capacitor that includes at least an electrode comprising such a composite composition. A supercapacitor featuring such a composite electrode exhibits an exceptionally high capacitance value and high electrical conductivity.

Owner:SAMSUNG ELECTRONICS CO LTD +1

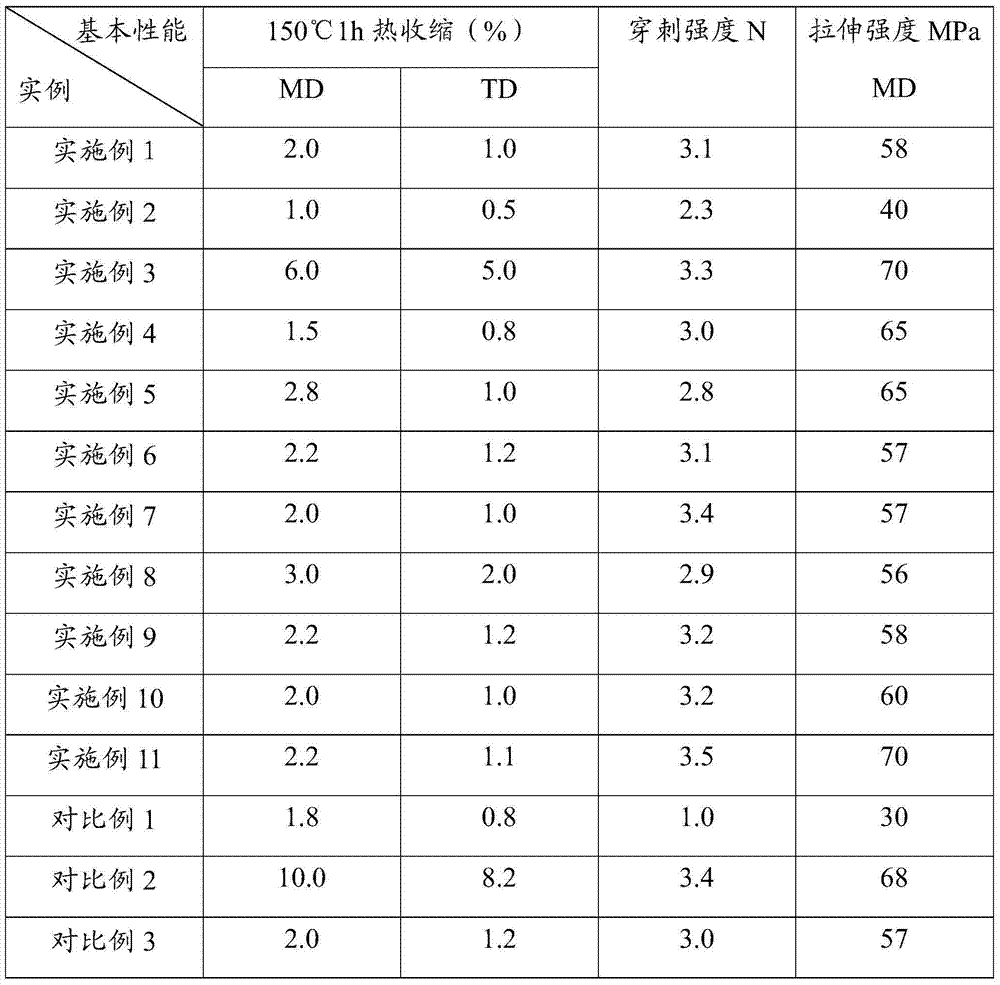

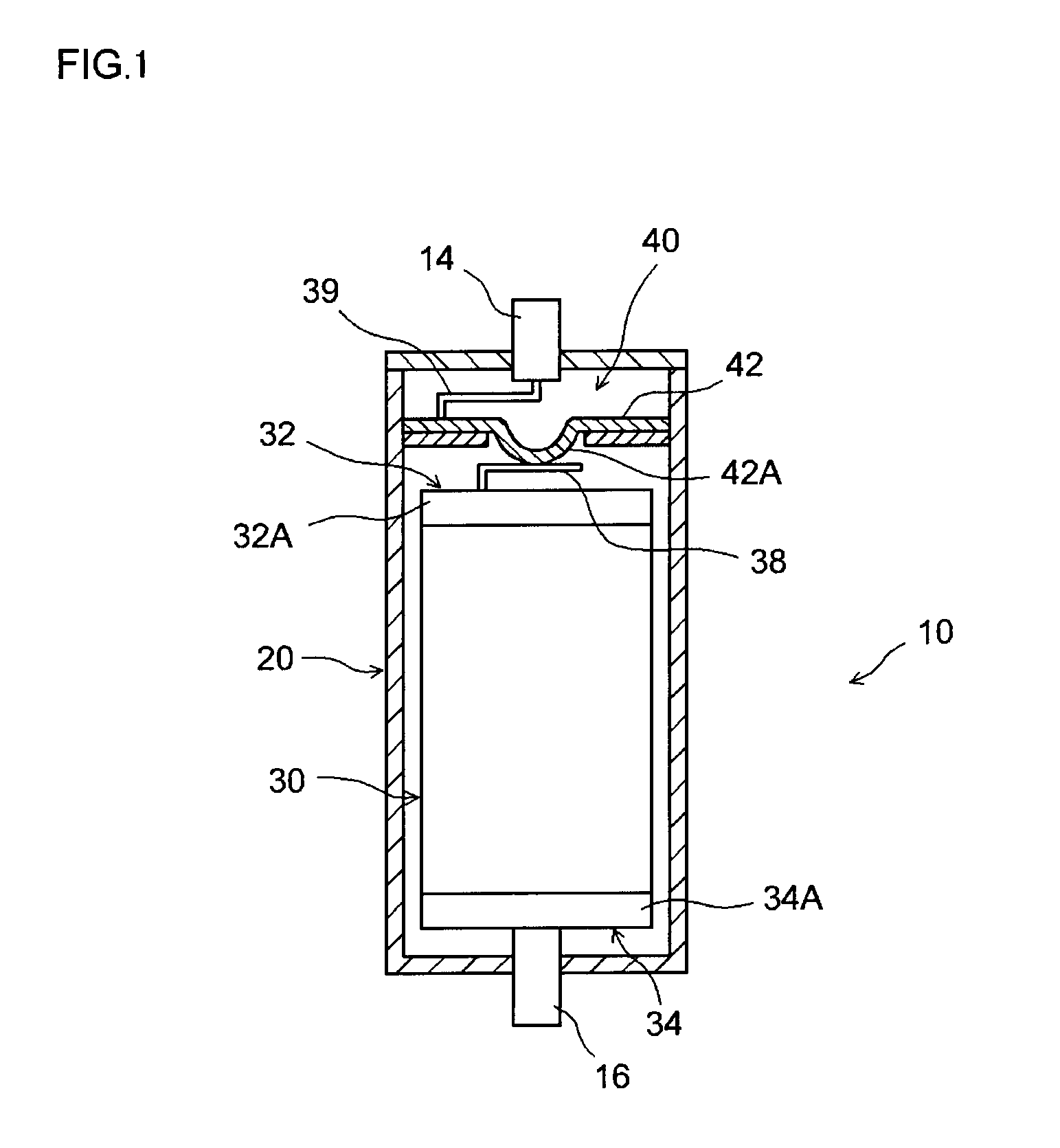

Novel modified non-woven fabric lithium-ion battery diaphragm and preparation method thereof

ActiveCN103928649AEnsuring Winding ProcessabilityEnsuring satisfactory winding processabilityFinal product manufactureSecondary cellsElectrical batteryPhysical chemistry

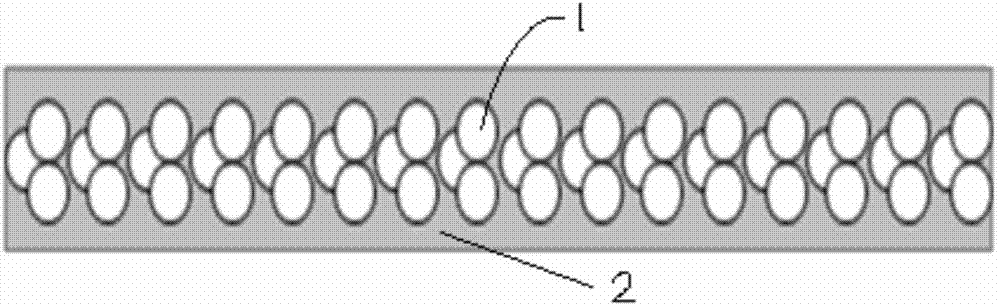

The invention relates to a novel modified non-woven fabric lithium-ion battery diaphragm. The diaphragm comprises a modified non-woven fabric base material and a filling agent compounded on the modified non-woven fabric base material, wherein the modified non-woven fabric base material comprises a low-smelting-point material and a high-smelting-point material; the low-smelting-point material is subjected to melt crystallization treatment and the weight of the high-smelting point material accounts for 85-99.9% of the total weight of the base material; the residual amount is the low-smelting point material; the filling agent compounded on the modified non-woven fabric base material comprises organic polymer, a first filling material and / or a second filling material. The invention further relates to a preparation method of the battery diaphragm. The preparation method sequentially comprises the following steps: manufacturing a non-woven fabric fiber layer; manufacturing the modified non-woven fabric base material; preparing filling agent slurry; filling; removing a solvent; and carrying out post-treatment. The method is simple in operation and low in cost; a prepared product is low in water content, good in chemical stability and high in mechanical strength; the finished product rate of a battery is increased, the service life is prolonged and the safety is improved.

Owner:河南惠强新能源材料科技股份有限公司

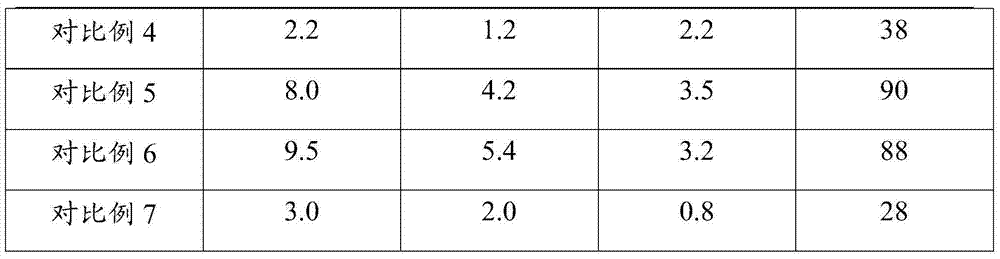

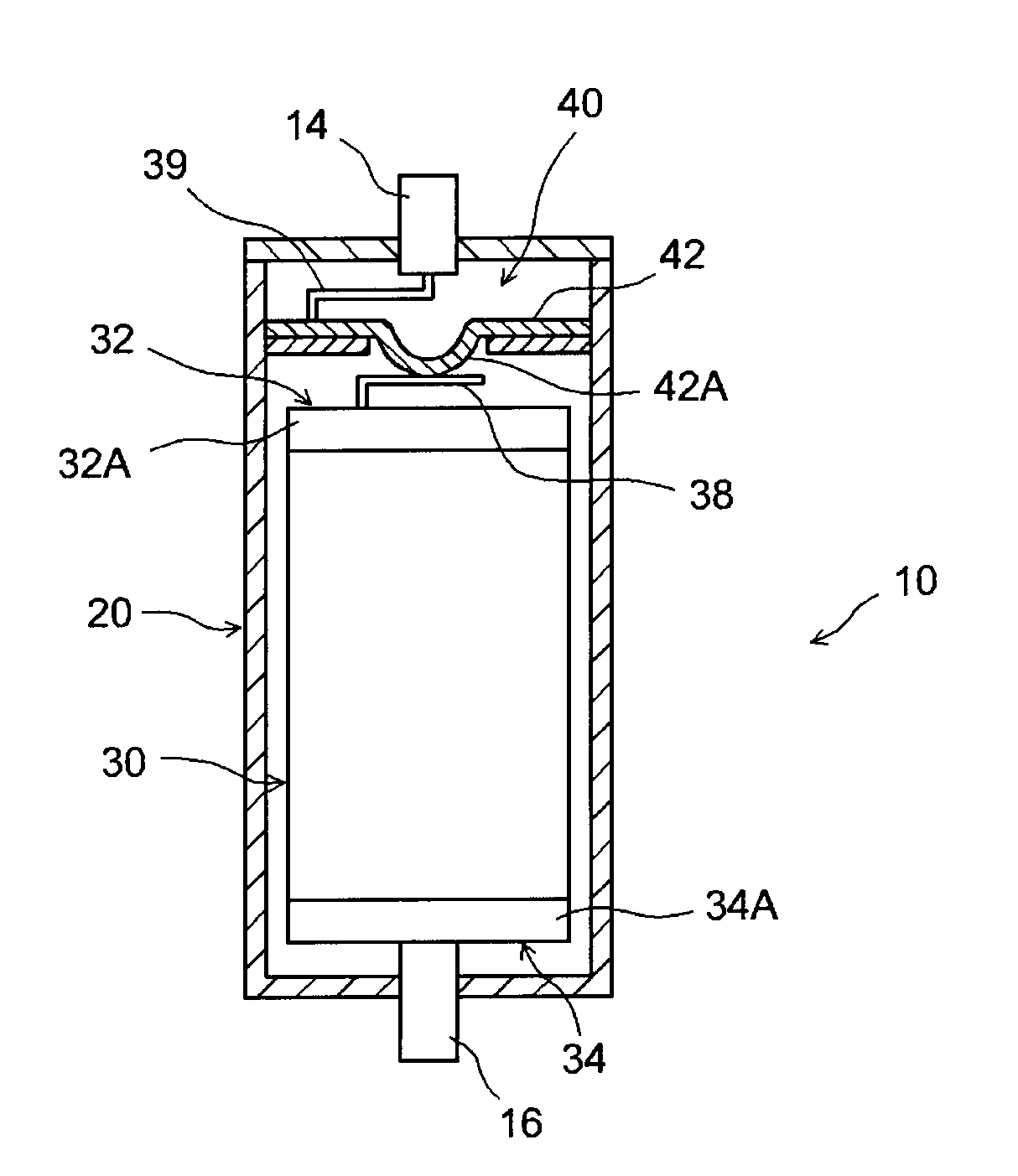

Lithium secondary battery and manufacturing method therefor

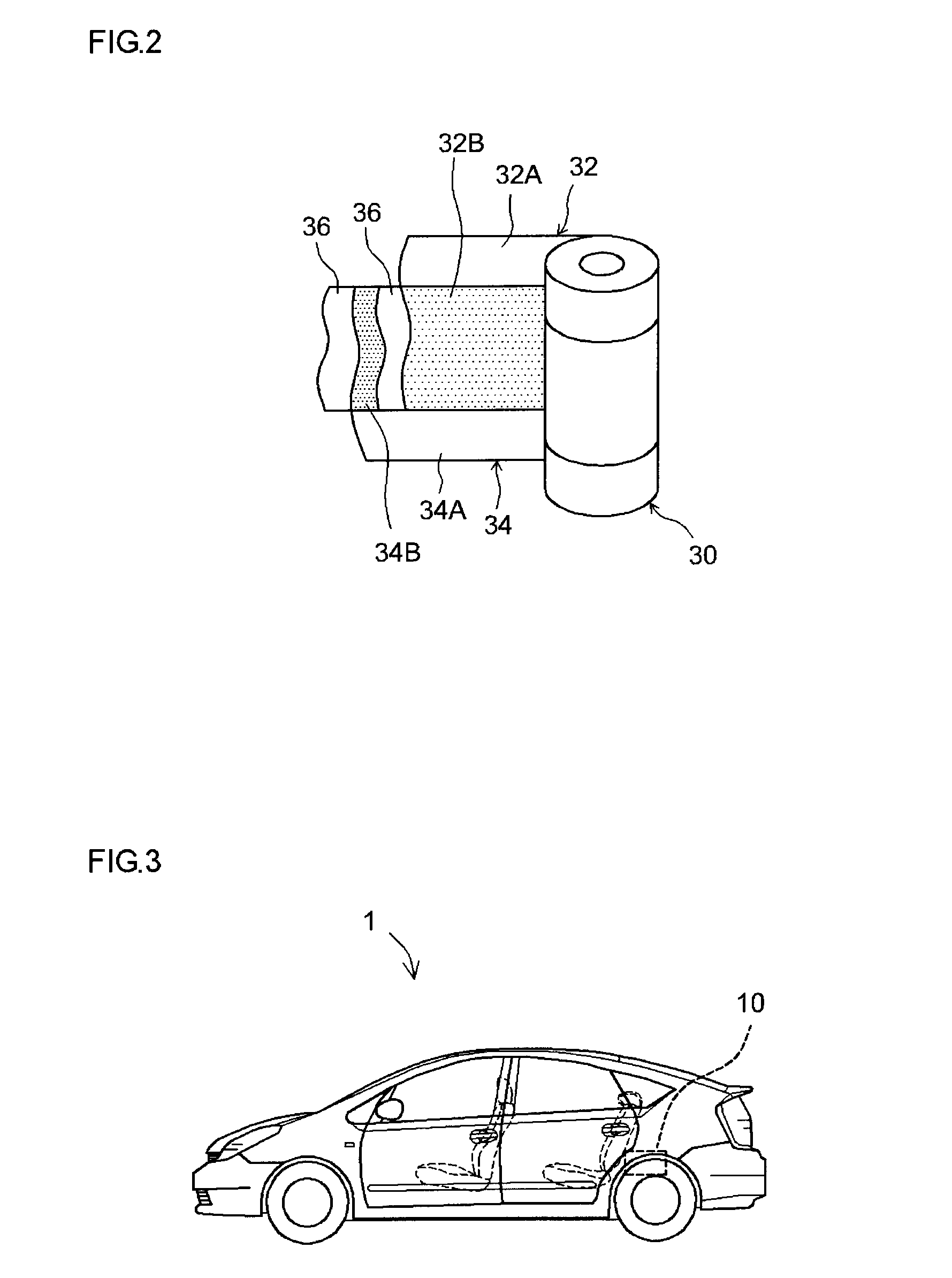

ActiveUS20110039160A1Reduce internal resistanceHigh performanceElectrode manufacturing processesFinal product manufactureLithium carbonateElectrical battery

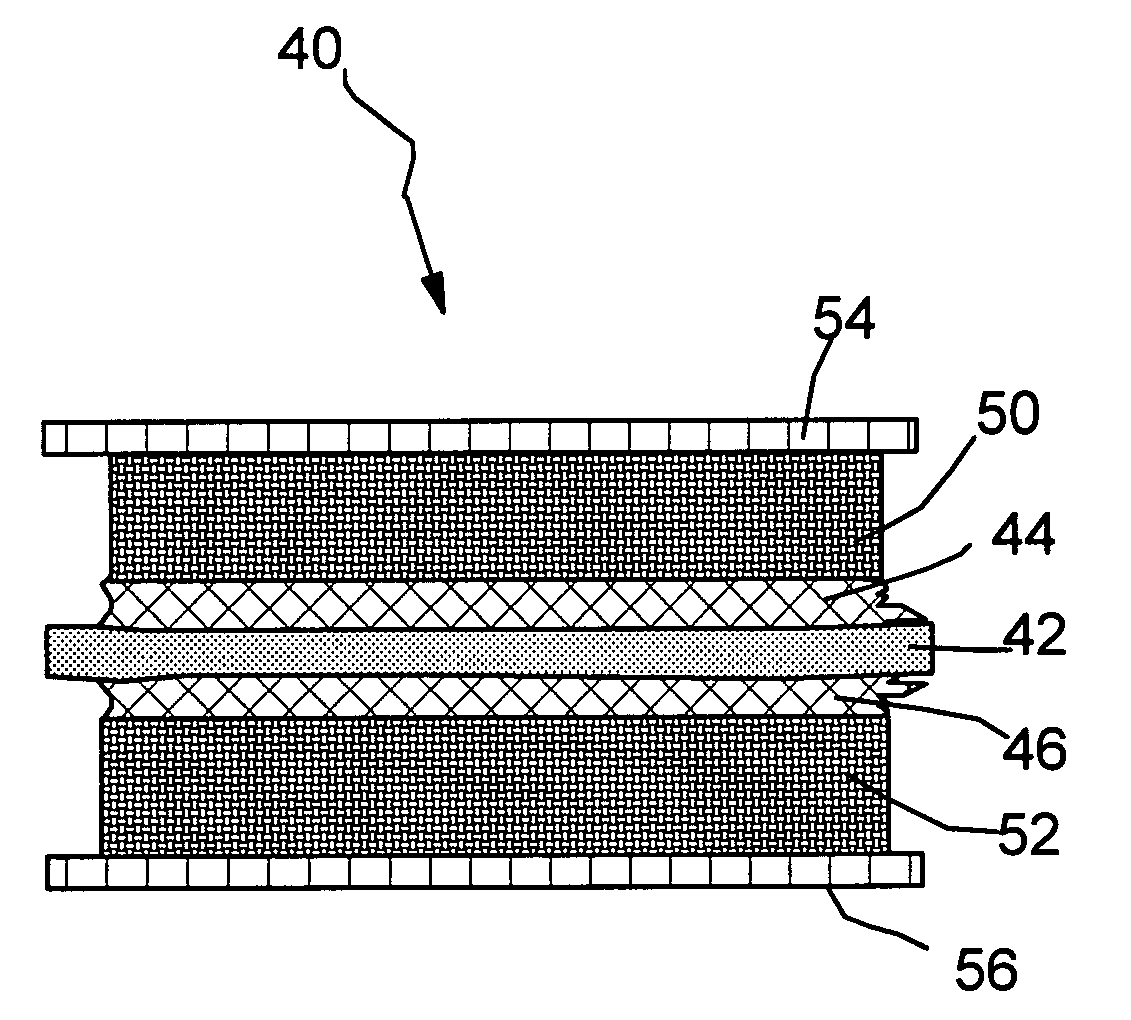

A lithium secondary battery (10) provided by the present invention includes a current interruption mechanism (40) operated by a rise in internal pressure. A positive electrode (32) of this battery (10) has a positive electrode mixture layer containing lithium carbonate, a conductive material and a positive electrode active material consisting primarily of a lithium-transition metal oxide. The lithium carbonate is disposed on the surface of the conductive material. Such a positive electrode mixture layer can preferably be fabricated using a positive electrode mixture composition containing a positive electrode active material and a composite conductive material comprising lithium carbonate retained on the surface of a conductive material.

Owner:TOYOTA JIDOSHA KK

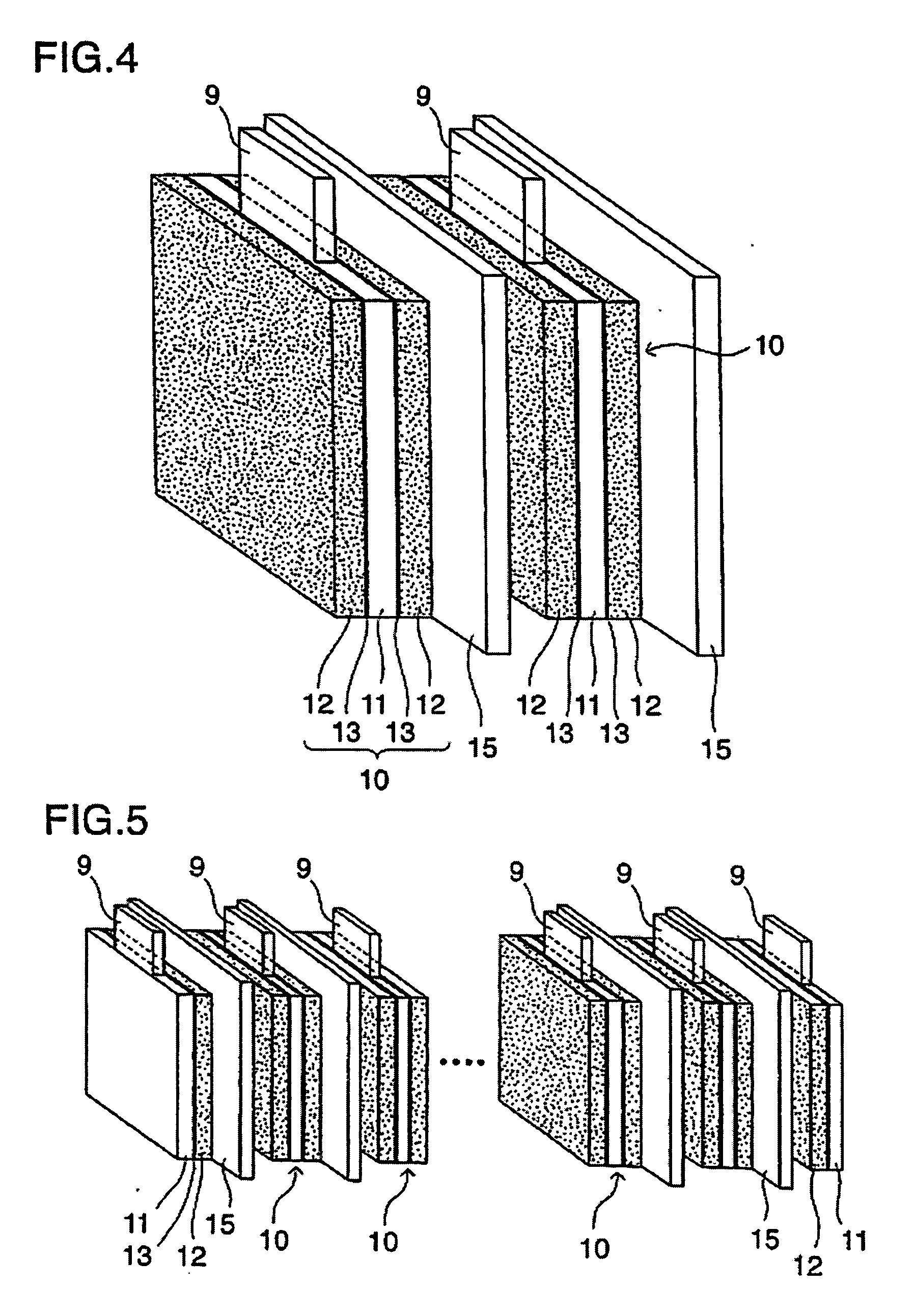

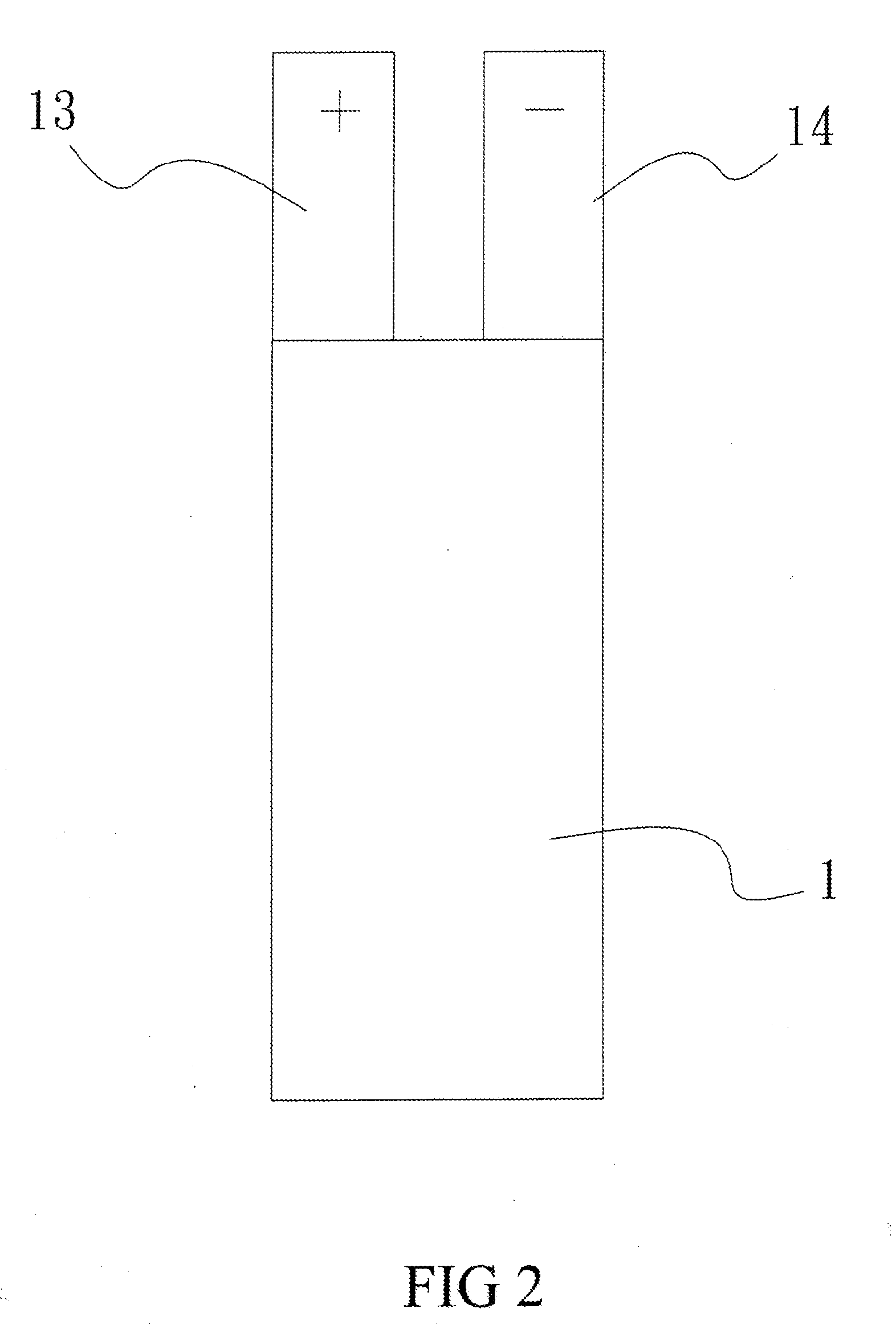

Secondary battery having third terminal other than positive and negative electrode terminals and battery comprising it

ActiveUS20050130037A1Reduce internal resistanceImprove accuracyNon-aqueous electrolyte accumulatorsFinal product manufactureElectrical batteryEngineering

A secondary battery in which temperature rise (heat generation) can be measured accurately at the time of quick charge / discharge, and a battery which can be configured readily using the secondary batteries while realizing low resistance. Separately from the positive and negative electrode terminals of a flat laminate film secondary battery, a third terminal is fixed perpendicularly thereto. The third terminal is connected with the electrode current collecting parts of a power generating element body constituting the secondary battery (1) and imparted with a potential equal to that of any one of the positive and negative electrode terminals. Inner temperature of the secondary battery is determined by measuring the temperature of the third terminal and a cell balancer circuit, or the like, is connected with the third terminal. The battery is configured by connecting the positive and negative electrode terminals directly in series.

Owner:NEC CORP

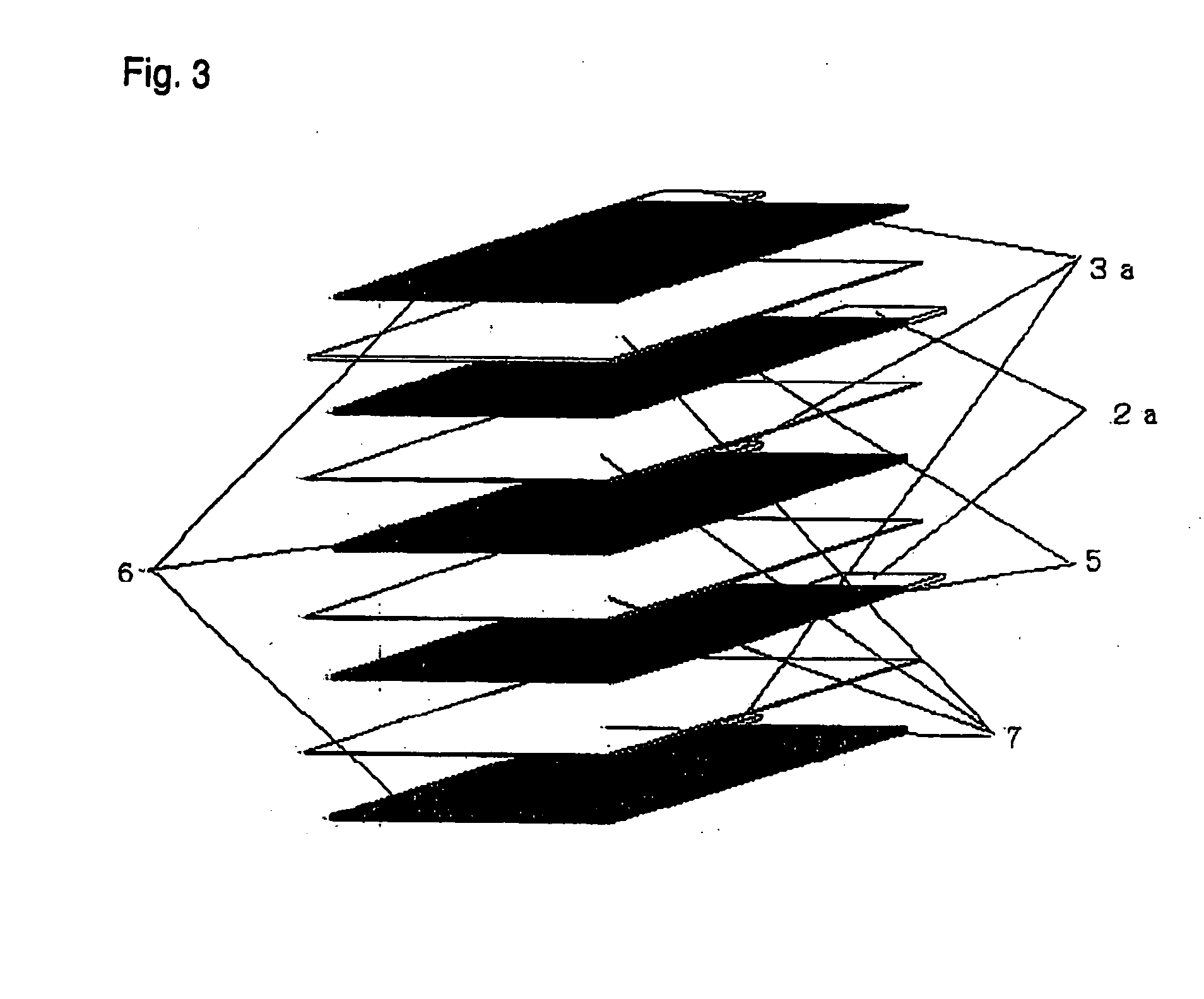

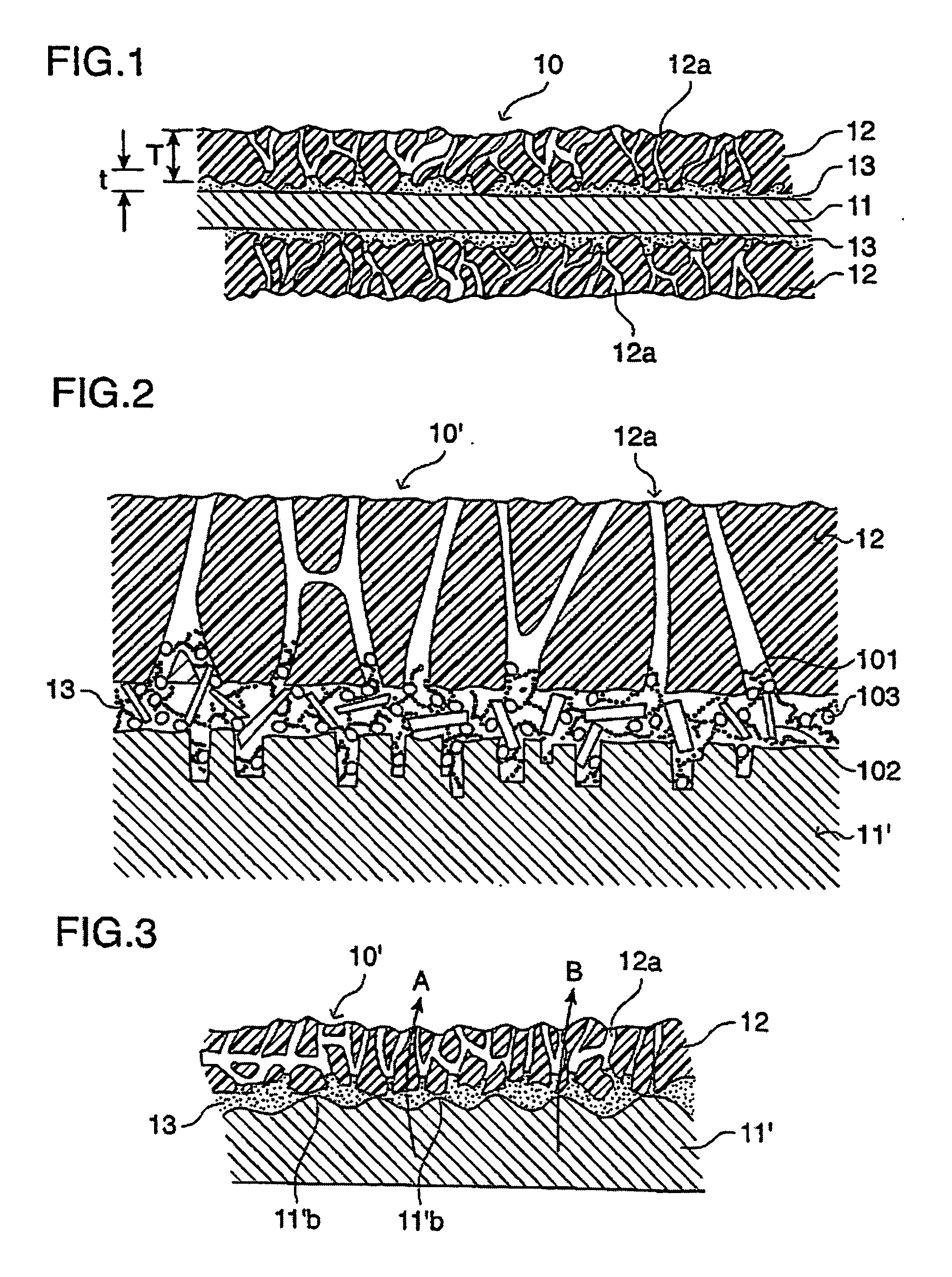

Electrode for electric double layer capacitor, method for manufacturing same, electric double layer capacitor, and conductive adhesive

InactiveUS20070177332A1Reduce internal resistanceHigh electric capacityNon-macromolecular adhesive additivesFixed capacitor electrodesPorous sheetAdhesive

The present invention is an electrode for electric double layer capacitors wherein a polarizable porous sheet composed of constituent materials including a carbonaceous electric double layer-forming material, a carbon material for ensuring conductivity, and a binder is integrated to at least one surface of a collector via a conductive intermediate layer; and is characterized in that the conductive intermediate layer contains a synthetic rubber and two more kinds of carbon materials having different particle diameters. According to the present invention, the electrode can be readily manufactured in a continuous manner with high heat resistant adhesion between the polarizable porous sheet and the collector and a low internal resistance; and when used in an electric double layer capacitor, it is possible to obtain an electrode capable of ensuring a higher capacity and lower internal resistance than is conventionally achieved.

Owner:JAPAN GORE TEX INC

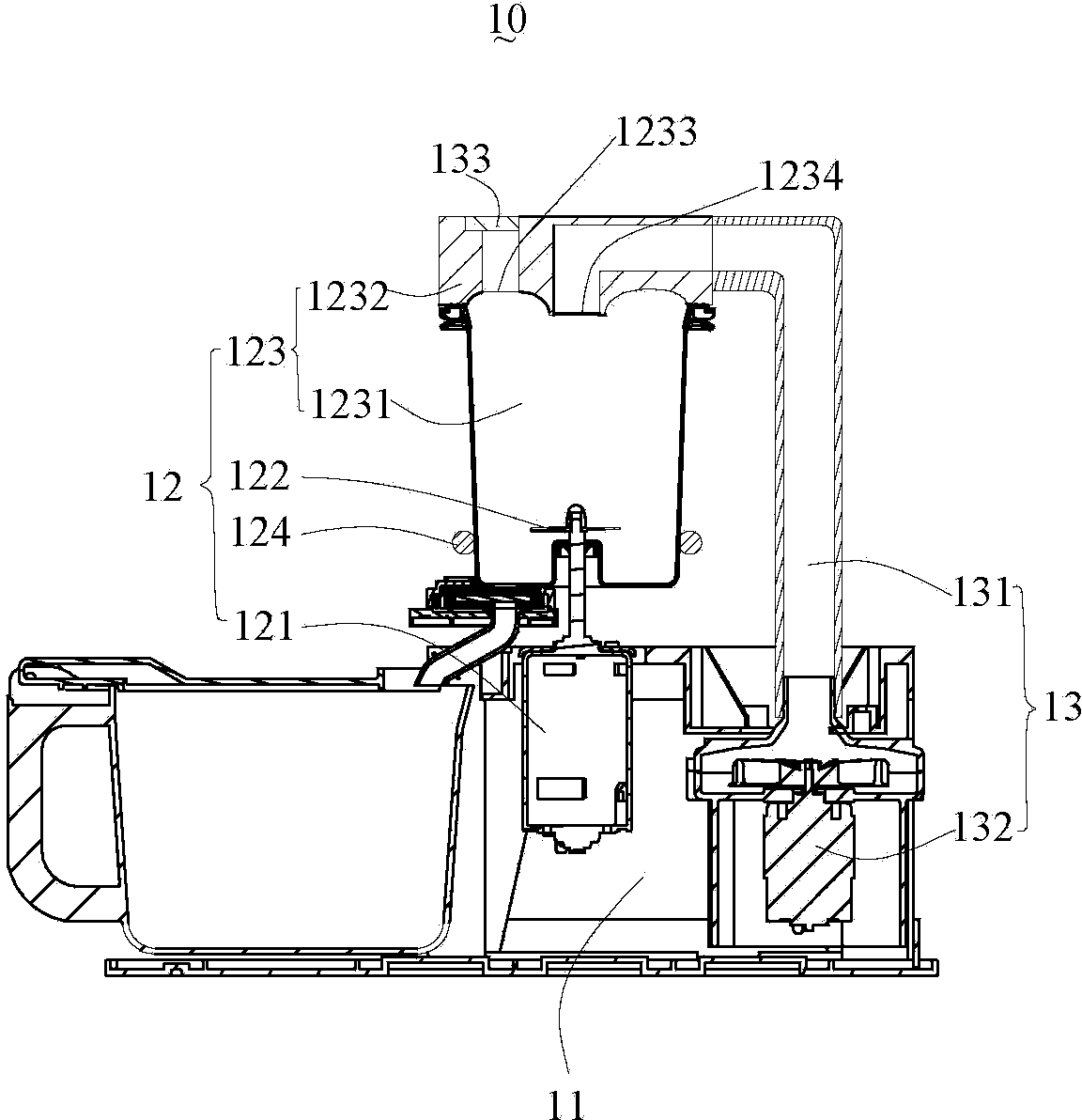

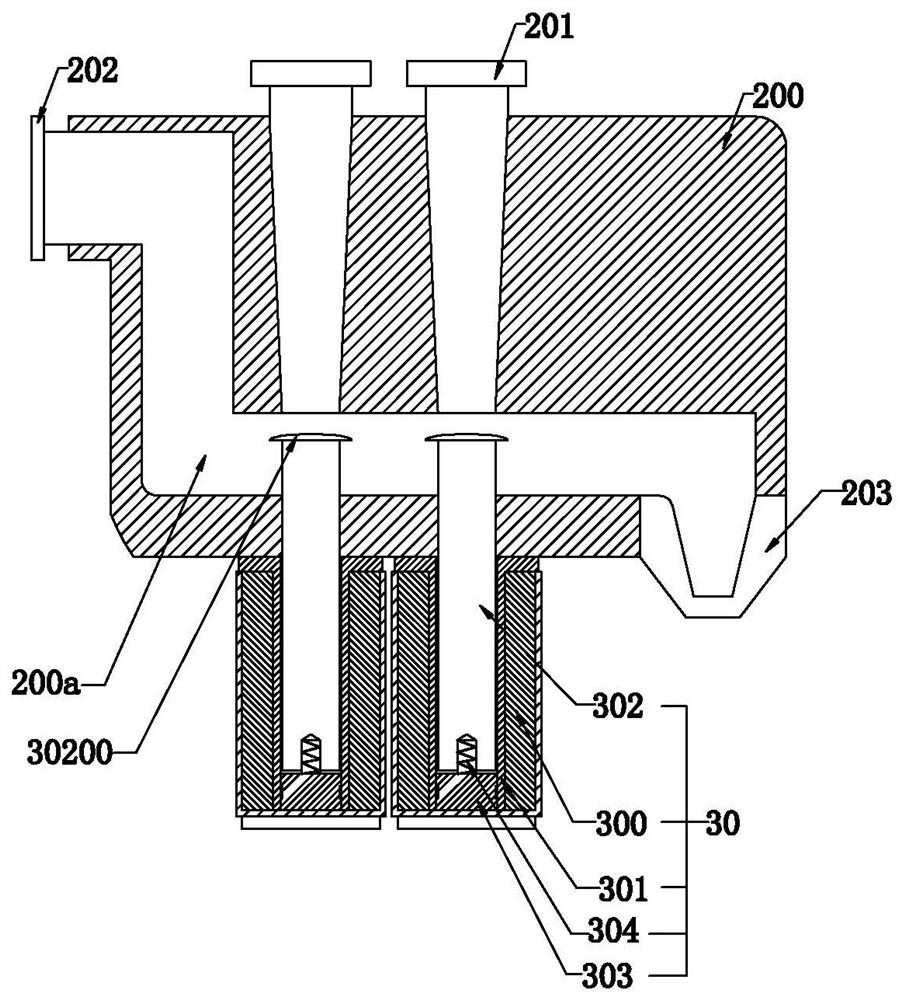

Rapid soybean milk making method of soybean milk maker

ActiveCN104545455AReduce the temperatureShorten the timeBeverage vesselsMilk substitutesCold airEngineering

The invention relates to a rapid soybean milk making method of a soybean milk maker. A cooking stage also includes the step of overflow prevention, the hot air in a pulverizer is sucked away by a sucking pump, the outside cold air rapidly enters the pulverizer via an air inlet under the difference between the outside air pressure and the air pressure in the pulverizer, the air which flows at high speed breaks rising soybean milk bubbles and decreases the surface temperature of the soybean milk liquid, so that overflow is prevented, consequently, the hot steam of cooking is sucked away by the sucking pump, the surface temperature of the soybean milk bubbles is decreased, the bubbles rapidly expand and break according to the principle of thermal expansion and contraction when the gas temperature in the bubbles is higher than the outside temperature, negative pressure is generated in the pulverizer as the hot steam is sucked away, the outside air is formed into high-speed airflow under the effect of pressure difference and is rapidly replenished into the pulverizer, the high-speed airflow also can break the bubbles of the soybean milk liquid, and thereby the efficiency of overflow prevention is increased greatly.

Owner:JOYOUNG CO LTD

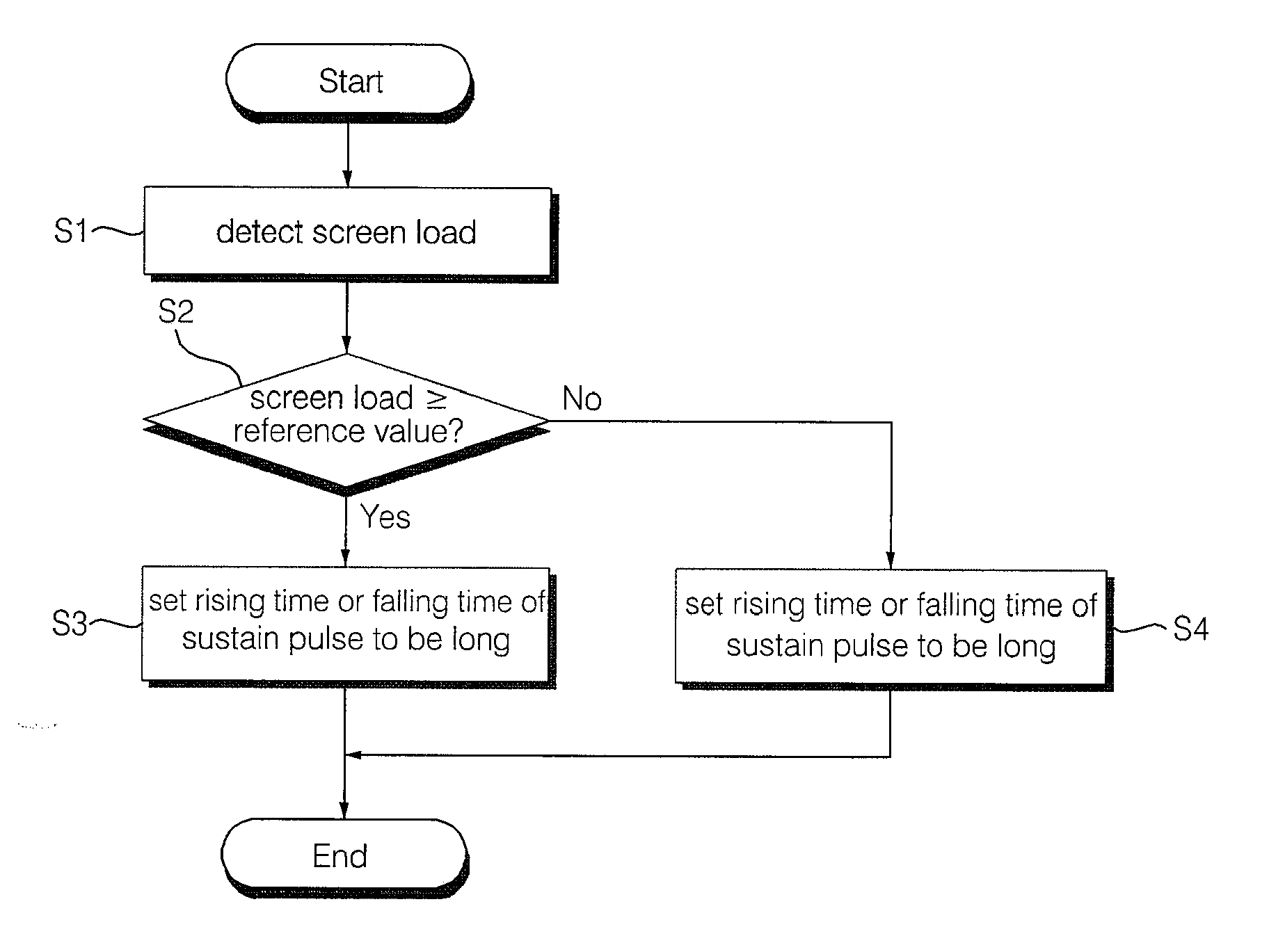

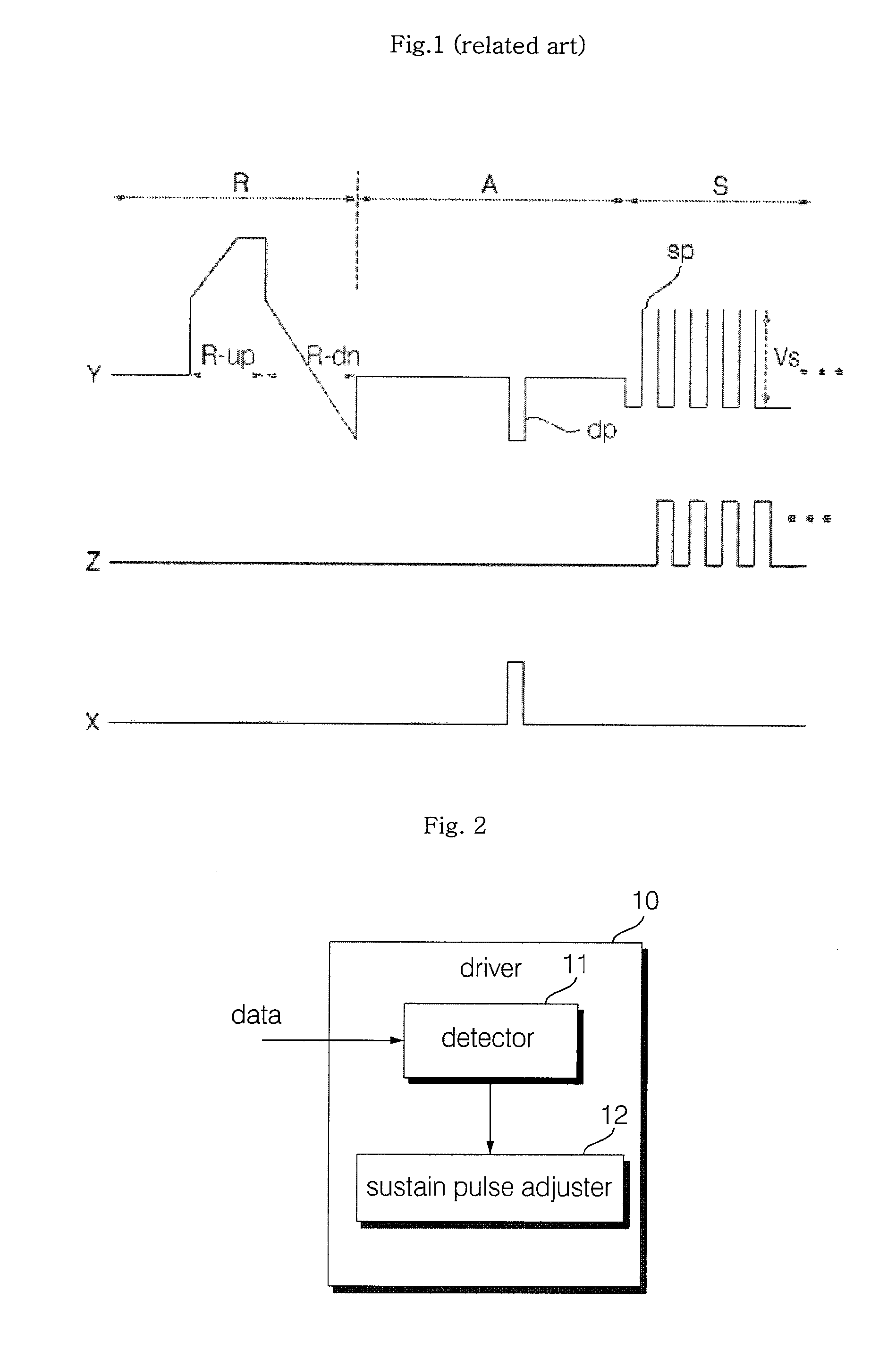

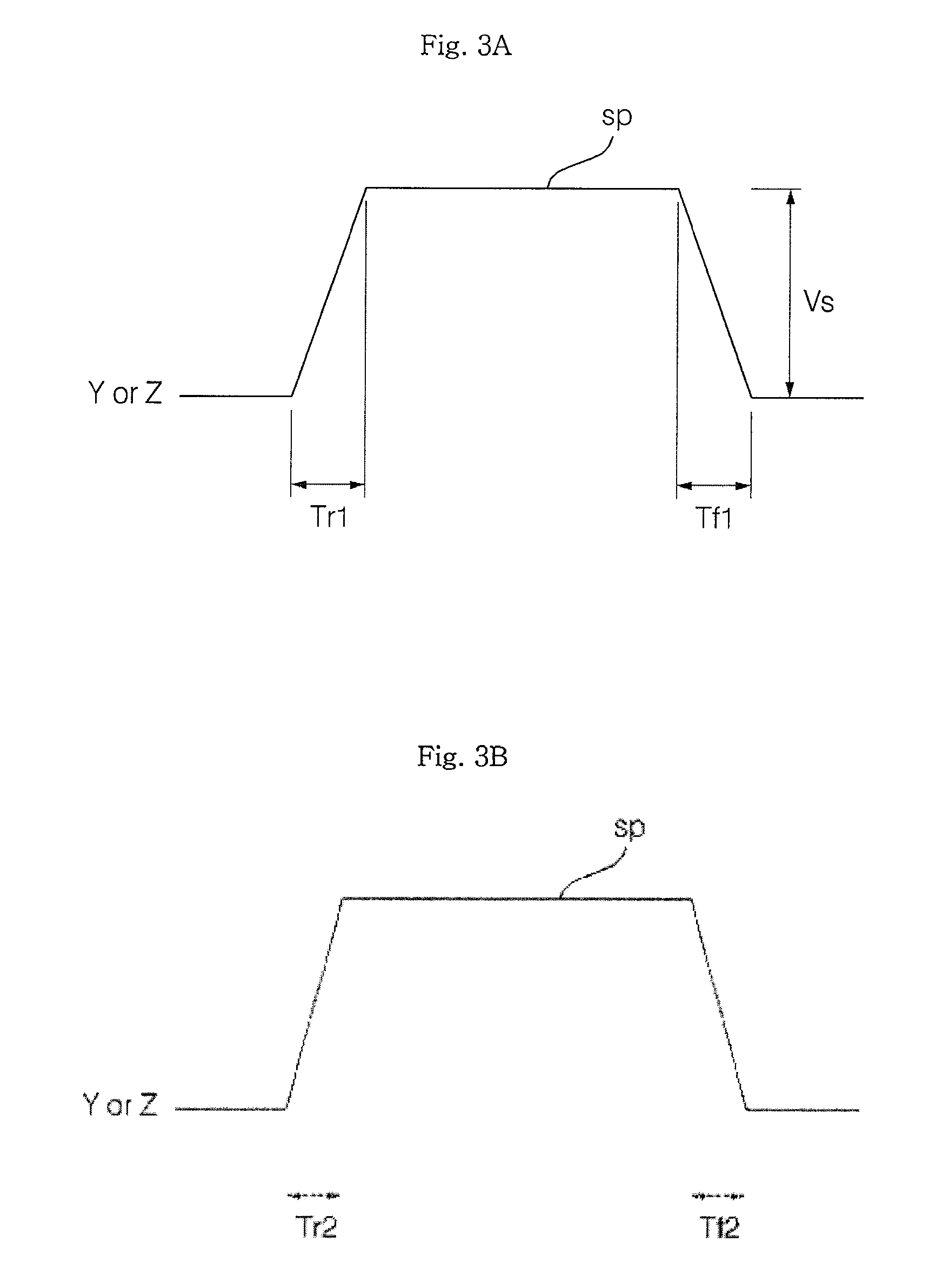

Plasma display device and operating method of the same

InactiveUS20060208964A1Reduce internal resistanceDischarge damageStatic indicating devicesVehicle heating/cooling devicesQuality characteristicsEngineering

There is provided a plasma display device which can improve a brightness characteristic and a driving method thereof, where a screen load is detected and a rising time or a falling time of a sustain pulse changes depending on the detected screen load. A rising time or a falling time of a sustain pulse is extended when the screen load is large, compared to when the screen load is small. Therefore, brightness and discharge efficiency of a plasma display device can be enhanced when the screen load is large and a voltage margin can be enhanced while having a stable brightness characteristic when the screen load is small, so that a picture quality characteristic can be improved while enhancing driving efficiency of a plasma display panel.

Owner:LG ELECTRONICS INC

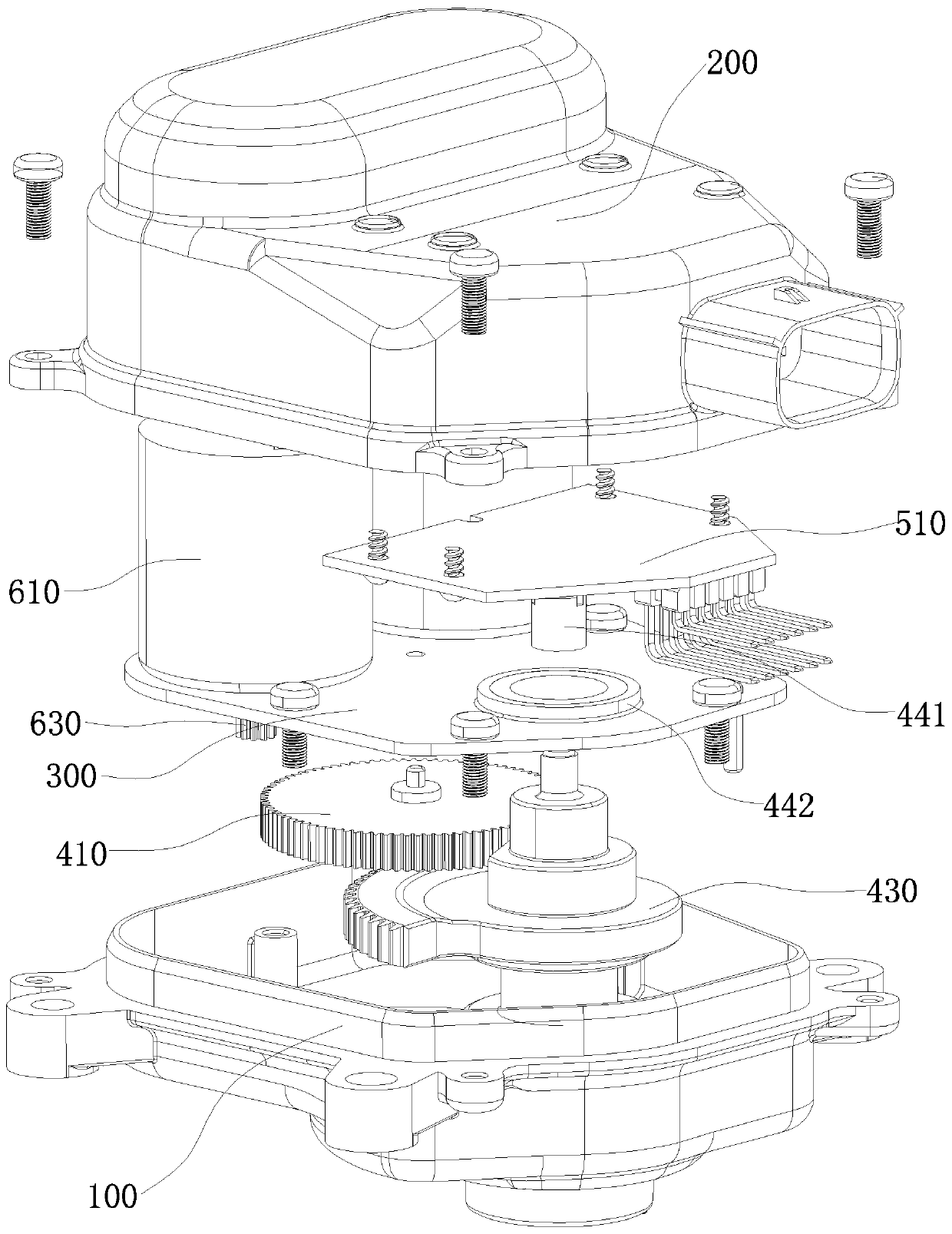

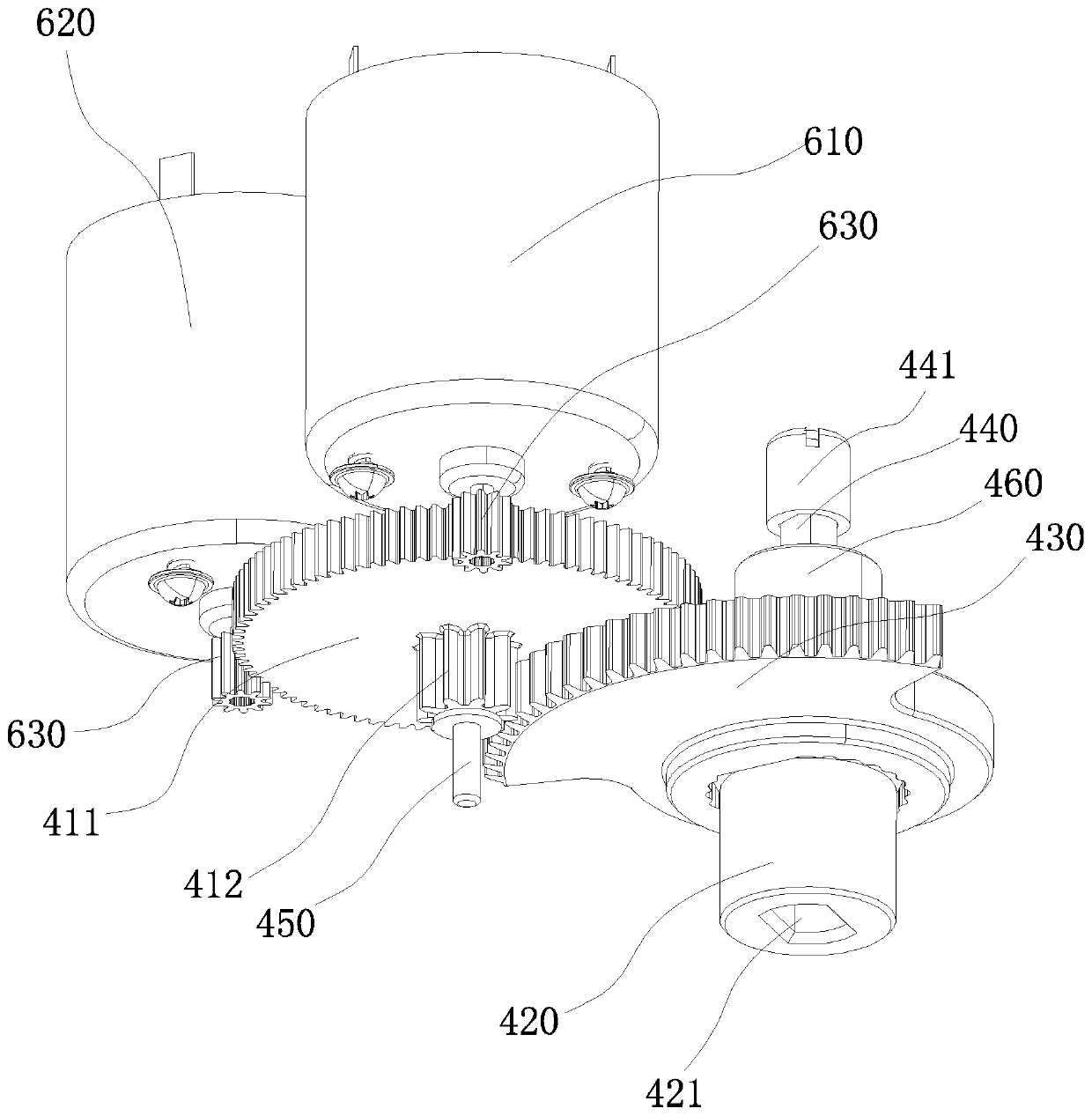

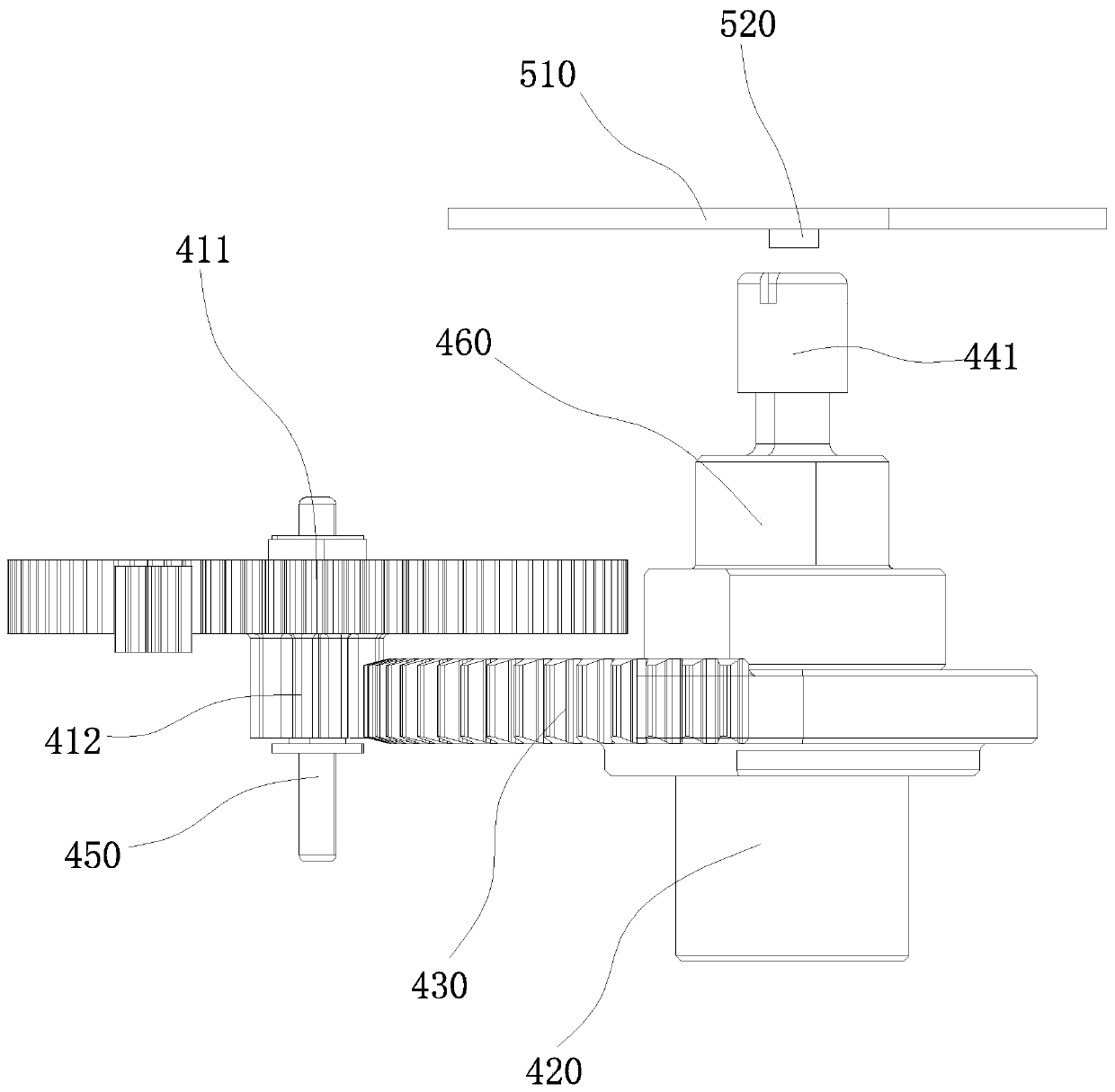

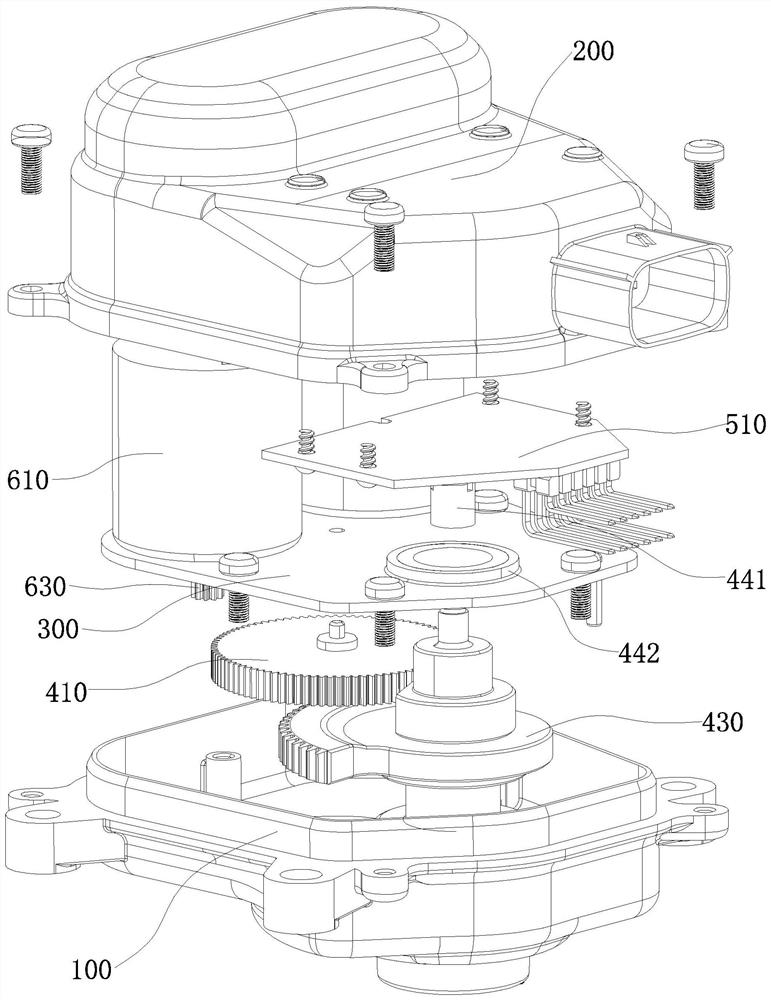

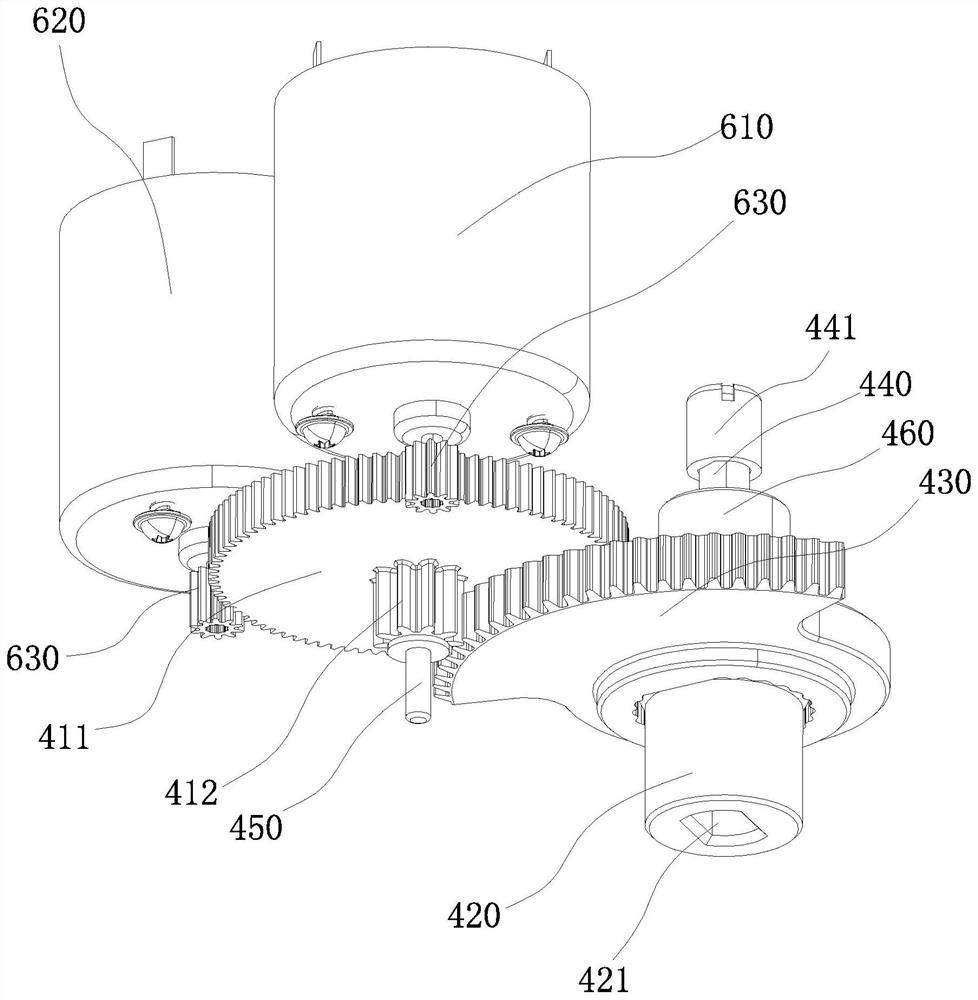

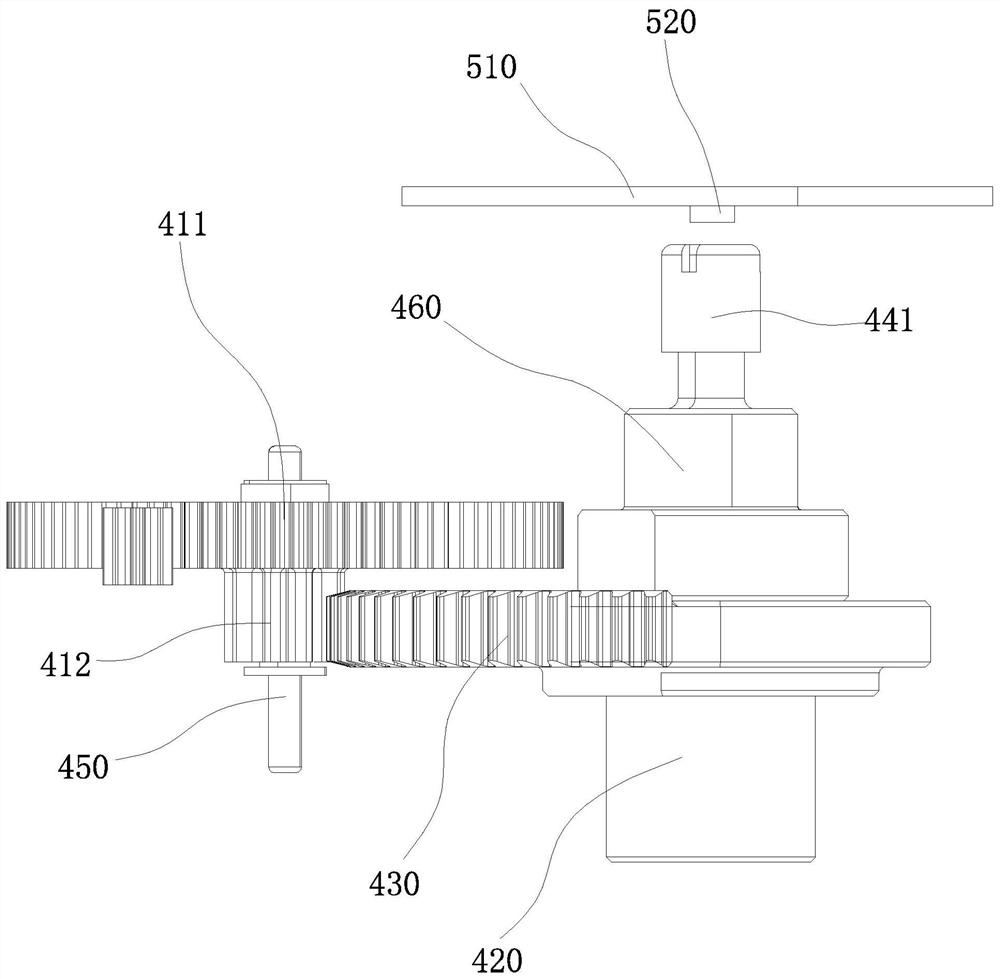

Gear shifting actuator

ActiveCN111089164AFile accurateAdaptableToothed gearingsGearing controlInternal resistanceControl cell

The invention provides a gear shifting actuator, and belongs to the technical field of gear shifting actuators for vehicles. The gear shifting actuator comprises a base, an upper cover, a transmissionunit, a power unit and a control unit, wherein the base is provided with an installation block connected with a gearbox; the upper cover is arranged on the base, and a sealed cavity is formed betweenthe base and the upper cover; the transmission unit is connected with the base and located in the sealed cavity, the transmission unit is provided with an output end, and the output end is used for being connected with the gearbox; the power unit is arranged in the sealed cavity and in linkage connection with the transmission unit; the control unit is electrically connected with the power unit, and the control unit senses the action of the transmission unit and controls the power unit to move. The gear shifting actuator has the benefits that transmission is conducted by using a non-worm-gearstructure, the internal resistance of the actuator is low, and the gear transmission can be more precise and more thorough.

Owner:NINGBO GAOFA AUTOMOTIVE CONTROL SYSTEM CO LTD

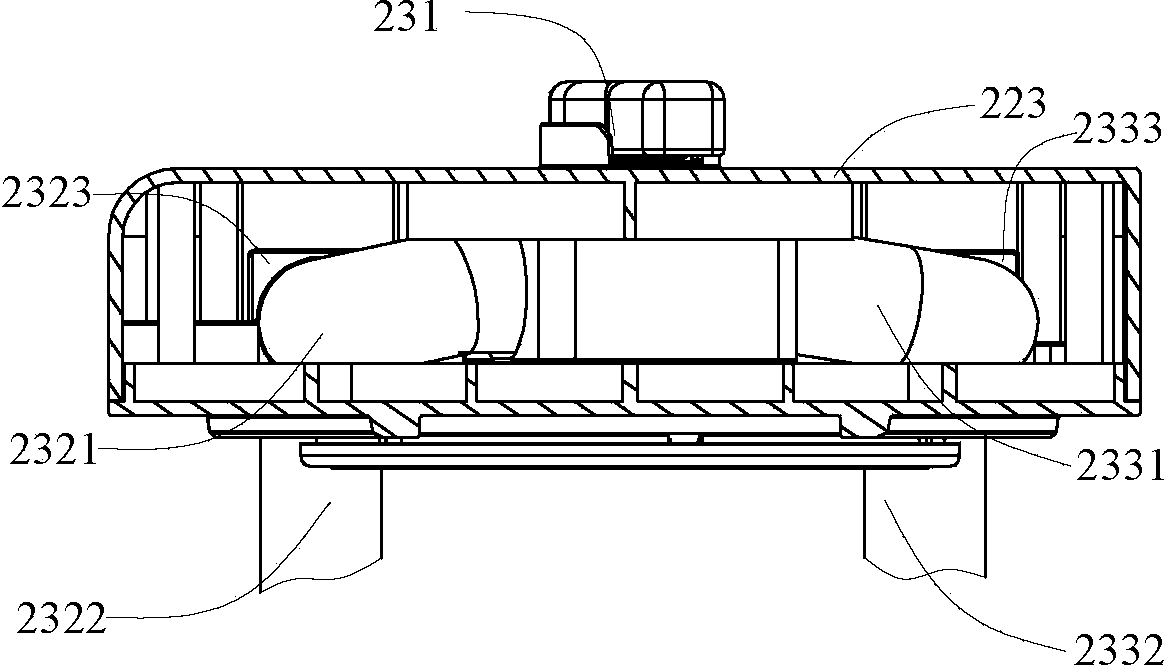

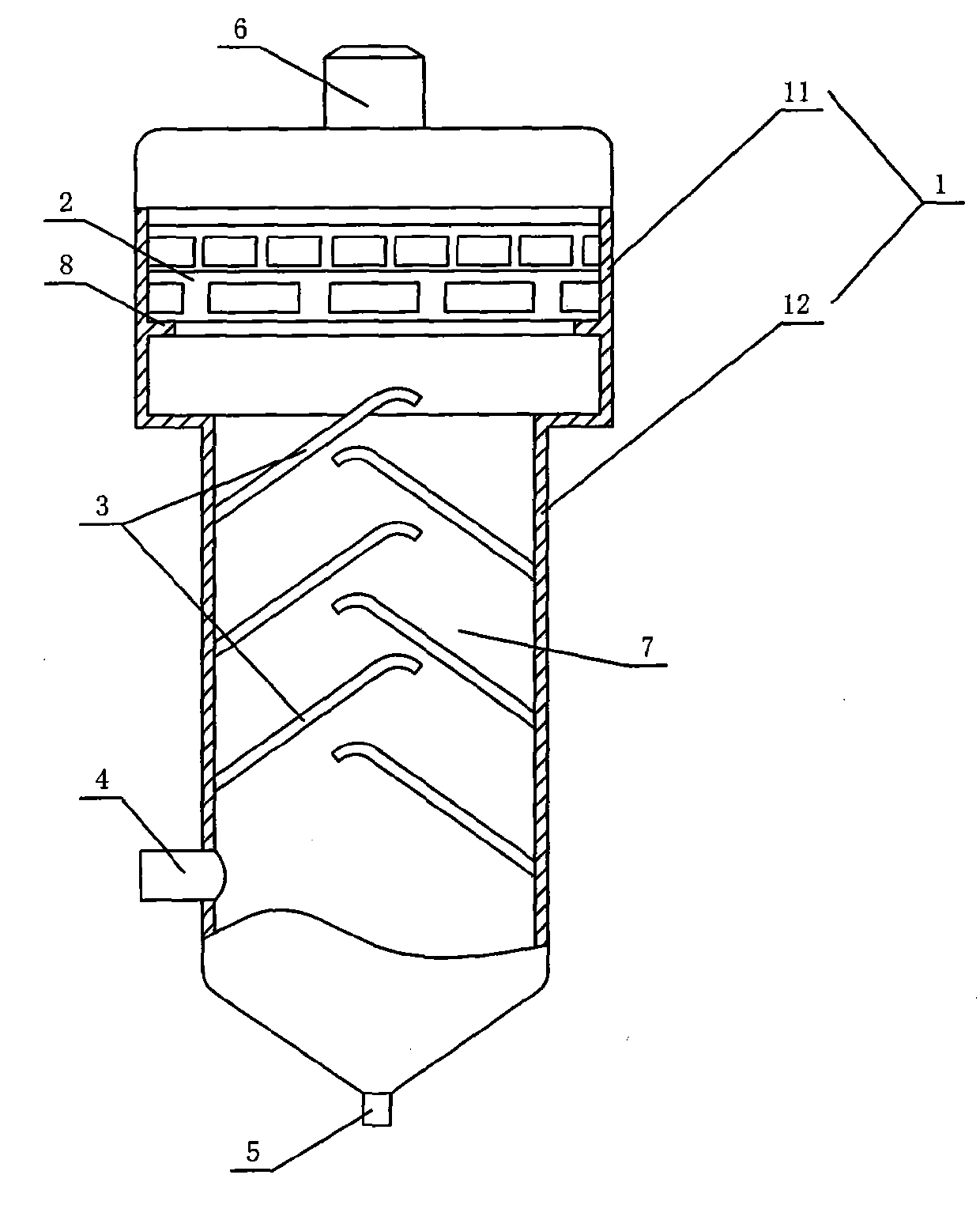

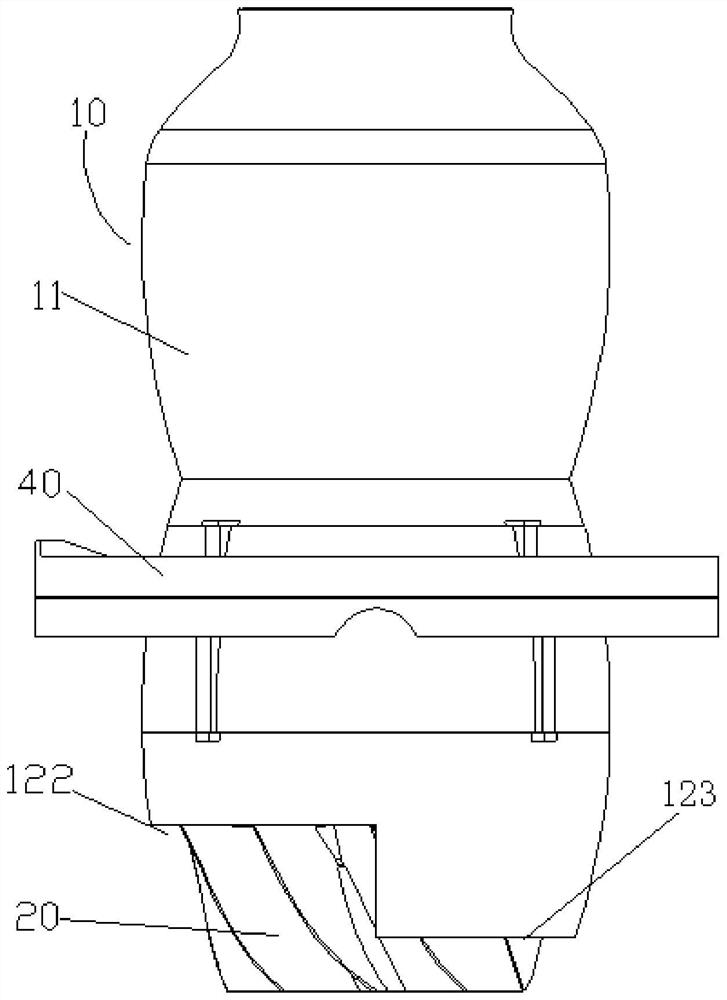

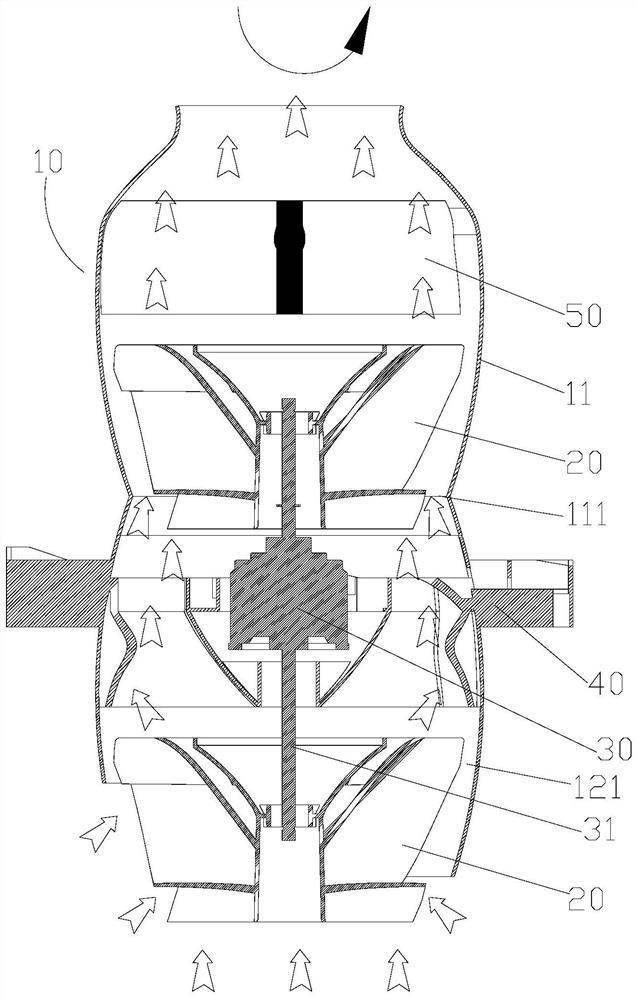

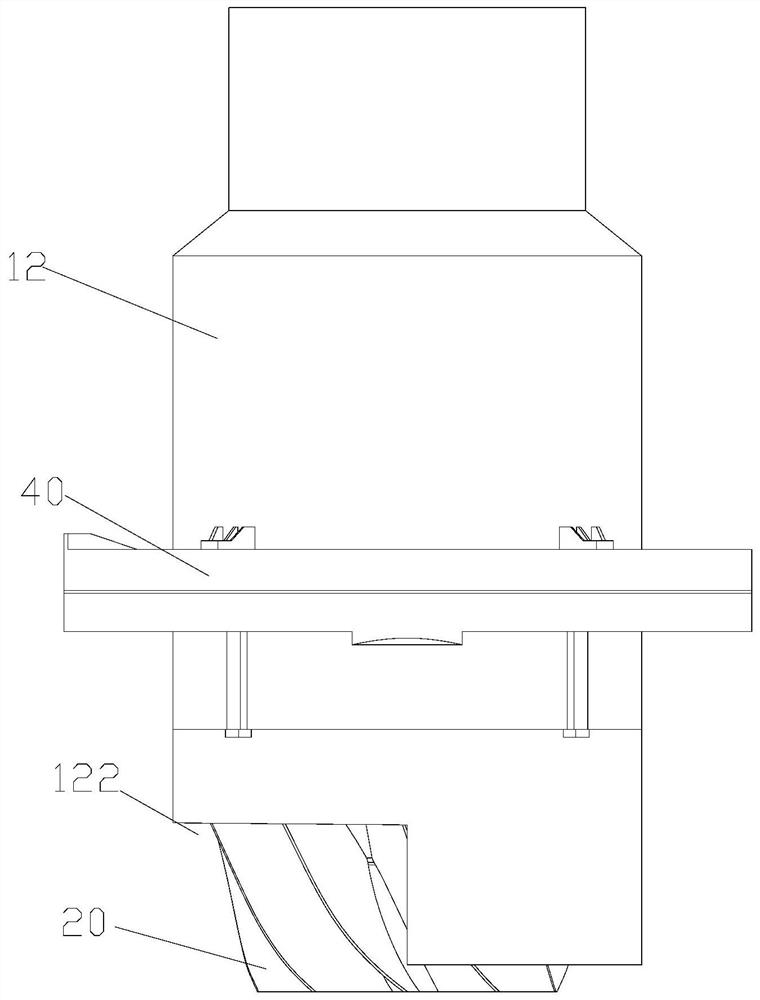

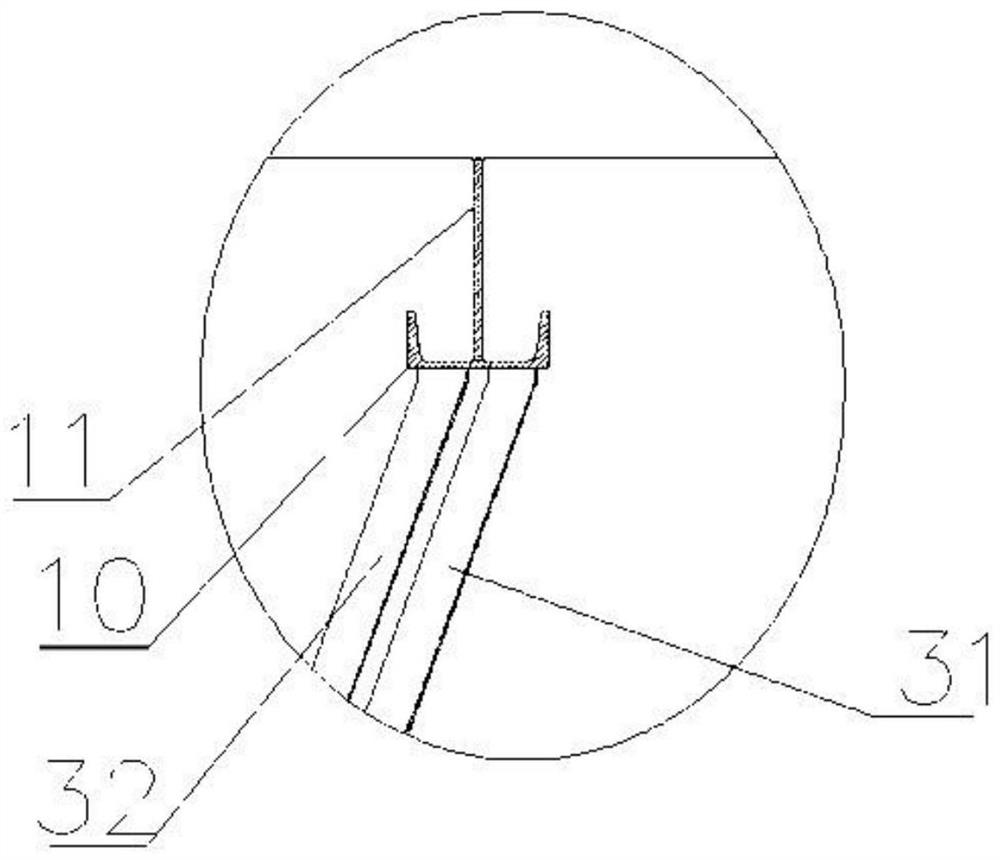

Oil-gas separator

InactiveCN103623667AReduce internal resistanceReduced risk of cloggingCombination devicesVertical projectionInternal resistance

The invention discloses an oil-gas separator which comprises an outer shell of which the side part is provided with a gas mixture inlet and the top is provided with an exhaust gas outlet, wherein the lower part of the inner cavity of the outer shell is fixedly provided with a plurality of baffles which obliquely protrudes upwards in opposite and are arranged at intervals in a staggered mode; the protruding ends of the baffles are overlapped on the vertical projection; the protruding end of each baffle is provided with a cambered section of which the inner cambered surface is arranged downward; the baffles divide the inner cavity of the outer shell into circuitously upward channels; the upper part of the inner cavity of the outer shell is provided with a filter screen; and the bottom of the outer shell is provided with an oil discharge outlet. The oil-gas separator can lower the blockage risk of the filter screen, reduce the internal resistance of the gas mixture passing through the inner cavity of the outer shell, prolong the time interval for cleaning or replacing the filter screen, and lower the maintenance cost.

Owner:GAOMI WANHE AXLE

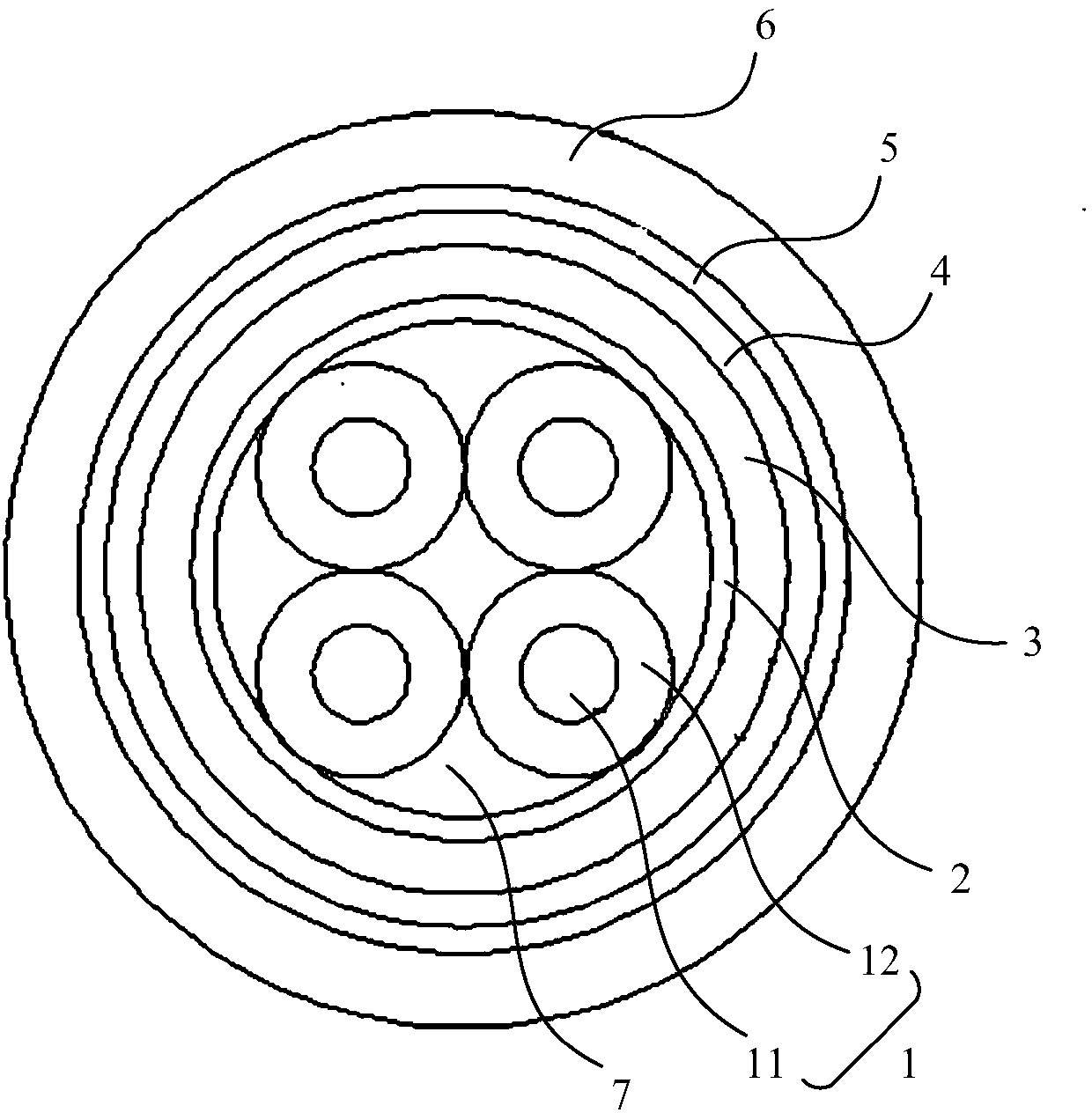

Circular shielding control towline cable and production method thereof

InactiveCN105513682AEasy to fixReduce internal resistancePower cables with screens/conductive layersInsulated cablesEngineeringCable carrier

The invention relates to a circular shielding control towline cable and a production method thereof. The cable comprises, from inside to outside, sequentially a cable core, a first wrapping layer (2) used for wrapping the cable core, an inner lining layer (3) used for wrapping the first wrapping layer (2), a braided layer (4) used for wrapping the inner lining layer (3), and an outer protection layer (6) used for wrapping the braided layer (4). The cable core is formed by intertwisting a plurality of insulation core wires (1), and the plurality of insulation core wires (1) can be fixedly bound together to form one integrated body by the first wrapping layer (2). The circular shielding control towline cable is not easy to disperse, and has advantages of good integrity, strong anti-bending capability, and long service lifetime.

Owner:SHENZHEN LIANJIAXIANG SCI & TECH

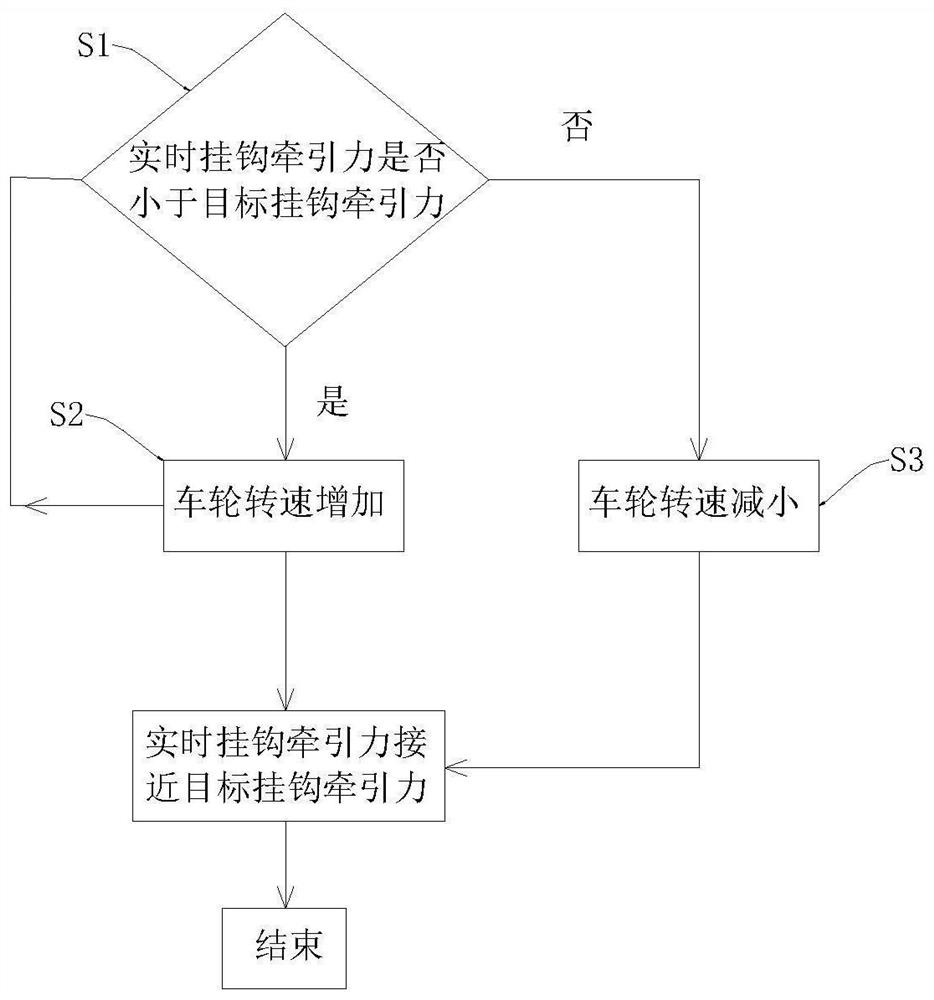

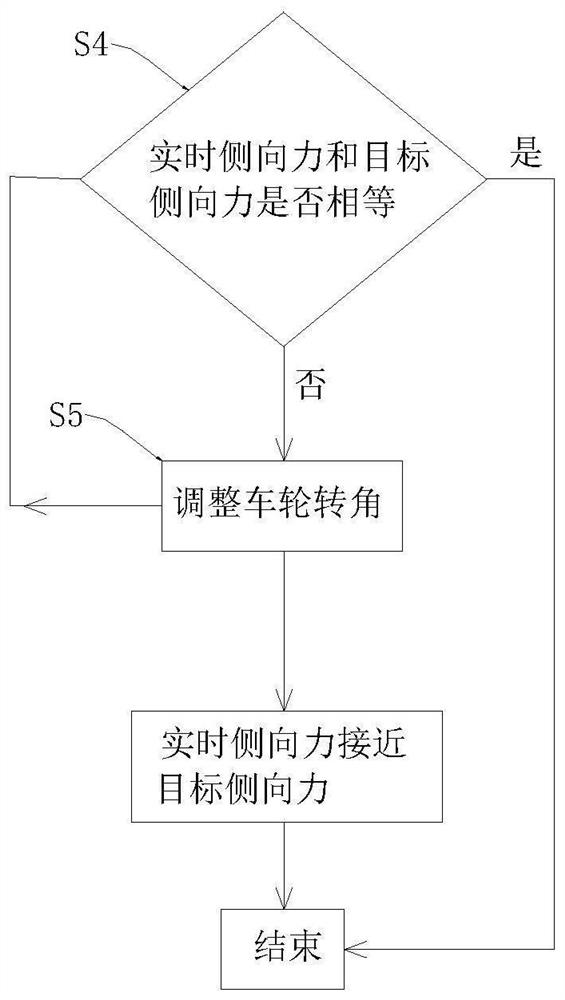

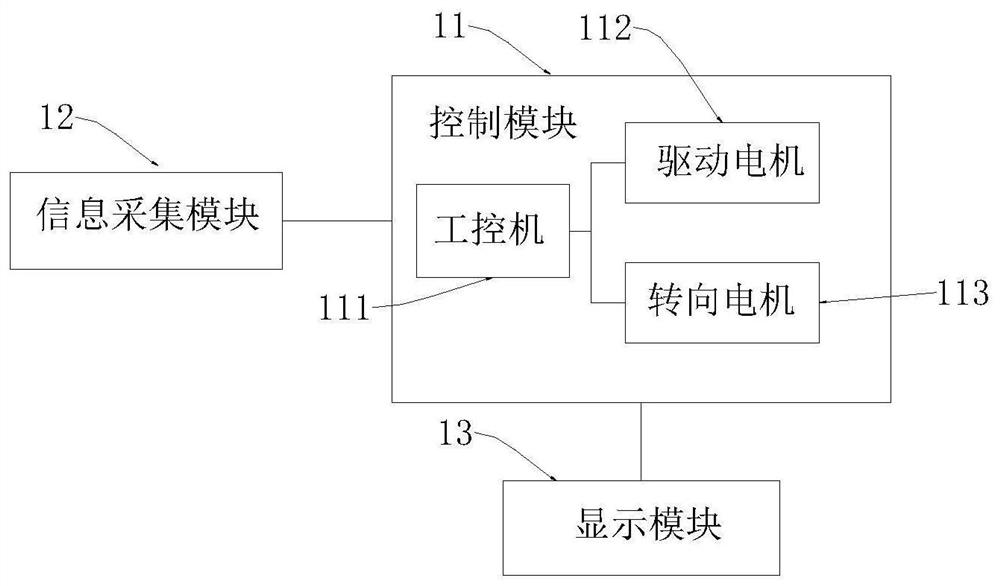

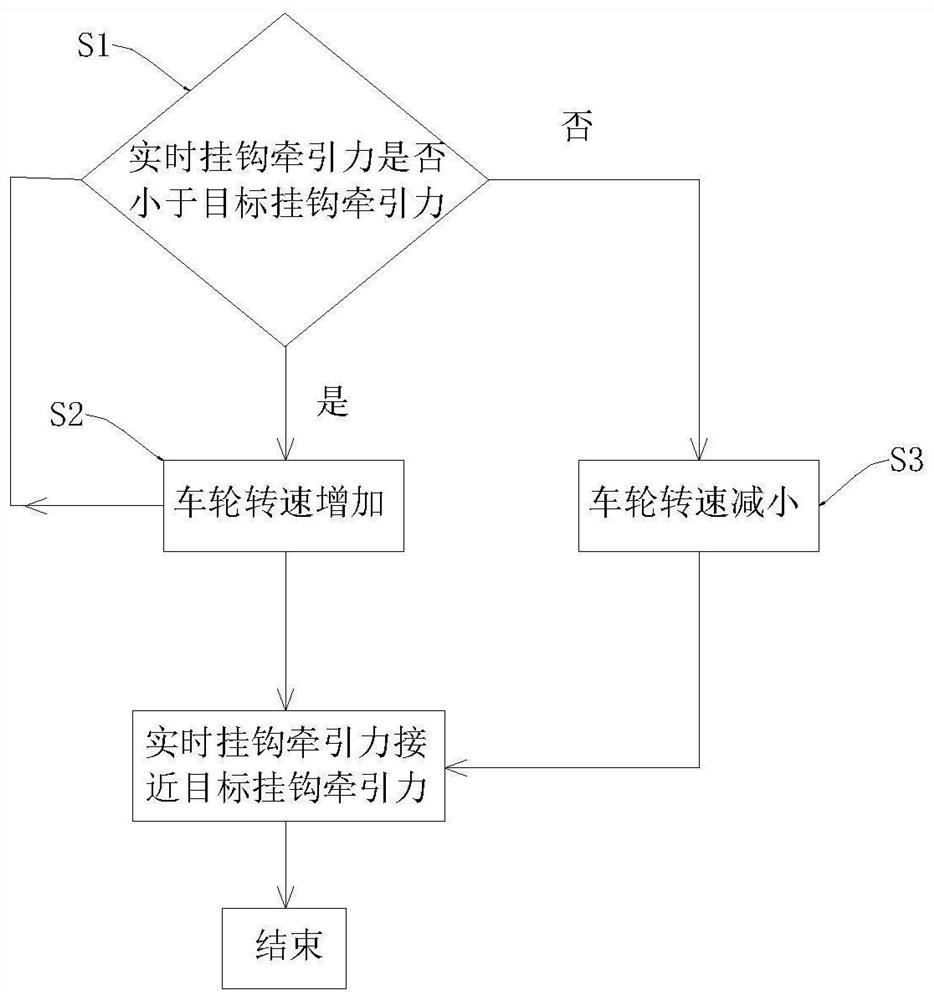

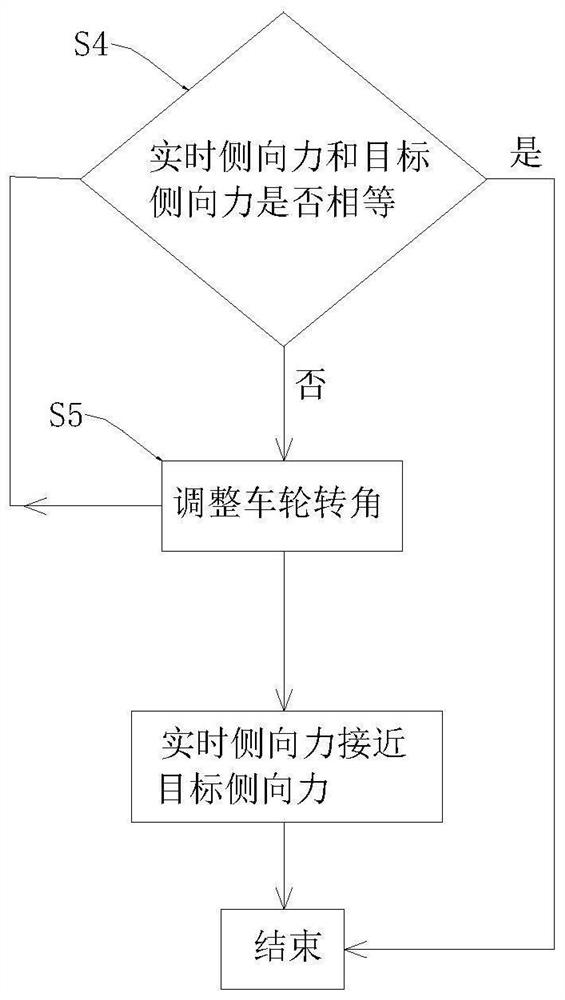

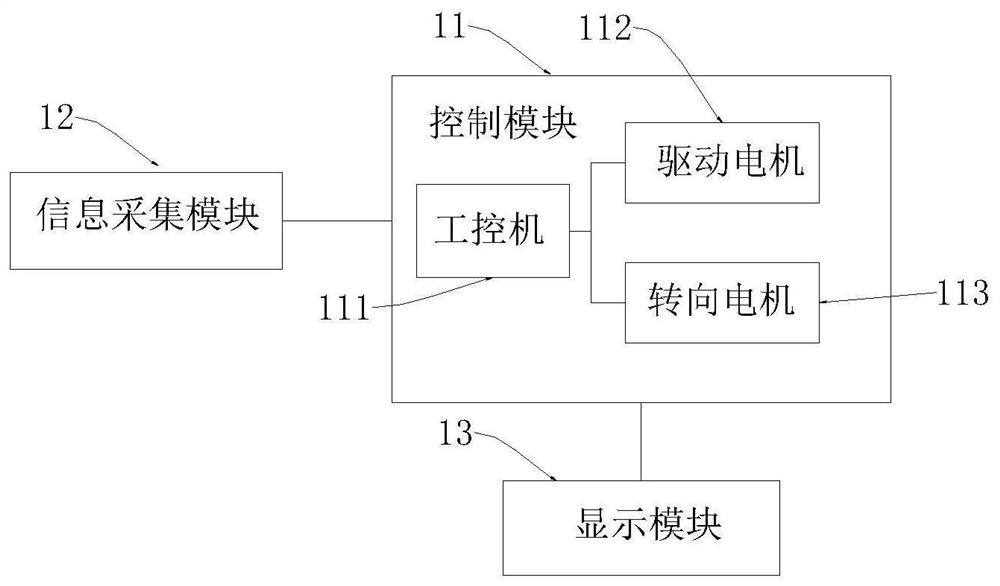

Active wheel following control method and system for planet probe vehicle and planet probe vehicle

ActiveCN111605729ASmall driving forceLow resistanceExtraterrestrial carsSpacecraft guiding apparatusEngineeringRobot control

The invention provides an active wheel following control method and system for a planet probe vehicle and a planet probe vehicle, which relate to the technical field of robot control. The method comprises the following steps that one or more wheels of the planet probe vehicle is optionally selected as supporting wheels, the rotating speed of the supporting wheel is adjusted, so that the real-timehook traction force Fx of the supporting wheel approaches the target hook traction force Fxd, the driving force and the resistance of the supporting wheel to the planet probe vehicle are reduced, andthe supporting wheel is used for providing supporting force for the planet probe vehicle body. By the adoption of the method, the supporting wheels only provide supporting force for the vehicle body,under the conditions that the number of the wheels is increased and the average load of the wheels is reduced, internal force confrontation between the wheels is reduced, and the planet probe vehicleis ensured to have high moving efficiency.

Owner:HARBIN INST OF TECH

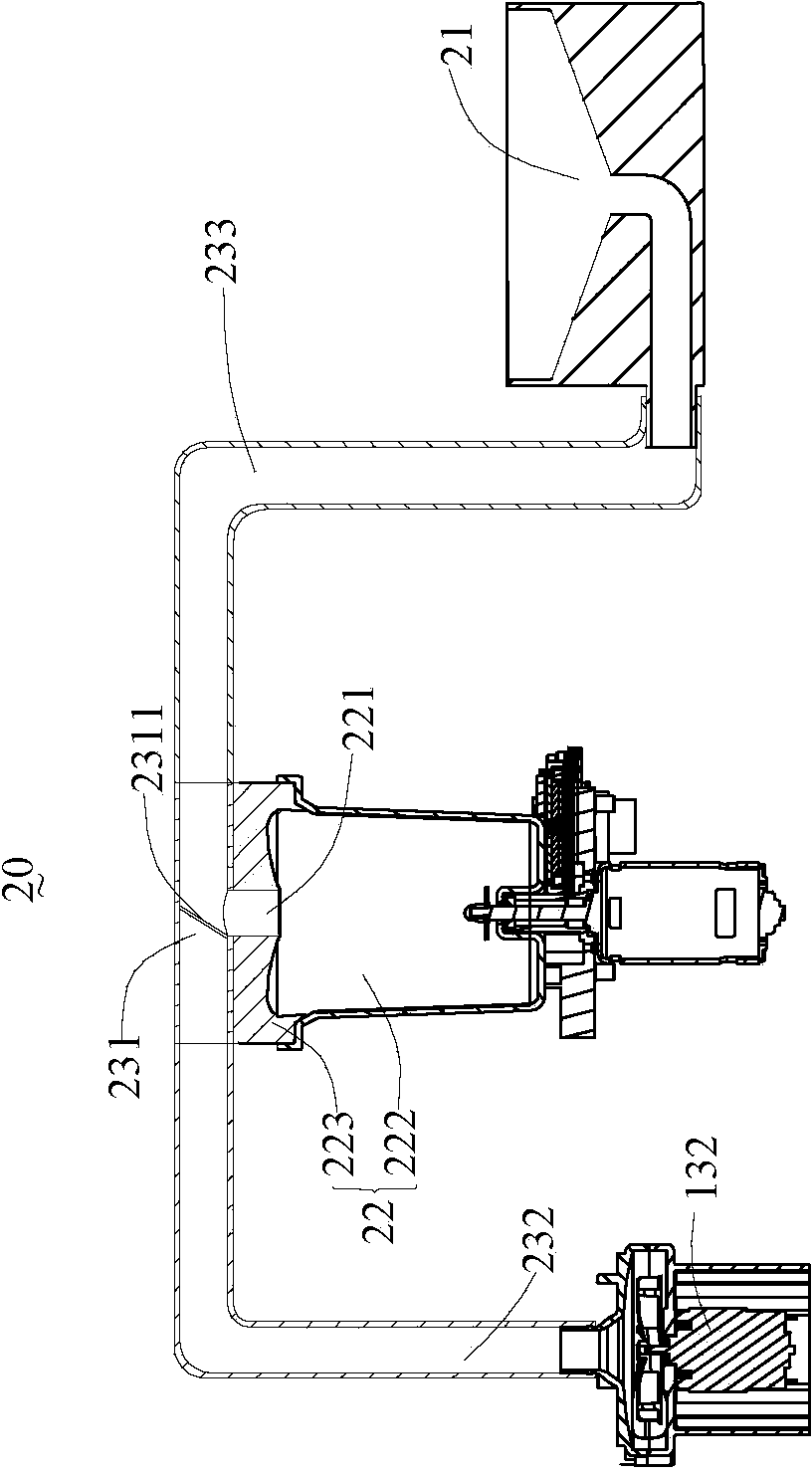

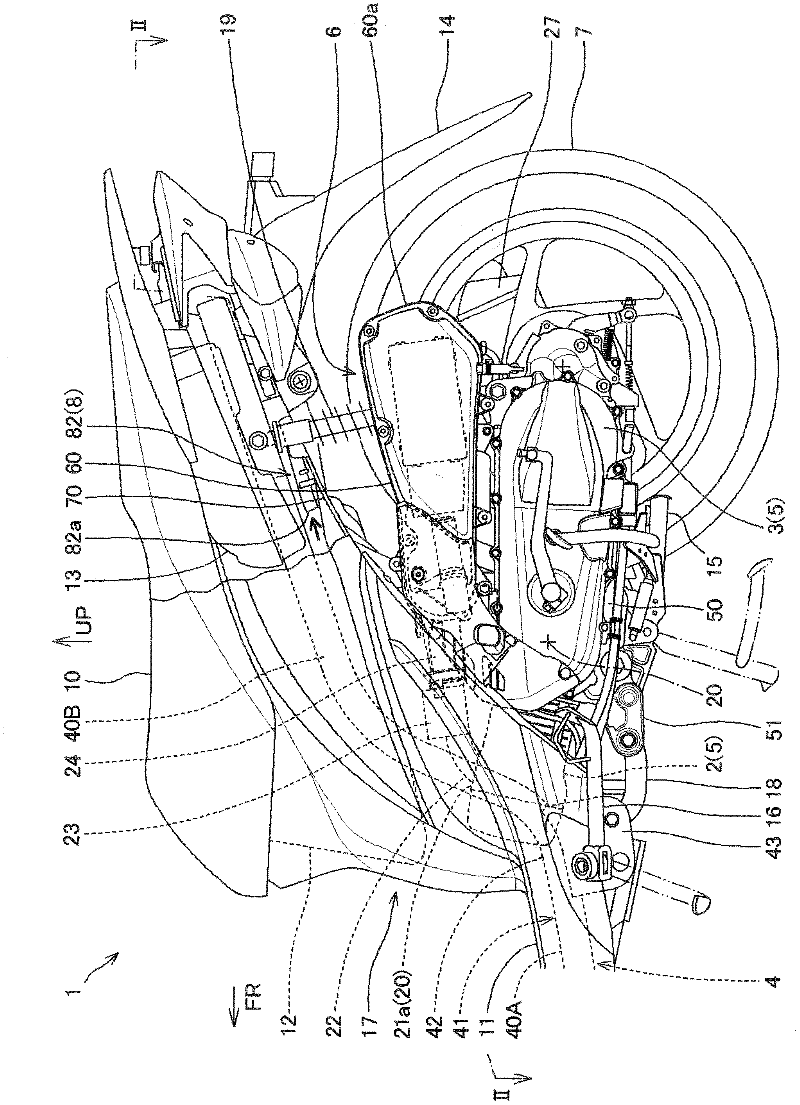

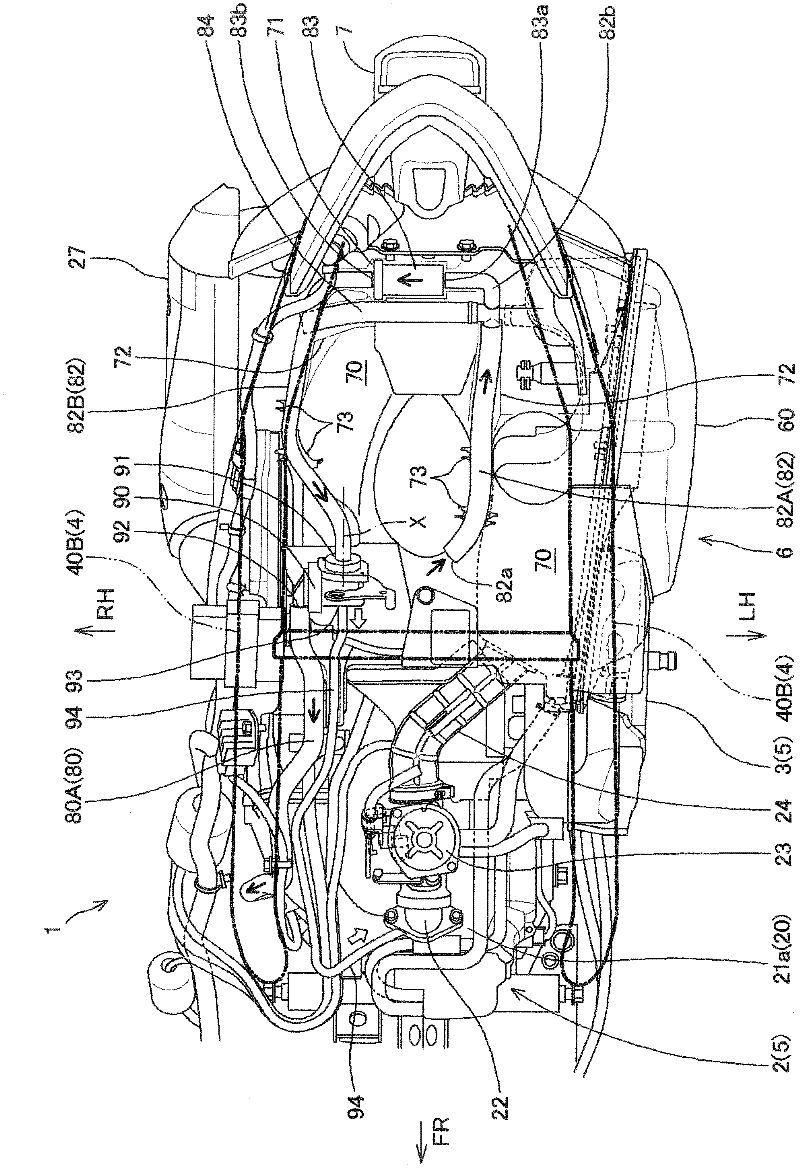

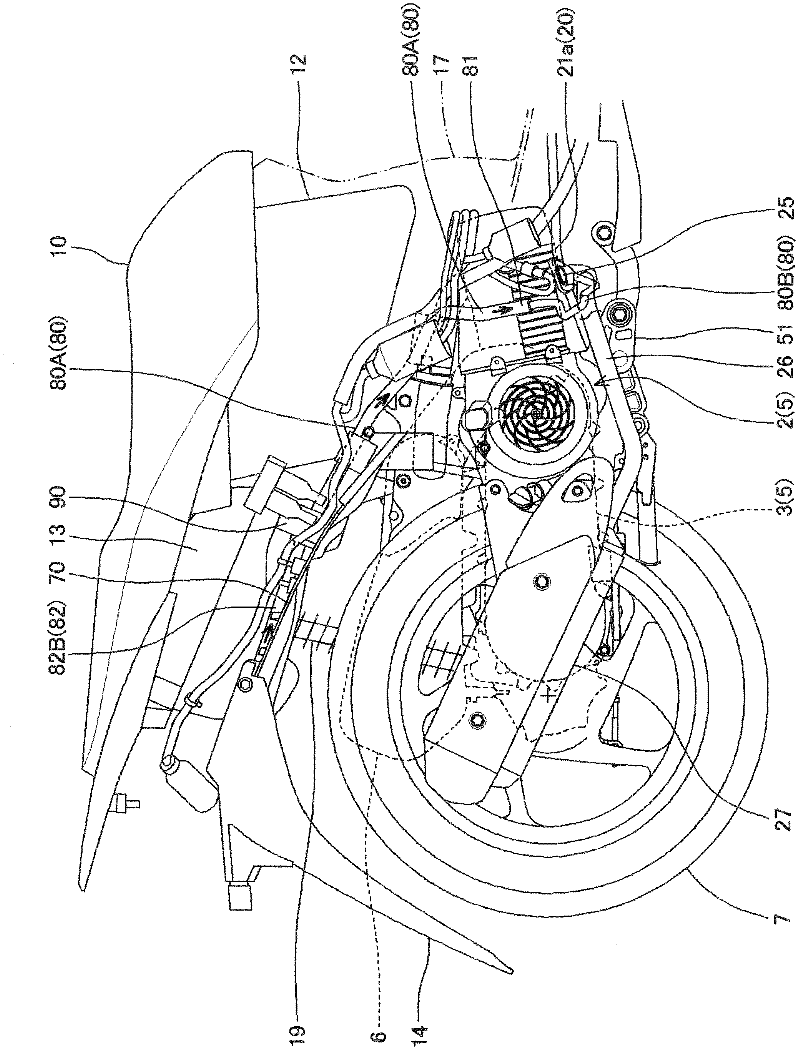

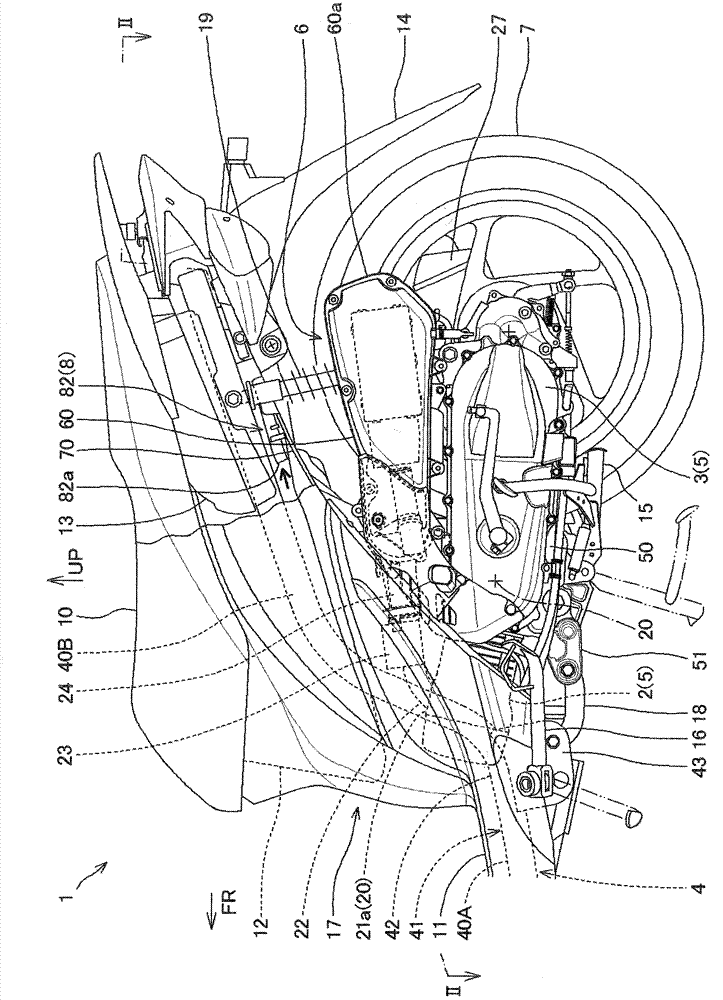

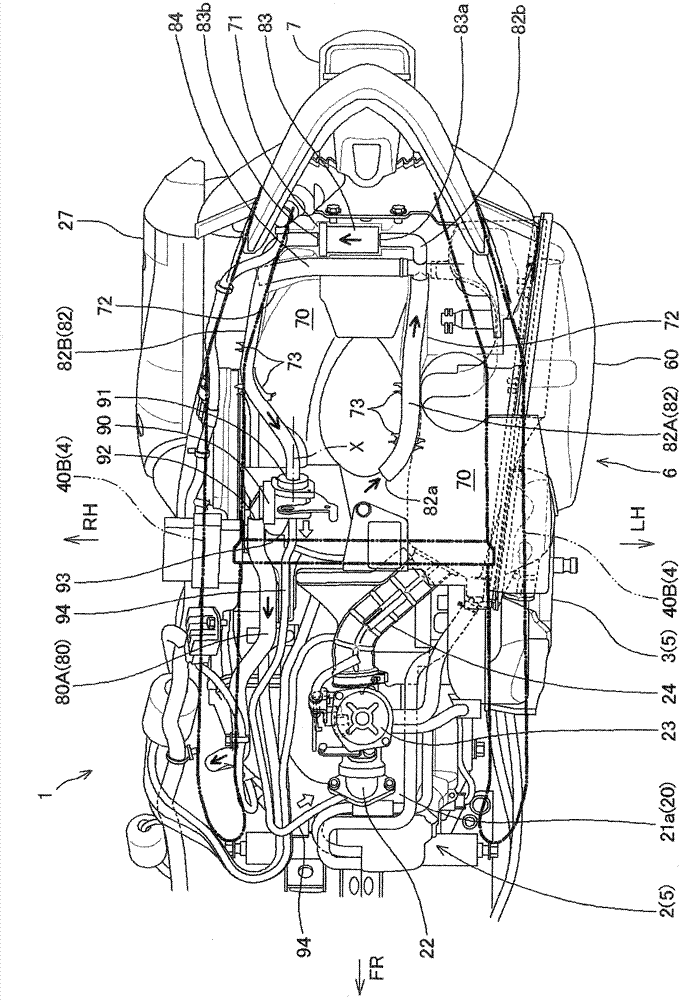

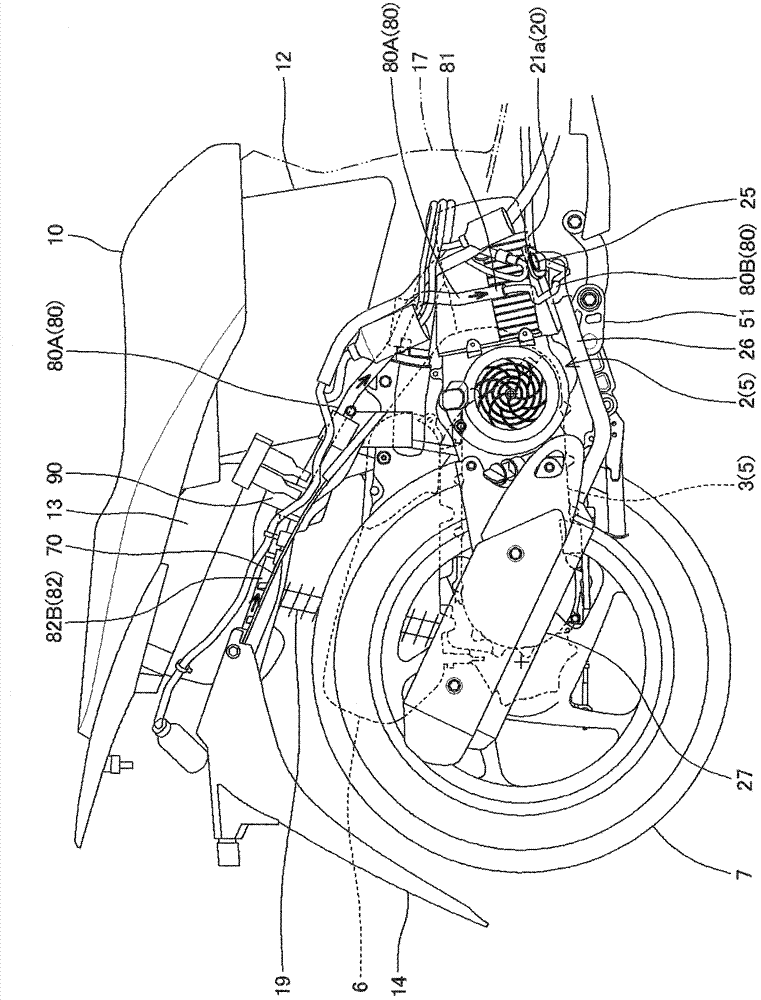

Exhaust purifying apparatus of saddle-ride type vehicle

ActiveCN102654072AIncrease configuration freedomSimple configurationInternal combustion piston enginesExhaust apparatusAir filterInternal combustion engine

An exhaust purifying apparatus achieving placement of components so as to prevent an increase in the size of the vehicle caused by the placement of the exhaust purifying apparatus while maintaining the performance of the exhaust purifying apparatus by secondary air in a saddle-ride type vehicle. An exhaust purifying apparatus of a saddle-ride vehicle includes a secondary air supply pipe of which one end is connected an exhaust passage of an internal combustion engine. A secondary air control valve is connected with the other end of the secondary air supply pipe for controlling the supply of secondary air to the secondary air supply pipe. An outdoor air introduction passage is connected to the secondary air control valve, wherein an air filter for secondary air and a resonant passage are installed in the middle of the outdoor air introduction passage.

Owner:HONDA MOTOR CO LTD

Air duct component and air conditioner

PendingCN112303016AIncrease functional capacityImprove efficiencyPump componentsLighting and heating apparatusFan bladeMechanics

The invention provides an air duct component and an air conditioner. The air duct component comprises an air duct body and fan blade assemblies, wherein the air duct component is provided with a circulation channel, the end plane of the first end of the air duct body is perpendicular to the axis of the circulation channel, a notch is formed in the side wall of the air duct body, the side wall, extending in the axis direction of the circulation channel, of the notch and the end plane are arranged in a stepped mode, the multiple fan blade assemblies are arranged in the circulation channel and are arranged at intervals in the axial direction of the circulation channel, and one of the multiple fan blade assemblies is located at the first end of the air duct body and protrudes out of the end plane. According to the air duct component, the air flow inlet direction and the air flow outlet direction can be switched, the fan blade assembly at the first end of the air duct body has the axial andradial air suction function, the efficiency of the fan blade assembly is improved, and meanwhile the effects of flow guide and noise reduction are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Oil-gas separator

InactiveCN103623666AReduce internal resistanceReduced risk of cloggingCombination devicesExhaust gasCavity wall

The invention discloses an oil-gas separator which comprises an outer shell of which the side part is provided with a gas mixture inlet and the top is provided with an exhaust gas outlet, wherein the lower part of the inner cavity of the outer shell is fixedly provided with a plurality of baffles which obliquely protrudes upwards in opposite and are arranged at intervals in a staggered mode; the protruding ends of the baffles are overlapped on the vertical projection; the baffles divide the inner cavity of the outer shell into circuitously upward channels; the upper part of the inner cavity of the outer shell is provided with a filter screen, and the bottom of the outer shell is provided with an oil discharge outlet; the outer shell is cylindrical and is composed of an upper section and a lower section; the diameter of the lower section is smaller than that of the upper section; the baffles are installed in the lower section, and the filter screen is installed in the upper section; the inner cavity wall of the upper section is provided with an inward convex annular boss; and the filter screen is installed on the annular boss. The oil-gas separator can lower the blockage risk of the filter screen, reduce the internal resistance of the gas mixture passing through the inner cavity of the outer shell, prolong the time interval for cleaning or replacing the filter screen, and lower the maintenance cost.

Owner:GAOMI WANHE AXLE

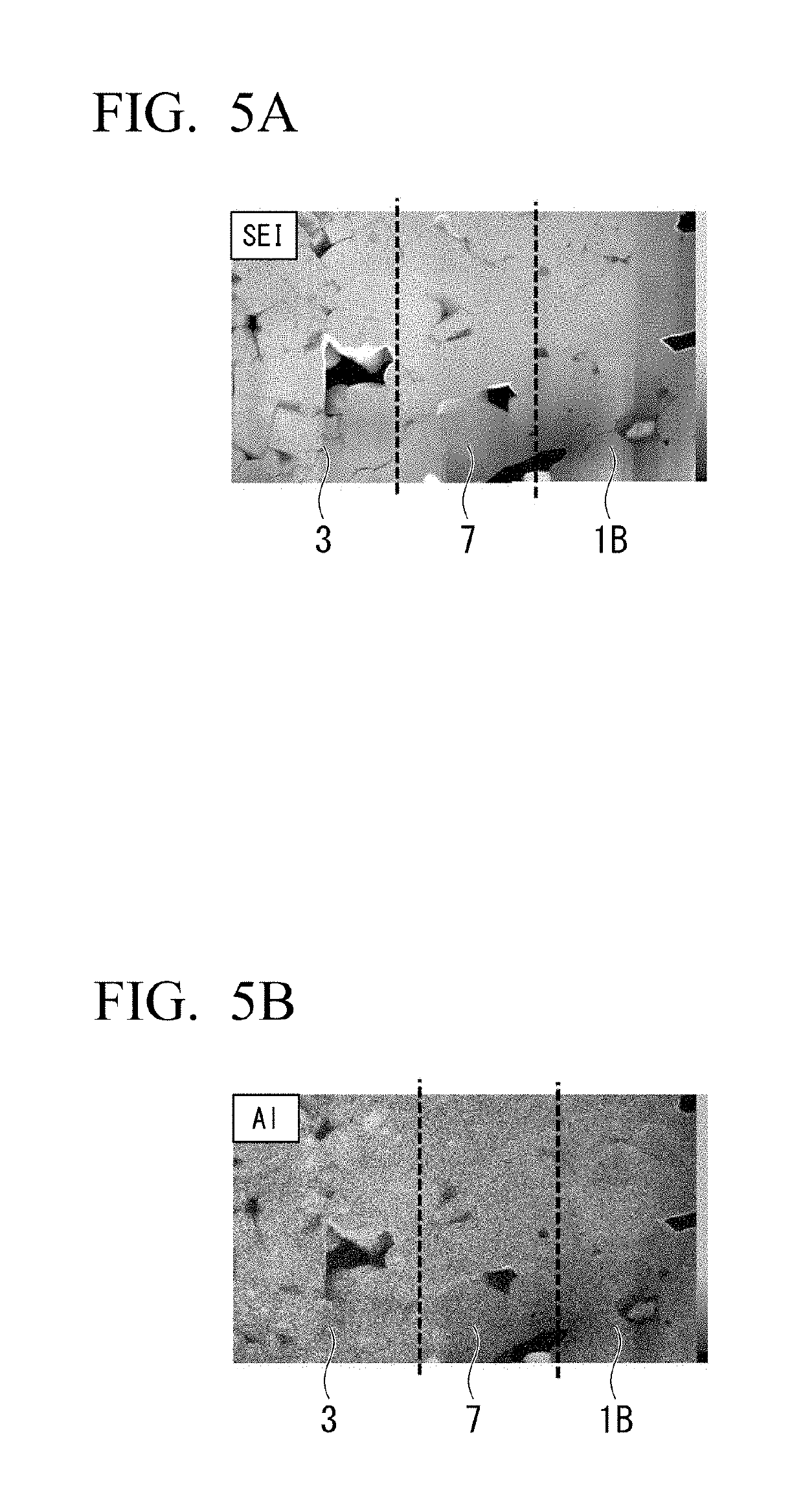

Active material and all-solid-state lithium-ion secondary battery

ActiveUS20190207254A1Increase capacityReduce internal resistanceCell electrodesOxide conductorsOxygen deficiencyAll solid state

An active material according to one aspect of the present invention includes a core region; and a shell region, in which an amount of transition metals in the core region is more than an amount of transition metals in the shell region, and an amount of oxygen deficiency in the shell region is more than an amount of oxygen deficiency in the core region.

Owner:TDK CORPARATION

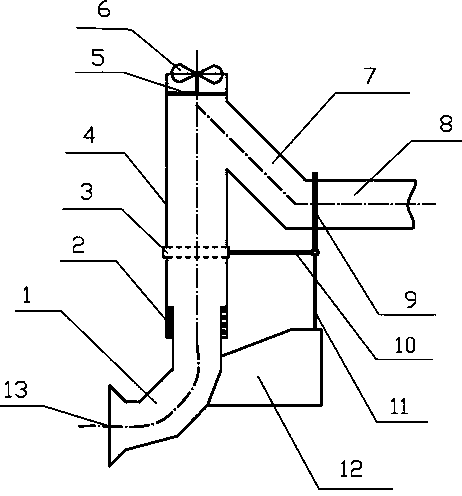

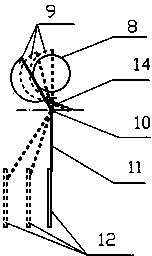

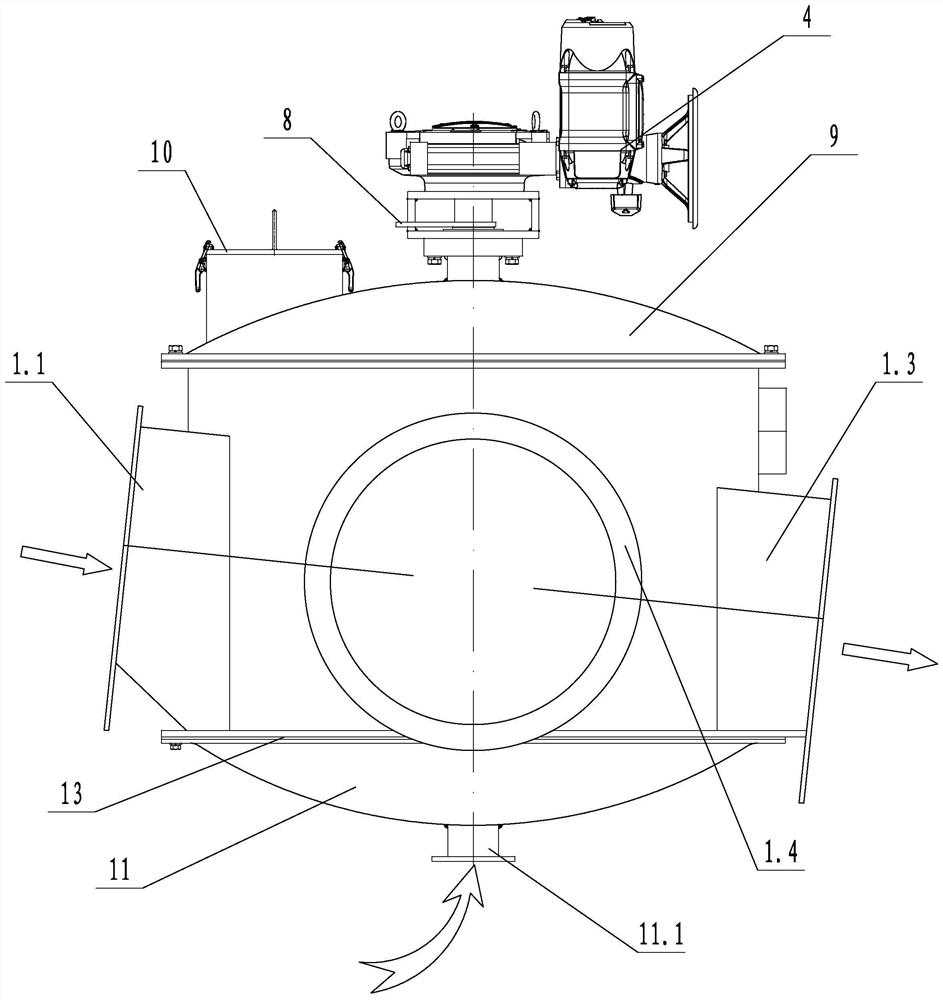

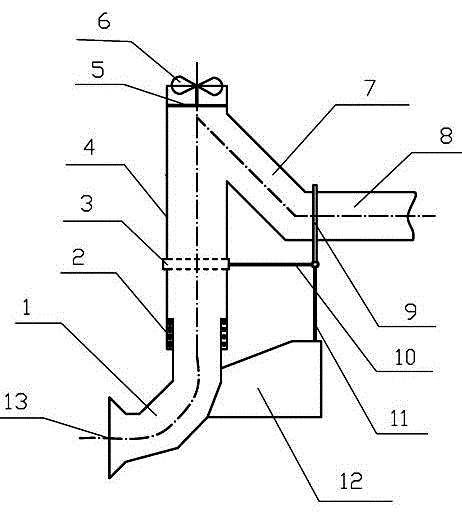

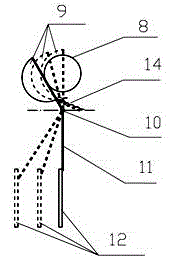

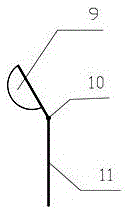

Natural induced air smoke exhaust device capable of being adaptive to wind direction and adjusting resistance in linkage mode

A natural induced air smoke exhaust device capable of being adaptive to the wind direction and adjusting resistance in a linkage mode is characterized in that the natural induced air smoke exhaust device comprises an air inlet pipe rotating along with the wind direction, a horn-shaped air inlet is formed in the lower end of the air inlet pipe, the upper end of the air inlet pipe is connected with the lower end of a vertical pipeline through a bearing in a sleeved mode, and the air inlet pipe pivots relative to the vertical pipeline; the air inlet pipe wall on the opposite side of the air inlet is provided with a vertical wind wing; a fixing support is arranged in the middle of the vertical pipeline, a supporting rod is arranged on the fixing support, an oscillating bar is hinged to the end of the supporting rod, a reset spring is arranged at the hinged position, a flue gate is fixed to the upper end of the oscillating bar, and the flue gate can reset to the half-aperture original position through the reset spring; the lower end of the oscillating bar extends to make single-face contact with the vertical wind wing; a flue and the vertical pipeline are converged at the upper portion of the vertical pipeline in the 45-degree included angle.

Owner:山东莱科能源生态开发有限公司

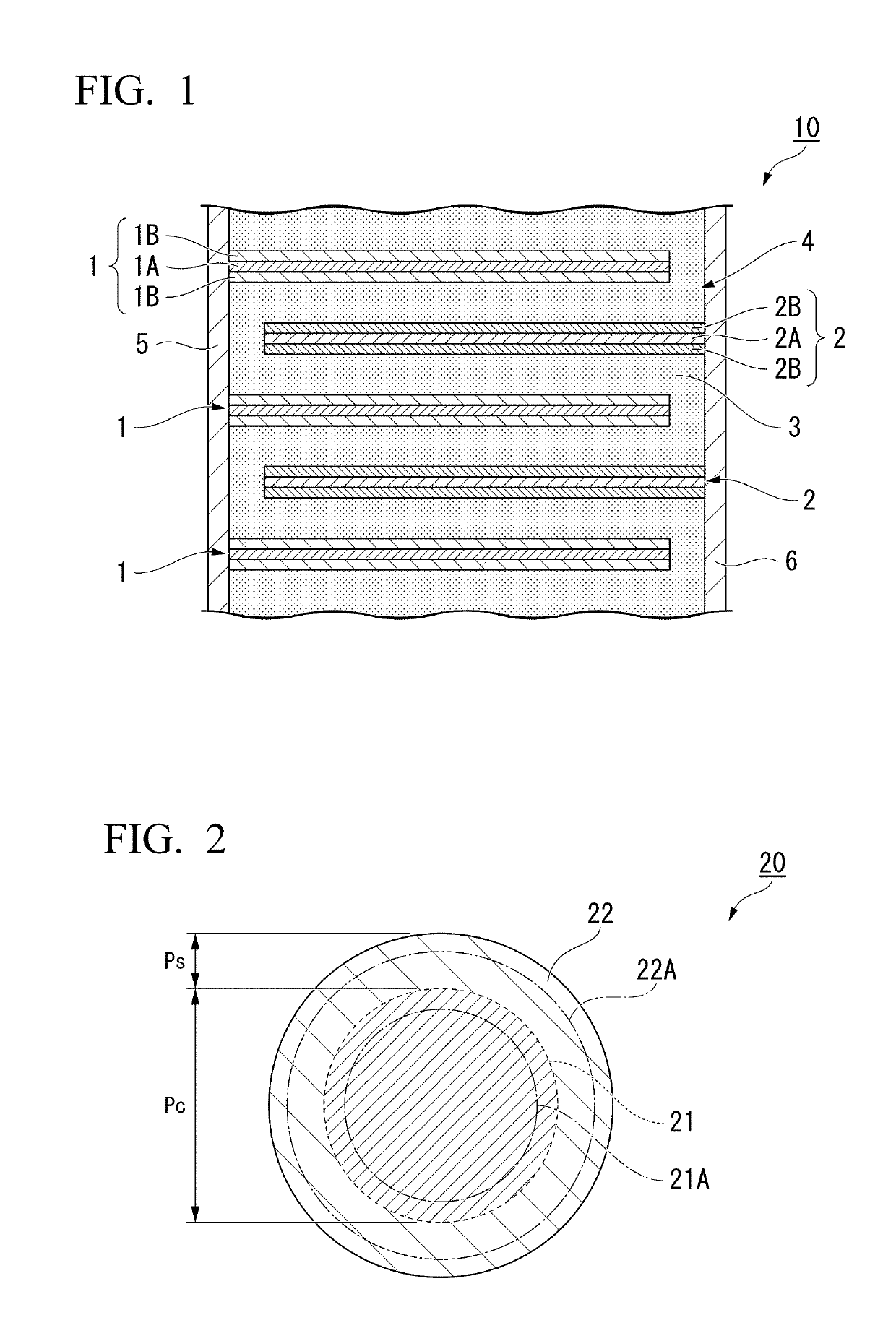

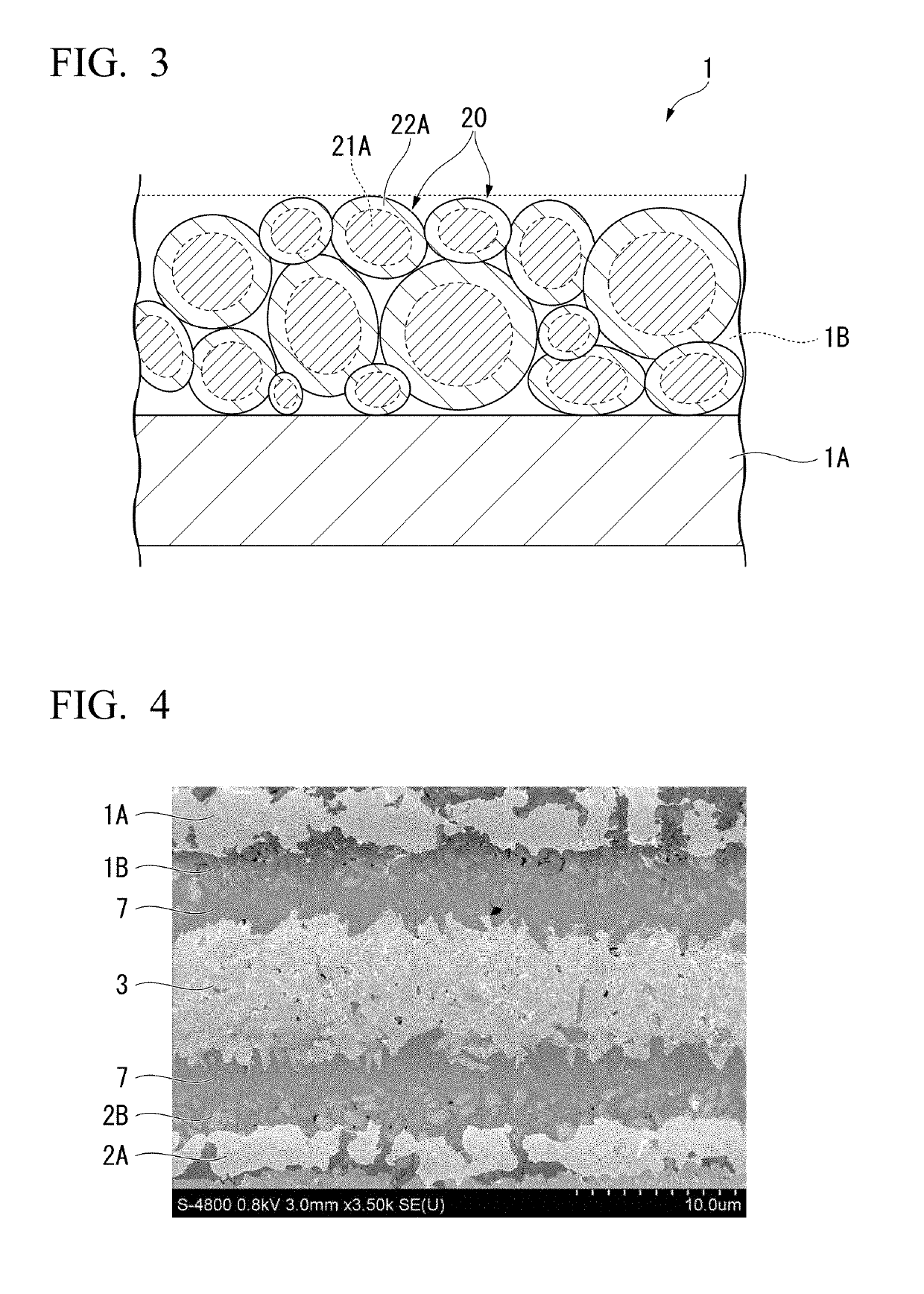

Lithium Polymer Battery

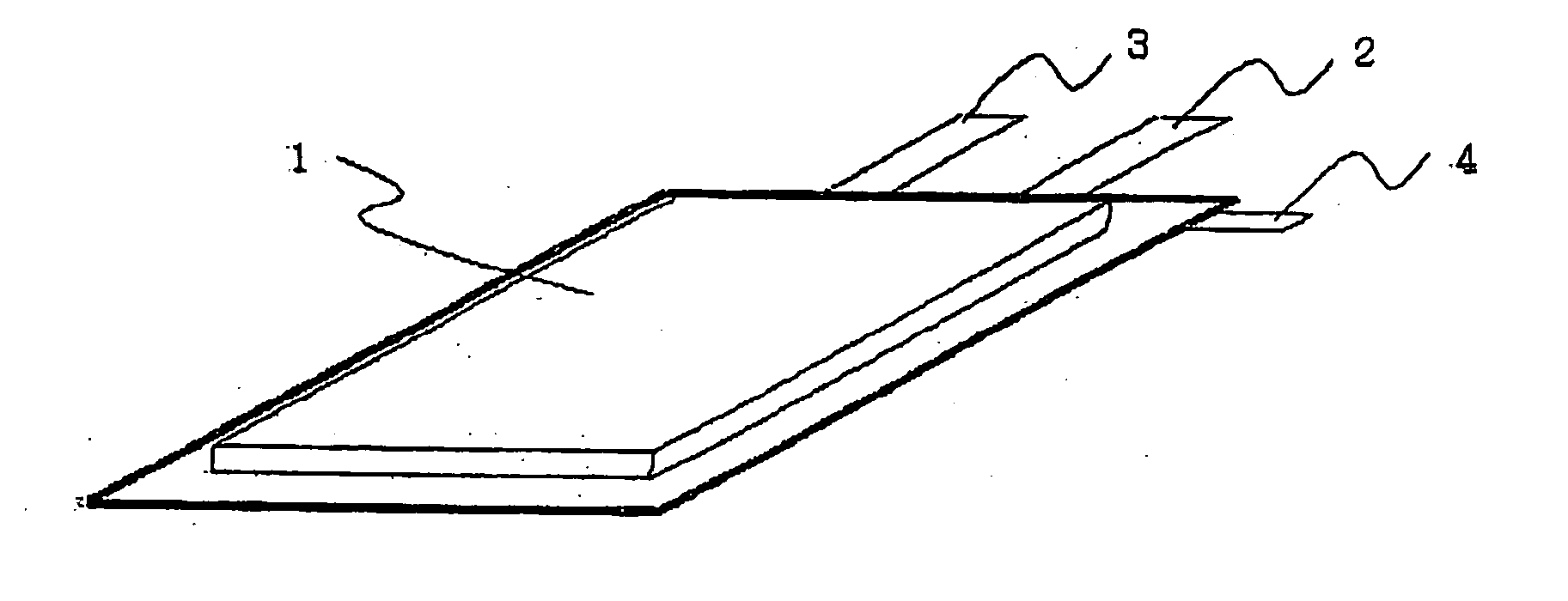

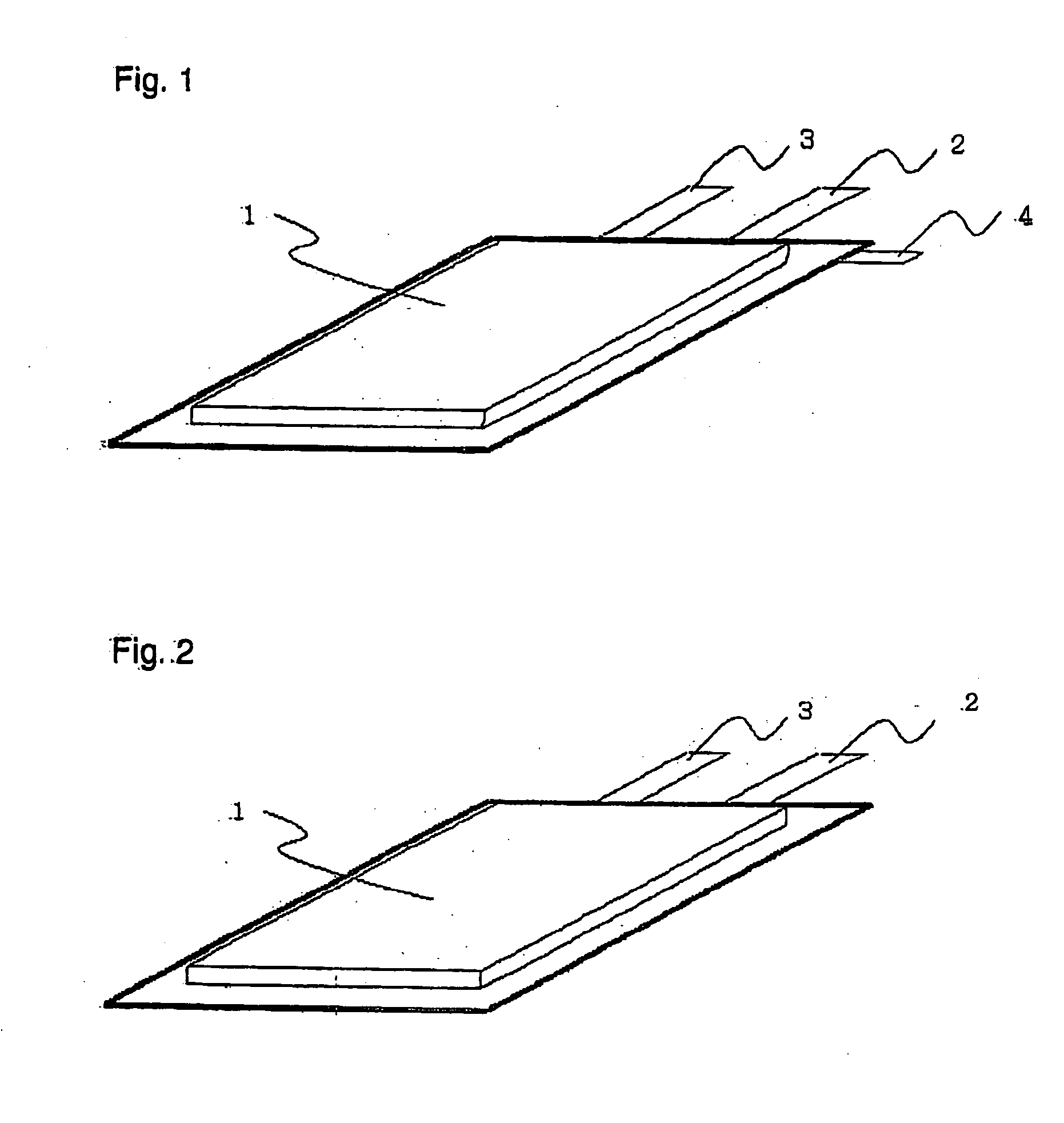

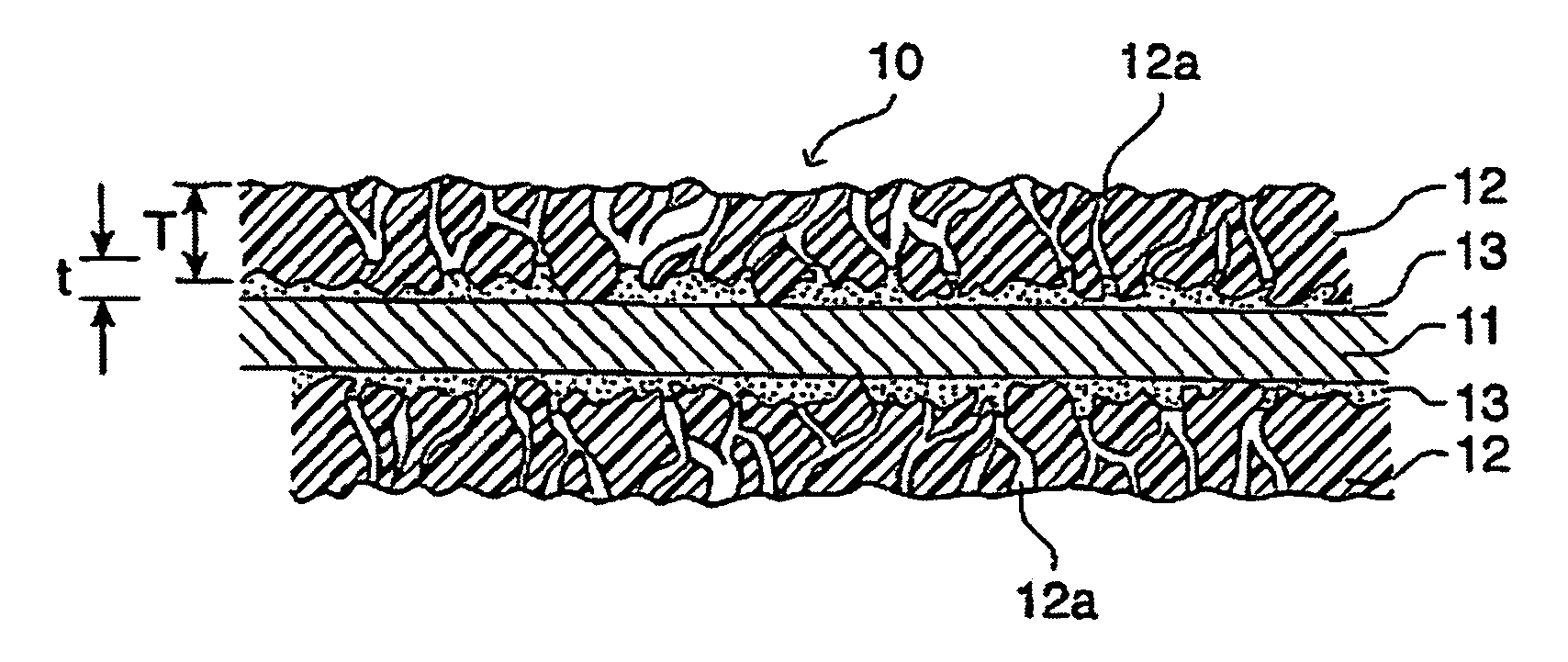

InactiveUS20090317706A1Reduce internal resistanceImprove performanceCell seperators/membranes/diaphragms/spacersCell electrodesLithium polymer cellEngineering

An improvement of lithium polymer secondary battery is disclosed. The Li-polymer battery is composed of an anode sheet, a cathode sheet and a separator film sandwiched therebetween. The anode sheet includes a positive collector and a pulp coated thereon, which is formed by positive material, conductive material, glue and solvent. The cathode sheet includes a negative collector and a pulp coated thereon, which is formed by negative material, conductive material, glue and solvent. The separator film includes glue and solvent for adhering between the anode sheet and cathode sheet. The anode and cathode sheet are provided with holes uniformly arranged. The holes are formed by using a knife to penetrate the sheets. The holes make the electrolyte easy to permeate through so that the internal resistance of battery can be reduced.

Owner:SUNYEN CO LTD

Cylindrical four-way powder distributing valve

InactiveCN113277321AEasy to replaceAvoid accumulationBulk conveyorsChutesStructural engineeringMechanical engineering

The invention discloses a cylindrical four-way powder distributing valve which comprises a valve shell, a first swing door, a second swing door and a driving part, wherein the inner wall of the valve shell is of a cylindrical structure, a powder inlet, a first outlet, a second outlet and a third outlet are sequentially formed in the side wall of the valve shell, and the second outlet and the third outlet are separated through a partition part; the first swing door and the second swing door are arranged in the valve shell and rotationally connected with the valve shell. One end of a rotating shaft of the first swing door and one end of a rotating shaft of the second swing door extend out of the valve shell and are connected with the output end of the driving part; the first swing door is arranged on the side close to the powder inlet, the rotating shaft of the first swing door is arranged in the center of the valve shell, the second swing door is arranged between the first outlet and the second outlet, and the rotating shaft of the second swing door is arranged on the side close to the first outlet. The invention provides a cylindrical four-way powder distributing valve which is convenient to machine and manufacture and capable of reducing internal resistance and reducing dead angles.

Owner:HANGZHOU FUYANG HENT ELECTROMECHANICAL ENG

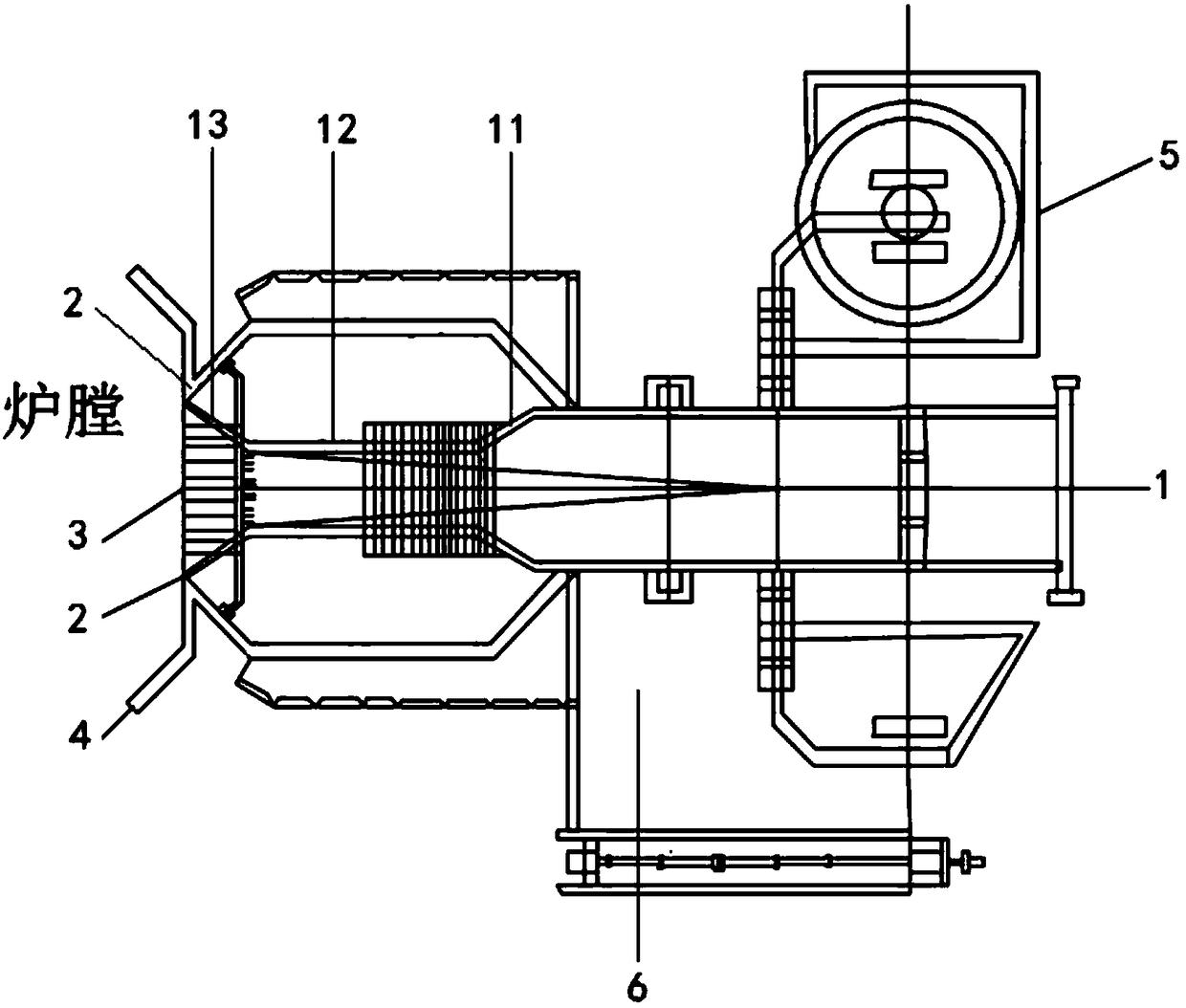

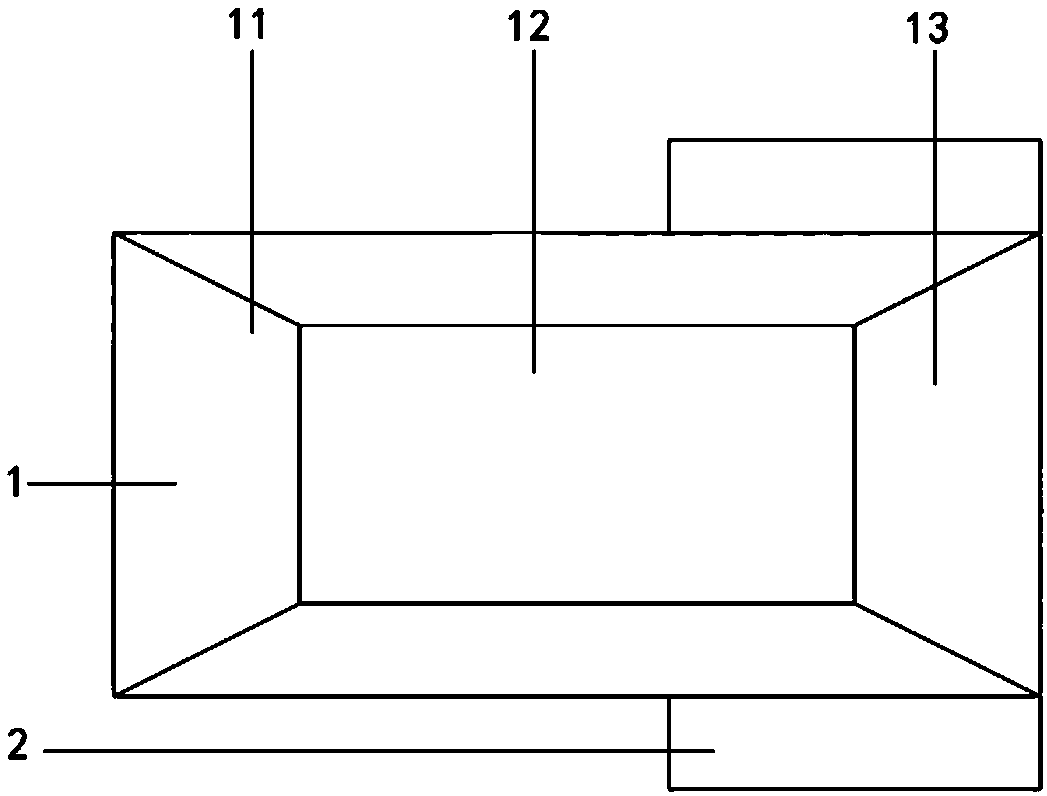

Low-NOx stable combustion burner for boiler

PendingCN108105765AIncrease the lengthReduce the temperaturePulverulent fuel combustion burnersDamper arrangementEngineeringHot Temperature

The invention relates to a low-NOx stable combustion burner for a boiler. The low-NOx stable combustion burner comprises a primary air pipe communicating with a hearth and a peripheral air pipe; a gradual shrinkage pipe, a straight pipe and a gradual expansion pipe are arranged on the section, before inserted in the hearth, of the primary air pipe; the maximum section area of the gradual shrinkagepipe is the same with the maximum section area of the gradual expansion pipe; and the peripheral air pipe sleeves the external of an outlet end of the primary air pipe. Compared with the prior art, the burner can lengthen the flame length and reduce the temperature of a central combustion area, so that generation of heat and fuel NOx is reduced, mutual ignition of burners on the same layer is facilitated, the fuel cost caused by ignition is reduced, uniform distribution of the whole hearth temperature is facilitated, and the coking and slagging problems caused by local high temperature are reduced.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

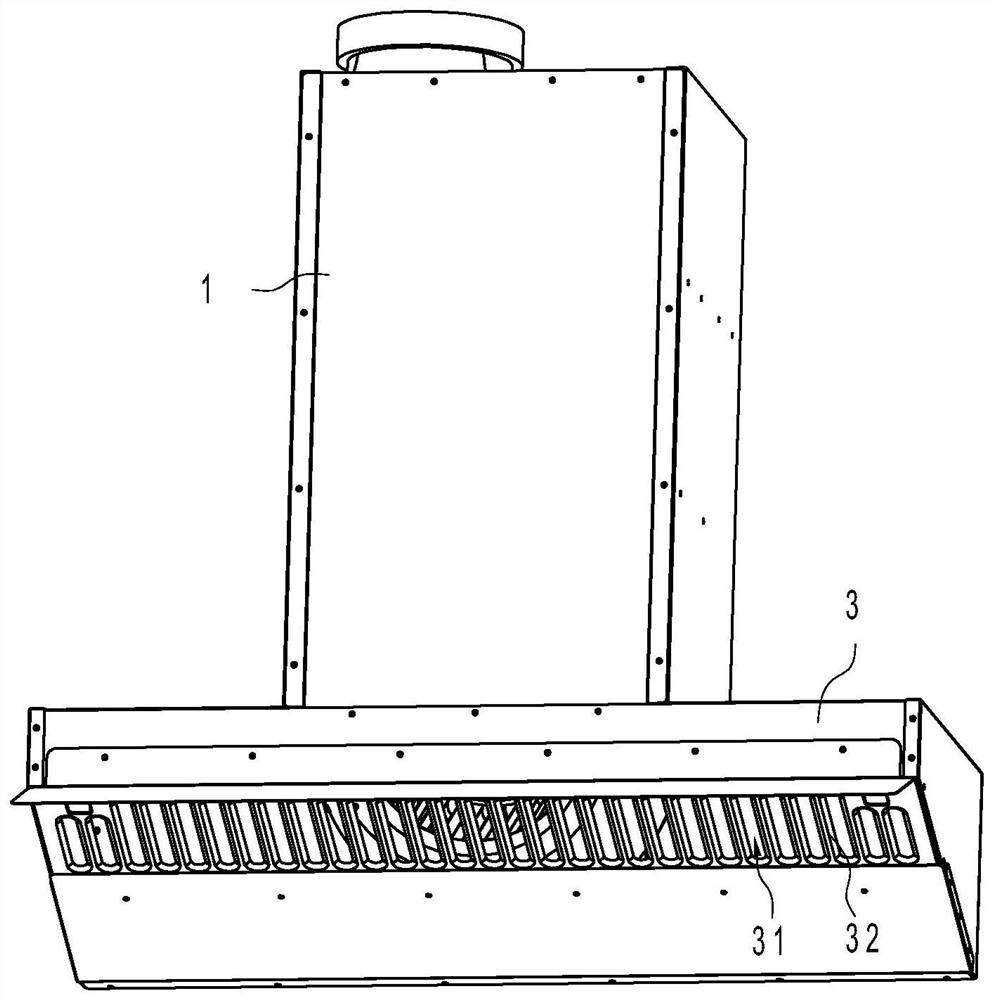

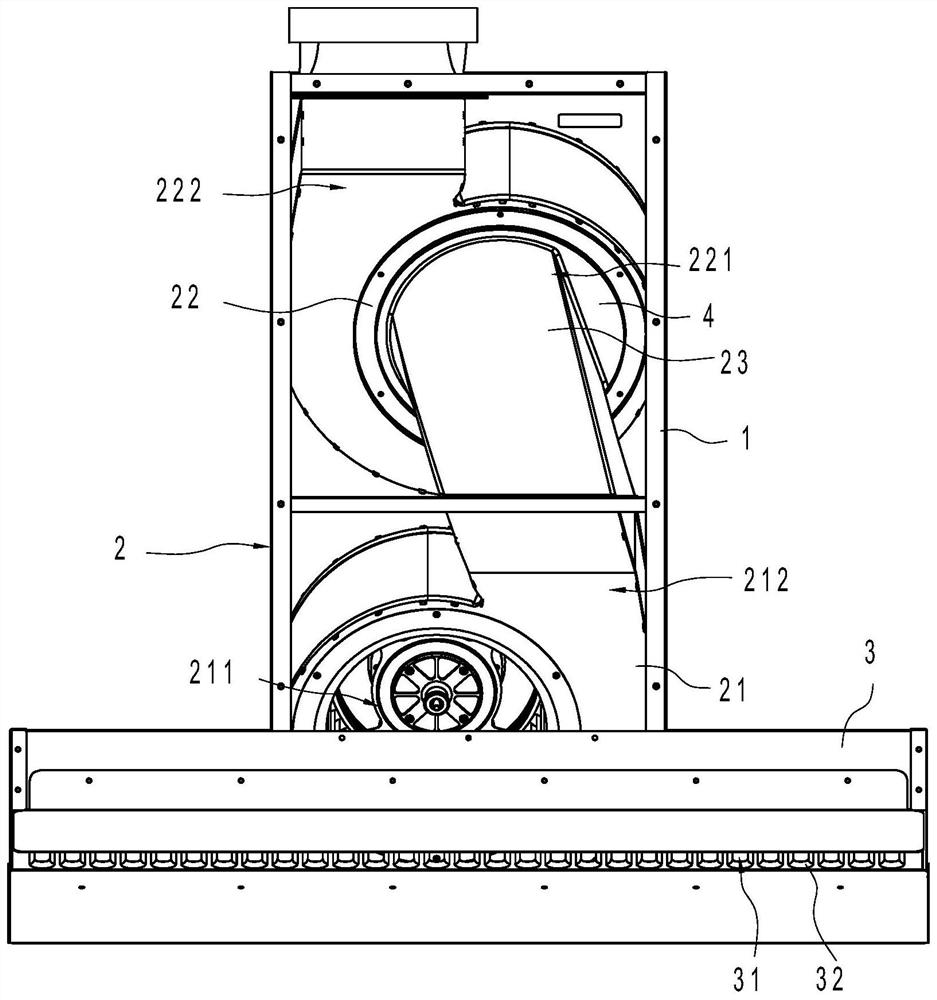

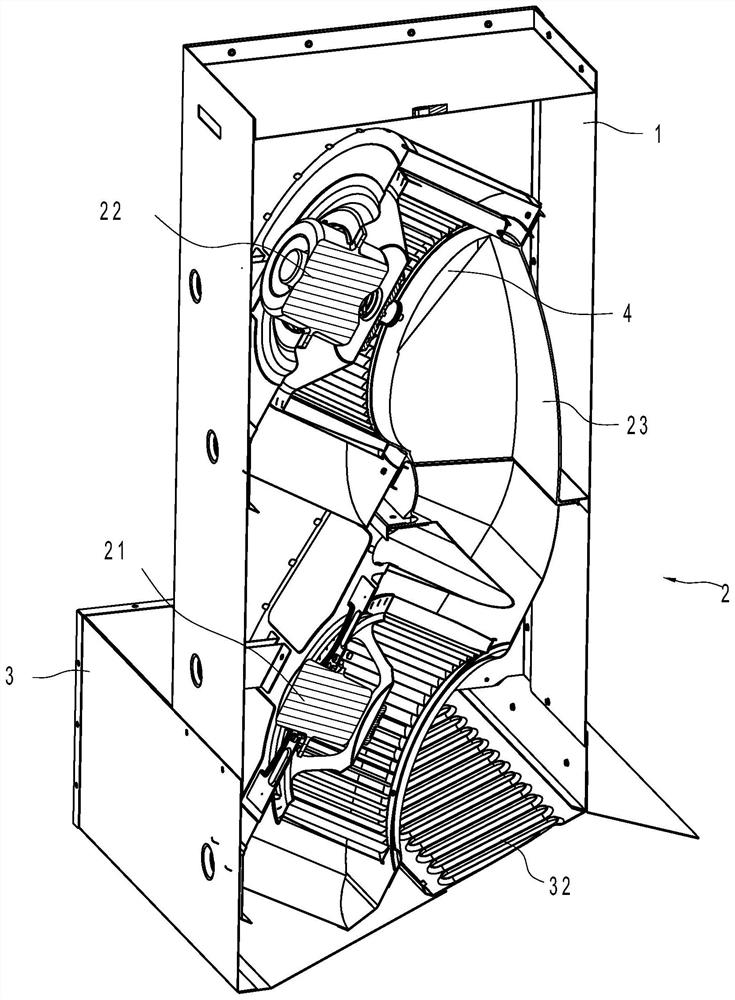

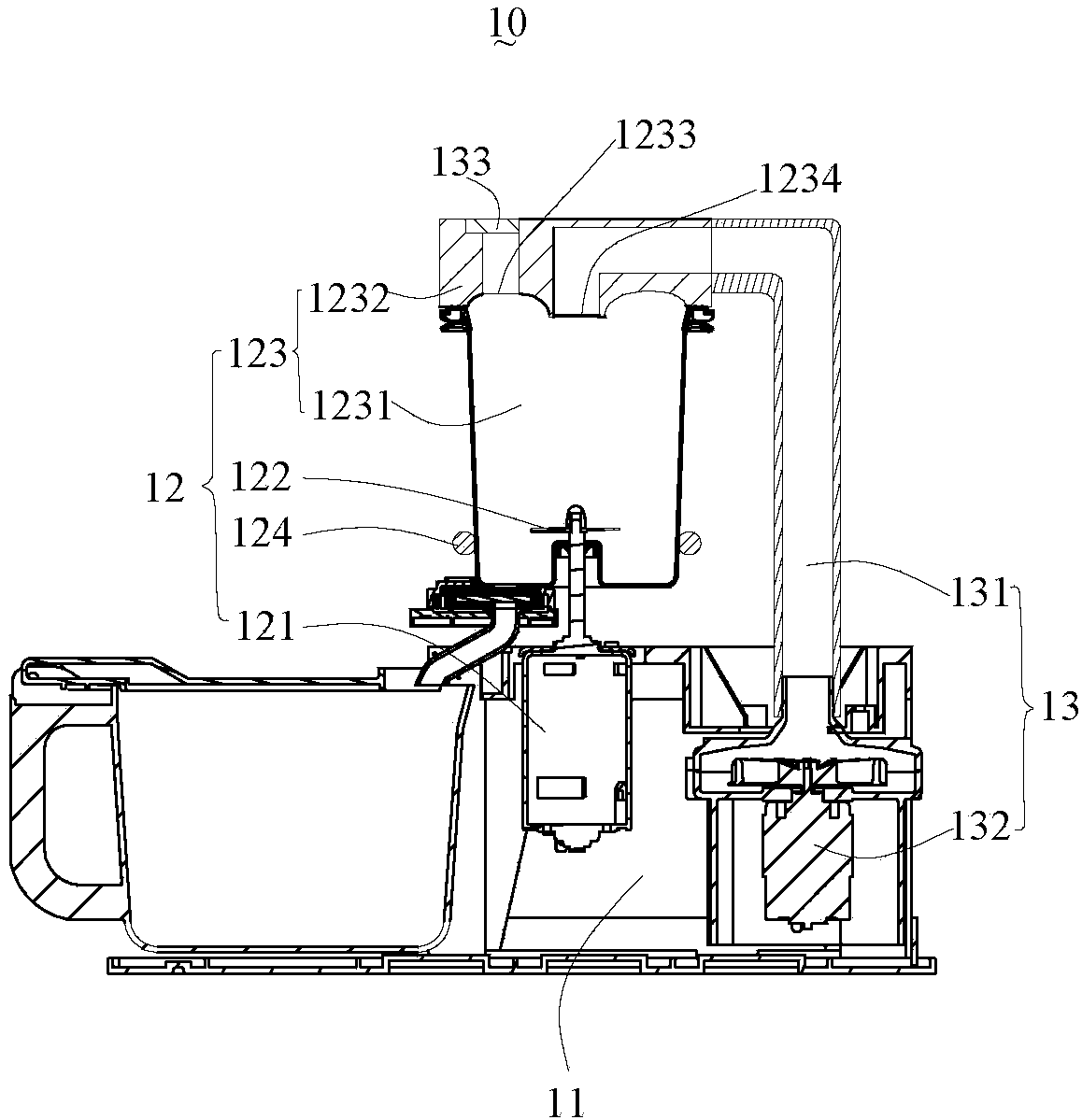

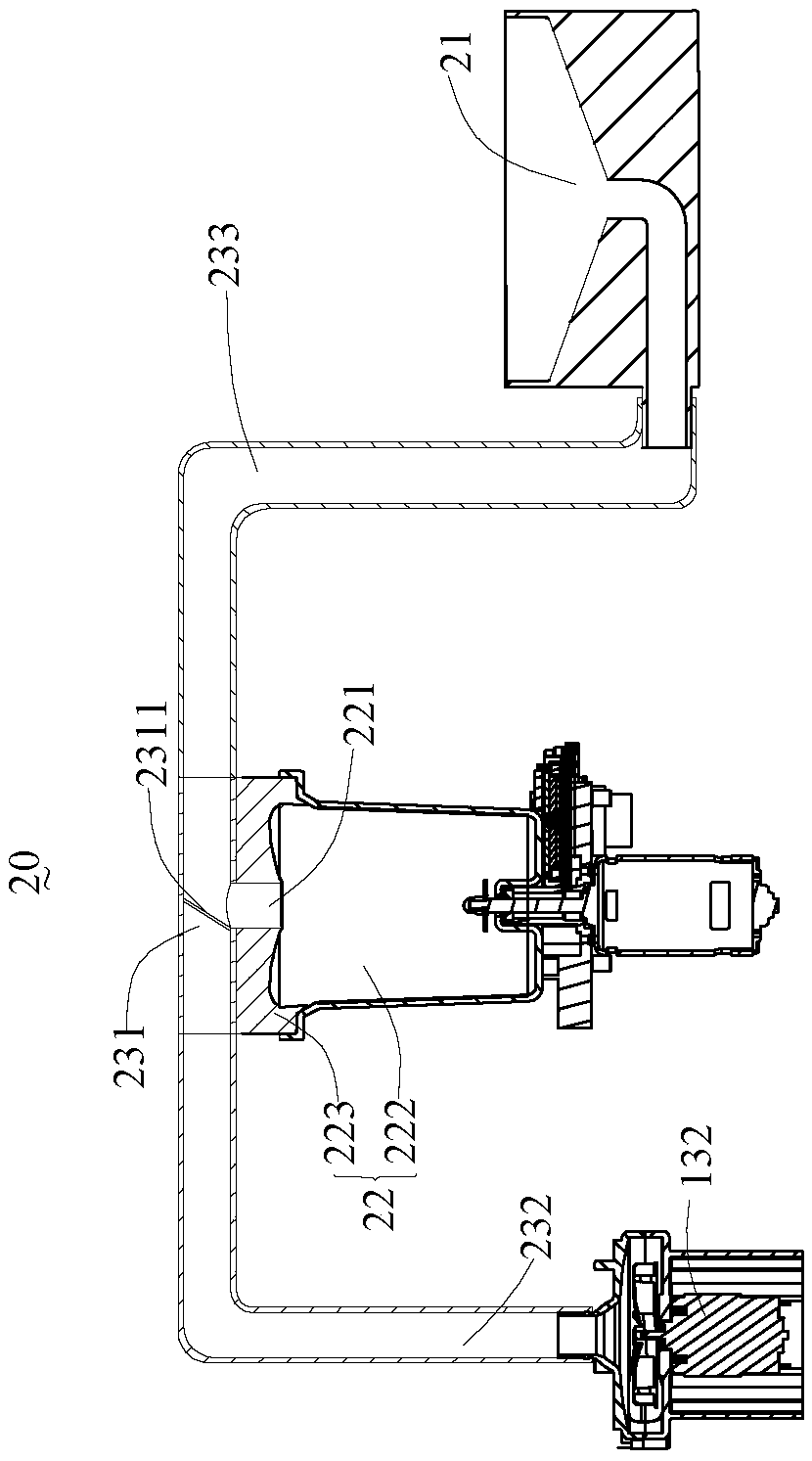

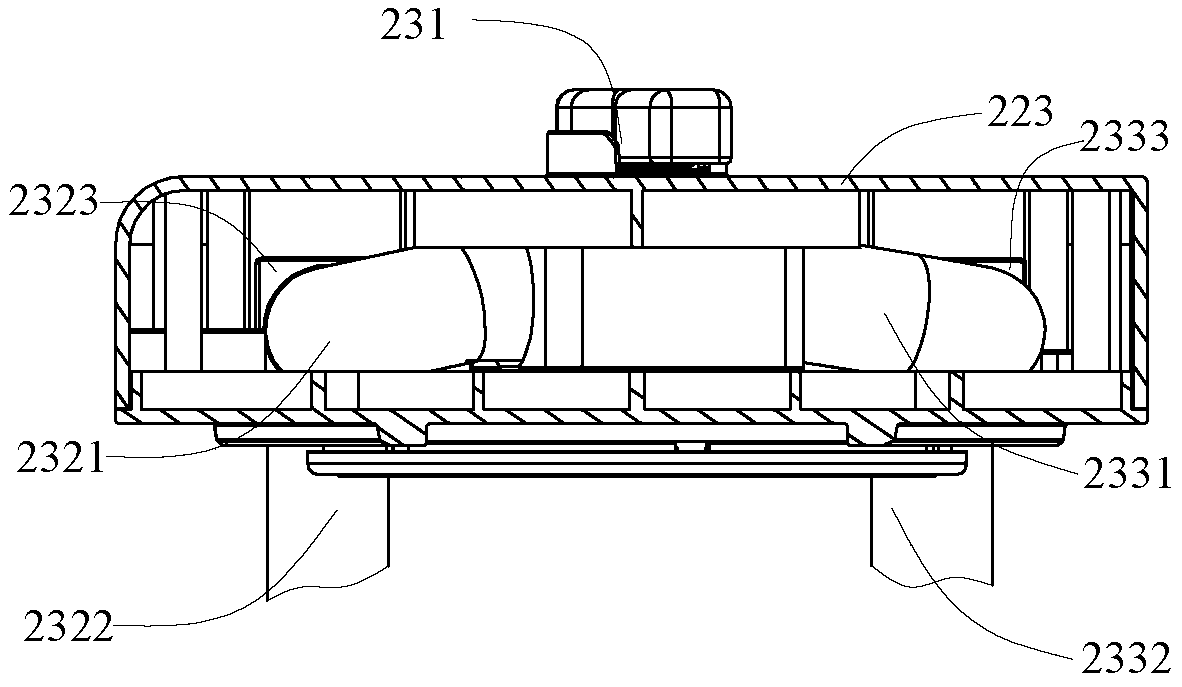

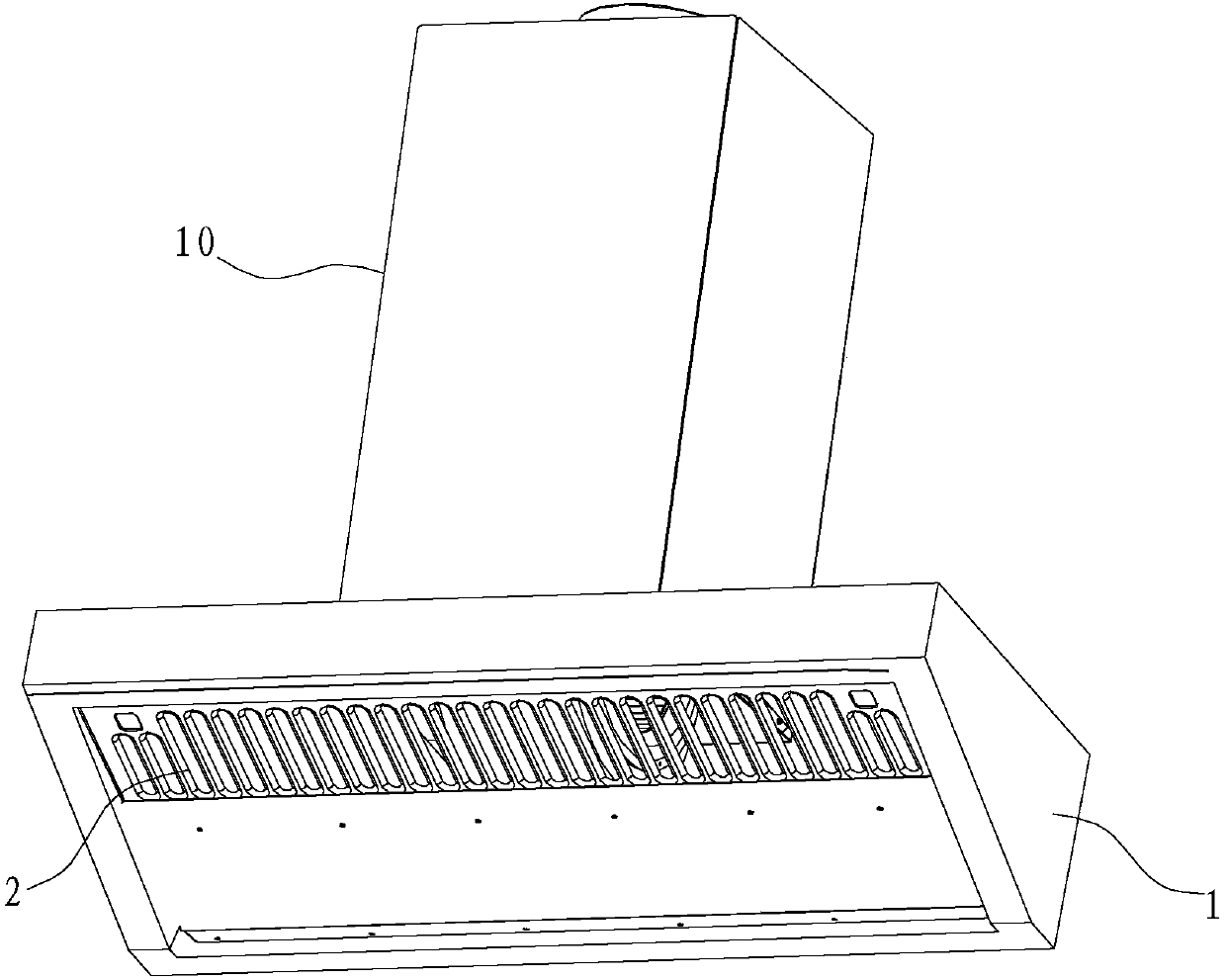

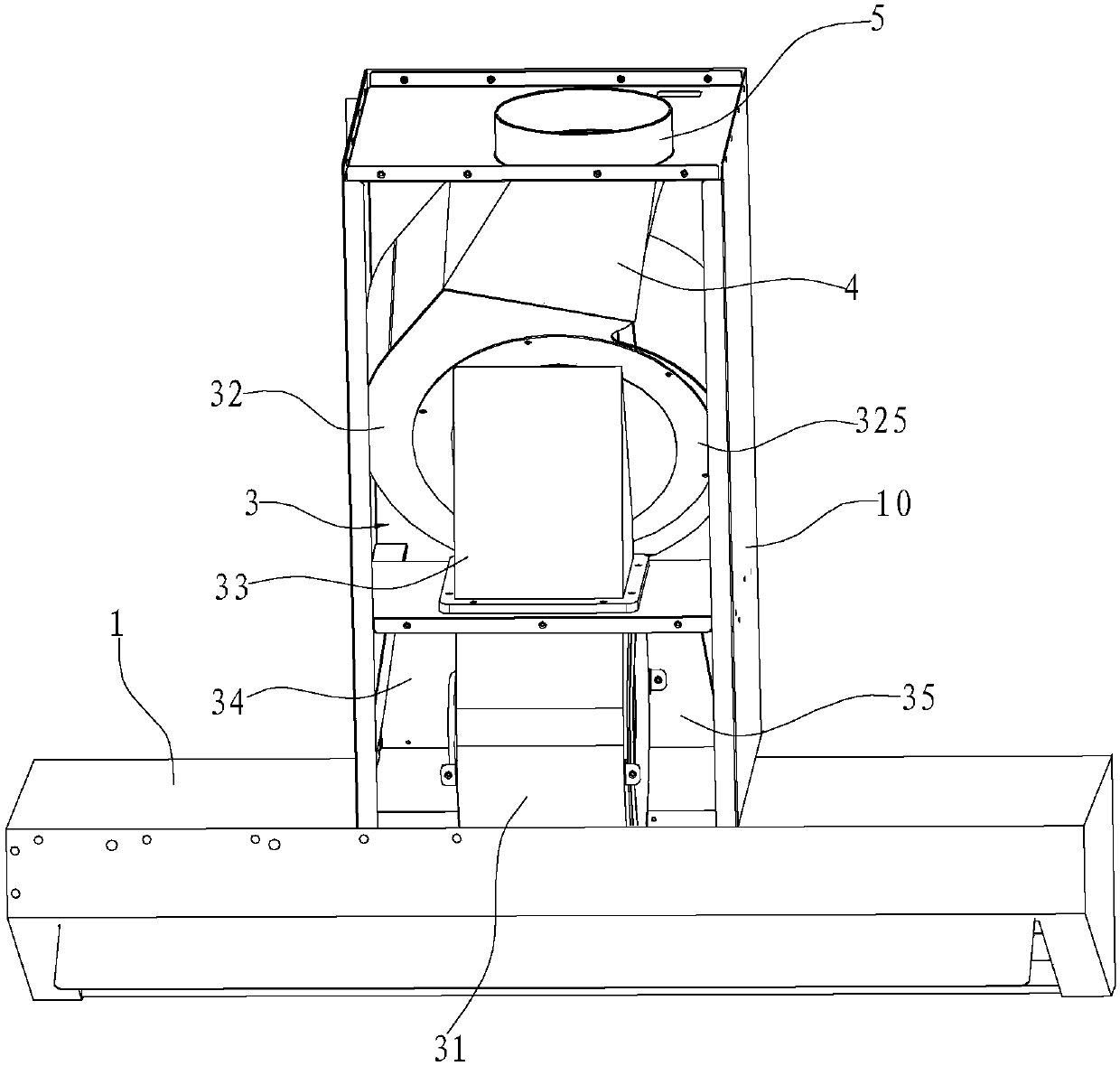

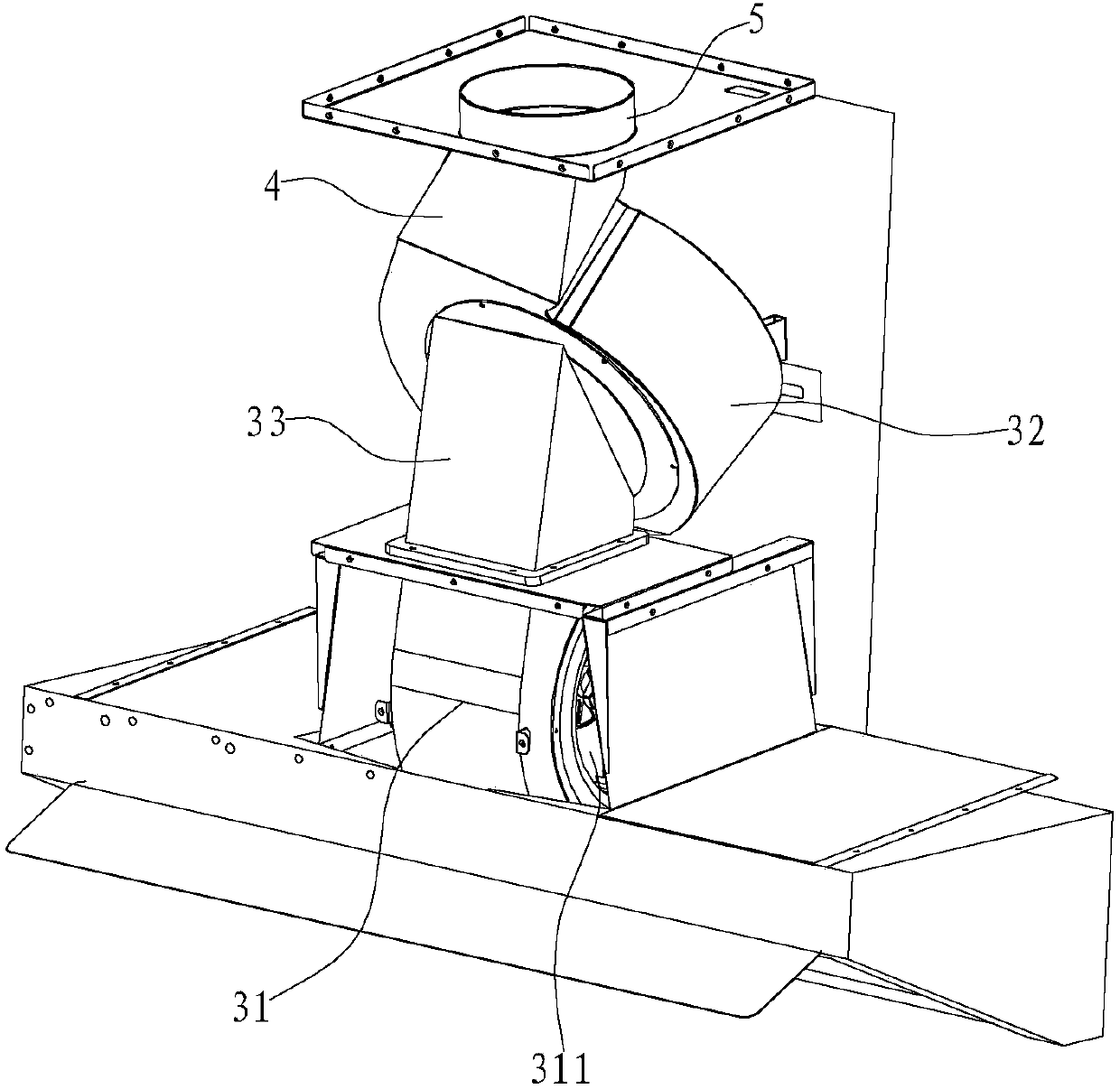

A range hood with double fans in series

ActiveCN111089068BShorten the lengthReduce internal resistanceDomestic stoves or rangesPump componentsElectric machineryNoise

A range hood with double fans in series, including a fan casing, a fan system is arranged in the fan casing, the fan system includes a first-stage centrifugal fan and a second-stage centrifugal fan, and the second-stage centrifugal fan is arranged on the first-stage Above the centrifugal fan, the first-stage centrifugal fan and the second-stage centrifugal fan are connected through a connecting pipe. The helical direction of the volute of the first-stage centrifugal fan is opposite to that of the second-stage centrifugal fan. A baffle is provided on the side of the air inlet away from the second air outlet of the secondary centrifugal fan, and one side of the connecting pipe is connected and sealed with the side of the baffle. By setting the opposite spiral direction and setting the baffle, the outlet airflow of the first-stage centrifugal motor can enter the air inlet area of the second-stage centrifugal fan more easily, preventing the airflow from turning and separating in the connecting pipe, and reducing the internal resistance. The noise is reduced and the sound quality is improved; at the same time, the airflow direction is straight through, which reduces the length of the connecting pipe.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

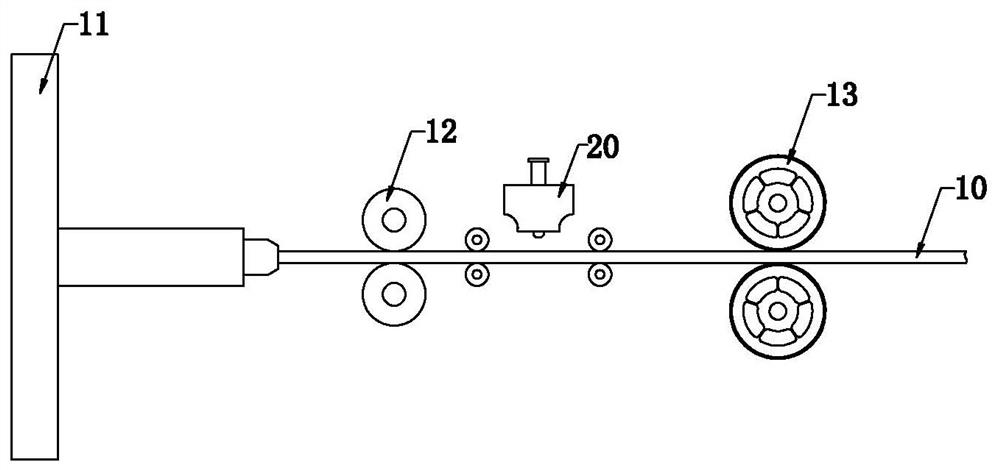

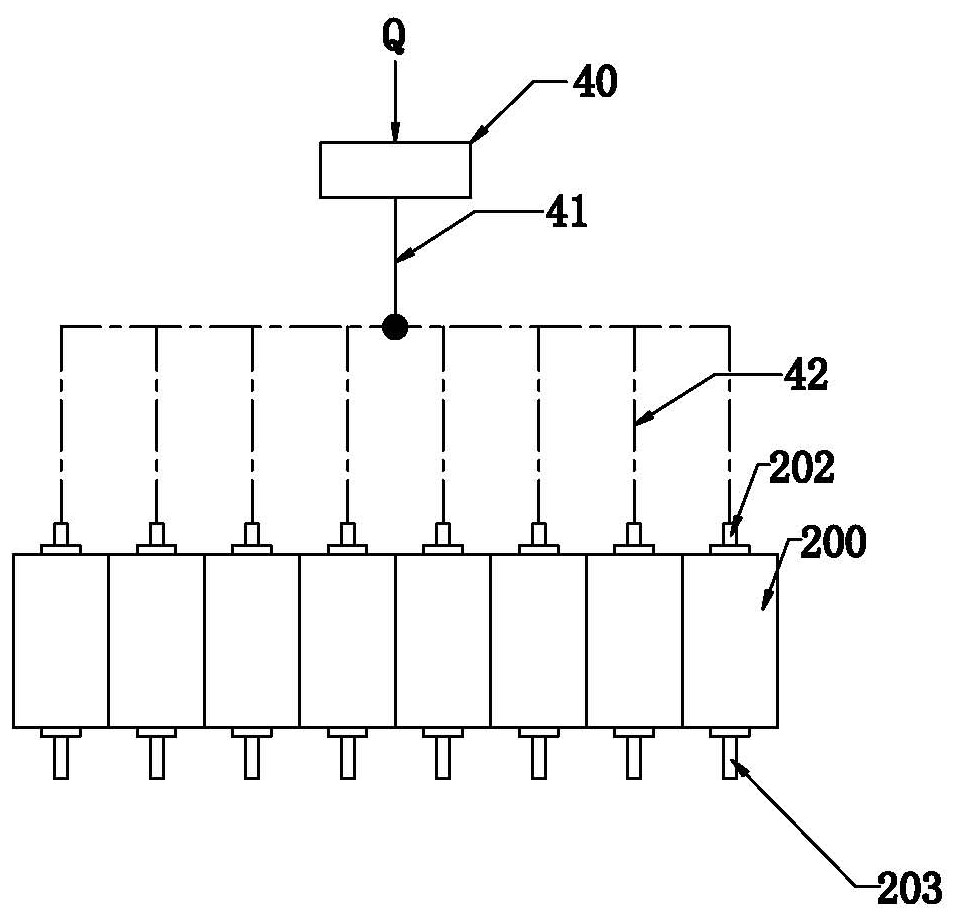

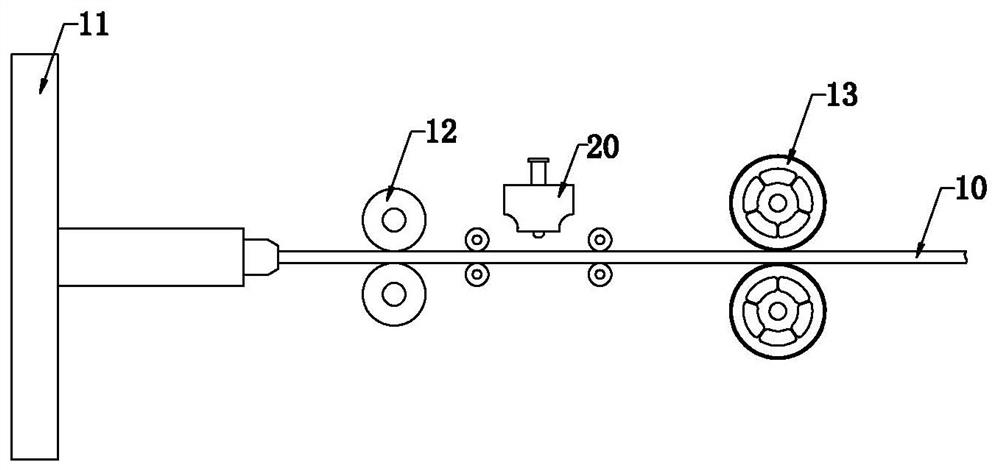

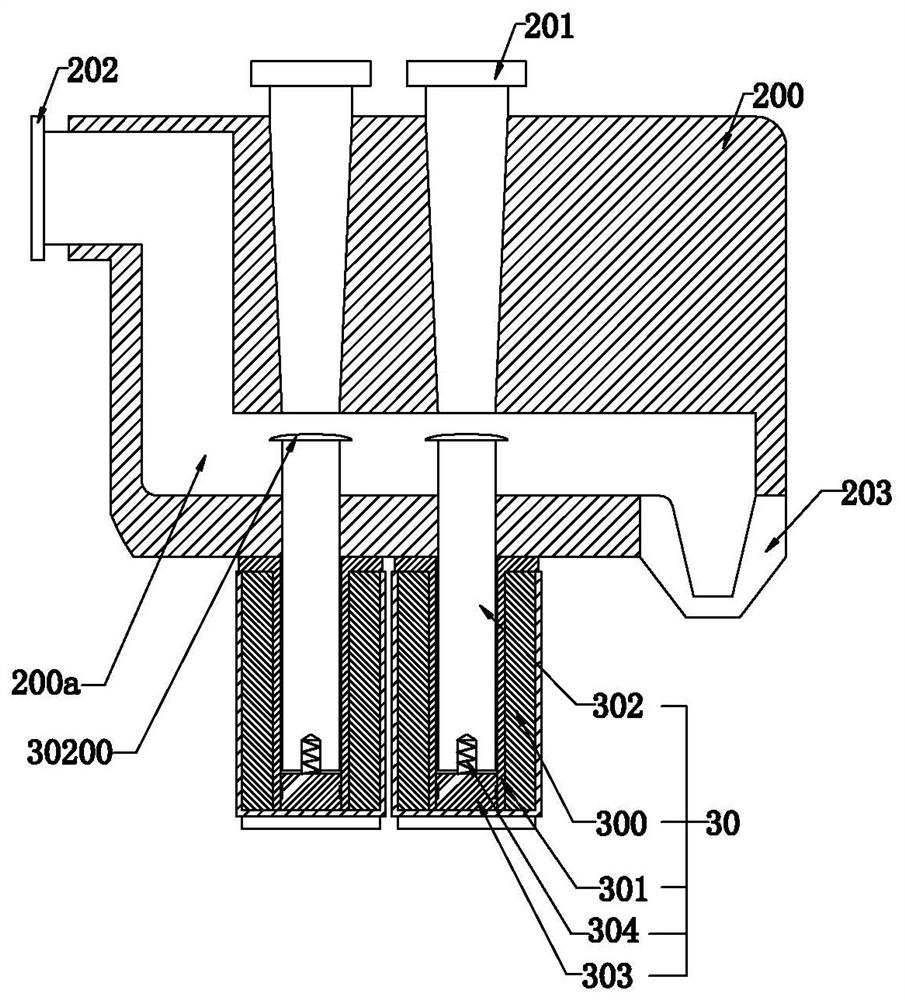

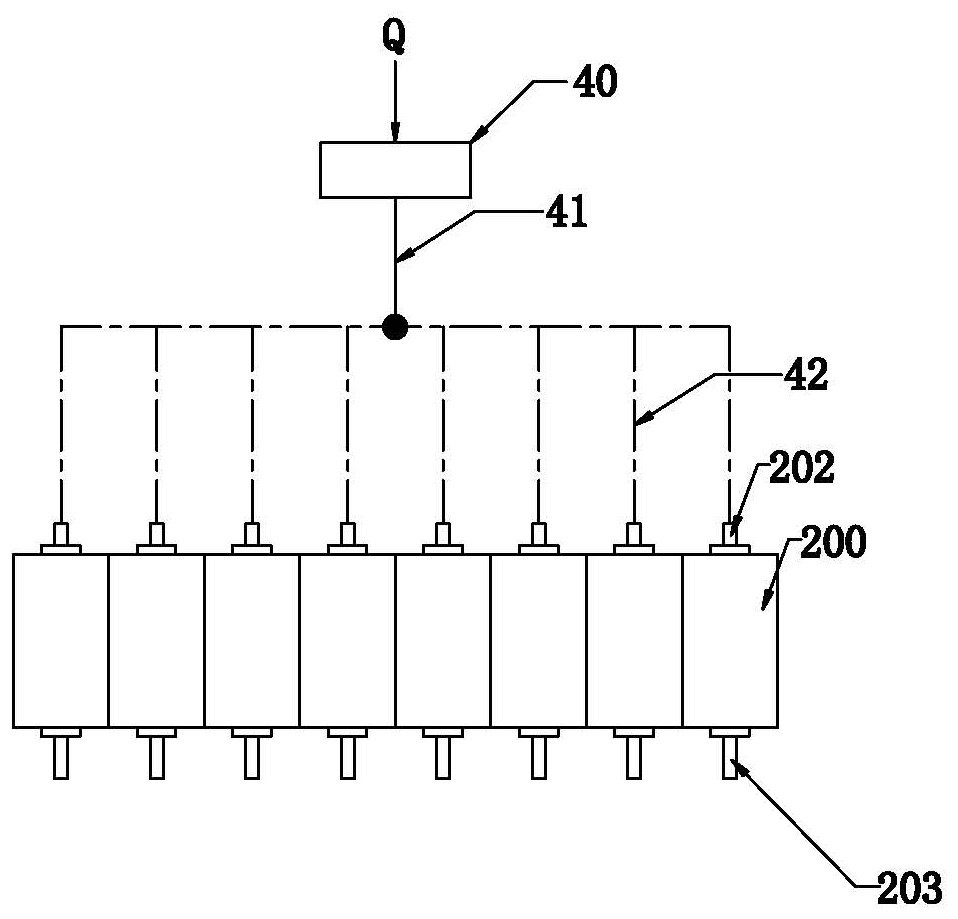

Extrusion system for flow battery bipolar plate production and extrusion method thereof

ActiveCN112238019AEasy to useLower internal resistanceLiquid spraying apparatusCollectors/separatorsEngineeringMechanical engineering

The invention relates to an extrusion system for flow battery bipolar plate production and an extrusion method thereof. The extrusion system comprises an extruding die used for pulling a bipolar plate, a heat preserving and conveying roller and a shaping roller, wherein the extruding die, the heat preserving and conveying roller and the shaping roller are sequentially arranged. The extrusion system is characterized by comprising a spraying module which is arranged between the heat preserving and conveying roller and the shaping roller and used for spraying addition agents to the bipolar plate.The spraying module at least comprises a spraying body which is provided with an air input end, two addition agent input ends and a spraying end. In the spraying process, air enters from the air input end and is sprayed out from the spraying end to form conveying airflow, all the addition agents are matched discontinuously through the both addition agent input ends, added into the spraying body,and mixed under the effect of the conveying airflow, and move to the spraying end until the addition agents are sprayed from the spraying end to the bipolar plate. The system has the beneficial effects that a conductive layer can be formed on the surface of the bipolar plate, the use effect of the bipolar plate is improved, and accurate proportioning can be realized, so that the forming quality ofthe conductive layer of the bipolar plate is ensured.

Owner:宁波市捷丰塑业有限公司

Extrusion system and extrusion method for bipolar plate production of flow battery

ActiveCN112238019BEasy to useLower internal resistanceLiquid spraying apparatusCollectors/separatorsMechanical engineeringBattery cell

The invention relates to an extrusion system and an extrusion method for the production of a liquid flow battery bipolar plate, including an extrusion die, a thermal insulation conveying roller, and a shaping roller arranged in sequence for pulling the bipolar plate, and is characterized in that: A spraying module between the heat-retaining conveying roller and the shaping roller and used for spraying additives on the bipolar plate; wherein, the spraying module includes at least one gas input end, two auxiliary agent input ends and a spraying end Spraying body; when spraying, the gas input end enters the air and sprays out to the spraying end to form a conveying airflow, and each additive is intermittently proportioned through each auxiliary agent input end and added to the spraying body and mixed under the action of the conveying airflow. The spraying end moves until it is sprayed onto the bipolar plate from the spraying end; the beneficial effect of the present invention is that a conductive layer can be formed on the surface of the bipolar plate, the use effect of the bipolar plate can be improved, and the ratio can be precisely matched to ensure that the bipolar Forming quality of the conductive layer of the board.

Owner:宁波市捷丰塑业有限公司

Quick pulping method of soybean milk machine

ActiveCN104545455BReduce the temperatureShorten the timeBeverage vesselsMilk substitutesCold airAir pump

The invention relates to a rapid pulping method for a soymilk machine. The boiling stage also includes an overflow prevention step. The air pump sucks away the hot air in the pulverizer, and the air pressure difference between the pulverizer and the outside makes the cold air in the outside Quickly enter the pulverizer from the air inlet, the high-speed flowing gas breaks the rising soy milk foam and lowers the temperature of the liquid surface of the soy milk to prevent overflow. In this way, the air pump sucks away the boiled hot steam, and the surface temperature of the slurry foam decreases. According to the principle of thermal expansion and contraction, when the temperature of the gas inside the bubble is higher than the outside temperature, the bubble expands and bursts rapidly. While the hot steam is pumped away, a negative pressure is formed inside the pulverizer, and the outside gas forms a high-speed airflow under the action of the pressure difference. Supplemented into the pulverizer, the high-speed airflow can also blow the foam of the slurry, thus greatly improving the anti-overflow efficiency.

Owner:JOYOUNG CO LTD

Planetary exploration vehicle wheel active following control method, system and planetary exploration vehicle

ActiveCN111605729BSmall driving forceIncrease the number ofExtraterrestrial carsSpacecraft guiding apparatusControl systemClassical mechanics

The invention provides an active following control method, a control system and a planetary exploration vehicle of a planetary exploration vehicle, which relate to the technical field of robot control. The method for actively following the wheels of the planetary rover includes the following steps: optionally, one or more wheels of the planetary rover are used as support wheels, and the rotational speed of the support wheels is adjusted to make the real-time hook traction force F of the support wheels. x Approaching target hitch traction F xd , so as to reduce the driving force and resistance of the support wheel to the planetary rover, so that the support wheel is used to provide a support force to the body of the planetary rover. By adopting this method, the support wheels only provide support force to the vehicle body, and under the condition of increasing the number of wheels and reducing the average load of the wheels, the internal force confrontation between the wheels is reduced, and the planetary exploration vehicle has a high moving efficiency.

Owner:HARBIN INST OF TECH

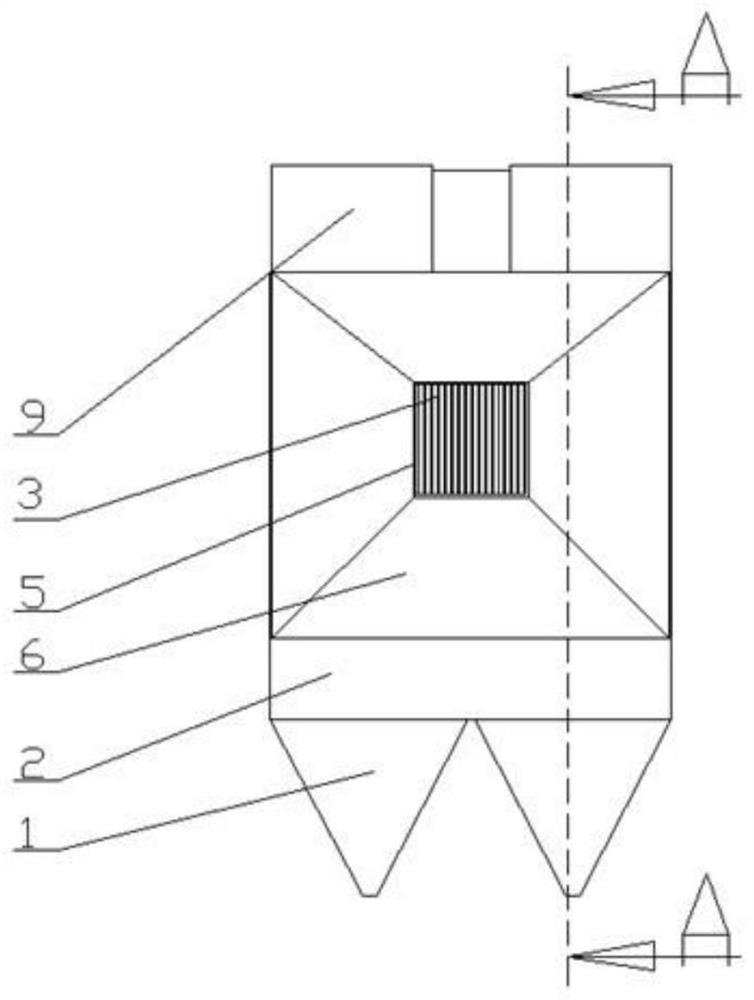

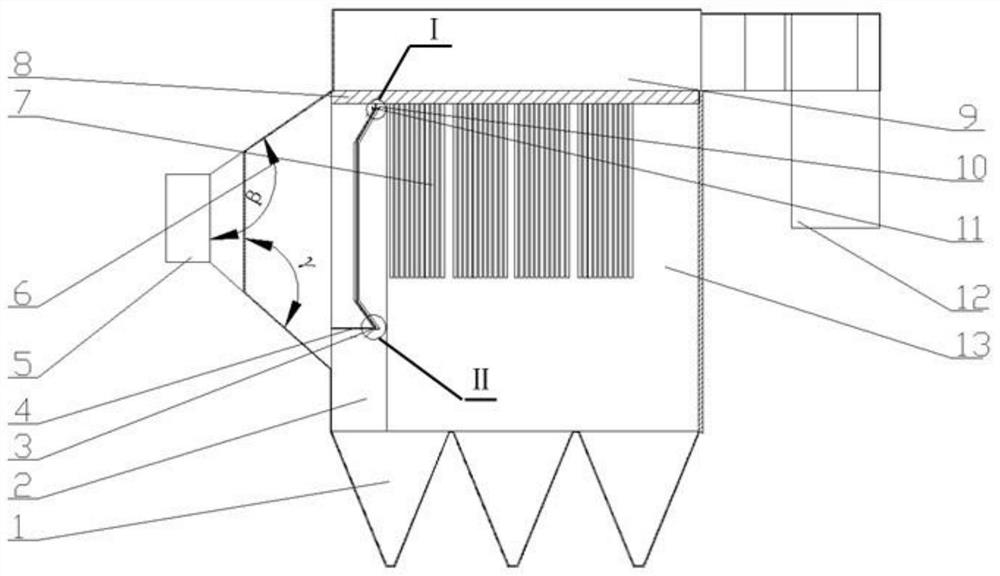

A bag filter

The invention provides a bag-type dust collector, which includes a box body, a pattern plate is arranged in the box body, and the box body is divided into an upper clean air chamber and a lower box body, the lower box body is provided with a plurality of ash hoppers, and the lower box body is provided with an air inlet The bell mouth, the flower plate is provided with several filter bags, the air inlet bell mouth and the lower box are provided with a deflector, the deflector includes a front deflector and a rear deflector, and the front deflector has a cross section of It is composed of semicircular guide grooves, the rear guide plate is composed of semicircular guide grooves with straight plates tangent to it on both sides, and the guide grooves of the front guide plate and the rear guide plate are divided into two parts. The openings are all facing the direction of the air inlet bell mouth, and both ends of the deflector are bent along the direction of the flue gas and have transition arcs. By changing the structure and installation arrangement of the deflector, the flue gas can enter Before the dust chamber, the large particles are subjected to inertial sedimentation, and it has stronger rigidity and greatly reduces the amount of deformation. It can also better realize the secondary distribution of the flue gas, and avoid the phenomenon of bag breaking due to excessive concentration of the flue gas. .

Owner:JIANGSU UNIV OF SCI & TECH

Exhaust purifying apparatus of saddle-ride type vehicle

ActiveCN102654072BIncrease configuration freedomSimple configurationInternal combustion piston enginesExhaust apparatusAir filterInternal combustion engine

An exhaust purifying apparatus achieving placement of components so as to prevent an increase in the size of the vehicle caused by the placement of the exhaust purifying apparatus while maintaining the performance of the exhaust purifying apparatus by secondary air in a saddle-ride type vehicle. An exhaust purifying apparatus of a saddle-ride vehicle includes a secondary air supply pipe of which one end is connected an exhaust passage of an internal combustion engine. A secondary air control valve is connected with the other end of the secondary air supply pipe for controlling the supply of secondary air to the secondary air supply pipe. An outdoor air introduction passage is connected to the secondary air control valve, wherein an air filter for secondary air and a resonant passage are installed in the middle of the outdoor air introduction passage.

Owner:HONDA MOTOR CO LTD

Two-stage series connection noise reduction structure and extractor hood with same

PendingCN109990350AReduce disorderShorten the lengthDomestic stoves or rangesLighting and heating apparatusInternal resistanceEngineering

The invention relates to a two-stage series connection noise reduction structure, including a primary fan and a secondary fan arranged above the primary fan. An air outlet of the primary fan is in communication with an air inlet of the secondary fan through a connection section. The primary fan and the secondary fan are centrifugal fans and are characterized in that with a normal plane of an air flow formed between the air outlet of the primary fan and the air inlet of the secondary fan as a reference, the projection of a main air inlet area of the secondary fan on the normal plane has an overlapping area with the projection of the air outlet of the primary fan on the normal plane. According to the two-stage series connection noise reduction structure, the length and tortuosity of the connection section are reduced effectively so that out air of the primary fan is directly connected to a main exhaust area of the air outlet of the secondary fan, the internal resistance between the two-stage fans is reduced, and turbulence of airflow is reduced, the flow rate of a fan system is increased, and noise is reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Self-adaptive wind direction and natural draft smoke exhaust device that can adjust resistance in linkage

ActiveCN103759281BReduce wearLow rotational resistanceChimneysDraught inductionEngineeringSelf adaptive

A natural induced air smoke exhaust device capable of being adaptive to the wind direction and adjusting resistance in a linkage mode is characterized in that the natural induced air smoke exhaust device comprises an air inlet pipe rotating along with the wind direction, a horn-shaped air inlet is formed in the lower end of the air inlet pipe, the upper end of the air inlet pipe is connected with the lower end of a vertical pipeline through a bearing in a sleeved mode, and the air inlet pipe pivots relative to the vertical pipeline; the air inlet pipe wall on the opposite side of the air inlet is provided with a vertical wind wing; a fixing support is arranged in the middle of the vertical pipeline, a supporting rod is arranged on the fixing support, an oscillating bar is hinged to the end of the supporting rod, a reset spring is arranged at the hinged position, a flue gate is fixed to the upper end of the oscillating bar, and the flue gate can reset to the half-aperture original position through the reset spring; the lower end of the oscillating bar extends to make single-face contact with the vertical wind wing; a flue and the vertical pipeline are converged at the upper portion of the vertical pipeline in the 45-degree included angle.

Owner:山东莱科能源生态开发有限公司

a shift actuator

ActiveCN111089164BFile accurateAdaptableToothed gearingsGearing controlInternal resistanceControl cell

Owner:NINGBO GAOFA AUTOMOTIVE CONTROL SYSTEM CO LTD

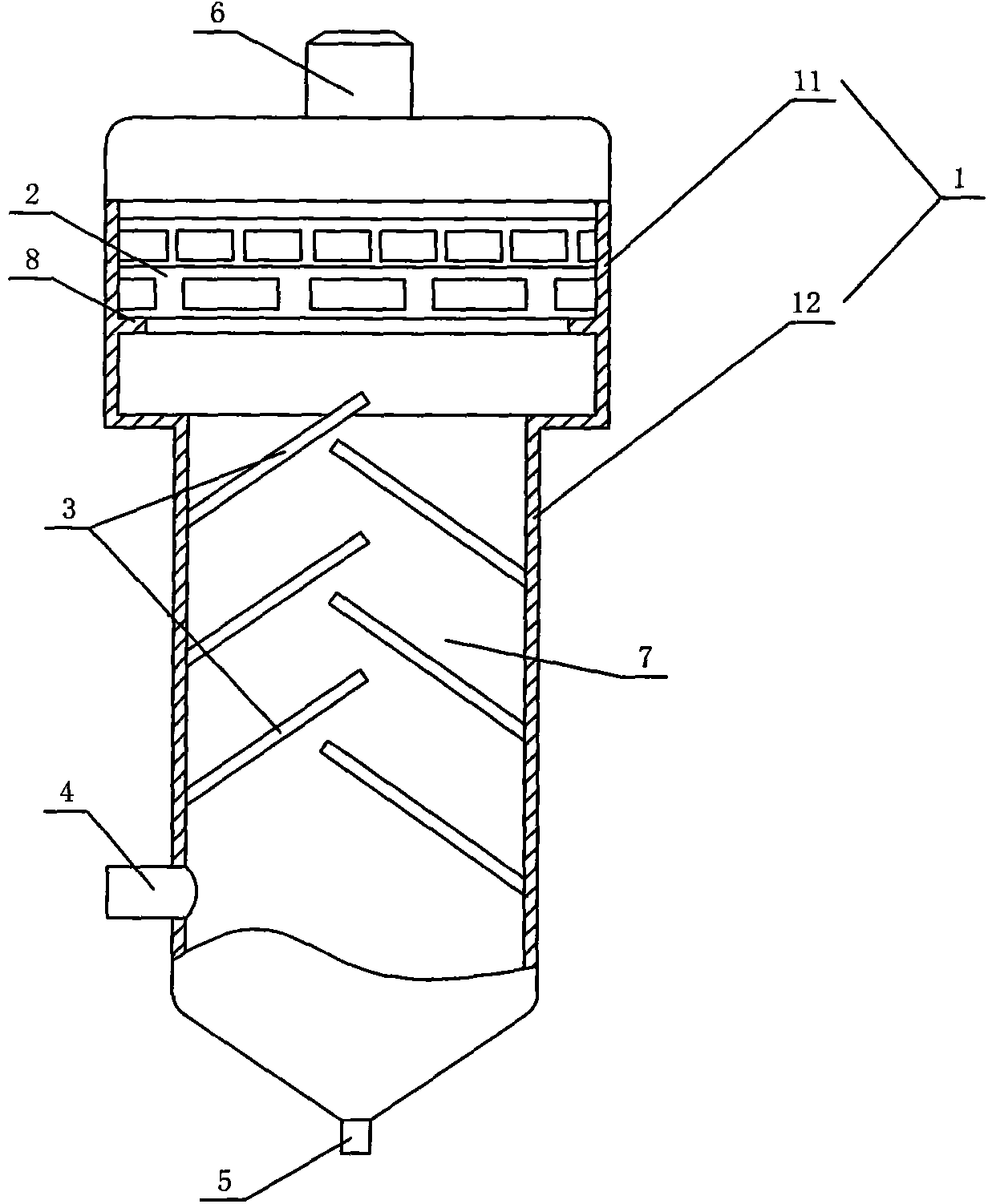

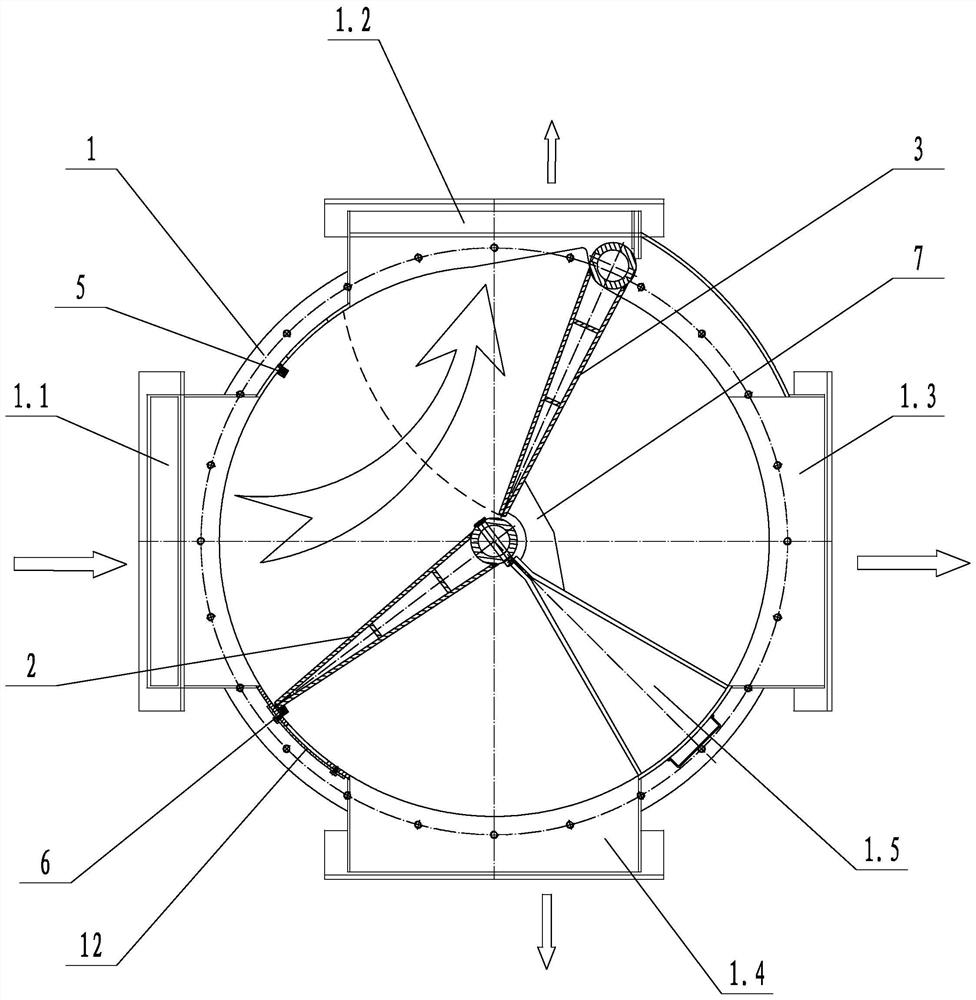

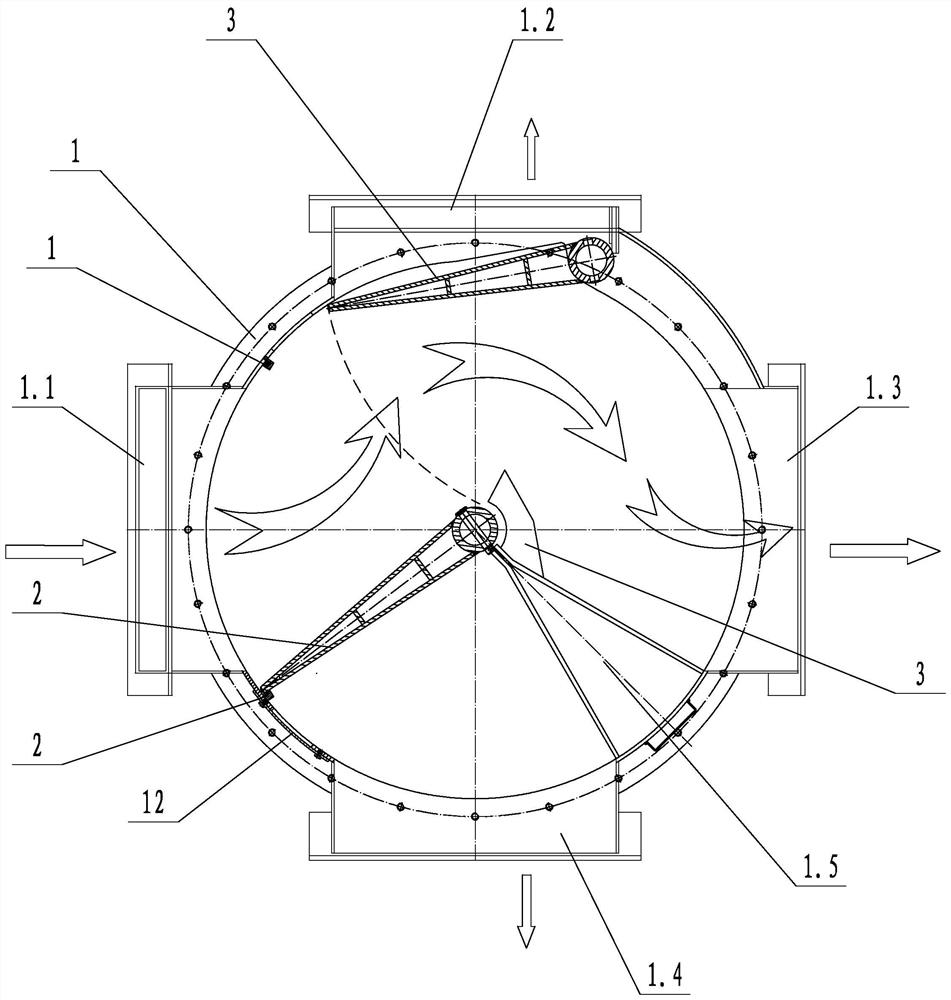

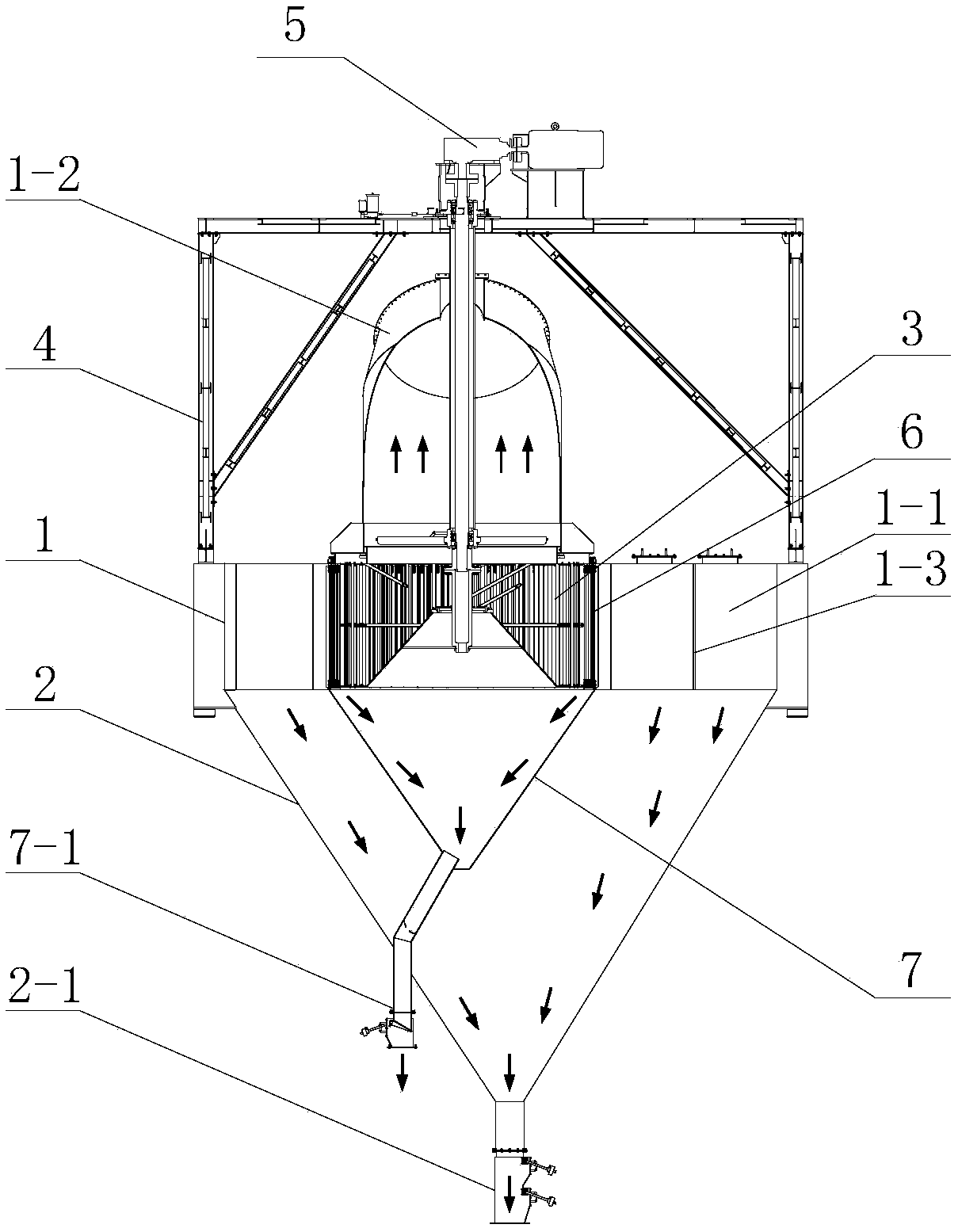

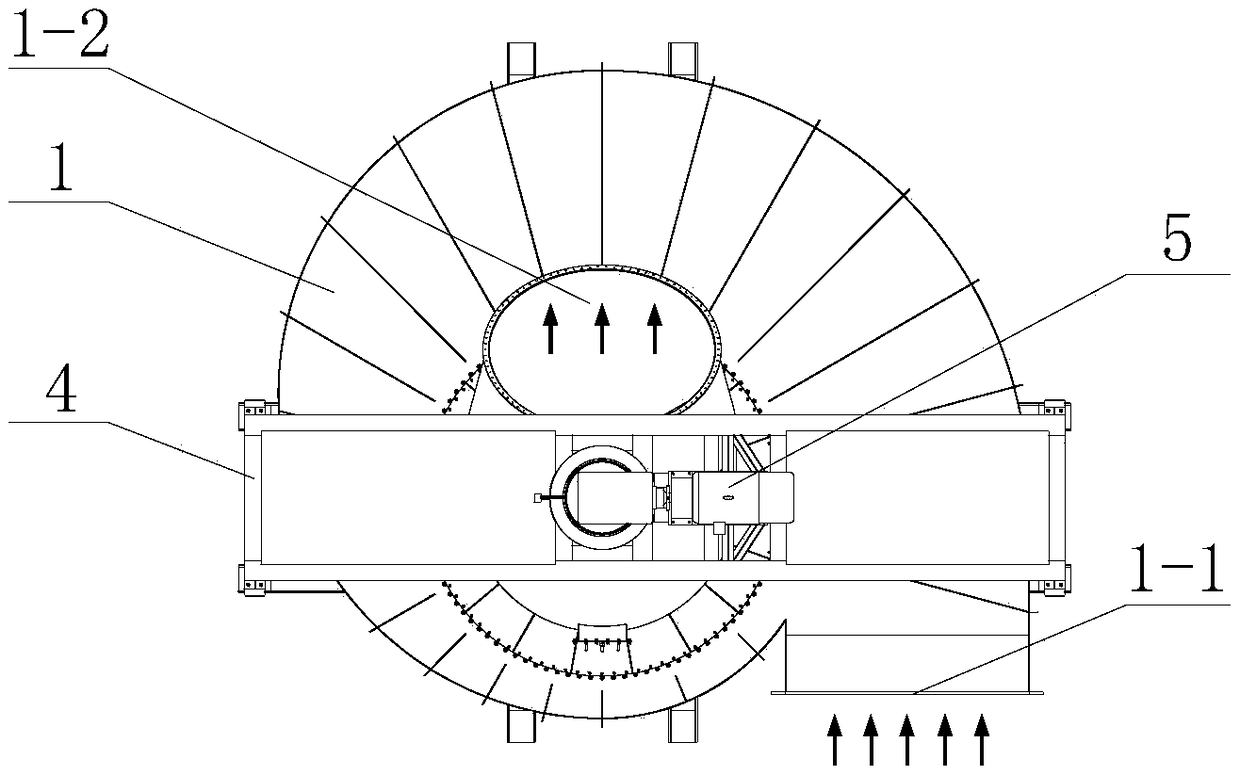

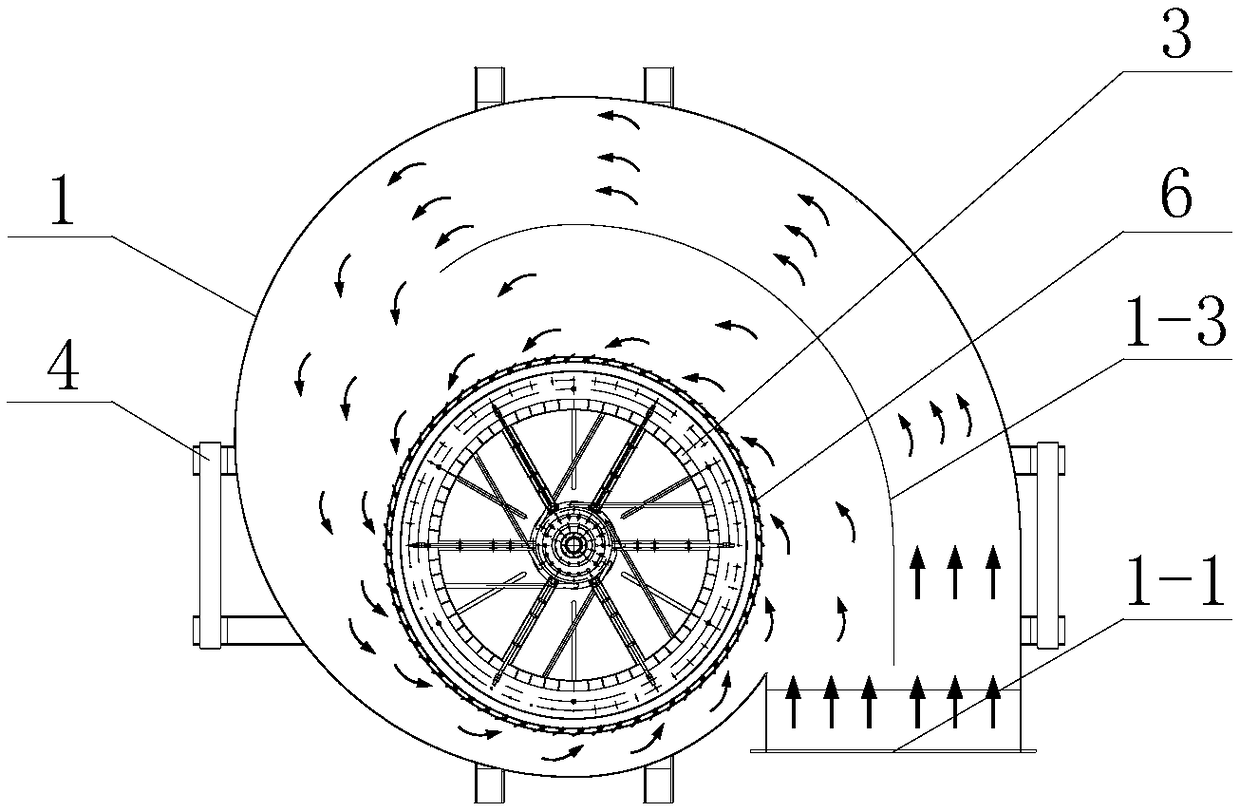

Vertical vortex powder selector adopting lateral air feeding, powder selection method implemented by vertical vortex powder selector, and application of vertical vortex powder selector

PendingCN109127169AReduce internal resistanceReduce process layout heightReversed direction vortexCentrifugesSelection methodMaterials science

The invention belongs to the technical fields of powder grinding and powder selection, and discloses a vertical vortex powder selector adopting lateral air feeding, a powder selection method implemented by the vertical vortex powder selector, and application of the vertical vortex powder selector. The vertical vortex powder selector comprises an upper vortex casing and a lower conical casing, wherein the vortex casing is horizontally arranged, and an open end of the vortex casing is provided with an air inlet; an air outlet is formed in the upper part of the vortex casing and connected with adust collection device; a cage rotor is arranged in the vortex casing, and the air outlet is formed above the cage rotor; a driving device is arranged above the vortex casing and connected with the cage rotor; air guiding blades are circumferentially arranged on the outer side of the cage rotor; a casing-shaped lower cone is arranged in the conical casing and placed right below the cage rotor; a medium and coarse powder discharging chute is communicated with the lower end of the lower cone, and the tail end of the medium and coarse powder discharging chute extends downwardly to the outside ofthe conical casing; and a coarse powder discharging chute is communicated with the lower end of the conical casing. The powder selector provided by the invention has the advantages of high reasonability in structure, high reliability in operation, less abrasion, high efficiency and low energy consumption.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com