Saw blade grinding machine of metal circular saw blade

A circular saw blade and grinding machine technology, applied in the field of grinding processing machinery, can solve the problems of limited range of applicable products, accurate adjustment and control, and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

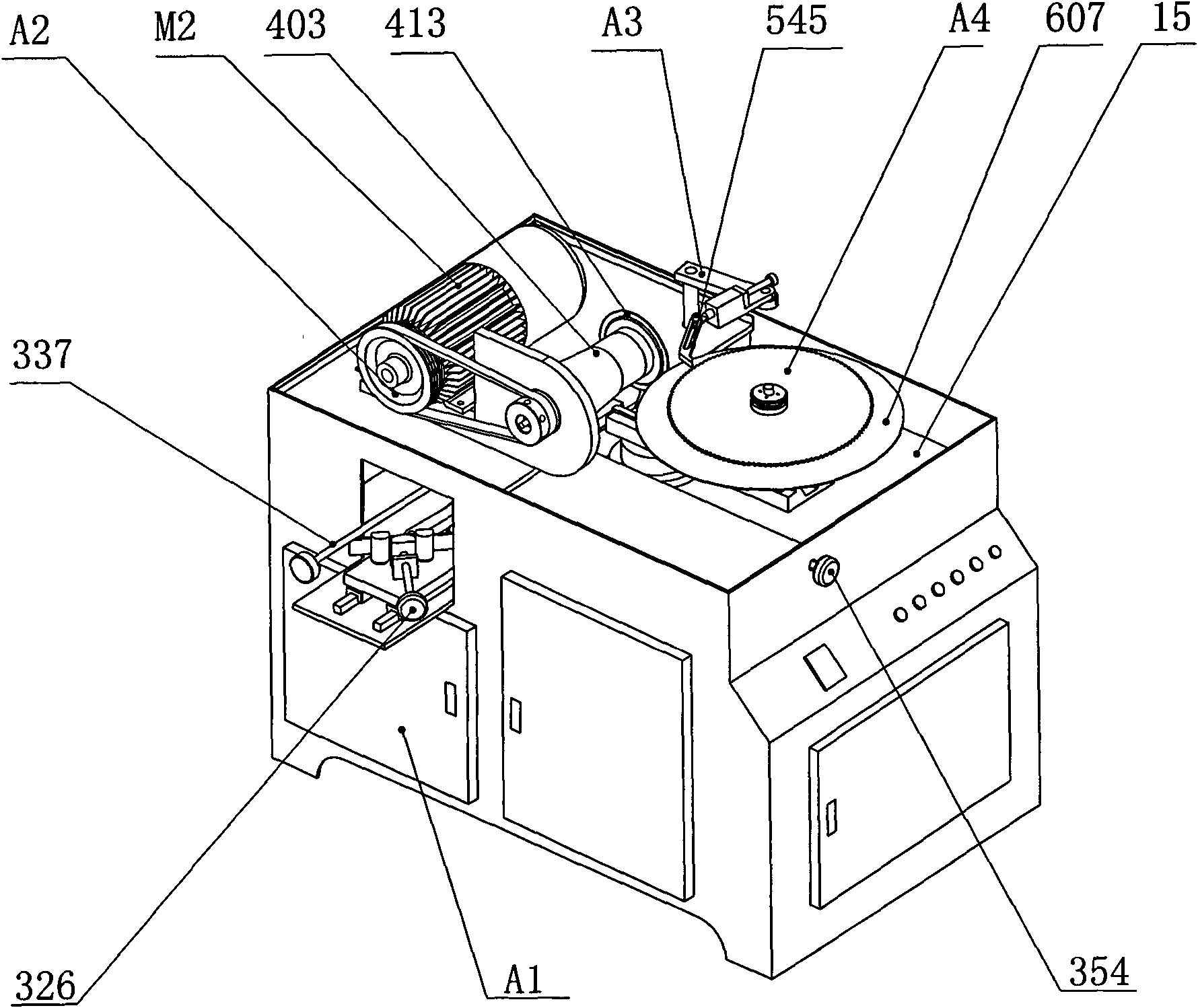

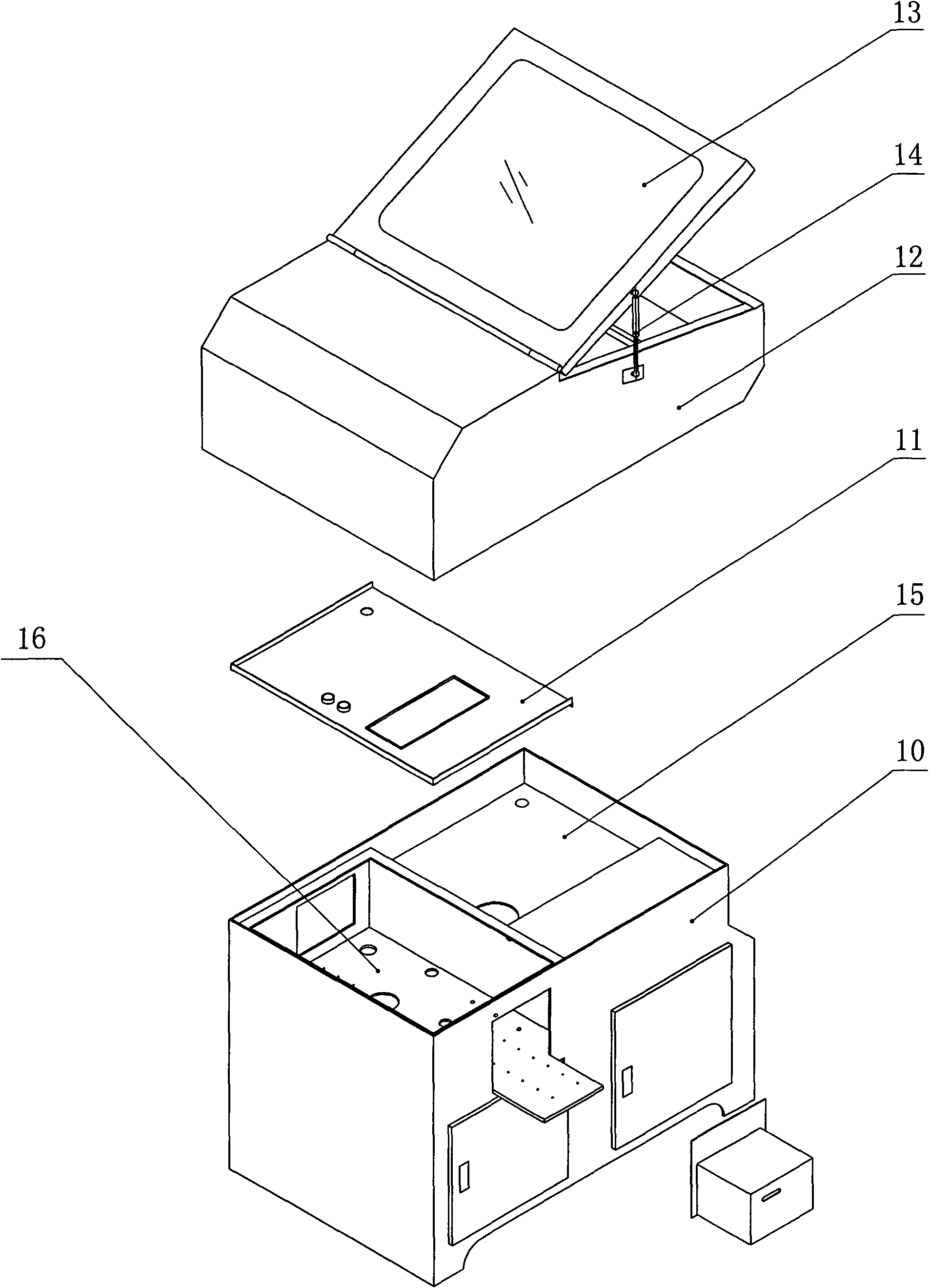

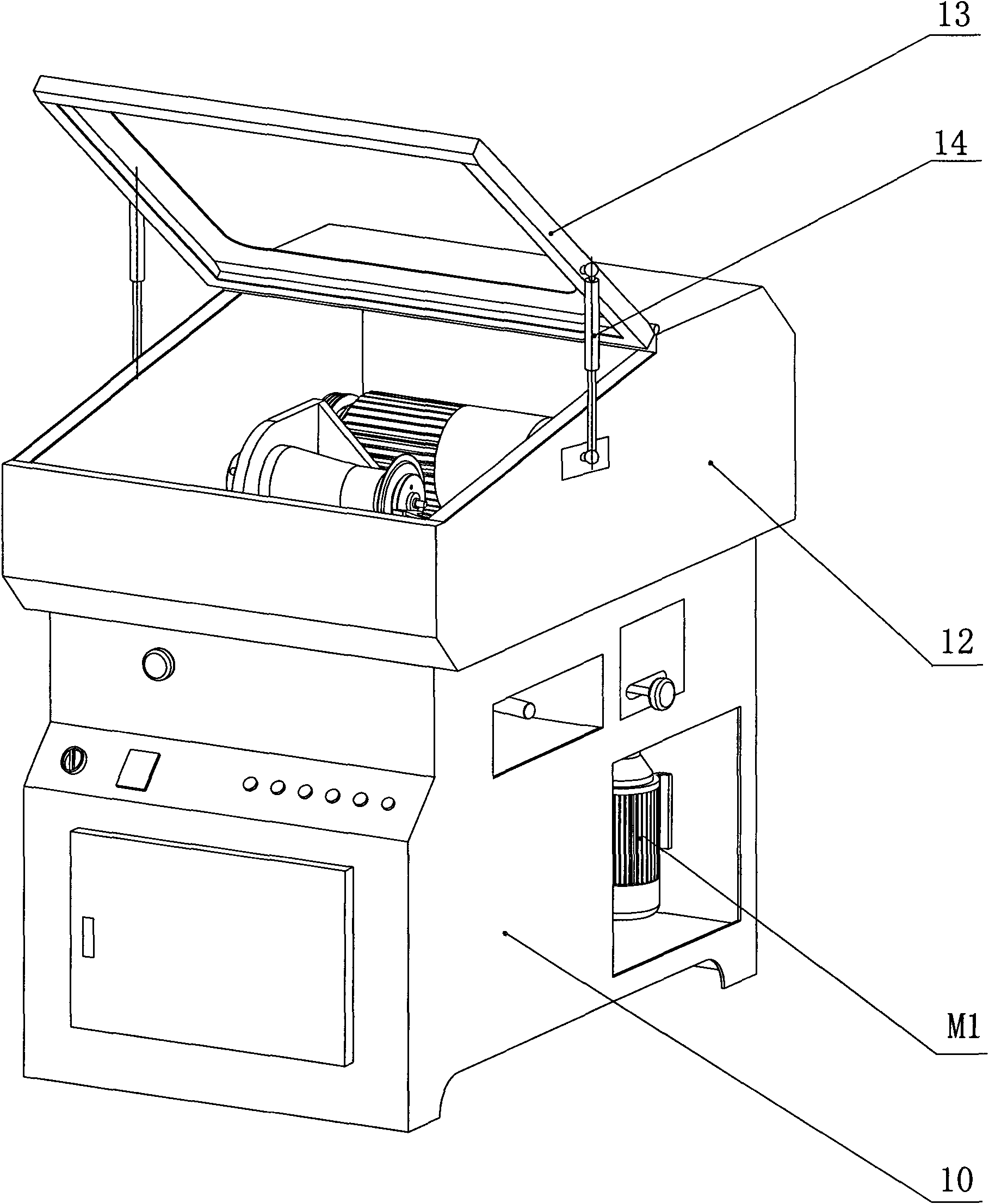

[0080] Such as figure 1 As shown, a saw blade grinder for a metal circular saw blade includes a frame A1, a tooth grinding cutter driving device A2, a saw blade stepping driving device A3 and a saw blade positioning device A4 arranged on the frame; The saw blade stepping driving device A3 is provided with a push claw 545, the tooth-grinding cutter driving device A2 includes a cutter driving motor M2, and the cutter driving motor M2 is driven and arranged on the cutter fixing frame 403 The cutting knife rotating shaft 409 and the cutting knife 413, the cutting knife 413 grinds the metal circular saw blade 607 on the saw blade positioning device A4; The power drive system drives the tooth-grinding cutter driving device A2 and the saw blade stepping driving device A3. The control system of the whole machine and each driving power system are also all accommodated in the frame A1, and of course the relevant control buttons can be arranged on the outer surface of the frame A1 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com