Multistage whirling vibration screening method

A vibratory screening and secondary screening technology, which is applied to chemical instruments and methods, screening, solid separation, etc., can solve the problems of low production efficiency, wear and crushing length, and small screening effective area, and achieve small footprint, Filter full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment this patent is further explained and illustrated. But the scope of protection of this patent is not limited to the specific implementation.

[0018] Multistage rotary vibration screening method of the present invention, its process is:

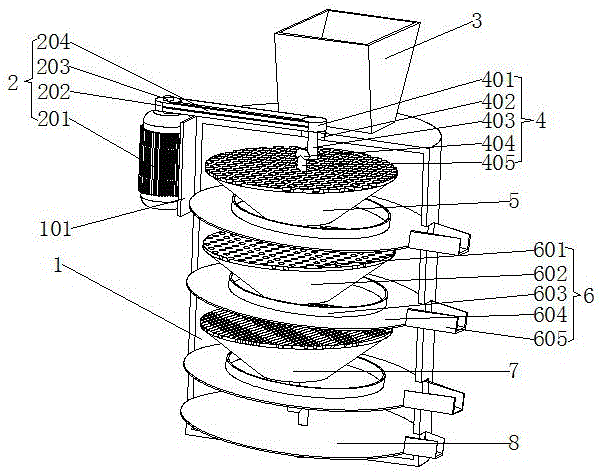

[0019] 1. Set the power mechanism 2 and the rotation mechanism 4 on the multi-stage rotary vibration screening device, connect the power mechanism 2 to the motor support 101 through bolts, weld the motor support 101 to the left side of the box body 1, and connect the power The mechanism 2 is connected to the rotating mechanism 4 through a V-belt;

[0020] 2. The rotating mechanism 4 is connected to the upper supporting plate of the box body 1 through the rolling bearing 402, and the feeding port 3 is set on the upper supporting plate; the secondary screening mechanism 6 is installed on the eccentric shaft 405 of the rotating mechanism 4 through a sleeve, A first-level scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com