Patents

Literature

38results about How to "Multiple benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

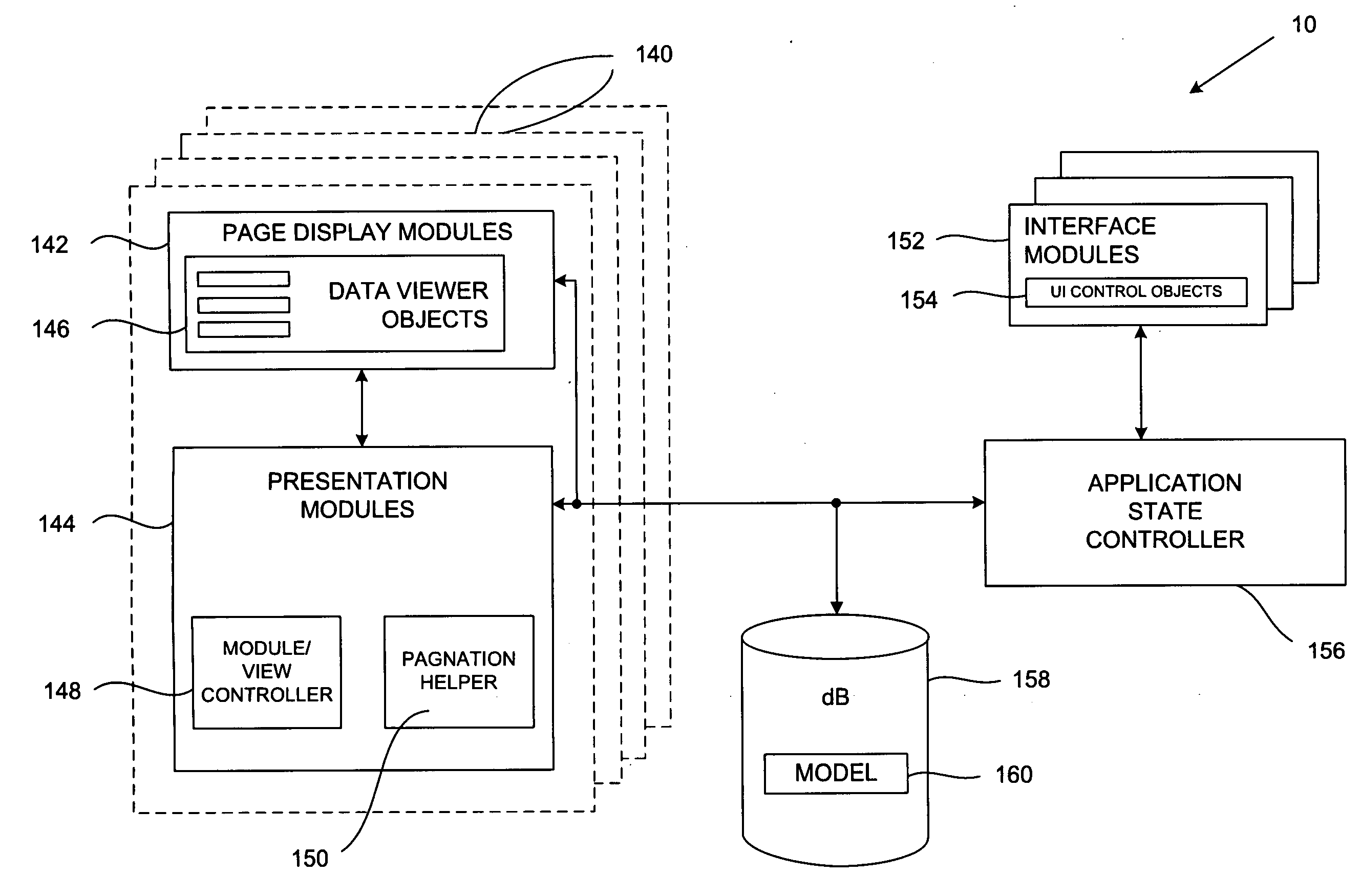

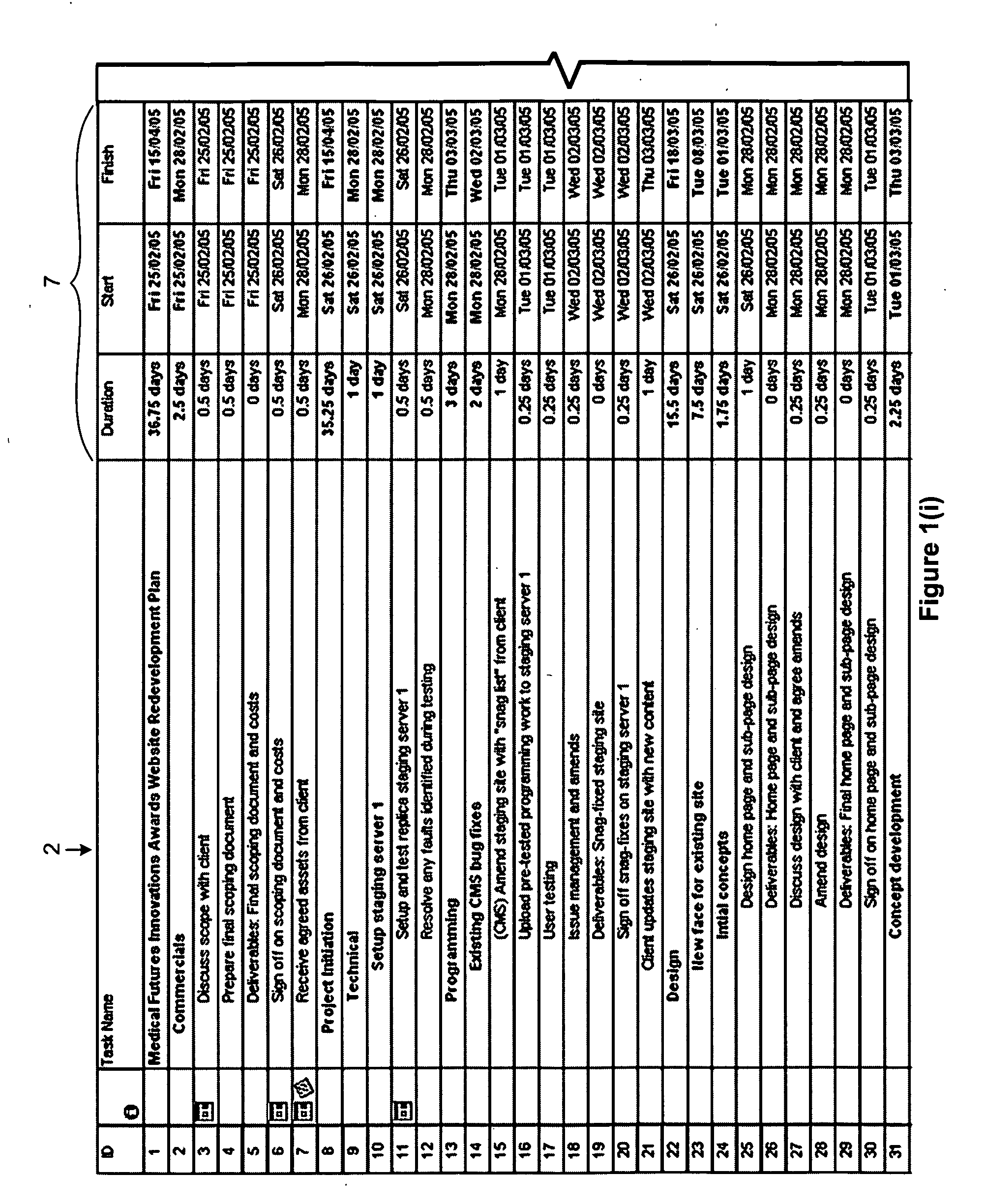

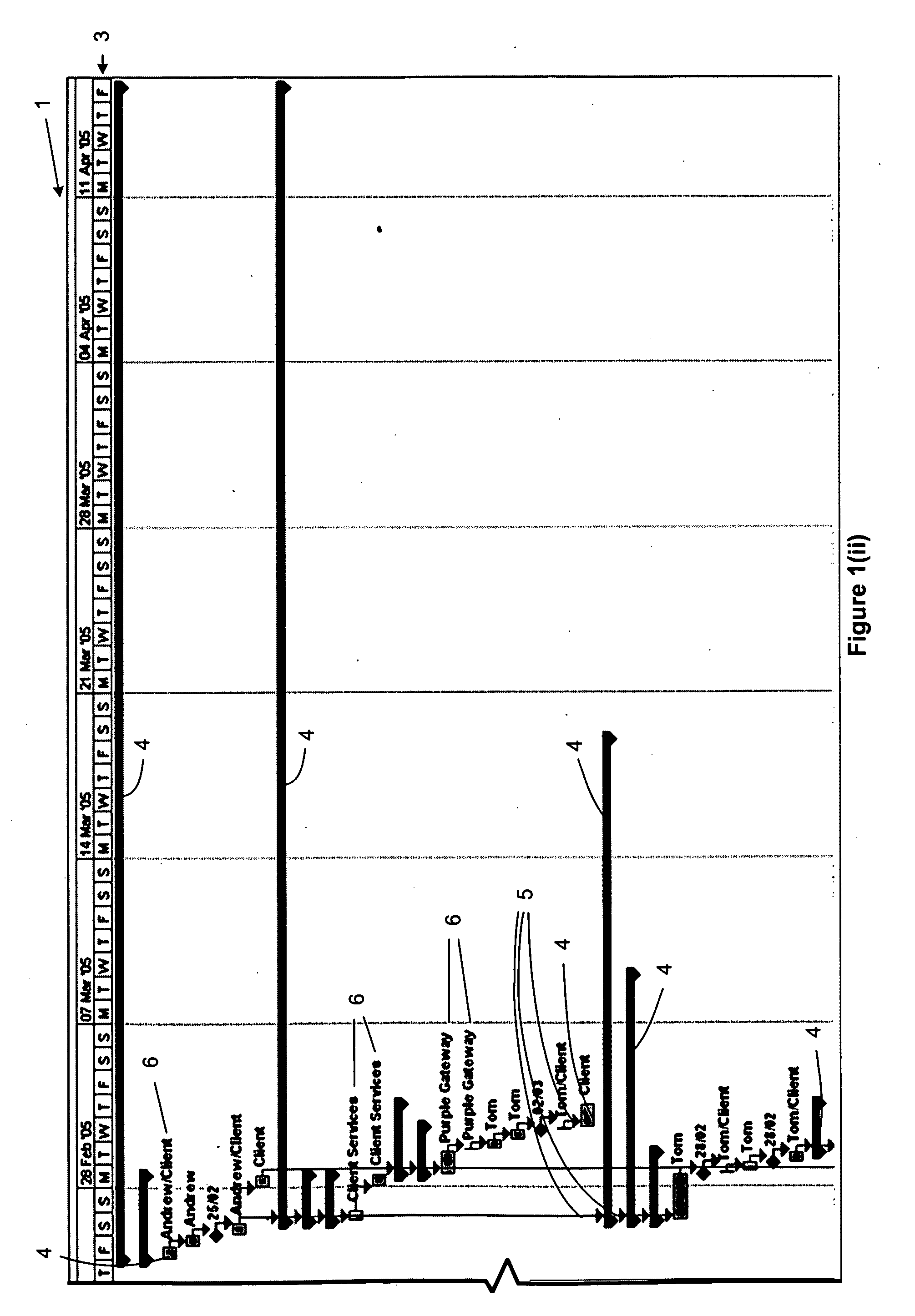

Graphical user interfaces

InactiveUS20090199113A1Quickly and easily thinkFacilitate communicationOffice automationResourcesGraphicsGraphical user interface

A Graphical User Interface (GUI) for use in project management is described. The GUI comprises: an interface module arranged to receive low-level user information relating to project events and high-level information relating to at least one project overview attribute; and a page generation module arranged to generate on a single hierarchical display page of the GUI: a structured detailed view portion for displaying editable project details within a data compilation with the low-level event-related user information represented as graphical components within the data compilation; and a management overview portion for displaying an editable project overview with the high-level information provided therein.

Owner:TORRIDON SOLUTIONS

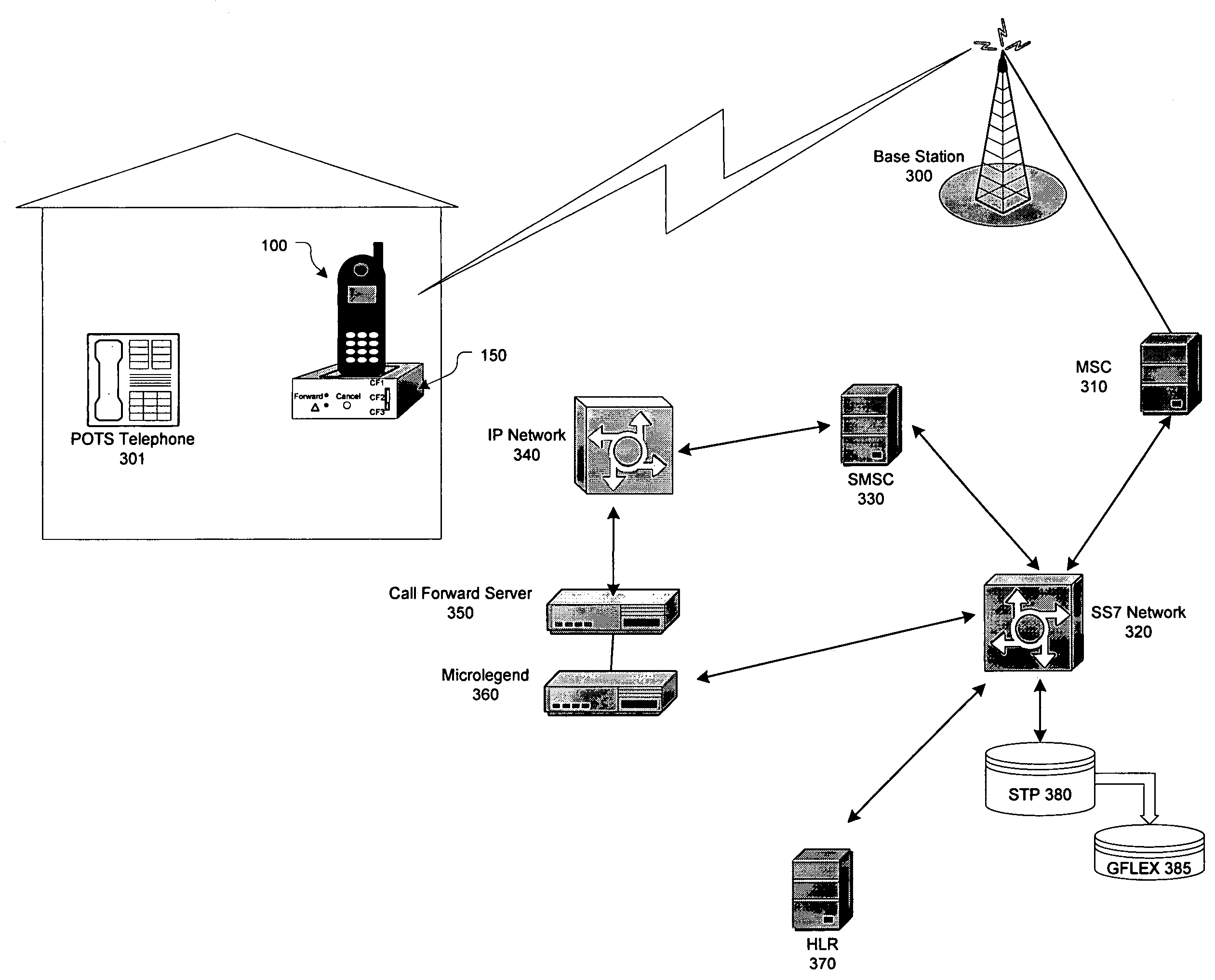

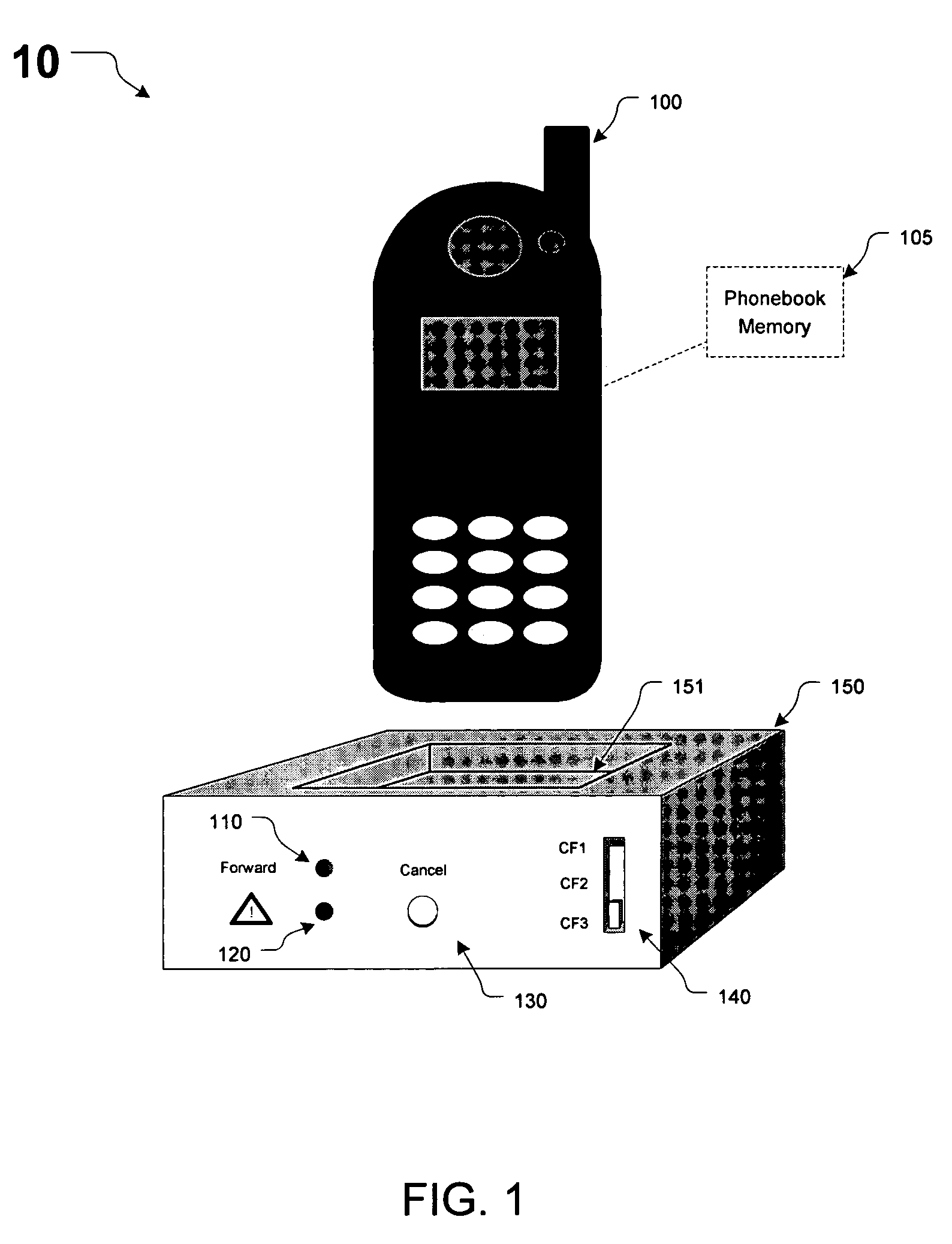

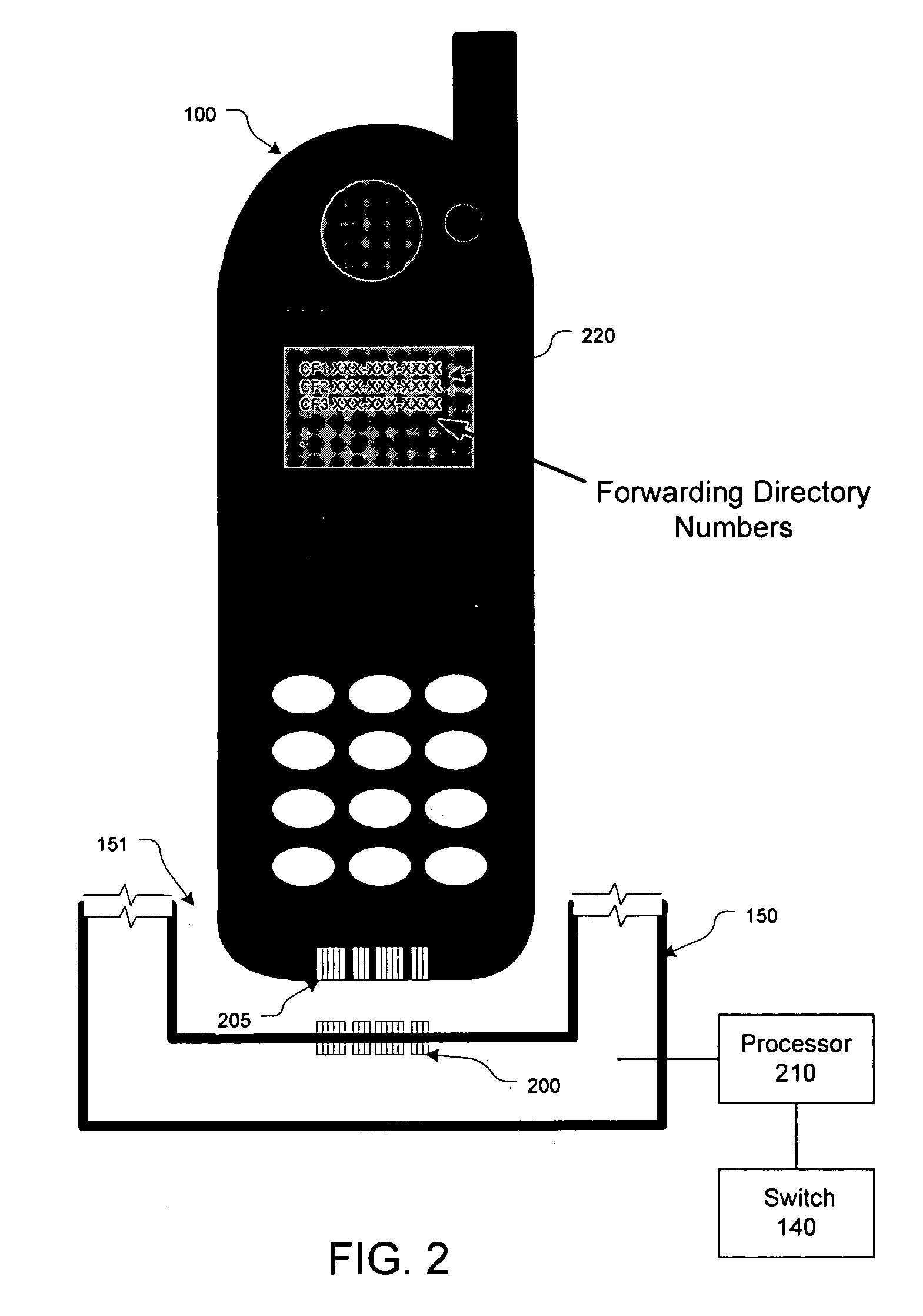

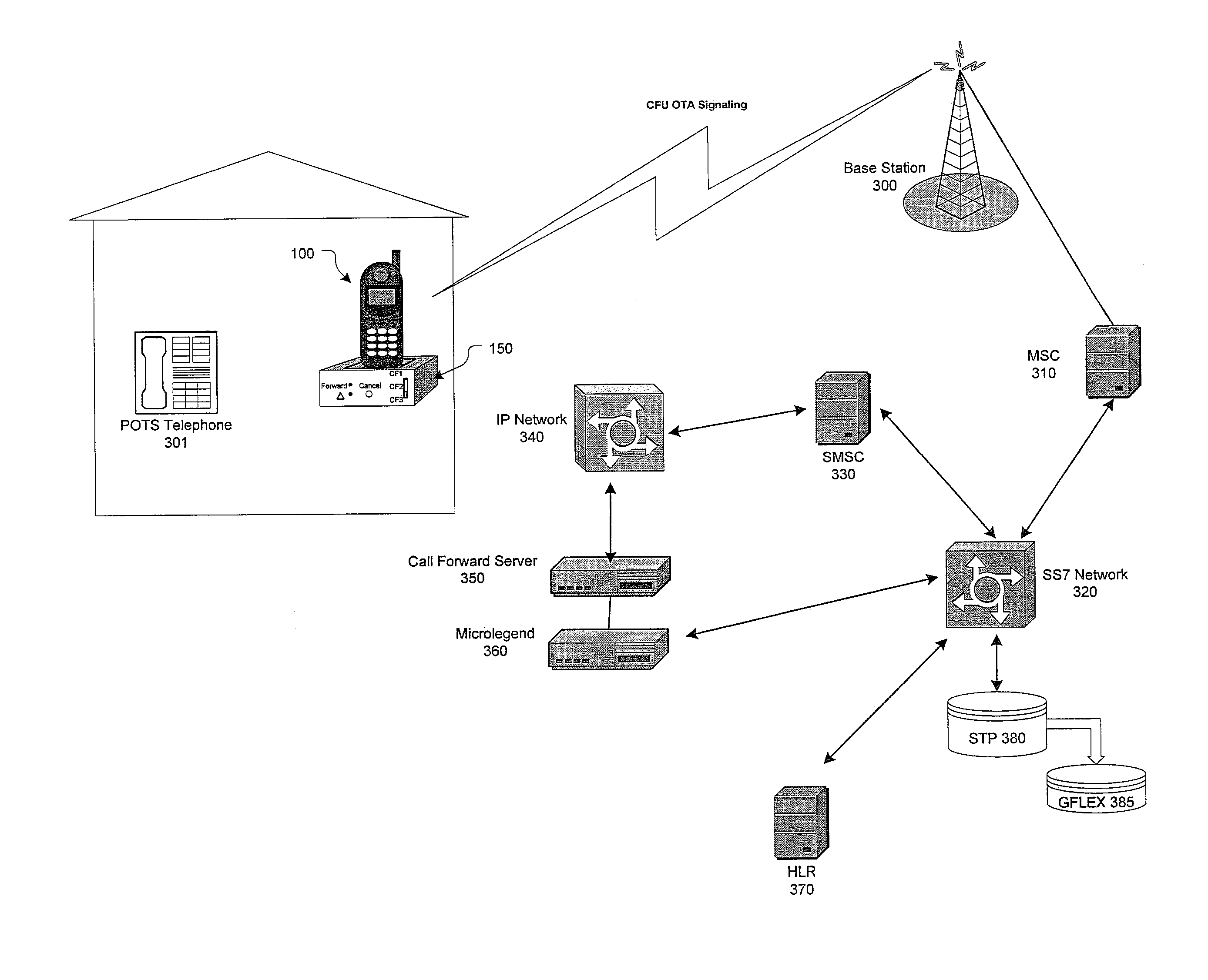

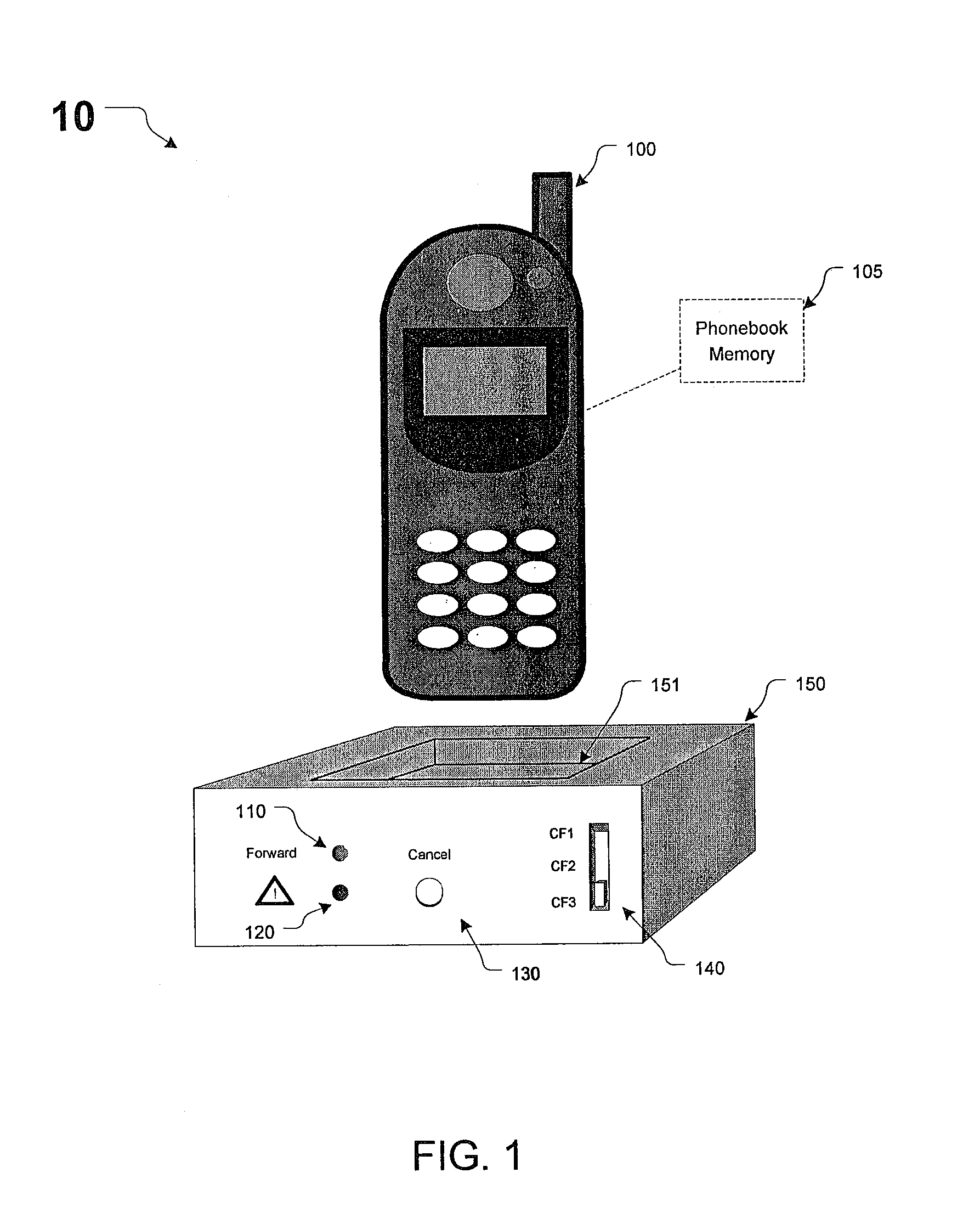

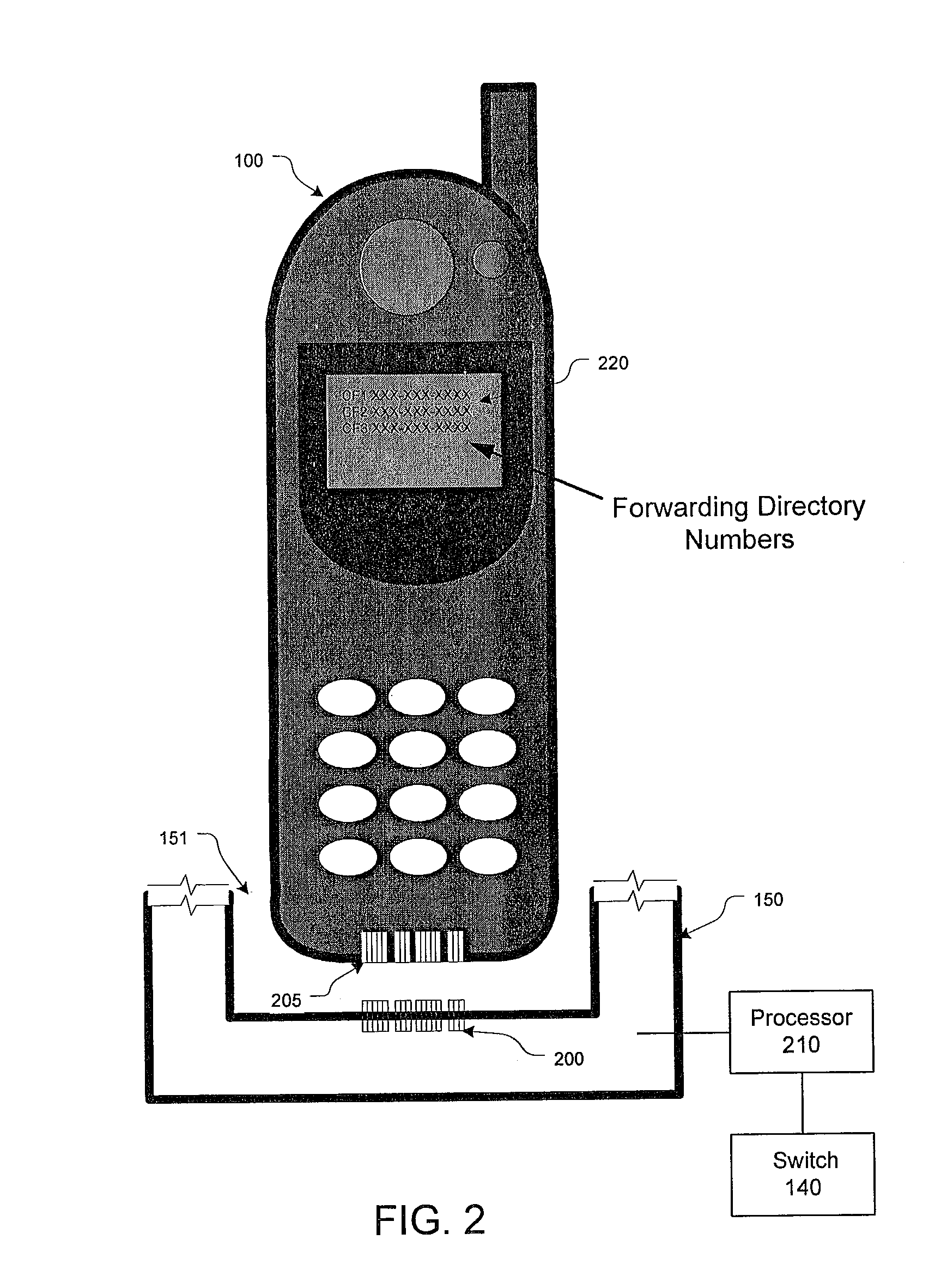

Systems and methods for automatic call forwarding in a wireless mobile station

ActiveUS7116975B1Easy to mergeService conveniently and inexpensivelySpecial service for subscribersCommmunication supplementary servicesCall forwardingMobile station

Apparatus, method and system for notifying a communications-switching center that subsequent communications directed to a wireless number associated with the wireless unit are to be routed to a destination number associated with the wireless unit. In response to a triggering event by the wireless unit through the base unit, the base unit causes the wireless unit to transmit an SMS message to the communications-switching center. The SMS message includes a notification that subsequent communications directed to the wireless number associated with the wireless unit are to be routed to the destination number associated with the wireless unit.

Owner:CINGULAR WIRELESS II LLC

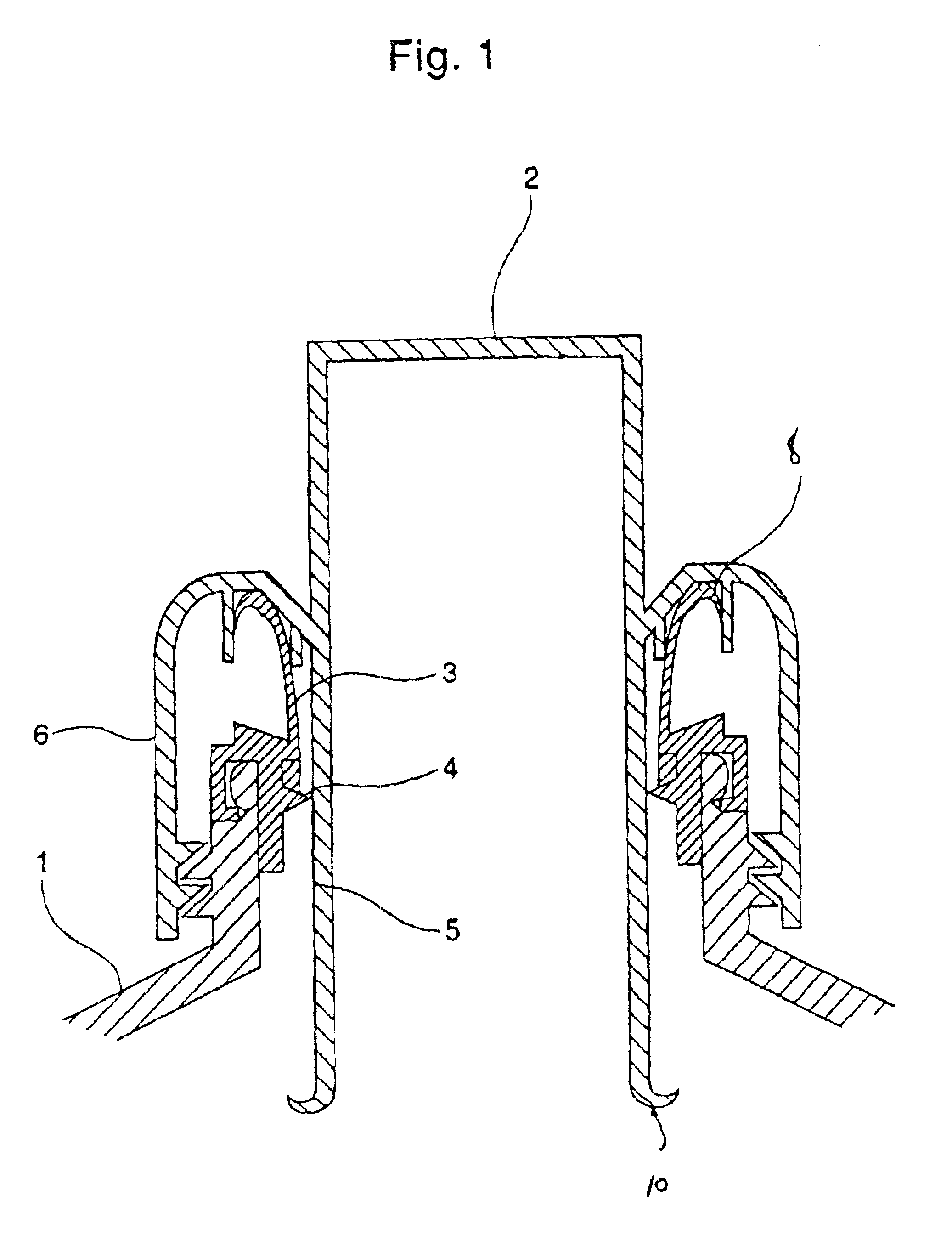

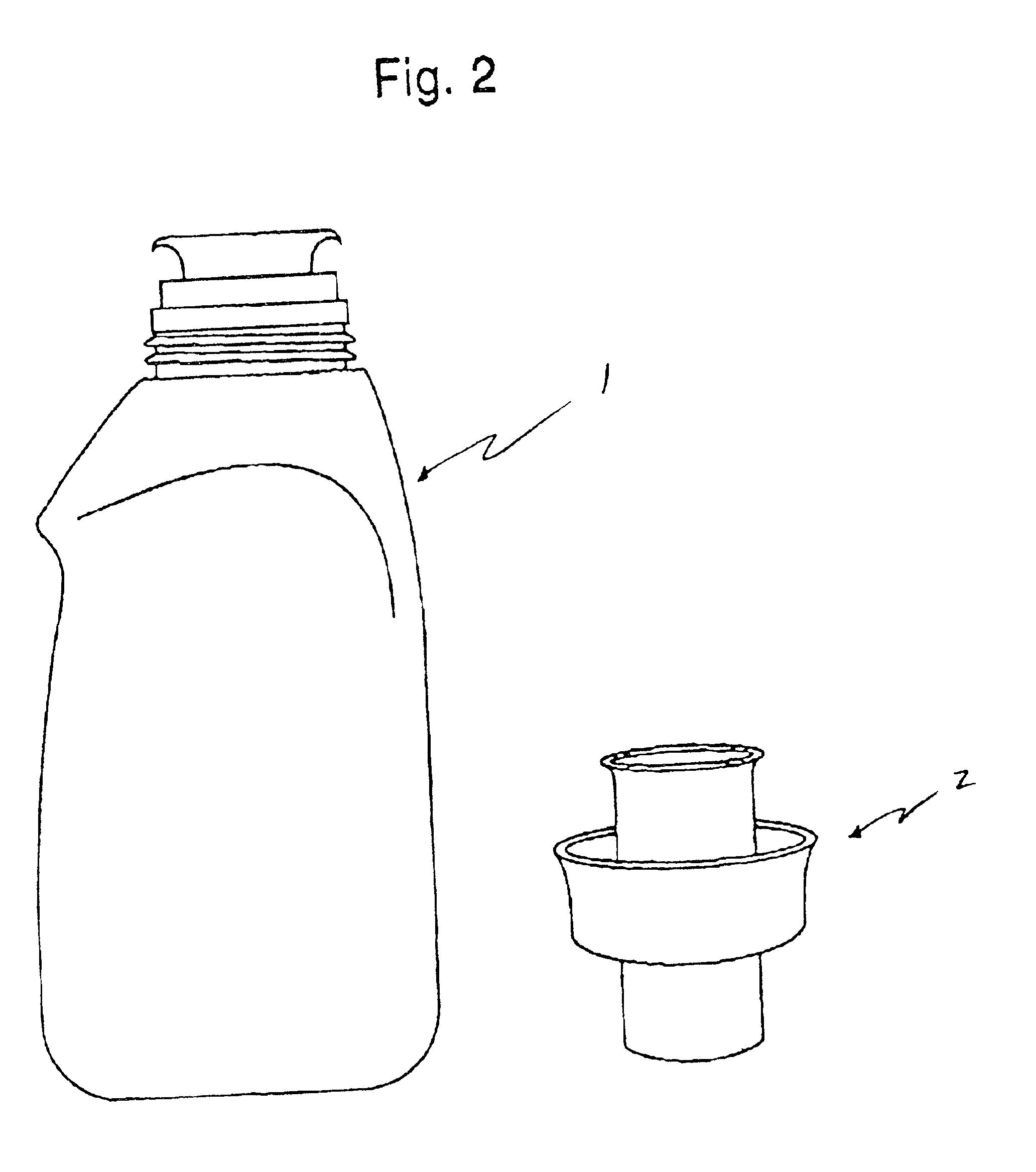

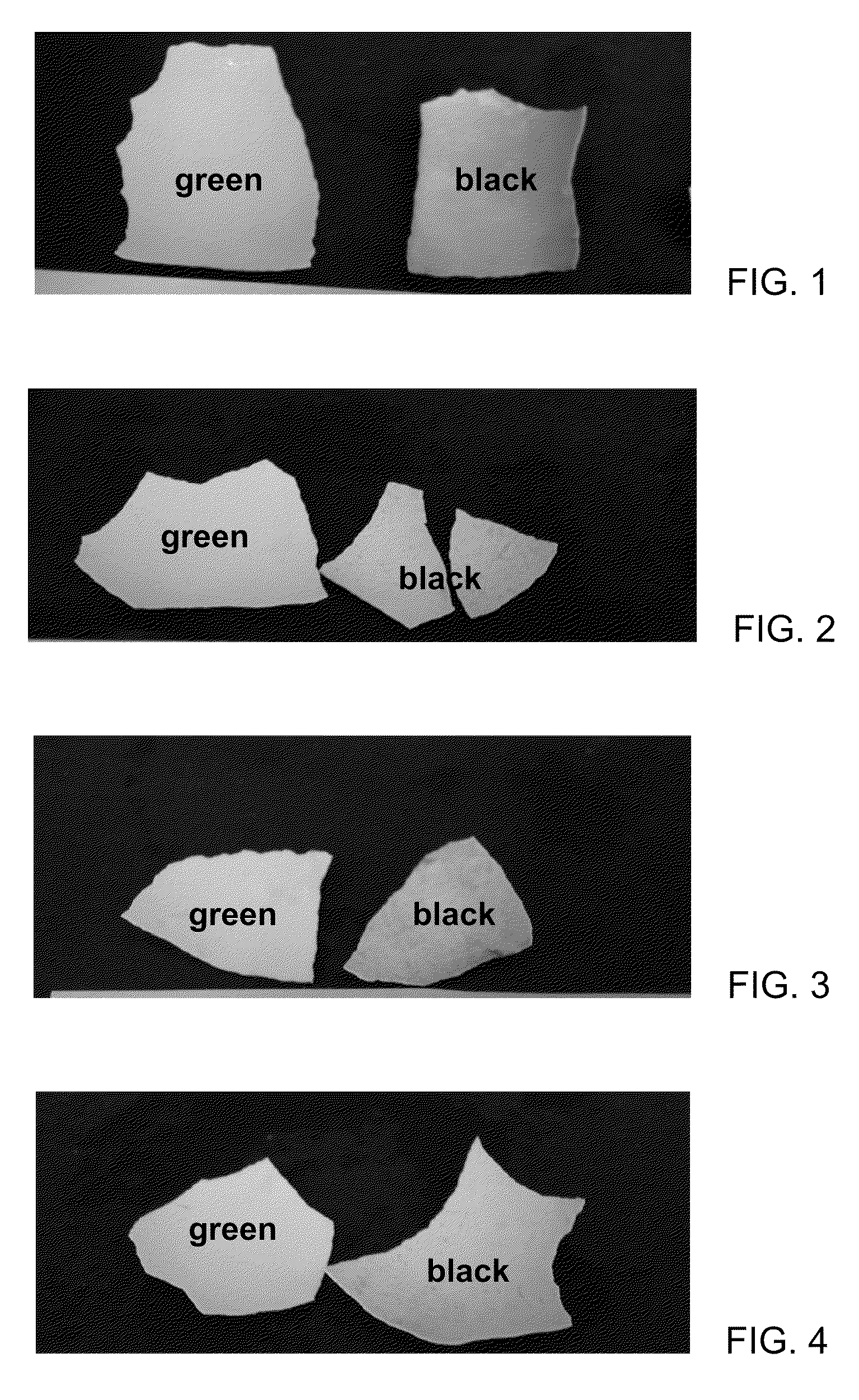

Multi-phase fabric care composition for delivering multiple fabric care benefits

A liquid rinse-added fabric care composition that is characterized by at least two visually distinct phases when the composition is at rest and wherein at least one of the phases contains a fabric care agent is provided. The composition forms a temporary mixture when shaken that allows a consumer to dose a representative sample of the composition and spontaneously re-forms at least two visually distinct phases when allowed to remain at rest. The fabric care agents present in one or more phases of the composition may include fabric softener actives, color care agents, perfumes, antibacterial agents, malodor control agents, ultraviolet protection agents, anti-abrasion, anti-wear & fabric integrity agents, wrinkle control agents, and mixtures thereof. The composition should also contain less than about 5%, preferably less than about 3%, and even more preferably less than about 1% by weight of detergent actives. The composition optionally may contain an electrolyte, phase stabilizer, a phase separation inducing polymer and / or a solvent. Methods for delivering one or more fabric care benefits to a fabric during a laundering operation using the compositions are also disclosed. Methods for conveying information to a consumer concerning a multi-phase liquid rinse-added fabric care composition are also provided. An article of manufacture comprising a liquid rinse-added fabric care composition that has at least two visually distinct phases and a container that enables a consumer to view the visually distinct phases that are present in the composition is also described. Alternatively, the container may comprise a double walled cap and an insert for removing excess composition that may adhere to the cap.

Owner:THE PROCTER & GAMBLE COMPANY

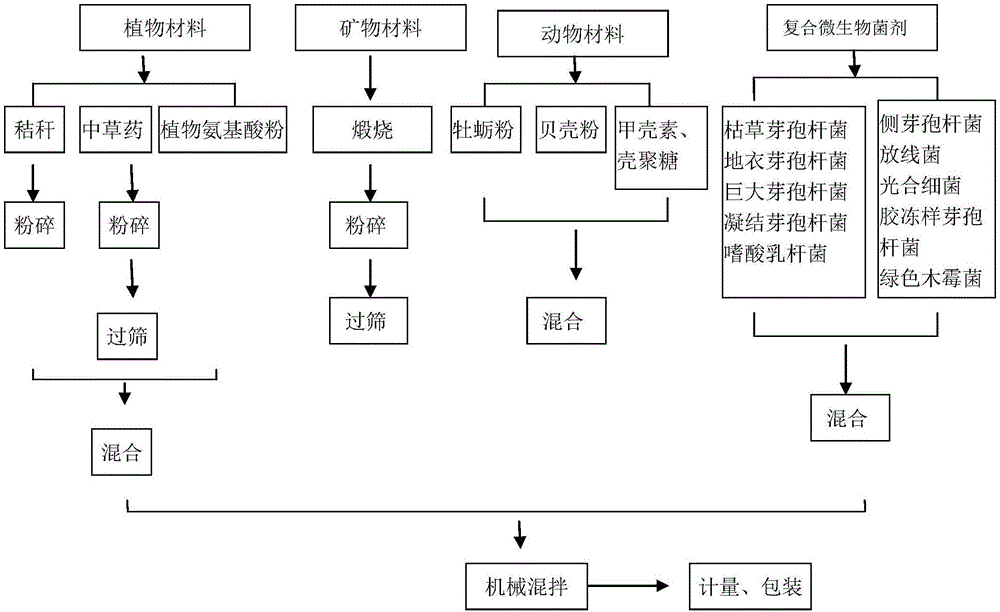

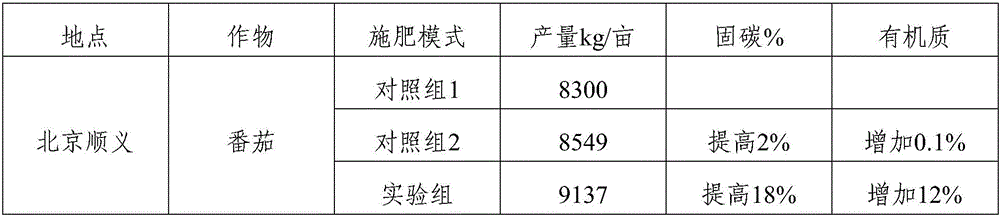

Soil-structure conditioner capable of stabilizing yield and fixing carbon and preparation method and application thereof

InactiveCN106316685AMultiple benefitsAvoid luxuryCalcareous fertilisersMagnesium fertilisersCation-exchange capacityAlkali soil

The invention relates to a soil-structure conditioner capable of stabilizing yield and fixing carbon and a preparation method and application thereof. The soil-structure conditioner comprises, by weight, 30-90 parts of plant materials, 1-40 parts of mineral materials, 1-30 parts of animal materials and 1-10 parts of compound microbial agent. The soil-structure conditioner has the advantages that carbon fixing and emission reduction of soil can be promoted, the formation of granular structures can be promoted, the water retention ability of the soil can be increased, and effective water supply is increased; the soil-structure conditioner can regulate soil pH and lower or reduce aluminum toxicity; saline-alkali soil can be improved, and base saturation degree and cation exchange capacity of the soil can be regulated; an imbalanced soil nutrition system can be conditioned, and effective nutrition supply is promoted.

Owner:仲元(北京)绿色生物技术开发有限公司 +2

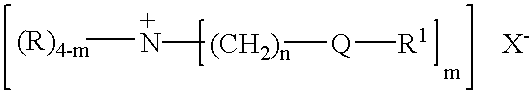

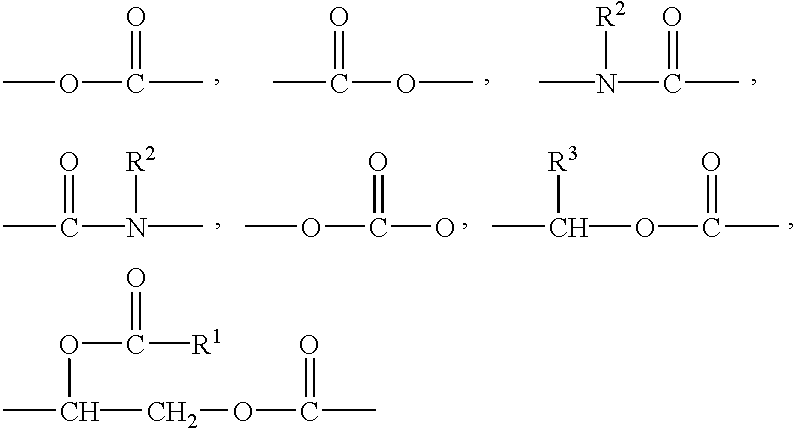

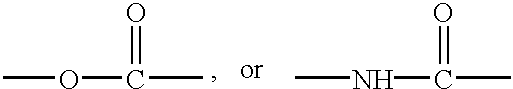

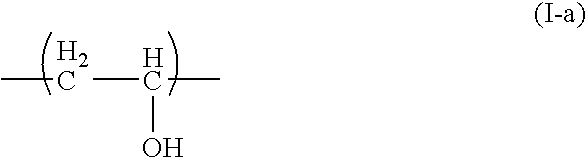

Oxa acids and related compounds for treating skin conditions

InactiveUS6071962AMultiple skin care benefitMultiple benefitsBiocideCosmetic preparationsCombinatorial chemistryAryl radical

Disclosed the use of compounds of Formula (I) depicted below, as active principals for treating skin conditions, compositions containing these compounds, and methods of treating skin conditions using these compounds and compositions. where R4 is (CR5R6-CR7R8-X1)n-CR9R10R11; n is an integer from 1 to 18; R1, R2, R3, R5, R6, R7, R8, R9, R10 and R11 are, independently, hydrogen or non-hydrogen substituents comprising alkyls, alkenyls, oxa-alkyls, aralkyls and aryls; and X, X1, Y and Z are, independently, oxygen, amine or sulfur, with preferred compounds being those in which X, X1, Y and Z are oxygen, and R1, R2, R3, R5, R6, R7, R8, R9, R10 and R11 are hydrogen.

Owner:AVON PROD INC

Multi-phase fabric care composition for delivering multiple fabric care benefits

InactiveUS6884766B2Multiple benefitsCapsCationic surface-active compoundsMedicineUltraviolet protection

A liquid rinse-added fabric care composition that is characterized by at least two visually distinct phases when the composition is at rest and wherein at least one of the phases contains a fabric care agent is provided. The composition forms a temporary mixture when shaken that allows a consumer to dose a representative sample of the composition and spontaneously re-forms at least two visually distinct phases when allowed to remain at rest. The fabric care agents present in one or more phases of the composition may include fabric softener actives, color care agents, perfumes, antibacterial agents, malodor control agents, ultraviolet protection agents, anti-abrasion, anti-wear & fabric integrity agents, wrinkle control agents, and mixtures thereof. The composition should also contain less than about 5%, preferably less than about 3%, and even more preferably less than about 1% by weight of detergent actives. The composition optionally may contain an electrolyte, phase stabilizer, a phase separation inducing polymer and / or a solvent. Methods for delivering one or more fabric care benefits to a fabric during a laundering operation using the compositions are also disclosed. Methods for conveying information to a consumer concerning a multi-phase liquid rinse-added fabric care composition are also provided. An article of manufacture comprising a liquid rinse-added fabric care composition that has at least two visually distinct phases and a container that enables a consumer to view the visually distinct phases that are present in the composition is also described. Alternatively, the container may comprise a double walled cap and an insert for removing excess composition that may adhere to the cap.

Owner:PROCTER & GAMBLE CO

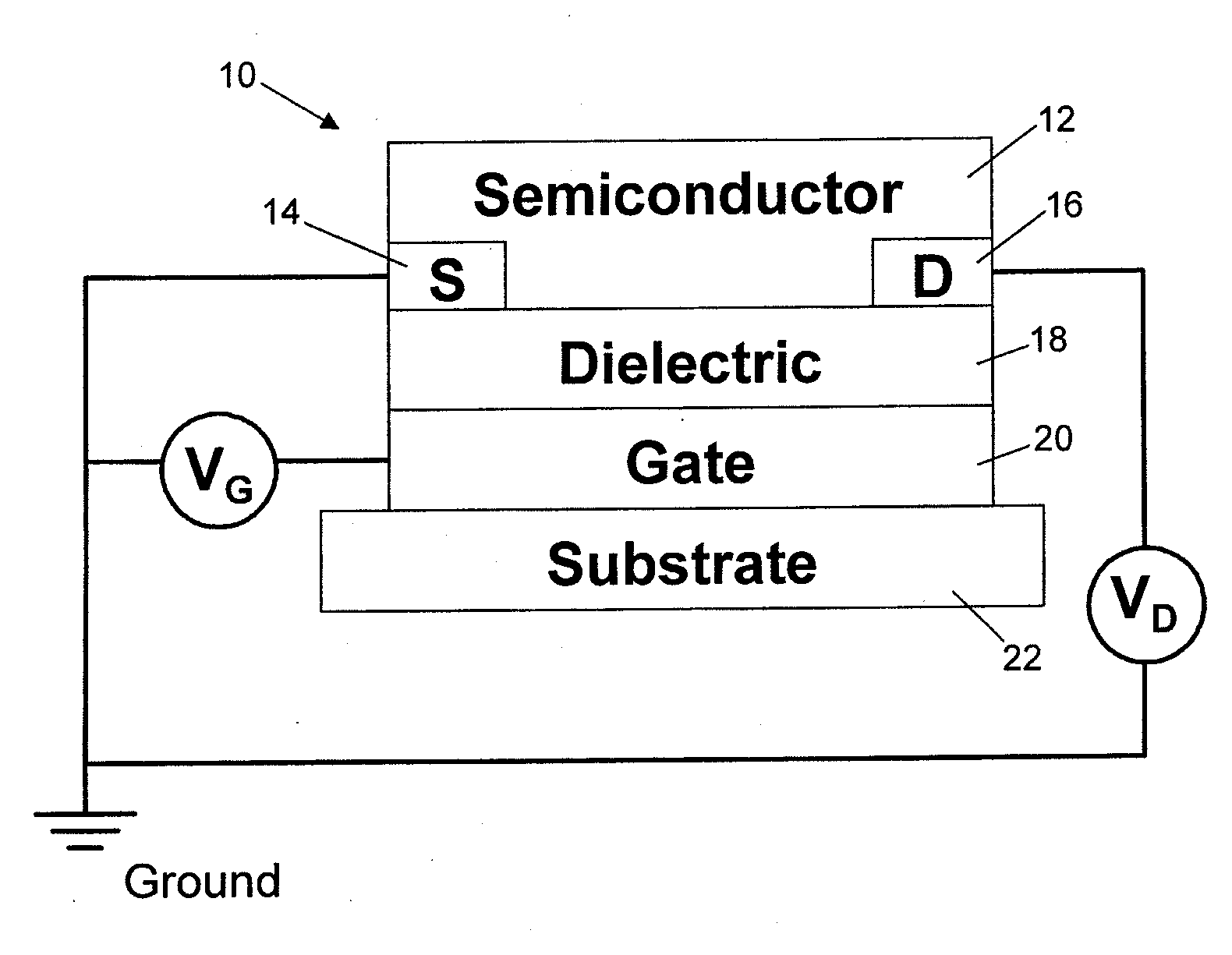

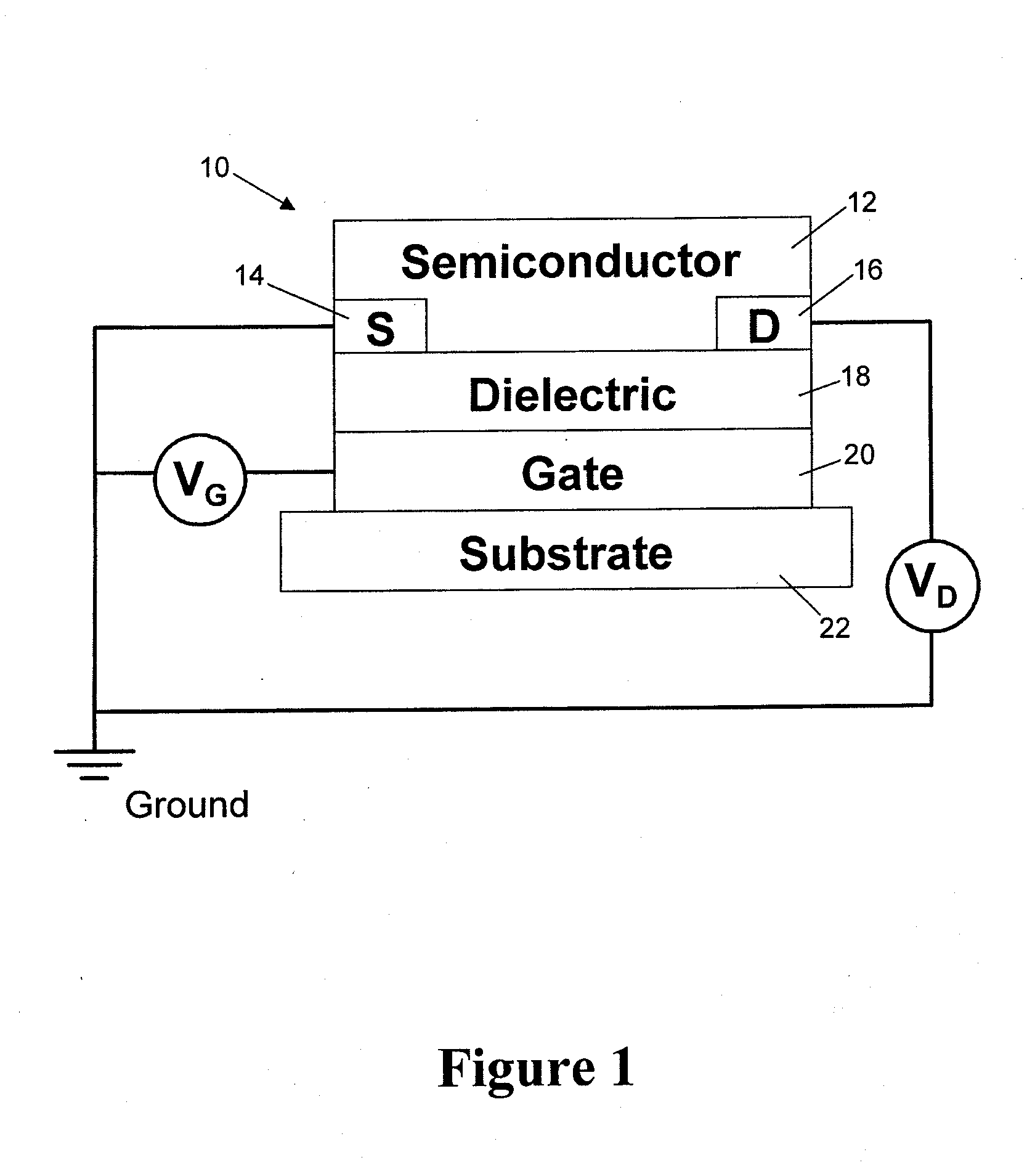

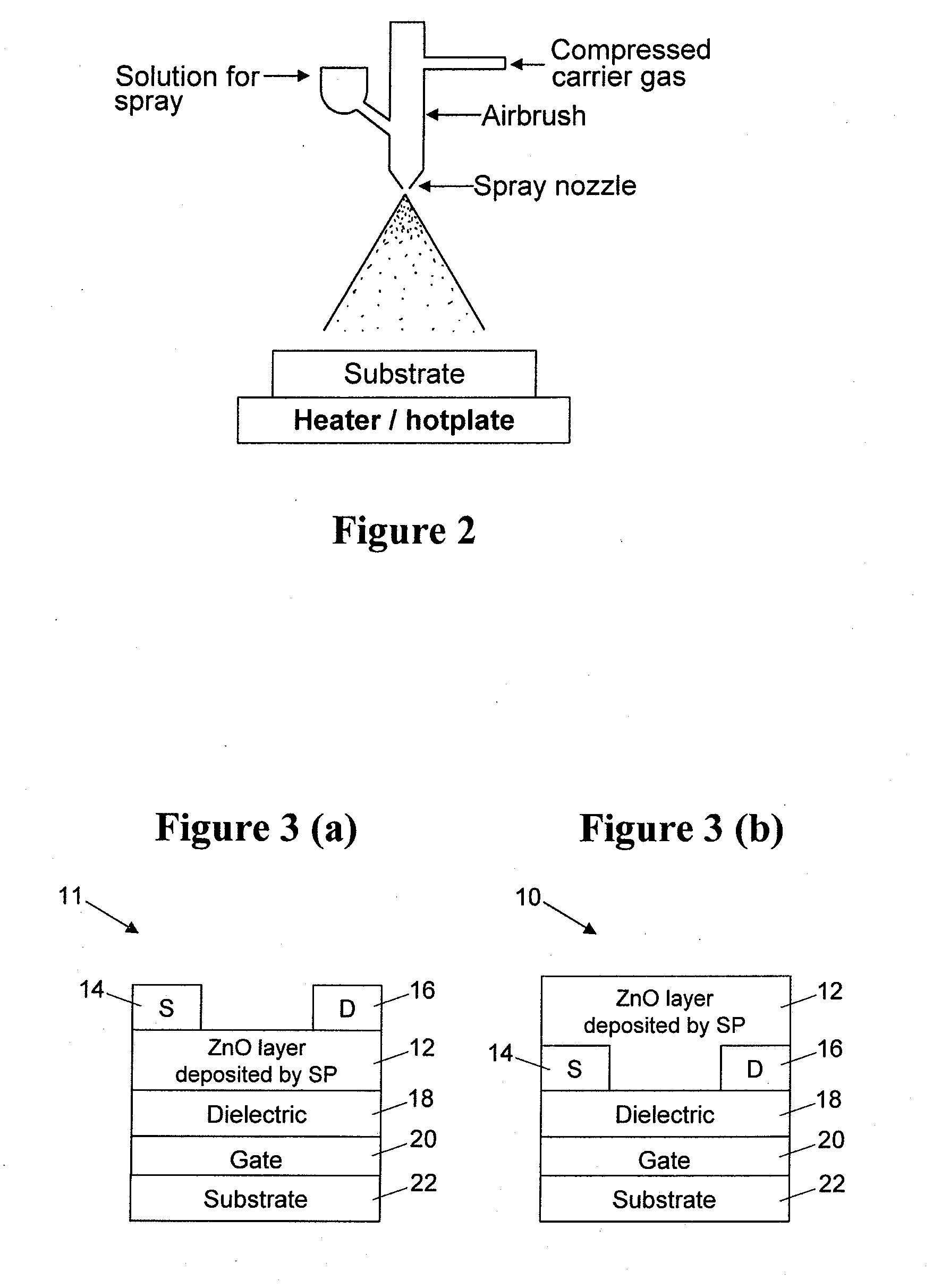

Low-voltage thin-film field-effect transistors

InactiveUS20110113859A1Easy to manufactureIncreasing geometrical capacitanceTransistorSolid-state devicesPhysical chemistrySpray pyrolysis

A low-voltage thin-film field-effect transistor is formed by forming a gate, forming a dielectric layer on the surface of the gate, forming a source region and a drain region, and forming a semiconductor layer adjacent the dielectric layer. The dielectric layer is formed as a native oxide layer by oxidizing the surface of the gate. The semiconductor layer is deposited by spray pyrolysis. The dielectric layer may be functionalized with a self-assembling monolayer dielectric layer. The dielectric layer may be formed as a self-assembling monolayer, without first forming a native oxide (or other) dielectric layer.

Owner:IMPERIAL INNOVATIONS LTD

Systems and methods for automatic call forwarding in a wireless mobile station

InactiveUS7450935B1Service conveniently and inexpensivelyReliable and more cost-efficientSpecial service for subscribersCommmunication supplementary servicesCall forwardingMobile station

Owner:AT&T MOBILITY II LLC

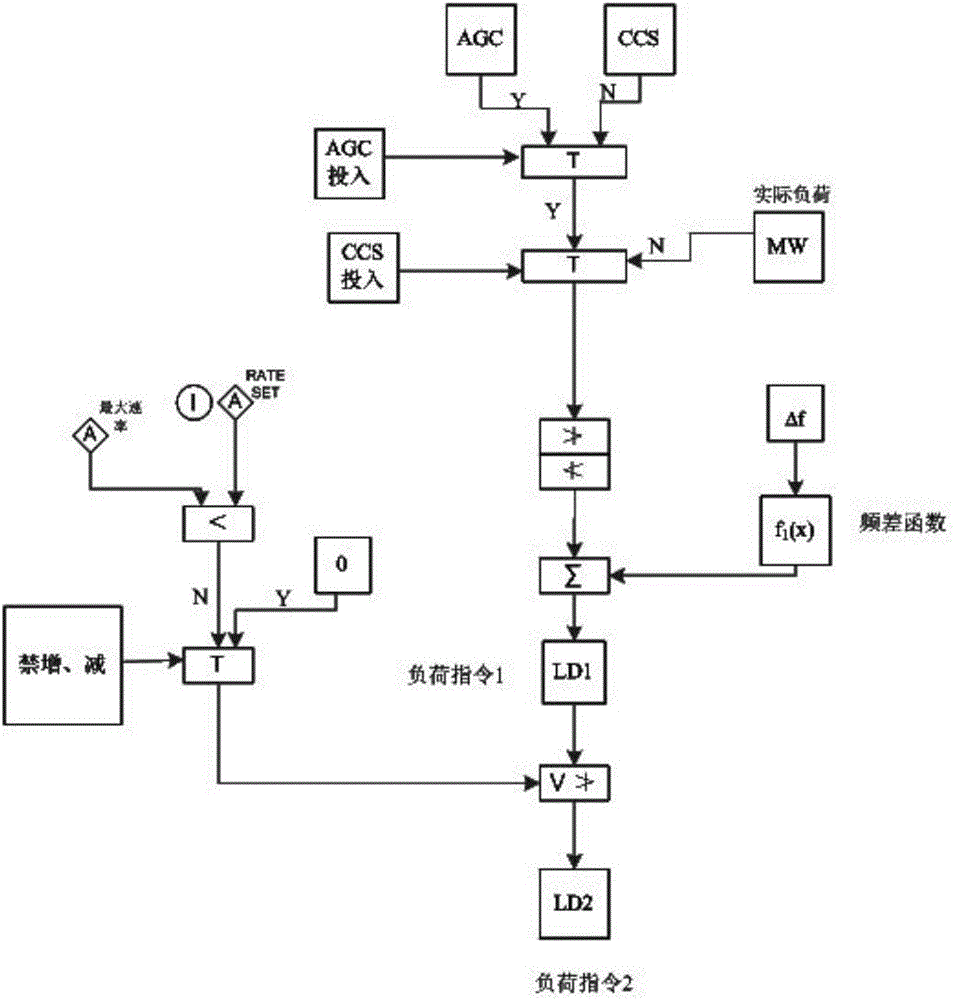

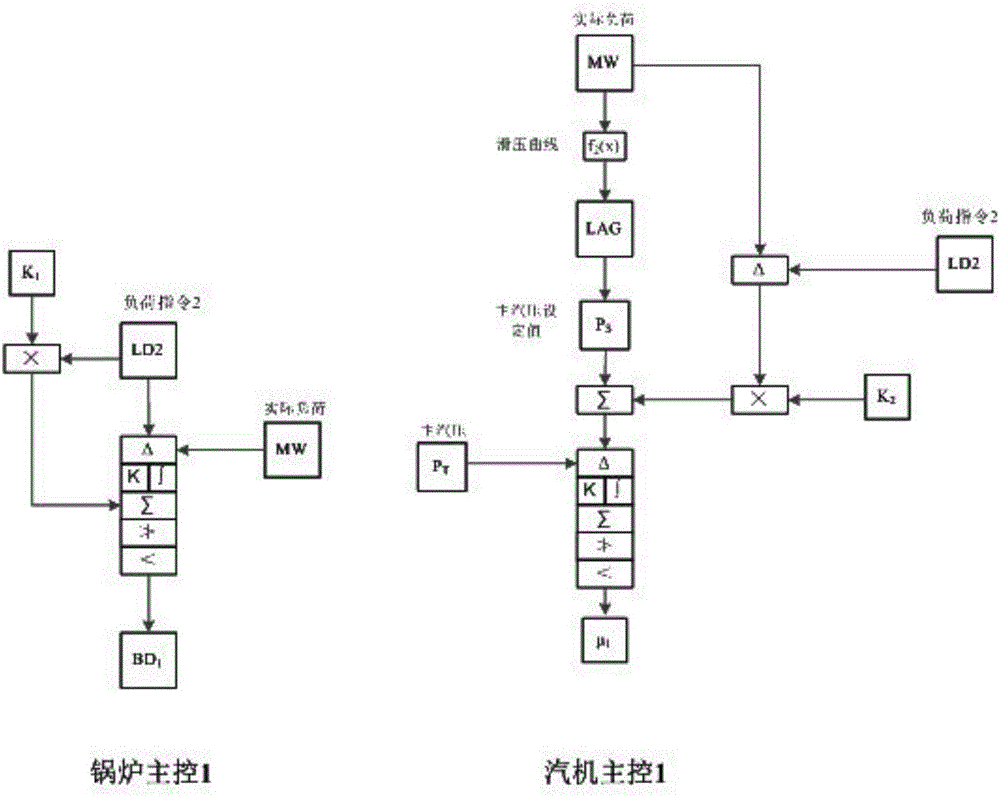

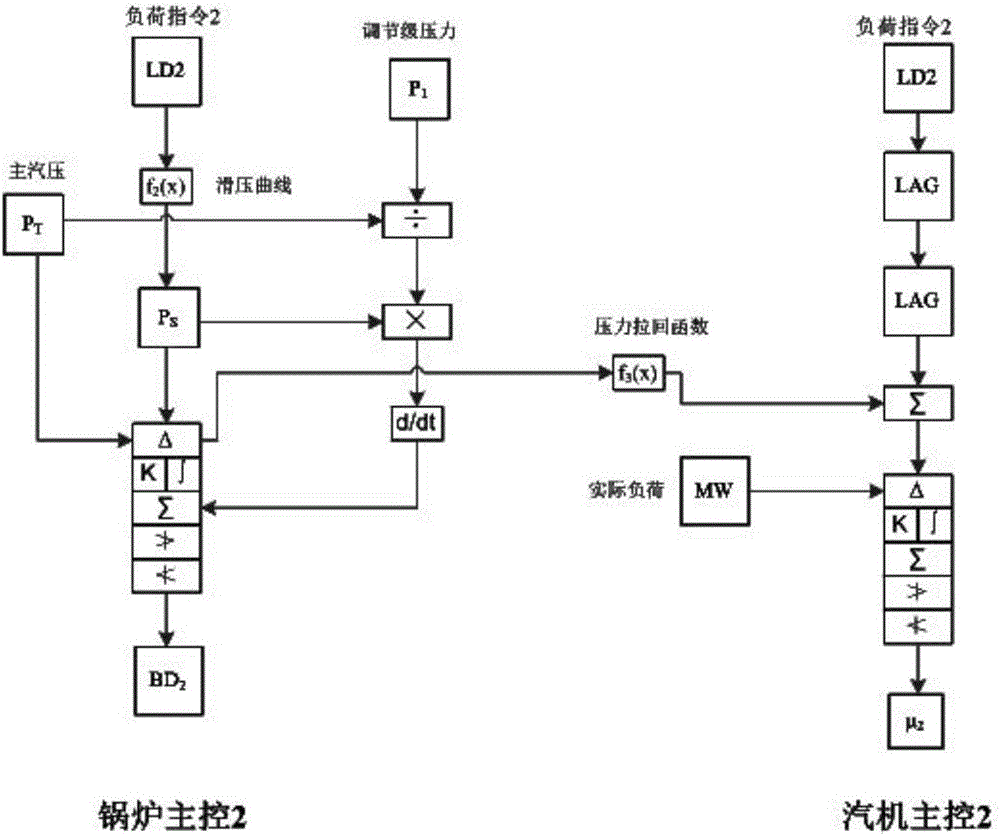

Whole-course load control method for supercritical direct current furnace

ActiveCN106224926AImprove automation control levelGuaranteed uptimeBoiler controlMachines/enginesLoad instructionEngineering

The invention relates to a whole-course load control method for a supercritical direct current furnace. The method mainly includes the steps that a load processing center generates load instructions; a boiler main control instruction BD and a steam turbine main control instruction mu are generated according to boiler main control instructions BD1, BD2 and BD3 and steam turbine main control instructions mu1, mu2 and mu3 generated by the load at the three phases of 0%-30% Pe, 30%-60% Pe and 60%-100% Pe through instruction optimization selection; and then the BD is fed into a fuel main control device, the mu is fed into a DEH for regulation control, and whole-course load control of the supercritical direct current furnace is achieved.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

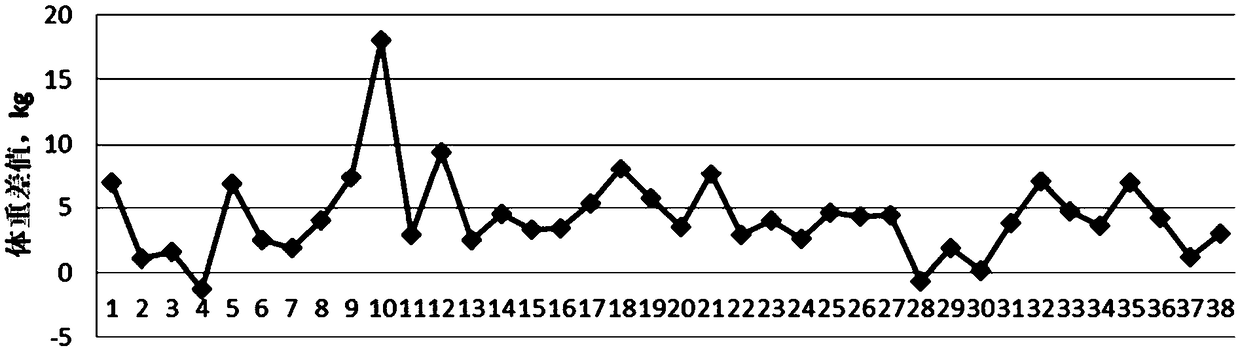

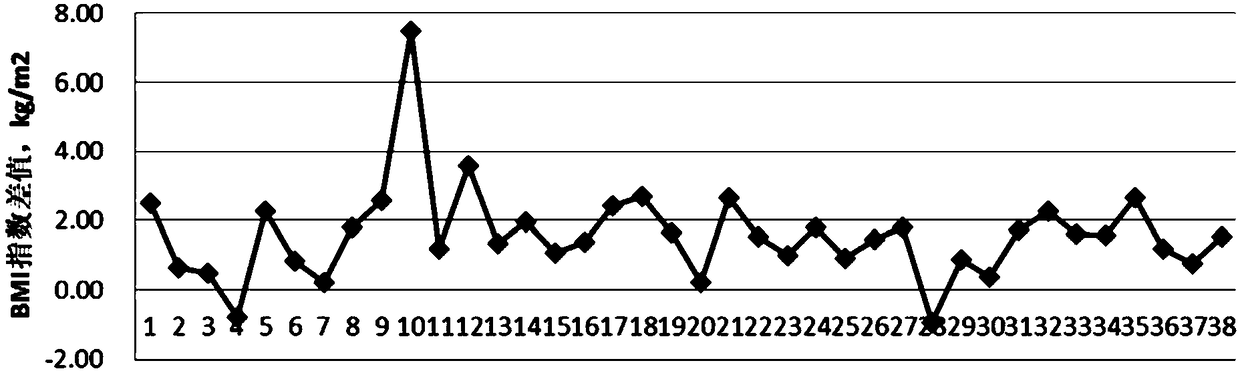

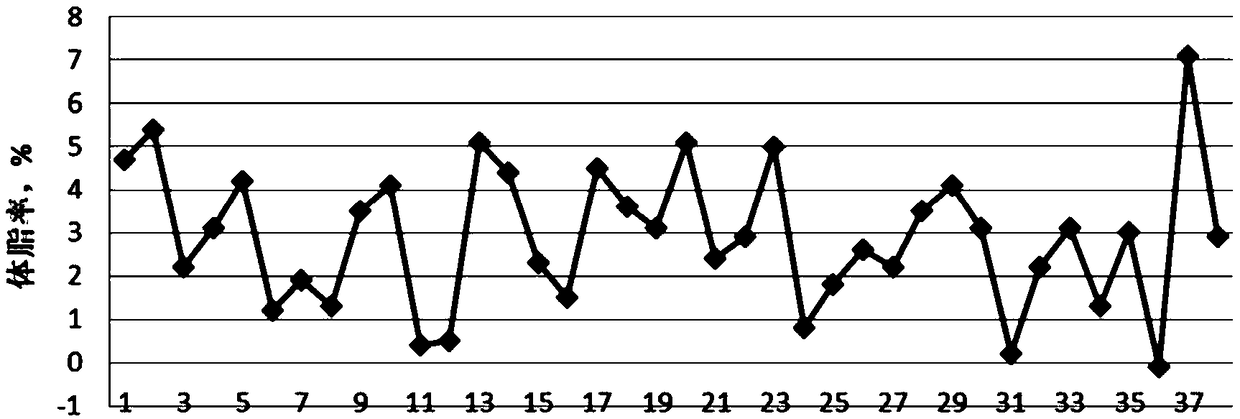

Weight-losing functional food containing conjugated linoleic acid

InactiveCN108703375AFormulation ScienceFormula stableLipidic food ingredientsFood ingredient functionsPerilla oilWhey protein powder

A weight-losing functional food containing conjugated linoleic acid comprises, by mass, the following components: 1-10 parts of conjugated linoleic acid glyceride microcapsule powder, 1-5 parts of flaxseed oil microcapsule powder, 1-5 parts of perilla oil microcapsule powder and 1-10 parts of protein powder; the protein powder is selected from wheat protein powder, whey protein powder, soybean protein powder, casein powder or a mixture thereof. According to the invention, a weigh-losing functional nutritional product which is scientific in formula, stable in product, and good in taste and is easily accepted by consumers is provided. The product uses the formula of high-fat and low-carbon, and utilizes functional grease to replace common meat and fat. The energy supply ratio of fat is morethan or equal to 45%, the energy supply ratio of carbohydrate is more than or equal to 35%, and is beneficial to human body absorption; the carbohydrate is replaced by dietary fiber and low GI carbohydrate, thereby avoiding the problem of fat conversion caused by common carbohydrate and improving the blood sugar control of a diabetic population. The food brings more benefits to the body while ensuring the effect of losing weight.

Owner:INNOBIO CORP LTD

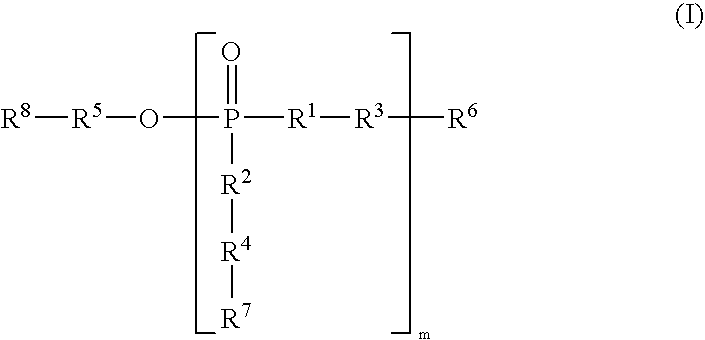

Mono-, di- and polyol phosphate esters in personal care formulations

ActiveUS7524800B2Reduced tendency can be washed and rinsed awayEnhanced adsorption of active ingredientsBiocideCosmetic preparationsPersonal carePhosphoric Acid Esters

A hydrophilized personal care formulation, which can be in the form of a hand or body soap (liquid or bar), lipstick, body wash, makeup remover, skin cleaner, hair conditioner, skin or hair moisturizer. The formulation employs an organophosphorus material or a mixture of an organophosphorus material, for example, mono-, di-, and polyol phosphate esters.

Owner:RHODIA OPERATIONS SAS

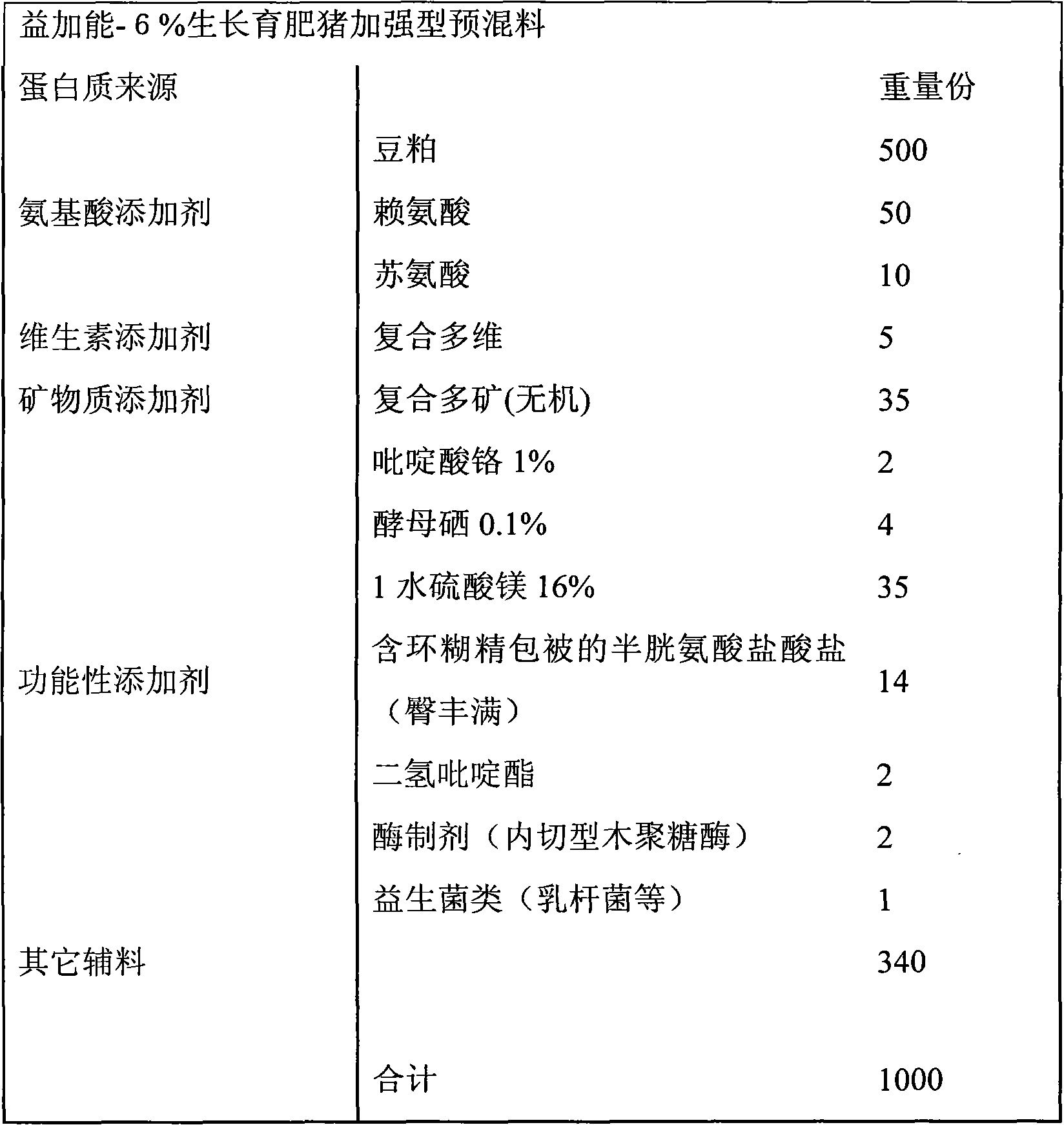

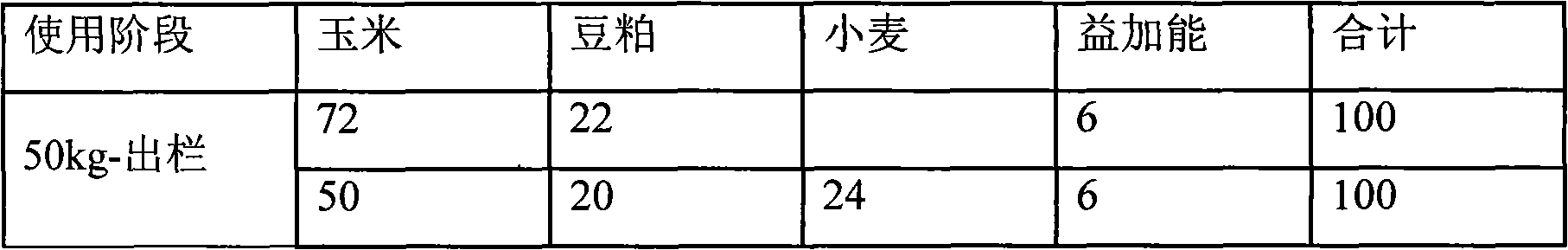

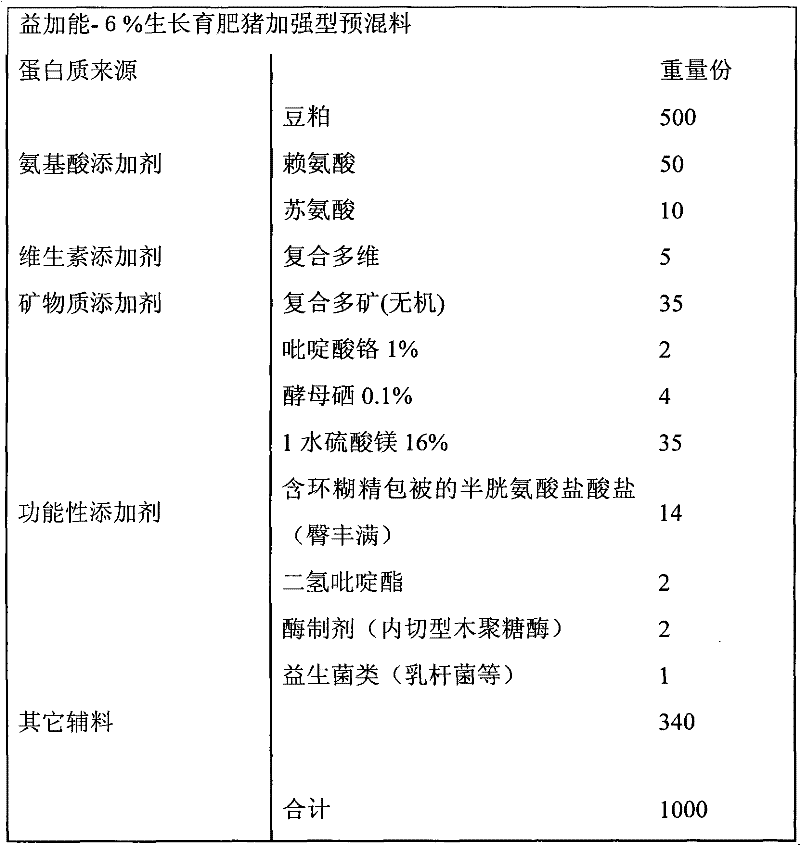

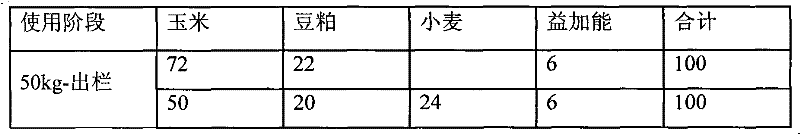

Growing-finishing pig composite pre-mixing feed

ActiveCN101548730APromote digestion and absorptionIncrease daily weight gainFood processingAnimal feeding stuffChemistryDigestion

The invention relates to a growing-finishing pig composite pre-mixing feed, belonging to the feed field, comprising: amino acid additive, inorganic trace element and organic trace element, vitamin additive, magnesium sulfate, bean pulp, functional additive, wherein the organic trace element comprises organic chrome, organic selenium, the amino acid additive comprises lysine and threonine, the functional additive comprises cysteine hydrochloride coated by cyclodextrin, dihydropyridine ester, enzyme preparation, probiotics. The feed can increase the digestion and absorption of nutritive material and daily gain and feed utilization rate, reduce marketing period; improve feed efficiency, reduce feed conversion ratio (the feed conversion ratio of the common feed is 0.2-0.4), greatly save the cultivation cost; increase muscle lipid content and meat flavor; reduce drip loss and improved meat taste.

Owner:北京劲能生物科技股份公司

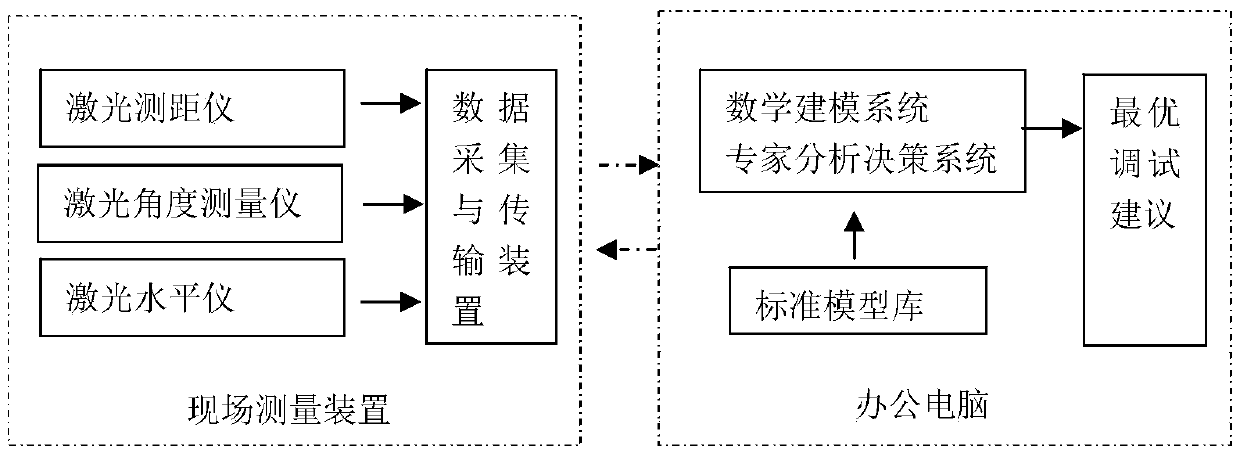

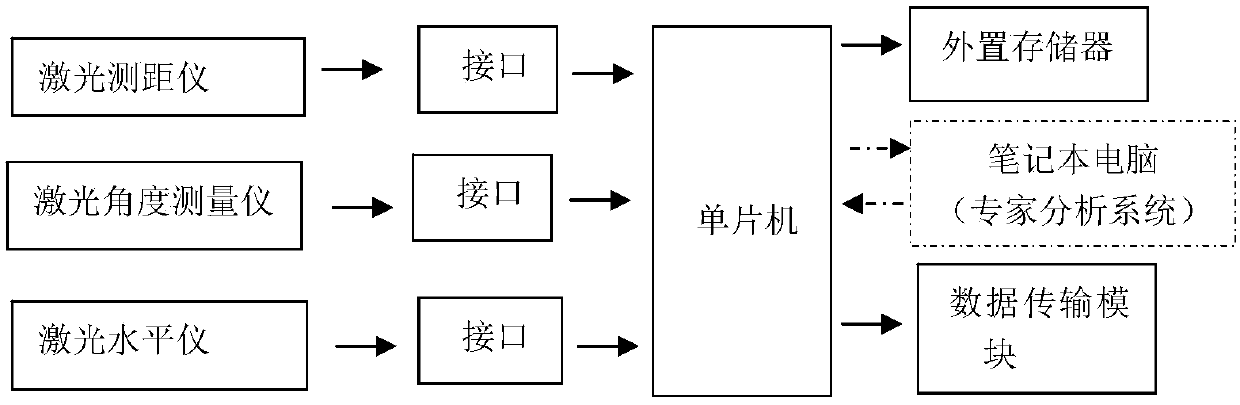

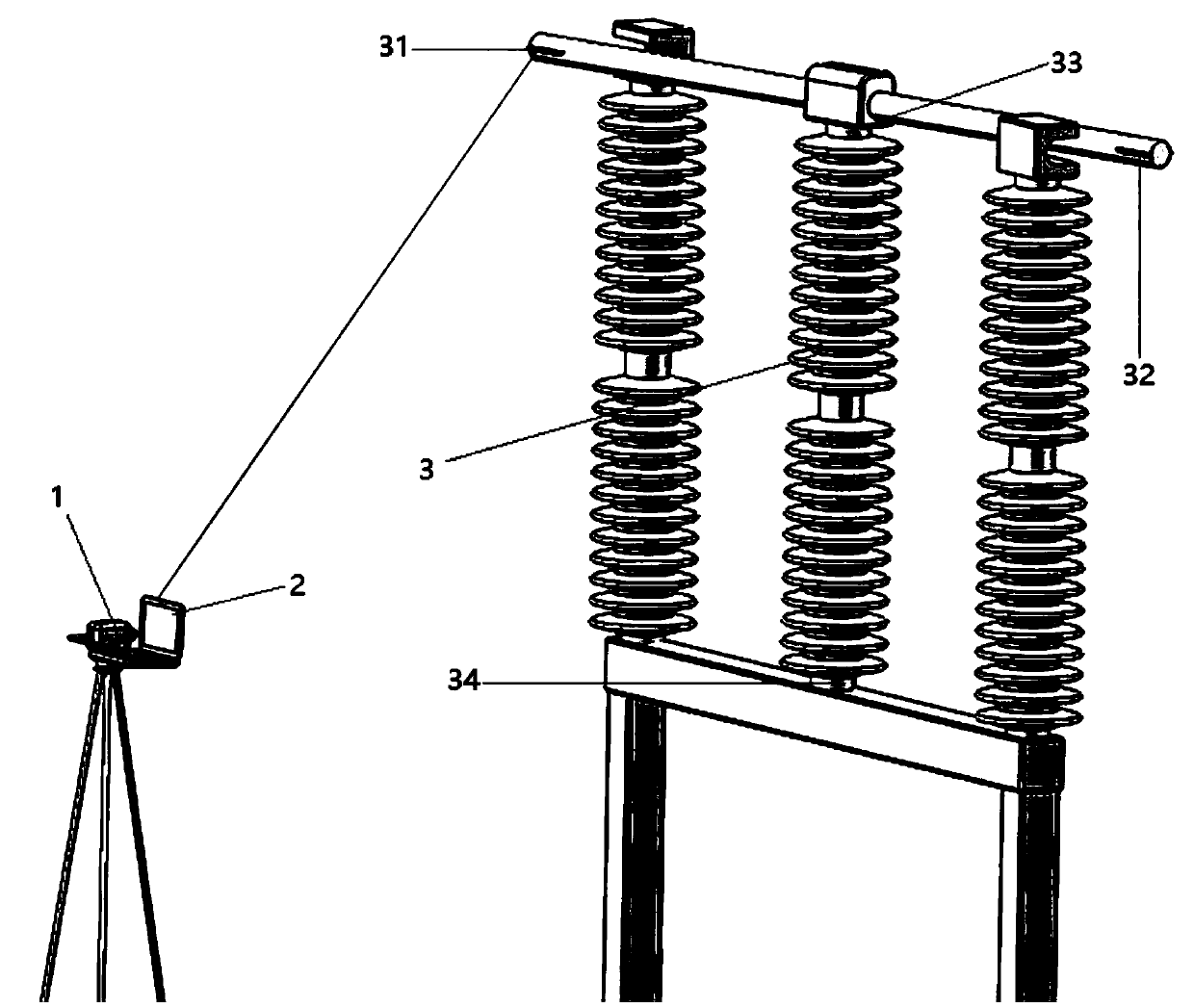

Intelligent debugging and calibration system of ultra-high voltage isolation switch based on laser measurement technology

ActiveCN108801141AHigh precisionEfficient acquisitionUsing optical meansDecision systemMathematical model

The invention relates to an intelligent debugging and calibration system of an ultra-high voltage isolation switch based on a laser measurement technology. The calibration system comprises a laser measurement sampling device, a mathematical modeling system and an expert analysis decision system, wherein the mathematical modeling system and the analysis system are installed in a debugging computer;the laser measurement sampling device collects various position parameters of a target isolation switch in a space coordinate system; the mathematical modeling system establishes a mathematical modelof the isolation switch space by using the position parameters collected by the laser sampling device; and the expert analysis decision system compares the actual mathematical model of the isolationswitch to be debugged with a standard spatial position model of the isolation switch stored in a database and gives an error and calibration scheme. Compared with the prior art, the ultra-high voltageisolation switch intelligent debugging and calibration system has the following advantages: the debugging process is completed in one step, the work efficiency is improved, and the debugging accuracyis improved.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

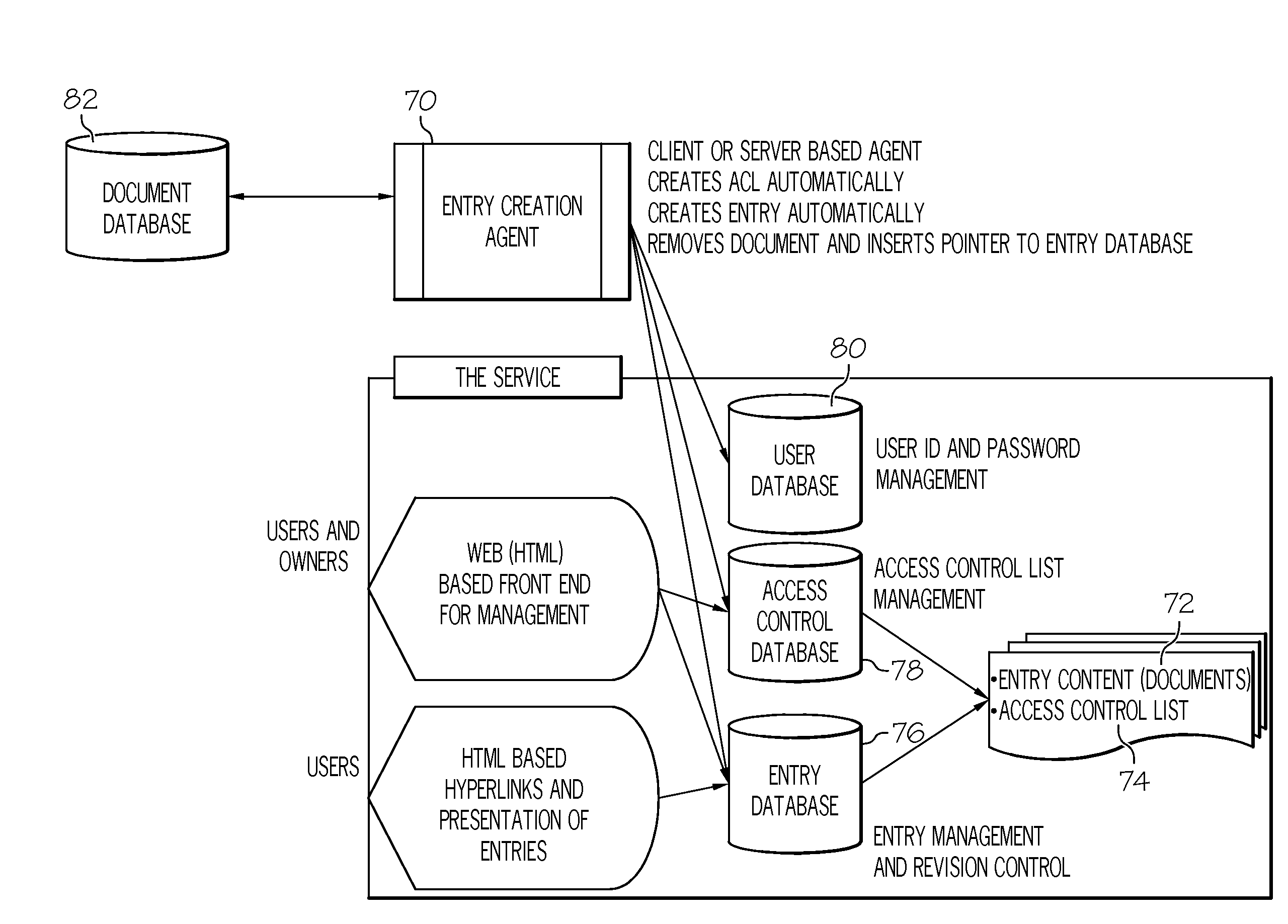

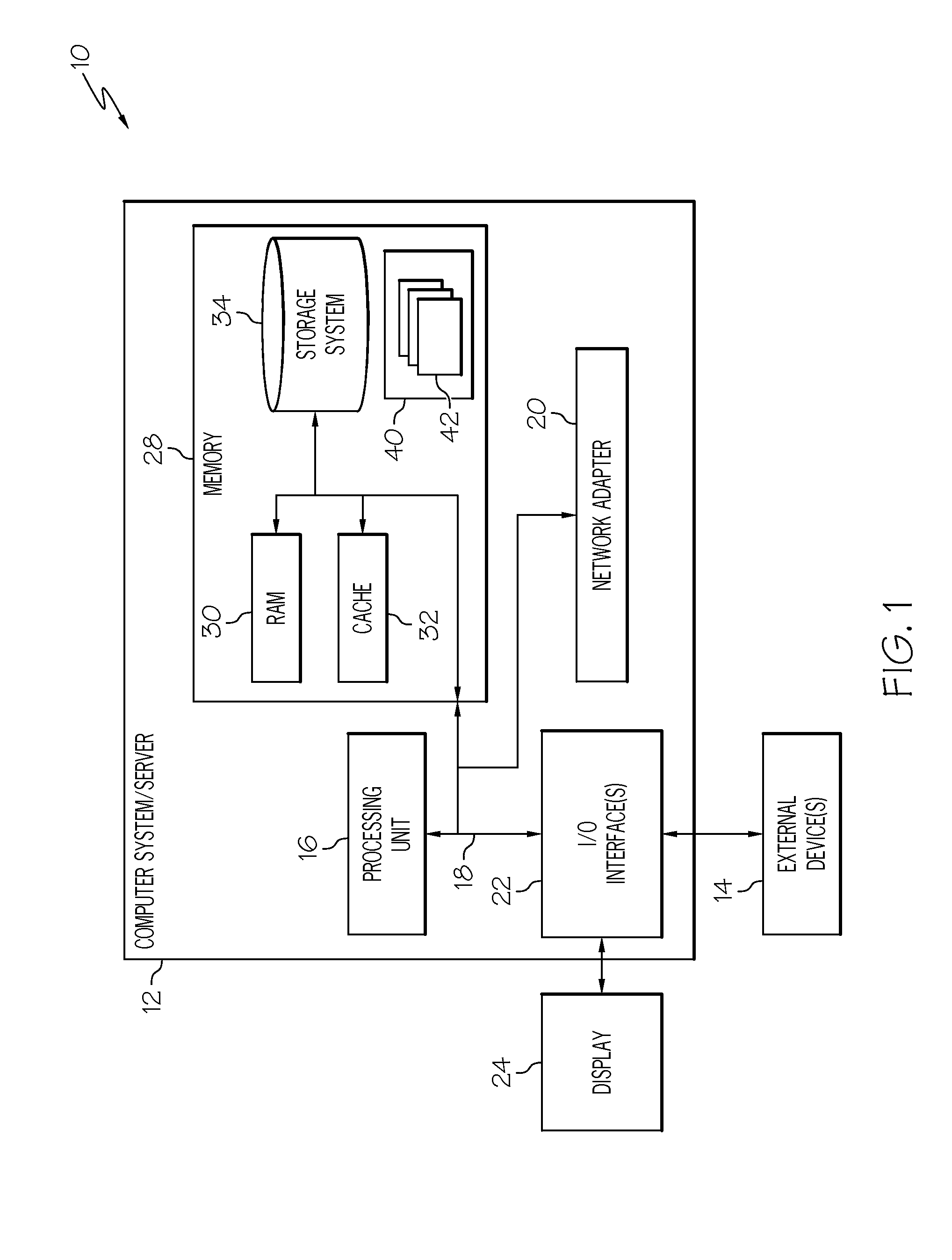

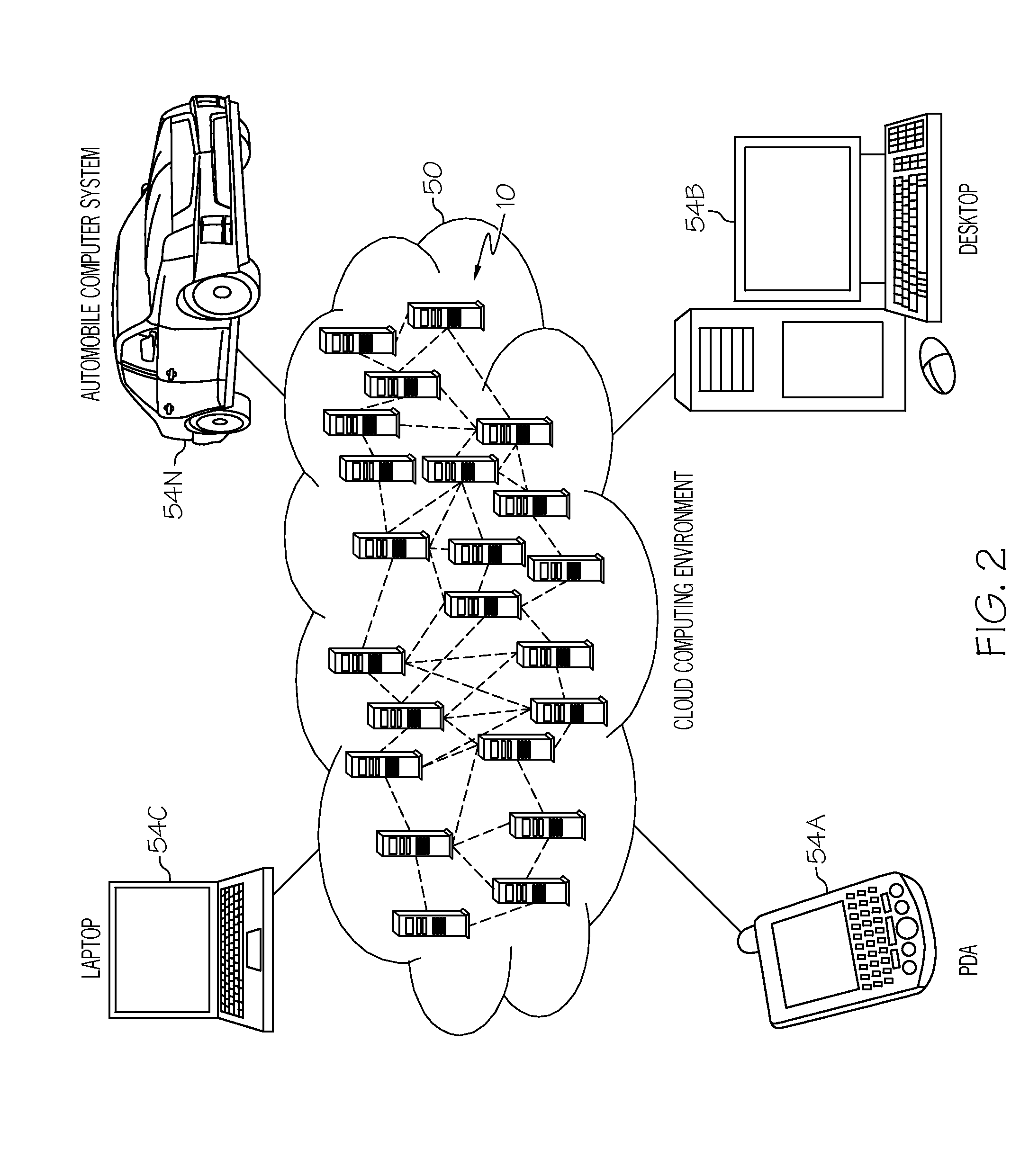

Dynamic access control for documents in electronic communications within a networked computing environment

ActiveUS20110258234A1Multiple benefitsMultiple in of controlDigital data processing detailsDigital data protectionInformation sharingElectronic communication

The present invention provides an approach to manage and control document transmission and electronic communication. Specifically, the present invention provides control over data associated with multiple types of data communication. Along these lines, embodiments of the present invention provide a hub and spoke communication model in order to achieve multiple benefits in terms of effectiveness, efficiency, flexibility, and control. This type of granular control is critical for information sharing within a networked computing environment. This approach is also useful for collaboration tools and can be augmented by the creation and management of access control lists (ACL's) for the hub-spoke system. To this extent, embodiments of the present invention provide functionality to automatically update ACL's as documents are being forwarded or otherwise communicated between multiple parties. These ACL's are kept up to date through the analysis of to whom (and where) a document has been sent.

Owner:KYNDRYL INC

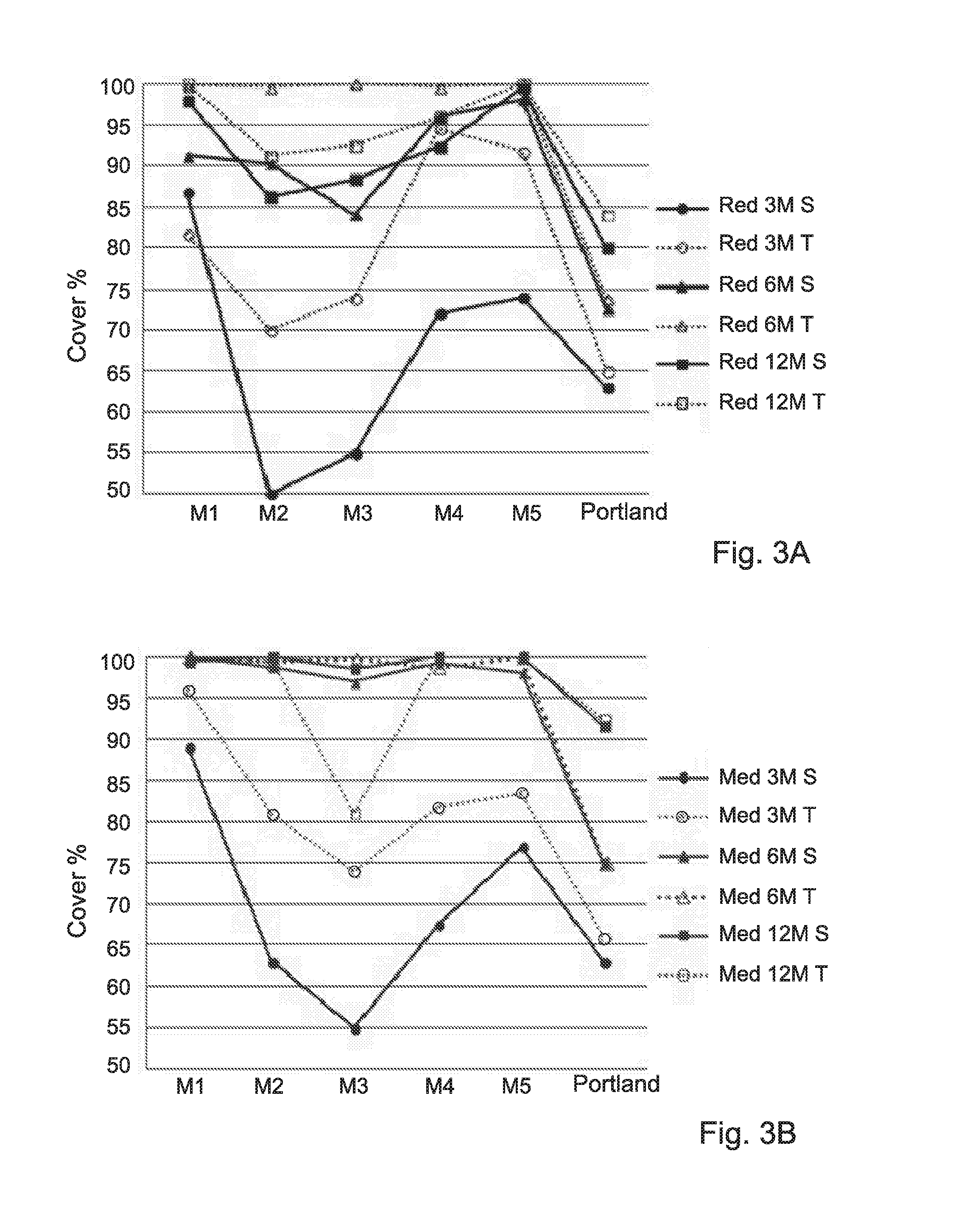

Methods and matrices for promoting fauna and flora growth

ActiveUS20150366170A1Facilitate depositionReduced footprintSeed and root treatmentPlant phenotype modificationFloraPlant growth

The invention provides a marine infrastructure comprising a concrete matrix having a pH of less than 12 for use in promoting the growth of fauna and flora in aquatic environment, and methods for promoting the growth of fauna and flora in aquatic environment, including endolitic and epilitic flora and endolitic and epilitic anaerobic and aerobic flora and fauna.

Owner:ECONCRETE TECH

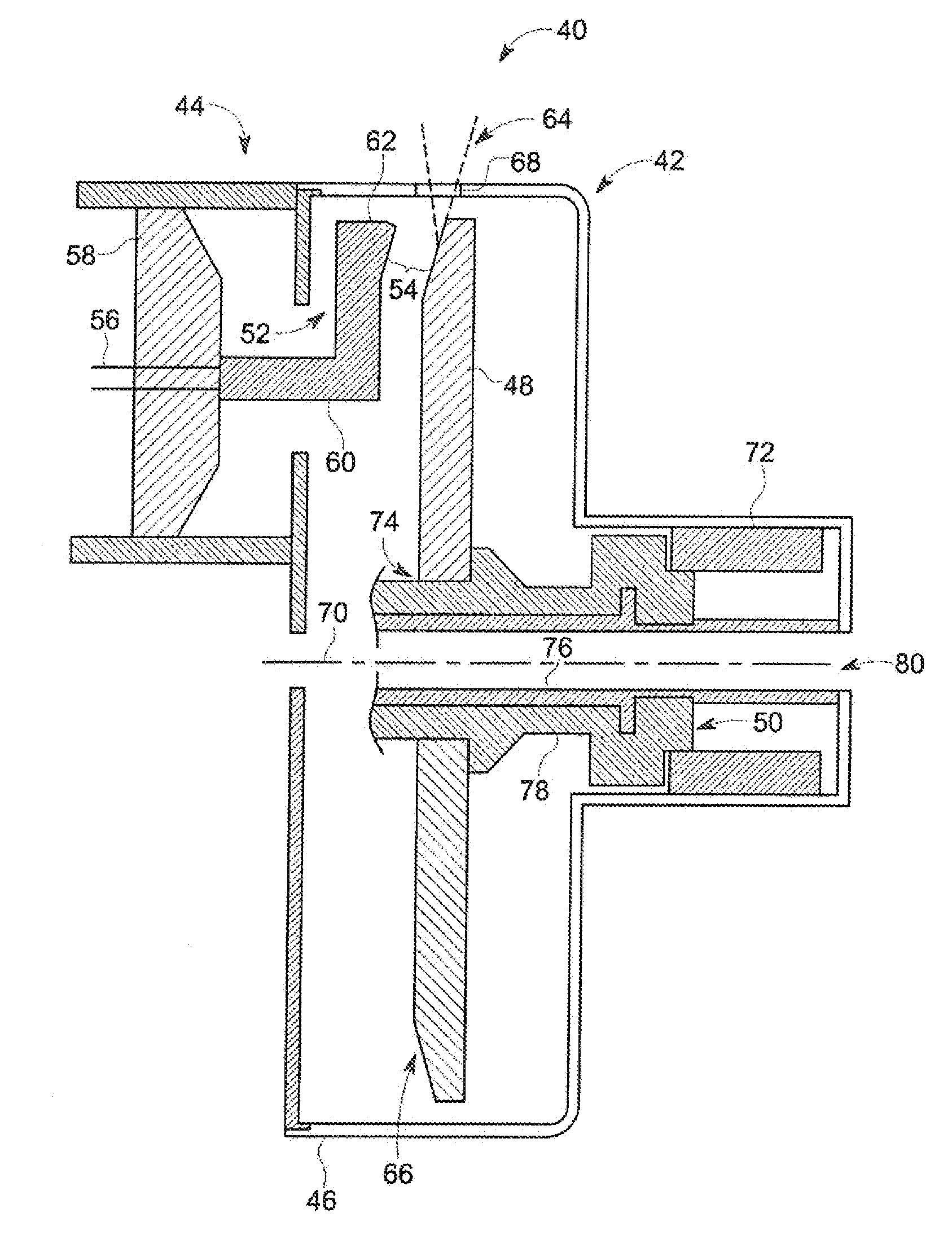

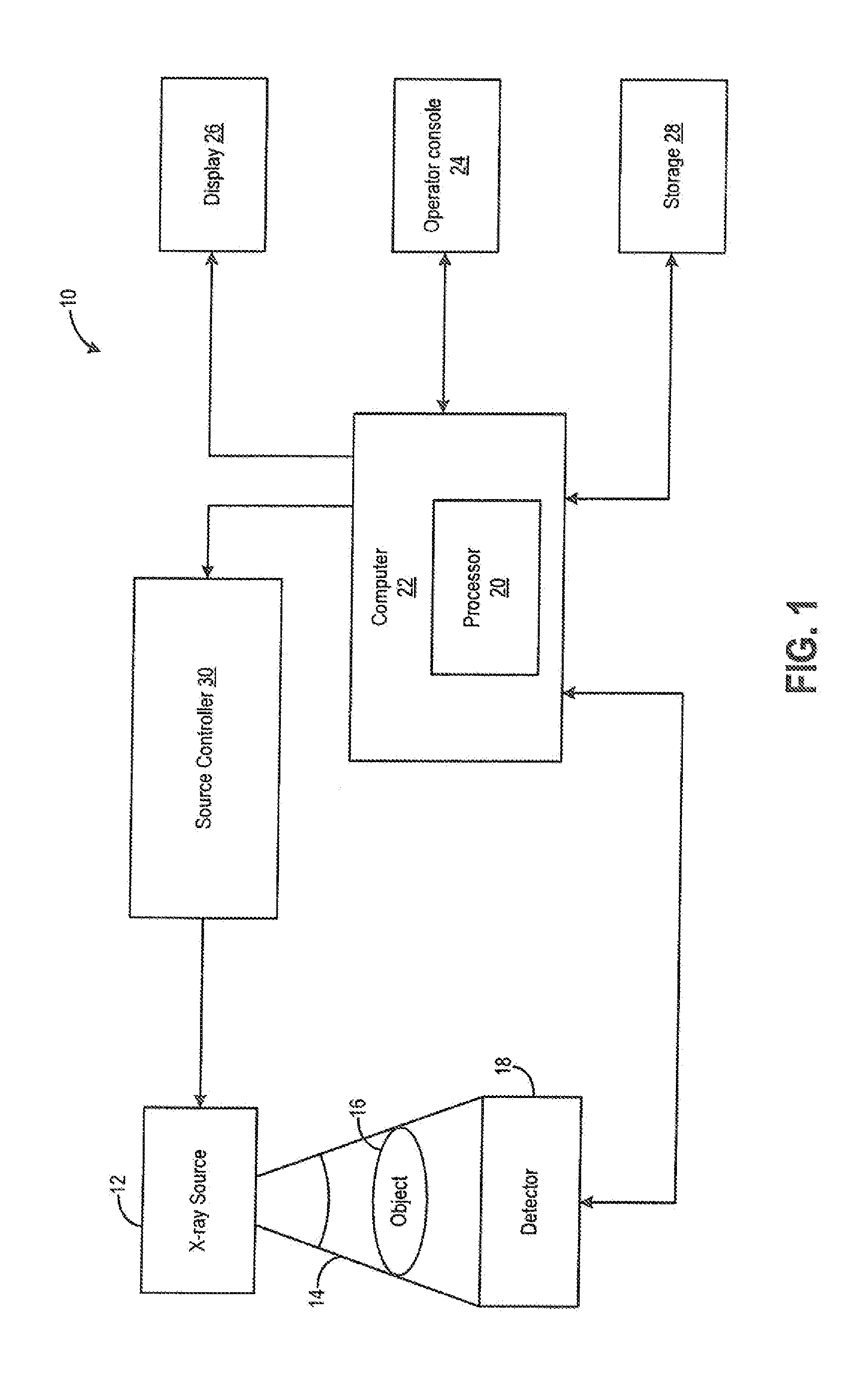

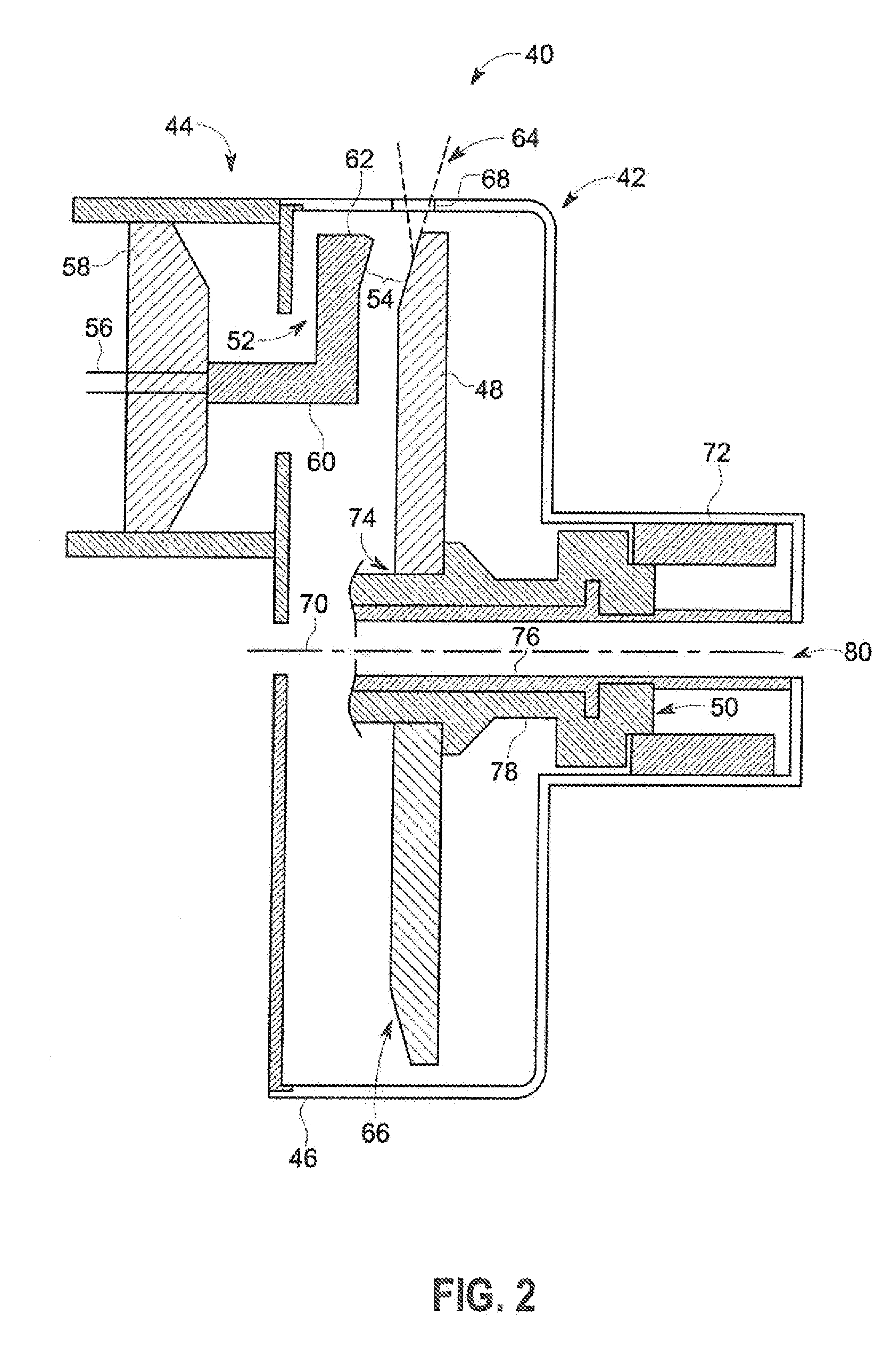

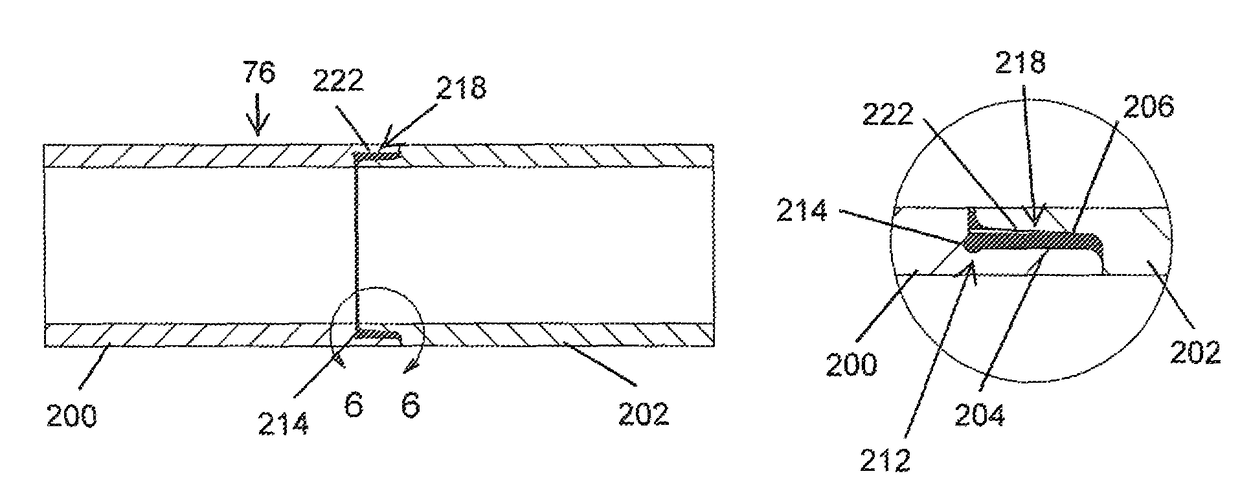

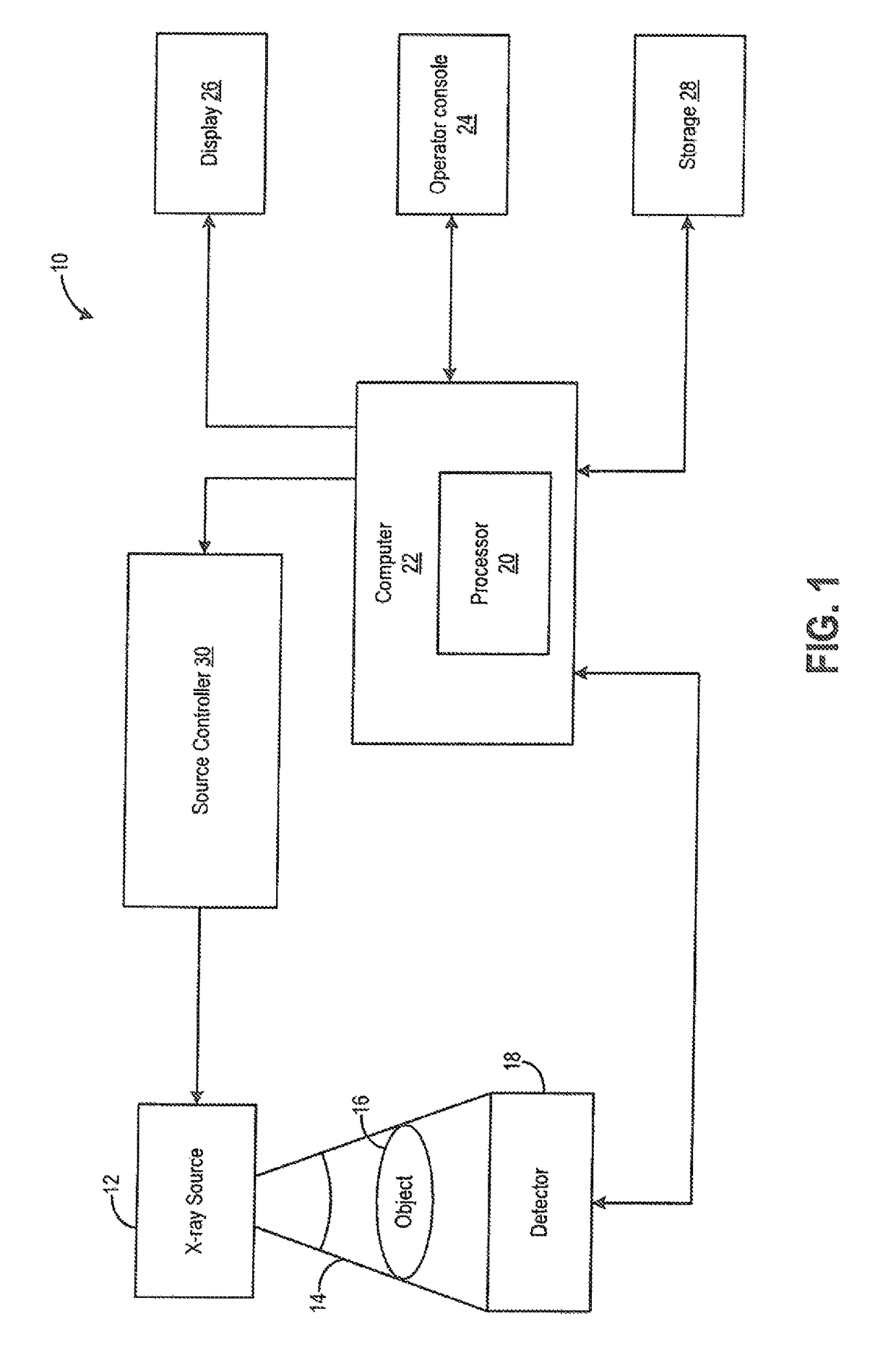

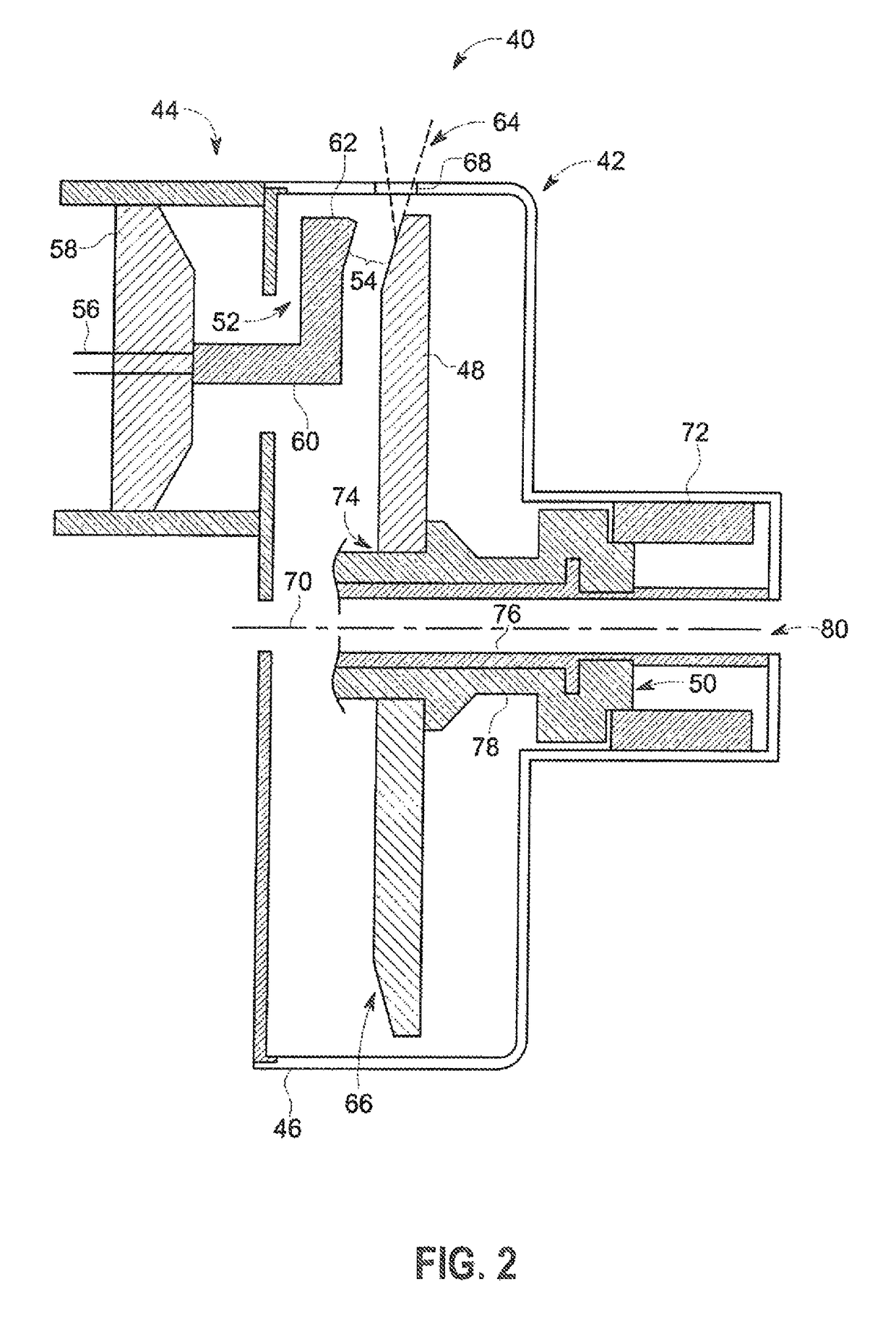

Friction Welding Of X-Ray Tube Components Using Intermediate Filler Materials

ActiveUS20160086760A1Increased microstructural controlReduce the temperatureLine/current collector detailsX-ray tube electrodesFriction weldingFilling materials

A structure and associated process for joining dissimilar materials to form various components of an x-ray tube is illustrated that utilizes one or more intermediate or interfacial filler material members positioned between the primary welding or mating surfaces of the base material components to be joined. The use of the interfacial or intermediate filler material preserves the multiple benefits of friction welding, as well as enabling the joining of highly dissimilar material components, decreasing the required joining temperature, and providing increased microstructural control of the resulting well or joint.

Owner:GENERAL ELECTRIC CO

Fabric enhancing composition

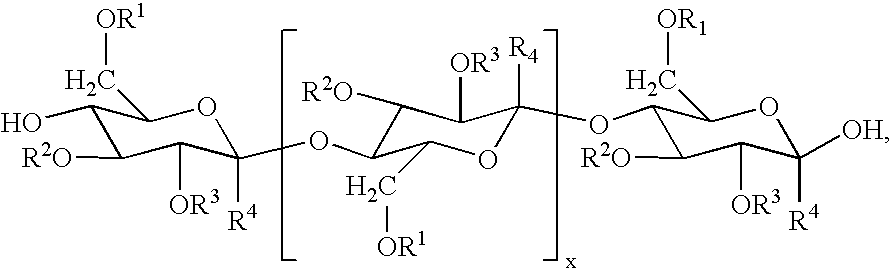

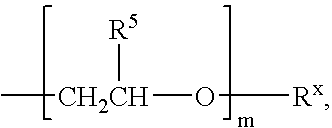

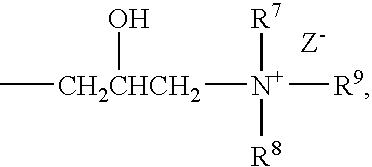

InactiveUS20060122094A1Few ingredientsMaintain the fabric's inherent water absorbencyNon-ionic surface-active compoundsPolymeric surface-active compoundsAdditive ingredientPolysaccharide

A rinse-added fabric enhancer composition has from about 0.01% to about 10% of a cationic polysaccharide polymer, from about 0.1 to about 50% of an anionic surfactant, and the balance adjunct ingredients. The cationic polysaccharide polymer has a weight average molecular weight of from about 400 g / mol to about 2,000,000 g / mol and a calculated charge density of from about 1% to about 50%, while the anionic surfactant has an alkyl chain having from about 6 to about 22 carbon atoms. The cationic polysaccharide polymer and the anionic surfactant undergo associative phase separation such that when the fabric enhancer composition is diluted with water at a ratio of water:fabric enhancer composition of 500:1, minimum transmittance is achieved within about 10 minutes.

Owner:THE PROCTER & GAMBLE COMPANY

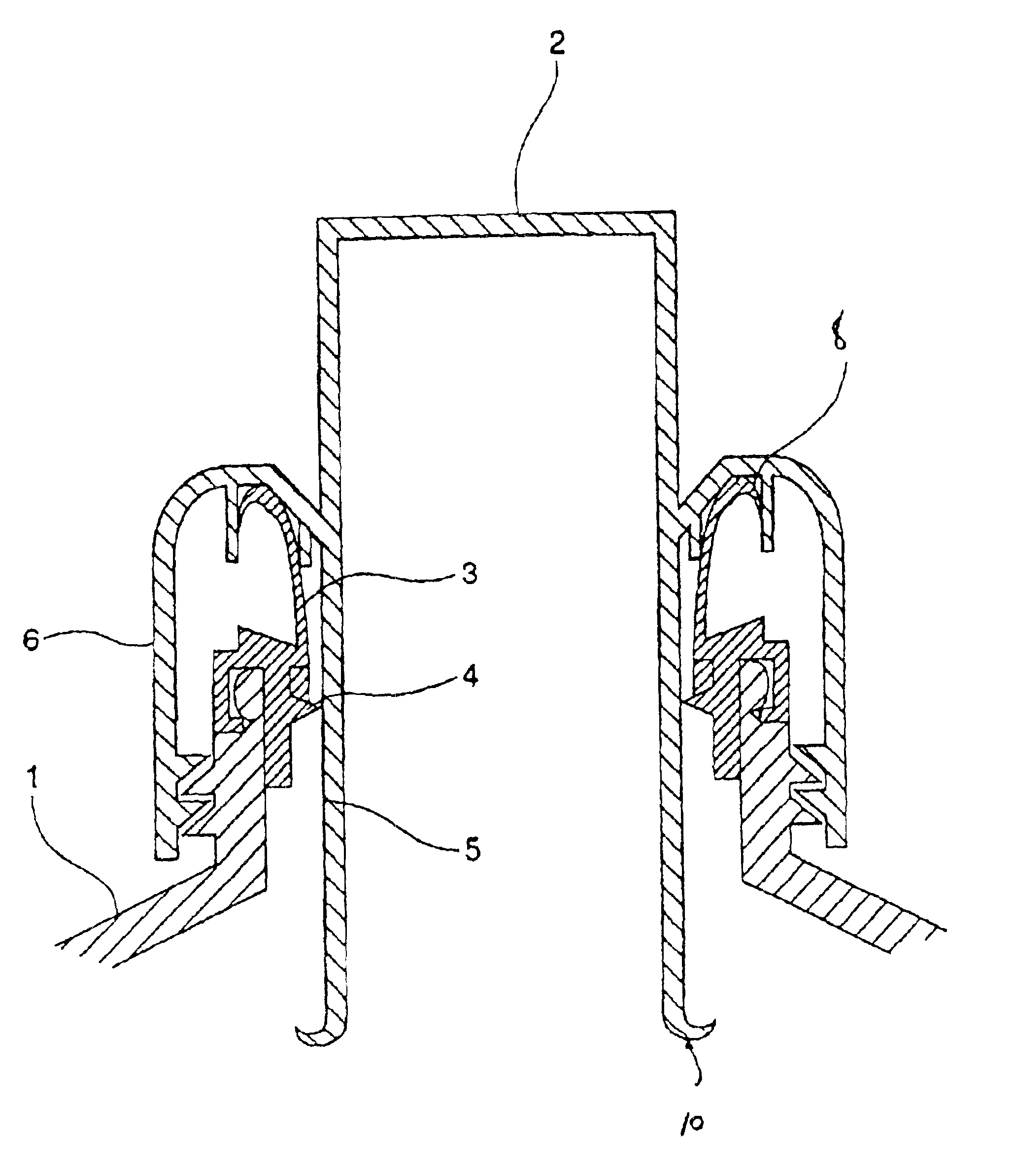

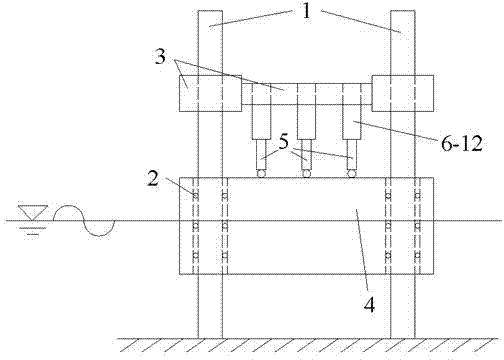

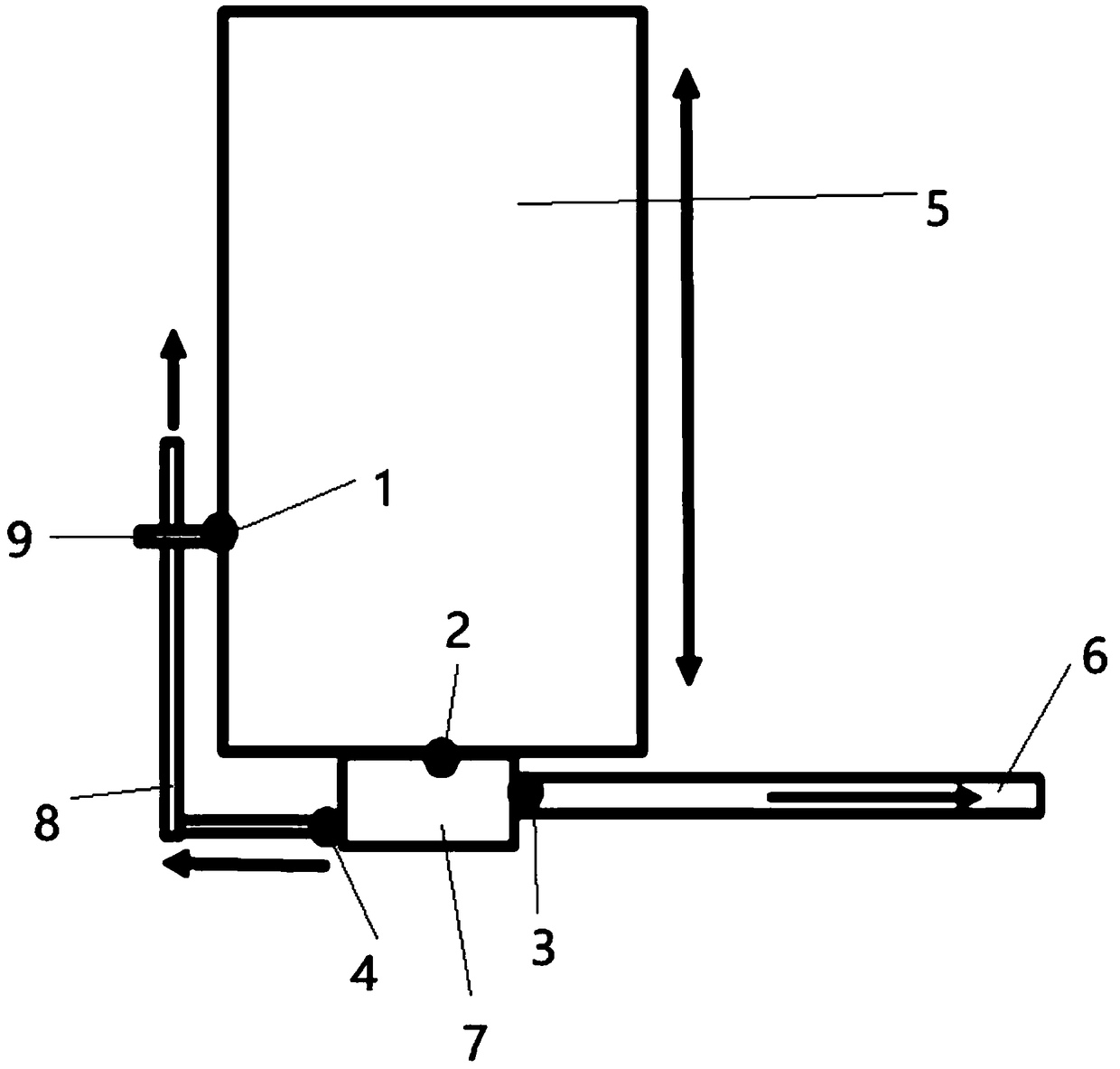

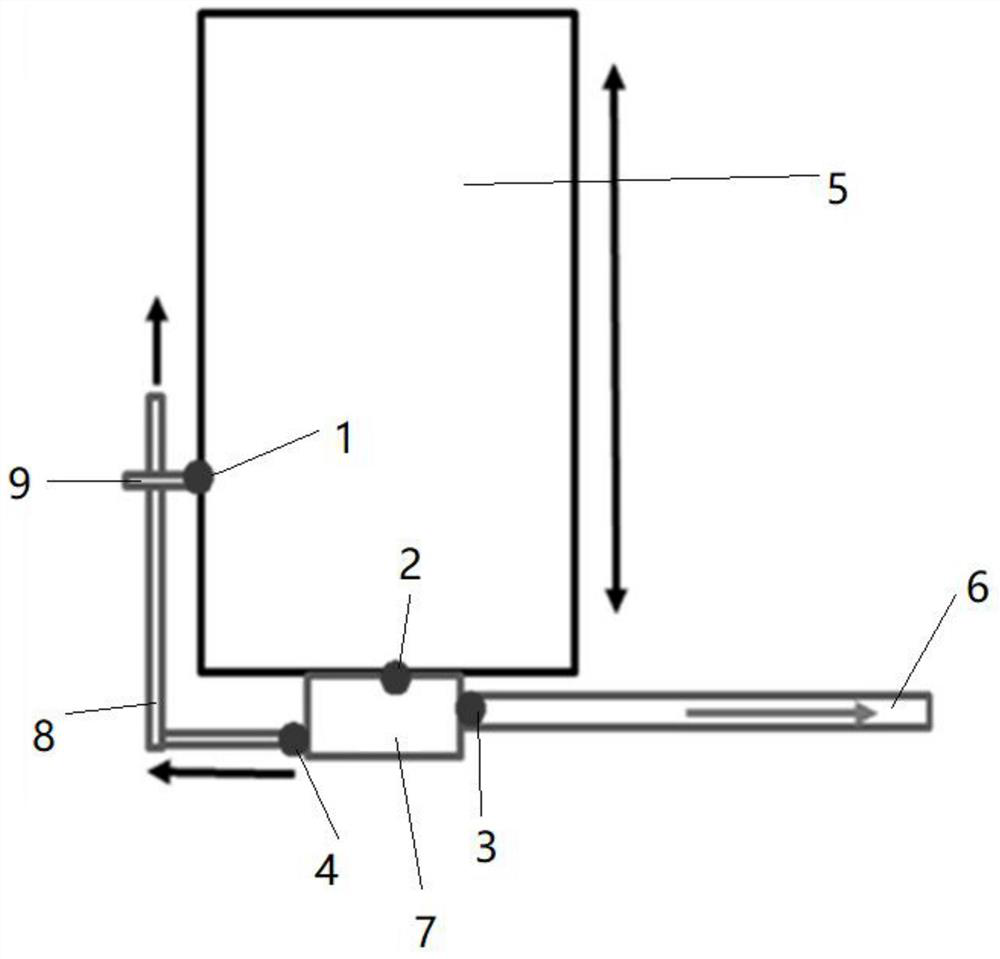

Thermoelectric conversion type wave power generation system

The invention discloses a thermoelectric conversion type wave power generation system. The thermoelectric conversion type wave power generation system is composed of a system with a guide pier (1) and a guide beam (3), a system with a guide wheel (2) and a floater (4), a connecting rod air cylinder acting system (5-9), a thermoelectric conversion and heat dissipation system (10-12) and the like. The thermoelectric conversion type wave power generation system combines the work-heat conversion principle and the modern thermoelectric conversion technology, the piston air cylinder system (5-9) is fixed above the floater (4), and thermoelectric conversion equipment (thermocouple) (10) is installed in the position, with higher temperature, of an air cylinder (6). The thermoelectric conversion type wave power generation system can act on the piston air cylinder system (5-9) through the mechanical energy generated when the floater (4) moves up and down along with waves to raise the temperature of the air cylinder, and the thermal energy is converted into electricity through the thermocouple (10). The thermoelectric conversion type wave power generation system is simple and reliable in design principle and low in manufacturing cost. As the requirement for utilizing marine energy resources is improved continuously, the power generation system has broad engineering application prospects, and can produce obvious social benefits.

Owner:HOHAI UNIV

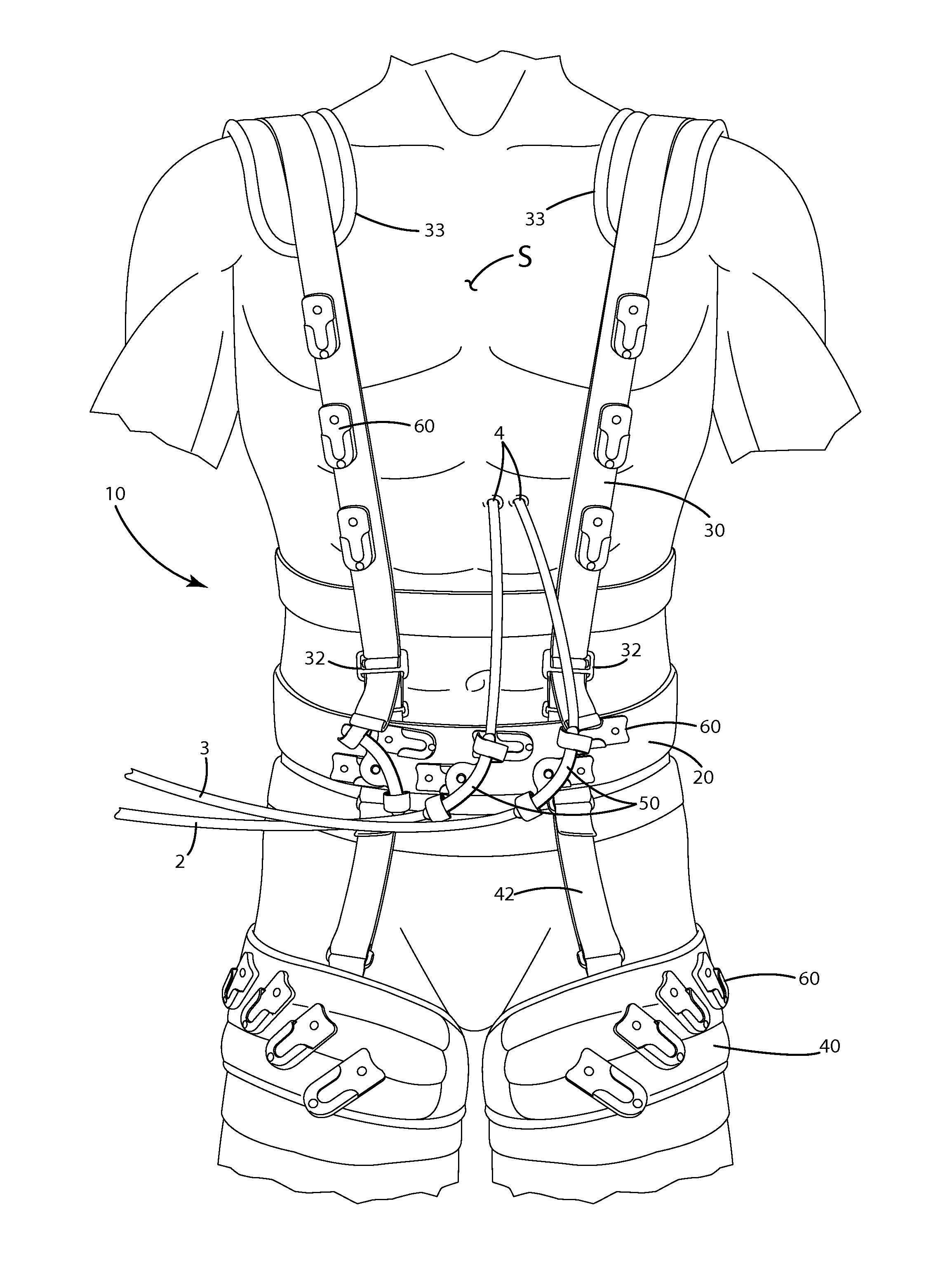

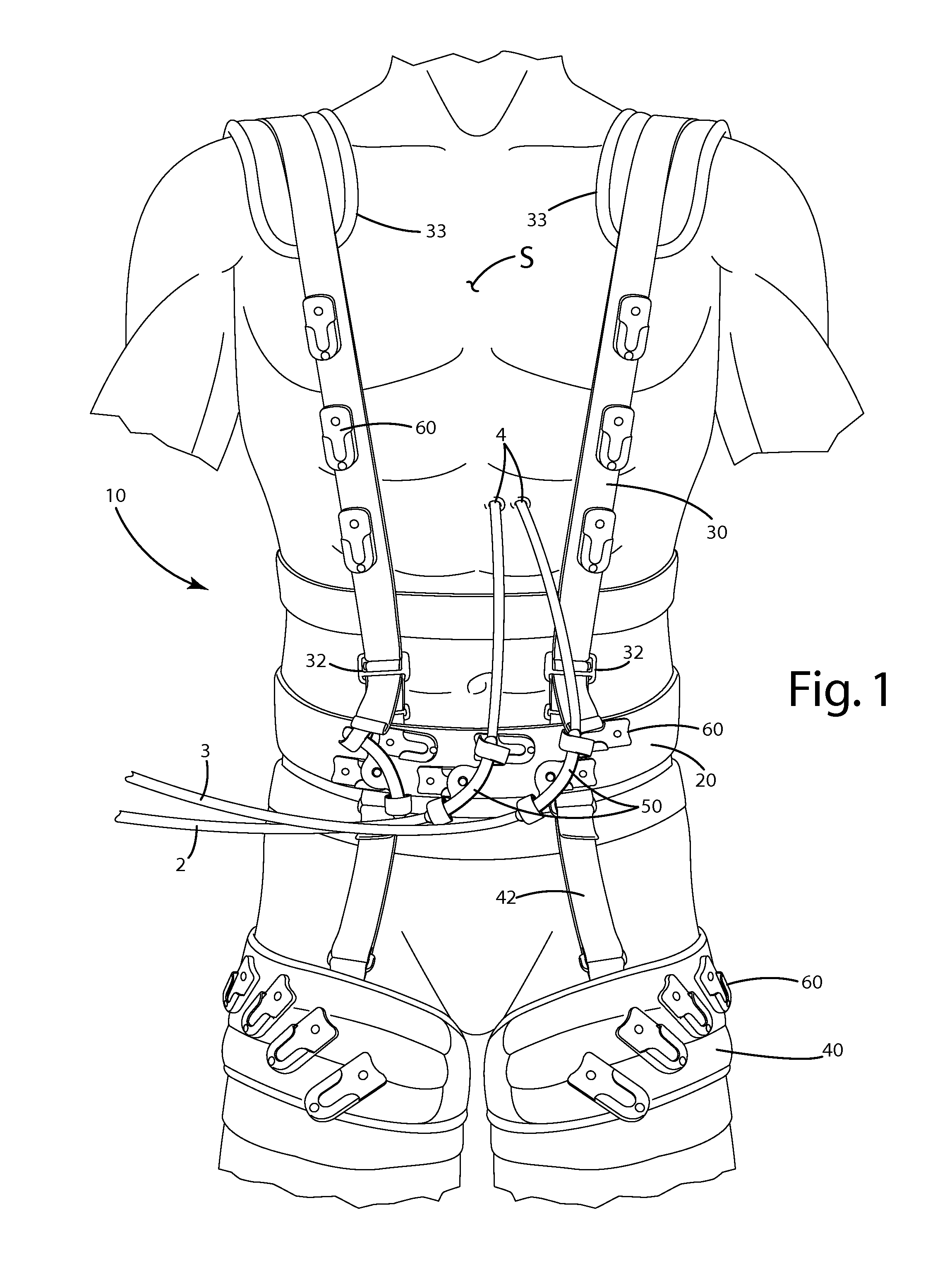

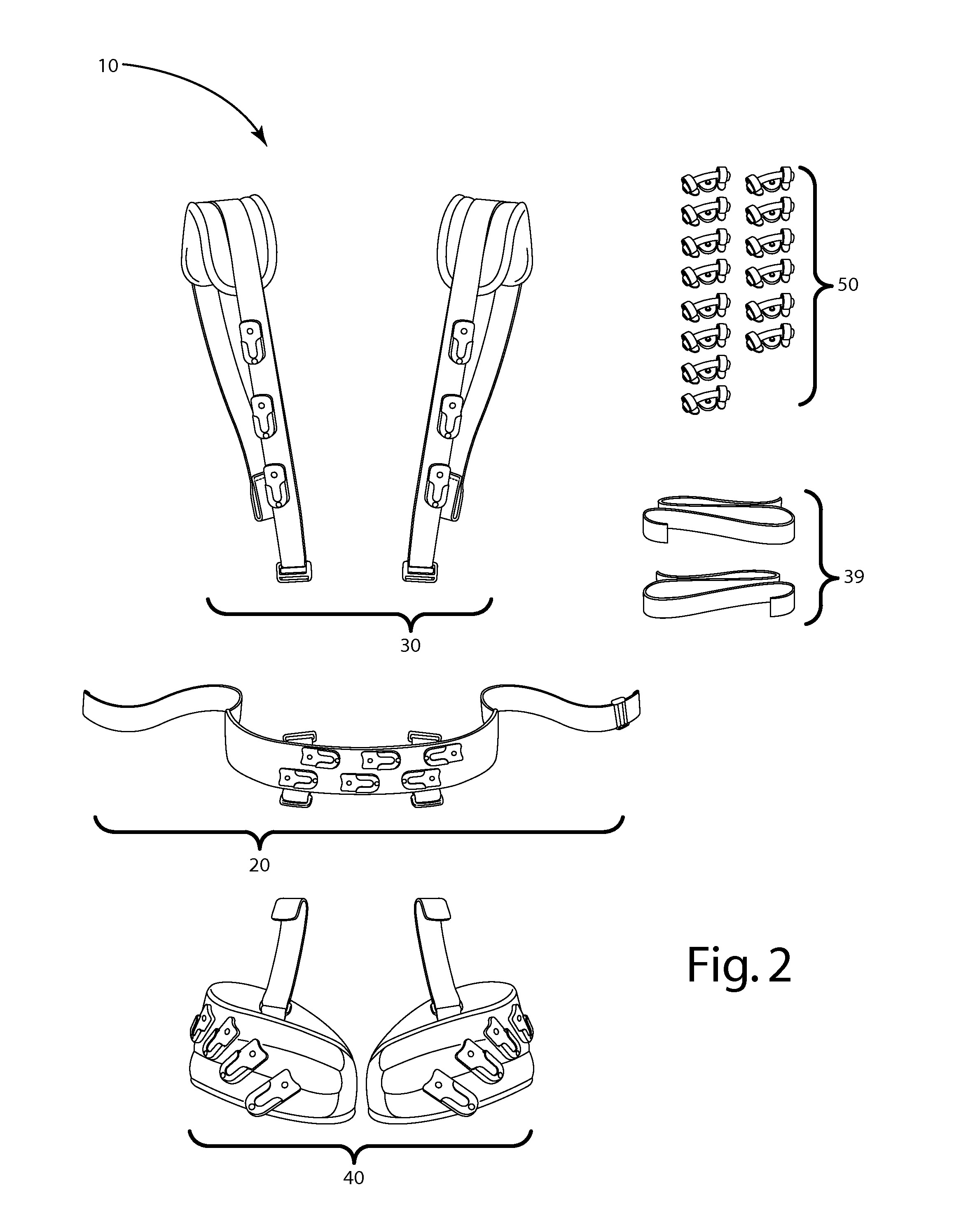

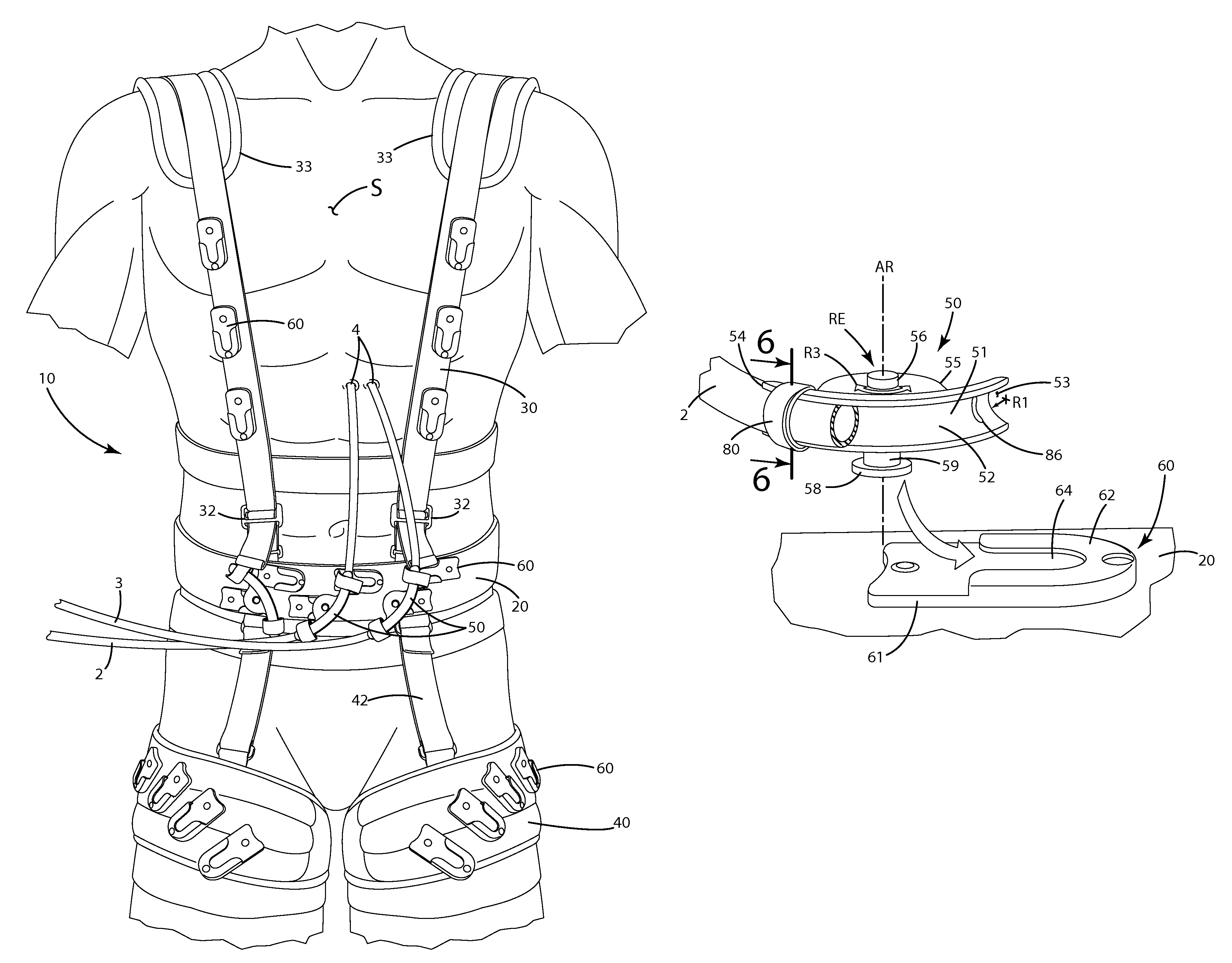

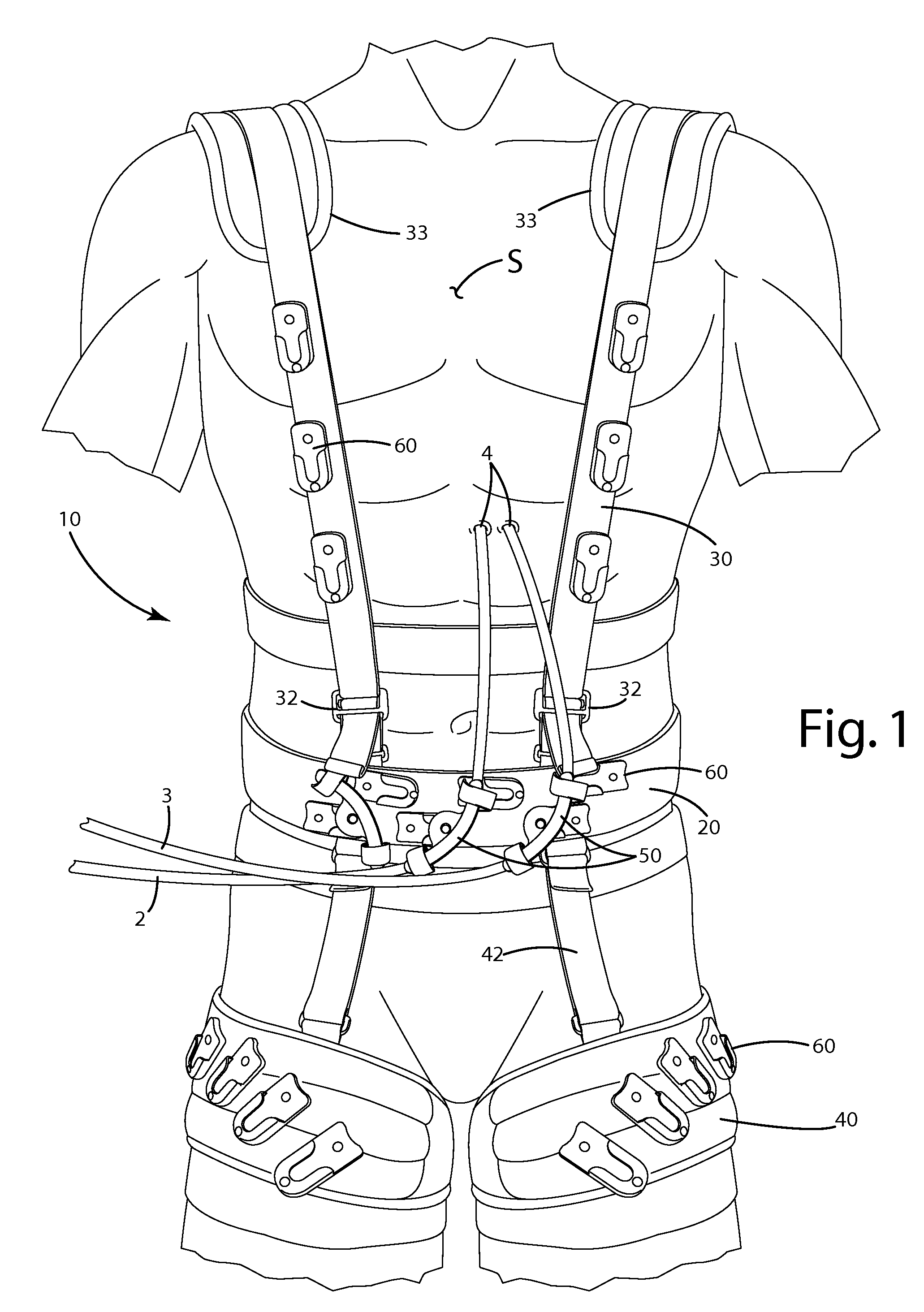

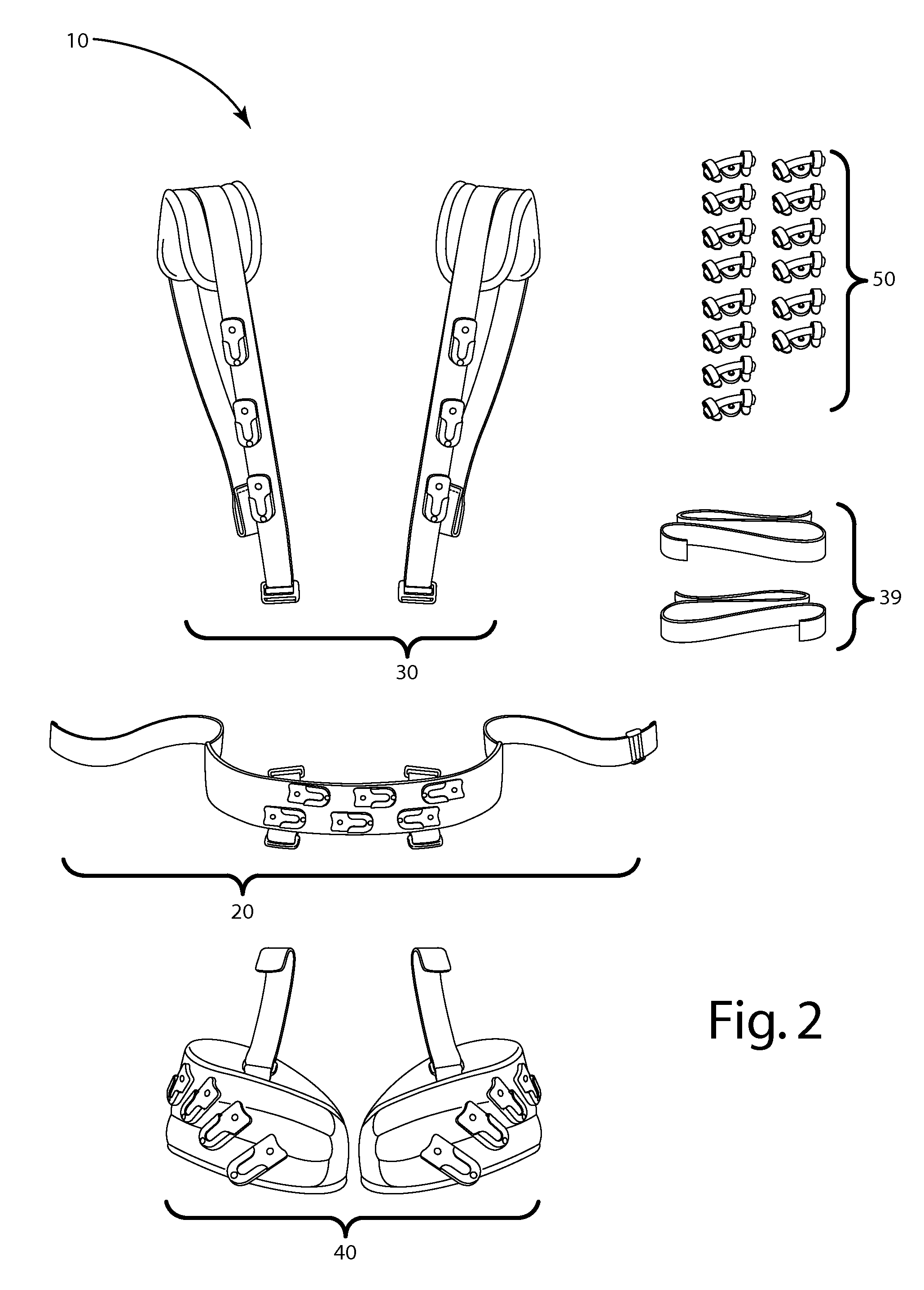

Medical tube harness

InactiveUS20140358090A1Prevent kinkingIncrease frictionCatheterInfusion needlesSubject matterTube placement

A medical tube harness that a subject wears to organize, orient and support medical tubes and reduce the potential for unintentional tugging, kinking, and / or dislodging of the tubes as they extend from a subject's internal cavities, organs, orifices and / or anchor sites on the subject. The harness can improve patient comfort and safety, and can provide multiple locations for strategic tube placement.

Owner:SPECTRUM HEALTH INNOVATIONS

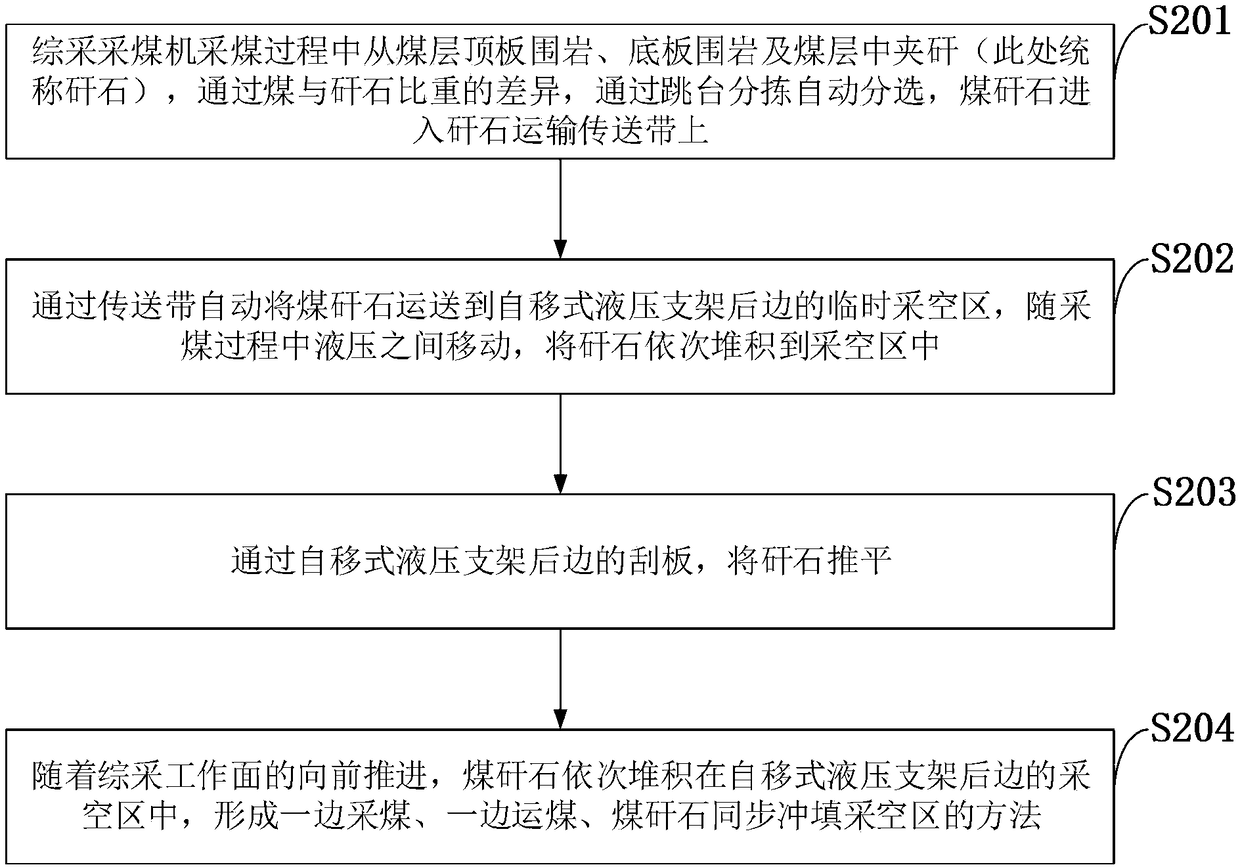

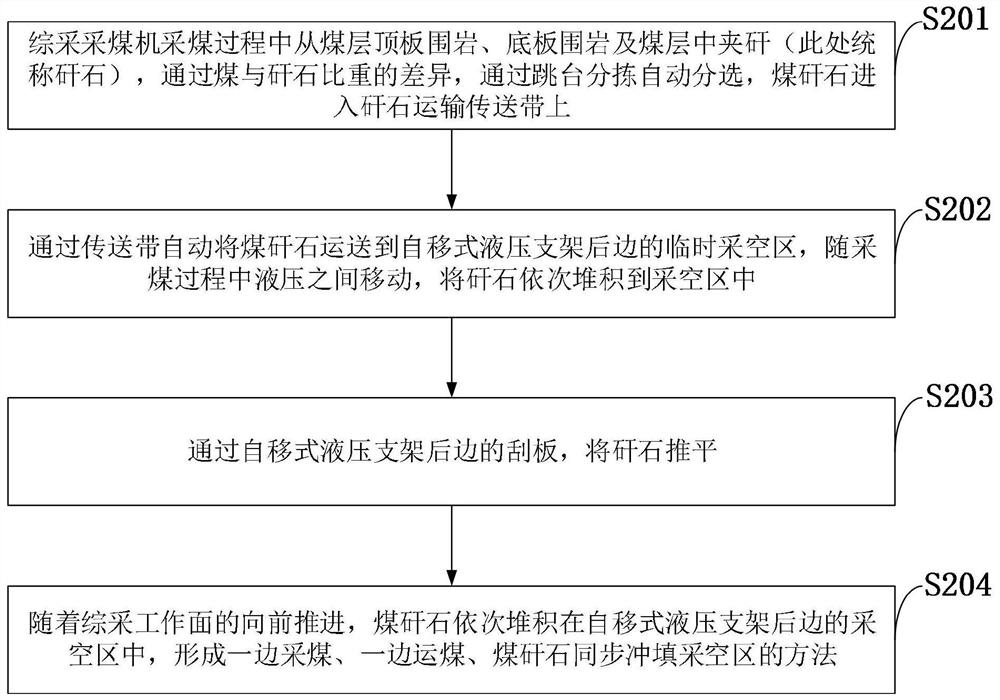

Fully mechanized coal gangue synchronous filling system and method based on the reduction of coal mining subsidence degree

ActiveCN109184784AReduce pollutionReduce geological environmental problemsUnderground miningSurface miningEcological environmentResource development

The invention belongs to the technical field of green mining environmental protection of underground coal resources and discloses a fully mechanized coal gangue synchronous filling system and method based on the reduction of a coal mining subsidence degree. Through the difference of the specific gravities of coal and coal gangue, through the dry jumping platform sorting machine sorting technology,the coal and the coal gangue are separated, and the coal gangue enters into a coal gangue automatic transport conveyor belt. Through a linkage scraper behind the self-moving fully mechanized mining hydraulic support of long wall mining method fully mechanized coal mining, the goaf where an overlying rock is not fallen yet formed by the fully mechanized mining behind the hydraulic support is filled with the coal gangue, and the technical method of mining coal and filling the goaf of the self-moving fully mechanized mining hydraulic support is filled with the coal gangue at the same time is formed. According to the system and the method, the overlying rock falling amount in the goaf is reduced, the damage degree of underground coal mining surface collapse is directly and indirectly reduced,and the sustainable development goal of the green development of coal resource development and mine ecological environment protection is achieved.

Owner:XIAN CENT OF GEOLOGICAL SURVEY CGS

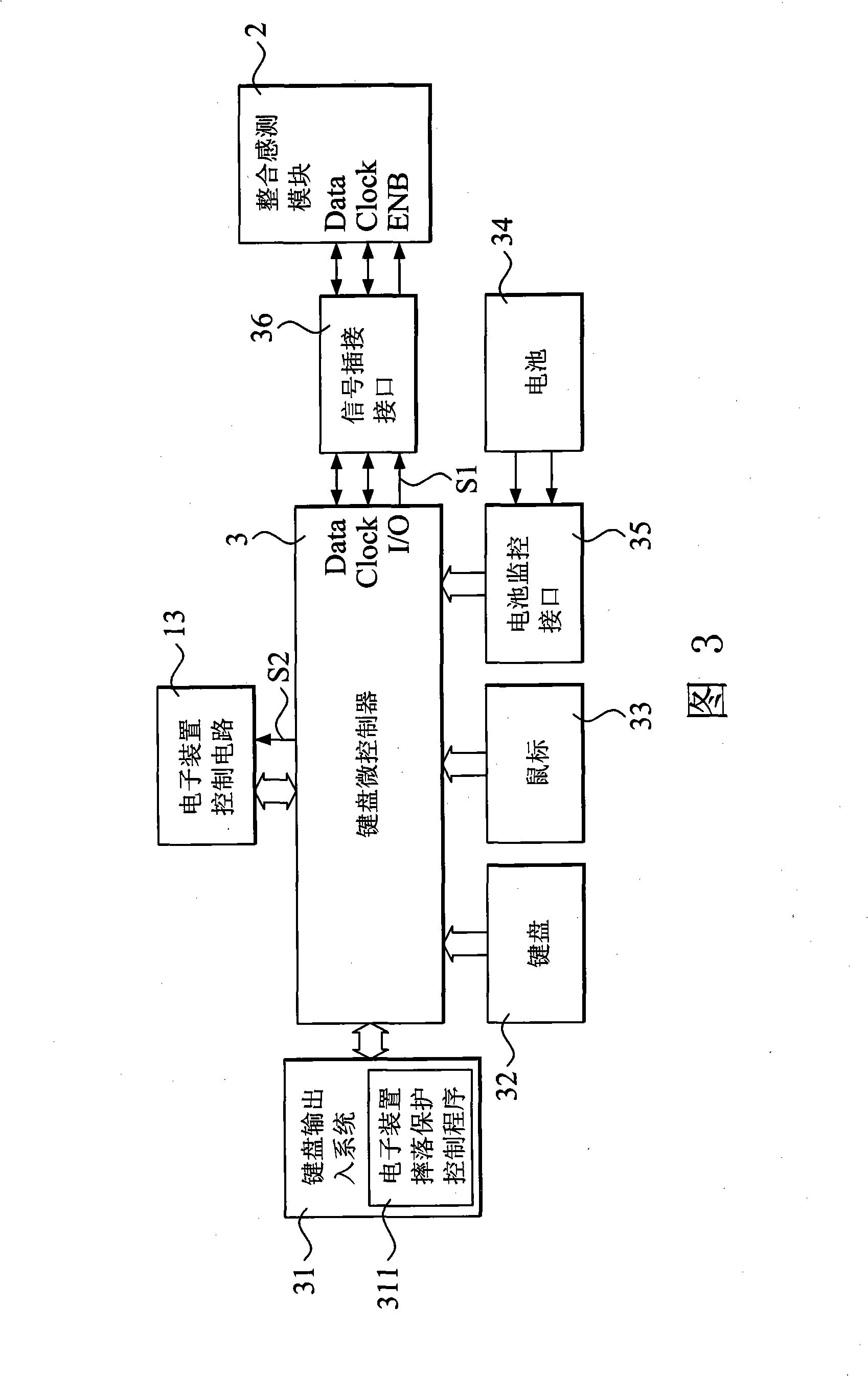

Integration sensing module capable of separating as movement sensing and electronic device falling protection

InactiveCN101354668AMany additional functionsMultiple benefitsHardware monitoringAcceleration measurementMicrocontrollerInternal memory

A separable integral sensing module for motion sensing and electronic device fall protection comprises a microcontroller, a fall sensing module, an electronic device signal transmission interface circuit, an internal memory storing a database of electronic device fall protection mode parameters and a motion signal sensing mode control program, and a battery unit. When the integral sensing module is connected with the electronic device through the electronic device signal transmission interface circuit, the electronic device produces an enabling signal to enable the integral sensing module to operate in an electronic device fall protection mode; and when the integral sensing module is separated from the electronic device, the integral sensing module operates in a motion signal sensing mode to sense the motion signal of a user.

Owner:MITAC COMP (SHUN DE) LTD +1

Friction welding of X-ray tube components using intermediate filler materials

ActiveUS9607801B2Increased microstructural controlReduce the temperatureDischarge tube assemblyX-ray tube electrodesFriction weldingEngineering

A structure and associated process for joining dissimilar materials to form various components of an x-ray tube is illustrated that utilizes one or more intermediate or interfacial filler material members positioned between the primary welding or mating surfaces of the base material components to be joined. The use of the interfacial or intermediate filler material preserves the multiple benefits of friction welding, as well as enabling the joining of highly dissimilar material components, decreasing the required joining temperature, and providing increased microstructural control of the resulting weld or joint.

Owner:GENERAL ELECTRIC CO

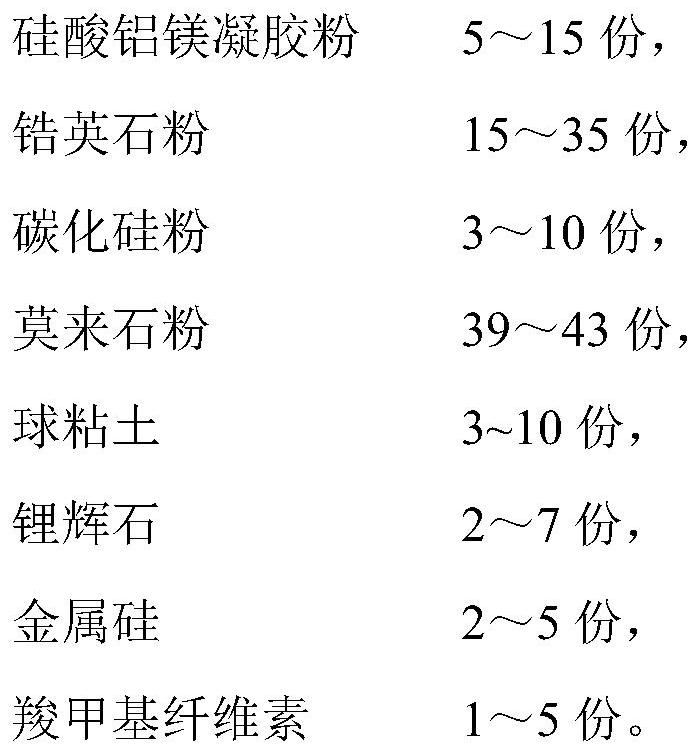

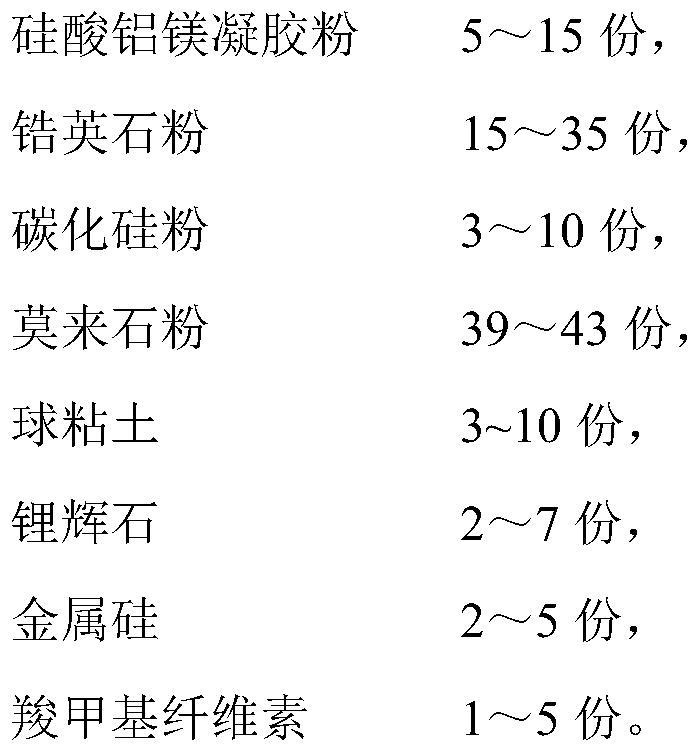

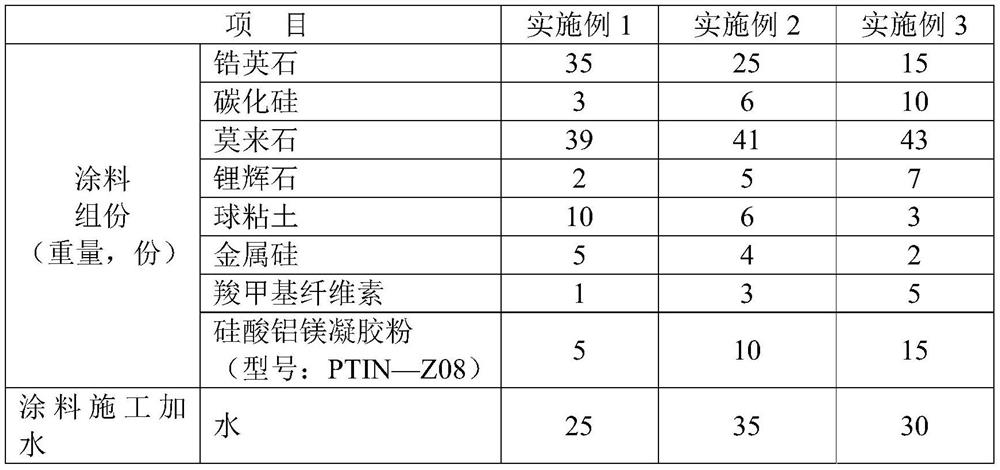

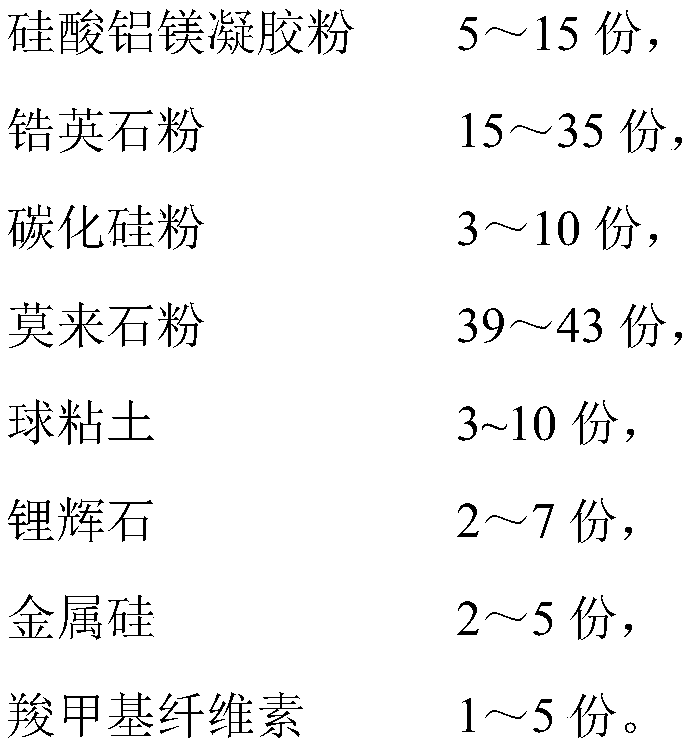

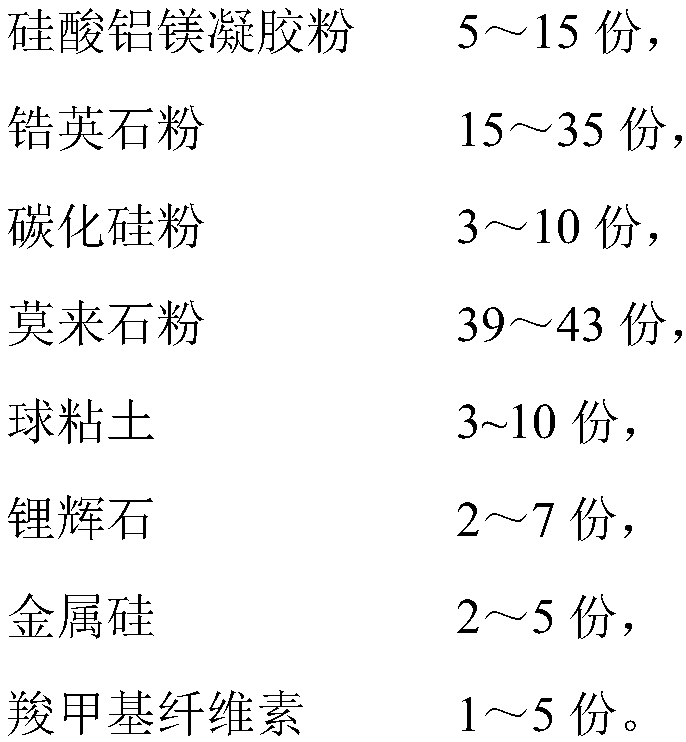

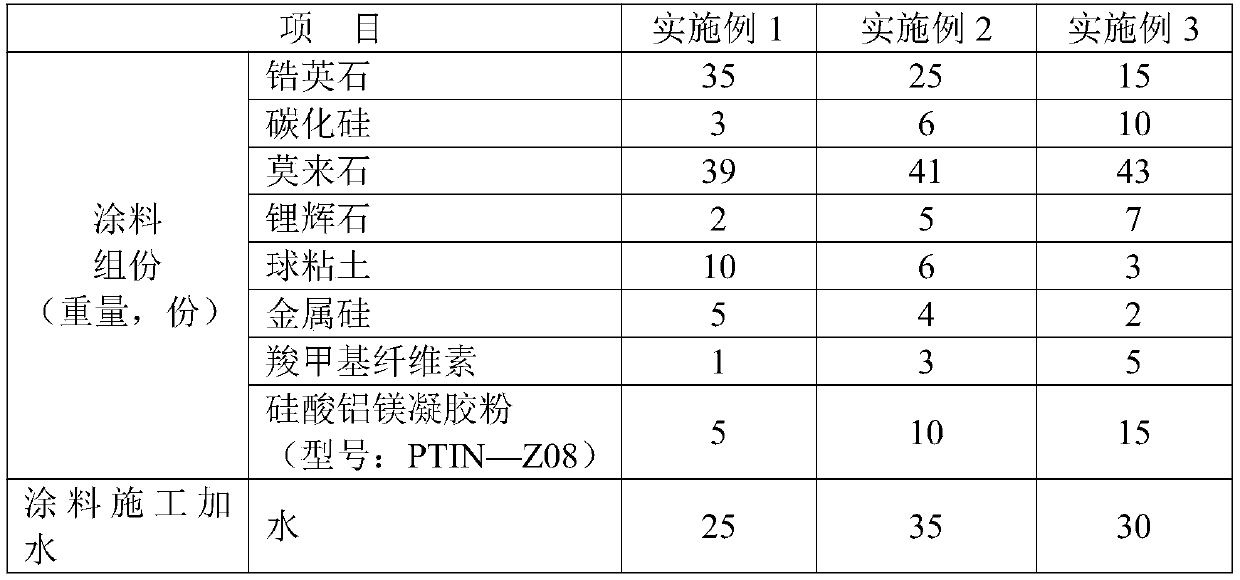

A kind of high-temperature energy-saving anti-corrosion coating for metal baffle of sintering trolley and its application

ActiveCN110628244BExtended service lifeReduce consumptionFireproof paintsAnti-corrosive paintsCarbide siliconAluminum magnesium silicate

The invention relates to a high-temperature energy-saving anti-corrosion paint for a metal baffle of a sintering trolley and an application method thereof. The paint contains 15-35 parts by weight of zircon powder, 3-10 parts by weight of silicon carbide powder, 39-43 parts by weight of mullite powder, 3-10 parts by weight of ball clay, 2-7 parts by weight of spodumene, metal silicon 2-5 parts by weight, magnesium aluminum silicate gel powder 5-15 parts by weight. Add water to prepare a fine slurry, spray or smear on the metal surface of the baffle, and after drying and heat treatment, the coating will firmly adhere to the metal surface of the baffle to form a high-temperature resistant, energy-saving and anti-corrosion ceramic coating. It can not only reflect the heat of the material layer, reduce the temperature of the inner wall of the baffle, but also protect the inner wall of the metal baffle from corrosion. This can prolong the life of the baffle plate, and at the same time have the effect of saving energy, which is very beneficial to reducing the production cost of sintered ore.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for recycling heavy metals in electroplating wastewater by using modified titanium nanotube

ActiveCN103641262ATo achieve the purpose of turning waste into treasureConducive to emission reductionWaste water treatment from metallurgical processMultistage water/sewage treatmentDistillationIon exchange

The invention discloses a method for recycling heavy metals in electroplating wastewater by using a modified titanium nanotube. The method comprises the following steps: soaking a titanium nanotube in absolute ethyl alcohol for 12-48 hours, and drying at 60-80 DEG C to obtain the modified titanium nanotube; adjusting pH of electroplating wastewater to 2-7, and then carrying out settling separation or filtering to remove solid impurities; filling the modified titanium nanotube into a packing column, introducing the pretreated electroplating wastewater into the modified titanium nanotube packing column, and carrying out ion exchange till the titanium nanotube is saturated by adsorption; and putting the modified titanium nanotube which is saturated by adsorption into a sodium hydroxide aqueous solution, soaking for 6-18 hours, then filtering out the modified titanium tube, and drying the solution by distillation to obtain heavy metal substances. According to the method disclosed by the invention, the heavy metal ions in the electroplating wastewater are caught and then recycled by the modified titanium nanotube; the modified titanium nanotube which is used for multiple times can also be used as a denitration catalyst, which is favorable for emission reduction of nitric oxides and having multiple benefits.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Medical tube harness

InactiveUS9327099B2Prevent kinkingIncrease frictionCatheterInfusion needlesEngineeringTube placement

A medical tube harness that a subject wears to organize, orient and support medical tubes and reduce the potential for unintentional tugging, kinking, and / or dislodging of the tubes as they extend from a subject's internal cavities, organs, orifices and / or anchor sites on the subject. The harness can improve patient comfort and safety, and can provide multiple locations for strategic tube placement.

Owner:SPECTRUM HEALTH INNOVATIONS

Method for recycling heavy metals in electroplating wastewater by using modified titanium nanotube

ActiveCN103641262BTo achieve the purpose of turning waste into treasureConducive to emission reductionWaste water treatment from metallurgical processMultistage water/sewage treatmentDistillationIon exchange

The invention discloses a method for recycling heavy metals in electroplating wastewater by using a modified titanium nanotube. The method comprises the following steps: soaking a titanium nanotube in absolute ethyl alcohol for 12-48 hours, and drying at 60-80 DEG C to obtain the modified titanium nanotube; adjusting pH of electroplating wastewater to 2-7, and then carrying out settling separation or filtering to remove solid impurities; filling the modified titanium nanotube into a packing column, introducing the pretreated electroplating wastewater into the modified titanium nanotube packing column, and carrying out ion exchange till the titanium nanotube is saturated by adsorption; and putting the modified titanium nanotube which is saturated by adsorption into a sodium hydroxide aqueous solution, soaking for 6-18 hours, then filtering out the modified titanium tube, and drying the solution by distillation to obtain heavy metal substances. According to the method disclosed by the invention, the heavy metal ions in the electroplating wastewater are caught and then recycled by the modified titanium nanotube; the modified titanium nanotube which is used for multiple times can also be used as a denitration catalyst, which is favorable for emission reduction of nitric oxides and having multiple benefits.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

High-temperature energy-saving anticorrosive coating material for sintering pallet metal baffle, and applications thereof

ActiveCN110628244AExtended service lifeReduce consumptionFireproof paintsAnti-corrosive paintsCeramic coatingMullite

The invention relates to a high-temperature energy-saving anticorrosive coating material for a sintering pallet metal baffle, and an application method thereof, wherein the coating material comprises,by weight, 15-35 parts of zirconite powder, 3-10 parts of silicon carbide powder, 39-43 parts of mullite powder, 3-10 parts of ball clay, 2-7 parts of spodumene, 2-5 parts of metal silicon and 5-15 parts of magnesium aluminum silicate gel powder. During the application, water is added to the coating material to prepare a fine slurry, the surface of a metal baffle is sprayed or coated with the fine slurry, and the coating is firmly attached to the surface of the metal baffle after drying and heat treatment so as to form a high-temperature-resistant energy-saving anti-corrosion ceramic coating.According to the invention, the coating material can reflect the heat of the material layer, reduce the temperature of the inner wall of the baffle, and protect the inner wall surface of the metal baffle from being corroded so as to prolong the service life of the baffle, achieve the energy-saving effect and easily reduce the production cost of sintered ore.

Owner:BAOSHAN IRON & STEEL CO LTD

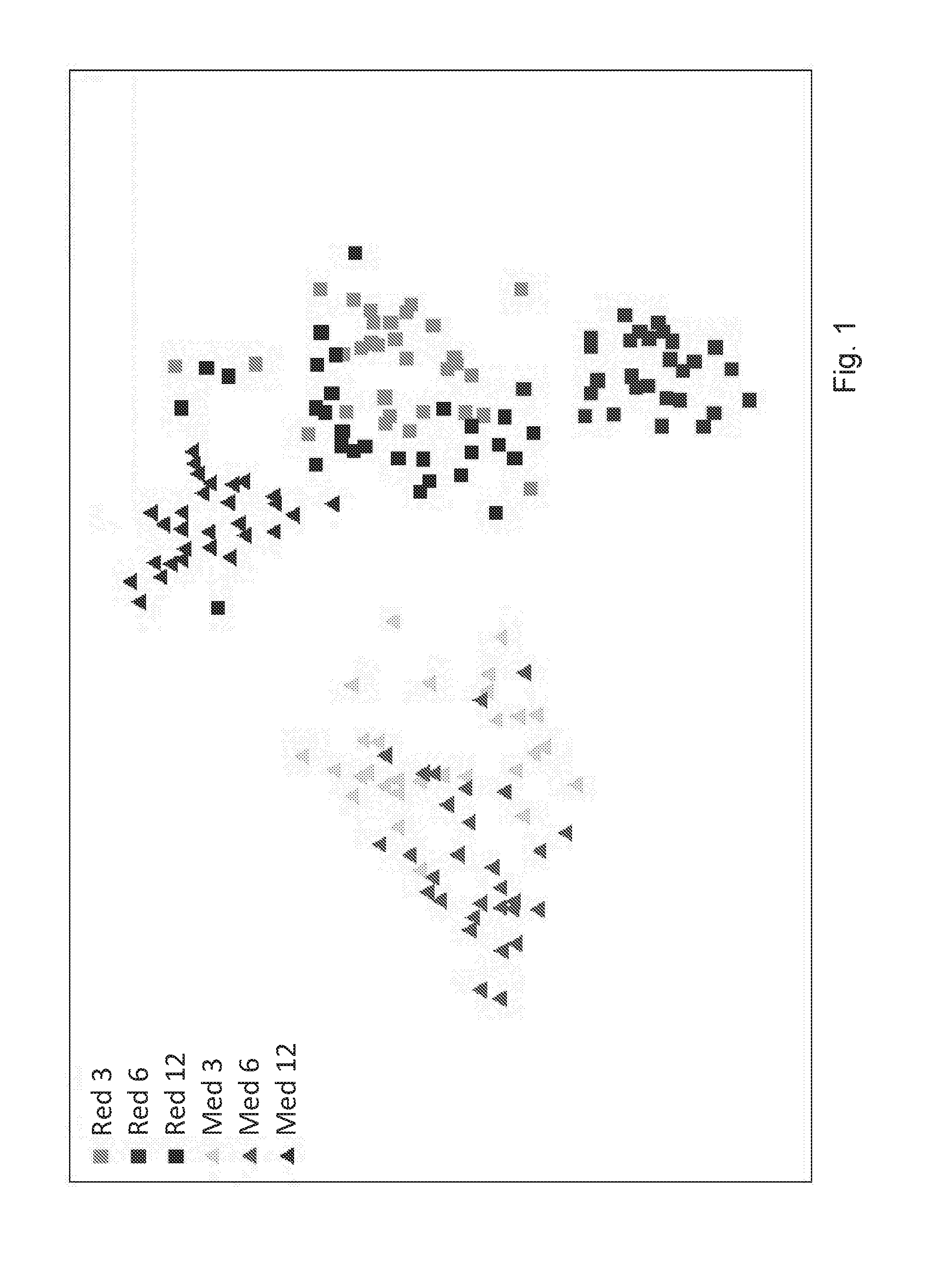

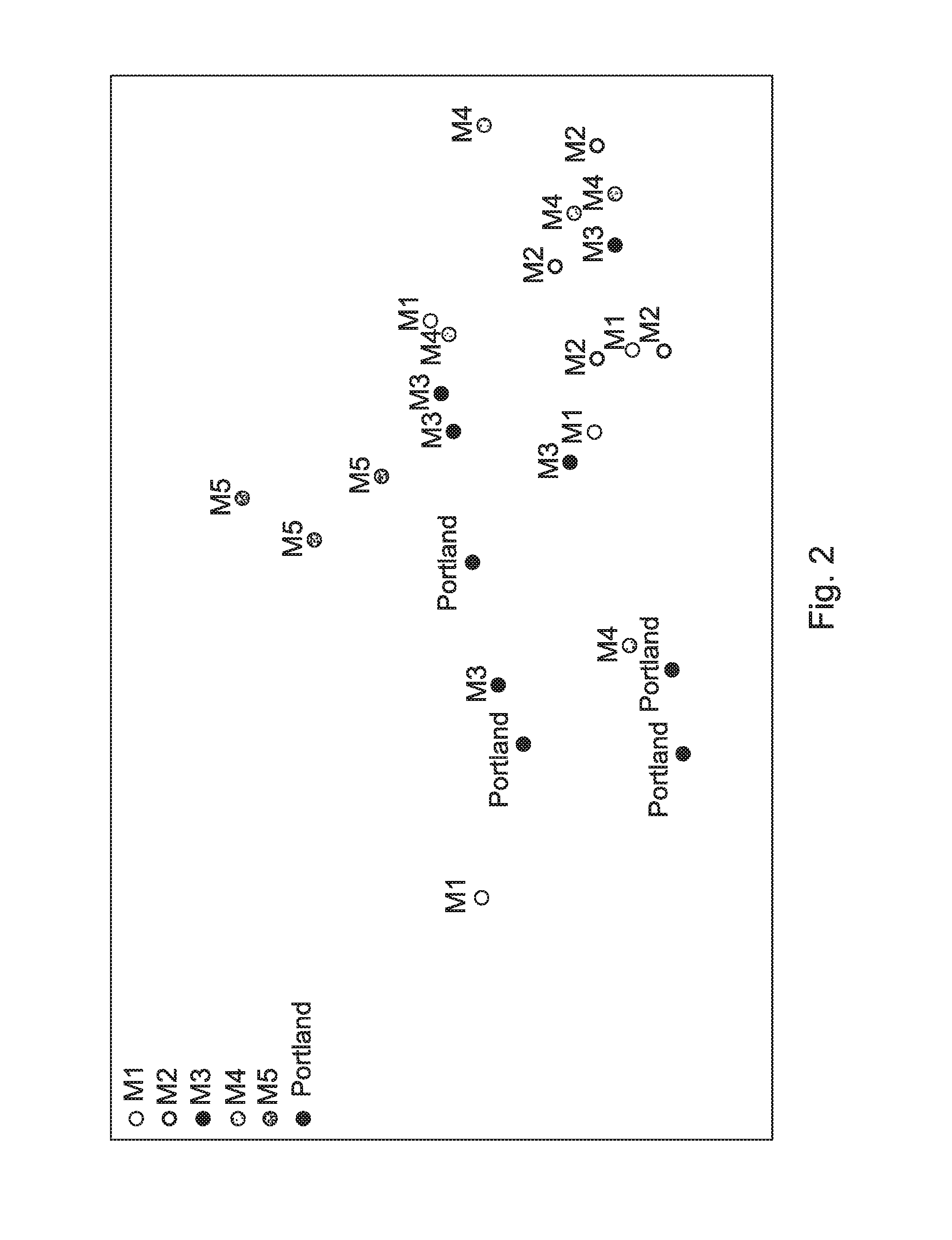

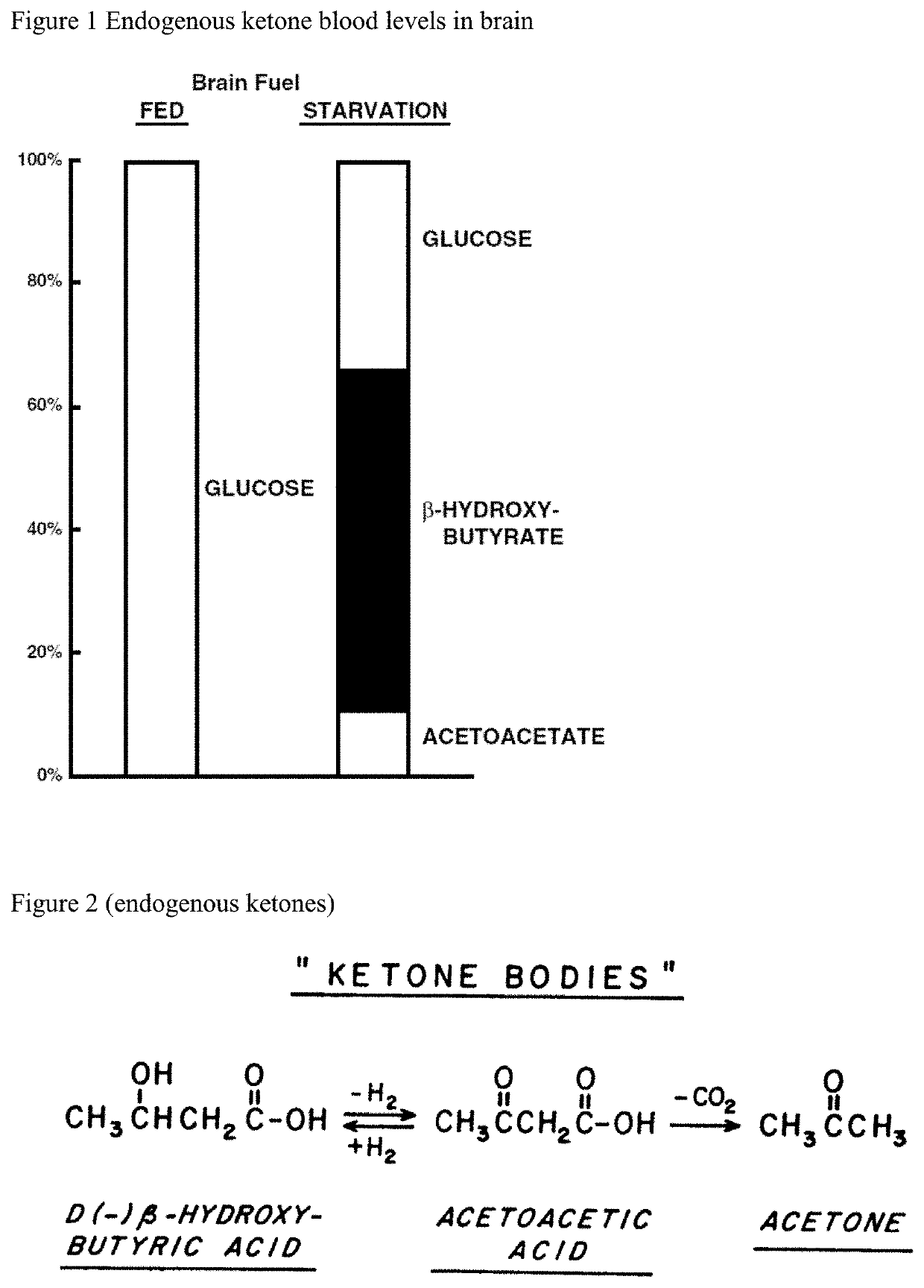

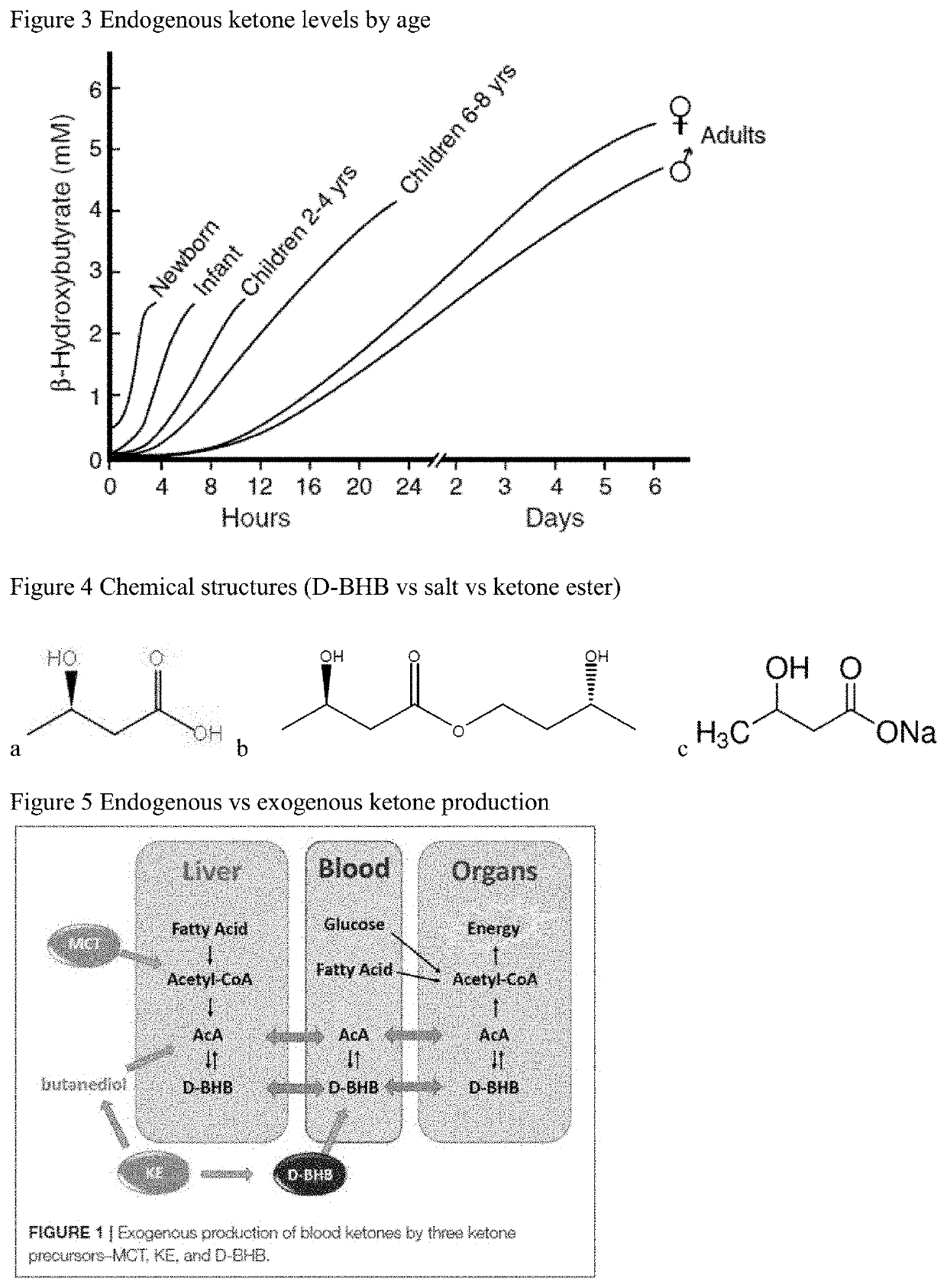

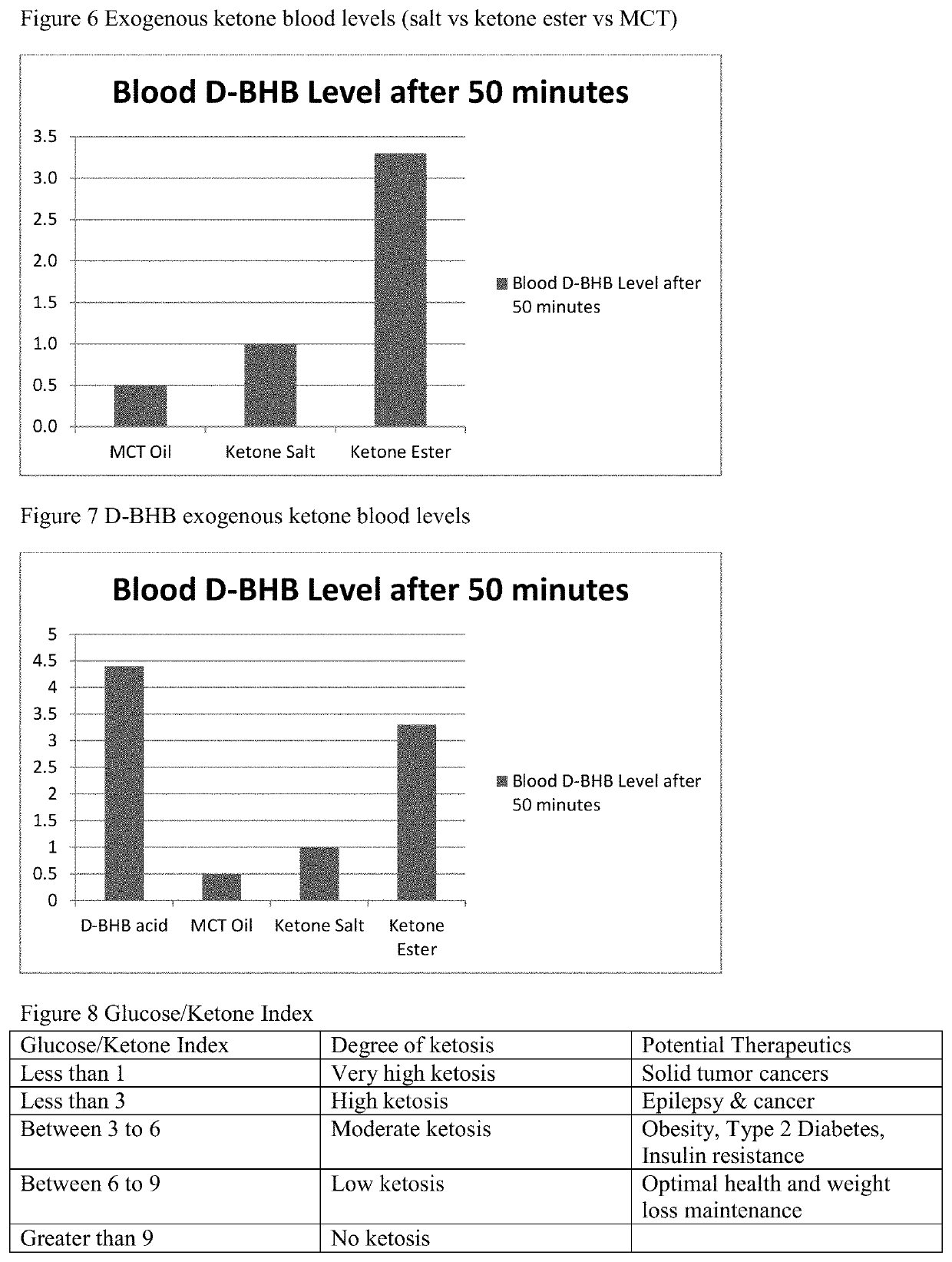

Exogenous ketone supplementation compositions, systems and methods

PendingUS20210322350A1Significant comprehensive benefitsEasily be indexedOrganic active ingredientsFood scienceBeta-Hydroxybutyric acidHydroxybutyric acid

The claimed invention addresses the benefits of exogenous ketone supplementation in a subject in need thereof. In particular, the exogenous ketone supplementation includes the natural D-Beta HydroxyButyric acid, also described as natural D-BHB. As detailed in representative FIG. 1, natural D-BHB is preferentially consumed in the brain to glucose and additionally has a wide range of positive regulatory effects on the body and mind. Consumer applications for supplementation with natural D-BHB include improved sleep, anti-hunger, anti-anxiety, improved cognitive enhancement and athletic duration and post workout recovery through consumption of 10 grams or more of natural D-BHB. Therapeutic applications for exogenous natural D-BHB supplementation include anti-cancer, anti-kidney disease, anti-cognitive disorders and improved viral resistance through consumption of 10-20 grams or more of D-Beta HydroxyButyric acid.

Owner:KETONE CLARITY LLC

Synchronous filling system and method for fully mechanized coal gangue based on reducing the degree of coal mining subsidence

ActiveCN109184784BReduce overburden cavingAvoid damageUnderground miningSurface miningLongwall miningSeparation technology

The invention belongs to the technical field of environmental protection for green mining of underground coal resources, and discloses a fully-mechanized coal gangue synchronous filling system and method based on reducing the degree of coal mining subsidence. Through the difference in the proportion of coal and coal gangue, the dry method jumping platform sorter Sorting technology separates coal from gangue, and gangue enters the gangue automatic transport conveyor belt; through the linkage scraper behind the self-moving fully mechanized mining hydraulic support of the longwall coal mining method, the coal gangue is filled behind the hydraulic support In the goaf where the overlying rock formed by fully mechanized mining has not yet collapsed, a technical method is formed to synchronously fill the produced coal gangue into the goaf of the self-moving fully mechanized mining hydraulic support while mining coal. The invention reduces the caving amount of the overlying rocks in the goaf, directly or indirectly reduces the damage degree of underground coal mining surface subsidence, and realizes the sustainable development goal of green development of coal resource development and mine ecological environment protection.

Owner:XIAN CENT OF GEOLOGICAL SURVEY CGS

Growing-finishing pig composite pre-mixing feed

InactiveCN101548730BImprove efficiencyPromote digestion and absorptionFood processingAnimal feeding stuffThreonineCyclodextrin

The invention relates to a growing-finishing pig composite pre-mixing feed, belonging to the feed field, comprising: amino acid additive, inorganic trace element and organic trace element, vitamin additive, magnesium sulfate, bean pulp, functional additive, wherein the organic trace element comprises organic chrome, organic selenium, the amino acid additive comprises lysine and threonine, the functional additive comprises cysteine hydrochloride coated by cyclodextrin, dihydropyridine ester, enzyme preparation, probiotics. The feed can increase the digestion and absorption of nutritive materialand daily gain and feed utilization rate, reduce marketing period; improve feed efficiency, reduce feed conversion ratio (the feed conversion ratio of the common feed is 0.2-0.4), greatly save the cultivation cost; increase muscle lipid content and meat flavor; reduce drip loss and improved meat taste.

Owner:北京劲能生物科技股份公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com