Patents

Literature

139results about How to "Improve fault" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

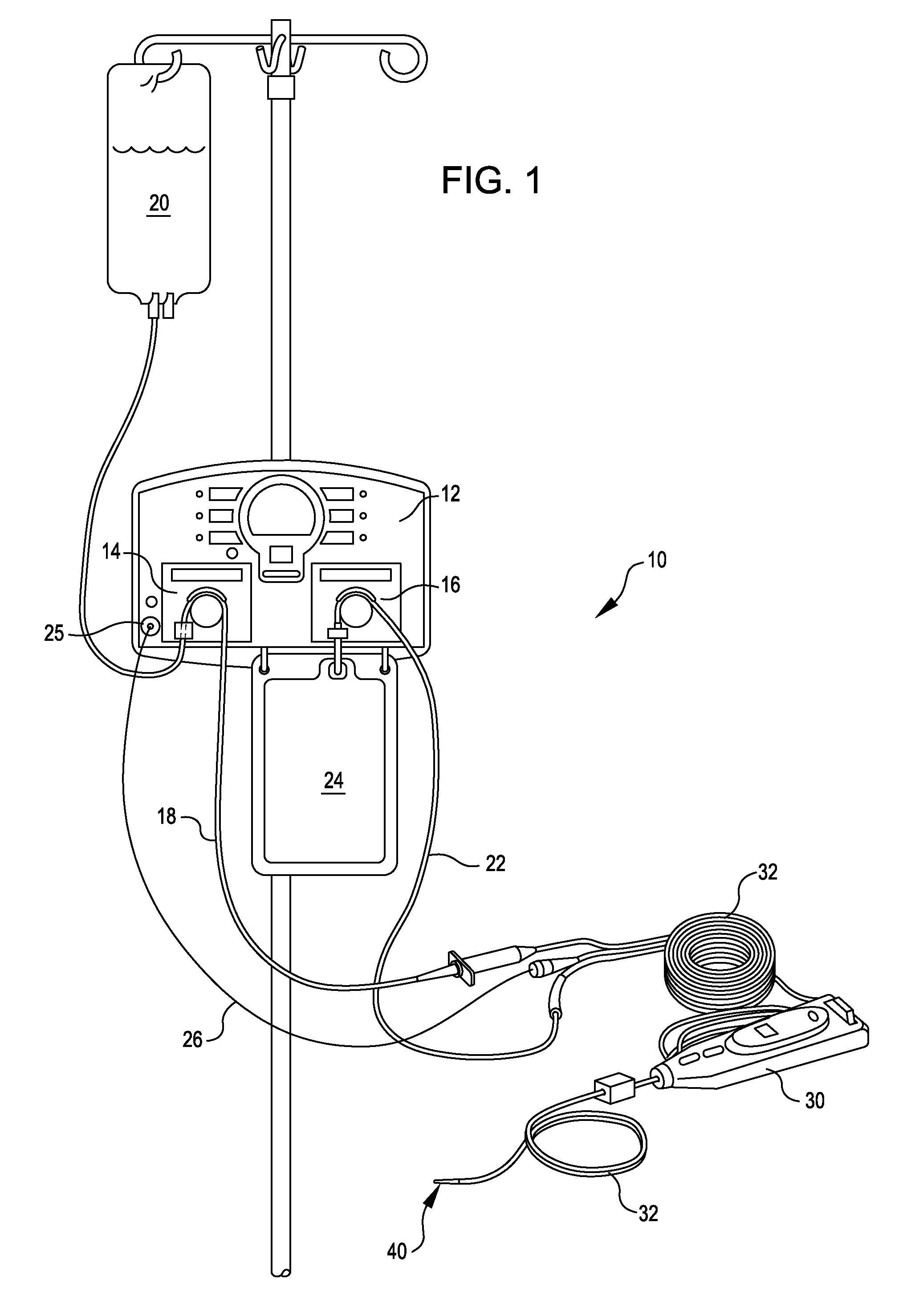

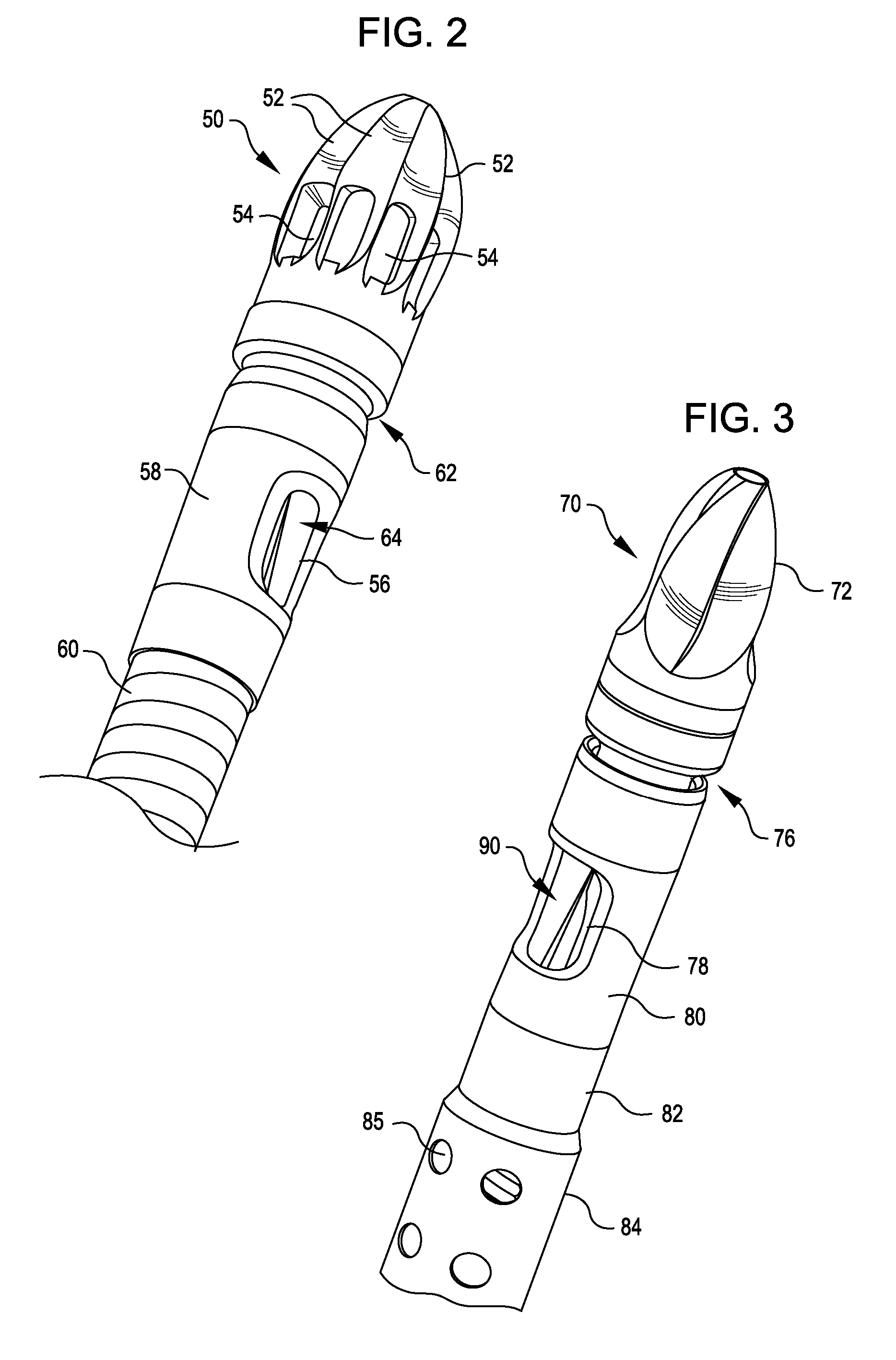

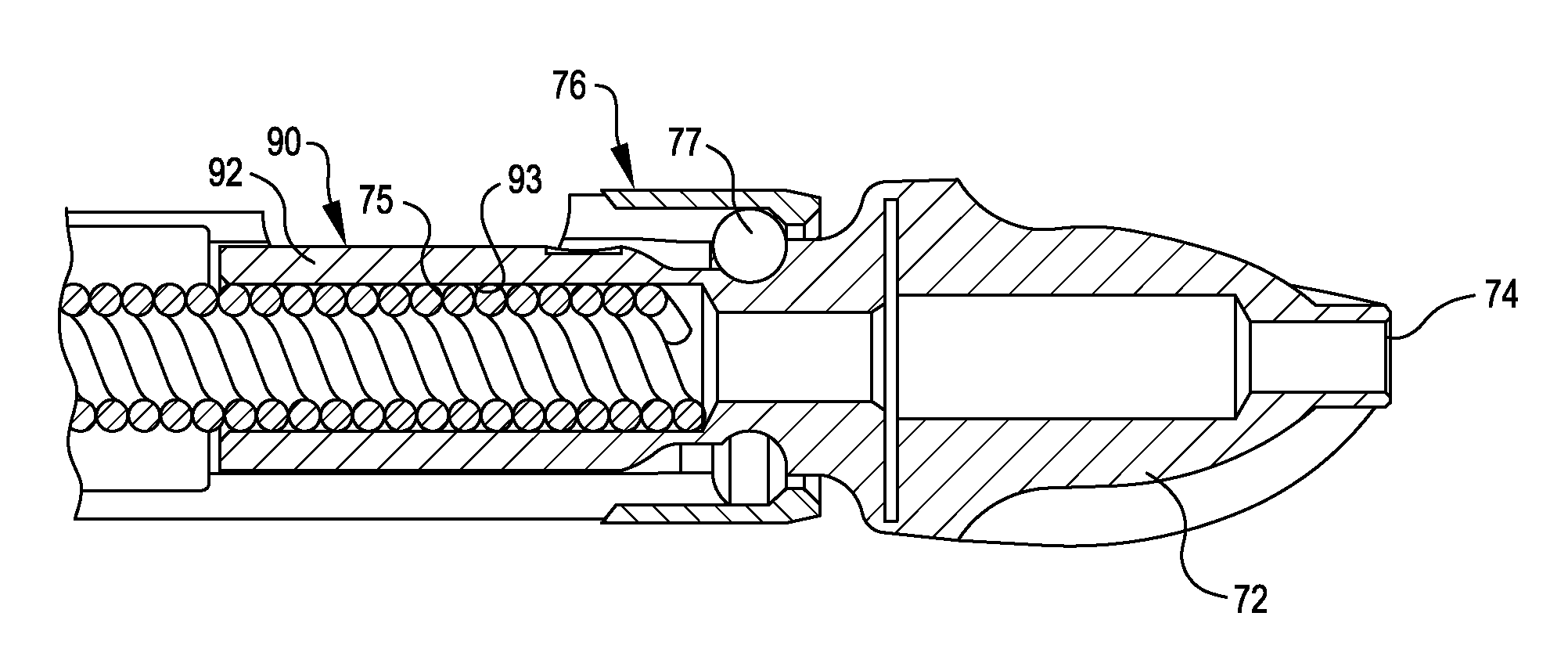

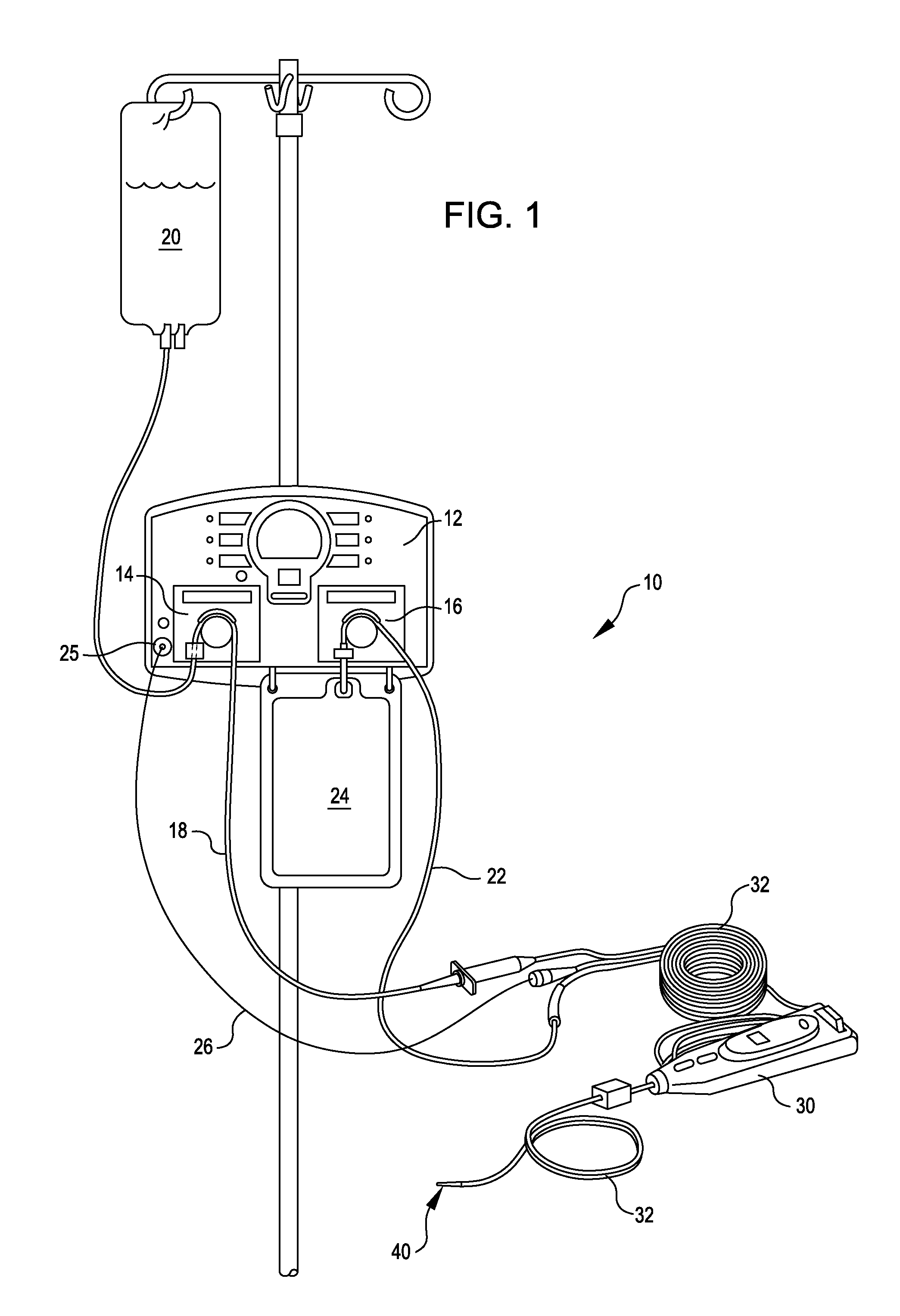

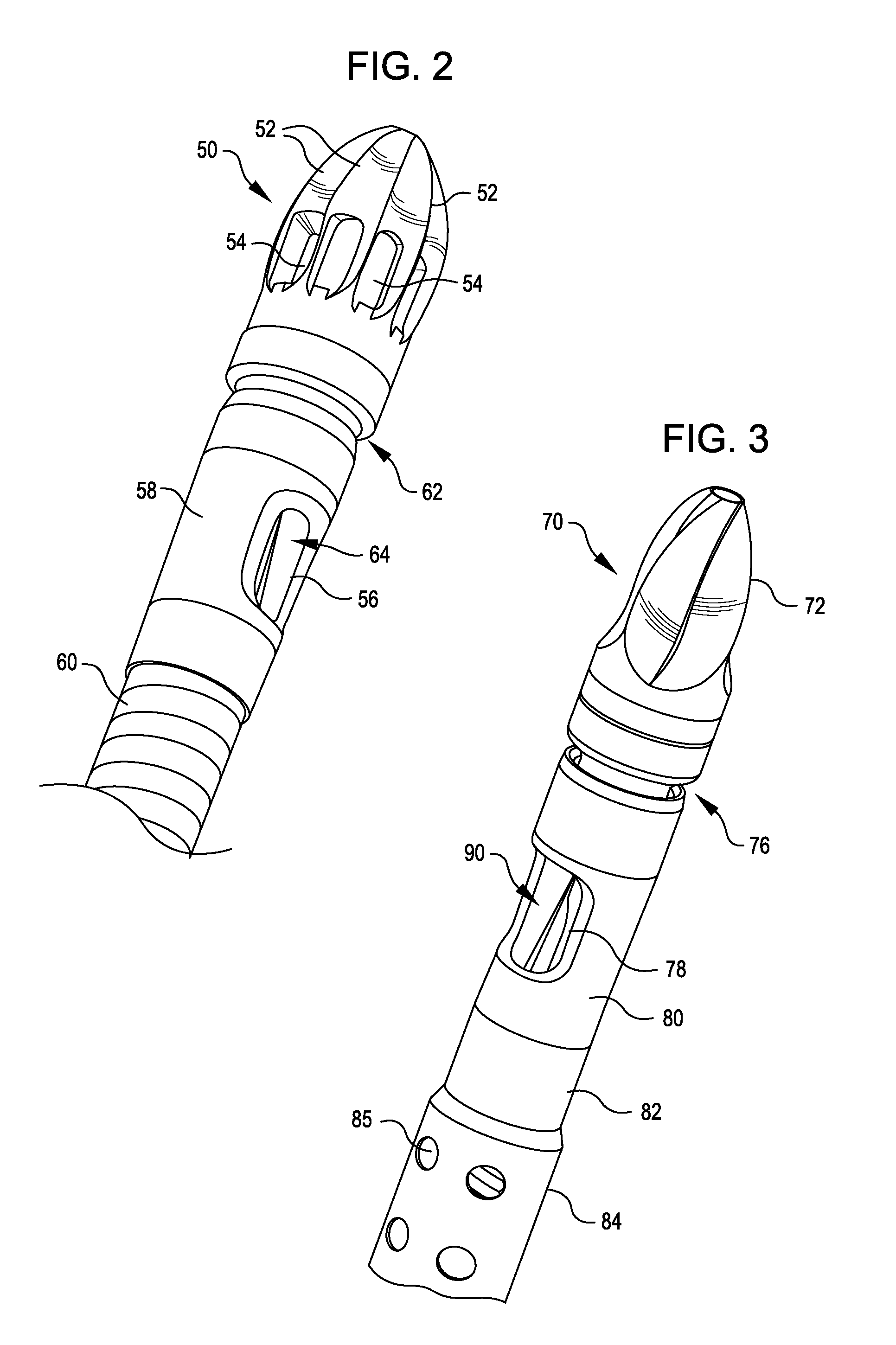

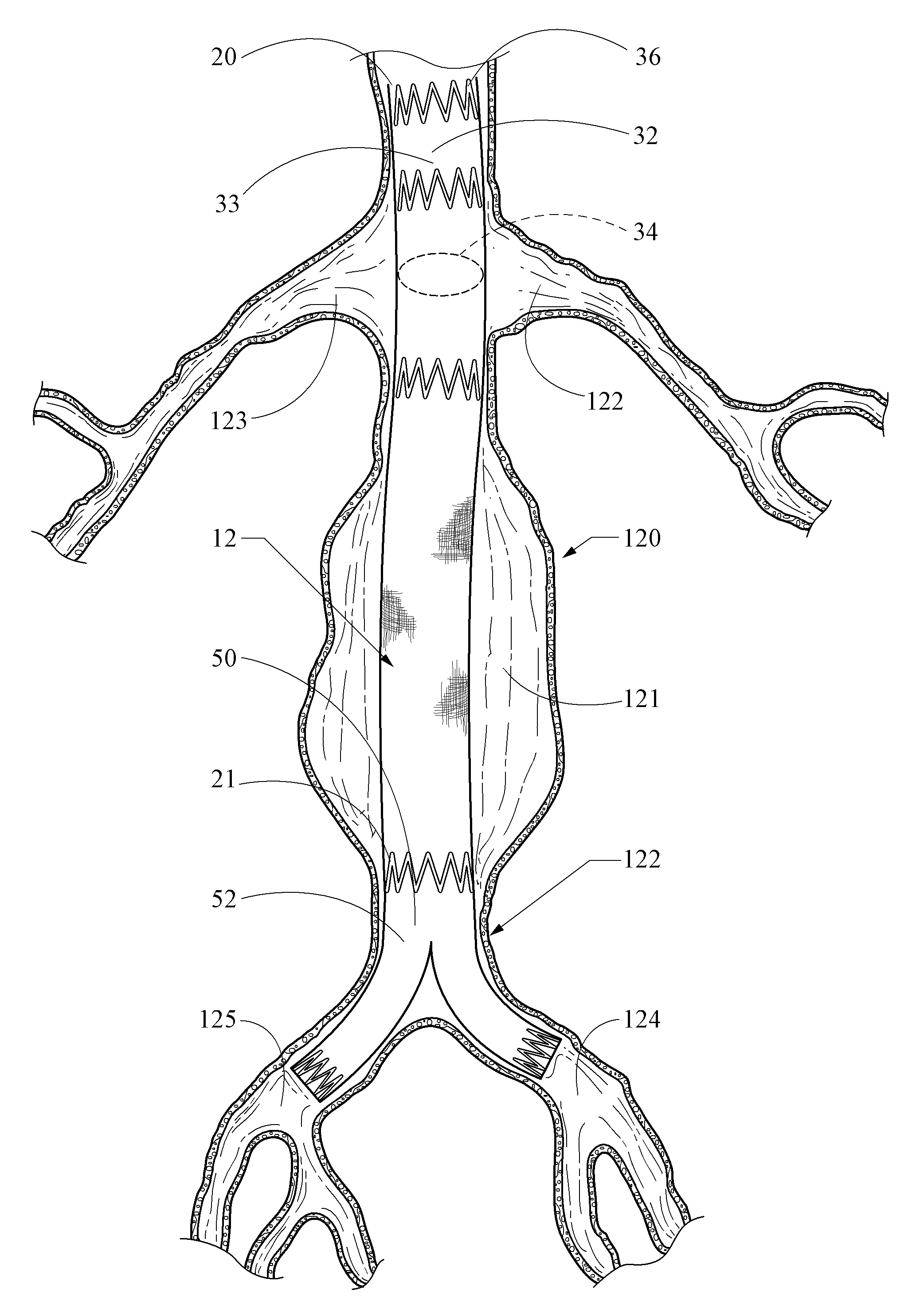

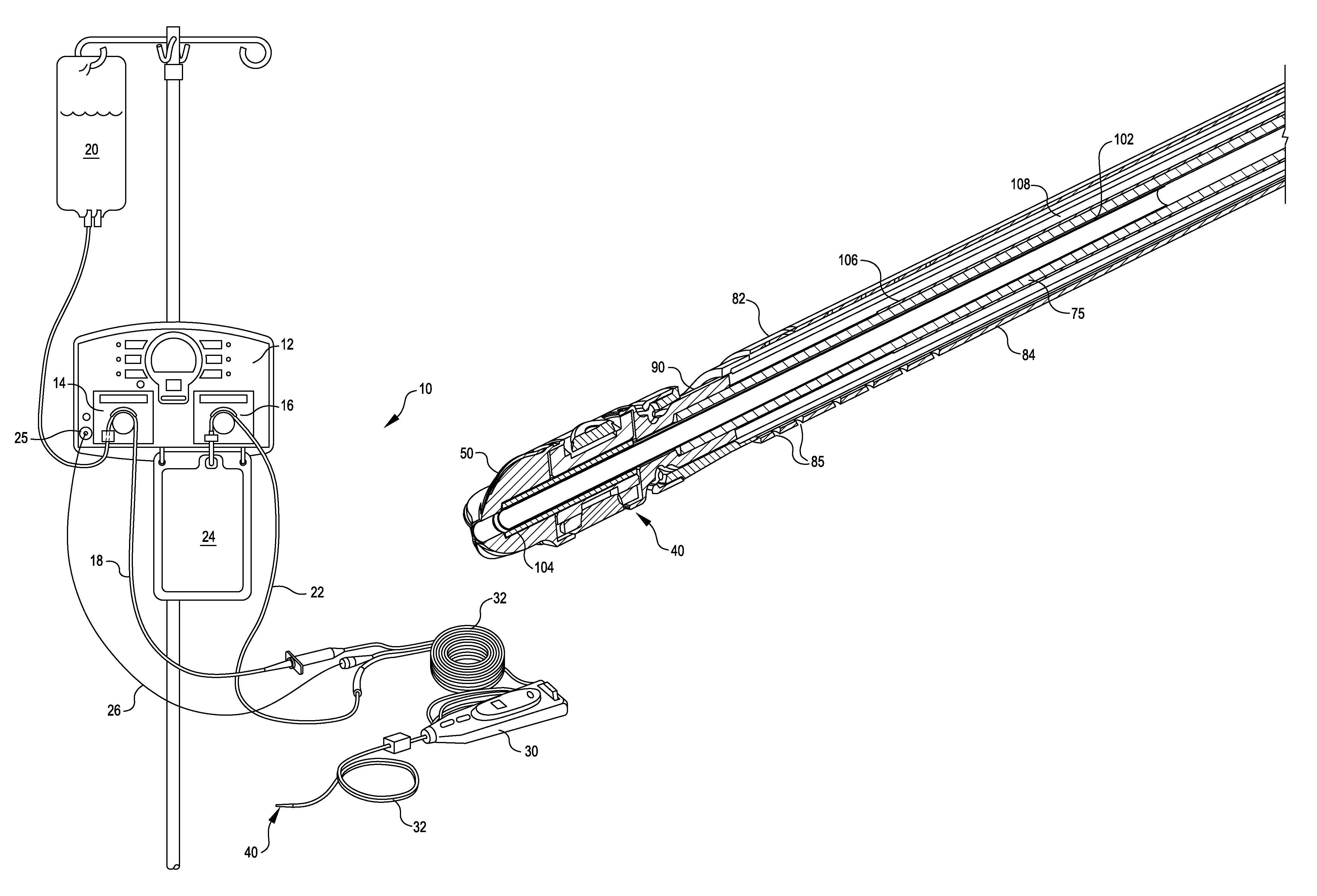

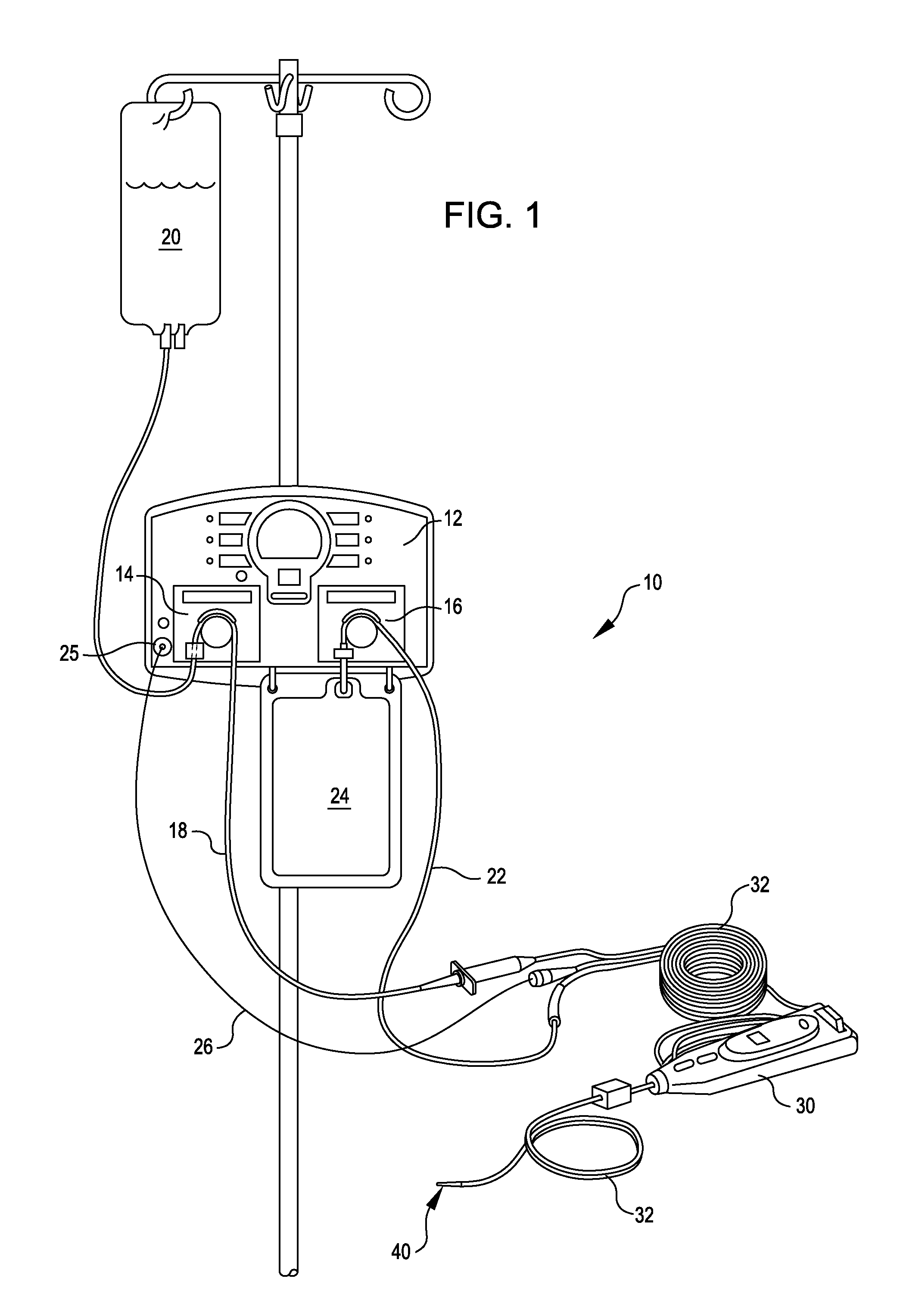

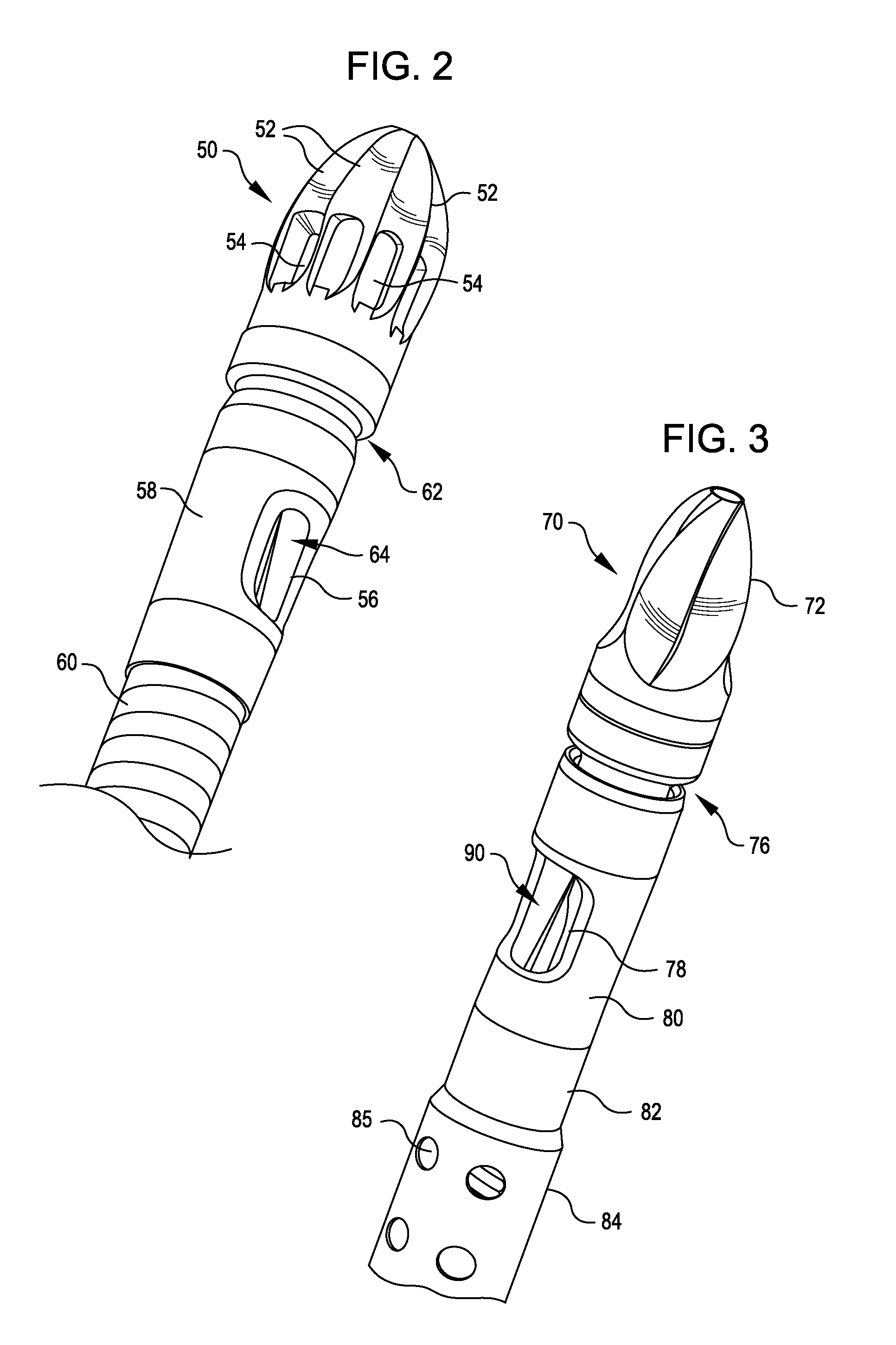

Interventional catheters incorporating an active aspiration system

An interventional catheter assembly comprises an operating head for removing obstructive material from a target site in a body lumen or cavity and at least one aspiration port located proximal to the operating head and penetrating the catheter assembly, the aspiration port being in communication with a sealed lumen that communicates with a vacuum system for withdrawing aspirate fluid and obstructive material from the target site. A rotatable member is positioned inside the catheter assembly at the site of the aspiration port and rotates during operation of the vacuum system. The rotatable member is provided with at least one upstanding bar that is sized to cooperate with the walls of the aspiration port and the inner surface of the catheter assembly to macerate debris that is drawn into the aspiration port.

Owner:BOSTON SCI MEDICAL DEVICE LTD

Interventional catheters incorporating an active aspiration system

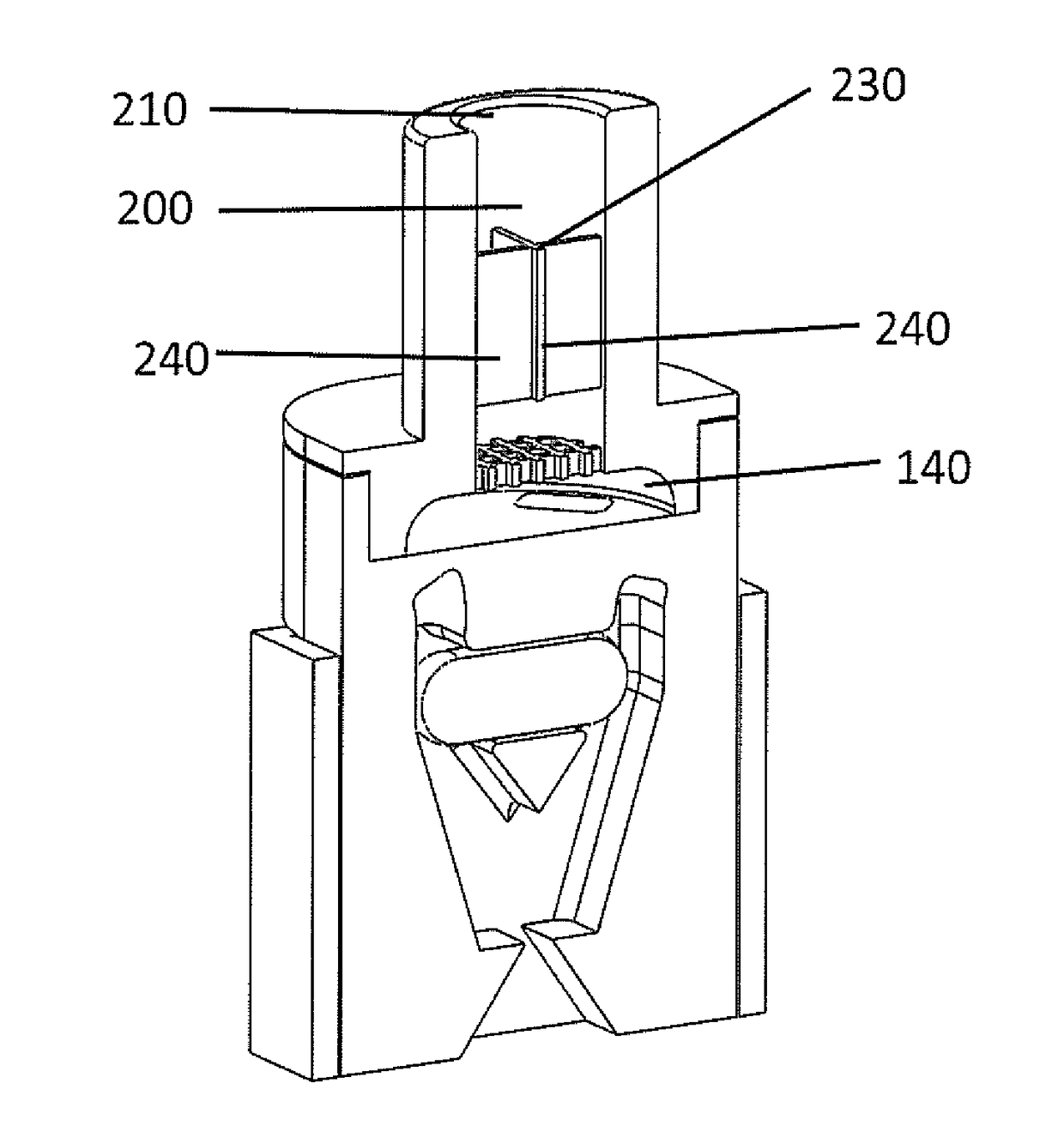

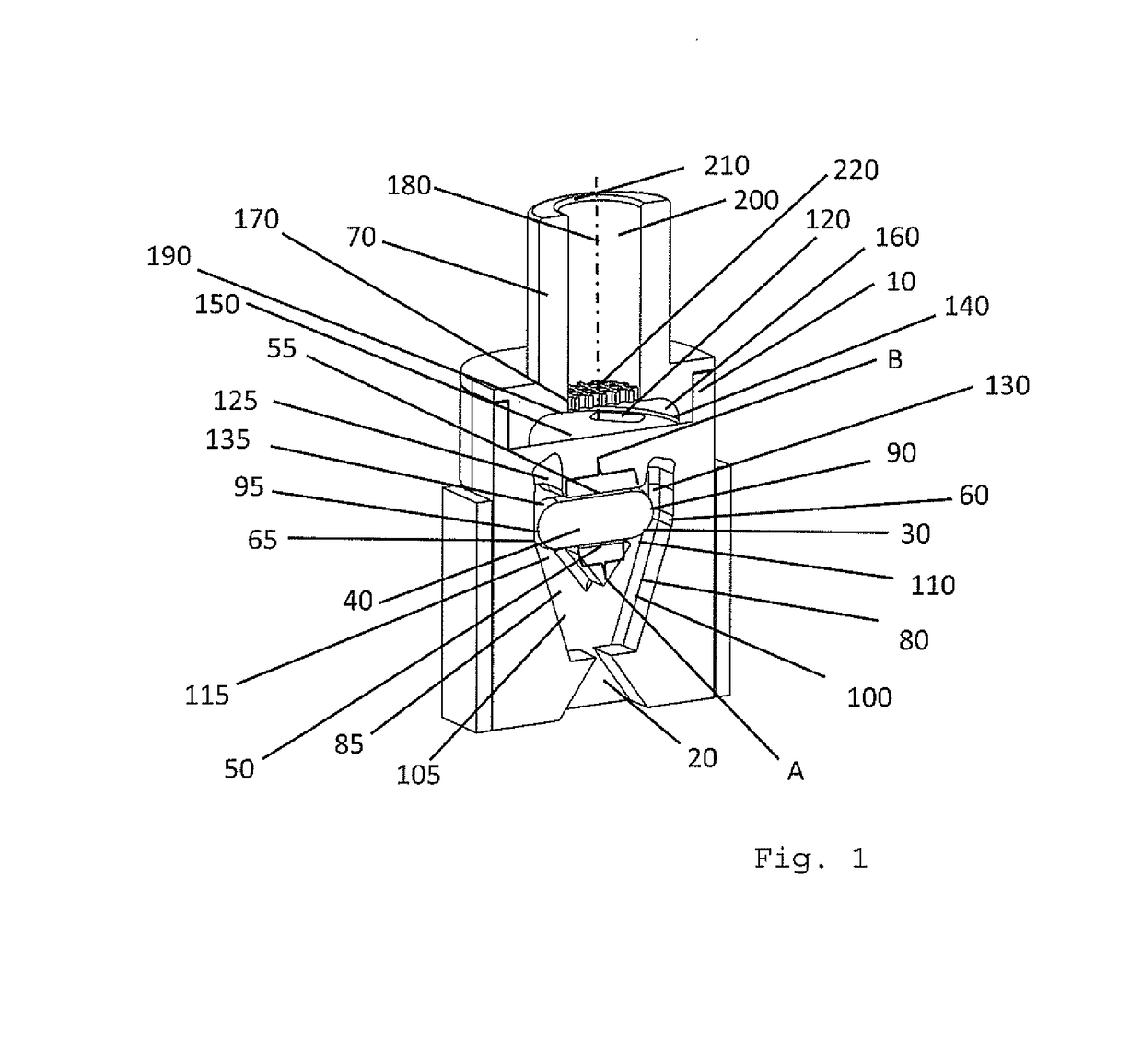

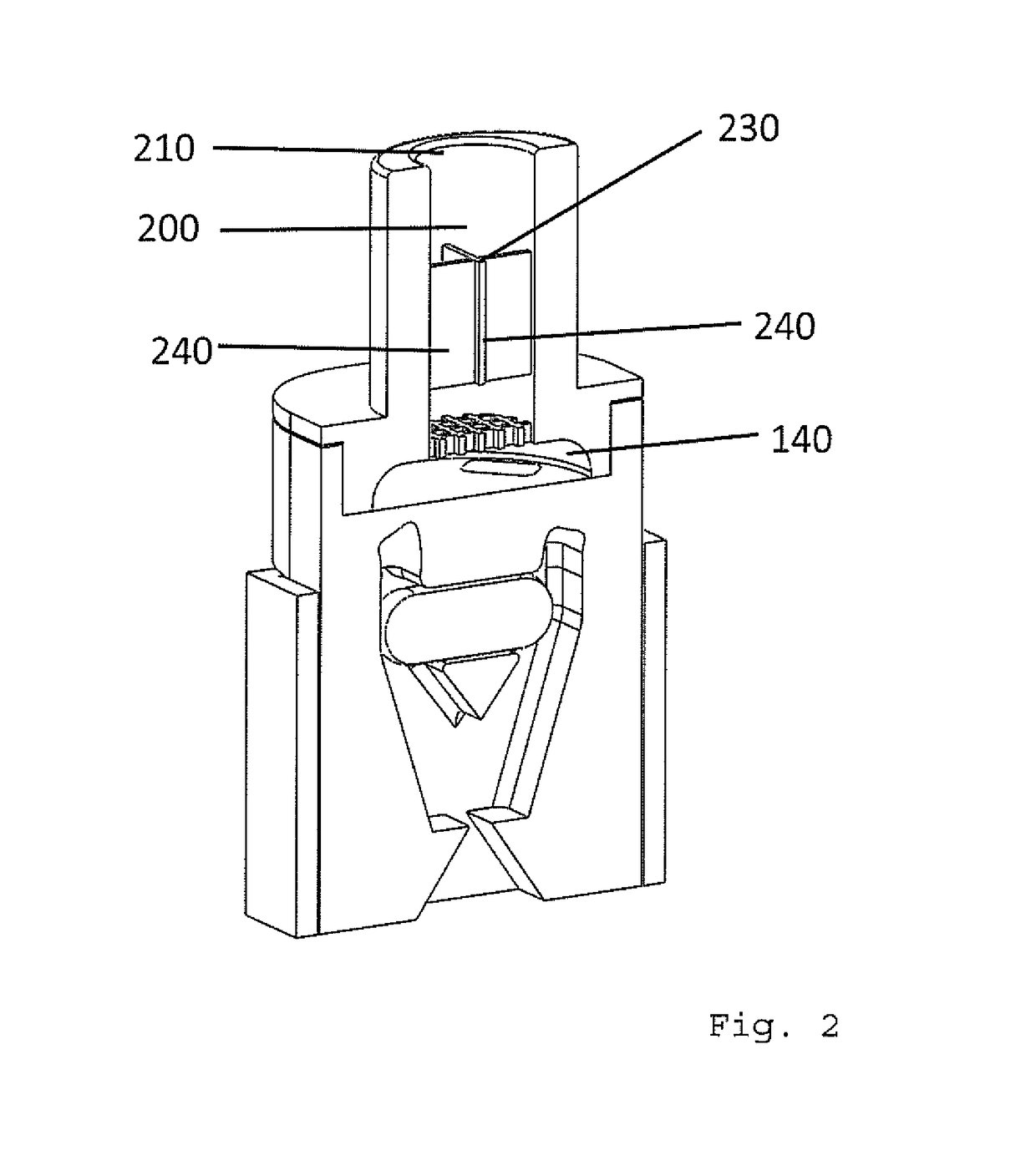

ActiveUS20110118660A1Reduce amountHigh and consistent aspiration pressureGuide wiresExcision instrumentsCatheterTarget site

An interventional catheter assembly comprises an operating head for removing obstructive material from a target site in a body lumen or cavity and at least one aspiration port located proximal to the operating head and penetrating the catheter assembly, the aspiration port being in communication with a sealed lumen that communicates with a vacuum system for withdrawing aspirate fluid and obstructive material from the target site. The interventional catheter incorporates an elongated guidewire lumen bushing extending proximally from a distal region of the operating head to reduce the clearance between the guidewire and the internal surface of the guidewire lumen during operation of the interventional catheter. This feature restricts entry of fluid and debris into the guidewire lumen and promotes maintenance of consistent and high aspiration pressure and volume during operation of the aspiration system and interventional catheter assembly.

Owner:BOSTON SCI LTD

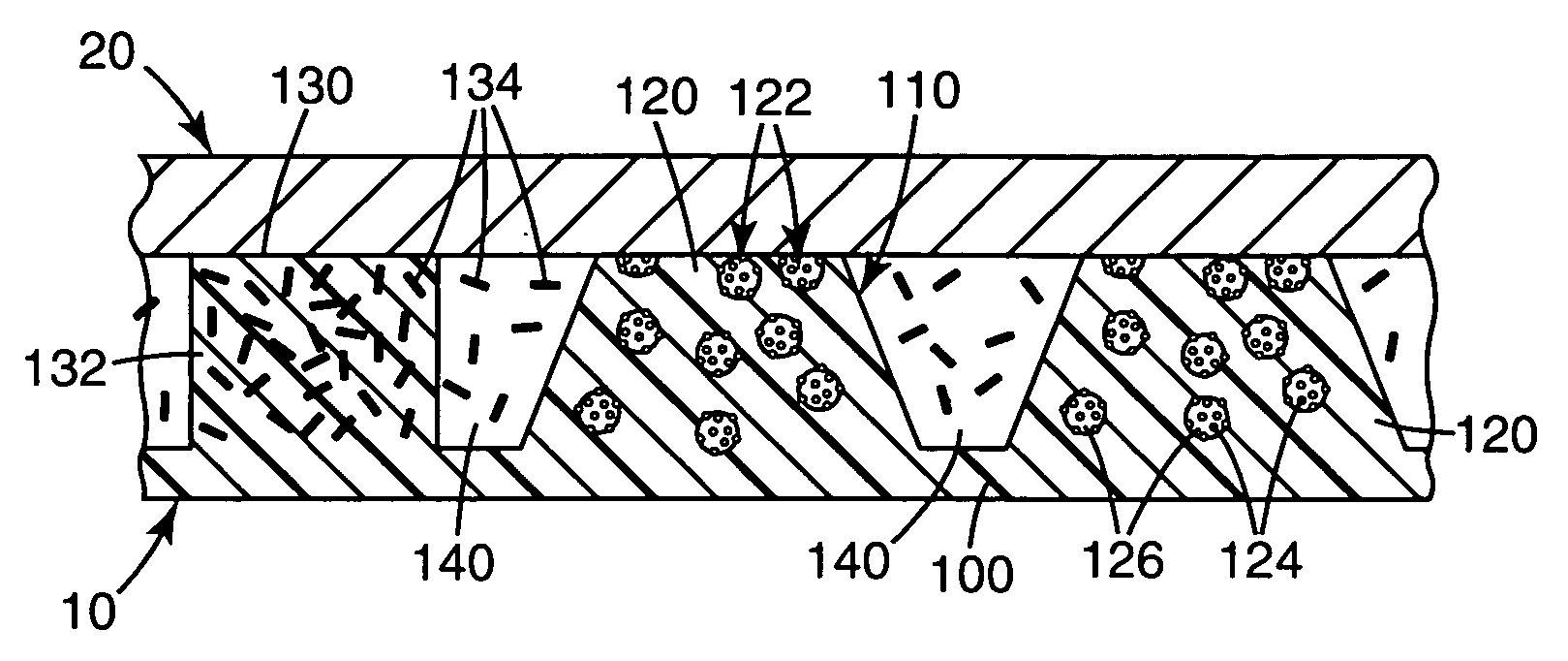

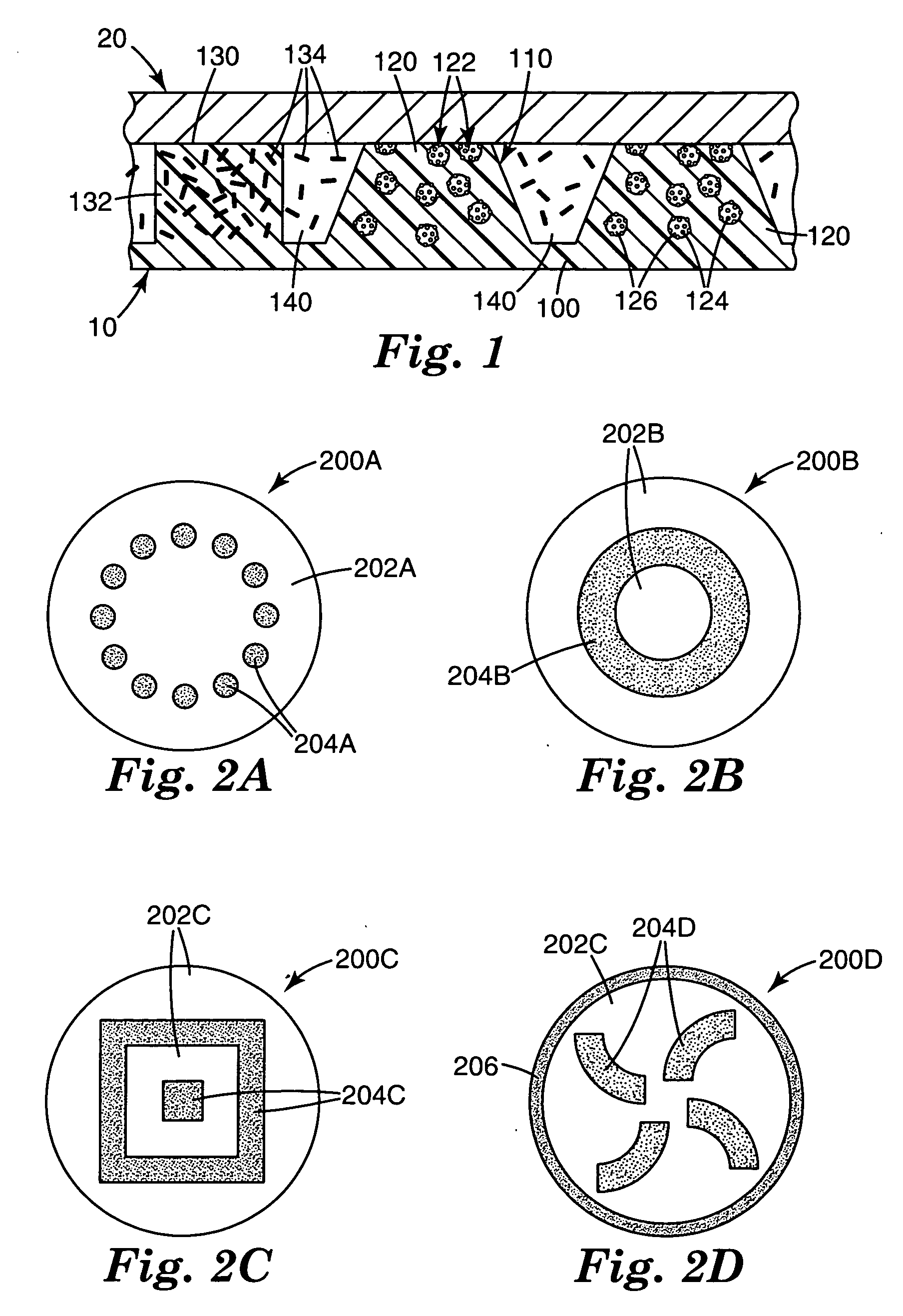

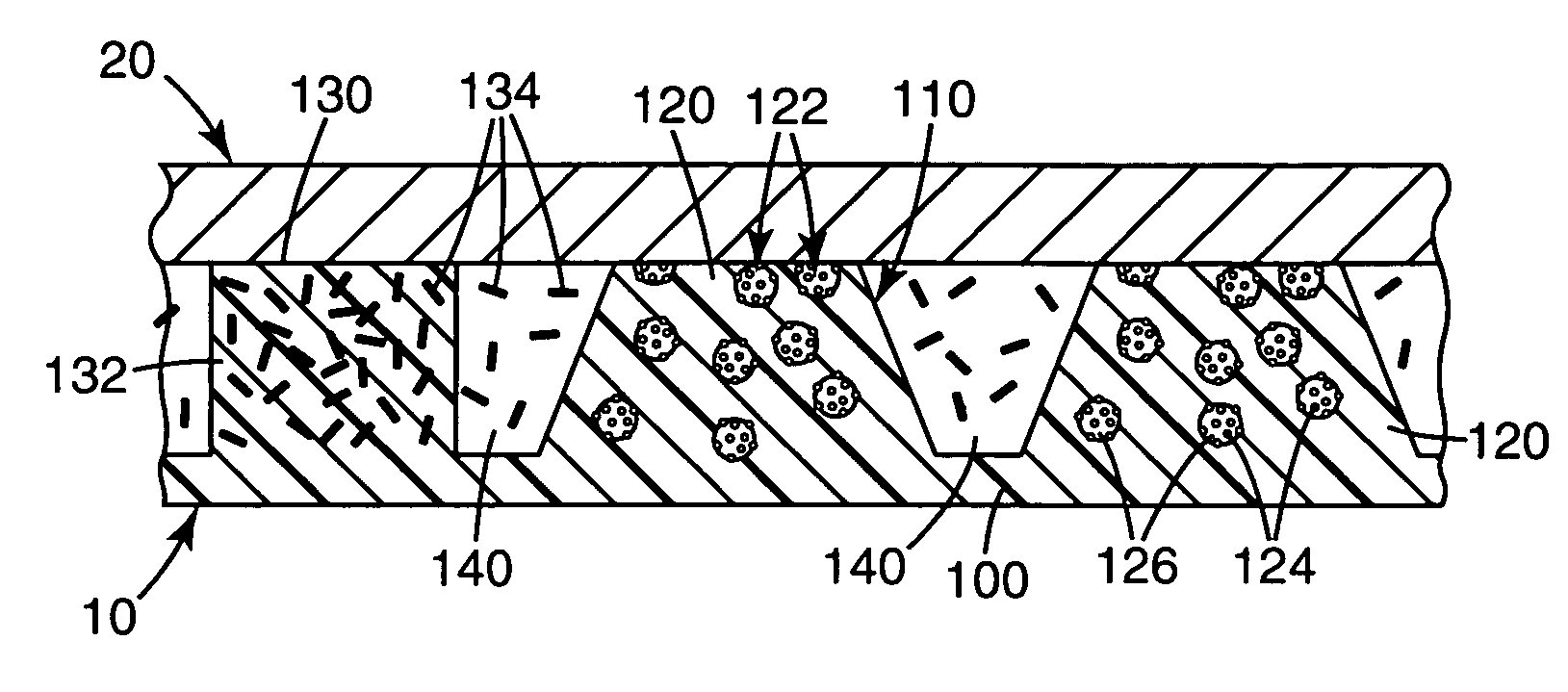

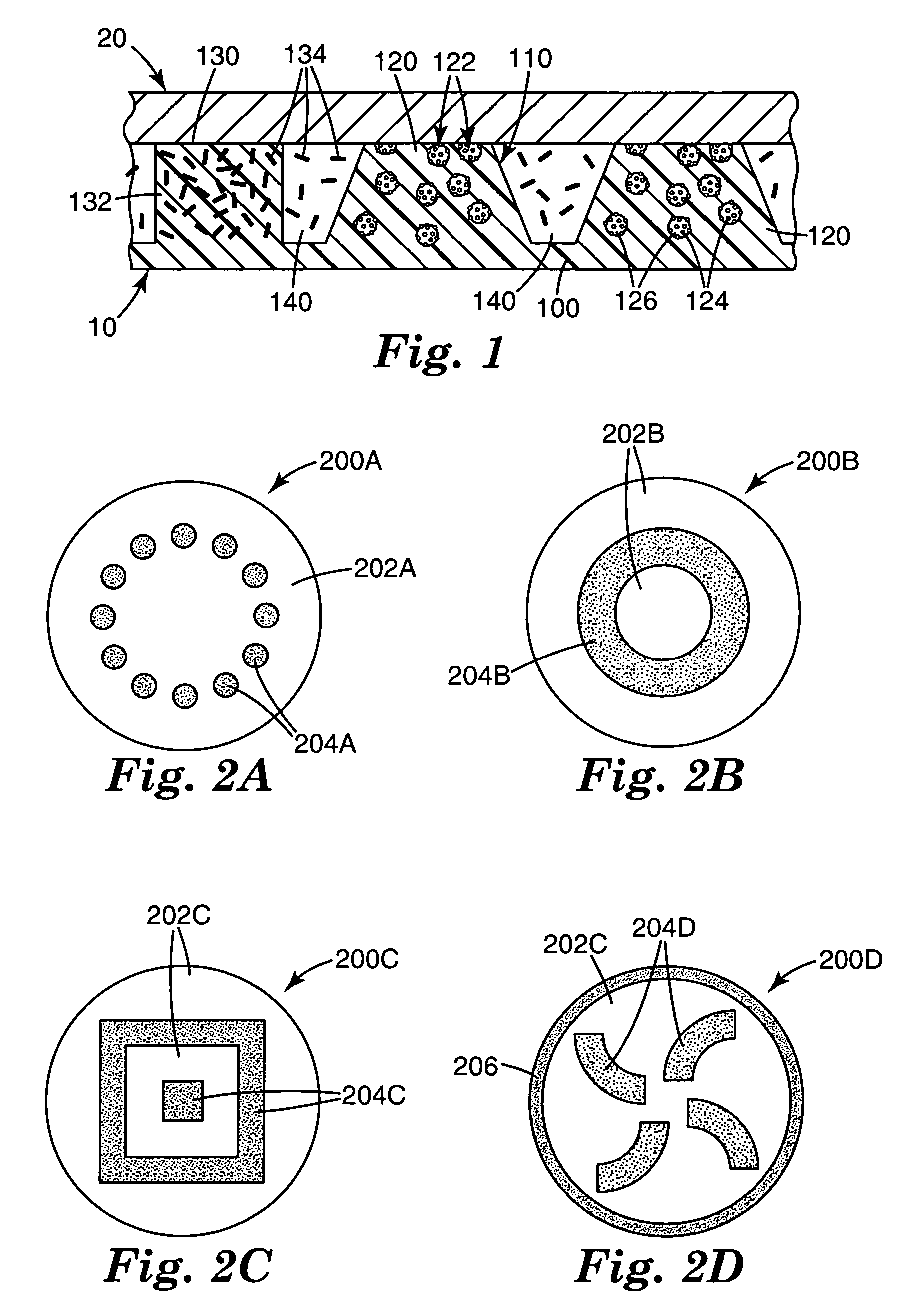

Abrasive agglomerate polishing method

ActiveUS20070026770A1Sufficient materialImprove faultPigmenting treatmentOther chemical processesHardnessMaterials science

Provided is a method of polishing comprising providing a workpiece, providing a fixed abrasive article, providing conditioning particles, and relatively moving the workpiece and the fixed abrasive article in the presence of the conditioning particles to modify the surface of the workpiece and to condition the fixed abrasive. The fixed abrasive article comprises a substrate having a first surface and a region of abrasive composites distributed on the first surface of the substrate. The abrasive composites include a composite binder and abrasive particles, which may be in abrasive agglomerates together with a matrix material. The abrasive particles are harder than the workpiece. The conditioning particles are sufficient to condition one or more of the composite binder, matrix material, and abrasive agglomerates. The hardness of the conditioning particles is less than the hardness of the workpiece and they do not substantially polish the workpiece.

Owner:3M INNOVATIVE PROPERTIES CO

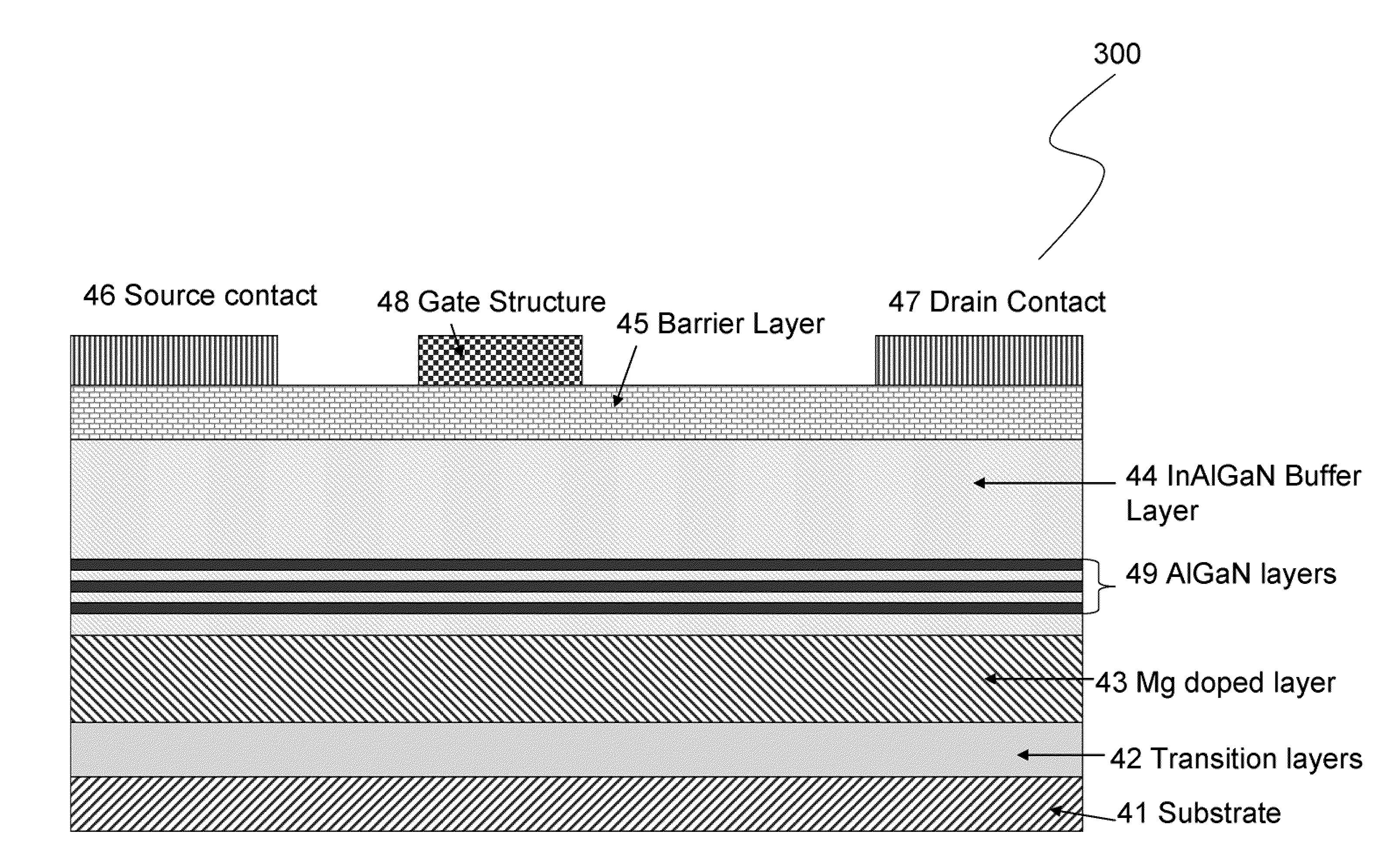

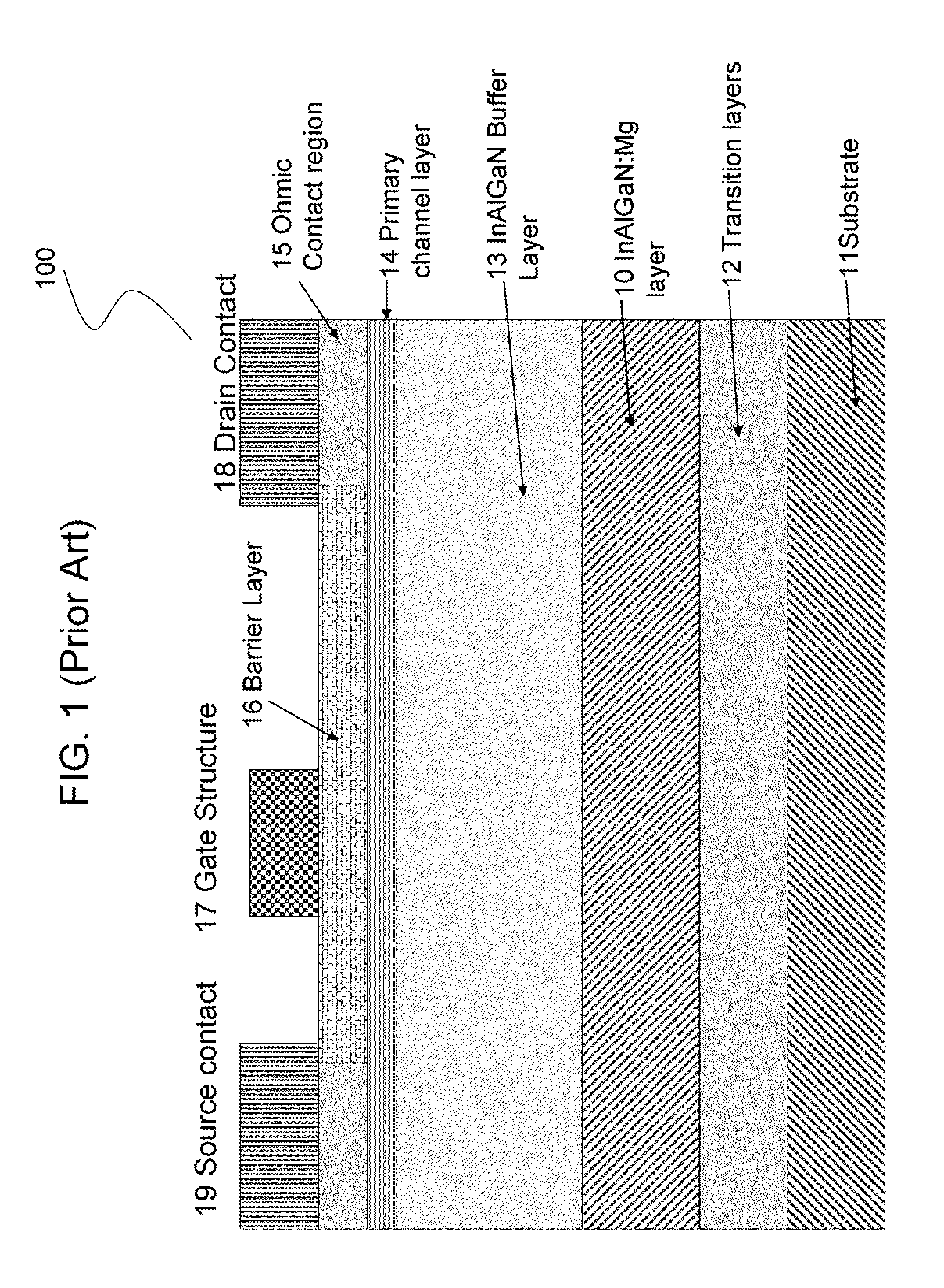

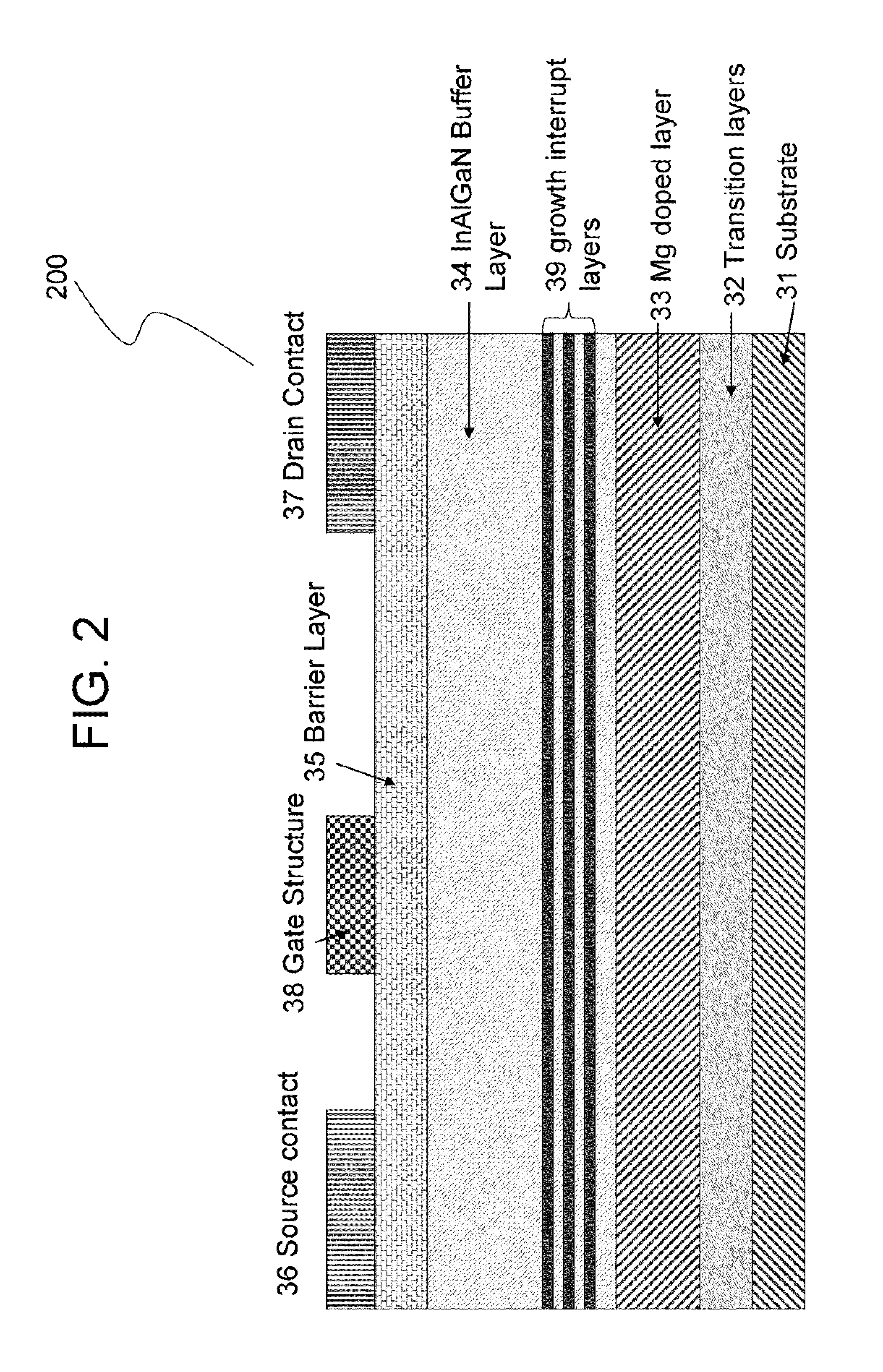

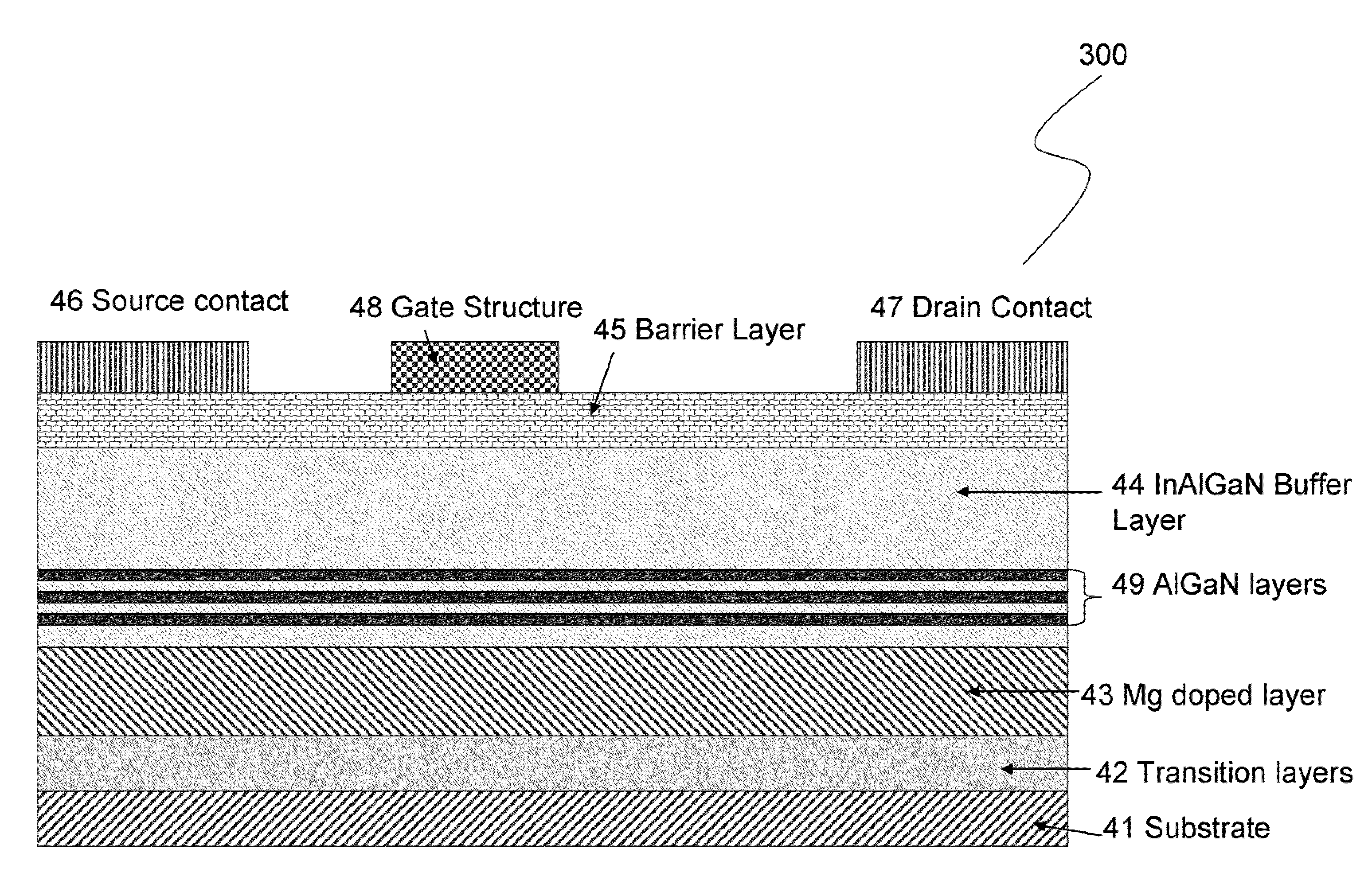

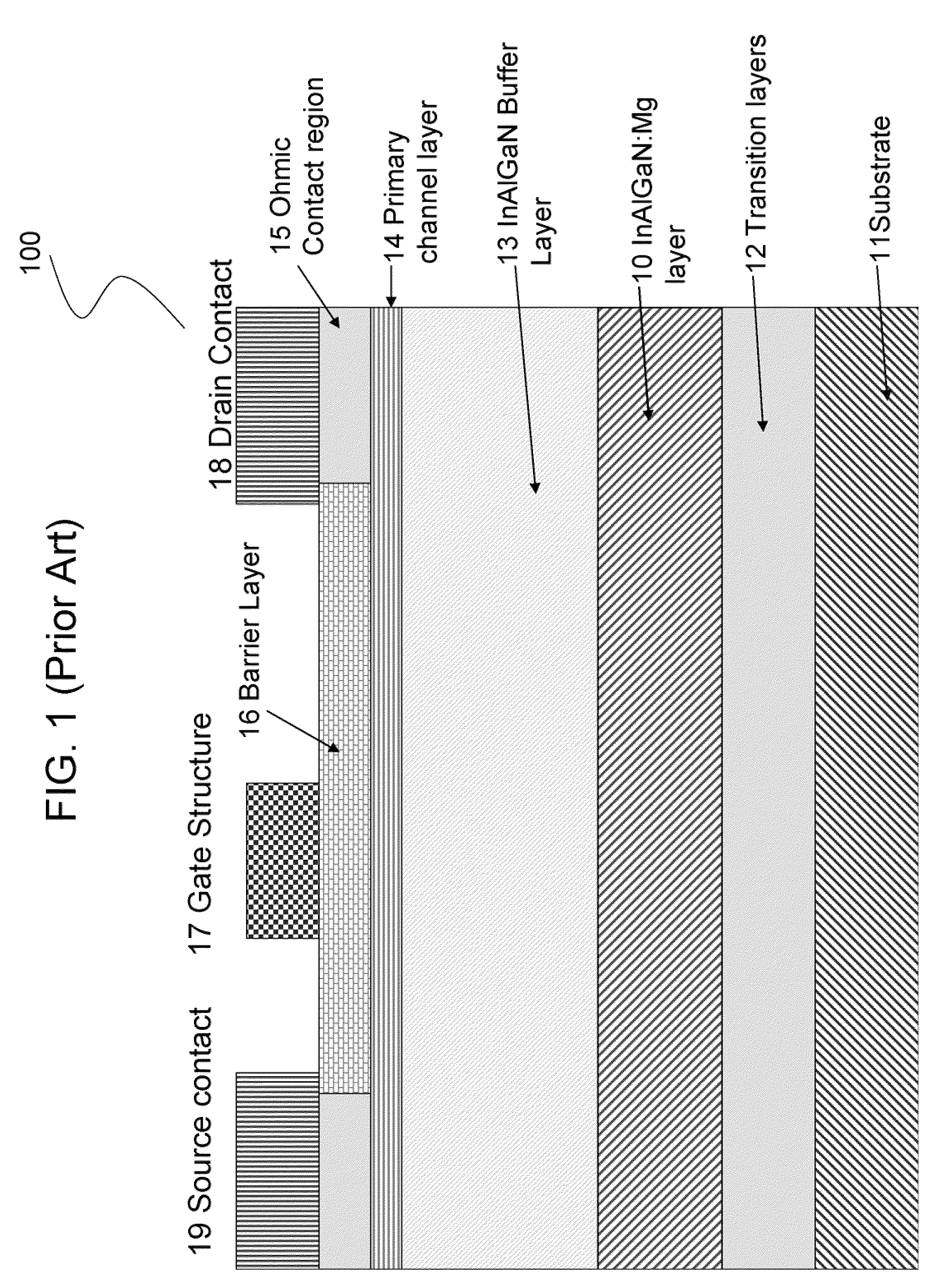

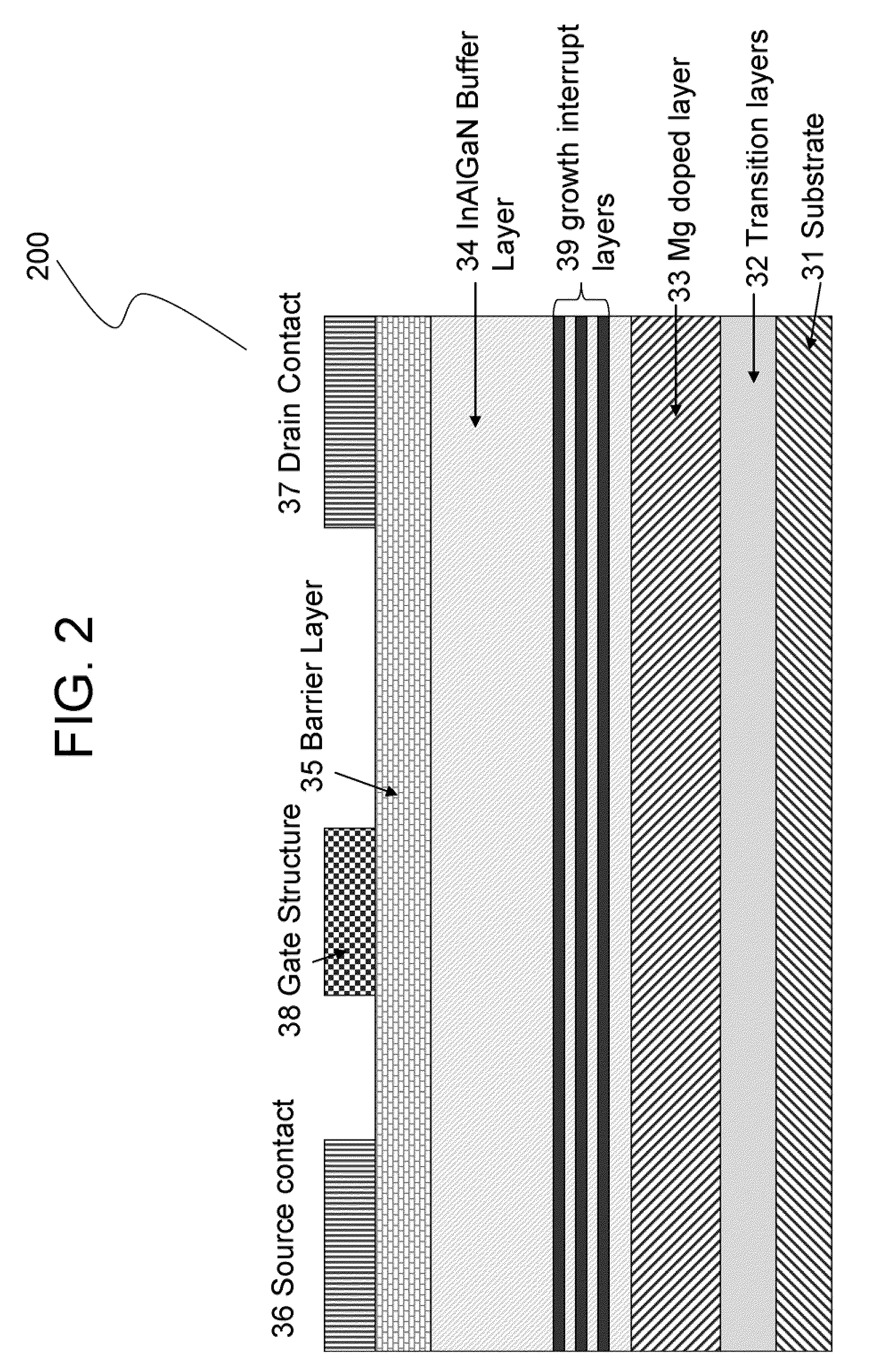

DOPANT DIFFUSION MODULATION IN GaN BUFFER LAYERS

ActiveUS20100258912A1Improve faultEliminate variationSemiconductor/solid-state device manufacturingSemiconductor devicesDopantStop flow

A semi-conductor crystal and method of forming the same. The method includes providing a flow of dopant and column III element containing gases, then stopping flow of dopant and column III element containing gases, reducing the temperature, restarting flow of column III containing gases and then elevating the temperature.

Owner:EFFICIENT POWER CONVERSION CORP

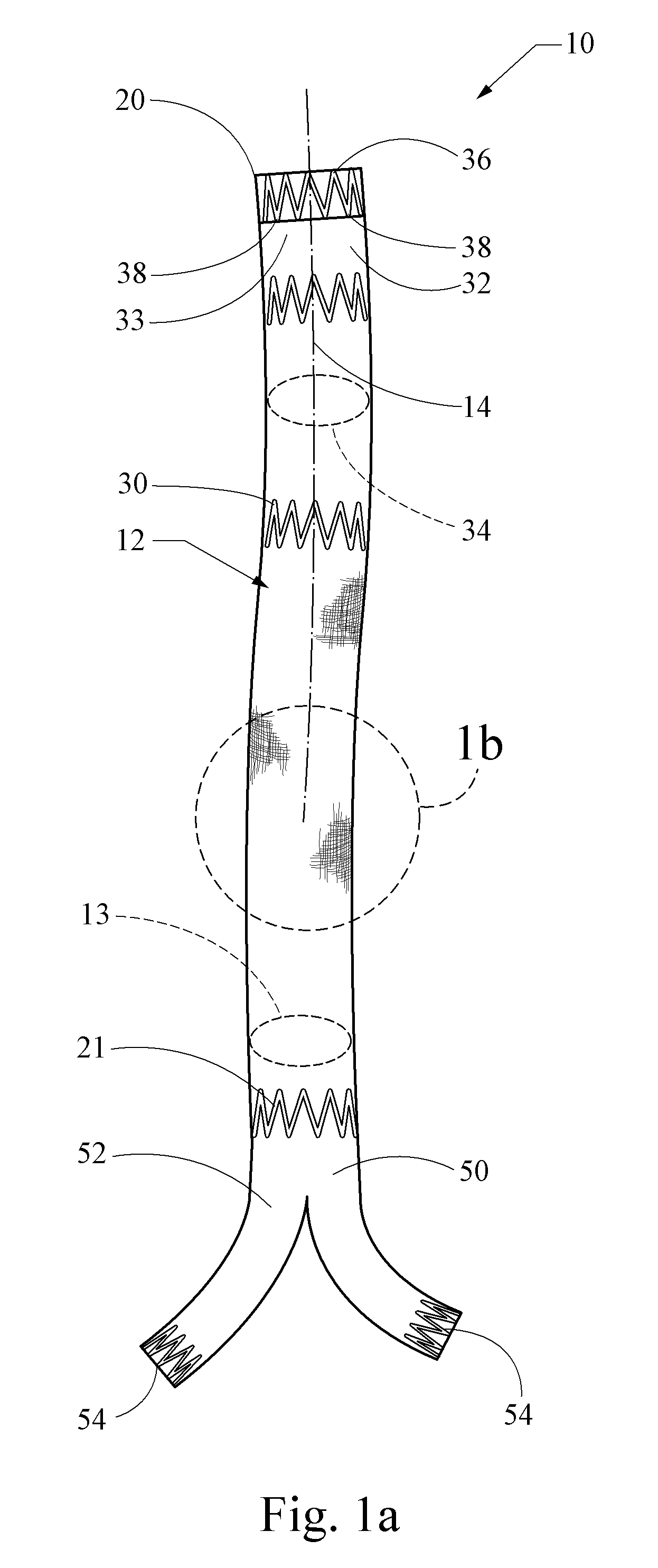

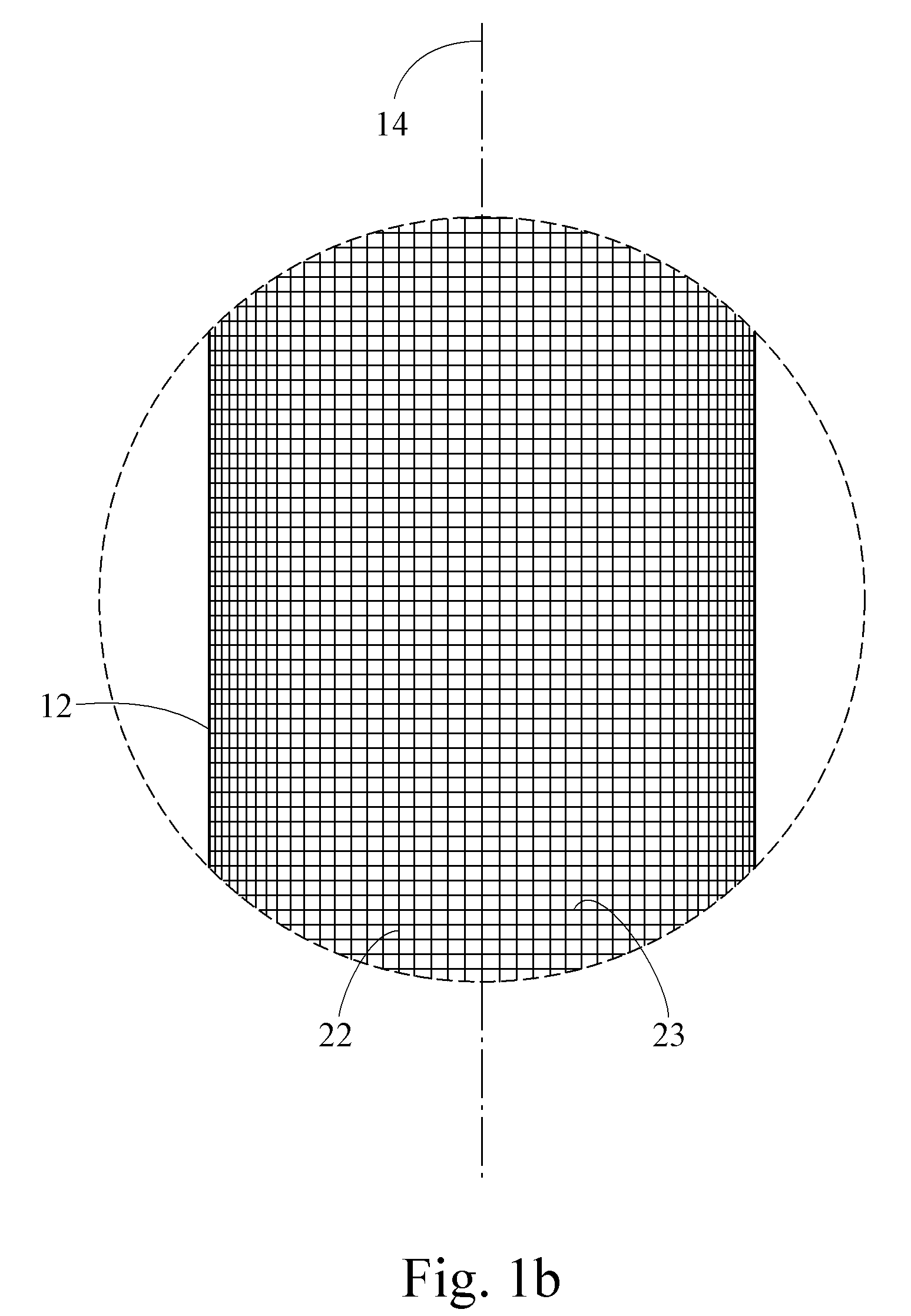

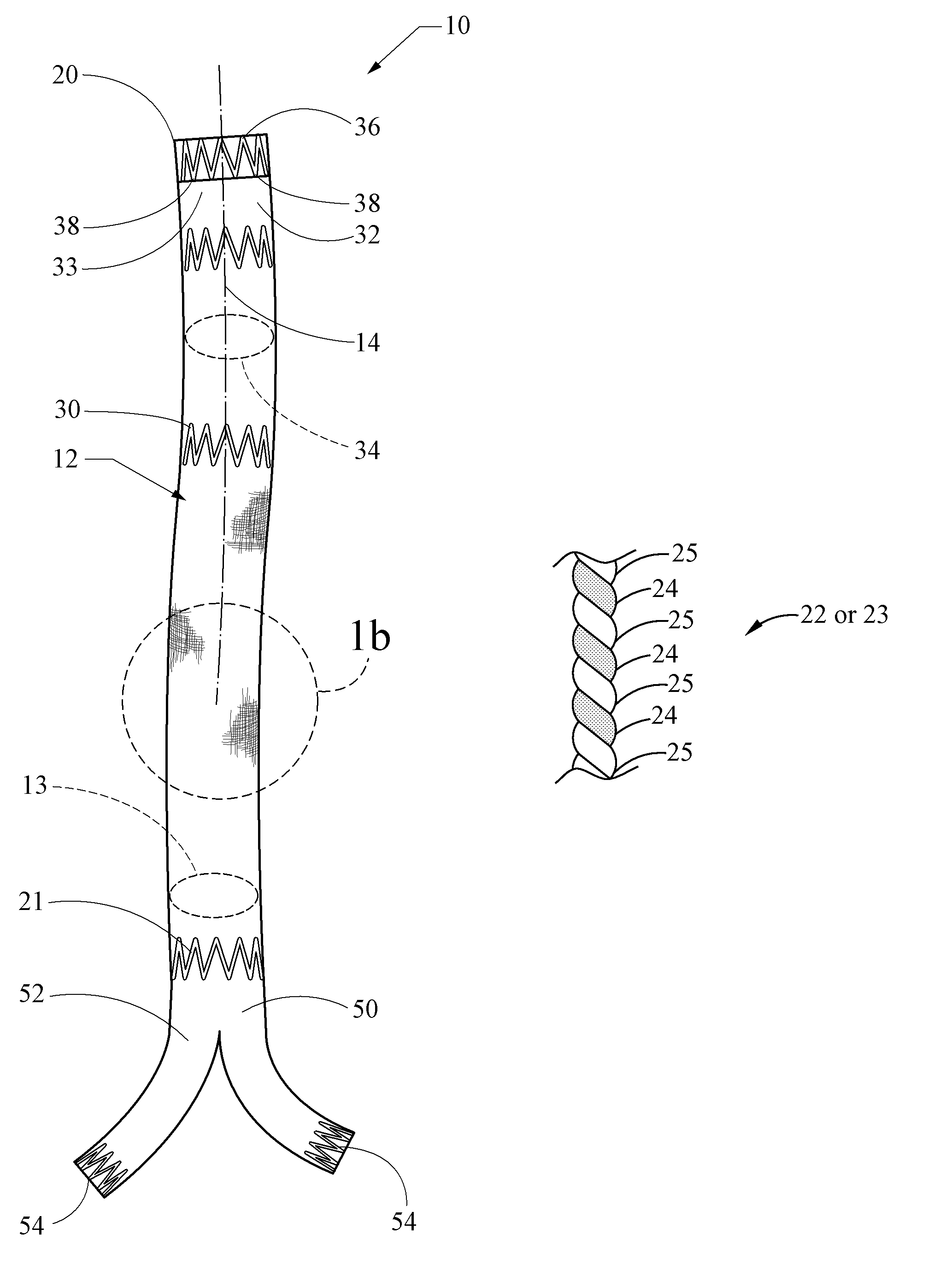

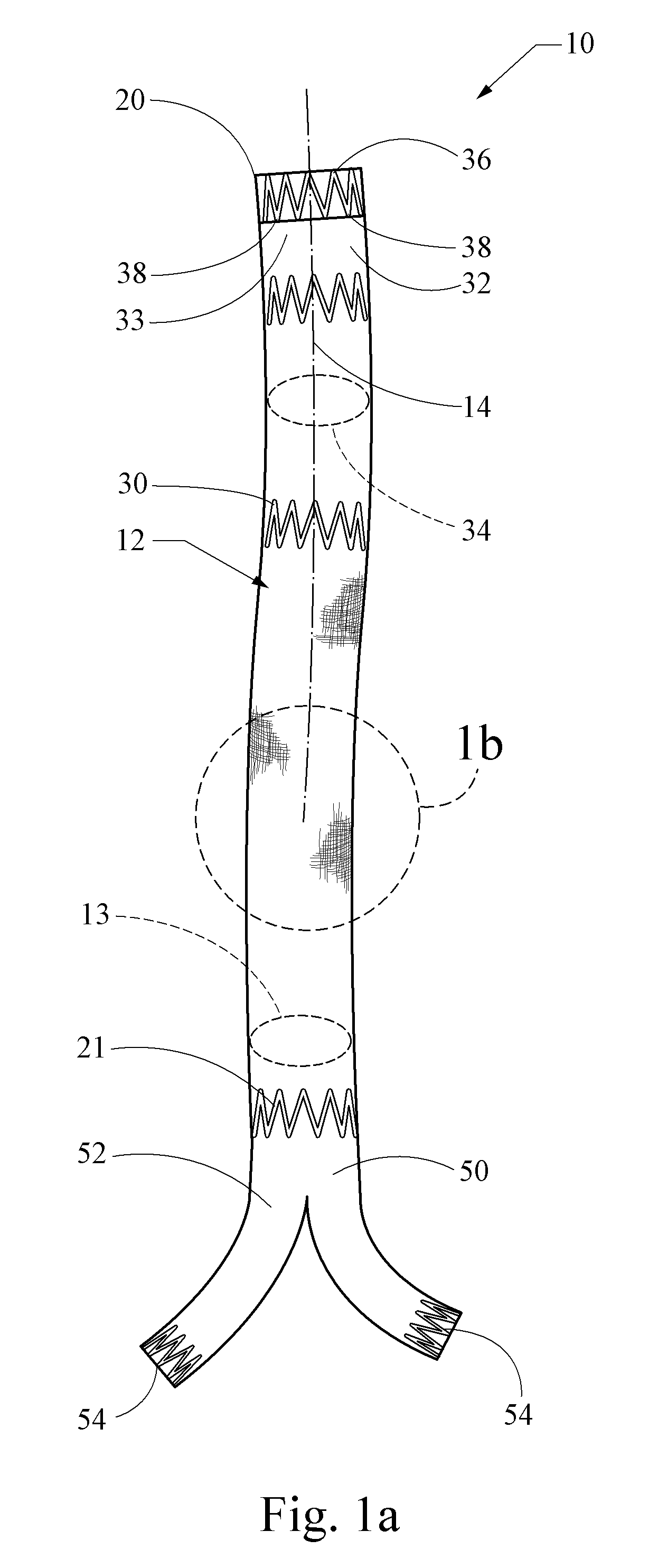

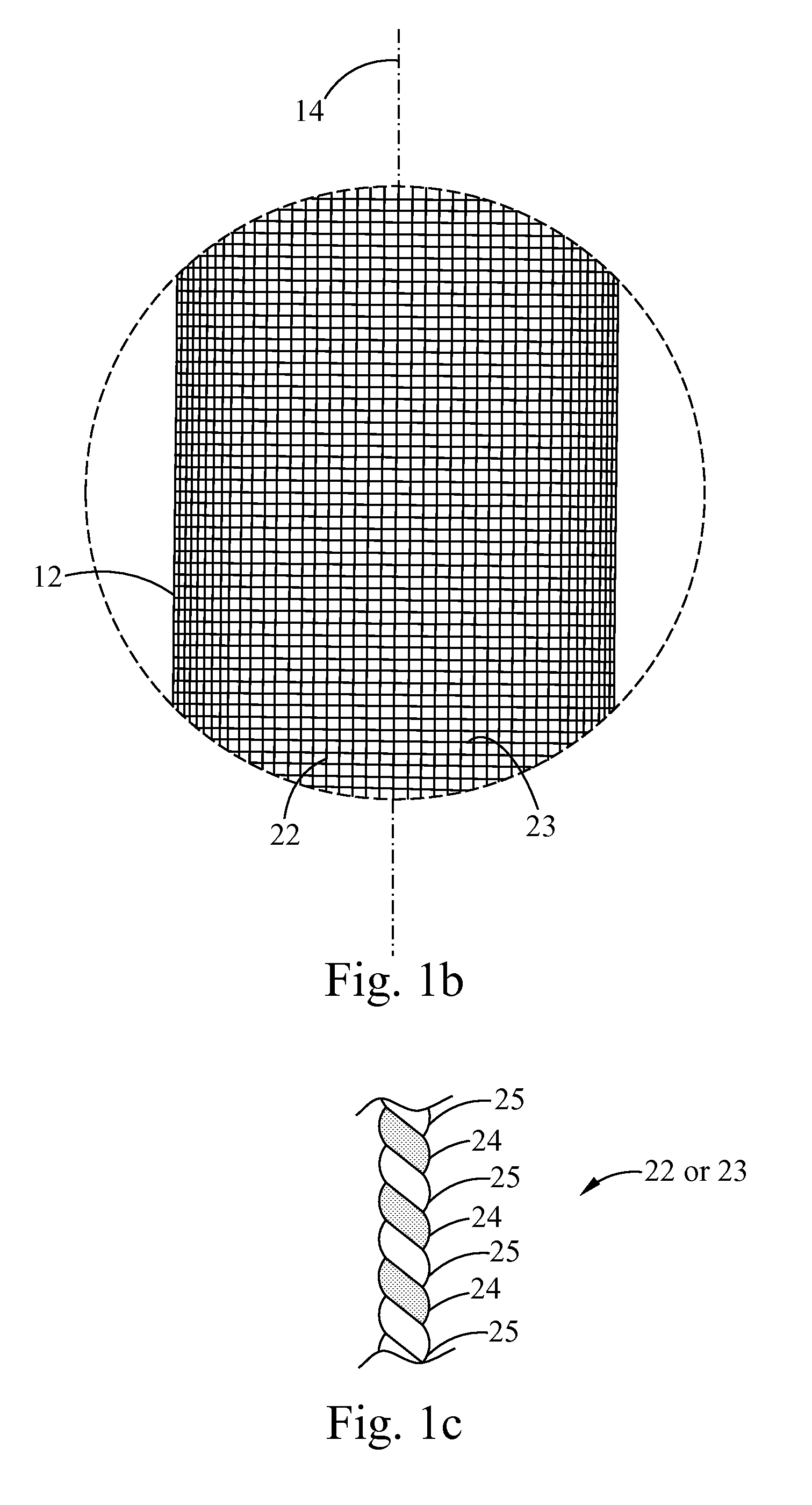

Implantable graft device having treated yarn and method for making same

Owner:COOK MEDICAL TECH LLC

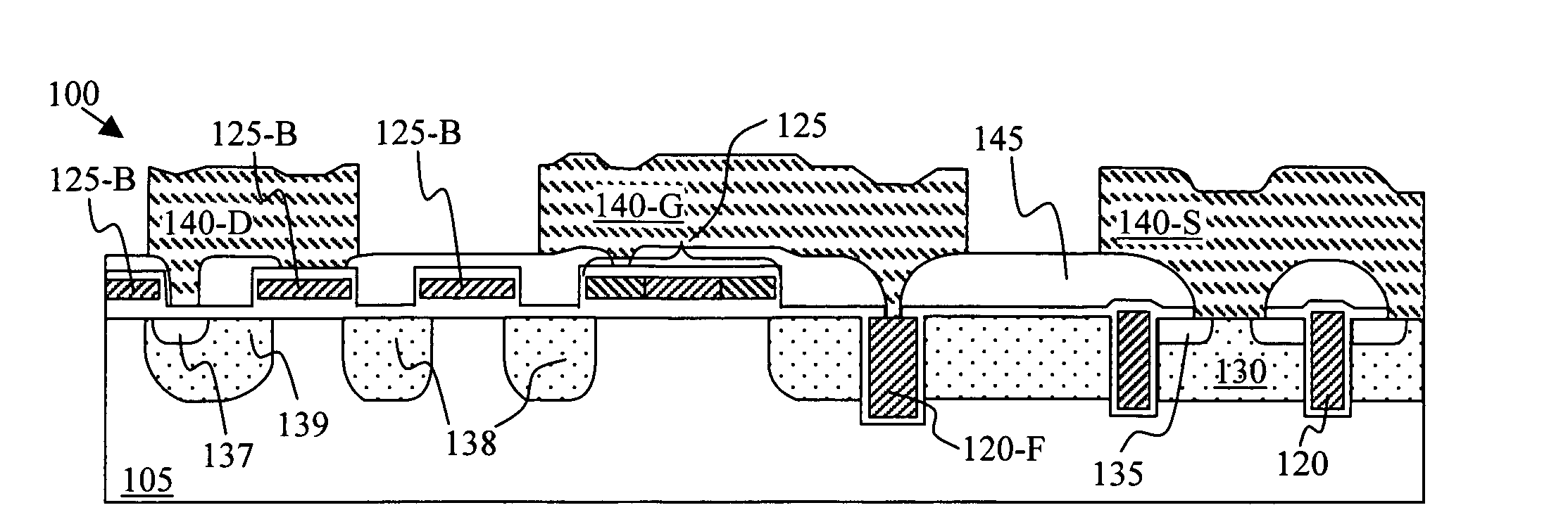

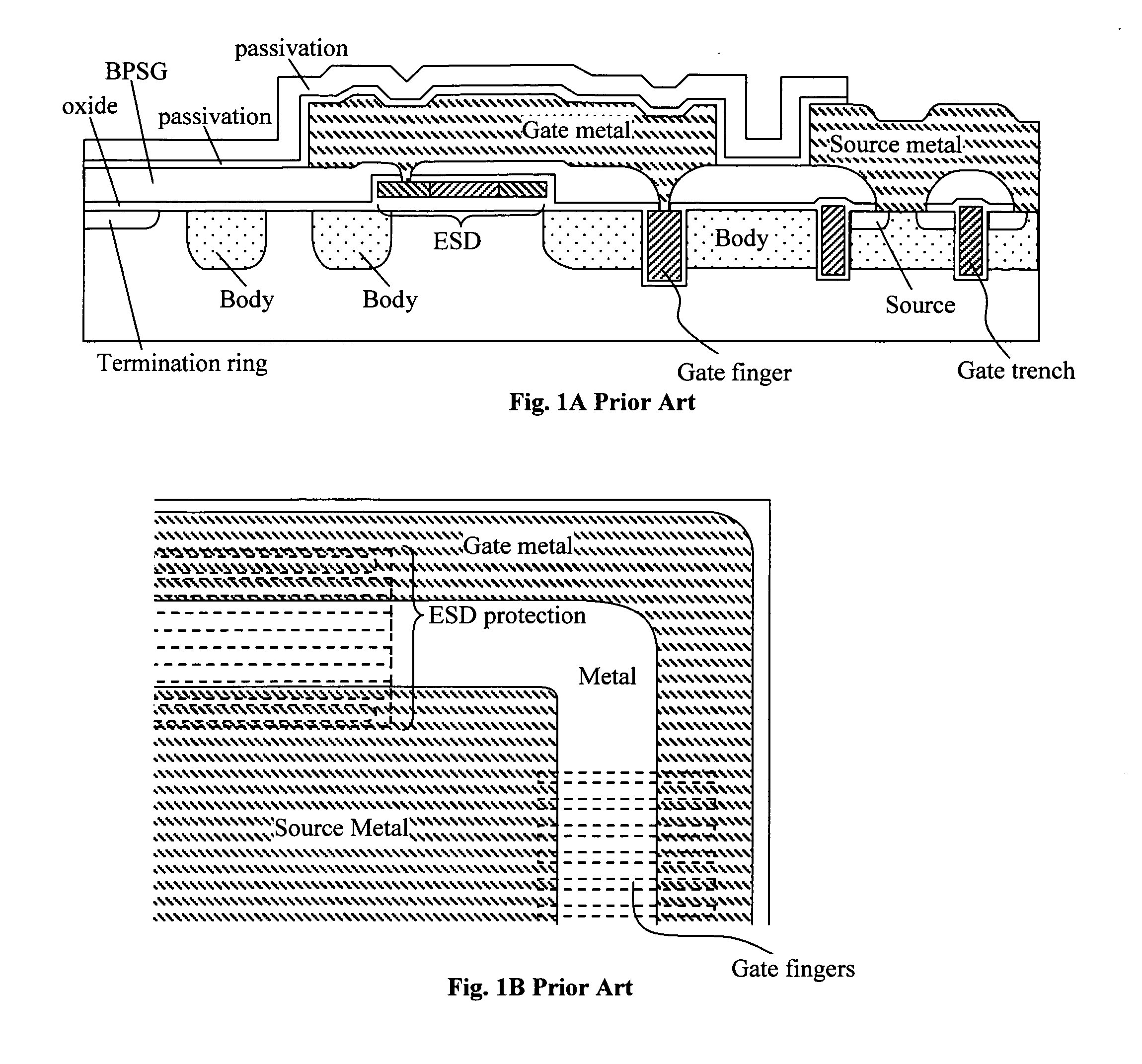

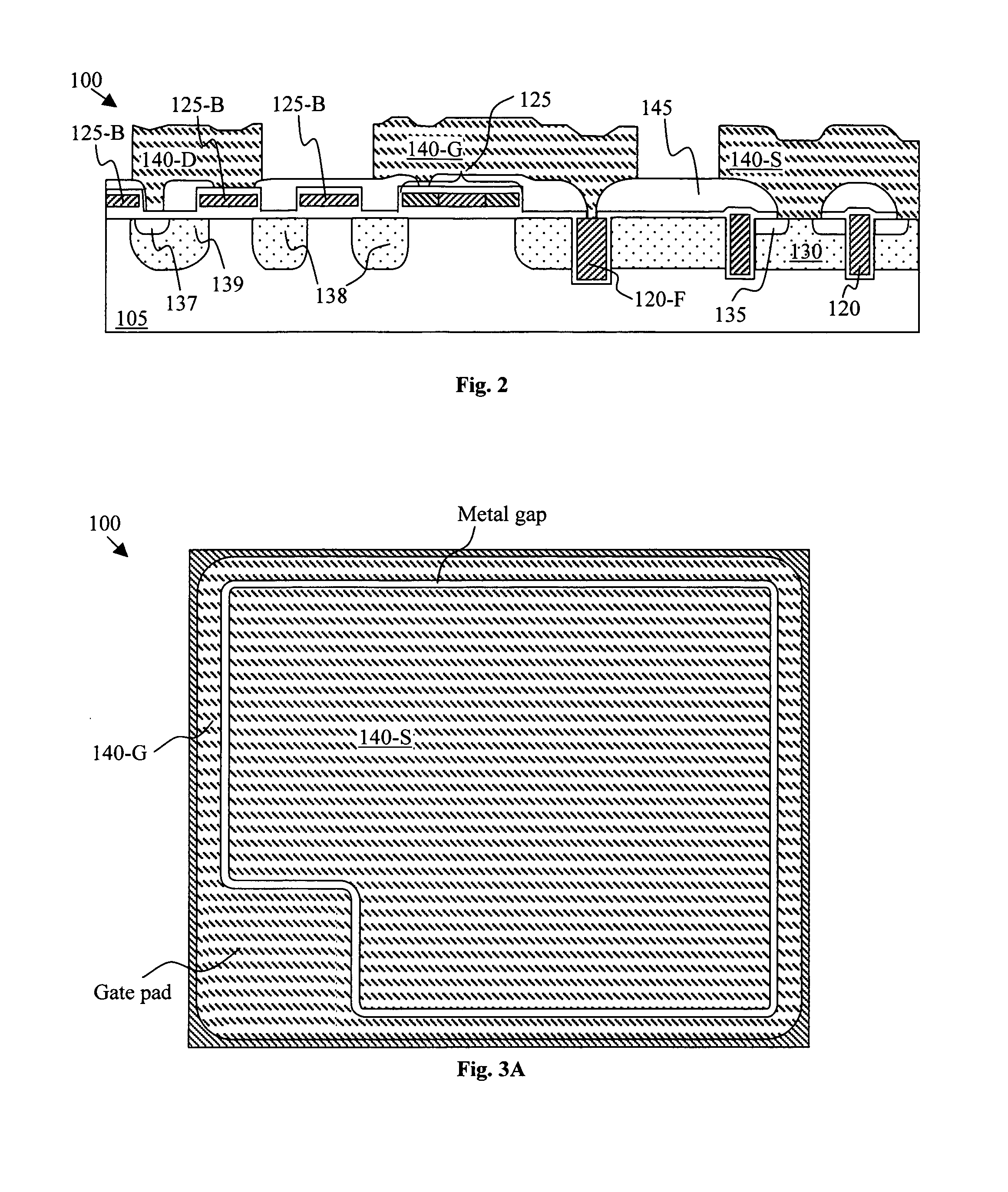

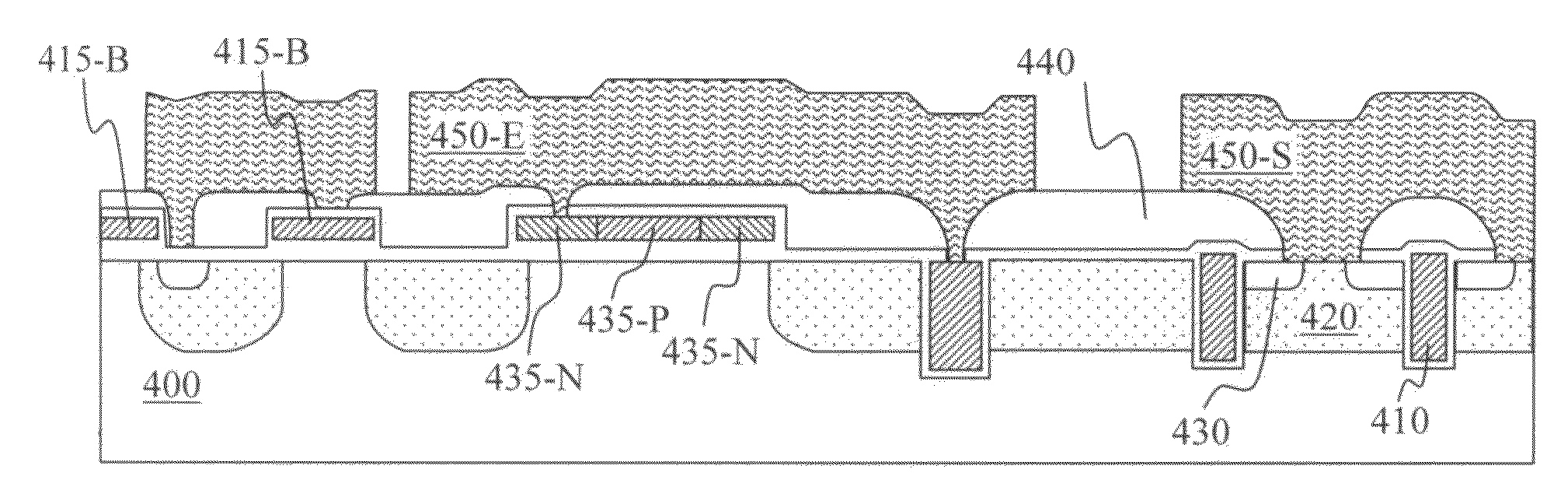

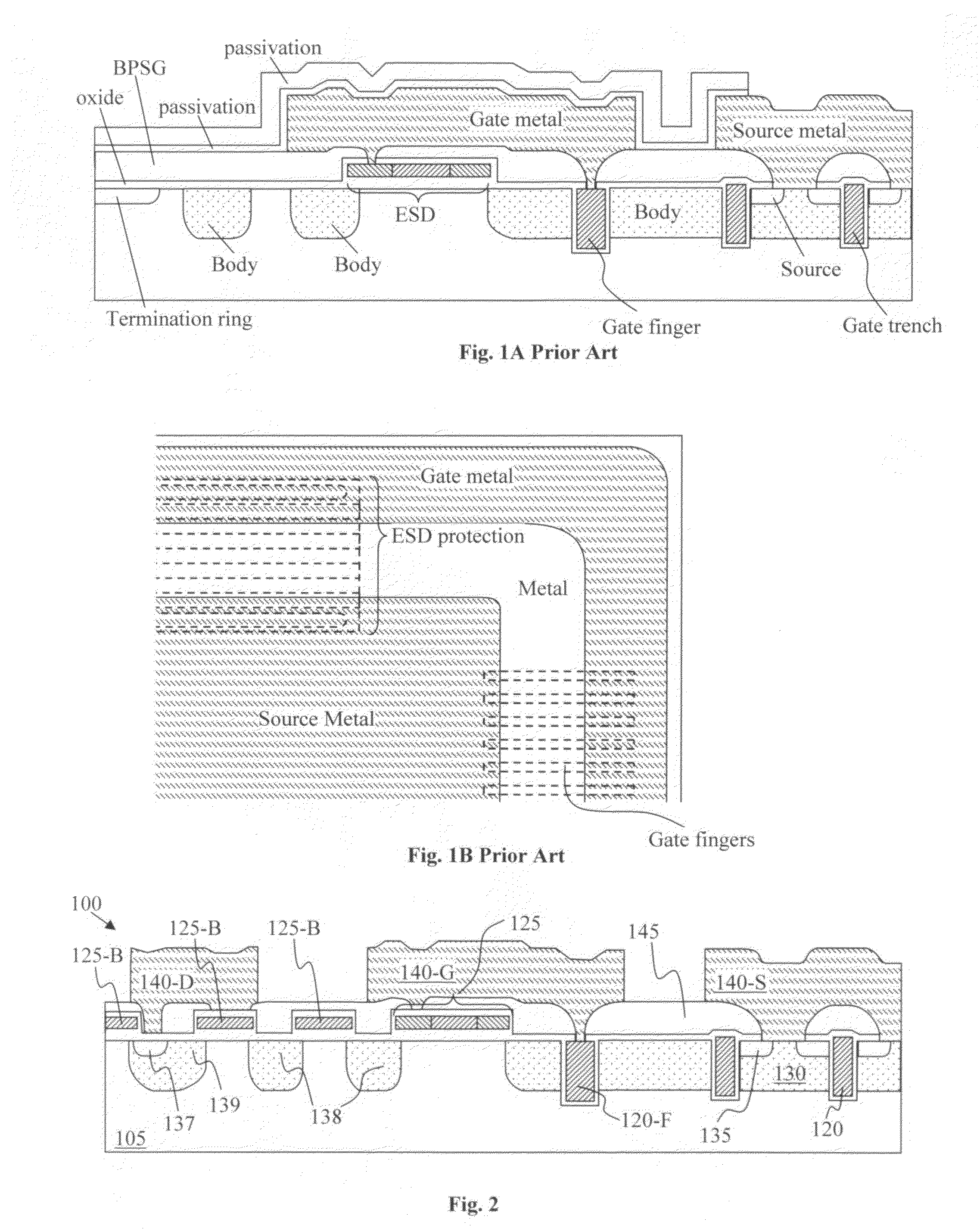

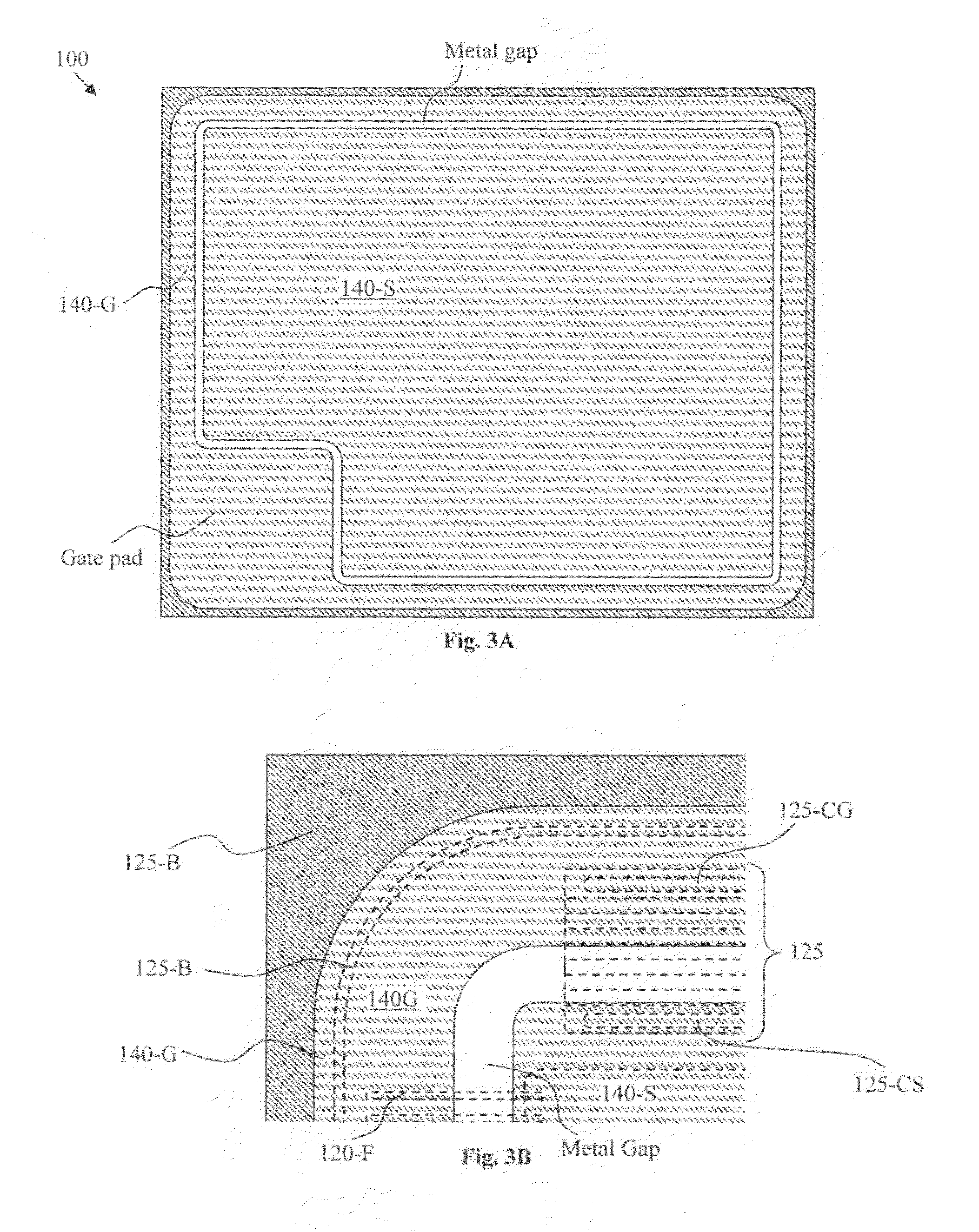

Reduced mask configuration for power mosfets with electrostatic discharge (ESD) circuit protection

ActiveUS20090166740A1Increase powerSimple manufacturing processTransistorSemiconductor/solid-state device detailsPower MOSFETBlocking layer

A semiconductor power device supported on a semiconductor substrate includes an electrostatic discharge (ESD) protection circuit disposed on a first portion of patterned ESD polysilicon layer on top of the semiconductor substrate. The semiconductor power device further includes a second portion of the patterned ESD polysilicon layer constituting a body implant ion block layer for blocking implanting body ions to enter into the semiconductor substrate below the body implant ion block layer. In an exemplary embodiment, the electrostatic discharge (ESD) polysilicon layer on top of the semiconductor substrate further covering a scribe line on an edge of the semiconductor device whereby a passivation layer is no longer required manufacturing the semiconductor device for reducing a mask required for patterning the passivation layer.

Owner:ALPHA & OMEGA SEMICON LTD

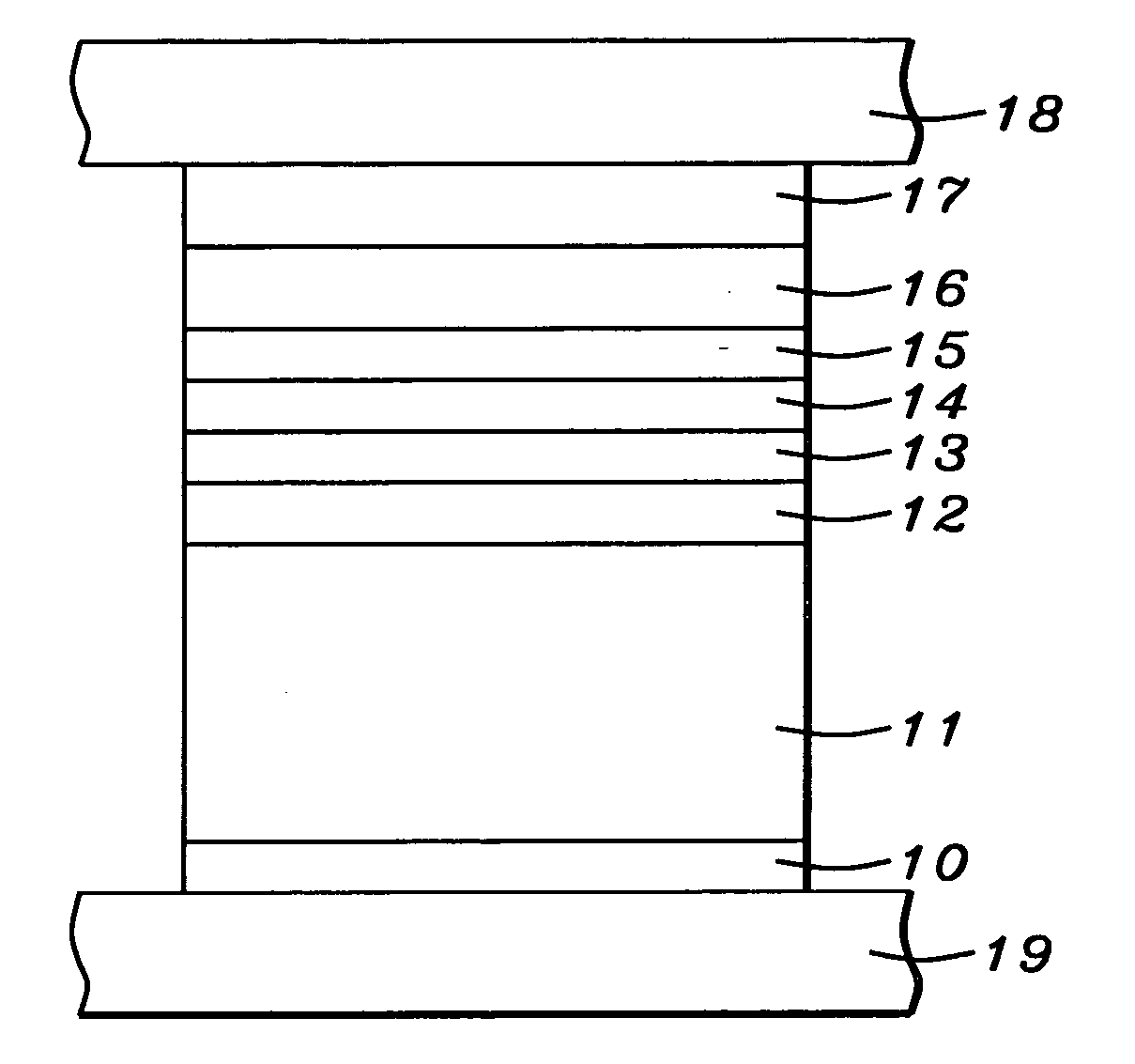

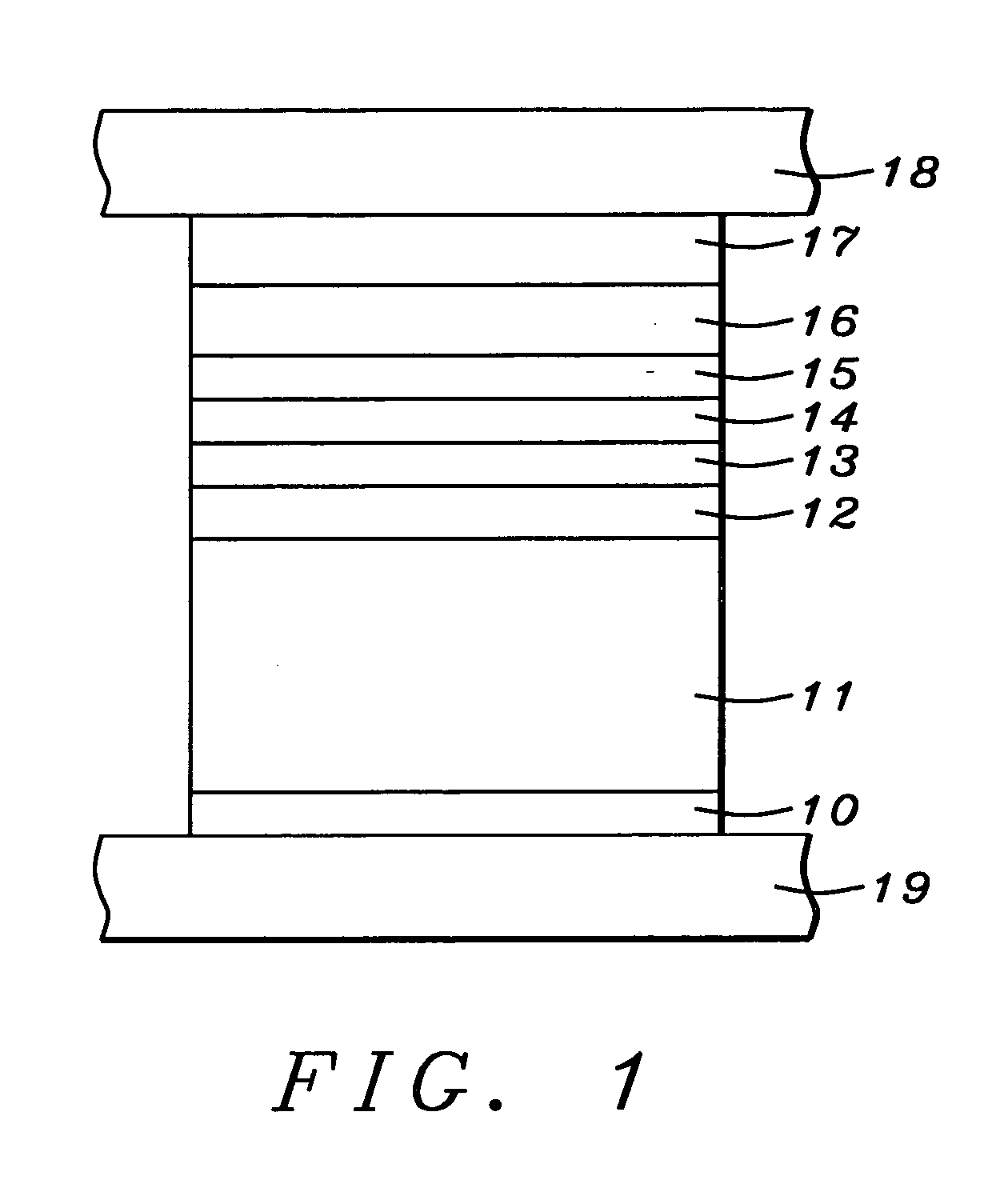

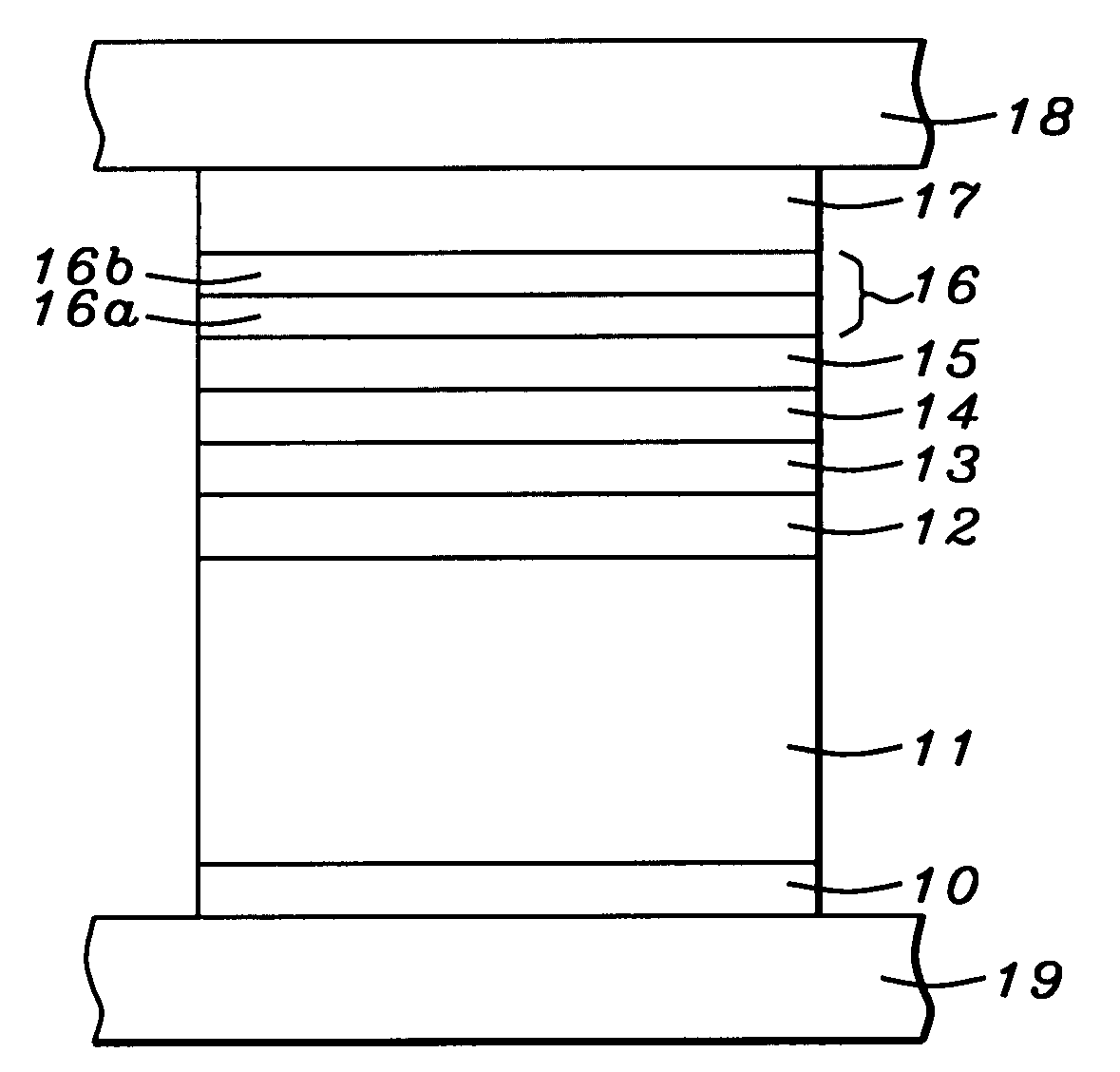

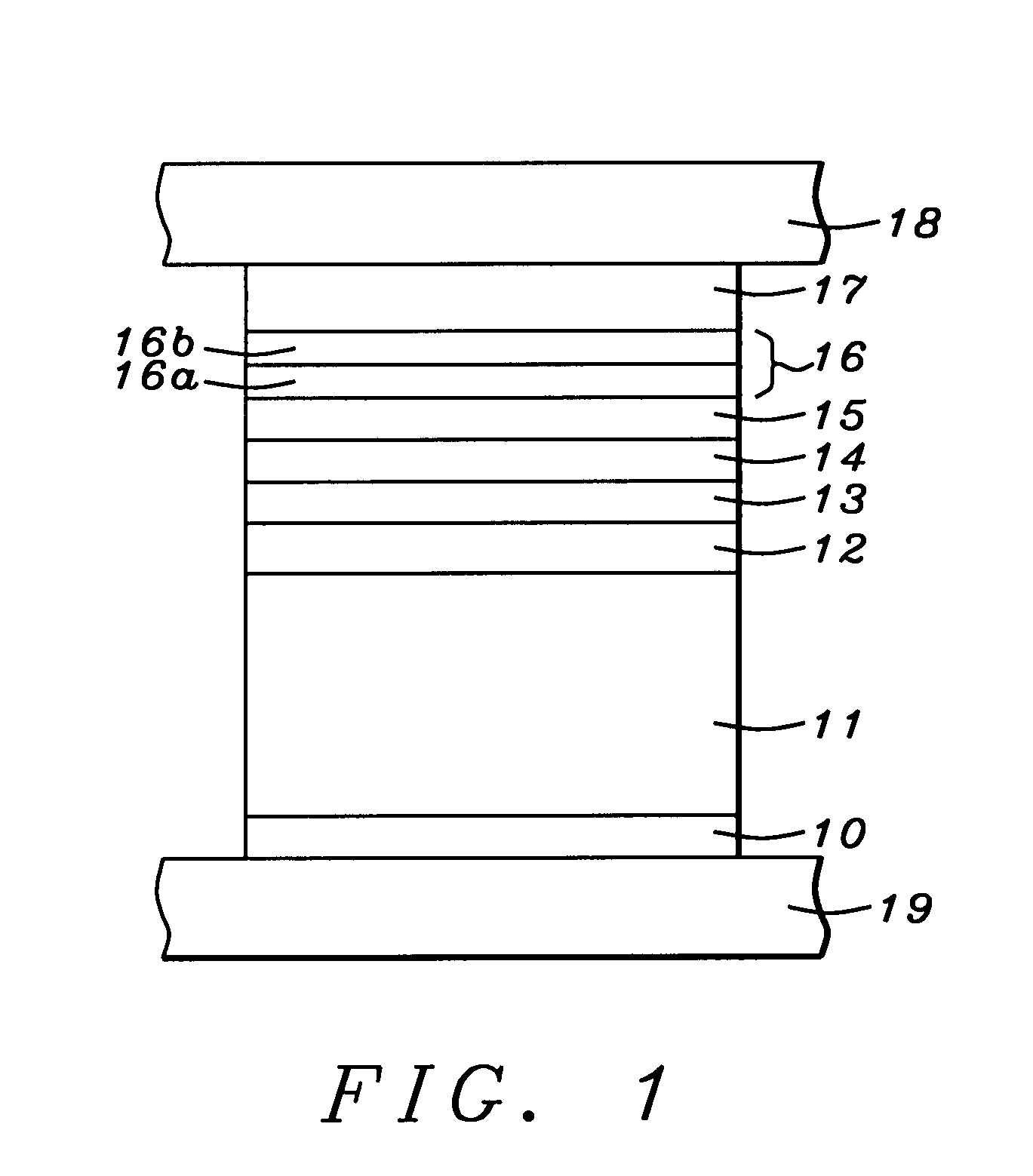

Amorphous layers in a magnetic tunnel junction device

InactiveUS20060209590A1High sensitivityImprove faultRecord information storageManufacture of flux-sensitive headsElectricityDielectric layer

An improved TMR device is disclosed. The ferromagnetic layers of the device, particularly those that contact the dielectric tunneling layer have an amorphous structure as well as a minimum thickness (of about 15 Å). A preferred material for contacting the dielectric layer is CoFeB. Ways of overcoming problems relating to magnetostriction are disclosed and a description of a process for manufacturing the device is included.

Owner:HEADWAY TECH INC +1

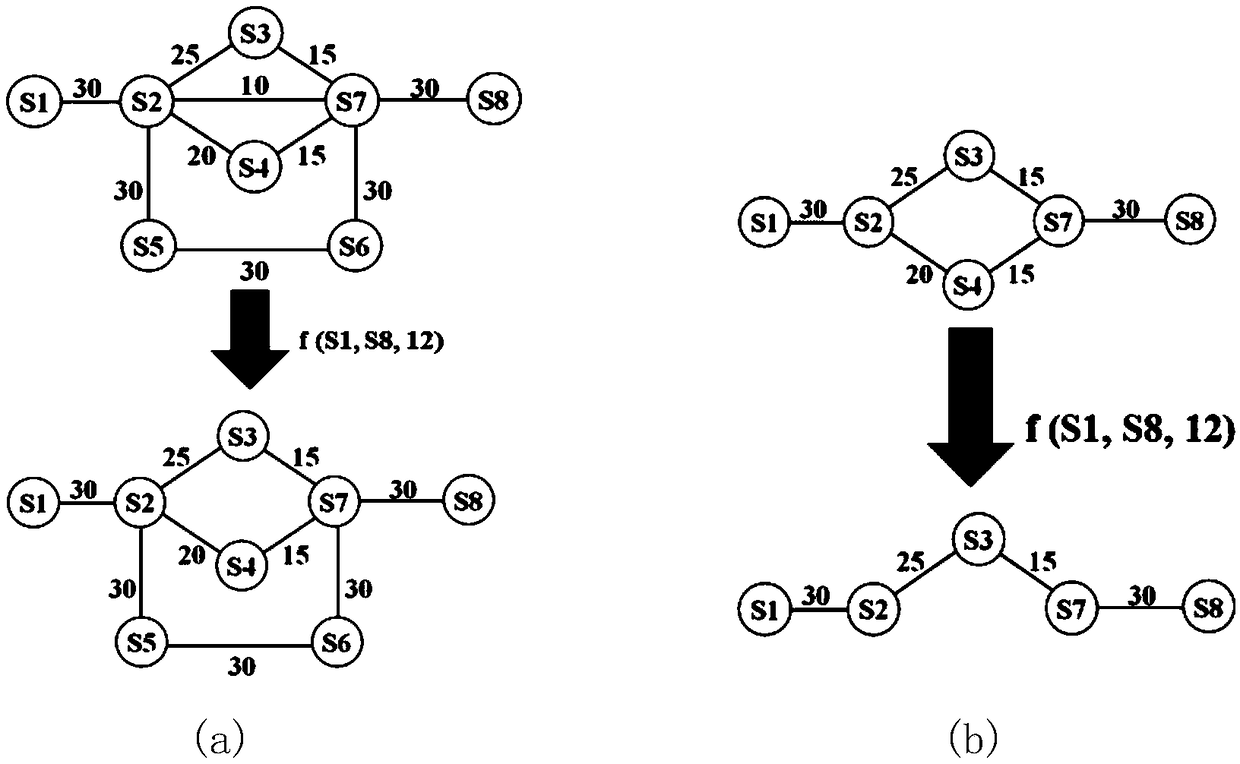

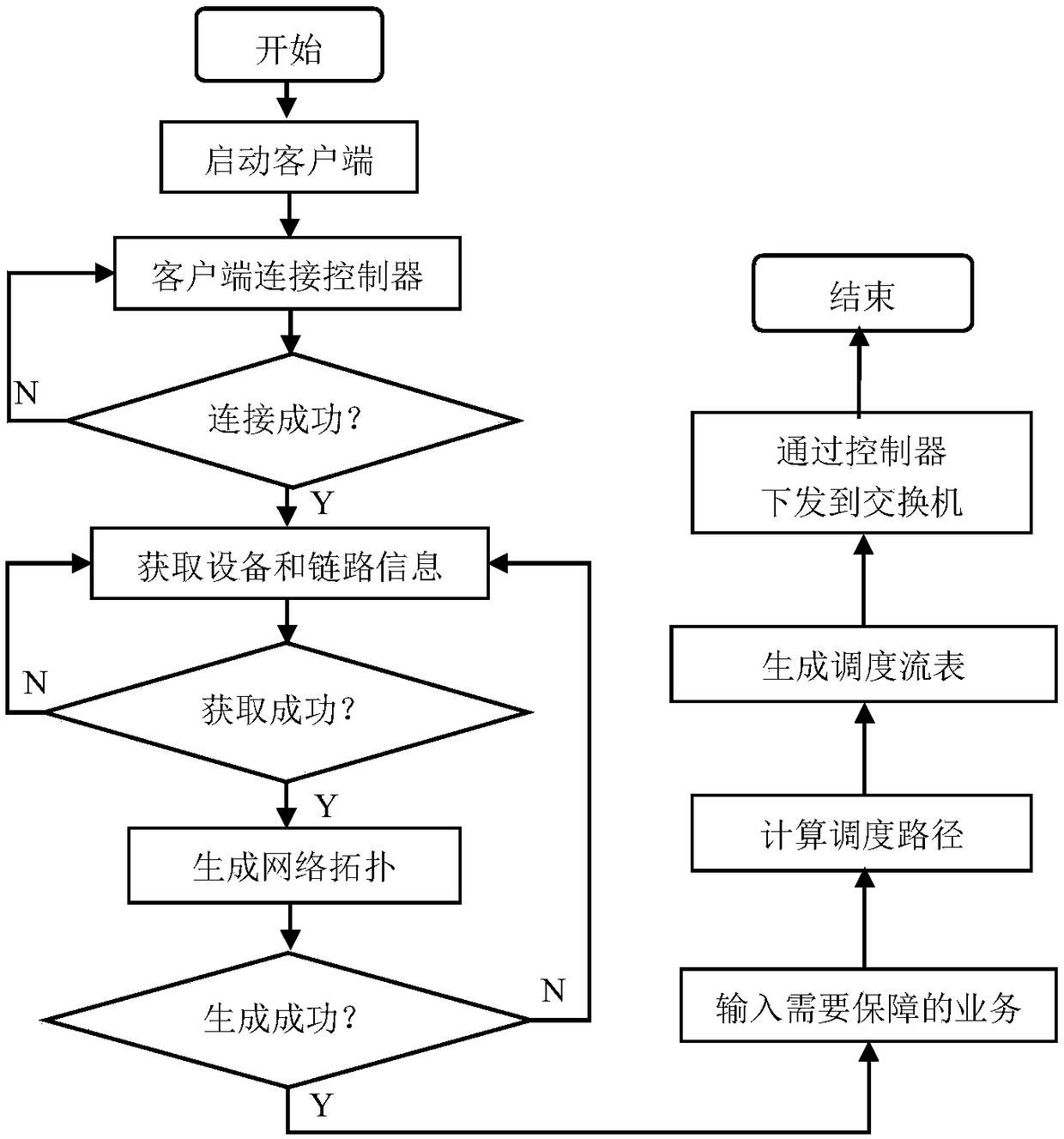

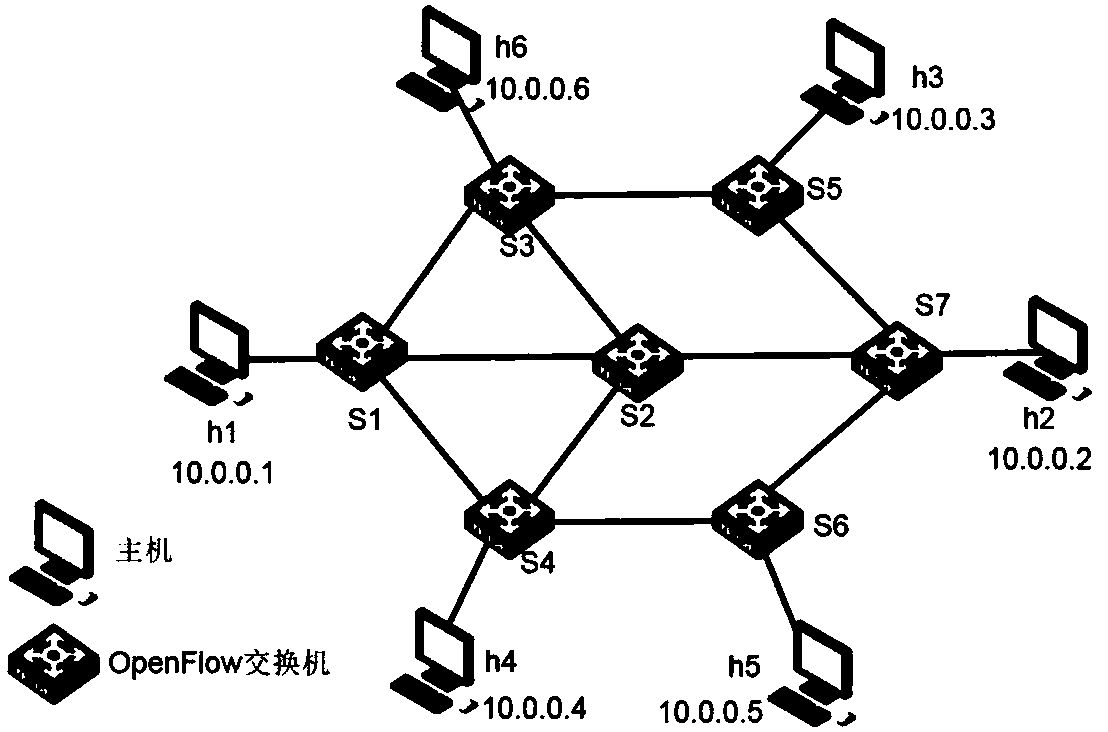

Method for traffic monitoring and business service quality guarantee strategy based on SDN

InactiveCN108809857AReduce the impactGuaranteed service qualityData switching networksService flowTraffic capacity

The invention discloses a method for a traffic monitoring and business service quality guarantee strategy based on SDN. The method comprises the following steps: a. creating a network topology under the SDN architecture, configuring an Openflow switch, and establishing a connection between the switch and an SDN controller; b. providing an open northbound API interface on the SDN controller; c, obtaining, by an application system program, complete device information and link information; d, inputting the business to be guaranteed according to the business requirements; e, according to a sourcedestination address of the service flow, transmitting an algorithm class to calculate a scheduling path, and generating the optimal scheduling path of the current network; f. transmitting the scheduling path in e into a strategy generation class, generating a scheduling flow table in combination with the business guarantee strategy in d, and issuing the scheduling flow table into the switch; and g. adding a data transmission queue to a switch port according to the scheduling flow table in f. By adoption of the method disclosed by the invention, the stable operation of the network business, theefficient use of the link bandwidth and the maximum optimization of the whole network performance are maximally guaranteed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

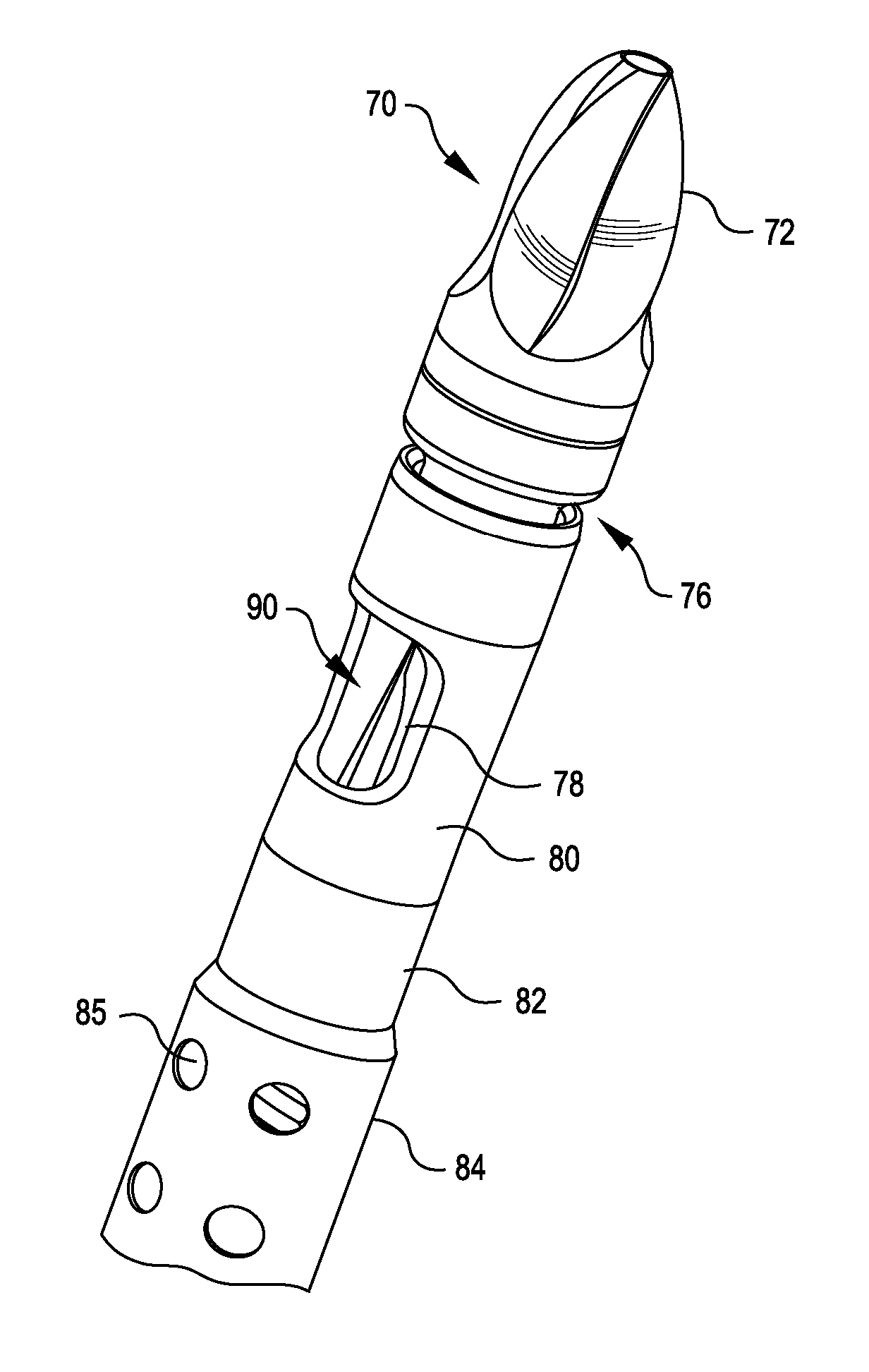

Interventional catheters incorporating an active aspiration system

ActiveUS8394078B2Improve faultAssisted movementCatheterExcision instrumentsCatheter deviceTarget site

An interventional catheter assembly comprises an operating head for removing obstructive material from a target site in a body lumen or cavity and at least one aspiration port located proximal to the operating head and penetrating the catheter assembly, the aspiration port being in communication with a sealed lumen that communicates with a vacuum system for withdrawing aspirate fluid and obstructive material from the target site. The interventional catheter incorporates an elongated guidewire lumen bushing extending proximally from a distal region of the operating head to reduce the clearance between the guidewire and the internal surface of the guidewire lumen during operation of the interventional catheter. This feature restricts entry of fluid and debris into the guidewire lumen and promotes maintenance of consistent and high aspiration pressure and volume during operation of the aspiration system and interventional catheter assembly.

Owner:BOSTON SCI MEDICAL DEVICE LTD

Dopant diffusion modulation in GaN buffer layers

ActiveUS8431960B2Improve faultEliminate variationSemiconductor/solid-state device manufacturingSemiconductor devicesDopantNitrogen

An enhancement mode gallium nitride (GaN) transistor with a Mg doped layer and a Mg growth interruption (diffusion barrier) layer to trap excess or residual Mg dopant. The Mg growth interruption (diffusion barrier) layer is formed by growing GaN, stopping the supply of gallium while maintaining a supply of ammonia or other nitrogen containing source to form a layer of magnesium nitride (MgN), and then resuming the flow of gallium to form a GaN layer to seal in the layer of MgN.

Owner:EFFICIENT POWER CONVERSION CORP

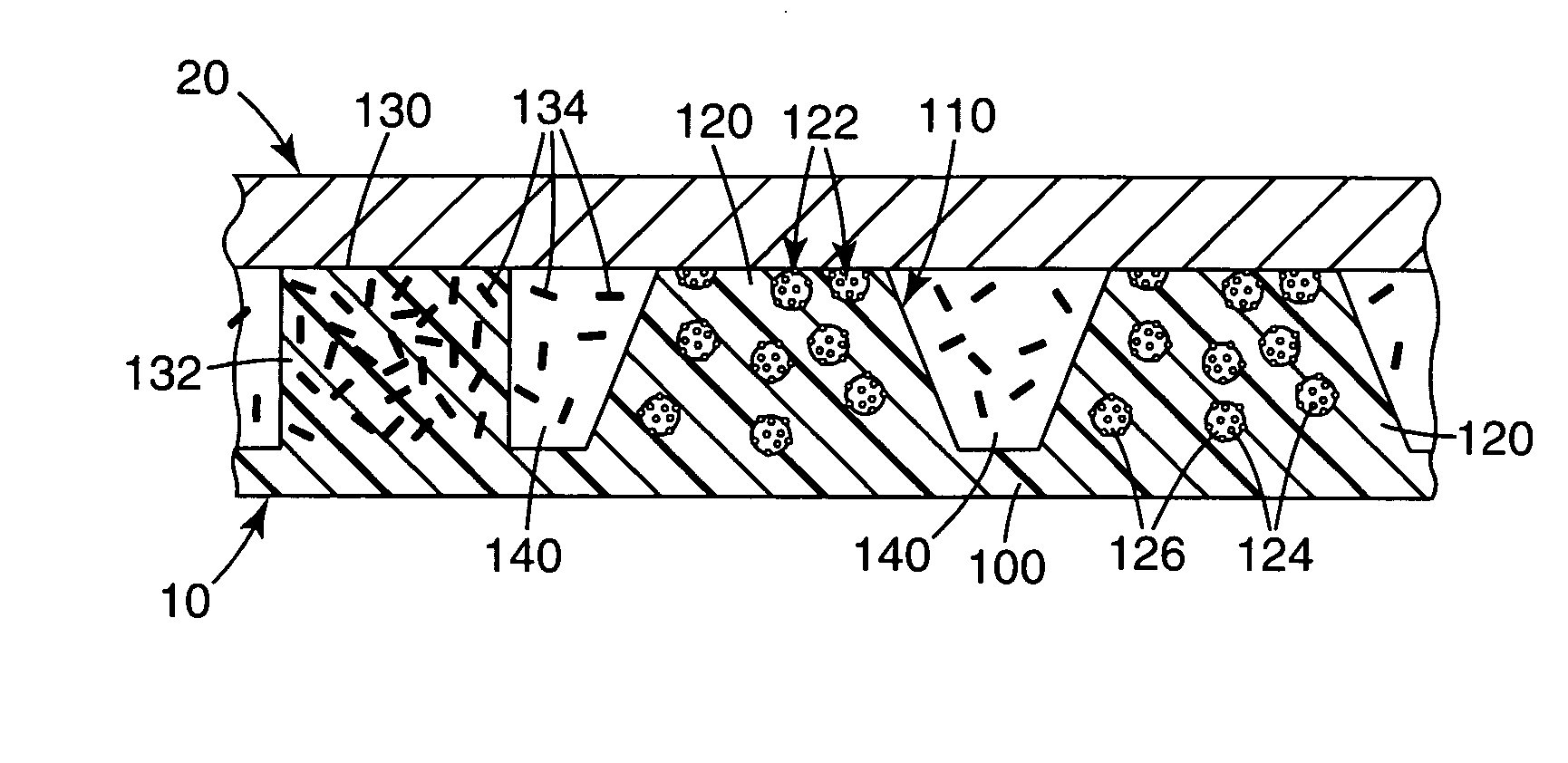

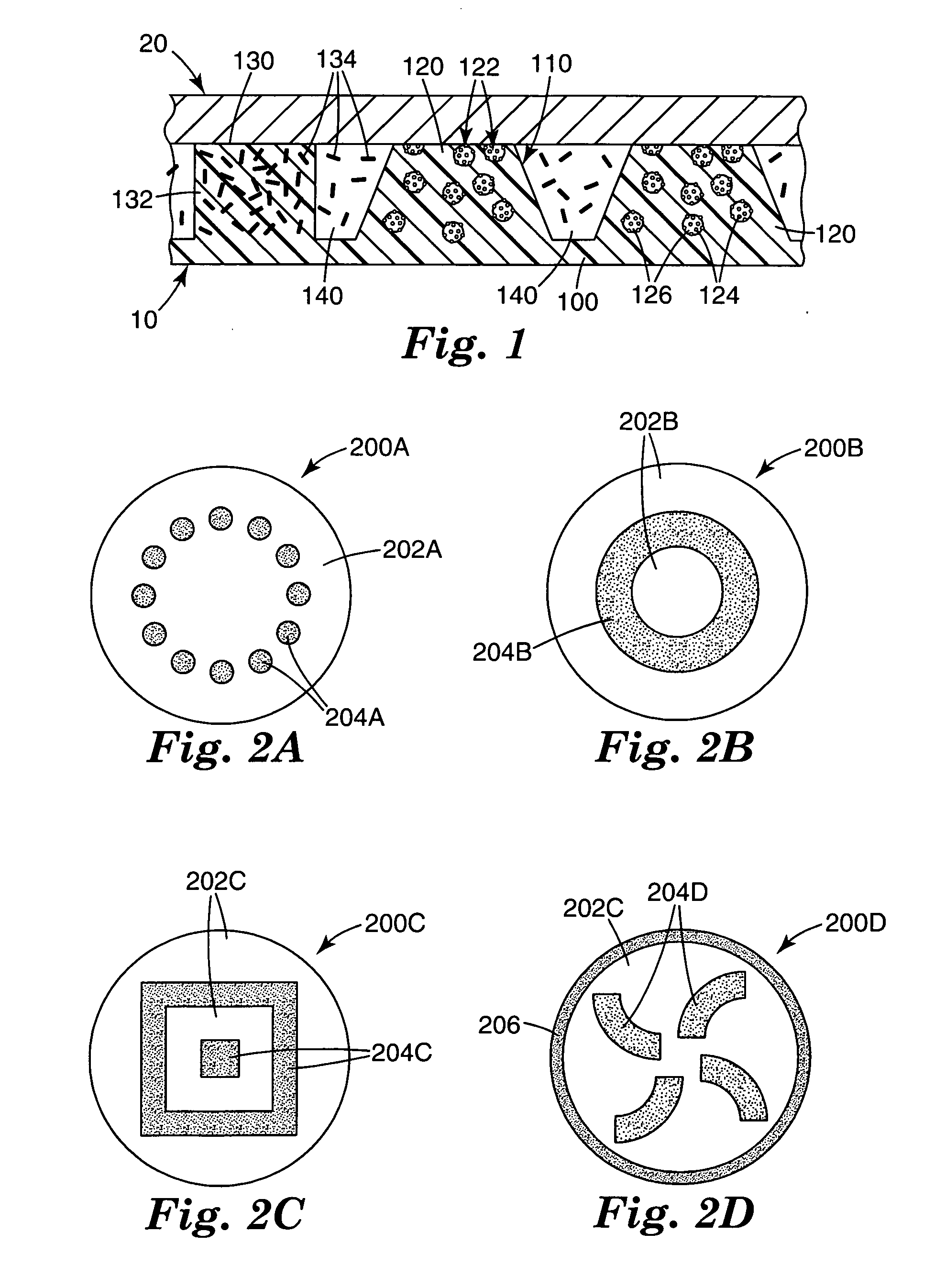

Abrasive agglomerate polishing method

ActiveUS7494519B2Sufficient materialImprove faultPigmenting treatmentOther chemical processesHardnessMaterials science

Provided is a method of polishing comprising providing a workpiece, providing a fixed abrasive article, providing conditioning particles, and relatively moving the workpiece and the fixed abrasive article in the presence of the conditioning particles to modify the surface of the workpiece and to condition the fixed abrasive. The fixed abrasive article comprises a substrate having a first surface and a region of abrasive composites distributed on the first surface of the substrate. The abrasive composites include a composite binder and abrasive particles, which may be in abrasive agglomerates together with a matrix material. The abrasive particles are harder than the workpiece. The conditioning particles are sufficient to condition one or more of the composite binder, matrix material, and abrasive agglomerates. The hardness of the conditioning particles is less than the hardness of the workpiece and they do not substantially polish the workpiece.

Owner:3M INNOVATIVE PROPERTIES CO

Reduced mask configuration for power mosfets with electrostatic discharge (ESD) circuit protection

ActiveUS20110076815A1Increase powerSimple manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringPower MOSFET

A semiconductor power device supported on a semiconductor substrate includes an electrostatic discharge (ESD) protection circuit disposed on a first portion of patterned ESD polysilicon layer on top of the semiconductor substrate. The semiconductor power device further includes a second portion of the patterned ESD polysilicon layer constituting a body implant ion block layer for blocking implanting body ions to enter into the semiconductor substrate below the body implant ion block layer. In an exemplary embodiment, the electrostatic discharge (ESD) polysilicon layer on top of the semiconductor substrate further covering a scribe line on an edge of the semiconductor device whereby a passivation layer is no longer required manufacturing the semiconductor device for reducing a mask required for patterning the passivation layer.

Owner:BHALLA ANUP +4

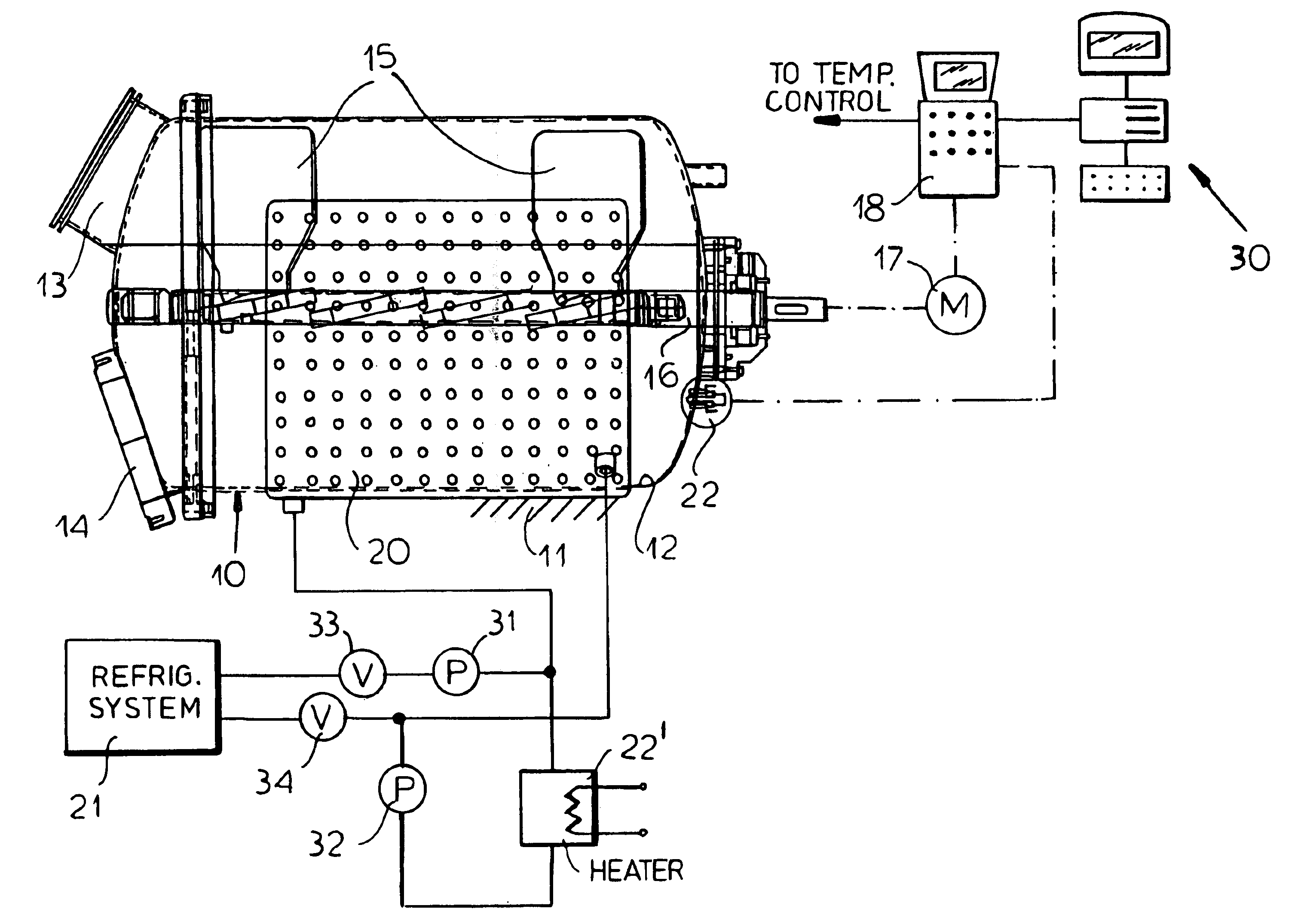

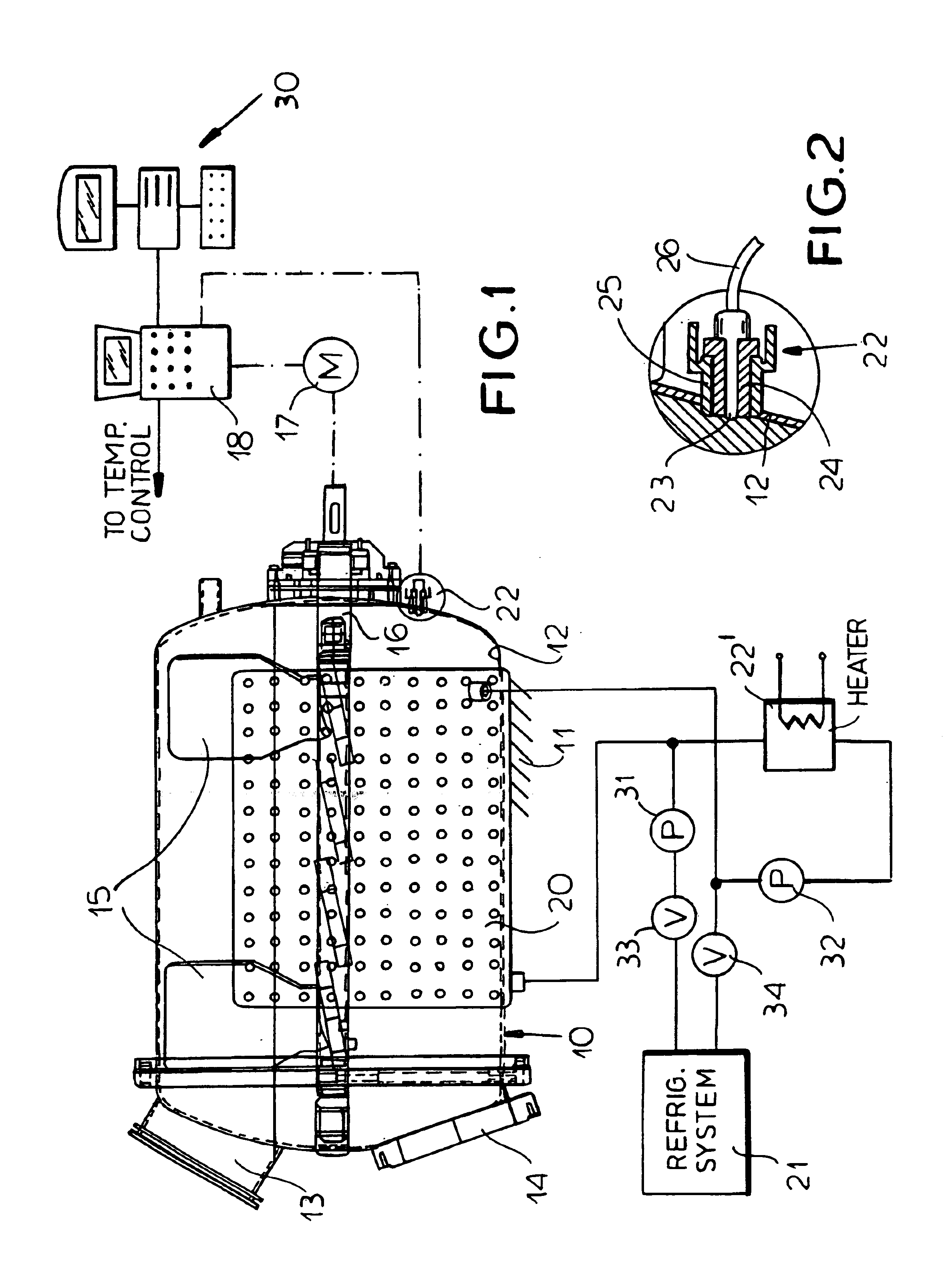

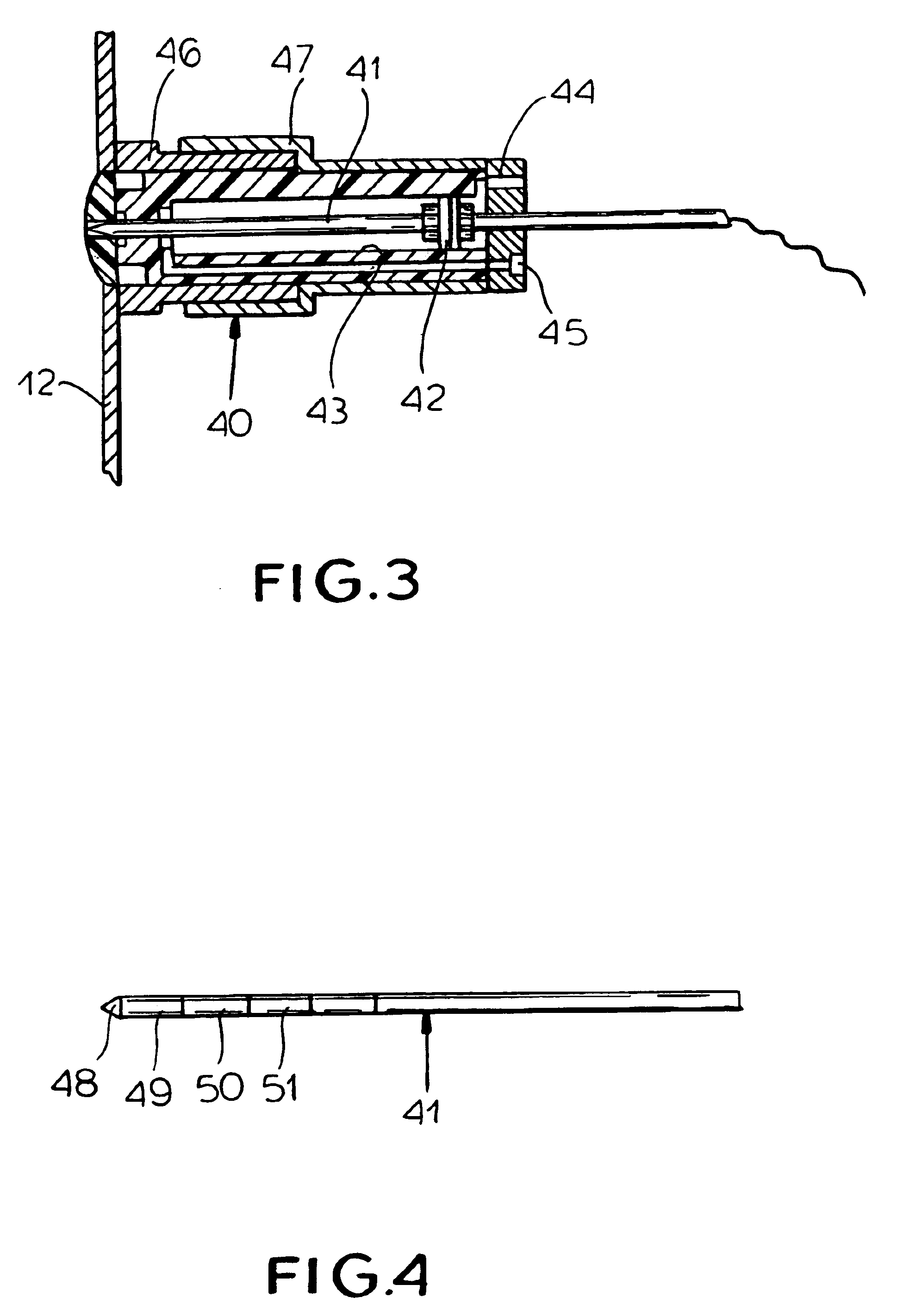

Method of and apparatus for the processing of meat

InactiveUS6730341B2Simple methodIncrease variabilityGrain huskingGrain polishingProcess engineeringWater holding capacity

The water holding capacity of meat is improved by agitating the meat at an alleged temperature with the processing solution and by maintaining the agitation temperature with precision. A preferred temperature is in the range of 45° to 60° F. and the agitation is preferably a massaging action after injection of the liquid into the meat. The heating or agitation at the elevated temperature can be carried out in one vessel while the subsequent cooling is carried out in at least one second vessel.

Owner:JOHN BEAN TECH CORP

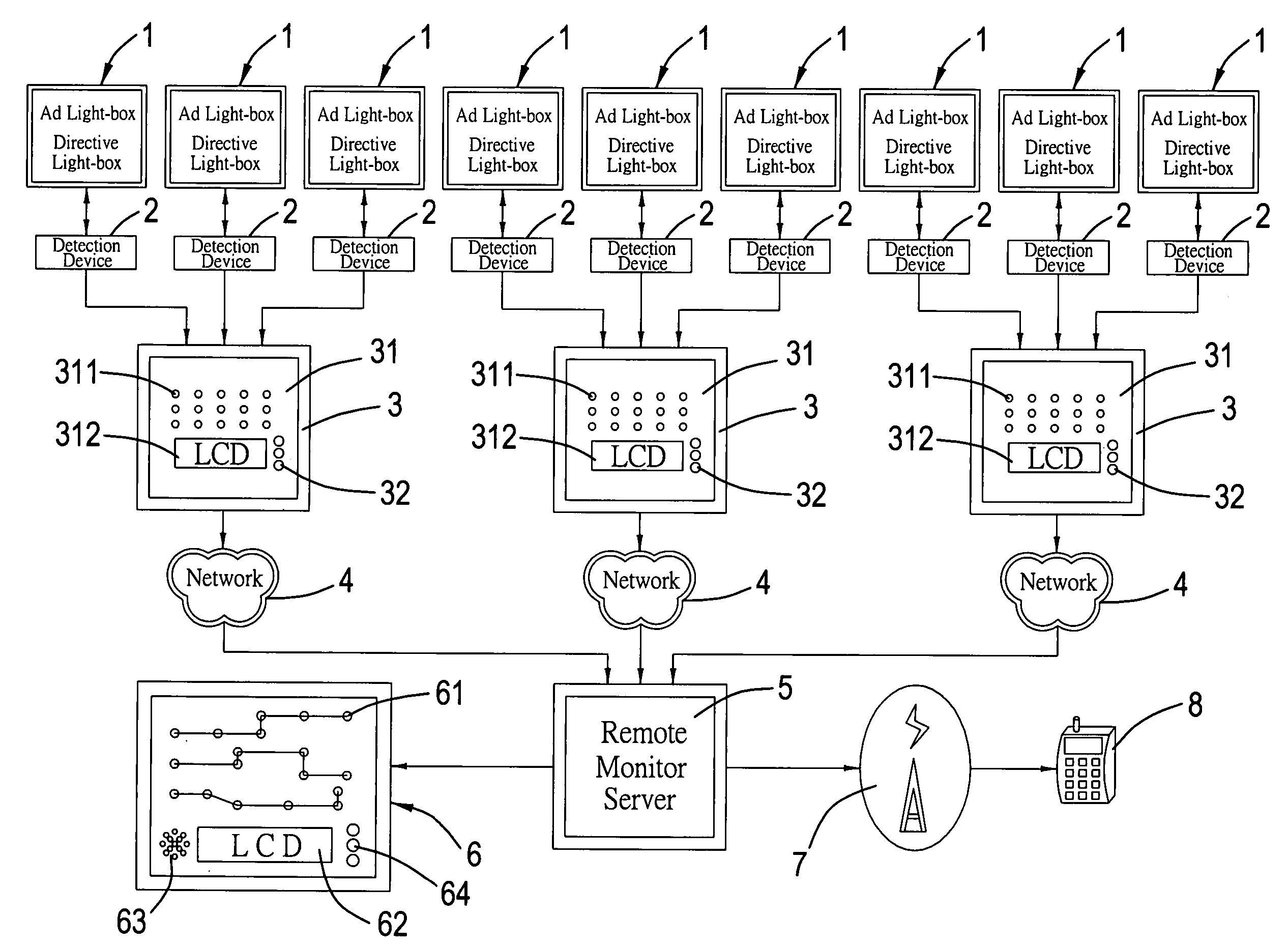

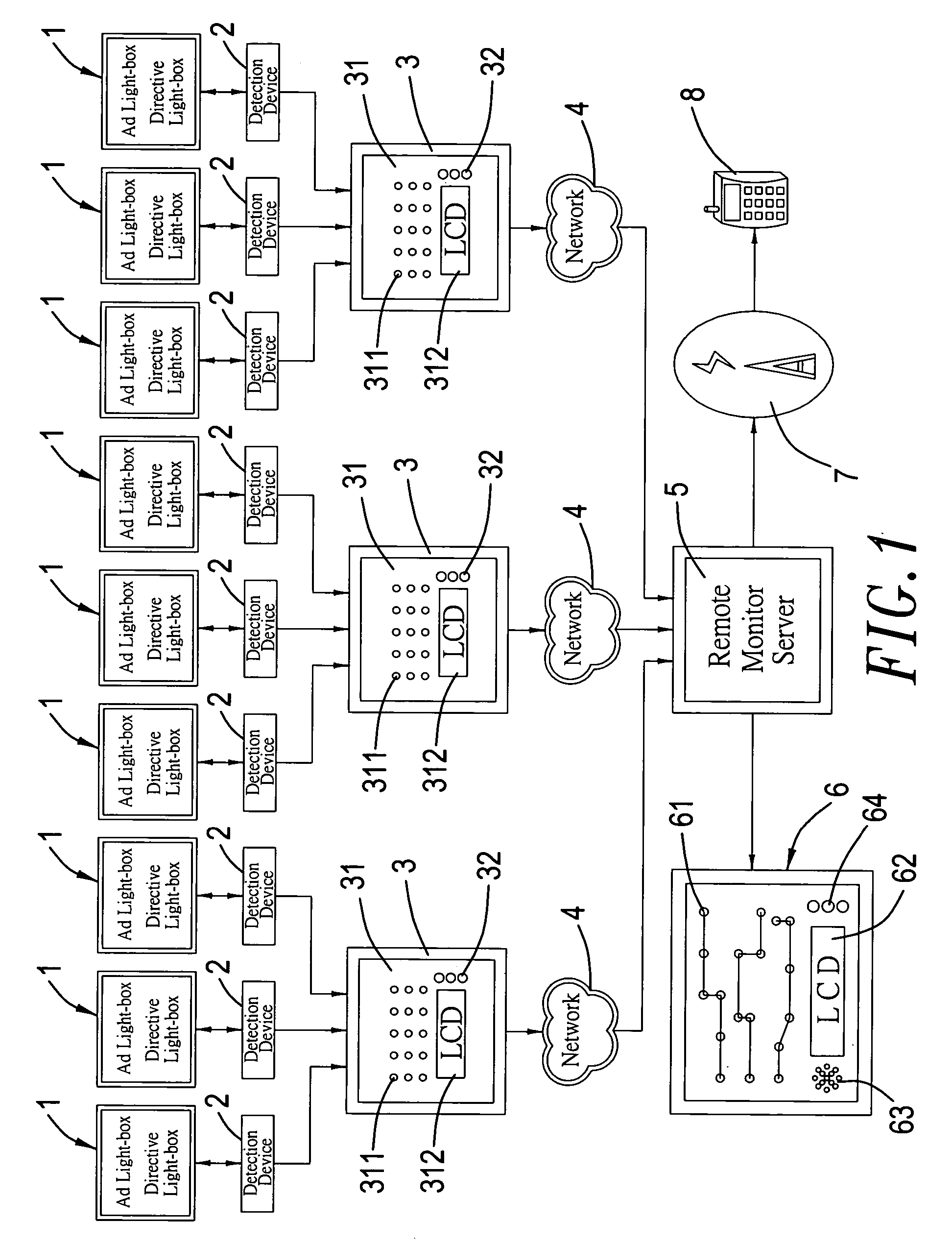

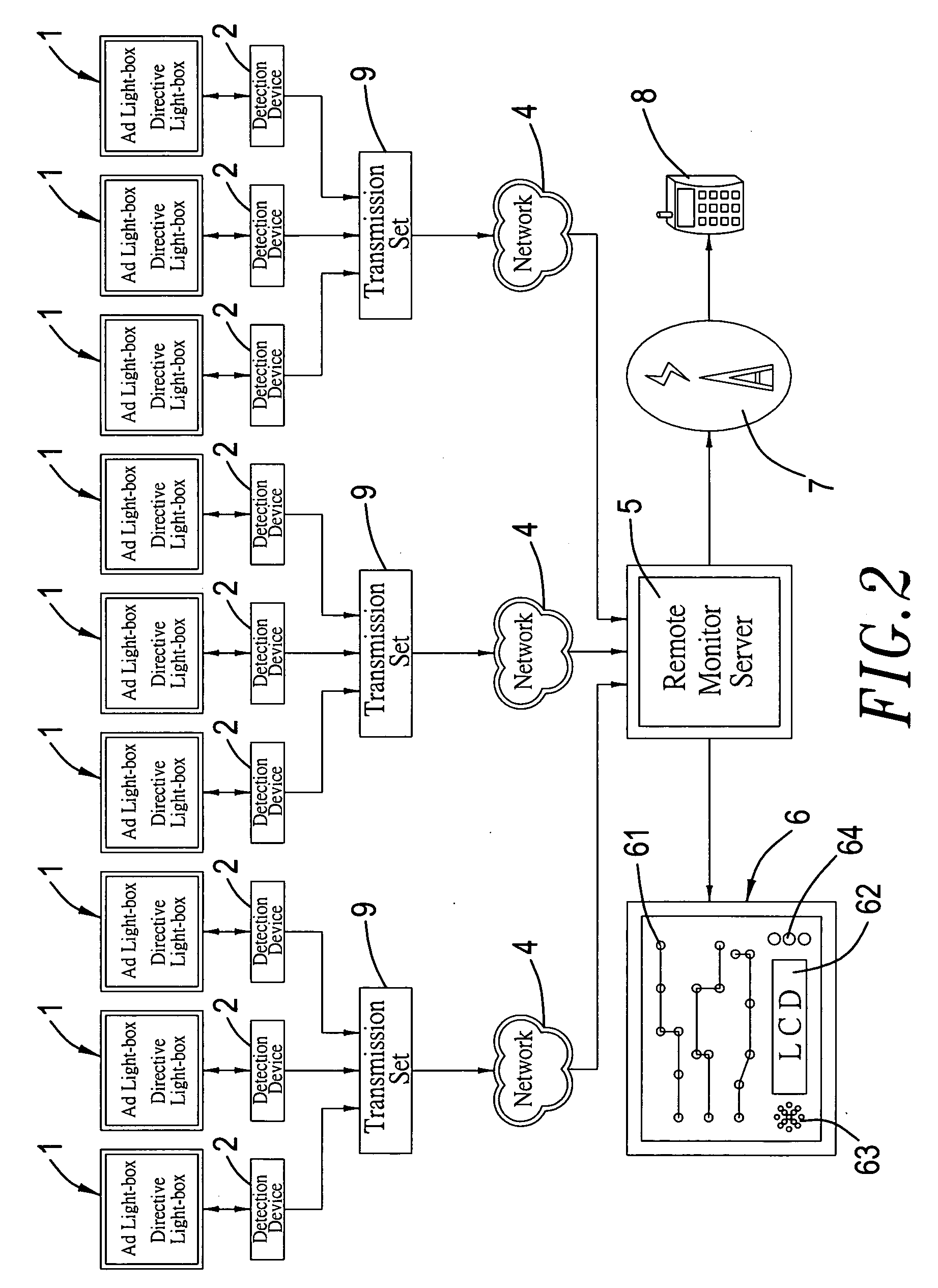

Advertising light-box network system with auto-detection and auto-monitor

InactiveUS20050179554A1Reduce labor costsImprove faultStatic indicating devicesAdvertisingThe InternetControl circuit

A advertising light-box network system with auto-detection and auto-monitor primarily is a system that installs a detection device in each advertising light-box of each area to detect whether a lamp body, a power supply device, or a control circuit board in the advertising light-box is abnormal, and send messages detected to a message receiving server of the area thereof for displaying, such that a maintenance worker of the area can get the real-time status of each advertising light-box in the area; and messages received by the message receiving server are sent by the message receiving server to a remote monitor server via internet to be converged and displayed on a remote display, thus a remote supervisor can get the status of all advertising light-boxes in all areas to achieve the object of real-time maintenance; also, the remote monitor server can send messages to a cellular phone, a PDA, or a notebook of a supervisor via a communication network so that the supervisor can 24-hour monitor the advertising light-boxes in all areas.

Owner:SALE FIRE PROTECTION EQUIP

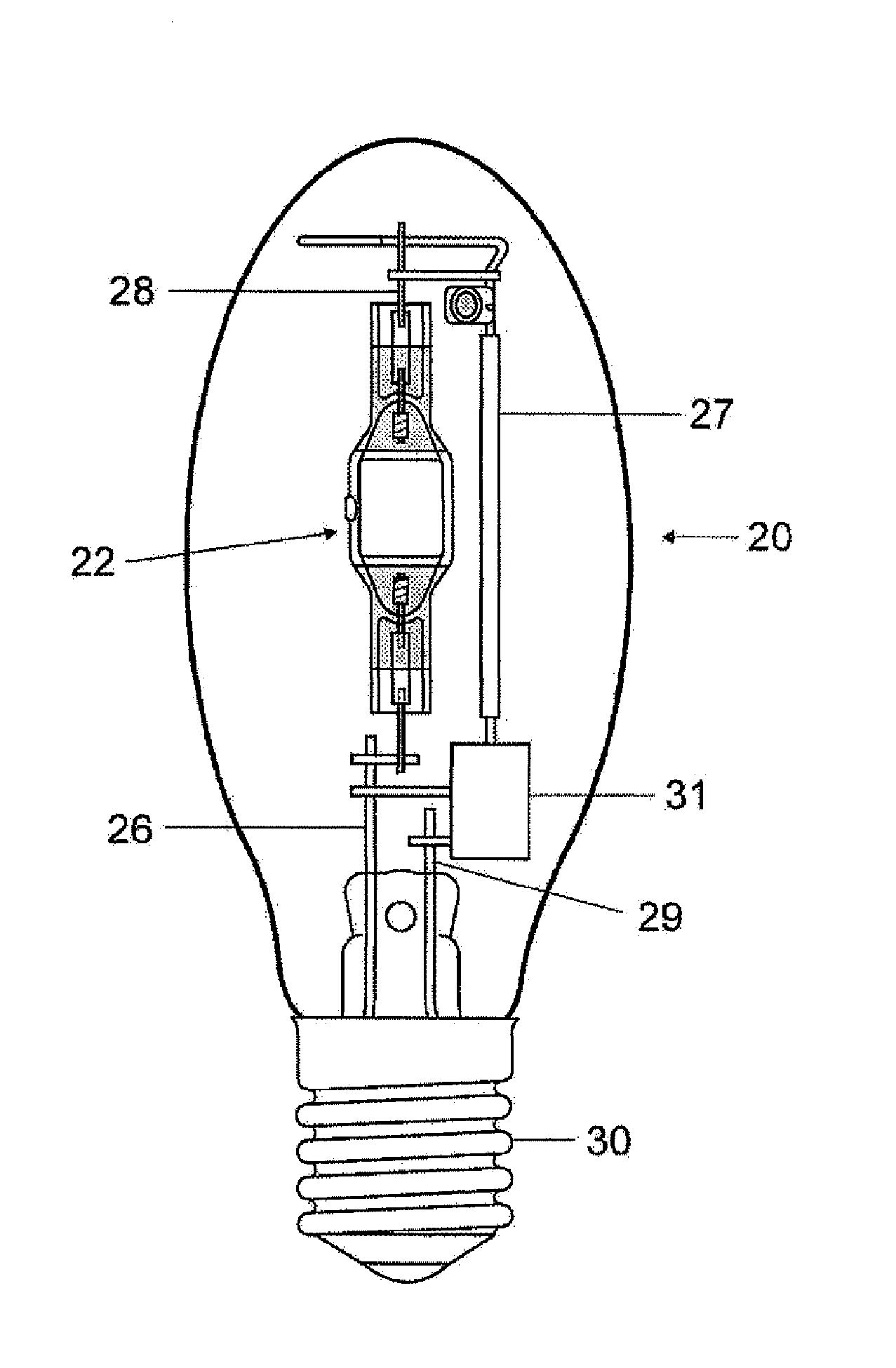

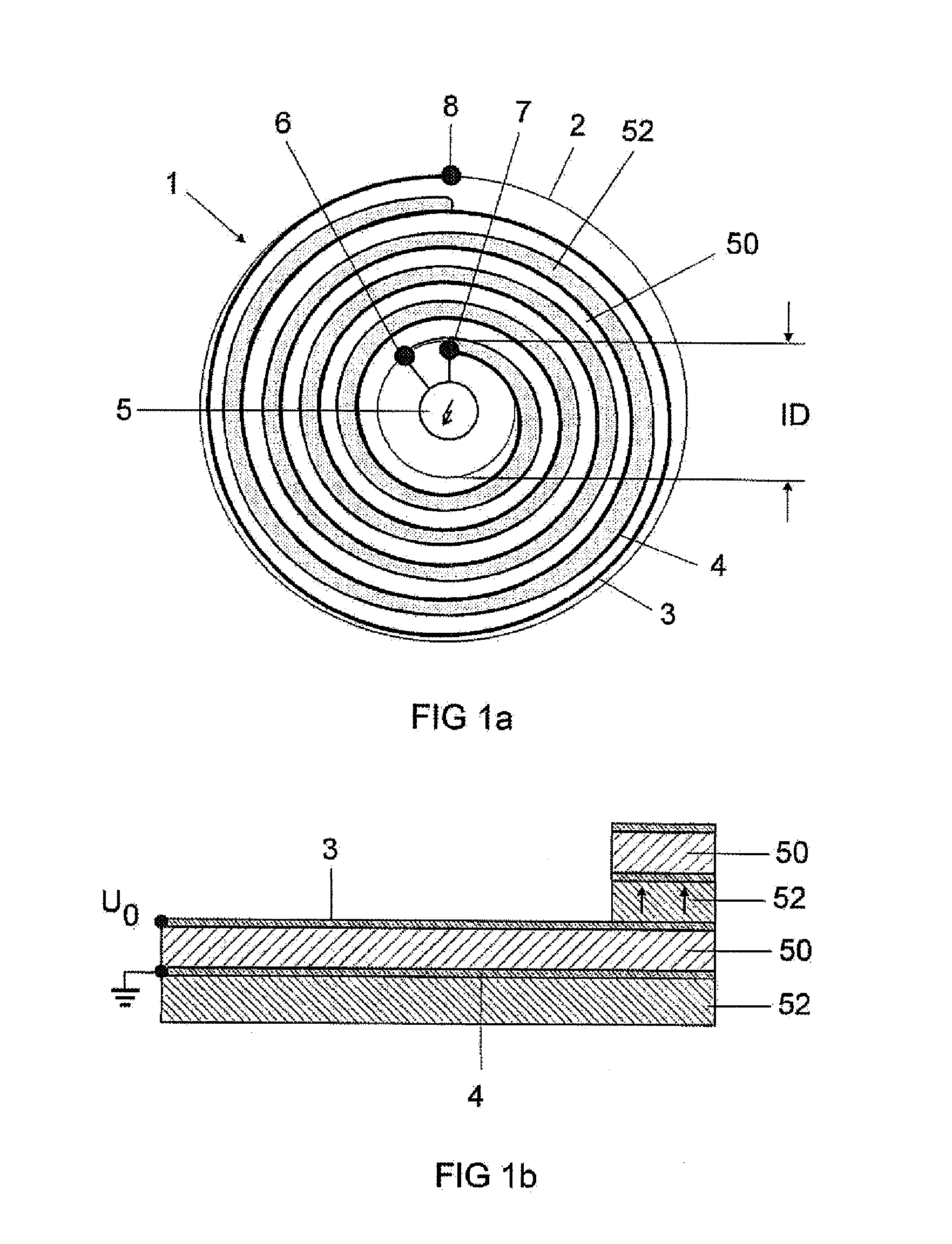

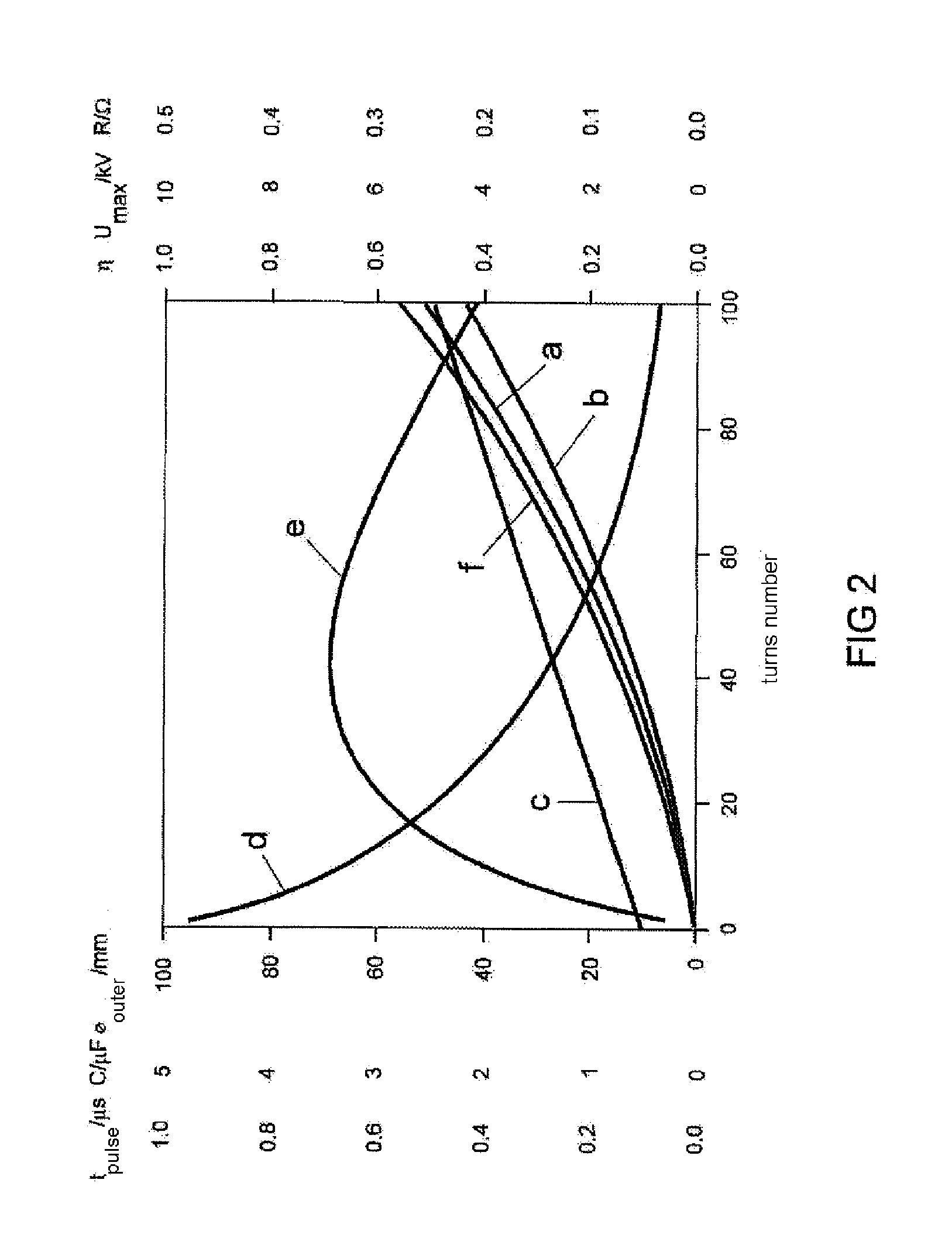

High-voltage pulse generator and high-pressure discharge lamp having such a generator

InactiveUS20100171426A1Increase capacitanceLarge temporal widthElectric lighting sourcesManufacturing dynamo-electric machinesSecondary layerCapacitance

A high-voltage pulse generator is provided. The high-voltage pulse generator may include a spiral pulse generator, the spiral pulse generator being configured as an LTCC component and being wound from at least two ceramic sheets and at least two metal layers, wherein the two ceramic sheets are joined to form a multilayer structure including at least one first layer of a capacitively acting ceramic sheet including a high permittivity of at least ∈r=10 and at least one second layer of an inductively acting ceramic sheet having a high permeability of at least μr=1.5, which are wound together with the metal layers to form a spiral.

Owner:OSRAM GMBH

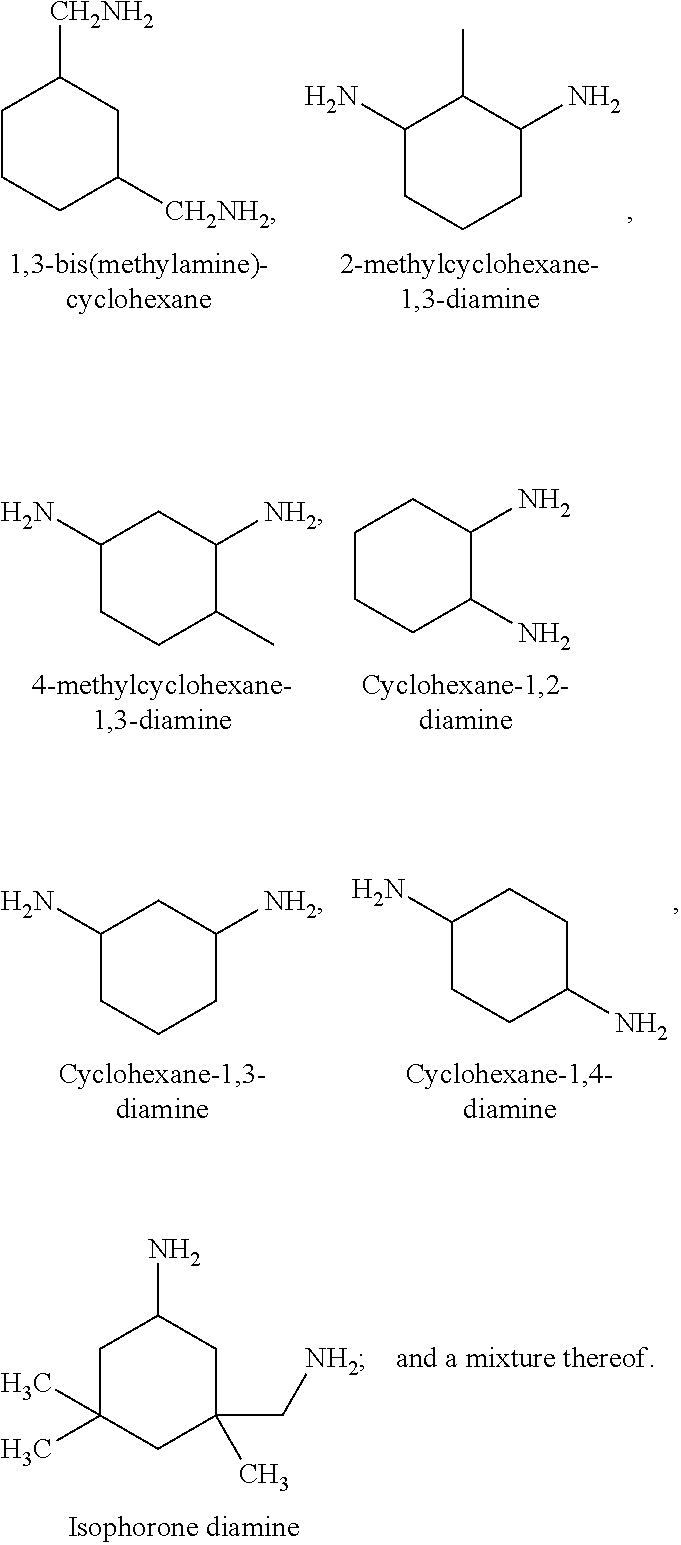

Cleaning product

InactiveUS20170121655A1Improve performanceEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsHydrogenEthyl group

A cleaning product including a spray dispenser and a cleaning composition suitable for spraying and foaming, the composition housed in the spray dispenser wherein the composition includes: i) from about 5 to about 15% by weight of the composition of a surfactant system; and ii) a glycol ether solvent selected from the group consisting of glycol ethers of Formula I: R1O(R2O)nR3, Formula II: R4O(R5O)nR6 and mixtures thereof wherein R1 is a linear or branched C4, C5 or C6 alkyl or a substituted or unsubstituted phenyl, R2 is ethyl or isopropyl, R3 is hydrogen or methyl and n is 1, 2 or 3 R4 is n-propyl or isopropyl, R5 is isopropyl, R6 is hydrogen or methyl and n is 1, 2 or 3 and a specific cyclic diamine.

Owner:THE PROCTER & GAMBLE COMPANY

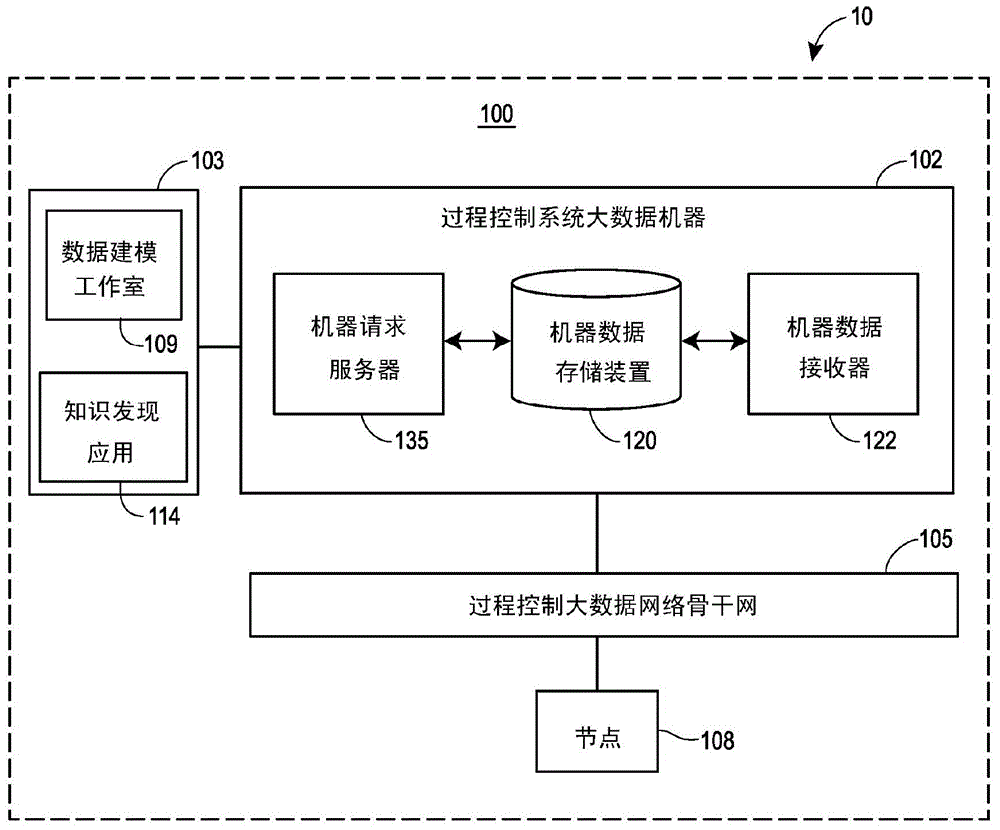

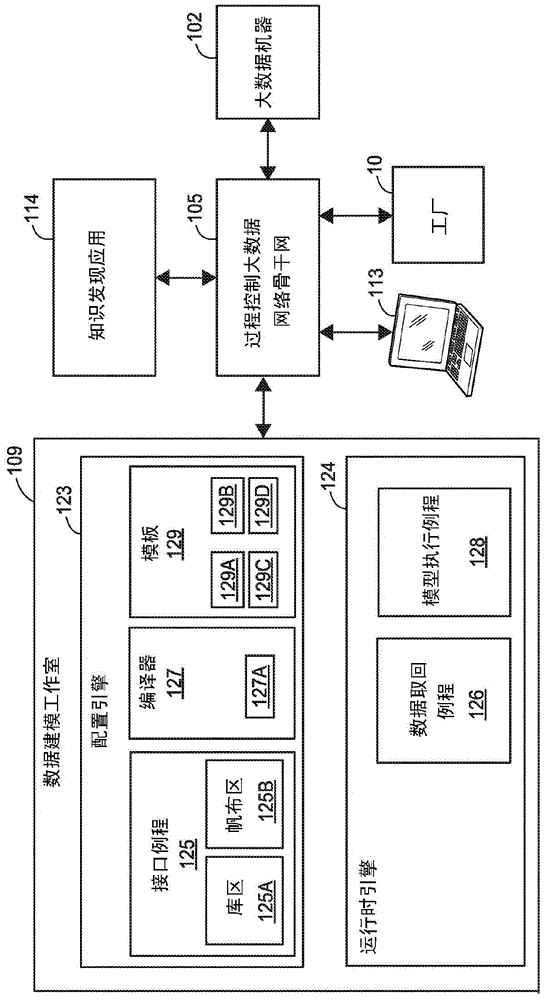

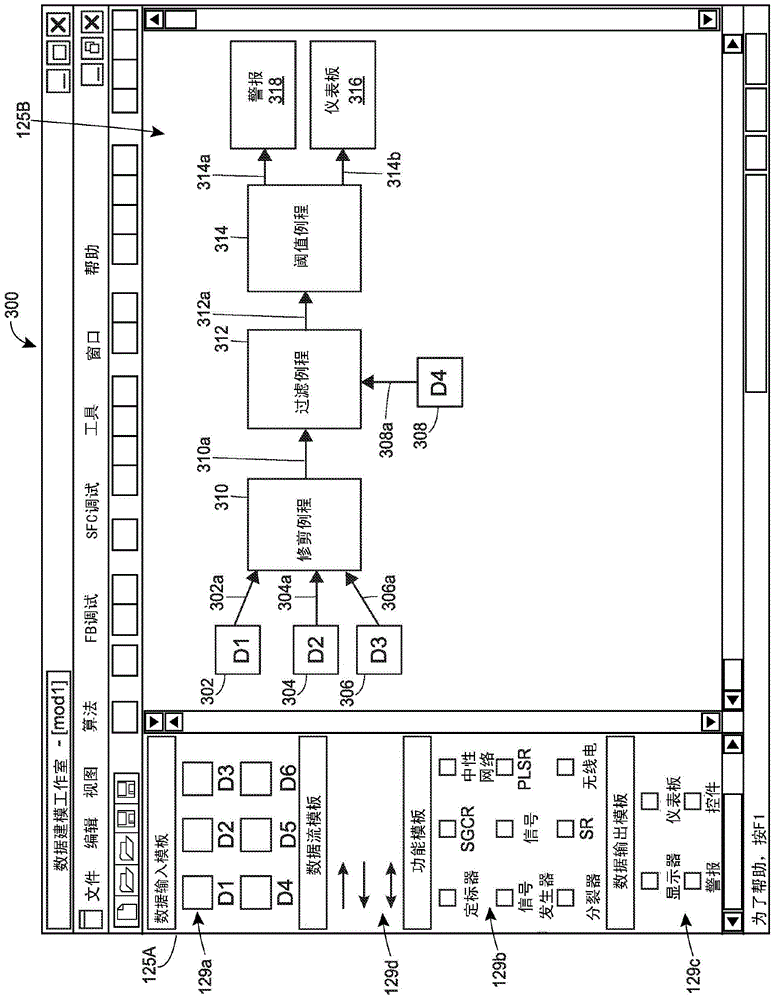

Data modeling studio

ActiveCN105051760AEasy to predictFacilitate trend analysisProgramme controlComputer controlGraphicsData modeling

A data modeling studio provides a structured environment for graphically creating and executing models which may be configured for diagnosis, prognosis, analysis, identifying relationships, etc., within a process plant. The data modeling studio includes a configuration engine for generating user interface elements to facilitate graphical construction of a model and a runtime engine for executing data models in, for example, an offline or an on-line environment. The configuration engine includes an interface routine that generates user interface elements, a plurality of templates stored in memory that serve as the building blocks of the model and a model compiler that converts the graphical model into a data format executable by the run-time engine. The run time engine executes the model to produce the desired output and may include a retrieval routine for retrieving data corresponding to the templates from memory and a modeling routine for executing the executable model.

Owner:FISHER-ROSEMOUNT SYST INC

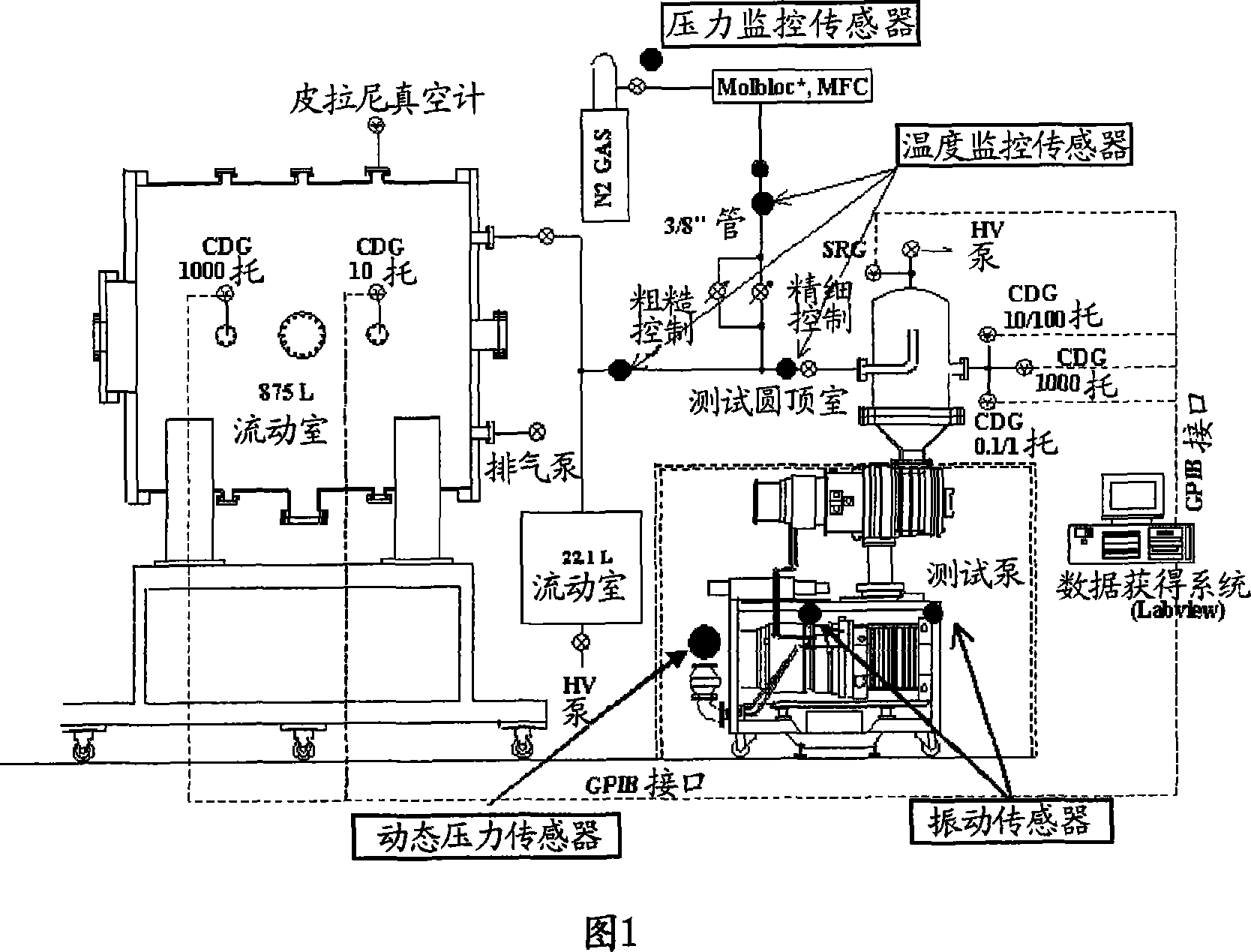

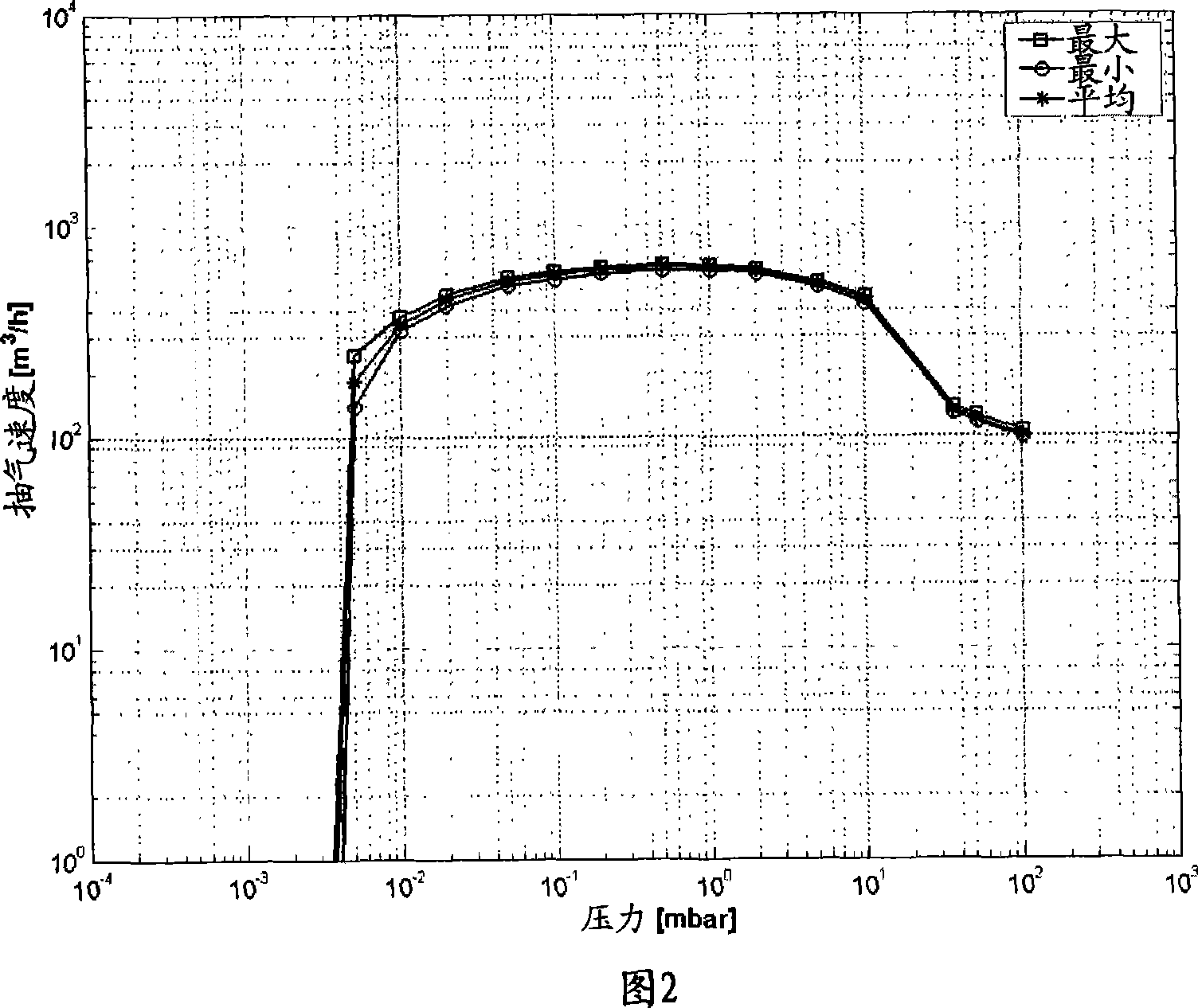

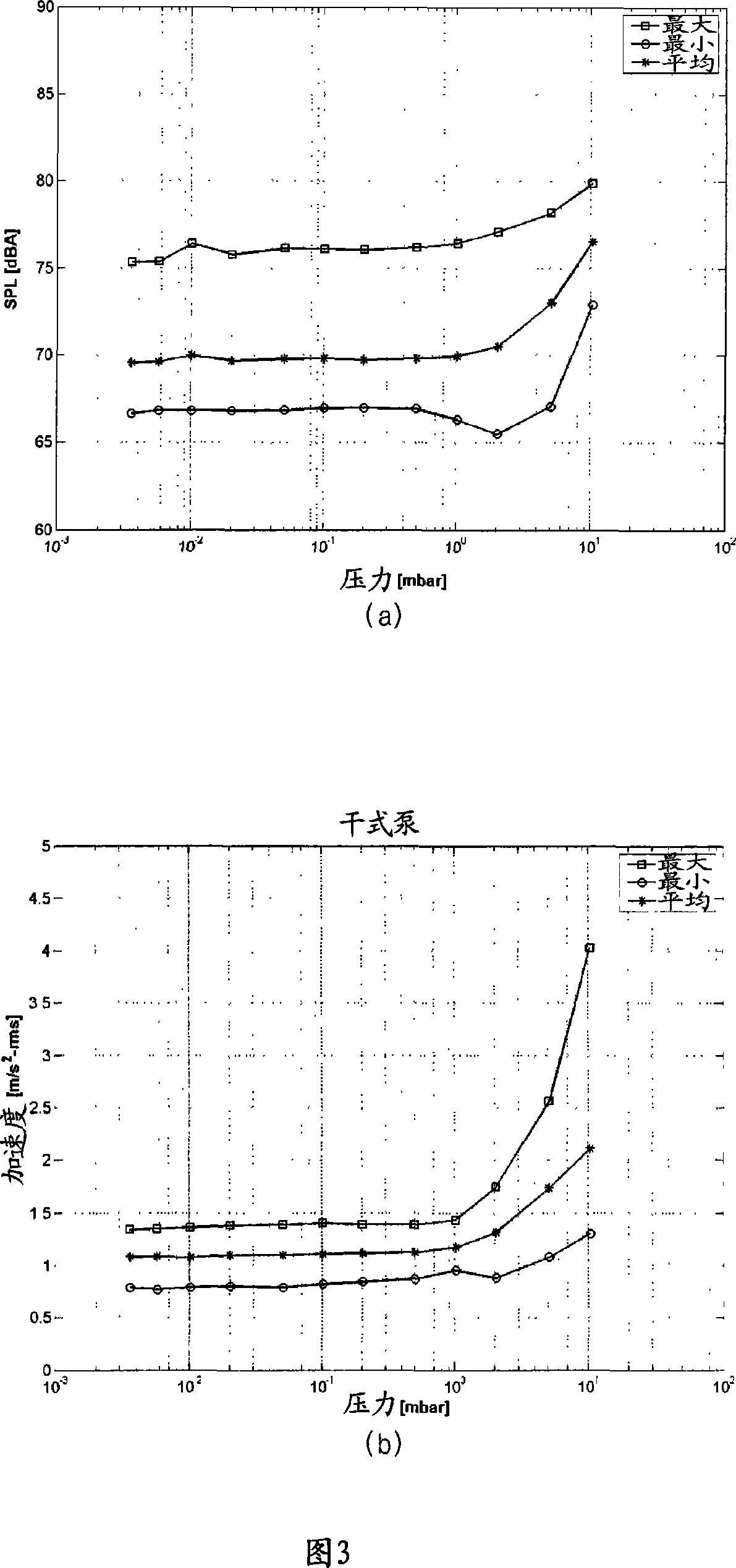

Trend monitoring and diagnostic analysis method for vacuum pump and trend monitoring and diagnostic analysis system therefor and computer-readable storage media including a computer program which perf

InactiveCN101080699AEarly detection of vacuum pump failure improvementImprove faultTesting/monitoring control systemsHardware monitoringPredictive maintenancePump failure

Owner:KOREA RES INST OF STANDARDS & SCI

Implantable graft device having treated yarn and method for making same

An implantable graft device having treated yarn is disclosed. The device includes a graft body forming a lumen defining a longitudinal axis and having proximal and distal ends. The graft body is constructed from a woven fabric having warp yarns aligned in a first direction and a weft yarns aligned in a second direction. At least one of the weft yarns and the warp yarns has an agent applied thereto defining treated yarns of the graft body.

Owner:COOK MEDICAL TECH LLC

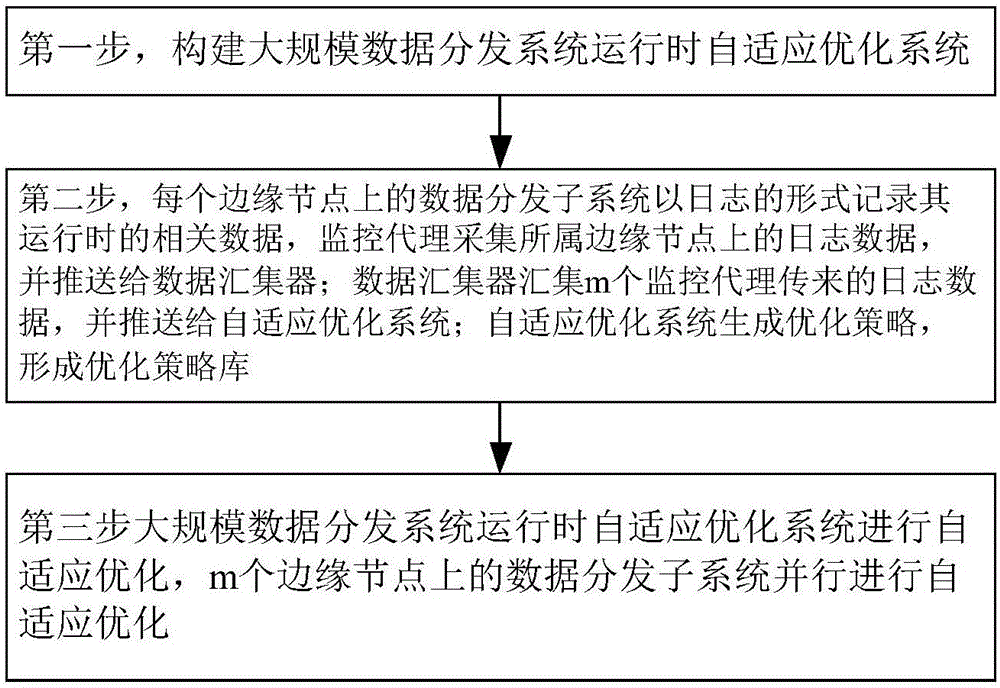

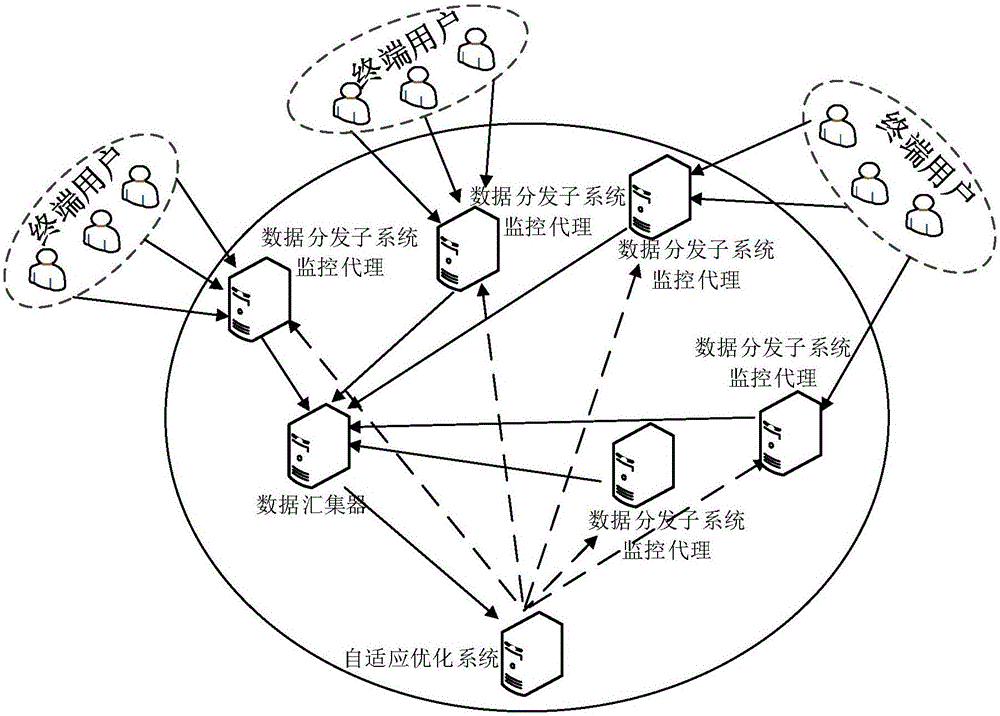

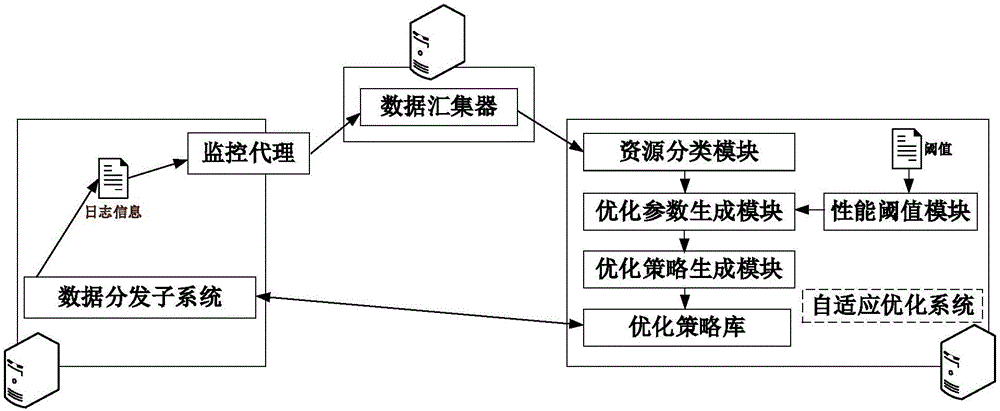

Adaptive optimization operation method of large-scale data distribution system

The invention discloses an adaptive optimization operation method of a large-scale data distribution system, and aims at providing a stable operation optimization method of the large-scale data distribution system. The technical scheme is as follows: firstly establishing an adaptive optimization system of the large-scale data distribution system, deploying a data distribution subsystem and a monitoring proxy on an edge node, and deploying a data collector and the adaptive optimization system on a central computing node; generating optimization strategies via a resource allocation module, a performance threshold module and an optimization strategy generation module of the adaptive optimization system to form an optimization strategy library; and obtaining the optimization strategy from the optimization strategy library by the data distribution subsystem on any edge node, and implementing optimization on the current edge node by adopting the optimization strategy. By adoption of the adaptive optimization operation method disclosed by the invention, fault optimization strategies of the large-scale data distribution system can be generated, and the majority of faults can be automatically restored by adopting the corresponding optimization strategies according to an operation state, so that the large-scale data distribution system operates stably.

Owner:NAT UNIV OF DEFENSE TECH

Self-contained conditioning abrasive article

ActiveUS20070026774A1High removal rateInhibition removal rateOther chemical processesBonded abrasive wheelsWear particleHardness

Provided is a fixed abrasive article for polishing a workpiece having a hardness comprising (a) a substrate having a first surface and a second surface, (b) a region of abrasive composites distributed on the first surface of the substrate, and (c) a region of conditioning amalgams distributed on the first surface of the substrate. The abrasive composites include a composite binder and abrasive particles of a first hardness, which first hardness is higher than the hardness of the workpiece. The amalgams include an erodible binder and conditioning particles sufficient to condition the composite binder and having a second hardness, which second hardness is less than the hardness of the workpiece and greater than the hardness of the composite binder. Also provided are other abrasive articles, and methods of making them.

Owner:3M INNOVATIVE PROPERTIES CO

Amorphous layers in a magnetic tunnel junction device

InactiveUS7369376B2High sensitivityImprove faultRecord information storageManufacture of flux-sensitive headsDielectric layerTunnel junction

An improved TMR device is disclosed. The ferromagnetic layers of the device, particularly those that contact the dielectric tunneling layer have an amorphous structure as well as a minimum thickness (of about 15 Å). A preferred material for contacting the dielectric layer is CoFeB. Ways of overcoming problems relating to magnetostriction are disclosed and a description of a process for manufacturing the device is included.

Owner:HEADWAY TECH INC +1

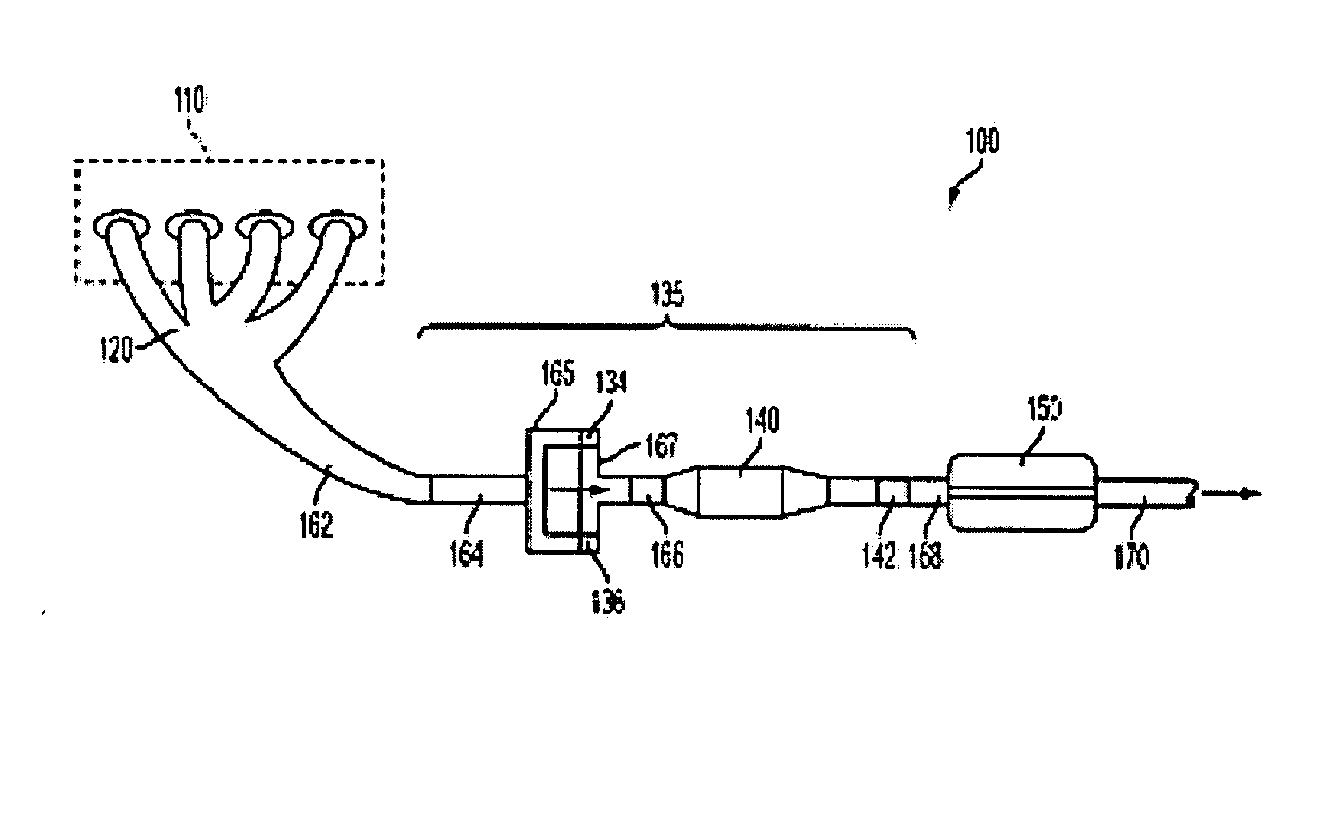

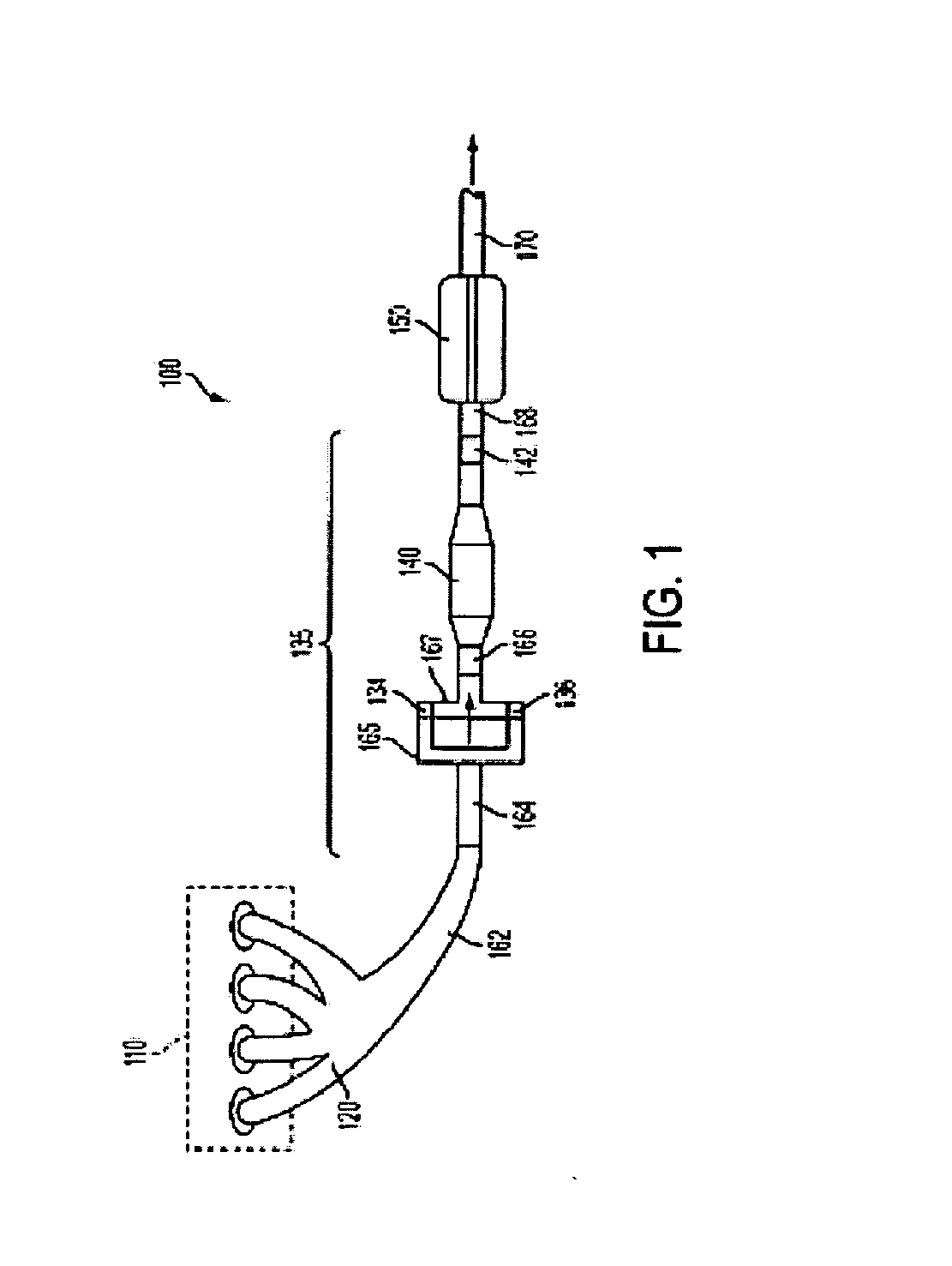

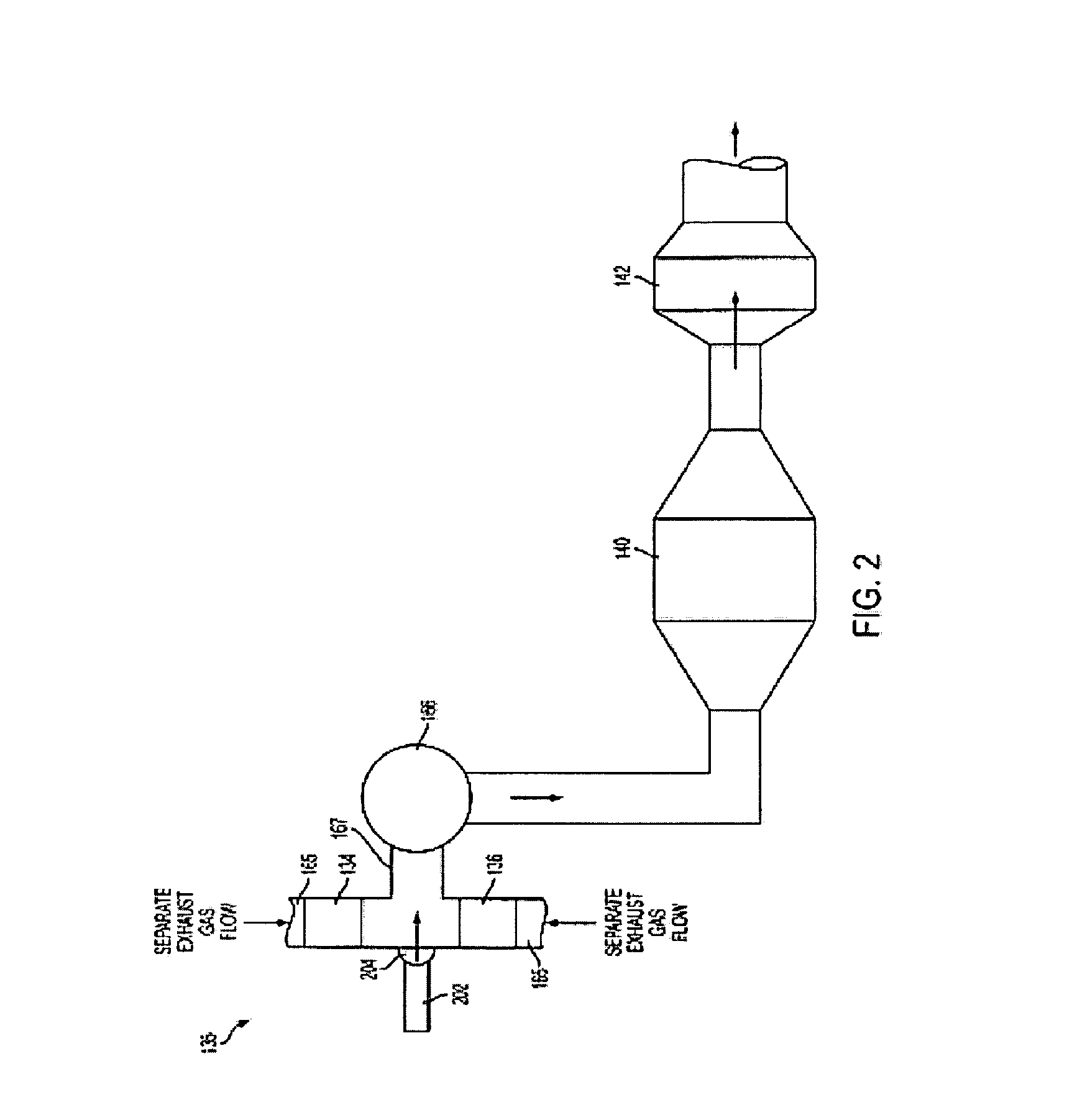

Diesel Turbine SCR Catalyst

ActiveUS20090249773A1More flexibilityReduce manufacturing costInternal combustion piston enginesSilencing apparatusExhaust gasInjector

A system for treating exhaust gases from an engine is described. The system includes, the exhaust gases routed from the engine to atmosphere through an exhaust passage, the system comprising: an injector directing a spray of reductant into the exhaust gases routed from the engine to atmosphere; an exhaust separation passage that separates an exhaust gas flow received from the engine into a plurality of separate exhaust gas flows; a plurality of oxidation catalysts, each of which receives one of the plurality of separate exhaust gas flows; a flow combining passage that receives the plurality of separate exhaust gas flows and combines them into a re-combined exhaust gas flow; a turbocharger that receives the re-combined exhaust gas flow from the flow combining passage; and a selective catalytic reduction catalyst positioned downstream of the turbocharger.

Owner:FORD GLOBAL TECH LLC

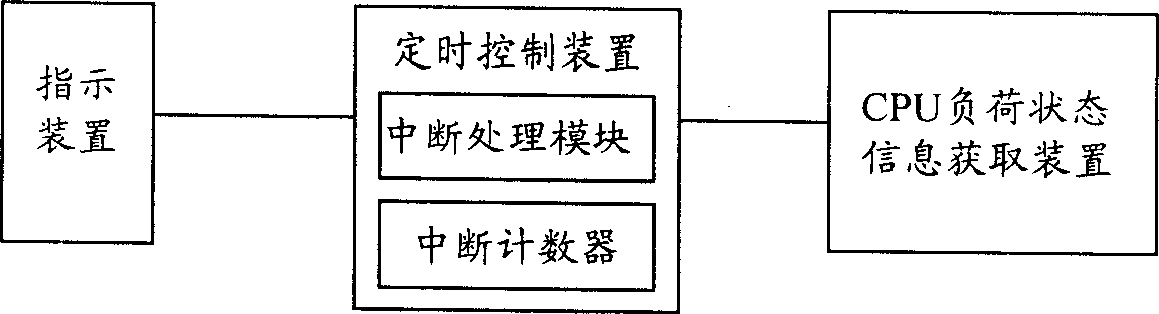

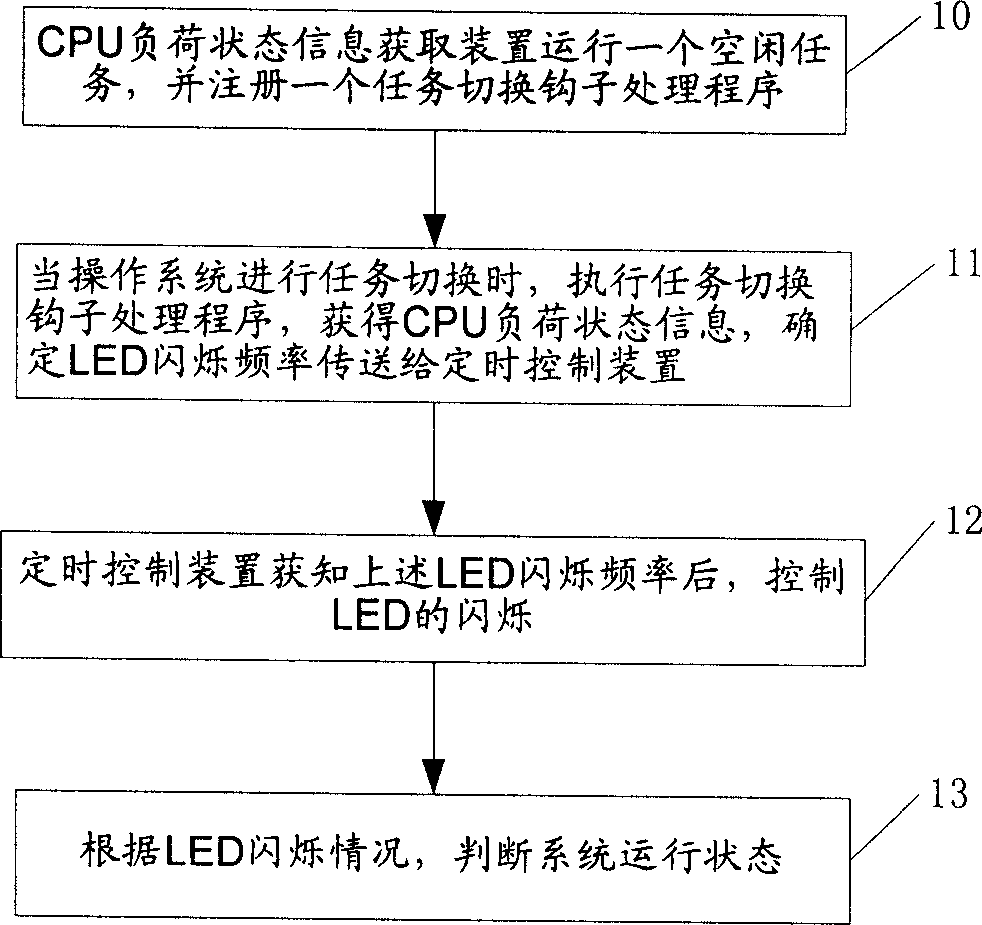

Apparatus and method for real-time indicating running state of computer system

InactiveCN1862506AUnderstand the load statusImprove faultHardware monitoringEngineeringComputers technology

The present invention relates to a device for real-time indicating running state of computer system in the field of computer technology and its method. Said invention utilizes the scintillation state of indication device to promptly indicate running state of computer system and running load of CPU, so that it can provide beneficial help for effectively locating system fault.

Owner:HUAWEI TECH CO LTD

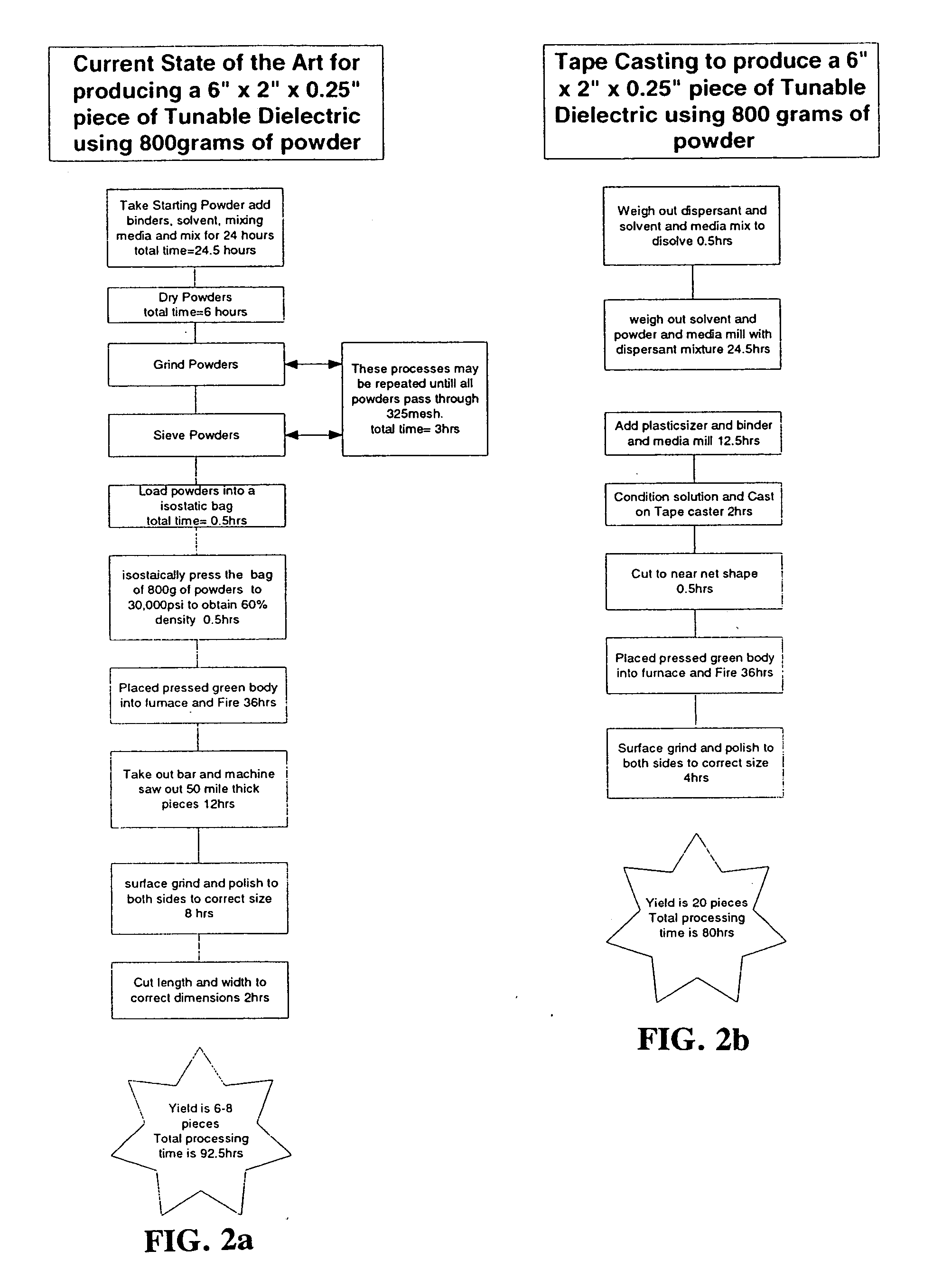

Method for producing low-loss tunable ceramic composites with improved breakdown strengths

InactiveUS20050176575A1High breakdown strengthImproved propertyFixed capacitor dielectricSynthetic resin layered productsBreakdown strengthMicrowave

Owner:NXP USA INC

Dry powder inhaler

ActiveUS20170333646A1Reduce swirlSmooth transitionMedical devicesMedical atomisersAirflowBiomedical engineering

The present invention relates to an inhaler device for delivering a dose of medicament in dry powder form from a container to a patient in need thereof. The inhaler comprises a swirl chamber in which particles of the medicament entrained in an airflow swirl upon inhalation thereby breaking up the agglomerates into finest dispersed powder.

Owner:PRESSPART MFG

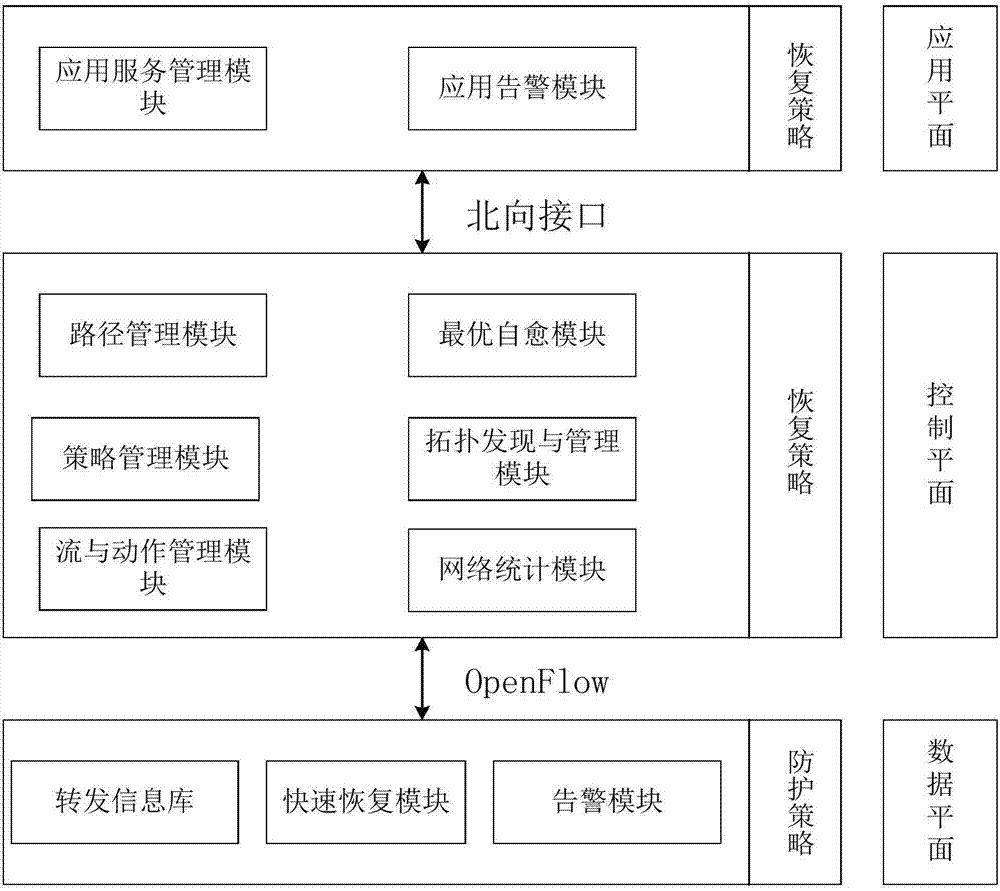

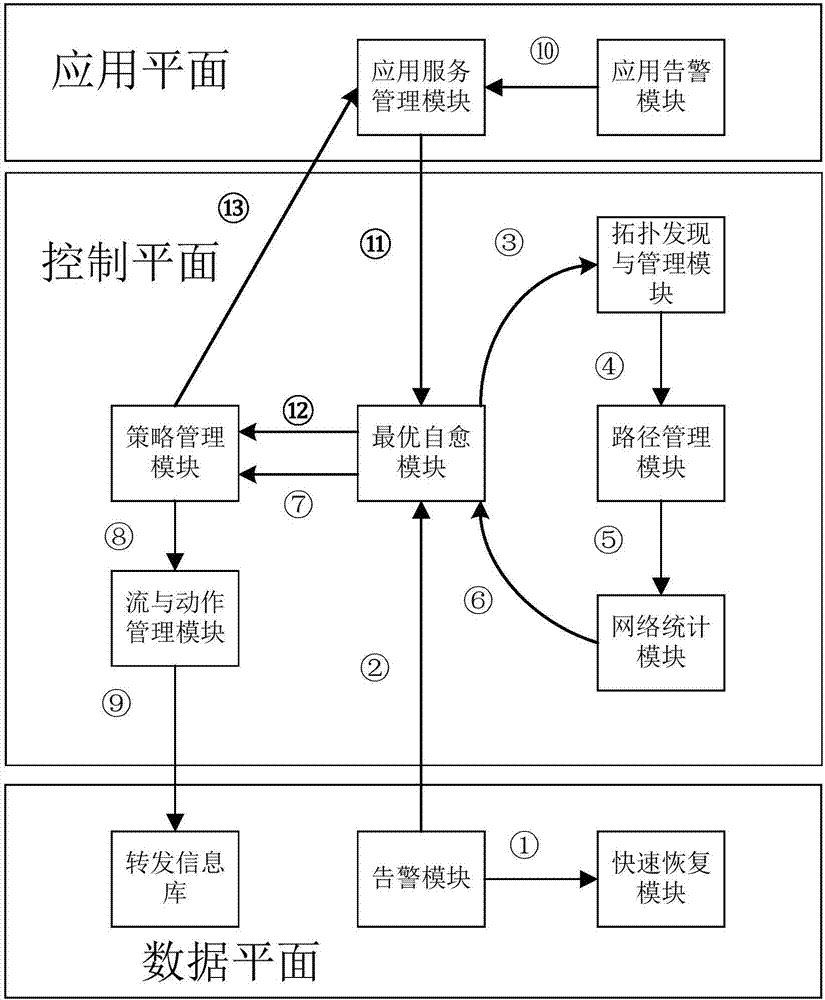

SDN (Software Defined Networking) self-healing method based on deep learning

The invention discloses an SDN (Software Defined Networking) self-healing method based on deep learning. The method comprises the steps that a corresponding self-healing module is added to each layer of an SDN; when an application fault occurs in an application layer, an application layer self-healing module and a control layer self-healing module coordinate and match to solve the fault, and normal operation of the network is recovered; and when a link fault occurs in a forwarding layer, the control layer self-healing module and a forwarding layer self-healing module coordinate and match to solve the fault, and the normal operation of the network is recovered. The invention innovatively provides an SDN self-healing framework. A set of complete self-healing mechanism is designed based on the self-healing framework. The application layer fault and the forwarding layer fault can be processed well. A network structure is optimized, the network cost is saved, the operation efficiency of the network is improved, and defects of the current SDN in self-healing related aspects are compensated.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

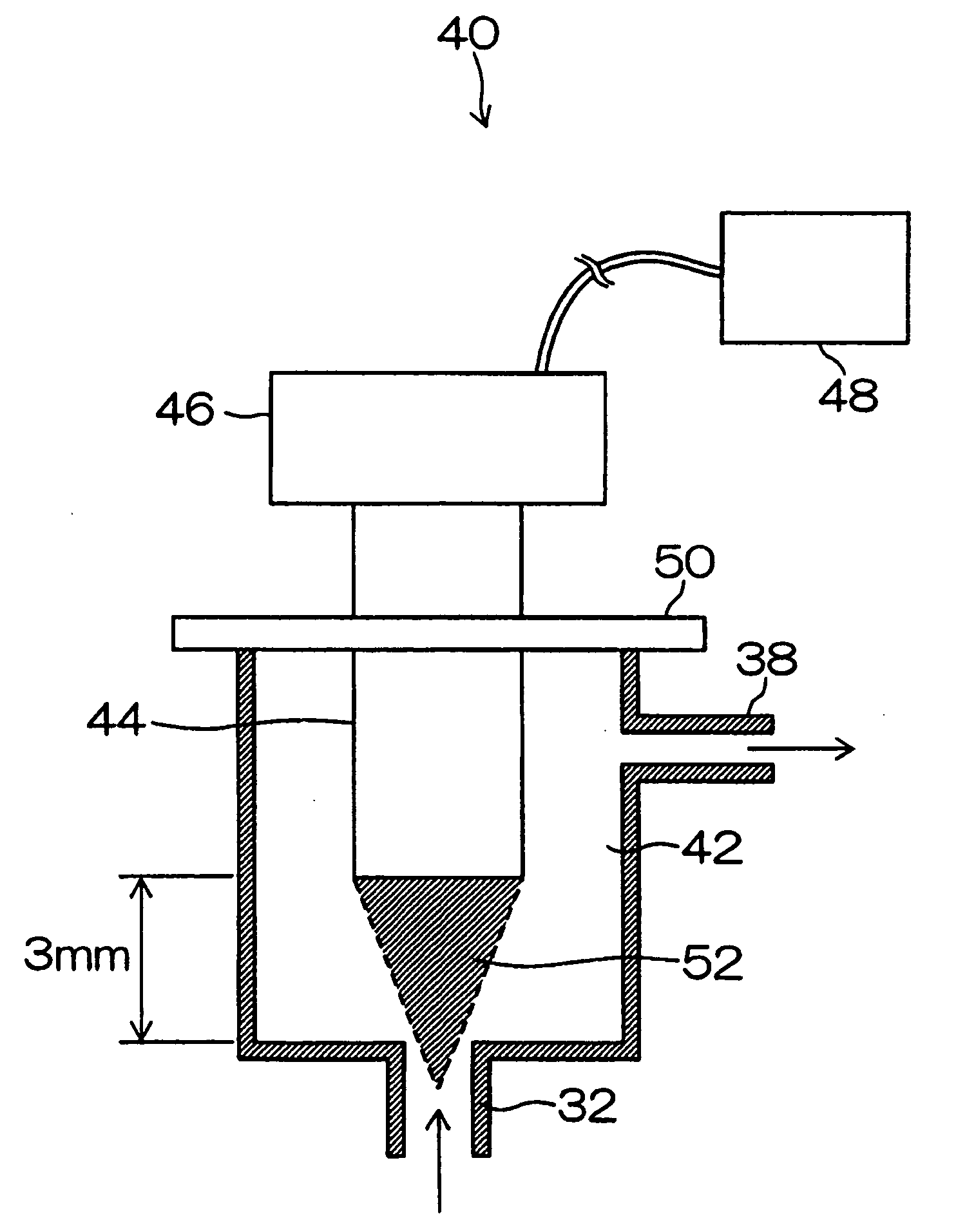

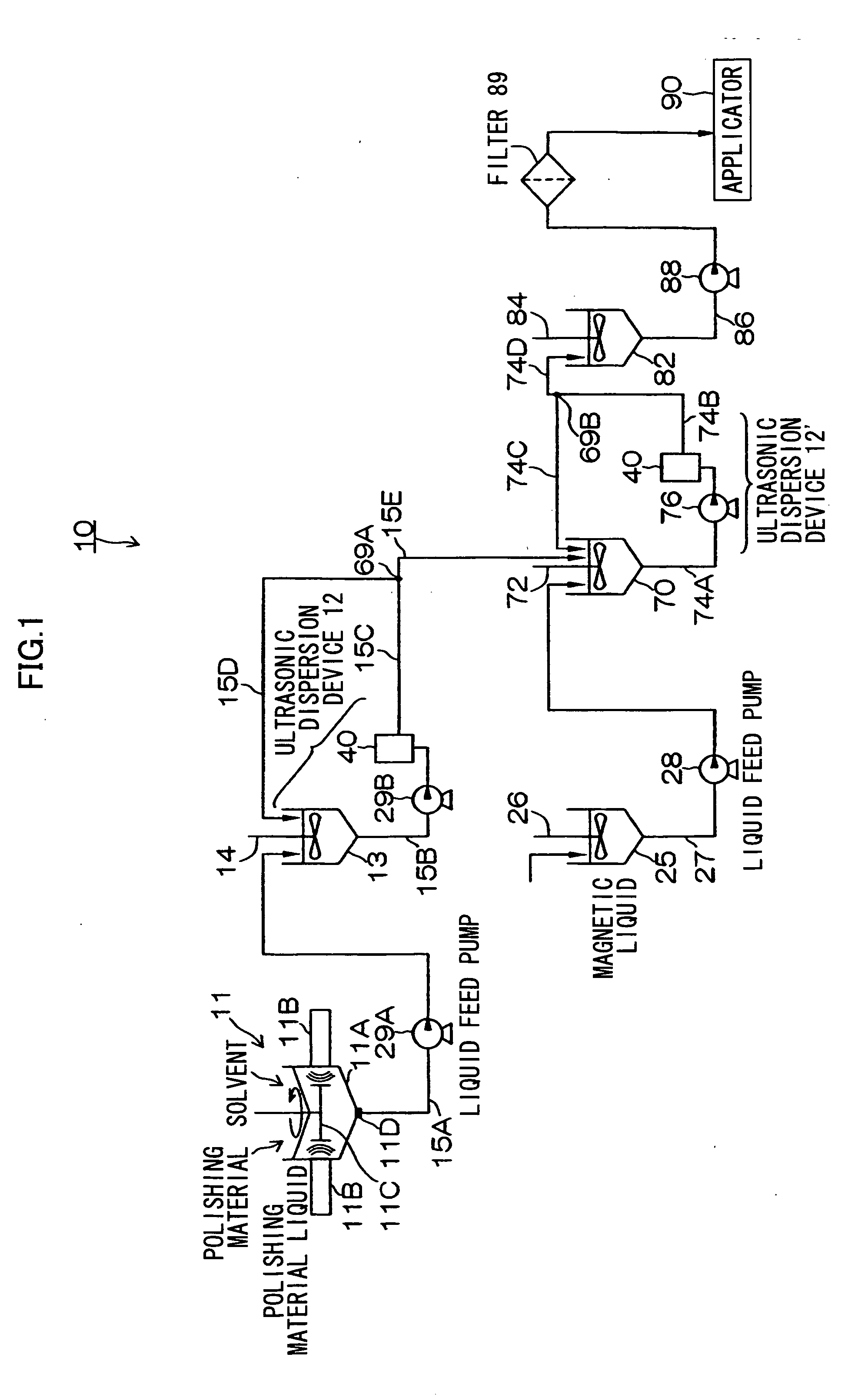

Method of manufacturing magnetic recording medium

ActiveUS20050153062A1Reduce wearPromoting the breakdown of agglomerated grainsRecord information storageCoating by liquid dispersionMagnetic liquidsSolvent

The present invention provides a method of manufacturing a magnetic recording medium that is made by applying a magnetic paint containing a ferromagnetic powder and a binder to a nonmagnetic support, wherein the magnetic paint contains a magnetic liquid, which contains the ferromagnetic powder and the binder, and a polishing material liquid, which contains a polishing material and a solvent, and wherein the magnetic liquid and the polishing material liquid are individually subjected to dispersion treatment, the magnetic liquid and the polishing material liquid are then mixed together, and after that, a mixed liquid of the magnetic liquid and the polishing material liquid are subjected to dispersion treatment by application of ultrasonic waves.

Owner:FUJIFILM CORP +1

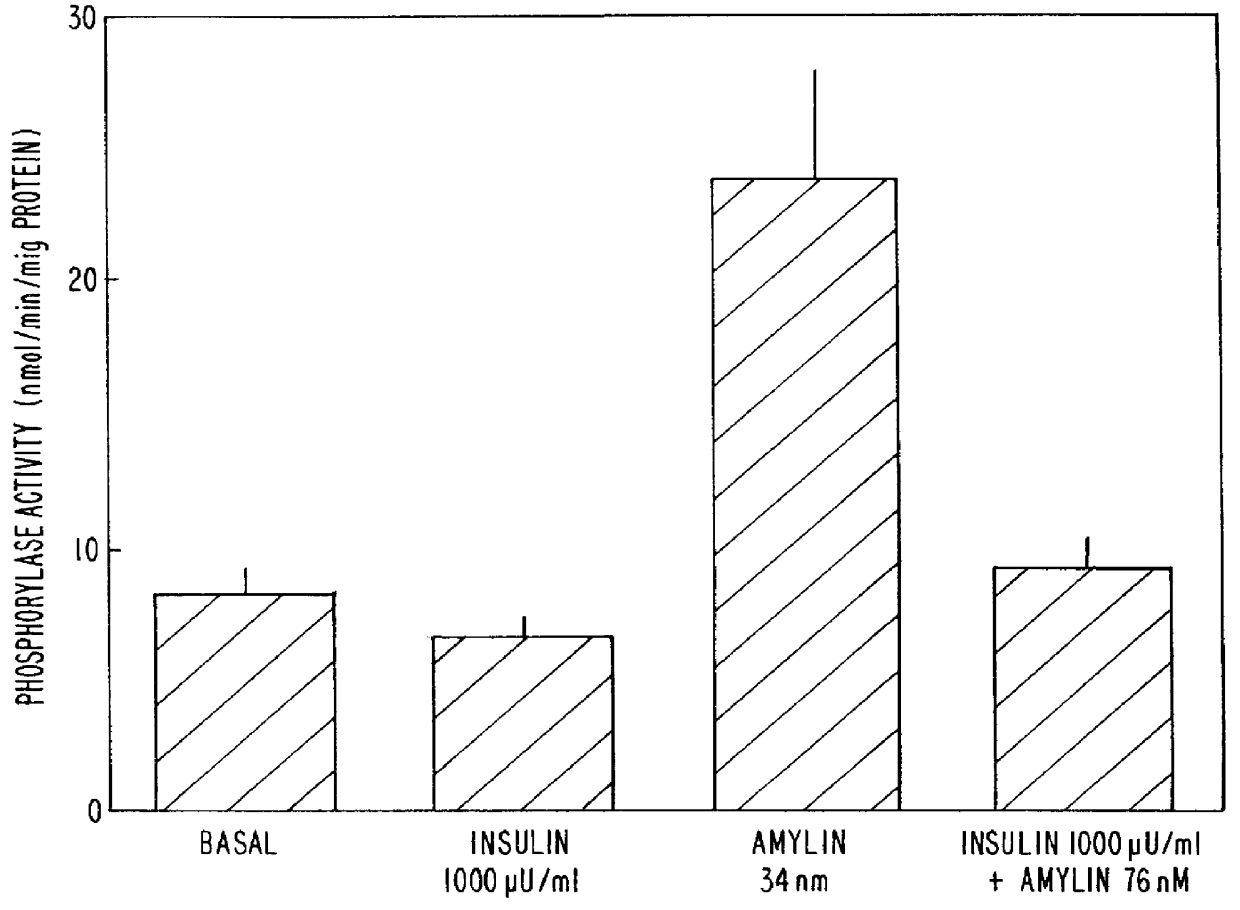

Amylin activity assays

InactiveUS6048514AIncrease productionImprove blood sugar levelsCompounds screening/testingHormone peptidesAcute hyperglycaemiaTest sample

Novel methods for use in identifying or assaying compounds which can simulate the ability of amylin to cause hyperlactemia and hyperglycemia in in vivo biological models, or for use in evaluating the potency of compounds known or suspected to simulate these actions of amylin, which involve introducing test samples into in vivo test systems and determining the presence or amount of a rise in lactate, or determining the presence or amount of a rise in lactate and a rise in glucose, following test sample administration.

Owner:ASTRAZENECA PHARMA LP

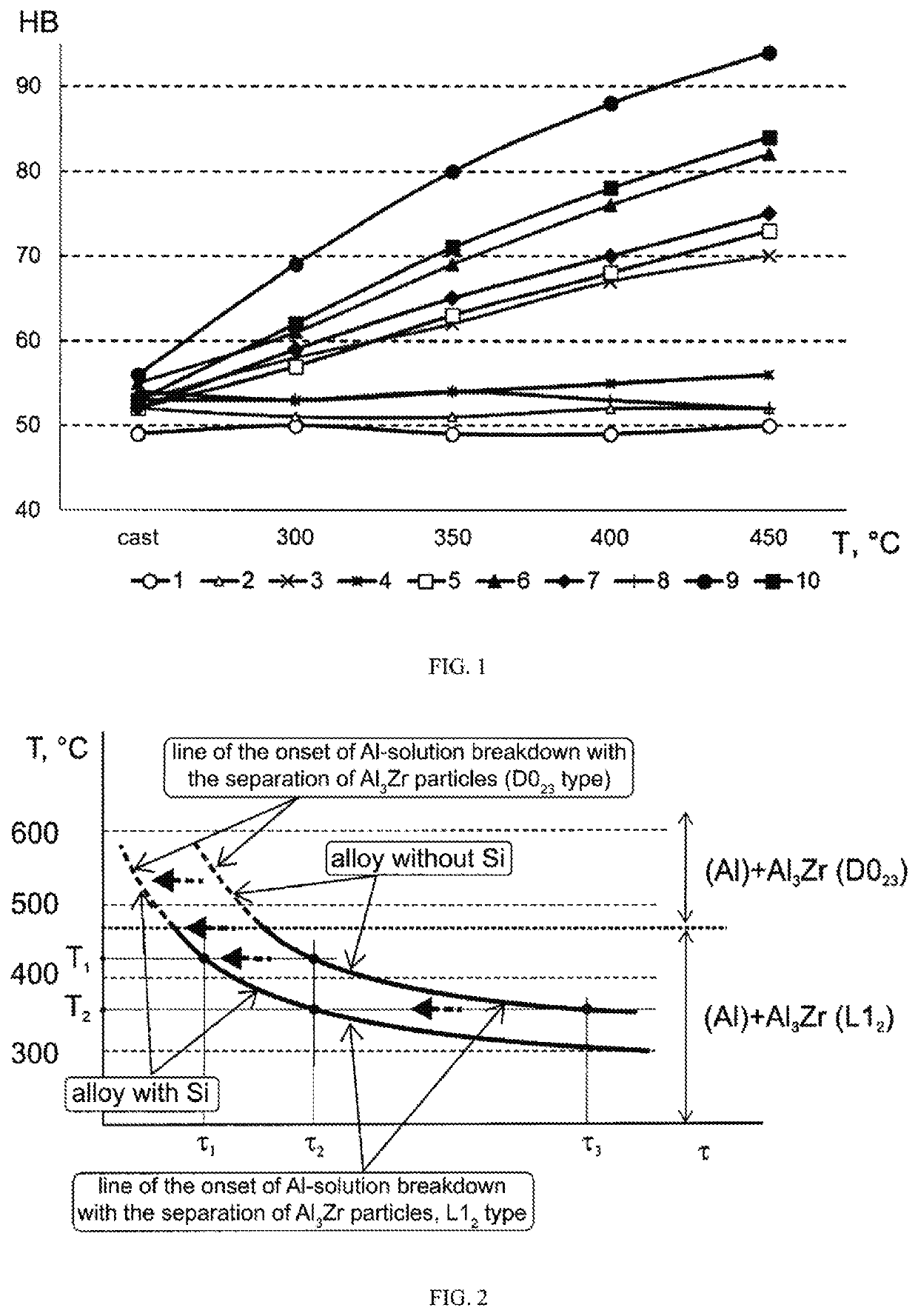

Aluminum-Based Alloy

The invention relates to the field of metallurgy of aluminum-based materials and can be used to produce articles (including welded structures) operated in corrosive environments (humid atmosphere, fresh or sea water, and other corrosive environments) and under high-load conditions, including at elevated and cryogenic temperatures. A new, inexpensive, high-strength aluminum alloy is provided with high physical and mechanical properties, performance, and corrosion resistance, in particular, high mechanical properties after annealing (tensile strength of at least 400 MPa, yield point of at least 300 MPa, and relative elongation of at least 15%) and high performance in deformation processing; wherein high performance in deformation processing is provided due to the presence of eutectic Fe-containing alloy phases, accompanied by increased mechanical properties due to the formation of compact particles of eutectic phases and secondary separation of the Zr-containing phase with the L12 crystal lattice. The aluminum alloy contains zirconium, iron, manganese, chromium, scandium, and optionally magnesium. It also additionally comprises at least one eutectics forming element selected from the group consisting of silicon, cerium and calcium, wherein the structure of the alloy is an aluminum matrix containing silicon and optionally magnesium, secondary separations of Al3(Zr,X) phases with the L12 lattice and a size of not more than 20 nm, wherein X is Ti and / or Sc, secondary separations of Al6Mn and Al7Cr, and eutectic phases containing iron and at least one element from the group consisting of calcium and cerium with an average particle size of not more than 1 μm, with the following phase ratio, wt. %:Secondary separations of Al3(Zr,Sc): 0.5-1.0;Secondary separations of Al6Mn and Al7Cr: 2.0-3.0;Eutectic particles containing iron and at least one element from the group consisting of calcium and silicon: 0.5-6.0;Aluminum matrix: the remainder.

Owner:OBSHCHESTVO S OGRANICHENNOY OTVETSTVENNOSTYU OBEDINENNAYA KOMPANIYA RUSAL INZHENERNO TEKHNOLOGICHESKIY TSENTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com