Cylindrical four-way powder distributing valve

A four-way material distribution, cylindrical technology, applied in the direction of conveying bulk materials, conveyors, slideways, etc., can solve the problems of inconvenient manufacturing, easy to increase resistance, etc., to facilitate processing and manufacturing, protect over-torque damage, avoid stacking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

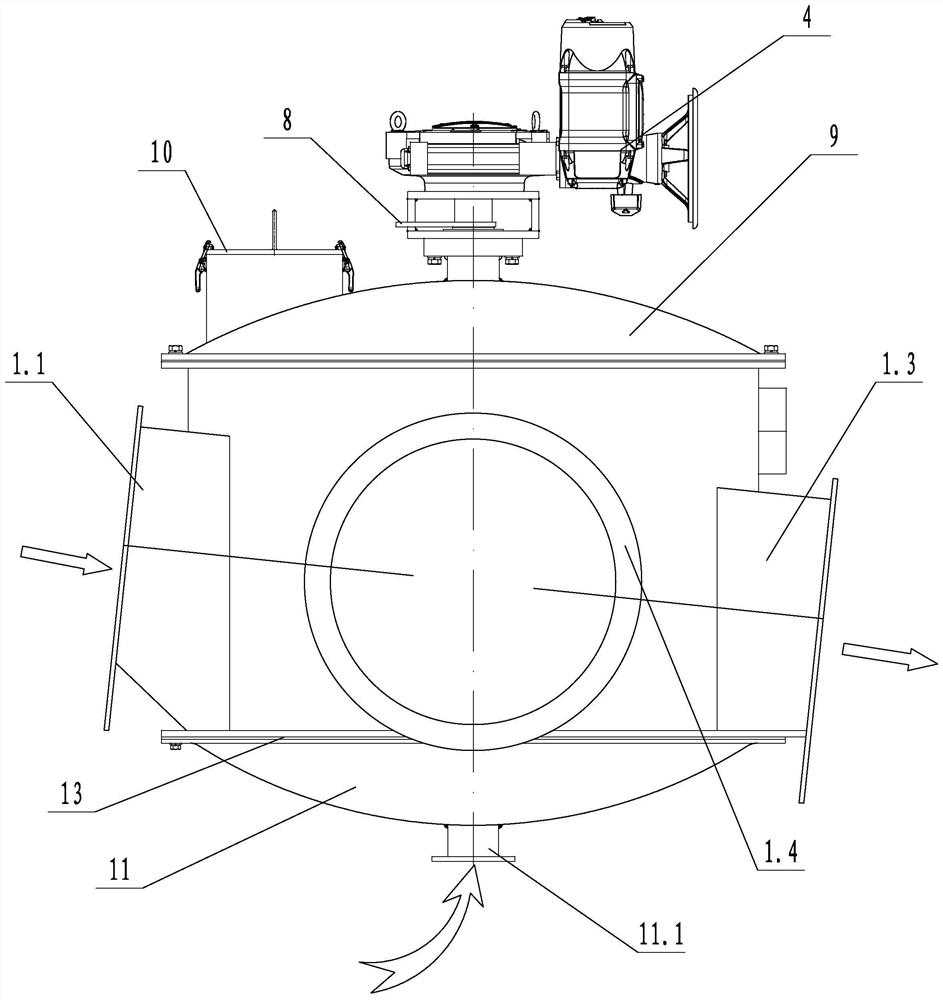

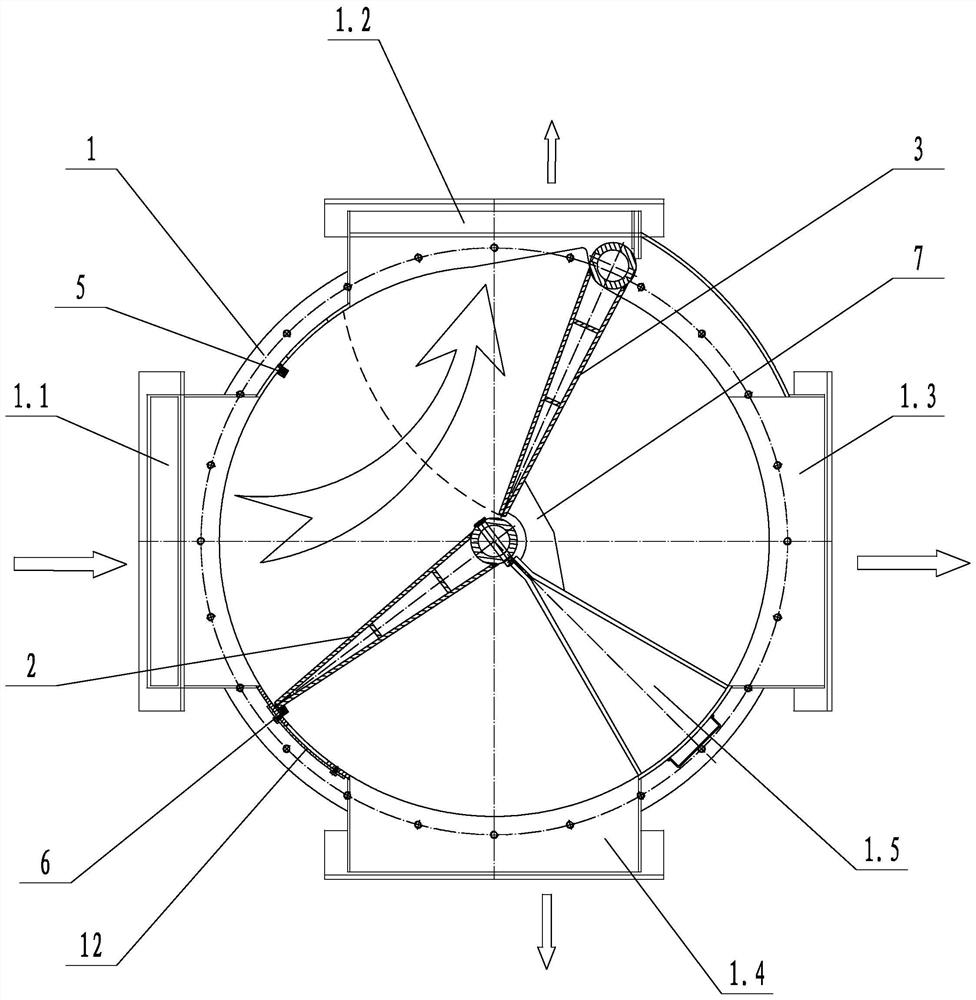

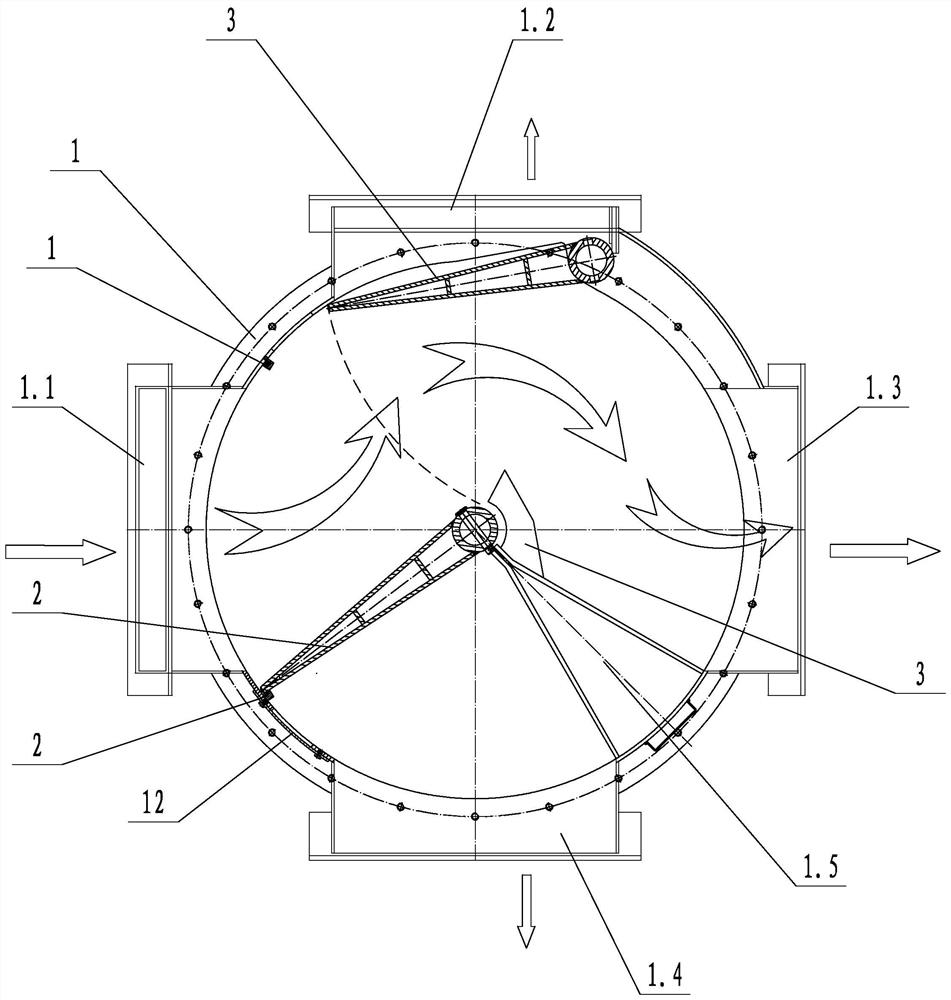

[0025] Such as Figures 1 to 4 As shown, a cylindrical powder four-way distributing valve includes a valve casing 1, a first swing door 2, a second swing door 3 and a driving member 4. The inner wall of the valve casing 1 is a cylindrical structure, A powder inlet 1.1, a first outlet 1.2, a second outlet 1.3 and a third outlet 1.4 are sequentially arranged on the side wall of the valve housing 1, the second outlet 1.3 and the third outlet 1.4 are separated by a partition 1.5, and the first pendulum The door 2 and the second swing door 3 are arranged in the valve casing 1 and are rotatably connected with the valve casing 1. One end of the rotation shaft of the first swing door 2 and the rotation shaft of the second swing door 3 stretches out of the valve casing 1 and is connected with the driving member. 4 is connected to the output end; the first swing door 2 is set on the side close to the powder inlet 1.1, the rotating shaft of the first swing door 2 is set at the center of ...

Embodiment 2

[0028] Such as figure 1As shown, on the basis of Embodiment 1, the bottom of the valve housing 1 is provided with an inflatable box 11, and the inflatable box 11 is provided with a suspension air inlet 11.1, and the inflatable box 11 and the bottom of the valve housing 1 pass through a partition and a breathable layer cloth. 13 separates, and is provided with several ventilation holes on the dividing plate and air-permeable layer cloth 13. The gas in the inflatable box 11 can enter the inside of the valve housing 1 to blow the material at the bottom of the valve housing 1 to prevent the material from accumulating in the valve housing 1 .

[0029] The beneficial effects of the present invention are: (1) convenient processing and manufacturing, which can reduce internal resistance and reduce dead angles, one inlet and two outlets of the distributing valve, one inlet and one outlet, and the other outlet has good sealing effect; It can effectively prevent over-opening and over-cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com