Synchronous filling system and method for fully mechanized coal gangue based on reducing the degree of coal mining subsidence

A technology of coal gangue and level, which is applied in the field of fully mechanized coal gangue synchronous filling system, can solve the problems of time synchronization of coal gangue filling, increased land acquisition and reclamation costs, and pollution of the environment caused by coal gangue occupation, so as to reduce surface subsidence. degree of damage, reduction of aquifer damage, and the effect of reducing the degree of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

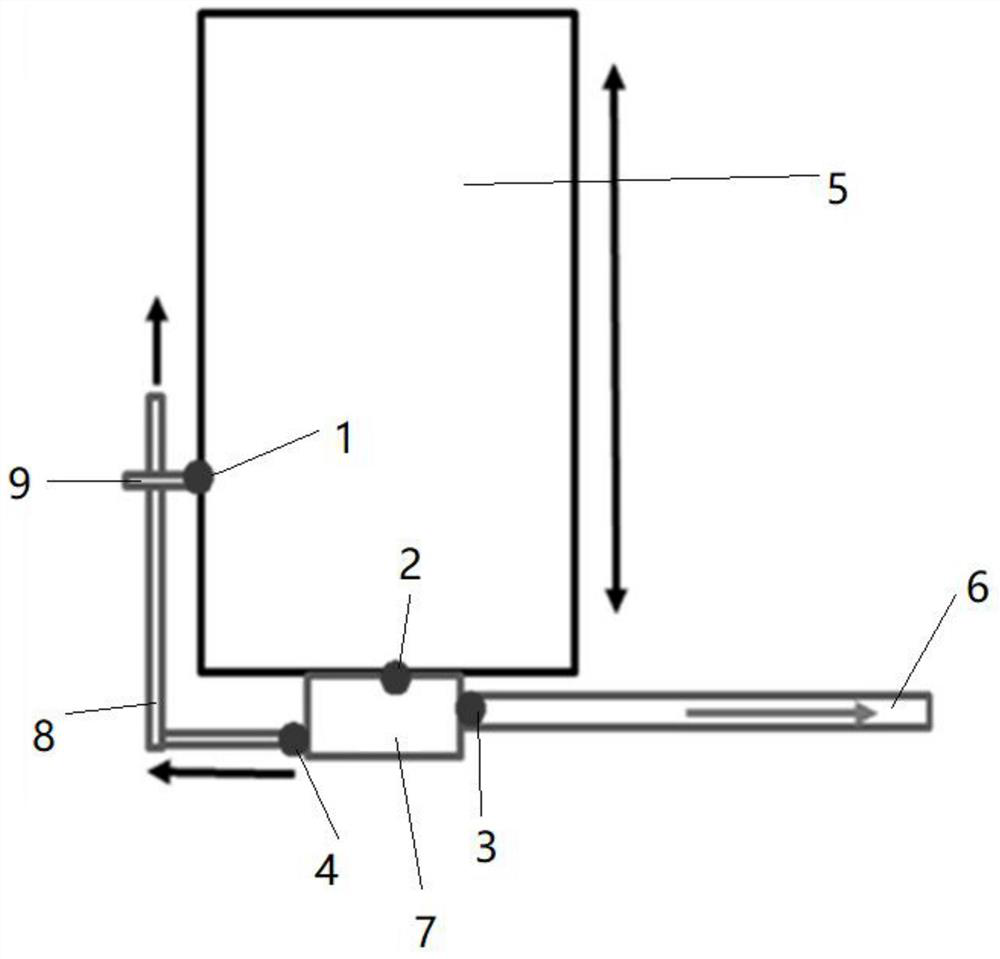

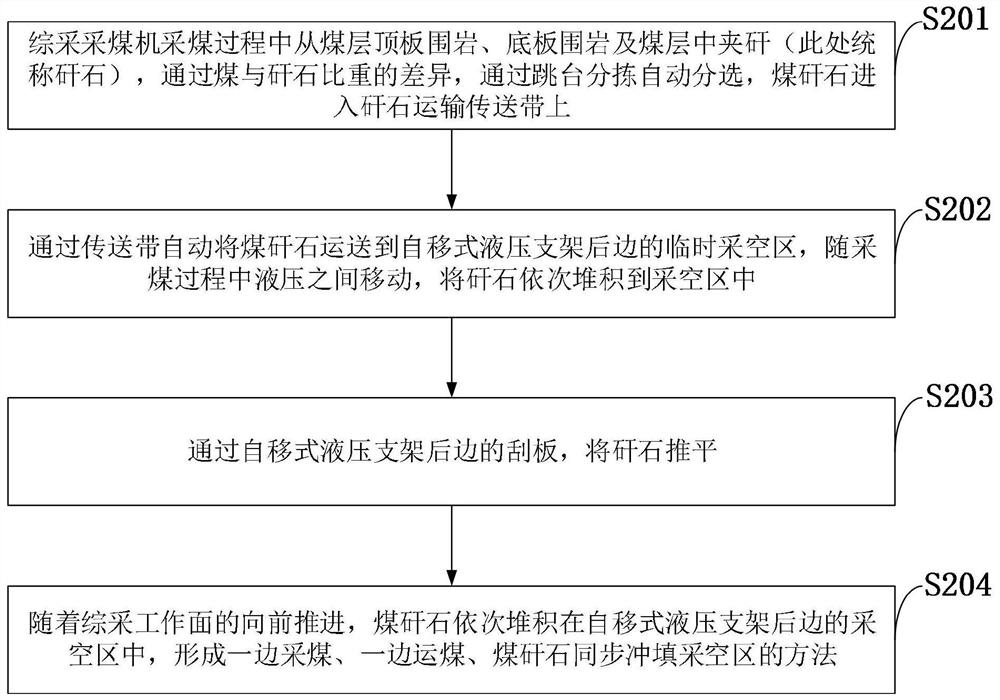

[0043] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0044] After the underground coal resources are mined, a certain goaf is formed. Since the roof surrounding rock above the coal seam is mostly mudstone and sandstone, the rock resistance to pressure is very small. The general working face length of fully mechanized coal mining is 200m and the working face advancing length It can reach 2000m, and the height of the coal seam formed by goaf can reach 3-8m. Therefore, in the underground space formed by goaf, the surrounding rock of the coal seam roof cannot support the pressure of the overlying rock with a thickness of tens of meters to more than 200 meters. The overly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com