High-speed capping machine for high caps

A technology of capping machine and high cap, which is applied in the field of canning equipment, can solve the problems of difficult to meet modern production and low efficiency of capping machine, and achieve the effect of ensuring simple and easy maintenance, fast and convenient adjustment, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

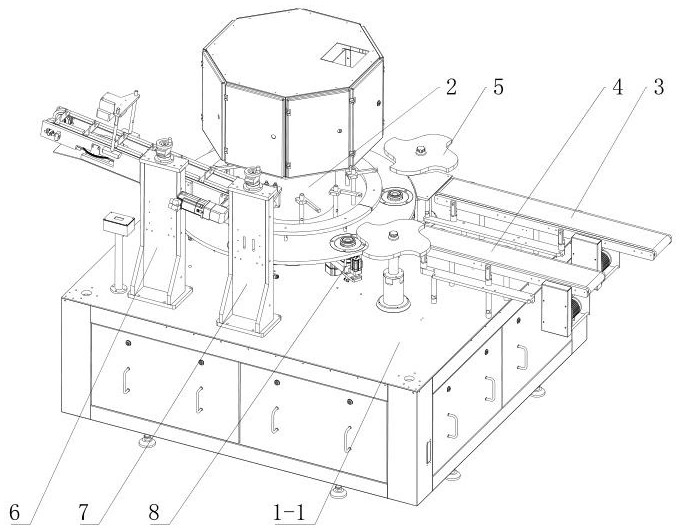

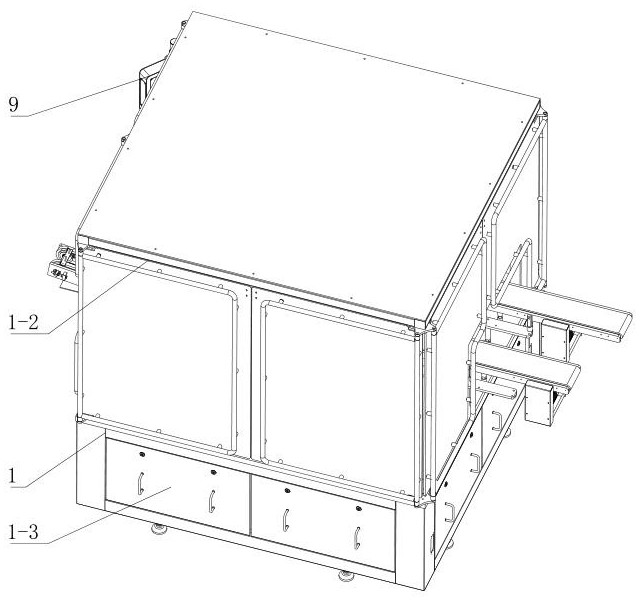

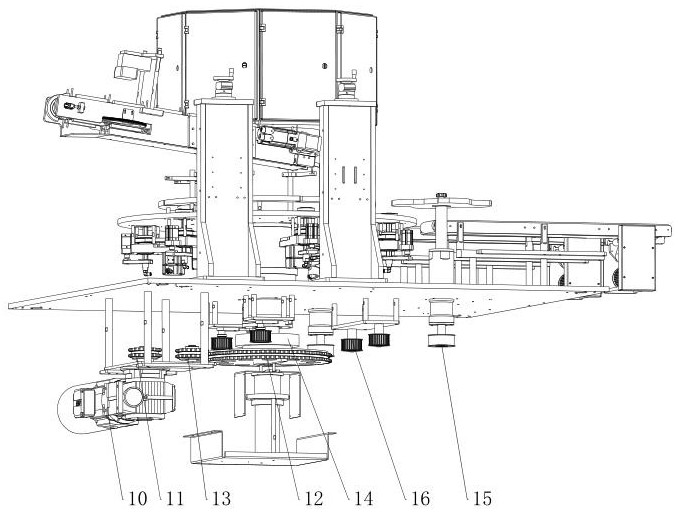

[0040] See figure 1 and figure 2 , the present invention has a frame 1, and the frame 1 includes a table top 1-1, an openable and closable dustproof part 1-2 is arranged on the outer side of the table top 1-1, and a door panel part 1-3 is arranged on the outer side of the bottom;

[0041] The rotating part 2, the rotating part 2 is rotatably passed through the middle part of the table 1-1 and installed, and is used for the rotating transportation turnover of the tank during the capping process;

[0042] Imported network chain part 3, the imported network chain part 3 is arranged on the table top 1-1, and the transport direction points to the inside of the rotating part 2;

[0043] The outlet network chain part 4, the outlet network chain part 4 is arranged on the table top 1-1, and the delivery direction points to the outside of the rotating part 2;

[0044] There are two star wheel parts 5, one of which is set at the position where the inlet network chain part 3 and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com