Patents

Literature

264results about How to "To achieve the purpose of turning waste into treasure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of nitrogen and oxygen in-situ doped porous carbon electrode material and application thereof

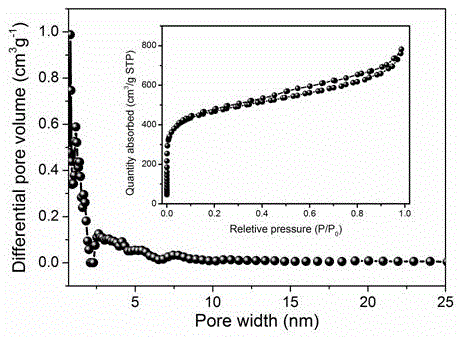

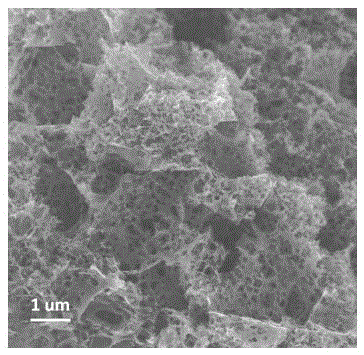

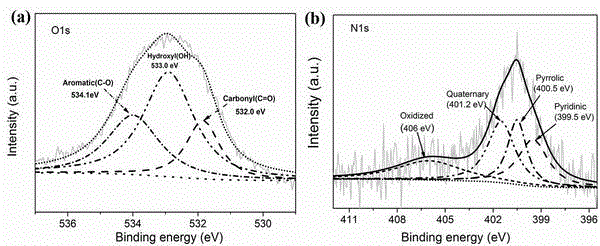

ActiveCN105575673AIncrease surface areaBest charge capacityHybrid capacitor electrodesHybrid/EDL manufacturePorous carbonApatite

The invention relates to a preparation method of nitrogen and oxygen in-situ codoped porous carbon electrode material and an application thereof. The nitrogen and oxygen in-situ codoped porous carbon electrode material is excellent in conductivity, great in chemical stability, three-dimensional and abundant in pore channels. An animal bone, such as an ox bone, a swine bone and a goat bone, is adopted to act as a carbon precursor. The organic component of collagen in the bone acts as a carbon and nitrogen source, and the inorganic component acts as a natural template to act as supporting material in the carbonization process and a pore channel regulating structure for controlling change and size of hydroxyapatite crystals so that the material is prepared. The porous carbon electrode material is abundant and prosperous in pore structures and has micropores, mesopores and macropores with the specific surface of being 1000-3000m<2>g<-1> so that the porous carbon electrode material can be used as supercapacitor electrode material.

Owner:BEIJING UNIV OF CHEM TECH

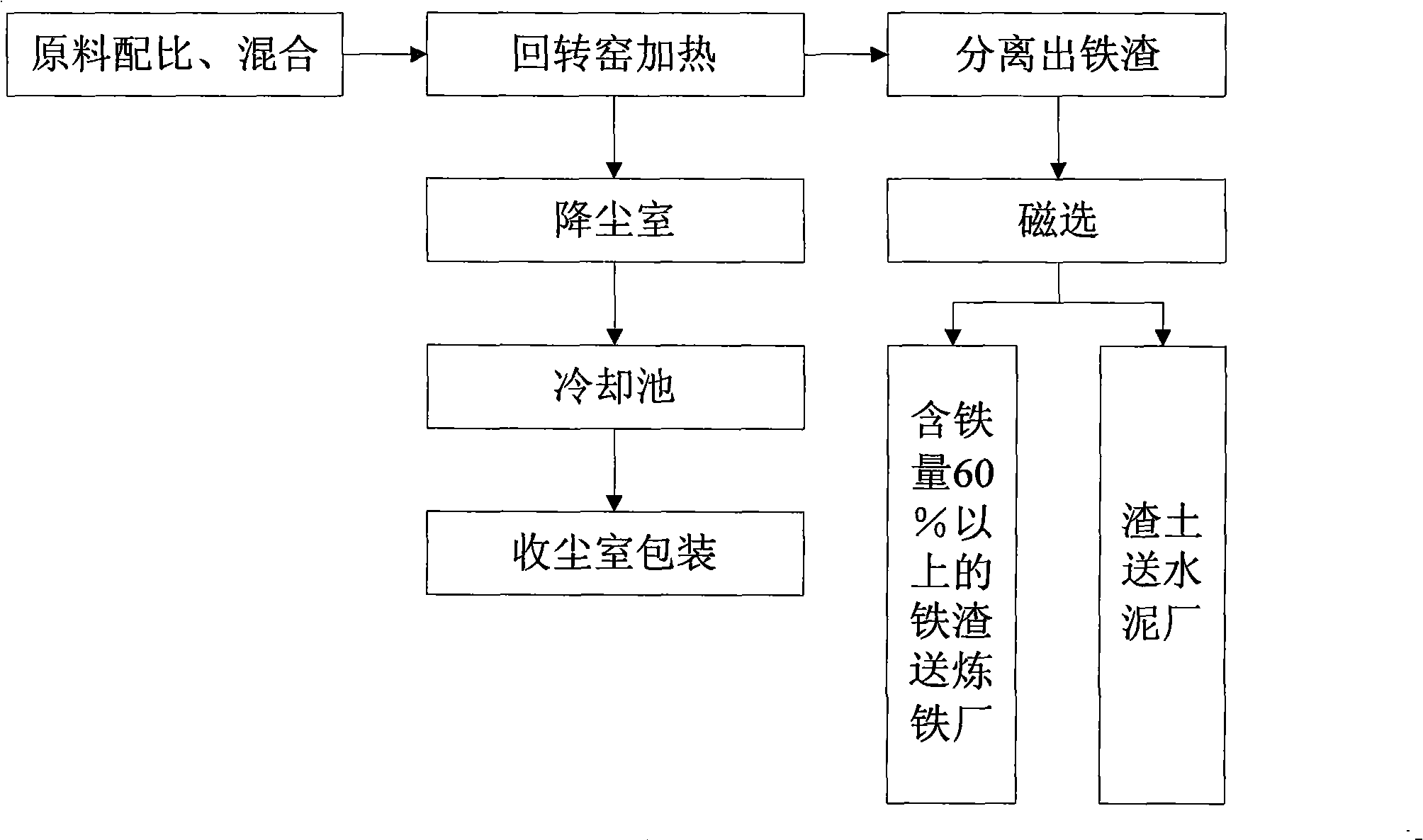

Dust-separation zinc extraction method

InactiveCN101343693ATo achieve the purpose of turning waste into treasureImprove resource utilizationSolid waste managementProcess efficiency improvementResource utilizationWaste material

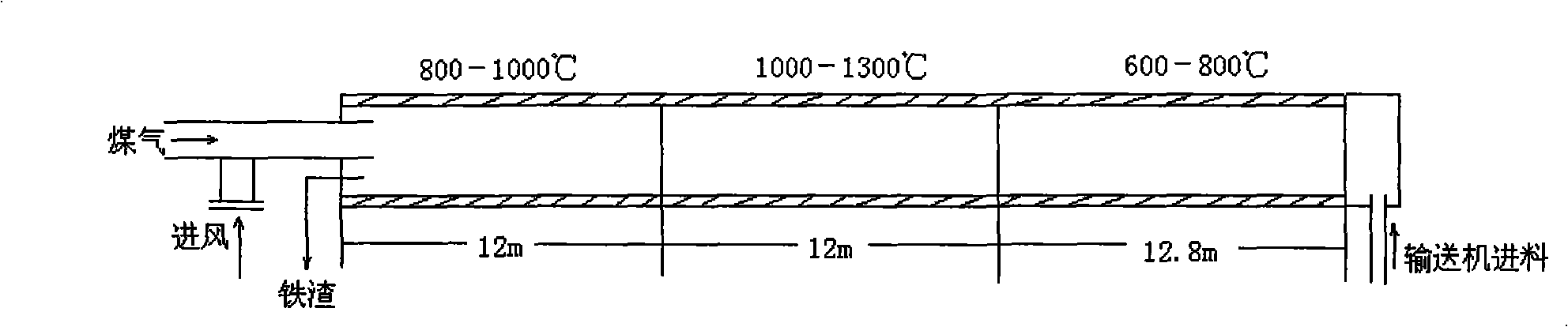

Disclosed is a dust removal and zinc extraction method. Raw materials are mixed and evenly stirred through a loader according to weight proportion, 30 percent to 40 percent of blast furnace dust removal ashes, 25 percent to 35 percent of power plant dust removal ashes, 25 percent to 35 percent of blast furnace gas slime, 5 percent to 10 percent of anthracite coal are evenly delivered to a rotary kiln to be heated for refining through a conveyor, then are delivered into a dedusting chamber to experience the atomization and separation, the raw materials are delivered into a cooling pond then and zinc oxide powder is forcedly sent into a dust collecting chamber by a suction blower, the dust is collected through a bag and is supplied to a zinc supply smeltery as the raw material. The iron residues separated in the heating and extracting process in the rotary kiln are magnetically separated through a magnet separator, the iron residues with the iron content of 60 percent are delivered to an iron smelting plant, and the residue soil is supplied to a cement plant as the raw material. The invention has the advantages that the iron residues and zinc powder are extracted and separated through adopting the processed waste material dust removal ashes in large-scale smelting enterprises, the purpose of changing wastes into valuables is realized, and the resource utilization rate is enhanced.

Owner:NANJING BANQIAO SLAG

Refining process for lepidolite in tantalum-niobium ore waste rocks

ActiveCN105251606ASolve the way outHigh Lithium Oxide ContentHigh gradient magnetic separatorsFlotationNiobiumIron removal

The invention relates to a refining process for lepidolite in tantalum-niobium ore waste rocks. A combined method with magnetic separation, high gradient magnetic separation, dense medium separation and flotation is adopted. The flotation adopts the process of rough flotation, dual fine flotations and sweeping. The process for refining the lepidolite from the granite-type tantalum-niobium ore waste rocks is provided. The tantalum-niobium ore waste rocks are crushed, screened, ground and subjected to high-frequency screening, spiral grading, permanent magnet magnetic separation for iron removal, high gradient magnetic separation, dense medium separation and flotation, so that lepidolite concentrates are obtained. By means of the method, the lepidolite concentrates are separated from the tantalum-niobium ore waste rocks. The lepidolite concentrates contain at least 4.5% of Li2O, at least 8.0% of K2O and Na2O and at most 0.10% of TiO2 and Fe2O3, the recovery rate of the lepidolite concentrates is larger than 80%, the qualities of the lepidolite concentrates meet the requirement of national standards, and the recovery rate of the lepidolite concentrates exceeds the industry level.

Owner:江西金辉再生资源股份有限公司

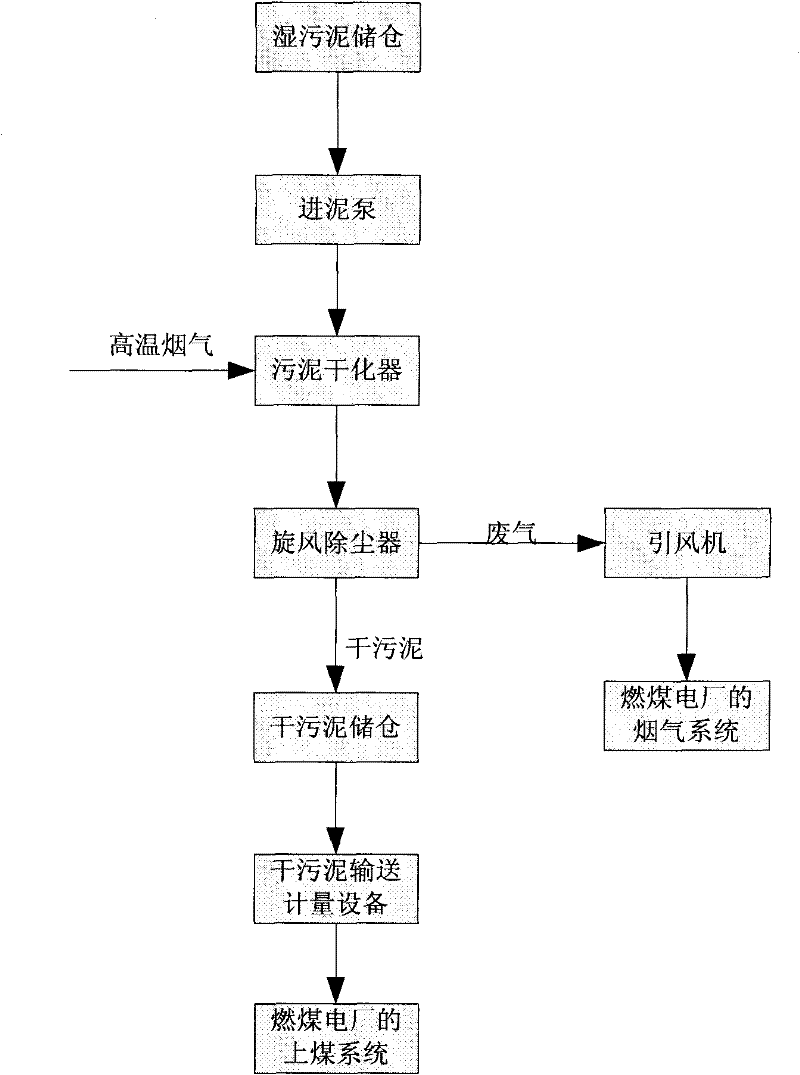

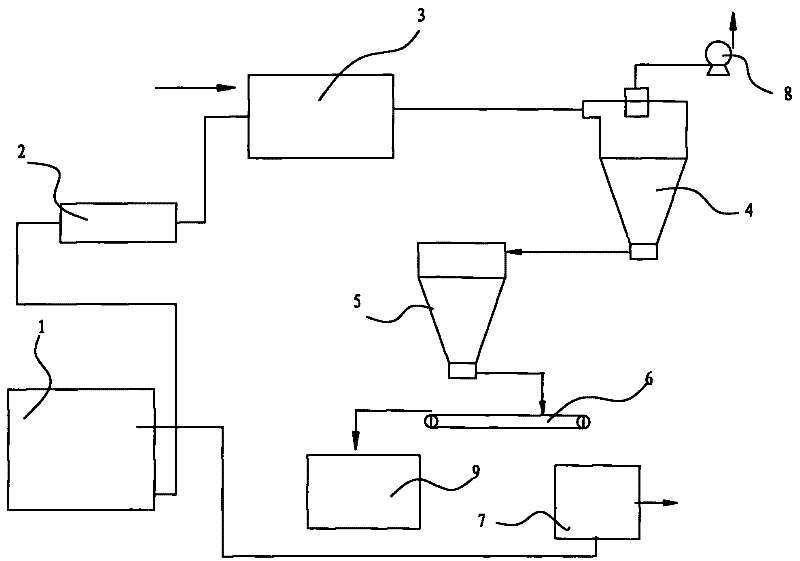

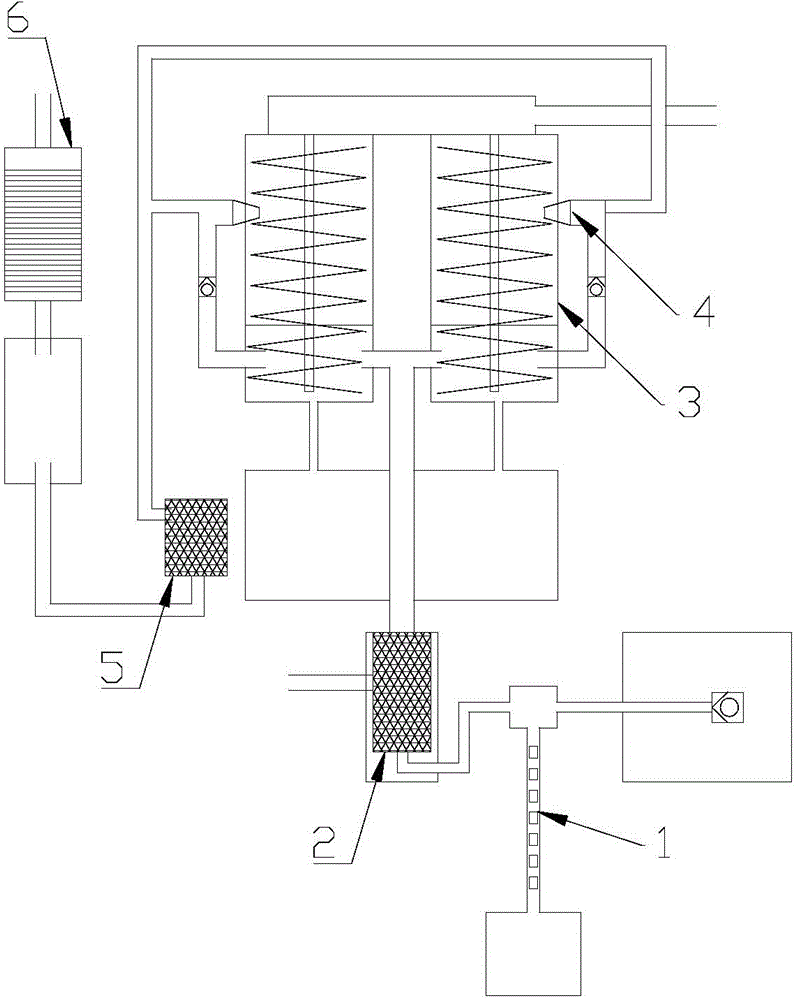

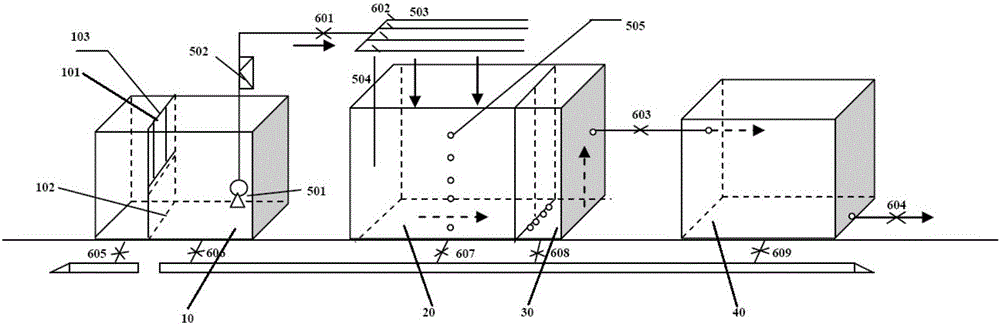

Sludge treatment and disposal system and method

ActiveCN102211845AReduce drying costsReduce environmental costsSludge treatment by de-watering/drying/thickeningIncinerator apparatusCyclonic spray scrubberDewatered sludge

The invention discloses a sludge treatment and disposal system, which is used for conveying dewatered sludge discharged by a sludge plant to a coal fired power plant to be combusted in a blended way after the dewatered sludge is dried. The sludge treatment and disposal system comprises a wet sludge storage bin, a sludge dryer, a sludge feeding pump, a cyclone dust collector, a dried sludge storage bin, dried sludge conveying equipment and a draught fan. The sludge feeding pump is respectively connected with the wet sludge storage bin and the sludge dryer. The cyclone dust collector is communicated with the sludge dryer so as to perform gas-solid separation on dried sludge and waste gas of the dryer. The dried sludge storage bin is connected with the cyclone dust collector so as to receivethe separated dried sludge. The dried sludge conveying equipment is connected with the dried sludge storage bin and used for conveying the dried sludge to a coaling system of the coal fired power plant. The draught fan is connected with a waste gas hole of the cyclone dust collector. According to the sludge treatment and disposal system disclosed by the invention, the sludge treatment and disposal cost can be effectively reduced; vast high-quality resources can be saved; and a way of using waste to treat waste is realized. The invention further discloses a sludge treatment and disposal method.

Owner:国能朗新明环保科技有限公司

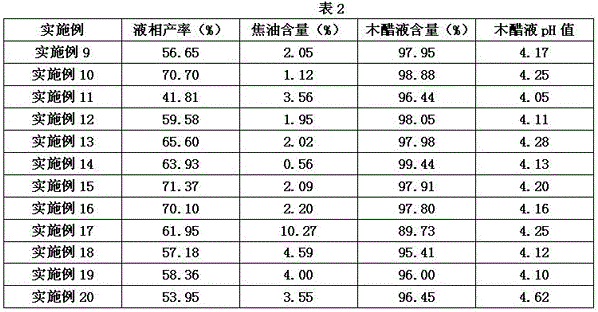

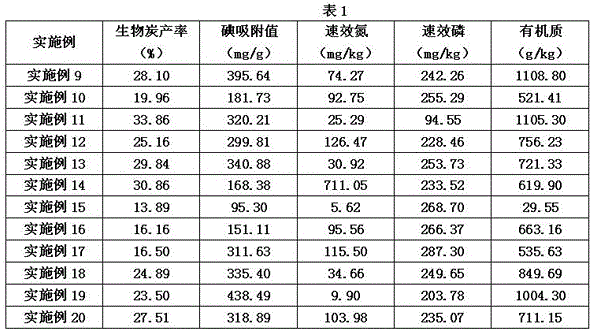

Sludge pyrolysis method adopting biomass adding

InactiveCN106433713APromote pyrolysisAchieve reductionSludge treatment by pyrolysisByproduct vaporizationMass ratioSludge

The invention relates to the technical field of sludge pyrolysis, in particular to a sludge pyrolysis method adopting biomass adding. The method comprises steps as follows: step one, firstly, biomass is crushed into powder, the biomass, sludge and a catalyst are uniformly mixed in a mass ratio being (0.25-4):1:(0.02-0.08), and a mixture is obtained; step two, the mixture is put in a reaction kettle, nitrogen is introduced to serve as protective gas, the temperature is increased to the pyrolysis temperature of 300-700 DEG C according to a certain temperature increasing procedure, and a solid-phase product, a liquid-phase product and a gas-phase product are obtained respectively. The sludge pyrolysis method adopting biomass adding not only promotes sludge pyrolysis, but also increases the product utilization value, the problem of environment pollution in the conventional sludge treatment process is solved, the reduction, stabilization, harmless and recycling targets of sludge are achieved, agricultural waste biomass is recycled, and the purpose of turning waste into wealth is achieved.

Owner:XINJIANG UNIVERSITY

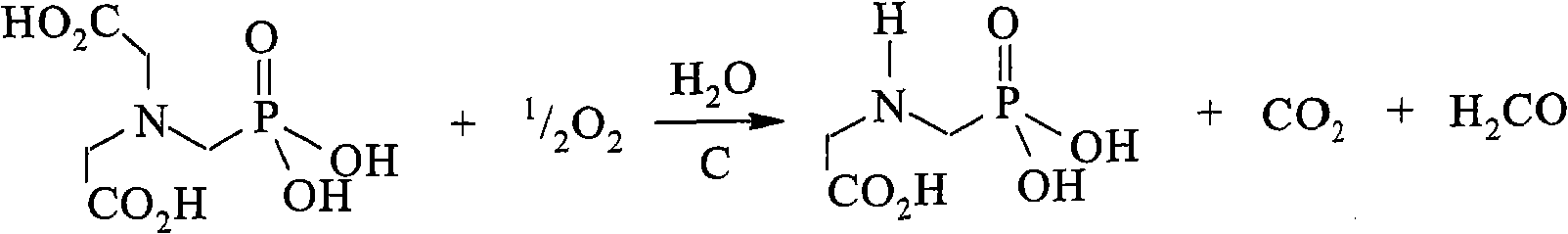

Comprehensive treatment method for glyphosate mother liquid

The invention relates to a comprehensive treatment method for mother liquid synthesized by oxidizing glyphosate by N-(Phosphonomethyl) iminodiacetic acid with an IDA (Iminodiacetic Acid) method. The mother liquid is treated by a condensed system to obtain condensed liquid and thin liquid, wherein the condensed liquid subjected to formaldehyde removal is used for preparing a gyphosate solution with high content or carrying out oxidation treatment, the treated thin liquid can be used for gyphosate production or biochemical treatment. The comprehensive treatment method not only recovers gyphosate, but also reduces the pollution to the environment.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Method for treating heavy-metal-containing wastewater by external electric field reinforced micro-electrolysis technology

InactiveCN102432087APromote migrationLower activation energyWater contaminantsWater/sewage treatmentElectrolysisEmission standard

The invention discloses a method for treating heavy-metal-containing wastewater by an external electric field reinforced micro-electrolysis technology, and belongs to the fields of water treatment technologies and recycling. In the method, the heavy-metal-containing wastewater is pretreated or not pretreated and then introduced into an external electric field reinforced micro-electrolysis reactor to be treated, a micro-electrolysis filler is filled in the reactor and is put in an external electric field with certain intensity, and micro-electrolysis reaction is promoted and reinforced through the reinforcing effect of the external electric field, so that metal ions in the wastewater are reduced into metal simple substances on the surface of the filler, and effluent can meet the requirement of the wastewater emission standard or can be directly recycled in the production process. The method has the advantages of high reaction speed, removal rate, recycling efficiency and environment compatibility and the like.

Owner:KUNMING UNIV OF SCI & TECH

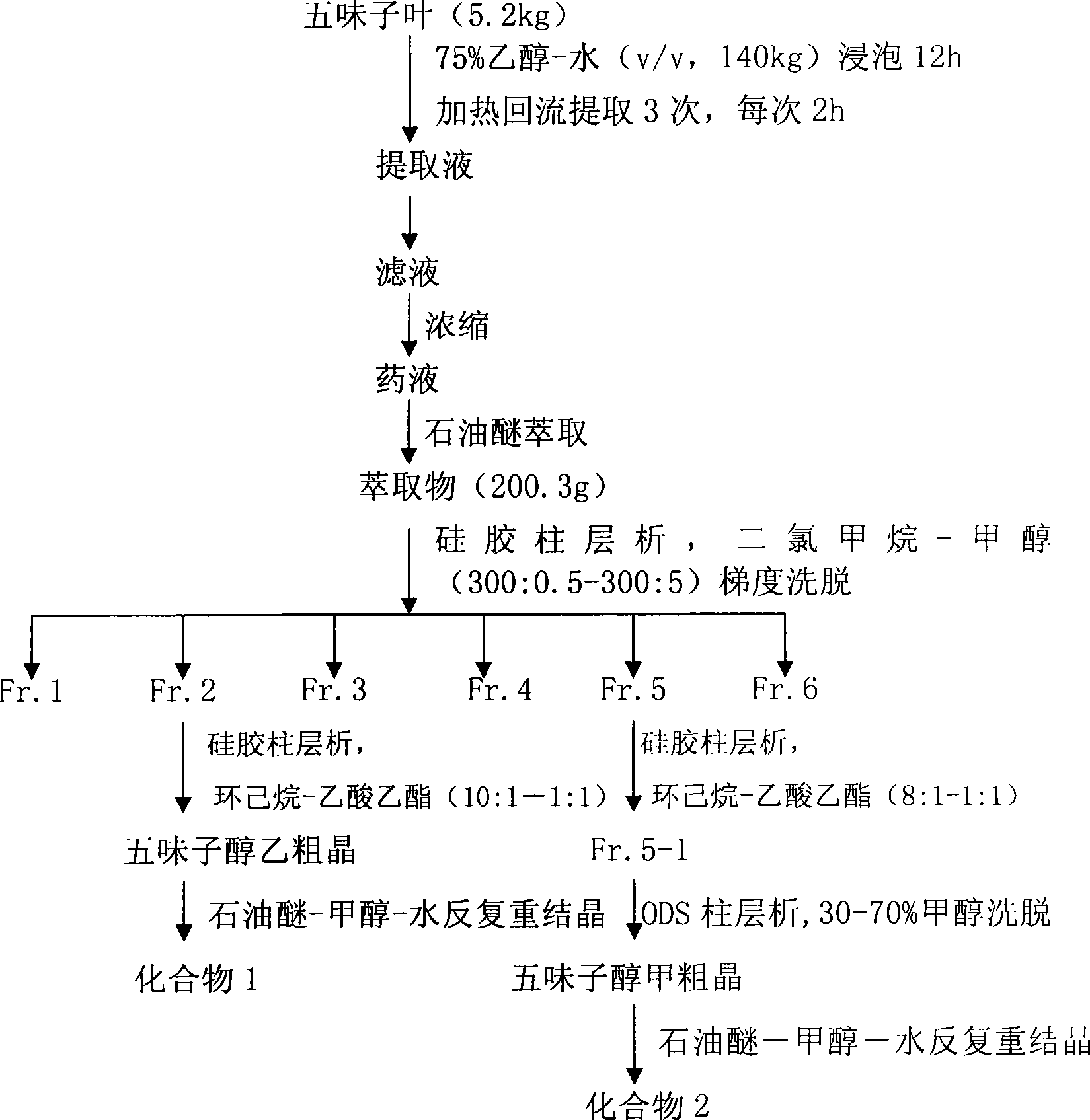

Novel technique for preparing schizandrol A and schizandrol B

ActiveCN101503341ASimple processEasy to operateNervous disorderEther separation/purificationBiotechnologyChromatographic separation

The invention belongs to the field of medical technology and discloses a new preparation technique of schizandrol B and schizandrol A in schisandra chinensis baill leaves. The technique comprises the steps: schisandra chinensis baill leaves are taken as raw material, ground and then processed by one or more technique(s) in solvent extraction method, organic solvent extraction method, resin adsorption method, normal phase column chromatography, reversed-phase column chromatography and the like, namely, the schisandra chinensis baill leaves are taken as raw material, extracting solution containing the schizandrol A and the schizandrol B is extracted by organic solvent; after extract is processed by repeated column chromatographic separation, the flowing parts containing the schizandrol A and the schizandrol B are collected, and the schizandrol A and the schizandrol B are obtained after repeated recrystallization of the condensate; the purities of the schizandrol A and the schizandrol B can be more than 98% by HPLC detection. The preparation method has simple technique, stable purity and good reproduction quality, can be used for replacing shizandra fruit to extract and prepare standard product, fully utilizes the resource of shizandra and relieve the situation that the supply of the shizandra fruit is not adequate to the demand.

Owner:SHENYANG PHARMA UNIVERSITY

PP/PET alloy material and preparation process thereof

InactiveCN101580612AImprove mechanical propertiesIncreased flexural modulusFlexural modulusNonwoven fabric

The invention belongs to the field of polymer composite materials, in particular relating to a PP / PET alloy material and preparation process thereof. The PP / PET alloy material is prepared from the following raw materials by weight percentage: 60 to 90 percent of PP / PET composite materials, 3 to 9 percent of compatibilizers, 6 to 30 percent of reinforcing agent, 0.5 to 6 percent of coupling agent, and 0 to 1 percent of antioxidant. The preparation process comprises the steps of drying, mixing, extruding, stretching and drawing and cooling and granulating. In the method, waste PP / PET composite films and / or PP / PET non-woven fabrics, serving as main raw materials, are added with a composite compatibilizer to promote the PP and PET to be compatible on the molecular level; the coupling agent and reinforcing agent can effectively improve the mechanical properties of the PP / PET composite materials; and the prepared PP / PET alloy material has a flexural modulus up to 1,900 MPa, good bending properties and high impact strength up to 120J / M, can be widely used for molding the plastic parts of electric appliances, toys and car parts; and in addition, the waste PP / PET composite films and / or PP / PET non-woven fabrics are adopted as main raw materials, so environment pollution is reduced greatly, and the purpose of changing waste into valuable is fulfilled.

Owner:DONGGUAN PUNENG PLASTIC TECH INDAL

Bacillus subtilis H8-3 and application thereof

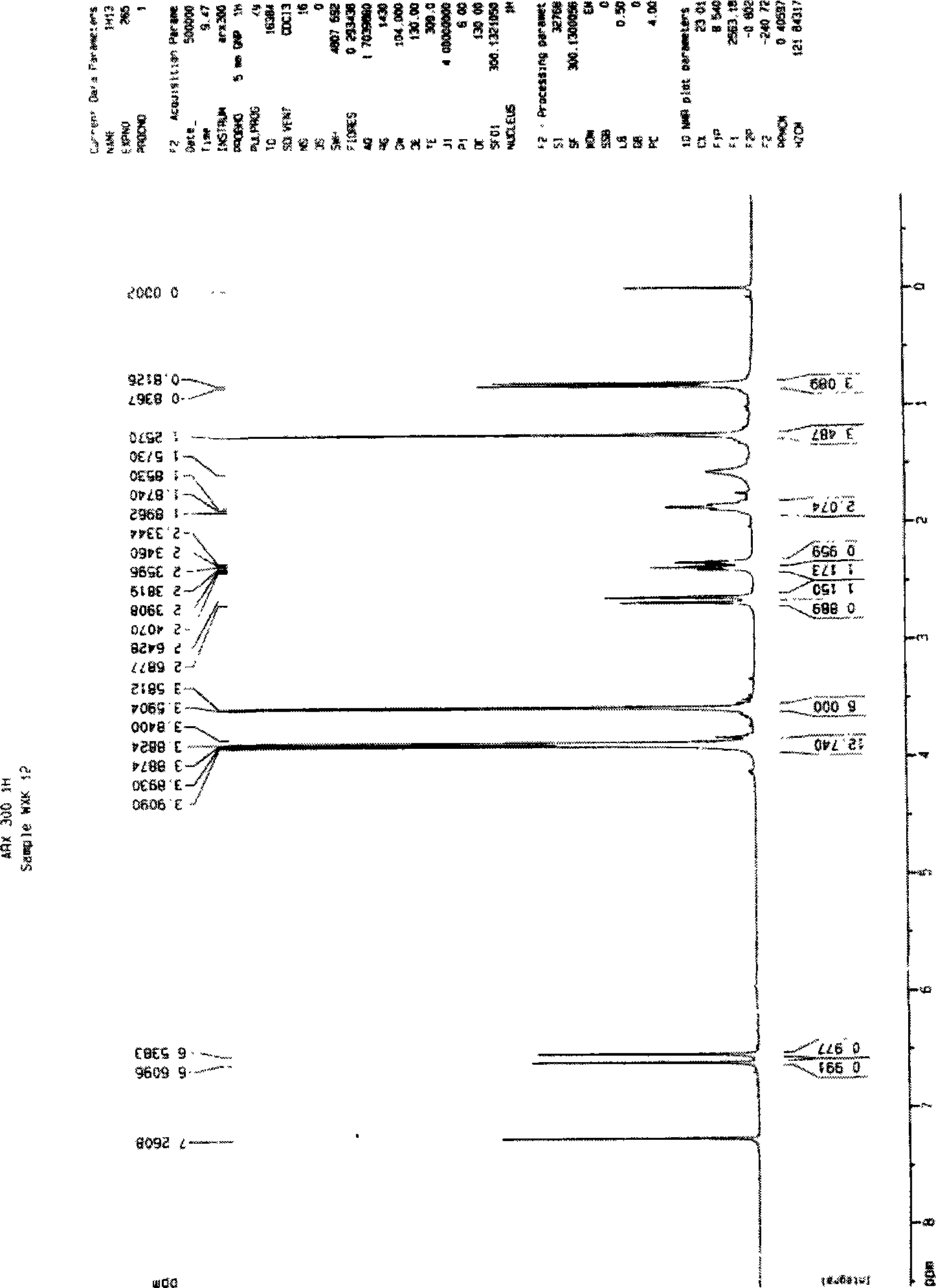

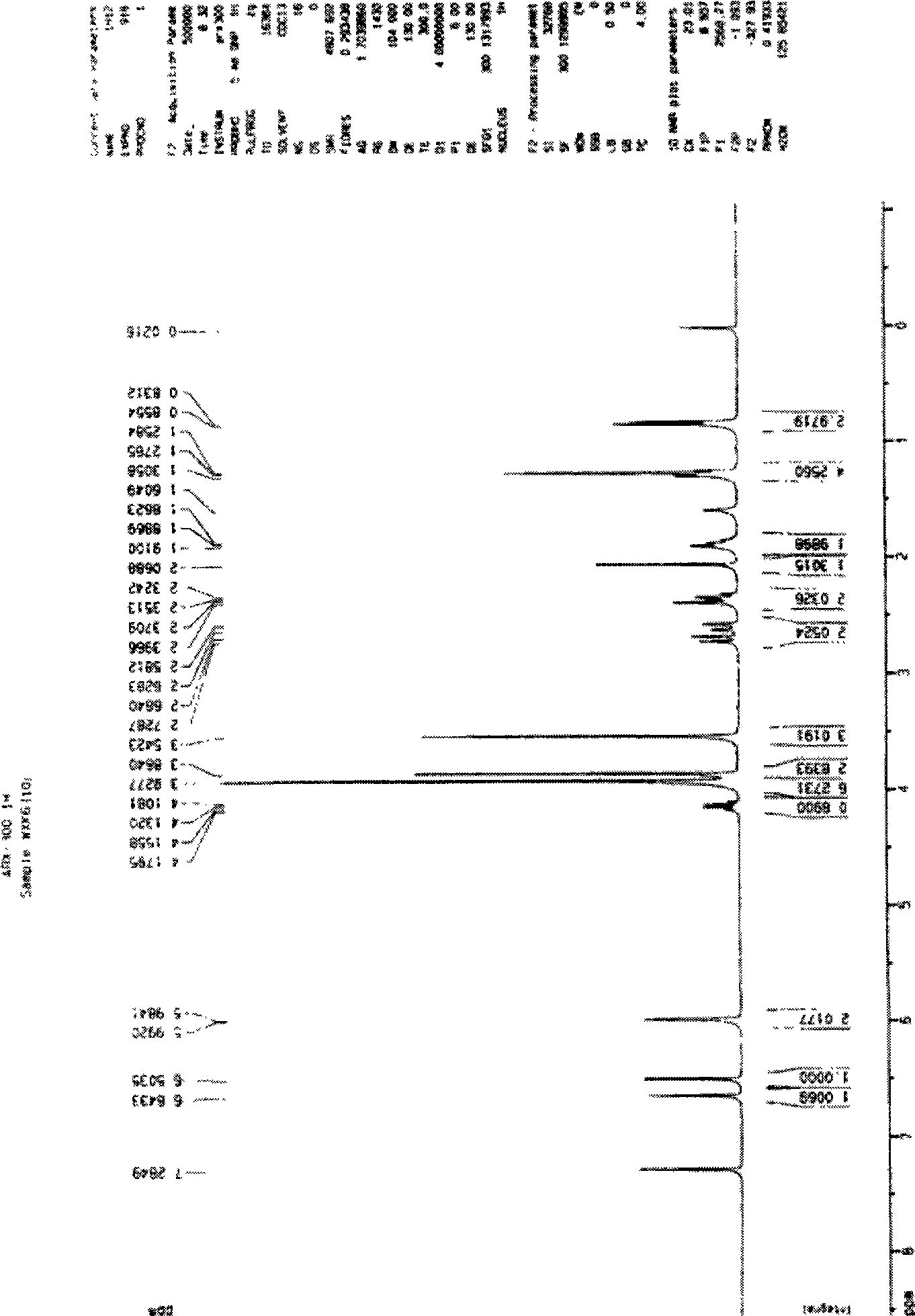

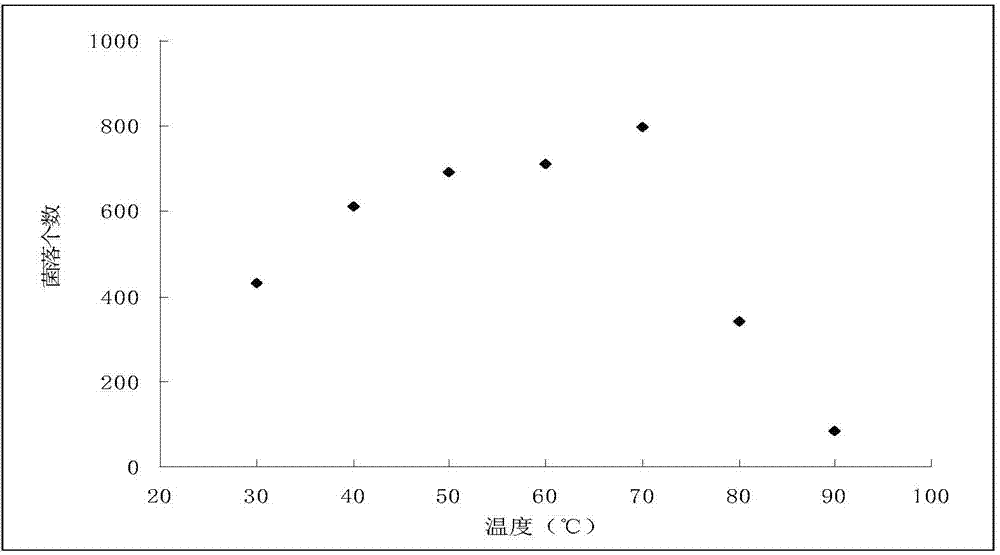

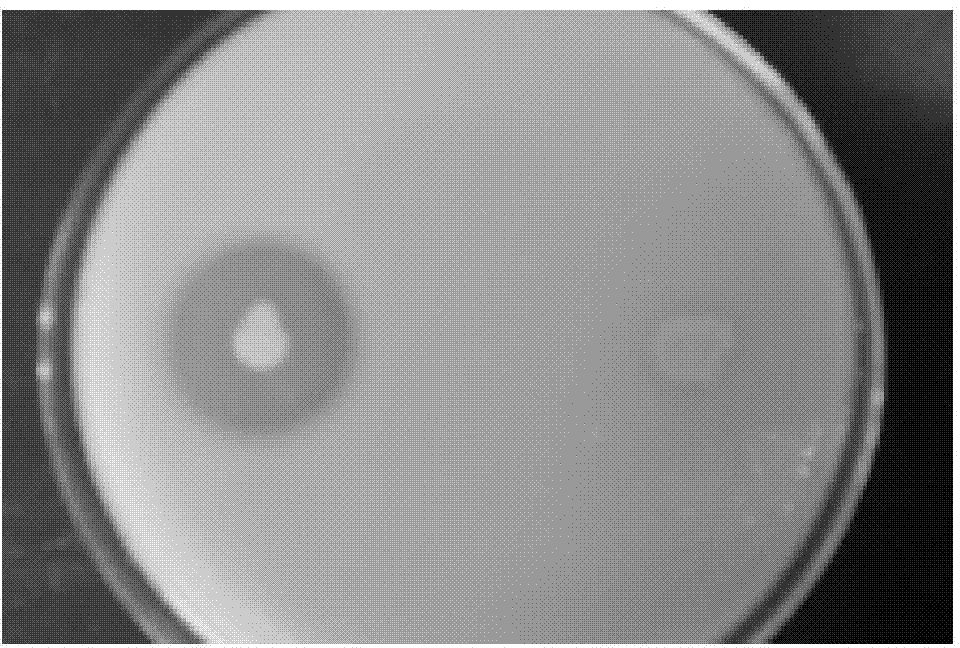

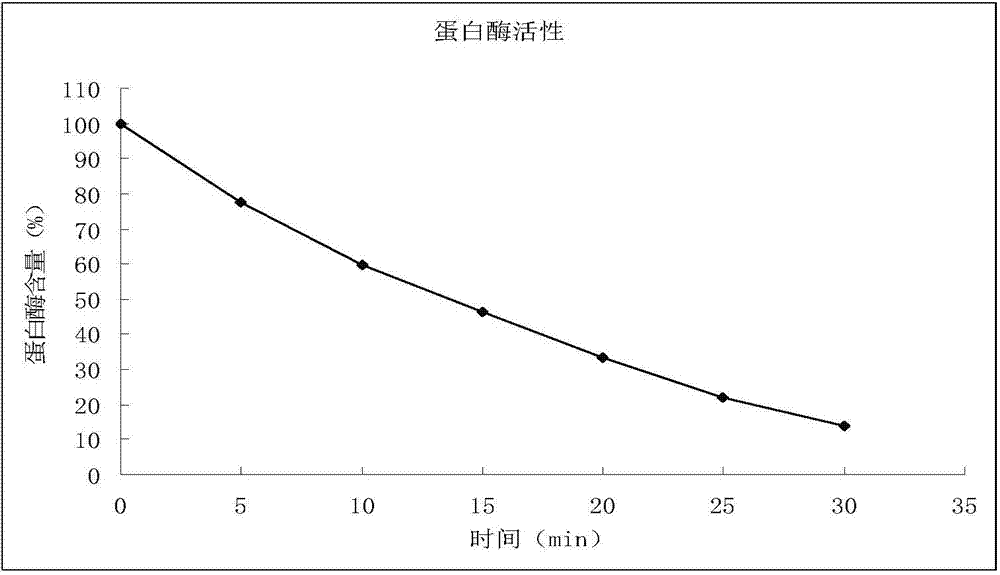

InactiveCN104328065AHigh temperature resistantIncrease protease activityBio-organic fraction processingBacteriaProteinase activityVirgibacillus species

The invention discloses a bacillus subtilis H8-3 and application thereof in preparation of a decomposed inoculant. The bacillus subtilis H8-3 is deposited with the CCTCC at Oct 21, 2013 in Hubei Wuhan university and is assigned the accession number CCTCC No:M 2013483. The bacillus subtilis H8-3 is high-temperature-resistant, can survive at 30-60 DEG C, is high in protease activity and is quick in growth. The decomposed inoculants prepared from the bacillus subtilis H8-3 is high-temperature-resistant and can secrete protease and lipase for high-efficiently fermenting animal wastes. Compost prepared through the decomposed inoculant is less in environmental pollution, is economical and is easy to use. When a product after compost treatment is subjected to subsequent treatment, the product can be employed as an organic fertilizer for achieving an object of turning waste into resources.

Owner:HANGZHOU FAMOXI BIOMEDICAL TECH

Method for preparing melamine phosphate (borate) fire retardant

InactiveCN101143876AHarm reductionAvoid corrosionGroup 3/13 element organic compoundsPhosphorus organic compoundsPhosphateMelamine phosphate

The present invention discloses a method which can prepare a phosphate (borate) melamine salt flame retardant by a dry process. According to the molar ratio of 1:2 to 4, small molecular polyol and inorganic acid containing phosphor or boron are uniformly mixed with lewis acid catalyst with one to one point five percent of the weight of the small molecular polyol, the temperature of the produced solution is raised to 100 to 150 DEG C, reaction lasts two to five hours, after melamine with the molar ratio of 1:1.5 to 2.5 of inorganic acid containing phosphor or boron is added, the produced solid is smashed into fine powder which can pass through a sieve with one hundred and twenty meshes, under a reaction temperature between 180 DEG C and 230 DEG C, reaction lasts one point five to four hours, and after the generated product is washed until the filtrate is neutral, the phosphate (borate) melamine salt flame retardant is produced by filtration, drying and smash. Because the dry process is applied, the present invention avoids the problem that the organic solvents used by the prior art harm environment and erode equipment, reduces energy consumption and production cost and avoids the problem of the hydrolysis of phosphate, which is caused by a reaction under the water phase; moreover, the present invention has the advantages of simple technique and convenient operation and is suitable for industrialized production.

Owner:应急管理部四川消防研究所

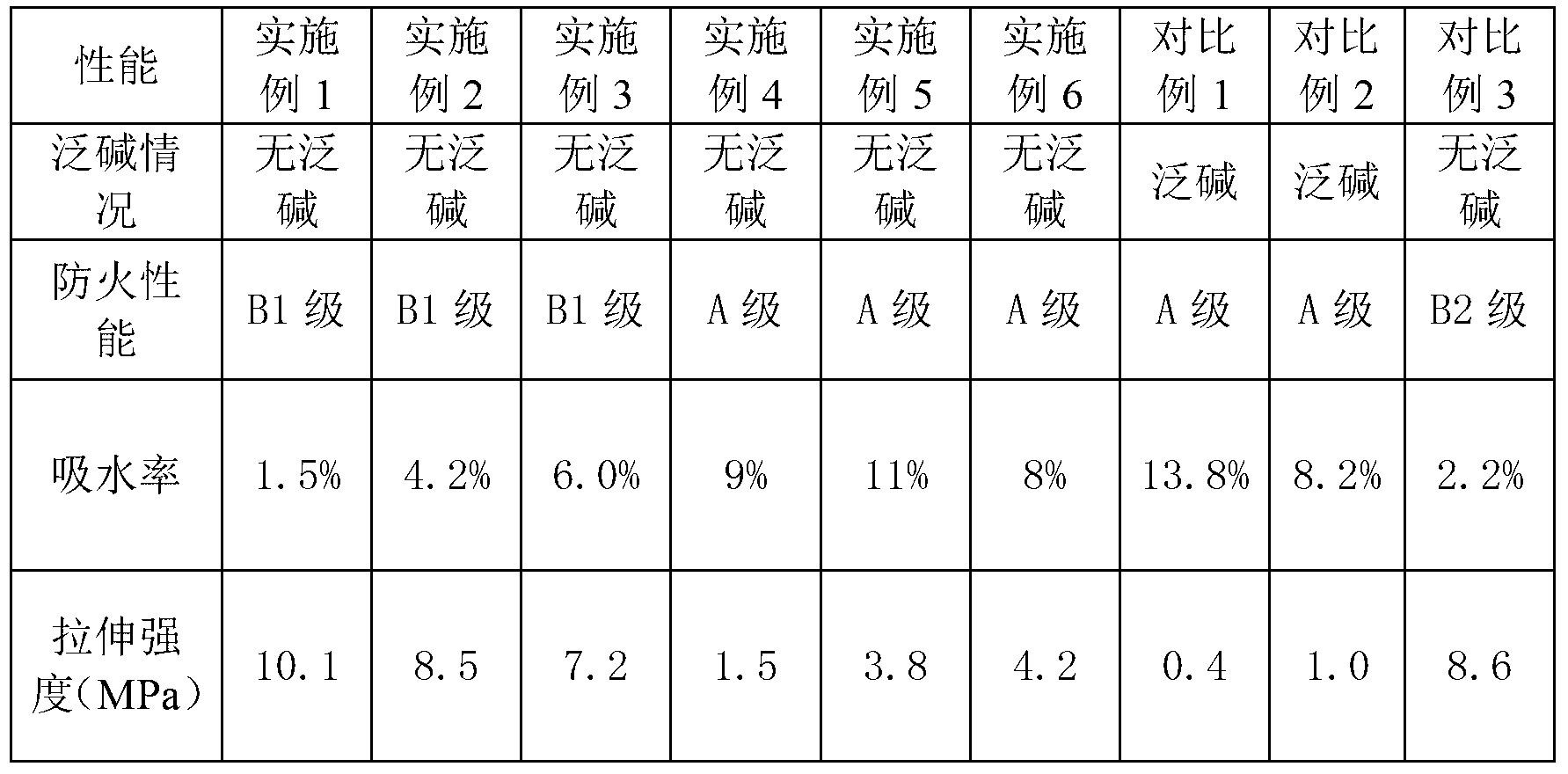

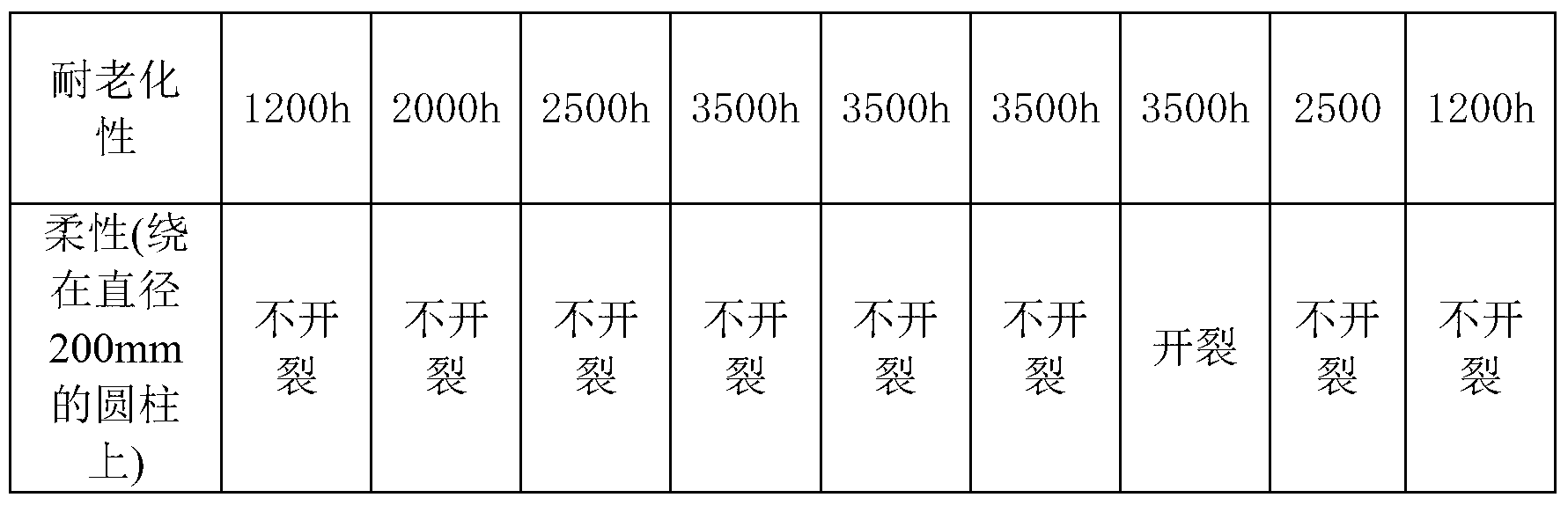

Flexible decorative sheet and manufacturing method thereof

ActiveCN103288405AHigh surface hardnessReduce the degree of polymerizationPolymer scienceAcrylic polymer

The invention discloses a flexible decorative sheet and a manufacturing method thereof. The flexible decorative sheet disclosed by the invention is composed of the following raw materials by mass percent: 30-60% of blast furnace mineral powder, 7-20% of acrylic polymer emulsion, 0.1-2% of fibre, 0.1-5% of water repellent, 0-3% of pigment, and the balance of filling material. According to the invention, the use amounts of cement and polymer emulsion are greatly reduced, so that the cost is greatly reduced; and the flexible decorative sheet disclosed by the invention has the characteristics of being excellent in ageing-resistant performance, good in fireproof performance and saltpetering-resistant.

Owner:GUANGXI PHOMI MCM CO LTD

Coal gasification slag all-component pervious concrete

InactiveCN112125589AQuick responsePromote growthSolid waste managementCement productionMining engineeringSlag

The invention discloses coal gasification slag all-component pervious concrete. Ground coal gasification slag is taken as a silicon-aluminum raw material to prepare a coal gasification slag geopolymerwith good mechanical properties as a cementing material; and screened coal gasification slag is used as aggregate to prepare the pervious concrete which have adaptive mechanical properties and waterpermeability and has good wear resistance and water purification performance. The aggregate and the silicon-aluminum raw material used in the invention are both the coal gasification slag, so that theindustrial solid waste coal gasification slag is fully utilized, and the purpose of resource utilization is achieved. Meanwhile, the coal gasification slag contains a certain amount of activated carbon, so that the adsorption performance of the pervious concrete can be improved, and the pervious concrete which has adaptive mechanical properties and water permeability and has good wear resistanceand water purification performance is obtained.

Owner:WUHAN UNIV OF TECH

Active sludge carbon and its making method and use

InactiveCN1493535AQuality is not affectedLow costSludge treatment by thermal conditioningSolid waste disposalIndustrial effluentSludge

An active sludge carbon is prepared from the active sludge obtained by treating sewage through treating it at 200-700 deg.C. It has high properties of the active carbon, so it can be used as filler of plastic products.

Owner:王炳坤

Method for producing sweet potato juice fermented beverage

The invention discloses a method for producing a sweet potato juice fermented beverage, comprising the following steps of: taking a fresh sweet potato juice generated in the process of producing sweet potato starch or vermicelli, and heating at a temperature of 100 DEG C for 5-10 min; after cooling to below 40 DEG C, mixing a bacteria solution after adding bread yeast and lactobacillus planetarium on a proportion of 2-20%; fermenting at the temperature of 25-35 DEG C for 18-48 hours; filtering, adding white sugar in a filter liquor and mixing uniformly; homogenizing through a high homogenizer; and sterilizing at the temperature of 85 DEG C for 30 min, thereby obtaining the sweet potato juice fermented beverage. The production method provided by the invention has the advantages of simple technology, high utilization rate of sweet potatoes, excellent market prospect and capabilities of achieving the purpose of turning waste into wealth and improving high added value and high benefit of the sweet potatoes.

Owner:广西宾阳县雄源食品厂 +1

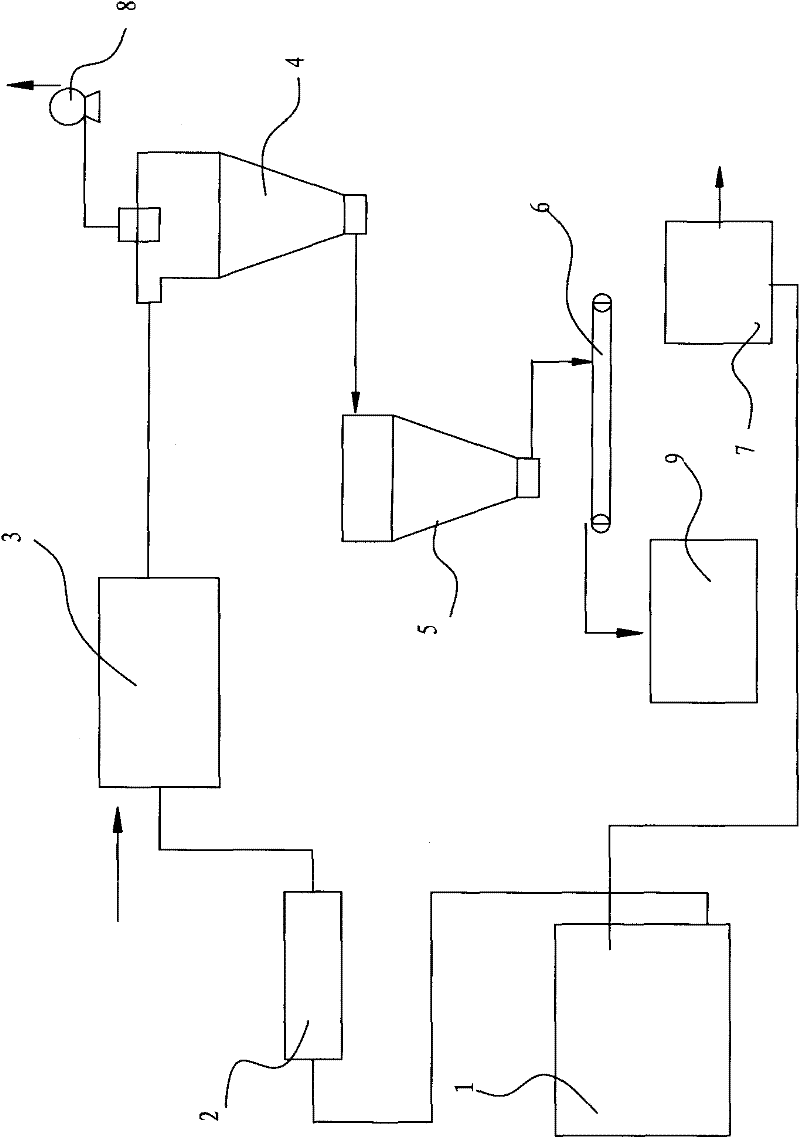

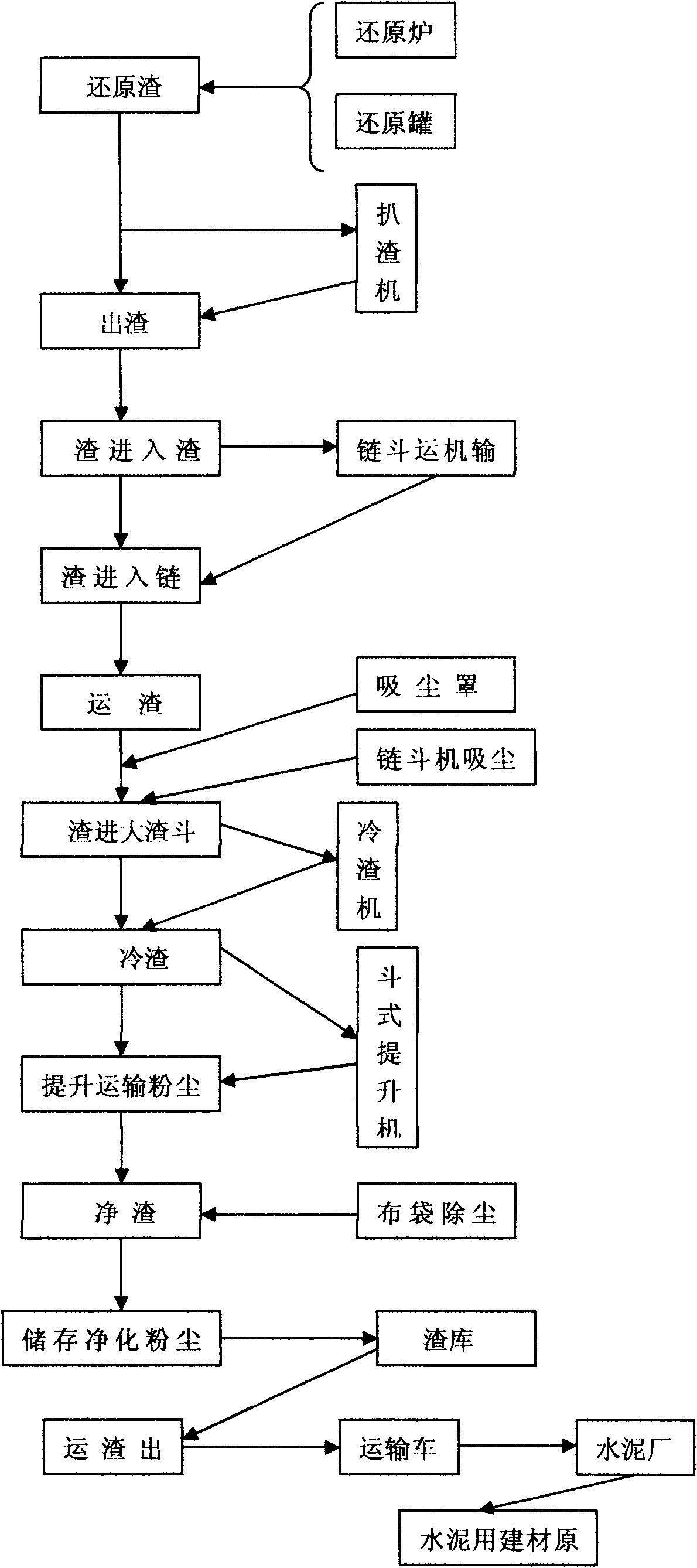

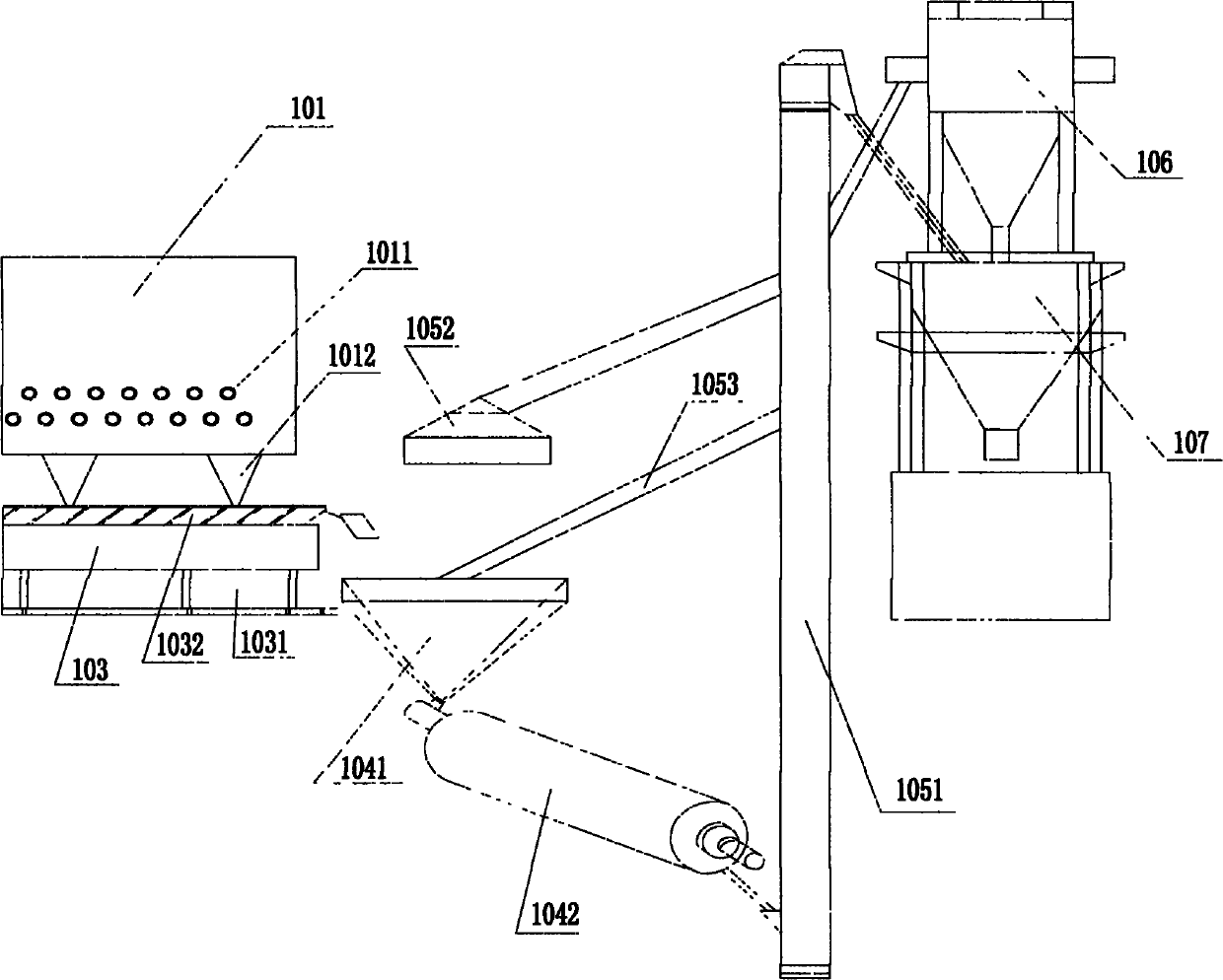

Magnesium smelting reduction deslagging and residual heat recycling device and process

InactiveCN102168186ANo pollution in the processRealize mechanical automationProcess efficiency improvementSlagBaghouse

The invention relates to a magnesium smelting reduction deslagging and residual heat recycling device and process, belonging to the field of metal magnesium smelting, in particular to a magnesium smelting reduction automatic deslagging and residual heat recycling device and technology. The device comprises a reducing furnace, a deslagging machine, a chain bucket conveyor, a slag cooling machine, a bucket elevator, a bag-type dust collector and a slag storeroom; mechanical automation is realized in whole deslagging, transportation, cooling, conveying and storage processes; the waste slag temperature is reduced from 1,000 DEG C or so to below 100 DEG C by the slag cooling machine; the residual heat of the waste slag is effectively recycled, and energy saving and emission reduction are realized; the waste slag does not fall on the ground in the deslagging process and is dry powdery slag after cooled and can be used as a building cement raw material, and the aim of changing waste materialinto things of value is achieved; and operation and storage are basically sealed in the whole process without environmental pollution.

Owner:宁夏惠冶镁业集团有限公司

Silicon micropowder reinforced polyethylene material and preparation method thereof

InactiveCN103642113ASolve poor tensile strength and impact resistanceSimple production methodSurface modificationContinuous production

The invention discloses a silicon micropowder reinforced polyethylene material and a preparation method thereof. The silicon micropowder reinforced polyethylene material contains the following ingredients in parts by weight: 40-98 parts of polyethylene, 1-50 parts of silicon micropowder, 0.1-5 parts of surface modifier and 0.1-5 parts of dispersant. According to the method, the silicon micropowder is mixed with polyethylene after the silicon micropowder is subjected to surface modification, the dispersant is added during mixing, and melt-extrusion granulation is carried out under the condition that the screw revolution rate and extrusion temperature of an extruder are set, so that a silicon micropowder modified polyethylene master batch with excellent performance is obtained. According to the silicon micropowder reinforced polyethylene material and the preparation method thereof, the disadvantages that the tensile strength and impact resistance of polyethylene are poor and the like can be effectively solved, the creep resistance and heat resistance of a polyethylene material are improved, and the comprehensive performance of a silicon micropowder modified polyethylene composite material is excellent, so that continuous production can be carried out.

Owner:GUIZHOU LANTU NEW MATERIALS

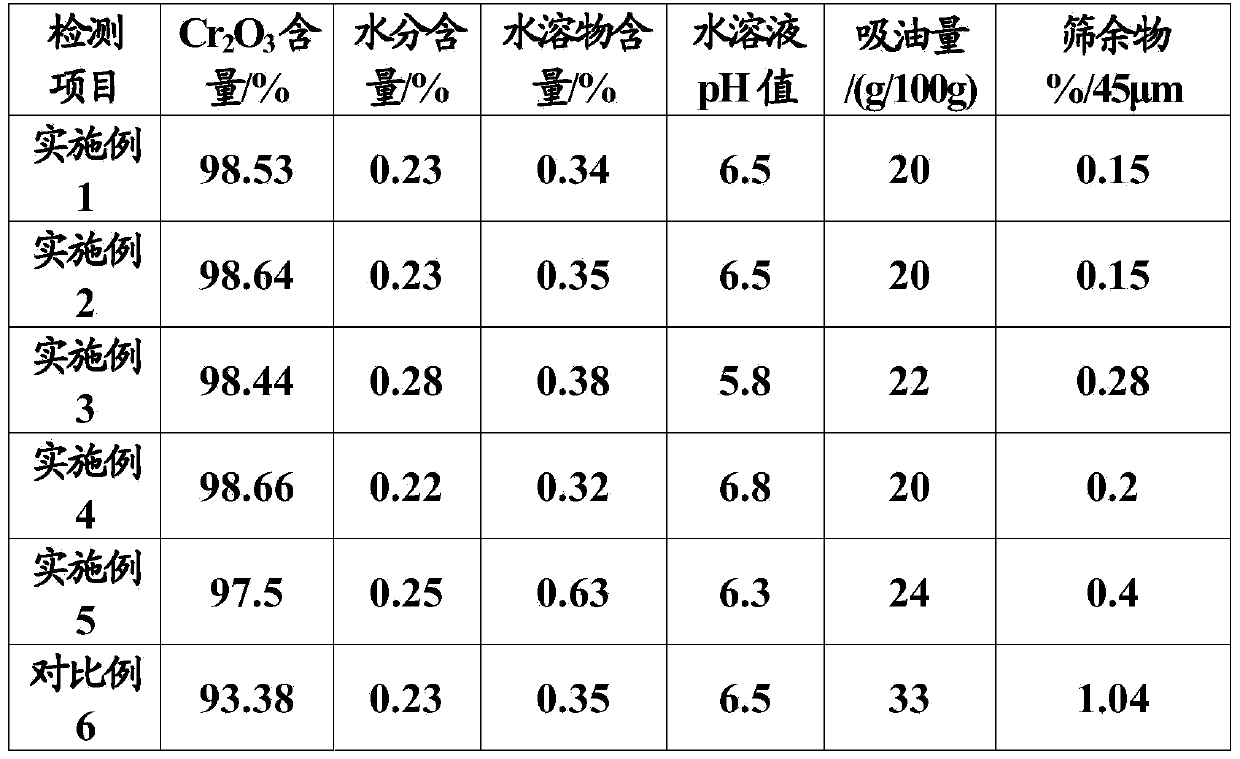

Method for treating naphthoquinone production liquid waste containing hexavalent chromium and vitamin K3 production wastewater and co-producing chromium oxide green

ActiveCN103613133AReduce COD valueEfficient disposalMultistage water/sewage treatmentChromium oxides/hydratesLiquid wasteNaphthoquinone

The invention relates to a method for treating naphthoquinone production liquid waste containing hexavalent chromium and vitamin K3 production wastewater and co-producing chromium oxide green. The method comprises the following steps: a) carrying out liquid phase reaction between the naphthoquinone production liquid waste and the vitamin K3 production wastewater at 80-260 DEG C, wherein the naphthoquinone production liquid waste is excessively used relative to a necessary dosage of complete reduction; b) adding a reducing agent into the obtained reaction mixture to reduce the residual hexavalent chromium; c) regulating the pH of the obtained reaction mixture to 5.5-8.5 to separate out chromium hydroxide, and separating to obtain the chromium hydroxide and filtrate; and d) transforming the chromium hydroxide obtained in the step c) into chromium oxide green. The method can be used for effectively treating the naphthoquinone production liquid waste and the vitamin K3 production wastewater generated in a vitamin K3 production chain and recycling effective components in the liquid waste to turn waste into wealth and improve the economic and environmental protection benefits at the same time.

Owner:绵阳市安剑皮革化工有限公司

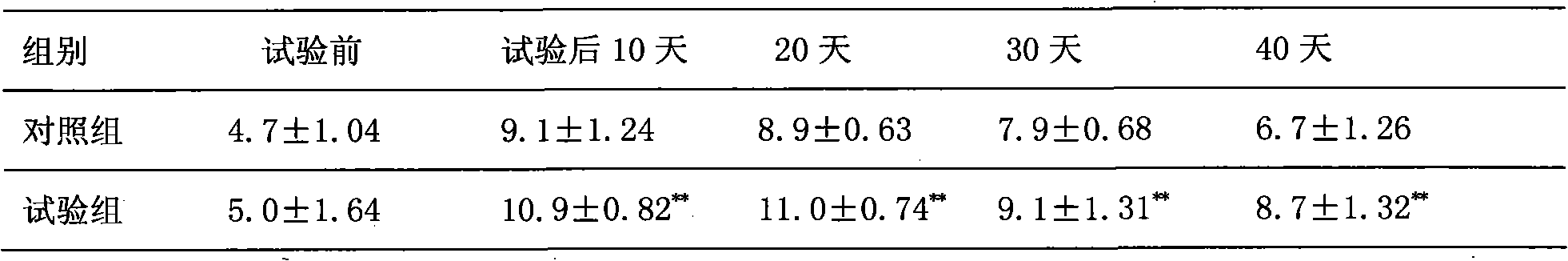

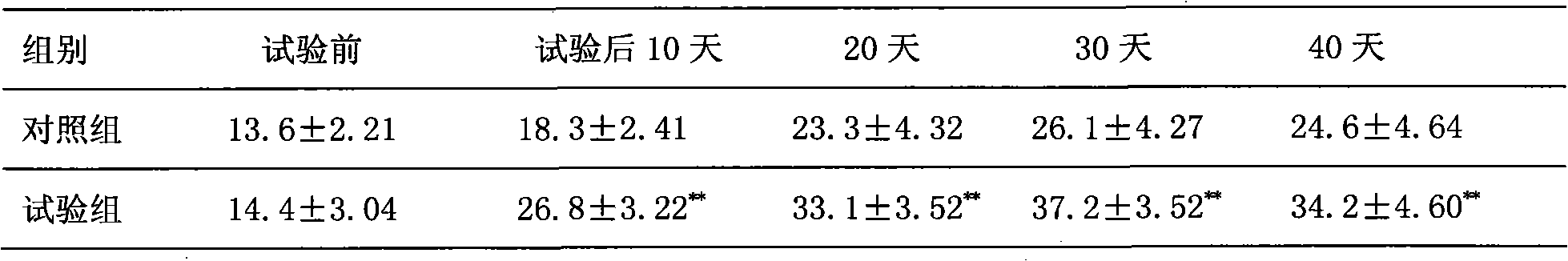

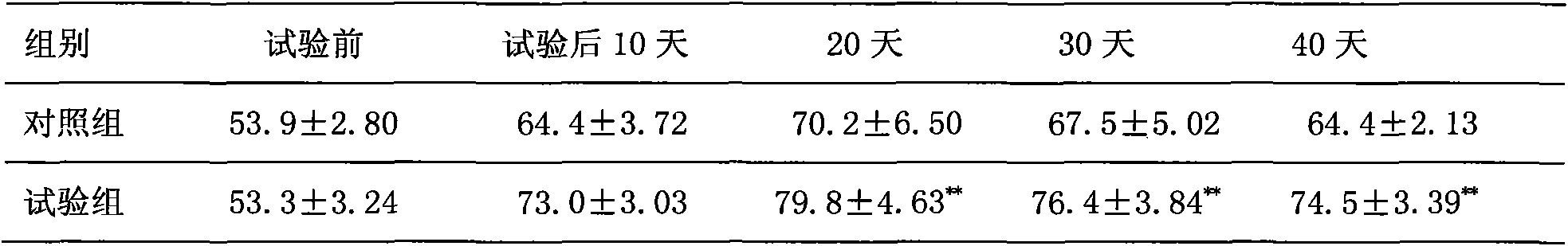

Plant source animal use immunopotentiator developed by cordyceps militaris fermented traditional Chinese medicine astragalus

InactiveCN101940611AImprove immune functionThe immune enhancement effect is obviousImmunological disordersPlant ingredientsBiotechnologyAnimal use

The invention provides a plant source animal use immunopotentiator developed by taking cordyceps militaris fungus as a fermentation fungus for fermenting traditional Chinese medicine astragalus. The immunopotentiator belongs to the field of animal health product. The traditional Chinese medicine astragalus and decoction dreg thereof are taken as raw materials where cordyceps militaris is inoculated. The content of cordyceps militaris is more than or equal to 15.7*106pcs / gram. The temperature in the fermentation process is maintained at 25 to 30 DEG C, and the fermentation time is 264 hours. After sterilization, the fermentation product is directly used to feed poultry or pigs and serves as an animal immunopotentiator. The plant source animal use immunopotentiator, which is a pollution-free plant source animal use immunopotentiator, has the advantages of wide raw material source range, low production cost, good immunoenhancement effect, no environmental pollution during production, fermentation product safe for human beings and livestock, and remarkable effect.

Owner:南京金优生物科技有限公司 +2

Solanaceous vegetable culture medium and preparation method thereof

InactiveCN103918531AFull of nutritionImprove the breeding effectCultivating equipmentsSoilless cultivationPeatMicrobiology

The invention belongs to the field of agriculture, and particularly relates to the field of plant cultivation, in particular to a solanaceous vegetable culture medium and a preparation method of the solanaceous vegetable culture medium. The preparation method for using fermentation bed waste packing for making the solanaceous vegetable culture medium and the obtained culture medium can fill in the blank in application of the fermentation bed waste packing to the solanaceous vegetable culture medium in the prior art. The culture medium comprises the fermentation bed waste packing, vermiculite, perlite and peat. Accordingly, the fermentation bed waste packing is recycled, and waste is turned into wealth.

Owner:启亚人工智能科技研究院(南京)有限公司

Special environmental-friendly anti-blocking agent for producing urea-based compound fertilizer by high-tower granulation and preparation method thereof

ActiveCN101985411ATo achieve the purpose of turning waste into treasureRaw materials are easy to getFertilizer mixturesVegetable oilAlcohol

The invention relates to a special environmental-friendly anti-blocking agent for producing urea-based compound fertilizer by high-tower granulation and a preparation method thereof. The special environmental-friendly anti-blocking agent comprises the following components in percentage by weight: 90% of acidification oil for vegetable oil and 10% of low-carbon alcohol. The preparation method comprises the following steps: adding 90% of the acidification oil for vegetable oil to a vacuum drying pot for vacuum drying by heating until water content is less than 0.5%; adding the dried acidification oil for vegetable oil to a decoloring pot, adding active carbon which accounts for 0.5%-1% of the weight of the acidification oil for vegetable oil while stirring, and reacting at the temperature of 800-900 DEG C for 2-3 hours; and adding the decolored acidification oil for vegetable oil to a blending tank, adding 10% of C6-C10 low-carbon alcohol while stirring evenly to finally obtain the anti-blocking agent. The anti-blocking agent in the invention has the advantages of excellent anti-blocking effect and less resource consumption, is pure natural, renewable and environmental friendly, and is capable of reducing agricultural production cost and increasing income of farmers.

Owner:HUBEI FORBON TECH

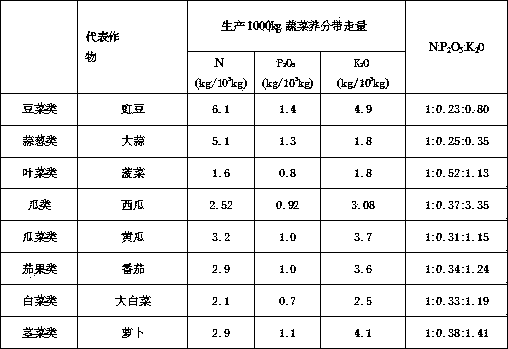

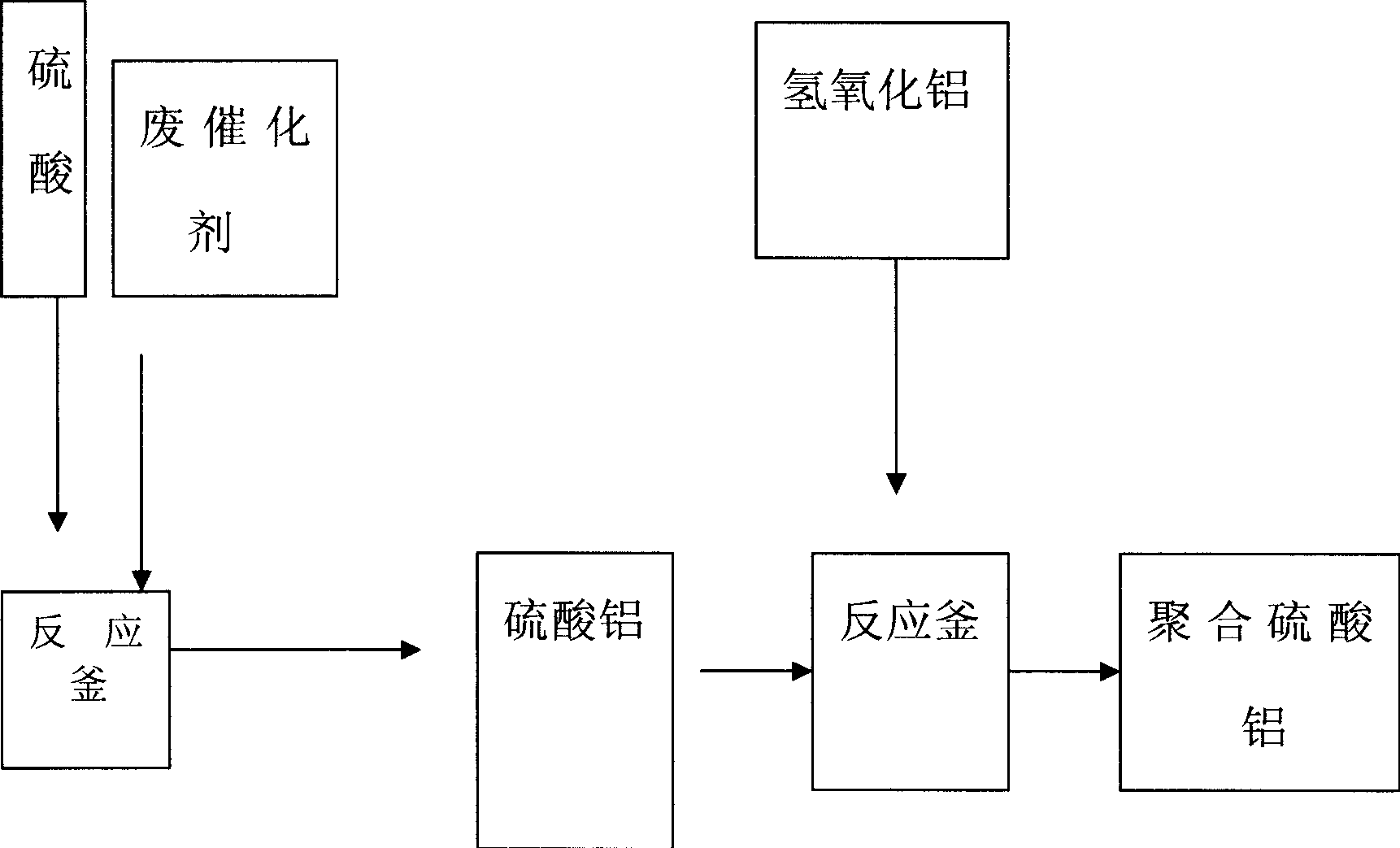

Method for preparing synthesized polymer aluminum sulphate through spent catalyst

ActiveCN1727282APollution controlOvercoming the lack of pollutionAluminium sulfatesAluminium sulfateAluminium hydroxide

A process for preparing the polymerized aluminium sulfate by used of the used catalyst includes such steps as dissolving the used industrial catalyst in sulfuric acid to prepare aluminium sulfate, and polymerizing aluminium hydroxide with aluminium sulfate to obtain the polymerized aluminium sulfate used as flocculant.

Owner:PETROCHINA CO LTD

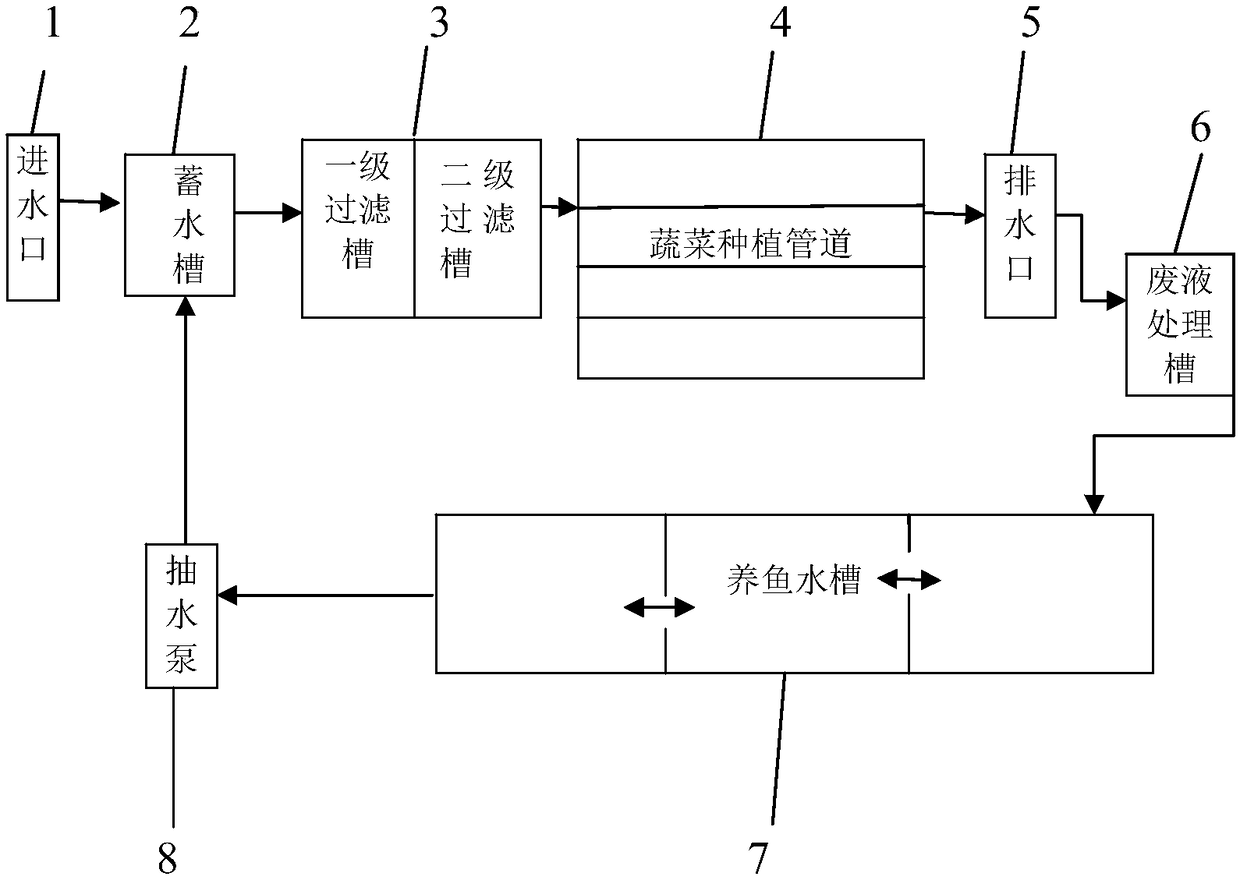

Fish and vegetable symbiotic system and application thereof

InactiveCN108812496ANot demandingReduce wasteWater/sewage treatment by irradiationWater contaminantsWater storage tankWater resources

The invention discloses a fish and vegetable symbiotic system and application thereof. The fish and vegetable symbiotic system includes a water inlet, a water storage tank, at least one filter tank, avegetable planting pipeline, a drainage port, a waste liquid treating tank and a fish framing water tank which are all connected in sequence; the fish framing water tank is lower than the position ofthe waste liquid treating tank. By adopting the fish and vegetable symbiotic system, firstly, vegetables are planted in the vegetable planting pipeline, and fish are farmed in the fish framing watertank; then, water in the fish framing water tank is transported into the water storage tank, and after being filtered by the filter tanks, the water is transported to the vegetable planting pipeline;finally, the water is transported to the waste liquid treating tank, and after being treated, the water is transported back to the fish framing water tank. In this way, water current circulation is formed, the eutrophic water can be converted into water suitable for survival of aquatic organisms, meanwhile, nutrient substances in the eutrophic water are used as plant fertilizer, therefore, waste of water resources is reduced, and the cost can be reduced.

Owner:SOUTH CHINA AGRI UNIV

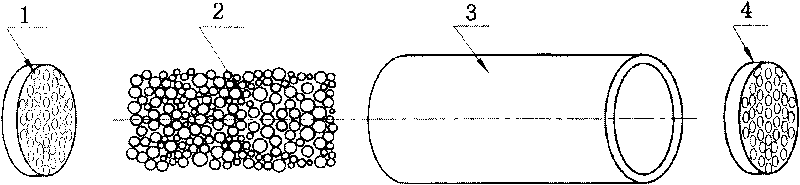

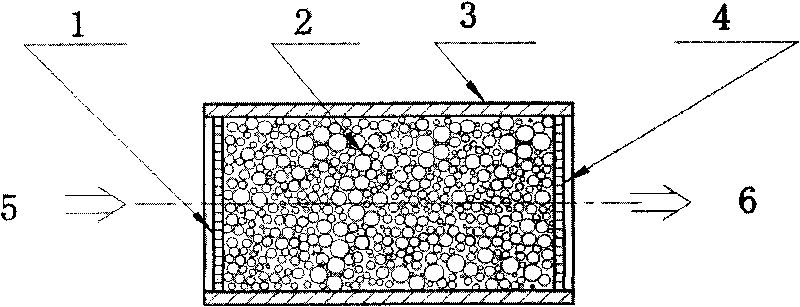

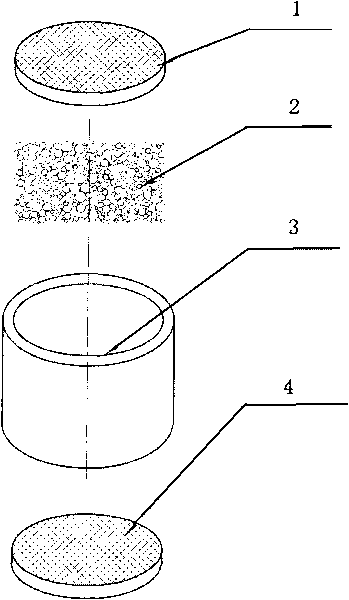

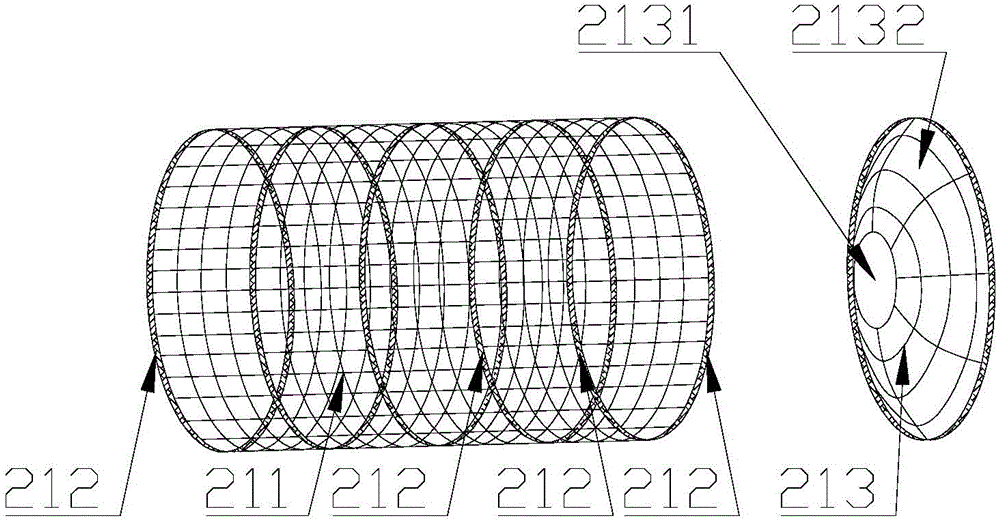

Molten metal magnesium solution or molten magnesium alloy solution filtering material and filter

InactiveCN101745269ALow costTo achieve the purpose of turning waste into treasureFoundry mouldsFoundry coresSolventFilter material

The invention provides a molten metal magnesium solution or molten magnesium alloy solution filtering material and a filter. The filtering material is composed of magnesia ceramic particles and / or calcium oxide ceramic particles, and the diameter of the particles is within 1 to 50mm. The filter is as follows: the magnesia ceramic particles and / or the calcium oxide ceramic particles are uniformly filled in a container made of high-chrome steel or low-carbon steel, the diameter of the particles is within 1 to 50mm, the container is respectively provided with an inlet and an outlet, and baffles used for covering the inlet and the outlet are respectively arranged at the positions of the inlet and the outlet. The filter is arranged on a conveying pipeline in equipment for preparing metal magnesium or magnesium alloy, or is arranged on a delivery pump inlet or a pouring outlet in smelting equipment for preparing metal magnesium or magnesium alloy. The filter can exert the functions of absorbing and blocking on impurities such as magnesia, solvent and the like in molten metal magnesium solution or molten magnesium alloy solution, so as to purify the molten metal magnesium solution or the molten magnesium alloy solution.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

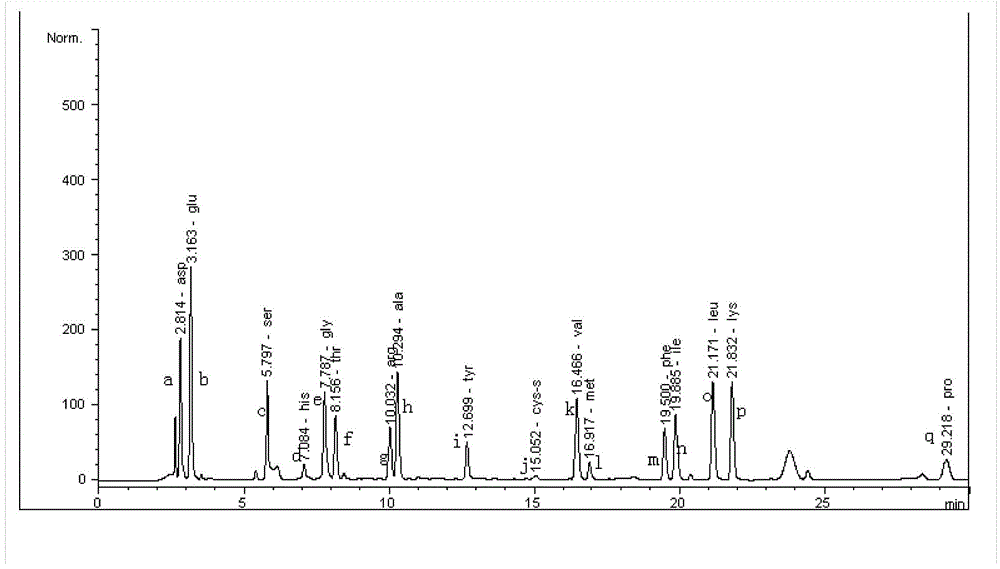

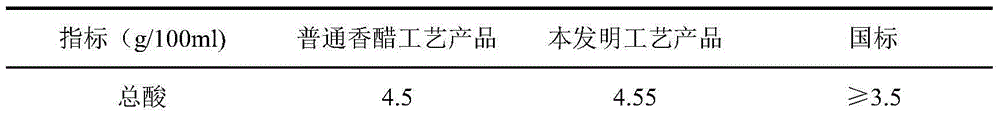

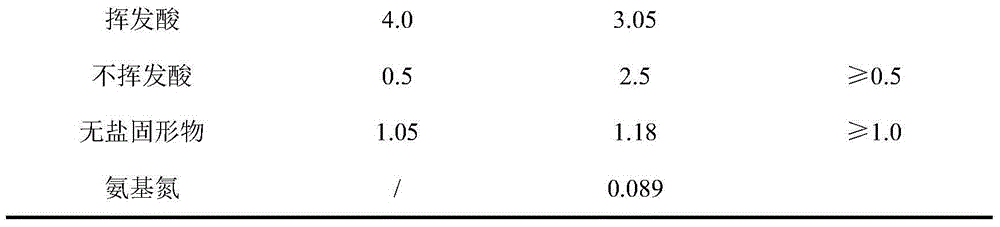

Production method of yellow water vinegar beverage

ActiveCN104357305AFully tap the potential valueReduce manufacturing costMicroorganism based processesVinegar preparationYeastSocial benefits

The invention discloses a production method of a yellow water vinegar beverage and belongs to the technical field of brewing. The production method comprises the following steps: carrying out biotransformation on yellow water by using lactic acid bacteria liquid to produce biotransformation liquid with a fragrant component of a vinegar beverage precursor; then, producing yellow water vinegar beverage-assistant rice wine by adopting special distiller's yeast; then mixing the yellow water biotransformation liquid with the assistant rice wine in a proportion of (7: 3); inoculating yeast; and controlling fermentation conditions to obtain the yellow water vinegar beverage. According to the production method disclosed by the invention, the brewing byproduct yellow water is thoroughly converted and utilized by combining microbiology, a brewing technique and a modern vinegar making technique, so that a novel beverage product with fragrances of vinegar and wine is produced. Therefore, zero emission of the yellow water is realized to achieve environmental protection to the maximum extent, but also the additional value in the white spirit industry is increased. The production method disclosed by the invention has huge economic and social benefits.

Owner:JIANGSU YANGHE BREWERY JOINT STOCK

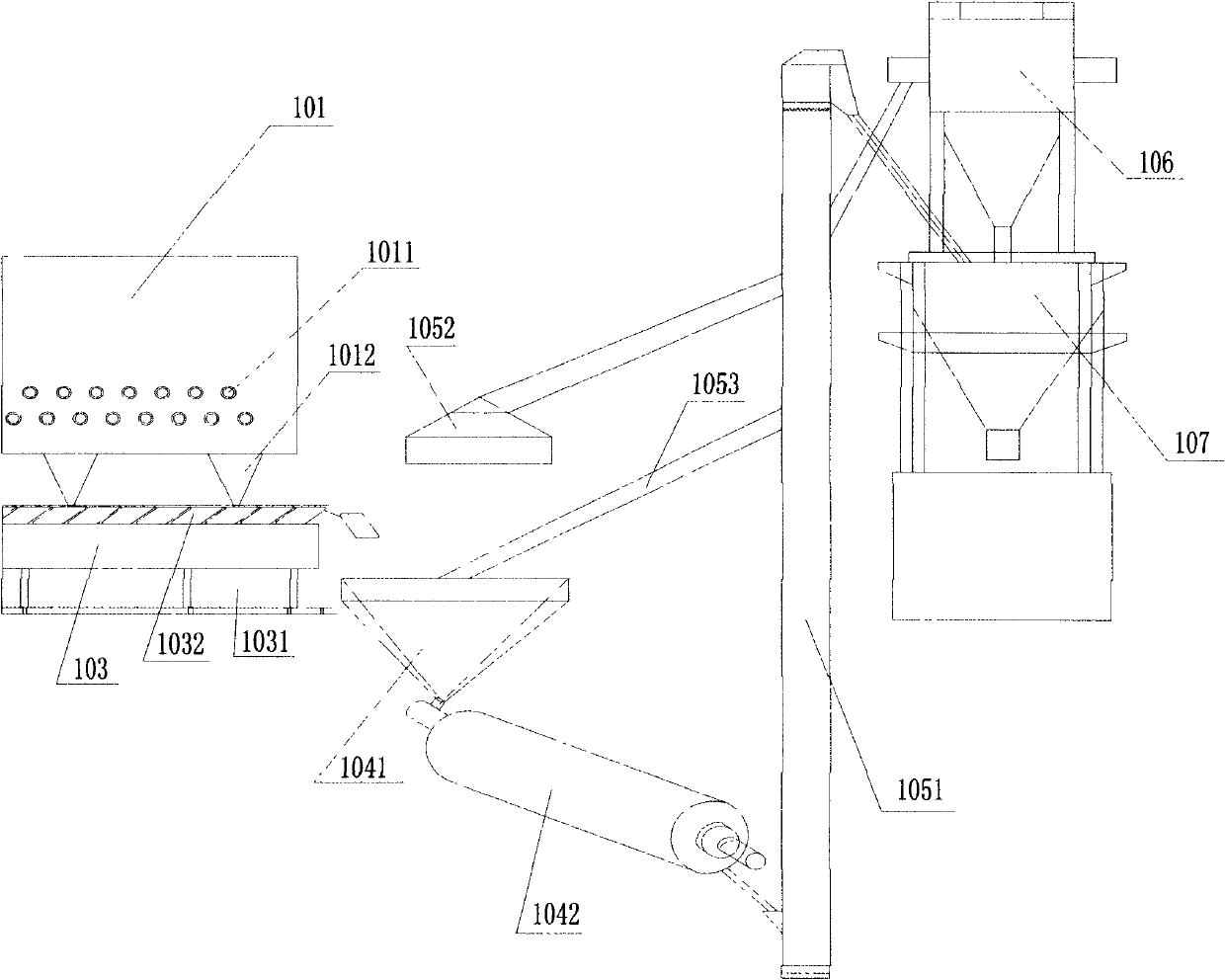

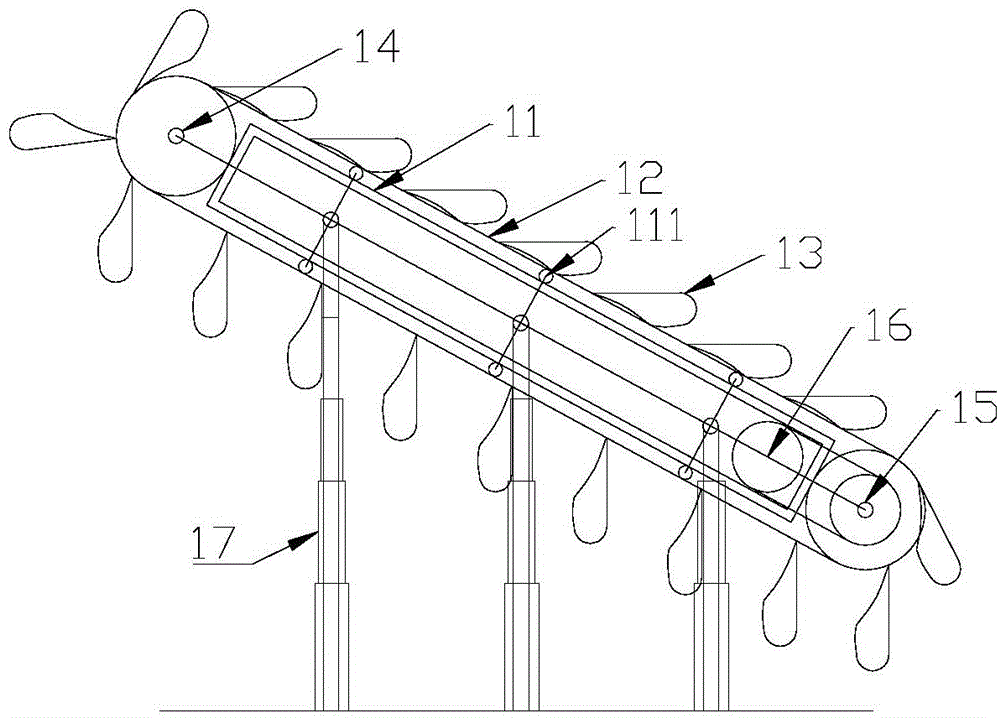

Building remaining mud processing technology and system

ActiveCN104874591ATo achieve the purpose of turning waste into treasureMeet the needs of modern productionSievingScreeningSoil organic matterFilter press

The invention discloses a building remaining mud processing technology and system. The uilding remaining mud processing system comprises a feeding device, a rotary screen, a sand scraping pit, an organic matter hydrocyclone separation device, an organic matter vibratory separation screen and a filter pressing separator. The building remaining mud processing technology and system adopt a pure physical process and device, high-content building remaining mud in building garbage is fully treated and recycled, large stone blocks, cement blocks, muck, fine sand, iron residues, organic matter and the like are respectively extracted from the building remaining mud, finally mud cakes and clear water are obtained, the purpose of turning waste into wealth is achieved, and the building remaining mud processing technology and system is green and environment-friendly and meets the modern production demand.

Owner:绿源环保有限公司

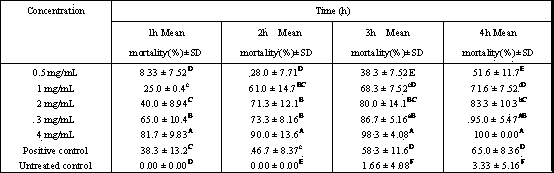

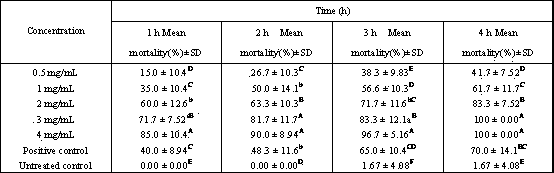

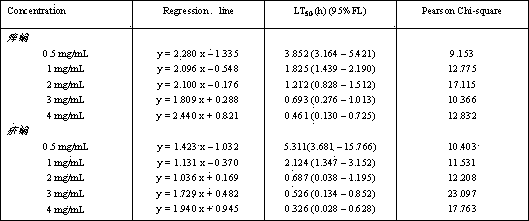

Preparation and application of plant source acaricide

InactiveCN104341285AImprove efficiencyLow toxicity hasOrganic active ingredientsAntiparasitic agentsPlant SourcesEthyl acetate

The invention relates to a high efficiency, low toxicity and environment-friendly plant insecticidal extract, which has a good killing effect on scab mites and Sarcoptes scabiei of rabbits and other animals. The acaricidal active ingredient of crofton weed is: 9-carbonyl-10, 11-dehydroagerophorone (euptox A). The preparation steps of a Euptox A liquid medicine include: subjecting leaf meal to methanol ultrasonic extraction; conducting ethyl acetate extraction; carrying out silica-gel column chromatography, macroporous resin column elution, and repeated silica-gel column chromatography to obtain euptox A; and conducting dissolving with a Tween-80 cosolvent to prepare euptox A containing liquid medicines of different concentrations. When the euptox A is 2mg / mL, it has a strong mite killing effect on Psoroptes cuniculi and Sarcoptes scabiei, and when the LT50 is 1.212 and 0.687h respectively, the LC50 within 2h on Psoroptes cuniculi and Sarcoptes scabiei are 0.902mg / mL and 1.068mg / mL respectively.

Owner:SICHUAN AGRI UNIV

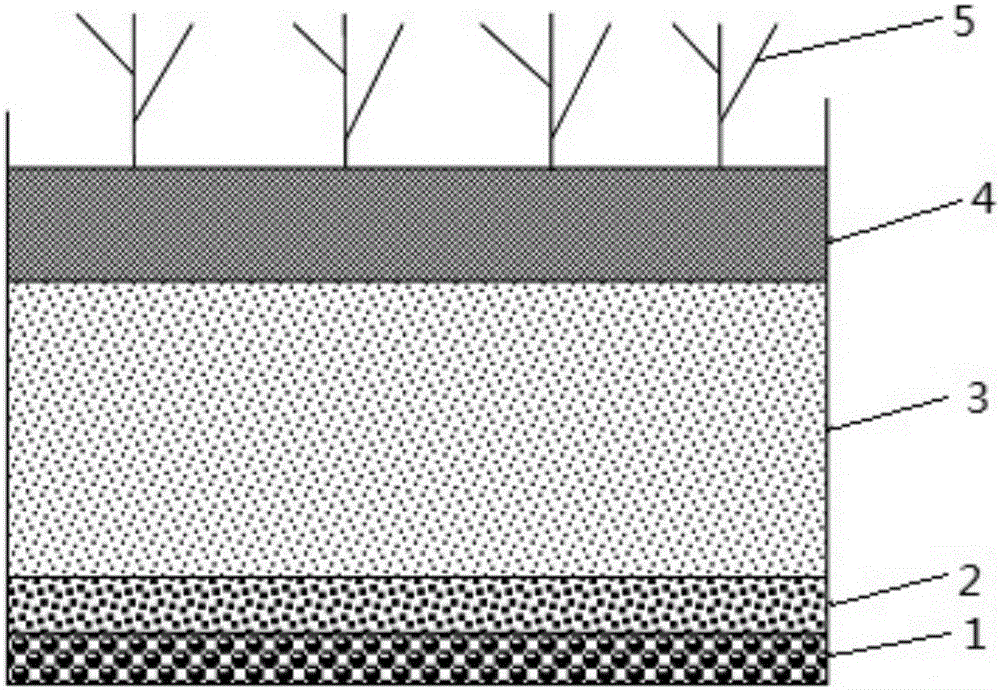

Rural domestic sewage manual wetland system and purification method

ActiveCN104986863APurifyGenerate economic valueSustainable biological treatmentBiological water/sewage treatmentBrickPurification methods

The invention provides a rural domestic sewage manual wetland system and a purification method. The system comprises at least one wetland bed formed with red bricks and straw as filler. The grain sizes of the filler gradually decrease from bottom to top. According to the method, domestic sewage is purified through the wetland beds formed with the red bricks and the straw as the filler. The grain sizes of the filler gradually decrease from bottom to top. Domestic swage is distributed on the upper portions of the wetland beds, and purified water is obtained at the bottoms of the wetland beds. By means of the system and the method, rural domestic sewage can be purified, rural abandoned straw and construction waste are adopted as wetland matrix, the price is low, but the sewage purification effect is good.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

Long-acting plant composite fertilizer

InactiveCN1357519AIncreased fructose contentPrevention and suppression of pests and diseasesFertiliser formsGranulation with special binding agentsField experimentAdhesive

The long-acting composite plant fertilizer consists of green material including foxtail-like sophora herb, alfalfa, plant ash, plant oil residue and adhesive and based on the production of farmyard manure. Its production includes the processes of drying, crushing, sieving, mixing, extrusion, pelletizing, and stoving. Field experiment shows that it has obvious yield increasing effect on rice, wheat, corn, melons and fruits and can reduce plant diseases and insect pests effectively.

Owner:XINJIANG TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing lithium-contained potassium sodium feldspar powder in tantalum-niobium ore waste rocks

ActiveCN105251594ASolve the way outTo achieve the purpose of turning waste into treasureGrain treatmentsLithium oxideNiobium

The invention relates to a method for preparing lithium-contained potassium sodium feldspar powder in tantalum-niobium ore waste rocks. A combined process with magnetic separation, high gradient magnetic separation, hydraulic cyclone and magnetic fluid separation is adopted. The tantalum-niobium ore waste rocks are crushed, screened, ground and subjected to high-frequency screening, spiral grading, permanent magnet magnetic separation for iron removal, high gradient magnetic separation, hydraulic cyclone and magnetic fluid separation, so that potassium sodium feldspar concentrates containing a certain amount of lithium are obtained. By means of the method, the lithium-contained potassium sodium feldspar concentrates with a high content of potassium oxide and sodium oxide, a trace content of lithium oxide and a low content of iron oxide, titanium oxide and manganese oxide are separated from the tantalum-niobium ore waste rocks. According to the lithium feldspar concentrates, Li2O accounts for 0.8-1.2%; the K2O and the Na2O altogether account for 7.5-9.0%; the TiO2 and the Fe2O3 altogether account for 0.1% or less; the SiO2 accounts for 66.0-71.0%; the Al2O3 accounts for 15.0-17.0%; the MnO2 accounts for 0.1% or less; the recovery rate of the lithium-contained potassium sodium feldspar concentrates is larger than 95%, and the qualities of the lithium-contained potassium sodium feldspar concentrates meet the requirement of industry standards.

Owner:江西金辉再生资源股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com