Patents

Literature

128results about How to "Meet the needs of modern production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

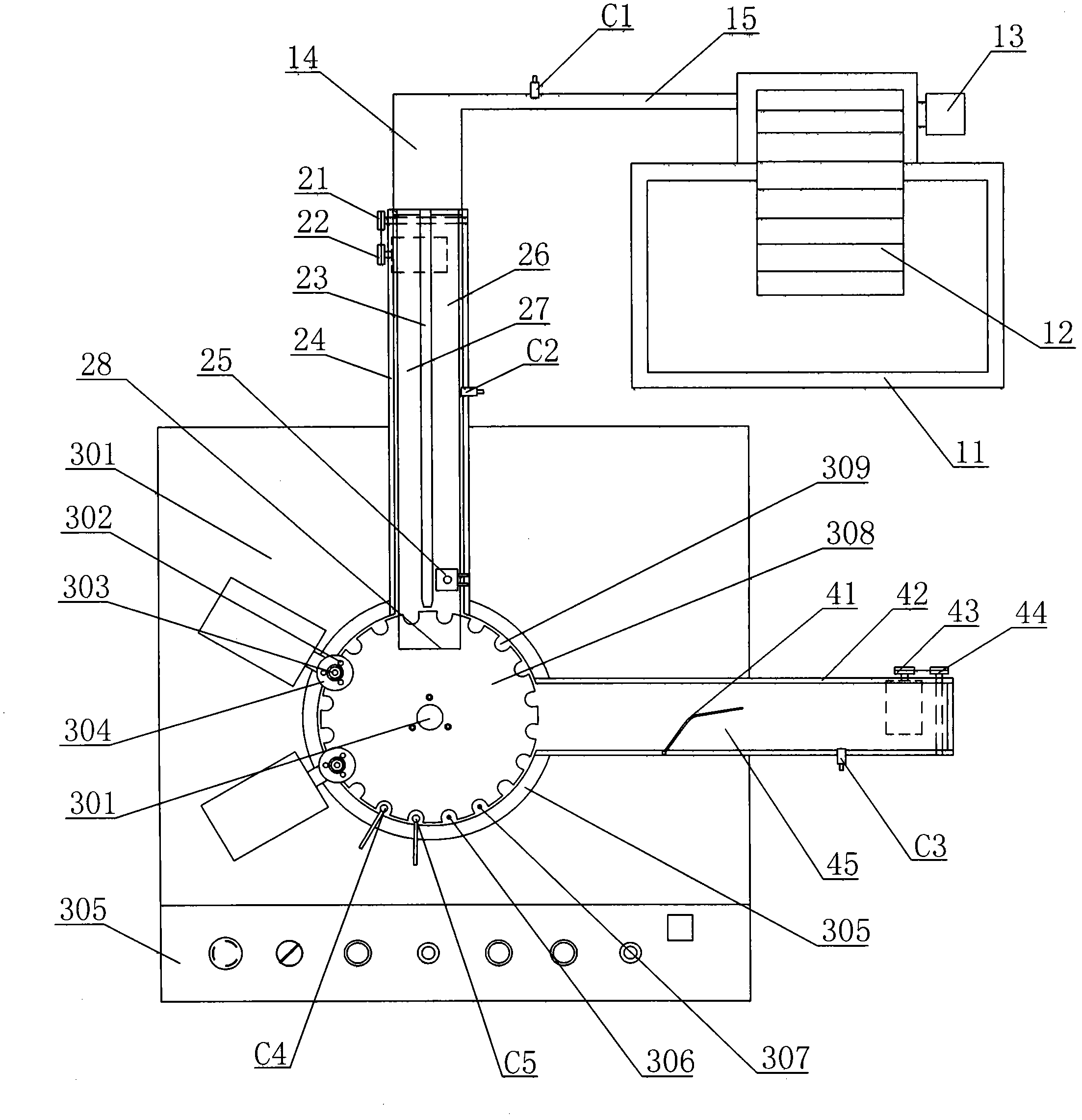

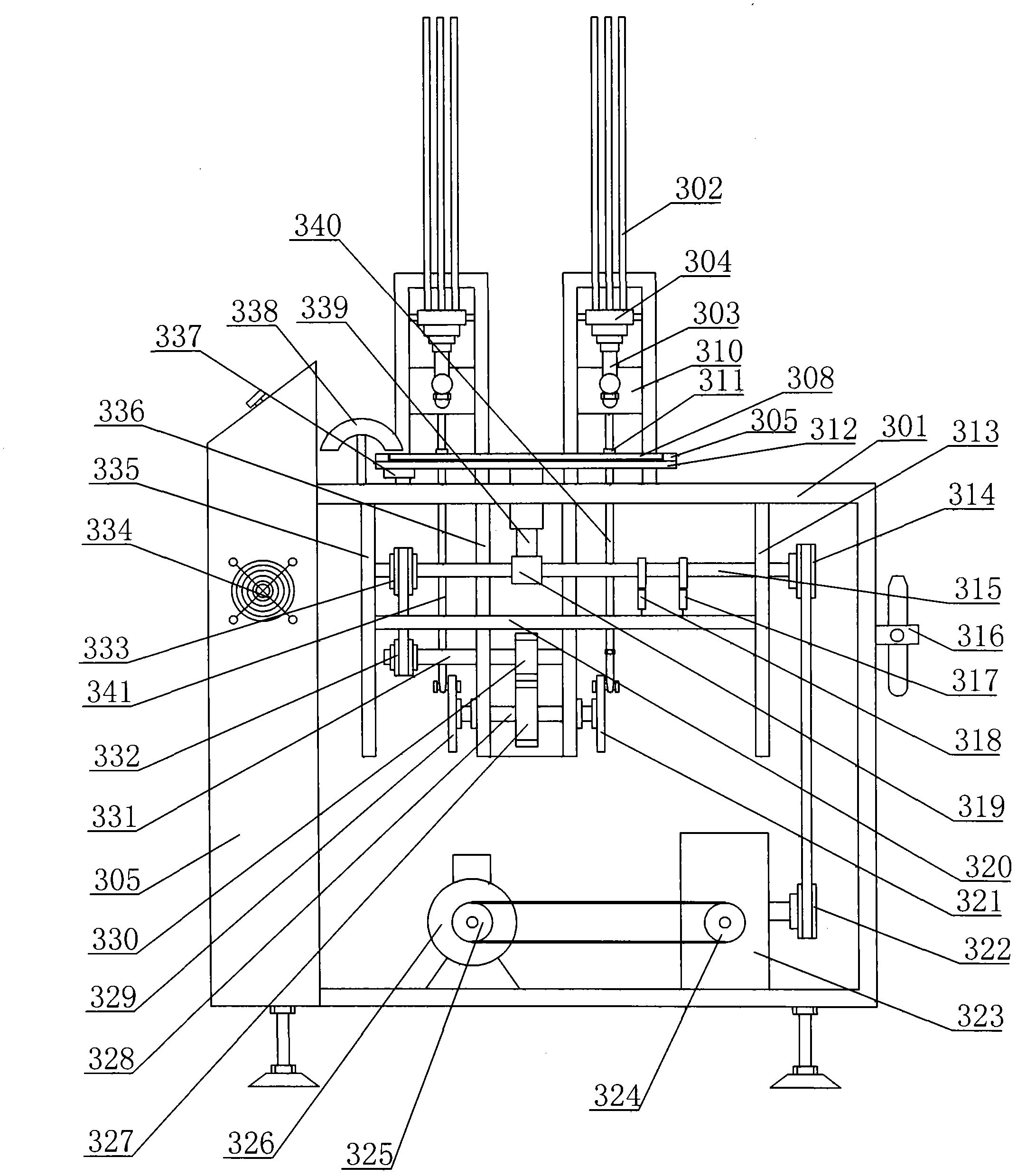

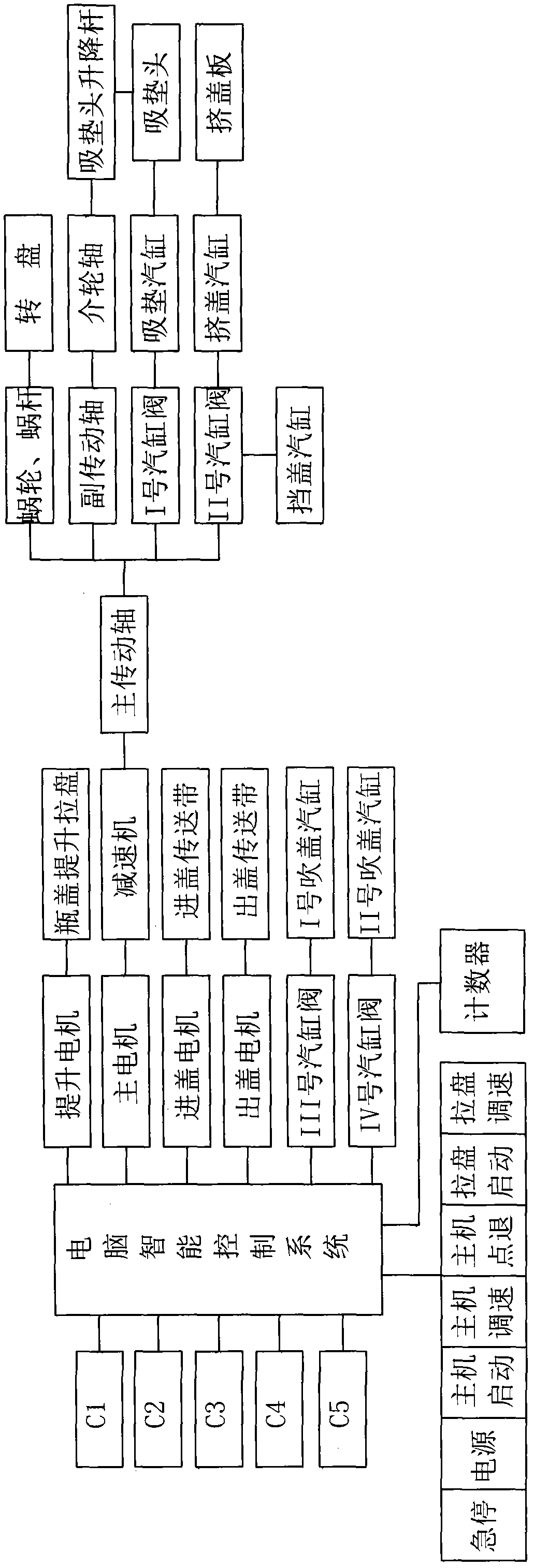

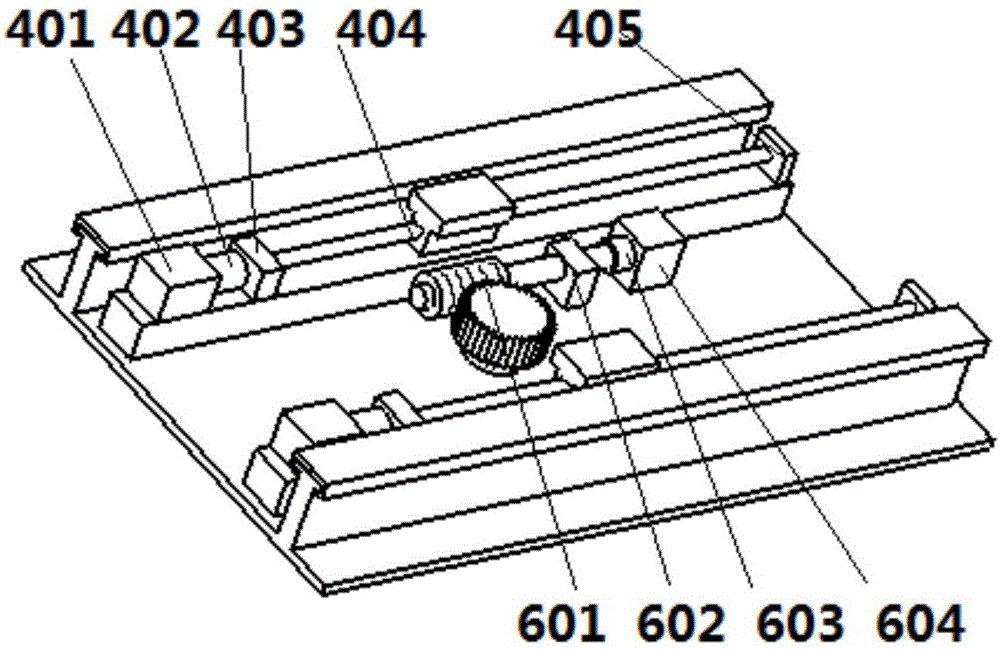

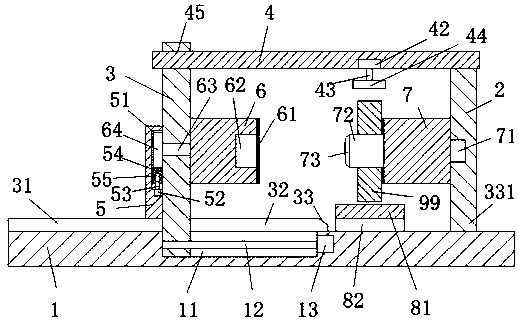

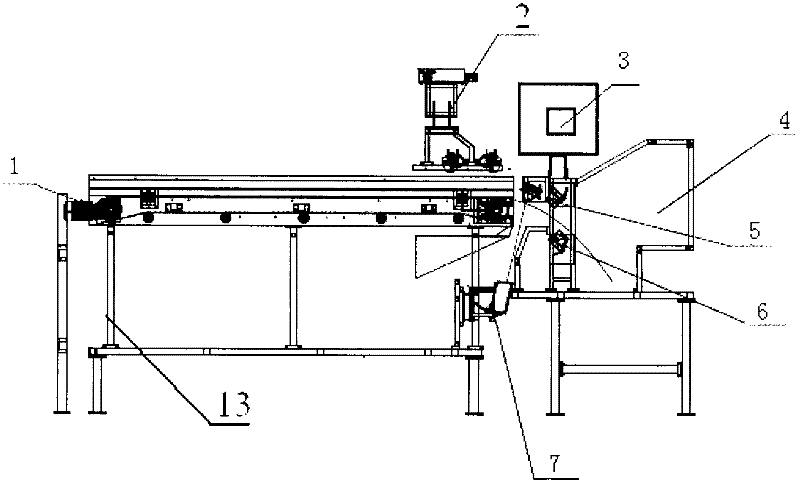

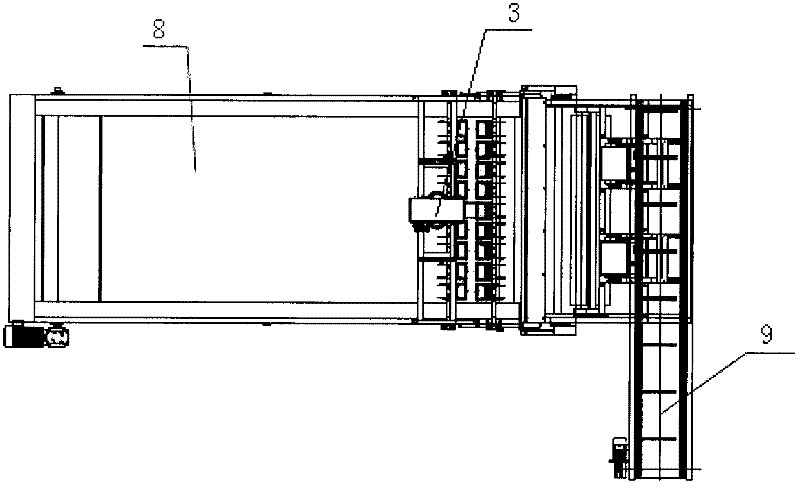

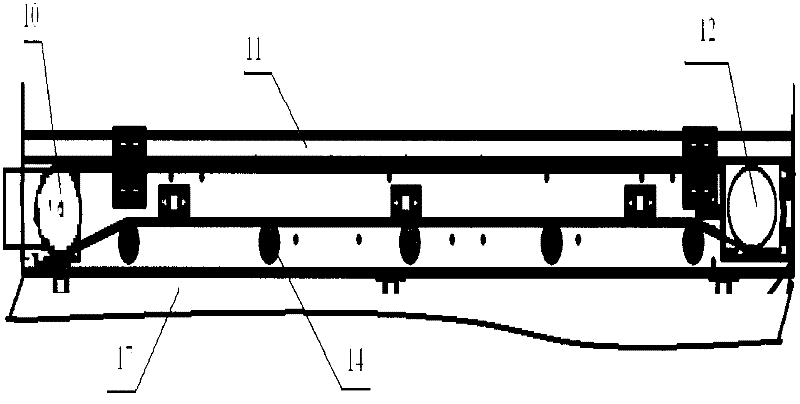

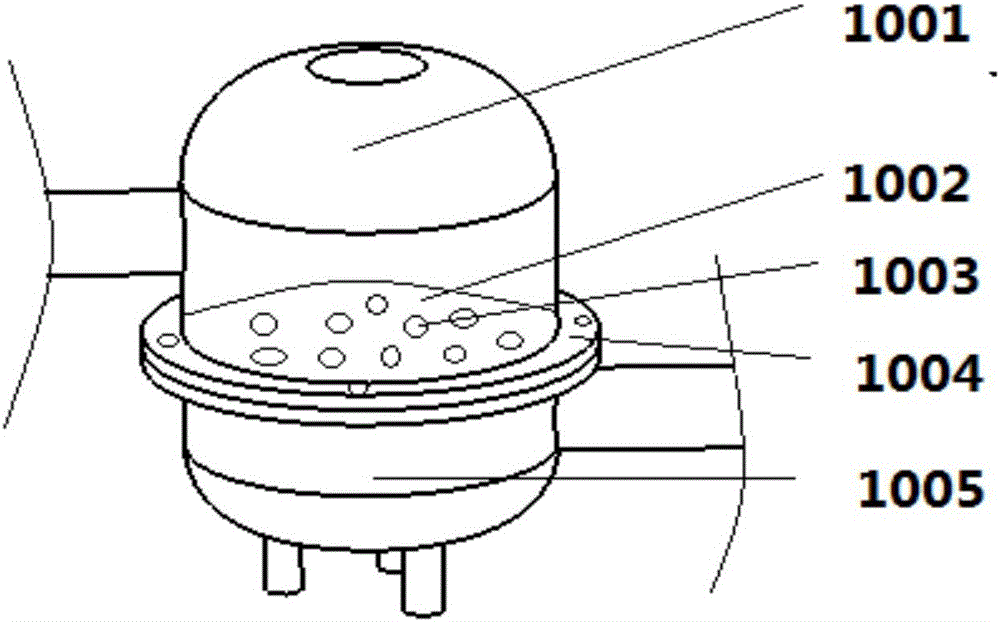

Full-automatic spacer imbedding machine for bottle caps

InactiveCN102554601AReduce labor intensityIncrease productivityMetal working apparatusBiochemical engineeringBottle cap

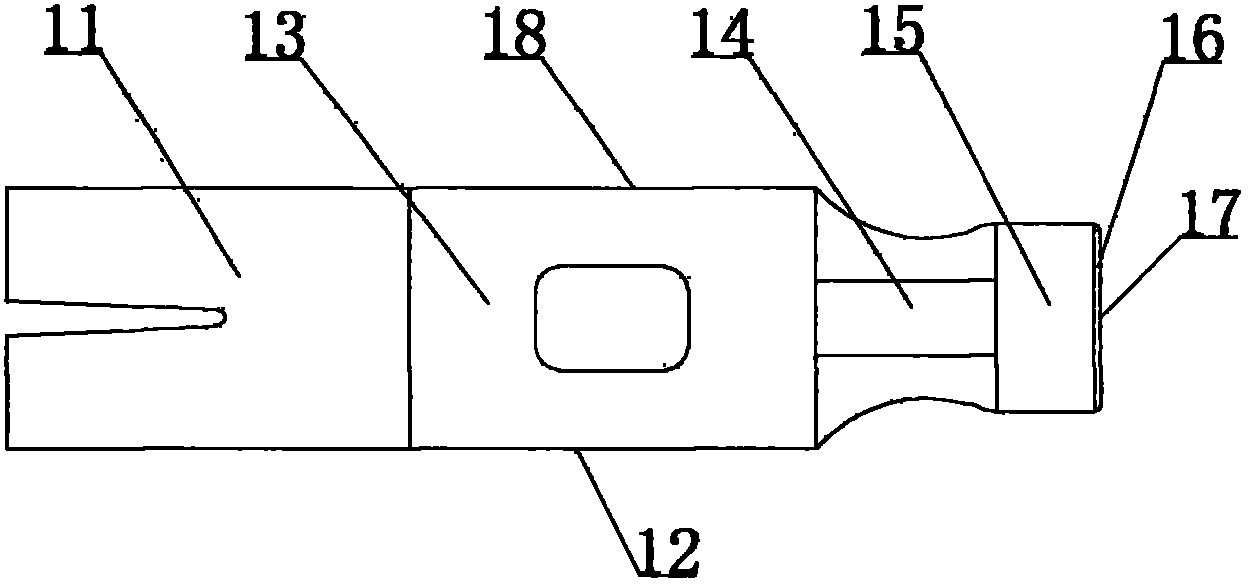

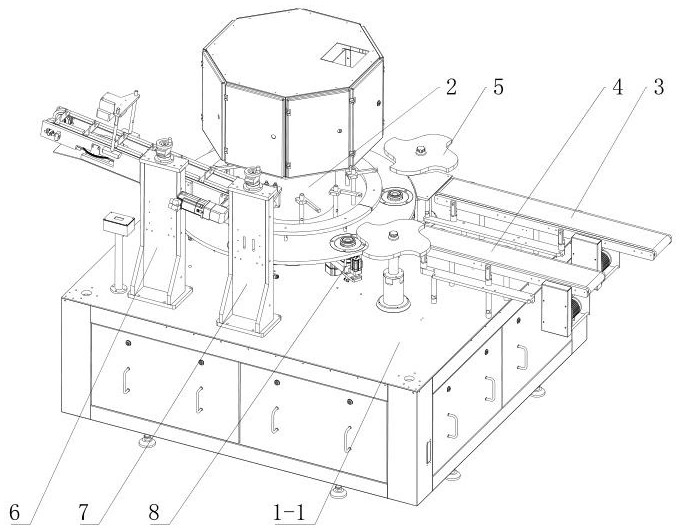

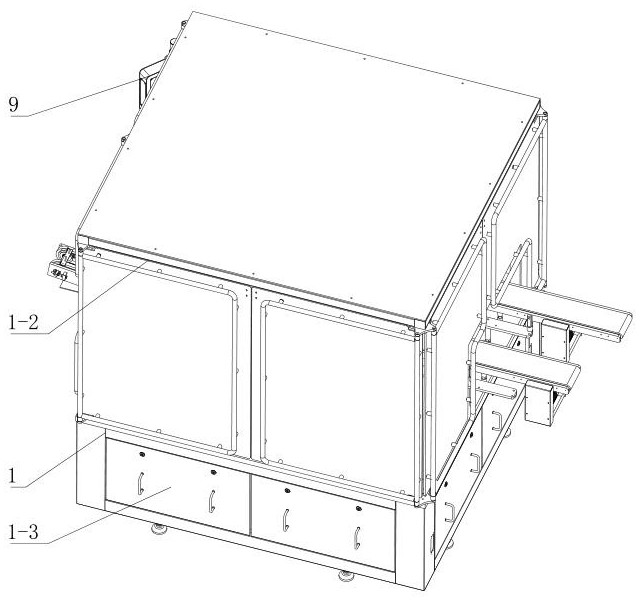

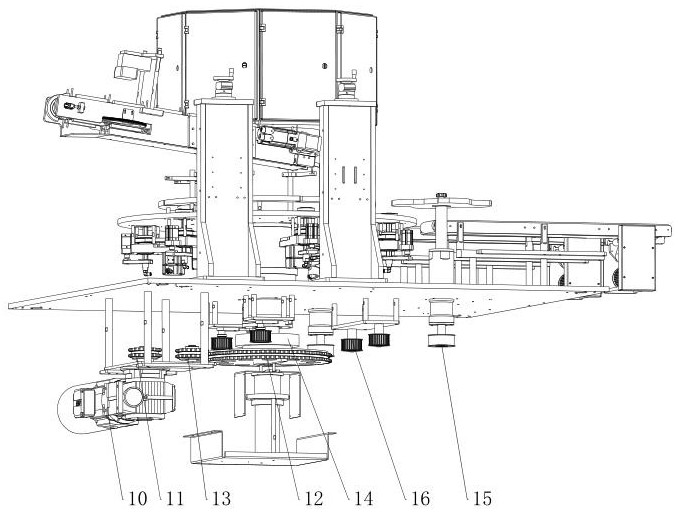

The invention discloses a full-automatic spacer imbedding machine for bottle caps, which is characterized by comprising an automatic cap sorting mechanism, a spacer imbedding mechanism, a bottle cap conveying mechanism, a bottle cap output mechanism, a computer intelligent control system and a sensor. Disorder bottle caps are arranged and outputted by the automatic cap sorting mechanism, spacers are imbedded into the bottle caps by the spacer imbedding mechanism, the bottle caps are conveyed to the spacer imbedding mechanism by the bottle cap conveying mechanism, and the bottle caps are outputted from the spacer embedding mechanism by the bottle cap output mechanism. The full-automatic spacer imbedding machine is high in automation degree, and can completely replace traditional manual operation, labor intensity of workers is greatly reduced, furthermore, production efficiency of an enterprise can be greatly enhanced, production cost of the enterprise is lowered, and needs of modern production are met.

Owner:孙德国

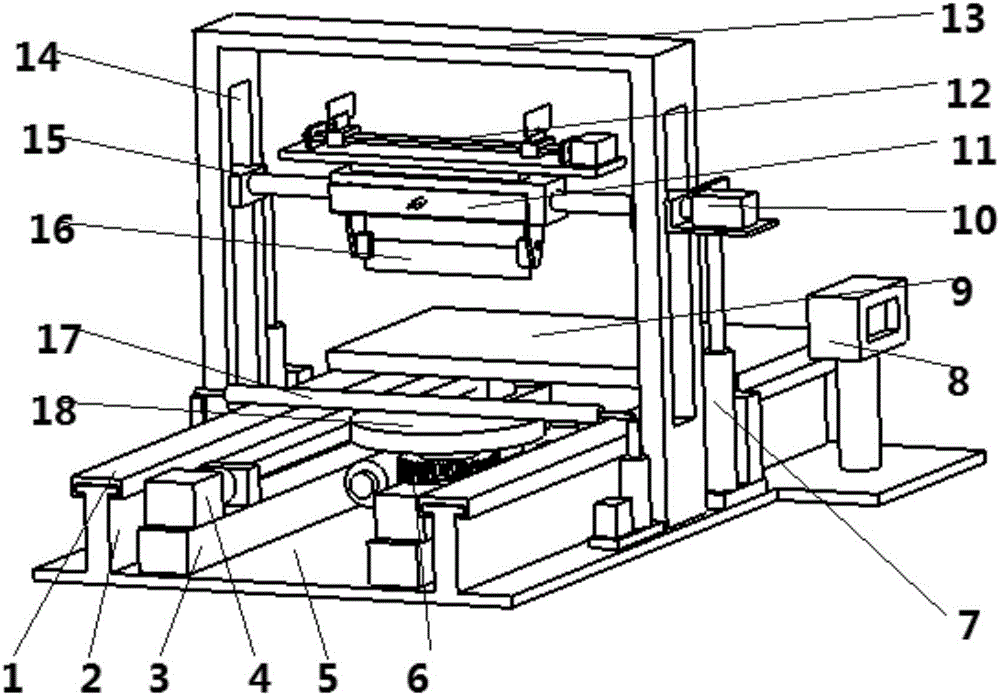

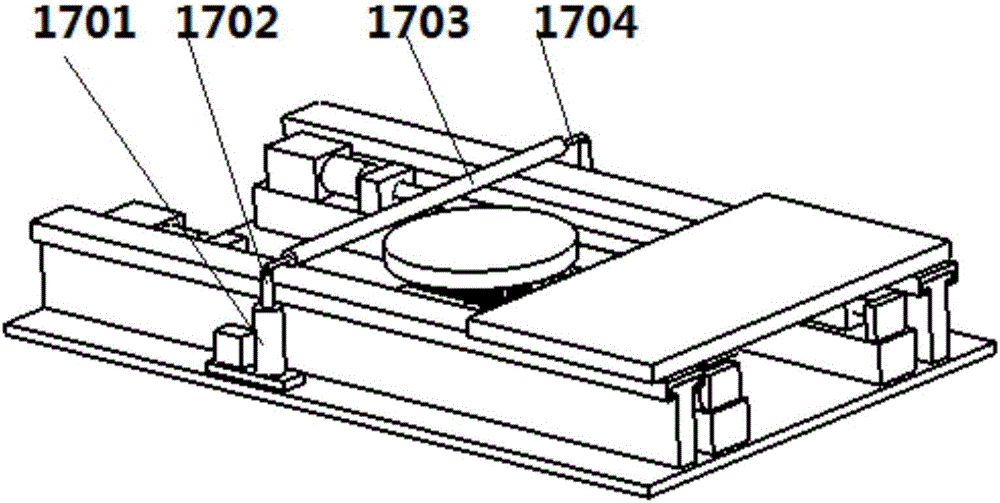

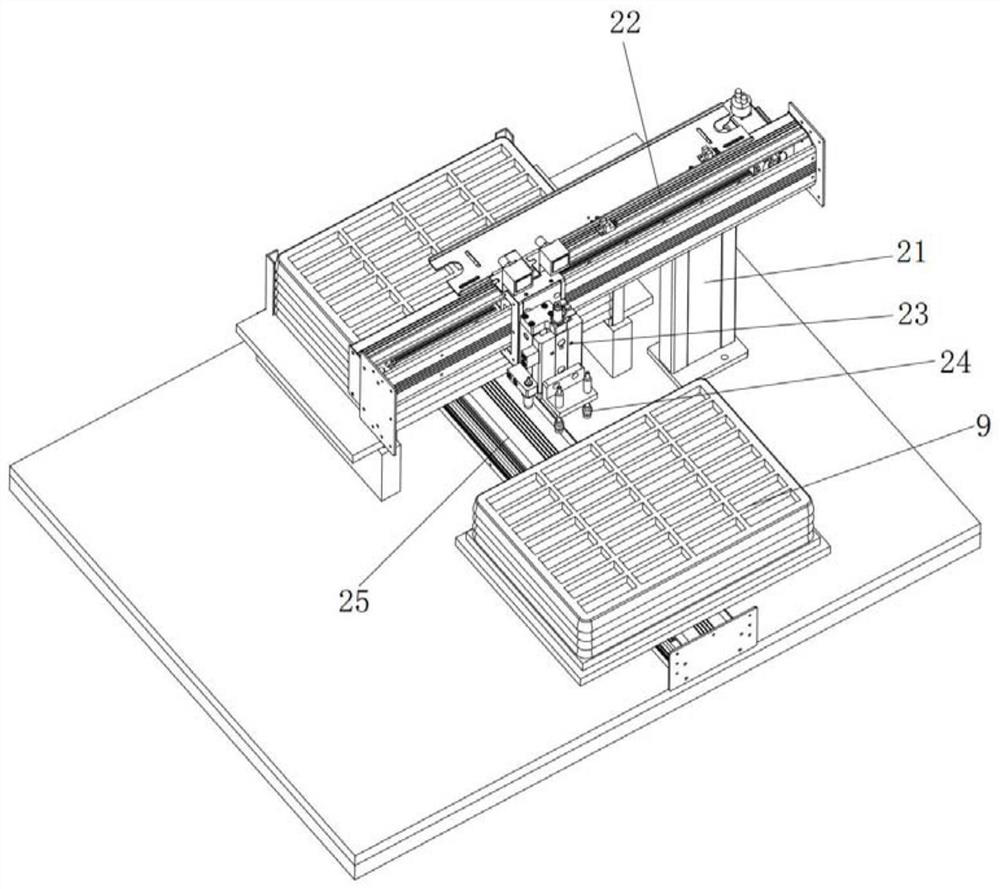

Sponge cutting machine fulfilling various cutting functions

The invention provides a sponge cutting machine with multiple cutting functions, which includes a base, a guide rail and a slide block are arranged on the base, a first workbench is fixed on the slide block, and a linear movement is provided between the first workbench and the base mechanism, the base is provided with a second workbench, a rotating mechanism is provided between the second workbench and the base, and a bracket is provided on the base, and vertical square grooves are opened on both sides of the bracket, and the square grooves are equipped with The guide block is provided with a first lifting mechanism on both sides of the base close to the support, passing through the two guide blocks through the first drive mechanism and rotatingly connected with a tool holder, and the tool holder is respectively provided with a first cutting device and a second cutting device. device and the third cutting device, the base is additionally provided with a control unit. A sponge cutting machine that realizes multiple cutting functions described in the present invention has a simple structure and is easy to operate, and can meet the needs of various cutting methods for large sponges on one piece of equipment, and has high cutting efficiency, which brings great benefits to enterprises. to higher earnings.

Owner:TIANJIN XINYIDA FURNITURE CO LTD

Processing technology of mower blade

The invention provides a processing technology of a mower blade and belongs to the technical field of garden equipment processing. The processing technology includes establishing a model, performing punching to acquire a blade blank, performing quenching, performing milling and cutting, performing edging on the blade blank, performing flaw detection, performing heat treatment, performing cooling and performing reheat treatment. By the use of the processing technology, the cutting blade is high in processing accuracy, service life of a mower is prolonged, repeated milling and utilization of the blade is facilitated, anti-corrosion effect of the blade is high, and requirements of modernization production are met.

Owner:安庆创跃电器有限公司

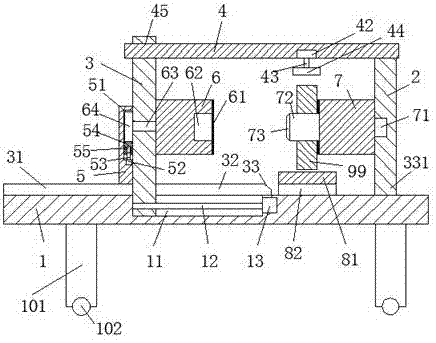

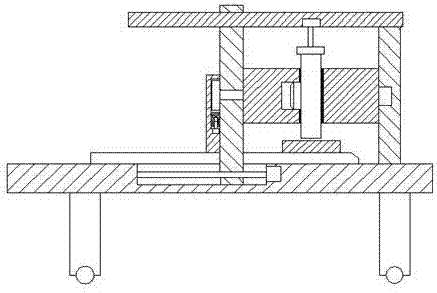

Welding device

InactiveCN107414380AImprove stabilityClamp firmlyWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineering

The invention discloses a welding device. The welding device comprises a bottom support and a fixing strip arranged on the bottom support. Foot columns are arranged at the bottom of the bottom support. Wheels are arranged at the bottoms of the foot columns in a rolling manner. The position, located on the left side of the fixing strip, on the bottom support is further provided with a sliding groove. The sliding groove is internally provided with a sliding frame capable of sliding left and right. A feeding groove is formed in the top of the sliding frame and internally provided with a top frame in a sliding manner. The right end of the top frame is fixedly connected with the fixing strip. The left end of the fixing strip is rotationally provided with a right turning table. The right end of the right turning table is rotationally connected with a first motor arranged in the fixing strip. The welding device is relatively simple in structure, the production cost is low, operation is simple, the annular piece welding efficiency is greatly improved, and waste of manpower resources is reduced; and the welding effect is good, the welding precision is high, and the modern production requirement is met.

Owner:东莞市兴连成灯饰有限公司

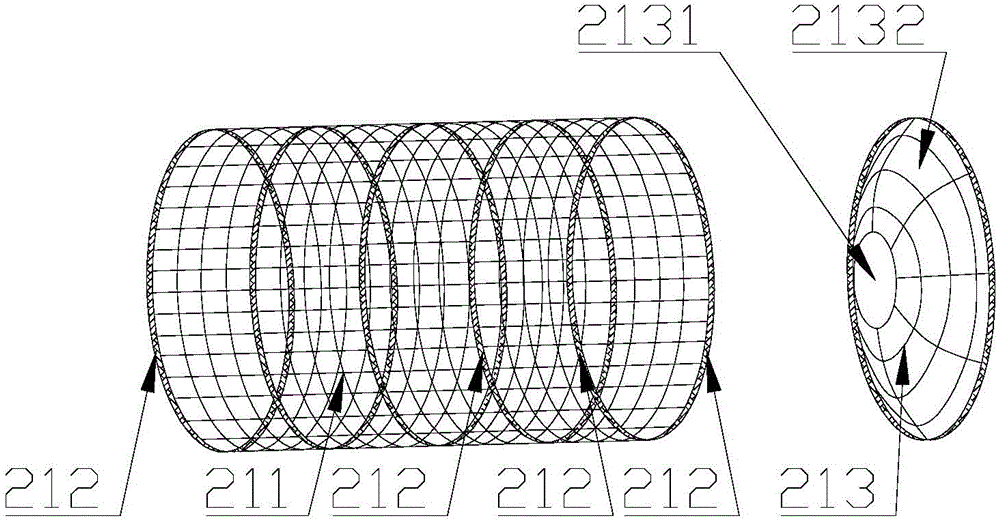

Building remaining mud processing technology and system

ActiveCN104874591ATo achieve the purpose of turning waste into treasureMeet the needs of modern productionSievingScreeningSoil organic matterFilter press

The invention discloses a building remaining mud processing technology and system. The uilding remaining mud processing system comprises a feeding device, a rotary screen, a sand scraping pit, an organic matter hydrocyclone separation device, an organic matter vibratory separation screen and a filter pressing separator. The building remaining mud processing technology and system adopt a pure physical process and device, high-content building remaining mud in building garbage is fully treated and recycled, large stone blocks, cement blocks, muck, fine sand, iron residues, organic matter and the like are respectively extracted from the building remaining mud, finally mud cakes and clear water are obtained, the purpose of turning waste into wealth is achieved, and the building remaining mud processing technology and system is green and environment-friendly and meets the modern production demand.

Owner:绿源环保有限公司

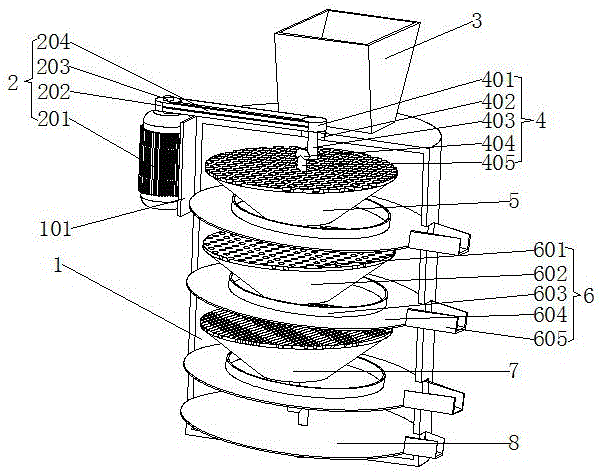

Multistage whirling vibration screening method

InactiveCN106111518APlay the role of shock absorptionFully screenedSievingScreeningScreening methodEngineering

The invention introduces a multi-stage rotary vibration screening method, which includes the use of a multi-stage rotary vibration screening device. The process is as follows: a power mechanism and a rotary mechanism are installed on the multi-stage rotary vibration screening device, and the power mechanism is connected to the motor support through bolts. On the top, weld the motor support to the left side of the box, and connect the power mechanism to the rotating mechanism through a V-shaped belt; connect the rotating mechanism to the upper support plate of the box through rolling bearings, and set the feeding port on the upper support plate ;The secondary screening mechanism is installed on the eccentric shaft of the rotating mechanism through the sleeve, and the primary, tertiary, and quaternary screening mechanisms are set; the raw materials are added to the primary screening mechanism, the device is started, and the raw materials pass through the primary screening in turn Mechanism, second-level screening mechanism, third-level screening mechanism, and finally discharge through the fourth-level discharge device. The multi-stage screening device adopted by Lili adopts belt transmission, which plays the role of buffering and absorbing vibration. The eccentric shaft drives the concave screening device to vibrate and rotate, and the screening is sufficient. The device occupies a small area. demand.

Owner:洛阳益矿机械设备有限公司

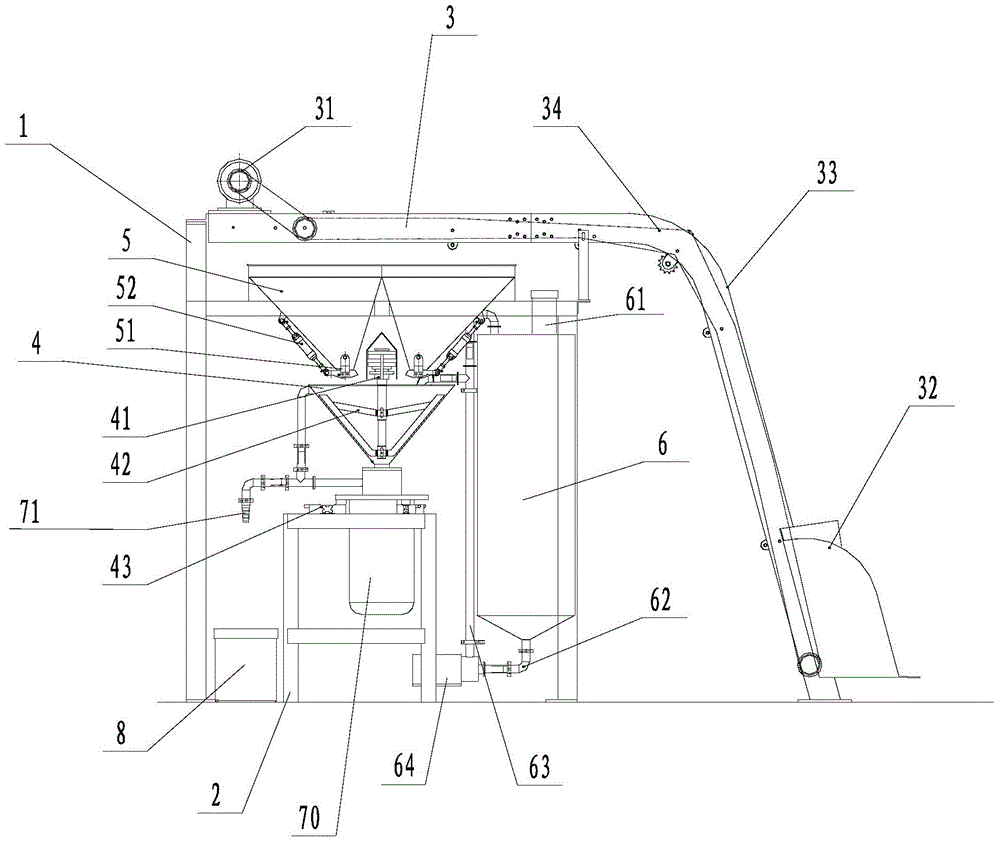

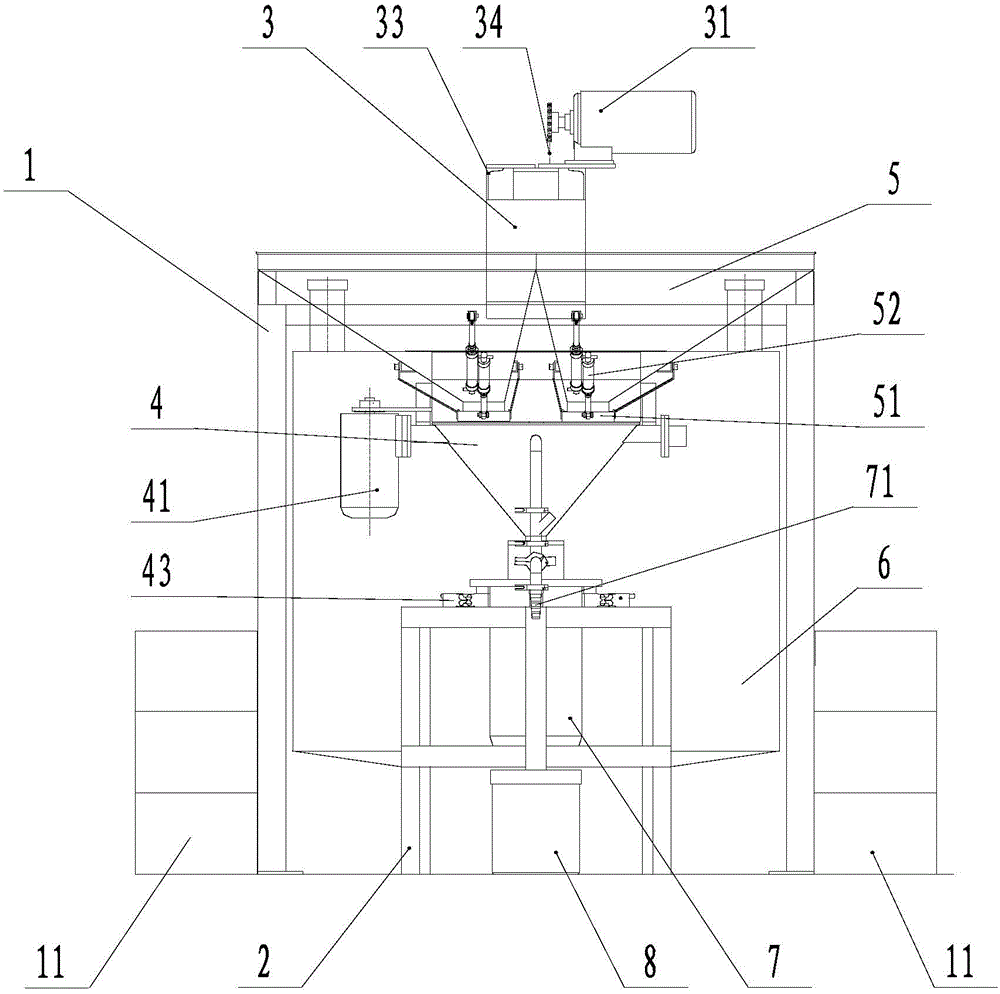

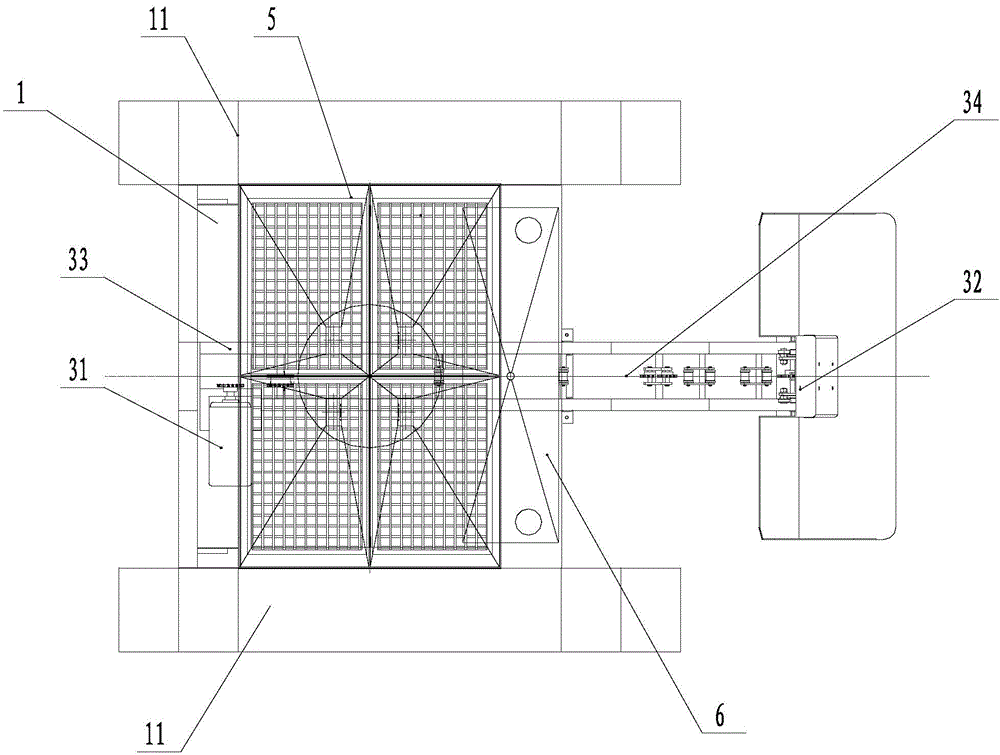

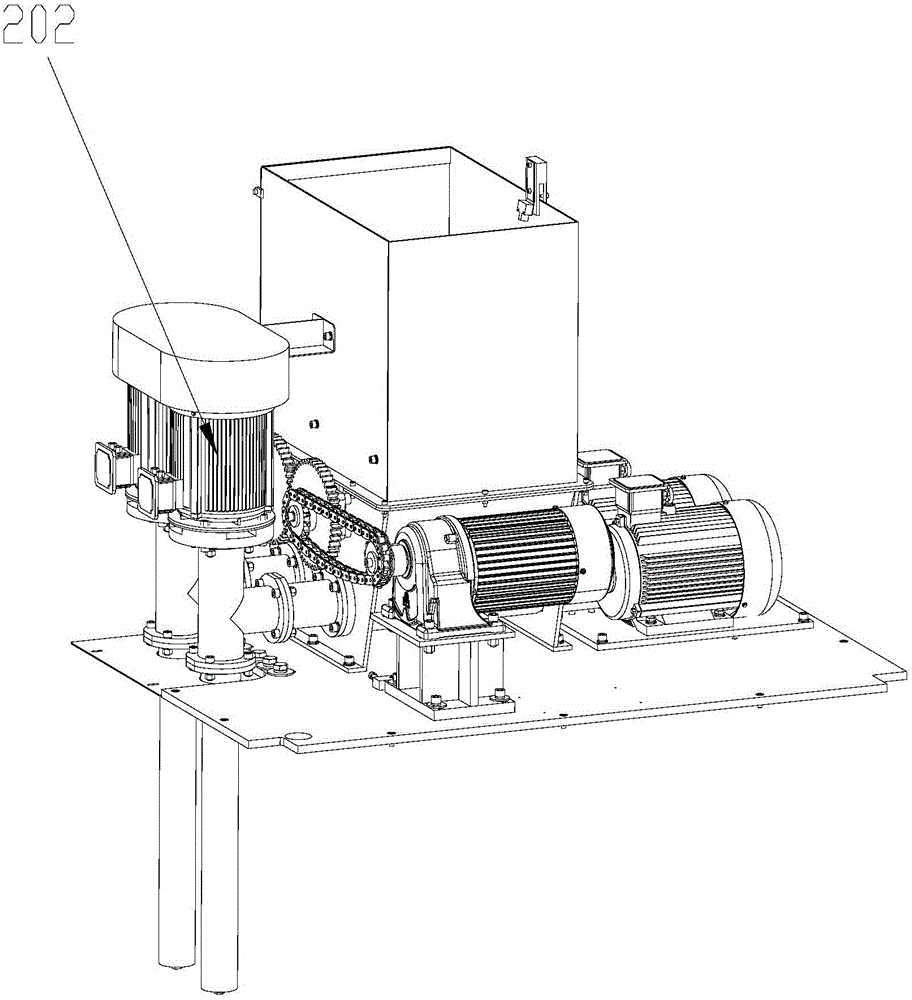

Liquid fertilizer preparation machine

InactiveCN104607093AEvenly proportionedReduce labor costsMixer accessoriesMixing liquids with solidsSanderAgricultural engineering

The invention discloses a liquid fertilizer preparation machine which comprises a main stander and a metering mixing sander, wherein the metering mixing sander is arranged in the main stander; the main stander is provided with a feed device used for inputting an original solid fertilizer; the metering mixing sander is provided with a metering mixing device; the main stander also internally comprises a feed hopper, an original paste barrel, an emulsifying device and a finished material barrel; the feed hopper is used for storing the original solid fertilizer input from the feed device; the original paste barrel provides a liquid paste blended fertilizer; the feed hopper and the original paste barrel respectively output feedstock to the metering mixing device, and the metering mixing device is used for weighing, metering, stirring and mixing the feedstock; the metering mixing device is connected with the emulsifying device and outputs a mixed fertilizer to the emulsifying device; and the emulsifying device is used for emulsifying and grinding the mixed fertilizer and outputting the processed fertilizer to the finished material barrel. According to the liquid fertilizer preparation machine disclosed by the invention, the automatic feed, blending, metering, mixing and emulsification are integrated, the labor cost is saved, the requirement on modern production can be met and the problem of blockage of fertilizing equipment can be solved as a produced liquid fertilizer finished product is uniform in proportion and free of precipitates.

Owner:和原生态控股股份有限公司

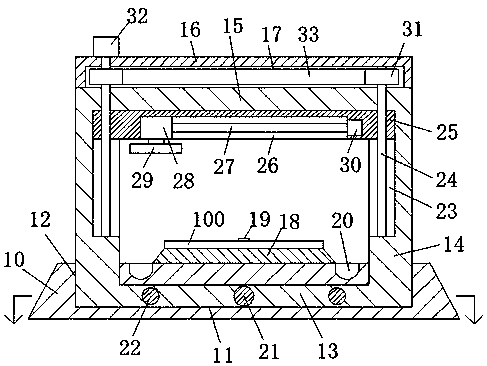

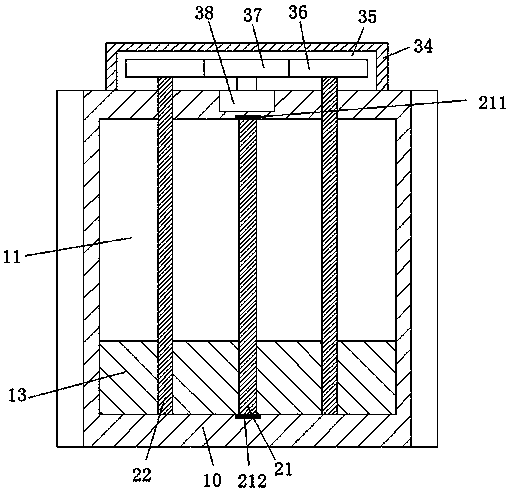

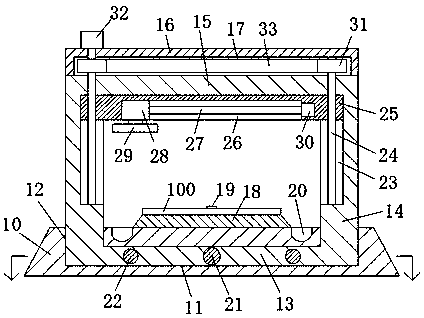

Full-automatic metal plate grinding device

InactiveCN108515397AAutomatic control of grinding operationsEasy to removeGrinding carriagesGrinding feedersEngineeringMechanical engineering

The invention discloses a full-automatic metal plate grinding device. The device comprises a device body. A working groove is formed in the device body and extends front and back. The left and right sides of the top end surface of the device body are symmetrically provided with through connecting grooves which extend front and back and communicate with the left and right ends of the working groovecorrespondingly. A metal plate fixing table extending front and back is arranged in the middle of the top end surface of the device body. The front and rear ends of the metal plate fixing table are symmetrically provided with metal plate clamps used for fixing a metal plate. The full-automatic metal plate grinding device is simple in structure, low in manufacturing cost and maintenance cost and capable of enabling up-down, front-back and left-right shifting work of a power grinding head to be automatically controlled; accordingly, the metal plate is comprehensively ground, the grinding efficiency of the metal plate is improved, the labor intensity of workers is relived, the working efficiency is improved, operation is easy and convenient, and automatic production is achieved; and the whole device is compact in structure and reliable in operation, and requirements of modern production are met.

Owner:苏州长鸿机械设备有限公司

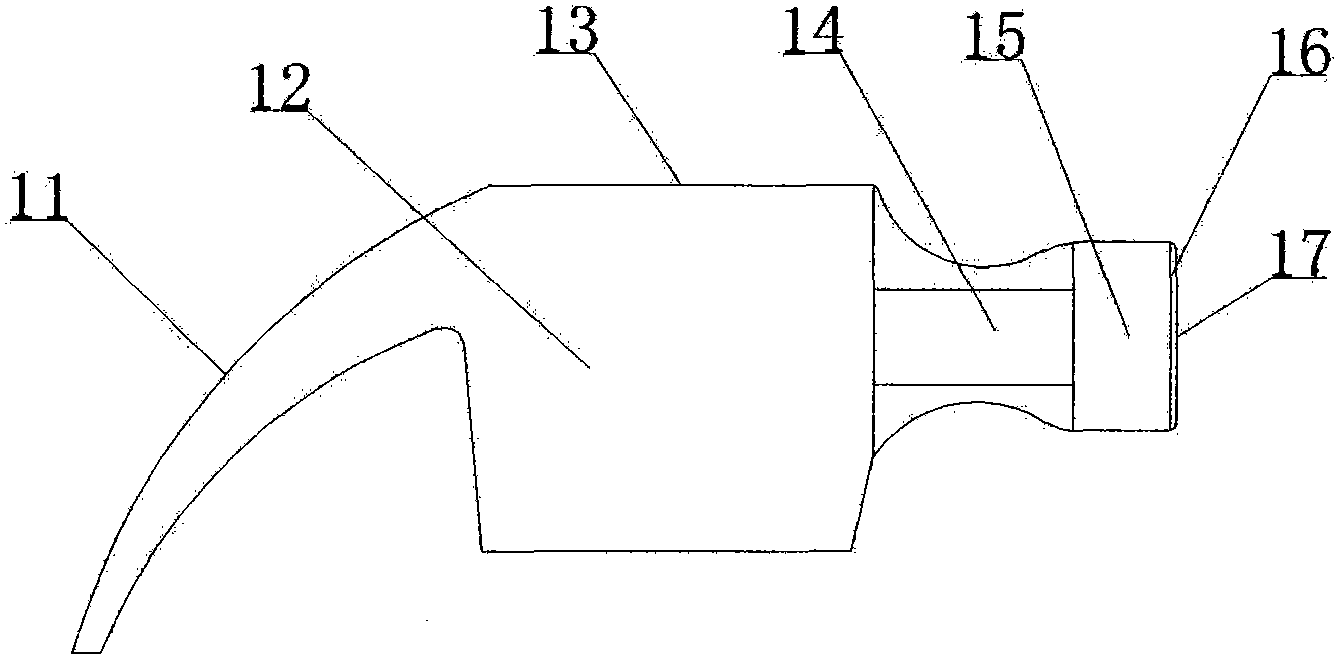

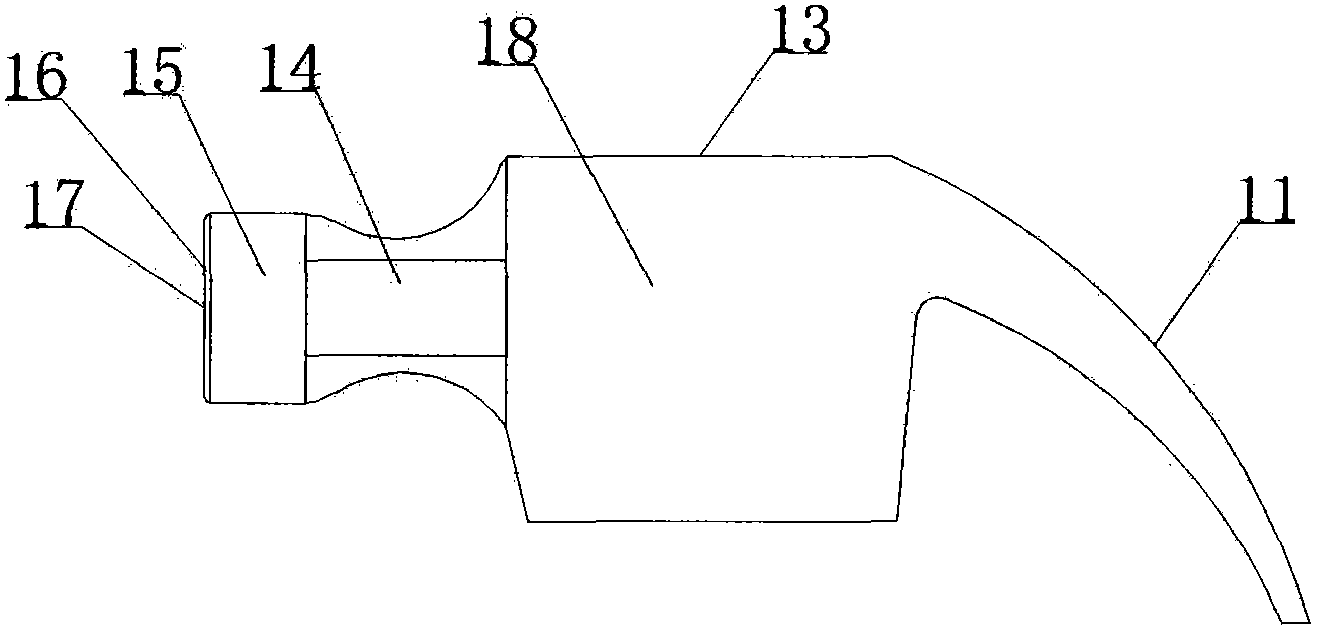

Milling machine for surfaces of hardware tools

InactiveCN102699797AHigh degree of automationReduce labor intensityGrinding drivesBelt grinding machinesAutomationElectric control

The invention discloses a milling machine for surfaces of hardware tools, comprising a box-shaped machine body as well as an electric control box, a power mechanism, a transmission mechanism, a work piece conveying mechanism and a milling system and a dust removing fan which are arranged in the machine body. Compared with the prior art, the milling machine for the surfaces of the hardware tools can be used for automatically milling the top surfaces, the knocking surfaces, the left lateral surfaces and the right lateral surfaces of the heads of hammers, and the arc surfaces of the tail parts of the hammer bodies, so that the degree of automation is high, labor and time can be saved, the labor strength of the workers can be reduced, the production efficiency of enterprises can be improved, the production cost of the enterprises can be reduced, and the requirements of modern production can be met.

Owner:张景宏

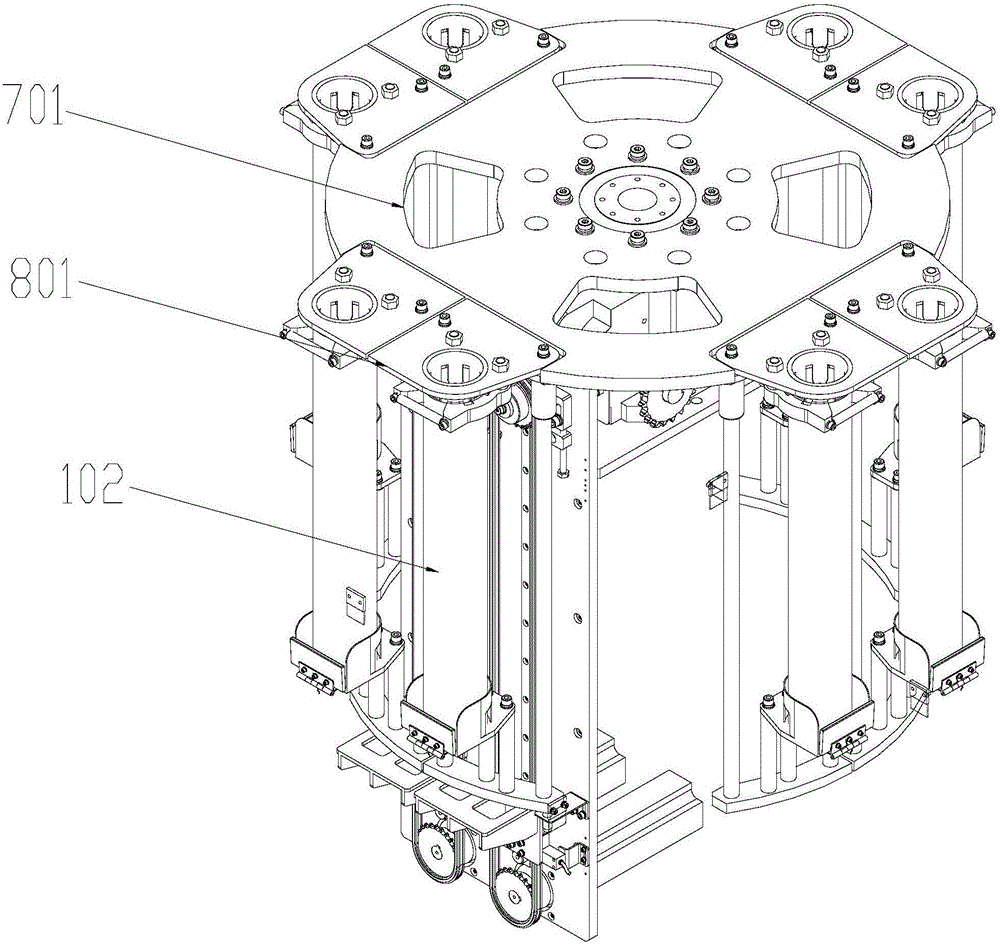

High-speed capping machine for high caps

ActiveCN113548614AImprove capping efficiencyMeet the needs of modern productionClosing machinesFlanged caps applicationMachineIndustrial engineering

The invention relates to the technical field of canning equipment, in particular to a high-speed capping machine for high caps. The high-speed capping machine is provided with a rack, a rotating part, an inlet net chain part, an outlet net chain part, a star wheel part, a cap feeding part, a cap pressing part, a tank body positioning part and a control part, and the control part is arranged on the rack and electrically connected with the rotating part, the inlet net chain part, the outlet net chain part, the star wheel part, the cap feeding part, the cap pressing part and the tank body positioning part, so that an integral control effect is achieved. The cap pressing efficiency is improved, the cap pressing speed reaches 100 pieces or above per minute, and the requirement of modern production is met. Cap feeding operation can be conducted on tank bodies with different heights through the cap feeding lifting part, the efficiency is high, and full automation is achieved. A visual camera can monitor whether the cap feeding work is normally carried out or not in real time, cap neglected loading is prevented, and it is ensured that the positions of the caps are correct when the caps are conveyed to the next procedure.

Owner:CHANGZHOU JOYO AUTOMATION EQUIP CO LTD

Wear-resistant metal adhesive

InactiveCN104371630AEasy to prepareLow costNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyFormate

The invention discloses a wear-resistant metal adhesive which comprises the following raw materials in parts by weight: 20-40 parts of epoxy resin, 25-40 parts of polyurethane formate, 15-20 parts of polyvinyl alcohol, 5-8 parts of iron oxide powder, 5-10 parts of titanium dioxide, 1-3 parts of emulsifier, 3-8 parts of flexibilizer, 1-3 parts of curing agent, 0.5-2 parts of flame retardant and 0.1-1 part of antioxidant. The wear-resistant metal adhesive disclosed by the invention is simple in preparation method and low in cost, and the obtained product is high in adhesive strength and short in curing time. Moreover, the tensile strength and mechanical property are improved, the heat resistance is high, and the requirement on modern production can be met.

Owner:昆山瑞昱化工有限公司

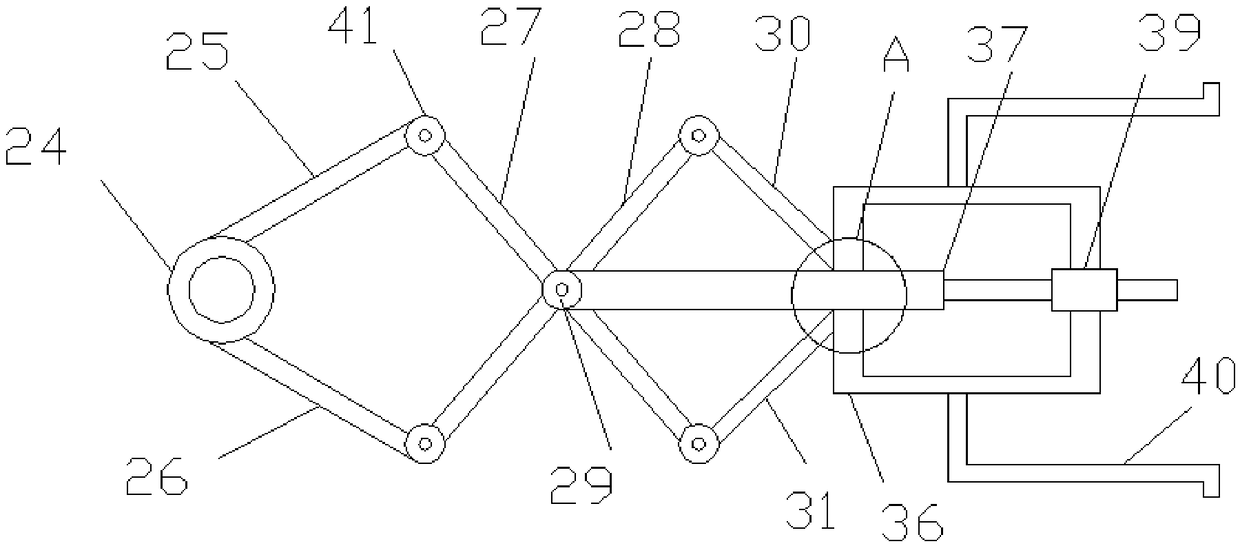

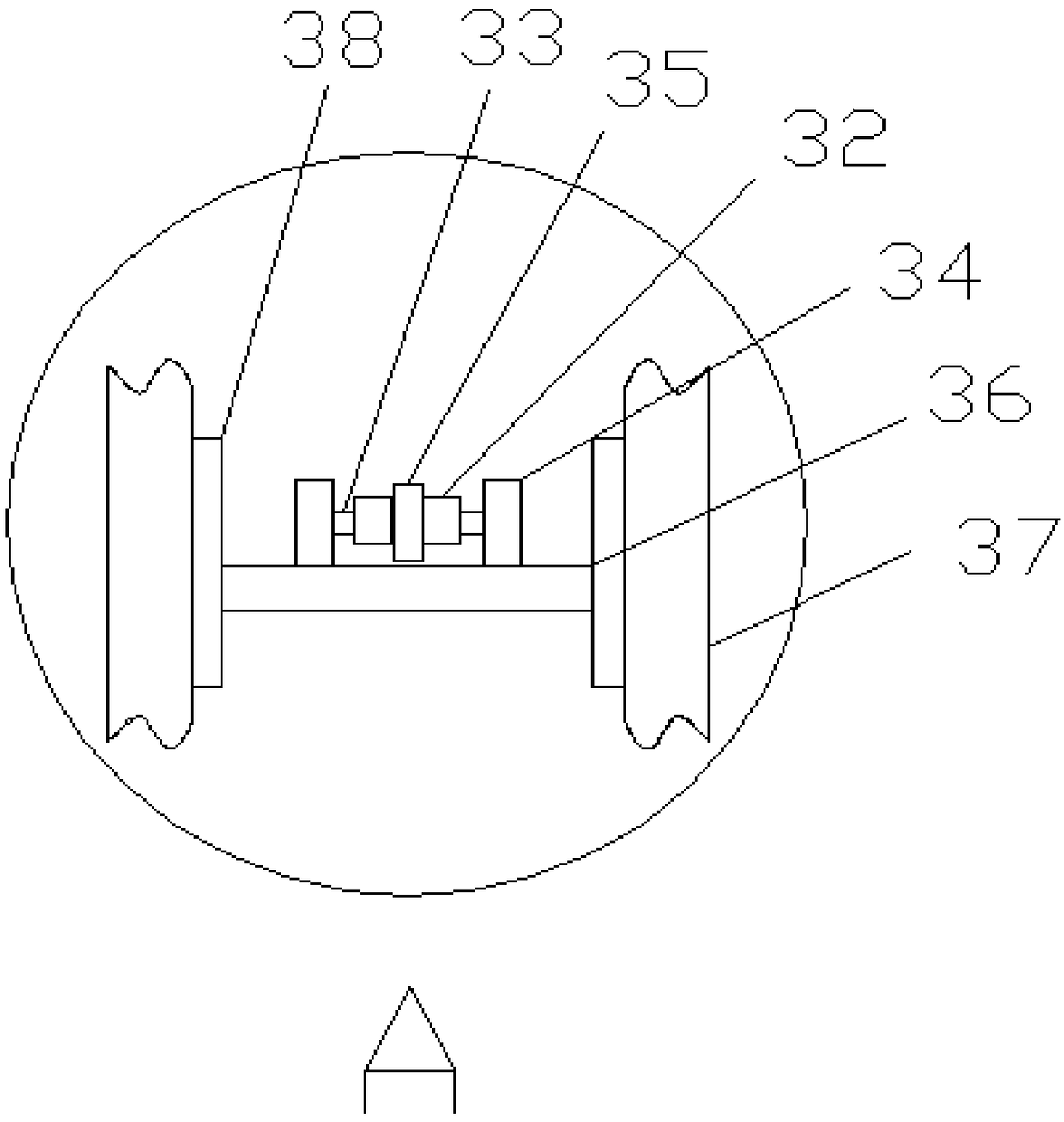

Moving-out and coring device

InactiveCN102151801ASimple structureEasy to useMoulding machinesEngineeringUltimate tensile strength

The invention discloses a moving-out and coring device which comprises a motor. An output shaft of the motor is connected with a rotating disc through a transmission mechanism; the transmission mechanism can be used for driving the rotating disc to rotate; and an inserted link for moving out a sand core is arranged on the rotating disc. The moving-out and coring device has a simple structure, is convenient to use, can effectively improve the moving-out efficiency of the sand core; and moreover, with the adoption of the moving-out and coring device, the labor intensity of workers can be reduced, and the time and labor are saved, therefore, the demands of modern production can be effectively met.

Owner:SUZHOU SUZHU FOUNDRY MACHINERY MFG

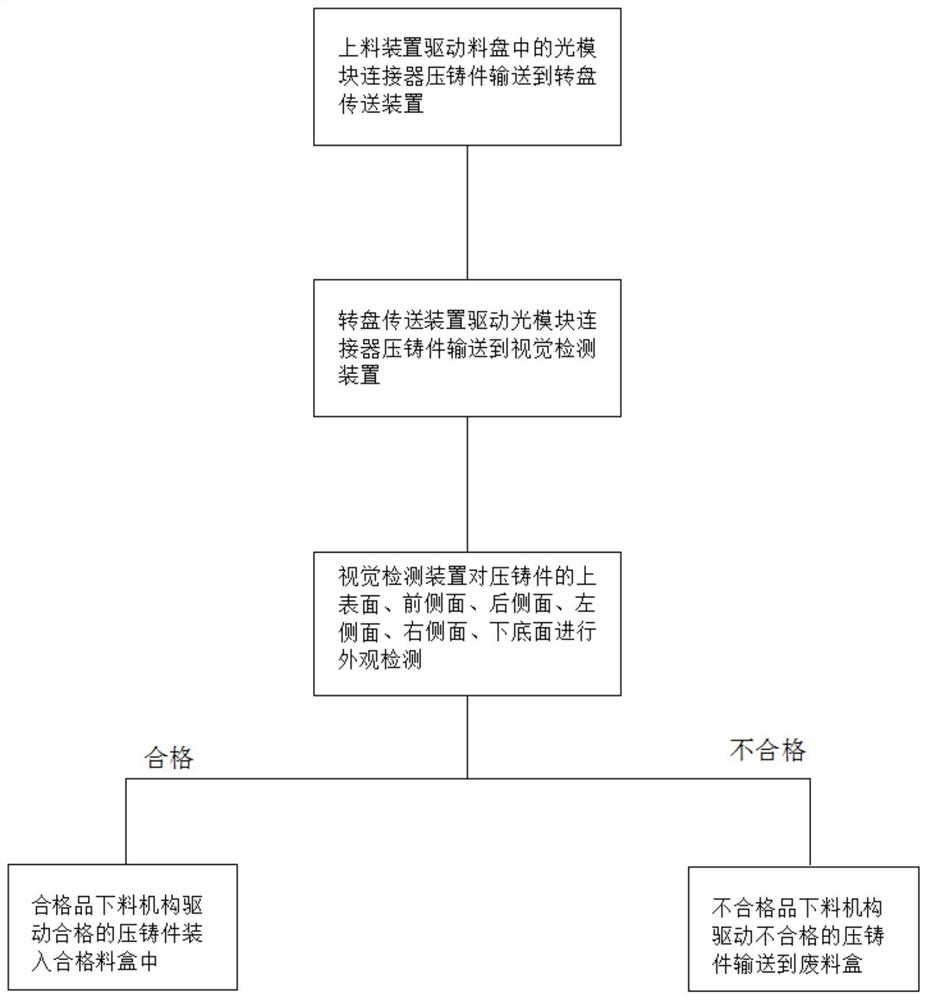

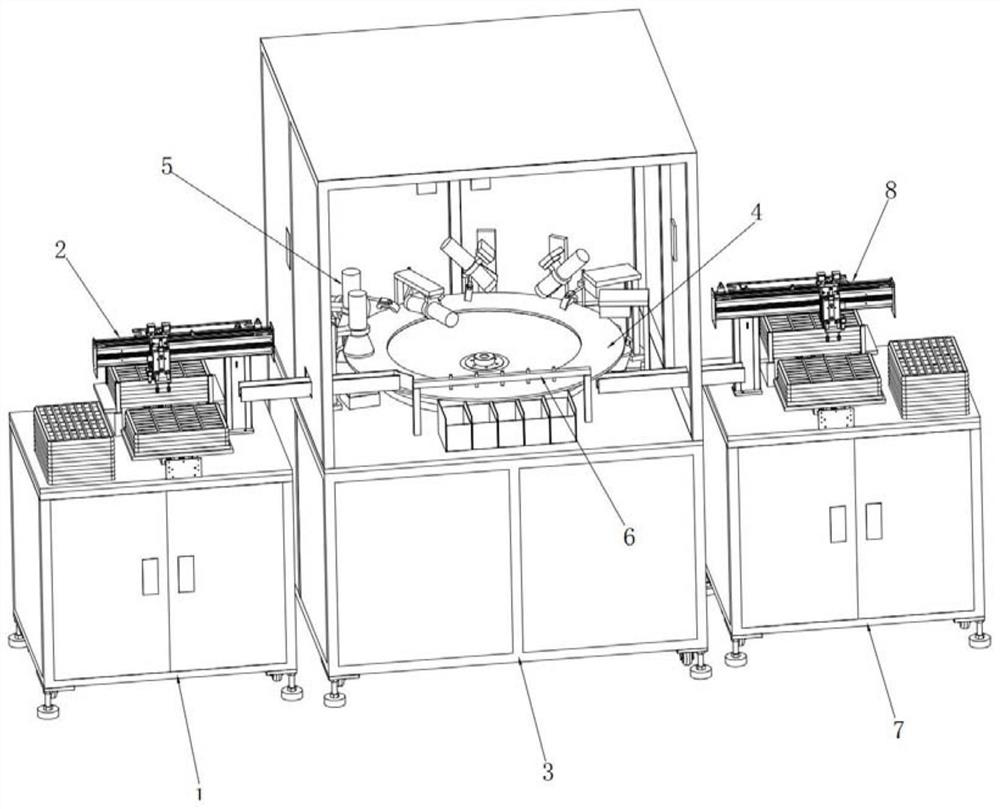

Intelligent appearance detection machine for optical module connector die casting and method thereof

InactiveCN112881420AImprove efficiencyImprove detection accuracyOptically investigating flaws/contaminationSortingOptical ModuleDie casting

The invention relates to an intelligent appearance detection machine for an optical module connector die casting and a method thereof. The intelligent appearance detection machine comprises a feeding machine frame, a feeding device, a main machine frame, a rotary disc conveying device, a visual detection device, an unqualified product discharging device, a discharging machine frame and a qualified product discharging device, the feeding machine frame is located on one side of the main machine frame, and the discharging machine frame is located on the other side of the main machine frame; the feeding device drives the optical module connector die castings in the trays to be conveyed to the rotary disc conveying device, the rotary disc conveying device drives the optical module connector die castings to be conveyed to the visual detection device, and the visual detection device detects whether the appearances of the die castings are qualified or not. The intelligent appearance detection machine for the optical module connector die casting and the method thereof have the advantages that the optical module connector die casting does not need to be manually taken, placed, observed and detected, the whole process is automatic, the efficiency is high, the labor cost is saved, the detection precision is high, and the modern production requirement is met.

Owner:DONGGUAN XINGHE PRECISION DIECASTING MOLD CO LTD

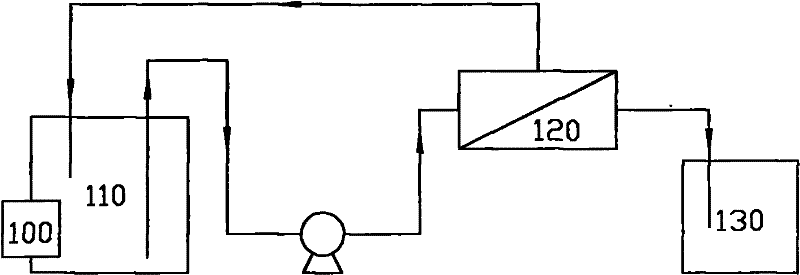

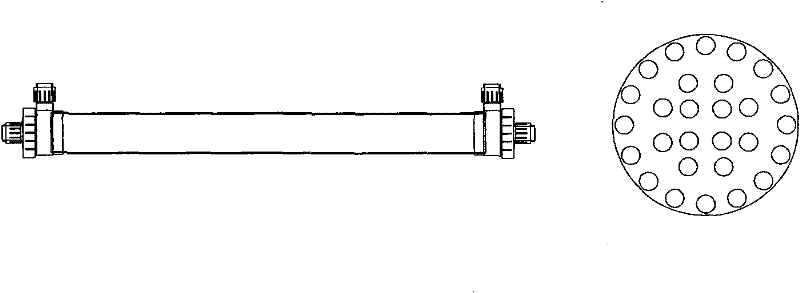

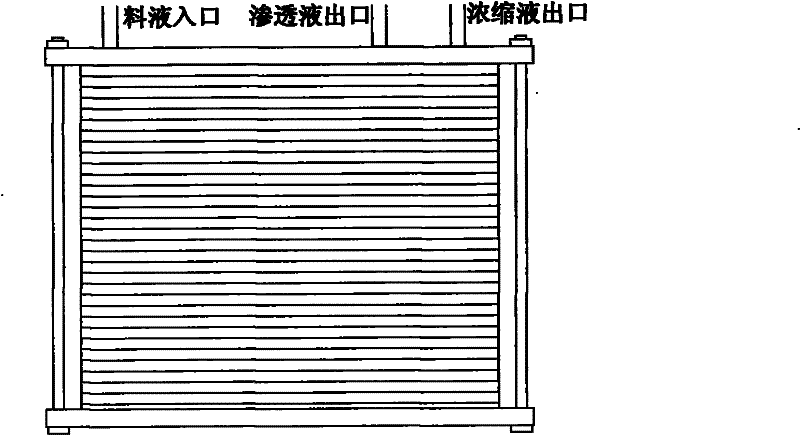

Method for purifying ginkgo flavones through membrane separation

InactiveCN102302522AReduce pollutionImprove separation efficiencyAntinoxious agentsAntiviralsChemistry

The invention relates to a production method for purifying ginkgo flavones by a membrane separation technology. The method is used for refining a ginkgo flavone crude product, and is characterized by comprising the following steps of: adding ethanol solution to dissolve the ginkgo flavone crude product serving as a raw material, pretreating, and making flavone solution permeate a membrane under certain pressure to form flavone solution with high purity. The membrane separation technology comprises an ultrafiltration coupling technology among ultrafiltration membranes of different pore sizes, a nanofiltration coupling technology among nanofiltration membranes of different pore sizes, and a coupling technology between ultrafiltration and nanofiltration. In one embodiment, the membrane can be immersed in a feed liquid kettle, percolate is obtained through suction filtering, and the membrane also can be positioned outside the kettle in different embodiments suitable for flavone treatment.

Owner:BEIJING FORESTRY UNIVERSITY

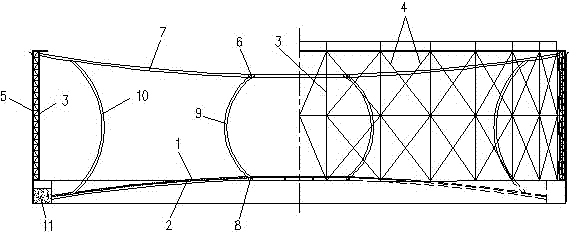

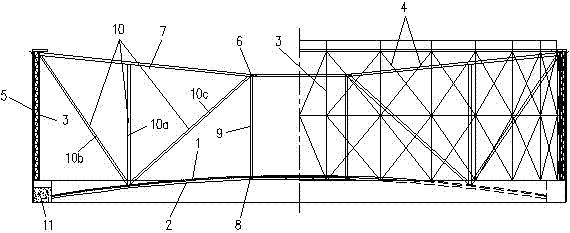

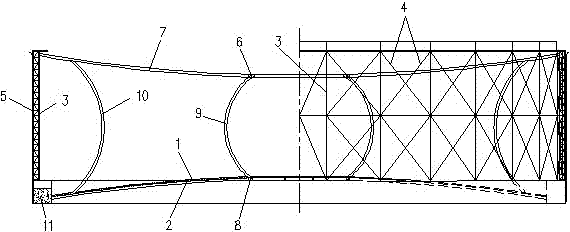

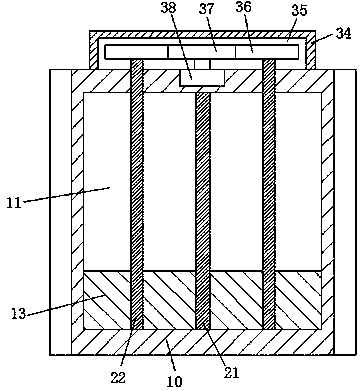

Gasholder pillow type piston

The invention discloses a gasholder pillow type piston, which comprises a spherical surface type piston plate, a lower support truss, upright posts, a support truss, a piston side wall plate, an upper support truss and a middle support truss, wherein the lower support truss is arranged on the piston plate and is matched with the shape of the piston plate, the upright posts are in parallel arrangement along the edges of the piston plate, the support truss is used for connecting the adjacent upright posts, the piston side wall plate is arranged on the upright posts, the upper support truss is arranged at the upper end of the upright posts, and the middle support truss is connected with the upper support truss and the lower support truss. The gasholder pillow type piston has the advantages that the lower support truss is arranged on the piston plate, the upper ends of the upright posts are also provided with the upper support truss, and the middle support truss is also arranged between the upper support truss and the lower support truss, so the rigidity and the intensity of the piston are greatly enhanced, the lateral stress capability of the piston is higher, the design dimensions of the diameter and the height of the piston can be increased, the volume of a gasholder can be improved, and the requirement of the modern production is met.

Owner:CISDI ENG CO LTD

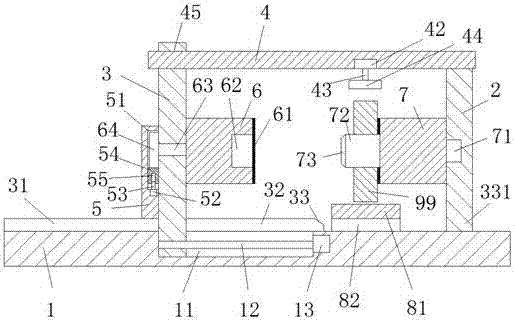

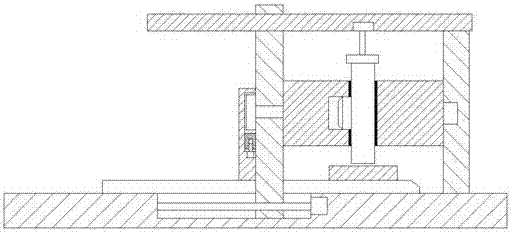

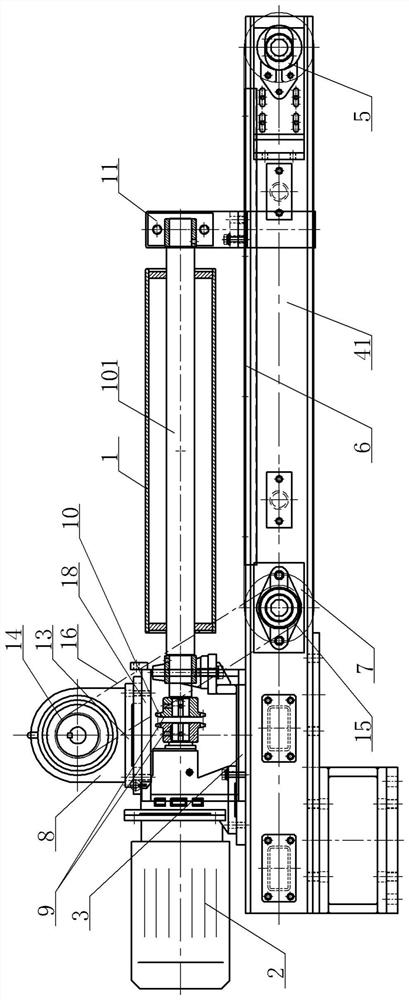

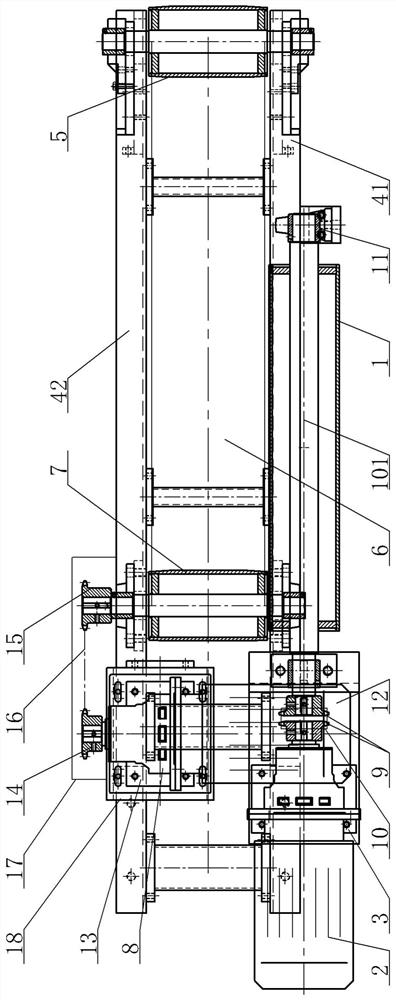

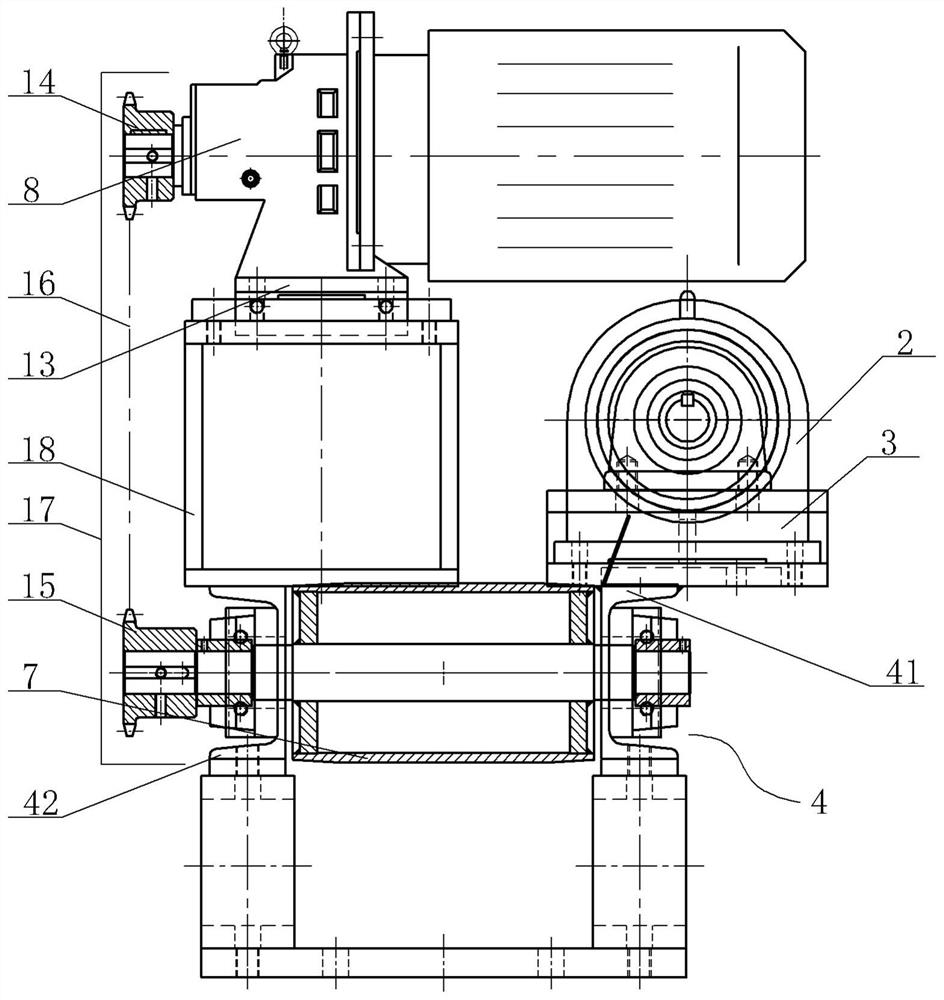

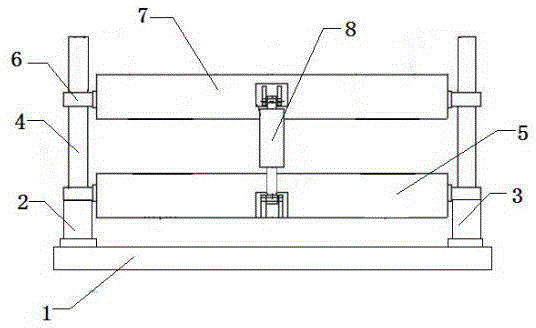

A ring grinding device

ActiveCN107263253BClamp firmlyStrong penetrating powerGrinding machinesGrinding work supportsEngineeringChassis

The invention discloses an annular workpiece polishing device which comprises an underframe and a fixing rack arranged on the underframe; a sliding groove is formed in a part, located on the left side of the fixing rack, of the underframe; a sliding rack capable of sliding horizontally is arranged in the sliding groove; an upper penetrable groove is formed in the top of the sliding rack; a transverse rack is slidingly arranged in the upper penetrable groove; the right end of the transverse rack is fixedly connected with the fixing rack; a right rotary table is rotationally arranged at the left end of the fixing rack; and the right end of the right rotary table is in power connection with a rotary driving motor arranged in the fixing rack. The annular workpiece polishing device is simple in structure, low in production cost and simple to operate, the polishing efficiency of an annular workpiece is improved substantially, the waste of manpower resources is reduced, the polishing effect is good, the polishing precision is high, and the requirements of modern production are met.

Owner:江苏宏威重工机床制造有限公司

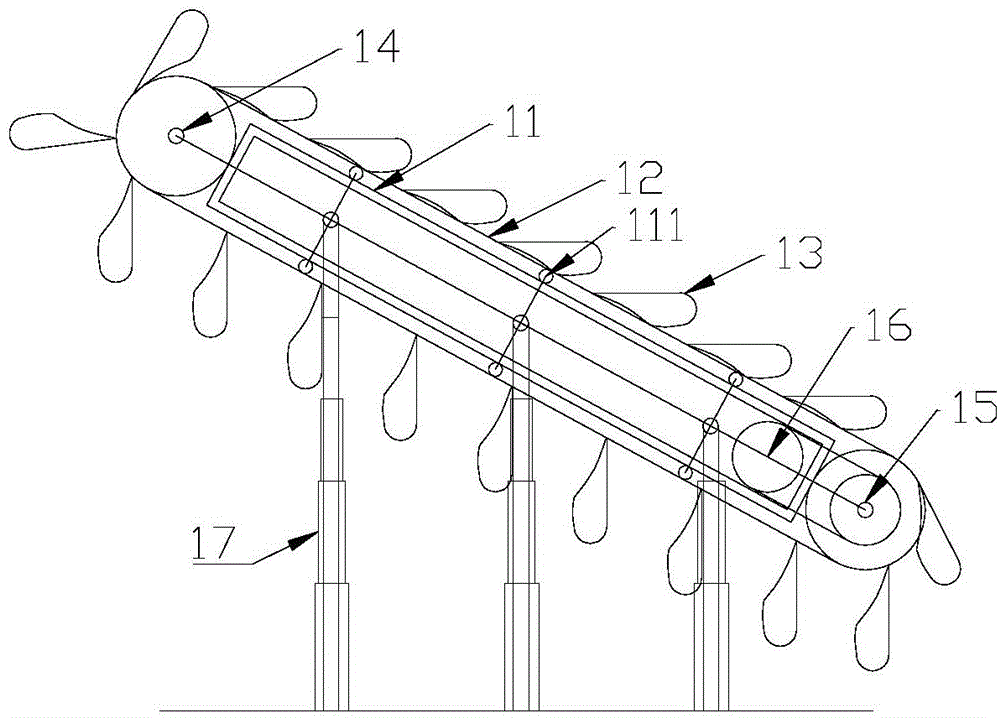

Novel multifunctional material separator

InactiveCN102652942ASave human resourcesMeet the needs of modern productionSortingPolyethylene terephthalate glycolDrive wheel

The invention relates to a novel multifunctional material separator. The novel multifunctional material separator comprises a feeding mechanism, a frame, an electric control mechanism, a data acquisition mechanism and a discharging mechanism, wherein the feeding mechanism is arranged on the frame; a belt motor is arranged on one side of the feeding mechanism; the feeding mechanism comprises a driving wheel, a conveyor belt and a driven wheel; the conveyor belt rotates around the driving wheel and the driven wheel; and the driving wheel is connected with the belt motor through a transmission mechanism. The novel multifunctional material separator is high in speed and efficiency, can meet requirements on modern production, can separate plastics made from different materials such as polyvinyl chloride (PVC), polypropylene (PP), polyethylene terephthalate (PET), polyamide (PA) and the like at the same time, and can further separate plastics with different colors.

Owner:南京易北环保科技有限公司

Labor-saving letter box device

ActiveCN107335577AClamp firmlyEasy to clamp and fixLiquid surface applicatorsKitchen equipmentFixed frameEngineering

Owner:广东高航知识产权运营有限公司

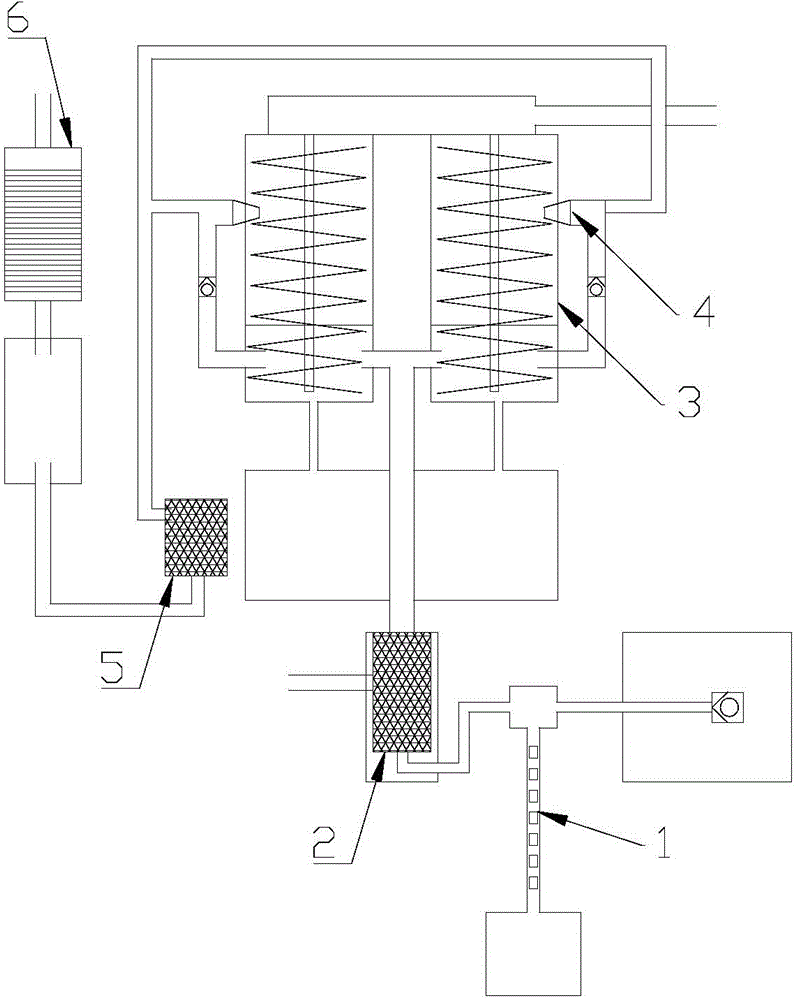

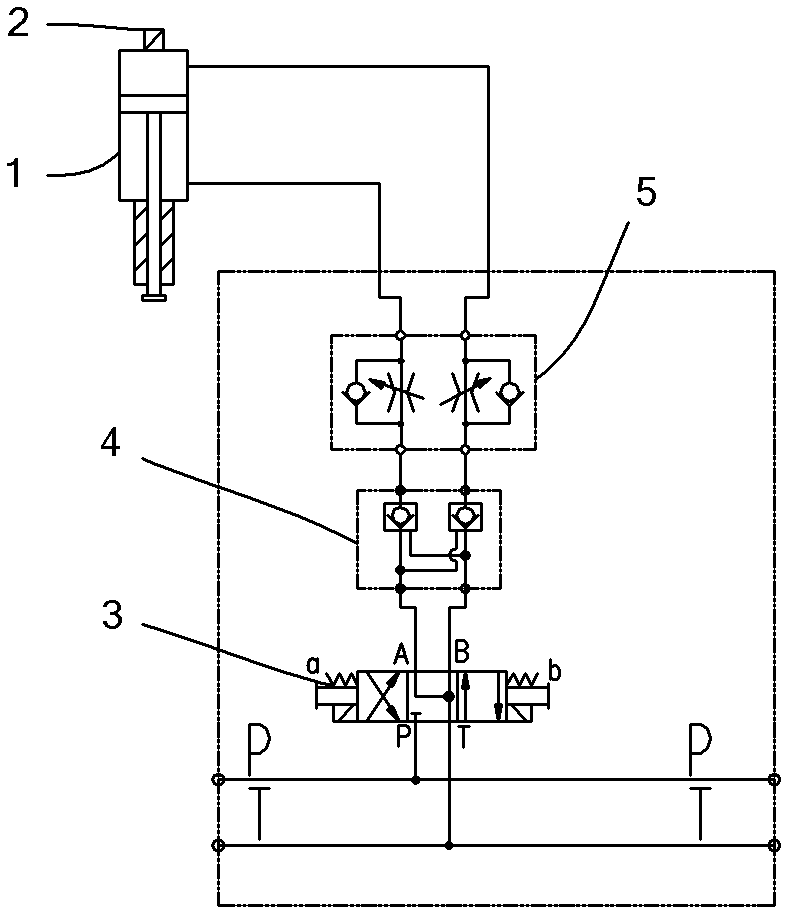

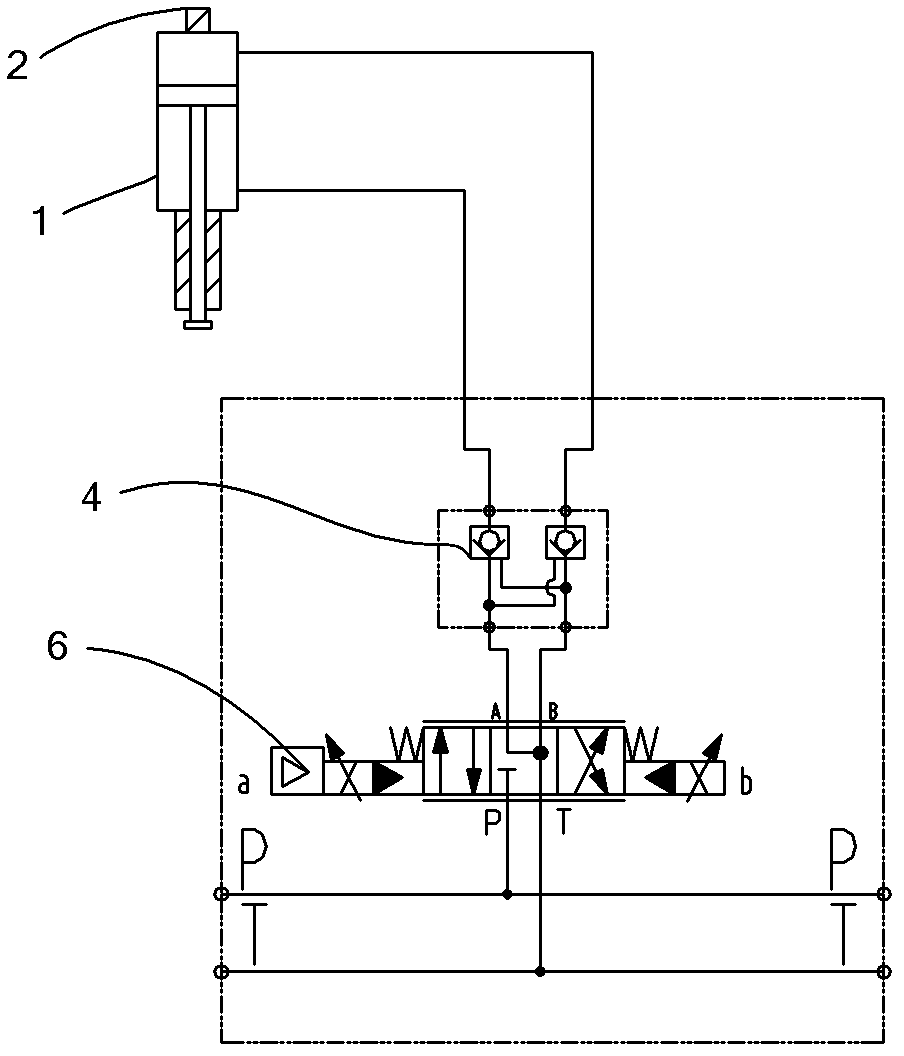

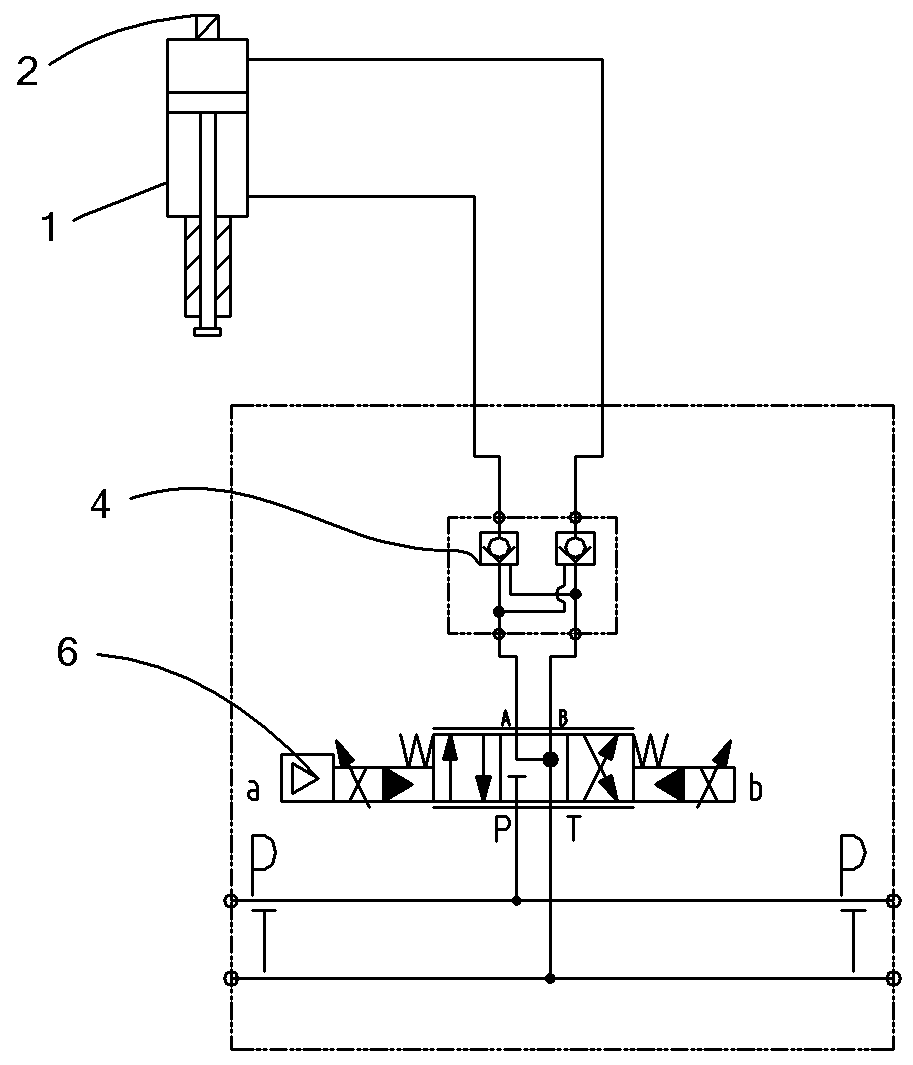

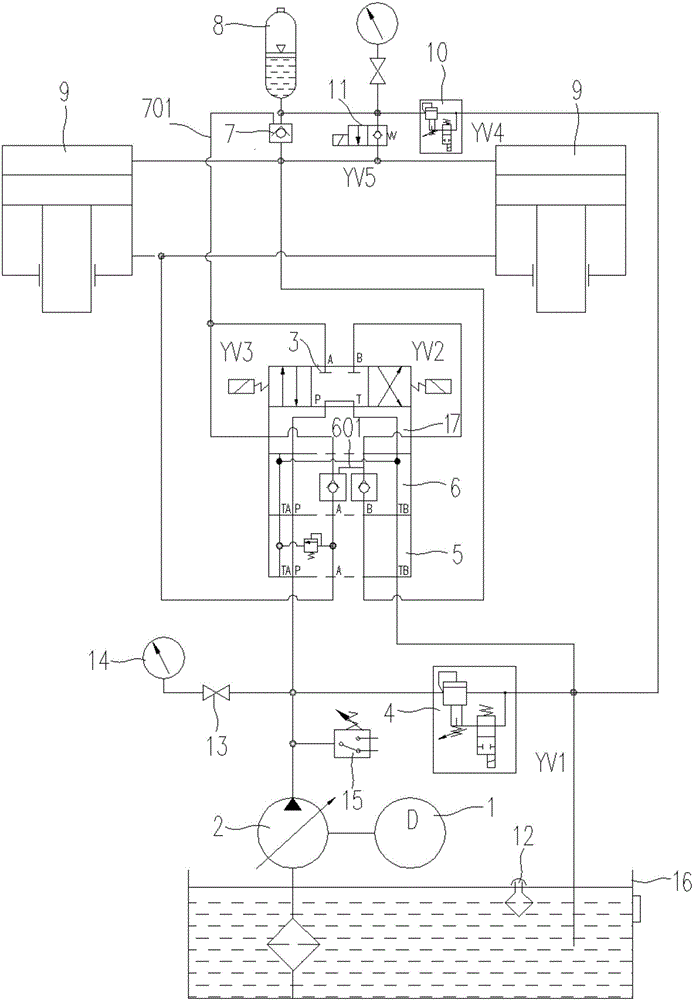

Hydraulic Control Device for Roll Balance Speed Adjustment in Continuous Pipe Mill

InactiveCN102284508AReduce climbingReduce insecurityRoll speed control deviceHydraulic cylinderRemote control

The invention discloses a hydraulic control device for adjusting the roll balance speed of a continuous pipe rolling mill, comprising: a reversing structure, the two ends of the reversing structure are respectively connected to a hydraulic oil circuit and a hydraulic cylinder, and the reversing structure can be remotely controlled; A throttling structure, the throttling structure is connected between the reversing structure and the hydraulic cylinder, and the throttling structure can be controlled remotely. The beneficial effect of the present invention is that, compared with the prior art, the present invention not only realizes all the functions of the prior art without adding hydraulic components, but also can remotely control the reversing structure and the throttling structure , so as to realize the reversing and speed adjustment through remote control, without on-site operation in the actual operation process, reducing the steps of climbing up and down, thereby reducing unsafe factors, reducing adjustment cycles, reducing labor, and greatly improving work efficiency. This makes the adjustment process safer, more humane, and more in line with the needs of fast-paced modern production.

Owner:TAIYUAN HEAVY IND

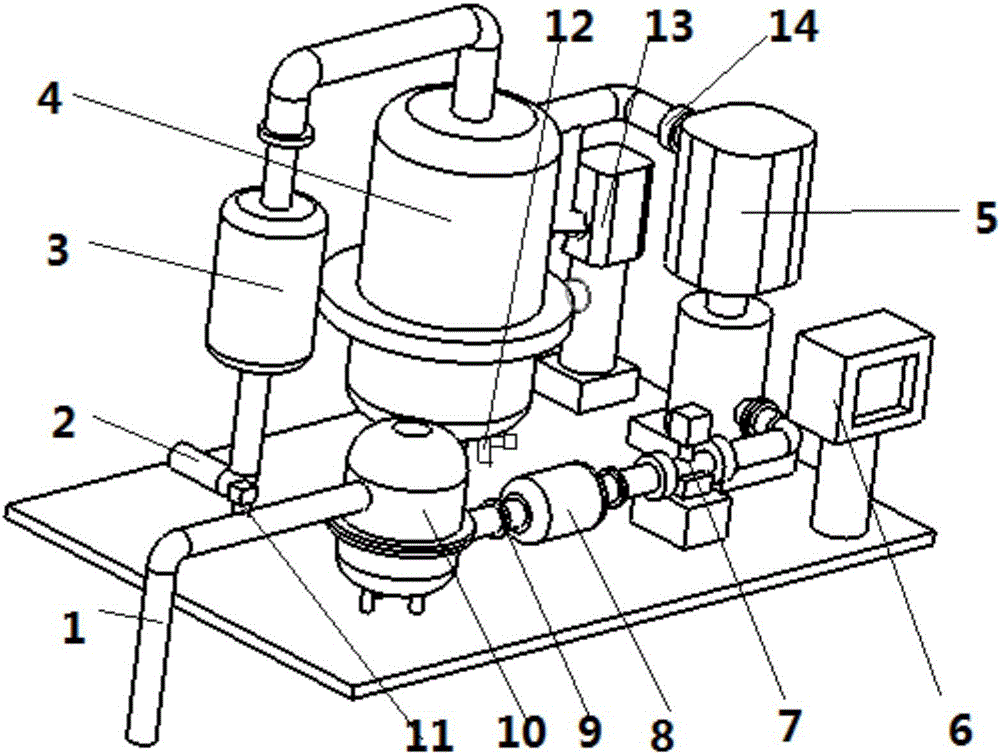

Wastewater treatment apparatus allowing recycling

InactiveCN106145495AEfficient separationSave energyFatty/oily/floating substances removal devicesWater contaminantsElectromagnetic valveWater pipe

The invention provides a recyclable waste water treatment equipment, comprising a base and a crude oil filter device, a fine oil filter device, a solenoid valve, a first water pump, an evaporator and a condenser placed on the base and connected sequentially through pipelines, The first water pump is controlled by the solenoid valve to suck out the waste water and pass through the coarse oil filter device and the fine oil filter device in turn, and the deoiled waste water enters the evaporator through the first water pump, and the evaporator passes through the second water pump and the outlet of the first water pump End connection, the coarse oil filter device includes the first filter device and the second filter device placed below it through flange connection, and a filter plate is arranged between the two, the water inlet pipeline is placed on the first filter device, and the outlet pipe The road is placed on the second filter device. The recyclable wastewater treatment equipment of the present invention enables industrial wastewater to be recycled, reduces the discharge of industrial wastewater, optimizes the surrounding environment and reduces the production and processing costs of enterprises.

Owner:TIANJIN XINYUE JINZHAO TECH DEV

Cutting and forming device

The invention discloses a cutting and forming device comprising a chassis and a frame plate arranged on the chassis. The front and rear end faces of the chassis are fixedly provided with fixed plates in which fixing holes are formed, and the chassis is also provided with a sliding chute at the left side of the frame plate; the sliding chute is internally provided with a sliding carrier capable of sliding right and left, and the top of the sliding carrier is provided with an upper groove in which a top disc is slidably arranged; and the right end of the top disc is fixedly connected to the frame plate. The cutting and forming device has the advantages of simple structure, low production cost and easy operation, and the cutting efficiency of plates is improved greatly; the waste of human resources is reduced, and the cutting efficiency is good; and the cutting accuracy is high, and the requirements of the modern manufacturing are met.

Owner:JIANGSU DNCON LASER TECH

Grinding machine

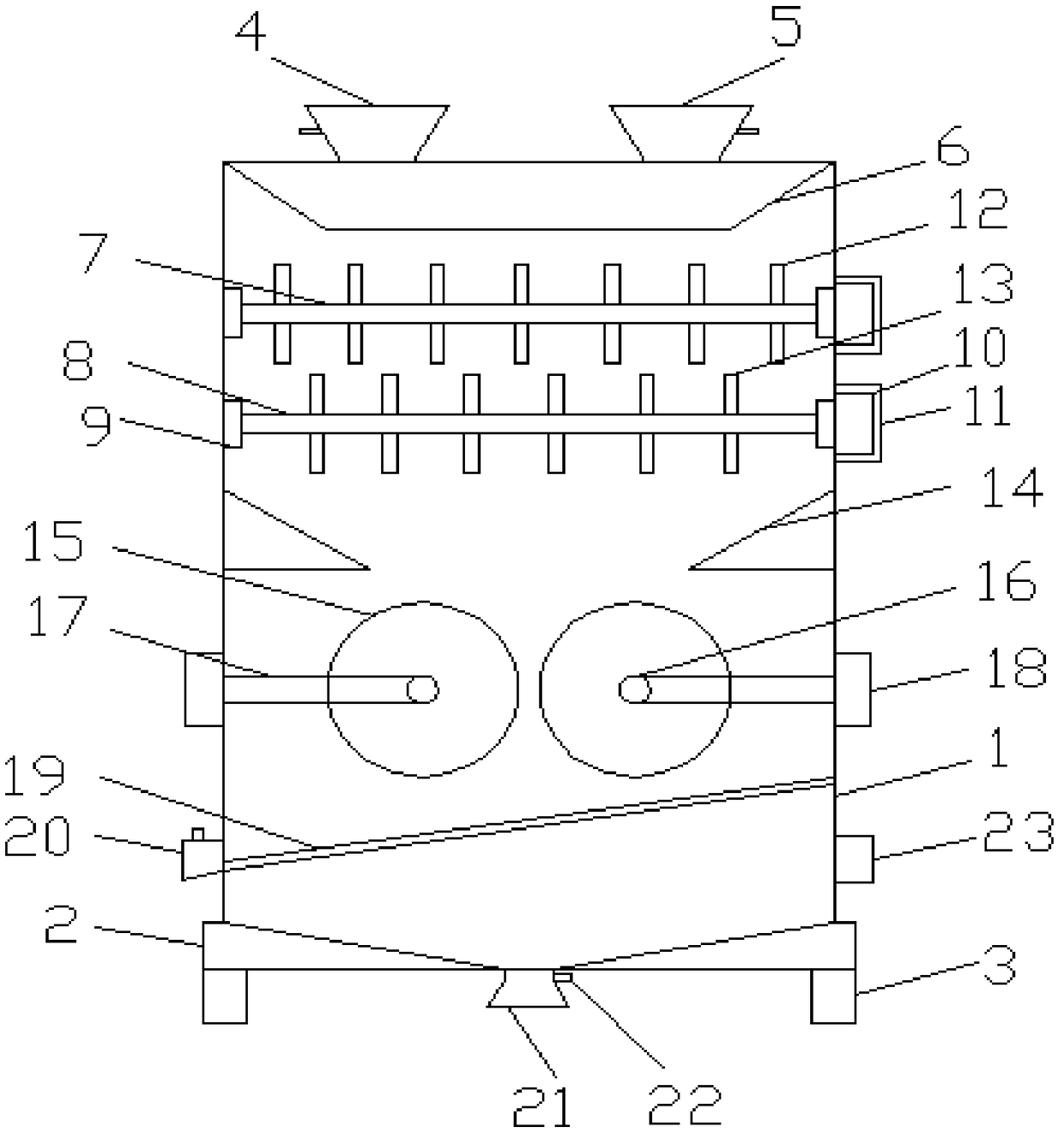

InactiveCN109365087AIncrease profitImprove feeding efficiencyGrain treatmentsEngineeringMechanical engineering

The invention discloses a grinding machine including a grinding machine body. The bottom of the grinding machine body is provided with a support frame, two sides of the top of the grinding machine body are symmetrically provided with a first feeding mouth and a second feeding mouth, the inner top of the grinding body is provided with a first discharging plate, a first rotary shaft is arranged under the first discharging plate, the first rotary shaft is provided with a plurality of sets of the first crushing knives, a second rotary shaft is arranged under the first rotary shaft, the second rotary shaft is provided with a plurality of sets of the second crushing knives, the second rotary shaft and two sides of the first rotary shaft are connected with the grinding machine body through a first bearing seat. The grinding machine has the beneficial effects of reasonable design and convenient usage. Compared with the traditional grinding machine, the grinding machine adds a crushing device,so that the grinding effects and grinding efficiency can be effectively improved and the grinding can better meet the needs of the modern production.

Owner:刘理想

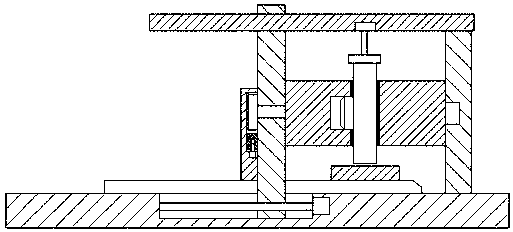

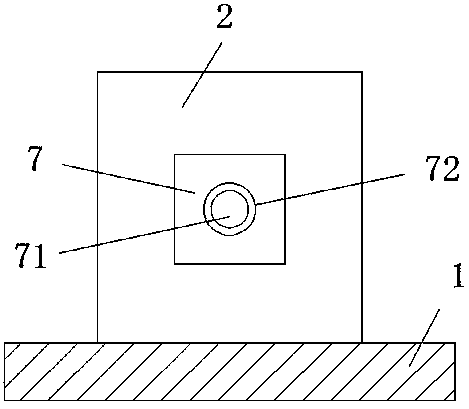

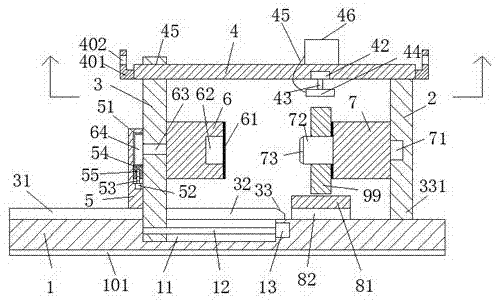

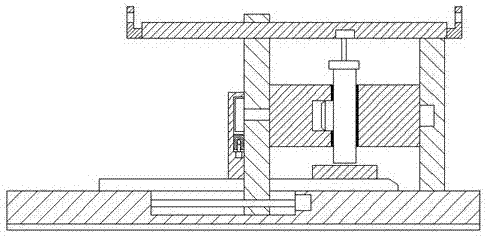

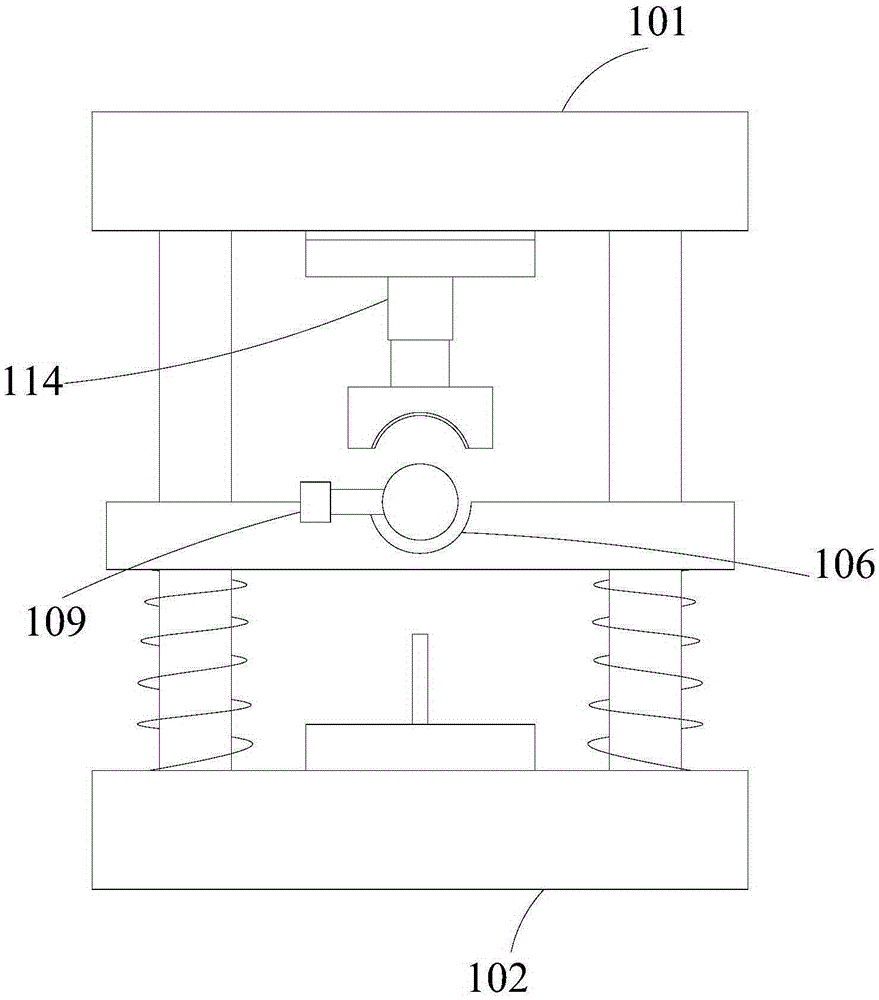

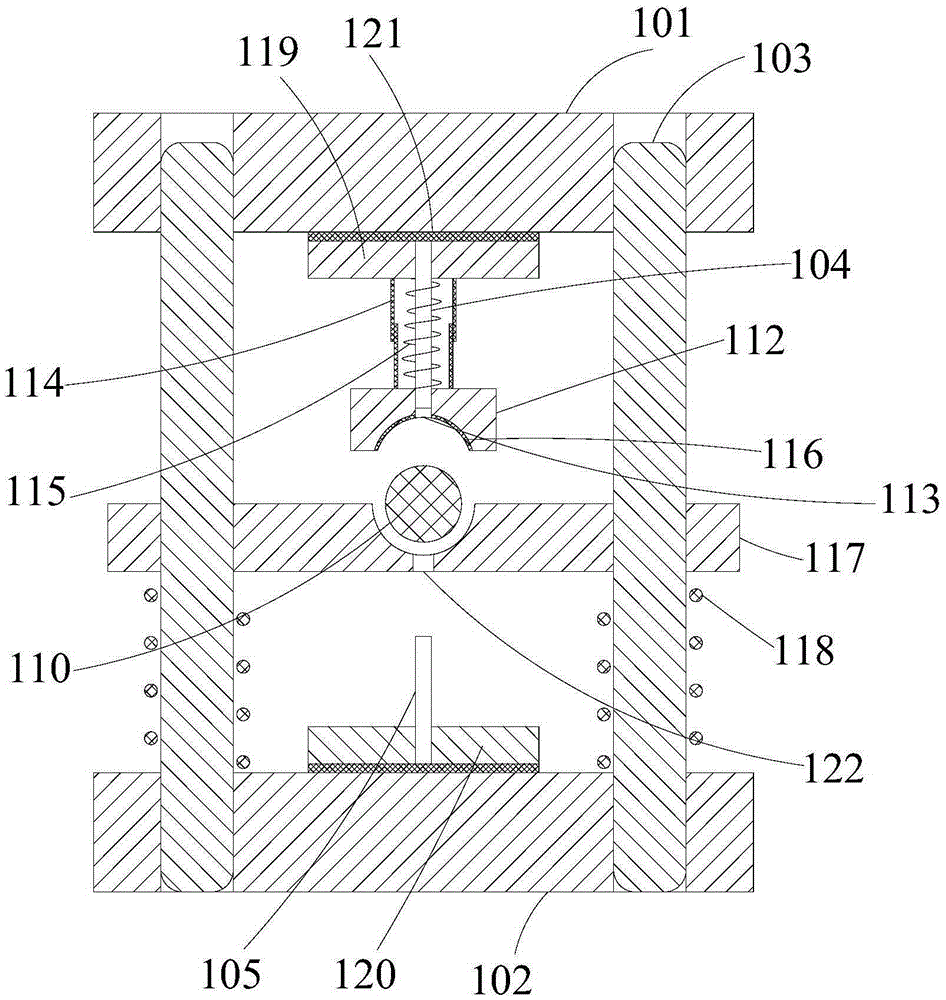

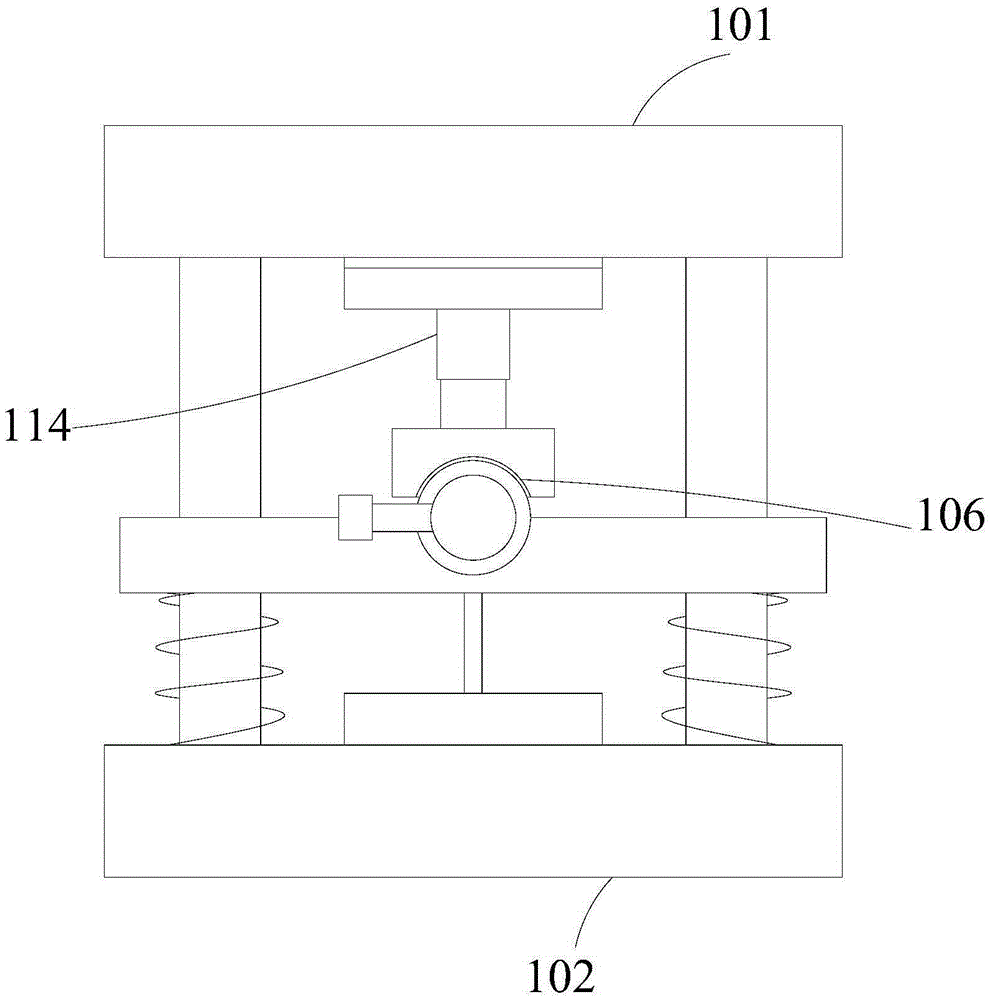

Piercing die for piercing in sidewall of round tube

The invention provides a piercing die for piercing in a sidewall of a round tube and belongs to the field of dies. The piercing die comprises an upper die holder and a lower die holder; the upper die holder is connected with the lower die holder through a guide column; the bottom of the upper die holder is connected with an upper terrace die; a round tube holding portion is longitudinally arranged on the lower die holder; the lower die holder is further connected with a positioning mechanism; the positioning mechanism comprises a driving assembly, a transmission assembly and a positioning assembly, all of which are orderly connected with each other; the positioning assembly comprises a columnar positioning rod that can be driven by the driving assembly to move in a longitudinal direction; when the round tube is placed on the round tube holding portion, the positioning rod can be inserted into the round tube while moving. Such a piercing die is capable of quickly and accurately piercing the sidewall of the round tube; a machined workpiece has the characteristics of high quality and high accuracy and is capable of meeting the requirements of modern production.

Owner:TAIZHOU RUNJIE LOGISTICS SAFETY EQUIP TECH CO LTD

Bending method of efficient bending machine

ActiveCN105909575ADownlink high speedHigh speed downlinkServomotor componentsServomotorsHydraulic cylinderFuel tank

The invention discloses a bending method of an efficient bending machine, and belongs to the technical field of the bending machine. An oil inlet of an oil pump is connected with an oil tank; an oil outlet of the oil pump is connected with a port P of a three-position four-way electromagnetic directional valve through a pipeline; a port T of the three-position four-way electromagnetic directional valve is connected with the oil tank through a pipeline; a port A of the three-position four-way electromagnetic directional valve is connected to an upper cavity of a hydraulic cylinder through a superposing valve set; a port B of the three-position four-way electromagnetic directional valve is connected to the upper cavity of the hydraulic cylinder through a superposing valve set; the upper cavity of the hydraulic cylinder is further connected with an energy accumulator through a hydraulic-control one-way valve. By improving a hydraulic system of the bending machine, the whole plate bending process of quickly descending, feeding, maintaining pressure and decompressing is efficiently controlled, high speed and stability of the quick descending stage as well as stability of the feeding stage are guaranteed; and meanwhile, the pressure maintaining effect is good, and the oil pressure of the upper cavity of the oil cylinder at the pressure maintaining stage is stable, so that the bending quality of plates is guaranteed.

Owner:ANHUI DONGHAI MACHINE MFG CO LTD

Grinding machine for metal plate

ActiveCN108515398AAutomatic control of grinding operationsEasy to removeGrinding drivesGrinding work supportsEngineeringUltimate tensile strength

The invention discloses a grinding machine for a metal plate. The grinding machine for the metal plate comprises a machine body. A work groove is formed in the machine body and extends back and forth.The end face of the machine body is provided with communicating grooves which are in left-right symmetry, and the communicating grooves extend front and back and communicate with the left end and theright end of the work groove. A metal plate fixing platform is arranged in the middle of the end face of the machine body and extends front and back. The front end and the back end of the metal platefixing platform are symmetrically provided with metal plate clamps used for fixing the metal plate. The grinding machine for the metal plate is simple in structure, low in manufacturing cost and maintenance cost, capable of automatically controlling upward, downward, frontward, backward, leftward and rightward displacement and work of a power polishing head, and therefore complete polishing workis conducted on the metal plate; and in this way, the polishing efficiency of the metal plate is improved, the labor intensity of workers is lowered, the work efficiency is improved, operation is easyand convenient, automatic production is achieved, and the whole grinding machine for the metal plate is compact in structure and reliable in operation and meets demands of modern production.

Owner:平湖市创微机械科技股份有限公司

Overturning and conveying device of open mill

PendingCN112047002AEasy to transportImprove work efficiencyConveyorsConveyor partsElectric machineryStructural engineering

The invention provides an overturning and conveying device of an open mill. By means of the overturning and conveying device, after being output by an overturning roller, materials directly fall intoa conveying channel capable of achieving transferring, it is ensured that the materials are transferred quickly and conveniently, the working efficiency is improved, and the modern production requirements are met. The input end of a conveying roller is connected with the output end of a first conveying motor, a first machine base of the first conveying motor is supported on a support on one side of a conveying roller way, the conveying roller way comprises supports on the two sides, and conveyor rollers are arranged at the two ends of the supports on the two sides in the length direction correspondingly. Rolling wheels of the conveyor rollers are arranged between the width areas of the supports on the two sides, a conveying belt is connected with the rolling wheels of the two conveyor rollers in a closed and wound manner, the conveying roller is arranged above the output face of the conveying belt, and the conveying roller enables materials to fall to the output face of the conveying belt. A power transmission roller is further connected to the conveying belt in the length direction in an engaged manner and connected with a second conveying motor.

Owner:ZHANGJIAGANG LANHANG MACHINERY

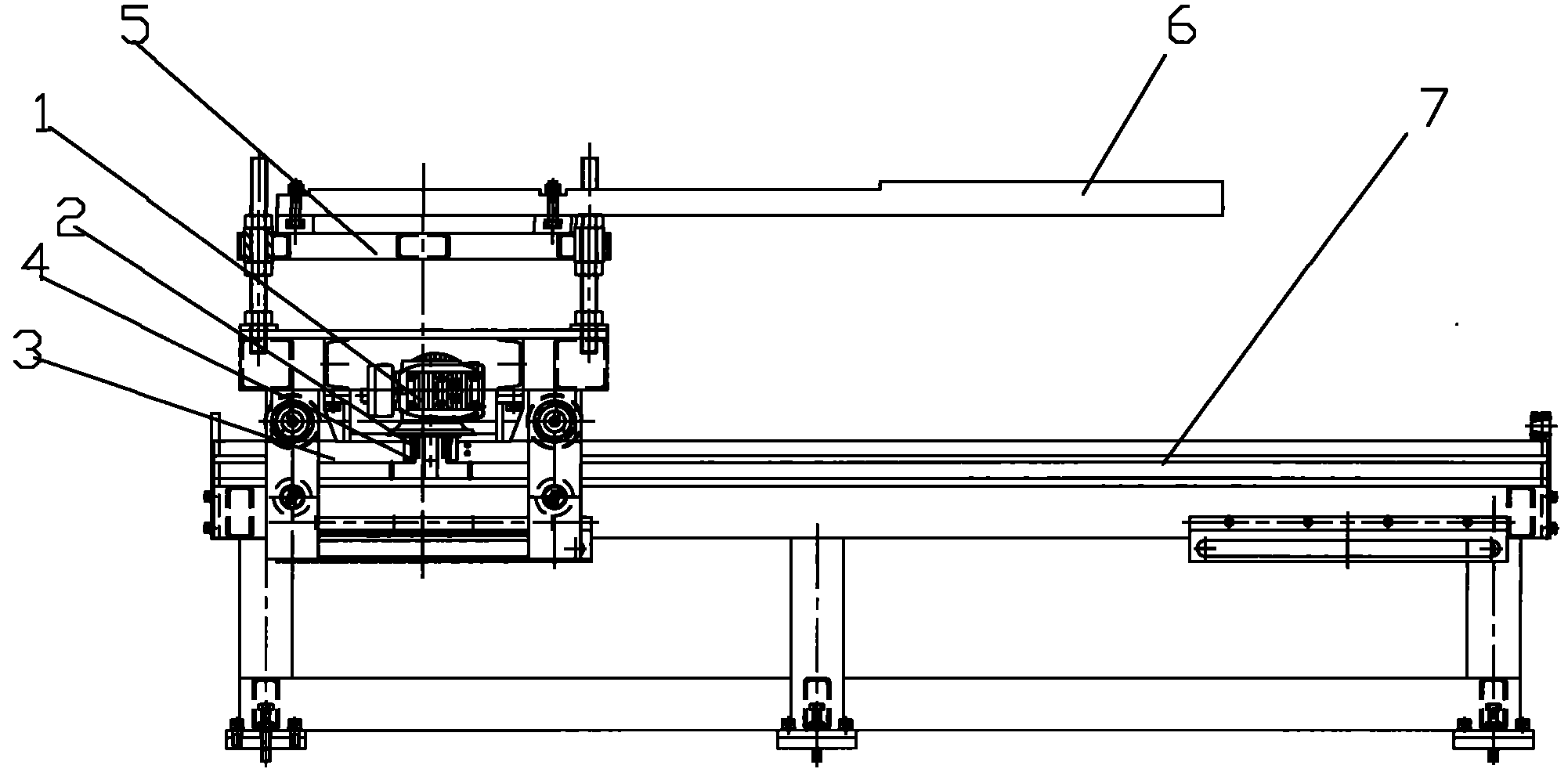

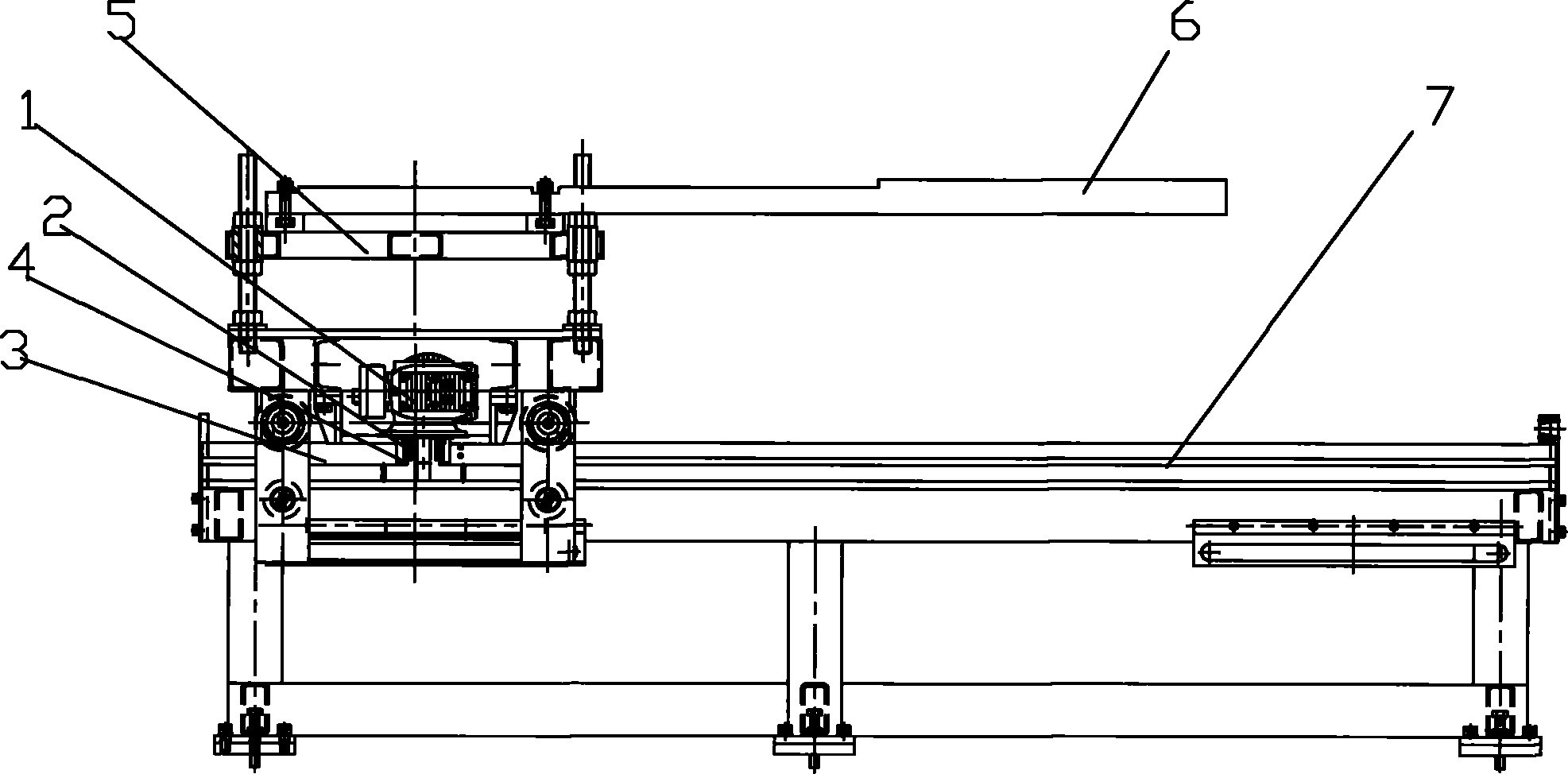

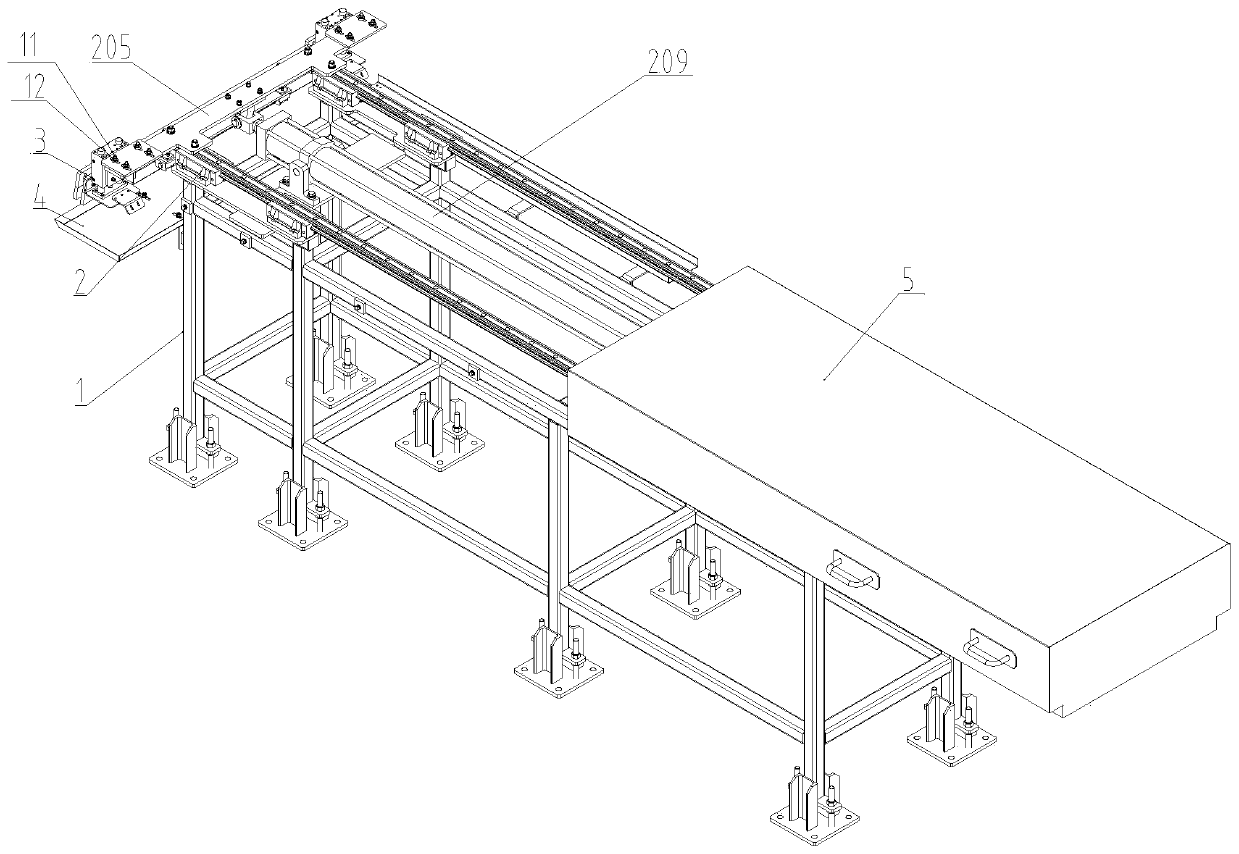

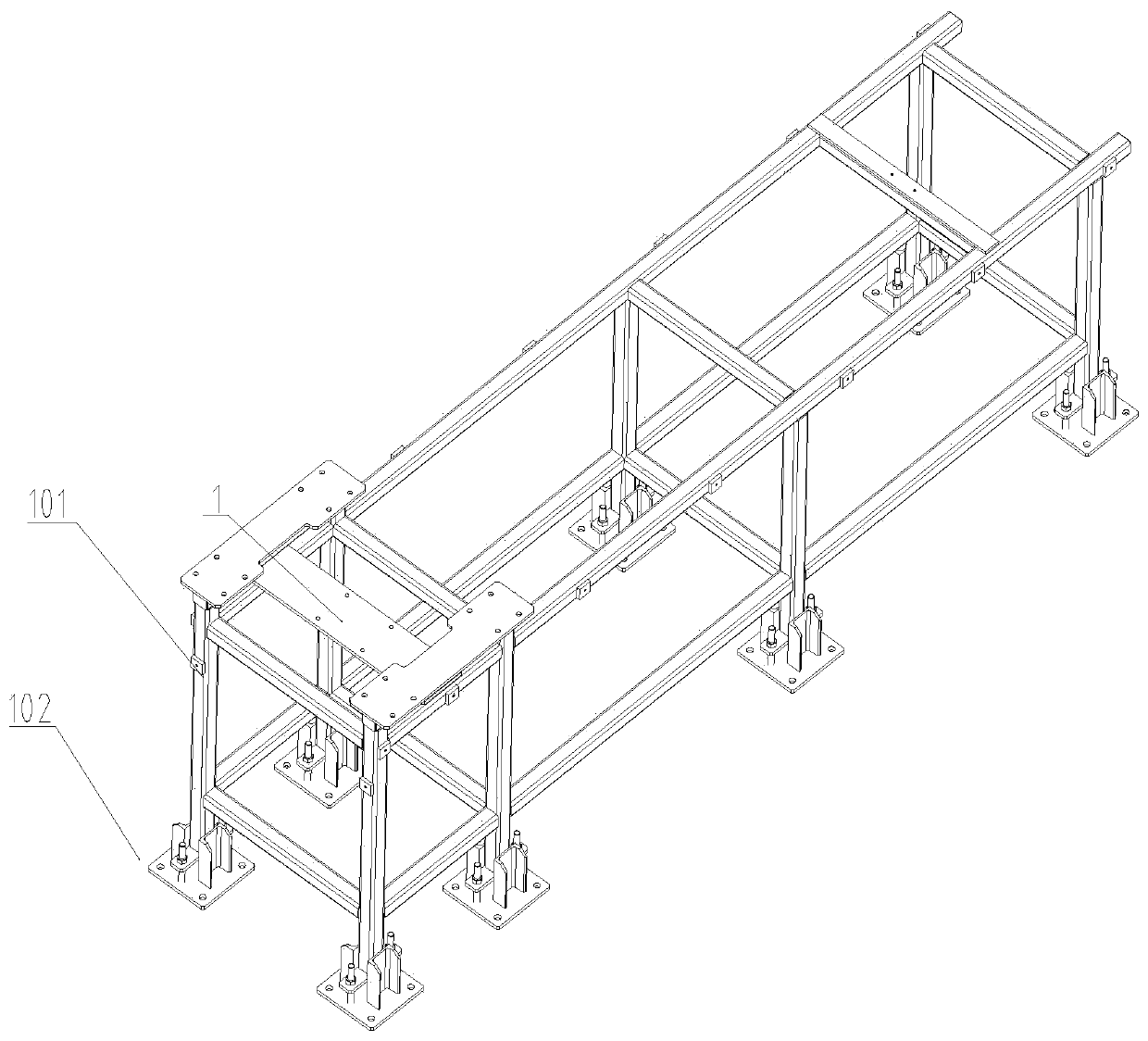

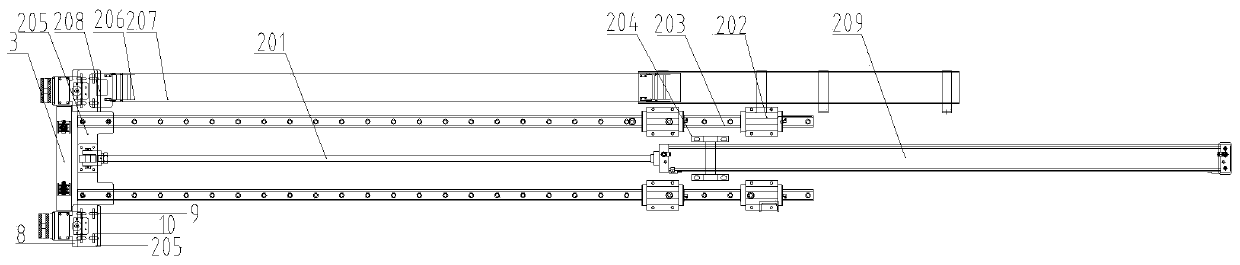

Automatic cleaning device for sliding plate combined assembly trolley track

PendingCN109835683ASmooth rideHigh degree of automationCleaningMechanical conveyorsMaterial removalSlide plate

The invention discloses an automatic cleaning device for a sliding plate combined assembly trolley track. The automatic cleaning device for the sliding plate combined assembly trolley track comprisesa device bracket, wherein the device bracket is provided with a linear telescopic driving device and a cleaning head assembly, the cleaning head assembly is driven by the linear telescopic driving device and can extend out of the front end of the device bracket to clean the sliding plate combined assembly trolley track, a material tray is fixed to the front end of the device bracket, the materialtray is used for carrying the cleaned debris on the sliding plate combined assembly trolley track, and the material tray is located below the cleaning head assembly. Dust, soft objects and metal objects on the track are cleaned by the cleaning head assembly which can move back and forth, so that a combined assembly trolley runs smoothly, the combined assembly qualification rate is greatly improved, the production efficiency is improved, manual material removal is avoided, and costs are reduced while the cleaning efficiency is improved. The automatic cleaning device has a high degree of automation, modern production requirements of a factory are met, and good practicability and market application value are achieved.

Owner:DONGFENG DESIGN INST

Dedicated guide device for manufacturing concrete block

InactiveCN106738294ACompact structureThe principle is simpleAuxillary shaping apparatusEngineeringCylinder block

The invention discloses a dedicated guide device for manufacturing a concrete block. The dedicated guide device is characterized by comprising a base, a left driving cylinder, a right driving cylinder, lead screws, a lower base clamping rack, nuts, an upper base clamping rack and a jacking oil cylinder, wherein the left driving cylinder and the right driving cylinder are arranged on the left and right sides of the base; the lead screws are fixedly connected with lifting pistons of the left driving cylinder and the right driving cylinder; two ends of the lower base clamping rack are fixedly connected onto cylinder blocks of the left driving cylinder and the right driving cylinder; left and right ends of the upper base clamping rack are arranged on the lead screws on left and right sides in a sleeving manner through mounting the nuts matched with threads of the lead screws; the nuts are movably connected onto the upper base clamping rack; the jacking oil cylinder as an auxiliary lifting device is fixedly mounted between the upper base clamping rack and the lower base clamping rack; and the left driving cylinder and the right driving cylinder are synchronous driving devices and can be hydraulic driving cylinders or pneumatic driving cylinders. The dedicated guide device is compact in structure and simple in principle, realizes free up-down motion, avoids breakage, reduces the rejection rate of a product, is high in degree of mechanization and meets modernized production demands.

Owner:谢晶晶

Sand cylinder running device of core shooter

The invention provides a sand cylinder running device of a core shooter. Due to the adoption of the sand cylinder running device, a sand cylinder is accurate in running limitation, free from adjustment, stable to run, stable and reliable, and high in safety, and the production efficiency is improved. The sand cylinder running device comprises a transverse beam, wherein a guide rail is arranged at the lower end of the transverse beam; the sand cylinder is hung on the guide rail through idler wheels; the sand cylinder running device is characterized in that one side of the transverse beam is connected with a rear bracket, the lower end of the rear bracket is connected with an air cylinder through an air cylinder bracket, a piston rod of the air cylinder is connected with the sand cylinder, and a limitation block is arranged on the guide rail.

Owner:WUXI KANGHUI MACHINE BUILDING

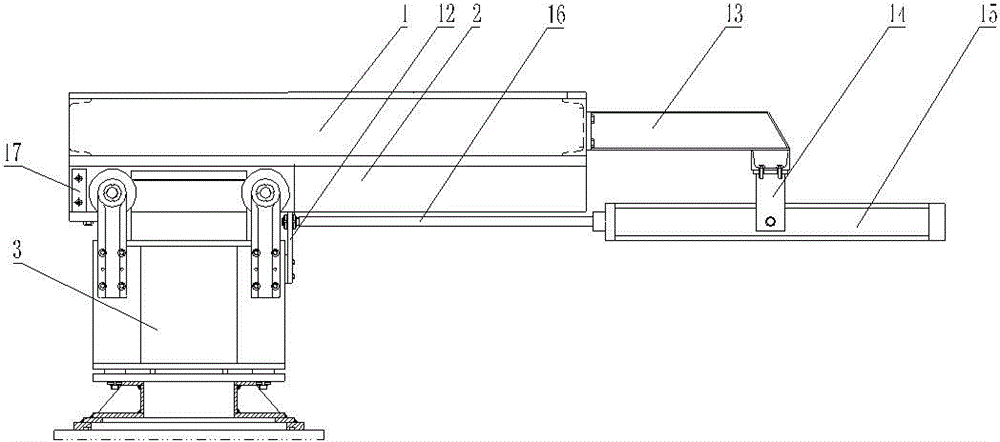

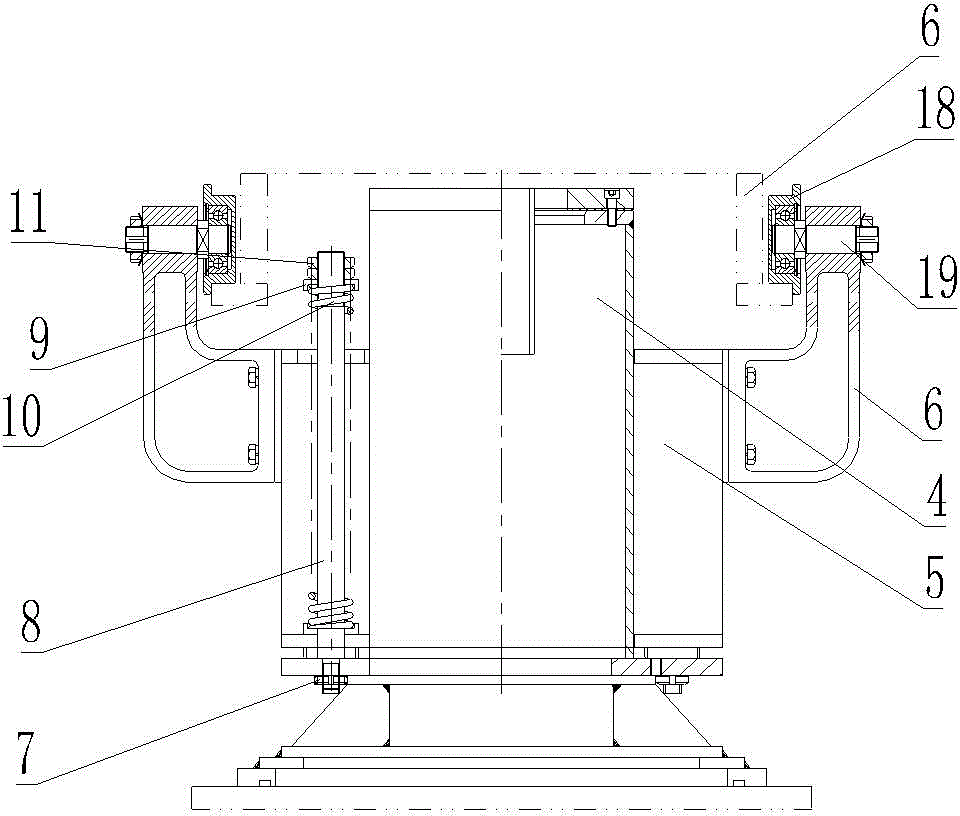

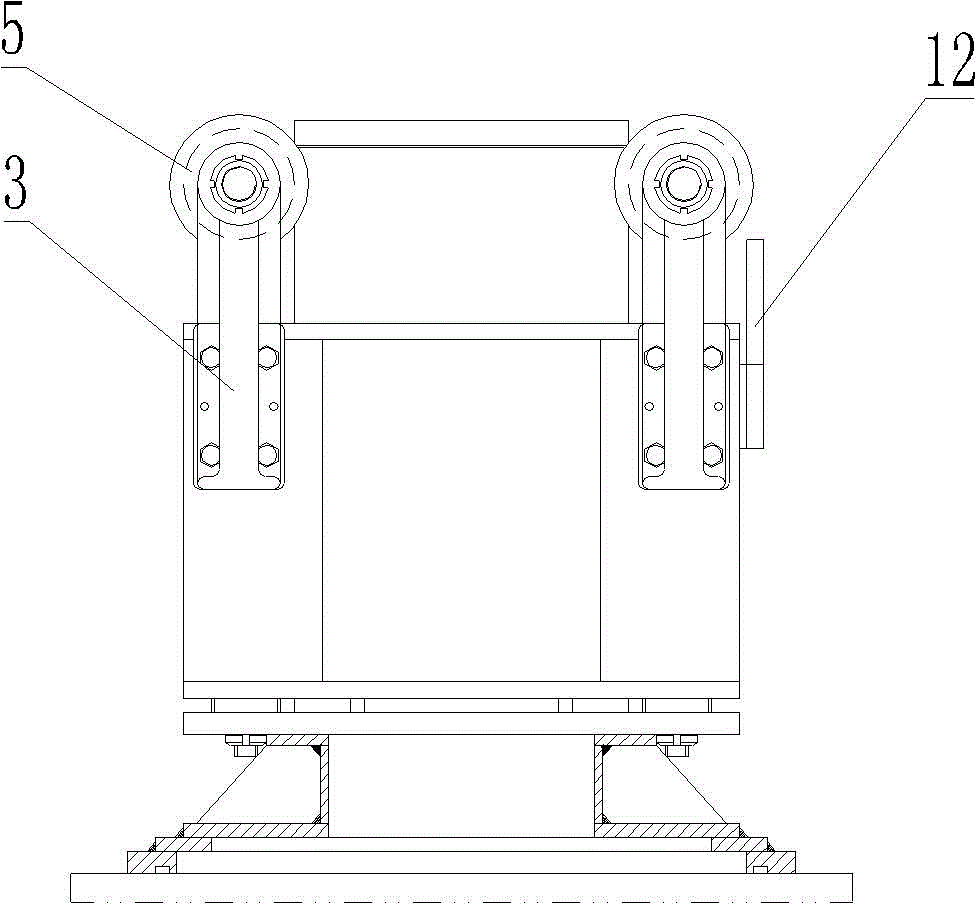

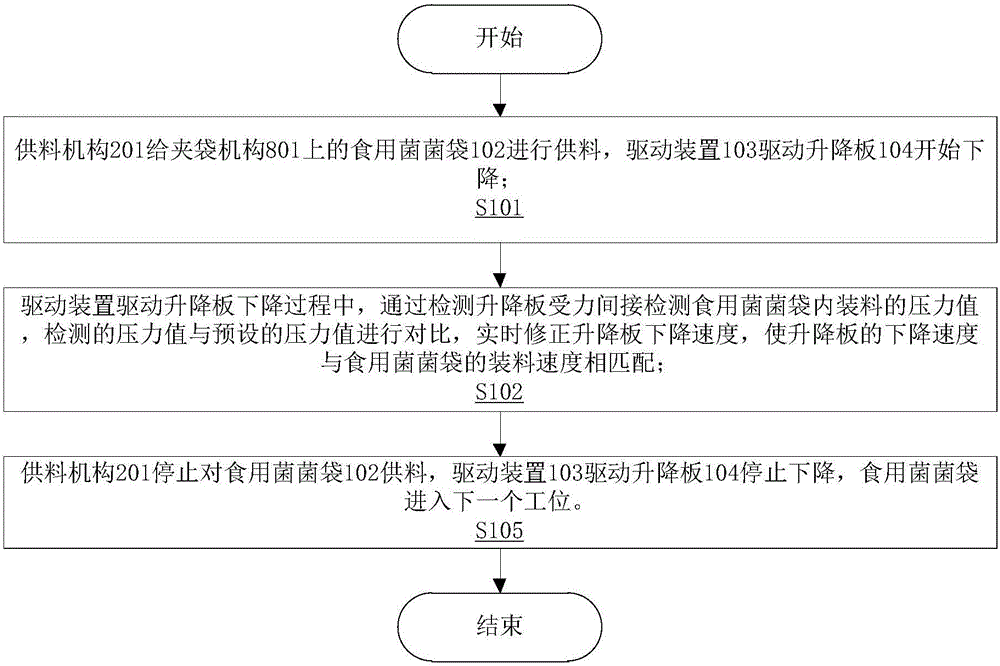

Edible fungus stick bagging mechanism control method and device

ActiveCN106171522AEvenly distributedGuaranteed tightnessPackaging automatic controlHorticultureMaterial supplyIndustrial engineering

The invention relates to an edible fungus stick bagging mechanism control method. The method includes the steps that a material supply mechanism supplies material to an edible fungus bag on a bag clamping mechanism, and meanwhile a driving device drives a lifting plate to descend; in the process that the driving device drives the lifting plate to descend, the pressure value of material contained in the edible fungus bag is indirectly detected by detecting the stress of the lifting plate, the detected pressure value is compared with a preset pressure value, and the descending speed of the lifting plate is corrected in real time, so the descending speed of the lifting plate is matched with the material containing speed of the edible fungus bag; the material supply mechanism stops supplying materials to the edible fungus bag, the driving device drives the lifting plate to stop descending, and the edible fungus bag enters a next station. The control method guarantees compactness of fungi in the discharging process, the situation that the edible fungus bag is empty or bursts is prevented, the method is more suitable for bagging of edible fungus sticks, and an edible fungus stick bagging mechanism high in productivity and good in benefit can be obtained.

Owner:FUJIAN HAIYUAN THREE DIMENSIONAL PRINTING HIGH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com