Patents

Literature

151results about How to "Improve UV protection effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing composite preservative film or coating from chitosan and alcohol soluble corn protein

InactiveCN106957458AStrong machineryLow costCoatingsFruits/vegetable preservation by coatingChemistryAqueous solution

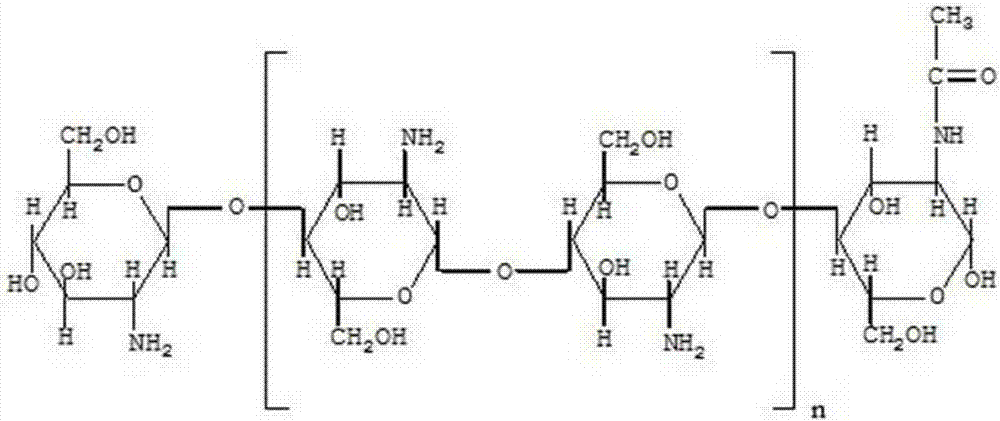

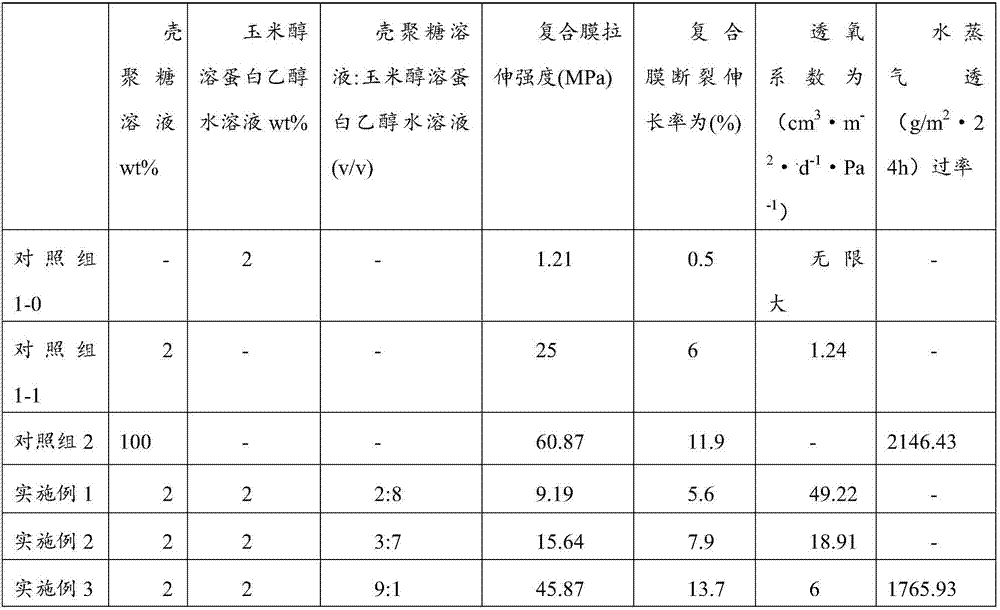

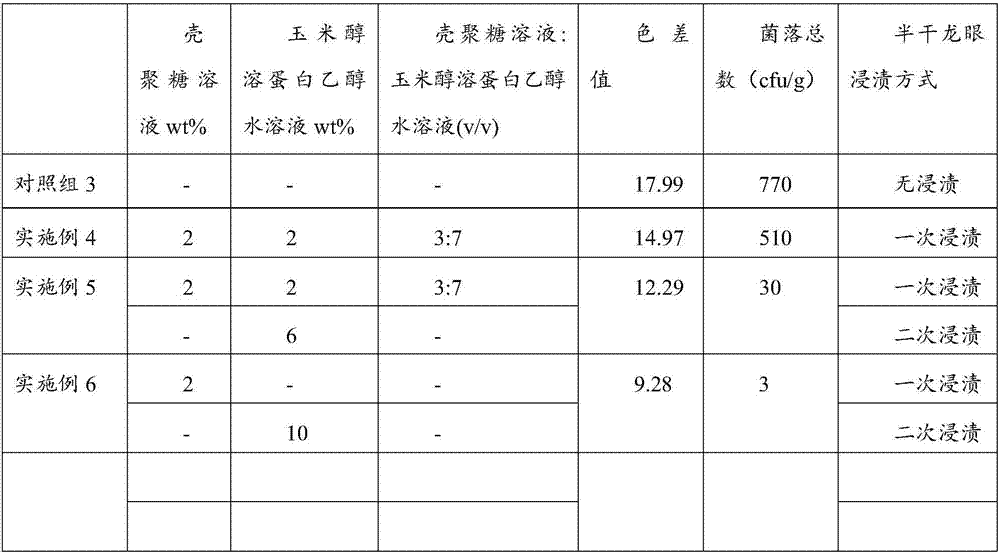

The invention relates to a method of preparing a composite preservative film or coating from chitosan and alcohol soluble corn protein. The method mainly comprises the following steps: (1) preparing 2wt% chitosan solution; (2) preparing 1-10wt% ethanol aqueous solution of alcohol soluble corn protein; (3) mixing the solutions prepared in the steps (1) and (2) in a volume ratio of 1:9 to 9:1 (v / v) to obtain a composite film solution; (4) flow casting the composite film solution obtained in step (3) and drying to obtain a film; or sequentially overlaying the solutions prepared in the steps (1) and (2) to obtain a double-layer preservative film. The chitosan-alcohol soluble corn protein composite preservative film or coating prepared in the invention is not only improved in the moisture resistance and ultraviolet resistance of a chitosan film, but also improved in the barrier property, mechanical properties and antibacterial activity of a alcohol soluble corn protein film, and is degradable, edible, etc. When the chitosan-alcohol soluble corn protein composite preservative film or coating prepared in the invention is used to package or wrap foods such as meat, oils and fats, fruits and vegetables, the quality guarantee period thereof can be effectively prolonged. Thus, the method has an extensive application prospect.

Owner:GUANGXI UNIV

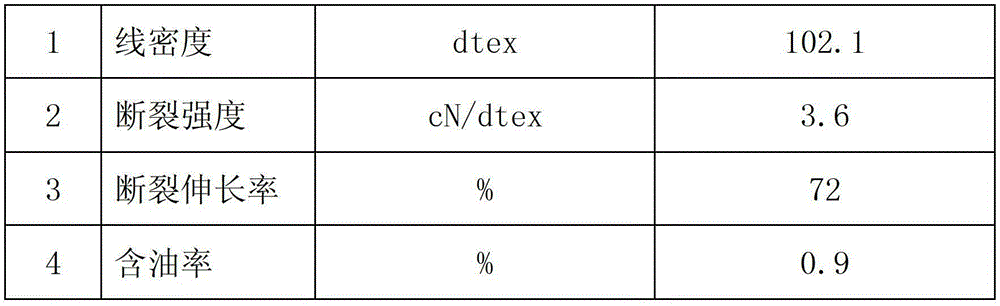

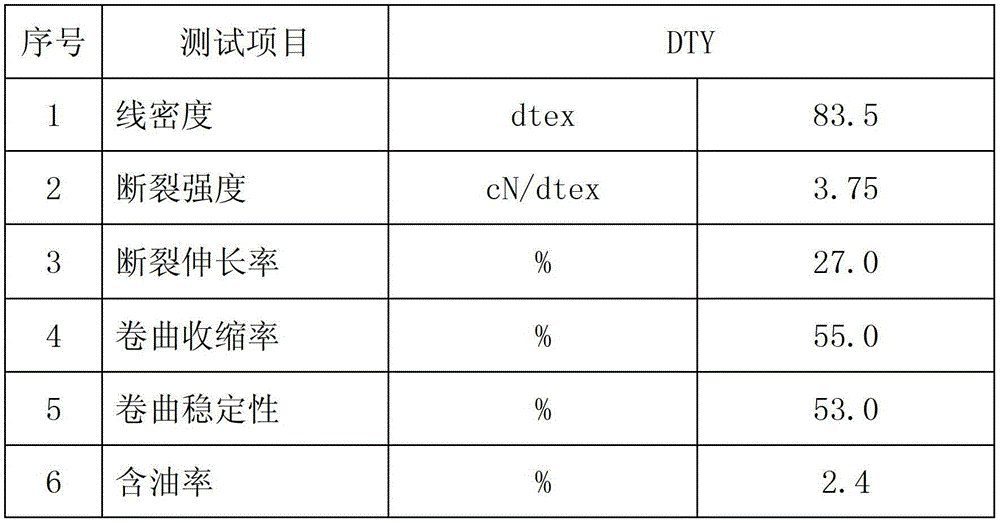

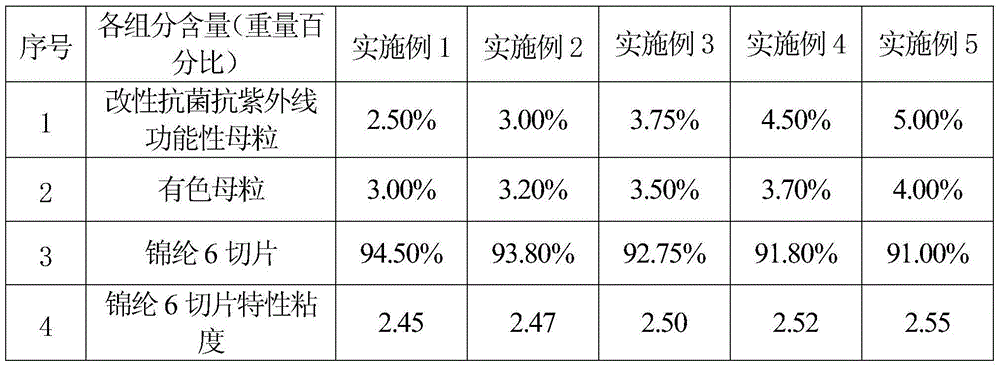

Antibacterial and anti-ultraviolet chinlon 6 colored elastic yarn and production method thereof

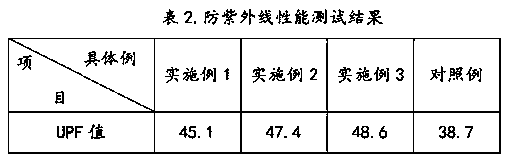

InactiveCN103147156AImprove antibacterial propertiesImprove UV protection effectArtifical filament manufactureMonocomponent polyamides artificial filamentUltravioletEngineering

The invention discloses an antibacterial and anti-ultraviolet chinlon 6 colored elastic yarn. The antibacterial and anti-ultraviolet chinlon 6 colored elastic yarn is prepared by heating, drawing, falsely twisting, oiling and winding a chinlon 6 POY (polyester ore-oriented yarn) filament yarn; the material of the chinlon 6 POY is prepared from chinlon 6 slices, modified antibacterial and anti-ultraviolet bi-functional chinlon 6 master batch and colored master batch; the modified antibacterial and anti-ultraviolet bi-functional chinlon 6 master batch is 2.5-5% of total mass of the mixed material; and the colored master batch is 3.0-4.0% of total mass of the mixed material. The elastic yarn designed by the production method disclosed by the invention has triple functions of color, bacterial resistance and ultraviolet resistance; the produced textile has obvious colored, antibacterial and anti-ultraviolet effects in comparison with common nylon textile; meanwhile, the subsequent processing and dyeing procedures are reduced; the antibacterial and anti-ultraviolet chinlon 6 colored elastic yarn is suitable for weaving various kinds of high-grade underwear, sportswear and socks, and used for military affairs and medical purposes, and has good stain-free antibacterial and anti-ultraviolet effects.

Owner:ZHEJIANG MESBON CHEM FIBER

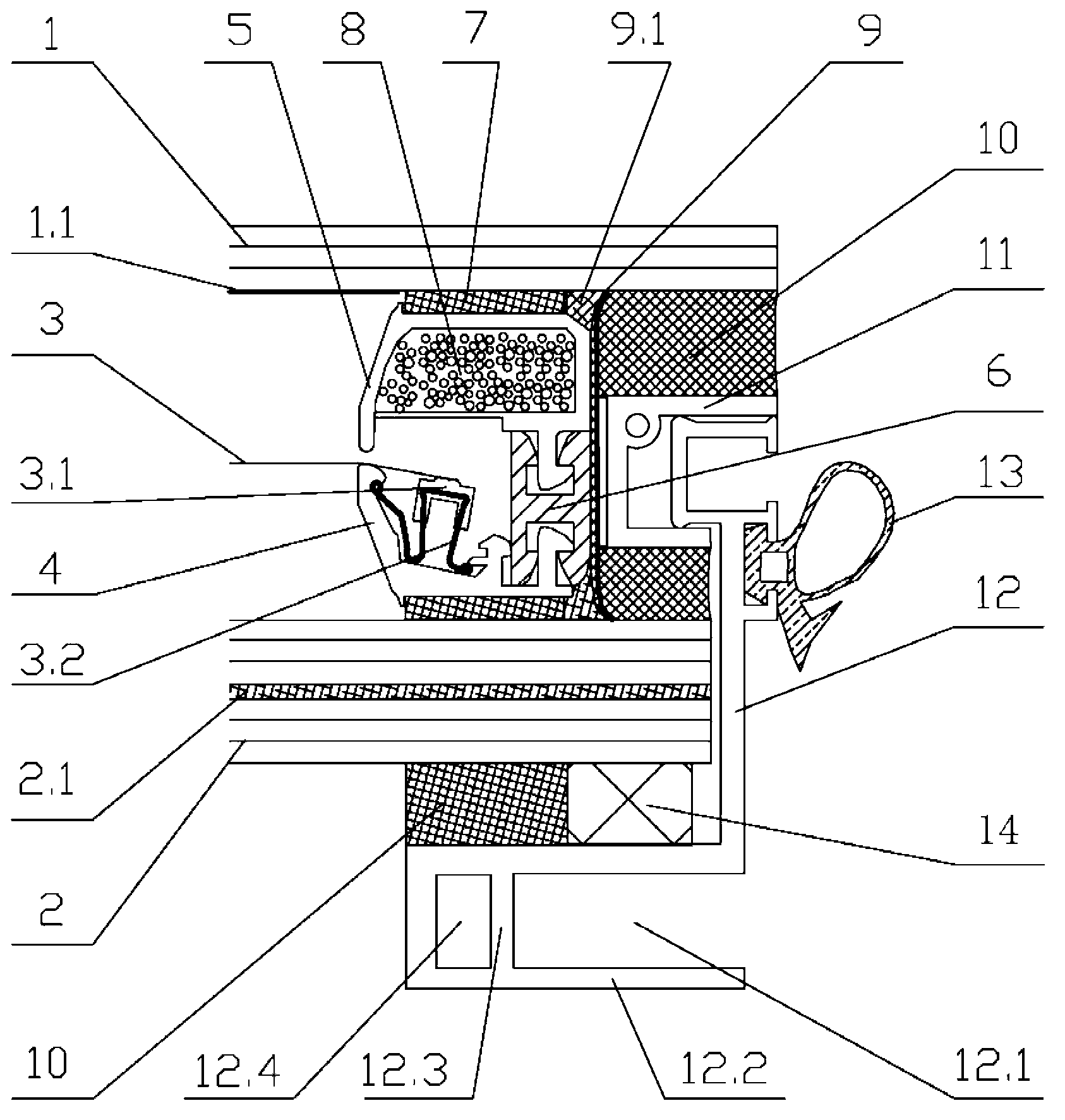

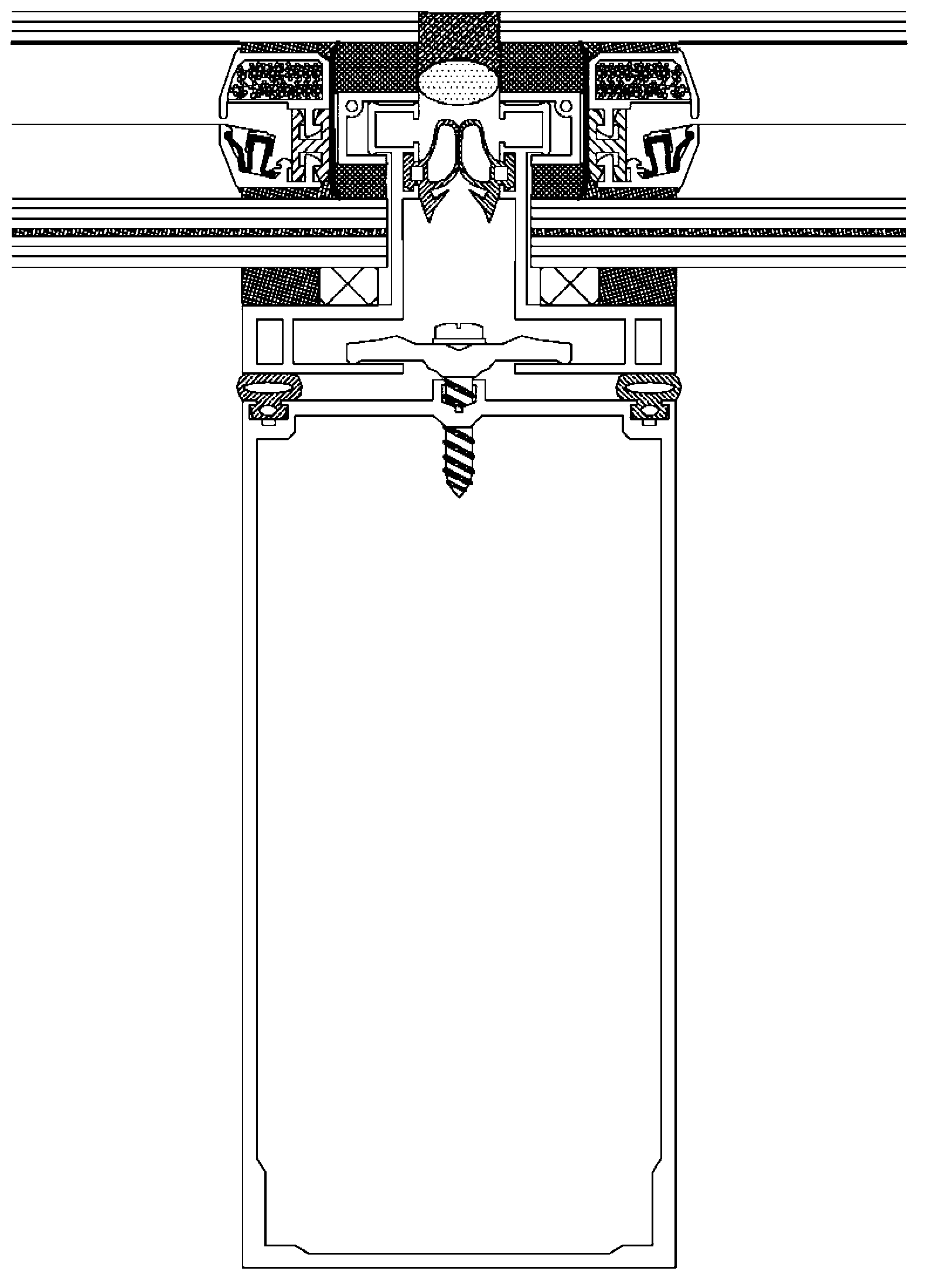

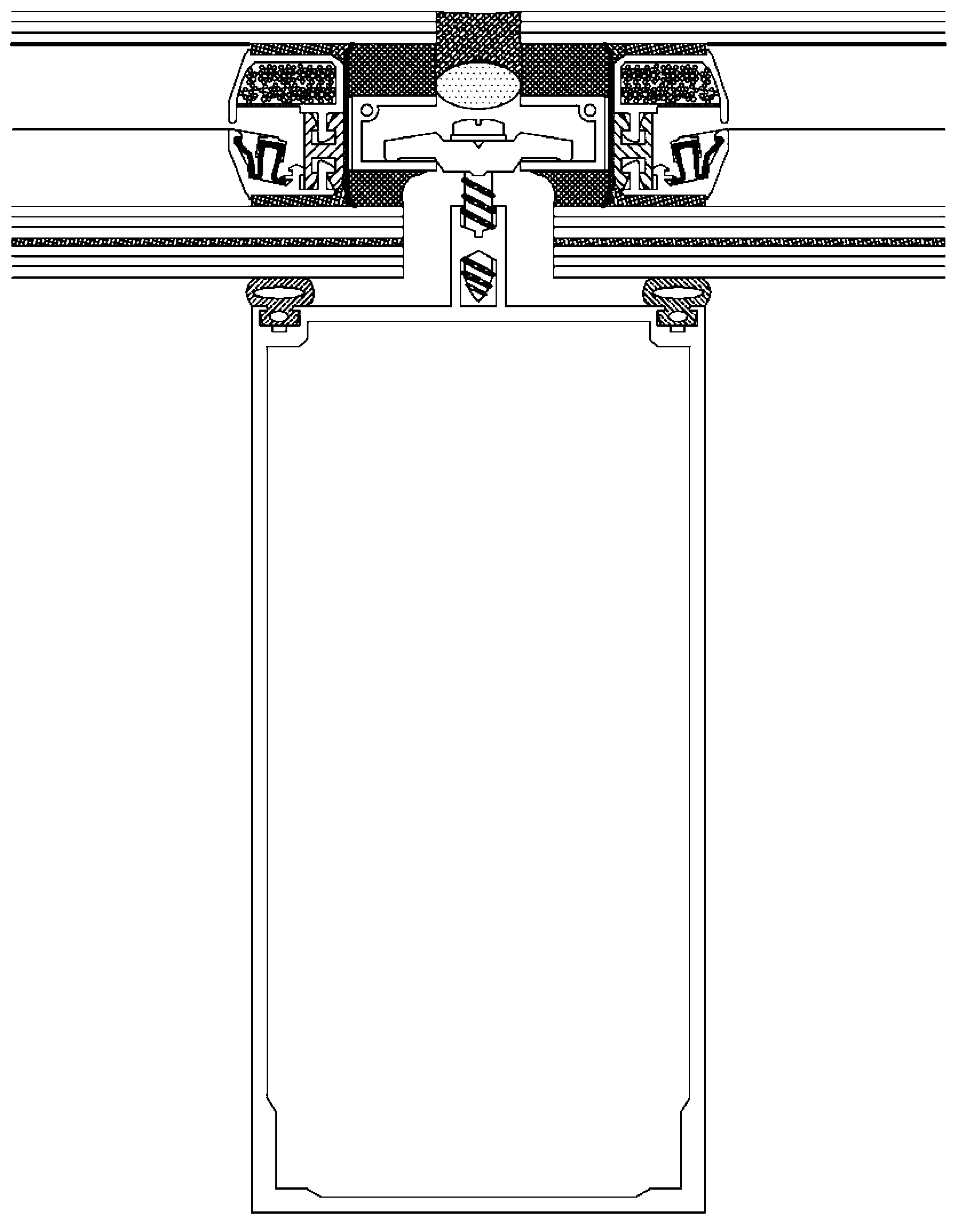

Double-hollow glass ceiling module with film suspended therein

ActiveCN103074966AConvenient lightingImprove heat insulationRoof covering using slabs/sheetsWallsMoisture condensationThermal deformation

The invention discloses a double-hollow glass ceiling module with a film suspended therein. An optical control film serves as a middle layer, and an internally suspended film structure frame, a mounting structure frame, a reinforcing separating strip and glass are sealed into an integral double-hollow glass plate. An inner structure frame and an outer structure frame are made from a novel heat-isolating material with a coefficient of thermal expansion similar to that of the glass. The internally suspended film structure frame is structurally connected through a heat-isolating bridge. A butyl rubber tape on the outer surface of the internally suspended film structure frame serves as a first sealing layer. A second sealing layer consists of the external reinforcing separating strip and a silicone structural sealant, the whole structure is always consistent to the thermal deformation of the glass, so that the sealing capability of the whole system is more reliable, and the heat-isolating property, the moisture condensation-preventing property, the sound-isolating property and the like are greatly improved. Dirt is not easily accumulated on the outer surface of a mounted ceiling, so that the ceiling is convenient to clean and maintain. The double-hollow glass ceiling module has a flexible assembling and mounting way, and can be applied to different vertical surfaces of an outer building rail.

Owner:伟视幕墙(淮安)有限公司

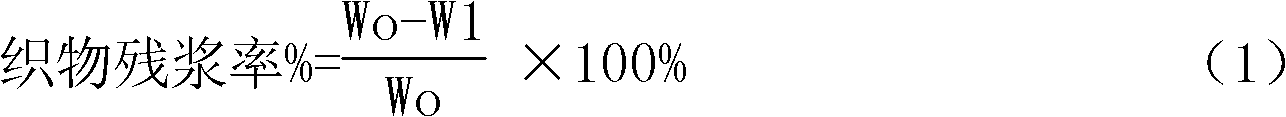

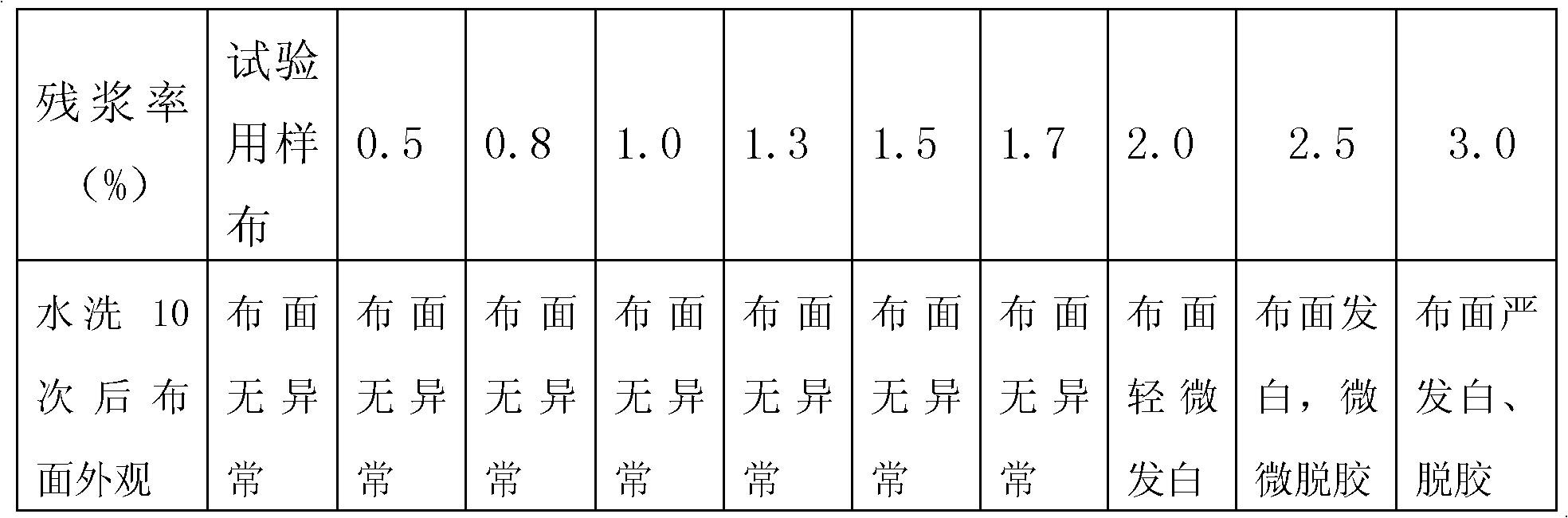

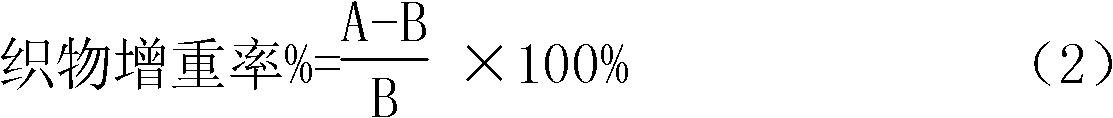

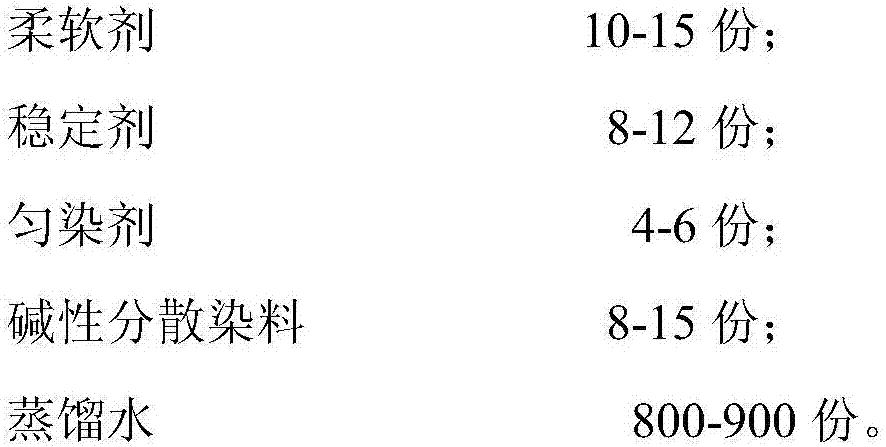

Post-treatment method of chinlon superfine denier fiber fabric

ActiveCN102505488AImprove tear resistanceOvercome the rough feelFibre typesDry-cleaning apparatus for textilesFiberHydrostatic pressure

The invention aims at the shortages that chinlon superfine denier fiber fabric of the prior art is easy in adhesive failure, low in hydrostatic pressure resistance, non-washable, low in tearing strength, , easy in impregnation of adhesive and inverse adhesion in the coating process, and the clothes made of the fabric is not stiff and smooth enough. Provided is a post-treatment method of the chinlon superfine denier fiber fabric. The method comprises three steps including desizing, calendering treatment and coating finishing, wherein, in the coating finishing step, one surface of the fabric is coated with a finishing agent A which is composed of components by weight part as follows: 86-90 parts of polyurethane resin, 4-8 parts of solvent A, 3-6 parts of bridging agent, 1-2 parts of promoter and 2-4 parts of titanium dioxide; the other surface of the fabric is coated with a finishing agent B which is composed of components by weight part as follows: 81.5-92.5 parts of silicone resin, 3-11 parts of solvent B, 2-5 parts of cross-linking agent and 2-5 parts of cross-linking catalyst. The fabric treated by the method disclosed by the invention is obviously improved in anti-tearing performance, anti-ultraviolet ray performance, static pressure resistance, stiffness and smoothness.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

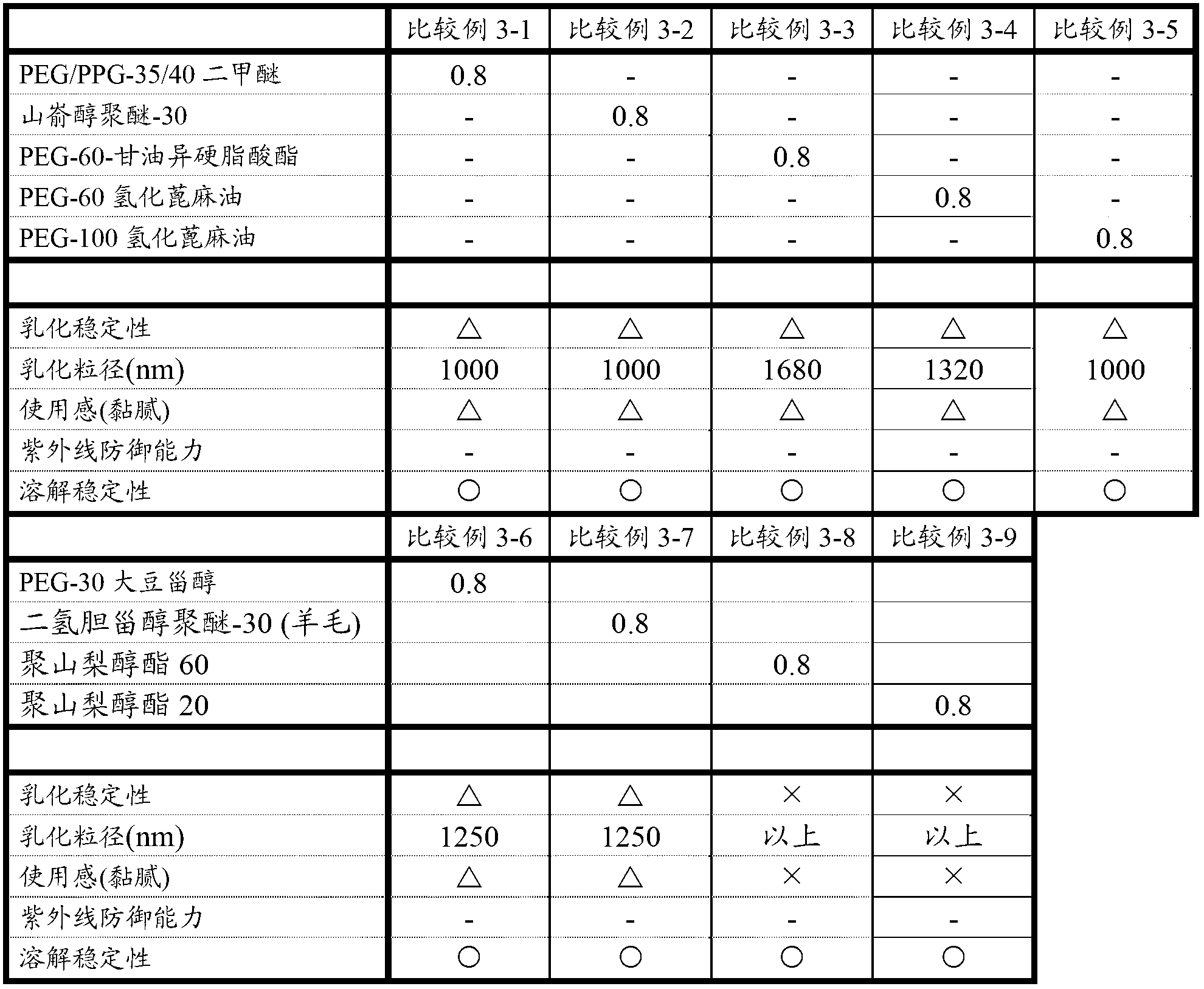

Sunscreen composition

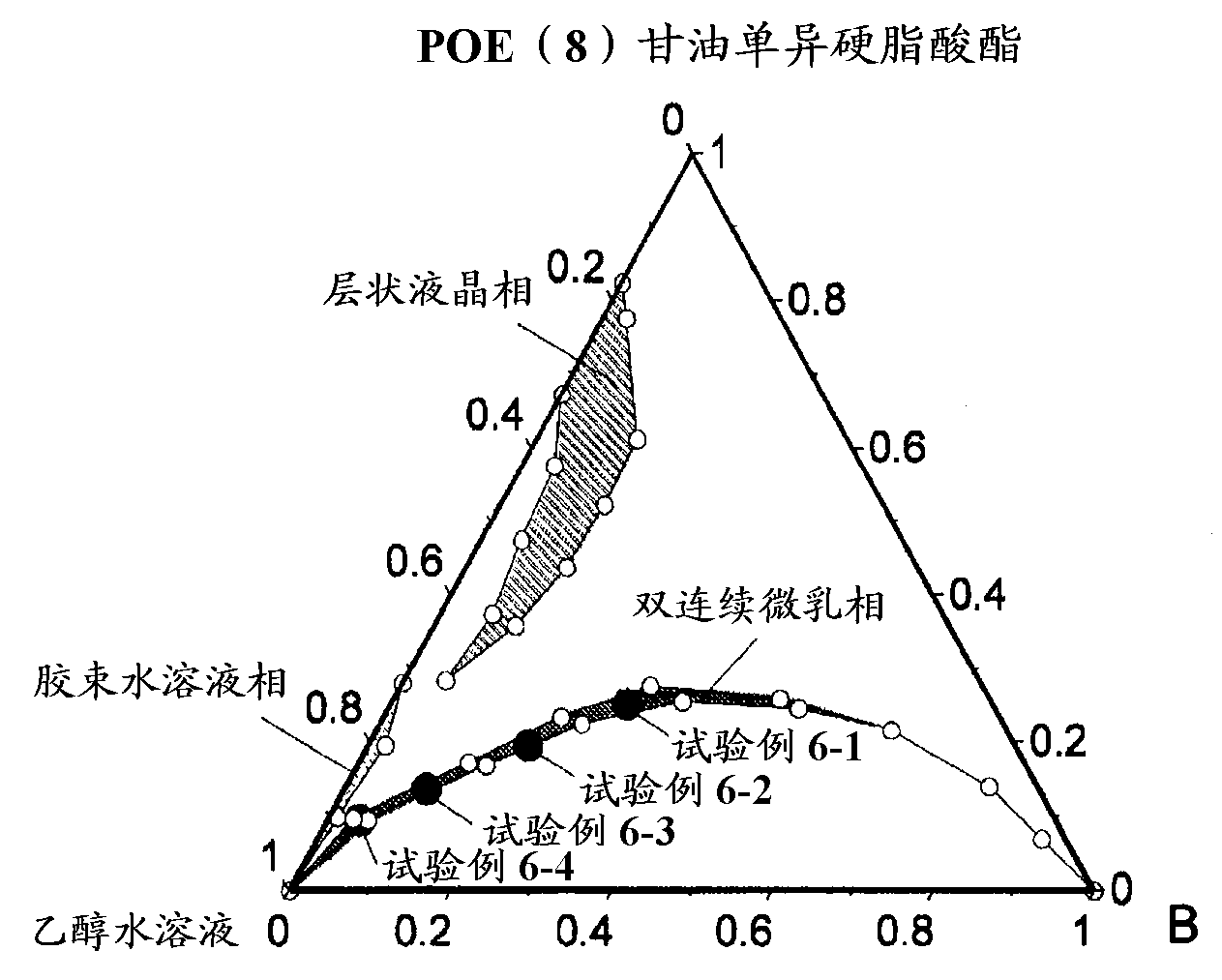

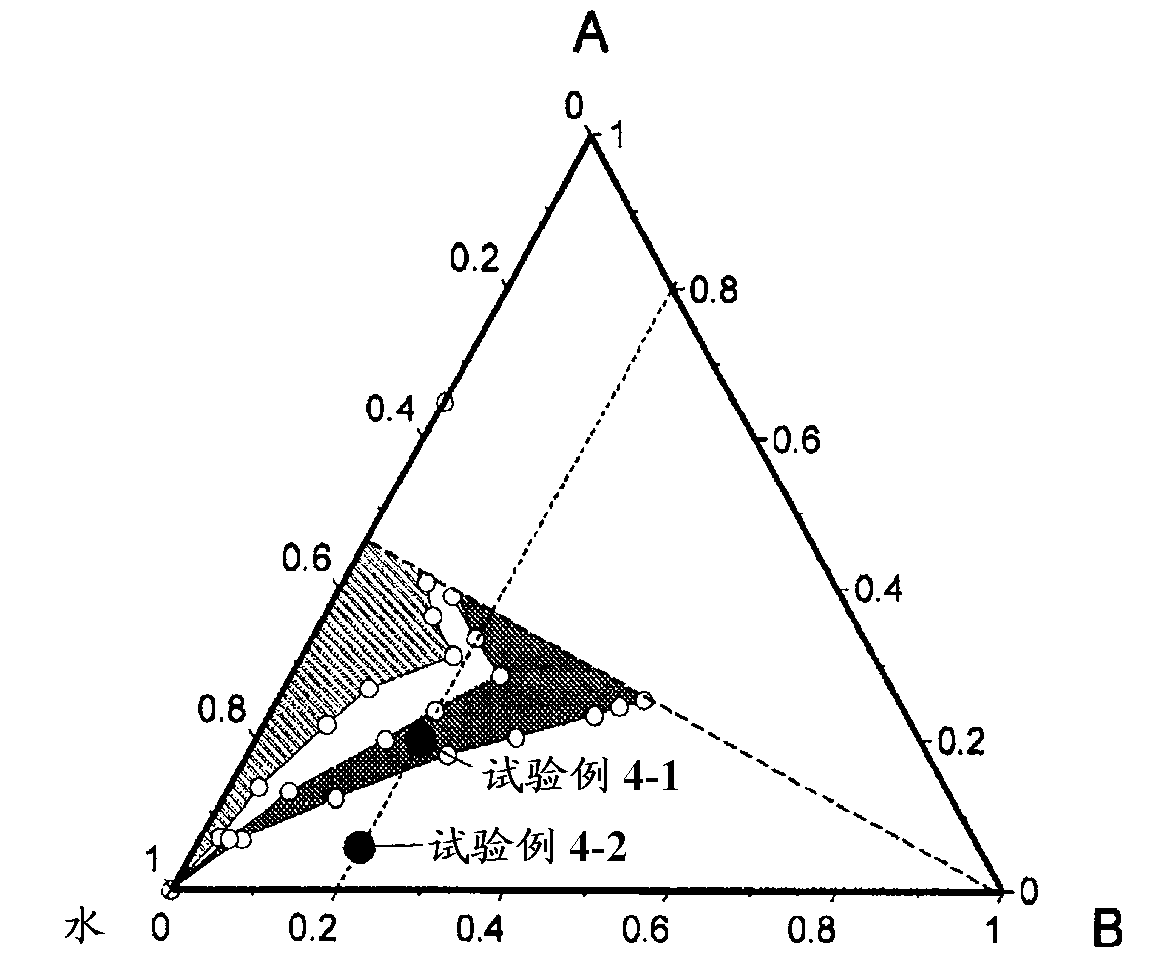

ActiveCN102844015AImprove UV protection effectGood touchCosmetic preparationsToilet preparationsActive agentUltraviolet protection

To provide a sunscreen composition which is excellent in ultraviolet protection ability and usability, well spreads on skin at the time of application and is excellent in coating film uniformity, has good conformability to skin, and is in a transparent bicontinuous microemulsion phase. The sunscreen composition includes (a) a surfactant, (b) water, (c) oil, and (d) a water-soluble ultraviolet absorber and / or an oil-soluble ultraviolet absorber, and is in a bicontinuous microemulsion phase.

Owner:SHISEIDO CO LTD

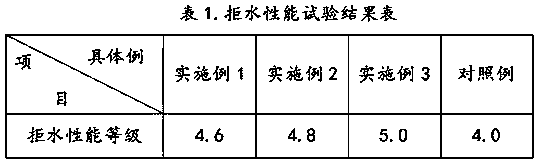

Umbrella cloth and manufacturing method thereof

InactiveCN107558231AImprove waterproof performanceNot easy to yellowFibre typesWoven fabricsPolyesterEmulsion

The invention discloses an umbrella cloth. The umbrella cloth comprises a fabric layer and a water-proof layer coating the fabric layer. The umbrella cloth is characterized in that the fabric layer isprepared by blending and weaving polyester fibers and acrylic fibers, wherein the water-proof layer is prepared from the following components in parts by weight: 35 to 45 parts of resin, 10 to 20 parts of silicone oil, 11 to 15 parts of cross-linking agent, 2.5 to 5.5 parts of adhesive and 1.5 to 4.5 parts of ultraviolet screening agent; the resin contains polyurethane emulsion and polyacrylate emulsion; the mass ratio of the polyurethane emulsion to the polyacrylate emulsion is 5 to 3; the silicone oil is prepared by mixing epoxy-modified silicone with polyether-modified silicone. The invention also aims at providing a method for manufacturing the umbrella cloth; the manufactured umbrella cloth has the advantages of good water-proof and ultraviolet-proof effects, light resistance and lowpossibility of yellowing while processing.

Owner:苏州雨维斯纺织纤维有限公司

Purple-light cross-linked low-smoke halogen-free high flame-retardant EVA cable and production method thereof

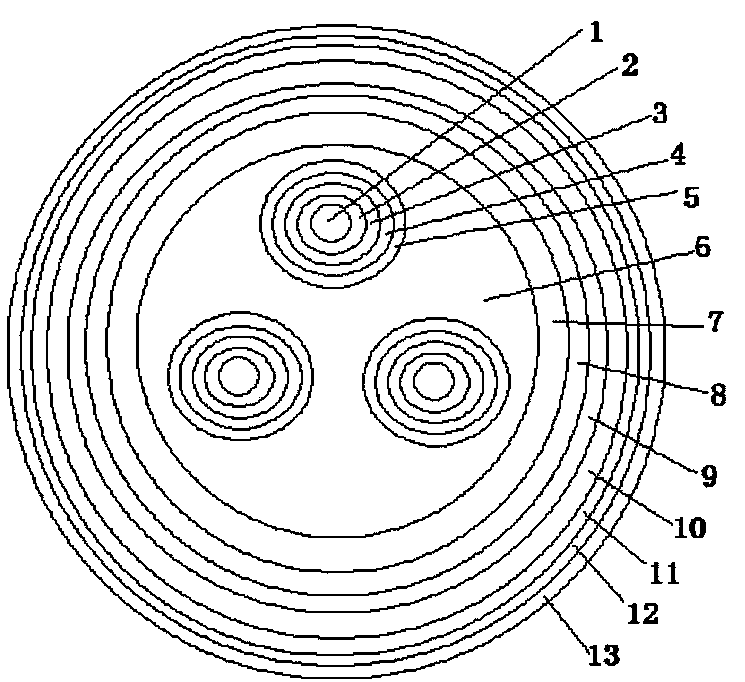

InactiveCN104200906AImprove performanceImprove shielding effectInsulated cablesCable/conductor manufactureLow smoke zero halogenGlass fiber

The invention provides a purple-light cross-linked low-smoke halogen-free high flame-retardant EVA cable which comprises conductors. Each conductor is covered with a shield layer, the shield layer is covered with a purple-light cross-linked insulating layer, the purple-light cross-linked insulating layer is covered with a ceramic silicone rubber layer, and the ceramic silicon rubber layer is covered with an anticorrosive layer. Flame-retardant glass fiber filling ropes are filled among the conductors, the conductors and the flame-retardant glass fiber filling ropes are together covered with a flame-retardant tape, the flame-retardant tape is covered with an internal purple-light cross-linked protective layer, the internal purple-light cross-linked protective layer is provided with an armor layer, the armor layer is covered with an external purple-light cross-linked protective layer, the external purple-light cross-linked protective layer is covered with a waterproof layer, the waterproof layer is covered with an SBS rubber layer, and the SBS rubber layer is coated with an ultraviolet-proof layer. The invention further provides a production method of the cable. The purple-light cross-linked low-smoke halogen-free high flame-retardant EVA cable is provided with multiple flame-retardant layers and the waterproof layer.

Owner:ZHANGQIU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

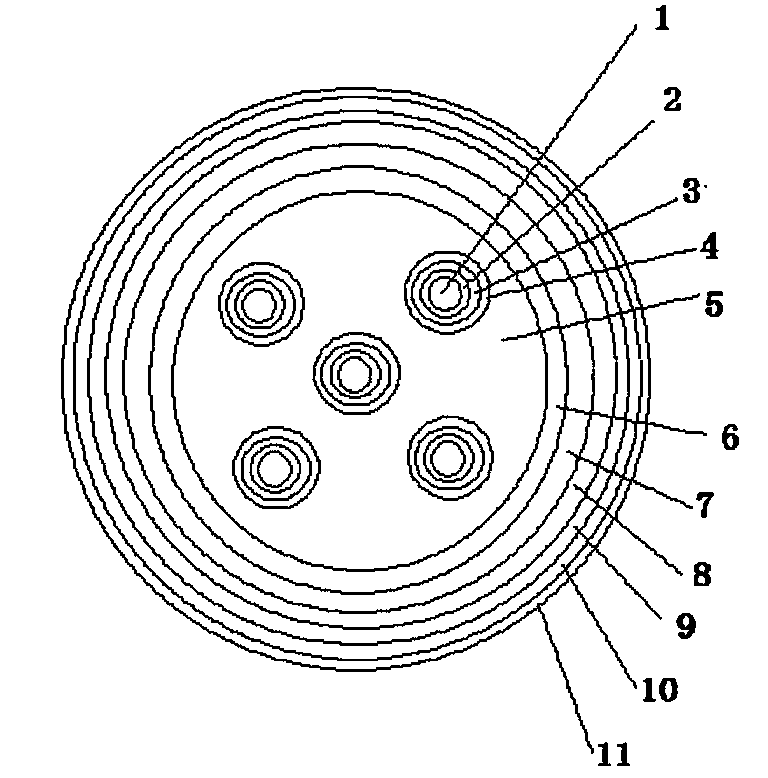

Irradiation cross-linking high-performance high flame-resistant electric wire and cable and preparation method thereof

InactiveCN104200905AFlame retardantImprove performanceClimate change adaptationInsulated cablesInsulation layerElectrical conductor

The invention provides an irradiation cross-linking high-performance high flame-resistant electric wire and cable which comprises conductors. A shielding layer is arranged outside each conductor, an irradiation cross-linking polyethylene insulation layer is arranged outside each shielding layer, a fire-resistant mica layer is arranged outside each irradiation cross-linking polyethylene insulation layer, the conductors are filled with rock wool ropes, a flame-resistant belt is arranged outside the conductors and the rock wool ropes, a flame-resistant polyethylene inner protection layer is arranged outside the flame-resistant belt, an armor layer is arranged outside the flame-resistant polyethylene inner protection layer, a flame-resistant polyethylene outer protection layer is arranged outside the armor layer, an abrasion-resistant layer is arranged outside the flame-resistant polyethylene outer protection layer, and an ultraviolet-proof layer coats the abrasion-resistant layer. The invention further provides a preparation method of the electric wire and cable. The irradiation cross-linking polyethylene insulation layers, the fire-resistant mica layers, the rock wool ropes, the flame-resistant polyethylene inner protection layer, the flame-resistant polyethylene outer protection layer and the abrasion-resistant layer have flame resistance, multiple layers are set, and the flame resistance of the electric wire and cable is far higher than that of similar products.

Owner:苏州天盛电线电缆有限公司

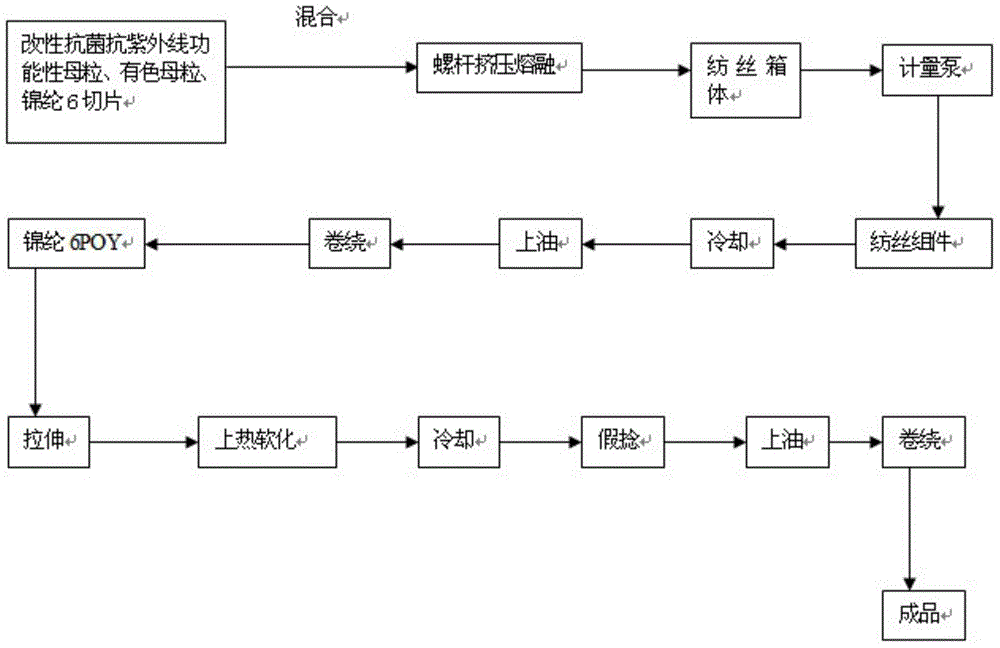

Functional chinlon 6 colored fiber and manufacturing method thereof

InactiveCN104060337AAntibacterial and UV resistantImprove antibacterial propertiesFilament forming substance formingMelt spinning methodsFiberMetering pump

The invention discloses a functional chinlon 6 colored fiber and a manufacturing method thereof. The colored fiber comprises the following materials in percentage by weight: 2.5 to 5 percent of modified antibacterial ultraviolet resistant functional master batch, 3.0 to 4.0 percent of colored master batch and 91 to 94.5 percent of chinlon 6 slices. The invention further discloses a manufacturing method of the functional chinlon 6 colored fiber, which comprises the following steps: a, mixing drying modified antibacterial ultraviolet resistant functional master batch, the colored master batch and chinlon 6 slices and adding the mixture in a screw extrusion machine to melt; b, extrusion spinning the mixed molten material through a metering pump, and then cooling, applying oil on and winding silk bundles for preparing chinlon 5 POY; c, stretching, thermal softening, and then cooling and false twisting the chinlon 6 POY; d, applying oil on and winding the false twisted silk bundles to obtain the finished products. The functional chinlon 6 colored fiber provided by the invention integrates triple functions of coloredness, antibacterial property and ultraviolet resistance, and reduces production processes and sewage discharge.

Owner:ZHEJIANG MESBON CHEM FIBER

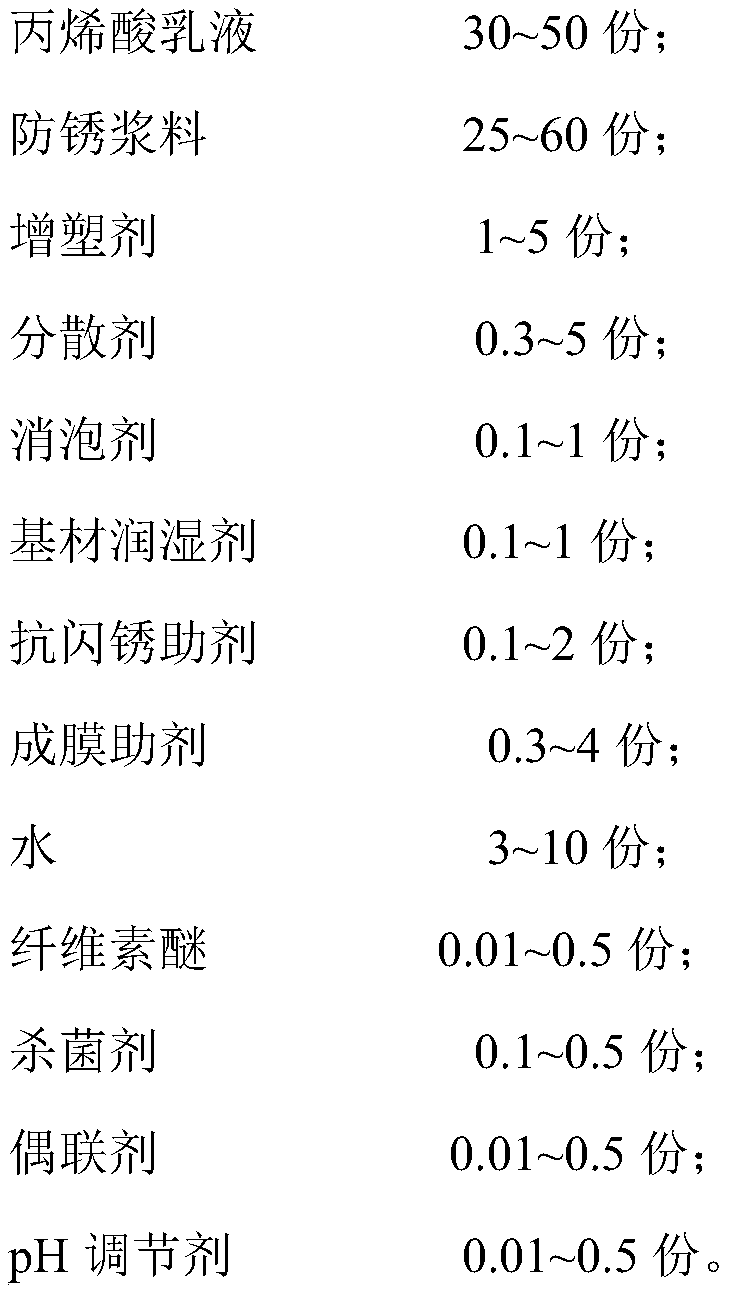

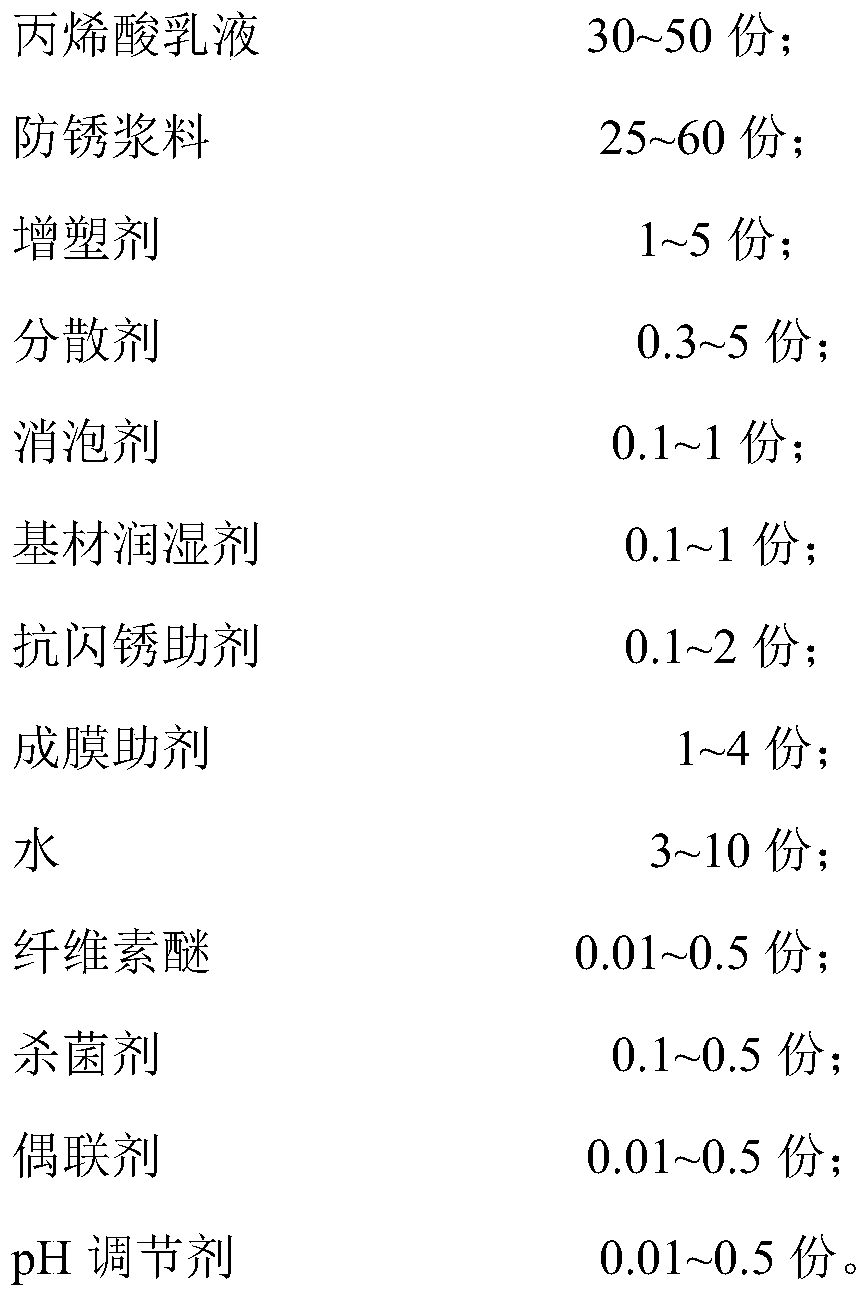

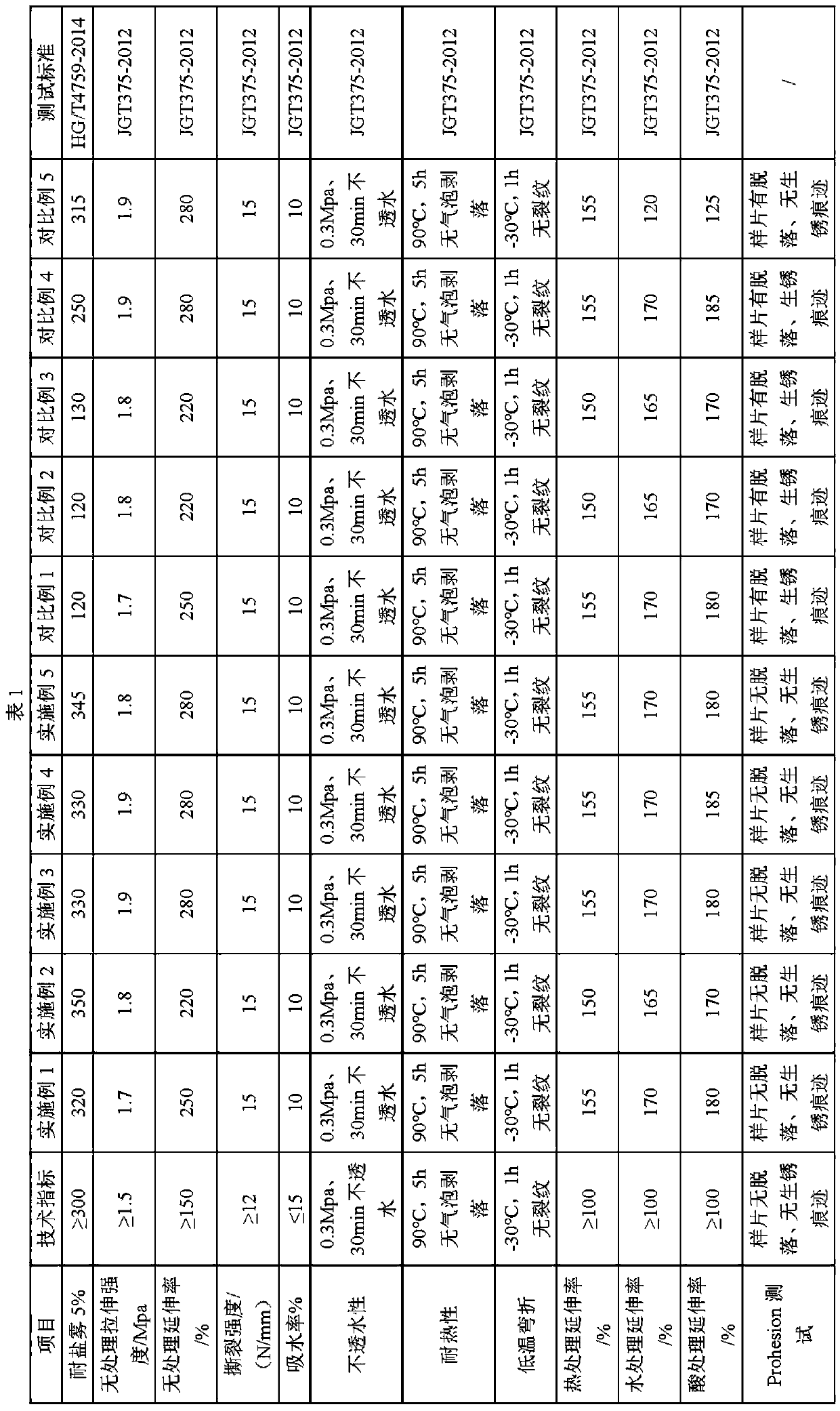

Flash rust-proof acrylic roof waterproof coating and preparation method thereof

The invention relates to the field of water proofing of metal roofs and particularly discloses a flash rust-proof acrylic roof waterproof coating which is prepared from, by weight, the following raw materials: 30-50 parts of an acrylic emulsion, 25-60 parts of antirust slurry, 1-5 parts of a plasticizer, 0.3-5 parts of a dispersing agent, 0.1-1 part of a defoaming agent, 0.1-1 part of a base material wetting agent, 0.1-2 parts of an anti-flash rust additive, 1-4 parts of a film forming assistant, 3-10 parts of water, 0.01-0.5 part of cellulose ether, 0.1-0.5 part of a bactericide, 0.01-0.5 part of a coupling agent and 0.01-0.5 part of a pH adjusting agent. The flash rust-proof waterproof effect of the roof waterproof coating with a flash rust-proof function is longer lasting than that of acommon metal roof waterproof coating, the anti-ultraviolet effect is good, and the service life of a base material is prolonged. The waterproof coating has high elongation rate, good elasticity, strong base layer deformation resistance, the capability of shielding cracks, water proofing and breathability.

Owner:KESHUN WATERPROOF TECH CO LTD

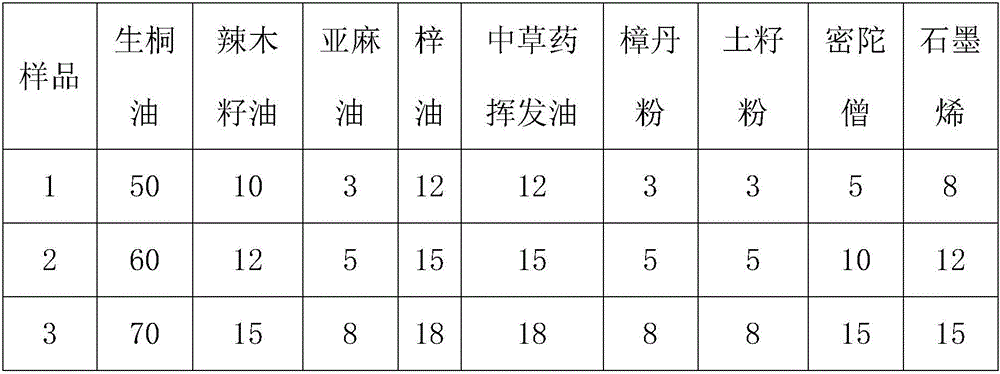

Ash oil putty for ancient architecture material and preparation method thereof

ActiveCN106189460AImprove anti-ultraviolet performanceImproves application continuityFilling pastesBrickPutty

The invention provides ash oil putty for an ancient architecture material and a preparation method thereof. The ash oil putty contains ash oil, a blood material and brick dust, wherein the mass ratio of the ash oil to the blood material to the brick dust is 1 to 1-3 to 5-10, the ash oil is prepared from raw tung oil, moringa seed oil, linseed oil, catalpa oil, Chinese herbal medicine volatile oil, minium powder, manganese dioxide metal drier, litharge, graphene and other raw materials. The blood material is prepared from pig plasma, quick lime water, activated carbon powder, light calcium powder, aerogel powder and hypocrellin. The brick dust is obtained by smashing oil-immersed black brick coarse granules. The ash oil, the blood material and the brick dust are mixed in proportion. The ash oil putty has good adhesion and toughness, increased tension, good coating continuity and is easy to construct. Dried ash oil putty does not crack, is easy to polish, also has excellent waterproof, anticorrosive, antibacterial and ultraviolet-proof properties, is especially suitable for repair and filling of the ancient architecture material, is especially used for ancient architecture wood materials and plays an excellent wood material filling effect.

Owner:BEIJING XINCHUZHIYUAN ENVIRONMENTAL PROTECTION TECH

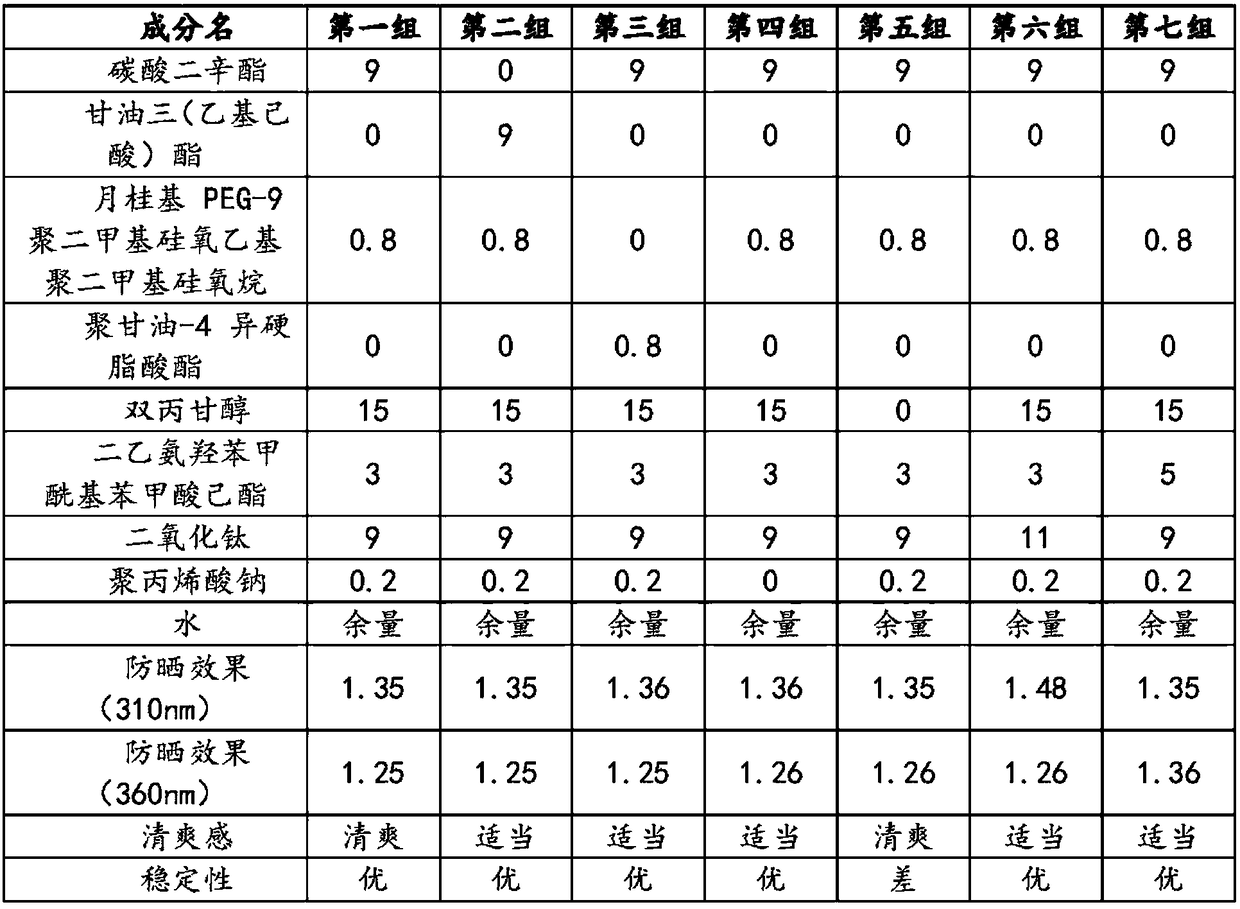

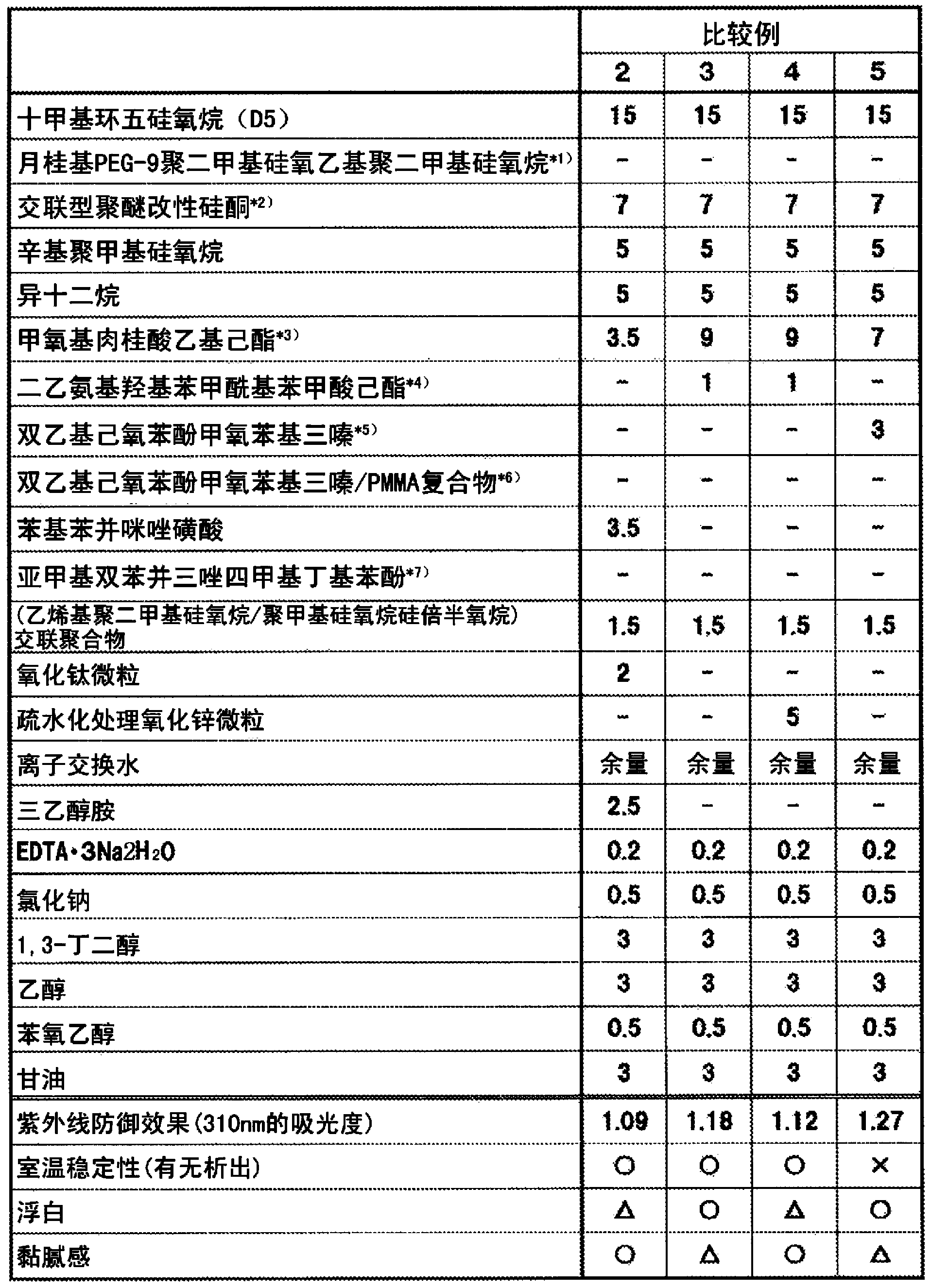

Water-in-oil emulsion sunscreen cosmetic

PendingCN107072919AHigh UV protection effectImprove UV protection effectCosmetic preparationsToilet preparationsWater in oil emulsionOil phase

Provided is a water-in-oil emulsion sunscreen cosmetic having a property not present in the prior art, of improved UV protection due to contact with water and / or sweat compared to directly after application, and which is also pleasant to use and easy to wash off. This water-in-oil emulsion sunscreen cosmetic contains: 6-40 mass % of a UV protector (A), an organic modified clay mineral (B), and an oil phase thickening agent (C) other than (B), and a silicone-based surfactant (D) having an HLB value of less than 8, wherein the ratio [total quantity of component (B) and component (C)] / [total quantity of non-volatile liquid oil components other than silicone oil (E)] is at least 0.04 but less than 0.68.

Owner:SHISEIDO CO LTD

Anti-ultraviolet solar film and preparation method thereof

The invention discloses an anti-ultraviolet solar film, which includes the following components mixed by weight: 40-50 parts of PET polyester chips, 7-8 parts of an inorganic ultraviolet absorbent, 4-5 parts of an anti-scratch agent, 2-3 parts of an anti-adhesion agent, and 0.001-0.015 part of a beta-1# decomposition transparent agent. The invention discloses a preparation method of the anti-ultraviolet solar film. The anti-ultraviolet solar film provided by the invention adopts the beta-1# decomposition transparent agent, improves the intermiscibility of the absorbent and PET, thereby greatly increasing the usage amount of the inorganic ultraviolet absorbent, so that the anti-ultraviolet solar film can have an excellent anti-ultraviolet line effect and avoid the human body fatigue caused by ultraviolet rays, and can be used as electronic films, building films, automotive films, aircraft explosion-proof films and the like. The film is clear, and can completely isolate ultraviolet rays.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

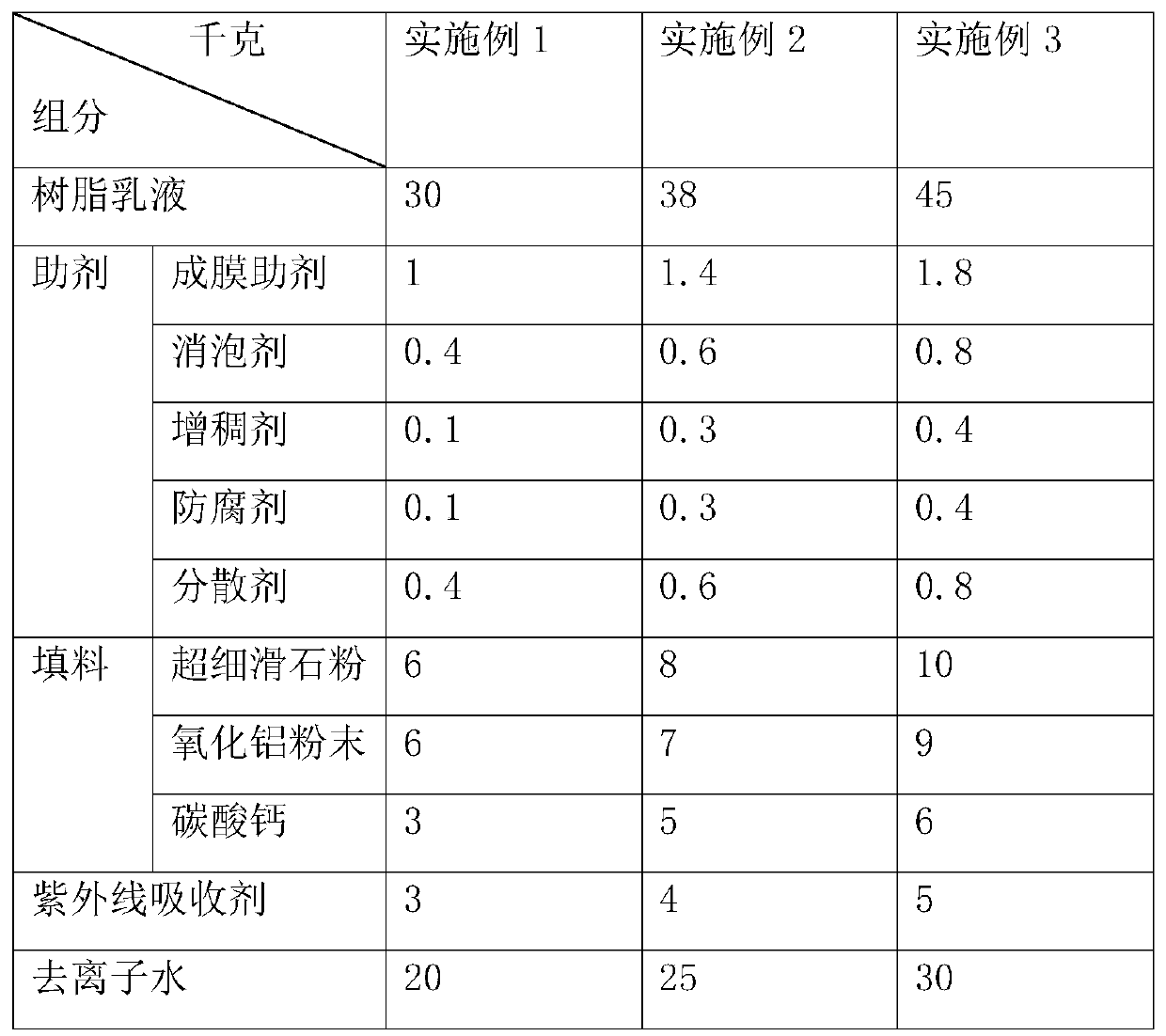

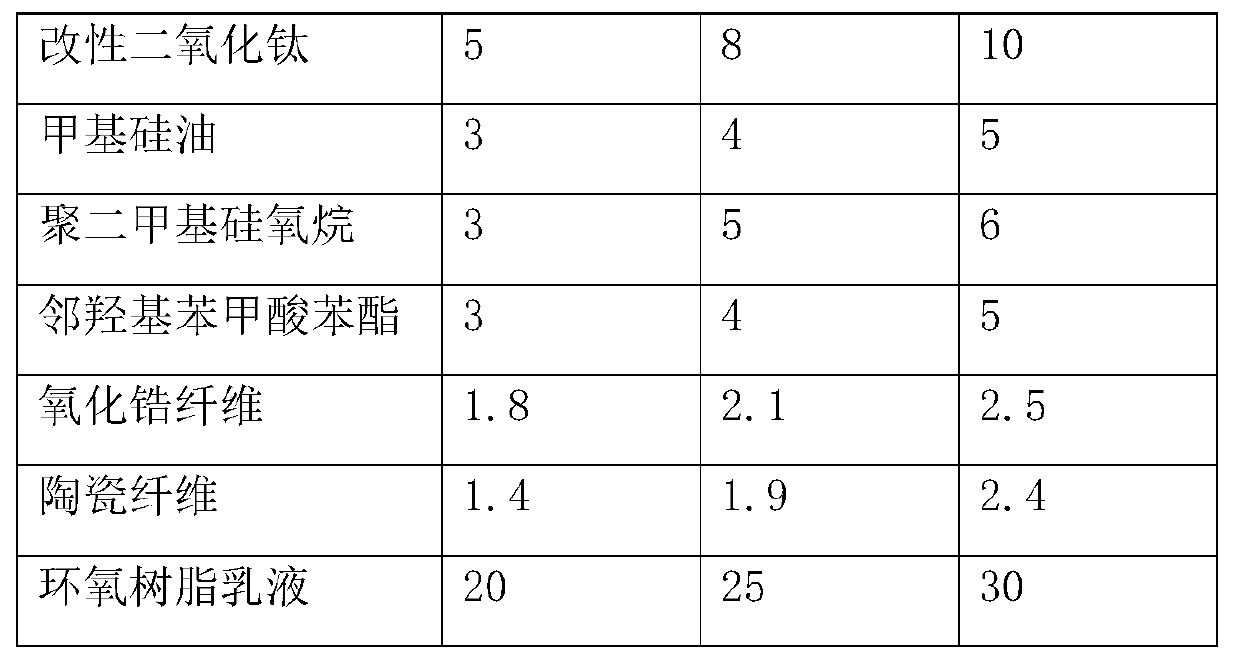

Anti-ultraviolet paint for cosmetic packing bottles and preparation method and application technique thereof

InactiveCN110054982AGood dispersionImprove adhesionLiquid surface applicatorsAnti-corrosive paintsEpoxyFiber

The invention discloses an anti-ultraviolet paint for cosmetic packing bottles and a preparation method and application technique thereof. The anti-ultraviolet paint is made from, by weight, 30-45 parts of resin emulsion, 4-8 parts of an aid, 6-10 parts of a filling material, 3-5 parts of an ultraviolet absorbent, and 20-30 parts of deionized water. The resin emulsion is made by mixing a silica-modified acrylate, polyurethane acrylate and hollow glass beads in a mass ratio of 1:(0.8-1):(0.5-0.8); the ultraviolet absorbent comprises, by weight, 5-10 parts of modified titania, 3-5 parts of methyl silicone oil, 3-6 parts of polydimethylsiloxane, 3-5 parts of phenyl salicylate, 1.8-2.5 parts of zirconia fiber, 1.4-2.4 parts of ceramic fiber, and 20-30 parts of epoxy resin emulsion. The anti-ultraviolet paint for cosmetic packing bottles has good heat insulation effect and high ultraviolet resistance.

Owner:广州澳盈日化包装用品有限公司

Cool three-phase emulsification type sun-screen cosmetic and preparation method thereof

PendingCN109498474APrevent tanningPrevent sunburnCosmetic preparationsToilet preparationsSkin sensePolyol

The invention provides cool three-phase emulsification type sun-screen cosmetic and a preparation method thereof. An excellent sun-screen function is realized through an oil-in-water-in-oil three-phase emulsification mode, a cool skin sense is provided, and the disadvantage that a sun-screen product is generally sticky can be effectively improved. The cool three-phase emulsification type sun-screen cosmetic is prepared from the following components: 5 to 15 percent of oil, 0.5 to 1 percent of a surfactant, 10 to 20 percent of polyol, 10 to 20 percent of a sun-screen agent, 0.1 to 1 percent ofa thickening agent and balance of water. The preparation method of the cool three-phase emulsification type sun-screen cosmetic comprises the following steps: dispersing the surfactant and the sun-screen agent into the oil, heating to 80 to 85 DEG C, keeping warm, stirring until uniformly mixing, then stirring and cooling to 40 to 42 DEG C, and keeping warm for standby use; dispersing the polyol and the thickening agent into the water, heating to 80 to 90 DEG C, keeping warm, stirring until uniformly mixing, then stirring and cooling to 40 to 42 DEG C, and keeping warm for standby use; stirring a prepared water-phase mixture at a high speed, slowly pumping a prepared oil-phase mixture into the water-phase mixture, homogenizing, scraping non-uniform materials, then stirring and homogenizingfor several minutes, cooling to 30 to 35 DEG C, and discharging.

Owner:ZHONGSHAN ZHONGYAN COSMETIC CO LTD

Preparation method of anti-aging and anti-bacterial PE pipe

The invention discloses a preparation method of an anti-aging and anti-bacterial PE pipe. The preparation method comprises the following steps: adding 3-8% of nano-modified bamboo charcoal plastic particles into PE resin, uniformly mixing, heating to 170-210 DEG C, then extruding by a twin-screw extruder, cooling and performing vacuum shaping to obtain the anti-aging and anti-bacterial PE pipe. The core of the invention is that the nano-modified bamboo charcoal plastic particles are adopted to replace carbon black and an inorganic metal antibacterial agent, so that the PE pipe has good anti-aging and anti-bacterial performances. The preparation method disclosed by the invention has the advantages of strong practicality, low cost, greenness and environmental friendliness, the nano-modified bamboo charcoal plastic particles have good dispersibility and stable natures, and the obtained PE pipe has excellent anti-aging and anti-bacterial performances, as well as relatively strong actual application value and market development prospects.

Owner:GUANGXI JIALI IND & TRADE

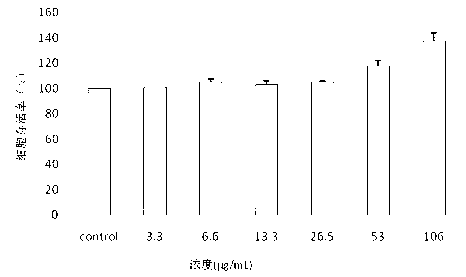

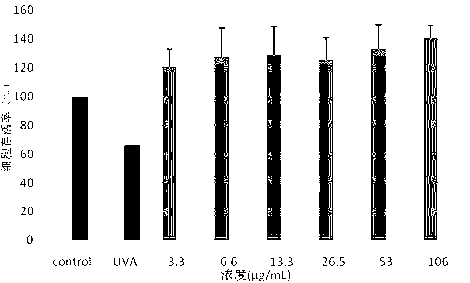

Application of porphyra polysaccharide to preparation of ultraviolet ray injury resistant skin care product

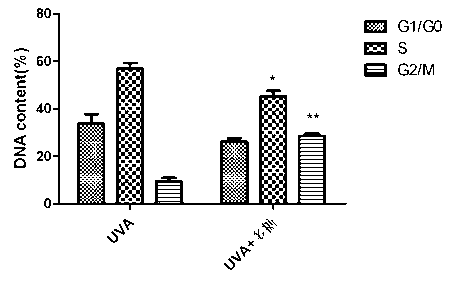

InactiveCN103263361ABoost superoxide dismutaseReduces free radical productionCosmetic preparationsToilet preparationsFibrocytePorphyra dioica

The invention discloses application of porphyra polysaccharide to preparation of an ultraviolet ray injury resistant skin care product. Experiments prove that the survival rate of fibroblast damaged by ultraviolet A (UVA) radiation can be obviously improved through porphyra polysaccharide, and the porphyra polysaccharide has an obvious effect of repairing the fibroblast with ultraviolet ray injury and also has an obvious ultraviolet-proof effect. The porphyra polysaccharide is applied to the skin care product and can be prepared into various forms of cream, emulsions, facial masks, toner, skin lotion, ointment, oiling agents, gel, aerosol, solutions or coating agents.

Owner:GUANGZHOU JINAN BIOMEDICINE RES & DEV CENT

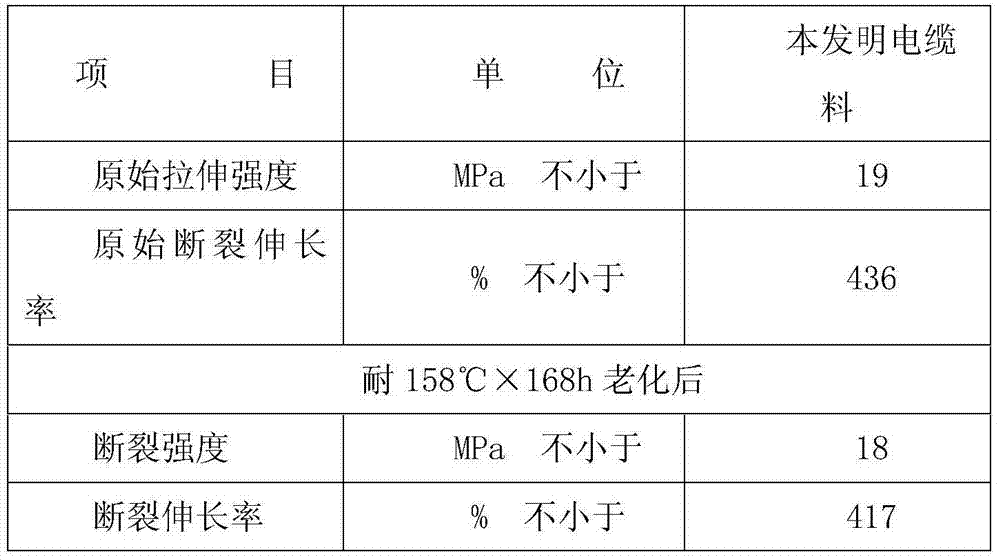

Anti-ultraviolet polyethylene electric cable insulation material and preparation method thereof

InactiveCN103756106AImprove stabilityUniform colorInsulatorsLinear low-density polyethylenePolystyrene

The present invention discloses an anti-ultraviolet polyethylene electric cable insulation material, which is characterized in that the anti-ultraviolet polyethylene electric cable insulation material is prepared from the following raw materials by weight: 40-45 parts of linear low density polyethylene, 14-18 parts of high density polyethylene, 1-2 parts of an antioxidant 1035, 4-6 parts of PE wax, 16-19 parts of general-purpose polystyrene, 2-3 parts of polyisobutylene, 3-4 parts of zinc stearate, 22-25 parts of dioctyl phthalate, 14-16 parts of dibutyl phthalate, 2-3 parts of zinc borate, 1-2 parts of an antioxidant DLTP, 2-3 parts of an anti-scorching agent CTP, and 6-8 parts of an auxiliary agent. The product has characteristics of good stability, uniform color, excellent ultraviolet resistance, excellent weather resistance, excellent toughness and excellent cracking resistance, and is mainly used for the protection layer of outdoor overhead electric wire electric cables or electric wire electric cables in other similar occasions.

Owner:WUHU JIACHENG ELECTRONICS TECH

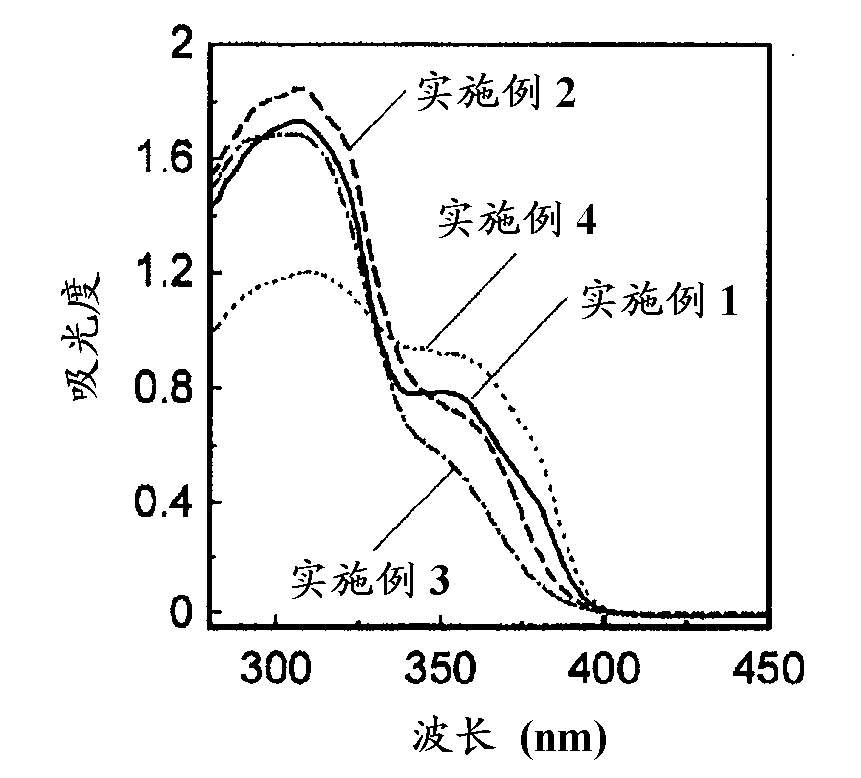

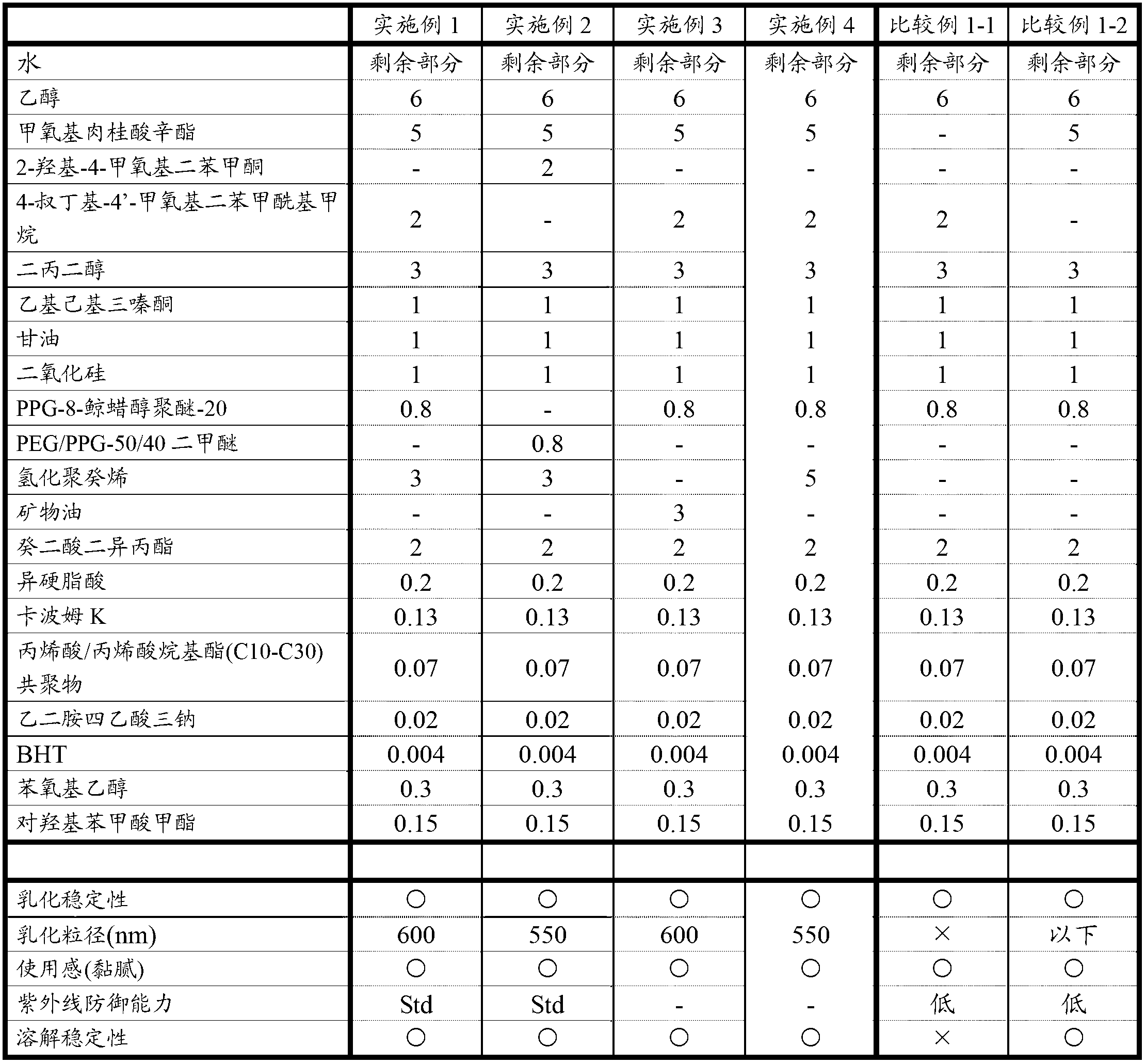

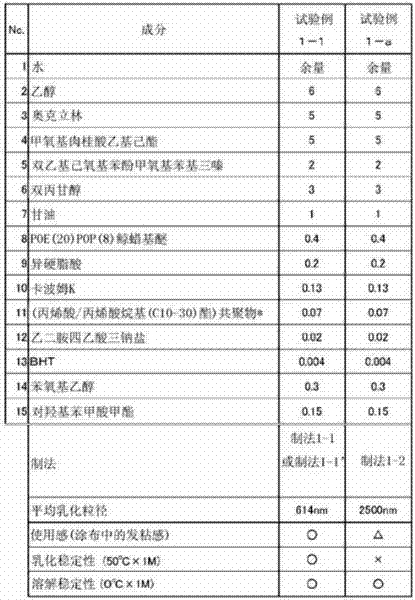

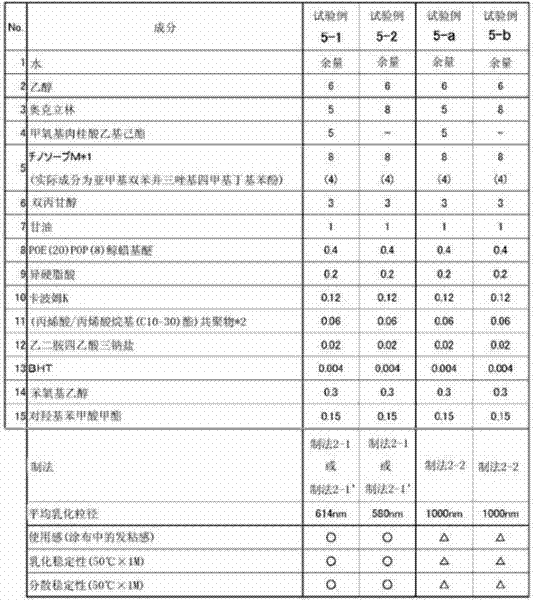

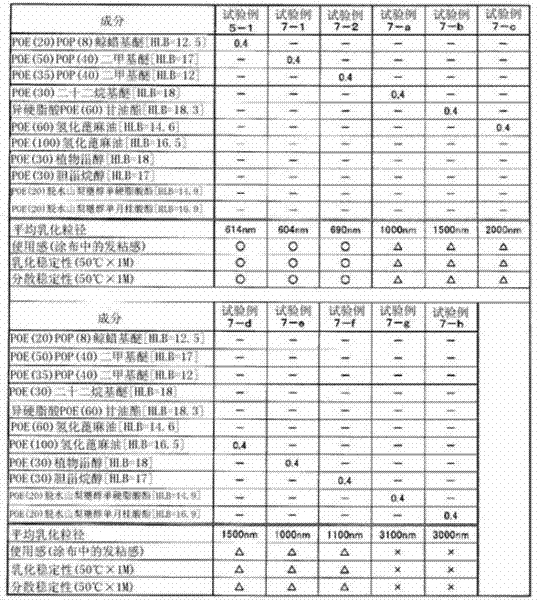

Oil-in-water emulsion sunscreen cosmetic composition

ActiveCN102740825AImprove UV protection effectEasy to useCosmetic preparationsToilet preparationsUltravioletUv absorber

Disclosed is an oil-in-water emulsion sunscreen cosmetic composition which has improved ultraviolet blocking capability by containing a large amount of an ultraviolet absorbent, while having excellent emulsion stability and good usability. Specifically disclosed is an oil-in-water emulsion sunscreen cosmetic composition which is characterized by containing (A) 1-7.5% by mass of octyl methoxycinnamate, (B) 0.5-4% by mass of t-butyl methoxybenzoyl methane and / or 2-hydroxy-4-methoxybenzophenone, (C) 0.5-3% by mass of a polyoxyethylene-polyoxyalkylene alkyl ether block polymer having a specific structure and (D) not less than 10% by mass of a nonpolar oil relative to the total amount of the oil component. The oil-in-water emulsion sunscreen cosmetic composition is also characterized by having an average emulsion particle diameter of not more than 700 nm.

Owner:SHISEIDO CO LTD

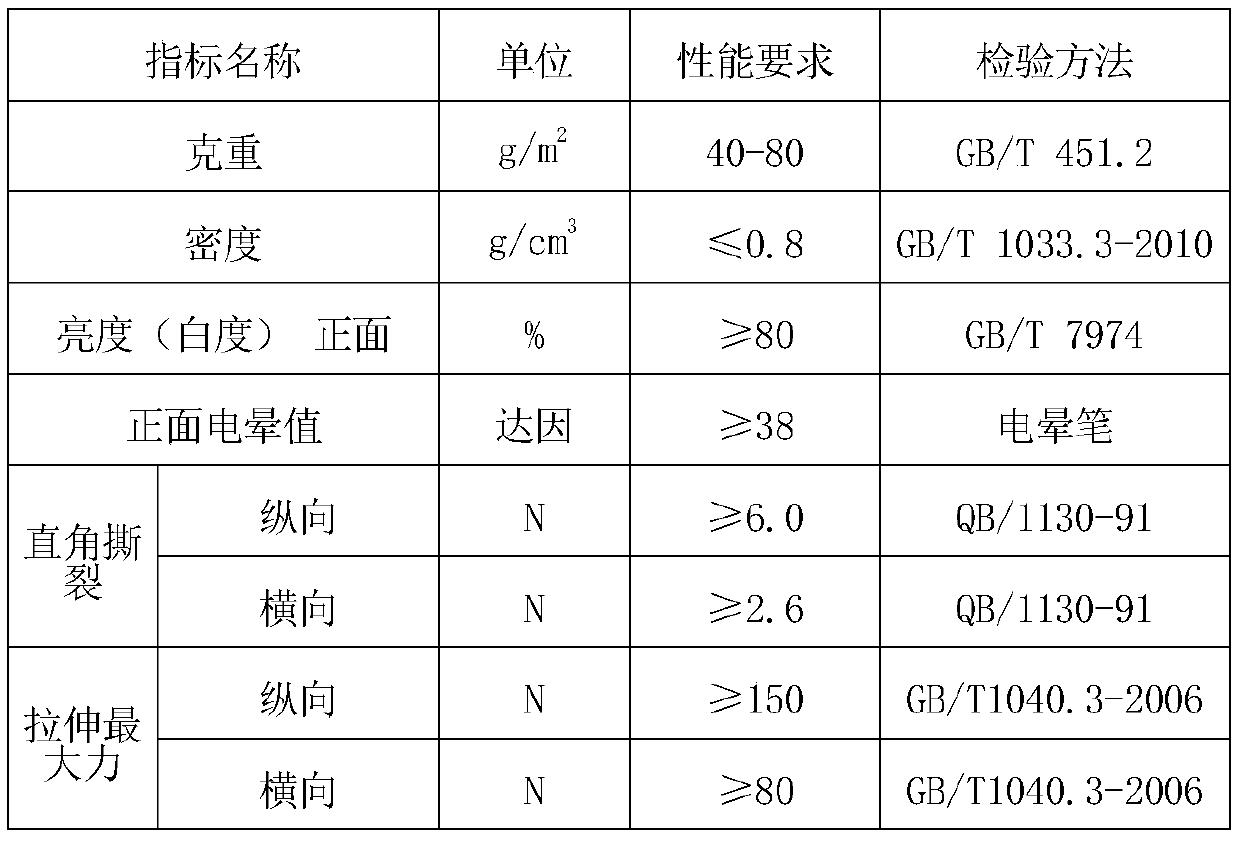

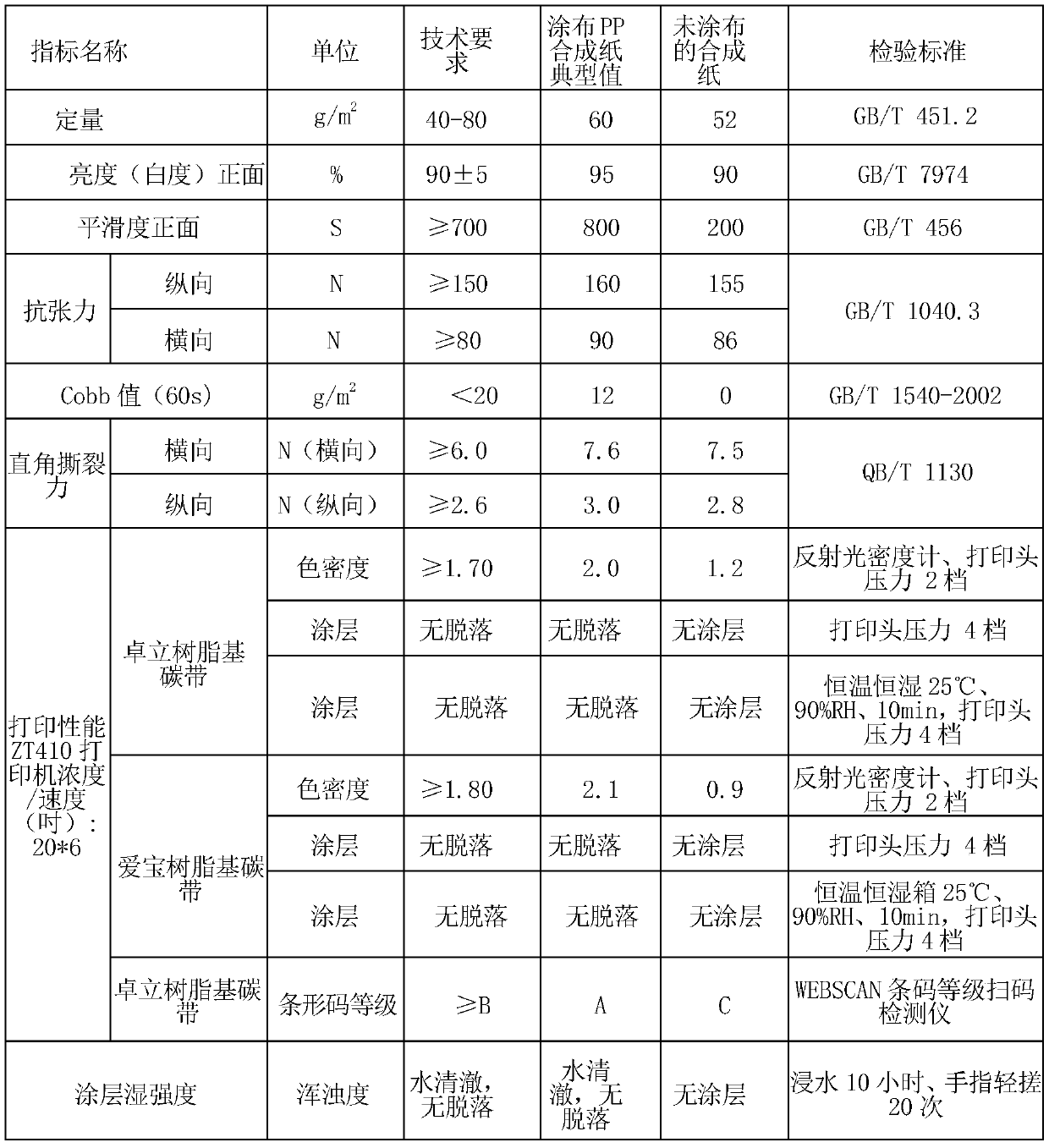

Coated matte PP synthetic paper and preparation method thereof

ActiveCN110230235AImprove printing effectImprove matchCoatings with pigmentsSpecial paperWaxEmulsion

The invention relates to a coated matte PP synthetic paper, which comprises PP synthetic paper and a coating layer coated on the surface of the PP synthetic paper. With the weight part of kaolin as the benchmark, the coating layer comprises the following raw materials by weight: 100 parts of kaolin, 0.8 part of a dispersant, 20-60 parts of an adhesive emulsion, 1-2 parts of a water repellent agent, 0.8 part of a pH regulator, 0.2-0.8 part of a defoamer and 80-150 parts of water. The paint of the formula provided by the invention is coated on the PP synthetic paper, the prepared coated PP synthetic paper is suitable for carbon band heat transfer printers of different types, at the same time has good matching properties with wax-based carbon band, mixed carbon band and resin-based carbon band, and has good waterproof and anti-ultraviolet performance, and better printing effect.

Owner:河北方大新材料股份有限公司

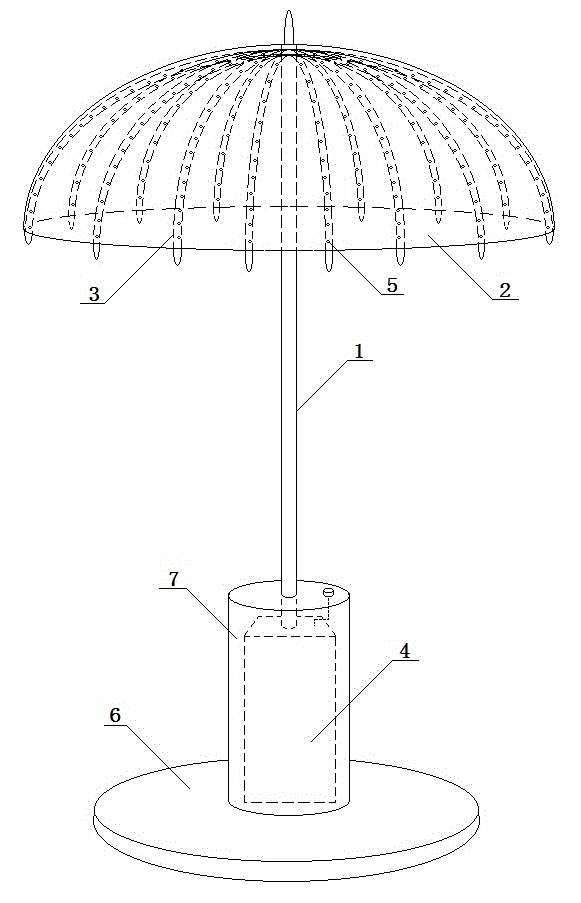

Outdoor landing temperature control umbrella

InactiveCN104305655AFresh airEmbody humanizationWalking sticksTemperature controlClassical mechanics

The invention relates to an outdoor landing temperature control umbrella which is improved from the landing umbrellas at present. An umbrella handle (1) and umbrella circumference support rods (3) are redesigned; a pipe and a cavity are introduced; an electric control fan (4) is combined to supply air to the downward side of umbrella cloth (2) so as to accelerate the flowing of the air below the umbrella cloth (2). By providing a favorable fresh-air environment to the users, the outdoor landing temperature control umbrella further embodies the humanization of the design and has a wide market popularization value.

Owner:SUZHOU HEXINMEI ELECTRONICS SCI & TECH CO LTD

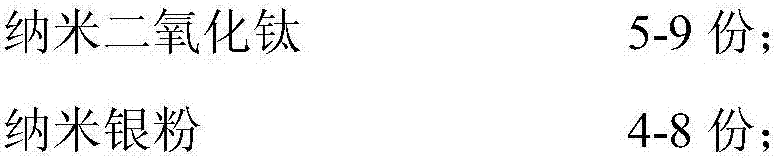

Manufacturing method for ultraviolet-proof flower-in-water fabric

InactiveCN107385956AHigh squeeze rateGood effectBiochemical fibre treatmentLight resistant fibresDesign patternDyeing

The invention relates to a manufacturing method for an ultraviolet-proof flower-in-water fabric. The manufacturing method comprises the following steps: S1, dyeing of a raw fabric; S2, surface dyeing removal; S3, fabric printing: printing designed patterns on a basic fabric by using a printer, and printing floating printing paste on the designed patterns to form designed floating printing patterns; S4, fabric treatment; and S5, padding treatment: impregnating the flower-in-water fabric obtained in the S4 step in padding liquid used in ultraviolet-proof treatment, carrying out single-dipping and single-nipping procedure, and drying at the temperature of 142-148 DEG C to obtain the ultraviolet-proof flower-in-water fabric, wherein the mangle expression is greater than or equal to 82%. The manufacturing method for the ultraviolet-proof flower-in-water fabric has the advantages of environmental protection, uniform color, washing resistance and good ultraviolet isolation property.

Owner:FUJIAN FORTUNES TEXTILE PRINTING & DYEING TECH

Ultraviolet-resistant fabric and preparation method thereof

ActiveCN107142741AImprove stabilityReduce layeringFireproof paintsPolyurea/polyurethane coatingsBenzotriazoleUv absorber

The invention discloses an ultraviolet-resistant fabric and a preparation method thereof. The fabric comprises a fabric surface layer and an ultraviolet-resistant layer deposited on the fabric surface layer, wherein the ultraviolet-resistant layer is a blending layer of polyurethane, sodium alginate, hydroxyethyl methyl cellulose, hindered amine light stabilizers, hydroxyphenyl benzotriazole ultraviolet absorbents, nano ultraviolet absorbents and rare earth fluorescent compounds. The fabric is excellent in ultraviolet-resistant effect, excellent in moisture absorption property, simple in production process, has resistance to sunlight and perspiration and does not need to be washed with water; a lot of water and energy can be saved; the fabric coated with the ultraviolet-resistant coating is soft, tough, washable and durable, and is excellent in properties.

Owner:嘉兴市俊发喷织有限公司

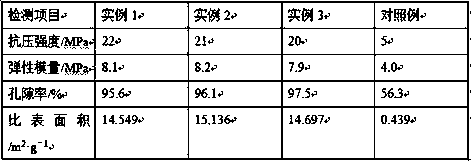

Preparation method of nano-cellulose-base porous composite material

The invention relates to a preparation method of a nano-cellulose-base porous composite material, belonging to the technical field of porous materials. The preparation method comprises the step of with bamboo raw fibers as a raw material, adding chitosan and agar, so as to prepare the nano-cellulose-base porous composite material. By adding graphene to prepare the nano-cellulose-base porous composite material, graphene belongs to a two-dimensional material and is a honeycomb-structure material formed by SP2 hybridized carbon atoms, has ultrahigh heat-conducting property, mechanical strength, gas impermeability and optical impermeability and excellent electrical conductivity and is taken as an inorganic nano-filler of the porous composite material, so that the mechanical properties of the porous composite material can be effectively improved; and by implanting carboxyl ions, the surface of graphene contains active functional groups, so that the cellular and biological reaction activities of the material are substantially improved.

Owner:赵文斌

Method for producing silver-gray, anti-ultraviolet and weather-resistant polyethylene overhead insulating material

InactiveCN101885874ASimple production processThe production process is reasonablePlastic/resin/waxes insulatorsLinear low-density polyethyleneWax

The invention discloses a silver-gray, anti-ultraviolet and weather-resistant polyethylene overhead insulating material, which relates to the technical field of production of production raw materials for cables. The insulating material mainly comprises ultraviolet absorbent, silver-gray master batch, antioxidant, PE wax, rheological agent, linear low-density polyethylene resin and high-density polyethylene resin. The insulating material is prepared from the high molecular weight polyethylene (PE) resin serving as the base material by processes of adding the silver-gray master batch, the ultraviolet absorbent and the antioxidant into the base material, and mixing, extruding, water-cooling, granulating and airing the mixture and the like. The rheological agent is colloid which enables the antioxidant and the ultraviolet absorbent to wrap the periphery of the silver-gray master batch during mixing and has better dispersibility during producing. The ultraviolet absorbent and the antioxidant have good liquidities and can be uniformly dispersed outside the silver-gray master batch at a high temperature to play a role in preventing ultraviolet rays; and the linear low-density polyethylene resin serving as a main raw material has effects on weather resistance and cracking resistance. The insulating material has good stability and uniform color.

Owner:镇国广

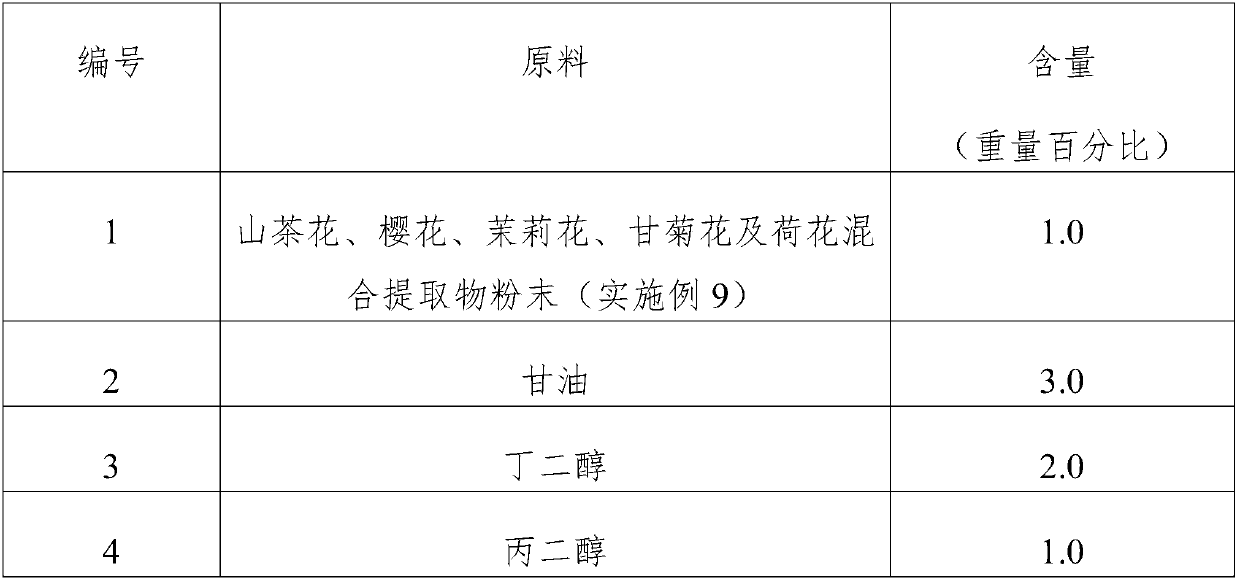

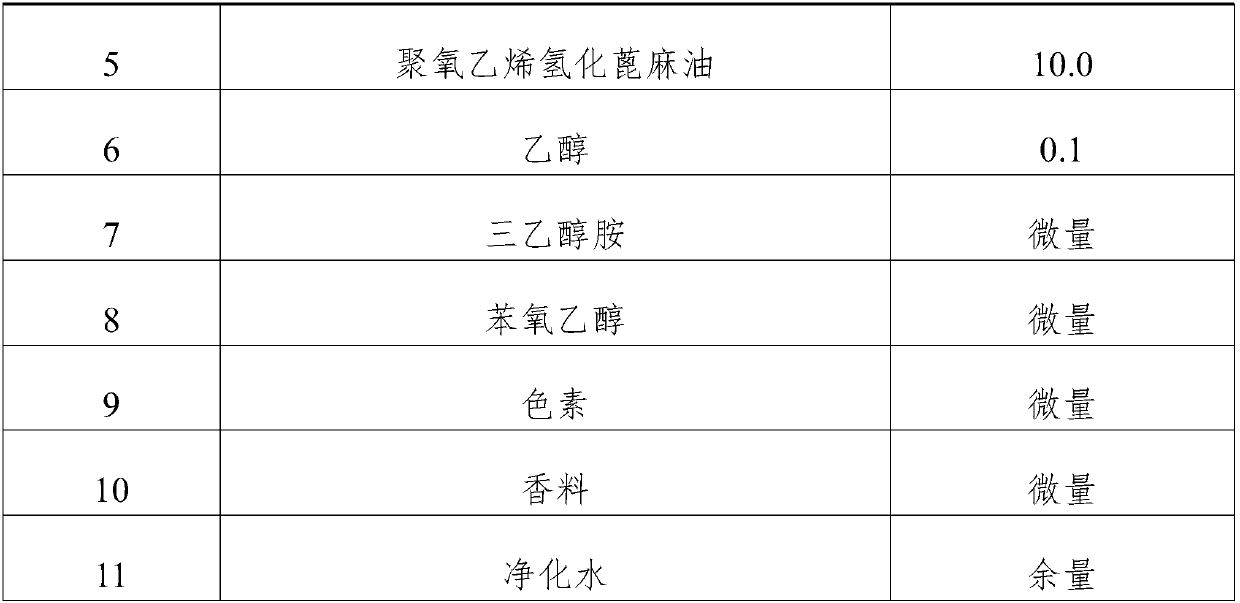

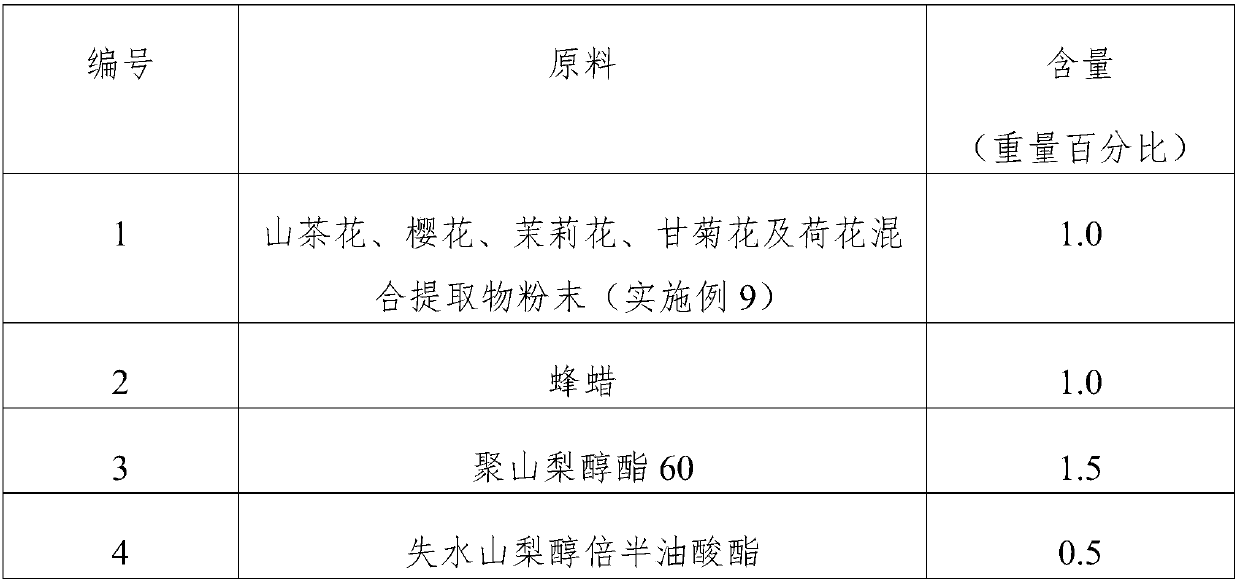

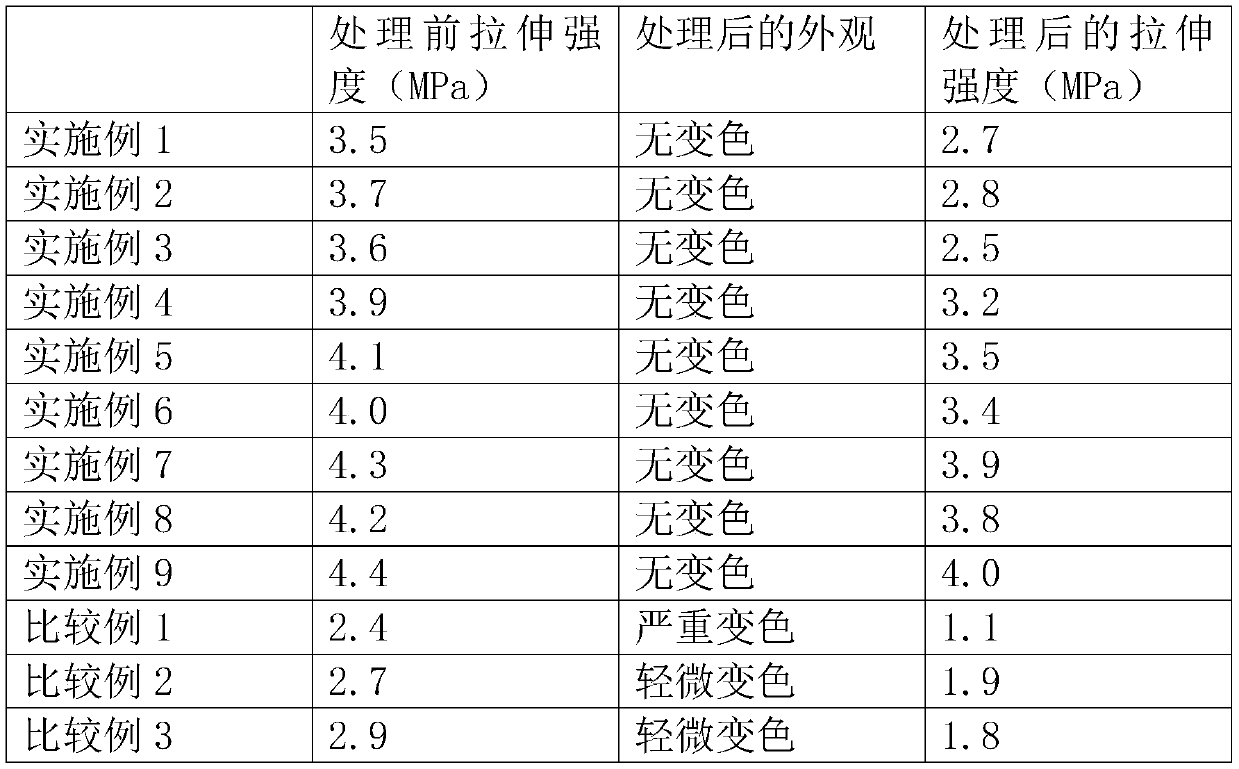

Cosmetic composition containing mixed extract of camellia flowers, cherry blossom flowers, jasmine flowers, chamomile flowers, and lotus flowers

InactiveCN107735076AImprove antioxidant capacityImprove UV protection effectCosmetic preparationsToilet preparationsUv blockingBiology

The present invention relates to a cosmetic composition containing a mixed extract of camellia flowers, cherry blossom flowers, jasmine flowers, chamomile flowers, and lotus flowers, the cosmetic composition not only being safe for the skin but also exhibiting excellent antioxidative and UV-blocking activities by a synergistic action thereof.

Owner:(株)杰恩宝

Silicon PU for plastic field material

InactiveCN110183845AExtended service lifeStrong waterproof abilityGround pavingsSilica fumePlasticizer

The invention relates to the field of plastic field materials, and provides a silicon PU for a plastic field material aiming at the problem that the service life of silicon PU is affected due to the fact that silicon PU is prone to erosion by ultraviolet rays. Silicon PU is prepared from the following components in parts by mass: 200-280 parts of polyether polyol, 70-85 parts of a plasticizer, 0.3-1 part of a dispersant, 680-750 parts of powder filler, 7-13 parts of pigment, 35-45 parts of a polyurethane curing agent, 15-30 parts of silicon powder, 0.5-3 parts of an antifoaming agent, 0.1-1 part of a leveling agent, 85-96 parts of dimethyl carbonate, 25-38 parts of methyl o-hydroxybenzoate, 0.5-1.5 parts of cellulose triacetate and 0.5-2 parts of fatty alcohol polyoxyethylene ether. By synergistic cooperation of added methyl o-hydroxybenzoate, cellulose triacetate and fatty alcohol polyoxyethylene ether, anti-ultraviolet performance of silicon PU is enhanced, waterproof performance ofsilicon PU is enhanced, tensile strength of silicon PU is not easily affected by wind, rain and sunlight, and the service life of silicon PU is prolonged.

Owner:广东领跑新材料科技有限公司

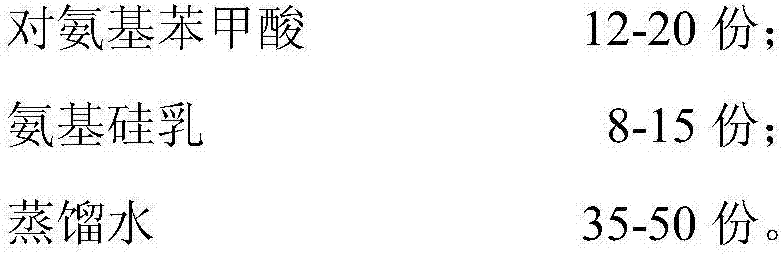

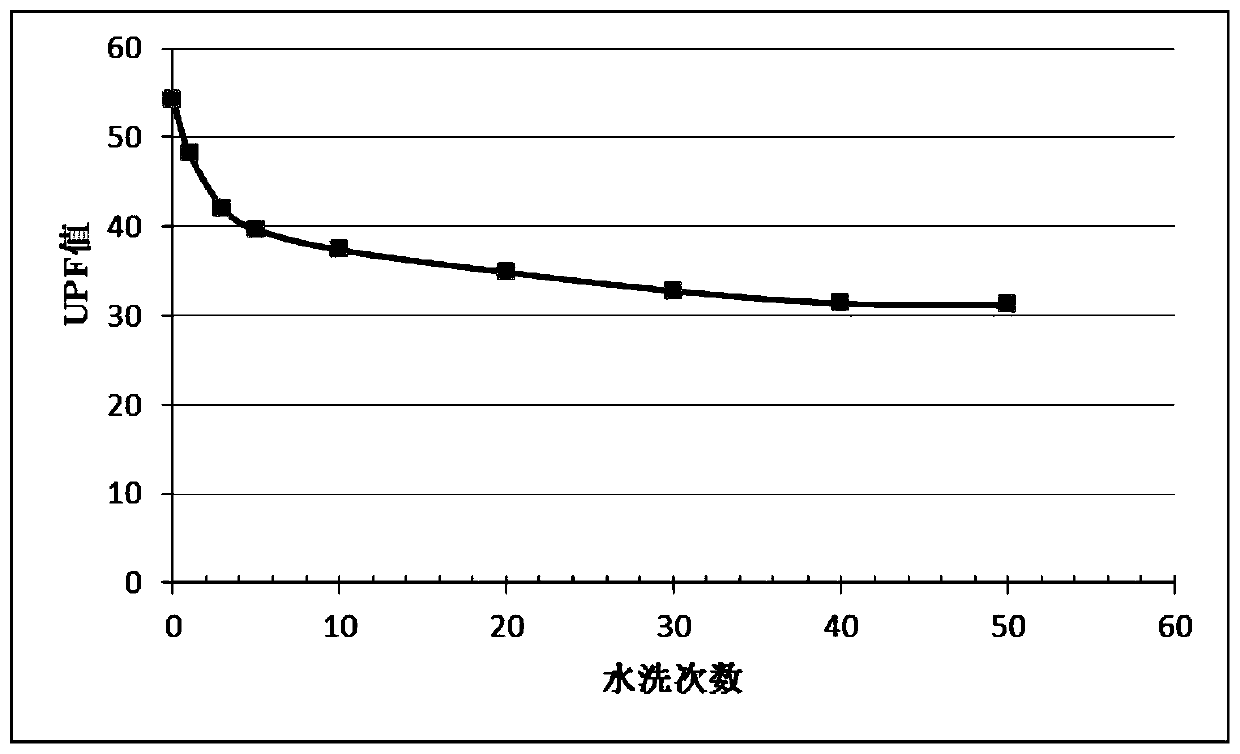

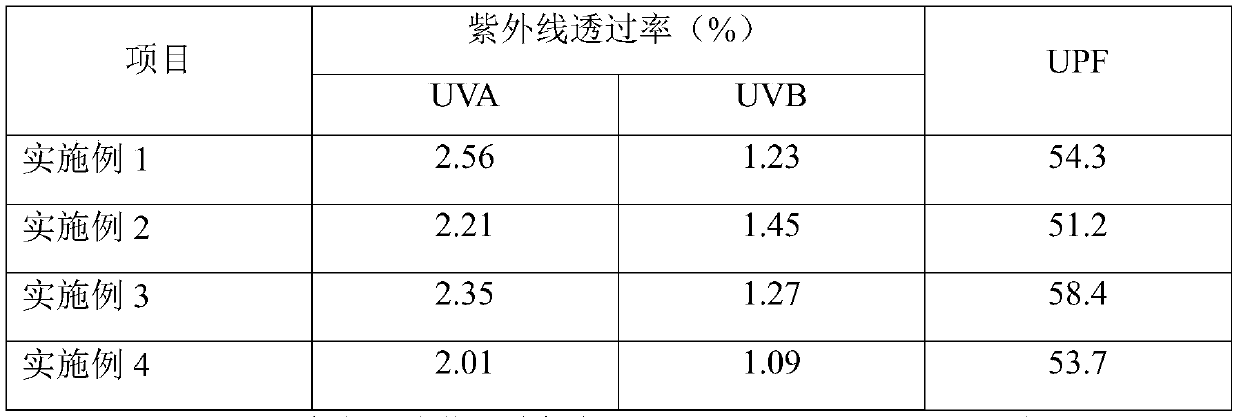

Making method of ultraviolet-proof cotton fabric

ActiveCN109853222AImprove UV protection effectGood UV protection durabilityPhysical treatmentVegetal fibresUltravioletPre treatment

The invention discloses a making method of an ultraviolet-proof cotton fabric. The method comprises the steps that firstly, chitosan is modified for preparing a modified chitosan dispersion solution,then zinc oxide is modified for preparing a modified zinc oxide dispersion solution, a cotton fabric is pretreated, subjected to padding in the modified chitosan dispersion solution for 30-50 min, roasted and then subjected to padding in the modified zinc oxide dispersion solution for 30-50 min, and circulation padding is conducted one or more times. The made cotton fabric has a good ultraviolet-proof effect and is durable, good in washing resistance, simple in process, capable of easily achieving industrialization and suitable for application and popularization.

Owner:YANCHENG INST OF TECH

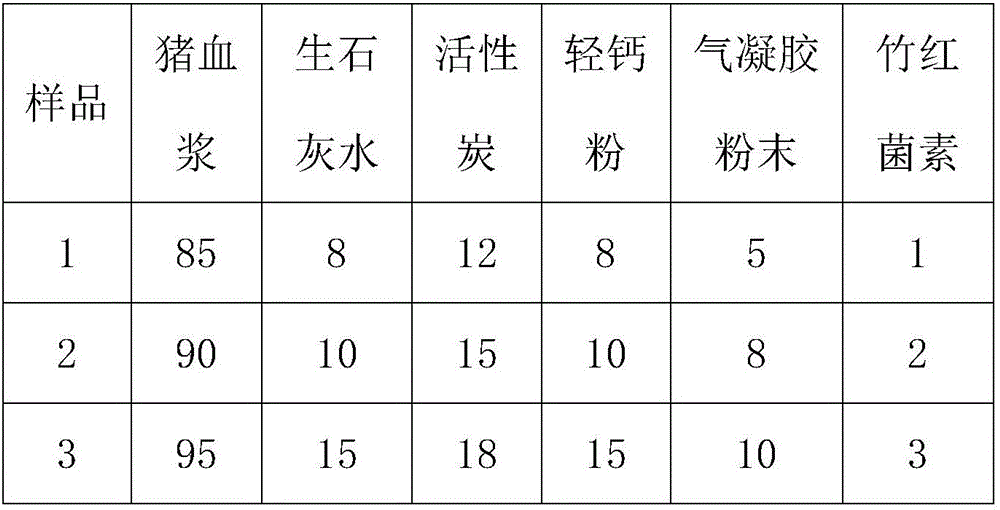

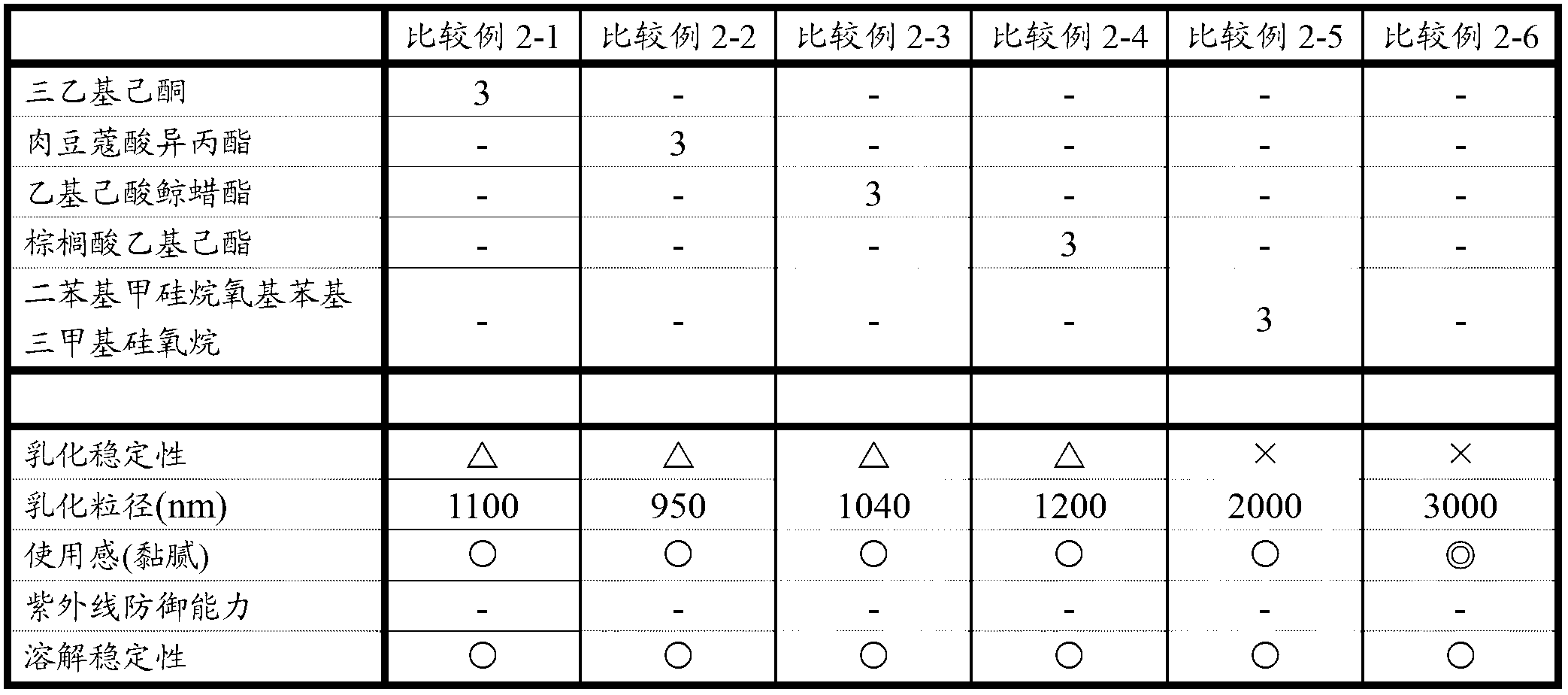

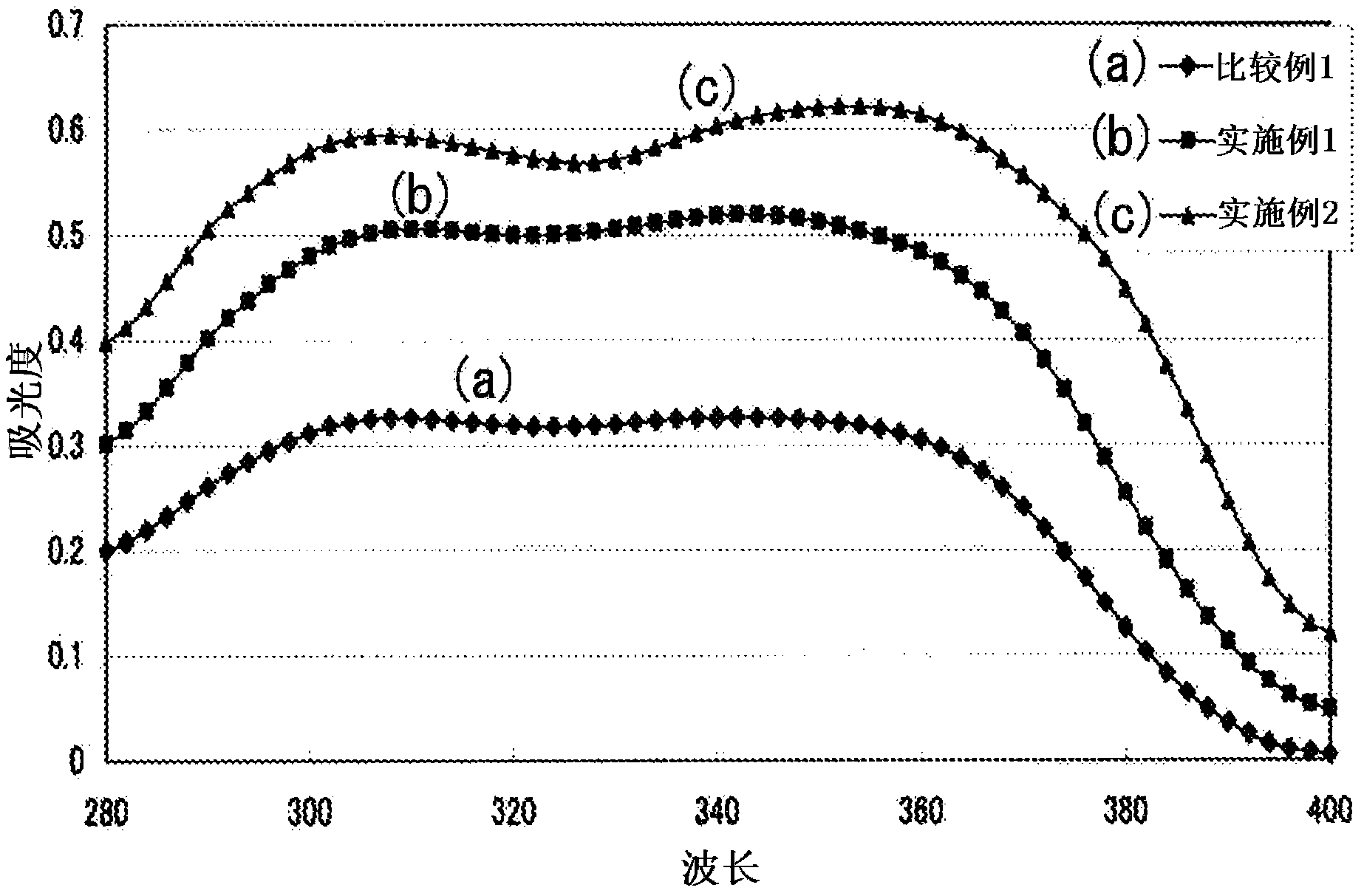

O/W emulsion composition

ActiveCN102202640AImprove UV protection effectImprove stabilityCosmetic preparationsTransportation and packagingUltraviolet lightsBis-ethylhexyloxyphenol methoxyphenyl triazine

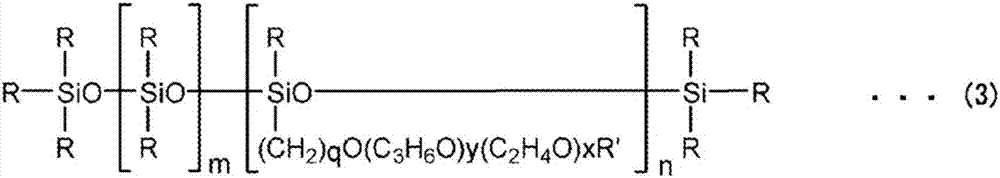

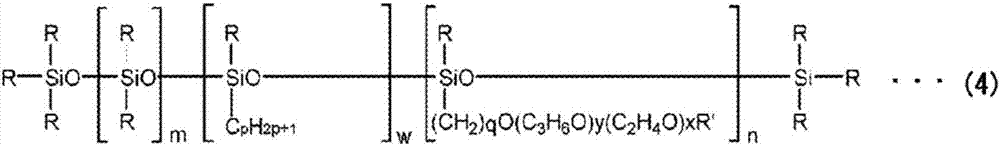

An O / W emulsion composition having excellent ultraviolet light blocking properties, preparation stability and feeling of use, wherein an oily organic ultraviolet absorbent such as octocrylene and a solid organic ultraviolet absorbent are blended. The O / W emulsion composition contains the components (a)-(c) mentioned below, and an oil phase containing the component (a) has an average particle diameter of not more than 700 nm. (a) an organic ultraviolet absorbent containing (a1) octocrylene, which is in an oil form at 20 DEG C (b) an organic ultraviolet absorbent selected from (b1) bis-ethylhexyloxyphenol methoxyphenyl triazine and (b2) methylene bis-benztriazolyl tetramethylbutylphenol, which is in a solid state at 20 DEG C (c) a polyoxyethylene / polyoxyalkylene alkyl ether block polymer represented by general formula (1) or (2): R1O-(PO)m-(EO)n-H (1) (In the formula, R1 represents a hydrocarbon group having 16-18 carbon atoms; PO represents an oxypropylene group; EO represents an oxyethylene group; PO and EO are added in blocks; and m and n respectively represent average mole numbers of added PO and EO and satisfy 70 > m > 4, 70 > n > 10 and n > m.) R2O-(AO)p-(EO)q-R3 (2) (In the formula, R2 and R3 may be the same or different and each represents a hydrocarbon group having 1-4 carbon atoms; AO represents an oxyalkylene group having 3-4 carbon atoms; EO represents an oxyethylene group; AO and EO are added in blocks; and p and q respectively represent average mole numbers of added AO and EO and satisfy 1 = p = 70, 1 = q = 70 and 0.2 < (q / (p + q)) < 0.8.)

Owner:SHISEIDO CO LTD

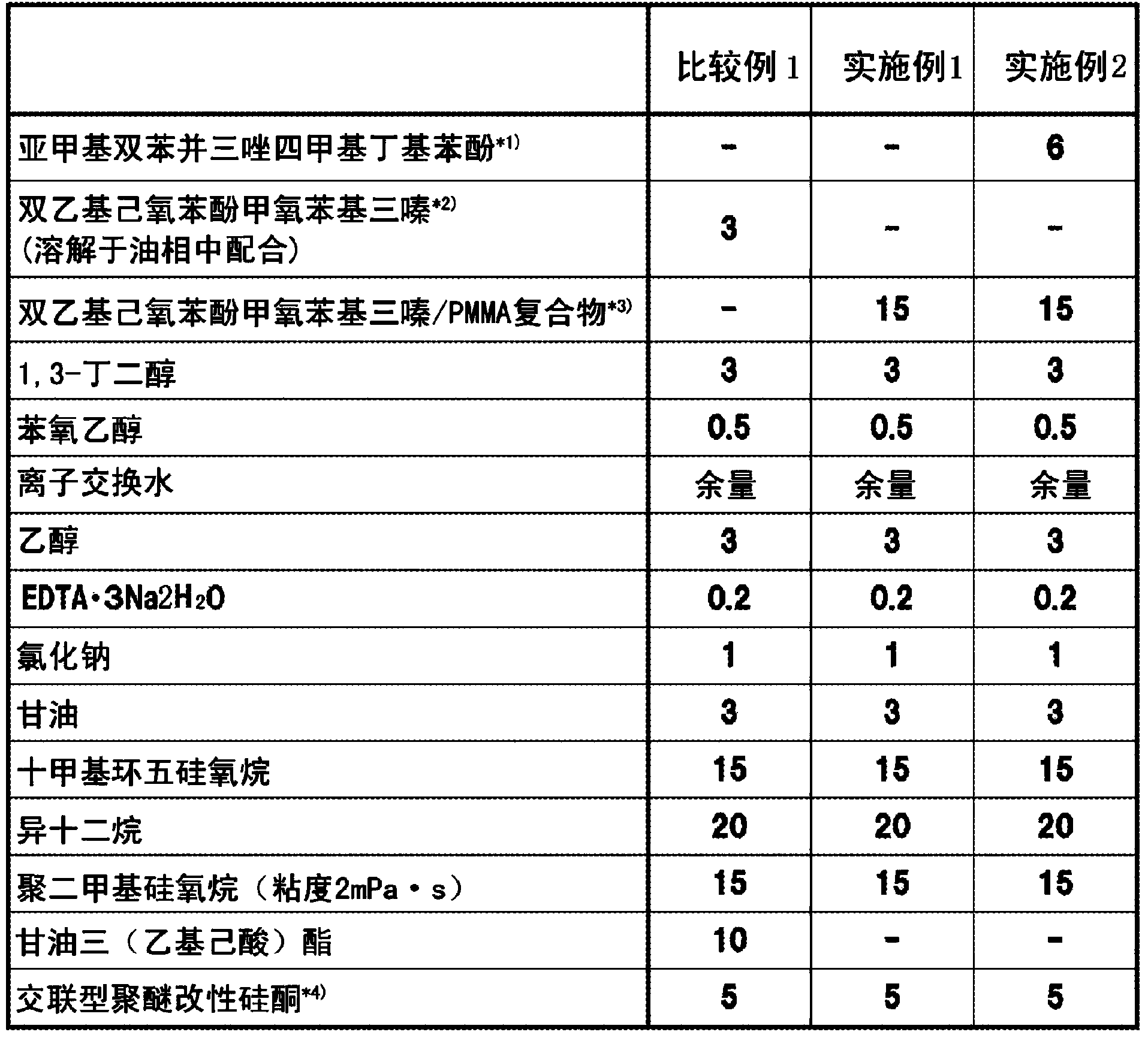

Sunscreen cosmetic

InactiveCN103402488AHigh UV protection effectImprove UV protection effectCosmetic preparationsToilet preparationsUltravioletOrganic polymer

Owner:SHISEIDO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com