A kind of preparation method of anti-ultraviolet knitted coated fabric

A technology of anti-ultraviolet and coated fabrics, which is applied in the direction of textiles, papermaking, fiber treatment, etc., can solve the problems of knitted fabrics such as stress deformation, etc., and achieve the effect of soft hand feeling, good anti-ultraviolet performance and good washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the drawings and specific embodiments, so as to better illustrate the technical features and product characteristics of the present invention.

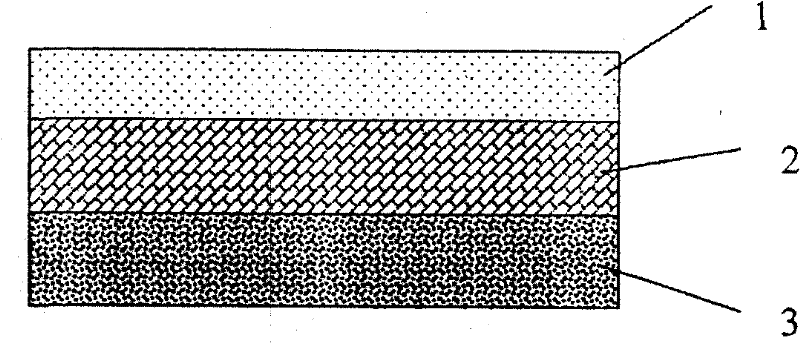

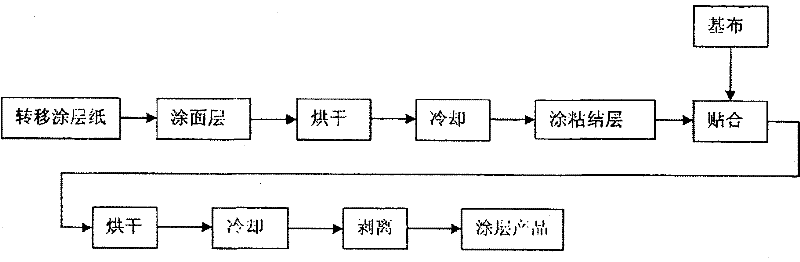

[0022] The invention adopts transfer coating technology, and the product structure is a layer layer 1, a layer of adhesive layer 2 and a layer of base cloth 3. Its processing steps are as follows:

[0023] 1), choose a weight of 100g / m 2 The pure cotton weft jersey fabric is used as the base fabric.

[0024] 2) Preparation of the surface coating agent: the surface coating agent is made of the following raw materials in weight ratio. 100 parts of polyurethane resin, 30 parts of toluene, 10 parts of pigment water. During the preparation process, use a mixer to fully stir, and then stand still for defoaming.

[0025] 3) Preparation of the adhesive layer coating agent: the adhesive layer coating agent is made of the following raw materials in weight ratio. 100 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com