Radiation-proof light-filtering contact lens and production method thereof

A technology of contact lenses and production methods, applied in glasses/goggles, optics, optical components, etc., can solve the problems of unsightly appearance, low ultraviolet protection performance, loss, etc., and achieve good moisture content and good oxygen transmission coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Hydroxyethyl methacrylate: 90 parts;

[0071] n-vinylpyrrolidone: 10 parts;

[0072] Ethylene glycol dimethacrylate: 0.3 parts;

[0073] Azobisisobutyronitrile: 0.15 parts;

[0074] Tetraphenyldimethacrylic acid (English name: 4-[(E)-phenyldiazenyl]phenyl-2-methacrylate): 0.7 parts;

[0075] Quinophthalone Solvent Yellow: 3 parts.

[0076] The method for making a contact lens using the contact lens material of this implementation may include the following steps in turn:

[0077] Step (1) making a half-mold: making a convex mold, the curvature of the inner side of the bottom is the same as that of the contact lens, as a forming mold for the contact lens.

[0078] The half-mold making process includes:

[0079] (1) Drying of raw materials: Put an appropriate amount of PBT granular raw materials into a dryer for drying and then take them out for use;

[0080] (2) Injection molding machine preparation: connect the power supply of the injection molding machine, turn on...

Embodiment 2-5

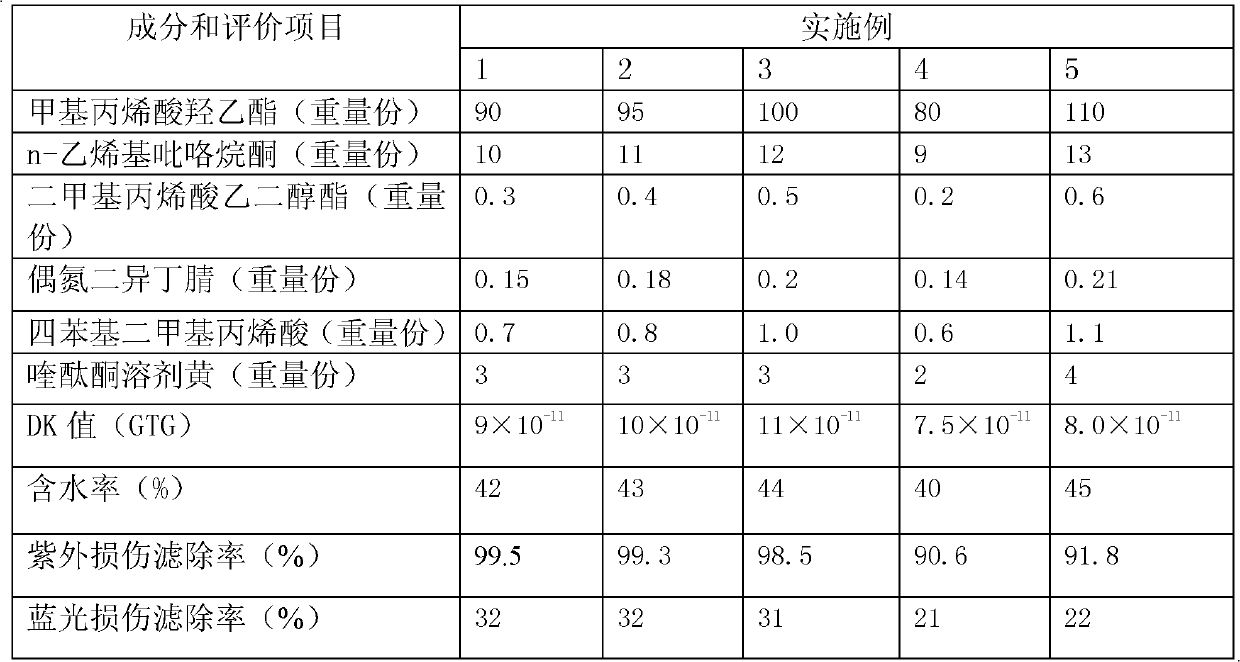

[0103] Embodiment 2-5 carries out the same operation as embodiment 1 except that the proportioning ratio of components is changed, and the results are shown in Table 1.

[0104] Table 1

[0105]

Embodiment 6-10

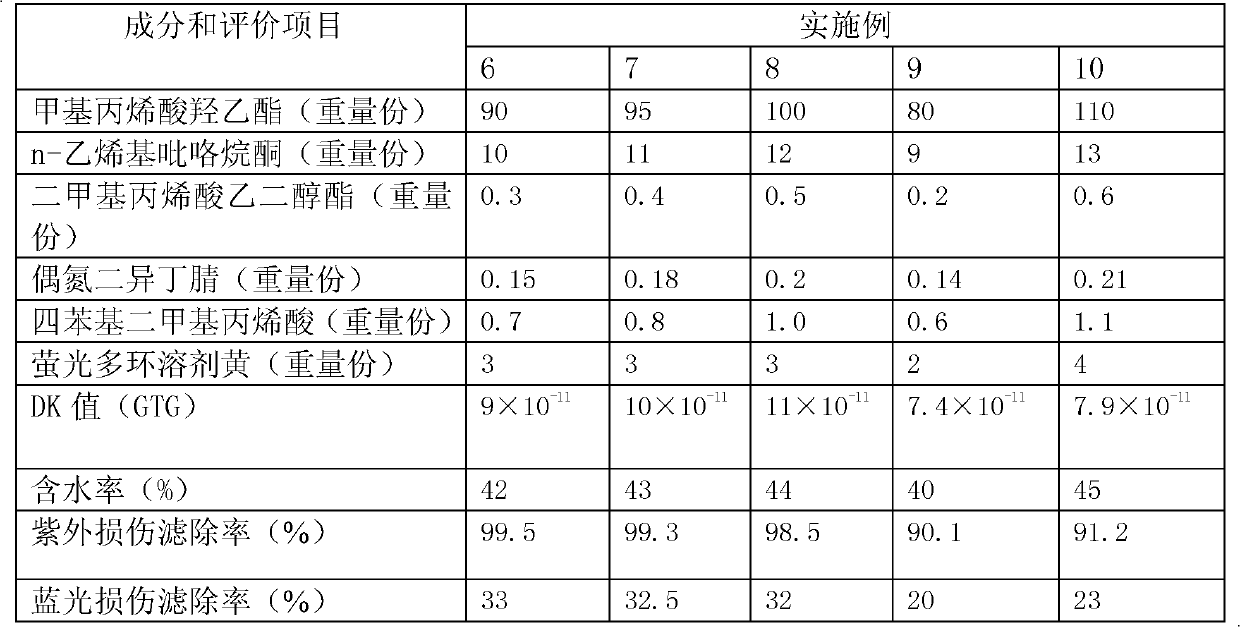

[0107] Embodiment 6-10 carries out the same operation with embodiment 1 except that the proportioning ratio of component is changed, and embodiment 6-10 and

[0108] The difference of Examples 1-5 is that quinophthalone solvent yellow is replaced by fluorescent polycyclic solvent yellow, and the results are shown in Table 2.

[0109] Table 2

[0110]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com