Biodegradable resin composition having improved mechanical properties, moldability, and weather resistance, and preparation method therefor

A resin composition and biodegradability technology, applied in the field of mechanical properties obtained from moldability and weather resistance, can solve the problem of long reaction time, unfavorable production costs, and difficulty in obtaining high molecular weight aliphatic/aromatic copolyester resins and other problems, to achieve the effect of improving formability and durability, excellent productivity and economy, and shortening the reaction rate of polycondensation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0136] Preparation example: preparation of multifunctional compound

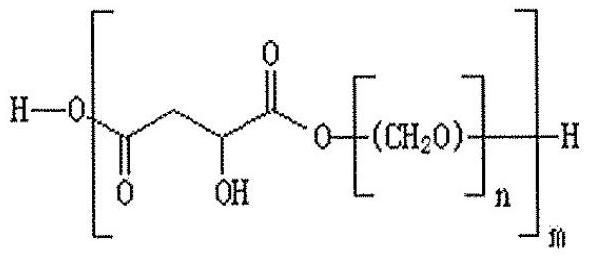

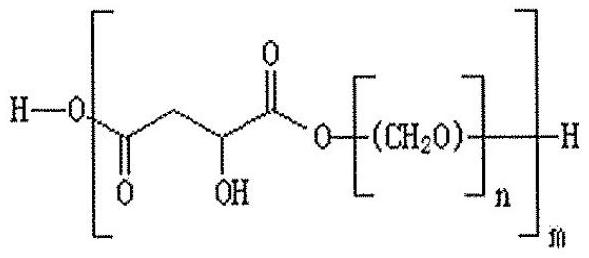

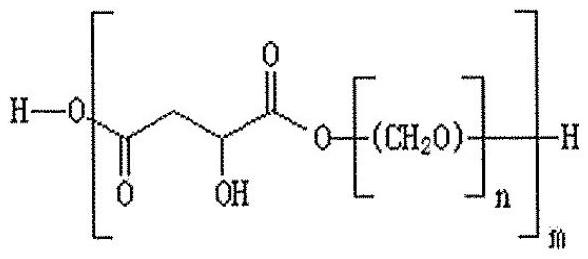

[0137] Replace the gas in a 1000ml round-bottomed flask with nitrogen, put in 268.16g of DL-malic acid, 148.96g of ethylene glycol and 0.02g of monobutyltin oxide as a catalyst, and perform esterification reaction at 120°C for two hours. When 2 moles of theoretically produced water as a by-product of the reaction flowed out, the reaction was confirmed to be complete, and the reaction was terminated to prepare a polyfunctional compound. The preparation process of the above-mentioned polyfunctional compound is represented as the following Reaction Formula 1.

[0138] Reaction 1

[0139]

[0140] (In the above reaction formula 1, m is an integer of 1 to 30.)

Embodiment 1

[0141] Embodiment 1: Preparation of biodegradable aliphatic polyester resin composition (1)

[0142] Replace the gas in the 100L reactor with nitrogen, put 29.23kg of adipic acid, 22.53kg of 1,4-butanediol and 300g of the polyfunctional compound obtained in the above preparation example into the reactor, raise the reaction temperature, and finally , after being fixed at 205° C., a theoretical amount of water was allowed to flow out. At this time, 10 g of dibutyltin oxide as a catalyst, 10 g of titanium isopropoxide, and 20 g of trimethyl phosphate as a stabilizer were added. Thereafter, the temperature of the reactor was raised, and polycondensation reaction was carried out at a temperature of 245° C. under a reduced pressure of 1.5 torr for 210 minutes to obtain an aliphatic polyester resin composition. Then, after mixing 100 kg of the resin composition obtained by the polycondensation reaction and 500 g of 1,6-hexamethylene diisocyanate with a high-speed mixer, a chain exte...

Embodiment 2

[0143] Embodiment 2: Preparation of biodegradable aliphatic polyester resin composition (2)

[0144] The gas in the 100L reactor was replaced with nitrogen, and 23.62kg of succinic acid, 22.53kg of 1,4-butanediol, and 300g of the polyfunctional compound obtained in the above preparation example were charged, and the reaction temperature was raised while stirring, and finally, After fixing to 205°C, water was allowed to flow out. At this time, 4 g of tetrabutyl titanate as a catalyst, 8 g of dibutyltin oxide, 8 g of titanium isopropoxide, and 15 g of trimethyl phosphate as a stabilizer were added. Thereafter, the temperature of the reactor was raised, and polycondensation reaction was carried out at a temperature of 245° C. under a reduced pressure of 1.5 torr for 181 minutes to obtain an aliphatic polyester resin composition. Then, after mixing 100 kg of the resin composition obtained by the polycondensation reaction and 500 g of 1,6-hexamethylene diisocyanate with a high-spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com