Making method of ultraviolet-proof cotton fabric

A technology of anti-ultraviolet and cotton fabrics, which is applied in the field of preparation of anti-ultraviolet cotton fabrics, can solve the problems of lack of anti-ultraviolet effect, long-lasting anti-ultraviolet effect, poor anti-ultraviolet effect of anti-ultraviolet fabrics, etc., and achieve good anti-ultraviolet effect, The effect of good UV protection durability and strong resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

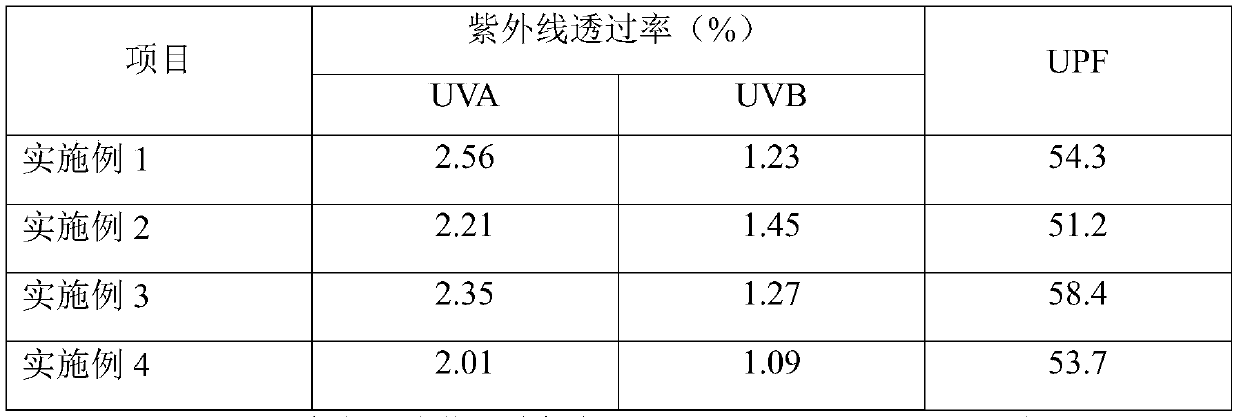

Embodiment 1

[0021] A preparation method of an anti-ultraviolet cotton fabric, comprising the following specific steps:

[0022] Step 1, preparation of modified chitosan dispersion: weigh 1g of chitosan, dissolve in 5mL of glacial acetic acid, add 95mL of deionized water, stir continuously for 2h, then add 5mL of 0.1mol / L magnesium chloride solution, and stir for 40min , to obtain a modified chitosan dispersion;

[0023] Step 2, preparation of modified zinc oxide dispersion: Weigh 1g of graphene oxide and dissolve it in deionized water, ultrasonically disperse for 30min, then add 10g of zinc oxide and 0.01g of cerium nitrate, stir evenly, and then add 50mL of 2mol / L KOH solution to it , after stirring again, move it into the reaction kettle and react at 180°C for 20h; after the reaction is completed, wash and dry; then sinter at 400°C for 6h under the condition of Ar gas; Active zinc oxide dispersion;

[0024] Step 3, pretreatment of cotton fabric: cotton fabric is irradiated under ultra...

Embodiment 2

[0027] A preparation method of an anti-ultraviolet cotton fabric, comprising the following specific steps:

[0028] Step 1, prepare modified chitosan dispersion: weigh 2g chitosan, dissolve in 2mL glacial acetic acid, add 98mL deionized water, stir continuously for 2h, then add 0.1mol / L magnesium chloride solution 3mL, stir 50min , to obtain a modified chitosan dispersion;

[0029] Step 2, preparation of modified zinc oxide dispersion: weigh 1g of graphene oxide and dissolve it in deionized water, ultrasonically disperse for 30min, then add 20g of zinc oxide and 0.1g of cerium nitrate, stir well, then add 5mol / L KOH solution 50mL to it , after stirring again, move it into the reaction kettle and react at 250°C for 14h; after the reaction is completed, wash and dry; then sinter at 600°C for 4h under the condition of Ar / H2 mixed gas; The modified zinc oxide dispersion is obtained;

[0030] Step 3, pretreatment of cotton fabric: cotton fabric is irradiated under ultraviolet lig...

Embodiment 3

[0033] A preparation method of an anti-ultraviolet cotton fabric, comprising the following specific steps:

[0034] Step 1, prepare modified chitosan dispersion: weigh 5g chitosan, dissolve in 4mL glacial acetic acid, add 96mL deionized water, stir continuously for 2h, then add 0.1mol / L magnesium chloride solution 3mL, stir for 40min , to obtain a modified chitosan dispersion;

[0035] Step 2, preparation of modified zinc oxide dispersion: Weigh 1 g of graphene oxide and dissolve it in deionized water, ultrasonically disperse for 30 minutes, then add zinc oxide and cerium nitrate, stir evenly, then add 50 mL of 5mol / L KOH solution to it, and again After stirring, move it into a reaction kettle and react at 200°C for 16 hours; after the reaction is completed, wash and dry; then sinter at a high temperature of 500°C for 5 hours under the condition of He gas; Zinc dispersion;

[0036] Step 3, pretreatment of cotton fabric: irradiating cotton fabric under ultraviolet light for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com