Patents

Literature

534 results about "Ultraviolet protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yes, ultraviolet (UV) eye protection matters. UV radiation from the sun can damage not only the skin of your eyelid but also the cornea, lens and other parts of the eye. UV exposure also contributes to the development of certain types of cataracts, growths on the eye and possibly macular degeneration.

Pressure-sensitive adhesive sheet

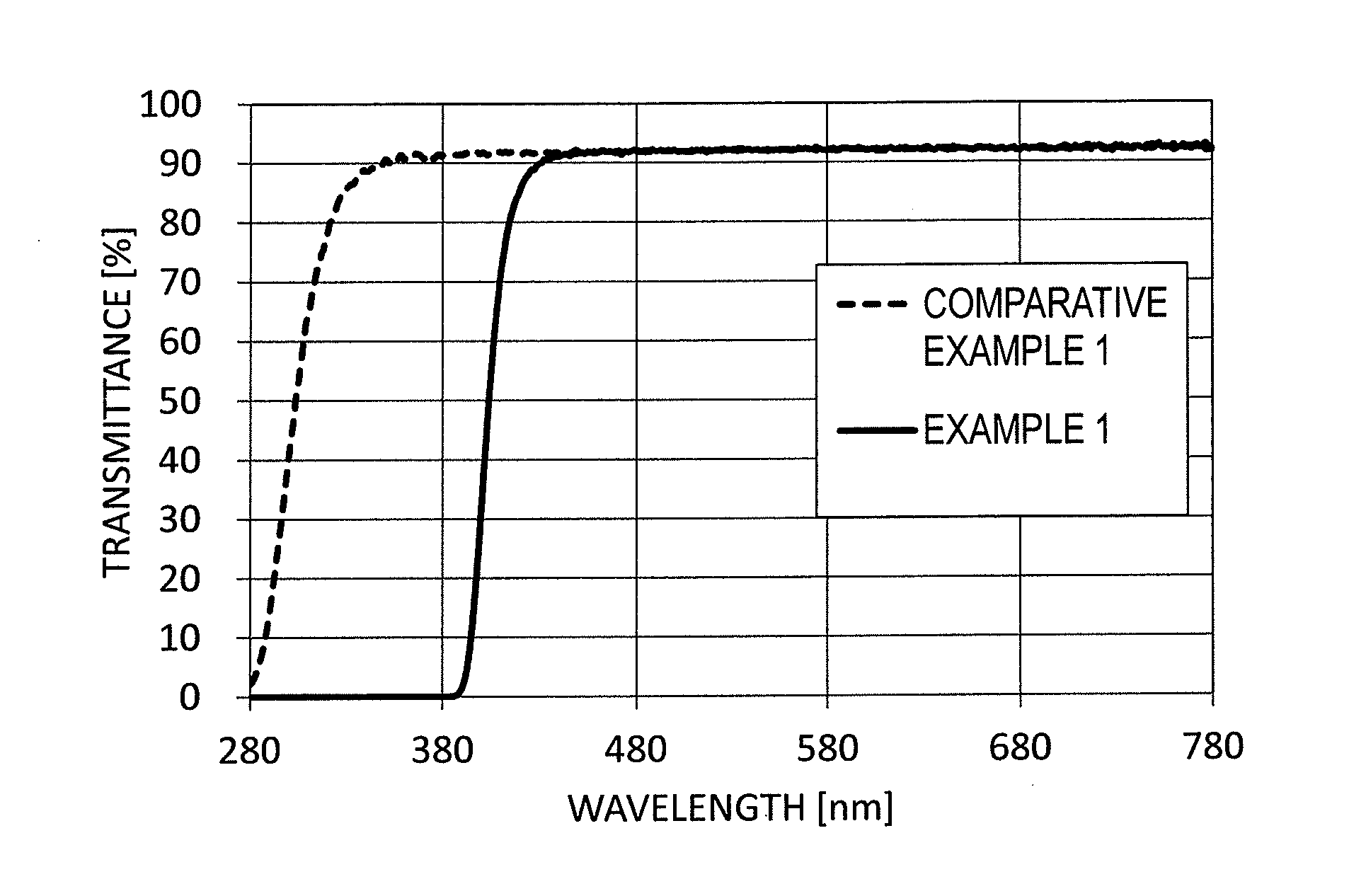

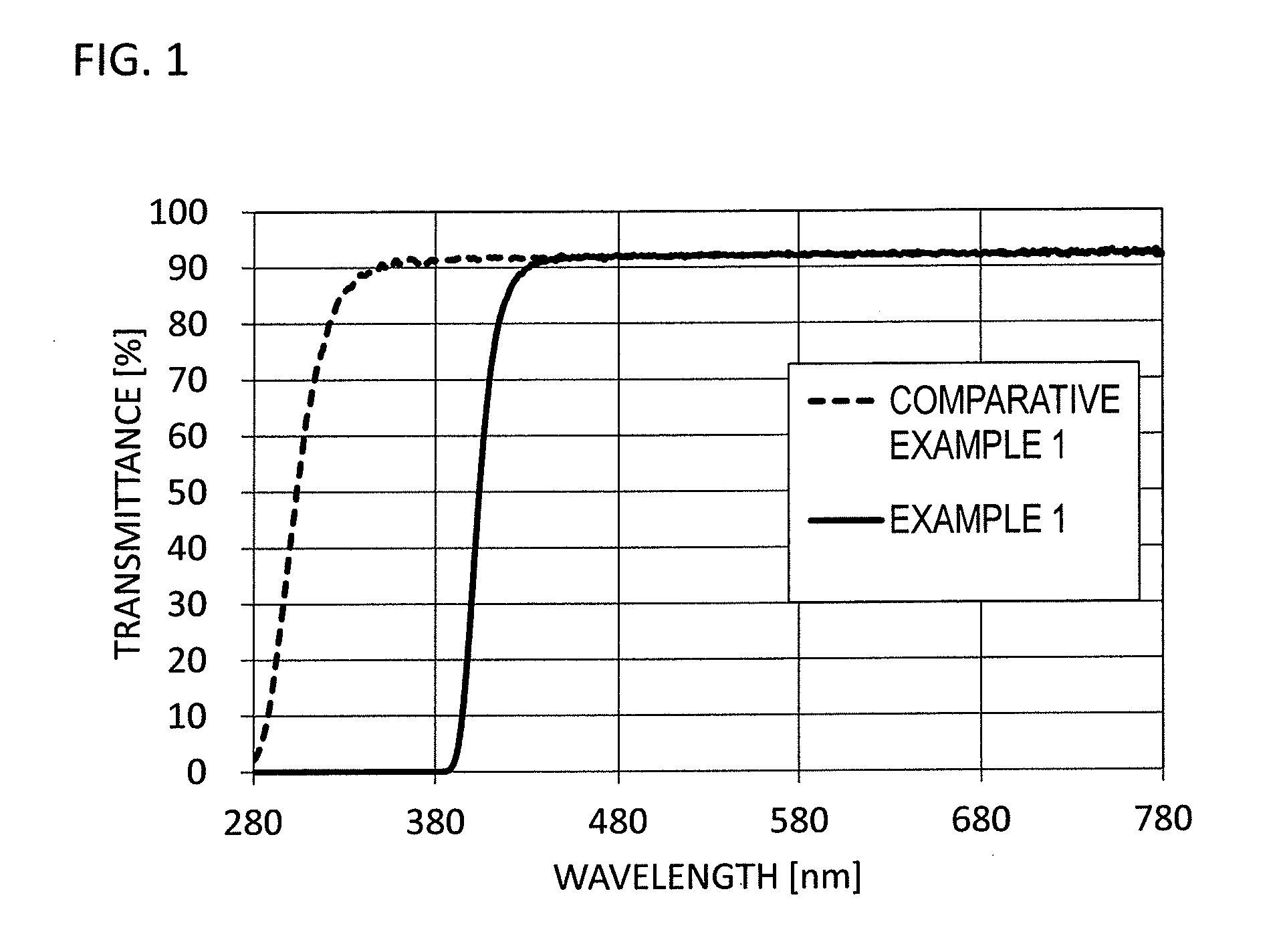

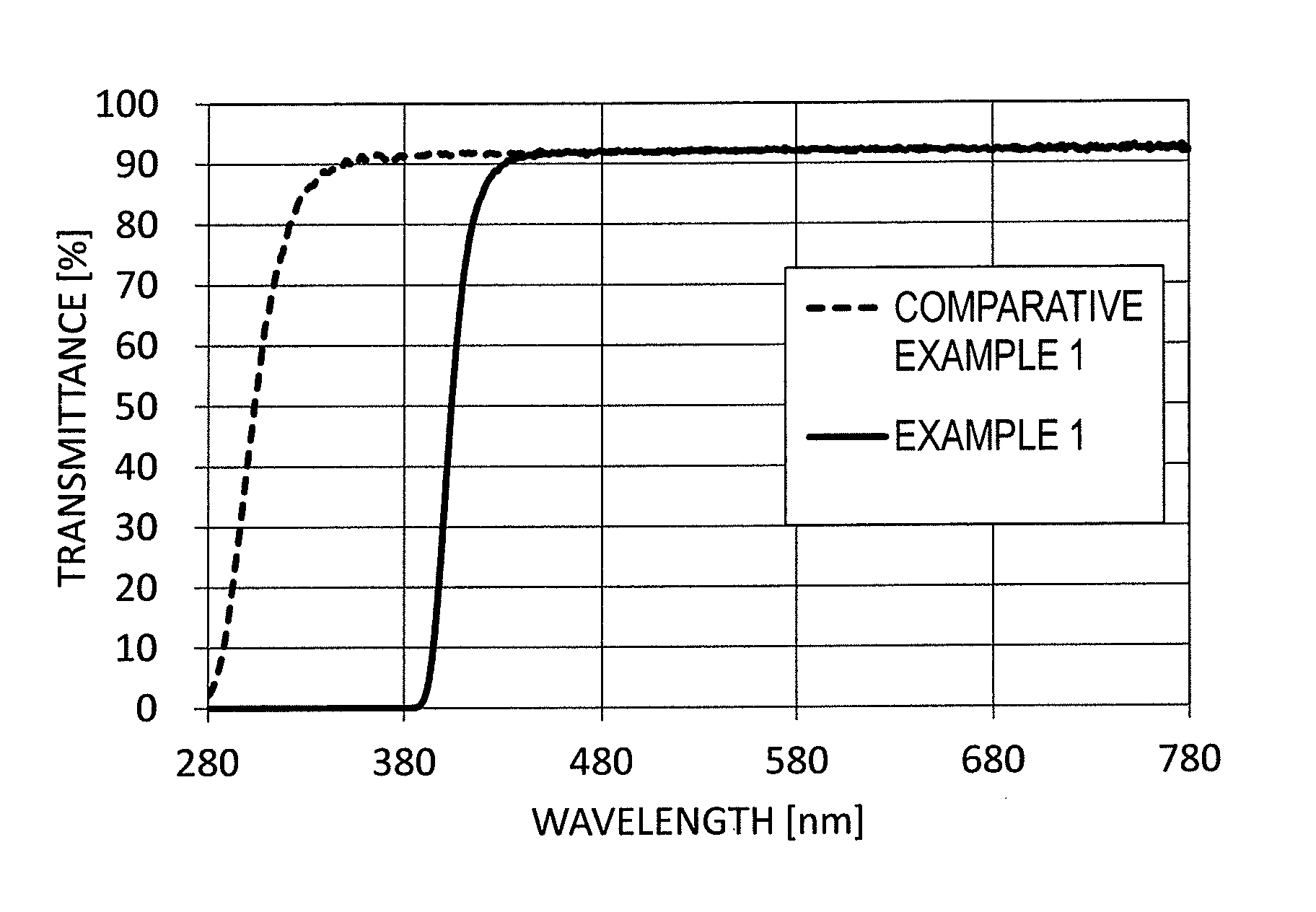

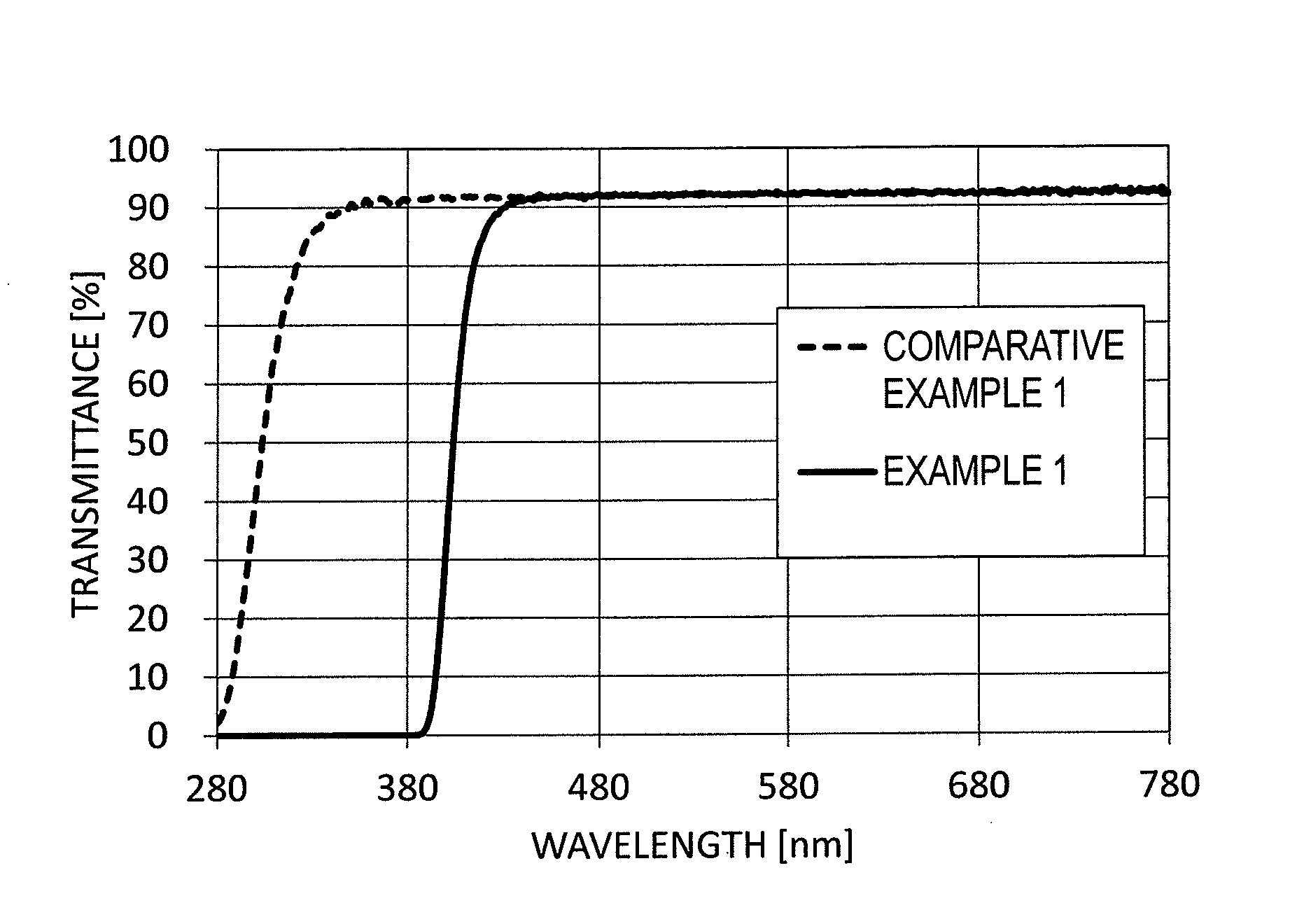

ActiveUS20130085215A1Improves UV protectionRetaining optical characteristicNon-macromolecular adhesive additivesEster polymer adhesivesDisplay deviceEngineering

The present invention realizes a display device or input device having excellent ultraviolet protection property for the touch panel, display element or the like, while retaining optical characteristics, even when a small amount of or no optical film is used. The pressure-sensitive adhesive sheet of the present invention has a total light transmittance of 85% or more, a light transmittance at a wavelength of 380 nm of 5% or less, and a haze of 3% or less. The pressure-sensitive adhesive sheet preferably includes a pressure-sensitive adhesive layer containing an acrylic polymer and a triazine-based ultraviolet absorber.

Owner:NITTO DENKO CORP

Ultraviolet-proof environmental-friendly polyvinyl chloride (PVC) modified material and preparation method thereof

Owner:广东祺龙科技有限公司

Pressure-sensitive adhesive sheet

ActiveUS9045670B2Improves UV protectionRetaining optical characteristicNon-macromolecular adhesive additivesSynthetic resin layered productsDisplay deviceEngineering

The present invention realizes a display device or input device having excellent ultraviolet protection property for the touch panel, display element or the like, while retaining optical characteristics, even when a small amount of or no optical film is used. The pressure-sensitive adhesive sheet of the present invention has a total light transmittance of 85% or more, a light transmittance at a wavelength of 380 nm of 5% or less, and a haze of 3% or less. The pressure-sensitive adhesive sheet preferably includes a pressure-sensitive adhesive layer containing an acrylic polymer and a triazine-based ultraviolet absorber.

Owner:NITTO DENKO CORP

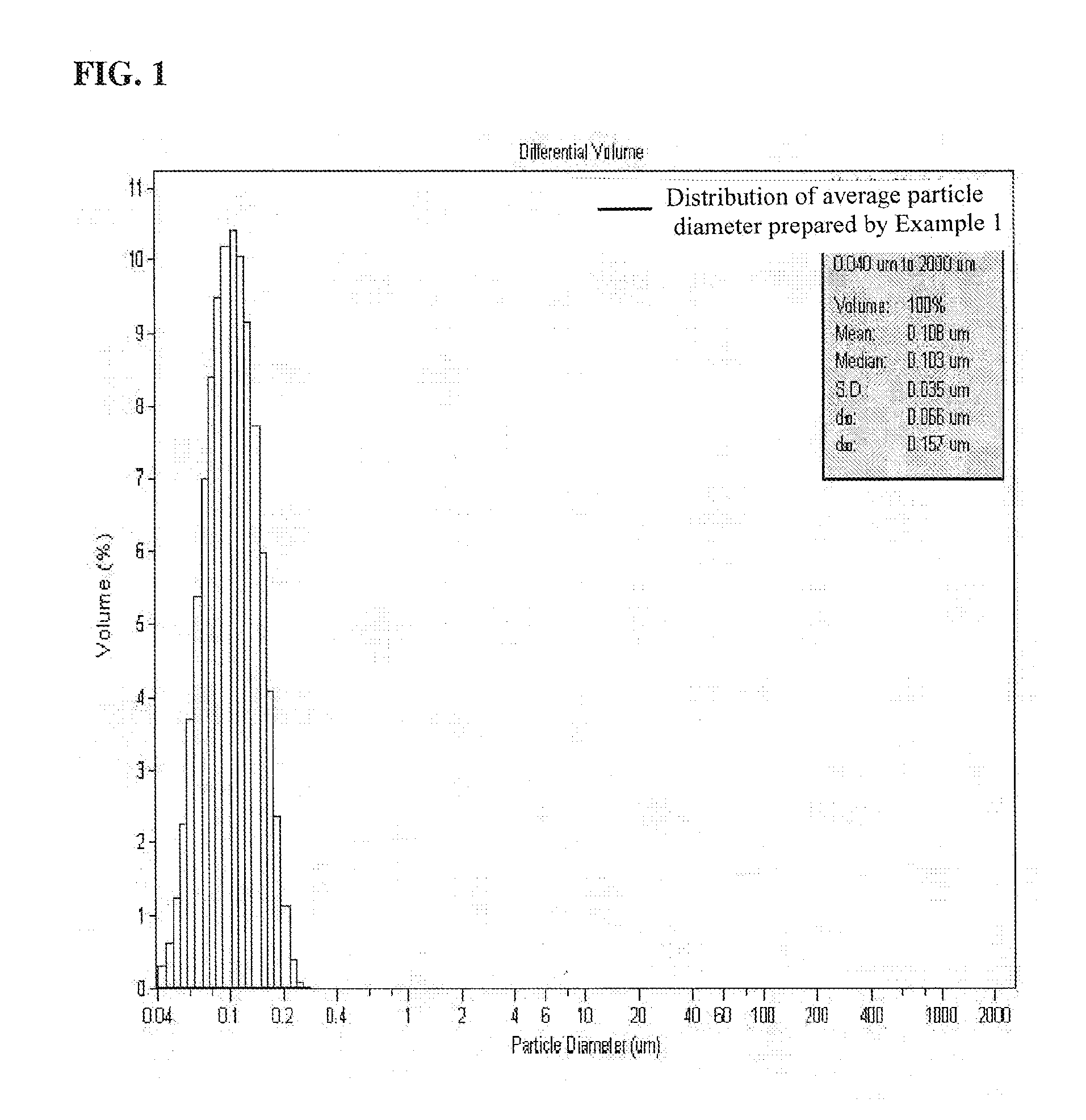

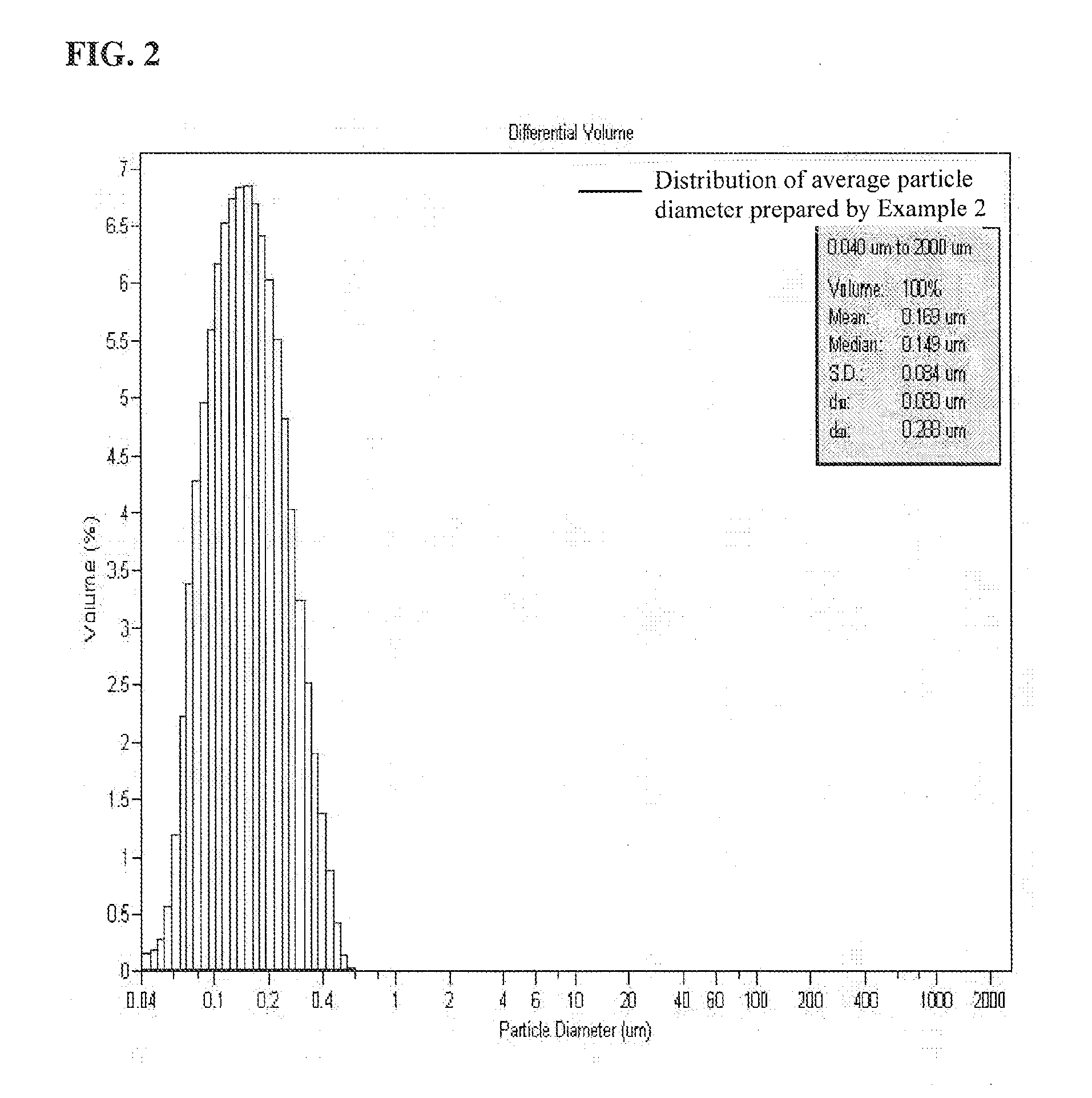

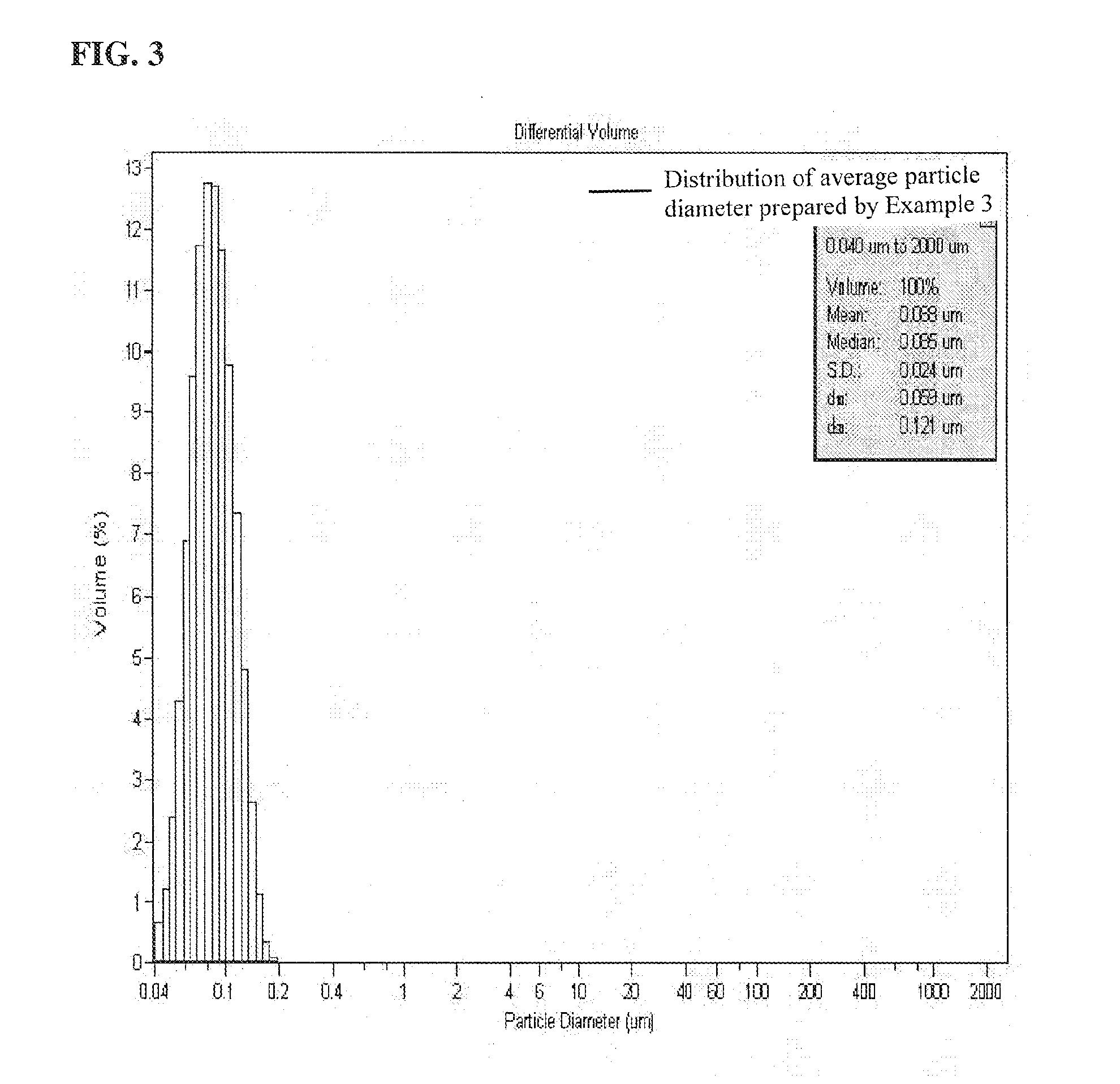

Disperse system having fine powder-typed inorganic metal oxide dispersed in water and preparing method for the same

InactiveUS20080188574A1Easy to cleanFeel lightCosmetic preparationsOther chemical processesAlkoxylationAqueous dispersion

This invention provides a disperse system having fine powder-typed inorganic metal oxide dispersed in water and preparing method for the same and more particularly, it provides a method for preparing a disperse system having fine powder-typed inorganic metal oxide dispersed in water characterized in that a) a hydrophobically treated fine powder-typed inorganic metal oxide; b) a sulfosuccinate or sulfosuccinamate or an alkoxylated alcohol dispersant; and c) water are mixed and dispersed by a high-speed bead mill and a disperse system having fine powder-typed inorganic metal oxide dispersed in water prepared by the same.The disperse system having fine powder-typed inorganic metal oxide dispersed in water of the present invention has excellent characteristics in that it has high transparency in the visible ray spectrum, it has excellent UV protection ability when applied to cosmetics, it provides better feelings than oil dispersions, and it has better water-proof property than existing water dispersions.

Owner:SUNJIN BEAUTY SCI CO LTD +1

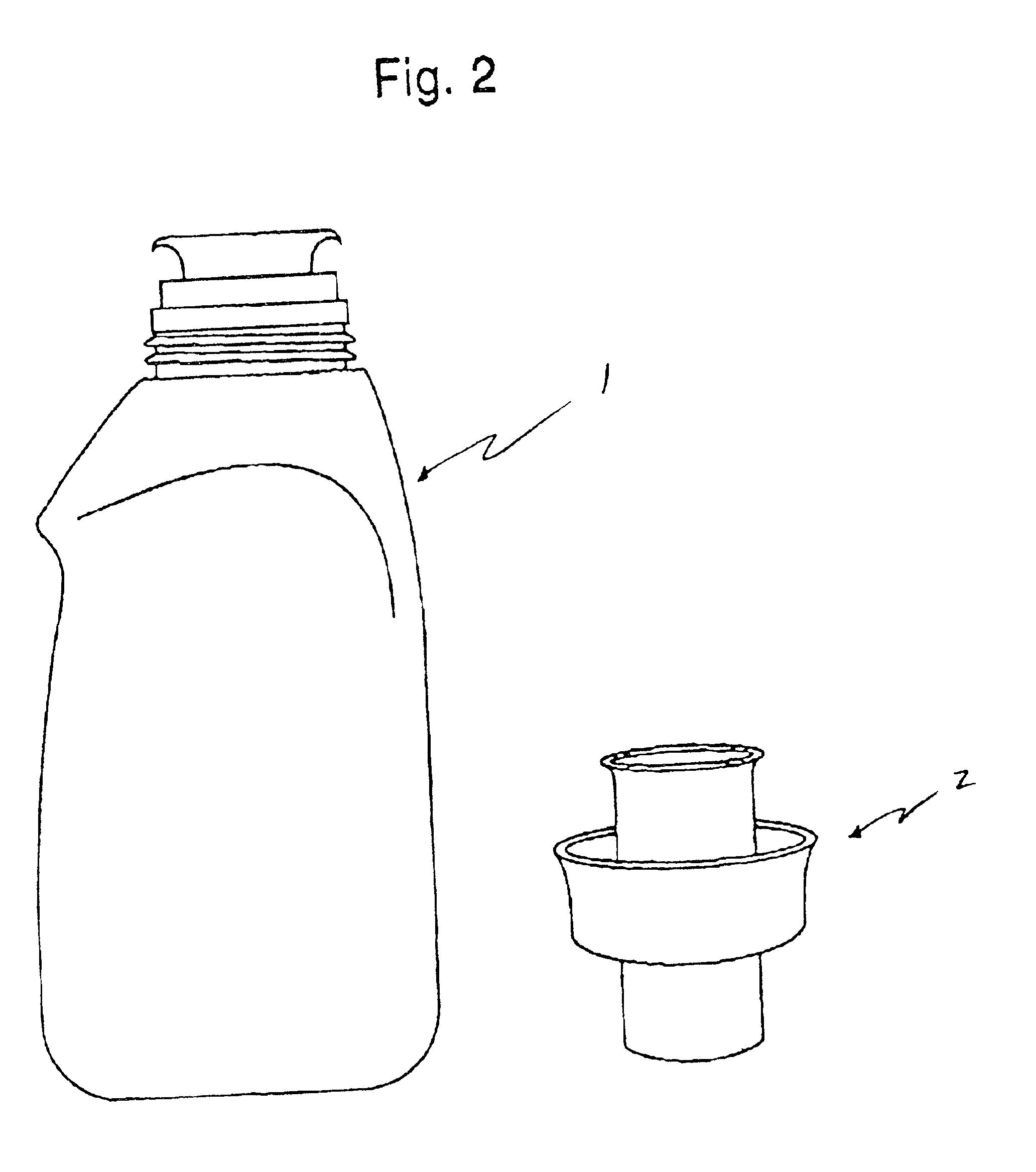

Multi-phase fabric care composition for delivering multiple fabric care benefits

A liquid rinse-added fabric care composition that is characterized by at least two visually distinct phases when the composition is at rest and wherein at least one of the phases contains a fabric care agent is provided. The composition forms a temporary mixture when shaken that allows a consumer to dose a representative sample of the composition and spontaneously re-forms at least two visually distinct phases when allowed to remain at rest. The fabric care agents present in one or more phases of the composition may include fabric softener actives, color care agents, perfumes, antibacterial agents, malodor control agents, ultraviolet protection agents, anti-abrasion, anti-wear & fabric integrity agents, wrinkle control agents, and mixtures thereof. The composition should also contain less than about 5%, preferably less than about 3%, and even more preferably less than about 1% by weight of detergent actives. The composition optionally may contain an electrolyte, phase stabilizer, a phase separation inducing polymer and / or a solvent. Methods for delivering one or more fabric care benefits to a fabric during a laundering operation using the compositions are also disclosed. Methods for conveying information to a consumer concerning a multi-phase liquid rinse-added fabric care composition are also provided. An article of manufacture comprising a liquid rinse-added fabric care composition that has at least two visually distinct phases and a container that enables a consumer to view the visually distinct phases that are present in the composition is also described. Alternatively, the container may comprise a double walled cap and an insert for removing excess composition that may adhere to the cap.

Owner:THE PROCTER & GAMBLE COMPANY

Large ultraviolet attenuating pigments

InactiveUS20090258072A1Efficient ConcentrationReduce UV radiationPowder deliveryCosmetic preparationsSunscreen agentsAdditive ingredient

Large particle sunscreen powders useful as ingredients in cosmetic compositions and in dispersions for incorporation into cosmetic compositions comprise a UV shielding agent in a matrix material. The macroparticle powders can be used in a wide range of cosmetic formulations, including sunscreens, eyeshadow, mascara, foundation, blusher, toner, lipstick and other compositions requiring ultraviolet protection.

Owner:KOBO PRODUCTS INC

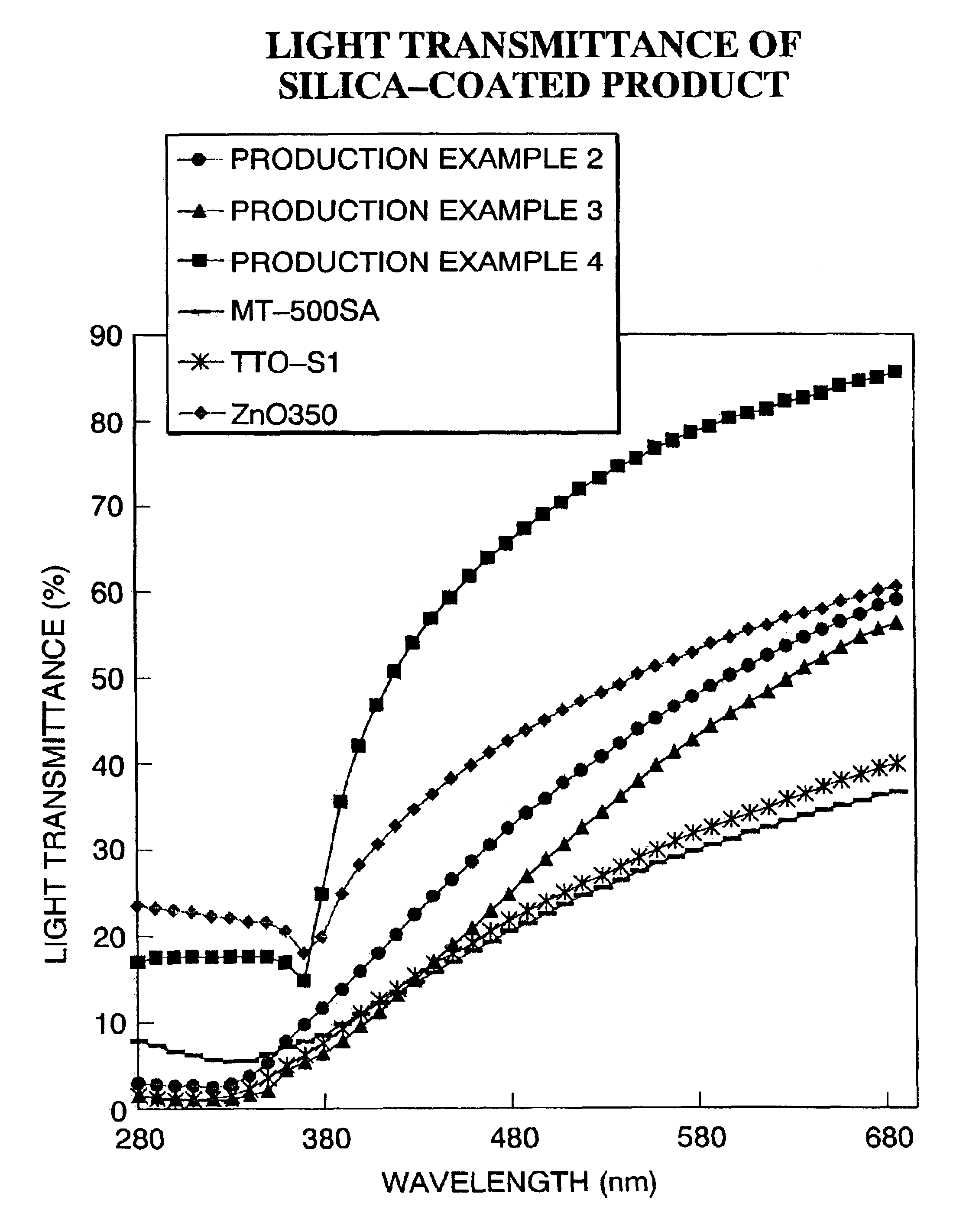

Cosmetic composition

InactiveUS6942878B2Improves UV protectionImprove security and stabilityCosmetic preparationsBiocideMass ratioAdditive ingredient

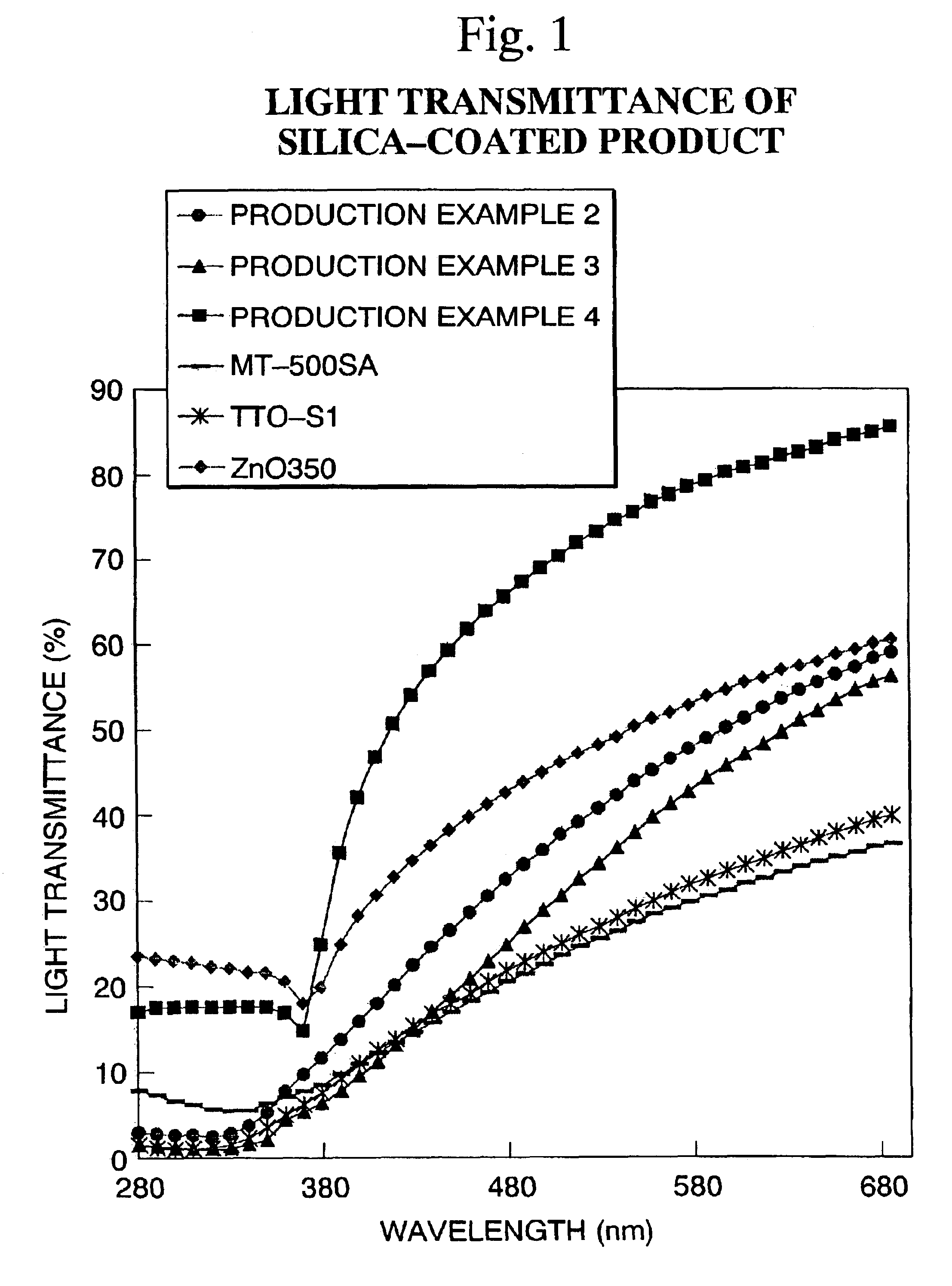

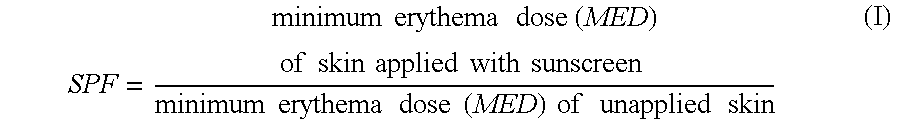

To provide a cosmetic composition having excellent ultraviolet protection against both UVB and UVA, causing neither unpleasant whitening to the applied skin nor skin irritation, and ensuring good feeling on use and high safety and high stability without causing decomposition of the ingredients blended in the cosmetic material, such as organic ultraviolet absorber. A cosmetic composition obtained by using fine particulate titanium oxide and fine particulate zinc oxide each surface-treated with silica, alumina or alumina / silica and having a primary particle size of 0.01 to 0.2 μm in combination and blending titanium oxide and zinc oxide at a mass ratio of 1:4 to 2:3, wherein SPF is maintained as compared with the case where the mass ratio of titanium oxide to zinc oxide is 1:0, and when applied to a thickness of 10 μm, the whiteness W value measured using the CIE color specification system is 20 or less.

Owner:RESONAC HOLDINGS CORPORATION

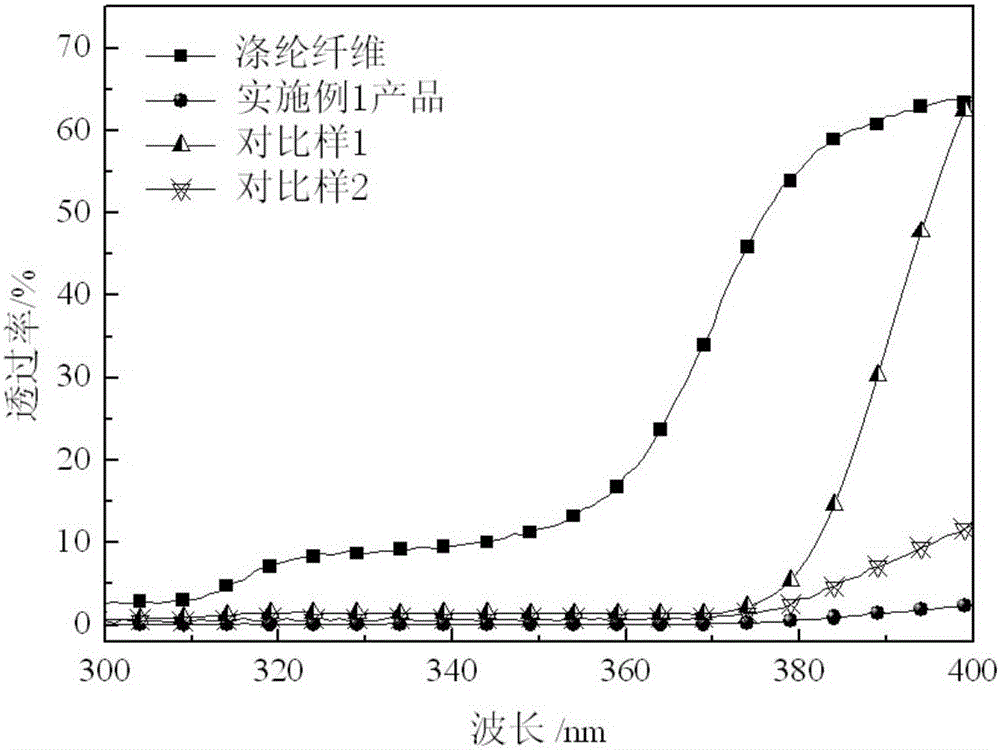

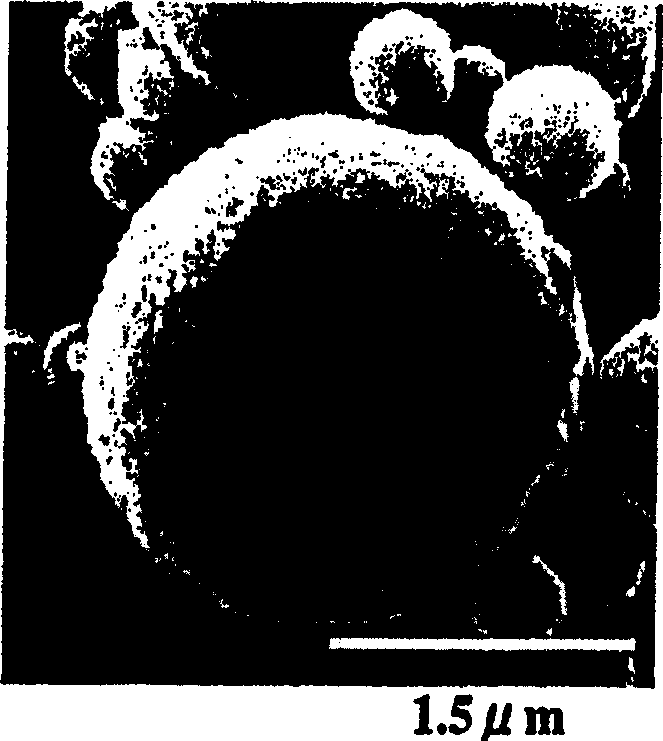

Preparation method of superhydrophobic ultraviolet resistant textile

InactiveCN102321974AReduce transmittanceStability functionFibre treatmentSurface roughnessUltraviolet protection

The invention provides a preparation method of a superhydrophobic ultraviolet resistant textile, which comprises the steps that: first, the surface of the textile is pre-treated; then a micro-particle in a core-shell structure with ultraviolet absorption action is loaded on the surface of the textile which is pre-treated so as to improve the surface roughness of the textile; and finally a low-surface energy substance is adopted to treat the textile which is loaded with the micro-particle in the core-shell structure. A contact angle between the textile which is prepared through the method and a water drop is more than 150 degrees, and the textile has stable superhydrophobic performance, and simultaneously has excellent ultraviolet protection performance.

Owner:SHAANXI UNIV OF SCI & TECH

Sun protection compositions comprising semi-crystalline polymers and hollow latex particles

Topically applicable cosmetic / dermatological UV protection compositions having enhanced SPF contain at least one organic UV screening agent and / or at least one inorganic screening agent, such compositions also containing at least the following constituents (A) and (B):A) a semi-crystalline polymer which is solid at ambient temperature and has a melting point of greater than or equal to 30° C., containing a) a polymeric backbone and b) at least one crystallizable organic side chain and / or one crystallizable organic block forming part of the backbone of this said polymer, said polymer having a number-average molecular mass Mn of greater than or equal to 1,000, andB) hollow latex particles having a particle size ranging from 150 to 380 nm, formulated into a topically applicable, physiologically acceptable medium therefor.

Owner:LOREAL SA

Sunscreen composition with enhanced SPF and water resistant properties

InactiveUS7175834B2Improve skinImprove water resistanceCosmetic preparationsToilet preparationsMedicineActive agent

The present invention relates to a sunscreen formulation which exhibits superior ultraviolet protection and water resistance than prior art sunscreen compositions. The sunscreen formulation comprises (a) a dispersion comprising a sunscreen active agent and (b) a base composition comprising a rheological modifying agent and water. The sunscreen formulation is substantially free of surfactants. According to a preferred embodiment, the sunscreen active agent is ethylhexylmethoxycinnamate, butylmethoxydibenzoylmethane, or a combination thereof. The sunscreen formulation preferably comprises a phosphorylated starch derivative as a rheological modifying agent. Another embodiment of the present invention is a method of protecting skin or hair from ultraviolet radiation by applying an effective amount of the sunscreen formulation of the present invention to the skin or hair.

Owner:COLLABORATIVE TECH

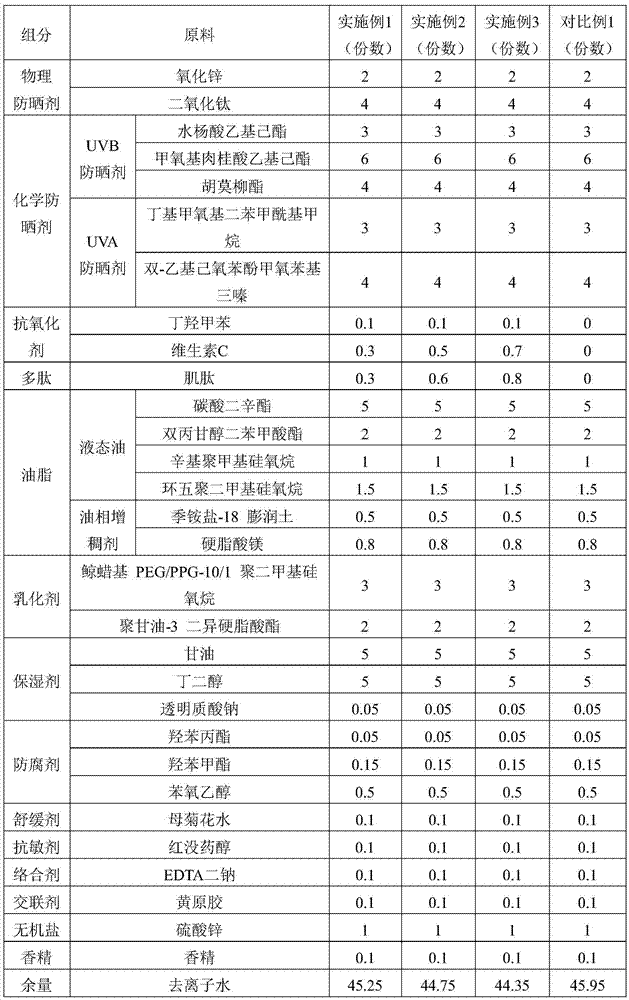

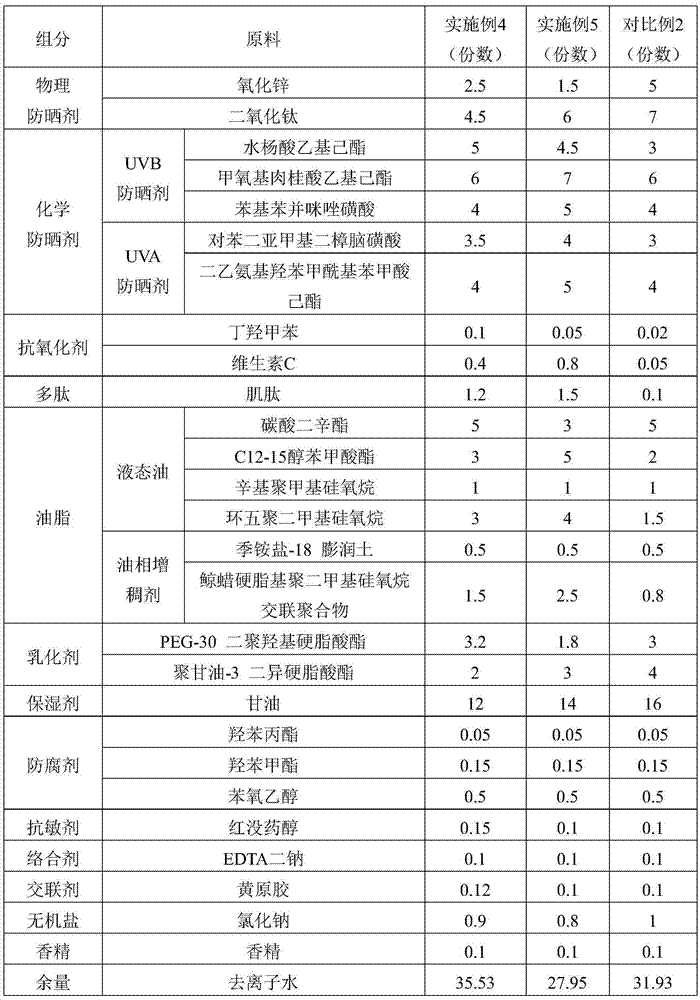

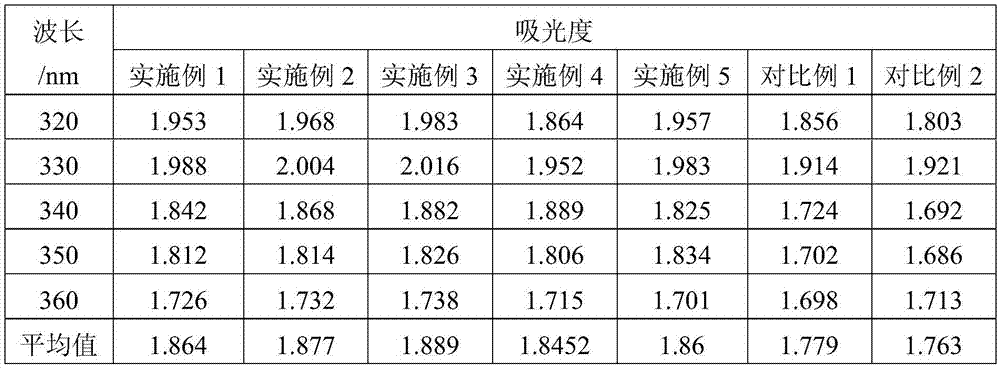

Sunscreen cream and preparation method thereof

ActiveCN105434188AStable heat testGuaranteed protective effectCosmetic preparationsToilet preparationsSunscreen agentsAntioxidant

The invention provides sunscreen cream and a preparation method thereof. In terms of the total weight of the sunscreen cream, the sunscreen cream comprises components as follows: 2%-10% of a physical sunscreen agent, 2%-30% of a chemical sunscreen agent, 0.01%-1% of an antioxidant, 5.5%-20% of grease, 2%-6% of an emulsifier, 3%-15% of a humectant, 0.1%-2% of polypeptide and 10%-85% of water, preferably, 5%-10% of the physical sunscreen agent, 15%-25% of the chemical sunscreen agent, 0.1%-0.8% of the antioxidant, 10%-20% of the grease, 4%-6% of the emulsifier, 8%-15% of the humectant, 0.1%-1.5% of the polypeptide and 22%-53% of the water. The sunscreen cream not only has ultraviolet protection function, but also can protect human tissue from getting infrared ray harm.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +1

Multi-phase fabric care composition for delivering multiple fabric care benefits

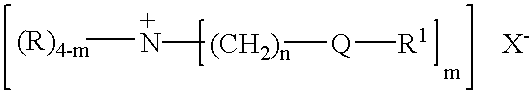

InactiveUS6884766B2Multiple benefitsCapsCationic surface-active compoundsMedicineUltraviolet protection

A liquid rinse-added fabric care composition that is characterized by at least two visually distinct phases when the composition is at rest and wherein at least one of the phases contains a fabric care agent is provided. The composition forms a temporary mixture when shaken that allows a consumer to dose a representative sample of the composition and spontaneously re-forms at least two visually distinct phases when allowed to remain at rest. The fabric care agents present in one or more phases of the composition may include fabric softener actives, color care agents, perfumes, antibacterial agents, malodor control agents, ultraviolet protection agents, anti-abrasion, anti-wear & fabric integrity agents, wrinkle control agents, and mixtures thereof. The composition should also contain less than about 5%, preferably less than about 3%, and even more preferably less than about 1% by weight of detergent actives. The composition optionally may contain an electrolyte, phase stabilizer, a phase separation inducing polymer and / or a solvent. Methods for delivering one or more fabric care benefits to a fabric during a laundering operation using the compositions are also disclosed. Methods for conveying information to a consumer concerning a multi-phase liquid rinse-added fabric care composition are also provided. An article of manufacture comprising a liquid rinse-added fabric care composition that has at least two visually distinct phases and a container that enables a consumer to view the visually distinct phases that are present in the composition is also described. Alternatively, the container may comprise a double walled cap and an insert for removing excess composition that may adhere to the cap.

Owner:PROCTER & GAMBLE CO

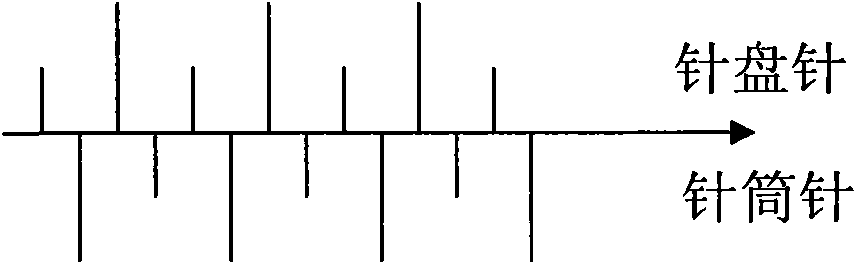

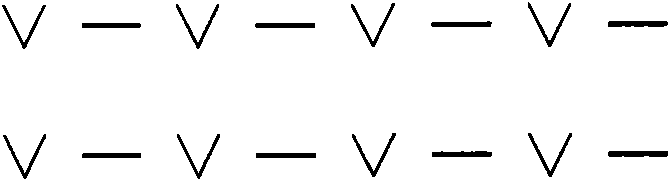

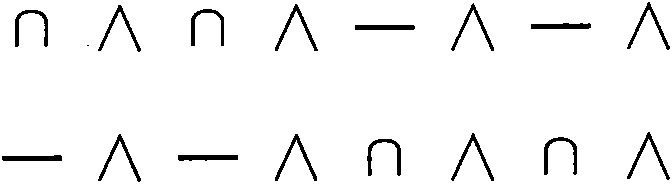

Ice-cold fiber knitted fabric and manufacturing method thereof

InactiveCN101613907AWith cooling functionReduce unit weightWeft knittingWarp knittingUltraviolet protectionPulp and paper industry

The invention relates to a fabric with a double-sided composite structure interweaved by cooling ice-cold fibers and cotton yarns. The inner layer of the fabric is formed by the ice-cold fibers and has a mesh-like tissue structure; and the outer layer of the fabric has a plain weave tissue structure. Australia AS / NZS 4399:1996 Evaluation and Classification of Ultraviolet Protective Fabric' standard tests show that the ultraviolet protection factor UPF level of the fabric reaches 50 +. A method for manufacturing the fabric comprises the following steps of: weaving, preprocessing, dyeing and scotching forming. The dyeing step comprises cotton dyeing, water washing, dewatering, polyamide fiber dyeing, water washing, color fixing and water washing in sequence. A coolfresh auxiliary agent and an uvioresistant auxiliary agent are added in one bath during dyeing, and the coolfresh auxiliary agent is added again by squeezing when scotching forming. The fabric combines the multiple functions of ice cooling, temperature reduction, coolfresh and uvioresistance into the whole fabric and is an ideal outdoor sportswear fabric.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

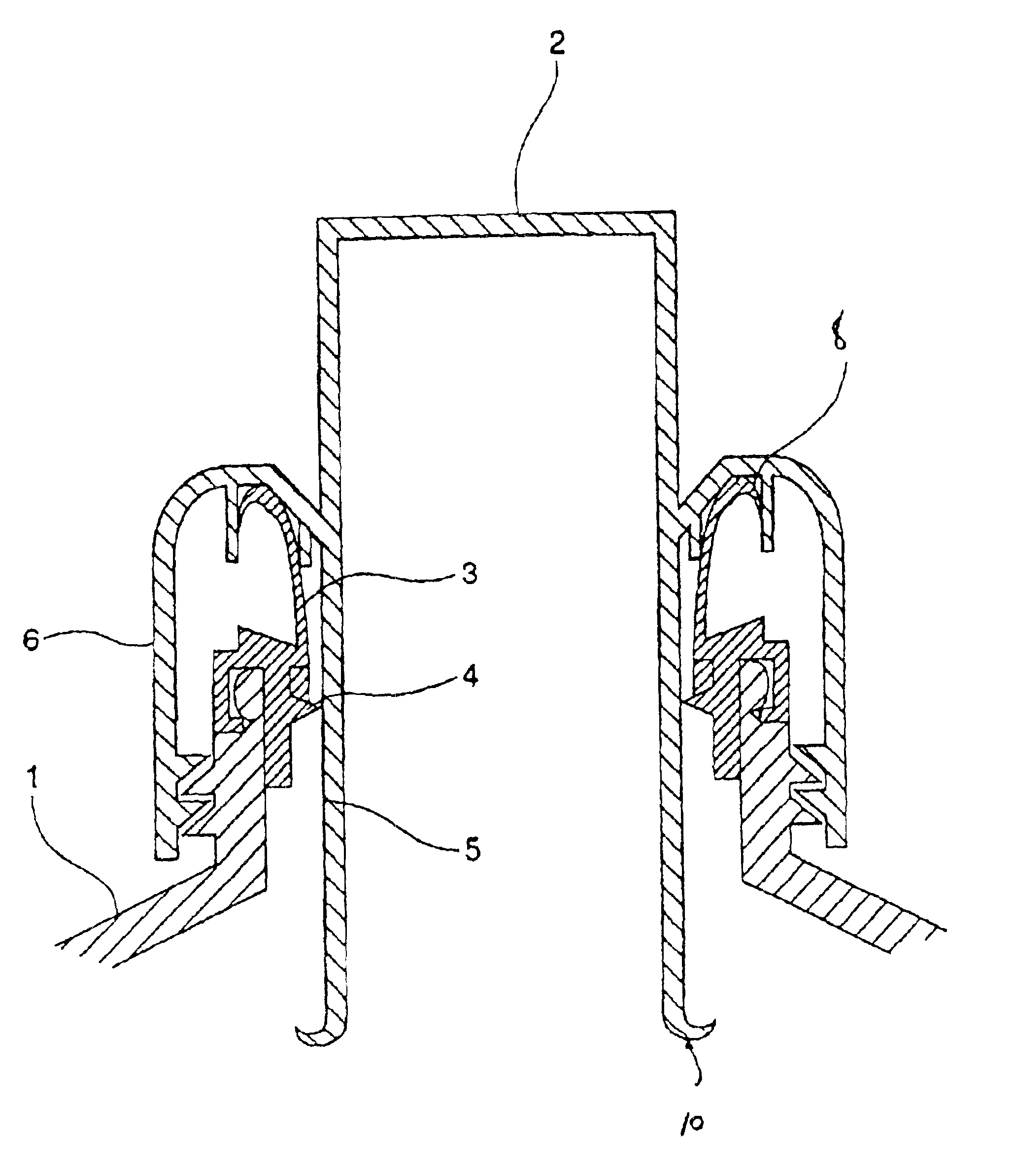

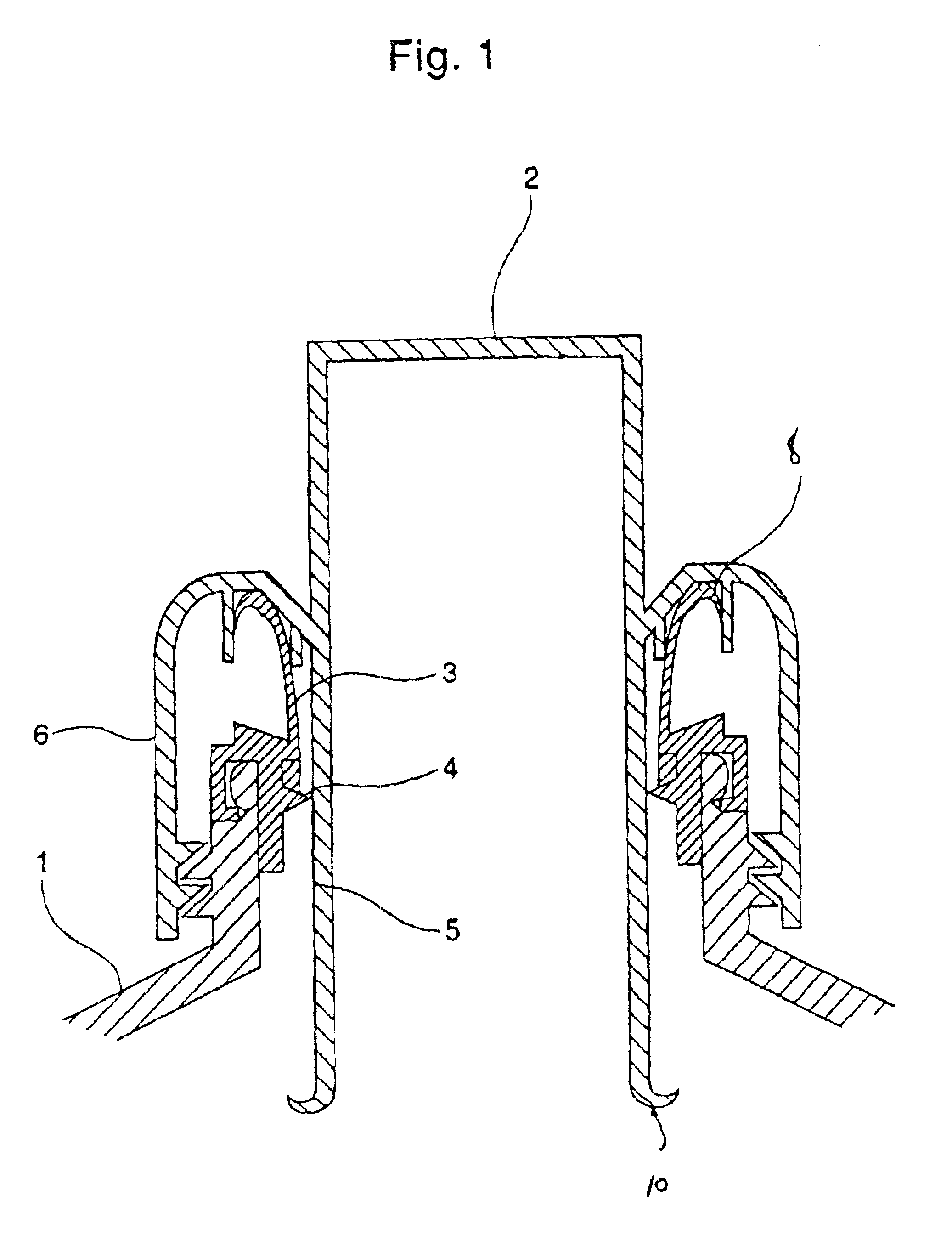

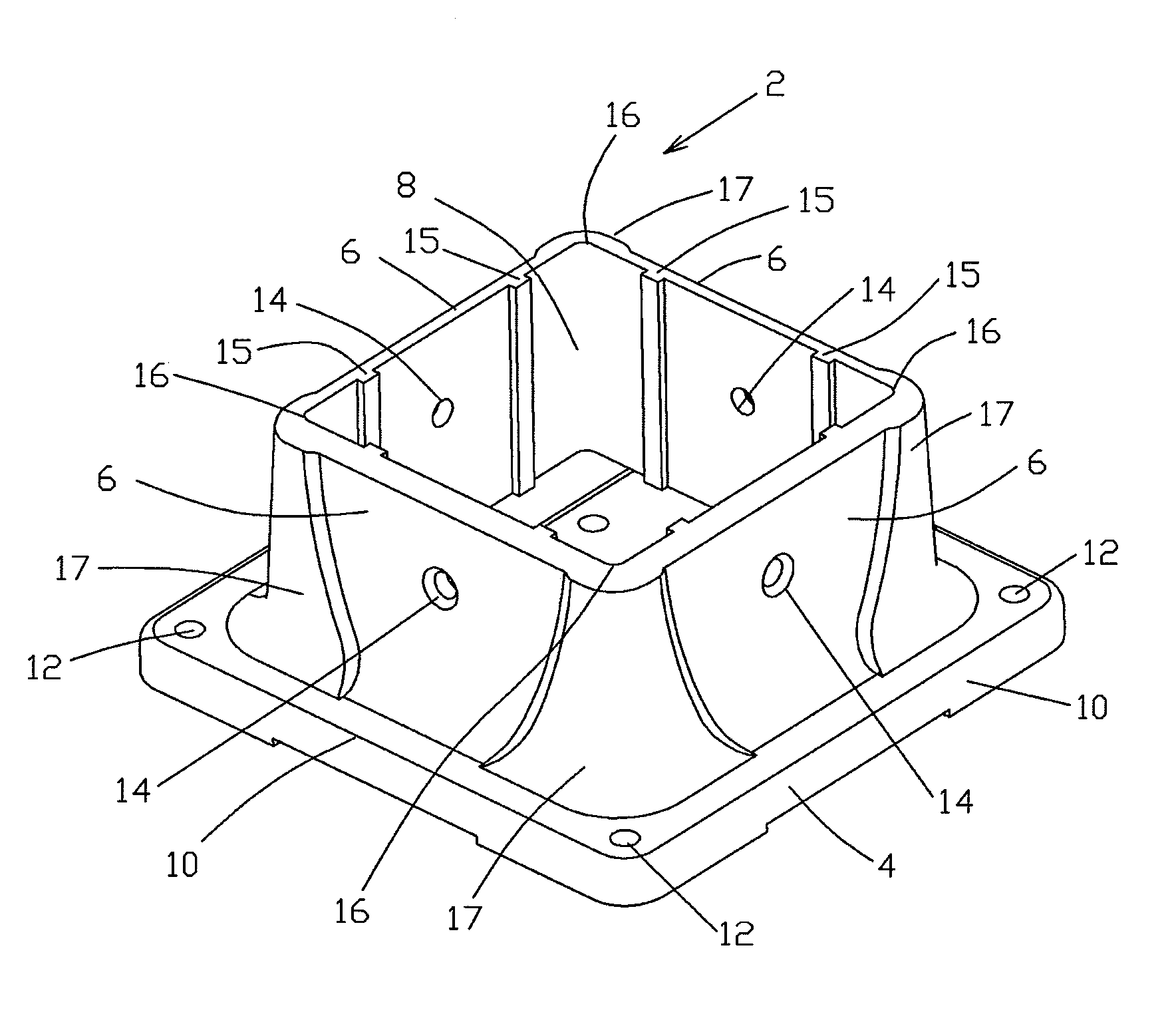

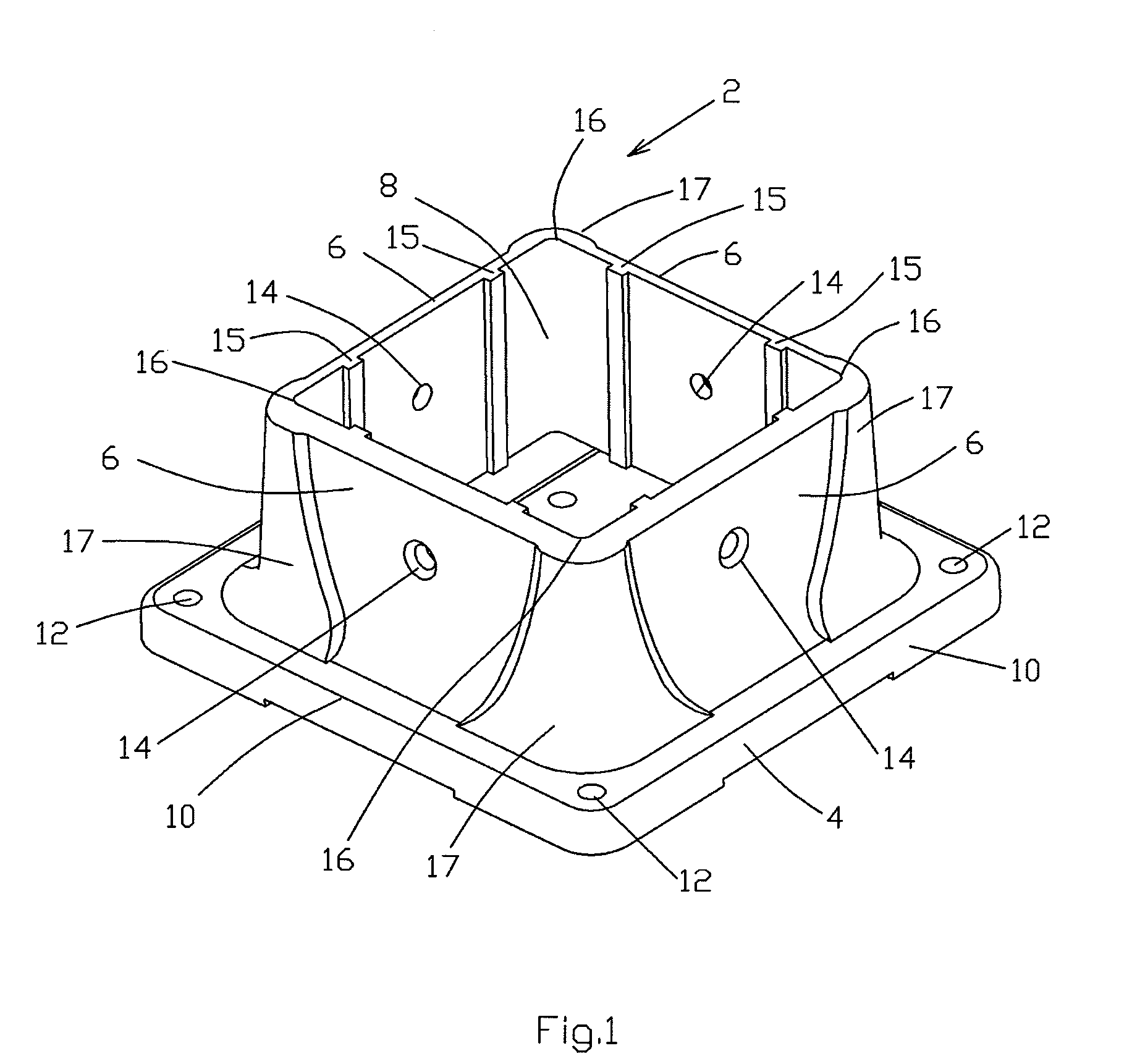

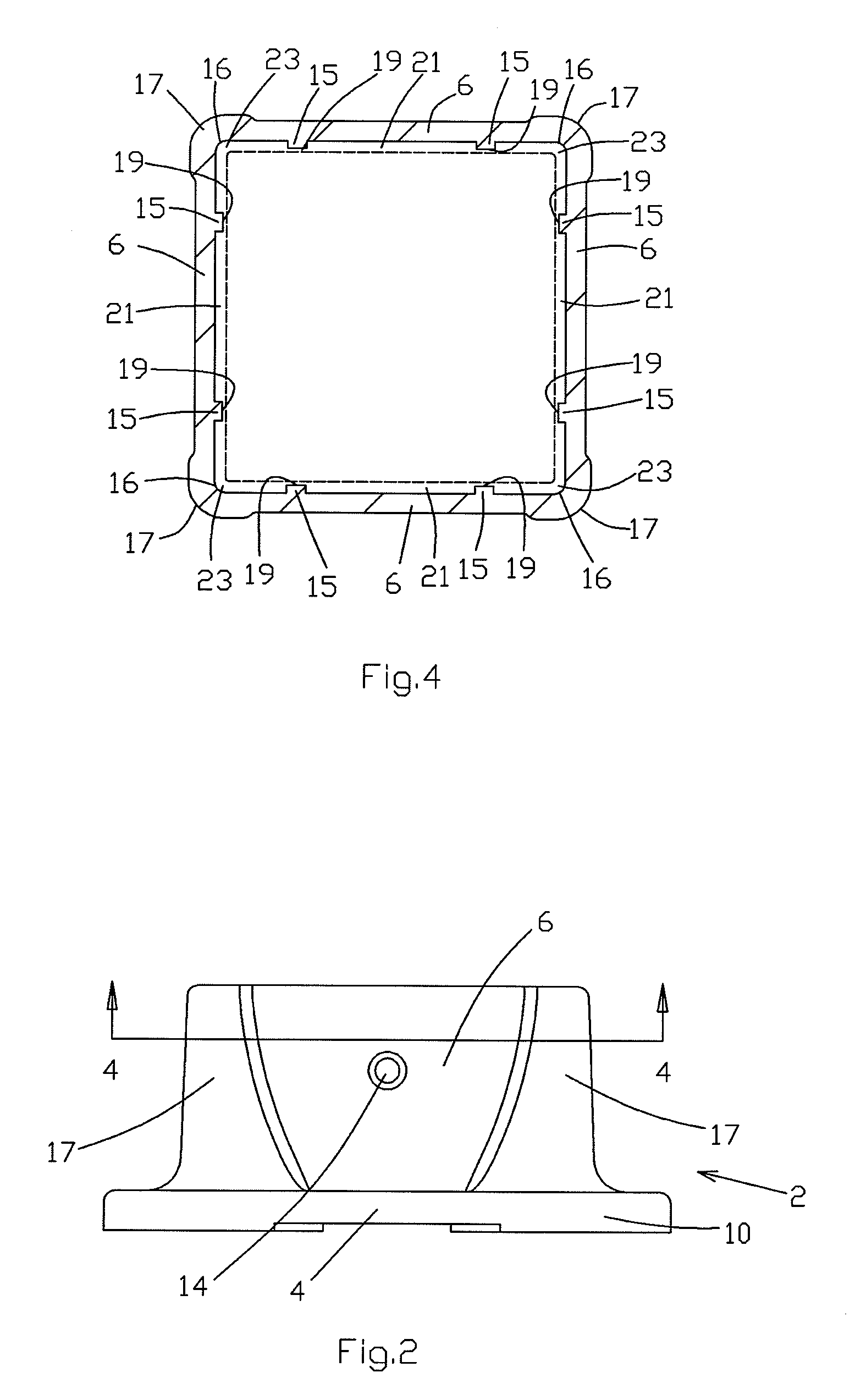

Post anchor

ActiveUS20070235616A1Control deformationReduce chanceStands/trestlesTowersUltraviolet protectionMechanical engineering

A post anchor for securing a support post for a structure comprises a base with four upstanding sidewalls forming a cavity into which a post is inserted, and means to secure the post inside the cavity. Interior ribs and exterior augmented corners resist deformation under pressure exerted by the post. Interior channels allow water to drain from inside the cavity toward a drain hole. The anchor post is slightly elevated relative to the ground, allowing air and water to circulate around the post and post anchor. The post anchor is made of a thermoplastic polymer which is given a textured surface, and may include an ultraviolet protection additive.

Owner:PEAK INNOVATIONS INC

Sunscreen composition

Disclosed is a water-in-oil emulsified sunscreen composition comprising by weight:(a) an effective amount of a UV protection agent;(b) from about 0.1% to about 70% of a non-thickening oil absorbing powder having a mineral oil absorbing ability of at least about 40 ml / 100 g;(c) at least about 10% of the entire composition of water; and(d) an oil phase comprising:(i) at least about 50% by weight of the oil phase of a volatile silicone oil; and(ii) from about 0.1% to less than the oil absorbing ability of the non-thickening oil absorbing powder of a non-volatile oil; wherein when the UV protection agent is a non-volatile liquid of hydrophobic nature, it is considered the non-volatile oil.

Owner:THE PROCTER & GAMBNE CO

Radiation-proof light-filtering contact lens and production method thereof

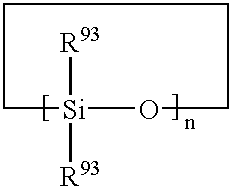

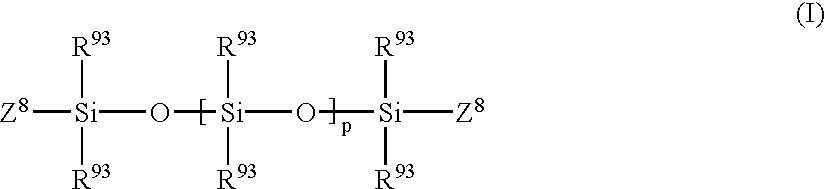

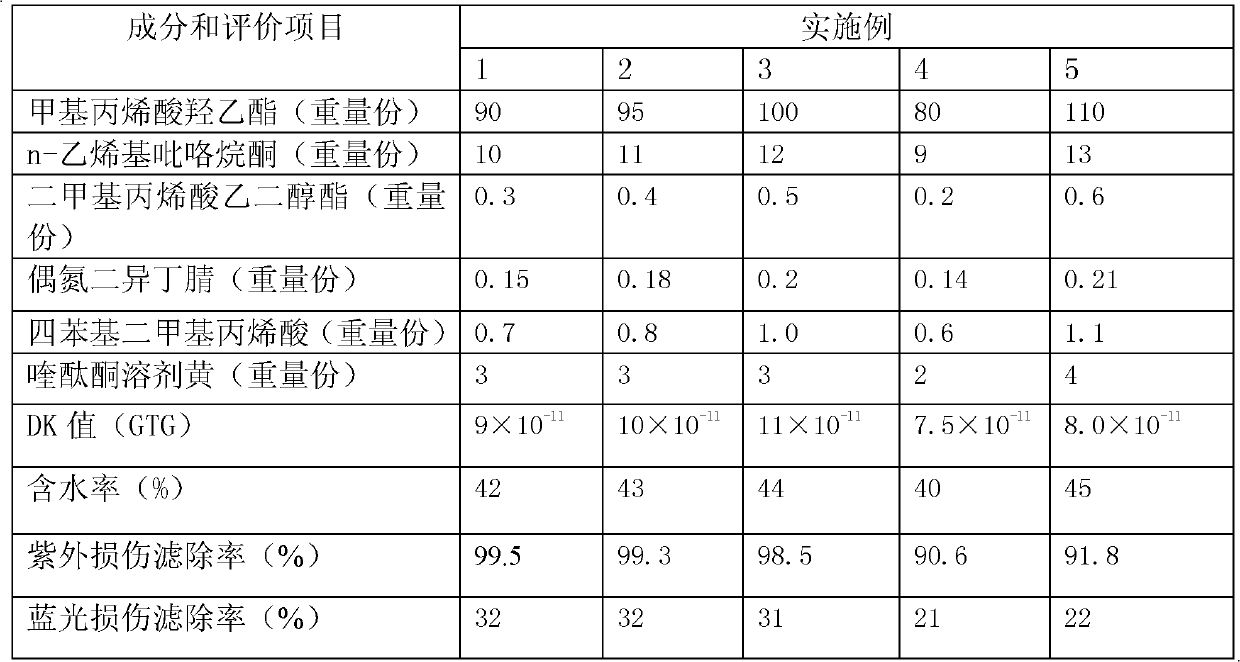

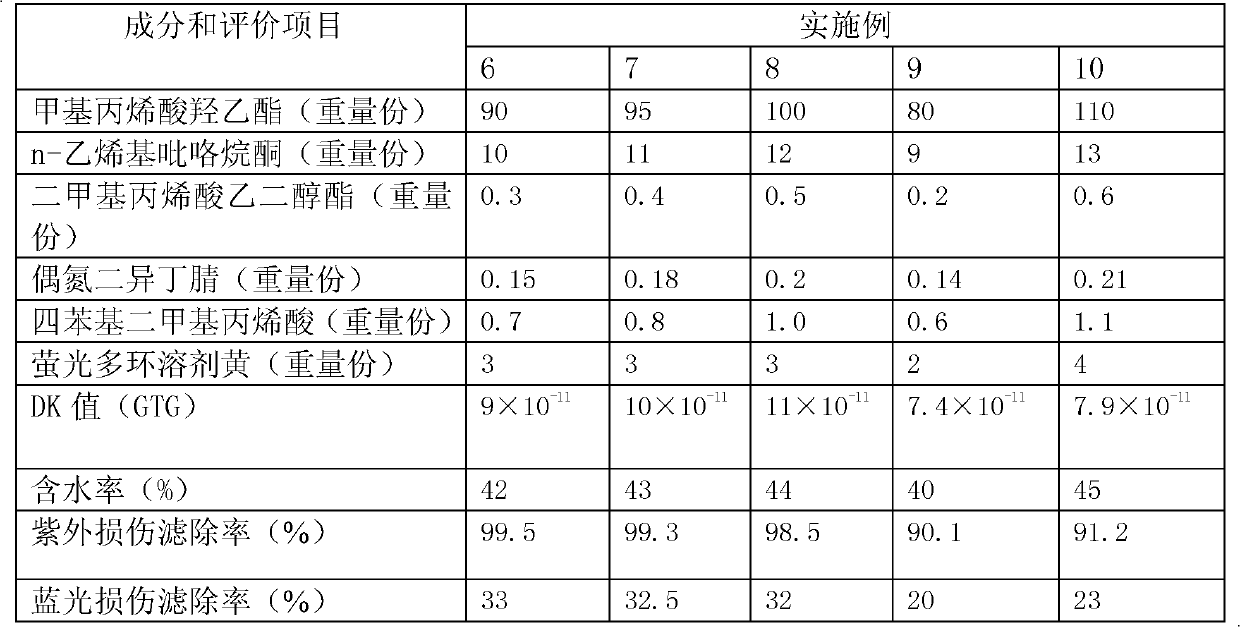

ActiveCN102382237AGood oxygen transmission coefficientIncrease moisture contentOptical articlesOptical parts(Hydroxyethyl)methacrylateUltraviolet

A radiation-proof light-filtering contact lens is characterized in that the weight ratio of each component of liquid material is as follows: 90 to 100 parts of hydroxyethyl methacrylate; 10 to 12 parts of ethenyl pyrrolidinone; 0.3 to 0.5 part of 2-propenoic acid, oxybis(2,1-ethanediyloxy-2,1-ethanediyl)ester; acrylic acid, diester with tetraethylene glycol; 0.15 to 0.2 part of 2,2'-dicyano-2,2'-azopropane azobisisbutyronitrile; 0.7 to 1 part of 4-[(E)-phenyldiazenyl]phenyl-2-methacrylate; and 3 parts of yellow pigment and dye for contact lenses. The contact lens has a good oxygen permeation coefficient, high moisture content, moderate hardness and fewer residues, and also has a good ultraviolet radiation protection effect and a good filtering effect on purple light and blue light.

Owner:北京自然美光学有限公司

Process for coloring a textile substrate

InactiveUS7018429B1Good light fastnessDurable lightfastnessPretreated surfacesDyeing processYarnUltraviolet protection

The present invention relates to methods of imparting color and ultraviolet protection to synthetic yarns or substrates. More specifically, the present invention is directed to a method of solution dyeing a polymeric material during polymerization to form a base color shade, and subsequently dyeing the polymeric material by either yarn dyeing or piece dyeing. Ultraviolet protection is also provided in the solution dyeing step, by introducing an ultraviolet stabilizing agent into the polymer. The base shade may then be transformed into a useful color pallet with enhanced lightfastness properties by applying a final color shade late in the fabric formation process.

Owner:SAGE AUTOMOTIVE INTERIORS INC

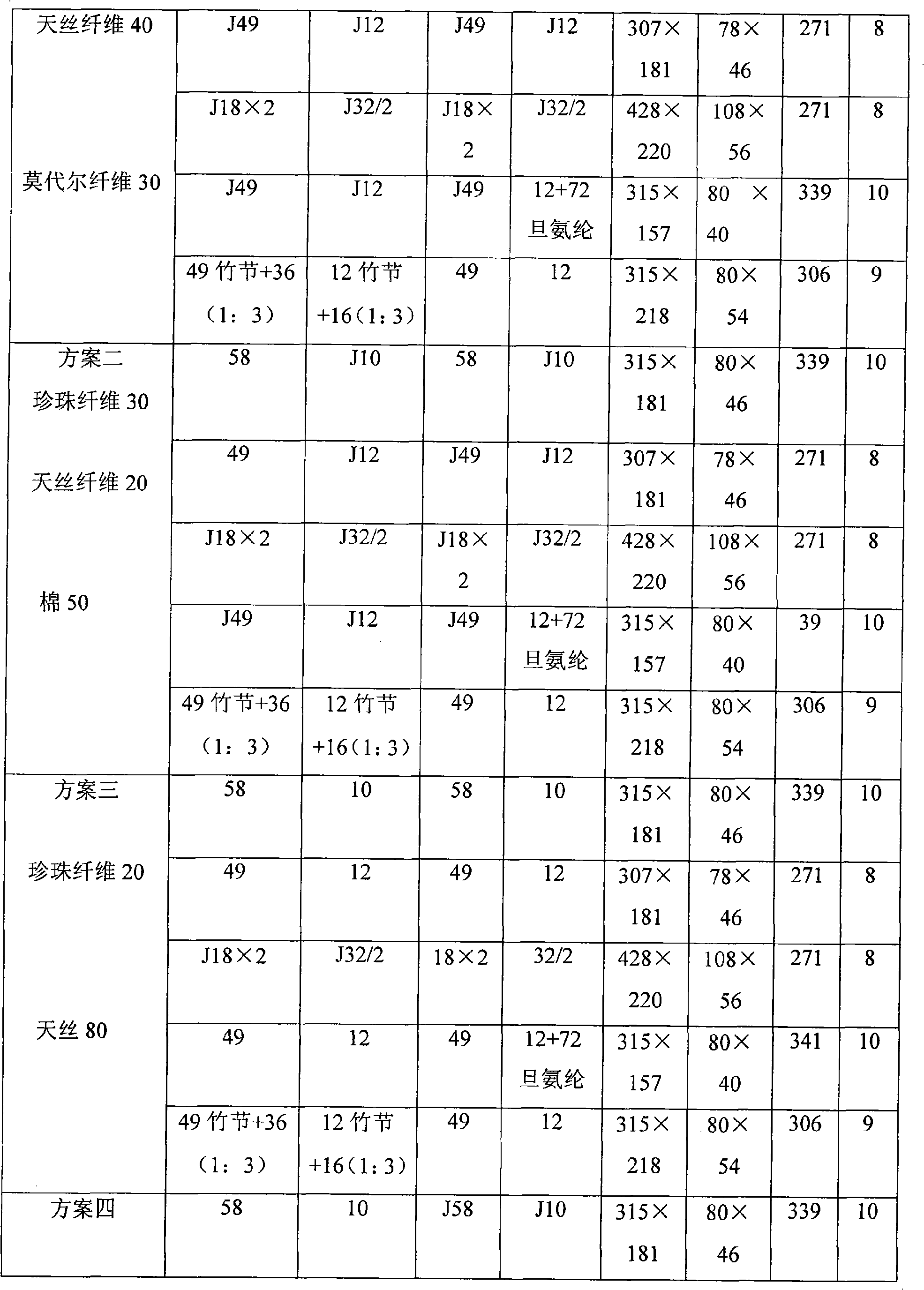

Multifunctional knit clothes fabric and technique for producing the same

InactiveCN101463526AMoisture wickingAntibacterial and deodorantWeft knittingFibre treatmentPolyesterFiber

A multifunctional knitted dress plus material has the functions of moisture wicking, as well as being uvioresistant, antibacterial and deodorant. The plus material is weaved by adopting moisture conductive polyester fiber, is formed by functional arrangement and is tested according to American AATCC79-200 absorbency test of bleached textiles standard, and the water-absorbing time of the plus material is 1 second before the plus material is washed and after the plus material is washed for 10 times and 20 times; according to the test standard of Australian AS / NZS 4399:1996 ultraviolet protection plus material evaluation and classification, the ultraviolet protection factor (UPF) level of the plus material reaches 35-50+; furthermore, according to the Switzerland SANITIZED AG SN 195 920 standard test, the antibacterial effect of the plus material shows that the growth of staphylococcus aureus ATCC 6538 is zero. The production technique comprises dyeing, and adding uvioresistant functional addition agent in dye bath; sizing finished products, antibacterial and deodorant addition agent as well as moisture absorption fast-dried addition agent are added into mangle.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

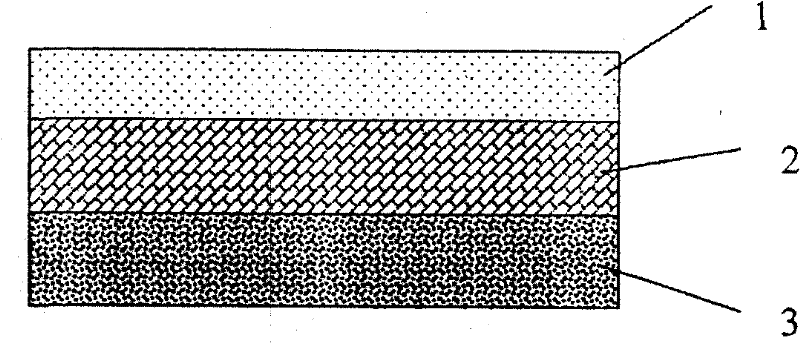

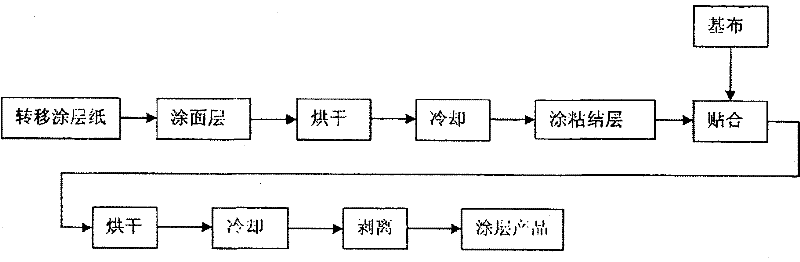

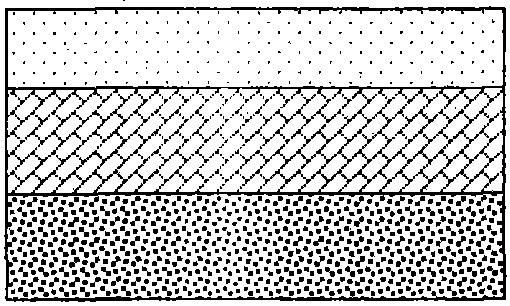

A kind of preparation method of anti-ultraviolet knitted coated fabric

ActiveCN102268820ASolve stress deformationImproves UV protectionFibre treatmentSurface layerUltraviolet protection

The invention relates to a preparation method of anti-ultraviolet knitted coated fabric. The preparation method is characterized in that through a transfer coating method, a knitted base material is coated with a surface layer composed of a surface layer polyurethane coating agent, and a bonding layer (bottom layer) composed of a bonding layer polyurethane coating agent, wherein the bonding layer polyurethane coating agent is added with anti-ultraviolet finishing agents. A result of a test shows that anti-ultraviolet knitted coated fabric prepared by the preparation method has good anti-ultraviolet functions and feels good.

Owner:GUANGDONG XINFENG TECH

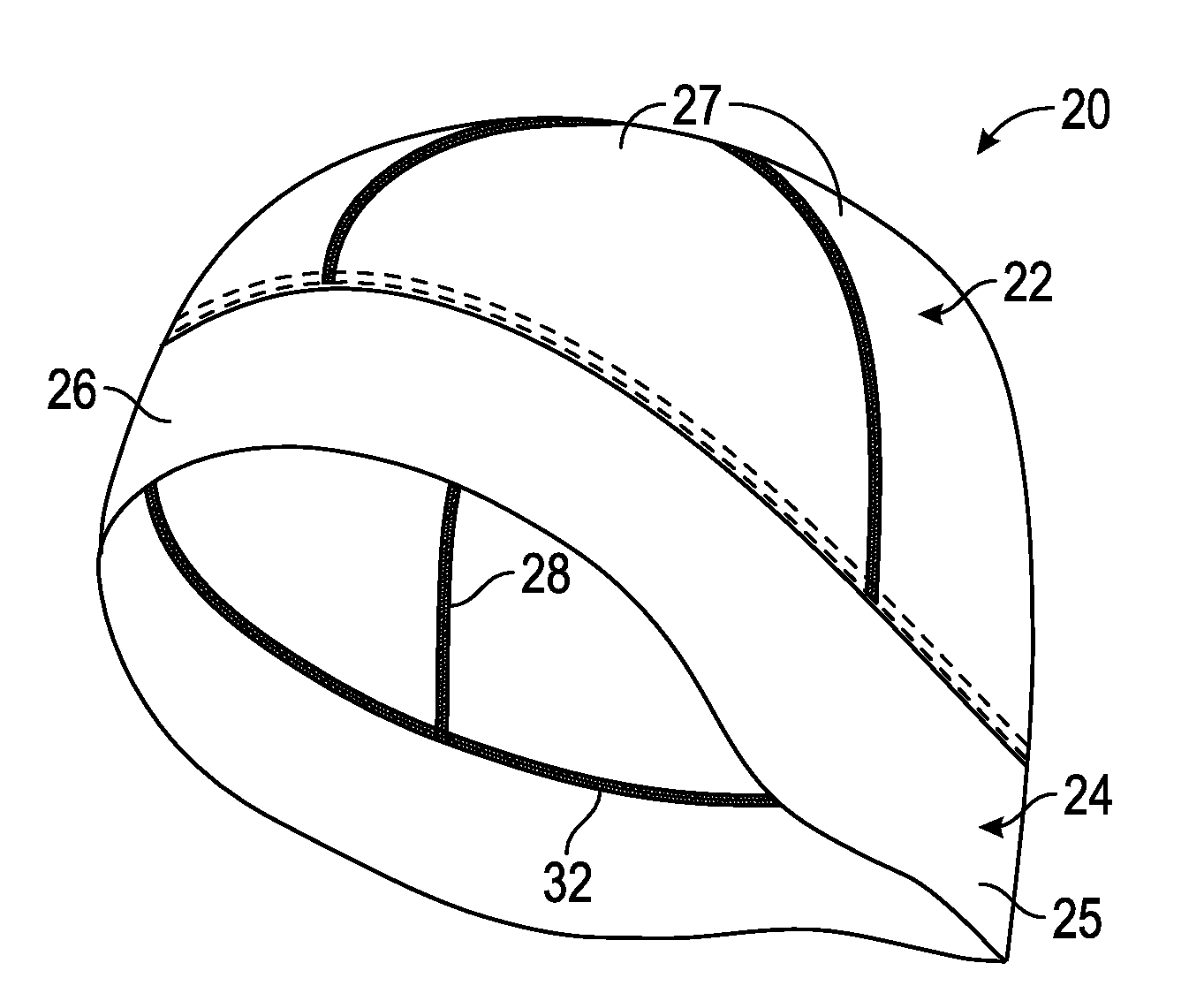

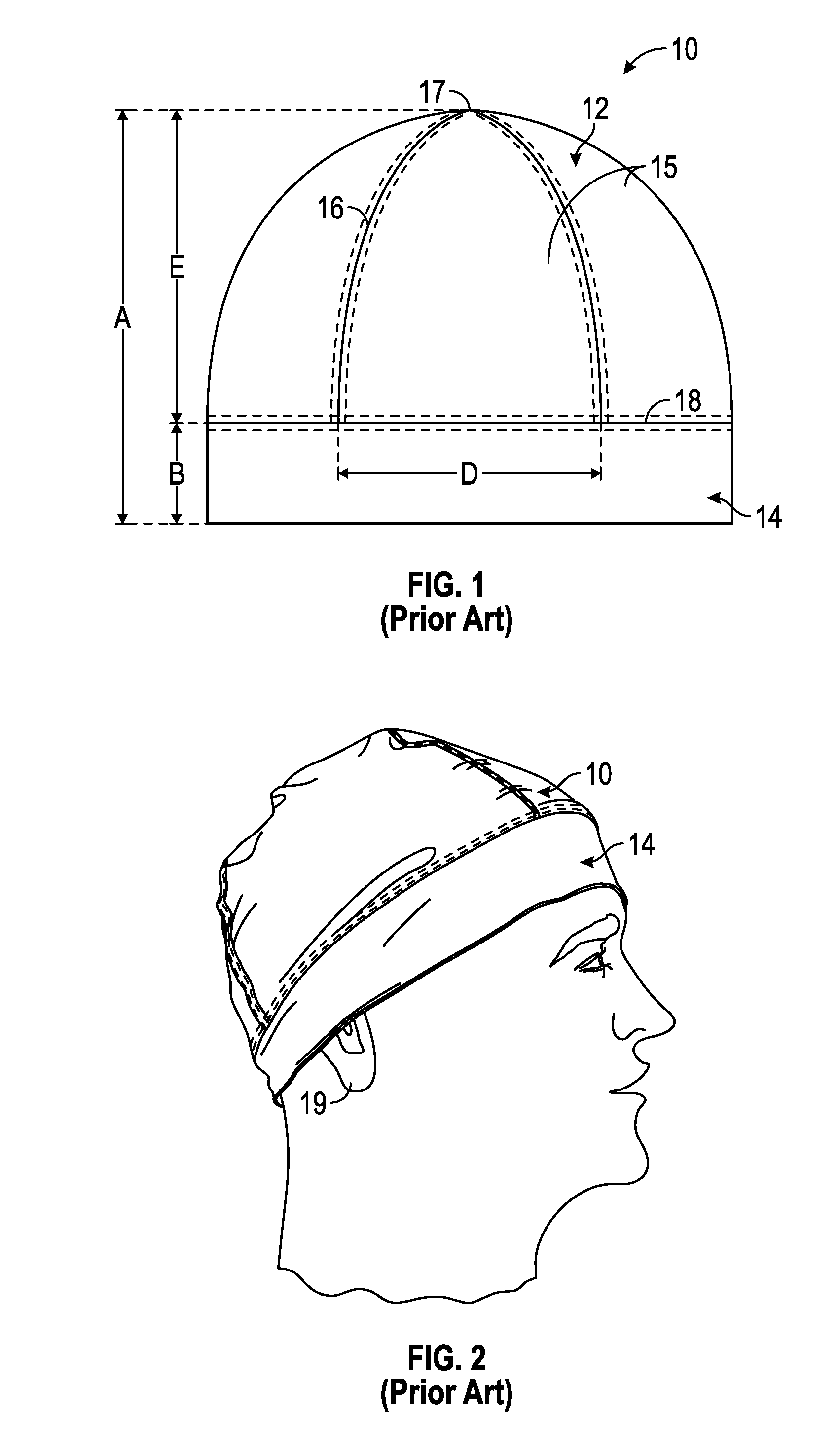

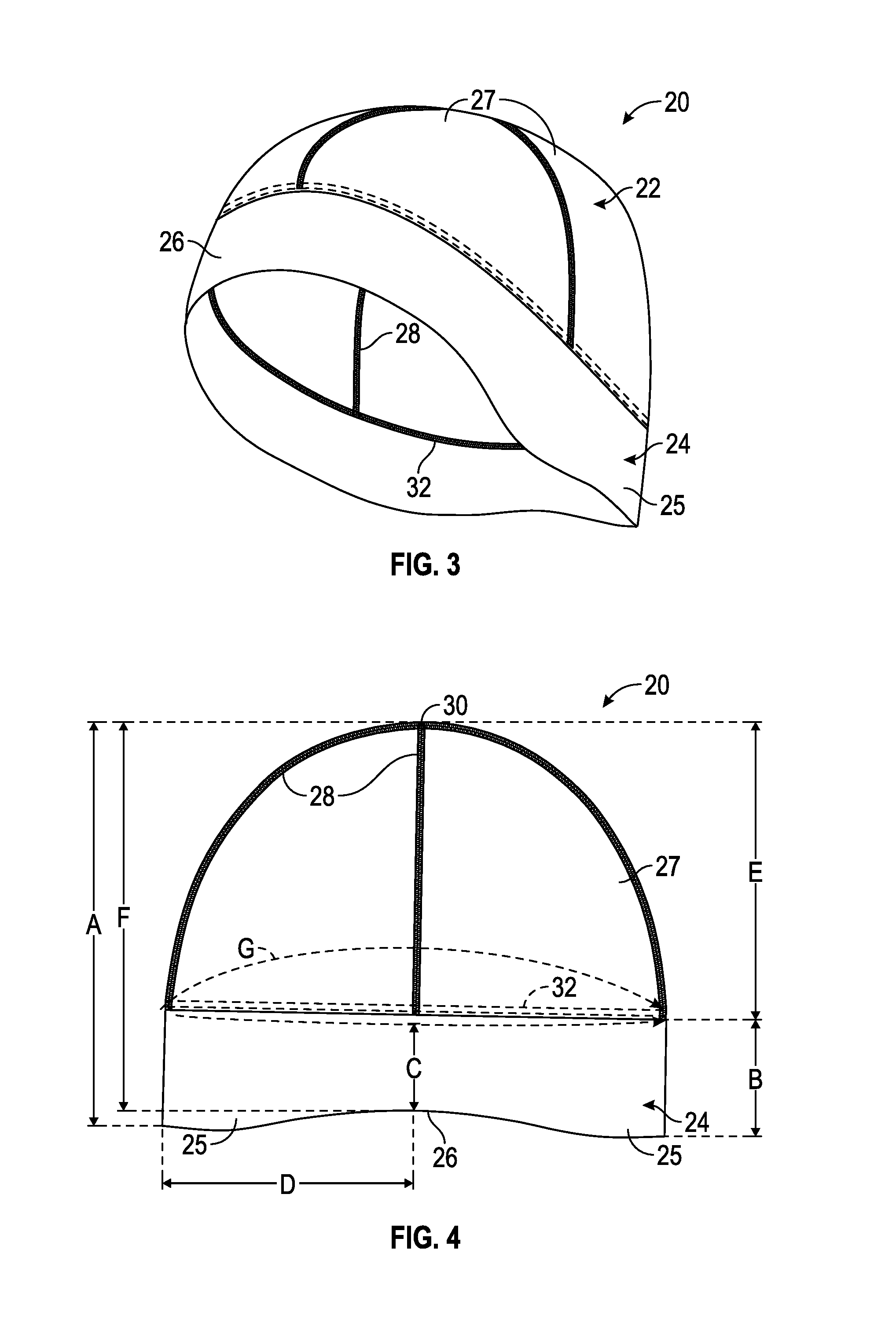

Sport/utility cap

InactiveUS20150335086A1Reduce sweatingIncrease radiative coolingHatsHeadwear capsUltraviolet protectionMoisture

A sport / utility or outdoor protective cap or hat is made of an ultraviolet protection factor (UPF) rated elasticated fabric which has the ability to wick moisture from the head of the wearer in addition to protecting the wearer's head covered by the cap from the sun. The cap has a dome-shaped body portion and a lower band or edge trim around the lower periphery of the dome-shaped portion. The lower band is of varying height, with wider or taller side portions to provide at least substantially full coverage for the ears. The dimensions of the cap are selected so that the cap fits closely and comfortably to the wearer's head with little or no rucking.

Owner:CHROME DOME

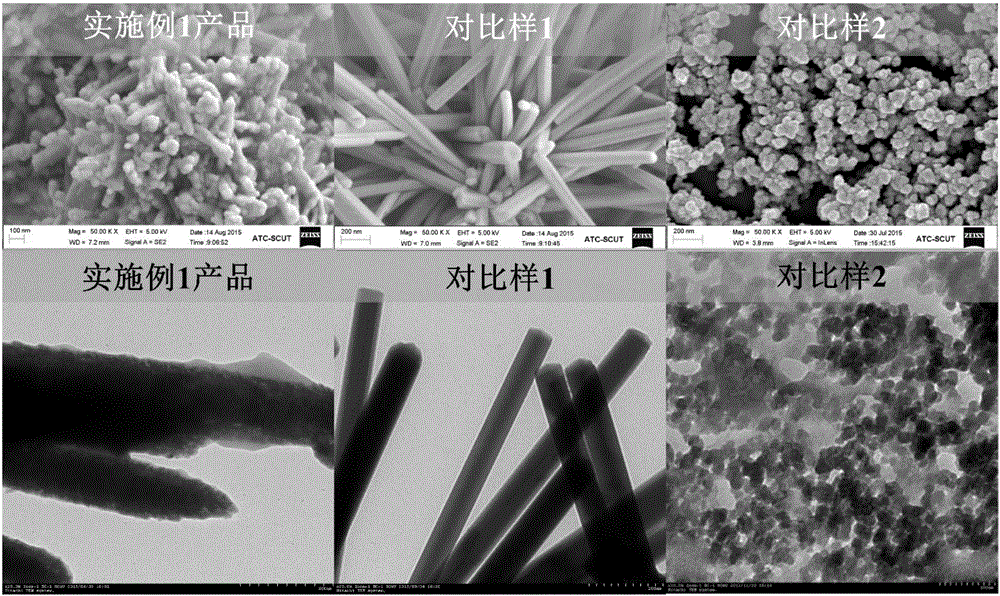

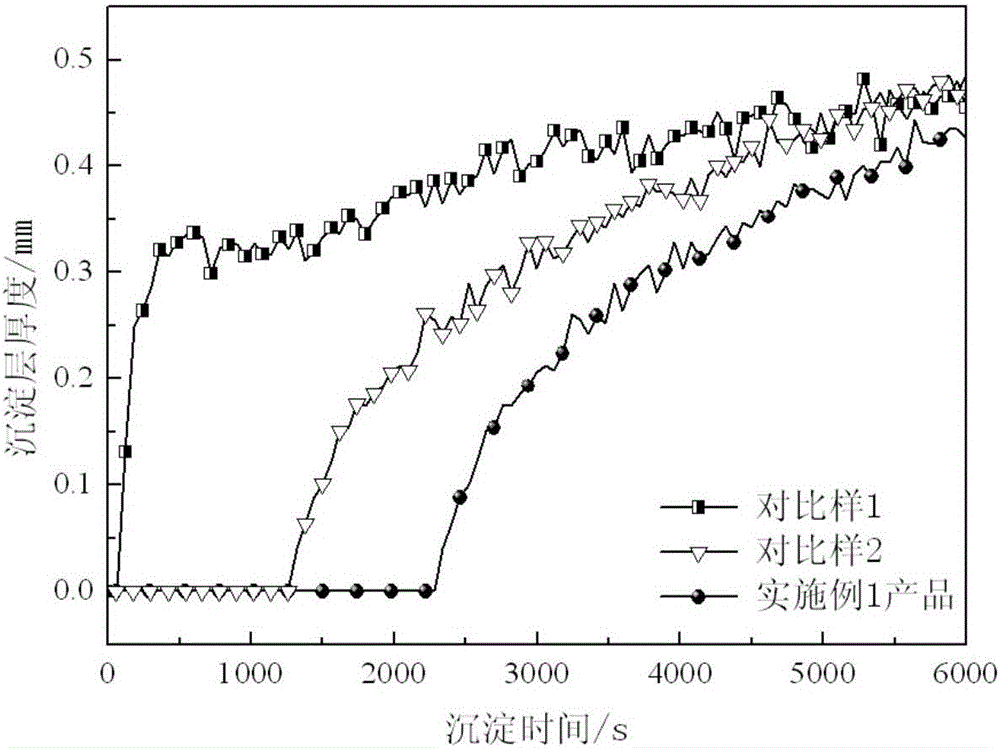

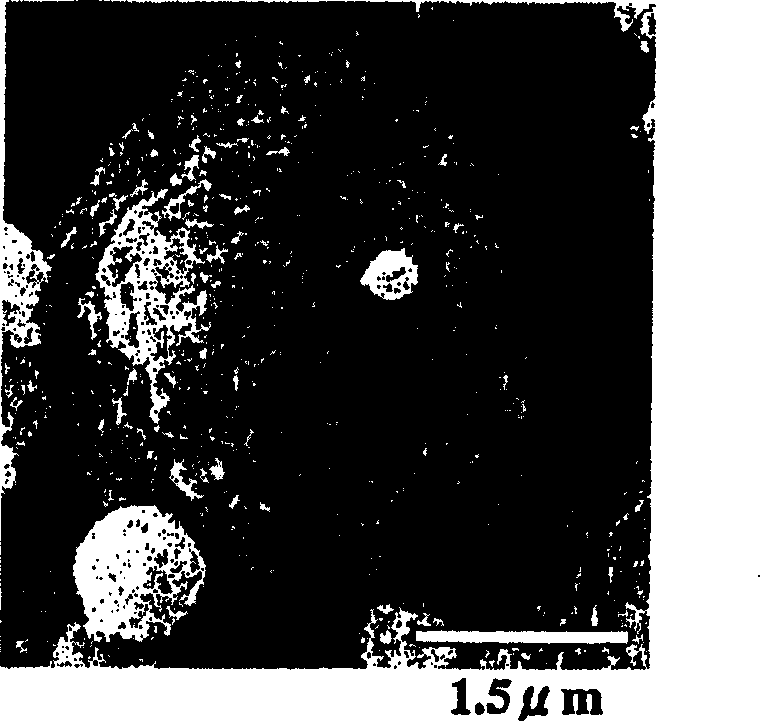

Anti-ultraviolet radiation lignin-based zinc oxide composite particles and preparation method and application thereof

The invention belongs to the technical field of nanocomposites, and discloses anti-ultraviolet radiation lignin-based zinc oxide composite particles for fabric and a preparation method and application in the fabric of the particles. The preparation method comprises the following steps that 1, pH of a lignin sulfonate aqueous solution is adjusted to be alkaline, heating is conducted, an active agent is added for reacting, a carboxylated reagent is added, an isothermal reaction is conducted, and carboxylated lignin sulfonate is obtained; 2, carboxylated lignin sulfonate prepared in the first step is prepared into an aqueous solution, the pH is adjusted to be alkaline, a zinc salt is added for reacting, reacting is conducted by heating, the pH is adjusted to be 9 to 11, reacting is conducted continuously, a cross-linking agent is added for reacting, cooling, ageing, separating and drying are conducted, and the lignin-based zinc oxide composite particles are obtained. According to the composite particles, agglomeration among nano zinc oxide particles is overcome, the particles are dispersed uniformly, adhesion to fabric fibers is improved, effective protection of UVA and UVB full-wave bands is provided, and the problem that the ultraviolet-protection capacity is limited is solved.

Owner:SOUTH CHINA UNIV OF TECH

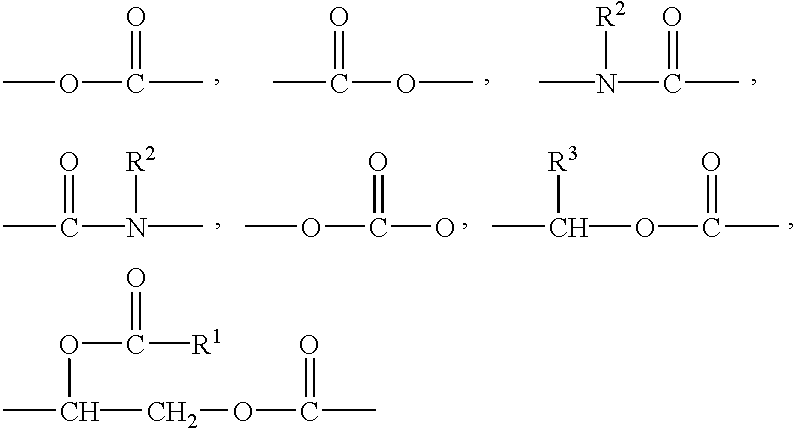

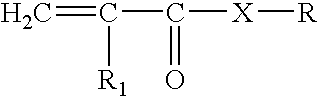

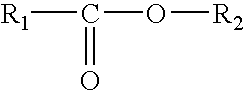

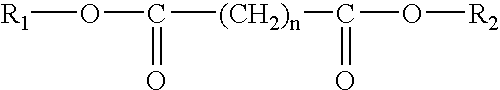

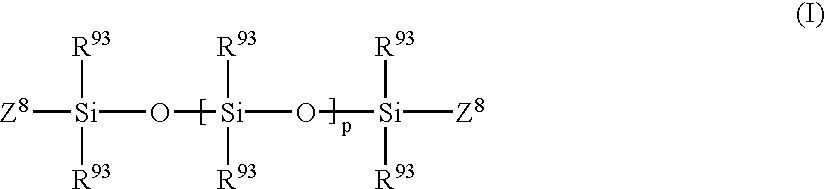

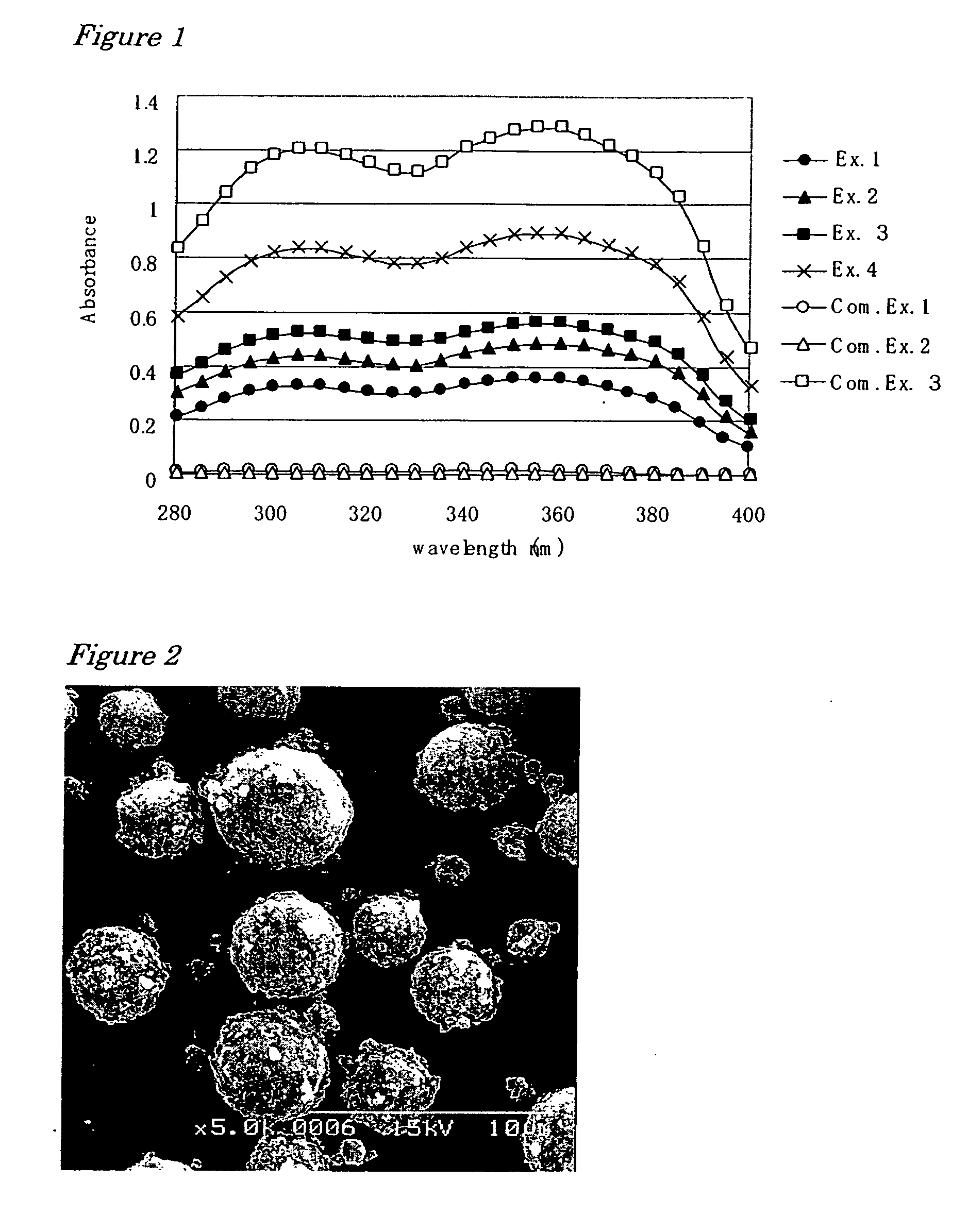

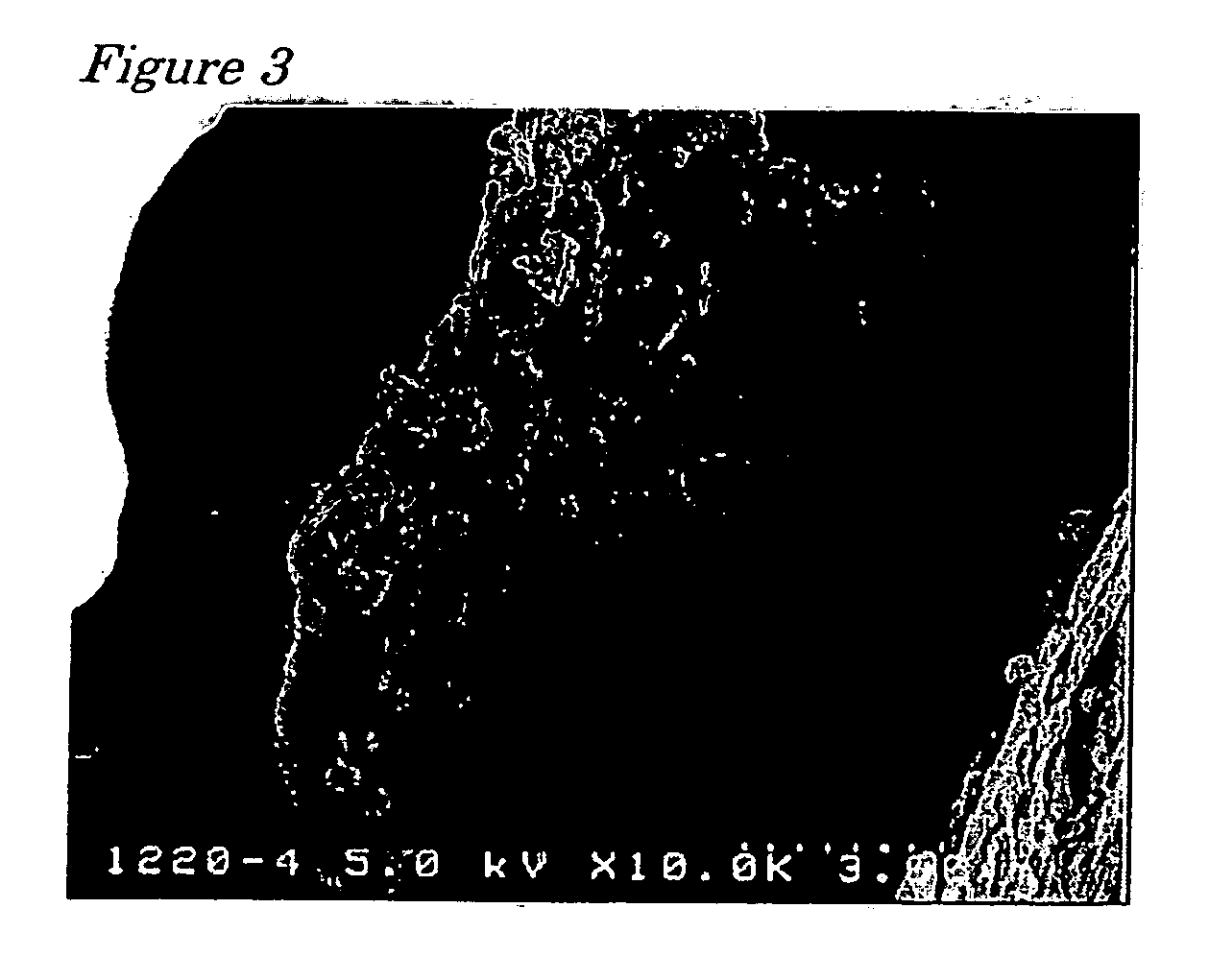

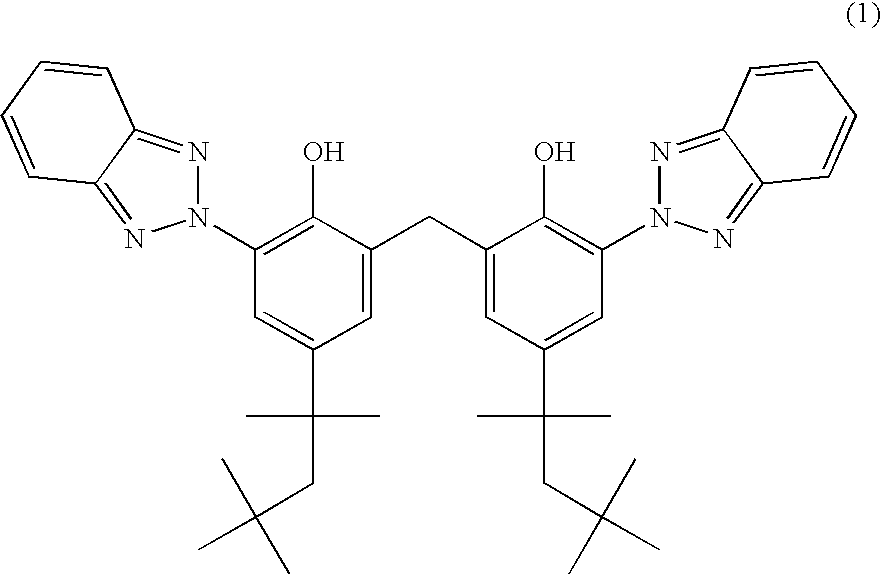

Ultraviolet ray absorbing composite powder

An ultraviolet-absorbing composite powder comprising a plurality of composite powder particles, wherein the composite powder particle consists of an inorganic or organic core particle having an average particle diameter of 0.5-100 μm, and a compound of formula (1): which is adsorbed to the surface of the core particle is provided. The composite powder of the invention exhibits an excellent UV ray protecting property as well as smooth and comfortable texture, and is useful for manufacturing cosmetic products.

Owner:IWASE COSFA

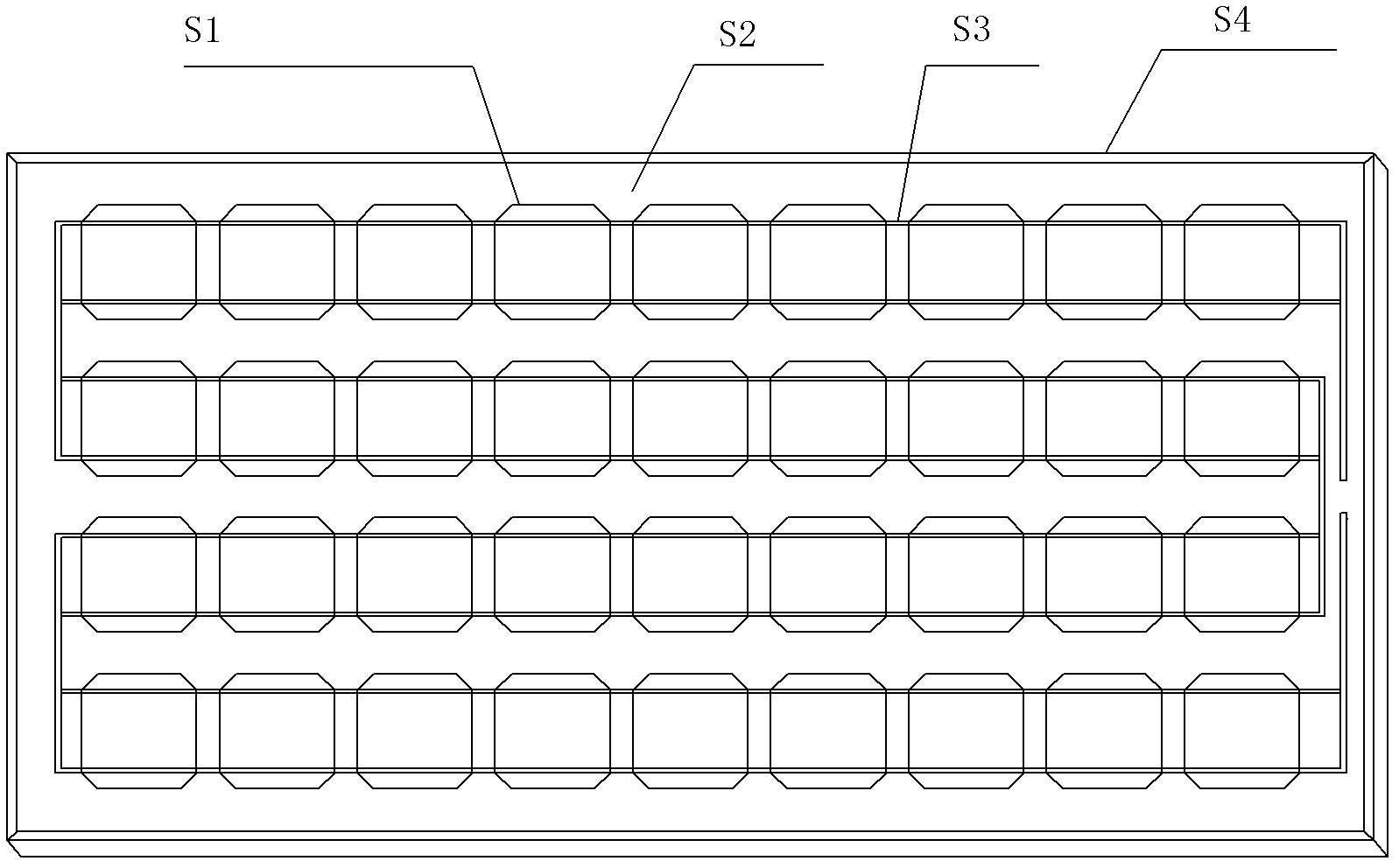

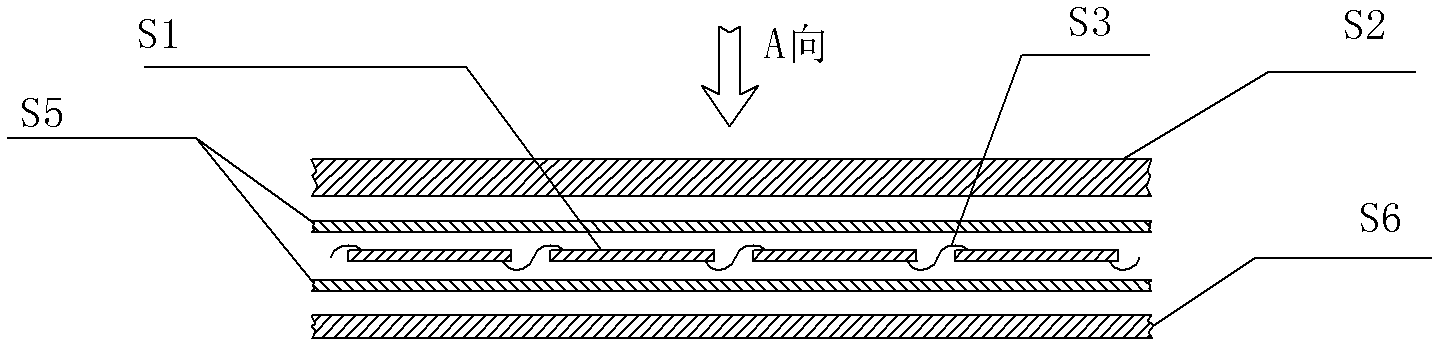

Building material type double-sided glass photovoltaic component and manufacturing method thereof

InactiveCN102916067AEasy to integrateImprove photoelectric conversion efficiencyPhotovoltaic supportsRoof covering using slabs/sheetsBuilding integrationMaterial type

The invention discloses a building material type double-sided glass photovoltaic component, comprising a solar cell core panel, an upper protective layer and a lower protective layer which are arranged at the two sides of the solar cell core panel; the upper protective layer and the lower protective layer are curved glass with the same curvature, the solar cell core panel is made of flexible material, and the curvature of the solar cell core panel is the same to the curvature of the upper protective layer and the lower protective layer. The invention also discloses a manufacturing method for the building material type double-sided glass photovoltaic component. The solar cell core panel can be integrated with the upper protective layer and the lower protective layer into a whole, so that the building material type double-sided glass photovoltaic component is formed and has the features of high photoelectric conversion efficiency, stable performance, long service, safety and reliability, heat insulation, heat preservation, sound insulation, ultraviolet protection, breakage resistance and selective light transmission, certain lighting demand is met, the double-sided lighting power generation is also realized, meanwhile the appearance radian is attractive and elegant, the integration of solar energy and building is realized conveniently, and the building material type double-sided glass photovoltaic component is particularly applicable to various buildings such as a photovoltaic glass curtain wall with complicated curves and planes, a photovoltaic glass lighting roof, a photovoltaic parking shed and a photovoltaic bus shelter.

Owner:SHENZHEN SANXIN FACADE ENG

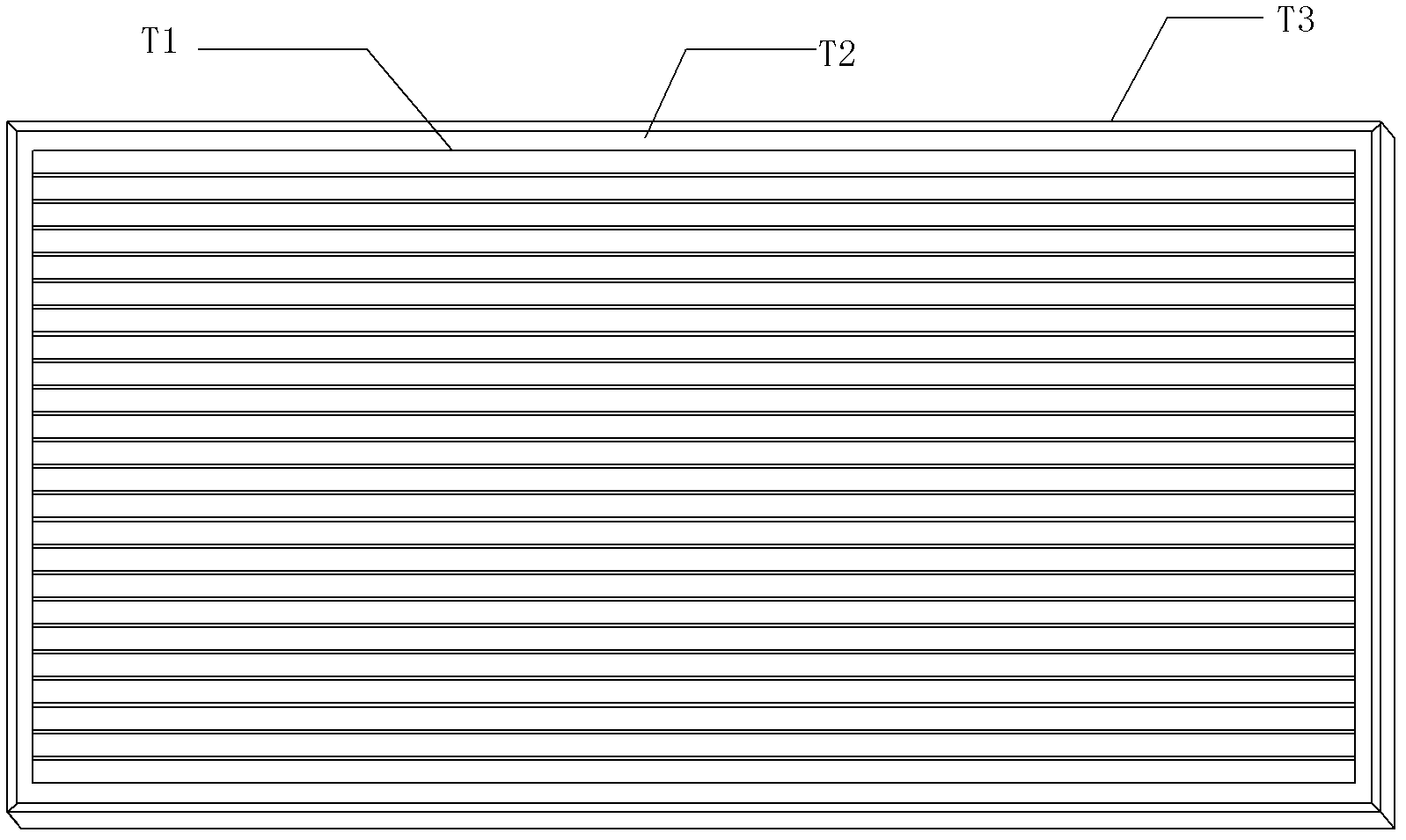

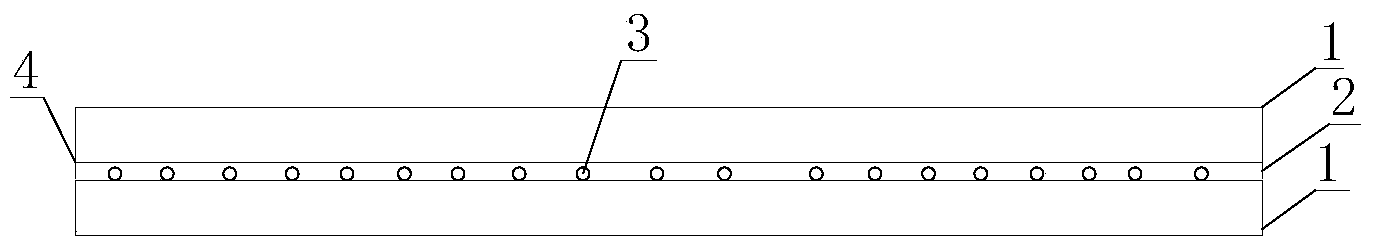

Transparent ultraviolet-proof projection screen and manufacturing method thereof

ActiveCN103472667AHigh transparencyImprove clarityLayered productsProjectorsInorganic saltsInter layer

The invention relates to a projection screen, in particular to a transparent ultraviolet-proof projection screen and a manufacturing method thereof. The projection screen comprises an interlayer, bonding layers and supporting layers from inside to outside. The interlayer comprises titanium dioxide and inorganic salt nanometer particles. The bonding layers enable the interlayer and the supporting layers to be fixed together, and the supporting layers are used for projecting the interlayer and supporting the screen. The manufacturing method comprises the steps that first, different transparent media such as glass or hardened acrylic or polyestercarbonate are selected to be used as the supporting layers according to thickness requirements; second, mixed nanometer particles are added into raw materials composed of glass or resin materials in the so-gel process; third, the fusion methods of the supporting layers and the inter layer involve a high-temperature physical pressing method and an adhesive method. Nanometer particles are evenly distributed inside the transparent ultraviolet-protection projection screen, so that the transparent ultraviolet-protection projection screen is high in transparency and high in definition. Under the condition of photo-permeability, the transparent ultraviolet-protection projection screen can absorb ultraviolet rays and catalyze indoor harmful substances to decompose, and compared with a projection screen of the same quality, has the advantages of being simple in production technology, low in cost and the like.

Owner:SHANGHAI LANMOU MEDIA TECH CO LTD

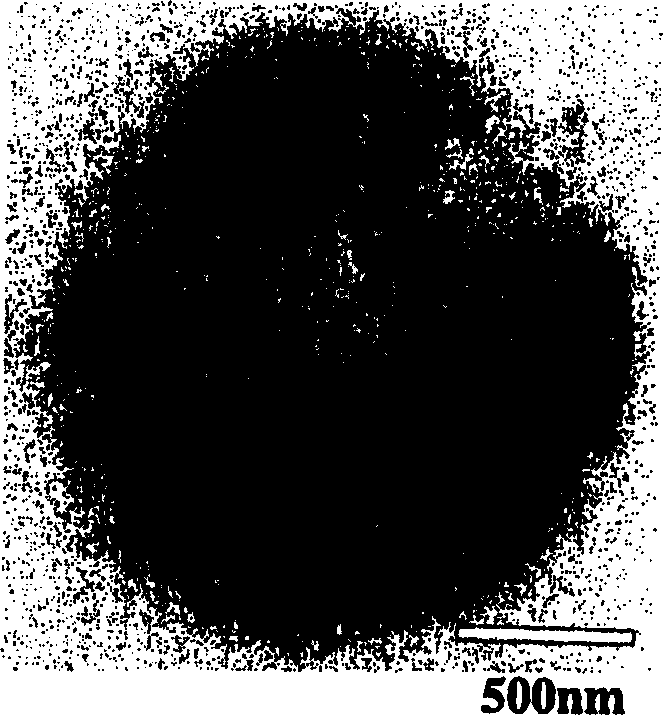

Composite polymer particle and method for preparing same

The invention provides a polymer composite particle having superb blending stability even in a W / O emulsion cosmetic, a highly effective ultraviolet protection effect and a good feeling in use. The invention also relates to a method of producing the polymer composite particle and a cosmetic composition containing the polymer composite particle. A preferred polymer composite particle contains a metal oxide coated with a silicone and / or fluorine compound and has an average particle diameter of 1 mu m or less, wherein the polymer composite particle is obtained by polymerizing a crosslinking agent with a vinyl monomer contained in an amount of 25% by weight based on 100% by weight of the sum of total of all the monomers and crosslinking agent and wherein the vinyl monomer has a solubility parameter calculated by the Fedors method of less than about 8.9. A preferred cosmetic composition may contain (A) a microparticle metal oxide having an average primary particle diameter of from 0.001 to 0.1 mu m, and (B) a flake zinc oxide having an average primary particle size of from 0.1 mu m to 1 mu m and an average thickness of from 0.01 mu m to 0.2 mu m, which provides ultraviolet protection ability and visible-light transmittance.

Owner:KAO CORP

Non-aerosol/aerosol dispensing of sunscreen sprays comprising spherical porous silica microparticles

Nonaerosol / atomizer pumps or aerosol dispensers comprise (A) a reservoir confining at least one vaporizable sunscreen composition suited for UV-photoprotecting the skin and / or hair against the damaging effects of UV radiation, the at least one vaporizable sunscreen composition comprising (1) a UV-photoprotecting amount of at least one UV-sunscreen and (2) an SPF-enhancing amount of generally spherical silica microparticles, formulated into (3) a topically applicable, cosmetically acceptable carrier therefor, and (B) at least one agent for pressurizing the at least one vaporizable sunscreen composition into a spray of fine sunscreen particles.

Owner:LOREAL SA

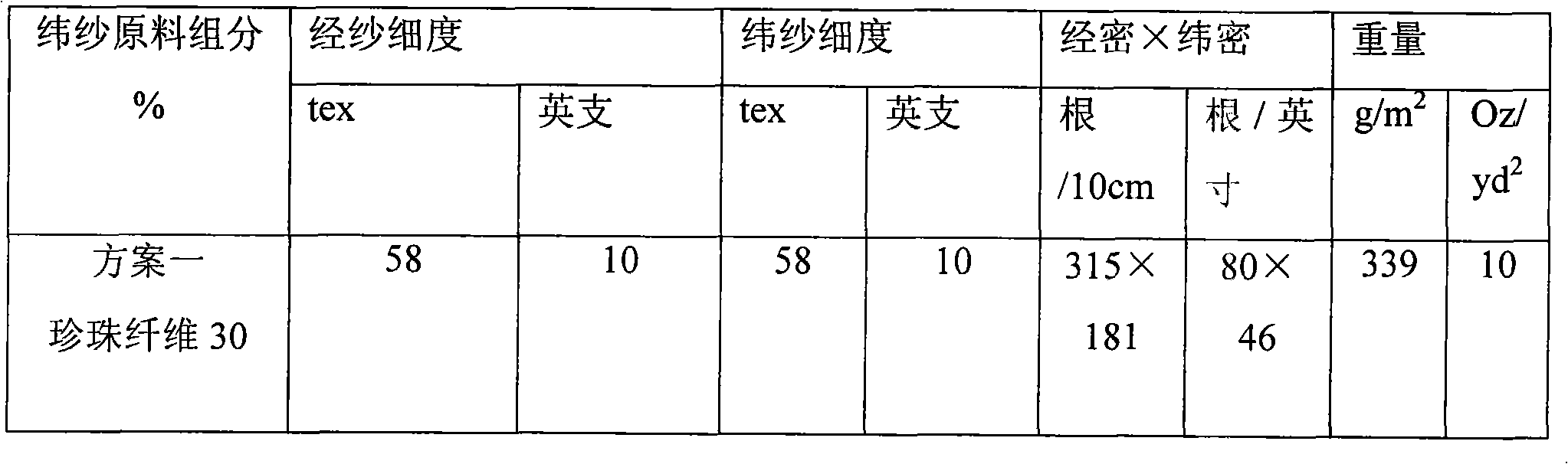

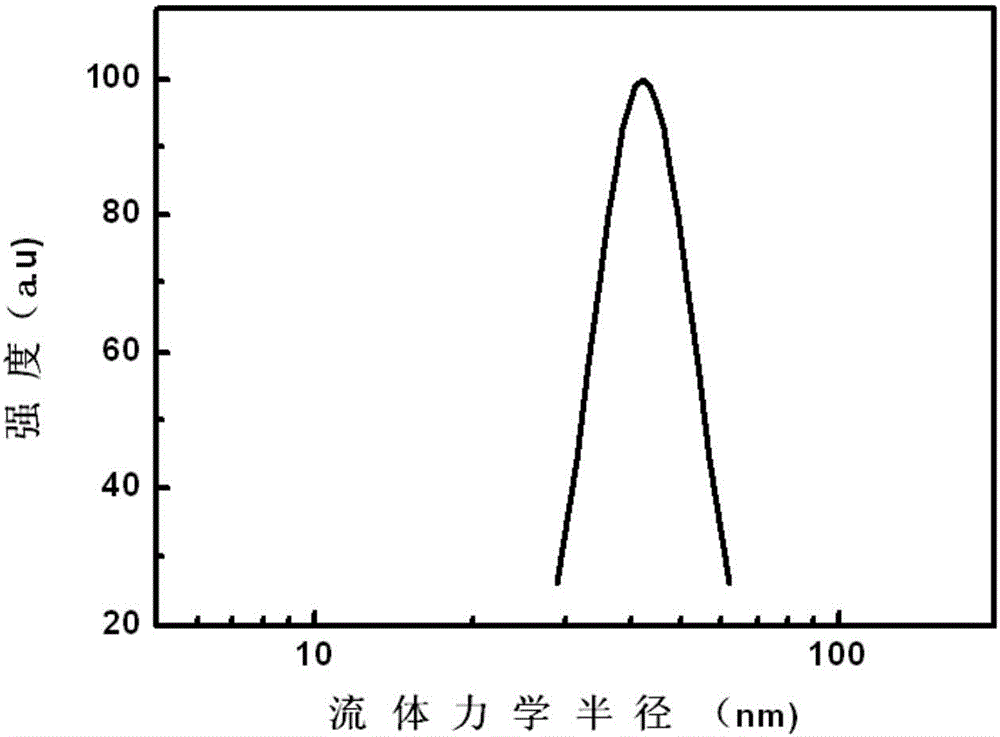

Pearl fibre denim fabric with functions of skin protection and health care

InactiveCN101597829ATimely adjustment of acid-base balanceImprove microcirculationWeft knittingWarp knittingCotton fibreMoisture absorption

The invention relates to a pearl fibre denim fabric with the functions of skin protection and health care. Denim fabric warp yarn adopts cotton fibre yarn, and weft yarn adopts pearl fibre mixed yarn; and the pearl fibre mixed yarn is one or the combination of pearl fibre, natural silky fibre, Modal fibre and cotton fibre, and the mass ratio of the pearl fibre in the weft yarn is 15% to 40%. The normal direction emissivity of the far infrared ray of the denim fabric is 0.81 to 0.898, the ultraviolet prevention feature (UPF) (ultraviolet protection coefficient) is greater than 50, and the denim fabric has the advantages of satiny texture, moisture absorption, ventilation, good serviceability and comfortable wearing.

Owner:DONGHUA UNIV +1

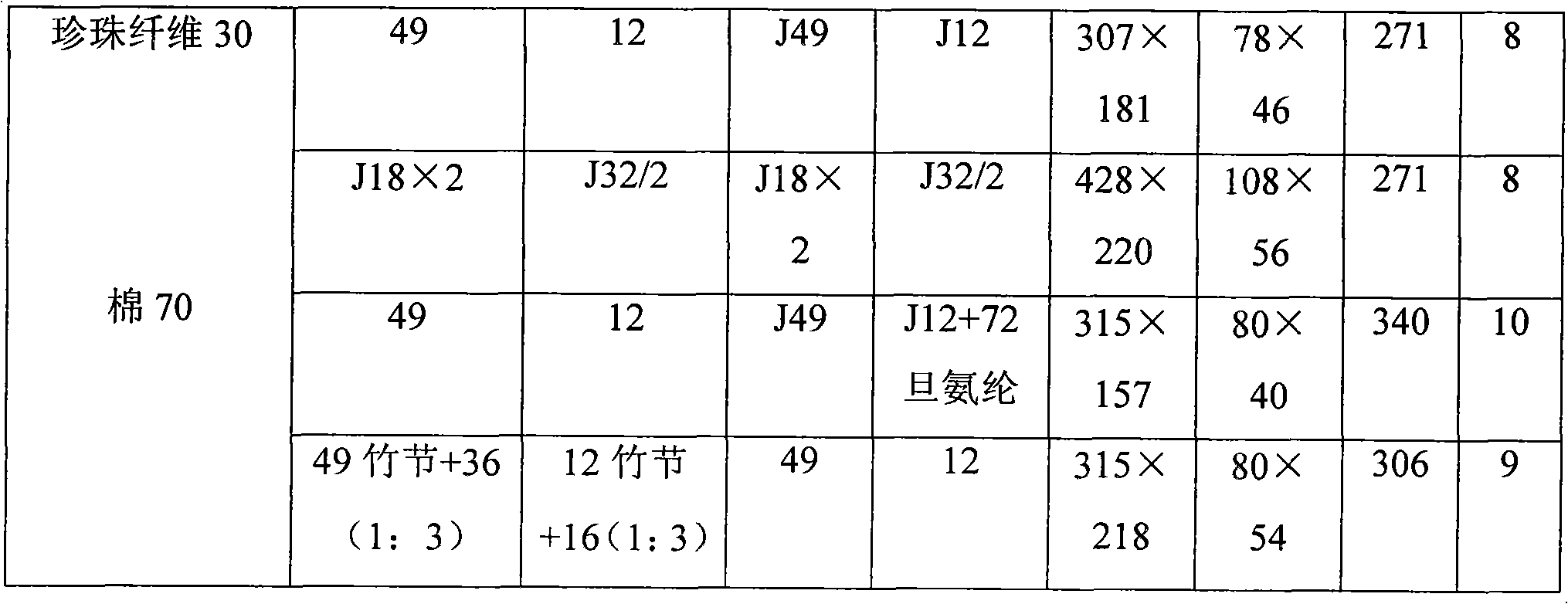

Microcapsules containing suspensions of biologically active compounds and ultraviolet protectant

Owner:ZENECA LTD

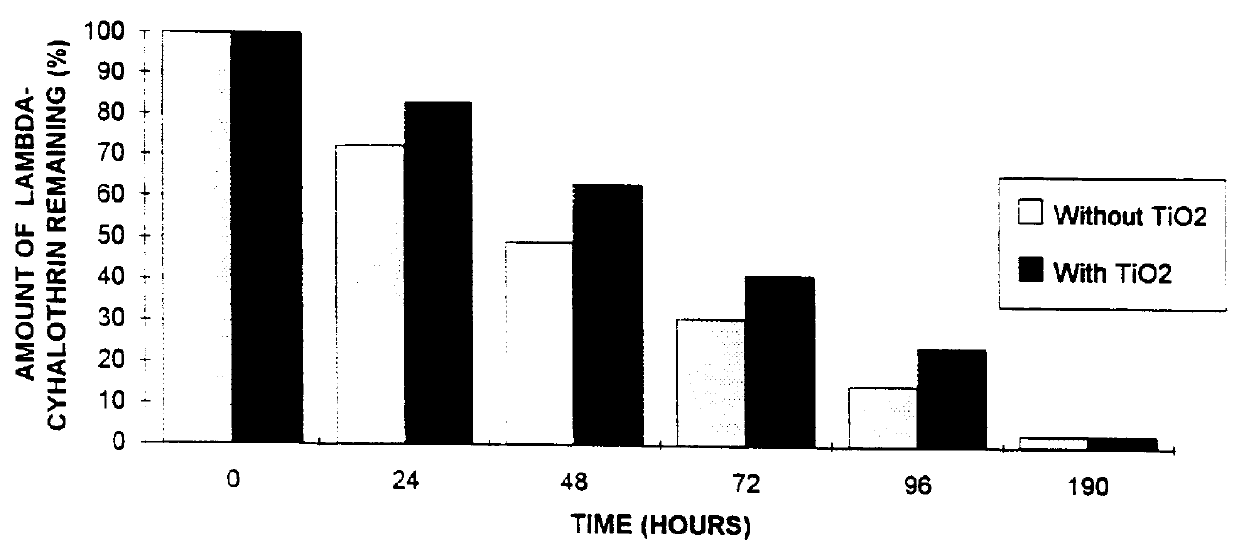

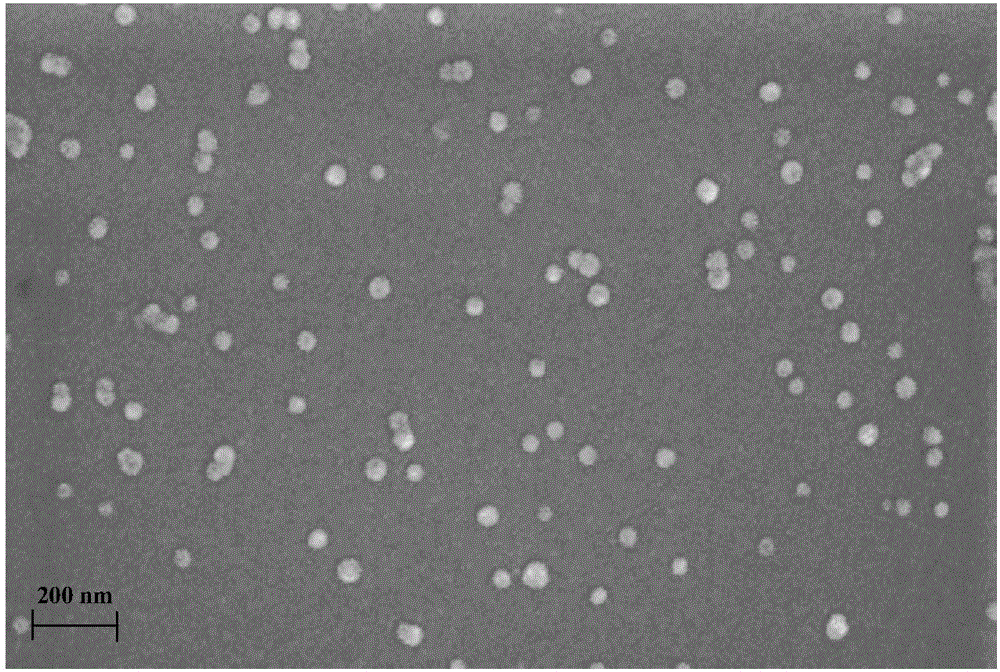

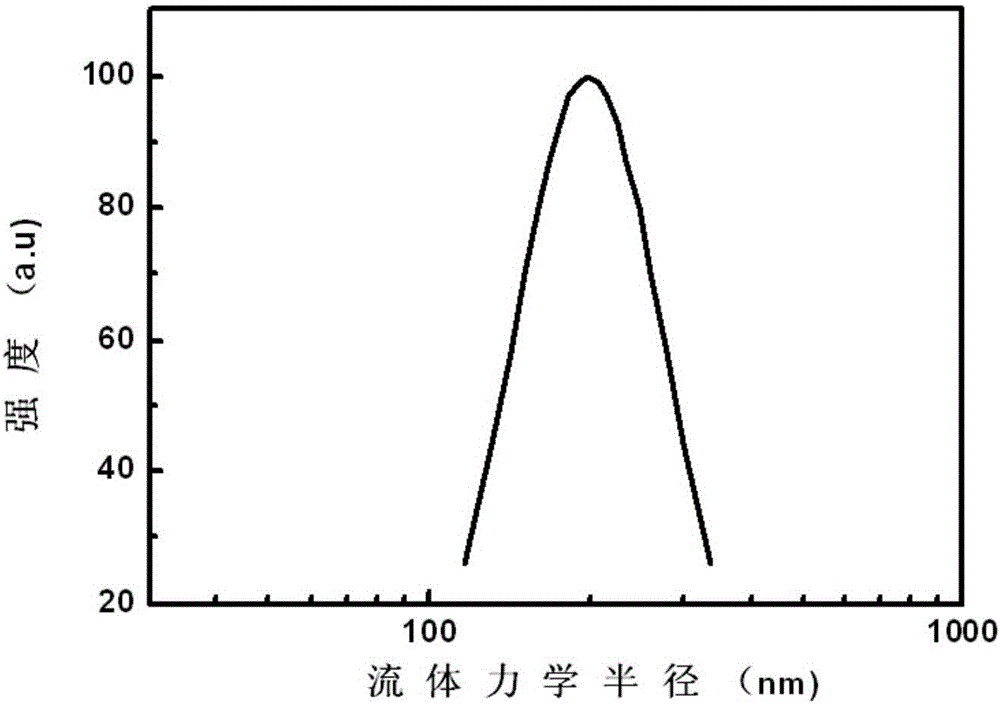

Lignin nano-particles with high ultraviolet protection performance and preparation method of lignin nano-particle

InactiveCN106361591APromote absorptionImprove antioxidant capacityCosmetic preparationsToilet preparationsHydrodynamic radiusChemical products

The invention belongs to the technical field of preparation of nano-materials, and discloses lignin nano-particles with high ultraviolet protection performance and a preparation method and application of the lignin nano-particles. The preparation method comprises the following steps: (1) dissolving 0.1-50 parts by weight of lignin in 1,000-2,000 parts by weight of an acetone / water mixed solvent to obtain a lignin organic solution; and (2) mixing the lignin organic solution in the step (1) with 1,000-4,000 parts by weight of water, and stirring to obtain the lignin nano-particles. The hydrodynamic radius of the lignin nano-particles is 50-300 nm, the lignin nano-particles are solid spherical particles of which hydrophilic groups are positioned externally and hydrophobic groups are positioned internally, the number of phenolic hydroxyl groups distributed on the unit area is large, the ultraviolet protection performance is the best, and the oxidation resistance is the most excellent. The size is controllable, the field of large-scale and high-value application of the lignin is expanded, and particularly, the lignin nano-particles which are used as ultraviolet protecting agents have huge application prospect in the field of high-end daily chemical products such as sun block and skin care.

Owner:SOUTH CHINA UNIV OF TECH

Production process of mirror plastic super-light umbrella fabric

InactiveCN102505486ALightweight and softGood shading effectWalking sticksFibre typesPolyesterUltraviolet protection

The invention provides a production process of a mirror plastic super-light umbrella fabric which is lightproof and has excellent anti-UV (ultraviolet) effect and bright appearance. The production process comprises the following steps of: selecting a gray fabric prepared by weaving superfine fibers, sewing the gray fabric, and then enabling the gray fabric to enter a desizing machine to undergo scouring pre-treatment, wherein the warps and wefts of the gray fabric are prepared by weaving superfine polyester drawn textured yarns; carrying out overflow dyeing on the fabric treated in the step 1; washing the dyed fabric, and then setting the fabric in a dying oven; calendering the set fabric; carrying out three-time coating on the calendered fabric; and post-setting the fabric undergone coating, thus finally obtaining a finished product. The production process has the following beneficial effects: the fabric has good anti-UV property; the UV shielding rate can be within 5 / 10,000; the UPF (ultraviolet protection factor) can reach 50+; and besides, the fabric has bright appearance.

Owner:蔡艺萍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com