A road guardrail and its construction method

A technology for highway guardrails and vertical directions, applied in roads, roads, road safety devices, etc., can solve problems affecting the stability and safety of roadbeds, complicated construction, and inconvenient construction, and achieve improved impact resistance, convenient construction, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

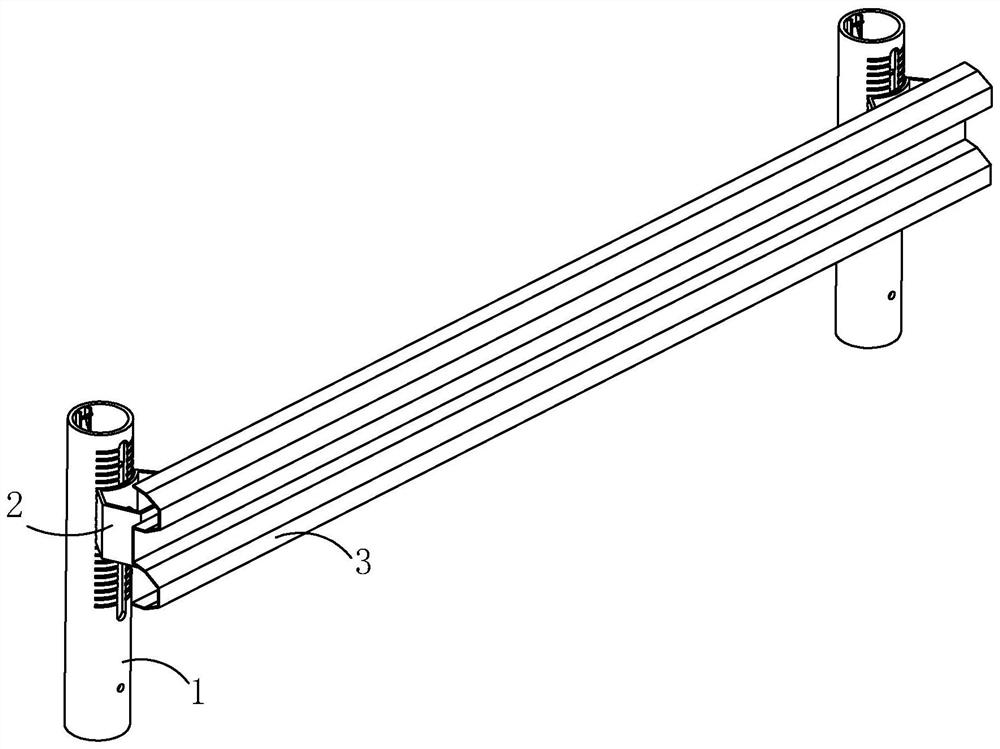

[0044] Such as figure 1 As shown, a road guardrail includes a column 1, an anti-blocking block 2 and a corrugated beam plate 3, the anti-blocking block 2 is arranged on the column 1, and the column 1 is a hollow structure with an upper end opening; the corrugated beam plate 3 is arranged on the anti-blocking block 2 on.

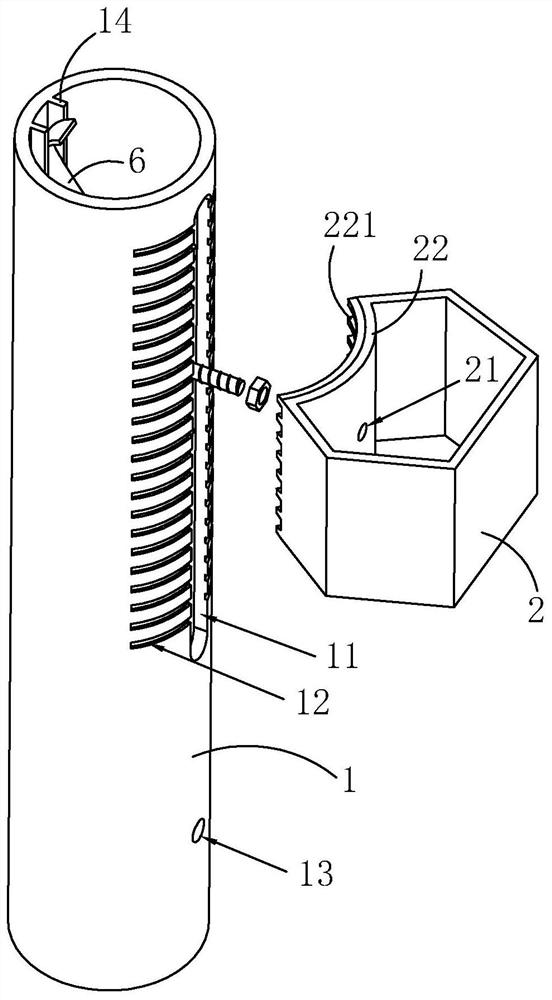

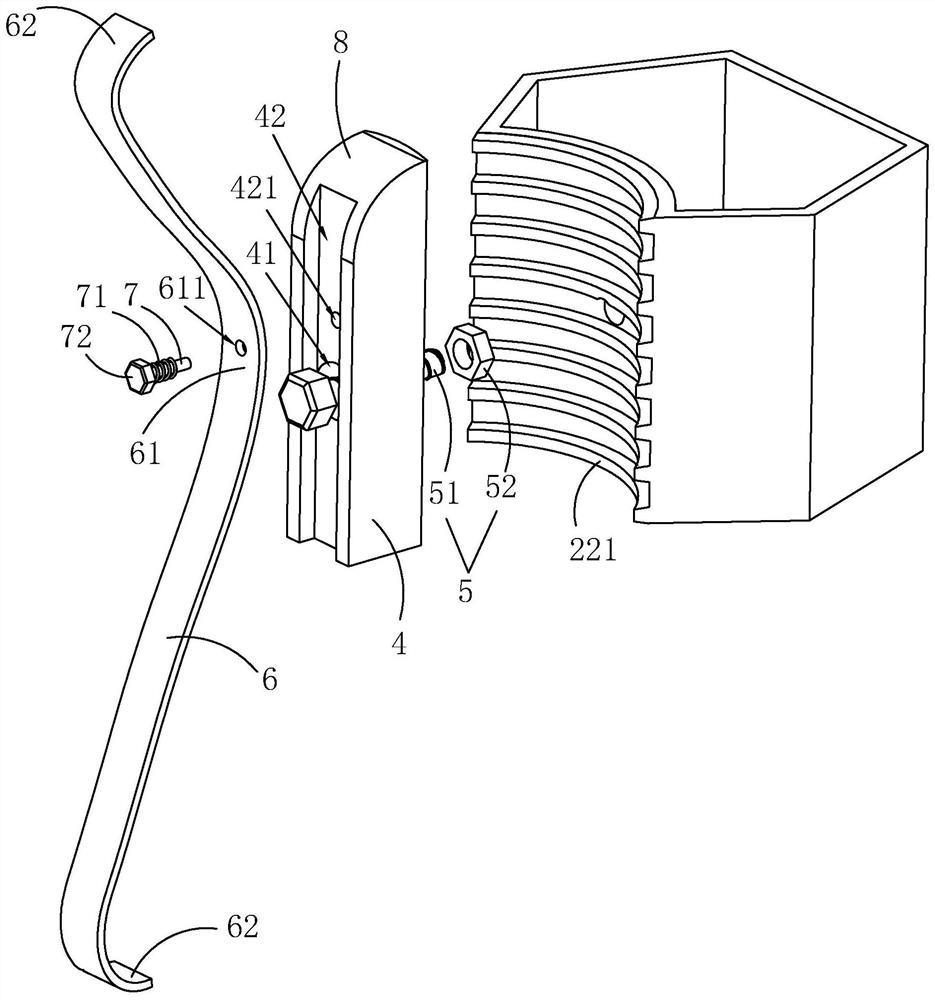

[0045] Such as figure 2 , 3As shown, the column 1 is provided with a mounting hole 11 along the vertical direction, and an adjusting block 4 is slidingly arranged in the column 1 along the length direction of the mounting hole 11; The positioning assembly 5 includes a positioning bolt 51 and a positioning nut 52 . An adjustment hole 41 penetrating through the adjustment block 4 is opened on the adjustment block 4 , and a positioning bolt 51 is passed through the adjustment hole 41 . The side wall of the anti-blocking block 2 is provided with a positioning hole 21 for the positioning bolt 51 to pass through, and the positioning bolt 51 passes through the ...

Embodiment 2

[0059] A construction method for a road guardrail, comprising the following steps:

[0060] S1. Stakeout, under the responsibility of the engineer, according to the requirements of the design drawings, carry out stakeout according to the construction layout drawing;

[0061] S2. Piling of column 1 and excavation of foundation pit. After the sample is placed, piling of column 1 and excavation of foundation pit of column 1 are carried out according to the sample line;

[0062] S3, bury pile, bury column 1;

[0063] S4. Install the guardrail. The guardrail components should be erected according to the design drawing, and a smooth and continuous installation effect should be achieved. All lap joints should be spliced in the direction of the vehicle;

[0064] S5. Guardrail adjustment, under the supervision of the engineer, adjust the overall line shape of the guardrail. The top surface of the wave beam should be in harmony with the line shape of the road. After the adjustment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com