Full-automatic spacer imbedding machine for bottle caps

A fully automatic, bottle cap technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the production efficiency needs to be improved, cannot meet the modern production, and the degree of automation is low, so as to improve the production efficiency and degree of automation of enterprises. The effect of high and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

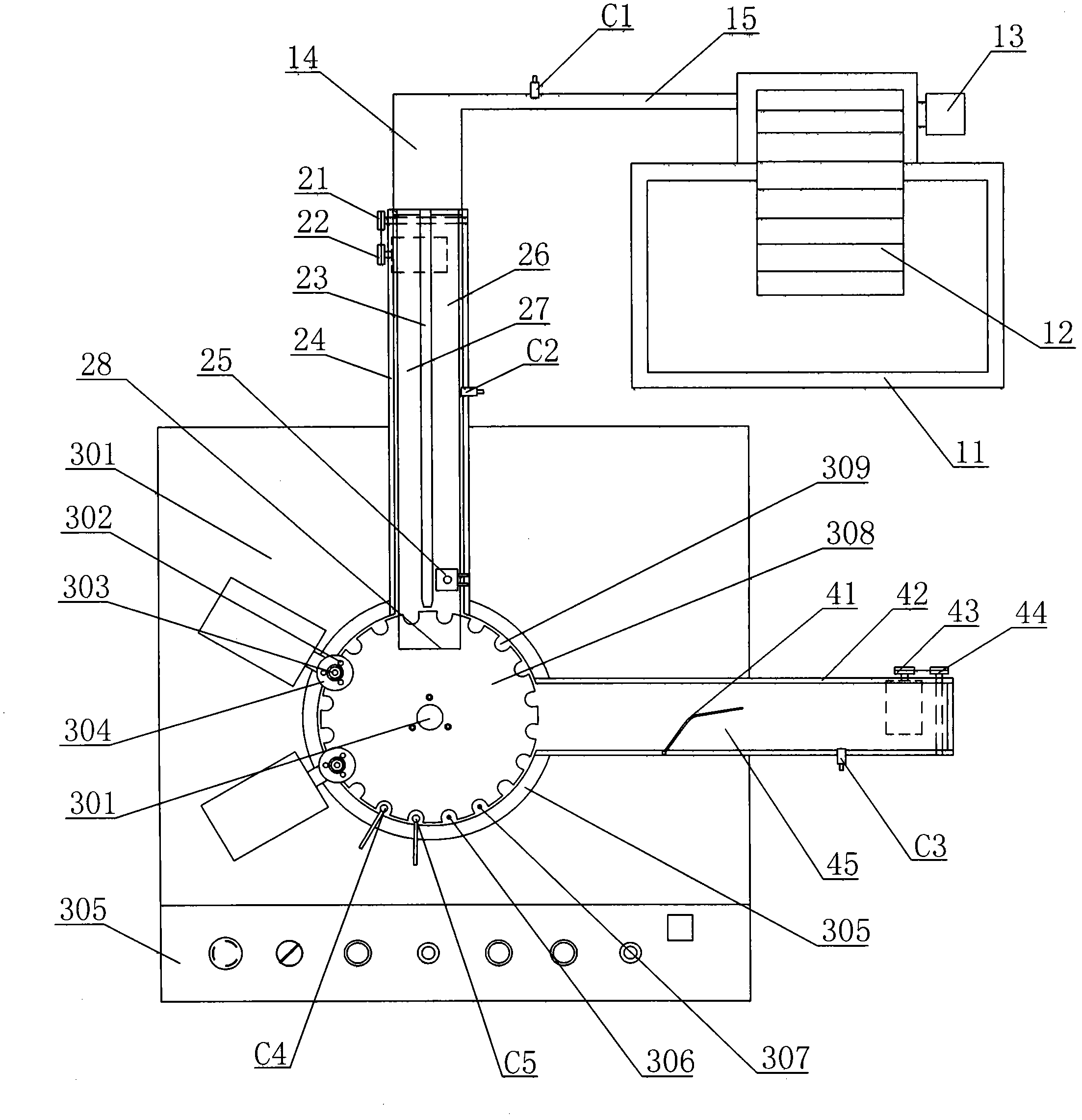

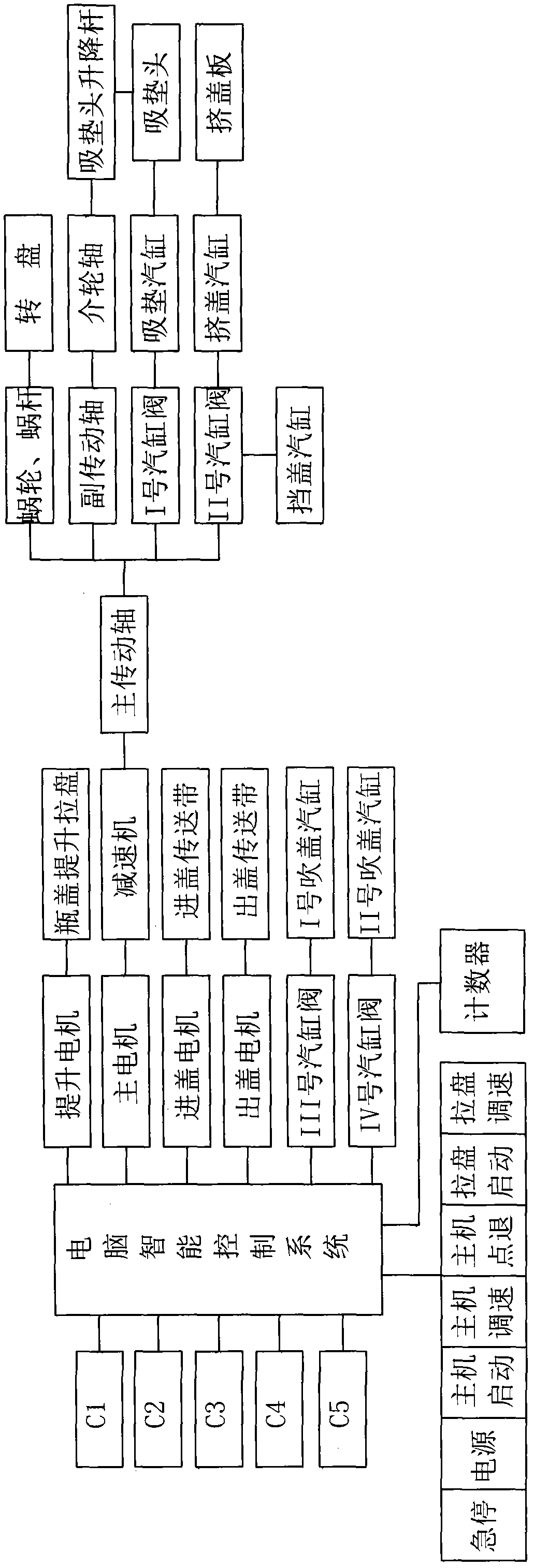

[0031] A fully automatic bottle cap filling machine, mainly including the following working mechanisms:

[0032] 1. An automatic cap sorting mechanism for arranging and outputting messy bottle caps and making all the caps open upwards;

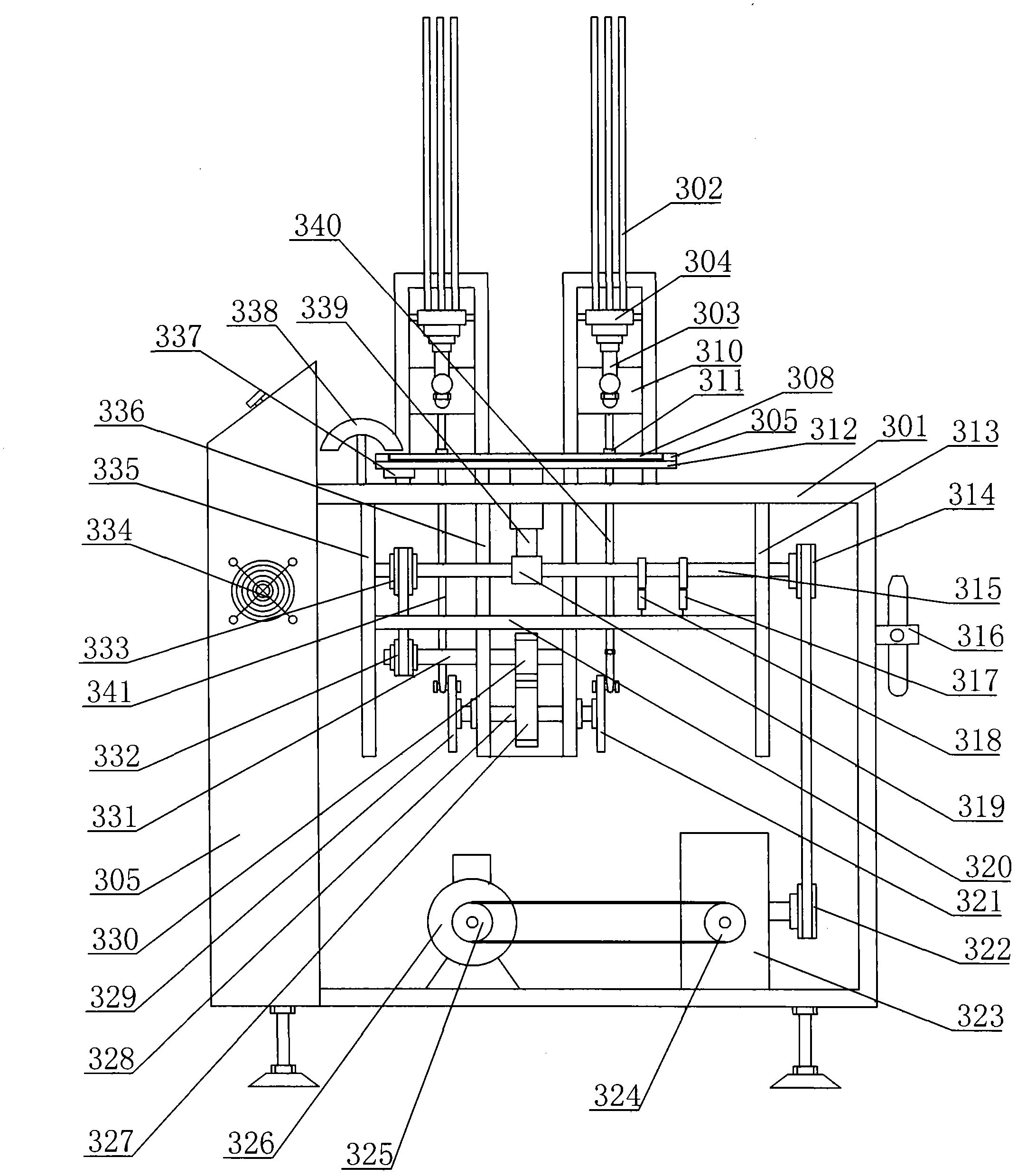

[0033] 2. The gasket insertion mechanism used to complete the action of inserting the sealing gasket into the bottle cap;

[0034] 3. It is installed between the automatic cap sorting mechanism and the gasket insertion mechanism, and is used to transport the sorted bottle caps to the gasket cap insertion mechanism in an orderly and accurate manner;

[0035] 4. The bottle cap output mechanism for outputting the bottle cap with the gasket inserted from the gasket insertion mechanism;

[0036] 5. A computer intelligent control system for controlling the work of the automatic cap unscrambling mechanism, the gasket insertion mechanism, the bottle cap conveying mechanism and the bottle cap output mechanism;

[0037] 6. A sensor used to monitor the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com