Patents

Literature

51results about How to "High mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

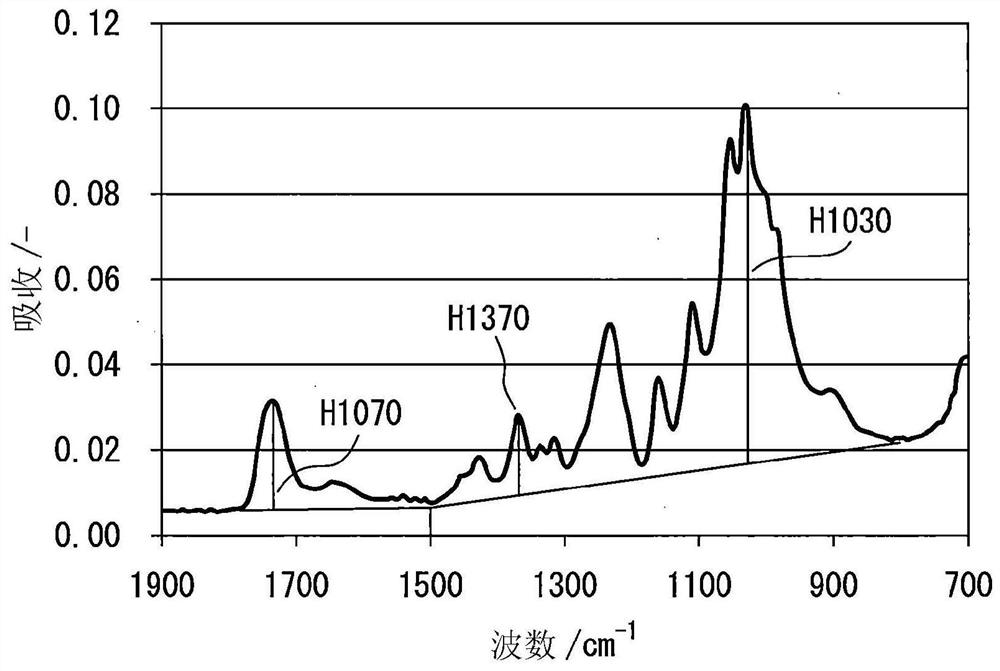

Process for producing porous silica particles, resin composition for antireflection coatings, article with antireflection coating, and antireflection film

InactiveCN103328382AIncrease productionImprove production efficiencySilicaAnti-reflective coatingsSilica particleAlcohol

The purpose of the present invention is to provide a process for producing porous silica particles which enables reduction in the particle diameter and which attains, in the production, a high yield relative to the volume of a reaction solution. A process for producing porous silica particles which have pores on the surface is provided in order to achieve the purpose. This process is characterized by including: a step of adding a mixed fluid (A) which comprises a tetraalkoxysilane, an alkylamine and an alcohol to a mixed fluid (B) which comprises ammonia, an alcohol and water to conduct the hydrolysis and condensation of the tetraalkoxysilane and thus obtain silica particles; and a step of removing the alkylamine from the silica particles.

Owner:DIC CORP

Preparation method of modified non-halogen fire retardant

InactiveCN1990824AGood compatibilityImprove mechanical propertiesFireproof paintsHigh concentrationHalogen

The invention relates to a method for producing modified non- halogen flame retardant, it employs in-situ polymerization and comprises following steps: putting non- halogen flame retardant into kneader with high cottage at 25- 200 Deg. C, stirring thoroughly, feeding inclinly, adding polymeric monomer and initiator for thorough polymerization, and getting packed modified non- halogen flame retardant. The invention is characterized in that it uses no solvent, the polymerization time is short, and the productivity is high, suitable for industrial production, and the shell thickness and strength of microcapsule are easy to control. The modified flame retardant is characterized by large stacking density, sound flame retardance, high concentration, strong currency and good processing performance.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

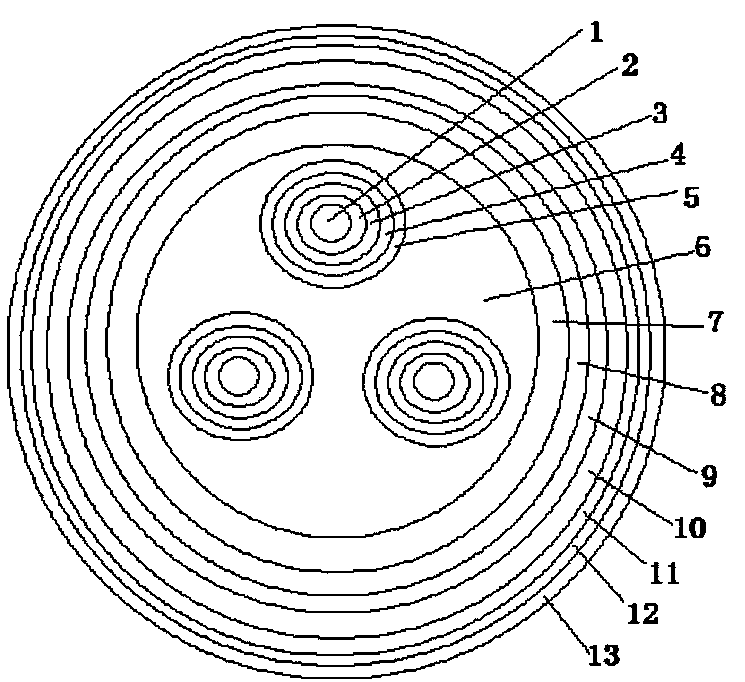

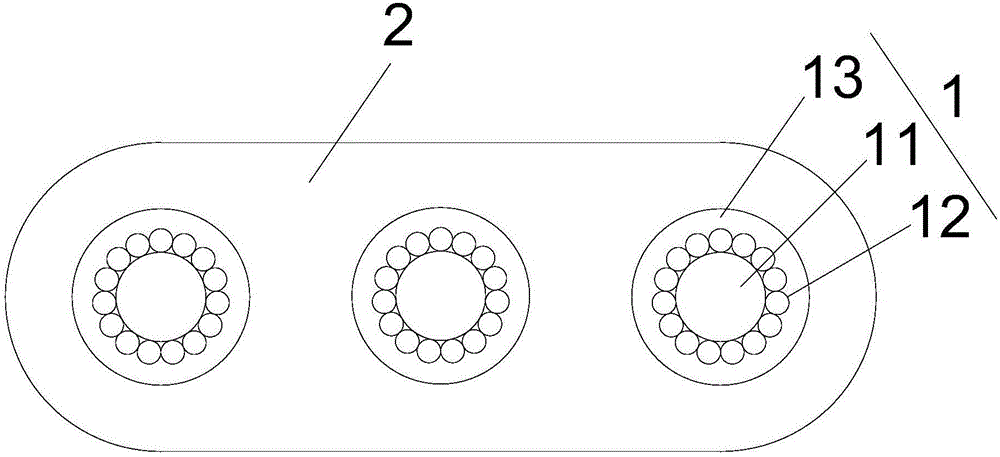

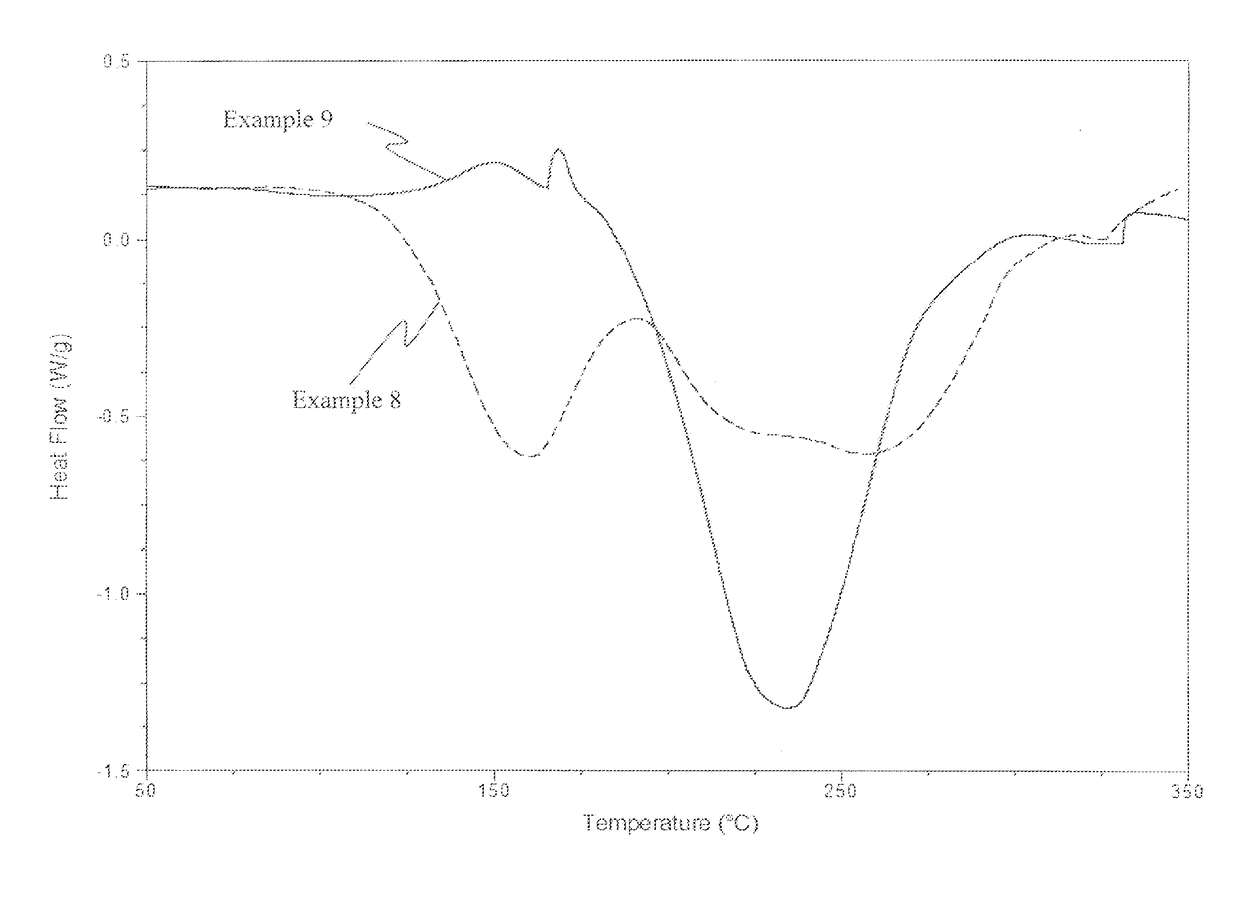

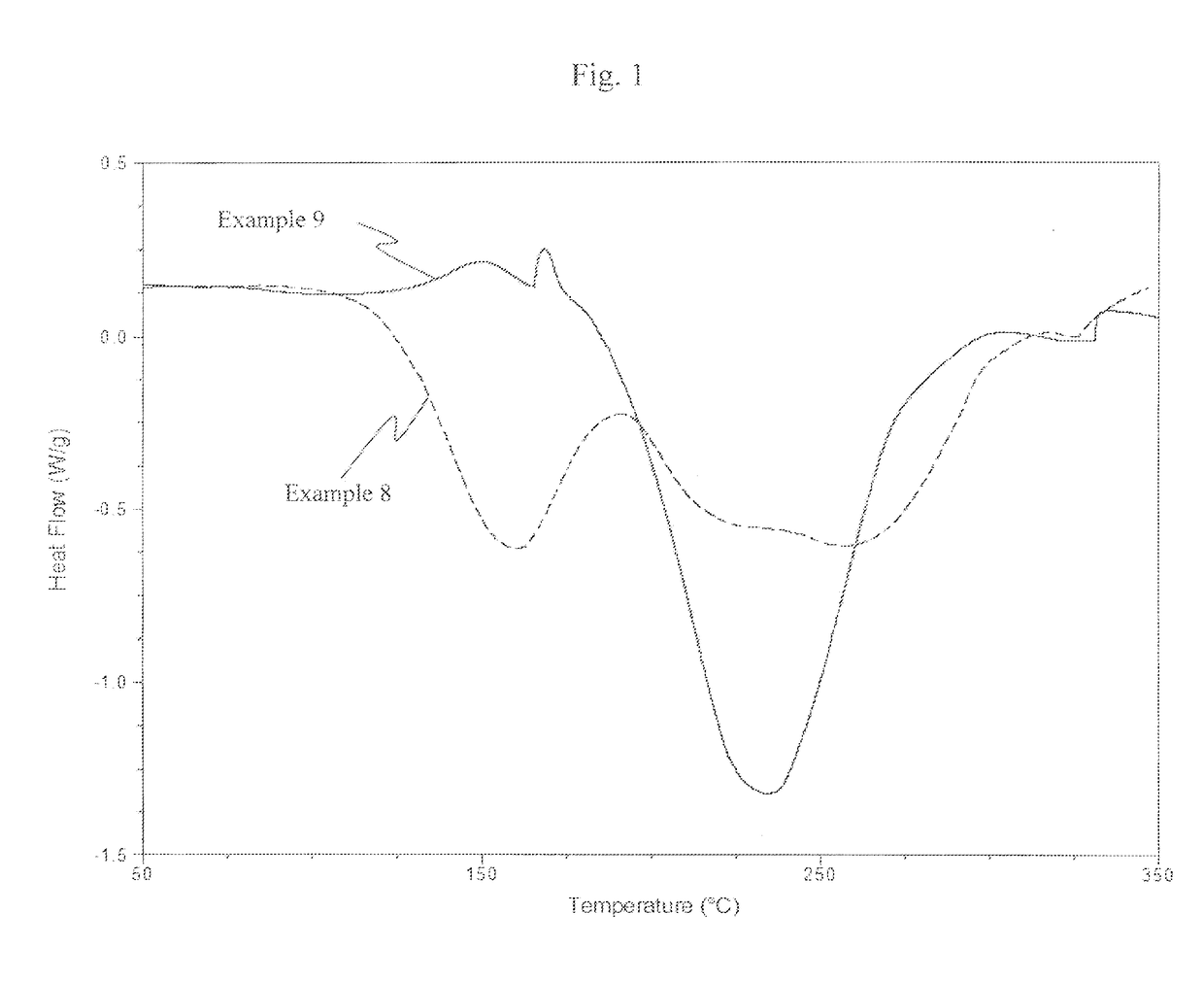

Polymer li-ion battery and the separator thereof

InactiveUS20130236765A1High mechanical propertiesHigh performance propertySecondary cellsCell component detailsPorous substrateLithium-ion battery

The invention pertains to the technical field of a polymer Li-ion battery, in particular to a polymer Li-ion battery separator, comprising porous substrate, wherein at least one surface of the porous substrate is coated with an inorganic coating and an organic coating; the organic coating, shaped like an island and / or linear distribution, is coated on the surface of the porous substrate and / or the inorganic matter coating.

Owner:NINGDE AMPEREX TECH +1

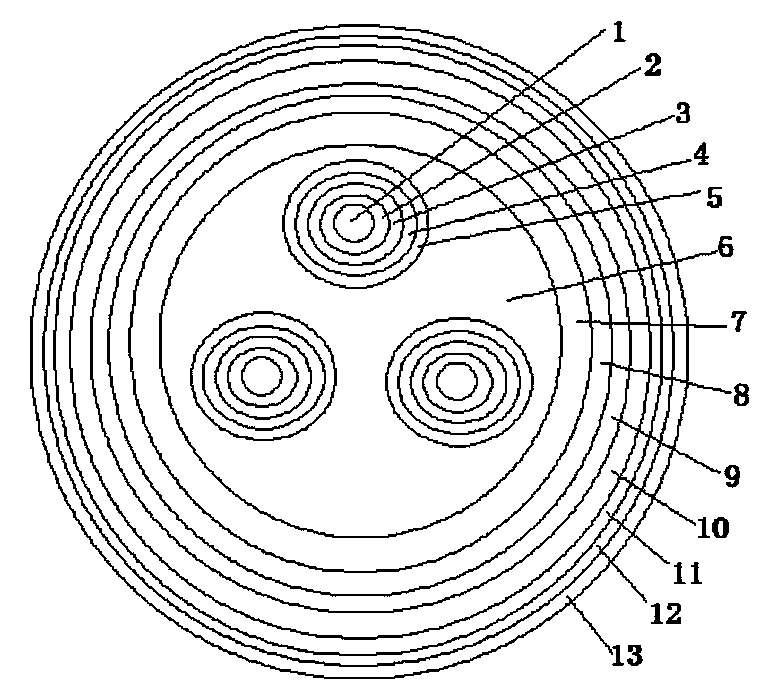

Purple-light cross-linked low-smoke halogen-free high flame-retardant EVA cable and production method thereof

InactiveCN104200906AImprove performanceImprove shielding effectInsulated cablesCable/conductor manufactureLow smoke zero halogenGlass fiber

The invention provides a purple-light cross-linked low-smoke halogen-free high flame-retardant EVA cable which comprises conductors. Each conductor is covered with a shield layer, the shield layer is covered with a purple-light cross-linked insulating layer, the purple-light cross-linked insulating layer is covered with a ceramic silicone rubber layer, and the ceramic silicon rubber layer is covered with an anticorrosive layer. Flame-retardant glass fiber filling ropes are filled among the conductors, the conductors and the flame-retardant glass fiber filling ropes are together covered with a flame-retardant tape, the flame-retardant tape is covered with an internal purple-light cross-linked protective layer, the internal purple-light cross-linked protective layer is provided with an armor layer, the armor layer is covered with an external purple-light cross-linked protective layer, the external purple-light cross-linked protective layer is covered with a waterproof layer, the waterproof layer is covered with an SBS rubber layer, and the SBS rubber layer is coated with an ultraviolet-proof layer. The invention further provides a production method of the cable. The purple-light cross-linked low-smoke halogen-free high flame-retardant EVA cable is provided with multiple flame-retardant layers and the waterproof layer.

Owner:ZHANGQIU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

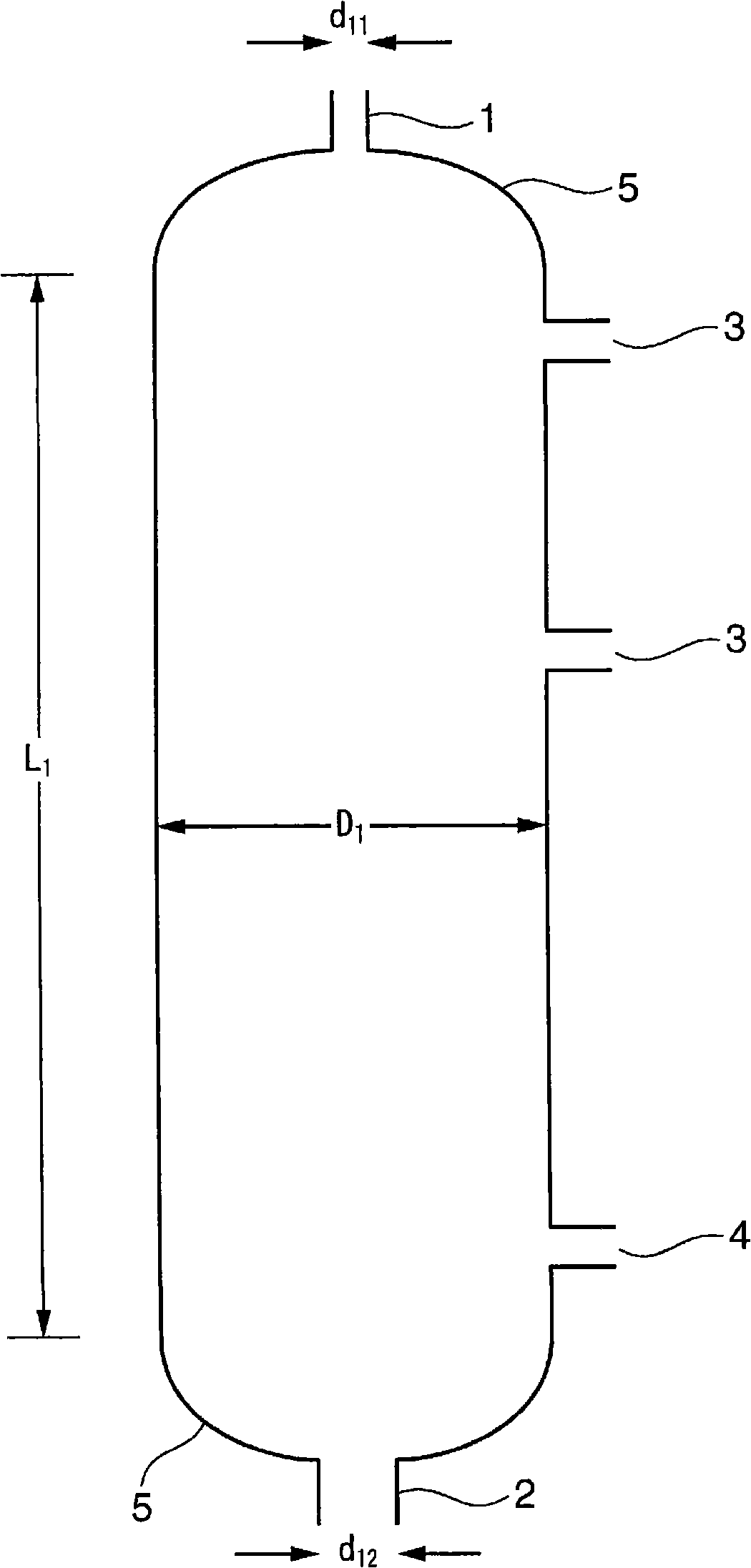

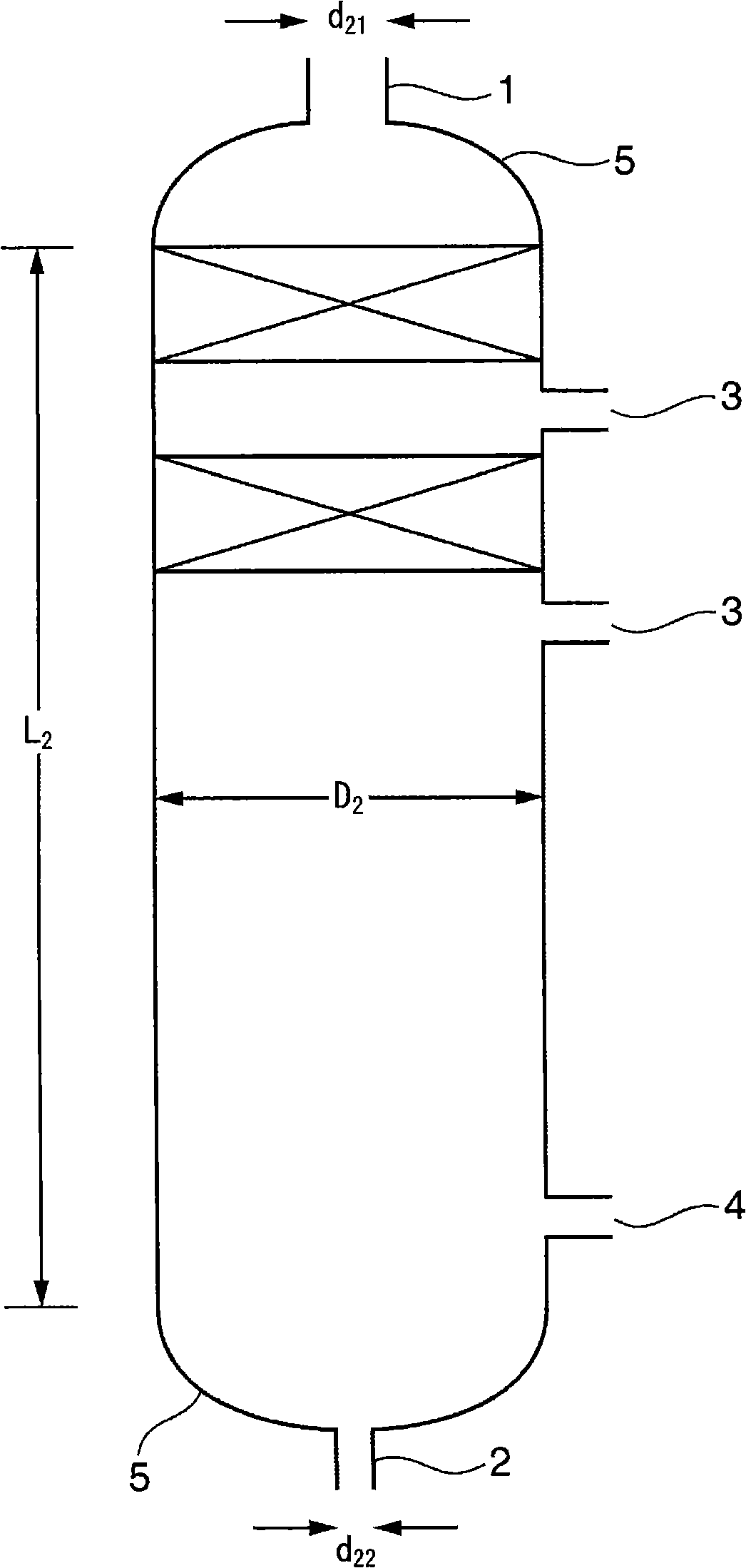

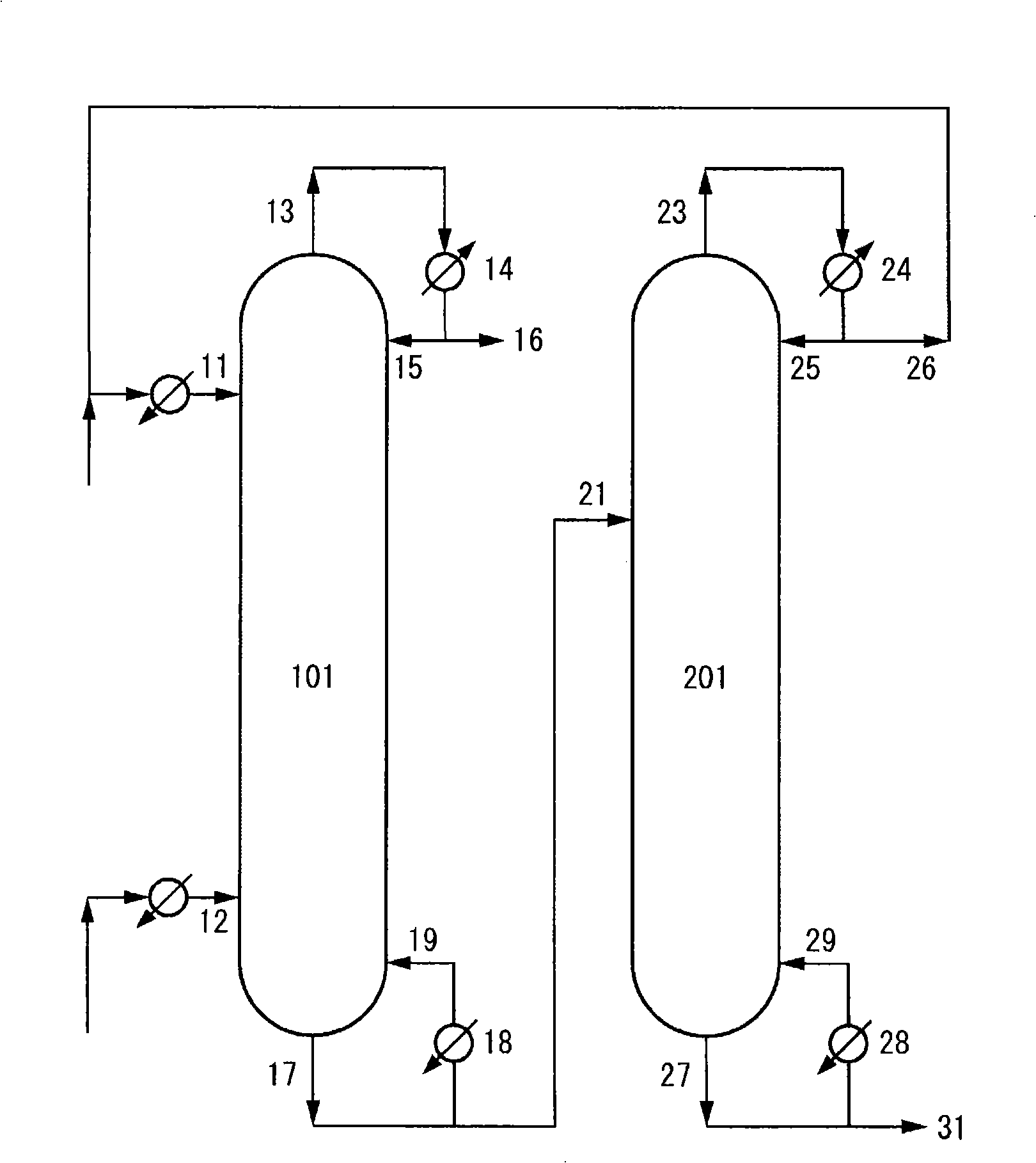

Industrial production process for high-quality aromatic polycarbonate

ActiveCN101321805AHigh mechanical propertiesImprove qualityChemical industryPreparation from organic carbonatesArylPolymer science

Disclosed is a specific process for producing a high-quality / high-performance aromatic polycarbonate free from discoloration and having excellent mechanical properties from a dialkyl carbonate and an aromatic dihydroxy compound stably, in an industrially large scale (e.g., 1 ton or more per hour) for a prolonged period of time (e.g., for 1000 hours or longer, preferably 3000 hours or longer, more preferably 5000 hours or longer). The process comprises the steps of: (I) producing a diaryl carbonate with two reactive distillation columns each having a specific structure; (II) purifying the diaryl carbonate to yield a highly pure diaryl carbonate; (III) preparing a molten prepolymer from an aromatic dihydroxy compound and the highly pure diaryl carbonate and treating the molten prepolymer with a guide contact flow-down type polymerizer having a specific structure to produce a desired aromatic polycarbonate; and (IV) recycling an aromatic monohydroxy compound, which is a by-product in the reaction in step (III), into step (I).

Owner:ASAHI KASEI KK

Epoxy and alkoxy silyl group-containing silsesquioxane and composition thereof

ActiveUS20150368397A1High gas barrier property propertyHigh mechanical propertiesSilicon organic compoundsSemiconductor/solid-state device detailsChemistryHydrosilylation

A silicon compound is described, being obtained by a hydrosilylation reaction of the following compound (a), compound (b) and compound (c). Compound (a) is a silsesquioxane derivative having two or more SiH in one molecule. Compound (b) is a compound having, in one molecule, epoxy and / or oxetanyl and an alkenyl having a carbon number of 2 to 18. Compound (c) is a compound having, in one molecule, an alkoxysilyl and an alkenyl having a carbon number of 2 to 18.

Owner:JNC CORP

Ferronickel slag magnesium phosphate binding material and application thereof

InactiveCN106630924AHigh yieldGuaranteed physical and mechanical propertiesSolid waste managementPorosityMagnesium phosphate

The invention discloses a ferronickel slag magnesium phosphate binding material and application thereof. The binding material is prepared from 6-12 parts of ferronickel slag, 12-25 parts of dead burned magnesia, 3-12 parts of phosphate and 1-10 parts of retarder. The ferronickel slag magnesium phosphate binding material is used in structural members requiring high strength in early age period and rush-repair work. The ferronickel slag magnesium phosphate binding material has the advantages of achieving rapid hardening and early strengthening, and being high in strength and small in shrinkage deformation, the interior structure is more compact, the porosity is low, and the durability including water tolerance is improved. Moreover, according to the ferronickel slag magnesium phosphate binding material, innocent treatment of the ferronickel slag is achieved, high-efficiency resource utilization of industrial waste residues is promoted, and on the premise that the mechanical properties of the binding material is guaranteed, the consumption of dead burned magnesia is reduced, the consumption of a non-renewable resource, namely magnesite, and energy loss are reduced, the production cost of the magnesium phosphate binding material is decreased, and therefore, economic benefits and environmental benefits are remarkable.

Owner:HOHAI UNIV

Manufacturing method for fibre-reinforced composite material, heat resistant material using said composite material, and heat resistant structural material using said composite material

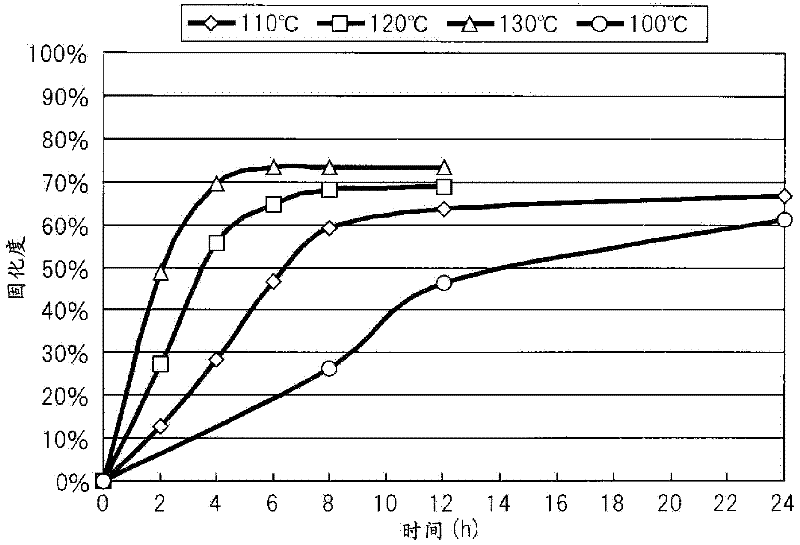

A method for manufacturing a fibre-reinforced composite material with good mechanical properties and high heat resistance, such that a plaster mold can be used for initial curing. A fibre-reinforced prepreg obtained by impregnating reinforced fibres with an epoxy resin composition which contains a triphenylmethane type epoxy resin (A), N, N, N', N'-tetraglycidyl diaminodiphenylmethane (B), and diaminodiphenylsulfone (C), undergoes an initial curing at 110-130 DEG C and furthermore undergoes a second curing at a temperature not less than the temperature of the initial curing.

Owner:MITSUBISHI CHEM CORP

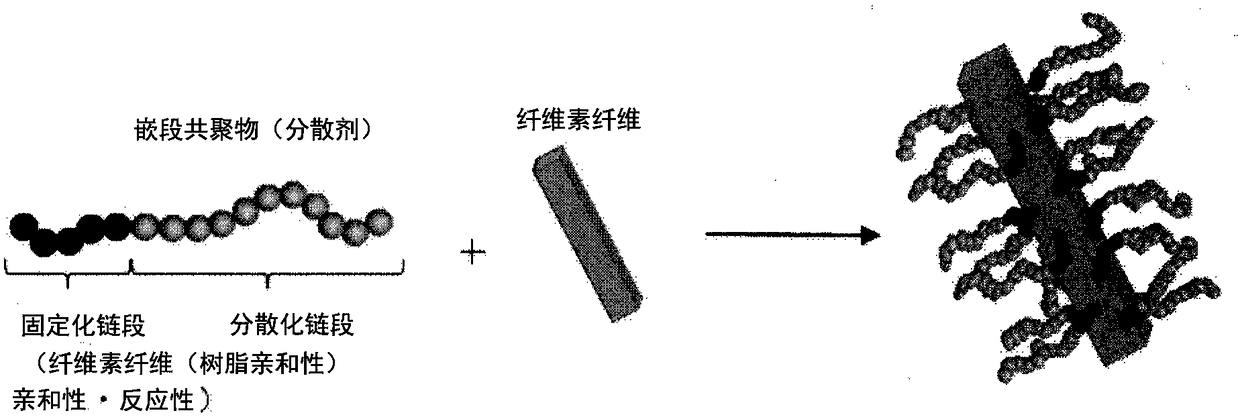

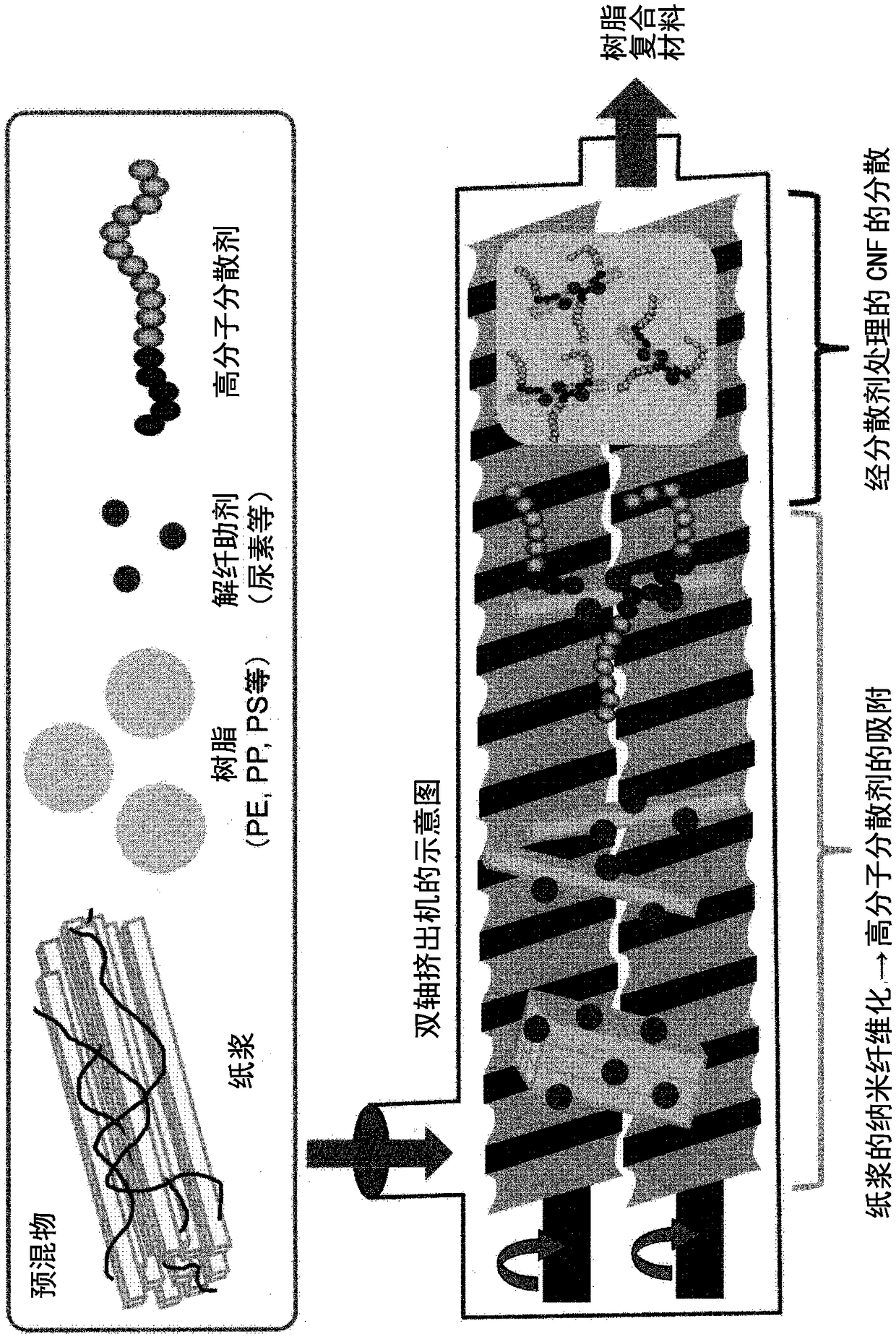

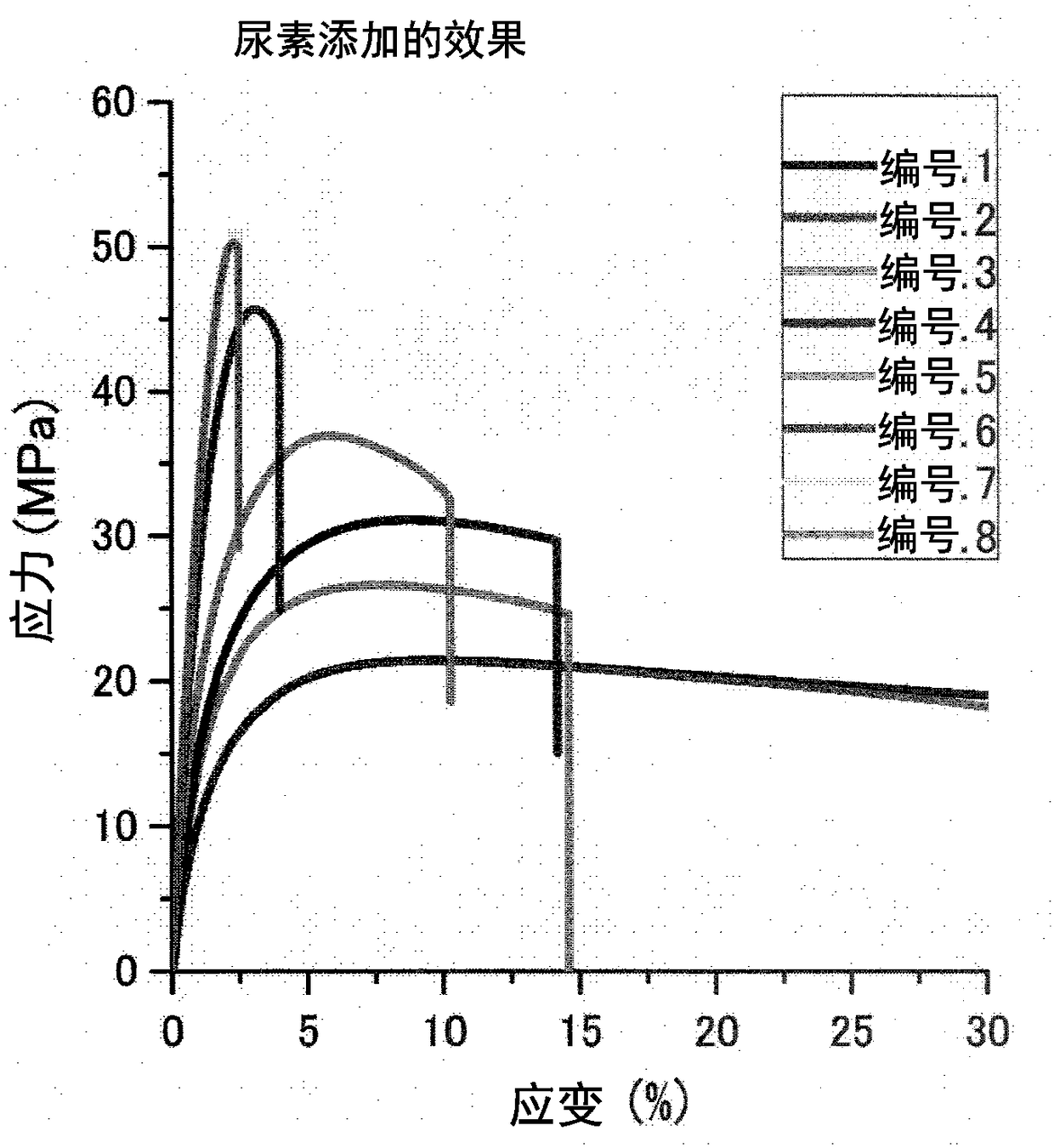

Resin composition and method for manufacturing same

The purpose of the present invention is to formulate a technique for manufacturing a resin composite material at low cost. Provided is a resin composition including cellulose fibers, a fiber-looseningauxiliary agent, and a resin.

Owner:KYOTO UNIV +1

Irradiation-resistant halogen-free high-flame-retardant EVA electric wire and manufacturing method thereof

ActiveCN104183317AImprove performanceImprove shielding effectInsulated cablesInsulated conductorsElectrical conductorMaterials science

The invention provides an irradiation-resistant halogen-free high-flame-retardant EVA electric wire which comprises a conductor. A shielding layer is arranged outside the conductor. An irradiation-resistant flame-retardant EVA insulating layer is arranged outside the shielding layer. A fireproof layer is arranged outside the irradiation-resistant flame-retardant EVA insulating layer. A high-temperature-resistant layer is arranged outside the fireproof layer. The conductor is filled with a flame-retardant fiberglass filling rope. A flame-retardant belt is arranged outside the whole conductor and the flame-retardant fiberglass filling rope. An inner irradiation-resistant flame-retardant EVA layer is arranged outside the flame-retardant belt. An armor layer is arranged outside the inner irradiation-resistant flame-retardant EVA layer. An outer irradiation-resistant flame-retardant EVA layer is arranged outside the armor layer. A waterproof and corrosion-proof layer is arranged outside the outer irradiation-resistant flame-retardant EVA layer. A wearing layer is arranged outside the waterproof and corrosion-proof layer. The exterior of the wearing layer is coated with an irradiation-resistant layer. The invention further provides a preparation method of the electric wire. The irradiation-resistant halogen-free high-flame-retardant EVA electric wire is obtained due to the arrangement of the multiple irradiation-resistant layers and the multiple flame-retardant layers.

Owner:珠海思科信电线电缆有限公司

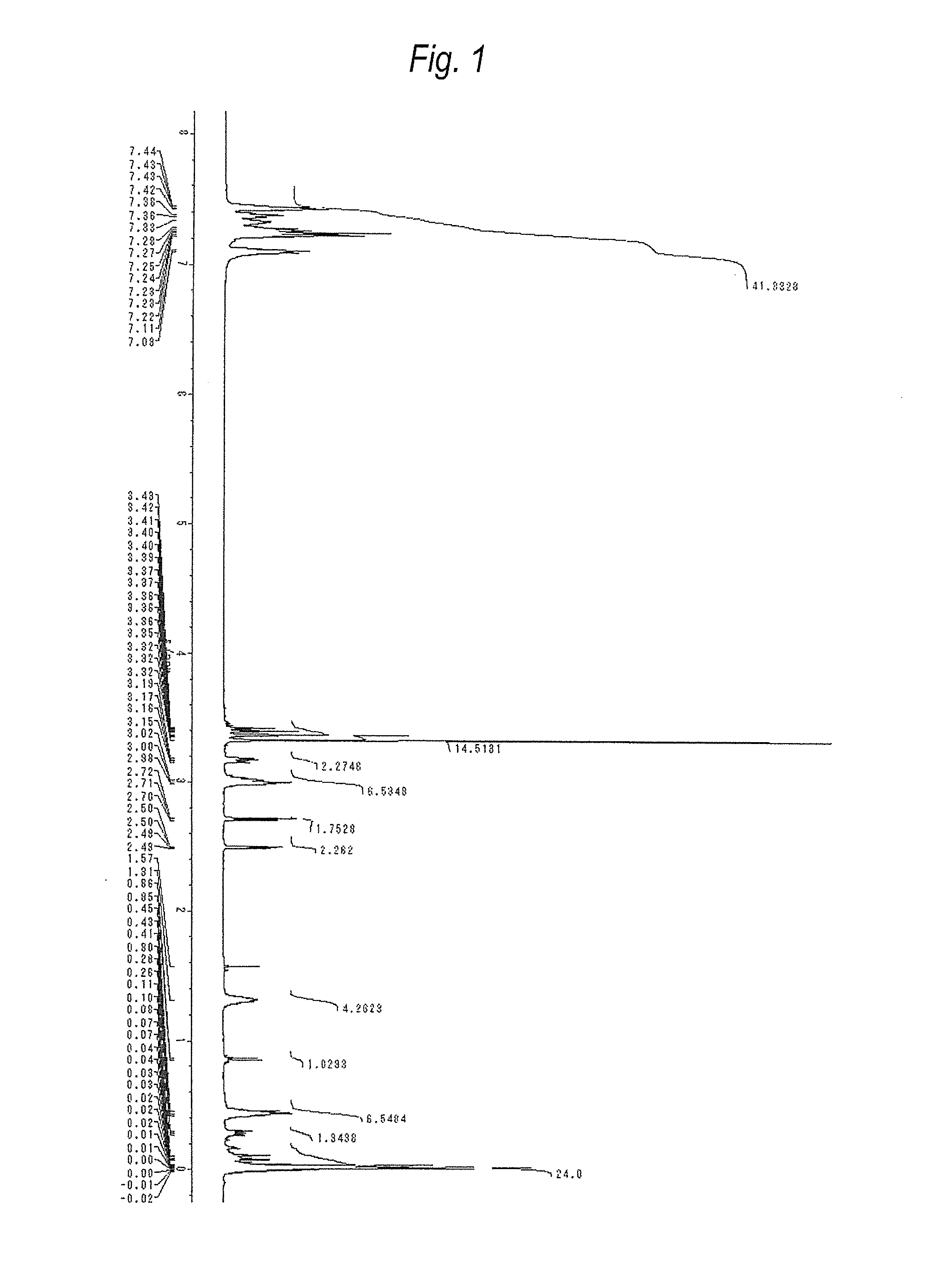

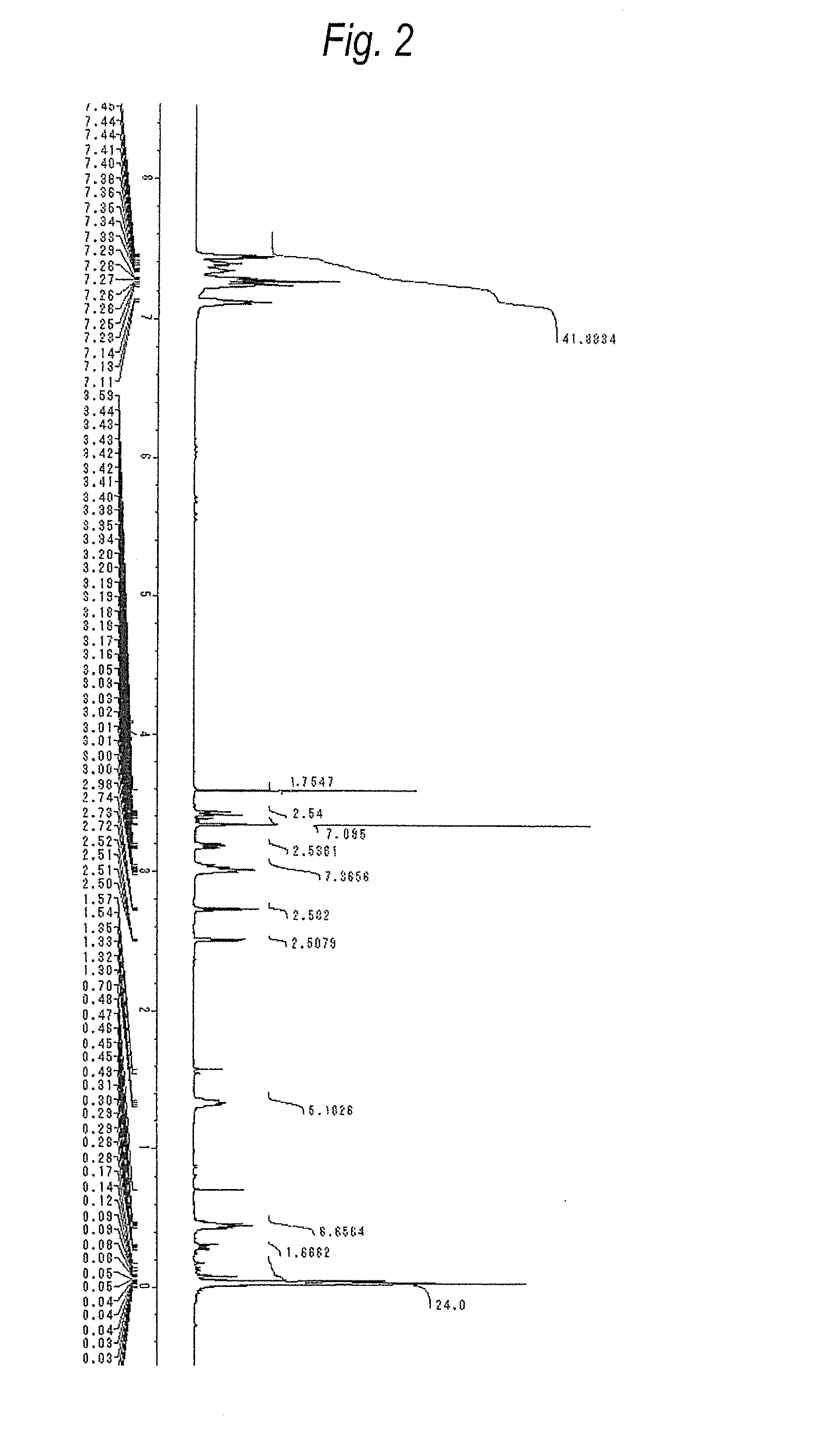

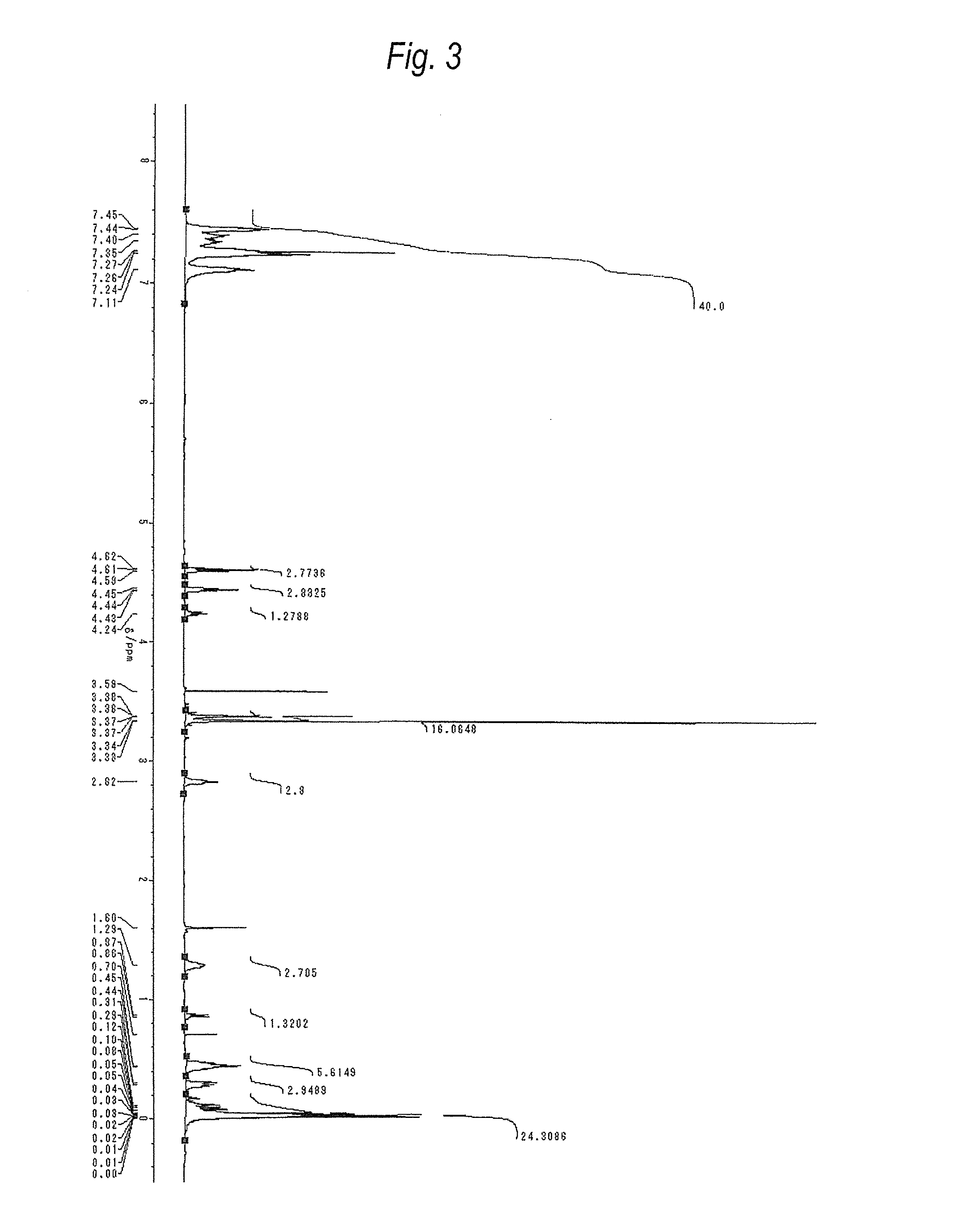

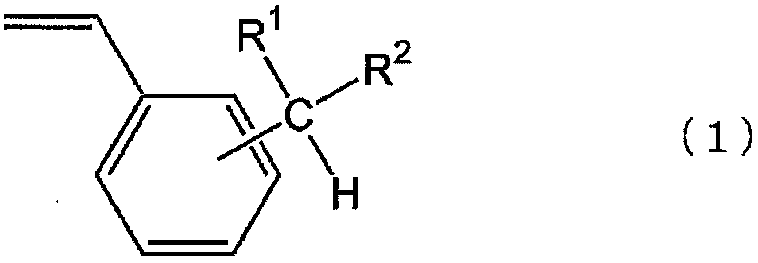

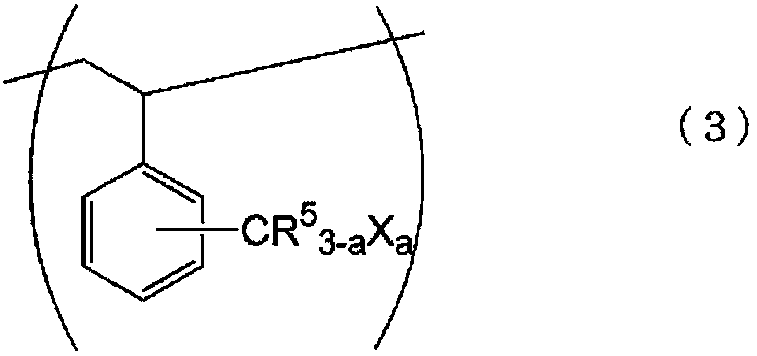

Process for producing thermoplastic elastomer, and thermoplastic elastomer

When producing a copolymer of a block (a) comprising an alkylstyrene and an isoolefin as main components and a block (b) comprising an aromatic vinyl monomer as a main component, it has been impossible in conventional techniques to inexpensively and stably produce, with simple equipment, a thermoplastic elastomer in which units of the alkylstyrene have been randomly introduced into the isoolefin polymer and which can retain excellent mechanical strength. The above-mentioned problem is solved by using a specific compound as a polymerization initiator and keeping the amount of the unreacted alkylstyrene present during the polymerization for producing the block (a) at up to 1 / 90 the total amount of the isoolefinic monomers.

Owner:KANEKA CORP +1

Expansion halogen-free flame-retardant PP/EVA (polypropylene/ethylene-vinyl acetate) wire and cable composition and method for manufacturing same

ActiveCN104217797AImprove performanceImprove shielding effectClimate change adaptationInsulated cablesGlass fiberPolymer science

The invention provides an expansion halogen-free flame-retardant PP / EVA (polypropylene / ethylene-vinyl acetate) wire and cable composition which comprises conductors. A shielding layer is arranged on the outside of each conductor, a PP / EVA composite insulating layer is arranged on the outside of each shielding layer, a high-temperature-resistant layer is arranged on the outside of each PP / EVA composite insulating layer, an expansion layer is arranged on the outside of each high-temperature-resistant layer, spaces among the conductors are filled with a filler rope made of flame-retardant glass fibers, a flame-retardant belt is arranged on the outsides of the integral conductors and the filler rope made of the flame-retardant glass fibers, an expansion belt is arranged on the outside of the flame-retardant belt, a PP / EVA composite protection layer is arranged on the outside of the expansion belt, a waterproof and anticorrosion layer is arranged on the outside of the PP / EVA composite protection layer, a radiation-resistant layer is coated on the outside of the waterproof and anticorrosion layer, and an abrasion-resistant layer is arranged on the outside of the radiation-resistant layer. The invention further provides a method for manufacturing the expansion halogen-free flame-retardant PP / EVA wire and cable composition. The expansion halogen-free flame-retardant PP / EVA wire and cable composition and the method have the advantage that the expansion halogen-free flame-retardant PP / EVA wire and cable composition is provided with the multiple expansion layers, the expansion belt and flame-retardant layers.

Owner:JIANGSU XINGHUA RUBBER BELT

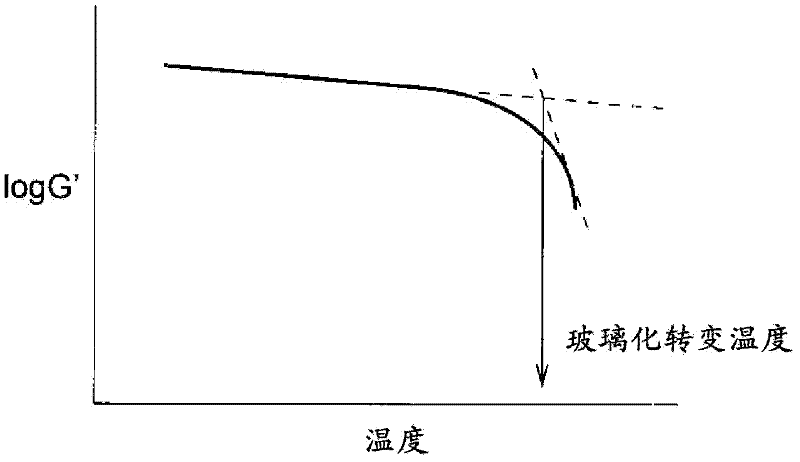

Actinic radiation-curable resin composition for shaping, shaping sheet, and shaped product

InactiveCN1989161AImprove mechanical propertiesHigh mechanical propertiesSynthetic resin layered productsPolyester resinSolvent

An actinic radiation-curable resin composition for shaping, comprising a polyester resin (R) having a number average molecular weight (Mn) of not less than 1,000 and not more than 8,000 and a polymerizable vinyl compound (V). In the composition from which a solvent has been removed, the temperature (T4) at which the complex viscosity coefficient (eta*) at a frequency of 1 Hz is 1 104 dPas is 30 DEG C or above, and the temperature (T6) at which the complex viscosity coefficient (eta*) at a frequency of 1 Hz is 1 106 dPas is 100 DEG C or below.

Owner:DIC CORPORATION

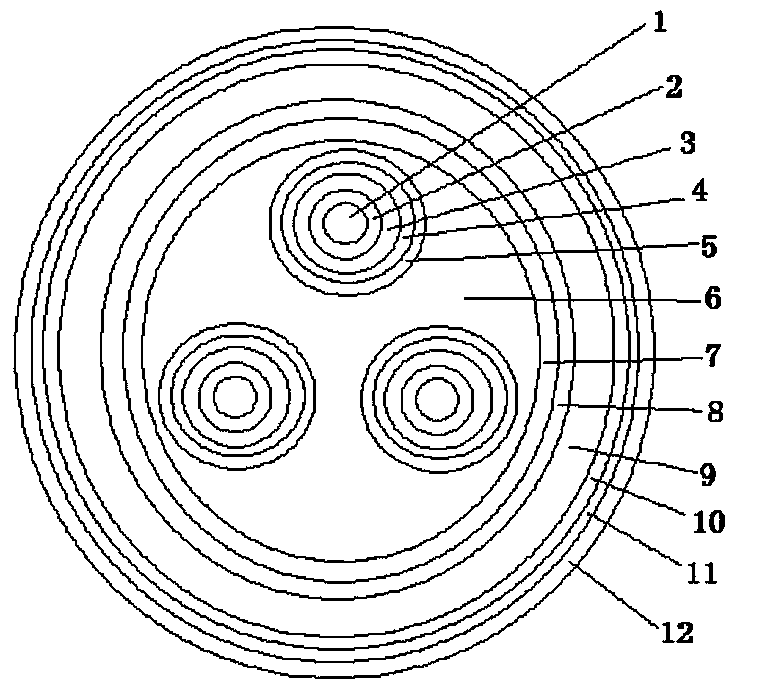

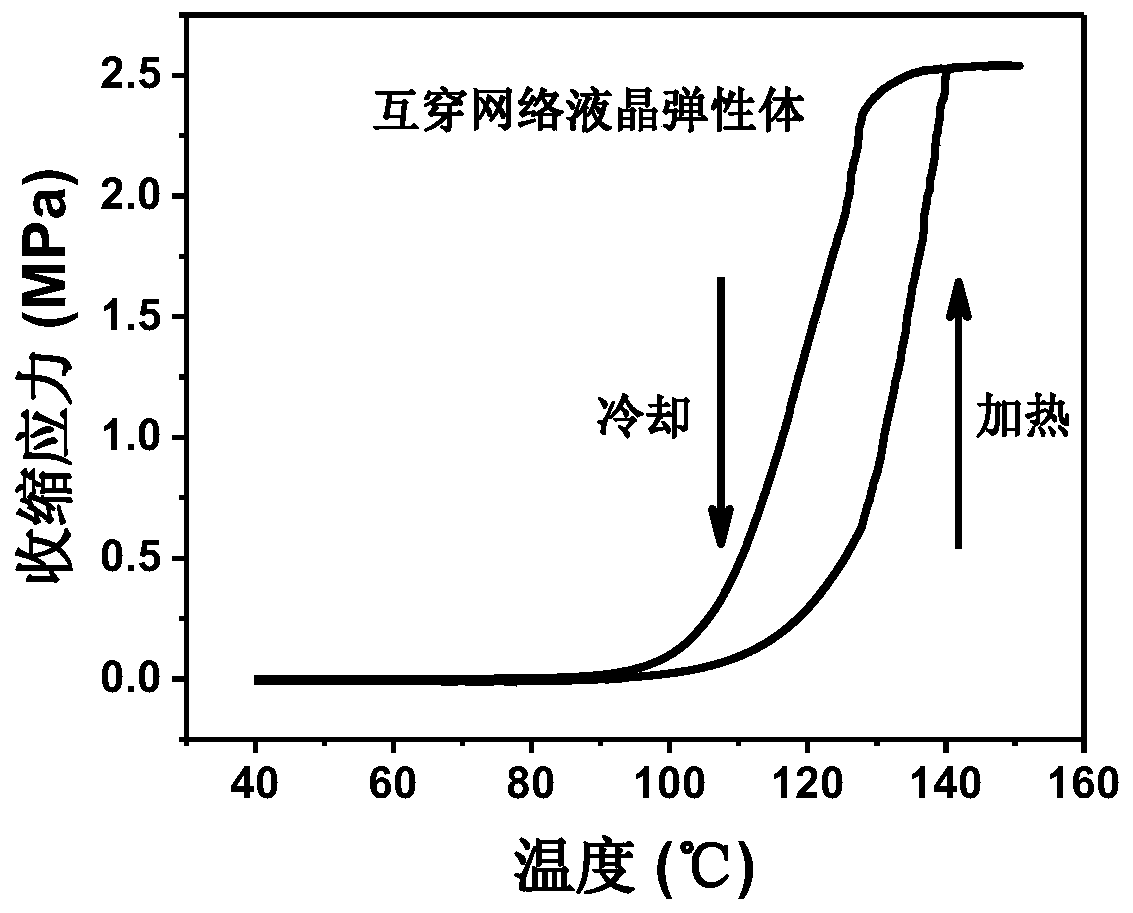

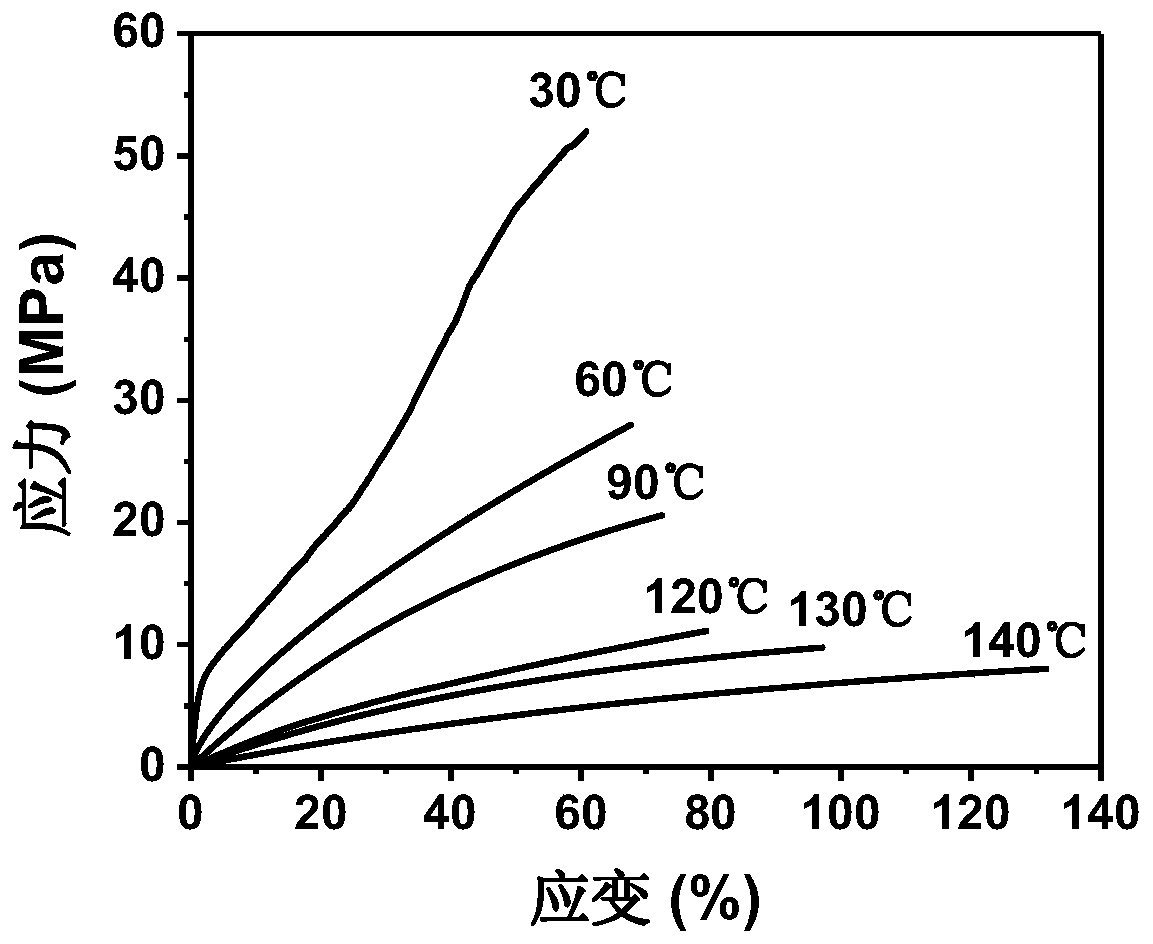

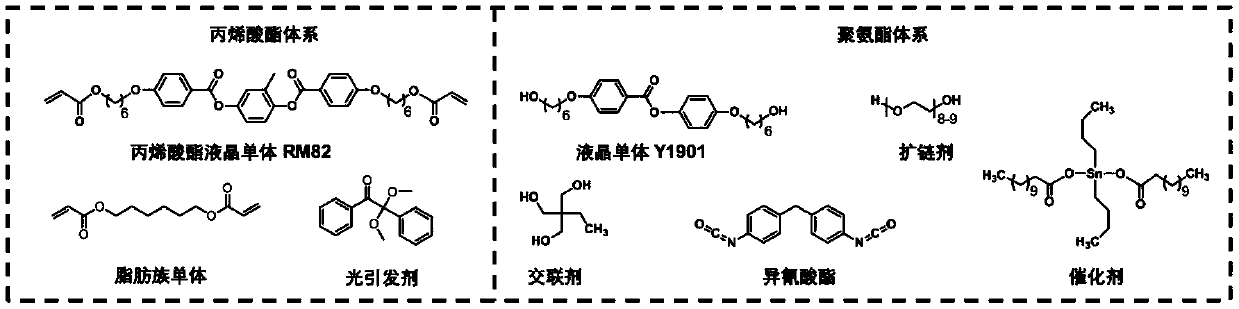

Liquid crystal polyacrylate-liquid crystal polyurethane interpenetrating network liquid crystal elastomer

ActiveCN110373016AResilientExcellent reversible deformationLiquid crystal compositionsBreaking strengthThermal stimulation

The invention discloses a liquid crystal polyacrylate / liquid crystal polyurethane interpenetrating network liquid crystal elastomer and preparation method and application thereof. Liquid crystal acrylate belongs to a first network, liquid crystal polyurethane belongs to a second network. Under the conditions of thermal polymerization and photoinitiation, mutually independent systems of the two liquid crystal systems are simultaneously polymerized to prepare a double liquid crystal system interpenetrating network liquid crystal elastomer (IPN-LCE). According to the preparation method ofliquid crystal polyacrylate / liquid crystal polyurethane interpenetrating network liquid crystal elastomer, theprepared interpenetrating network liquid crystal elastomer is ultra-high in mechanical propertiesand has a breaking strength of up to 7.9 MPa and an elastic modulus of 10.4 MPa at the isotropyphase inversion temperatureTi relative to theliquid crystal. Under thermal stimulation, a restoring forceof 2.53 MPa can be produced, the interpenetrating network liquid crystal elastomer with weight of 30,000 times that of the load is lifted. The liquid crystal polyacrylate / liquid crystal polyurethaneinterpenetrating network liquid crystal elastomer, mechanical properties are ultra-high,the high practical application value is realized, and the interpenetrating network liquid crystal elastomer canbe used in the fields such as shape memory materials and artificial muscles.

Owner:SOUTHEAST UNIV

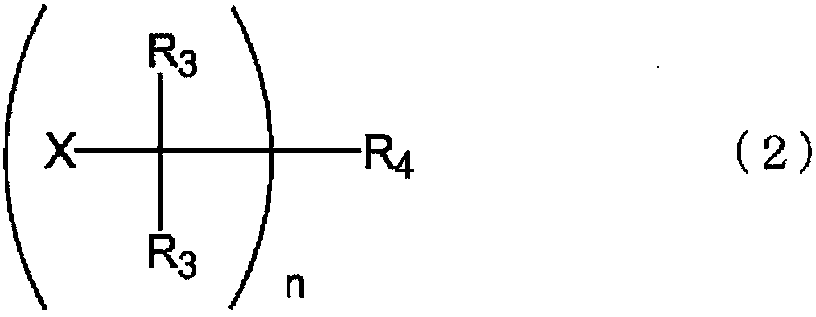

Polyol for polyurethane preparation and polyurethane preparation method using same

In order to provide a polyol that resolves such issues as insufficient mechanical properties and moisture resistance in urethane elastomers and polyurethane foams produced using prior polyols, a polyol (PL) for polyurethane preparation is disclosed that comprises the following polyol (a) and the following strength-enhancing agent (b). Polyol (a): a polyoxyalkylene polyol that is the alkylene oxide adduct of an active hydrogen-containing compound (H), in which at least 40% of a hydroxyl group positioned on the terminal is a primary hydroxyl group-containing group represented by general formula (I). [In general formula (I), R1 represents a hydrogen atom or a C1-12 alkyl group, cycloalkyl group, or phenyl group.] Strength-enhancing agent (b): a compound that is at least one compound selected from the group comprising an ester compound, a thioester compound, a phosphoric acid ester compound, and an amide compound, and that is derived from a polyvalent aromatic carboxylic acid with a valence of 2 or higher.

Owner:SANYO CHEM IND LTD

Sclera external pressurized biologic composite materials and preparation method

InactiveCN101829365ASoft textureHigh mechanical propertiesSurgeryProsthesisCross-linkChemical reaction

The invention provides sclera external pressurized biologic composite materials which comprise 5-40 percent of pharmaceutical grade hyaluronic acid glucuronic acid, wherein the light transmittance of the pharmaceutical grade hyaluronic acid glucuronic acid is no more than 98 percent, the haemolysis is not detected, streptococcus haemolyticus is not detected, the total amount of the mycete and the saccharomycetes is no more than 10CFU / g, the mechanical tensile strengthen is larger than 3Mpa, the tearing strengthen is larger than 5kN / M, and the materials accord with the biologic safety requirements of three types of national medical devices. The invention takes hyaluronic acid as basic raw materials, carries out chemical crosslinking for more than two times with cross-linking agent to prepare crosslinking hyaluronic acid materials with high intensity, lowers toxic cross-linking agent residues through chemical reaction and is sterilized to prepare biologic materials which accord with three types of national medical devices. In the invention, through a composite crosslinking method, the sandwich type ultrahigh intensity crosslinking hyaluronic acid materials with higher surface rigidity and better interior elasticity are prepared, and the contradiction between the biocompatibility and the mechanical strength can be efficiently solved.

Owner:HANGZHOU FIRST PEOPLES HOSPITAL

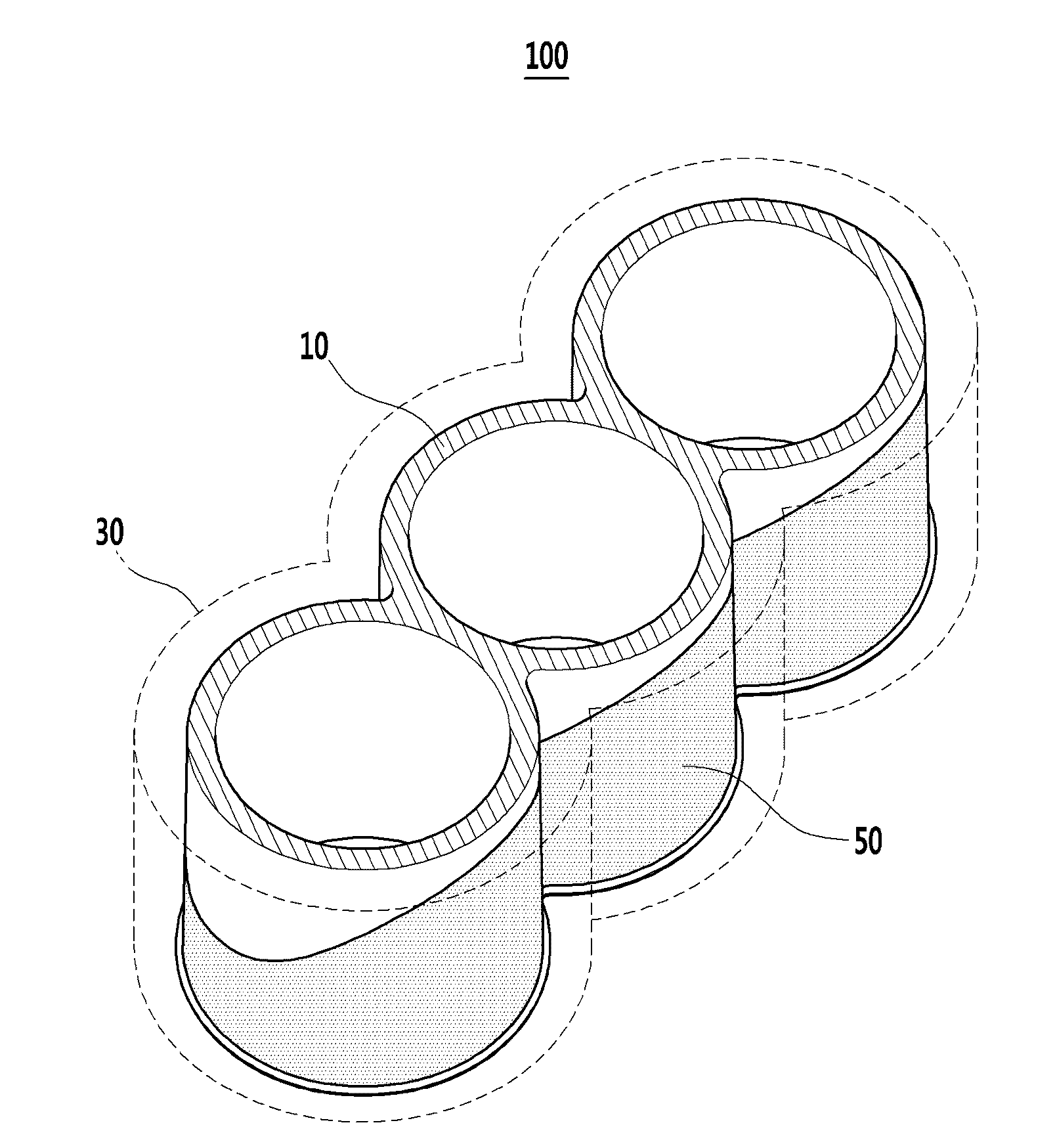

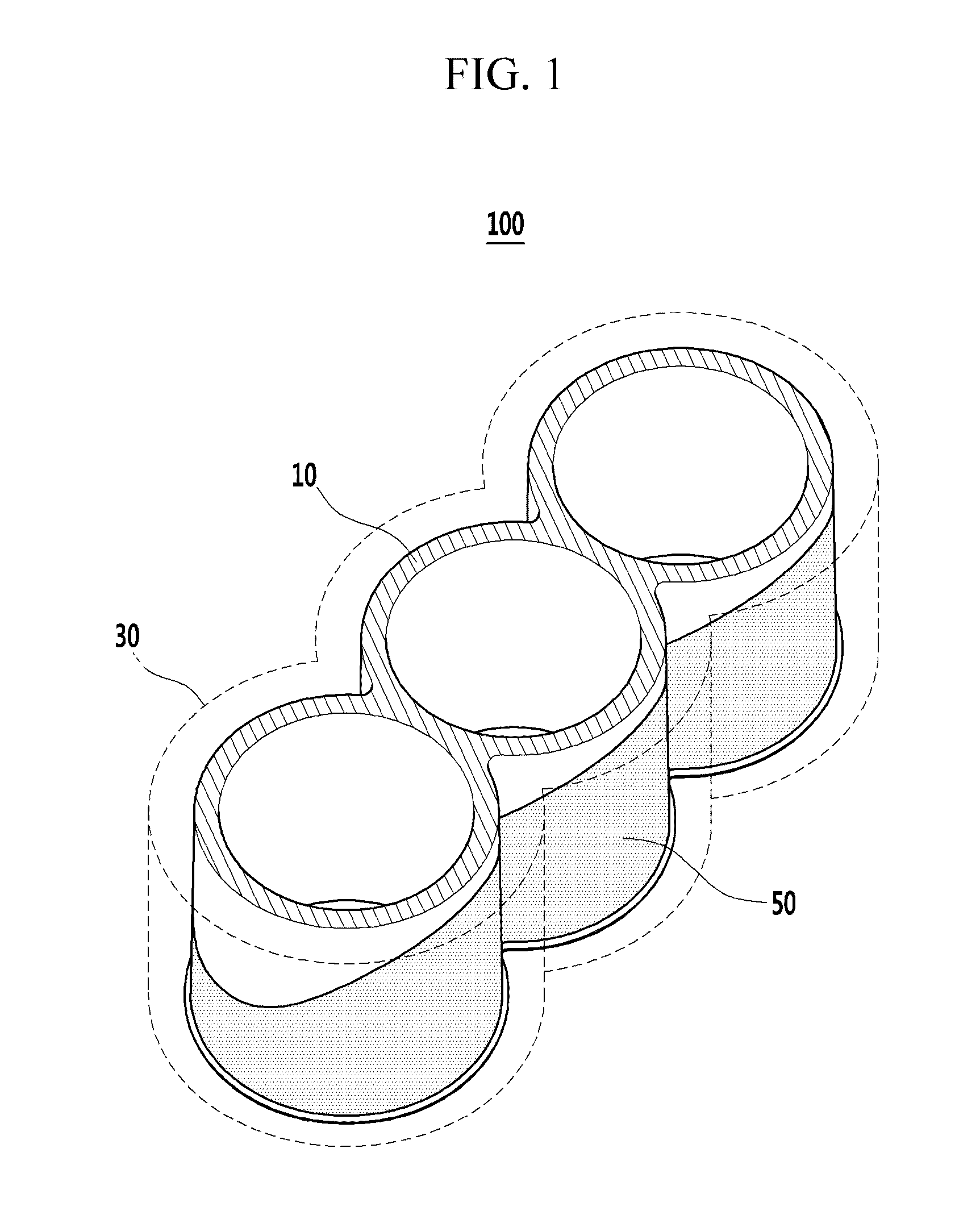

Cylinder block for engine of vehicle

InactiveUS20160326979A1High heat resistanceHigh mechanical propertiesCylinder headsCylindersCoolant flowPolyamide-imide

A cylinder block for an engine includes a cylinder liner and a water jacket through which a coolant flows, the water jacket being formed along a circumference of the cylinder liner, where an insulation coating layer made of a polyamideimide resin and an aerogel dispersed in the polyamideimide resin may be formed at an external circumferential surface of the cylinder liner.

Owner:HYUNDAI MOTOR CO LTD

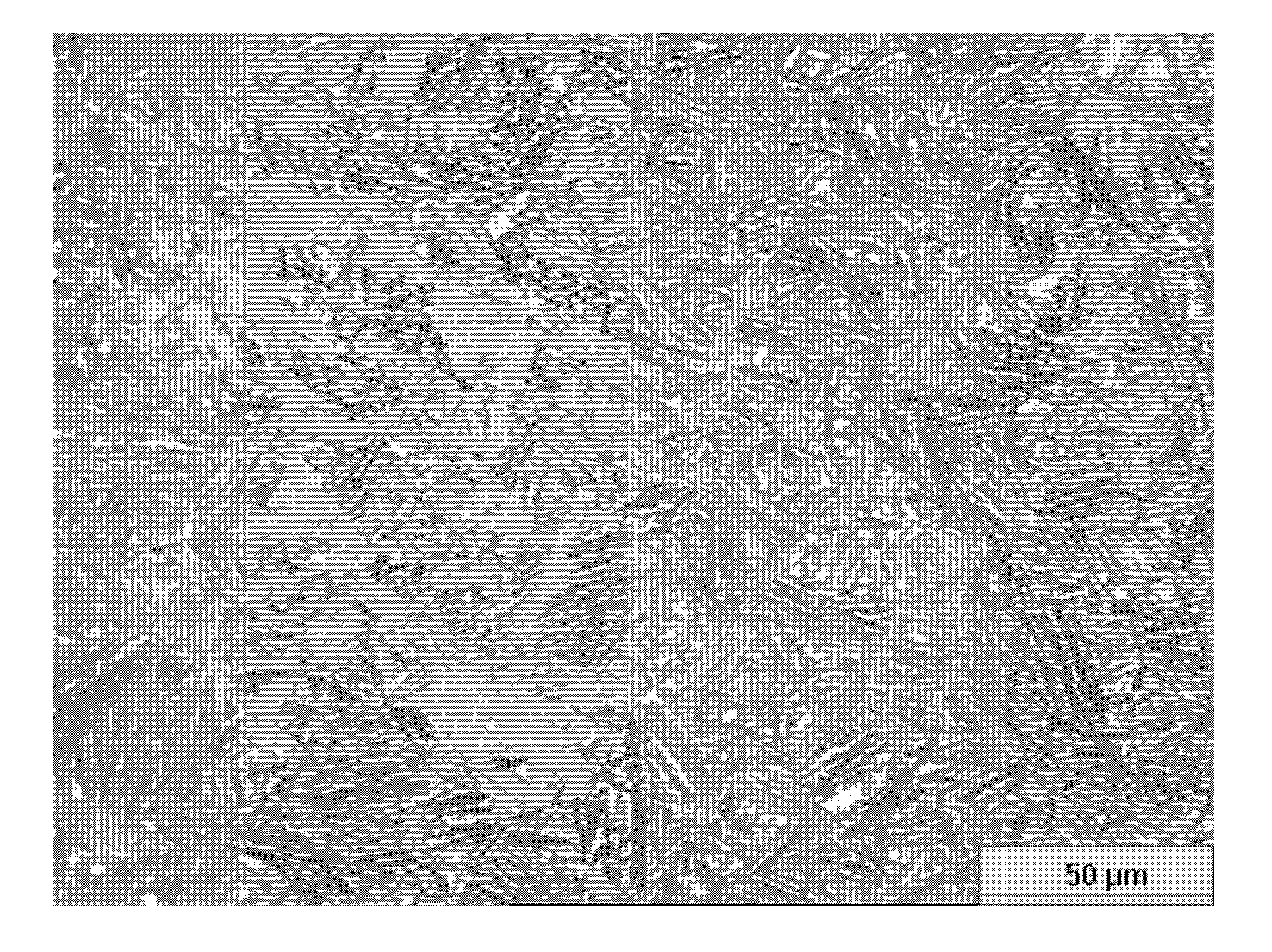

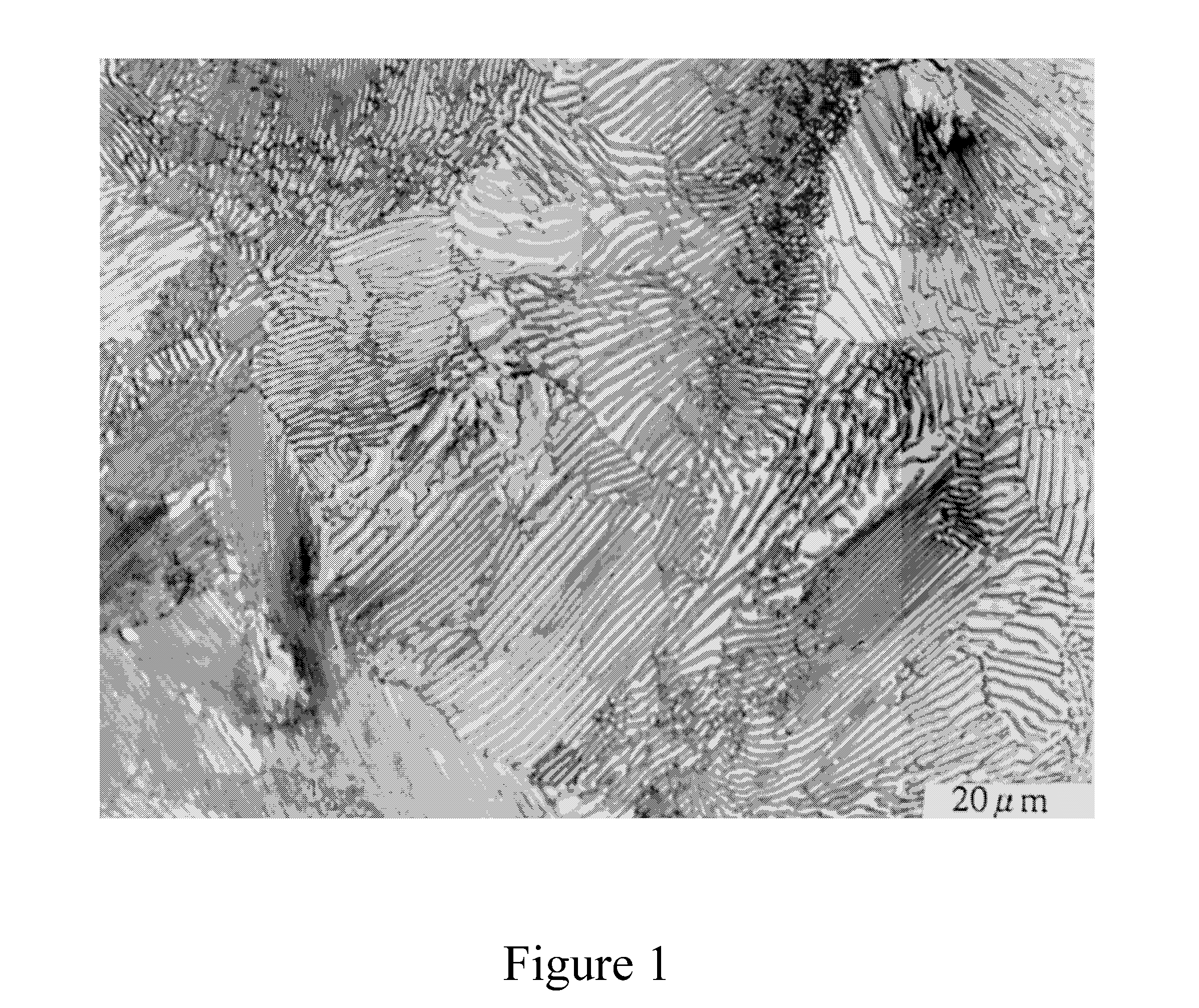

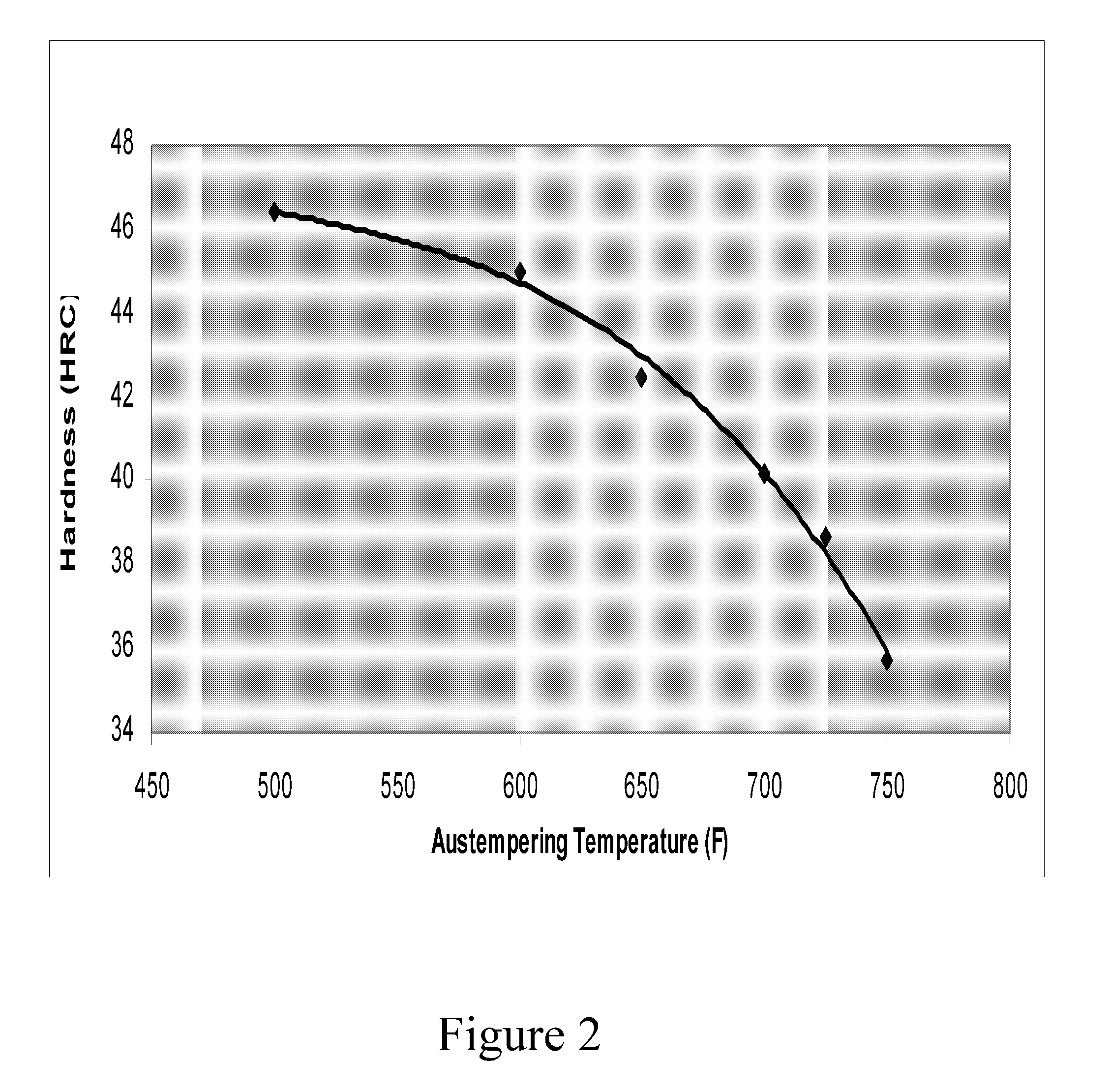

Development of a high strength high toughness bainitic steel

A bainitic steel with simultaneous high yield strength and high fracture toughness includes at least 5 volume percent austenite as well as iron, carbon, and silicon. The silicon is present in an amount of at least 1.5 weight percent of total weight of the bainitic steel. A method of forming the steel by austempering is also provided.

Owner:WAYNE STATE UNIV

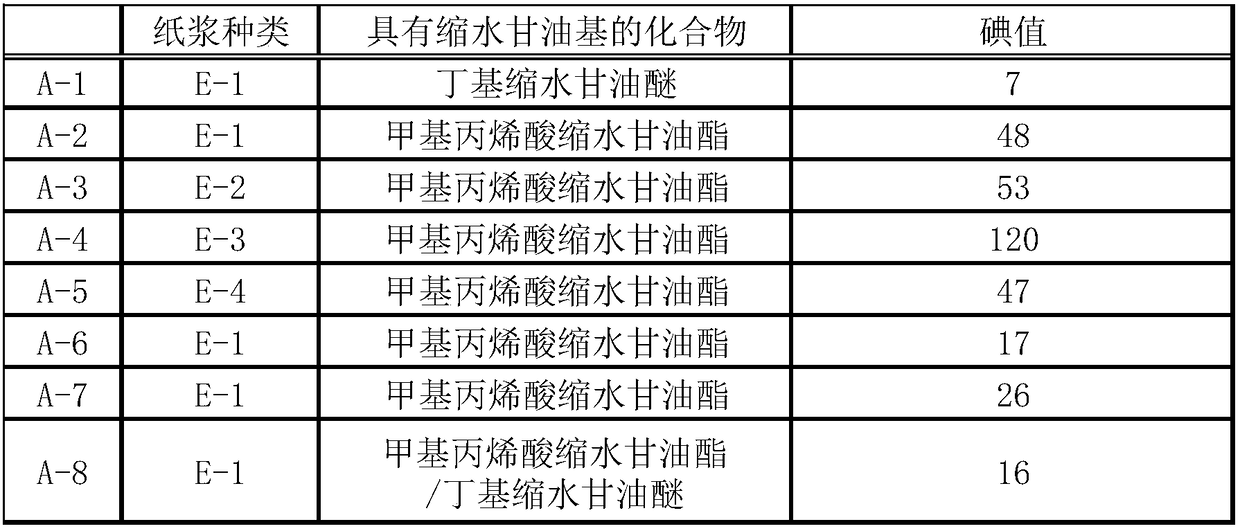

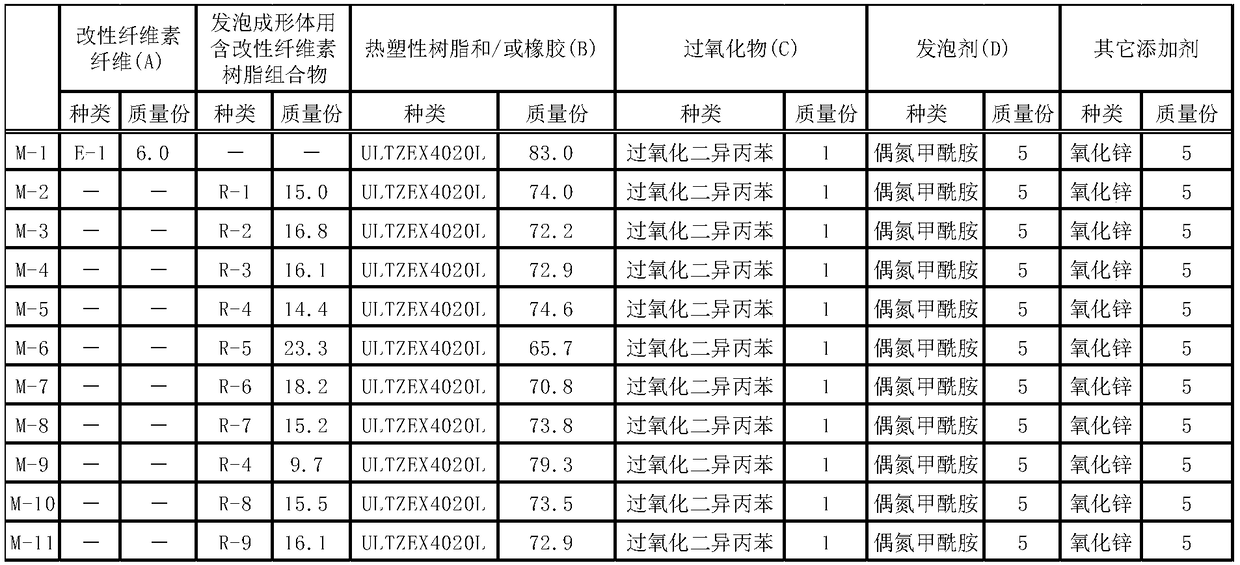

Composition for molded foam and production method therefor, molded foam and production method therefor, and modified cellulose-containing resin composition for molded foam

The purpose of the present invention is to provide: a composition for molded foam which contains a peroxide and a foaming agent and which is obtained by uniformly dispersing cellulose fibers in a resin for a foam molding material having high hydrophobicity, such as a thermoplastic resin or a rubber; and a foam having superior mechanical physical properties obtained by reacting the composition formolded foam during foam molding. The composition for molded foam contains modified cellulose fibers (A) having an unsaturated bond, a thermoplastic resin and / or a rubber (B), a peroxide (C), and a foaming agent (D).

Owner:SEIKO PMC CORP

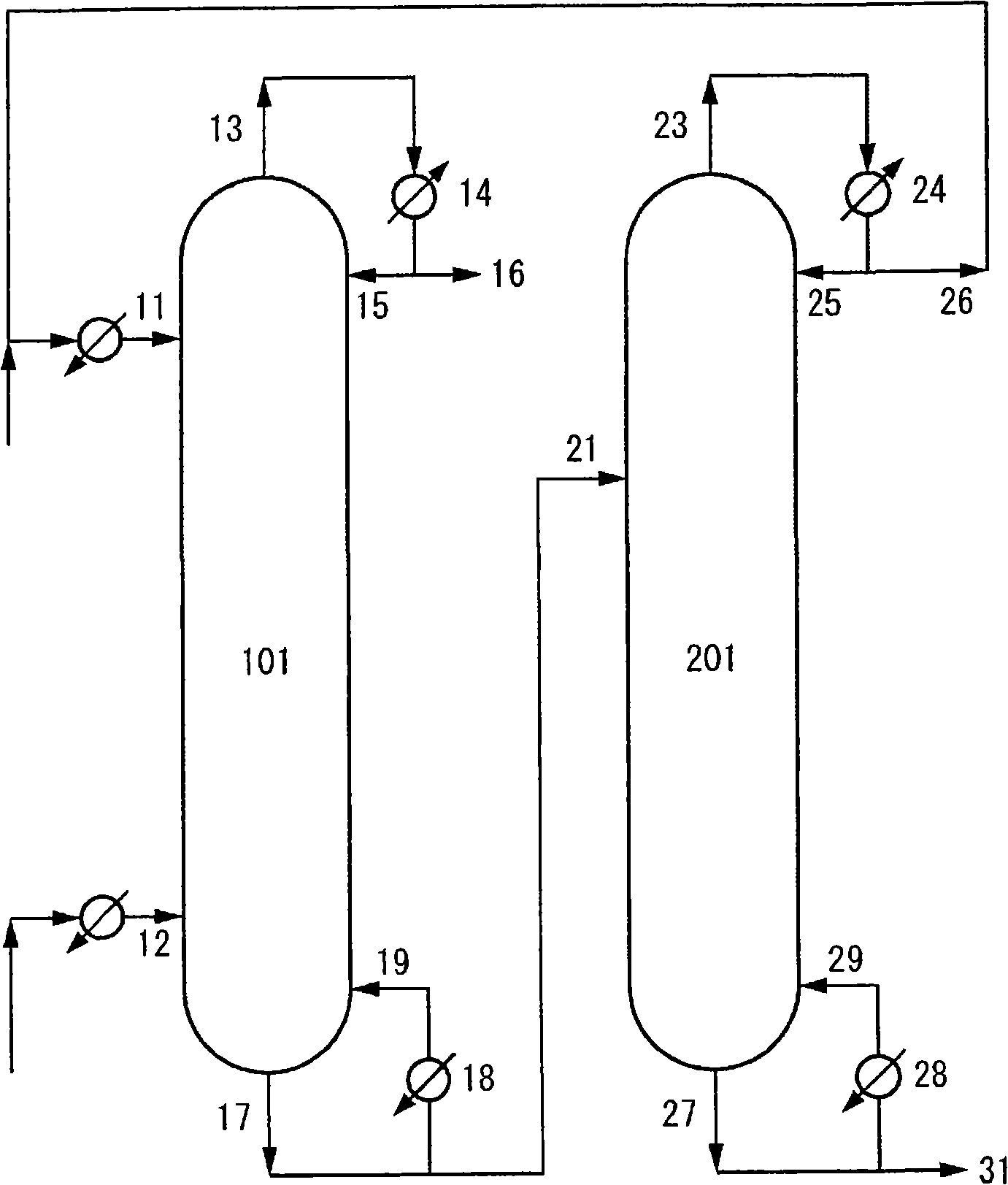

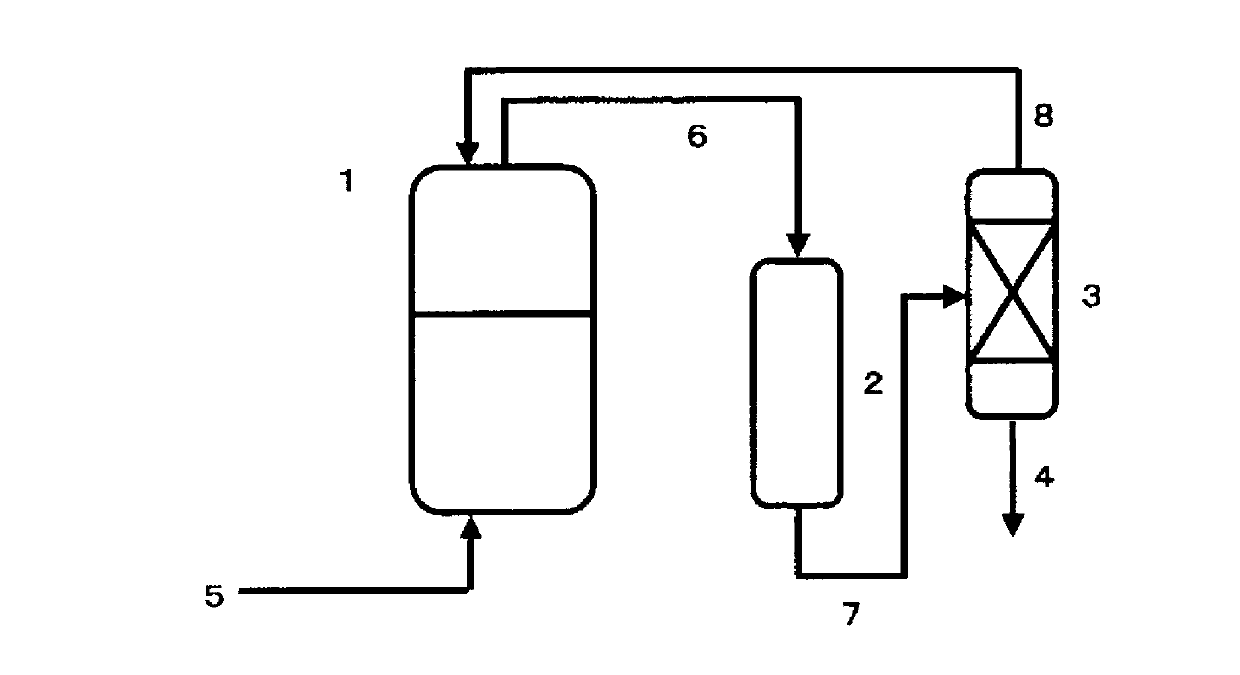

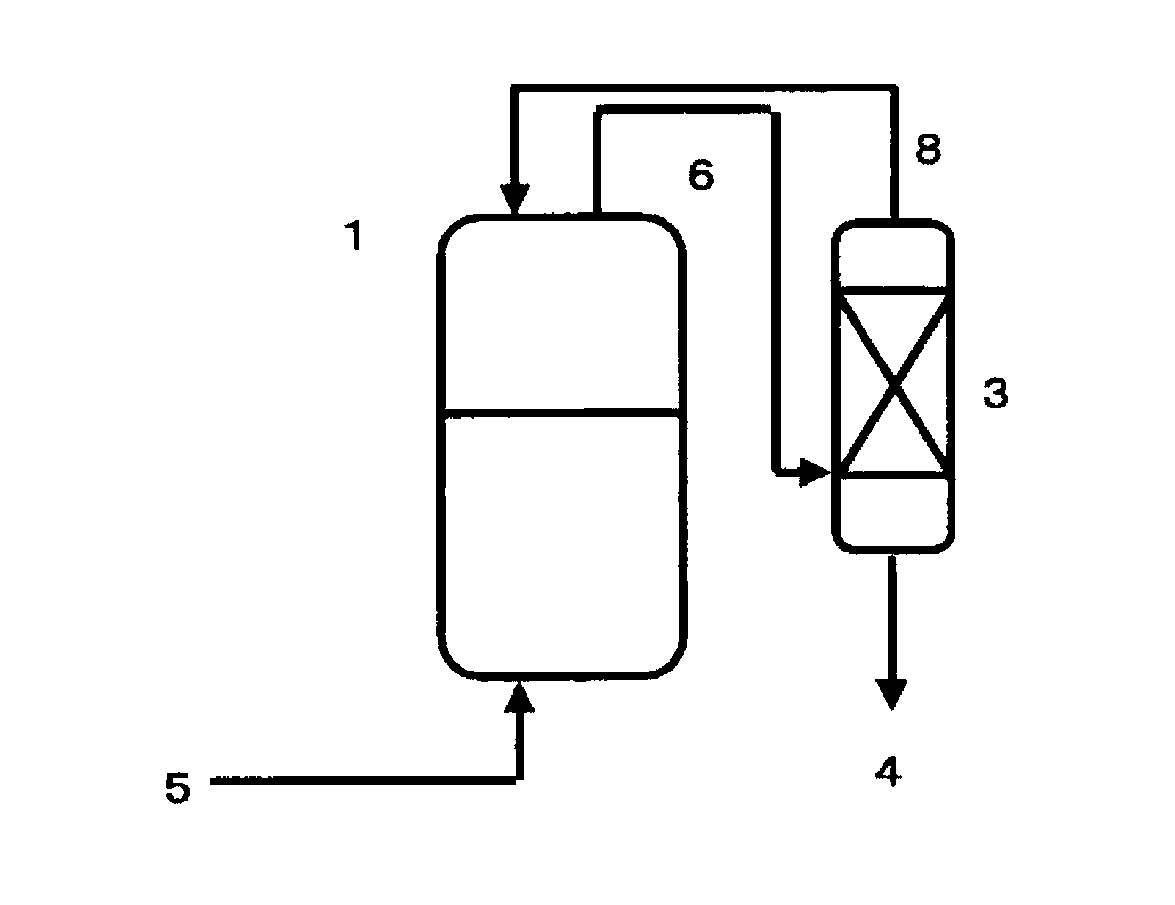

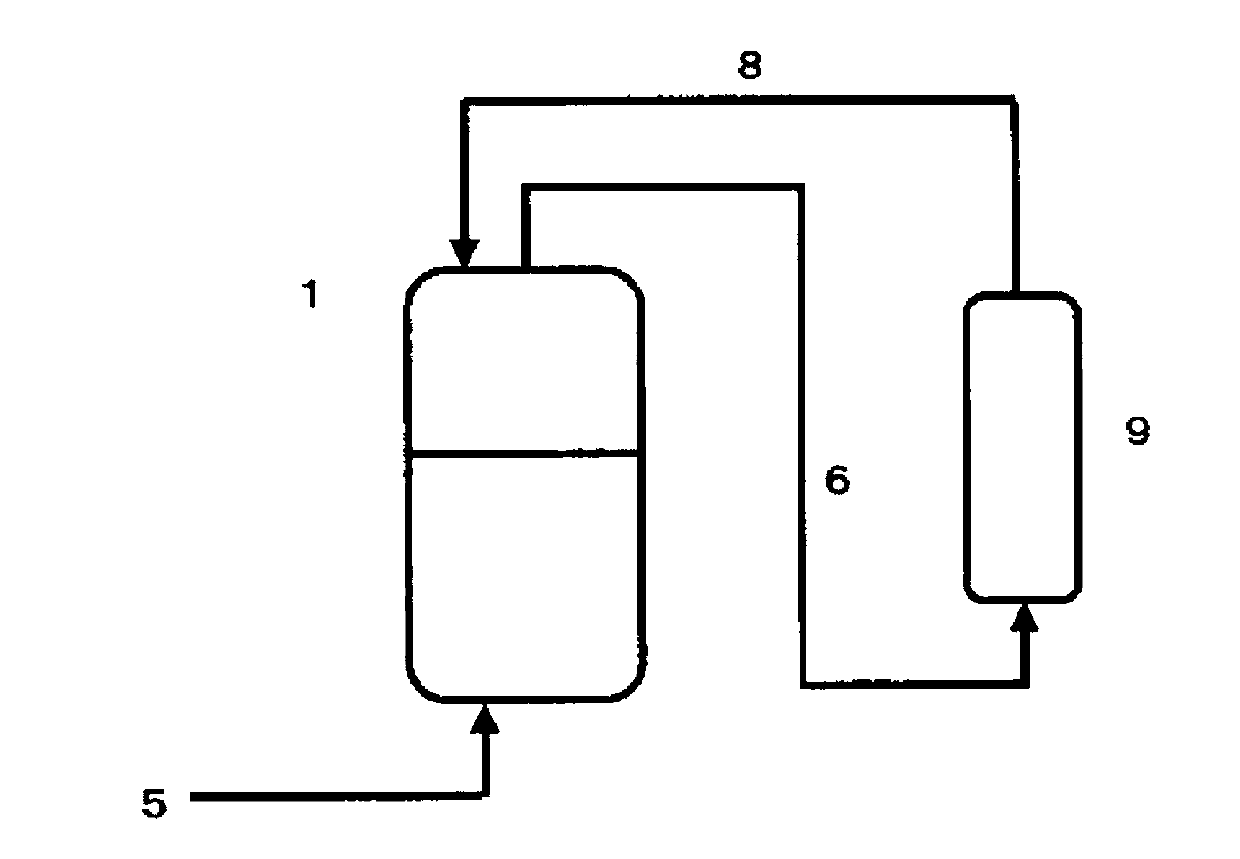

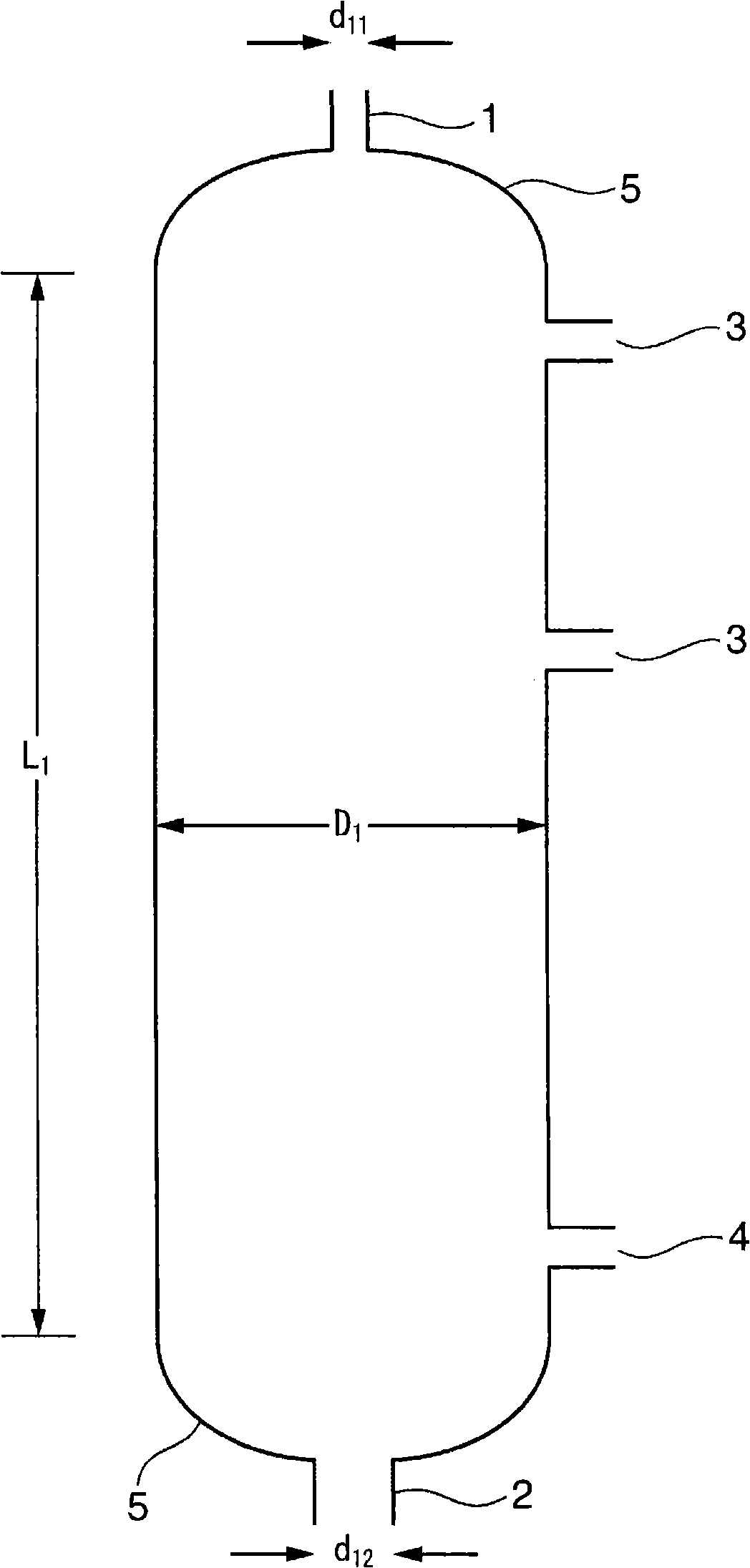

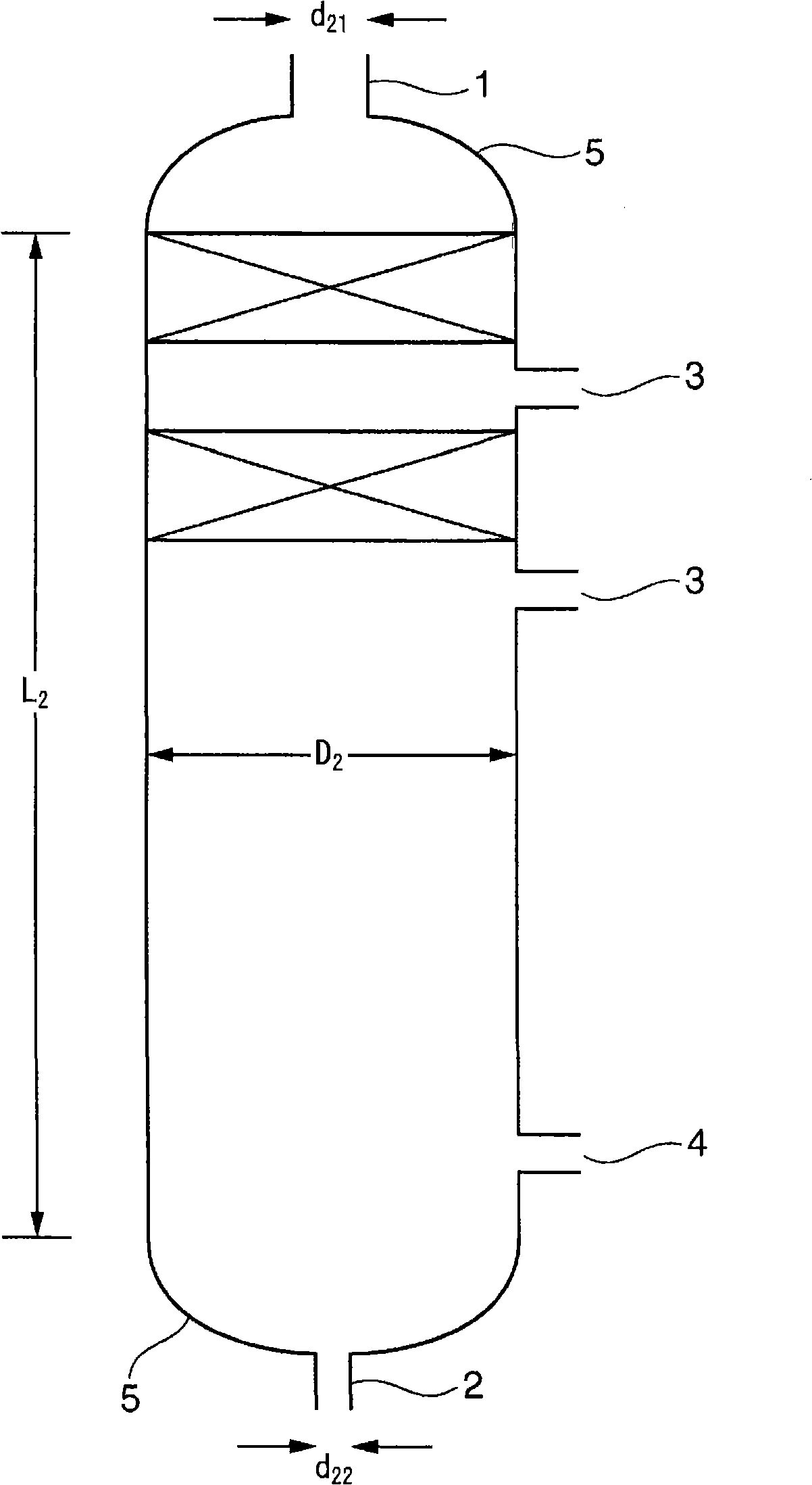

Process for industrially producing high quality aromatic polycarbonate

ActiveCN101331168AEfficient preparationStable manufacturingChemical industryPreparation from organic carbonatesPhenolPolycarbonate

A practical process for stable production of a high quality / high performance aromatic polycarbonate not stained and having excellent mechanical properties from a dialkyl carbonate and an aromatic dihydroxy compound on an industrial scale in large amount (for example, 1 ton or more per hour) over a prolonged period (for example, 1000 hours or longer, preferably 3000 hours or longer, or still preferably 5000 hours or longer). The production of the aromatic polycarbonate from the dialkyl carbonate and the aromatic dihydroxy compound can be attained by the process comprising the step (I) of producing diphenyl carbonate by using two reactive distillation columns with specified structures, step (II) of obtaining high purity diphenyl carbonate therefrom by using a high boiling point substance separation column (A) and diphenyl carbonate purification column (B) with specified structures, and step (III) of producing an aromatic polycarbonate from a molten prepolymer obtained from an aromatic dihydroxy compound and the high purity diphenyl carbonate with the use of a guide contact flow-down type polymerizer with specified structure, and step (IV) of recycling phenol produced as by-product to the step (I).

Owner:ASAHI KASEI KK

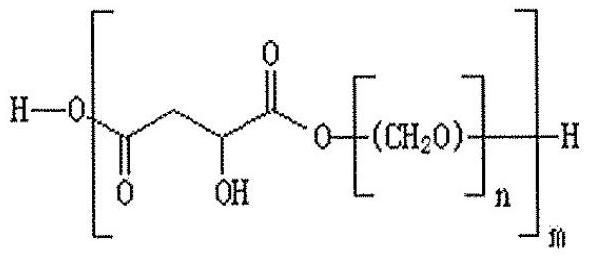

Biodegradable resin composition having improved mechanical properties, moldability, and weather resistance, and preparation method therefor

The present invention relates to a biodegradable resin composition having improved mechanical properties and moldability and a preparation method therefor and, more specifically, to a biodegradable resin composition and a preparation method therefor, wherein the biodegradable resin composition is obtained by mixing an acid component, containing an aliphatic dicarboxylic acid or a mixture component of an aliphatic dicarboxylic acid and an aromatic dicarboxylic acid, with an aliphatic diol in the presence of a multi-functional compound and sequentially carrying out an esterification reaction, a transesterification reaction, a polycondensation reaction, a chain extension reaction, and a solid-state polymerization reaction, and the biodegradable resin composition has excellent productivity and economic efficiency through an improved reaction rate, retains superb tensile strength, elongation rate, and processability, and is environmentally friendly through the biodegradation thereof in nature when buried.

Owner:TLC KOREA CO LTD

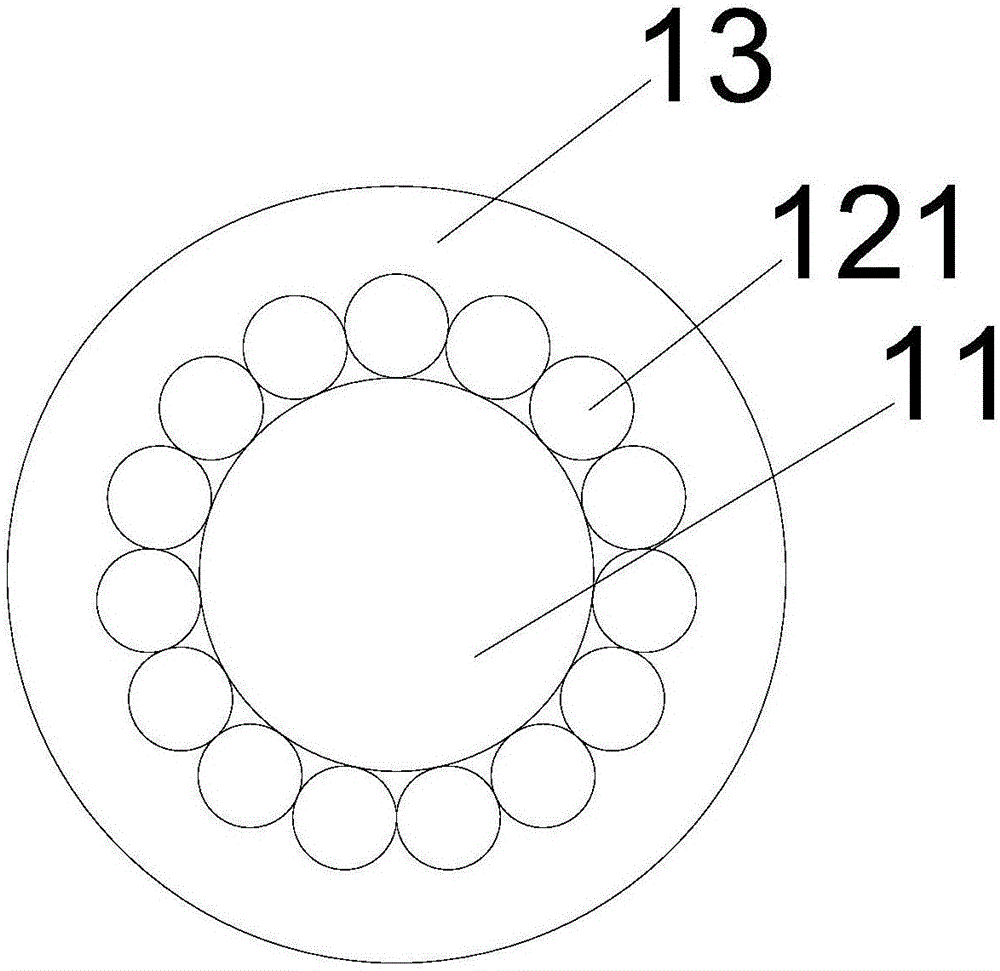

Light winding drum flat cable with high tensile resistance and resistant to bending

PendingCN105810310AImprove bending performanceReduce weightDetails of conductive coresFlat/ribbon cablesInsulation layerElectrical conductor

The invention discloses a light winding drum flat cable with high tensile resistance and resistant to bending. The cable comprises wire cores and a sheath layer, wherein a plurality of wire cores are arranged in parallel and are all coated in the sheath layer, the cross section of the sheath layer is of a long waist shape, each wire core comprises a reinforcement core, a conductor layer and an insulation layer, the conductor layer is formed by winding a plurality of conductor wires at the periphery of the reinforcement core, and the insulation layer wraps the periphery of the conductor layer. The cable has the characteristics of high tensile resistance, flexibility, bending resistance, oil resistance and flame retardancy.

Owner:安徽龙庵电缆集团有限公司

DMC-CF (dimethyl carbonate-carbon fiber) type high-strength composite and application thereof in manhole cover

InactiveCN107418242AHigh specific strengthImprove fatigue resistanceArtificial islandsUnderwater structuresFiberPliability

The invention discloses a DMC-CF (dimethyl carbonate-carbon fiber) type high-strength composite and an application thereof in a manhole cover and relates to the technical field of road facilities. The composite has the properties of being light in weight, high in specific strength, high in seismic performance, good in anti-fatigue performance, resistant to high temperature, acid and alkali and chemical corrosion, good in insulation performance, voltage-resistant, higher in mechanical performance, good in damage safety, high in bearing force, high in precision, low in expansion coefficient, high in weather resistance, sufficient in flame retardance, mildew-proof, water-resistant, oil-resistant, resistant to rust, good in damping and noise reducing performance, sound-proof, bounce-proof, high in anti-theft property, environment-friendly, energy-saving, pollution-free, convenient to mount, good in flexibility, high in strain capacity, good in thermodynamic property, favorable for large-area overall forming and maintenance-free; when the composite is applied to preparation of the manhole cover, the problems occurring in the use process of conventional cast iron well lid or a manhole cover made of a non-metal composite in the prior art are solved.

Owner:XIAMEN JINTING IND TRADE

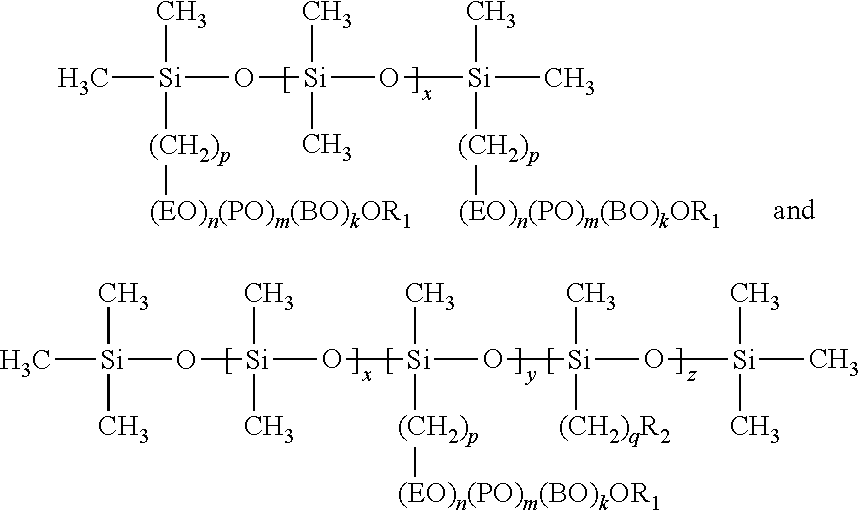

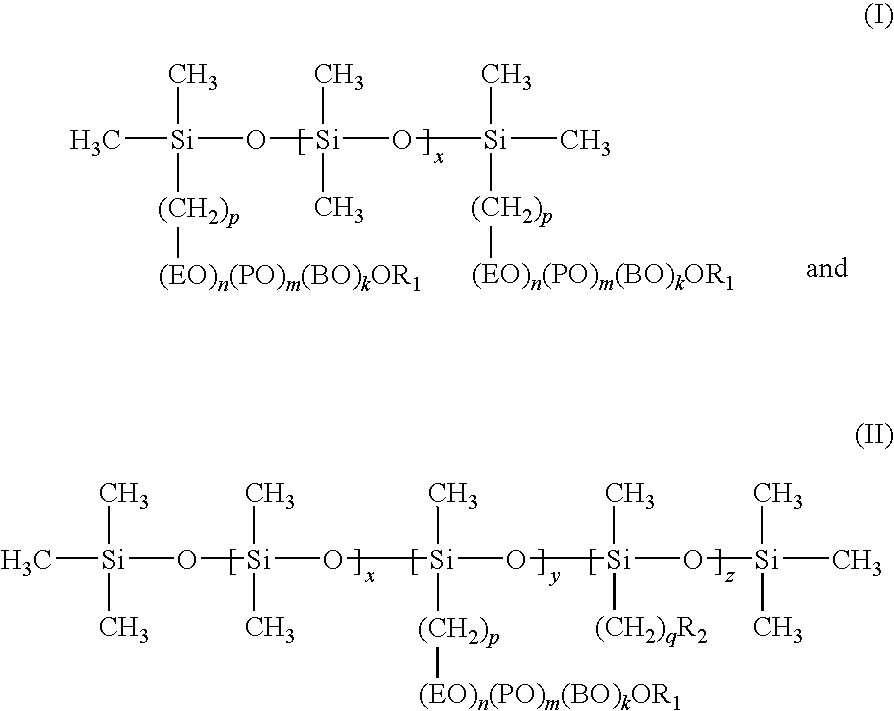

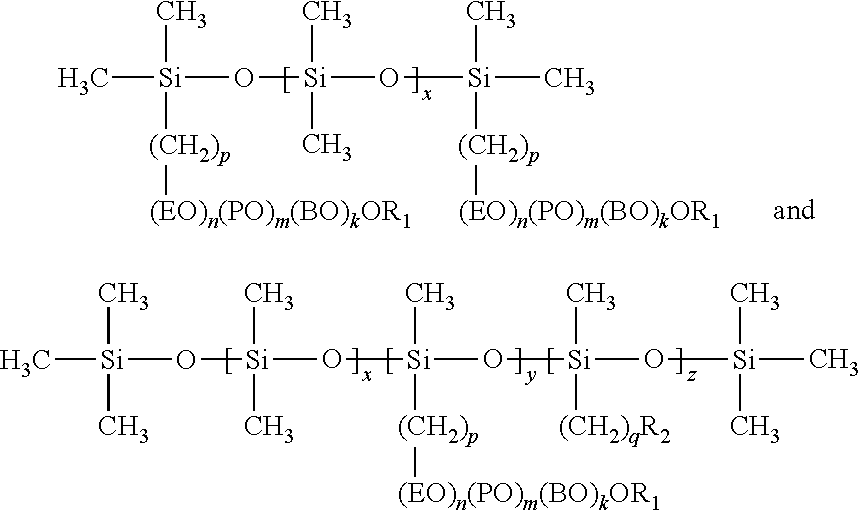

Thermosetting compositions comprising silicone polyethers, their manufacture, and uses

InactiveUS20100311891A1Reduce moisture absorptionLow viscositySynthetic resin layered productsThin material handlingPolymer chemistrySilicone

Thermosetting compositions comprising (a) at least a first thermosetting resin, and (b) at least one silicone polyether, methods of making such thermosetting compositions, and thermoset products made from the compositions.

Owner:DOW GLOBAL TECH LLC

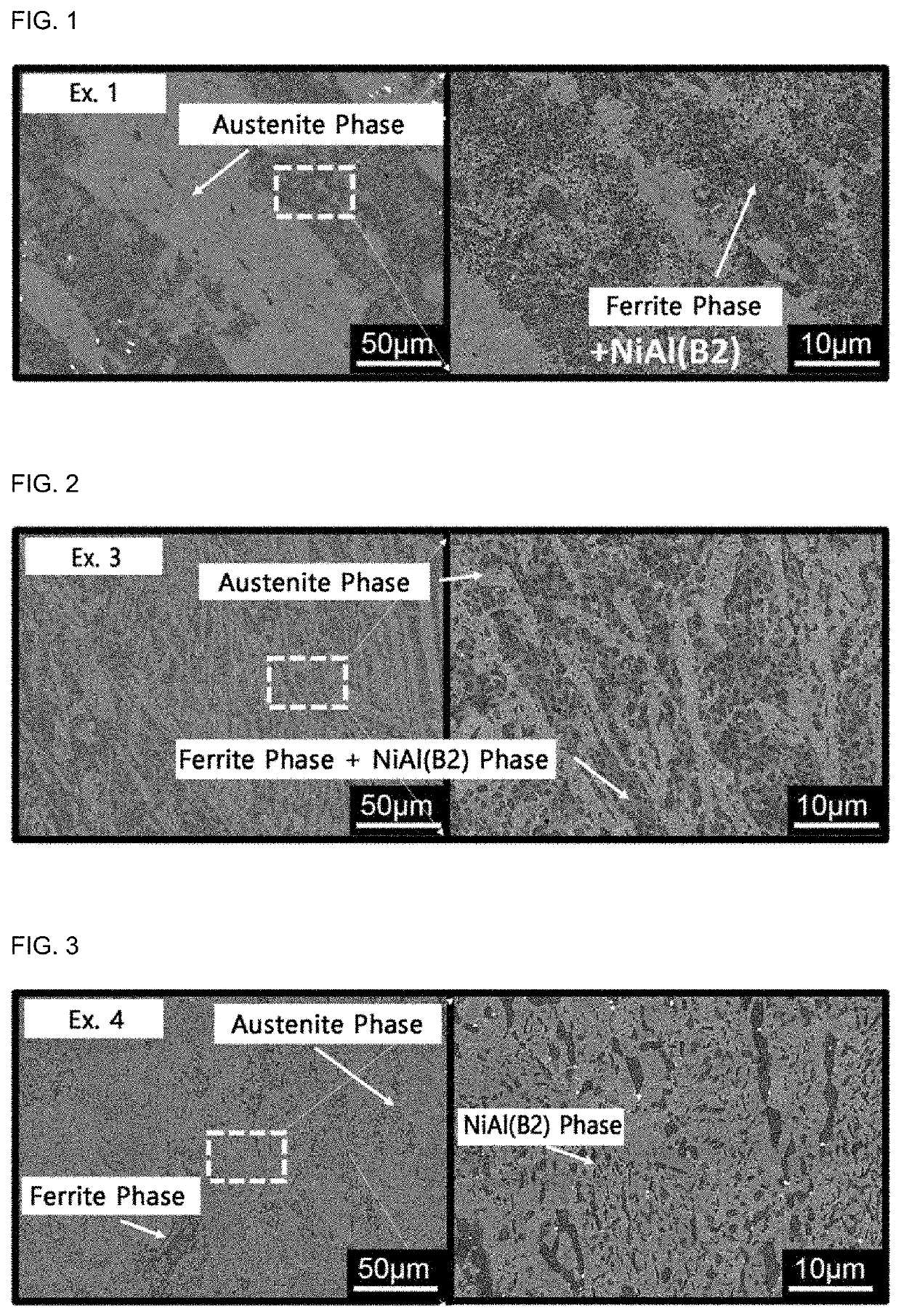

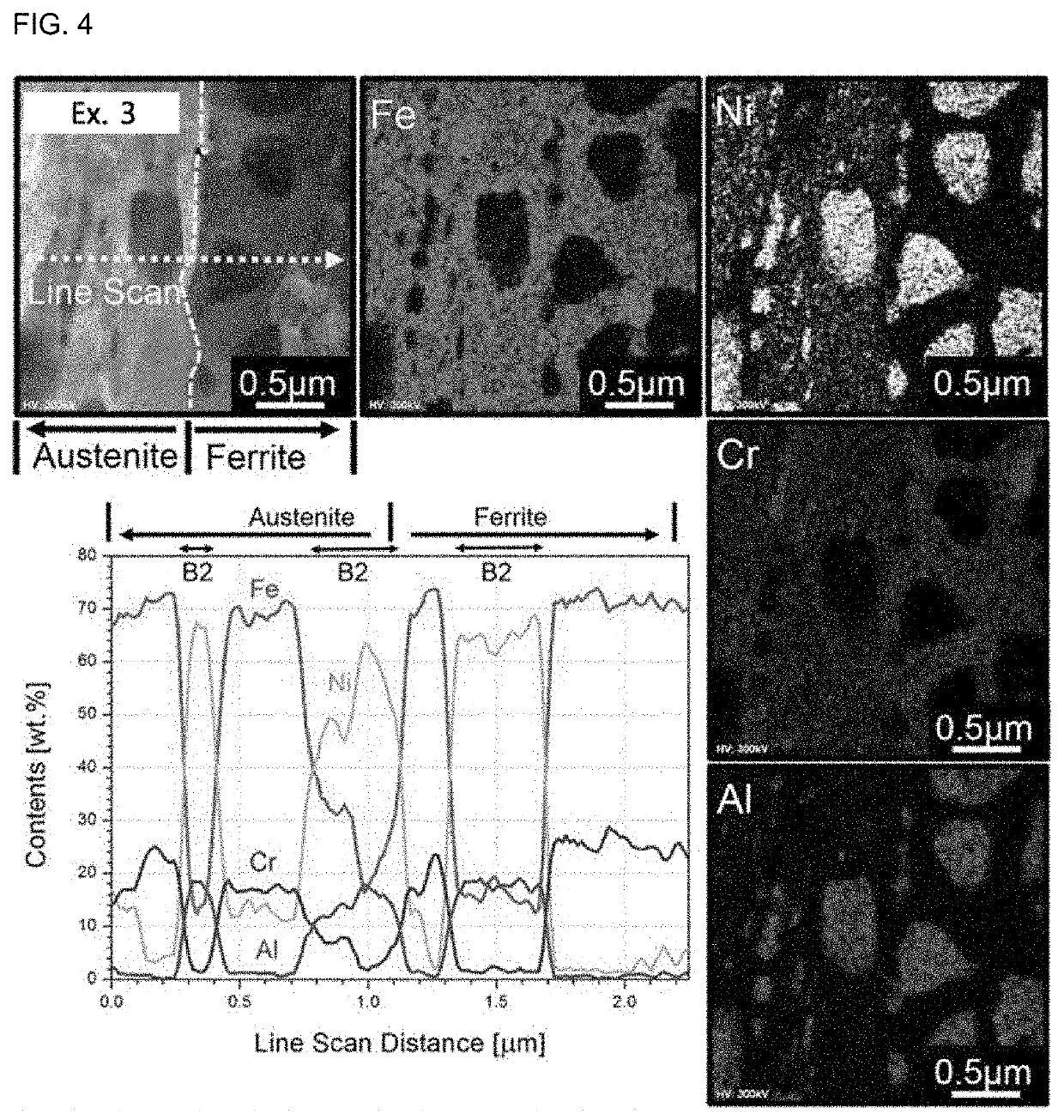

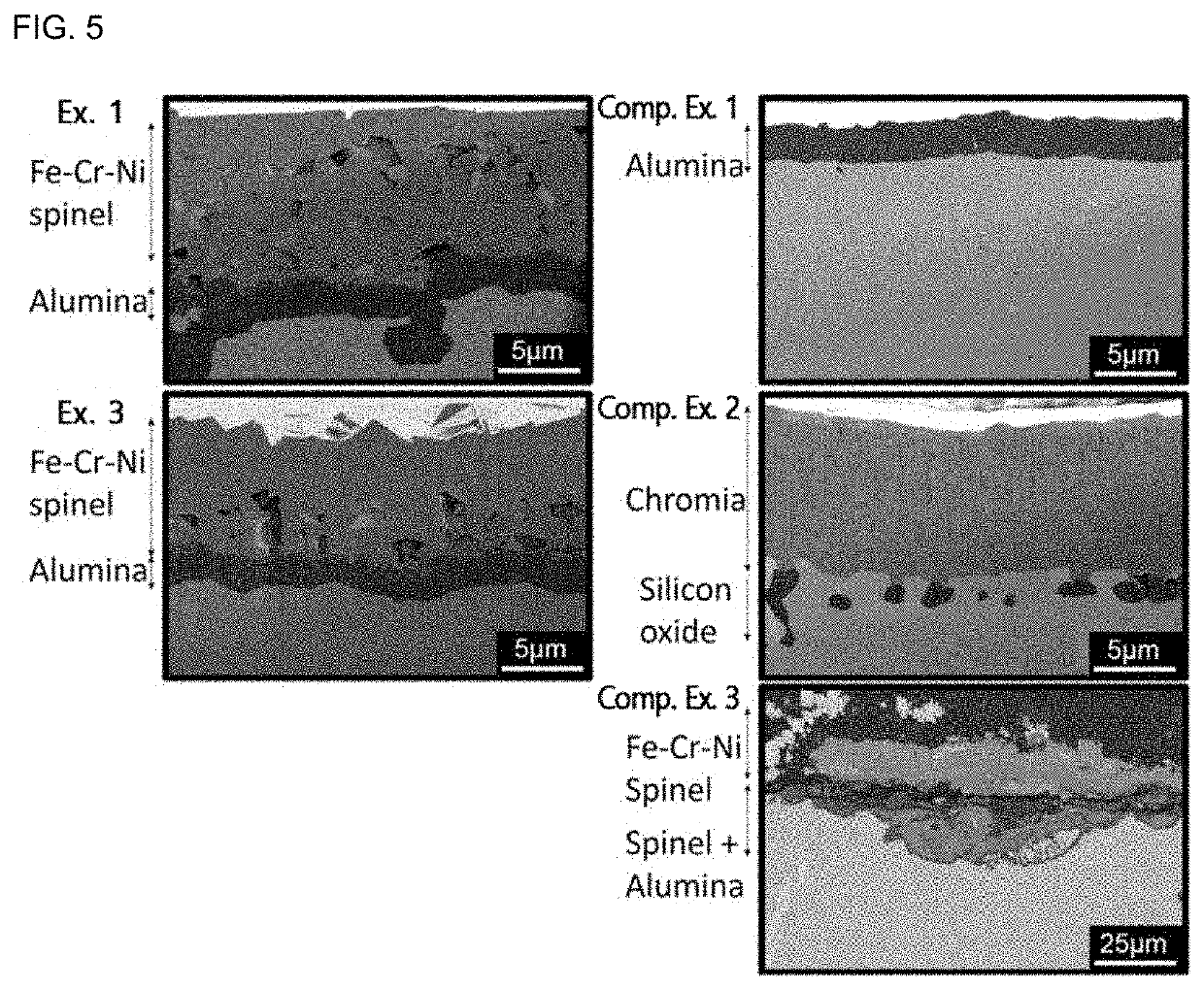

HIGH-STRENGTH Fe-Cr-Ni-Al MULTIPLEX STAINLESS STEEL AND MANUFACTURING METHOD THEREFOR

ActiveUS20200056257A1Excellent accident-toleranceExcellent structural materialNuclear energy generationFurnace typesSS - Stainless steelUltimate tensile strength

The present disclosure relates to a high-strength Fe—Cr—Al—Ni multiplex stainless steel and a manufacturing method therefor. The multiplex stainless steel comprises 35 to 67 wt % of iron (Fe), 13 to 30 wt % of chrome (Cr), 15 to 30 wt % of nickel (Ni), and 5 to 15 wt % of aluminum (Al) and has a multiplex structure in which an austenite phase accounting for high ductility, a ferrite phase accounting for high strength, and an NiAl(B2) phase providing both strength and high-temperature steam oxidation resistance, exist in combination. The multiplex stainless steel can secure necessary fabricability and mechanical strength even if for / in a thin state, can maintain integrity as a structural member in a normal operation condition of a light-water reactor thanks to the formation of a chrome oxide layer thereon, and can form a stable oxide layer including alumina under a high-temperature steam environment, which is plausible in a high-temperature nuclear accident, thereby providing exceptionally improved resistance to serious accidents.

Owner:KOREA ADVANCED INST OF SCI & TECH

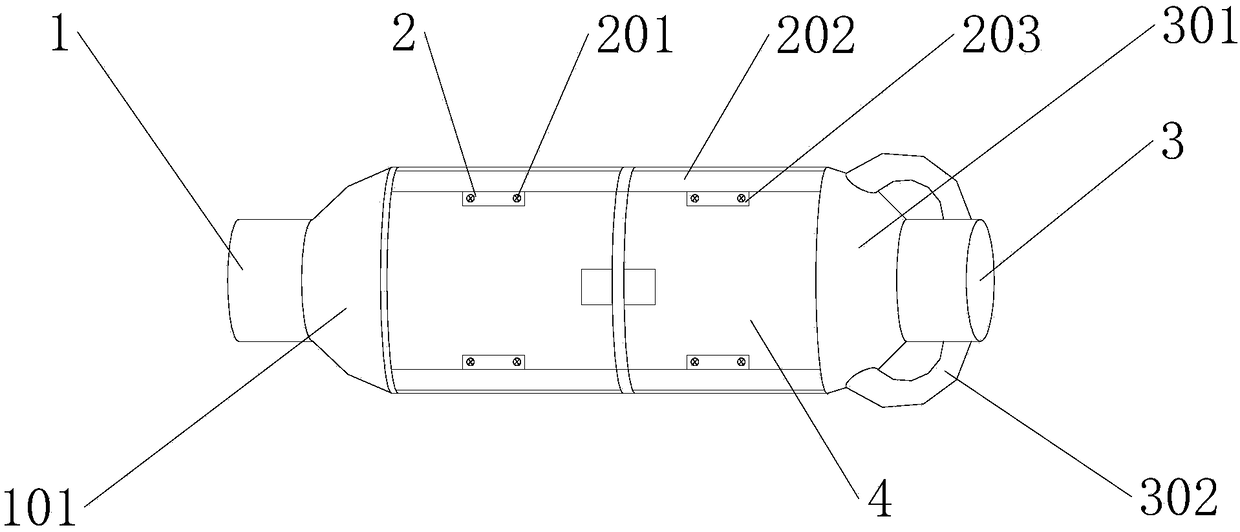

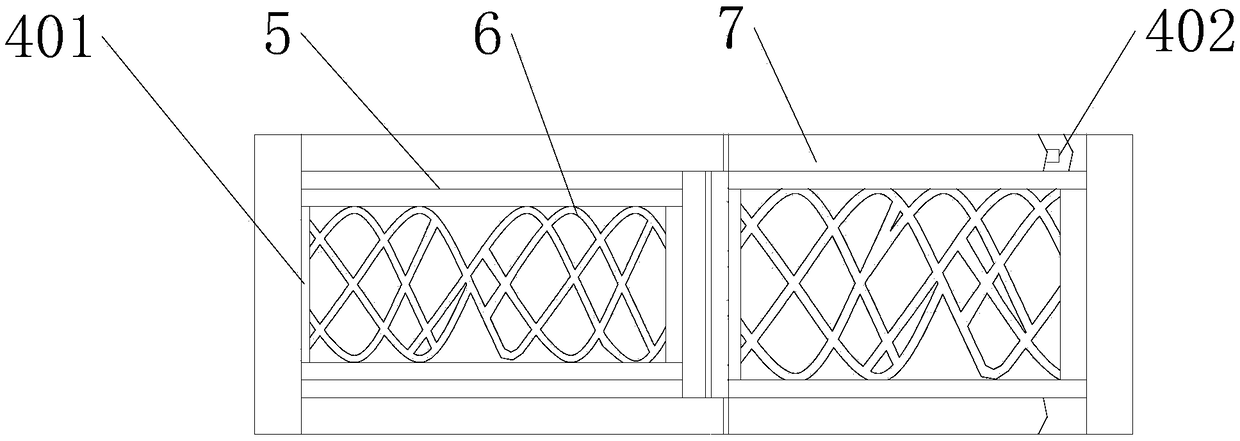

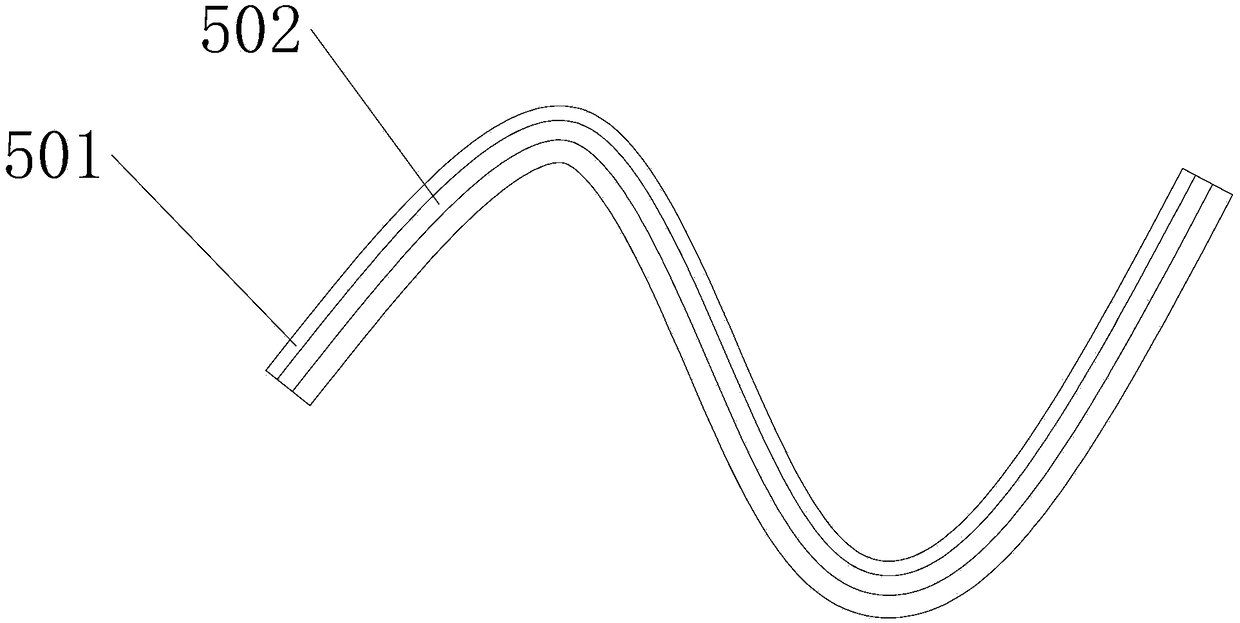

Double-layer particle filter system based on foam alloy

PendingCN108757110AImprove mechanical propertiesHigh mechanical propertiesExhaust apparatusSilencing apparatusAlloyEngineering

The invention discloses a double-layer particle filter system based on foam alloy. The double-layer particle filter system comprises a shell, a catalytic oxidizer and a porous pipe. An air inlet groove is formed in the left side of the shell and is fixedly connected with the shell. An air inlet cavity is formed in the air inlet groove and is closely attached to the air inlet groove. At least eightfixers are arranged on the outer side face of the shell and are embedded into the shell. According to the double-layer particle filter system based on the foam alloy, a cover plate can be fixed to the shell through the fixers; and when the quantity of soot in a soot collection groove is too large, the fixers can be dismounted by rotating bolts, then the cover plate is opened to clean the interiorof the soot collection groove, and thus, the practicability of the double-layer particle filter system based on the foam alloy is improved.

Owner:上海诺骋工程机械排气系统有限公司

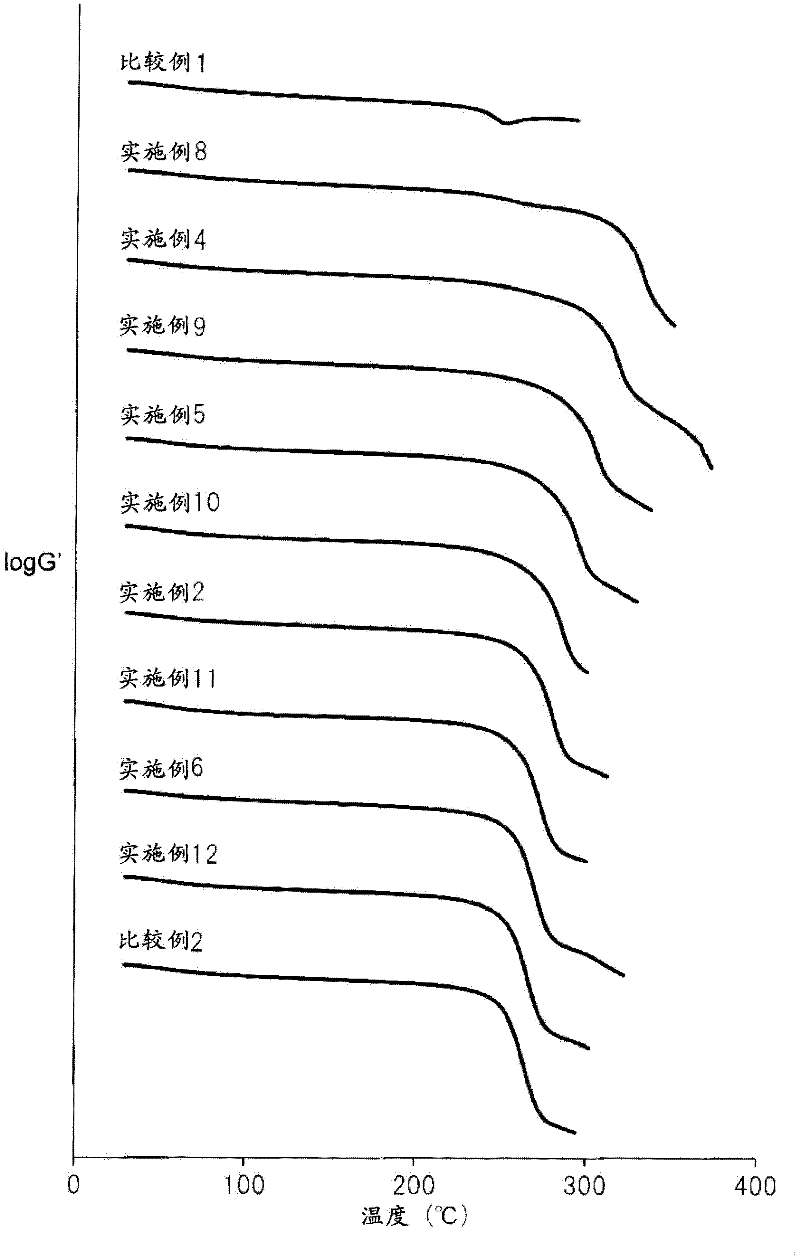

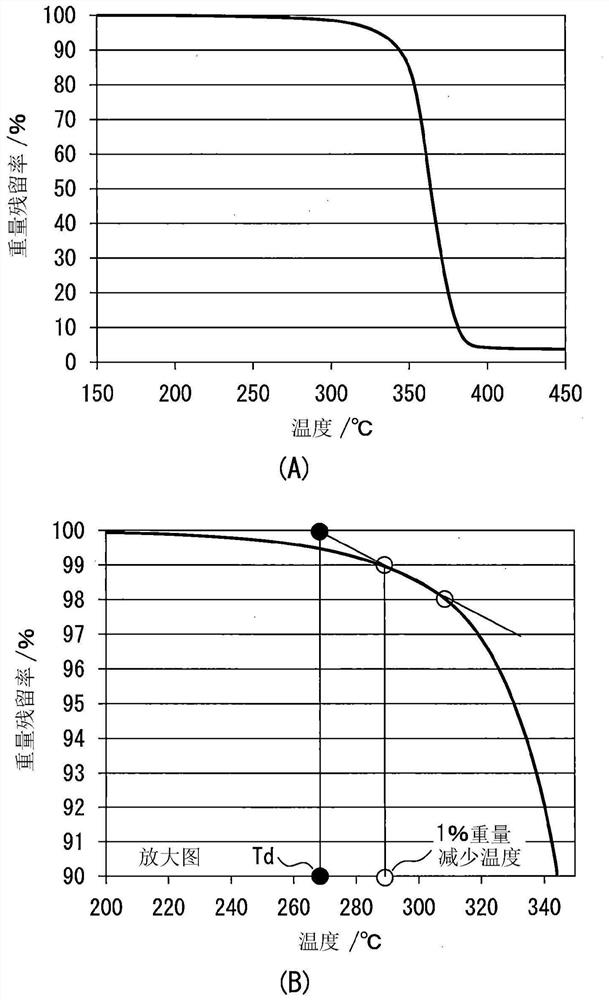

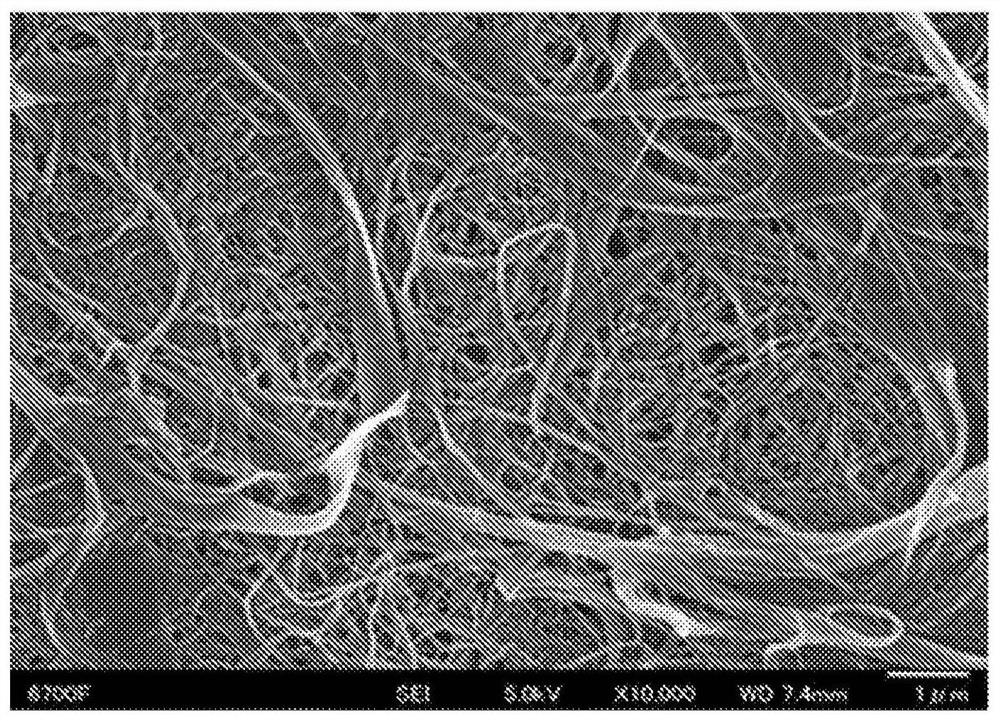

Highly heat-resistant resin composite including chemically modified, fine cellulose fibers

ActiveCN112204095AHigh mechanical propertiesPaper/cardboardSynthetic cellulose fibresPolymer scienceIn vehicle

Provided is a resin composite having high mechanical properties which make the resin composite moldable into and usable as members for use in applications such as vehicle-mounted members and electrical materials. The resin composite comprises 0.5-40 mass% chemically modified, fine cellulose fibers and a resin, wherein the chemically modified, fine cellulose fibers have a pyrolysis initiation temperature (TD) of 270 DEG C or higher, a number-average fiber diameter of 10 nm or larger but less than 1 micron, and a degree of crystallinity of 60% or higher. In a preferred embodiment, the chemicallymodified, fine cellulose fibers have a coefficient of variation (CV) in DS unevenness ratio, DSs / DSt, of 50% or less, the DS unevenness ratio being the ratio of the modification degree (DSs) of the surface layers of the fibers to the modification degree (DSt) of the whole of the fibers.

Owner:ASAHI KASEI KK

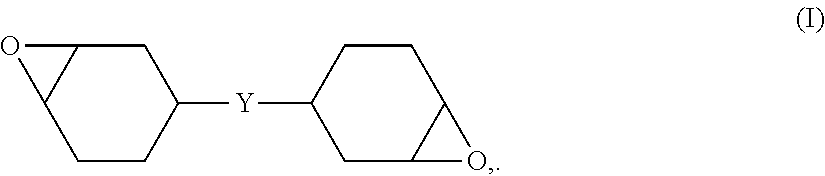

Epoxy resin compositions and fiber-reinforced composite materials prepared therefrom

InactiveUS20180244874A1High level heat resistanceHigh strength propertiesSynthetic resin layered productsHeat resistanceFiber-reinforced composite

This invention relates to an epoxy resin composition for a fiber-reinforced composite material, which contains at least the following constituent components [A], [B], [C] and [D]:[A] at least one epoxy resin (other than a cycloaliphatic epoxy resin represented by formula (I));[B] at least one amine curing agent[C] at least one latent add catalyst[D] at least one cycloaliphatic epoxy resin represented by formula (I), wherein Y is a single bond or represents a divalent structure having a molecular weight less than 45 g / molThis epoxy resin composition is useful in the molding of fiber-reinforced composite materials. More particularly, it is possible to offer an epoxy resin composition for a fiber-reinforced composite material where the cured material obtained by heating has a high level heat resistance and strength properties.

Owner:TORAY IND INC

High strength gypsum production method

InactiveCN104512922AHigh purityImprove mechanical propertiesCalcium/strontium/barium sulfatesEnergy inputHigh pressureMixing tank

The present invention discloses a high strength gypsum production method, which comprises: crushing a gypsum raw material, grinding into gypsum powder with a particle size of 50-100 [mu]m, conveying the grinded gypsum powder into a mixing tank through conveying equipment to prepare a gypsum slurry with a concentration of 1200-1500 g / cm<2>, heating the gypsum slurry to a temperature of 30-100 DEG C through a heat conduction oil heating system, transferring the uniformly-mixed gypsum slurry into a crystal transition device through a high pressure slurry pump, carrying out further dilution, concurrently adding a crystal transition agent, carrying out primary crystallization, transferring the obtained gypsum crystal into the follow-up crystallization device, carrying out secondary crystallization, conveying the obtained gypsum slurry into a centrifuge separator to separate, introducing hot wind with a temperature of 40-160 DEG C into the centrifuge separator during the separating, placing the separated wet gypsum crystal into a dryer to further dry, and conveying into a material tank through the convey equipment, wherein the generated gypsum crystal has characteristics of high purity, strong mechanical property, high drying performance and high compressive strength.

Owner:QINGDAO SHOUSHENG IND

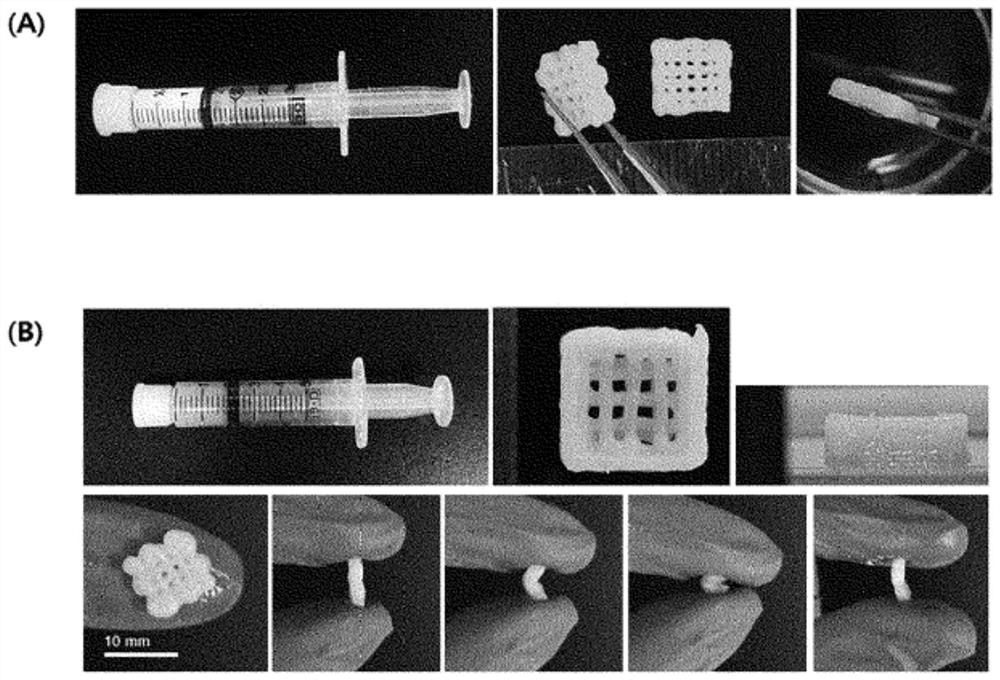

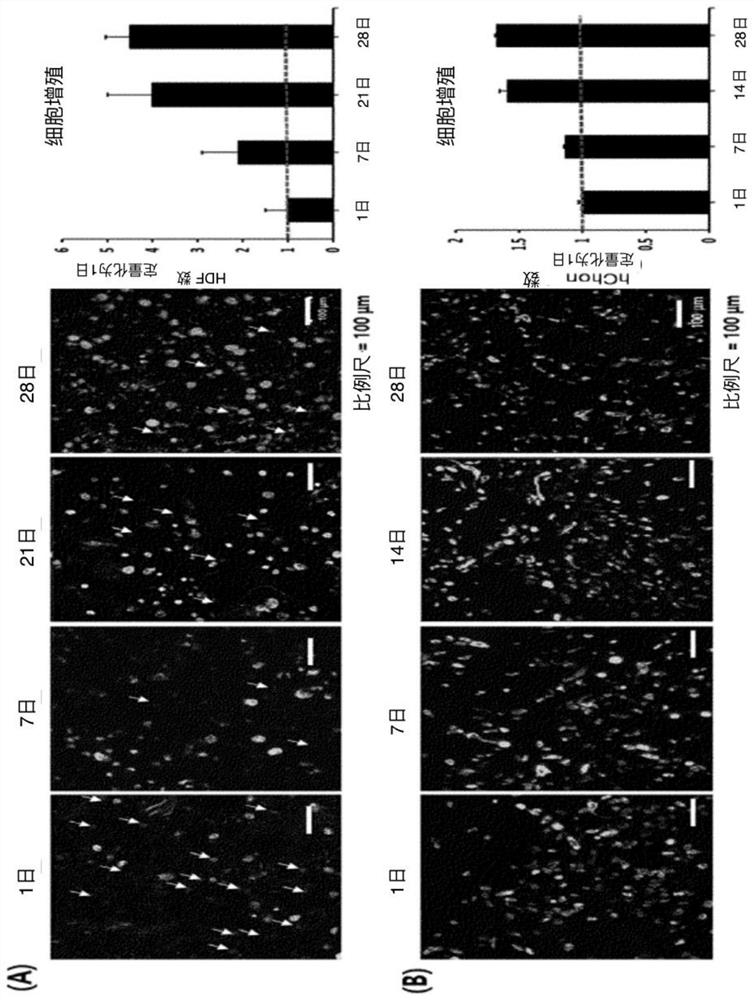

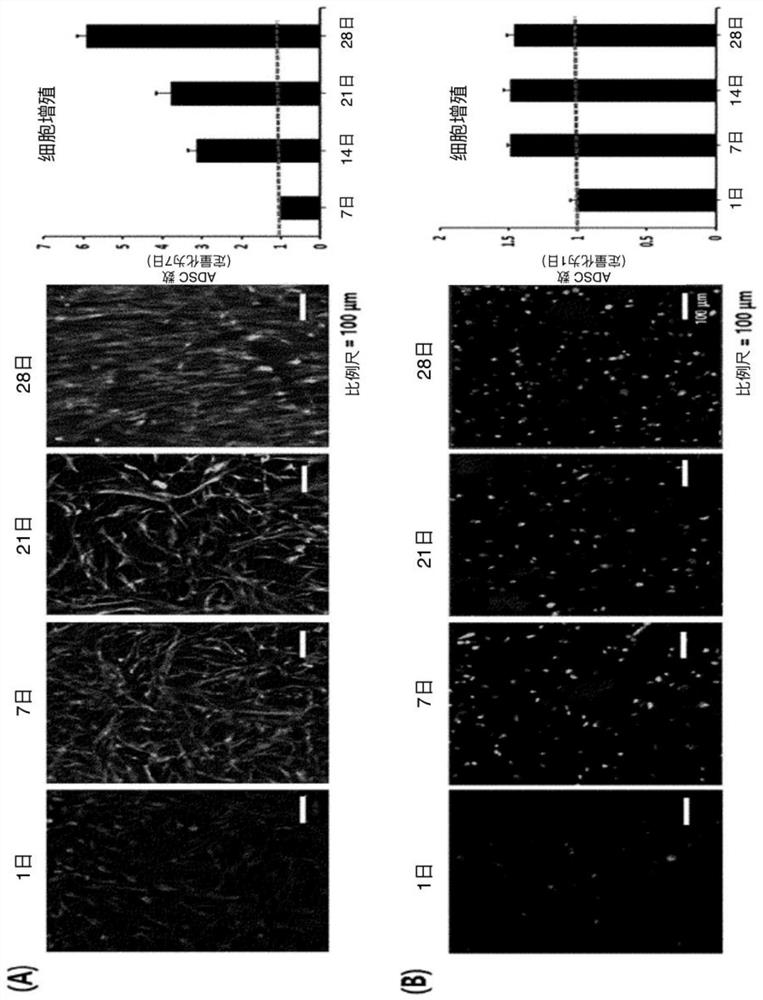

Bio-ink composition for 3D printing, containing human-derived component and having tissue-specific cell differentiation effect, and preparation method therefor

PendingCN113195652AHigh mechanical propertiesHigh cell affinityInksEngineeringBiomedical engineering

The present invention relates to a bio-ink composition for three dimensional (3D) printing, and a preparation method therefor. The present invention can provide: a bio-ink composition having a synergistic effect on the differentiation of cells into a specific tissue according to tissue specificity of a human-derived component contained in the bio-ink composition; and a preparation method therefor.

Owner:爱恩斯生物科技(昆山)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com