Beer outlet valve of beer barrel

A beer keg and valve body technology, which is applied in the field of beer keg outlet valves, can solve problems such as complex operation and complex structure, and achieve the effects of simple operation, good stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

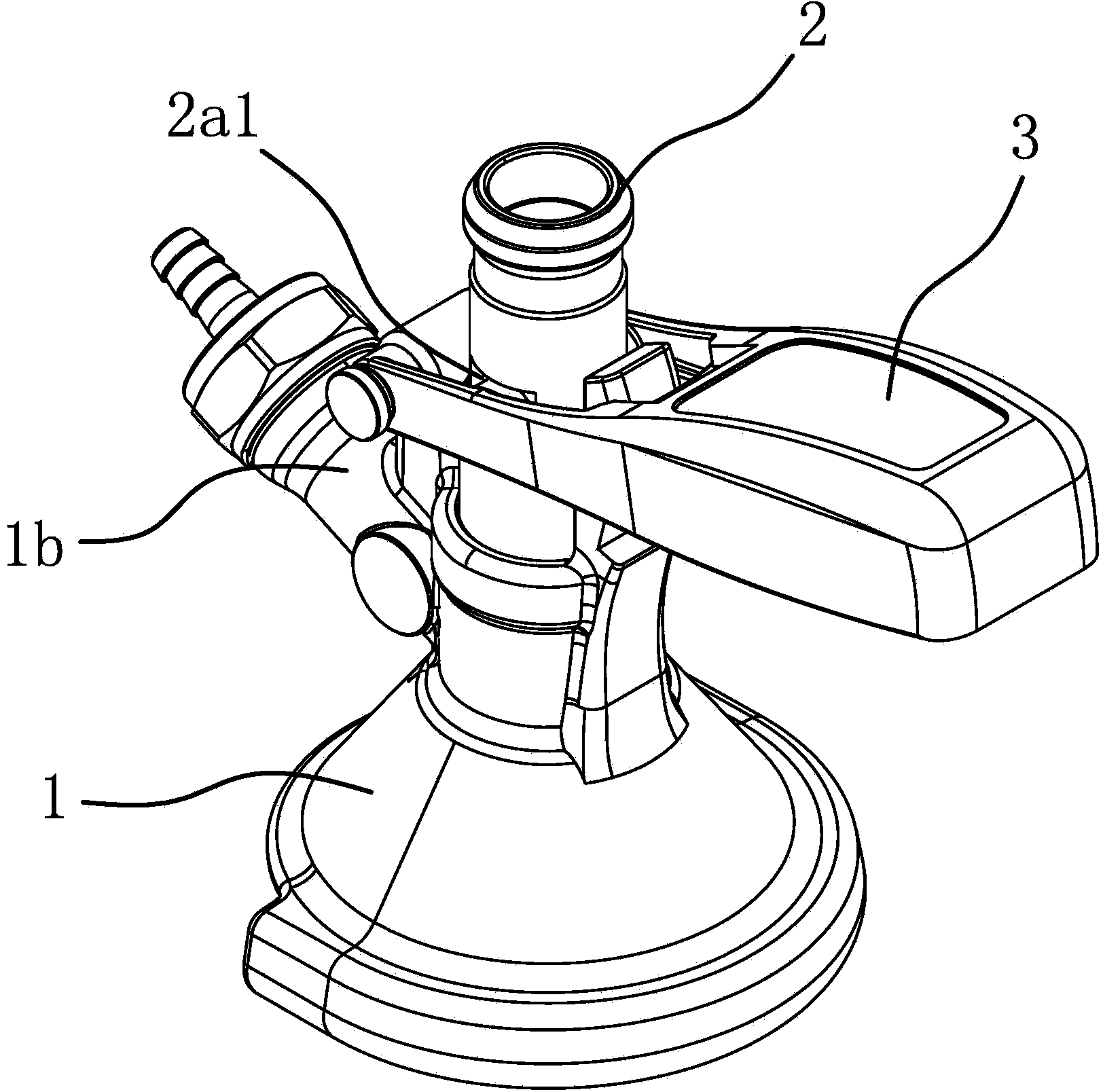

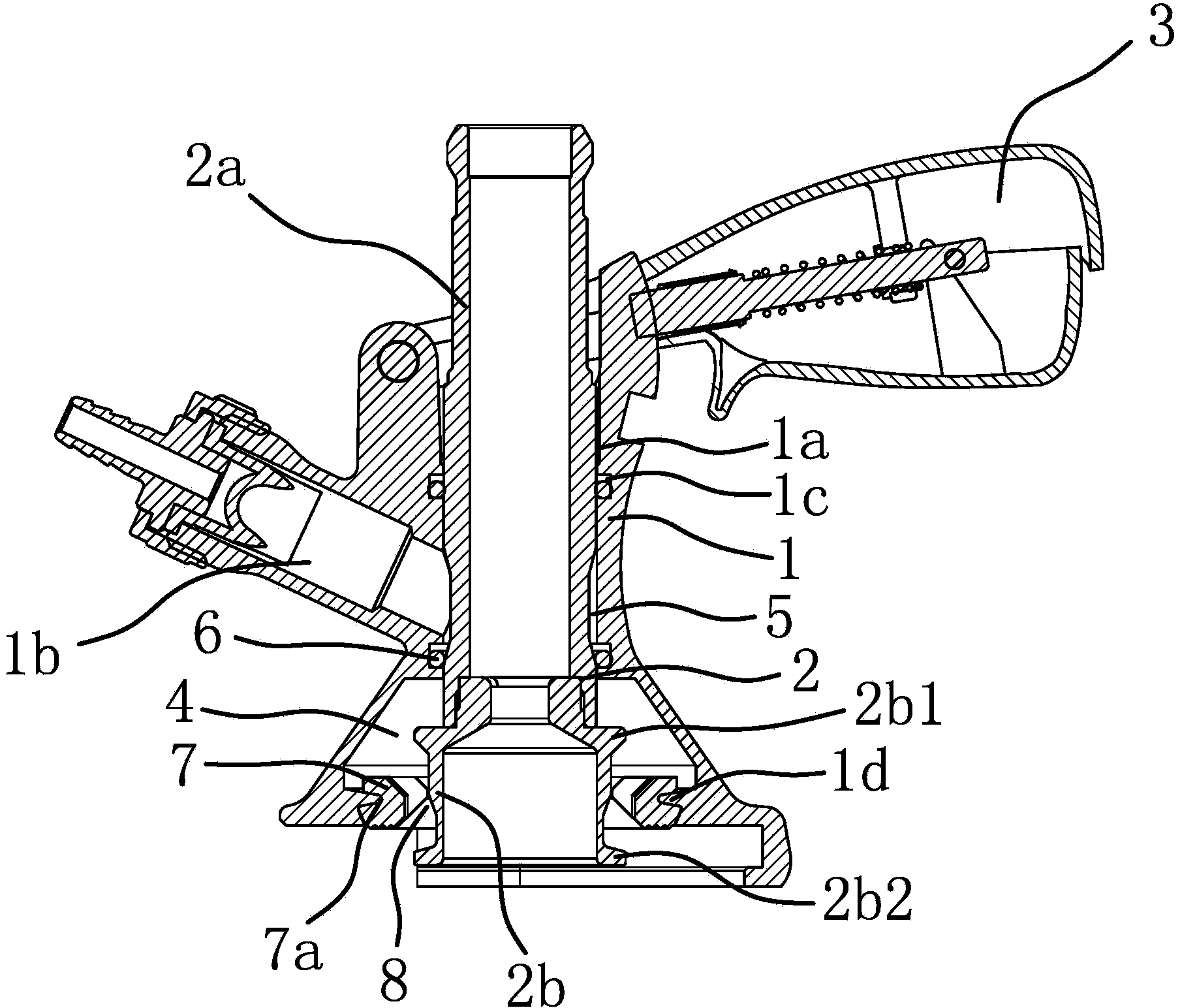

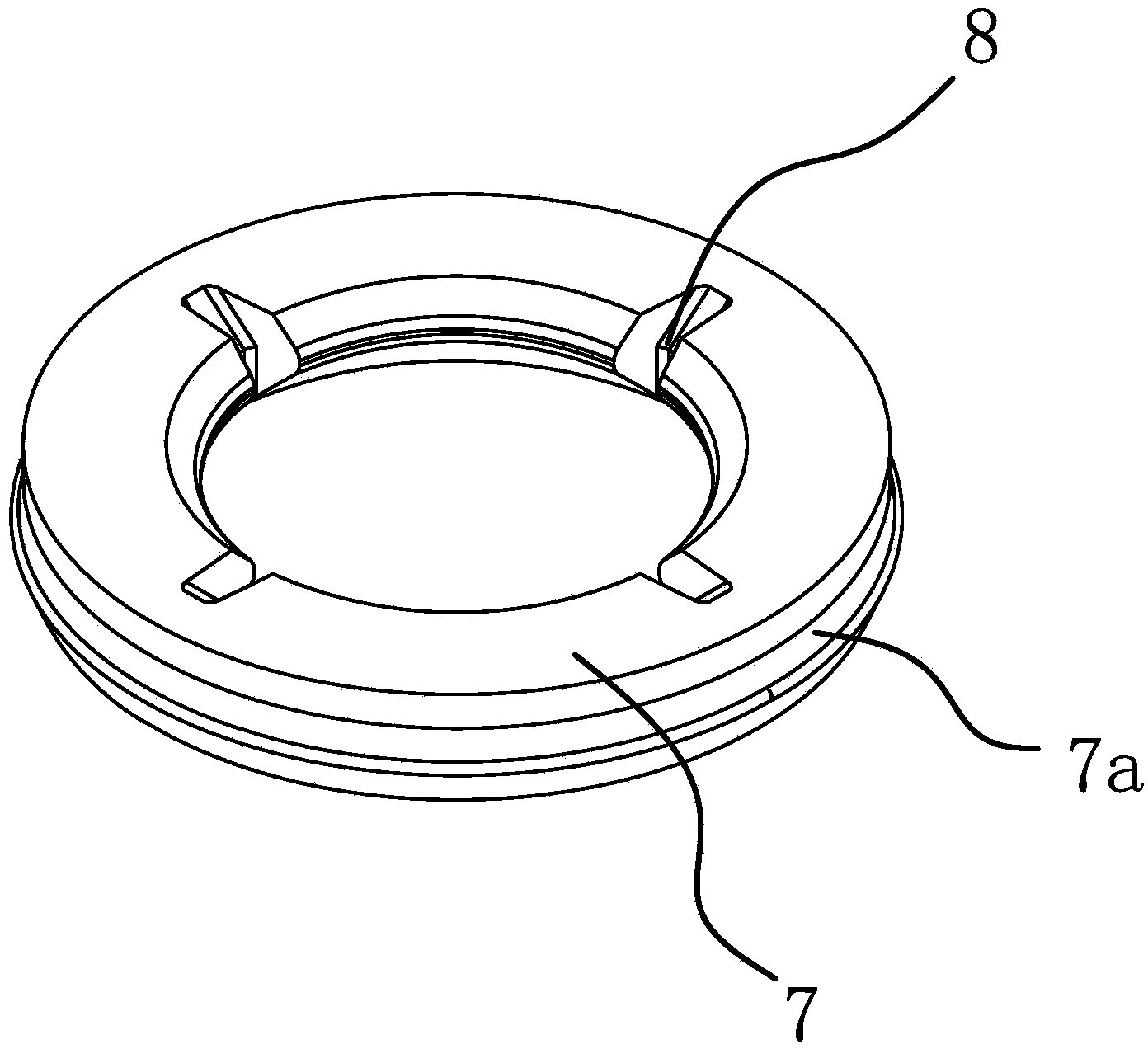

[0030] like figure 1 , 2 As shown, the wine outlet valve of the beer keg includes a valve body 1, a wine guide pipe 2, a handle 3, an air intake structure and a guide pad 7.

[0031] The center of the valve body 1 has a guide hole 1a penetrating in its axial direction, and the side of the valve body 1 has an air inlet pipe 1b, one end of the air inlet pipe 1b communicates with the guide hole 1a, and the other end is connected with the gas delivery device. There is a pair of seal ring seats 1c on the side wall of the guide hole 1a, one seal ring seat 1c is located above the connection between the intake pipe 1b and the guide hole 1a, and the other seal ring seat 1c is located at the connection between the intake pipe 1b and the guide hole 1a below. The bottom of the valve body 1 is in the shape of a conical cone to match the shape of the joint with the beer keg, and the inside of the bottom of the valve body 1 has an air outlet 4 that is consistent with its external shape, an...

Embodiment 2

[0035] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the air intake structure includes the air inlet that is recessed in the middle of the wine guide tube 2 along its axial direction and the air inlet between the valve body 1 and the air intake pipe. A pair of sealing rings 6 between 1b, the air inlet of this kind of structure has a smaller area and is more convenient to process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com