Overturning and conveying device of open mill

A technology of conveying device and mill, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of inability to meet modern production and low work efficiency, and meet the needs of modern production, improve work efficiency, and transfer Quick and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

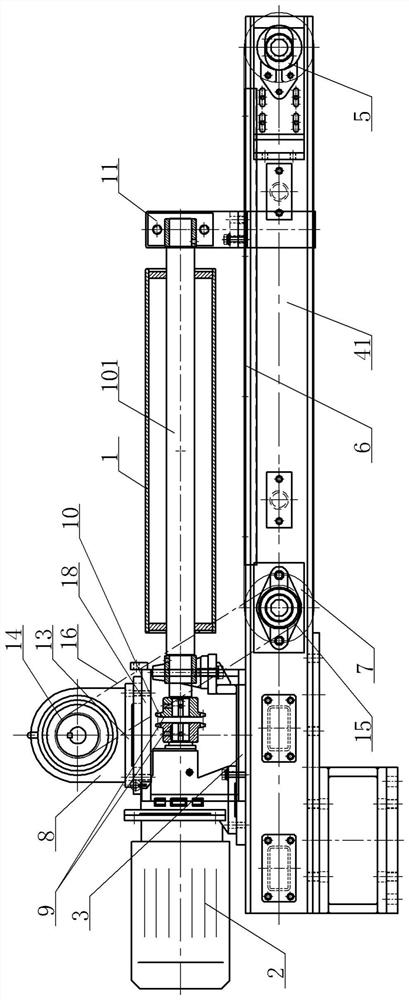

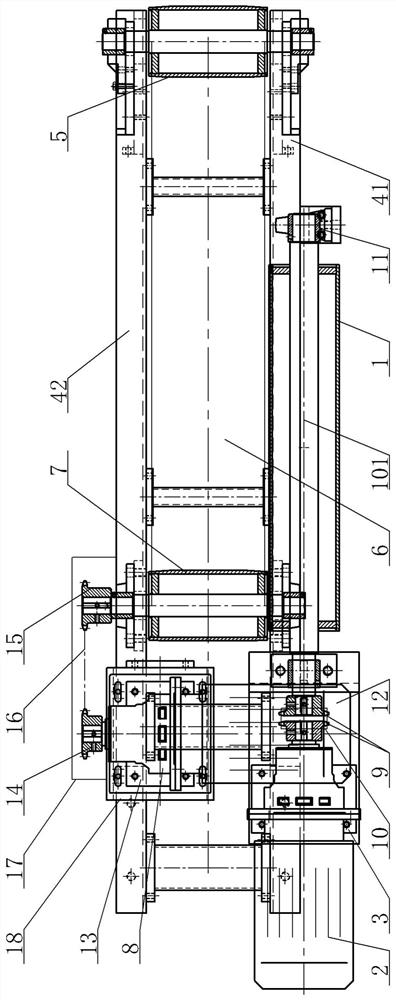

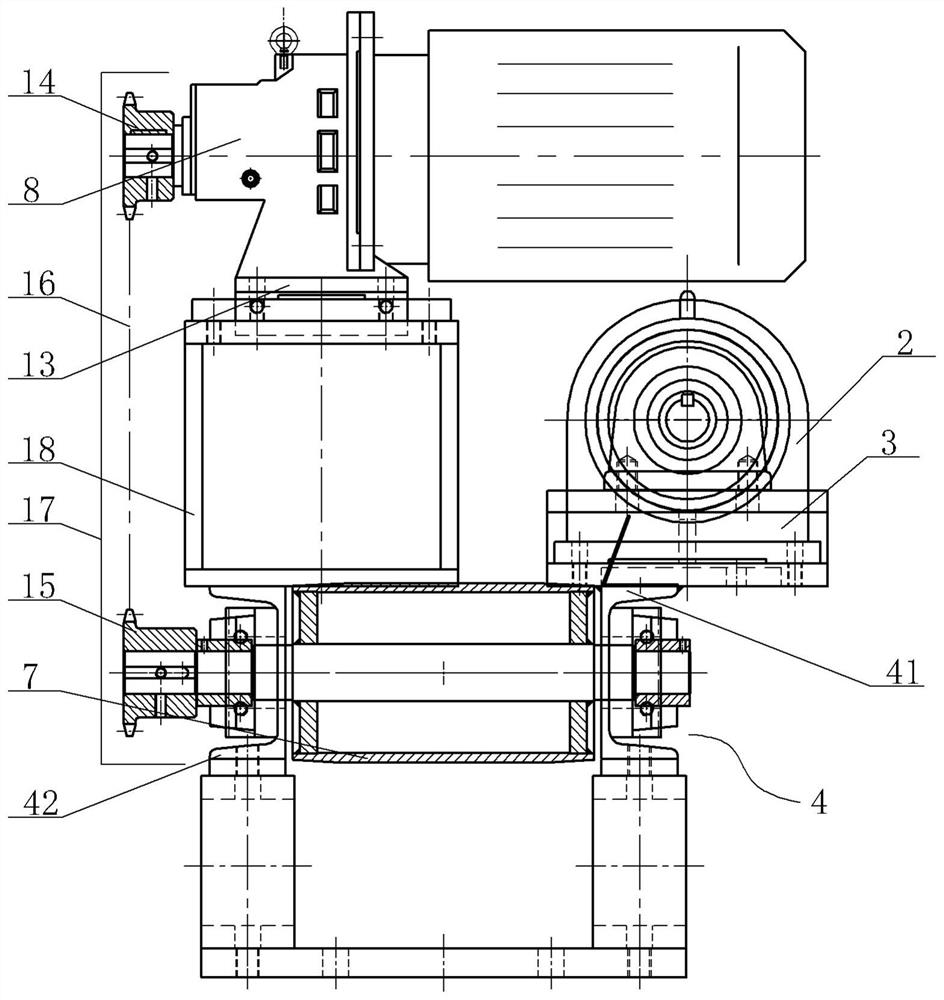

[0017] Turning conveying device of mill, see Figure 1-Figure 3 : it comprises a conveying roller 1, the input end of the conveying roller 1 is connected with the output end of the first conveying motor 2, the first base 3 of the first conveying motor 2 is supported on the side support 41 of the conveying roller table 4, and the conveying roller The road 4 includes two side supports, specifically one side support 41 and the other side support 42. The two ends of the length direction of the two sides supports are respectively provided with conveying rollers 5, and the rollers of the conveying rollers 5 are arranged in the width area of the two sides supports. Between them, the conveyor belt 6 is closed and wound around the rollers of the two conveyor rollers 5, and the conveyor roller 1 is arranged obliquely above the output surface of the conveyor belt 6, and the conveyor roller 1 drops the material to the output surface of the conveyor belt 6, and the conveyor belt 6. A pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com