Building material type double-sided glass photovoltaic component and manufacturing method thereof

A photovoltaic component and double-sided glass technology, which is applied in the support structure of photovoltaic modules, semiconductor/solid-state device manufacturing, photovoltaic modules, etc. The radian is beautiful and generous, the photoelectric conversion efficiency is high, and the performance is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

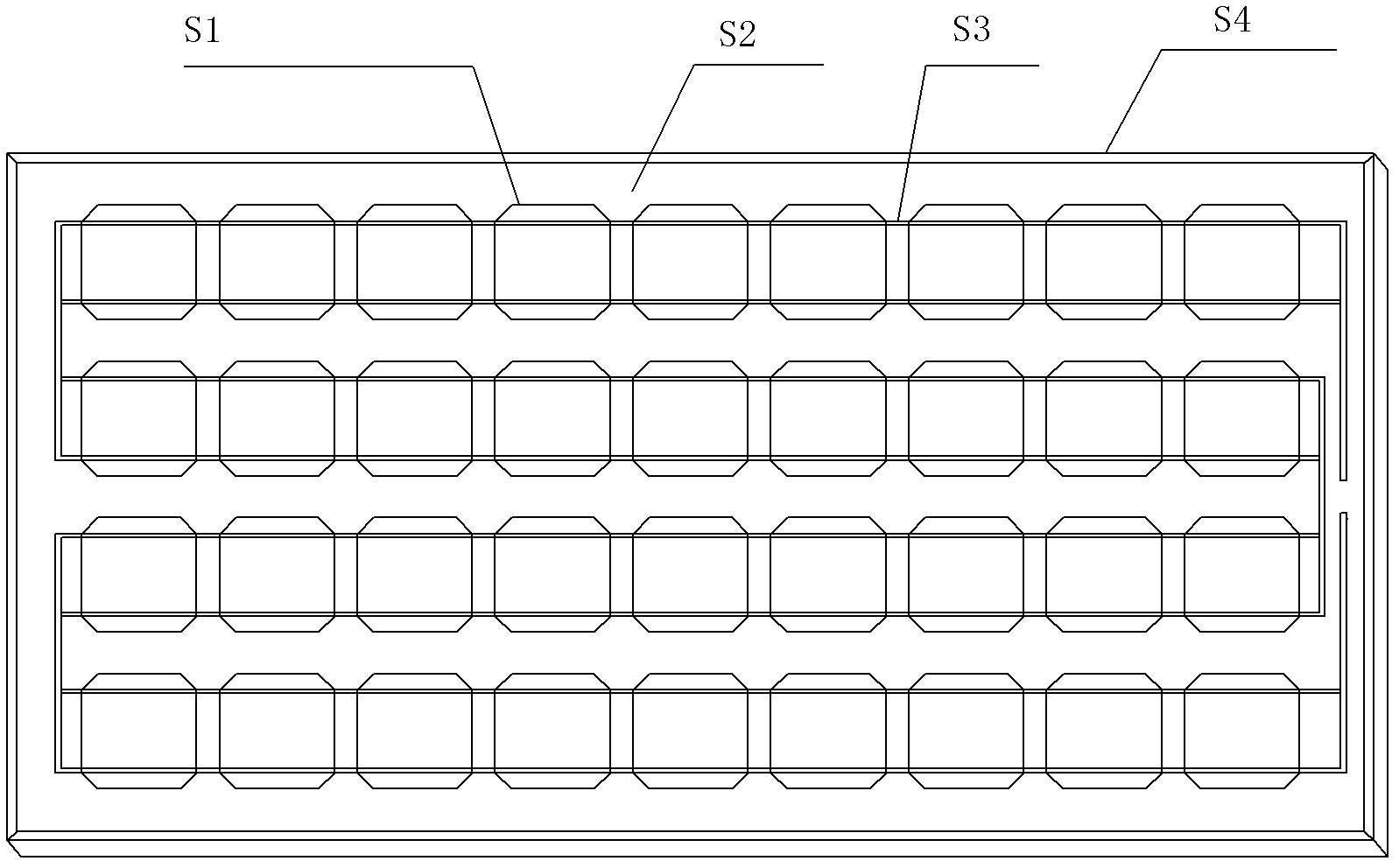

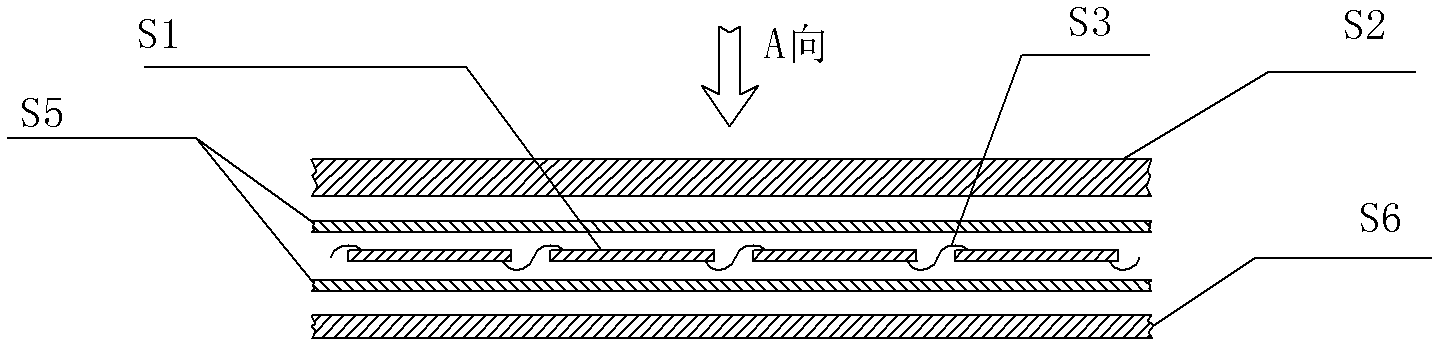

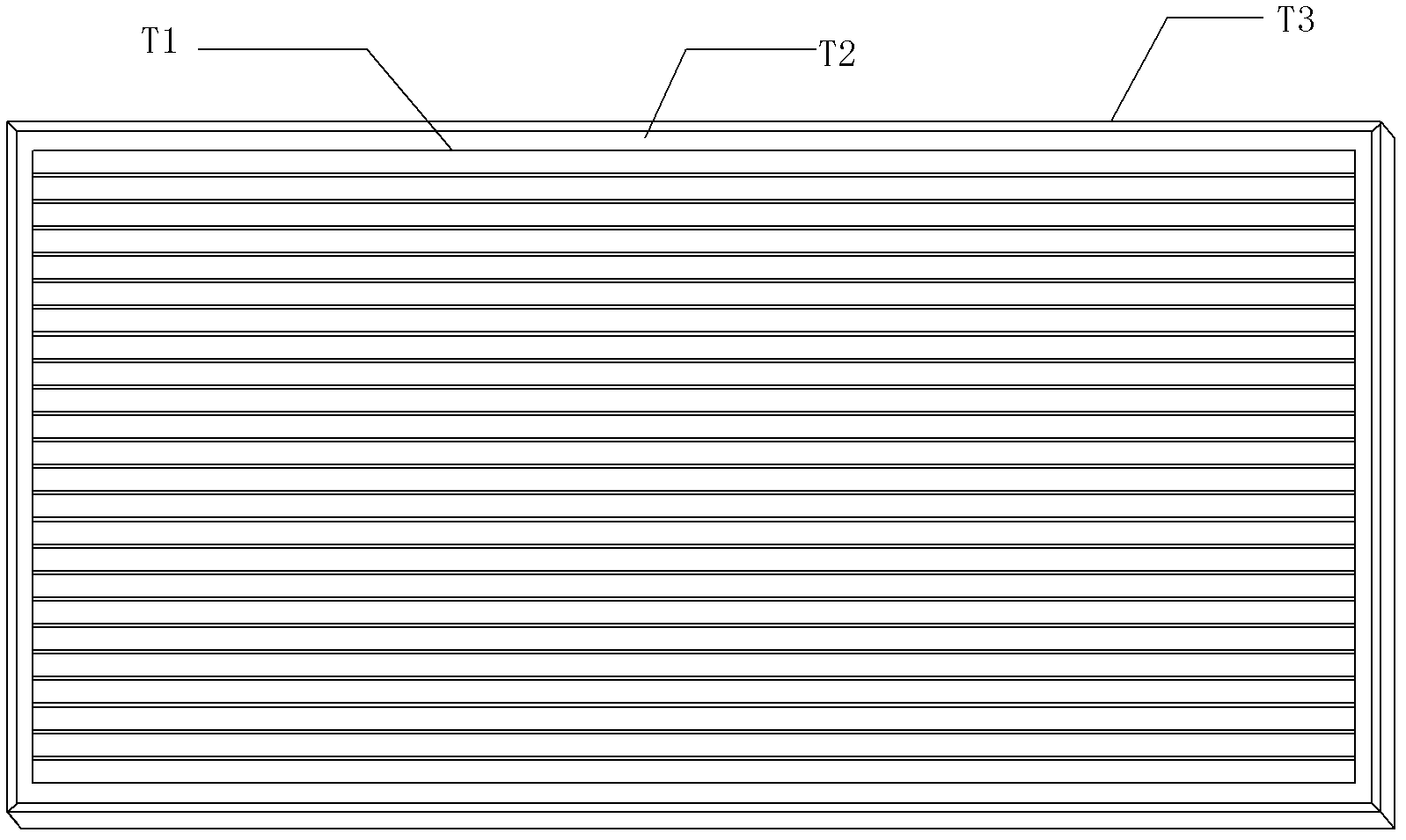

[0067] Such as Figure 6A , Figure 6B , Figure 6C , Figure 6D , Figure 6E Shown are the structural schematic diagrams of the single curved surface type, the folded curved surface type, the compound curved surface type, the spherical crown type multi-curved curved surface type, and the twisted multi-curved curved surface type of the building material type double glass photovoltaic component of the present invention; Figure 6F It is a schematic diagram of the metal foil substrate solar cell building material type double glass photovoltaic component of the present invention Figure 1 , Figure 6G It is a schematic diagram of the metal foil substrate solar cell building material type double glass photovoltaic component of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com