Expansion halogen-free flame-retardant PP/EVA (polypropylene/ethylene-vinyl acetate) wire and cable composition and method for manufacturing same

A wire and cable, intumescent technology, applied in the field of intumescent halogen-free flame retardant PP/EVA composite wire and cable and its preparation, can solve the problems of lack of halogen-free flame retardant research and other problems, and achieve the effect of excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

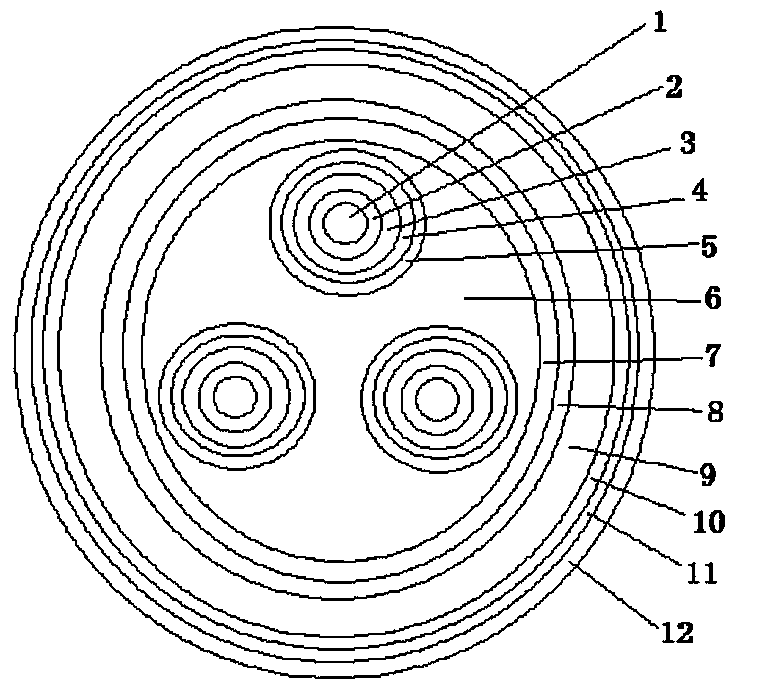

[0079]An intumescent halogen-free flame-retardant PP / EVA composite wire and cable, comprising three conductors 1, a shielding layer 2 is provided on the outside of the conductors 1, and a PP / EVA composite insulating layer 3 is provided on the outside of the shielding layer 2. The PP / EVA composite insulating layer 3 is provided with a high temperature resistant layer 4 outside, the high temperature resistant layer 4 is provided with an expansion layer 5 outside, the conductor 1 is filled with a flame retardant glass fiber filling rope 6, and the entire conductor 1 and The flame-retardant glass fiber filled rope 6 is provided with a flame-retardant tape 7 outside, and the conductor 1 forms a whole with the shielding layer 2, PP / EVA composite insulating layer 3, high-temperature resistant layer 4, and expansion layer 5, which are symmetrical Distributed in the flame-retardant belt 7, the flame-retardant belt 7 is provided with an expansion belt 8, the expansion belt 8 is provided ...

Embodiment 2

[0111] An intumescent halogen-free flame-retardant PP / EVA composite wire and cable, comprising three conductors 1, a shielding layer 2 is provided on the outside of the conductors 1, and a PP / EVA composite insulating layer 3 is provided on the outside of the shielding layer 2. The PP / EVA composite insulating layer 3 is provided with a high temperature resistant layer 4 outside, the high temperature resistant layer 4 is provided with an expansion layer 5 outside, the conductor 1 is filled with a flame retardant glass fiber filling rope 6, and the entire conductor 1 and The flame-retardant glass fiber filled rope 6 is provided with a flame-retardant tape 7 outside, and the conductor 1 forms a whole with the shielding layer 2, PP / EVA composite insulating layer 3, high-temperature resistant layer 4, and expansion layer 5, which are symmetrical Distributed in the flame-retardant belt 7, the flame-retardant belt 7 is provided with an expansion belt 8, the expansion belt 8 is provided...

Embodiment 3

[0143]An intumescent halogen-free flame-retardant PP / EVA composite wire and cable, comprising three conductors 1, a shielding layer 2 is provided on the outside of the conductors 1, and a PP / EVA composite insulating layer 3 is provided on the outside of the shielding layer 2. The PP / EVA composite insulating layer 3 is provided with a high temperature resistant layer 4 outside, the high temperature resistant layer 4 is provided with an expansion layer 5 outside, the conductor 1 is filled with a flame retardant glass fiber filling rope 6, and the entire conductor 1 and The flame-retardant glass fiber filled rope 6 is provided with a flame-retardant tape 7 outside, and the conductor 1 forms a whole with the shielding layer 2, PP / EVA composite insulating layer 3, high-temperature resistant layer 4, and expansion layer 5, which are symmetrical Distributed in the flame-retardant belt 7, the flame-retardant belt 7 is provided with an expansion belt 8, the expansion belt 8 is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com