Intake duct for model turbine tester and model turbine tester

A technology of air intake pipe and tester, which is applied in the direction of instrumentation, engine testing, machine/structural component testing, etc. It can solve problems such as installation difficulties and achieve the effects of correcting processing deviations, fast connection forms, and tight installation coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered.

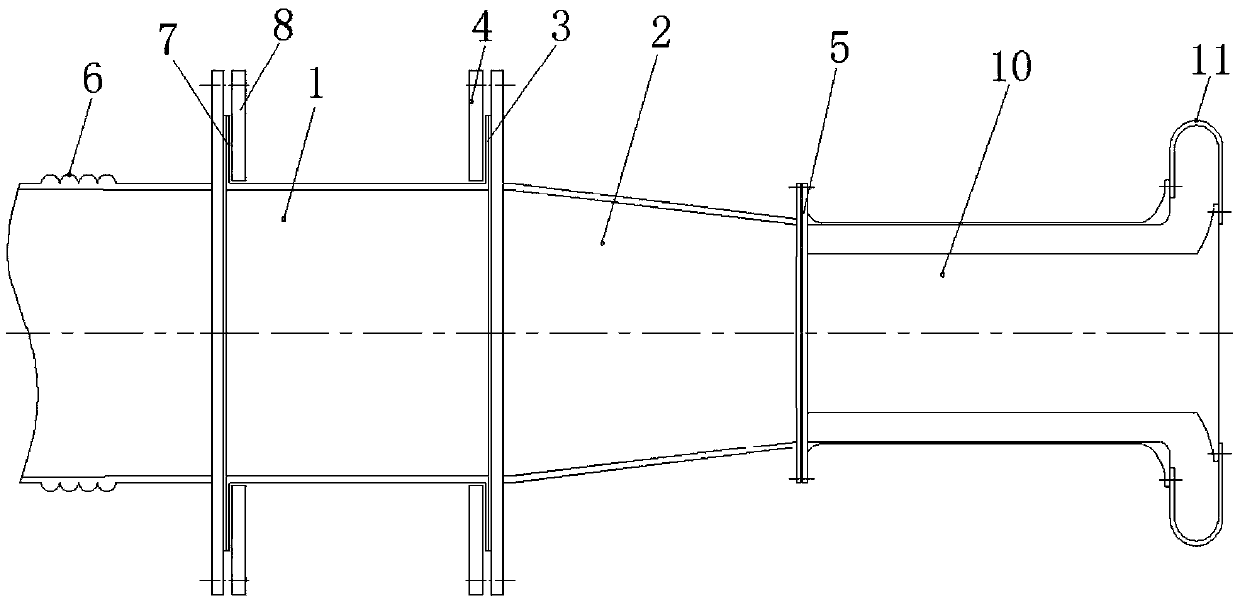

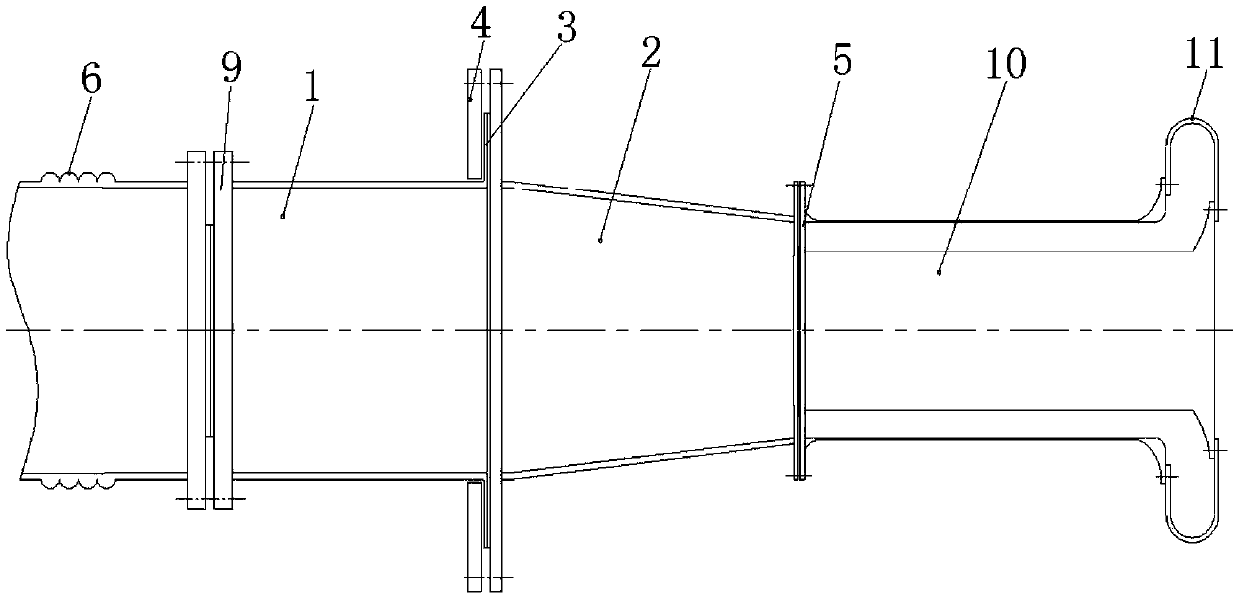

[0024] figure 1 It is one of the schematic diagrams of the structure of the intake pipe for the model turbine tester in the preferred embodiment of the present invention; figure 2 It is the second schematic diagram of the structure of the intake pipe for the model turbine tester in the preferred embodiment of the present invention.

[0025] like figure 1 and figure 2 As shown, the intake pipe used in the model turbine tester of this embodiment includes an intake pressure stabilizing section 1 and an intake transition section 2, the intake stabilizing section 1 is connected with the intake transition section 2, and the intake air The first end of the pressure stabilizing section 1 is provided with a first annular flange 3 protruding radially outward from the pipe, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com