Resin composition and method for manufacturing same

A technology of resin composition and manufacturing method, which is applied in the field of resin composition and its manufacture, can solve the problems of not improving the components of defibrillation, etc., and achieve the effects of low cost, reduced manufacturing cost, and less environmental load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

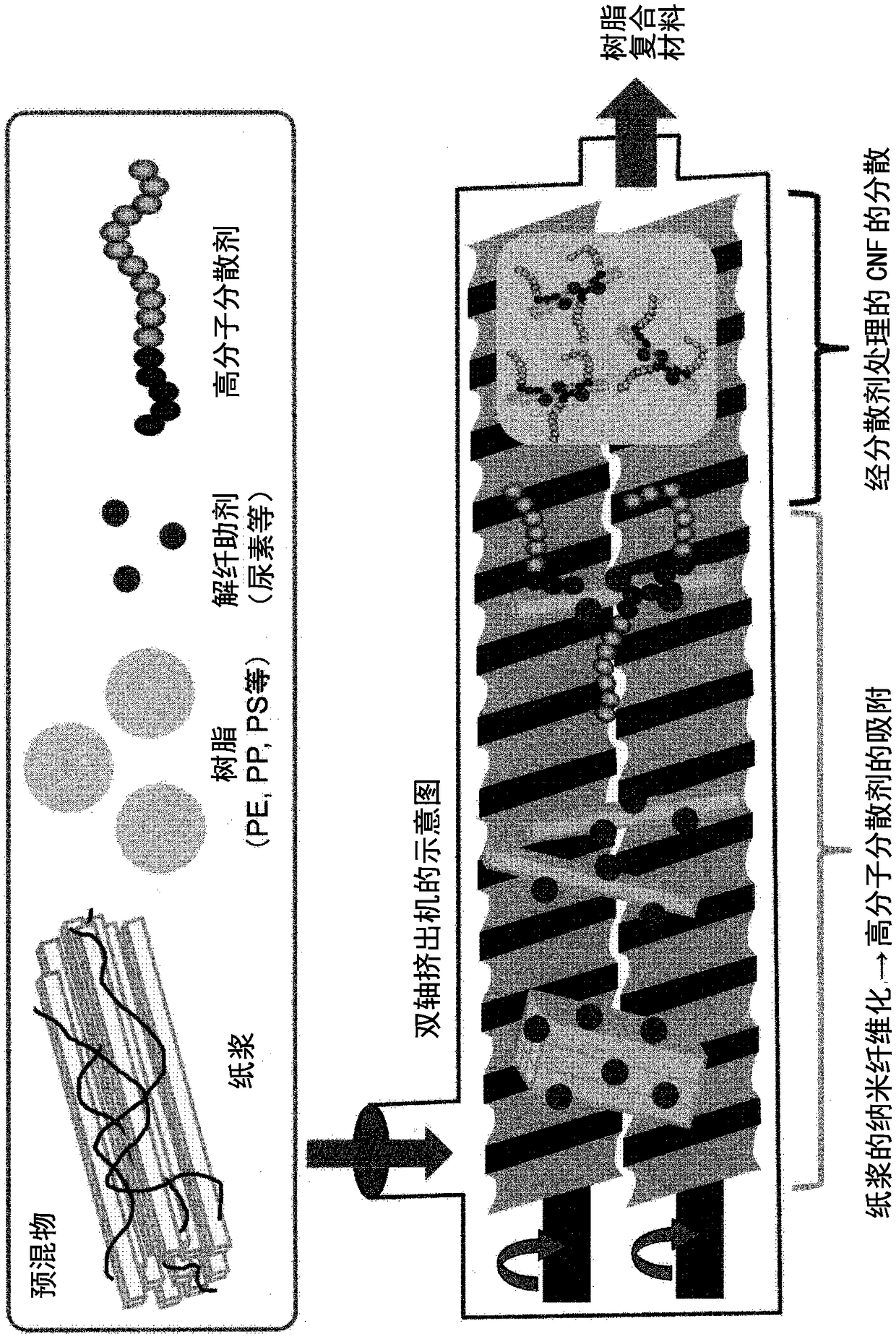

[0104] In the preparation of the resin composition of the present invention, a fiber disintegrating agent and a resin such as high-density polyethylene are added to cellulose fibers such as wood-derived pulp to prepare a mixture (premix). By melt-kneading this mixture using a twin-screw kneader (twin-screw extruder) or the like, the cellulose fibers can be defibrated down to the nanoscale.

[0105] Wherein, the timing of adding the fiber-defibrating aid is not limited.

[0106]The disintegrating aid can be mixed into a dry mixture (premix) containing cellulose fibers and resin by adding it during pulp beating or by adding it to water containing pulp.

[0107] As a result, a composite resin material containing CNF and exhibiting high mechanical properties can be produced. In the resin composition of the present invention, by including a defibrating aid, in the resin composition, the preparation of CNF (fibrillation of cellulose fibers), the dispersion of CNF in the resin, and ...

Embodiment

[0304] Hereinafter, the present invention will be described in more detail with reference to Examples and Comparative Examples.

[0305] The present invention is not limited thereto.

[0306]

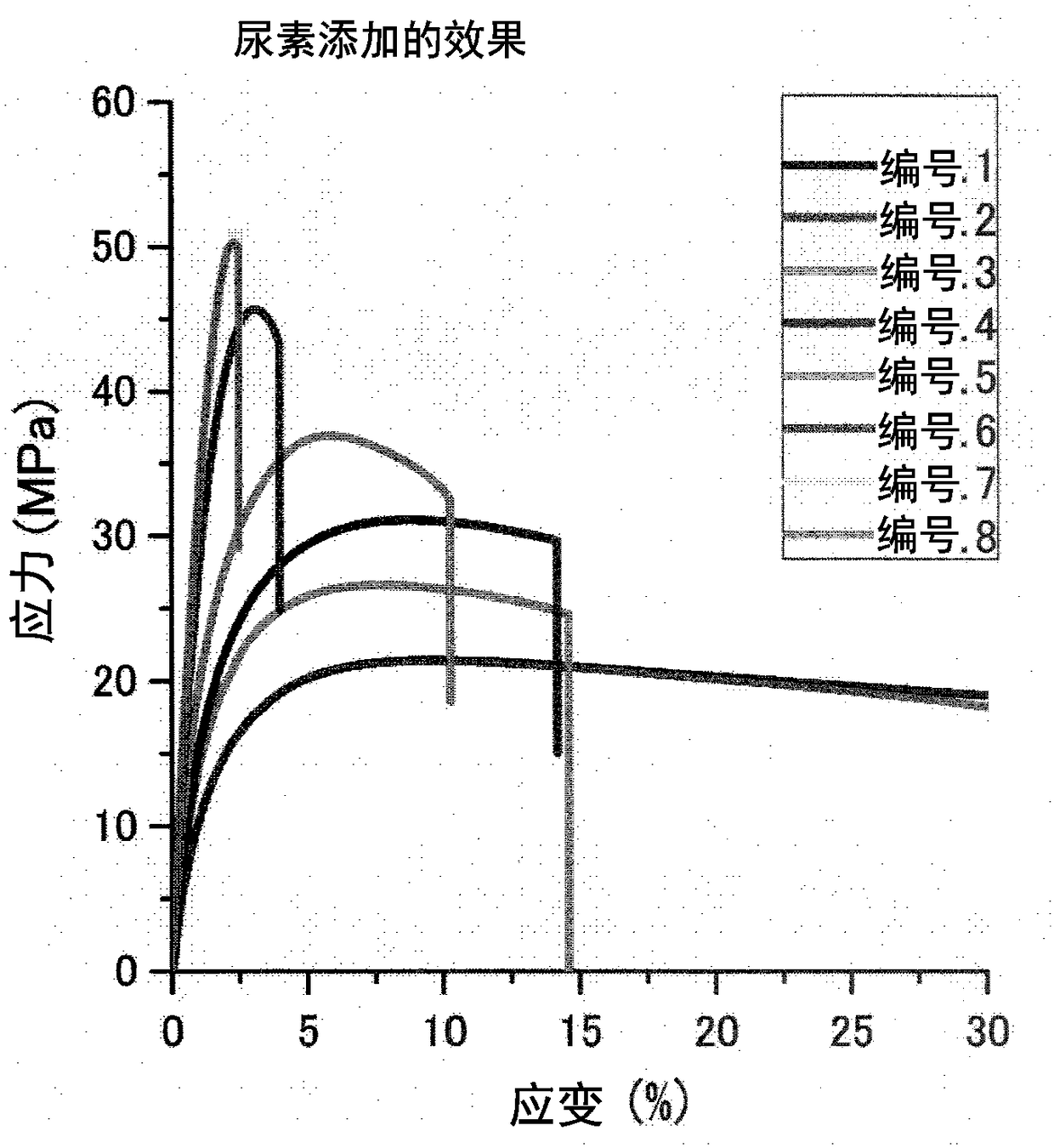

[0307] The embodiment is a technique of producing a resin composite material at low cost by using a defibrillating agent (urea, etc.) and a dispersant (a water-soluble polymer dispersant, etc.) for pulp. This process is a pretreatment process of water system without using organic solvents.

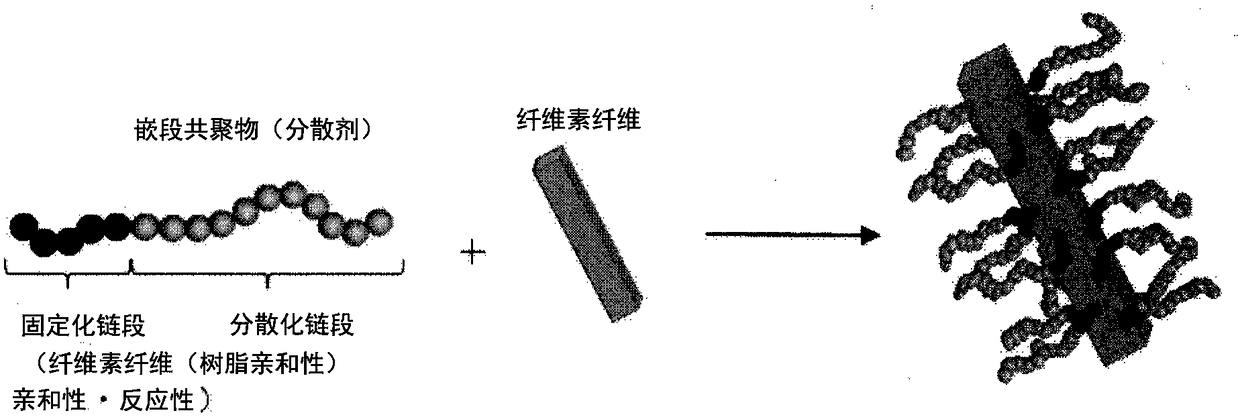

[0308] (1) Dispersant used (block copolymer)

[0309] The scheme of the dispersant is shown below.

[0310] [chemical formula 3]

[0311]

[0312] The scheme of the dispersant is shown in Table 4.

[0313] [Table 4]

[0314]

[0315] Dissolve the monomer that becomes the resin affinity segment (chain A): dicyclopentenyloxyethyl methacrylate (DCPOEMA) (manufactured by Hitachi Chemical, FA-512M) in an amphiphilic solvent (such as propylene glycol monopropyl ether) for living free radic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com