Dedicated guide device for manufacturing concrete block

A technology of concrete blocks and guide devices, which is applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problem of inability to ensure that the left and right ends of the upper clamp blank frame move upwards synchronously, the block rejection rate increases, and the production increase To meet the needs of modern production, reduce the scrap rate and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

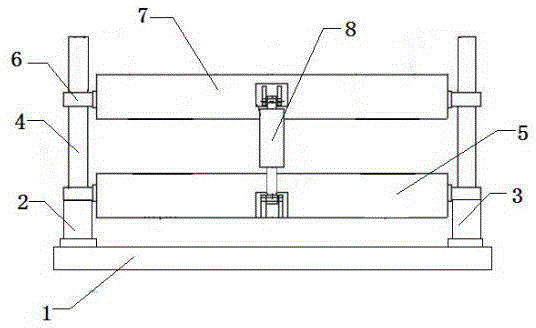

[0013] This embodiment provides a special guiding device for concrete block manufacturing, which is characterized in that: the special guiding device for concrete block manufacturing includes a base (1), a left driving cylinder (2), a right driving cylinder (3), a wire Bar (4), lower clamp blank frame (5), nut (6), upper clamp blank frame (7), jacking cylinder (8);

[0014] Among them: including the base (1), the left drive cylinder (2) and the right drive cylinder (3) are arranged on the left and right sides of the base (1), and the screw rods ( 4), the two ends of the lower clamp blank frame (5) are fixed on the cylinder body of the left and right drive cylinders (2, 3), and the left and right ends of the upper clamp blank frame (7) are adapted to the threads of the lead screw (4) by installing The nut (6) is sleeved on the lead screw (4) on the left and right sides, and the nut (6) is movably connected to the upper blank frame (7), between the upper blank frame (7) and the ...

Embodiment 2

[0018] This embodiment provides a special guiding device for concrete block manufacturing, which is characterized in that: the special guiding device for concrete block manufacturing includes a base (1), a left driving cylinder (2), a right driving cylinder (3), a wire Bar (4), lower clamp blank frame (5), nut (6), upper clamp blank frame (7), jacking cylinder (8);

[0019] Among them: including the base (1), the left drive cylinder (2) and the right drive cylinder (3) are arranged on the left and right sides of the base (1), and the screw rods ( 4), the two ends of the lower clamp blank frame (5) are fixed on the cylinder body of the left and right drive cylinders (2, 3), and the left and right ends of the upper clamp blank frame (7) are adapted to the threads of the lead screw (4) by installing The nut (6) is sleeved on the lead screw (4) on the left and right sides, and the nut (6) is movably connected to the upper blank frame (7), between the upper blank frame (7) and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com