Piercing die for piercing in sidewall of round tube

A technology of sidewall punching and punching die, applied in the direction of punching tools, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing efficiency, affecting production work, increasing production costs, etc., to improve strength and rigidity, improve enterprise Benefit, the effect of low equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

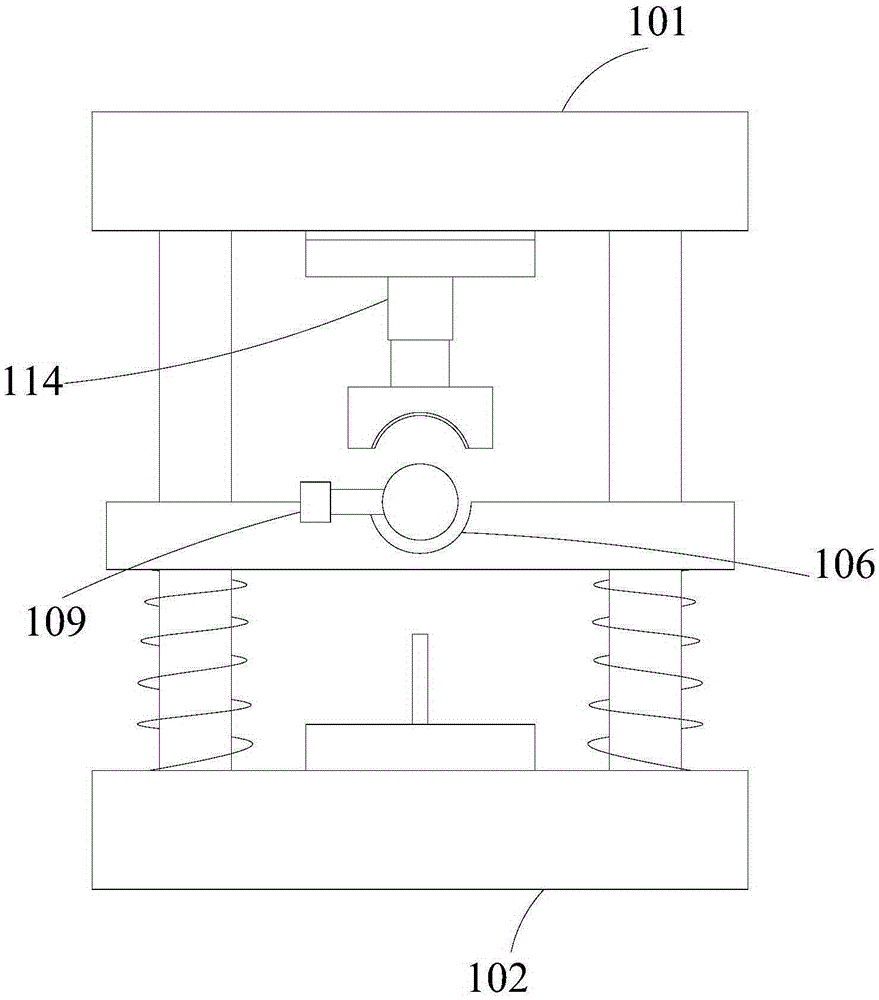

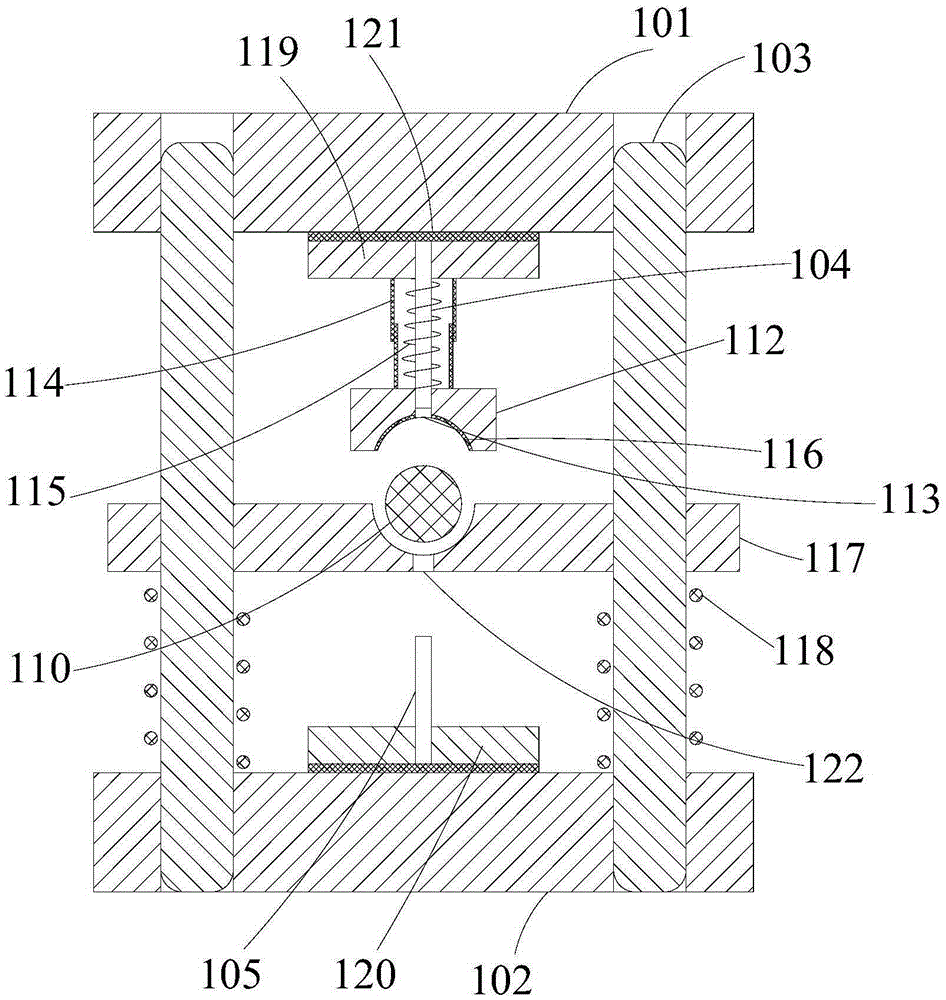

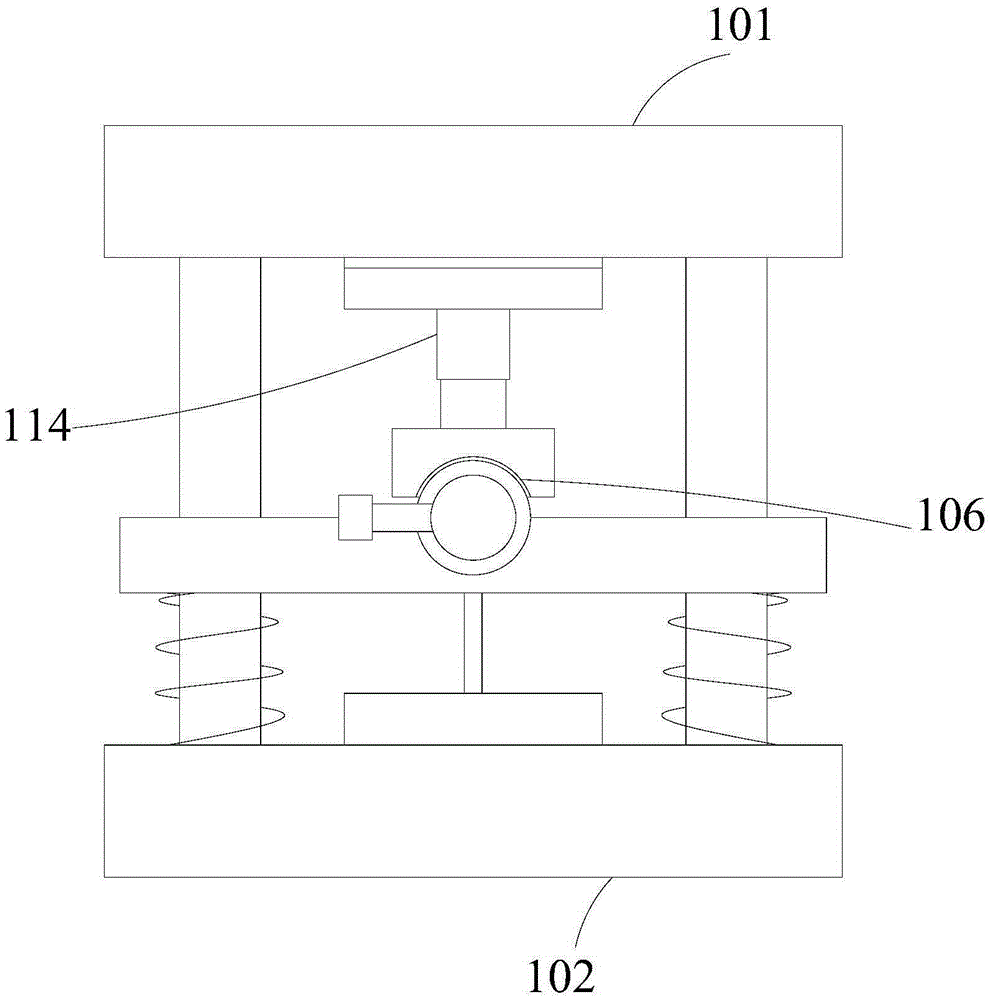

[0077] A punching die for punching holes on the side wall of a circular tube, comprising an upper die base 101 and a lower die base 102, the upper die base 101 and the lower die base 102 are connected by a guide post 103, and the bottom of the upper die base 101 is connected There is an upper punch 104; the lower mold base 102 is longitudinally provided with a circular tube placement part 106, and the lower mold base 102 is also connected with a positioning mechanism; the positioning mechanism includes a driving assembly, a transmission assembly and a positioning assembly connected in sequence, and the positioning assembly includes a columnar The positioning rod 110 is driven by the drive assembly so that the positioning rod 110 can move longitudinally; when the round tube is placed on the round tube placement part 106, the positioning rod 110 can be inserted into the inside of the round tube during the movement.

[0078] There are two sets of positioning assemblies, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com