Patents

Literature

46results about How to "Good waterproof and corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Purple-light cross-linked low-smoke halogen-free high flame-retardant EVA cable and production method thereof

InactiveCN104200906AImprove performanceImprove shielding effectInsulated cablesCable/conductor manufactureLow smoke zero halogenGlass fiber

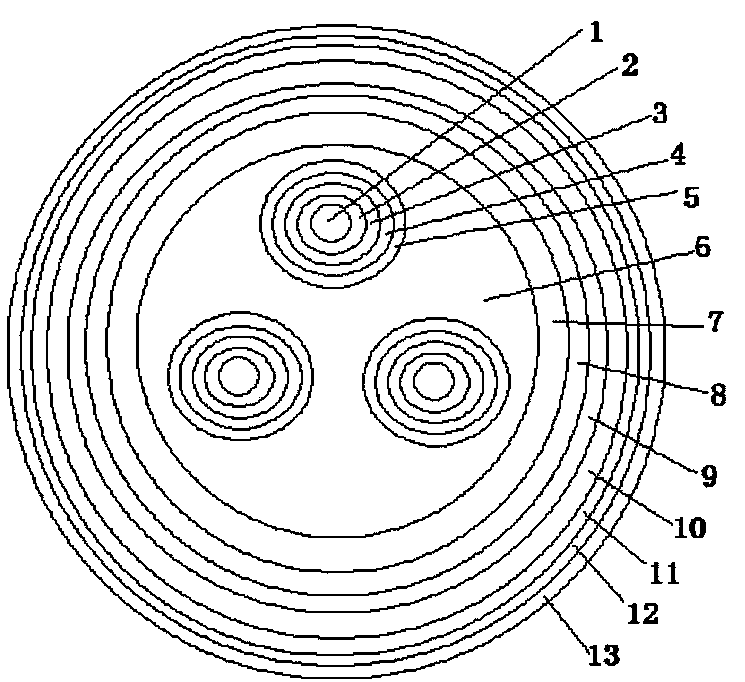

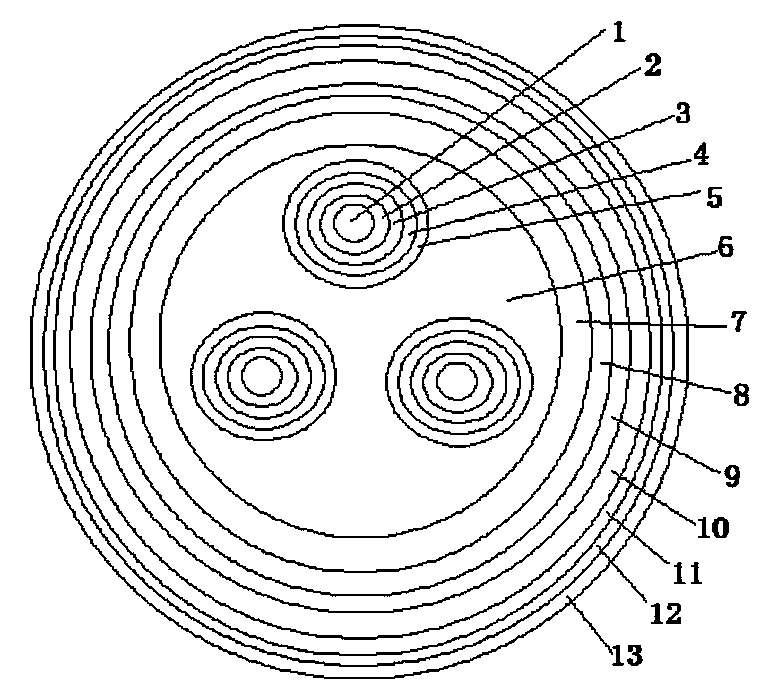

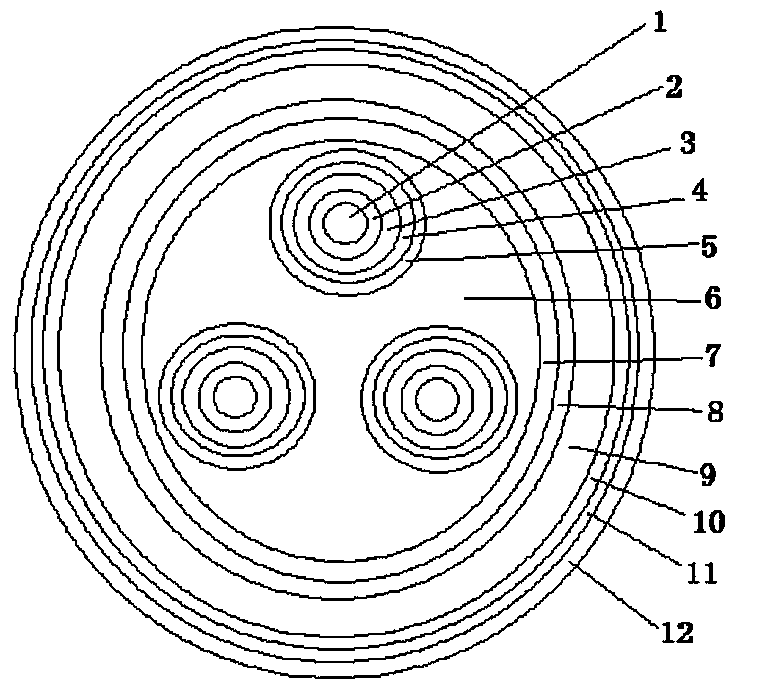

The invention provides a purple-light cross-linked low-smoke halogen-free high flame-retardant EVA cable which comprises conductors. Each conductor is covered with a shield layer, the shield layer is covered with a purple-light cross-linked insulating layer, the purple-light cross-linked insulating layer is covered with a ceramic silicone rubber layer, and the ceramic silicon rubber layer is covered with an anticorrosive layer. Flame-retardant glass fiber filling ropes are filled among the conductors, the conductors and the flame-retardant glass fiber filling ropes are together covered with a flame-retardant tape, the flame-retardant tape is covered with an internal purple-light cross-linked protective layer, the internal purple-light cross-linked protective layer is provided with an armor layer, the armor layer is covered with an external purple-light cross-linked protective layer, the external purple-light cross-linked protective layer is covered with a waterproof layer, the waterproof layer is covered with an SBS rubber layer, and the SBS rubber layer is coated with an ultraviolet-proof layer. The invention further provides a production method of the cable. The purple-light cross-linked low-smoke halogen-free high flame-retardant EVA cable is provided with multiple flame-retardant layers and the waterproof layer.

Owner:ZHANGQIU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

Improved high-temperature-resistant metal anti-corrosive paint

The invention relates to improved high-temperature-resistant metal anti-corrosive paint, which consists of the following components in parts by mass: 30-40 parts of GHNK high-temperature-resistant adhesive, 15-20 parts of polyaniline / graphene composite material, 15-20 parts of coloring pigment, 5-10 parts of superfine talcum powder, 5-10 parts of superfine mica powder, 5-10 parts of kaolin, 0.2-0.5 parts of SN-612 flatting agent, 0.3-0.5 parts of wetting agent X-405, 0.1-0.3 parts of dimethyl ethanolamine, 0.1-0.3 parts of anti-corrosive agent 981, 0.5-1 part of GHP 101 thickening agent, 0.1-0.3 parts of tributyl phosphate and 4-13 parts of water. The paint prepared by the invention has the advantages of excellent water-proof and anti-corrosive properties, high temperature resistance, alkaline resistance, weathering resistance, scrub resistance, artificial aging resistance and the like, passivation and corrosion inhibition of a metal base material can be realized, meanwhile, the use of heavy metals such as chromium which can cause environmental pollution is avoided, and the paint is easy to prepare, low in cost and is easy for industrial batch production.

Owner:冯斌

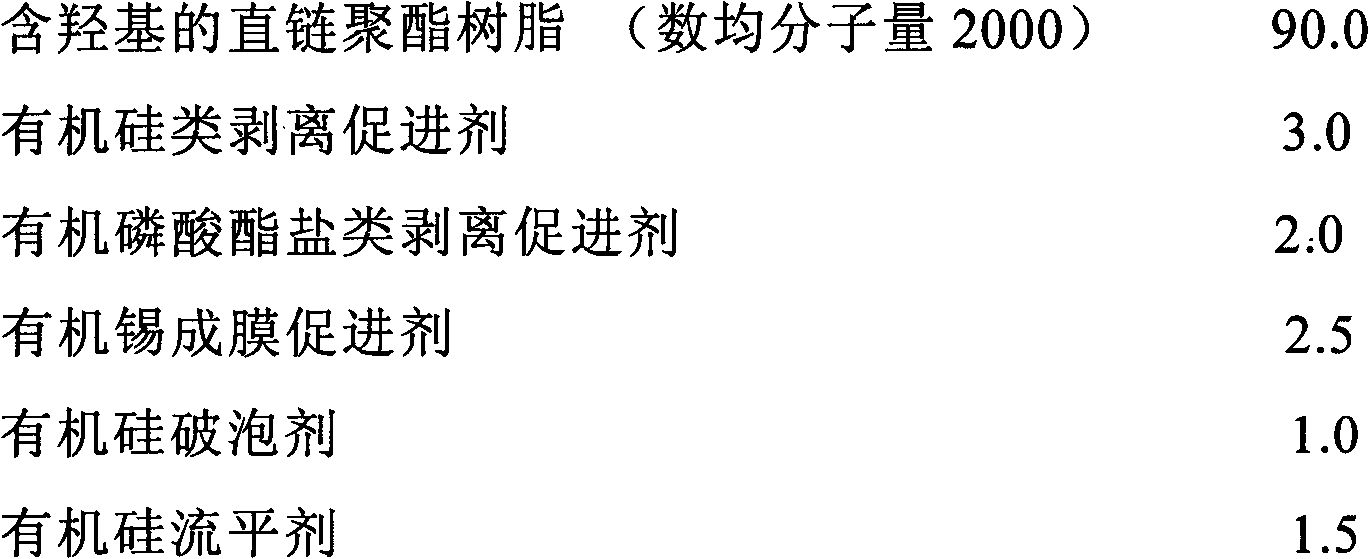

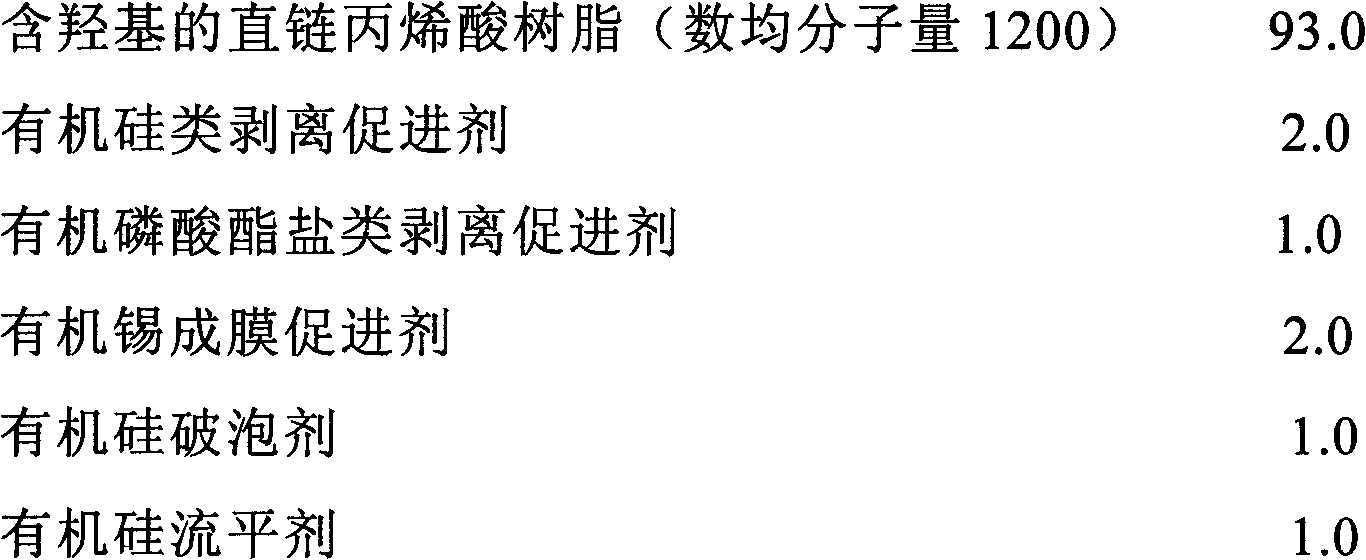

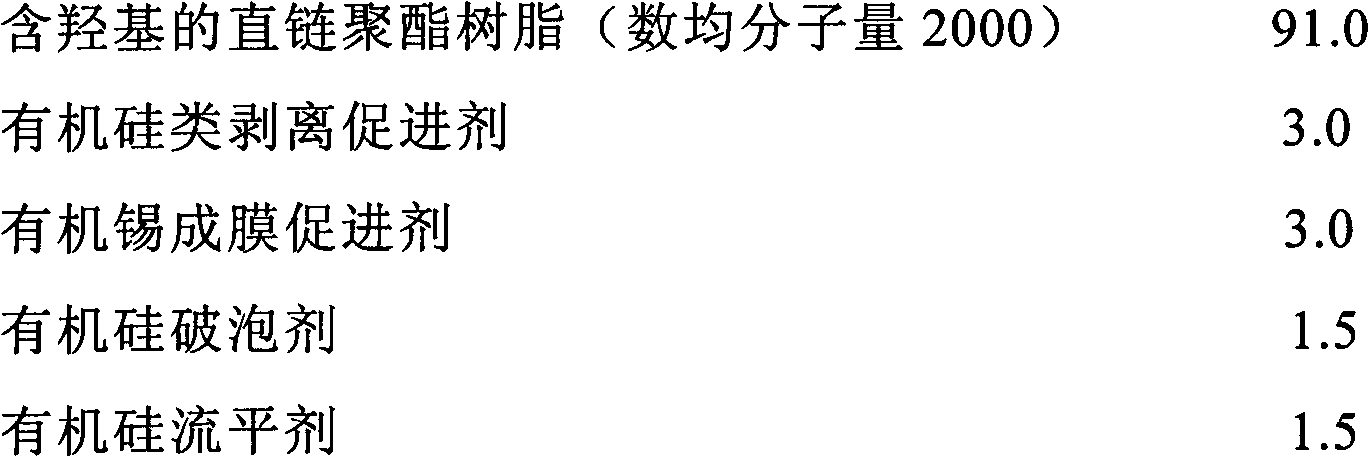

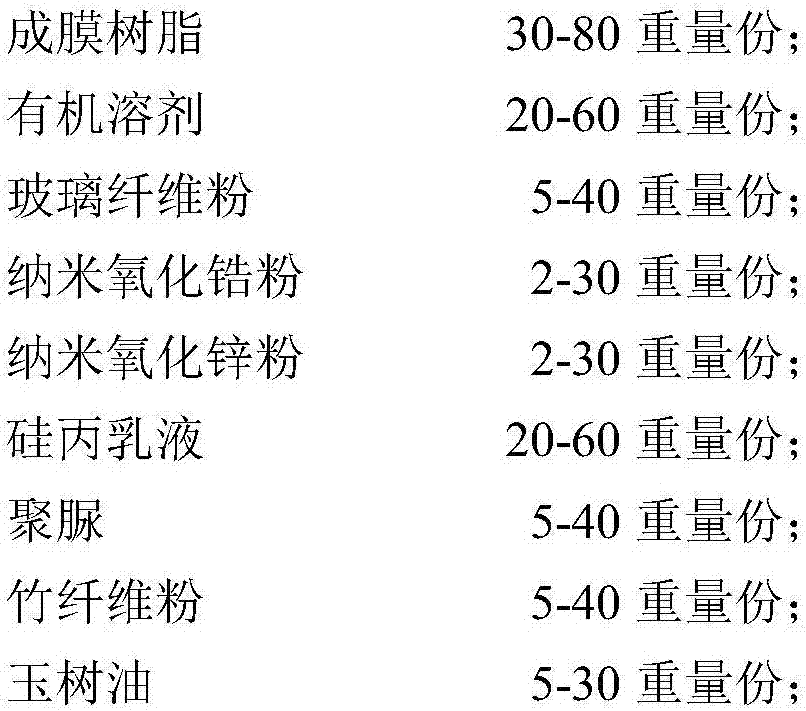

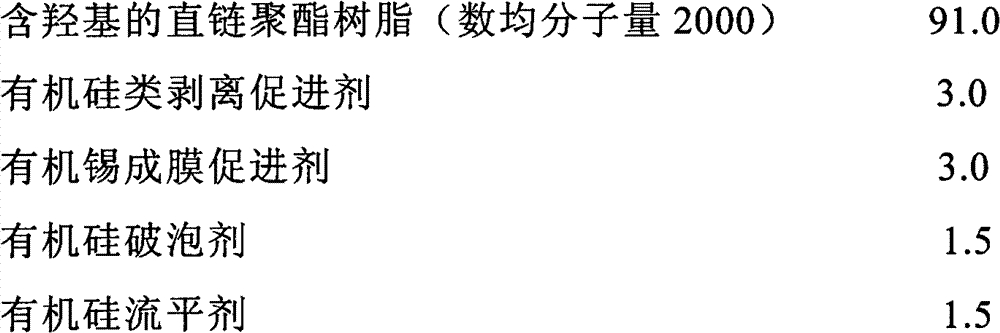

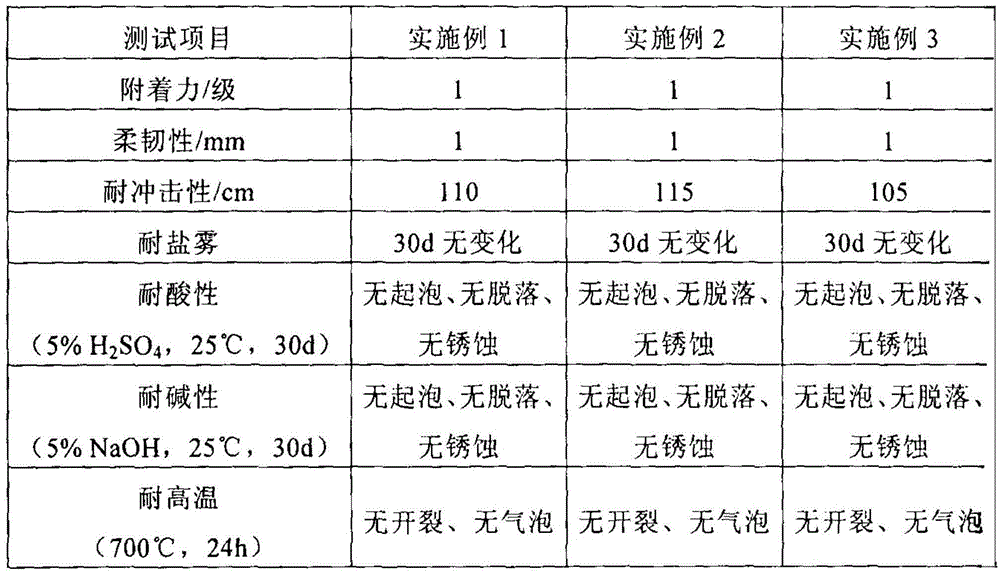

Strippable heat-proof antirust protective film coating and preparation method thereof

InactiveCN102863888AImprove compactnessGood waterproof and corrosion resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinPolyester resin

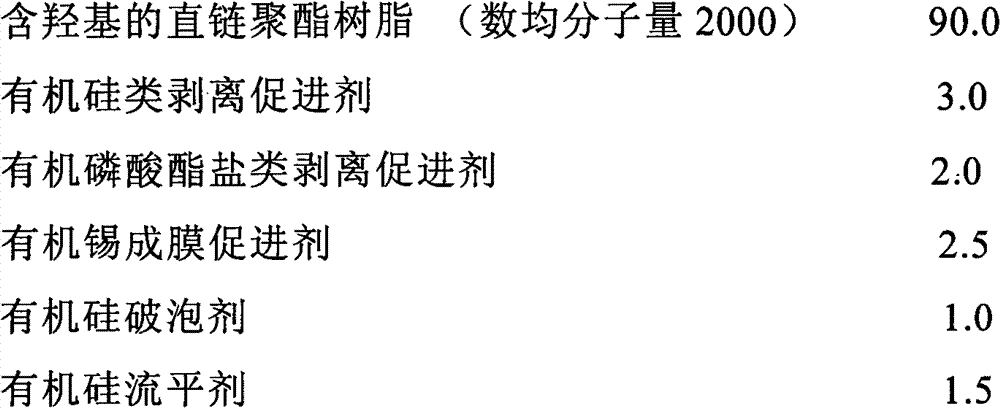

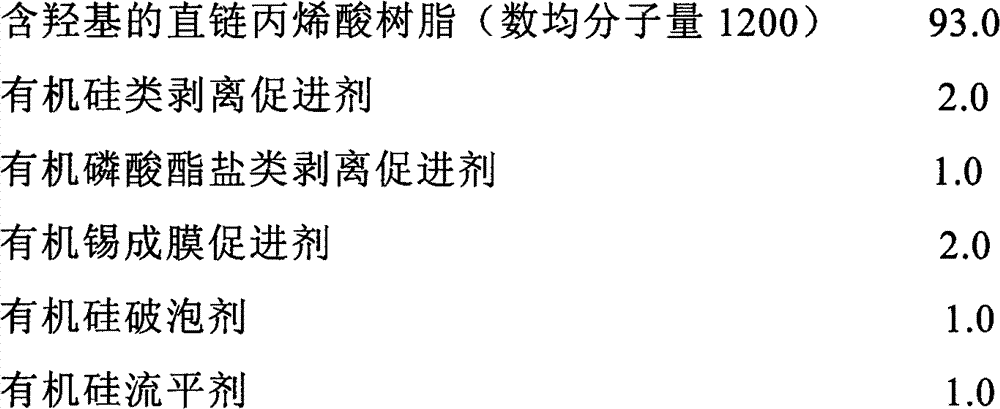

The invention relates to strippable heat-proof antirust protective film coating and a preparation method thereof. The raw material of the protective film coating is formed by paint and curing agent. The paint comprises, by weight, 88-96 parts of linear chain polyester resin or acrylic resin containing hydroxide radical, 2.0-5.0 parts of stripping accelerant, 1.0-3.0 parts of film-forming accelerant, 0.5-2.0 parts of antifoaming agent and 0.5-2.0 parts of flatting agent. The curing agent comprises, by weight, 25-40 parts isocyanate polymer. The linear chain polyester resin or the acrylic resin containing the hydroxide radical is heated and stirred and then added in other components except the curing agent, the isocyanate polymer is added in the mixture during usage, and the strippable heat-proof antirust protective film coating is obtained after even mixing. The strippable heat-proof antirust protective film coating does not contain solvent, meets environment-friendly requirements, simultaneously has high waterproof performance, oil resistance, temperature resistance, abrasion resistance and strippable performance, can have metal surfaces, stripping surfaces, plastic surfaces and the like at the same time, and has temporary antirust protection effects.

Owner:SHANGHAI DATONG TABERNACLE NEW ENERGY SAVING MATERIALS CO LTD

Irradiation-resistant halogen-free high-flame-retardant EVA electric wire and manufacturing method thereof

ActiveCN104183317AImprove performanceImprove shielding effectInsulated cablesInsulated conductorsElectrical conductorMaterials science

The invention provides an irradiation-resistant halogen-free high-flame-retardant EVA electric wire which comprises a conductor. A shielding layer is arranged outside the conductor. An irradiation-resistant flame-retardant EVA insulating layer is arranged outside the shielding layer. A fireproof layer is arranged outside the irradiation-resistant flame-retardant EVA insulating layer. A high-temperature-resistant layer is arranged outside the fireproof layer. The conductor is filled with a flame-retardant fiberglass filling rope. A flame-retardant belt is arranged outside the whole conductor and the flame-retardant fiberglass filling rope. An inner irradiation-resistant flame-retardant EVA layer is arranged outside the flame-retardant belt. An armor layer is arranged outside the inner irradiation-resistant flame-retardant EVA layer. An outer irradiation-resistant flame-retardant EVA layer is arranged outside the armor layer. A waterproof and corrosion-proof layer is arranged outside the outer irradiation-resistant flame-retardant EVA layer. A wearing layer is arranged outside the waterproof and corrosion-proof layer. The exterior of the wearing layer is coated with an irradiation-resistant layer. The invention further provides a preparation method of the electric wire. The irradiation-resistant halogen-free high-flame-retardant EVA electric wire is obtained due to the arrangement of the multiple irradiation-resistant layers and the multiple flame-retardant layers.

Owner:珠海思科信电线电缆有限公司

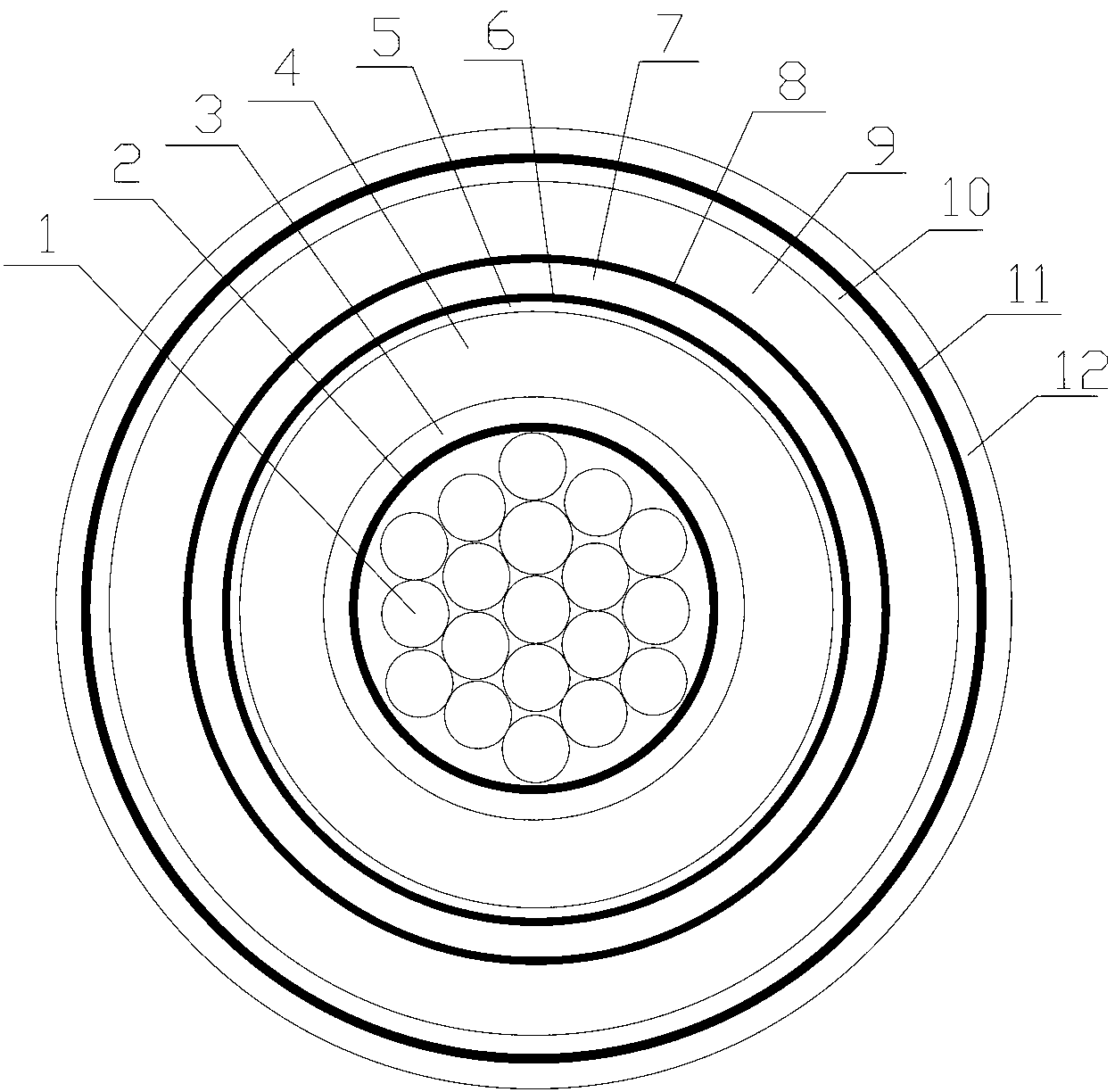

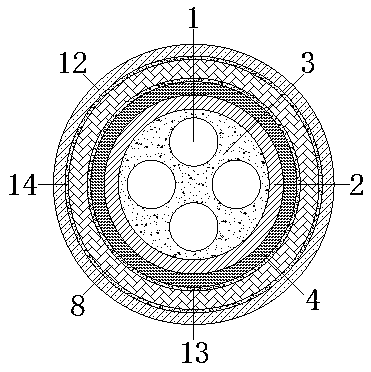

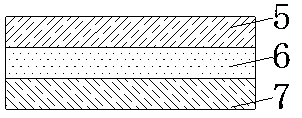

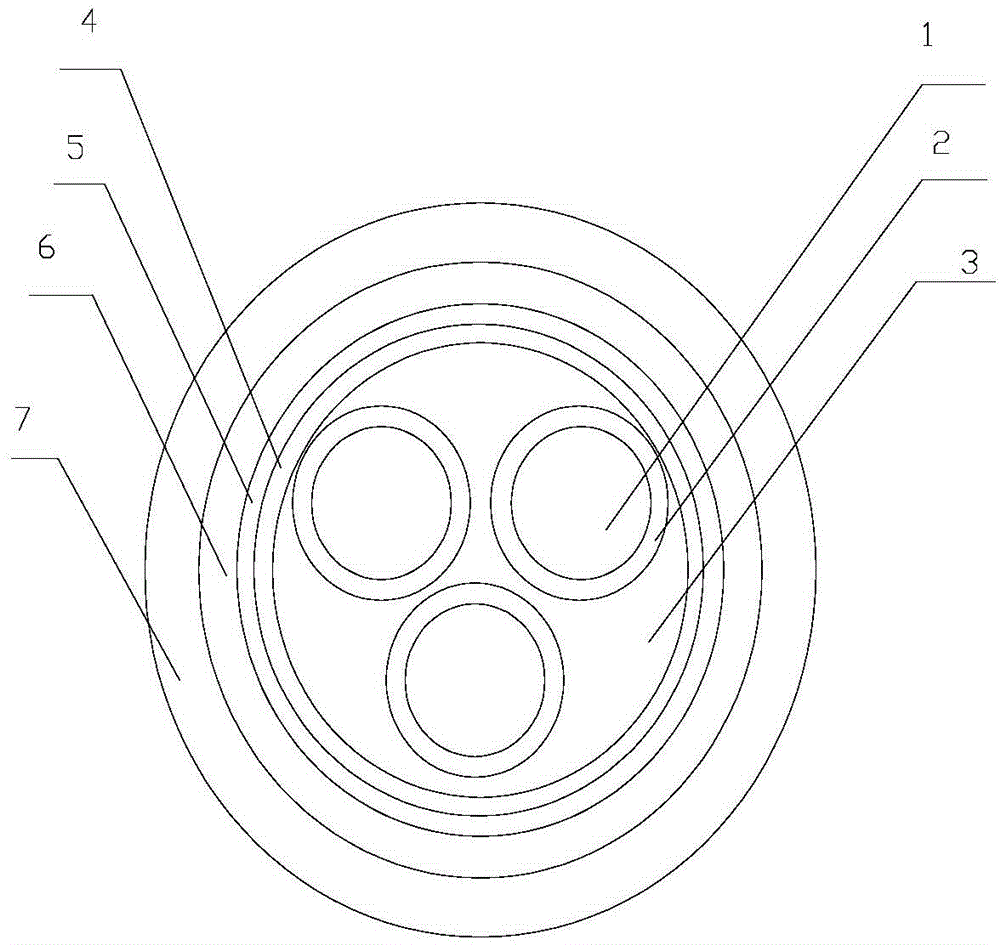

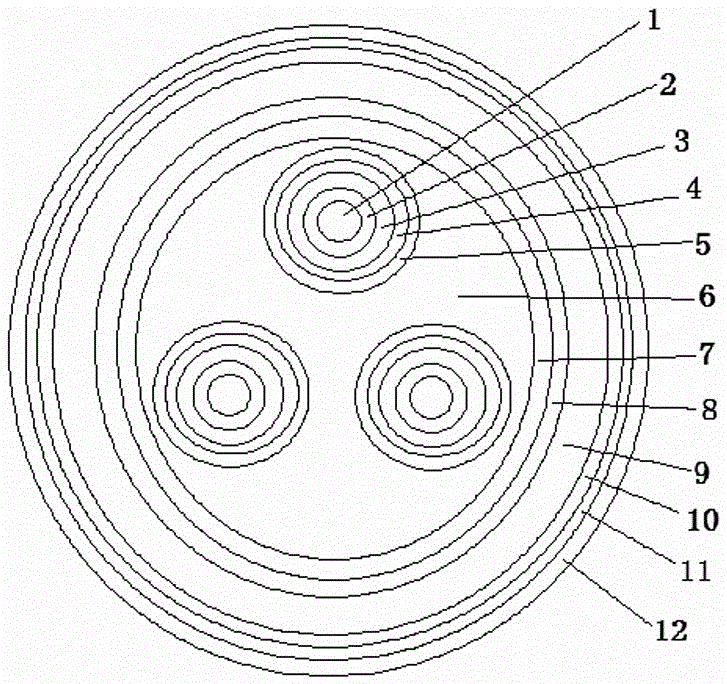

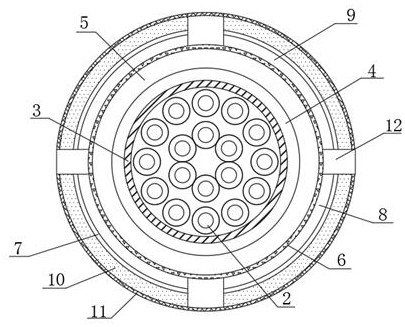

Water-proof anti-corrosion electric power flexible cable

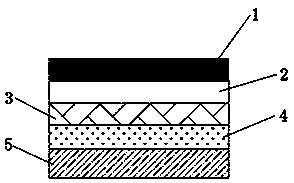

InactiveCN103021549AGood waterproof and corrosion resistanceExtended service lifeRubber insulatorsPower cables with screens/conductive layersInsulation layerElectrical conductor

The invention provides a water-proof anti-corrosion electric power flexible cable which comprises a conductor (1). A conductor shielding layer (3), a rubber insulation layer (4), an insulation shielding layer (5), a first braided shielding layer (7), an inner sheath (9), a second braided shielding layer (10), a water-proof layer (11) and an outer sheath (12) are sequentially wrapped on the periphery of the conductor (1) from the inside to the outside. The outer sheath is made of chlorosulfonated polyethylene rubber which is composed of the following raw materials, by weight, 100 parts of chlorosulfonated polyethylene rubber, 6-12 parts of dichloro ureide, 6-9 parts of antimony oxide, 3-10 parts of alkali lead phthalate, 50-70 parts of argil, 3-7 parts of triallyl isocyanurate, 3-4 parts of N-phenyl-a-naphthylamine, 1-2 parts of vinyl silane, 70-80 parts of carbon black, 2-4 parts of dioctyl phthalate, 18-25 parts of chlorinated paraffin oil and 1-3 parts of dissoluble polytetrafluoroethylene. The water-proof anti-corrosion electric power flexible cable has good water-proof and anti-corrosion performance and prolongs the service life.

Owner:ANHUI HUININGELECTRIC INSTR & APPLIANCE GRP

Metal anticorrosive paint

ActiveCN103436141AGood waterproof and corrosion resistanceAchieve passivationAnti-corrosive paintsPolyether coatingsChemistryHeavy metals

The invention discloses a metal anticorrosive paint which is prepared by stirring the following raw materials in parts by weight: 100-110 parts of epoxy resin, 20-30 parts of benzoic acid resin, 10-15 parts of diphenyl ether resin, 15-18 parts of dimethylbenzene, 15-25 parts of cerium oxide, 6-10 parts of n-butanol, 8-12 parts of polybenzimidazole, 10-12 parts of KH-550, 10-15 parts of talcum powder, 3-8 parts of dimethylethanolamine, 6-10 parts of barium dinonylnaphthalene sulfonate and 50-60 parts of water. The commercial test proves that the prepared paint has the advantages of excellent water resistance and excellent corrosion resistance, can implement passivation and corrosion inhibition of the metal substrate, avoids using chrome and other heavy metals possibly causing environmental pollution, is simple to prepare and low in cost, and can be easily put into industrial production.

Owner:江苏悠谷未来科技有限公司

Expansion halogen-free flame-retardant PP/EVA (polypropylene/ethylene-vinyl acetate) wire and cable composition and method for manufacturing same

ActiveCN104217797AImprove performanceImprove shielding effectClimate change adaptationInsulated cablesGlass fiberPolymer science

The invention provides an expansion halogen-free flame-retardant PP / EVA (polypropylene / ethylene-vinyl acetate) wire and cable composition which comprises conductors. A shielding layer is arranged on the outside of each conductor, a PP / EVA composite insulating layer is arranged on the outside of each shielding layer, a high-temperature-resistant layer is arranged on the outside of each PP / EVA composite insulating layer, an expansion layer is arranged on the outside of each high-temperature-resistant layer, spaces among the conductors are filled with a filler rope made of flame-retardant glass fibers, a flame-retardant belt is arranged on the outsides of the integral conductors and the filler rope made of the flame-retardant glass fibers, an expansion belt is arranged on the outside of the flame-retardant belt, a PP / EVA composite protection layer is arranged on the outside of the expansion belt, a waterproof and anticorrosion layer is arranged on the outside of the PP / EVA composite protection layer, a radiation-resistant layer is coated on the outside of the waterproof and anticorrosion layer, and an abrasion-resistant layer is arranged on the outside of the radiation-resistant layer. The invention further provides a method for manufacturing the expansion halogen-free flame-retardant PP / EVA wire and cable composition. The expansion halogen-free flame-retardant PP / EVA wire and cable composition and the method have the advantage that the expansion halogen-free flame-retardant PP / EVA wire and cable composition is provided with the multiple expansion layers, the expansion belt and flame-retardant layers.

Owner:JIANGSU XINGHUA RUBBER BELT

An anti-corrosion coating for stainless steel

ActiveCN103483949BGood waterproof and corrosion resistanceAchieve passivationAnti-corrosive paintsPolyester coatingsIsobutanolSilanes

The invention discloses an anticorrosive paint for stainless steel. The anticorrosive paint is prepared by mixing the following raw materials in parts by weight: 50-70 parts of alkyd resin, 30-40 parts of silicon dioxide emulsion, 60-70 parts of polyvinyl acetate resin, 6-12 parts of phenyl trimethoxy silane, 10-20 parts of isobutanol, 10-14 parts of acetone, 8-14 parts of polybenzimidazole, 5-9 parts of KH-570, 11-14 parts of talcum powder, 12-14 parts of dimethyl ethanolamine, 7-10 parts of petroleum sodium sulfonate and 80-100 parts of water. The industrial tests prove that the anticorrosive paint has the advantages of terrific water resistance and corrosion resistance, can realize passivation and corrosion inhibition of a metal substrate, and avoids the use of heavy metals such as chromium which can cause environmental pollution; furthermore, the anticorrosive paint for the stainless steel is simple to prepare, low in cost and easy in industrial production.

Owner:SUZHOU CHANGSHENG ELECTROMECHANICAL

Water tank with anticorrosive and insulating performance for hanging garment steamer

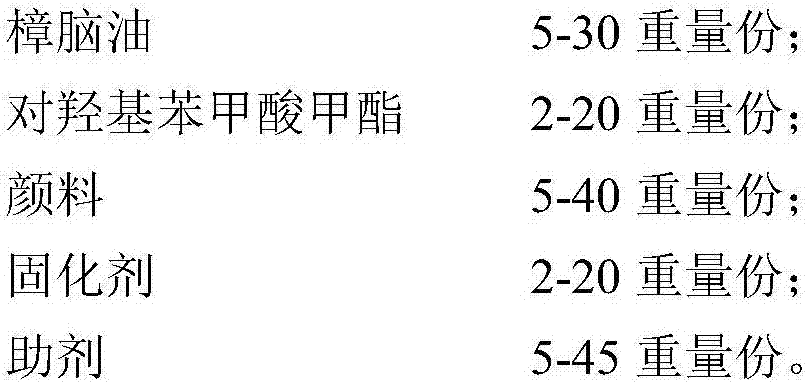

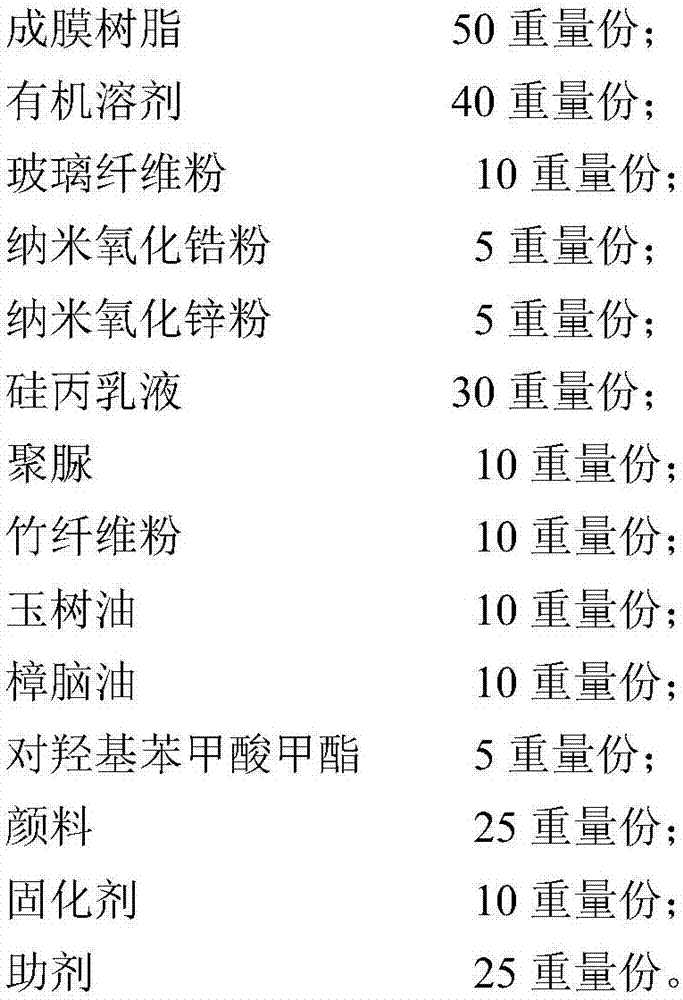

InactiveCN107189630AWith cleanImprove insulation performanceAntifouling/underwater paintsPaints with biocidesCorrosionWaste management

The invention discloses a water tank with anticorrosive and insulating performance for a hanging garment steamer. The water tank comprises a water tank body and an anticorrosive and insulating layer, wherein the anticorrosive and insulating layer is arranged on the inner wall of the water tank body; the anticorrosive and insulating layer is made through brush-coating anticorrosive and insulating paint and then drying. According to the water tank with the anticorrosive and insulating performance for the hanging garment steamer, which is provided by the invention, the anticorrosive and insulating layer is arranged on the inner wall of the water tank, has quite good antibacterial, anticorrosive, waterproof and durable performance, and can be used for effectively inhibiting the corrosion, on the inner wall of the water tank, of water in the water tank of the hanging garment streamer; the water in the water tank of the hanging garment streamer is kept clean; thus, the use effect of the hanging garment streamer can be guaranteed; meanwhile, the service life of the water tank of the hanging garment steamer can be also improved; further, the anticorrosive and insulating layer also has favorable insulating performance, and can be used for improving the safety of the water tank of the hanging garment streamer. The water tank with the anticorrosive and insulating performance for the hanging garment steamer, which is provided by the invention, is safe and durable, is excellent in waterproof and anticorrosive performance, can be used for keeping the water in the water tank clean, and is good in use effect and long in service life.

Owner:苏州市海朋生活家电有限公司

Sea cable

InactiveCN108242286AGood waterproof and corrosion resistanceExtended service lifeInsulated cablesInsulated conductorsCorrosionInsulation layer

The invention discloses a sea cable comprising a sea cable comprising 4 cable wires; the surfaces of the 4 cable wires are provided with a glass fiber insulation layer; a ceramic polyolefin thermal-insulation layer is arranged between the cable wire and the glass fiber insulation layer; one side, far away from the ceramic polyolefin thermal-insulation layer, of the glass fiber insulation layer isprovided with a waterproof layer; the waterproof layer comprises a polyethylene glycol terephthalate layer. The waterproof layer, the polyethylene glycol terephthalate layer, a polyurethane layer, a PTFE layer, a corrosion resistance layer, a polyethylene layer, an epoxy resin layer, a polycarbamate layer and an aluminium alloy protection layer are matched in usage, thus solving the problems thatan existing sea cable is poor in a waterproof corrosion resistance effect on the seabed, so the cable is easy to be damaged; the sea cable is good in waterproof corrosion resistance effects, can prolong the sea cable service life, and can improve the practical value of the sea cable.

Owner:苏州旺谦纺织科技有限公司

Production process of China fir integrated board

InactiveCN105799005ASave resourcesGood waterproof and corrosion resistanceWood veneer joiningProcess engineeringIndustrial engineering

The invention discloses a production process of a China fir integrated board. The production process comprises following steps of a board cutting step, a board splicing step, a gluing step, a compacting step, a polishing step, a secondary gluing step, a secondary compacting step, a grinding and polishing step, a paper pasting step, a edge cutting step and a packaging step and the like. Beneficial effects of the production process of the China fir integrated board are that the wood resource is saved, the China fir integrated board is good in waterproof and corrosion-proof performances, can be prevented from being damaged by worms, and is prevented from ageing crack.

Owner:SHIFANG MIDEE WOOD IND

Environmentally-friendly high-permeability modified epoxy rusty coating

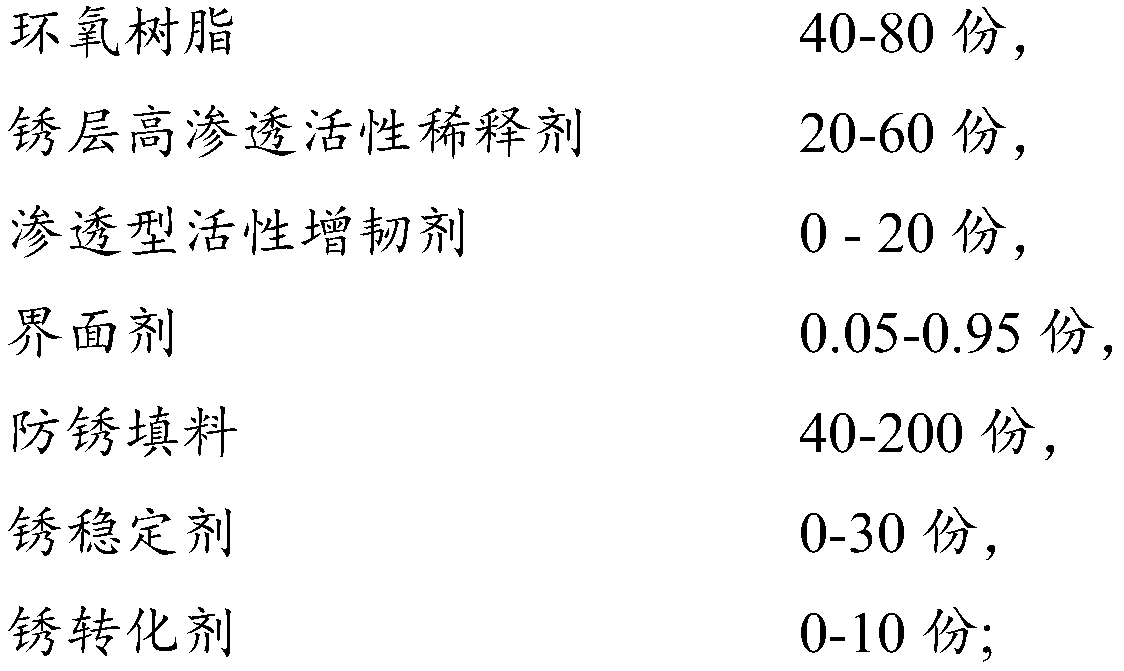

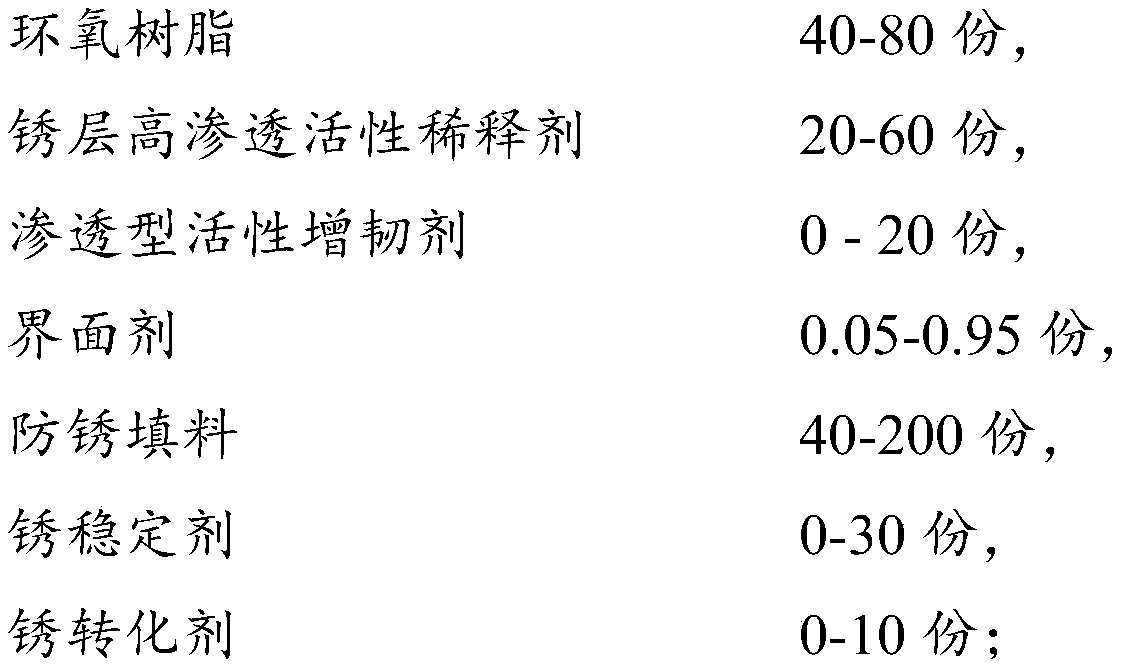

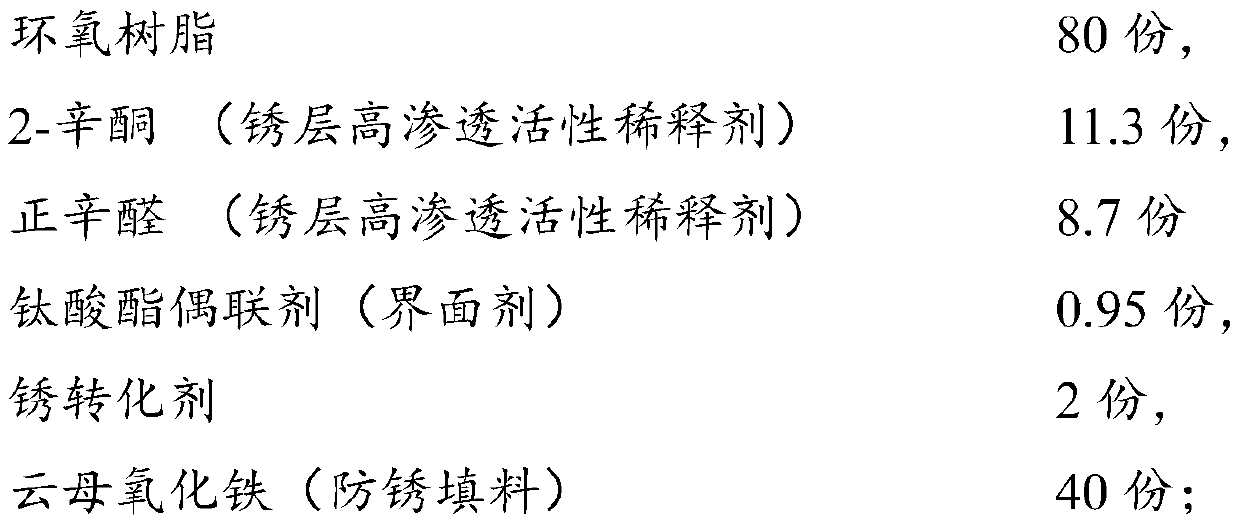

InactiveCN110835490AImprove mechanical propertiesGood adhesionAnti-corrosive paintsEpoxy resin coatingsPolymer scienceGlycidyl ethers

The invention provides an environmentally-friendly high-permeability modified epoxy rusty coating, and belongs to the technical field of coatings. The coating is composed of a component A and a component B, the component A comprises at least one of a glycidyl ether compound and a mixture of an aldehyde compound and a ketone compound, at least one of a rust stabilizer and a rust conversion agent, epoxy resin, an interface agent and an antirust filler, and the component B comprises an amine curing agent, a curing accelerator and a moisture-consuming functional curing agent. The aldehyde compound, the ketone compound and the glycidyl ether compound enable the coating to have excellent permeability, and also can participate in system reactions under the action of the amine curing agent, so that the problem of environmental pollution caused by VOCs generated in the film forming process is greatly reduced, and the flexibility and the adhesive property of the coating are improved; and the moisture-consuming functional curing agent can consume moisture in a rust layer, so it is ensured that the rust layer is not rusted any more, and the curing of the epoxy resin is also ensured.

Owner:广州永科新材料科技有限公司

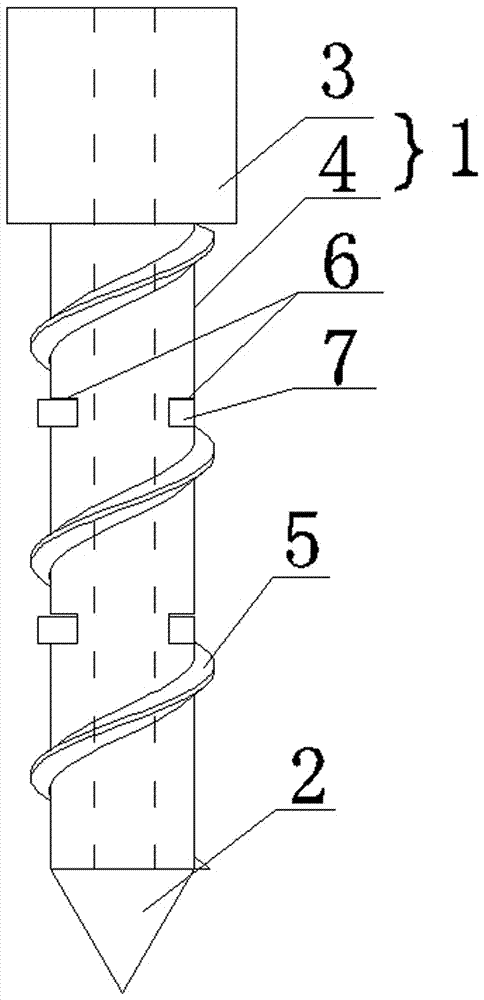

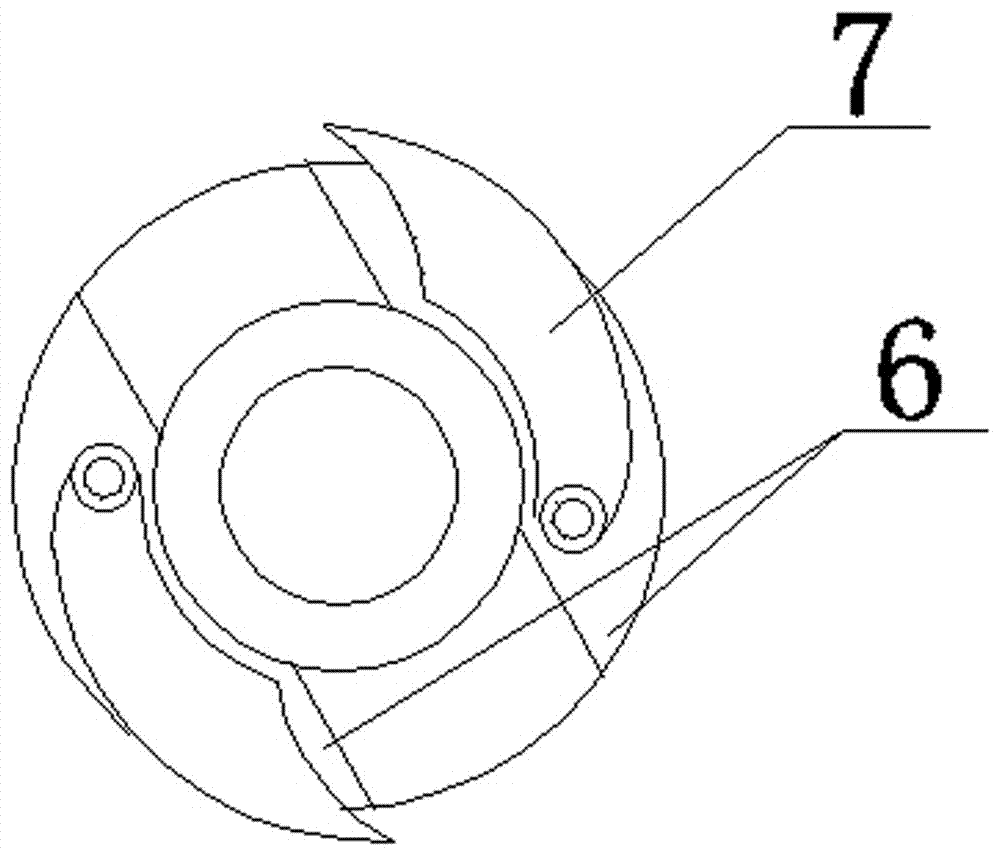

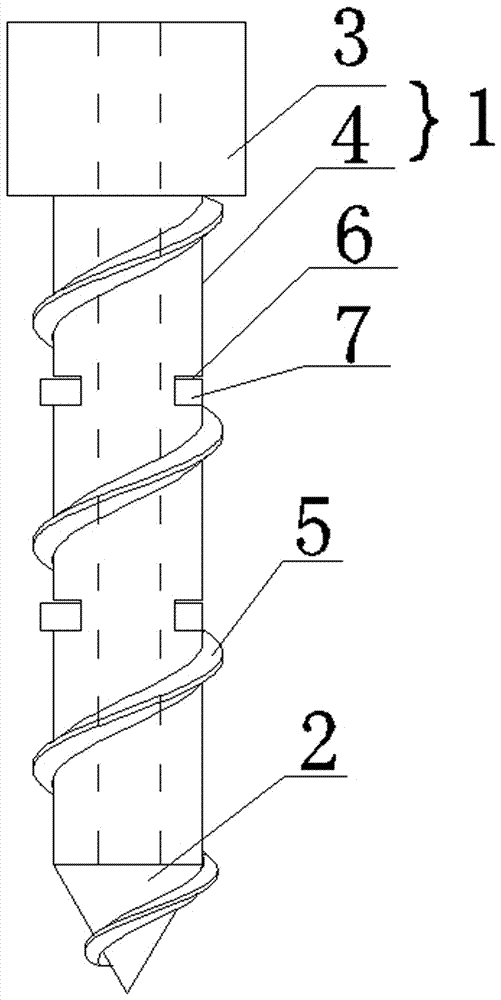

Prefabricated concrete pipe pile for overhead power transmission line

ActiveCN107090847AReduce weightLow costSolid waste managementFoundation engineeringUltimate tensile strengthPower transmission

The invention discloses a prefabricated concrete pipe pile for an overhead power transmission line. The prefabricated concrete pipe pile comprises a hollow pipe pile and a pile head; the hollow pipe pile comprises an upper pipe pile and a lower pipe pile, the outer diameter of the upper pipe pile is larger than that of the lower pipe pile, and a screw is arranged on the exterior of the lower pipe pile; a pile expanding device is arranged on the lower pipe pile and comprises two arc-shaped grooves which are formed in the symmetrical positions of the same circumference of the lower pipe pile, an annular steel plate matched with the corresponding arc-shaped groove is hinged to the bottom of each arc-shaped groove, the tail end of each annular steel plate stretches out of the corresponding arc-shaped groove, and the direction that the annular steel plates are arranged in the arc-shaped grooves is consistent with the screwing-in direction of the screw. According to the prefabricated concrete pipe pile for the overhead power transmission line, foundation settlement can be reduced, the rigidity of the pipe pile can be improved, the using amount of concrete can be decreased, and the construction cost of the prefabricated pipe pile can be reduced; in addition, the strength of the concrete is high, the contact area of the prefabricated pipe pile and soil mass is large, and therefore the bearing capacity of the prefabricated pipe pile can be enhanced.

Owner:STATE GRID CORP OF CHINA +2

Silicon carbide fiber cable material and preparation method thereof

The invention discloses a silicon carbide fiber cable material and a preparation method thereof. The silicon carbide fiber cable material is prepared from the following raw materials in parts by weight: 30 to 50 parts of organic silicon modified acrylate, 35 to 45 parts of epoxy resin, 20 to 30 parts of BNDB, 5 to 15 parts of styrene, 10 to 20 parts of No. 800 paraffin base rubber oil, 9 to 15 parts of pentaerythritol, 10 to 20 parts of chlorinated polyethylene, 10 to 20 parts of ethylene-octene copolymer elastomer, 8 to 12 parts of silicon carbide fiber, 4 to 8 parts of active magnesium oxide, 4 to 8 parts of active zinc oxide, 6 to 12 parts of calcium carbonate, 3 to 7 parts of microcrystalline wax, 1 to 5 parts of plasticizer, 1 to 5 parts of fire retardant, 1 to 5 parts of antioxidant and 1 to 3 parts of stabilizer. The preparation method of the silicon carbide fiber cable material comprises the steps of performing crushing, inductive heat treatment, mixing, pelleting and the like on the raw materials. The silicon carbide fiber cable material provided by the invention is simple in preparation, excellent in flame retardant property, and good in waterproofness and corrosion resistance, does not easy to age, is high in tensile strength and compressive strength and long in service life, can be widely applied in various fields, and has a good market prospect.

Owner:合肥博创机械制造有限公司

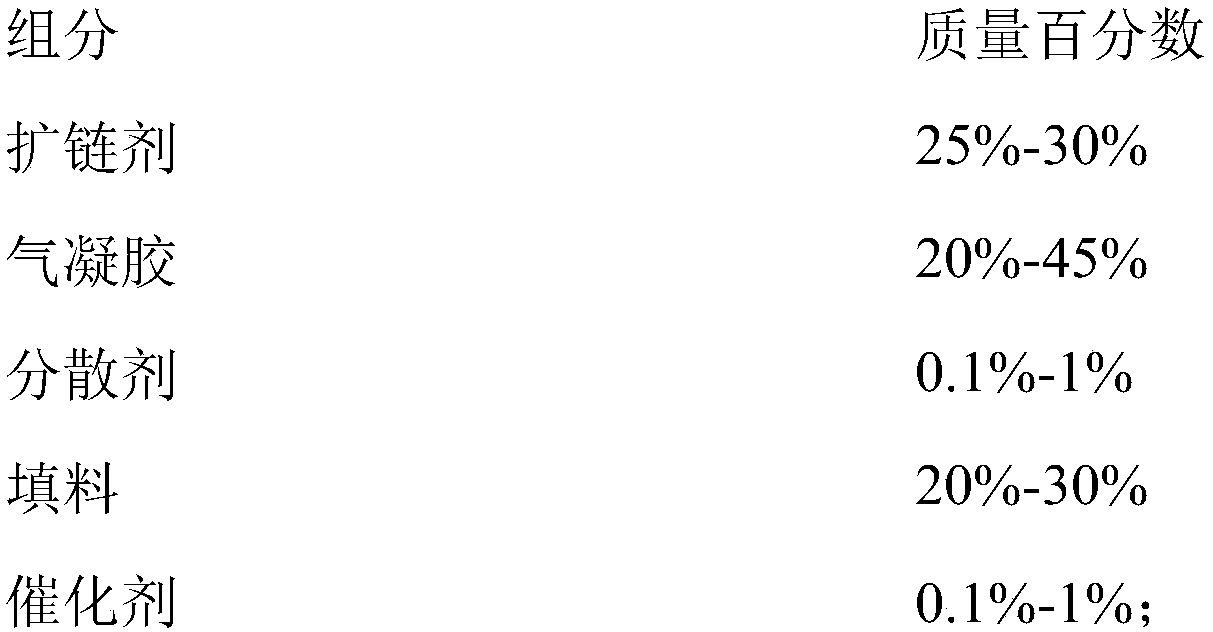

Bulletproof polyurethane-fiber composite material and preparation method thereof

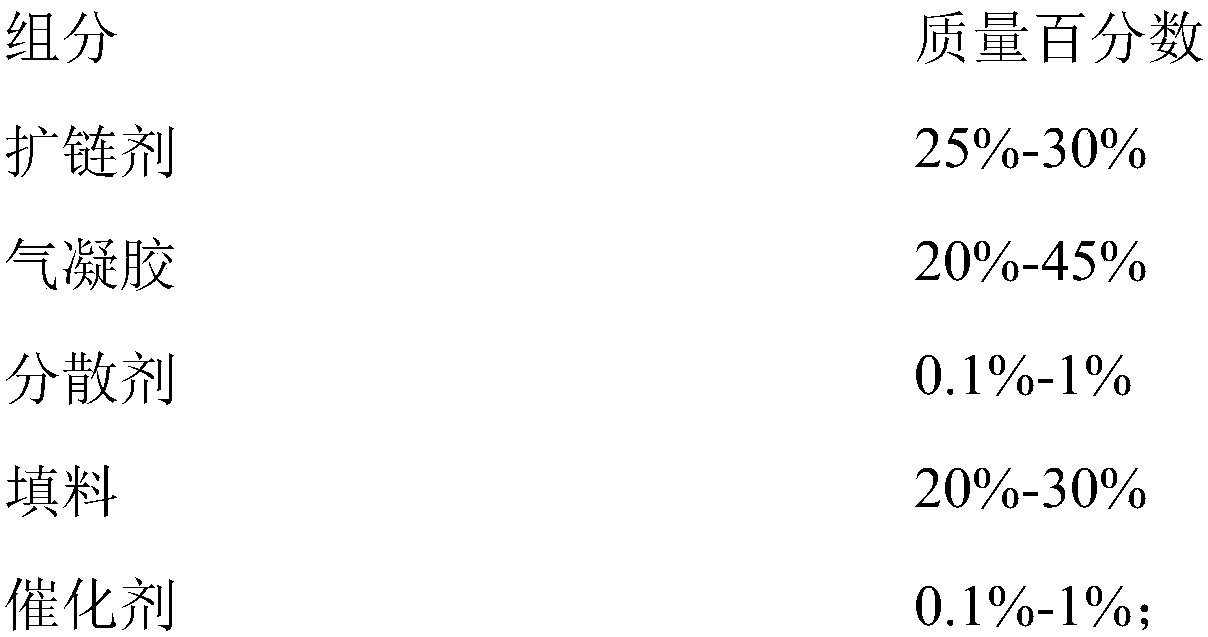

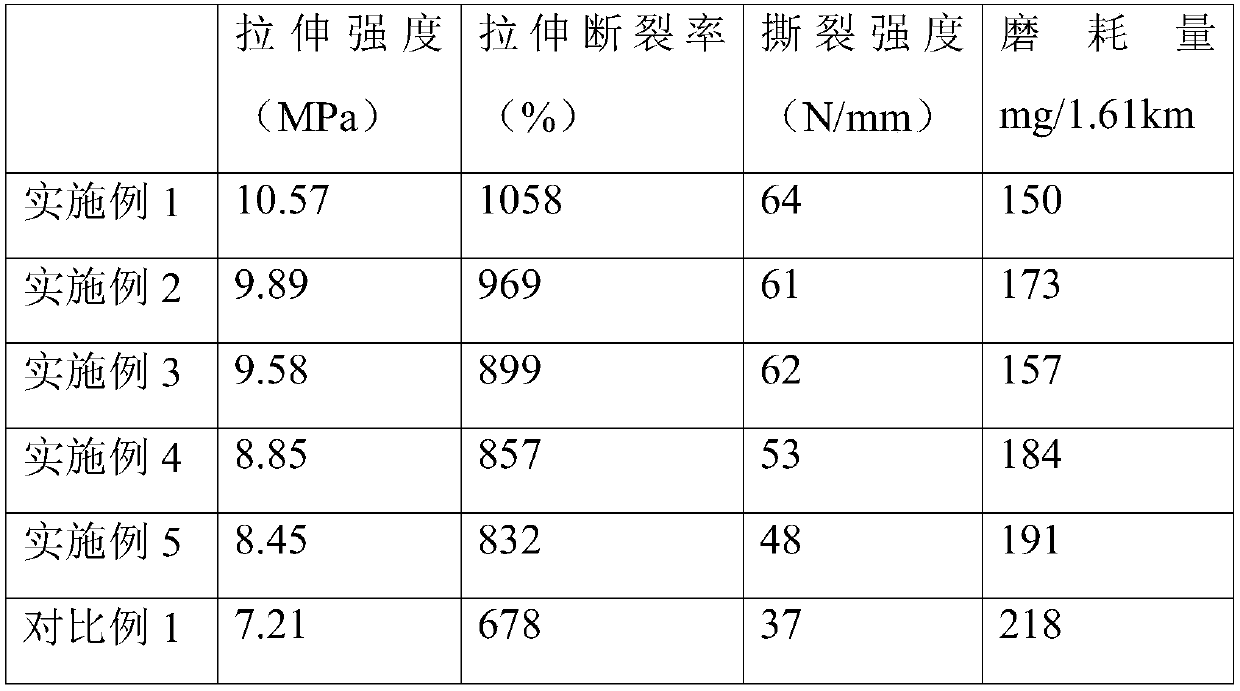

The invention relates to the field of bulletproof materials and discloses a bulletproof polyurethane-fiber composite material and a preparation method thereof. The polyurethane-fiber composite material comprises the following components in percent by weight: 20wt.%-60wt.% of fiber and 40wt.%-80wt.% of polyurethane composition, wherein the polyurethane composition is prepared by mixing a componentA and a component B according to the volume ratio of 1-10:1; the component A is isocyanate prepolymer synthesized by 40wt.%-60wt.% of isocyanate and 40wt.%-60wt.% of polymer polyol; the component B isprepared by mixing 25wt.%-30wt.% of chain expanding agent, 20wt.%-45wt.% of aerogel, 0.1wt.%-1wt.% of dispersing agent, 20wt.%-30wt.% of filler and 0.1wt.%-1wt.% of catalyst. The polyurethane-fiber composite material and the preparation method disclosed by the invention have the beneficial effects that the instantaneous deformation resistance and capability of responding to bad weather environment of a bulletproof plate can be enhanced, and better protection can be provided for the material and structure of a bullet inserting plate, so that the protective capability and the service life of the bulletproof plate are improved; simultaneously, due to good toughness of the polyurethane material, certain buffering-layer action also can be achieved, and the damage caused by deformation of the bulletproof inserting plate can be reduced.

Owner:长沙盾甲新材料科技有限公司

A flame retardant module and a preparing method thereof

The invention discloses a flame retardant module and a preparing method thereof, and relates to the field of fire-proof sealing materials. Raw materials of the module include modified vermiculite powder, silicon carbide powder, flame retardant resin, bauxitic rock, light-burned magnesia, aluminum silicate fibers, ethyltrimethoxysilane, N-hydroxymethyl acrylamide, acrylic acid, a calcium oxide expanding agent, a flame retardant, a foaming agent and a foam stabilizer. The preparing method includes fully mixing the raw materials and casting the mixtures into the mold in stages, pressing, naturally airing, and molding. The module is simple and convenient to prepare and is high in molding and drying speeds. A finished product of the module has characteristics of high compressive strength and a high fire-proof flame retardant degree, has greatly prolonged service lifetime, and is suitable for large-scale production and application.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

Anti-corrosion paint for steel

ActiveCN103436146BGood waterproof and corrosion resistanceAchieve passivationAnti-corrosive paintsPolyether coatingsChromiumN-Butyl acetate

The invention discloses a steel anticorrosive paint which is prepared by stirring the following raw materials in parts by weight: 60-70 parts of alcohol acid resin, 40-50 parts of diphenyl ether resin, 30-40 parts of 424 resin, 8-12 parts of methyl isobutyl ketone, 6-10 parts of n-butyl acetate, 10-15 parts of potassium octatitanate whisker, 7-9 parts of amino polyhedral oligomeric silsesquioxane, 8-14 parts of KH-580, 14-19 parts of mica powder, 7-11 parts of tributyl phosphate, 5-9 parts of heptadecenyl imidazolinyl alkenyl succinate and 80-90 parts of water. The commercial test proves that the prepared paint has the advantages of excellent water resistance and excellent corrosion resistance, can implement passivation and corrosion inhibition of the metal substrate, avoids using chrome and other heavy metals possibly causing environmental pollution, is simple to prepare and low in cost, and can be easily put into industrial production.

Owner:江苏悠谷未来科技有限公司

Waterproof anti-corrosion rubber material for automobile seal strips and preparation method thereof

The invention discloses a waterproof anti-corrosion rubber material for automobile seal strips, wherein the rubber material is prepared from the following raw materials in parts by weight: 100-120 parts of ethylene-propylene-diene monomer, 40-60 parts of white carbon black, 2-4 parts of zinc oxide, 1.5-2.5 parts of sulfur S80, 1.5-2.5 parts of an anti-aging agent MB, 0.3-0.5 part of an accelerator TMTD, 0.5-1 part of zinc naphthenate, 3-5 parts of trimethoxymethylsilane, 0.3-0.5 part of petroleum sodium sulfonate, 0.5-1 part of tetrabutyl titanate, 0.15-0.25 part of a titanate coupling agent NDZ-401, 6-8 parts of a nano graphite powder, 1-2 parts of a polytetrafluoroethylene wax micro-powder, 15-25 parts of castor oil, and 3-5 parts of hydroxyl-fluoro silicone oil. The rubber material has the advantages of good abrasion resistance, lasting antifriction performance, and good waterproof and anti-corrosion properties, and has the advantages of long service life and good sealing performance when used as automobile seal strip materials.

Owner:闻承岳

Strippable heat-proof antirust protective film coating and preparation method thereof

InactiveCN102863888BImprove compactnessGood waterproof and corrosion resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinPolyester resin

The invention relates to strippable heat-proof antirust protective film coating and a preparation method thereof. The raw material of the protective film coating is formed by paint and curing agent. The paint comprises, by weight, 88-96 parts of linear chain polyester resin or acrylic resin containing hydroxide radical, 2.0-5.0 parts of stripping accelerant, 1.0-3.0 parts of film-forming accelerant, 0.5-2.0 parts of antifoaming agent and 0.5-2.0 parts of flatting agent. The curing agent comprises, by weight, 25-40 parts isocyanate polymer. The linear chain polyester resin or the acrylic resin containing the hydroxide radical is heated and stirred and then added in other components except the curing agent, the isocyanate polymer is added in the mixture during usage, and the strippable heat-proof antirust protective film coating is obtained after even mixing. The strippable heat-proof antirust protective film coating does not contain solvent, meets environment-friendly requirements, simultaneously has high waterproof performance, oil resistance, temperature resistance, abrasion resistance and strippable performance, can have metal surfaces, stripping surfaces, plastic surfaces and the like at the same time, and has temporary antirust protection effects.

Owner:SHANGHAI DATONG TABERNACLE NEW ENERGY SAVING MATERIALS CO LTD

A kind of graphene-based high temperature resistant anti-corrosion coating and preparation method thereof

InactiveCN103589281BImprove anti-corrosion performanceSmall sizeAnti-corrosive paintsEpoxy resin coatingsEpoxySulfide

The invention relates to a high temperature resistant anticorrosion coating based on graphene and a preparation method thereof. The high temperature anticorrosion coating comprises the following components by the mass percentage: 5-60% of epoxy resin, 3-30% of polyphenylene sulfide resin, 3-30% of amino resin, 1-10% of a pigment, 1-20% of graphene, 3-50% of n-butyl alcohol, 0.1-0.3% of a defoaming agent, 0.1-10% of polyhydroxy acid sodium salt, 0.1-5% of benzenedicarboxylic acid dibutyl ester, 0.5-1.0% of bentonite, and 0.2-0.5% of a leveling agent. Compared with the prior art, the prepared coating has the advantages of quite excellent waterproof and anticorrosion performance, high temperature resistance, weather resistance, alkali resistance, impact resistance, artificial aging resistance and the like, and the preparation method has the advantages of good controllability, simple operation, low production cost, and easy industrialized production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Mining control cable

InactiveCN104681168ANovel structureGood shielding electric fieldPlastic/resin/waxes insulatorsPower cables with screens/conductive layersElectrical conductorAging resistance

The invention discloses a mining control cable, which comprises an insulating cable core, an inner sheath layer and an outer sheath layer, wherein the insulating cable core is formed by a single stranded conductor or a plurality of stranded conductors with extruded insulating layers; PP (propene polymer) rope filler is laid in a gap between the insulating cable core and a shielding layer in parallel; the inner side of the outer sheath layer is also provided with an armor layer. The mining control cable disclosed by the invention is novel in structure, and has a good shielding electric field and excellent properties of compression strength, tensile strength, fire resistance, water resistance, corrosion resistance, ageing resistance and the like.

Owner:WUXI YIXIANG CABLE

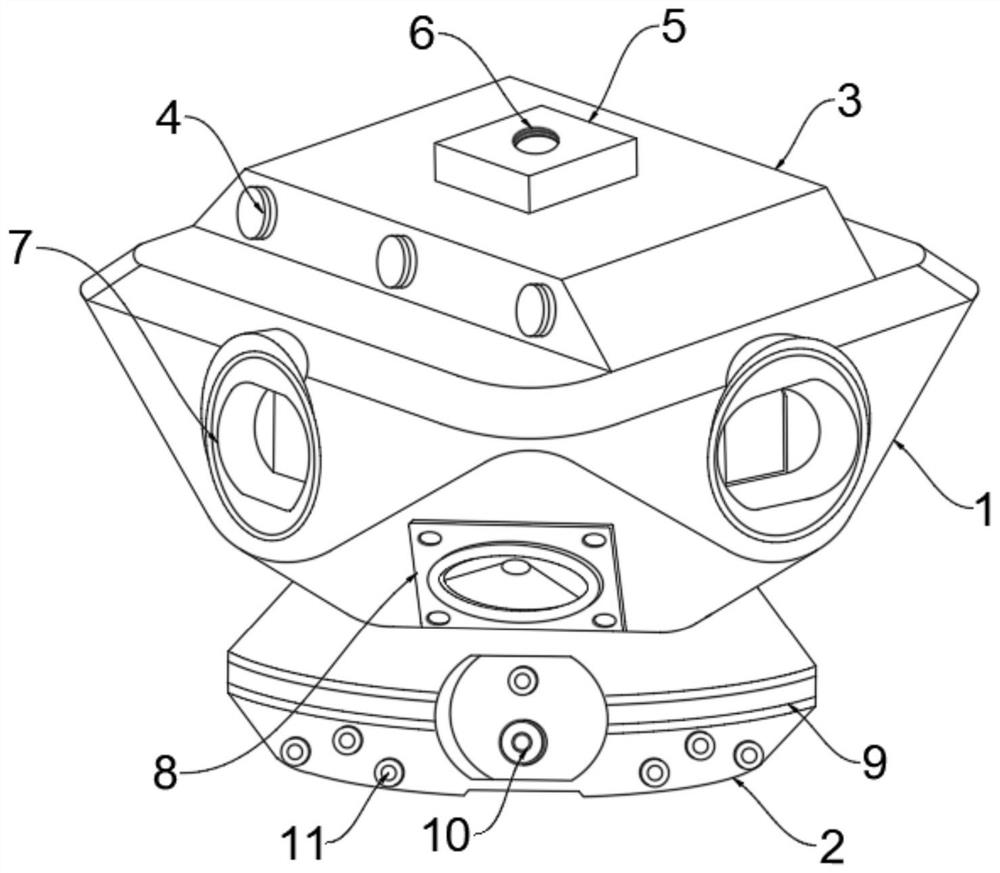

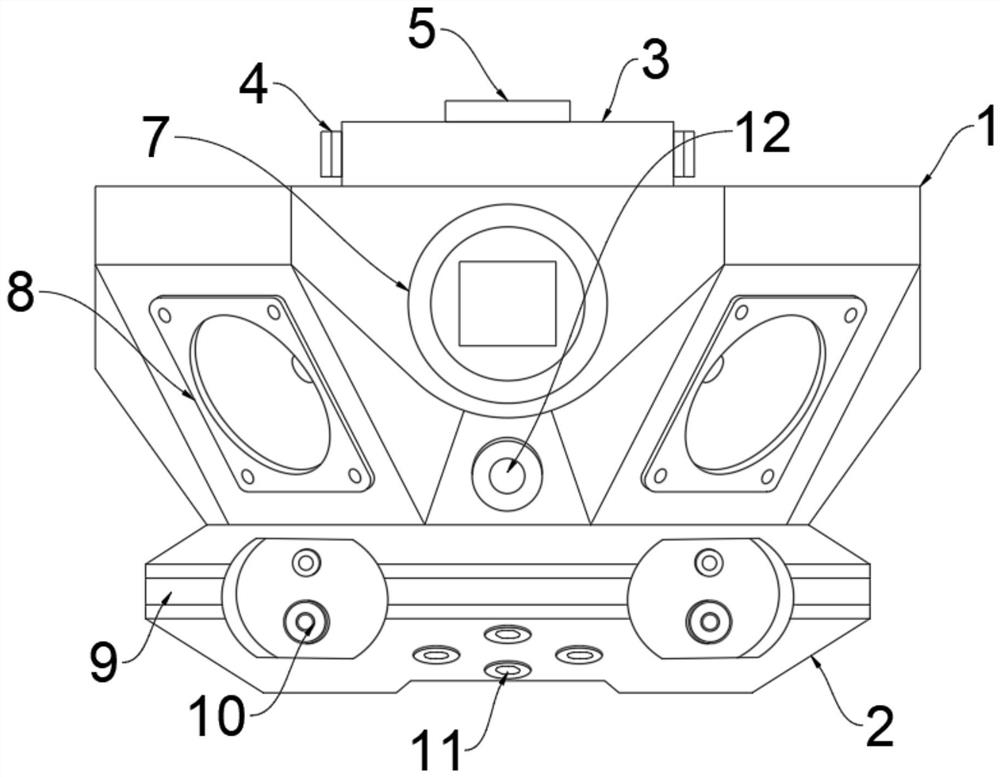

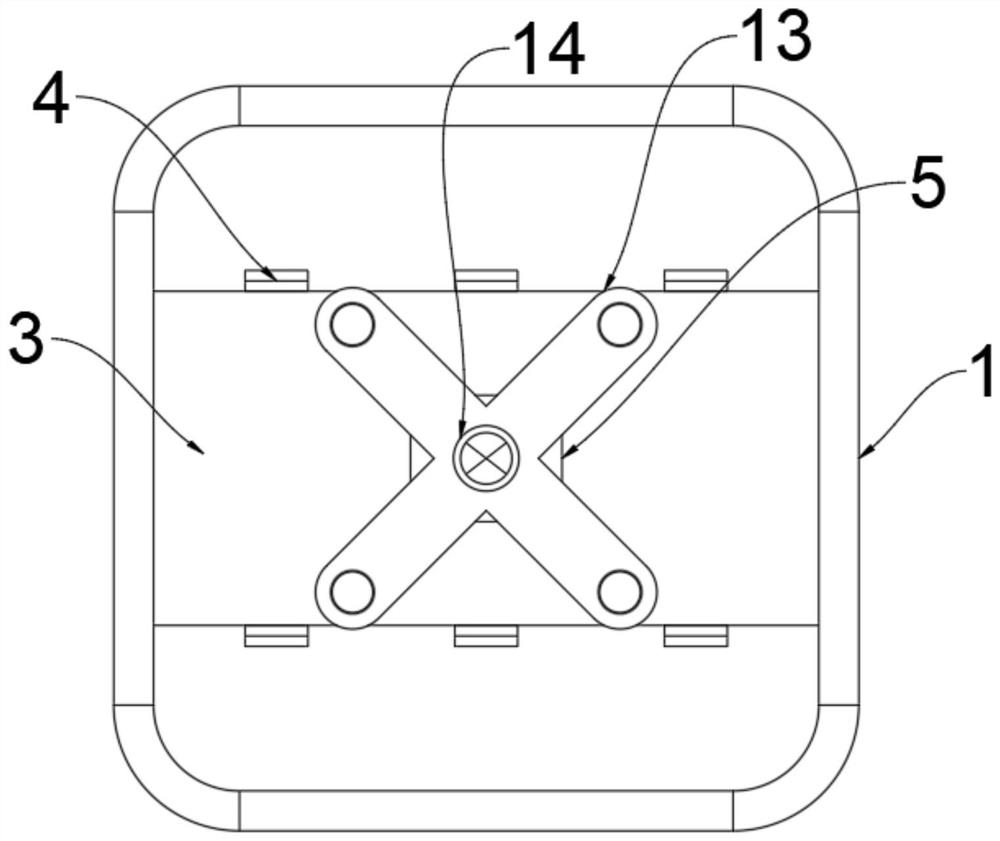

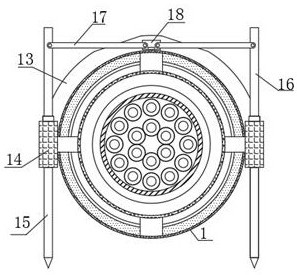

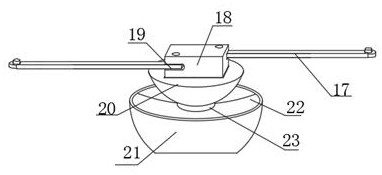

Unmanned aerial vehicle bird repelling device

ActiveCN113331170AAchieve visual stimulationImprove driving effectTelevision system detailsColor television detailsAutomotive engineeringElectrical and Electronics engineering

The invention discloses an unmanned aerial vehicle bird repelling device, relates to the technical field of unmanned aerial vehicles, and aims to solve the problems of long bird repelling time and slow effect due to the fact that manual patrol and vehicle patrol are adopted in airports generally and multiple persons and multiple devices are allocated for patrol. The unmanned aerial vehicle bird repelling device is characterized in that a second bearing shell body is arranged below a first bearing shell body, a positioning table is arranged above the first bearing shell body, the positioning table and the first bearing shell body are integrally formed, six tweeters are mounted on the two sides of the positioning table, five flashing lights are mounted on the periphery of the first bearing shell body and below the second bearing shell body, four ultrasonic horns are mounted between the adjacent flashing lights on the periphery of the first bearing shell body, and a high-definition camera is mounted below the ultrasonic horn at the front end.

Owner:南京千里眼航空科技有限公司

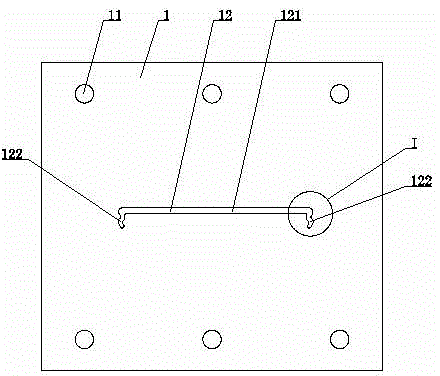

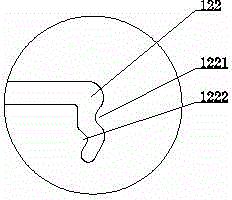

Wood-plastic cable trough cover extrusion die

The invention discloses a wood-plastic cable trough cover extrusion die which comprises a die plate (1). The extrusion die is characterized in that a plurality of round holes (11) are formed in the die plate (1), a die hole (12) is formed in the middle of the die plate (1), a horizontal hole (121) is formed in the die plate (12), S-shaped holes (122) are symmetrically formed in the two ends of the horizontal hole (121), the right side of each S-shaped hole (122) is provided with a right arc-shaped protrusion (1221), and the left side face of each S-shaped hole (122) is provided with a left arc-shaped protrusion (1222). A product processed through the extrusion die is high in strength, good in waterproof performance and corrosion resistance, low in cost and long in service life.

Owner:HUANGSHI HONGXING PLASTIC MOLD

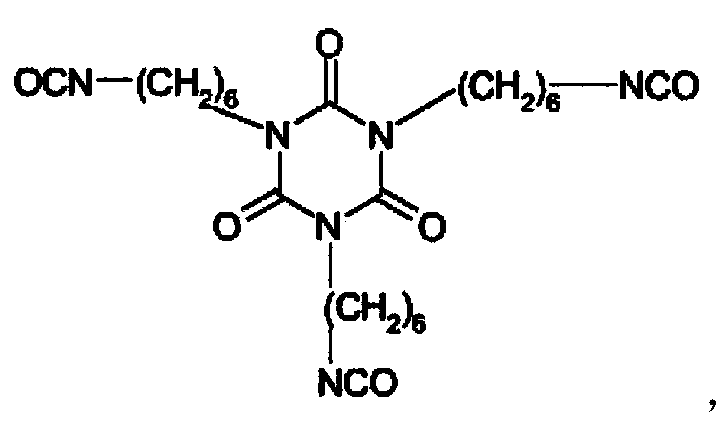

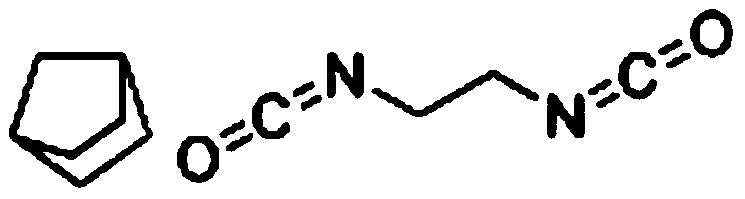

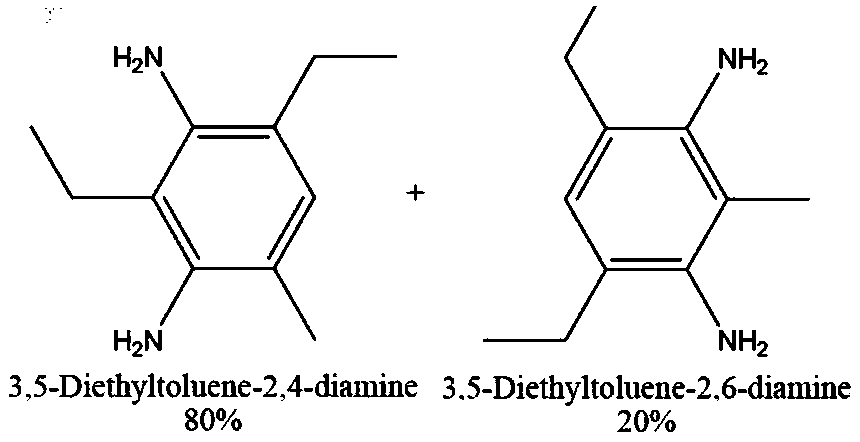

Three-network copolymerized castable for bus duct

The invention relates to a three-network copolymerized castable for a bus duct. The castable comprises the following components in parts by mass: 10-30 parts of a prepolymer of hexamethylene diisocyanate (HDI) tripolymer; 10 to 30 parts of a prepolymer of norbornane diisocyanate (NBDI) and polyether polyol; 5 to 15 parts of epoxy resin E51; adding a cross-linking agent according to the calculatedamount; 15-20 parts of aluminum hydroxide powder; 20 to 25 parts of aluminum oxide; and 1 to 25 parts of chopped glass fiber shreds; according to the invention, HDI, NBDI and epoxy resin E51 are usedas resin bases; the three-network copolymerized pouring material for the bus duct is prepared by adding a proper amount of water into the raw materials to form a network structure in a three-network copolymerized form, and adding a proper amount of filler, and has the advantages of very good loading property, excellent weather resistance, excellent chemical resistance, excellent flame retardancy,excellent water resistance and excellent corrosion resistance, and greatly prolonged service life.

Owner:JIANGSU UNIV OF SCI & TECH

Insulated composite halogen-free flame-retardant wire and cable and preparation method thereof

InactiveCN104200881BInsulation superImprove performanceInsulated cablesCable/conductor manufactureGlass fiberElectrical conductor

Owner:深圳市科威普电子有限公司

Washing resistant metal material

InactiveCN108215389AImprove performanceHard textureInorganic adhesivesCoatingsTetrachloroethyleneMetal

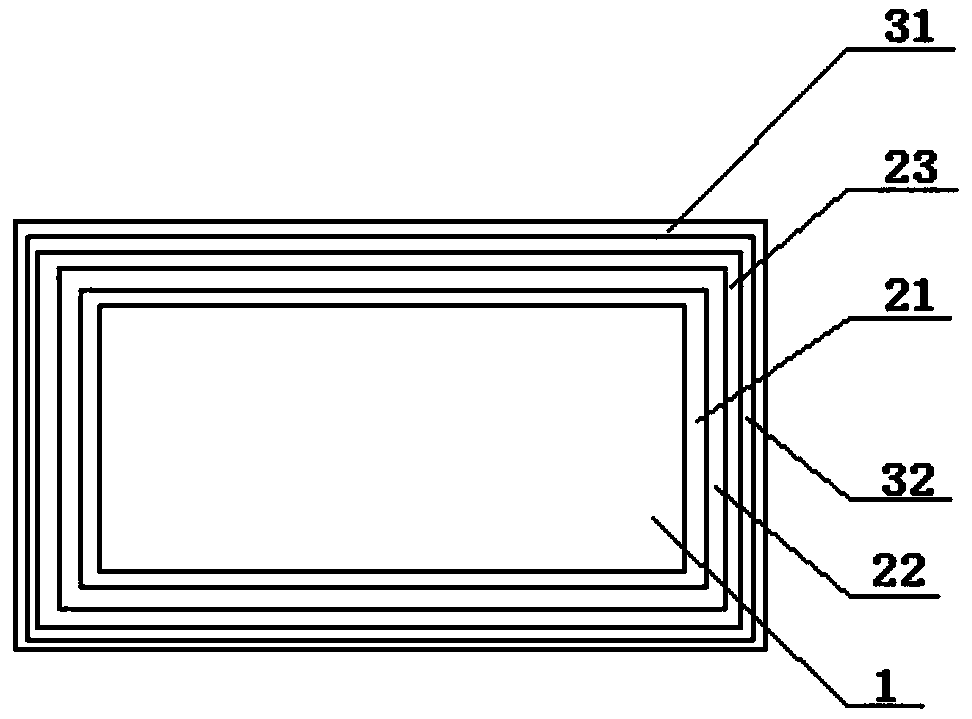

The invention relates to a washing resistant metal material. The washing resistant metal comprises a bottom layer of metal (1) and a composite layer of metal (2), and the washing resistant metal material is characterized in that the washing resistant metal further comprises a corrosion prevention layer (3); the composite layer of metal (2) is formed through sequential binding of a magnetic alloy layer (21), a fiber metal layer (22) and a hydrogen storage material layer (23); the magnetic alloy layer (21) is bound to be a whole with the bottom layer of metal (1); the corrosion prevention layer(3) is prepared from a solidifying layer (31) and a teflon layer (32); and the solidifying layer (31) is connected integrally with the hydrogen storage material layer (23) through a curing agent. Thewashing resistant metal material has the advantages of being washing resistant, salt mist resistant, good in tetrachloroethylene dry cleaning resistant effect and long in service life.

Owner:宁波远欣石化有限公司

Warm-keeping house

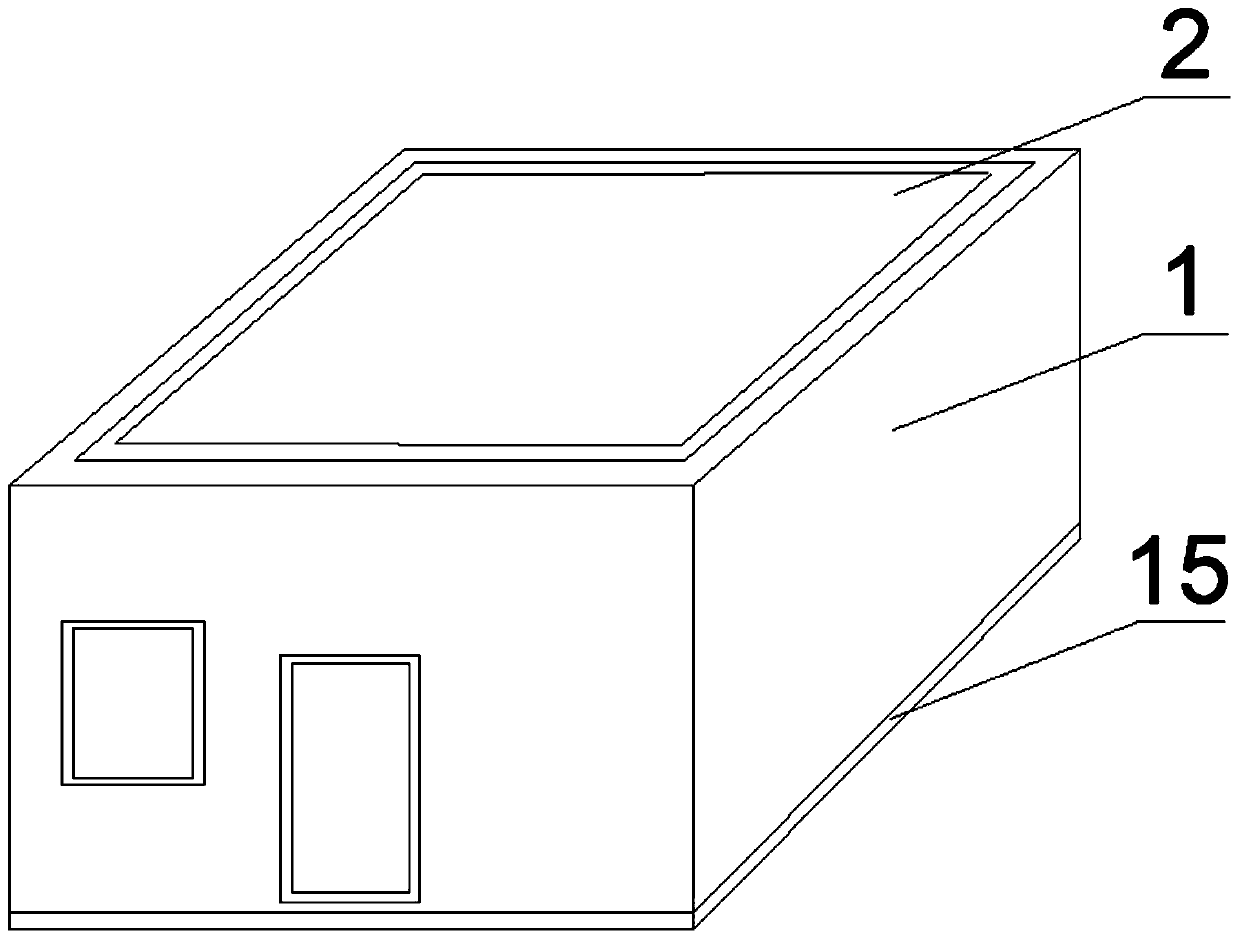

PendingCN111561183AReduce usageImprove heating effectRoof covering using slabs/sheetsLighting and heating apparatusThermodynamicsInsulation layer

The invention relates to the field of warm-keeping houses, in particular to a warm-keeping house. The warm-keeping house aims to solve the problems that power consumption is large and potential safetyhazards exist due to the fact that electric heaters and other independent heating products need to be used due to the fact that an existing portable house does not have an independent heating function when used in the northeast of China, environmental protection is poor and the construction difficulty is large due to the fact that a portable house with a heat preservation layer is made of organicheat preservation materials and a common portable house is not provided with the heat preservation layer, the potential safety hazard of safe sinking exists when the portable house is used on the river surface due to heavy weight, and the appearance and color are single. According to the warm-keeping house, a wall body is sequentially provided with a shell, a waterproof layer, the heat preservation layer, a single-phase counter-heating layer, a graphene electric heating layer and a heat conduction layer from outside to inside, the wall surface can achieve the self-heating purpose, and the heat preservation performance is better; and a joint transition position between the wall body and a door and window adopts a sealing system formed by two new materials of a waterproof vapor-proof film and a waterproof vapor-permeable film, so that the airtightness of the warm-keeping house is improved, and the warm-keeping function is enhanced.

Owner:王岩

Preparation method of waterproof and moldproof paint for cupboard

InactiveCN109321020AAvoid breedingSimple processFireproof paintsAntifouling/underwater paintsPolyvinyl alcoholAntimony trioxide

The invention provides a preparation method of waterproof and moldproof paint for a cupboard. The preparation method comprises the following steps of weighing the following raw materials including organosilicone modified polyacrylamide, polyketone resin, polyether resin, graphene modified polyvinyl alcohol, nanometer titanium dioxide, antimonous oxide, chlorinated paraffin, nanometer magnesium hydroxide, superfine mica powder, white carbon black, nanometer silicon dioxide, high viscosity attapulgite clay, diatomite, an moldproof additive, a pigment and a defoamer, respectively crushing the rawmaterials, and performing uniform mixing to obtain a paint film. The preparation method of the waterproof and moldproof paint for the cupboard is simple in process and convenient to operate; and theprepared paint is applied to the cupboard, has the characteristics of rapid drying speed, good waterproof performance, good corrosion resistant performance and strong adhesion force, also has better flame retardant performance and self-cleaning performance, effectively inhibits breeding of molds and provides guarantee to safe and long-term use of the cupboard.

Owner:合肥永泰新型建材有限公司

Saline-alkali-resistant soil buried protection pipe integrated control cable

PendingCN113130125ASave process and materialGood waterproof and corrosion resistanceInsulated cablesCable installations in underground tubesAlkali soilSoil science

The invention discloses a saline-alkali-resistant soil buried protection pipe integrated control cable. The cable comprises a cable body, a plurality of groups of cable cores are uniformly distributed in the cable body, the outer rings of the plurality of groups of cable cores are wrapped with a belting layer, the outer side of the belting layer is provided with an aramid fiber reinforcement layer, the outer side of the aramid fiber reinforcement layer is sleeved with an expansion sheath, the expansion sheath is attached to the inner side of a metal shielding pipe, a blocking layer is arranged on the outer side of the metal shielding pipe, and a low-density oil cavity is formed in the lower half area between the blocking layer and the metal shielding pipe. According to the saline-alkali-resistant soil buried protection pipe integrated control cable, the cable and the outer protection pipe are combined together to form an integrated structure, on one hand, the procedure of independently sleeving the protection pipe is reduced, on the other hand, the metal pipe is directly used as an armored shielding layer of the cable, the procedure and materials for installing the armored shielding layer of the cable are reduced, and the cable is suitable for different working conditions and brings better use prospects.

Owner:ANHUI DUJIANG CABLE GROUP

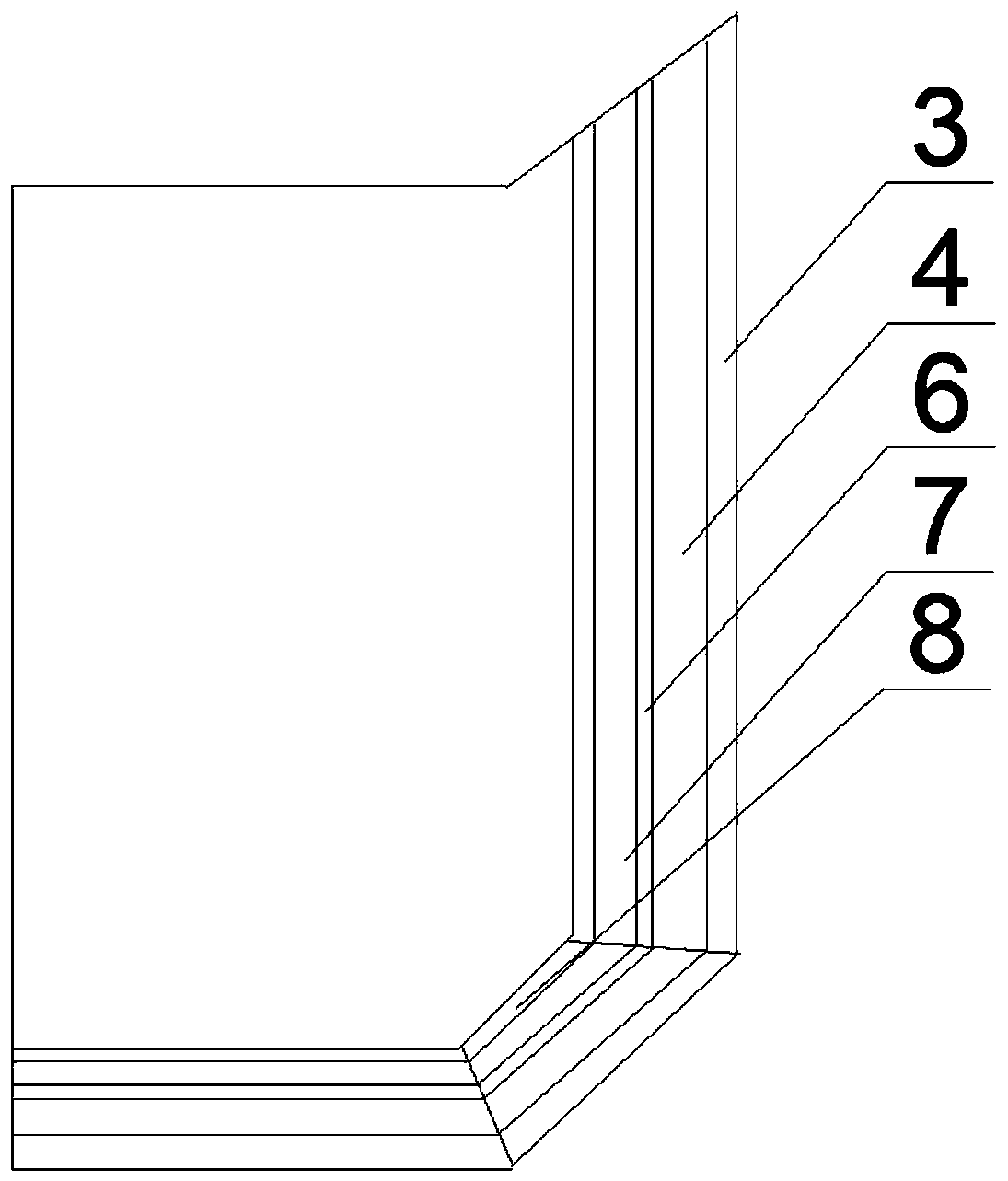

Plate structure for diving detector information transmission box

InactiveCN110815964ALightweight structureStrong toughnessLayered productsInformation transmissionEngineering

The invention discloses a plate structure for a diving detector information transmission box, the plate structure sequentially comprises a first layer plate, a second layer plate, a third layer plate,a fourth layer plate and a fifth layer plate, and every two of the first layer plate, the second layer plate, the third layer plate, the fourth layer plate and the fifth layer plate are mutually bonded and integrally formed by hot pressing. The first layer plate, the second layer plate, the third layer plate, the fourth layer plate and the fifth layer plate are the same in thickness. And the outer sides of the first layer plate and the fifth layer plate are coated with waterproof paint. Sealing edge sealing structures are arranged on the edges of the first layer plate, the second layer plate,the third layer plate, the fourth layer plate and the fifth layer plate. Compared with the prior art, the plate structure for the diving detector information transmission box has the advantages of being light in weight, high in toughness and good in waterproof and anti-corrosion performance, normal use of a detector can be guaranteed, and it is guaranteed that work is completed successfully.

Owner:江苏趋云信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com