Pearl fibre denim fabric with functions of skin protection and health care

A pearl fiber, denim fabric technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of rough reverse side of the fabric, increased tactile difference, decreased comfort, etc., to achieve good durability, accelerated microcirculation, microcirculation enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

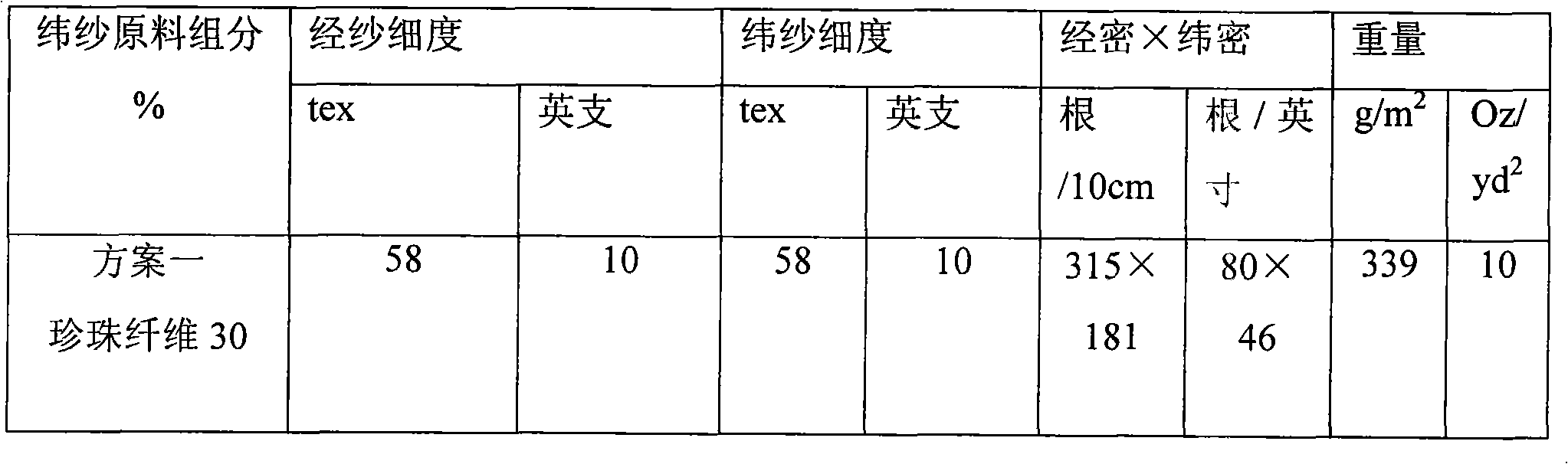

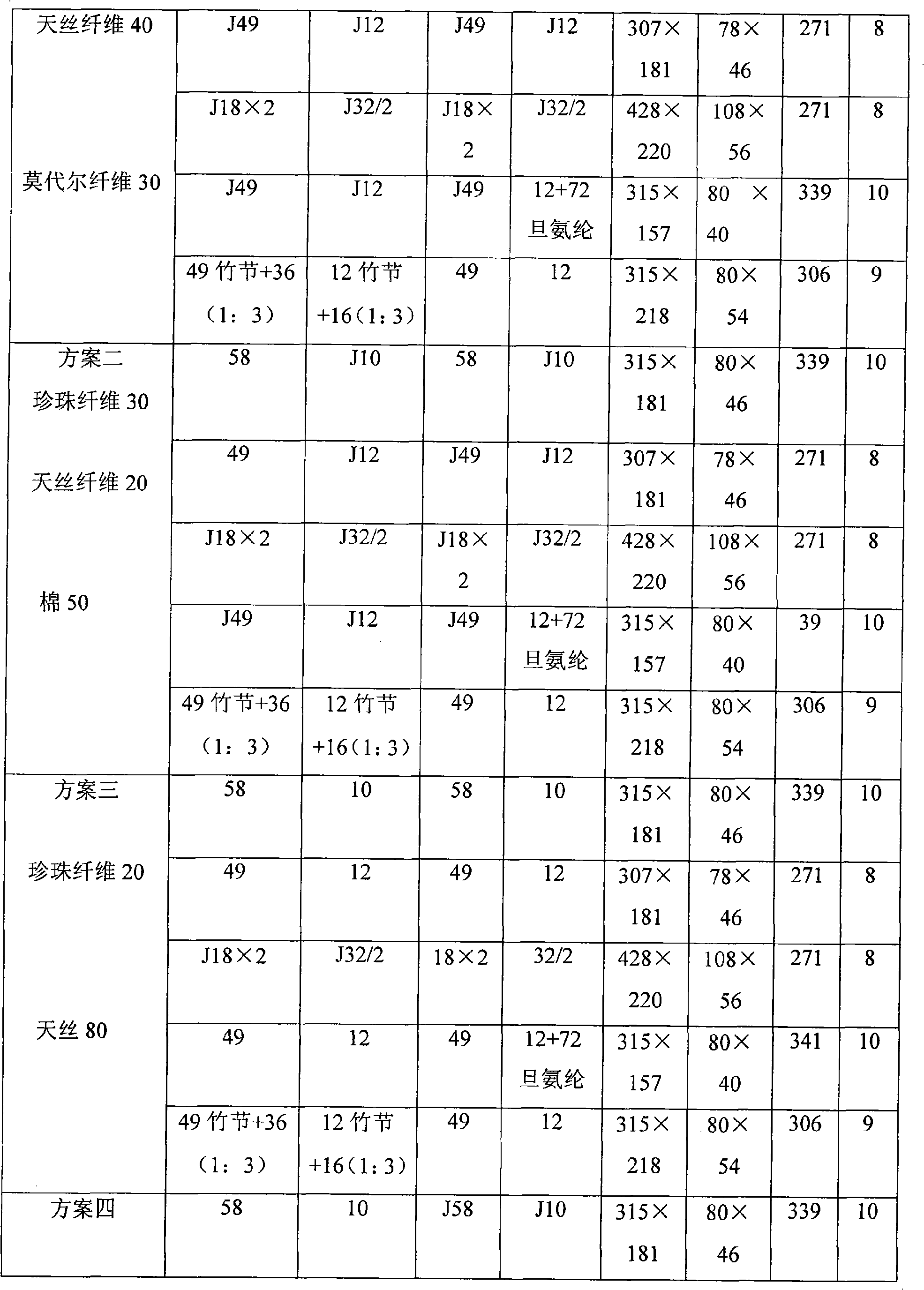

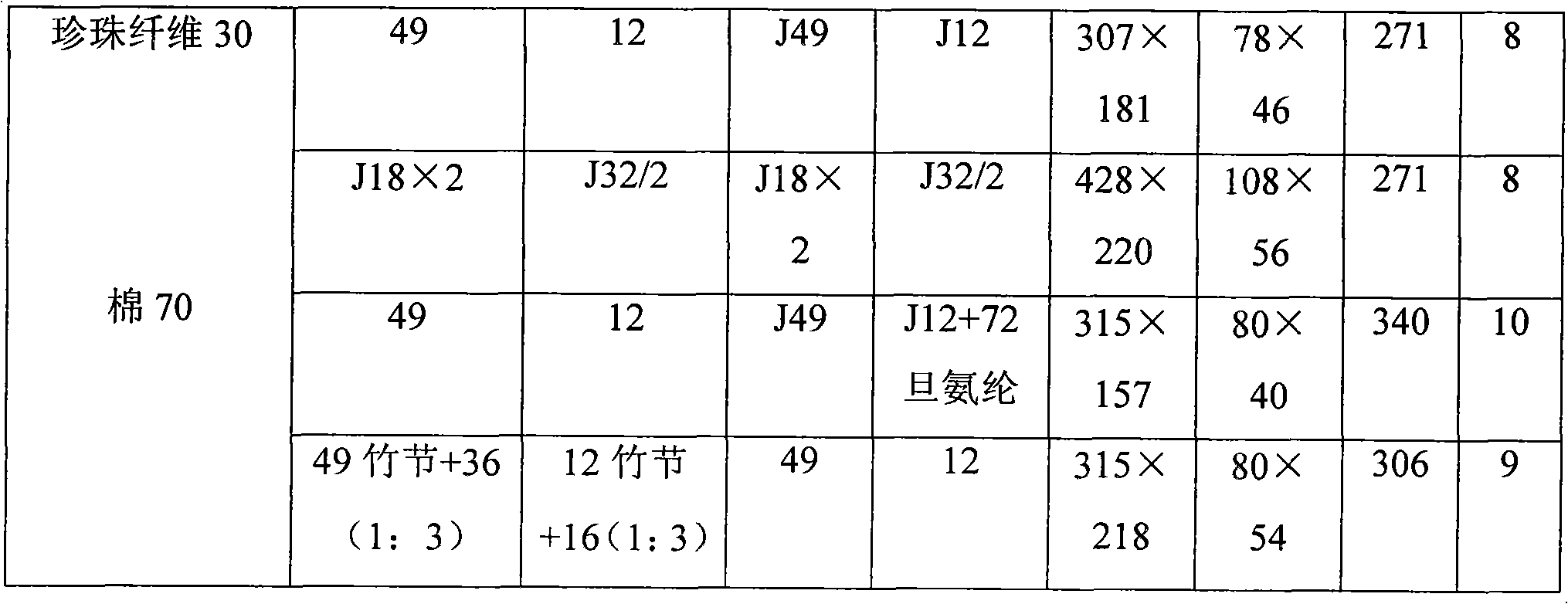

[0034] According to actual needs, the composition of the weft yarn and its mass ratio can adopt one of the following schemes:

[0035] Blending scheme 1 - pearl fiber 15% to 40%, tencel fiber 20% to 50%, modal fiber 20% to 40%;

[0036] Blending scheme 2 - 15% to 40% of pearl fiber, 20% to 40% of tencel fiber, and 30% to 50% of cotton fiber;

[0037] Blending scheme 3 - pearl fiber 15% to 40%, tencel fiber 60% to 85%;

[0038] Blending scheme 4 - 15% to 40% of pearl fiber and 60% to 85% of cotton fiber.

[0039] The weft yarn can be spun into 8 s ~42 s woven yarn.

[0040] The component ratio and specification of each scheme embodiment of pearl fiber jeans with skin care and health care functions according to the present invention are shown in the table below:

[0041] Basic parameters of pearl fiber denim fabric

[0042]

[0043]

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com