Silicon PU for plastic field material

A field and plastic technology, used in buildings, roads, pavements, etc., can solve problems such as affecting the service life of silicon PU, loss of strength, hardening, etc., and achieve the effect of not easy wind and rain erosion, improved compactness, and good UV resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

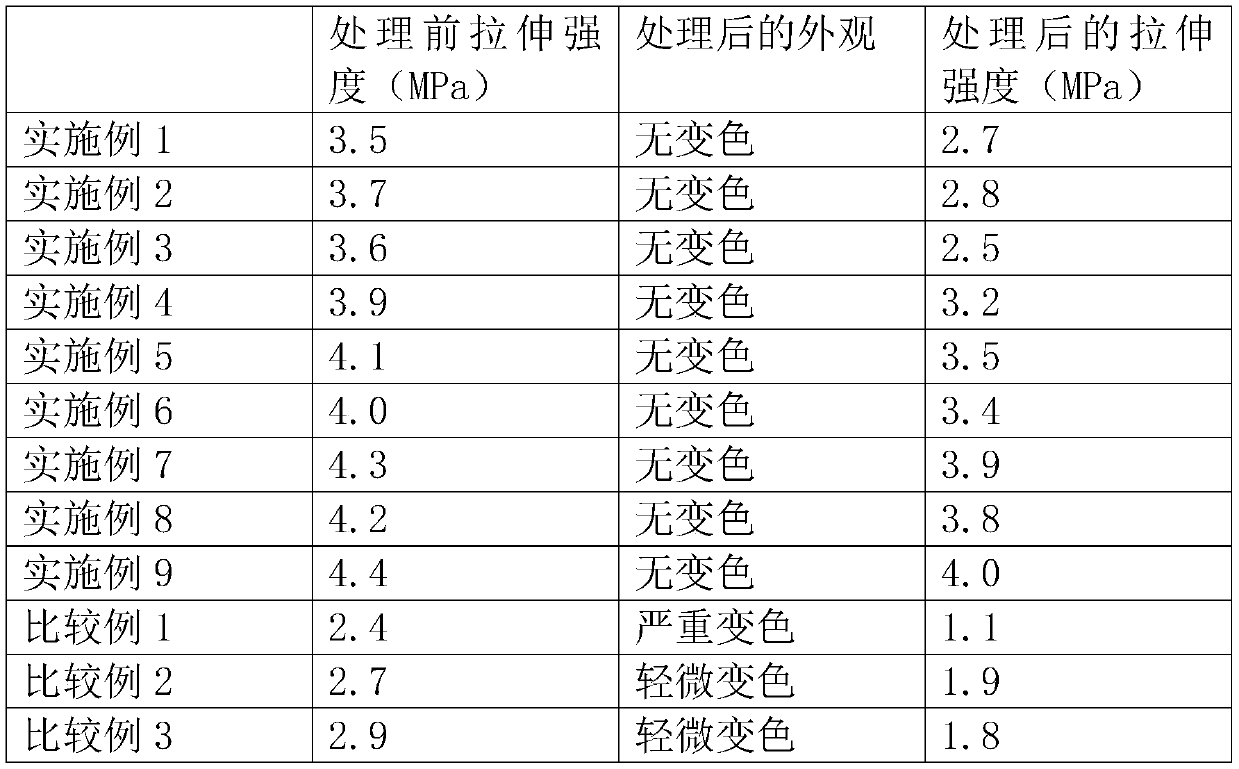

Examples

Embodiment 1

[0084] A silicon PU for plastic field materials, comprising the following components in parts by mass:

[0085] Polyether polyol 200kg; plasticizer 85kg; dispersant 0.5kg; talcum powder 660kg; kaolin 60kg; colorant 13kg; polyurethane curing agent 43kg; Methyl ester 96kg; methyl o-hydroxybenzoate 28kg; cellulose triacetate 0.5kg; fatty alcohol polyoxyethylene ether 2kg.

[0086] In this embodiment, the particle size of the talc powder is 400 mesh.

[0087] In this embodiment, the particle size of kaolin is 600 mesh.

[0088] The preparation method of silicon PU for plastic field materials is as follows:

[0089] S1, add polyether polyol 200kg, plasticizer 85kg in reactor;

[0090] S2. Raise the temperature in the reactor to 40°C, add 660kg of talcum powder, 60kg of kaolin and 13kg of colorant, and raise the temperature while adding;

[0091] S3. Raise the temperature in the reactor to 165° C., and perform dehydration operation;

[0092] S4. After dehydration for 0.5h, redu...

Embodiment 2

[0096] A silicon PU for plastic field materials, comprising the following components in parts by mass:

[0097] Polyether polyol 250kg; plasticizer 70kg; dispersant 1kg; talcum powder 655kg; kaolin 35kg; colorant 7kg; polyurethane curing agent 45kg; silicon powder 25kg; ; Methyl o-hydroxybenzoate 38kg; Cellulose triacetate 1.3kg; Fatty alcohol polyoxyethylene ether 0.5kg.

[0098] In this embodiment, the particle size of the talc powder is 600 mesh.

[0099] In this embodiment, the particle size of kaolin is 700 mesh.

[0100] The preparation method of silicon PU for plastic field materials is as follows:

[0101] S1, add polyether polyol 250kg, plasticizer 70kg in reactor;

[0102] S2. Raise the temperature in the reactor to 45°C, add 655kg of talcum powder, 35kg of kaolin and 7kg of colorant, and raise the temperature while adding;

[0103] S3. Raise the temperature in the reactor to 168° C., and perform dehydration operation;

[0104] S4. After dehydration for 0.6h, re...

Embodiment 3

[0108] A silicon PU for plastic field materials, comprising the following components in parts by mass:

[0109] Polyether polyol 280kg; plasticizer 83kg; dispersant 0.3kg; talcum powder 650kg; kaolin 30kg; colorant 11kg; polyurethane curing agent 35kg; Methyl ester 85kg; methyl o-hydroxybenzoate 25kg; cellulose triacetate 1.5kg; fatty alcohol polyoxyethylene ether 1.5kg.

[0110] In this embodiment, the particle size of the talc powder is 800 mesh.

[0111] In this embodiment, the particle size of kaolin is 800 mesh.

[0112] The preparation method of silicon PU for plastic field materials is as follows:

[0113] S1, add polyether polyol 280kg, plasticizer 83kg in reactor;

[0114] S2. Raise the temperature in the reactor to 50°C, add 650kg of talcum powder, 30kg of kaolin and 11kg of colorant, and raise the temperature while adding;

[0115] S3. Raise the temperature in the reactor to 170° C., and perform dehydration operation;

[0116] S4, after dehydration for 0.5h, re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com