Trend monitoring and diagnostic analysis method for vacuum pump and trend monitoring and diagnostic analysis system therefor and computer-readable storage media including a computer program which perf

一种真空泵、趋势的技术,应用在半导体制造工艺领域,能够解决不能提供装备安全危险、不能获得参考数据、不能工艺或机器操作参数的总改变响应等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

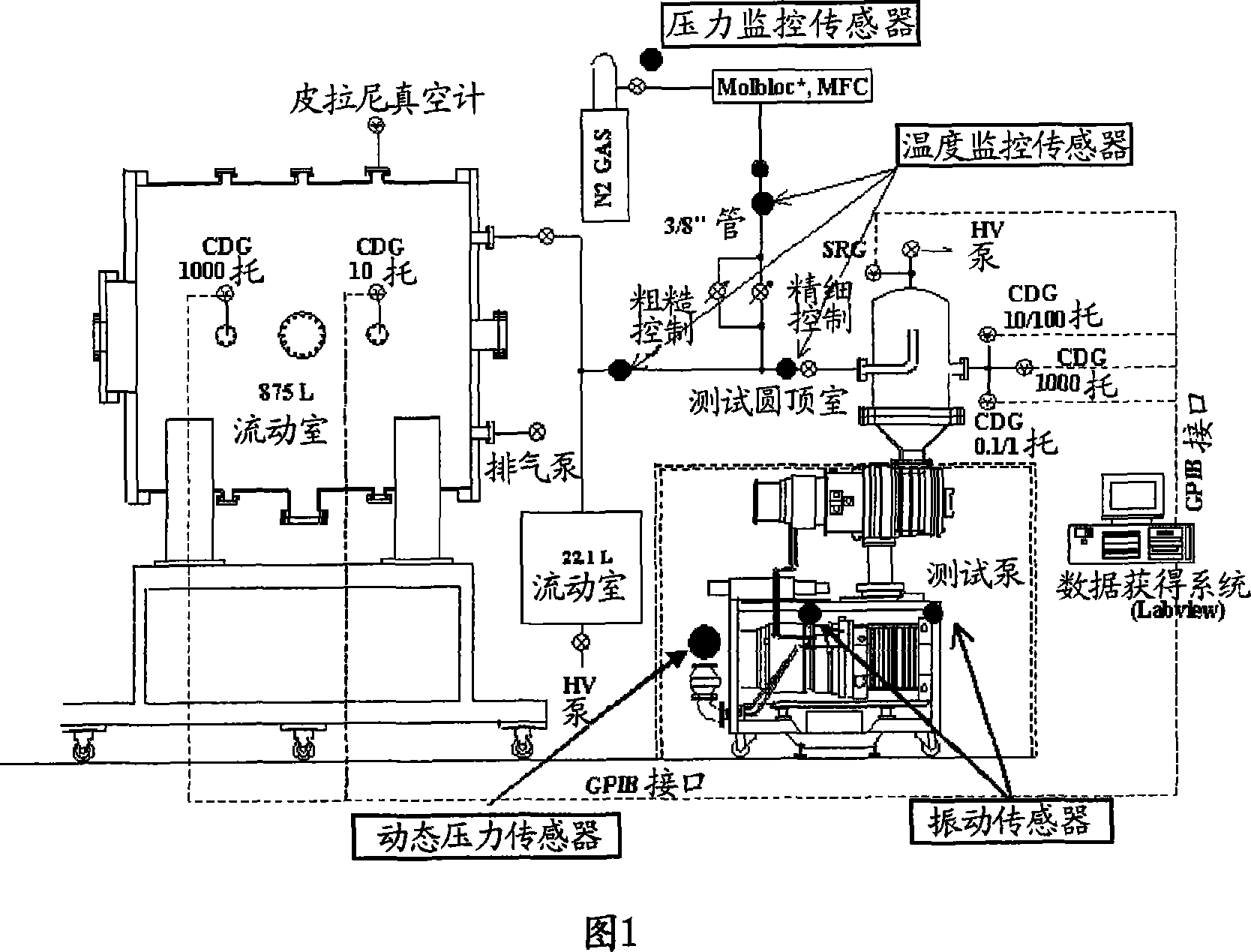

[0031] Active Diagnostic Algorithms of Vacuum Pumps

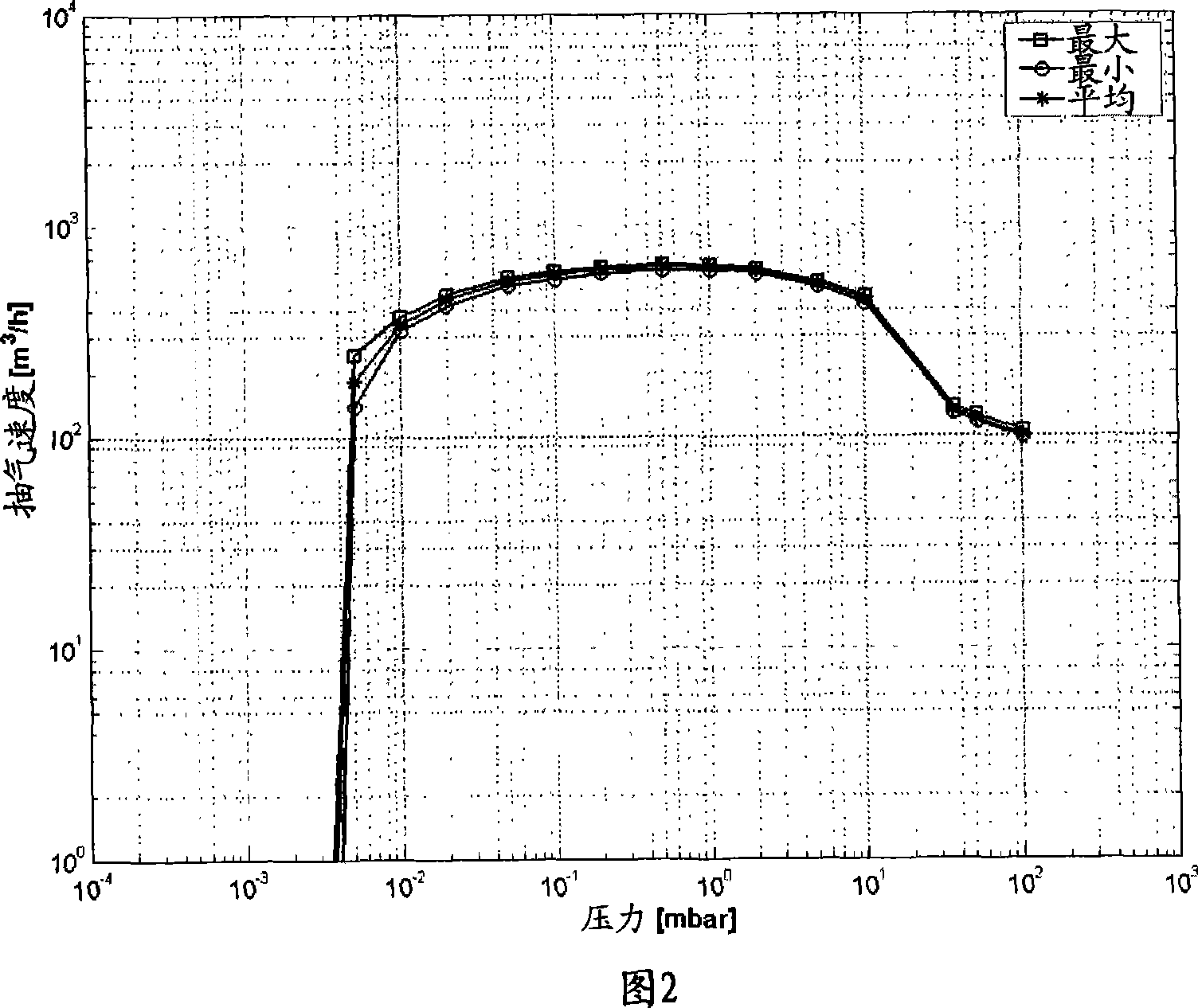

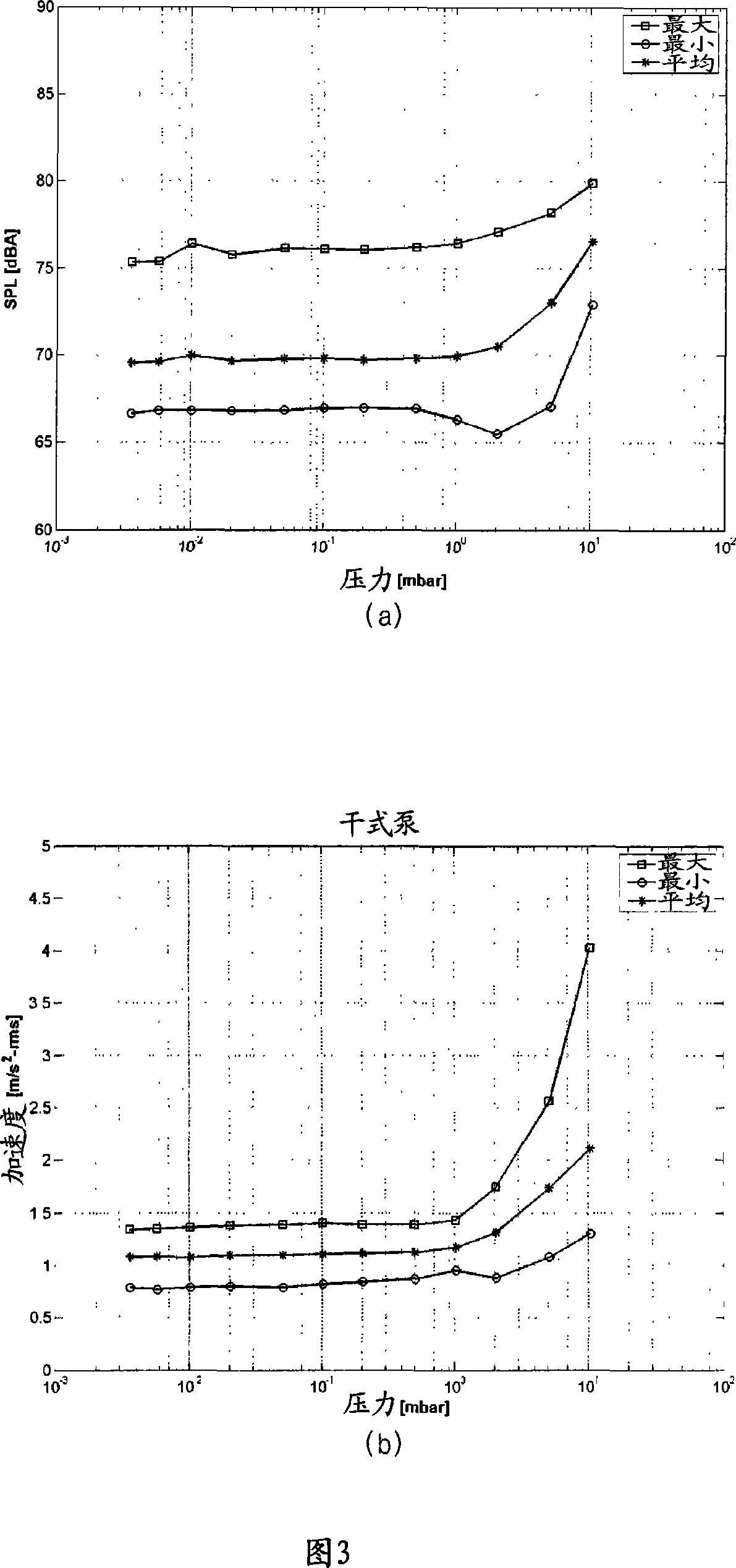

[0032] A state variable in the present invention is defined as one of the periodically sampled physical parameters chosen to quantitatively examine the operating conditions of the vacuum pump under consideration. There are various state variables related to pump operation, such as engine current, intake and discharge pressure, acoustic pressure signal, mechanical vibration signal, purge gas pressure and its flow rate, body temperature, cooling water temperature, lubricating oil pressure and vacuum pump level, etc. . These vacuum pump status variables have been used to diagnose vacuum pump operating conditions. However, a limited number of state variables are chosen to enable effective diagnostics of the vacuum pump. Their selection in the present invention has been made on the basis of gas loading dependence. If the state variable response dependence on the intake pressure of the vacuum pump is high, it is classified as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com