Pitaya peel-based edible packaging film and preparation method thereof

A technology of pitaya peel and packaging film, applied in packaging, wrapping paper, transportation and packaging, etc., to achieve excellent antibacterial properties, simple preparation method, and the effect of improving shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

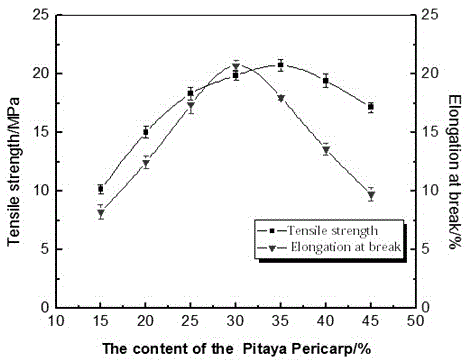

[0035] Taking the edible packaging film based on pitaya peel, its components are pitaya peel slurry concentrations are product 1: 15%, product 2: 20%, product 3: 25%, product 4: 30%, product 5: 35% , Product 6: 40%, Product 7: 45%; the amount of sodium alginate and glycerin added is 0.35% and 0.20% of the above slurry, respectively;

[0036] (1) Choose fresh pitaya peel and cut it into 1.5×1.5cm cubes, blanching with 2% sodium chloride solution at 85°C for 2 minutes, pick up and rinse with cold water, and drain;

[0037] (2) According to the different ratios of dragon fruit peel: distilled water (ranging from 15:85 to 45:55), put it into a beater and beat for 10 minutes to make a film slurry;

[0038] (3) Add 0.35% sodium alginate and 0.20% glycerin to the membrane slurry, and homogenize for 8 minutes at a homogenization speed of 16000r / min to make the slurry fine and uniform;

[0039] (4) Degas for 50 minutes when the vacuum degree is -0.095MPa, and pour out the membrane slu...

Embodiment 2

[0042] The edible packaging film based on pitaya peel, its component is pitaya 35% (W / W), water 65% (W / W); Make film slurry, sorbitol is 0.2% of making film slurry quality , the sodium carboxymethyl cellulose addition is 0.35% of the quality of the film slurry, and the preparation method is the same as in Example 1.

Embodiment 3

[0044] The edible packaging film based on pitaya peel is composed of 35% pitaya peel and 65% water; the film slurry is made, glycerin is 0.3% of the mass of the film slurry, and the amount of sodium alginate added is Membrane slurry 0.4%, preparation method is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com