Ash oil putty for ancient architecture material and preparation method thereof

A technology of ancient buildings and gray oil, which is applied in the field of gray oil putty of ancient building materials and its preparation, can solve the problems of insufficient pulling force and low viscosity of gray oil putty, and achieve the effects of enhanced pulling force, good viscosity and elimination of taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the gray oil that is used for ancient building material of present embodiment 1, comprises the following steps:

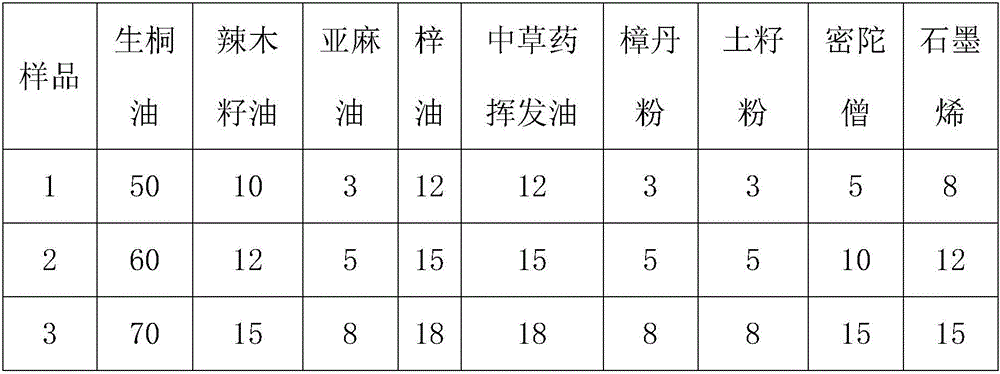

[0048] Step 1, prepare each raw material according to the gray oil described in above-mentioned table 1 record;

[0049] Step 2. Preparation of mixed vegetable oil: Add raw tung oil into the reaction tank, heat it to 180°C, and keep it warm for 30 minutes. During the heating and heat preservation process, keep the raw tung oil in an oxygen-enriched atmosphere, and control the oxygen-enriched atmosphere to the volume of oxygen The score is 48%. Then add Moringa seed oil, linseed oil and catalpa oil to raw tung oil, mix well and heat up to 200°C to obtain mixed vegetable oil;

[0050] Step 3, preparation of mixed powder: adding camphordan powder and earth seed powder to graphene powder, and grinding for 90 minutes in a planetary grinder to obtain mixed powder;

[0051] Step 4. Add the mixed powder obtained in Step 3 to the mixed veg...

Embodiment 2

[0052] Example 2 blood samples

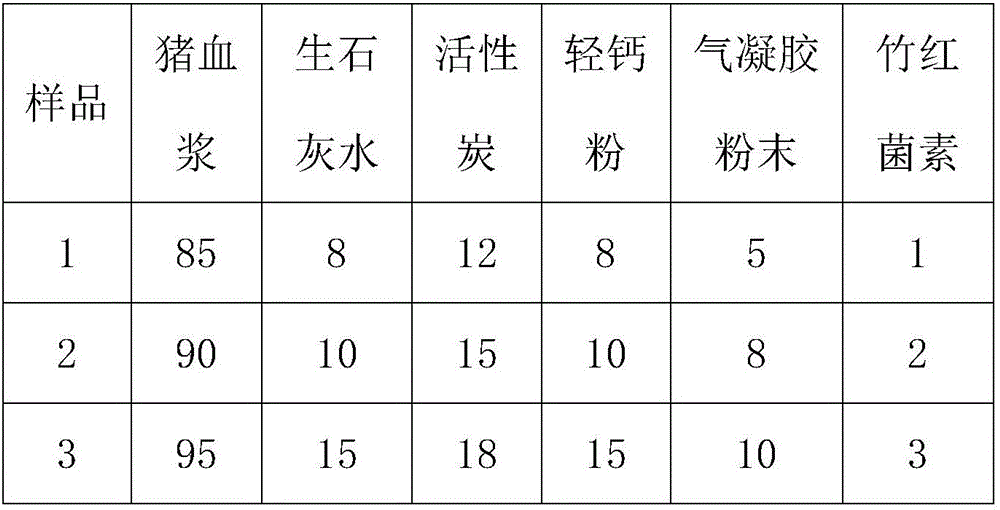

[0053] The blood material of this embodiment 2 is to be made by the raw material that comprises the following parts by weight: 85-95 parts of pig plasma with moisture content lower than 50%, 8-15 parts of quicklime water, 12-18 parts of activated carbon, 8 parts of light calcium powder -15 parts, 5-10 parts of airgel powder and 1-3 parts of hypocrellin.

[0054] Wherein, the particle size of the activated carbon is 1-10 μm, the particle size of the light calcium powder is 200-800 nm, and the particle size of the airgel powder is 20-50 μm; The mass ratio is 1:8-10, obtained by dissolving quicklime in water.

[0055] Specifically, it can be prepared by using specific raw materials in parts by weight as shown in Table 2 below.

[0056] Table 2

[0057]

[0058] The preparation method of the blood material of the present embodiment 2 comprises the following steps:

[0059] Step 1. Prepare pig plasma with a water content lower than 50%: coagu...

Embodiment 4

[0070] Embodiment 4 gray oil putty

[0071] The ash oil putty for ancient building materials of this embodiment 4 includes the ash oil of embodiment 1, the blood material of embodiment 2 and the brick ash of embodiment 3, wherein, control described ash oil, blood material and brick ash The mass ratio is 1:1-3:5-10. Mix the three together in proportion, and you get it.

[0072] Specifically, the gray oil putty sample 1 includes the gray oil sample 1 of embodiment 1, the blood material sample 1 of embodiment 2 and the brick ash sample 1 of embodiment 3, wherein the control of the gray oil, blood material and brick ash sample The mass ratio is 1:1:5. Mix the three together in proportion, and you get it.

[0073] Gray oil putty sample 2, comprising the gray oil sample 2 of embodiment 1, the blood material sample 2 of embodiment 2 and the brick ash sample 2 of embodiment 3, wherein, control the mass ratio of described gray oil, blood material and brick ash It is 1:2:7. Mix the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com