Patents

Literature

31results about How to "Precise hole position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

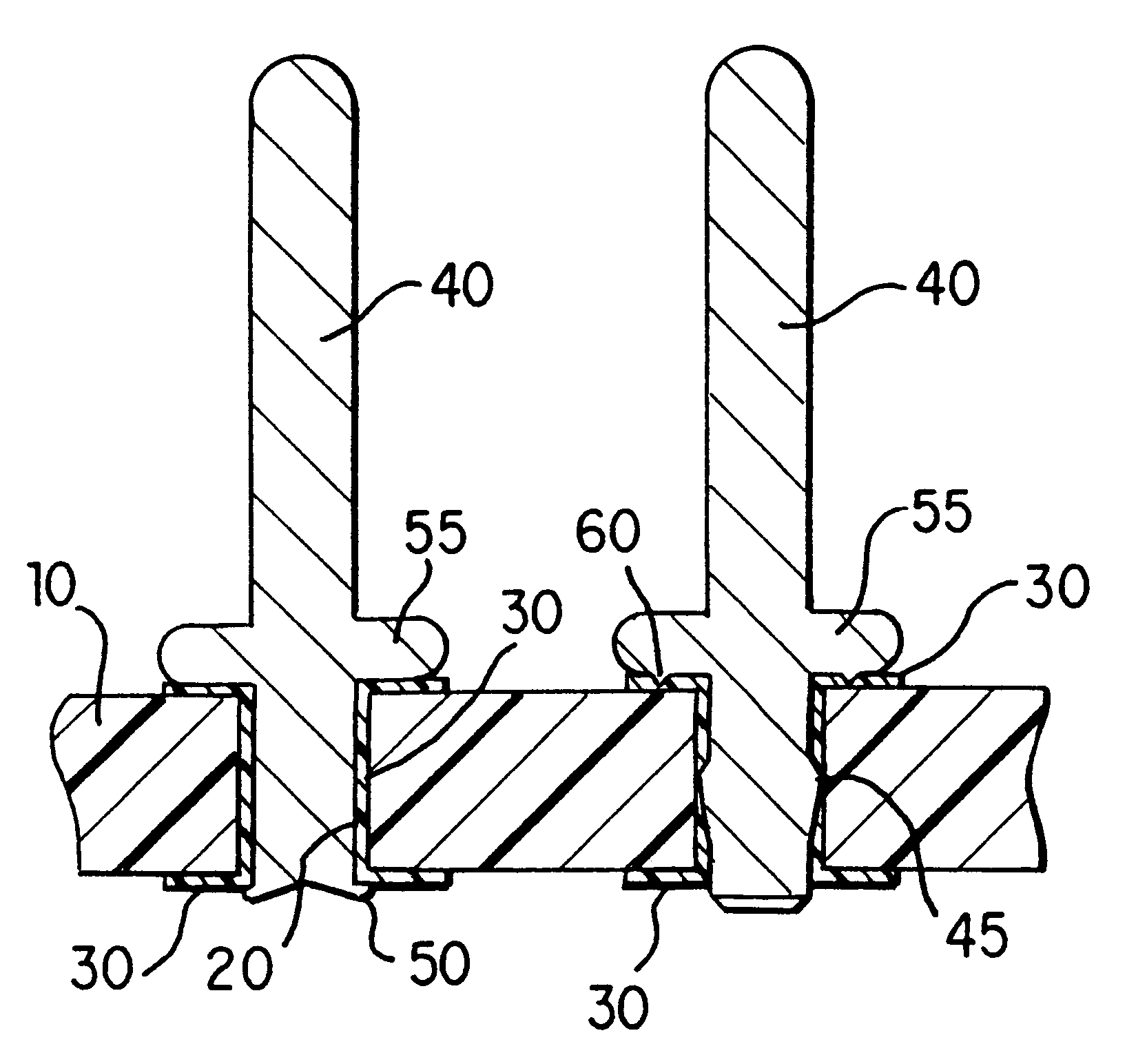

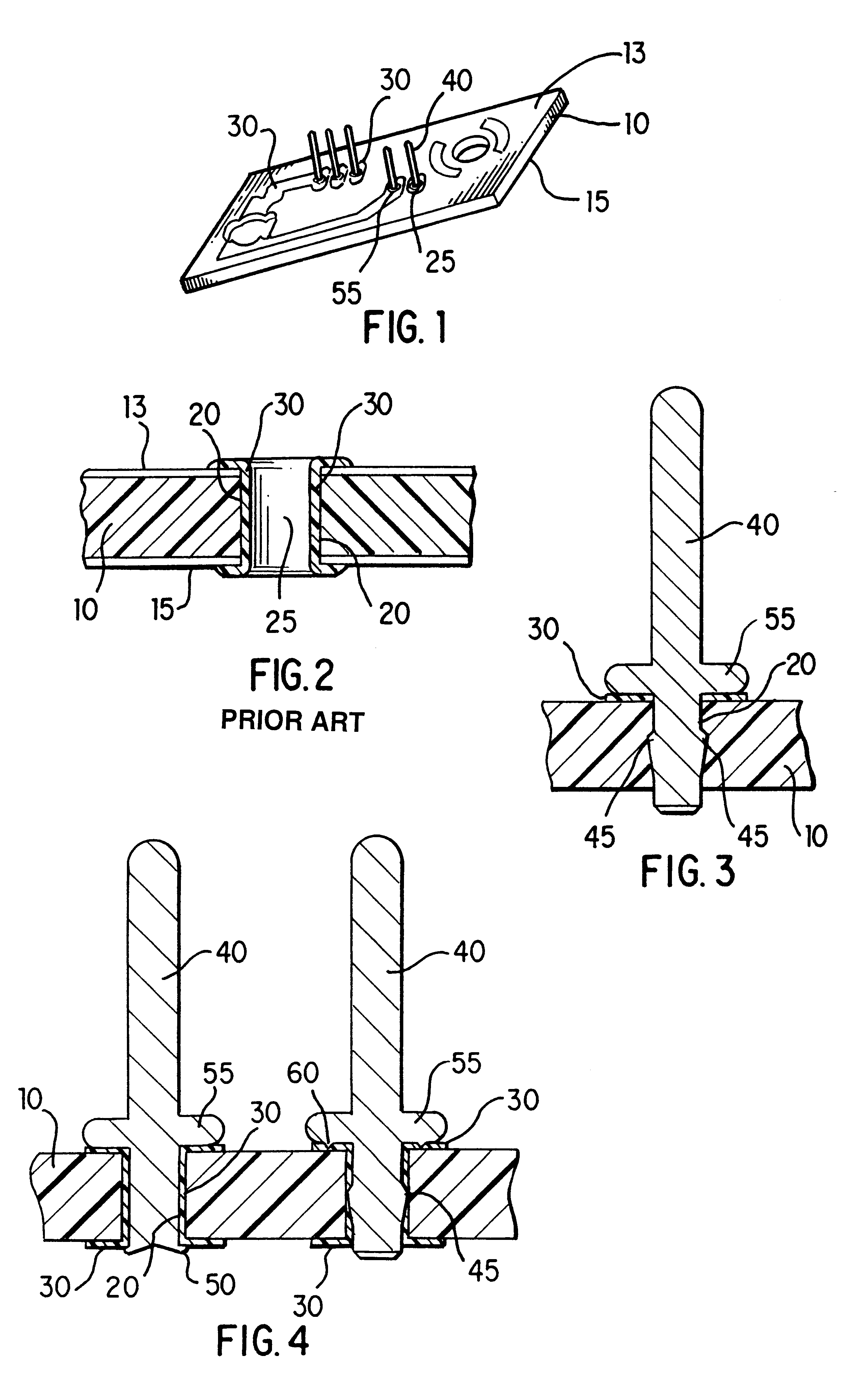

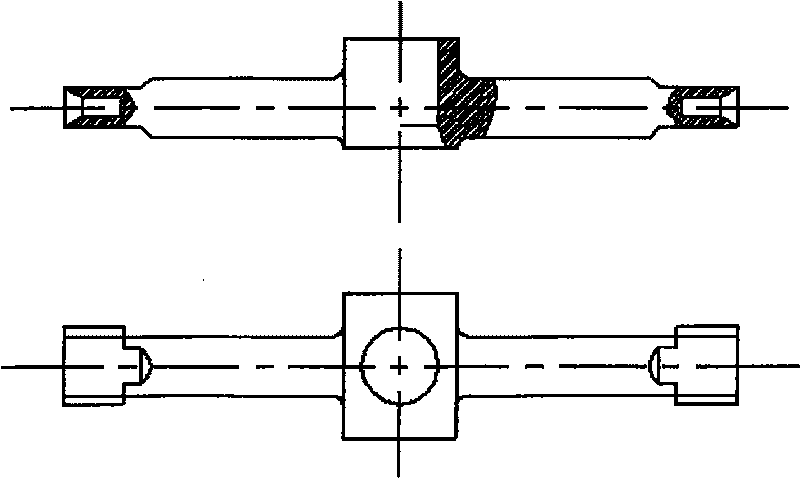

Solderless pin connection

InactiveUS6217346B1Reduce complexityPrecise hole positionPrinted circuit assemblingLighting support devicesEngineeringPrinted circuit board

A solderless pin connection for a printed circuit board wherein a substrate is printed with polymer thick film. The substrate includes an inner surface defining a hole. The polymer thick film is applied along a top surface of the substrate and along the inner surface. The polymer thick film may additionally be applied along a bottom surface of the substrate with an additional layer along the inner surface. A pin, having a diameter less than a diameter of the hole, is press fit within the polymer thick film along the inner surface the pin. The pin is staked with respect to the substrate using a mechanical connection such as barbs or a folded portion on a staked end of the pin.

Owner:ILLINOIS TOOL WORKS INC

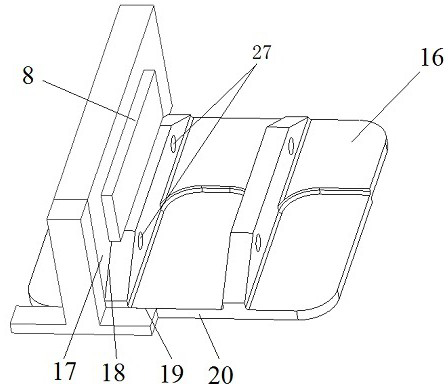

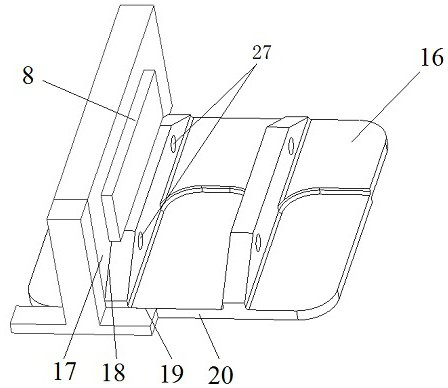

Process for drilling side of furniture plate and special processing device thereof

The invention relates to a process for drilling the side of a furniture plate. The process is characterized by comprising the following steps of: (a) flatly placing the plate on a horizontal platform, wherein the unprocessed end leans against an L-shaped positioning block on the horizontal platform; (b) driving a vertically lifting main pressing block and an auxiliary pressing block so as to press the upper surfaces of the unprocessed end and the processed end and prevent the unprocessed end from jumping during processing; (c) driving a plurality of drills positioned on the side of the processed end of the plate so as to feed towards the plate end and drill the side of the plate; and (d) after the drilling process is finished, returning the drills, lifting the pressing blocks, manually taking out the plate and finishing the process of drilling the side of the plate. The process is simple, and convenient and fast to implement; and processing equipment is simple in structure and convenient and fast to operate, can effectively improve the drilling efficiency, guarantee accuracy of the hole position and guarantee success of subsequent production of products.

Owner:FUTIAN FUZHOU ARTS & CRAFTS

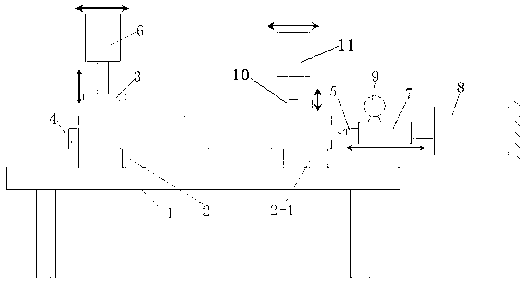

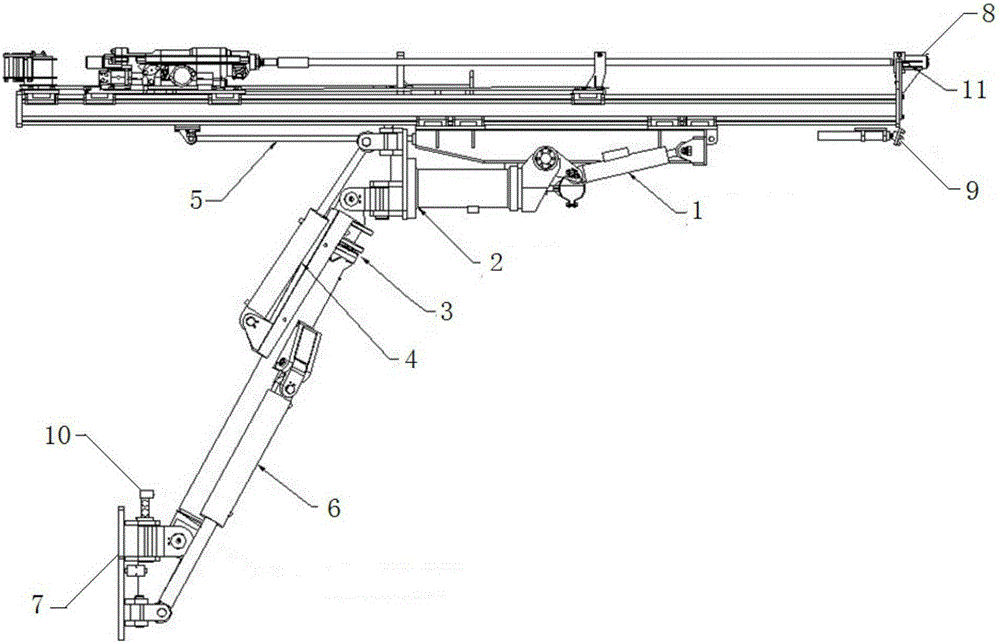

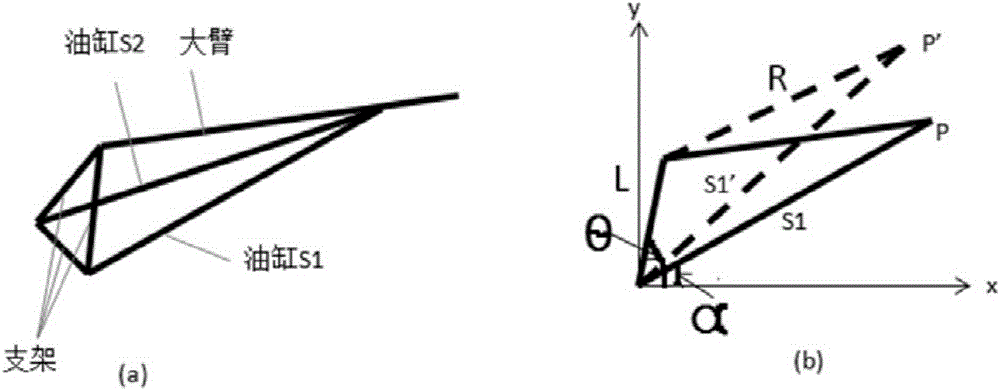

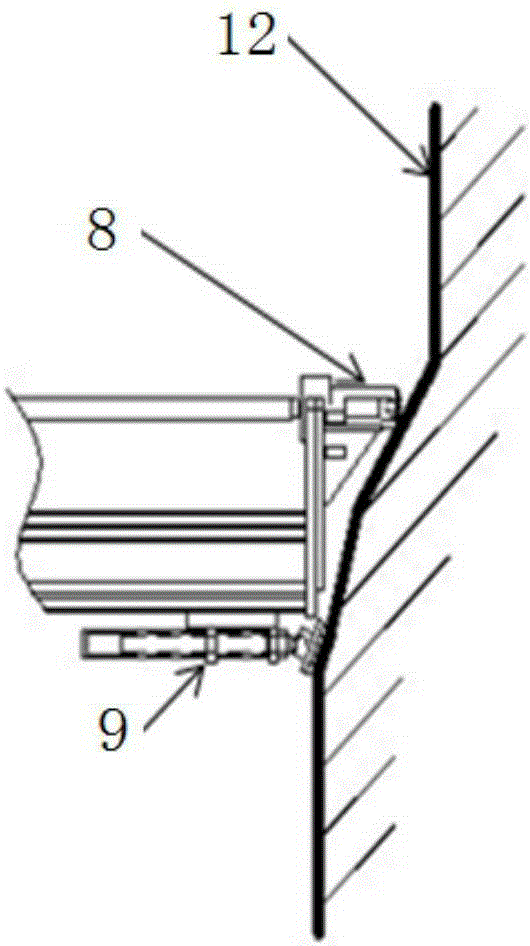

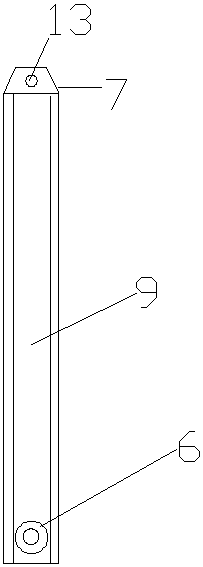

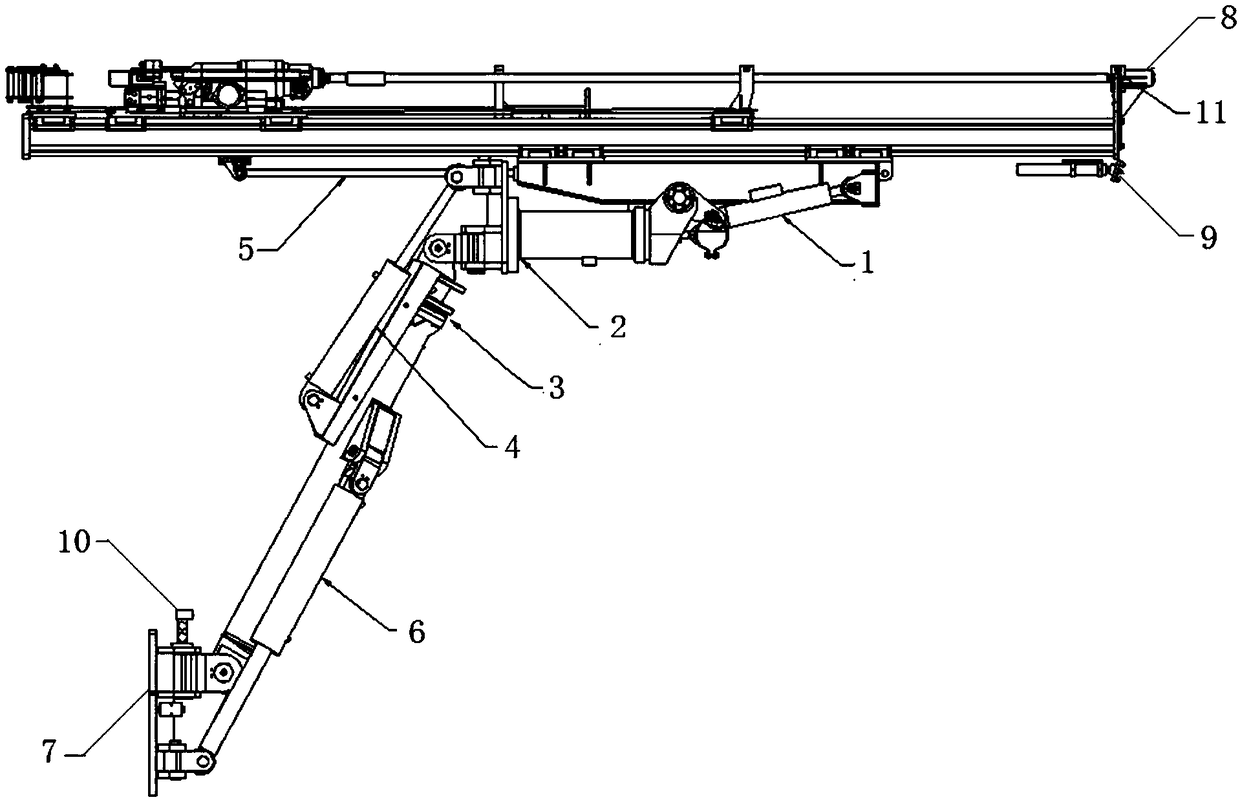

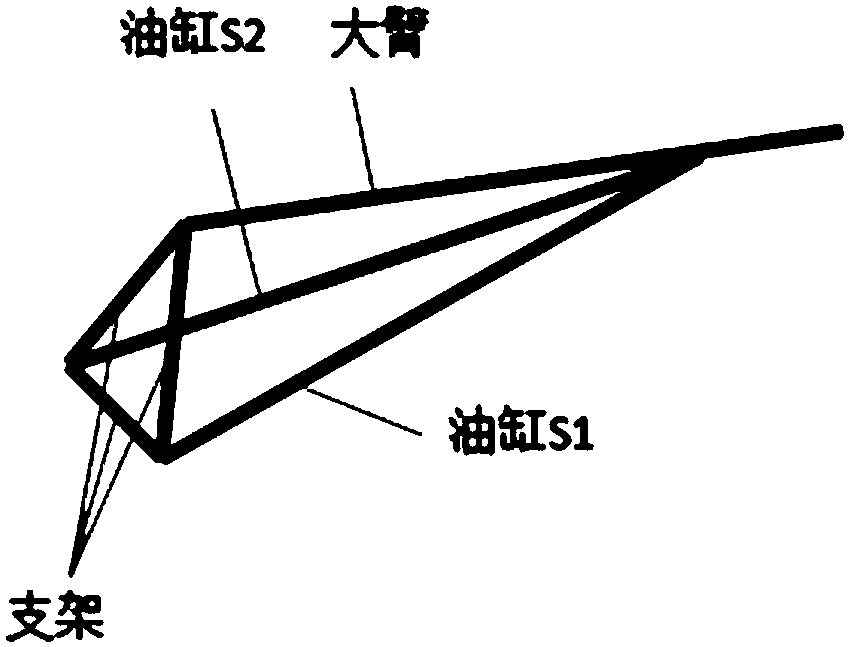

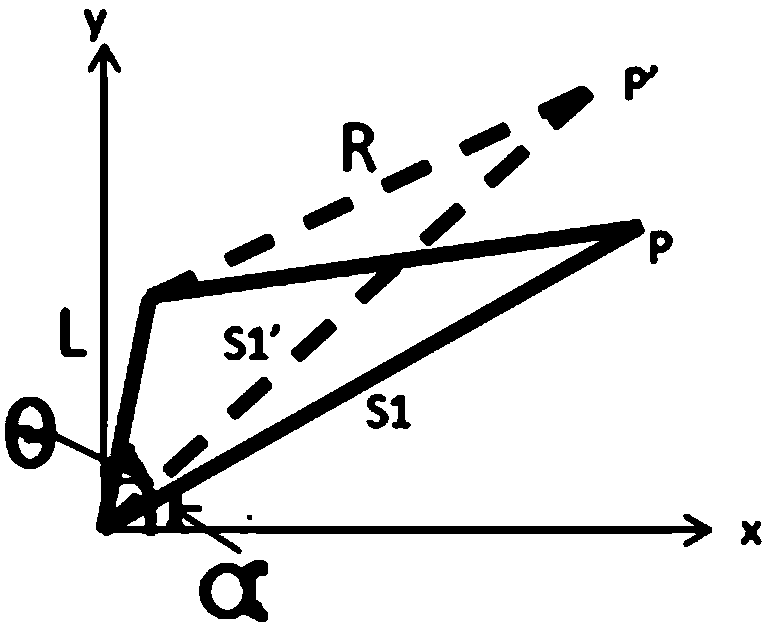

Drilling automatic positioning device and method for tunneling and drilling jumbo

ActiveCN105257274APrecise hole positionHigh degree of automationAutomatic control for drillingTelescopic cylinderDrill hole

The invention discloses a drilling automatic positioning device and method for a tunneling and drilling jumbo. The device comprises a drilling supporter, a distance measuring sensor, an advancing beam positioner, displacement sensors, an angle sensor, a laser alignment part, an interactive display terminal, a controller and a handle. The distance measuring sensor is used for determining a position relation among the tunneling and drilling jumbo, an advancing beam and an operation roadway face; the displacement sensors are respectively arranged on a near-slope oil cylinder, a telescopic oil cylinder, a pitch oil cylinder, a compensating cylinder and a lift cylinder; the angle sensor is arranged on a rotary oil cylinder; the interactive display terminal is used for the display of data and the selection and setting of a hole arrangement mode; the controller is used for receiving an instruction and driving a hydraulic valve, controlling strokes of oil cylinders, calculating the position and pose of the advancing beam by the measured data of the sensors, and finally determining the position of a drill; the handle is used for controlling the operation of the jumbo. According to the device and the method, drilling automatic positioning is realized according to the hole arrangement mode, the automation degree of the drilling jumbo is improved, the technical requirements on operators are reduced, the efficiency of tunnel operation is improved and the service lives of a drill pipe and the drill are prolonged.

Owner:上海绿钻机械有限公司 +1

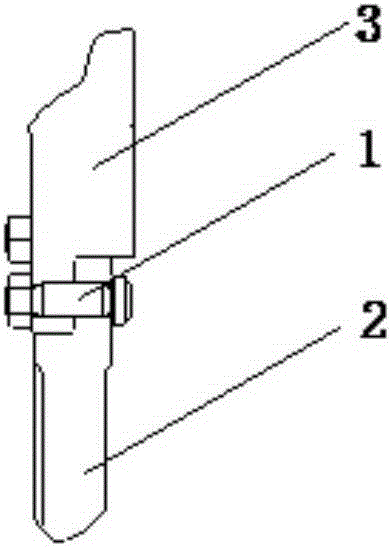

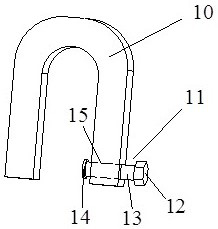

Turning hole making device

InactiveCN103042413ASimple structureReliable positioningPositioning apparatusMetal-working holdersCost savingsHole making

The invention relates to the industry of axle manufacturing, in particular to a turning hole making device which comprises a drilling device and a compressing device. A drilling part is fixed on the drilling device and is connected through a rotary shaft. The compressing device is fixed to a body and the drilling part through studs. The turning hole making device is simple in structure, is more convenient than the traditional machining methods for workpiece clamping and is reliable in positioning. The position of made holes is accurate. Changing the original structure of parts is not needed, detaching a pattern plate and the compressing device is not needed, tool utilization rate can be increased effectively, operation is facilitated for operators, and labor intensity is reduced to a certain degree for workers, time and tool waste is reduced, and cost saving and productivity increasing are combined effectively.

Owner:QINGTE GRP

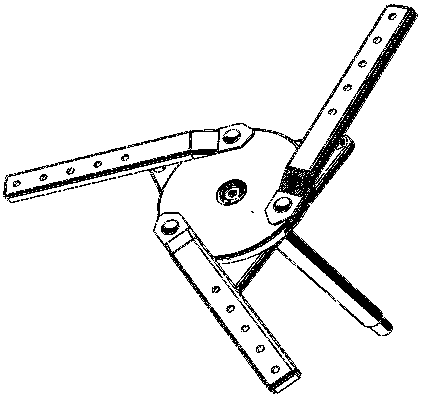

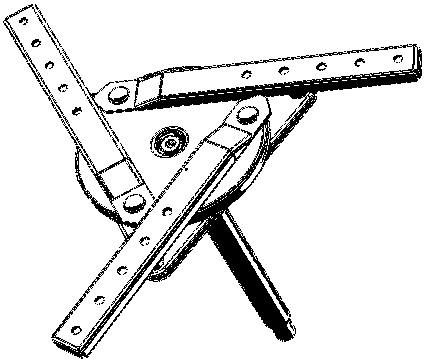

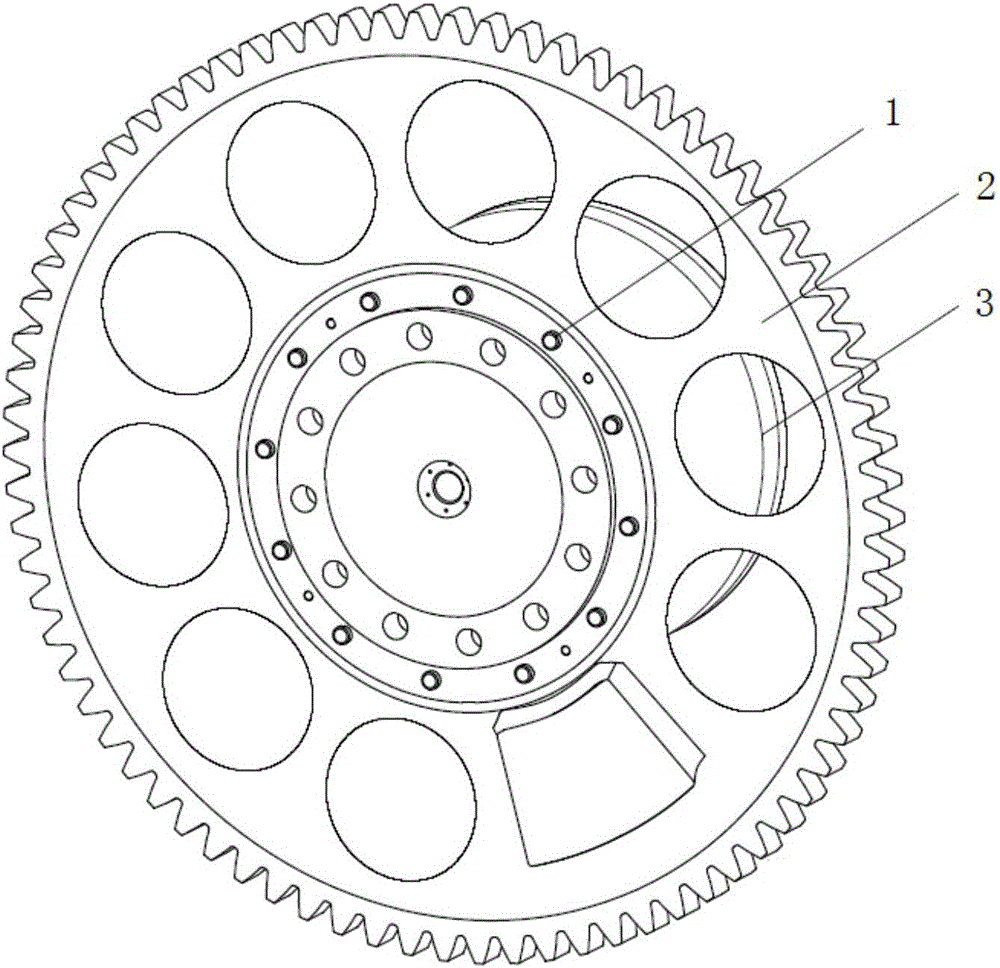

Fast adjustment trifurcate synchronous telescopic rotation clamp

PendingCN107695879AEasy to assembleEasy to installGrinding work supportsEngineeringAngular orientation

The invention relates to the field of clamp devices, in particular to a fast adjustment trifurcate synchronous telescopic rotation clamp. The fast adjustment trifurcate synchronous telescopic rotationclamp comprises fast sliding groove supporting arms, a rotary disc, a directional triangular disc and a rotating shaft rod. A shaft hole A is formed in the center of the directional triangular disc.The rotating shaft rod is inserted in the shaft hole A. A rotating shaft rod ejecting head is arranged on the top of the rotating shaft rod. The rotating shaft rod ejecting head is inserted in a concave hole formed in the center of the axis of the rotary disc. The concave hole has a large upper portion and a small lower portion, and the rotating shaft rod ejecting head is sleeved with a fast clamping sleeve and is fixed in the concave hole after being inserted in the concave hole so that the rotating shaft rod can drive the rotary disc to rotate rotationally. Guide positioning shoes are arranged at the positions of the three corners of the directional triangular disc. Each fast sliding groove supporting arm comprises a bottom connector at the bottom of the fast sliding groove supporting arm and a groove rod which integrally extends from the connector and is provided with a bottom sliding groove, wherein multiple adjustable insertion holes are formed in an ejecting piece of the groove rod at equal intervals. The guiding positioning shoes of the triangular disc are clamped in the bottom sliding grooves and slide in the bottom sliding grooves. The concave hole is matched with the rotary disc.

Owner:南充市乐福尔工贸有限公司

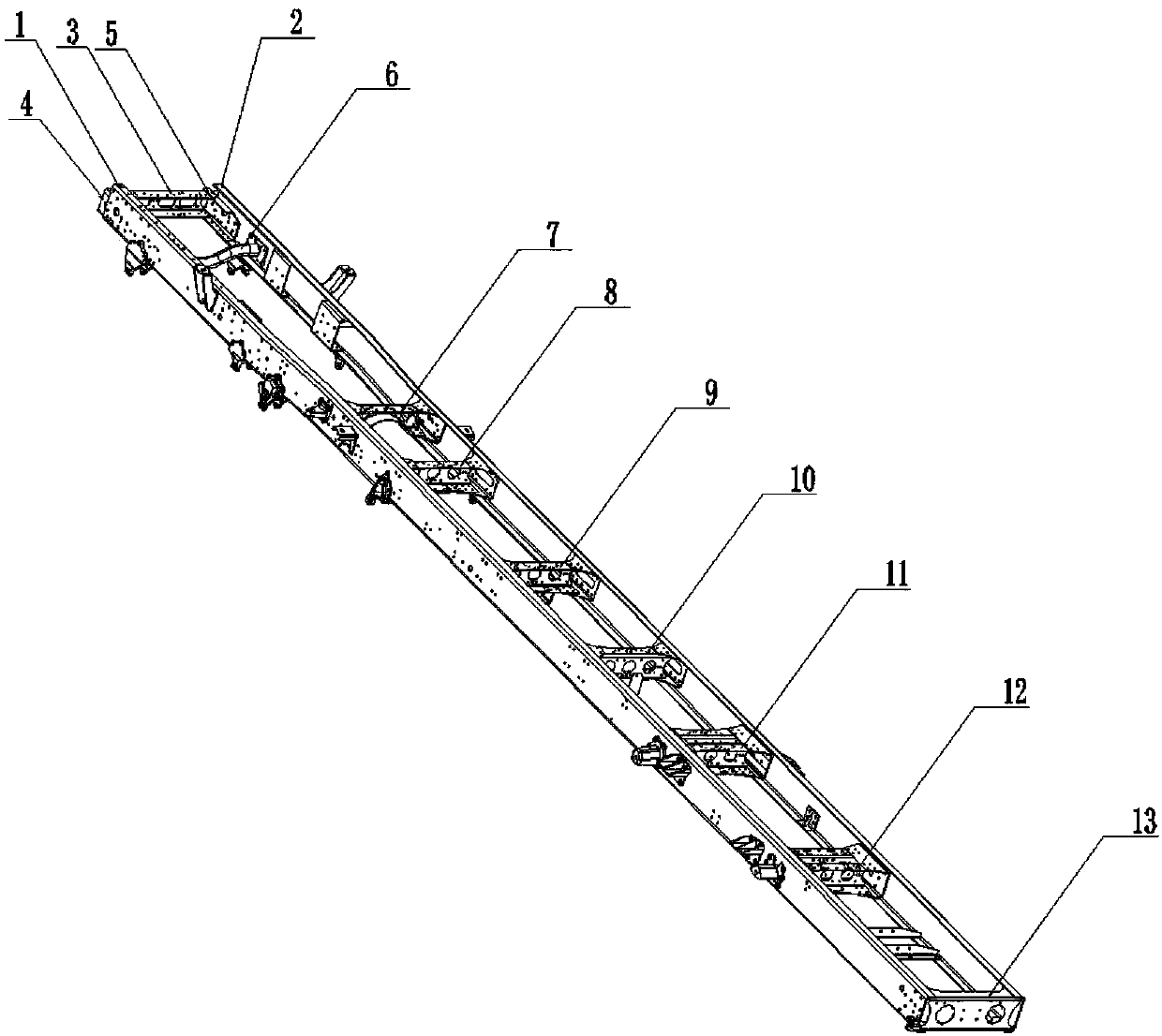

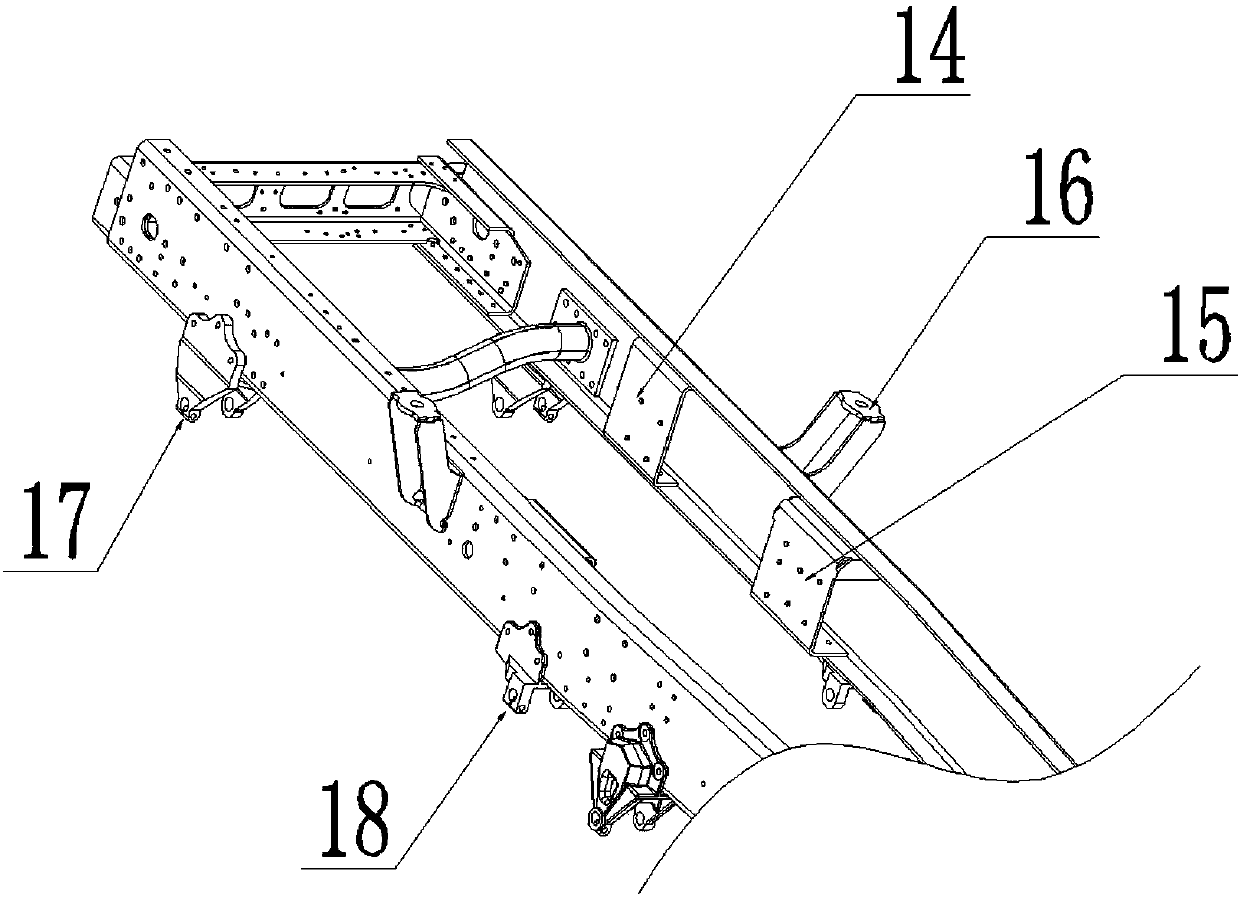

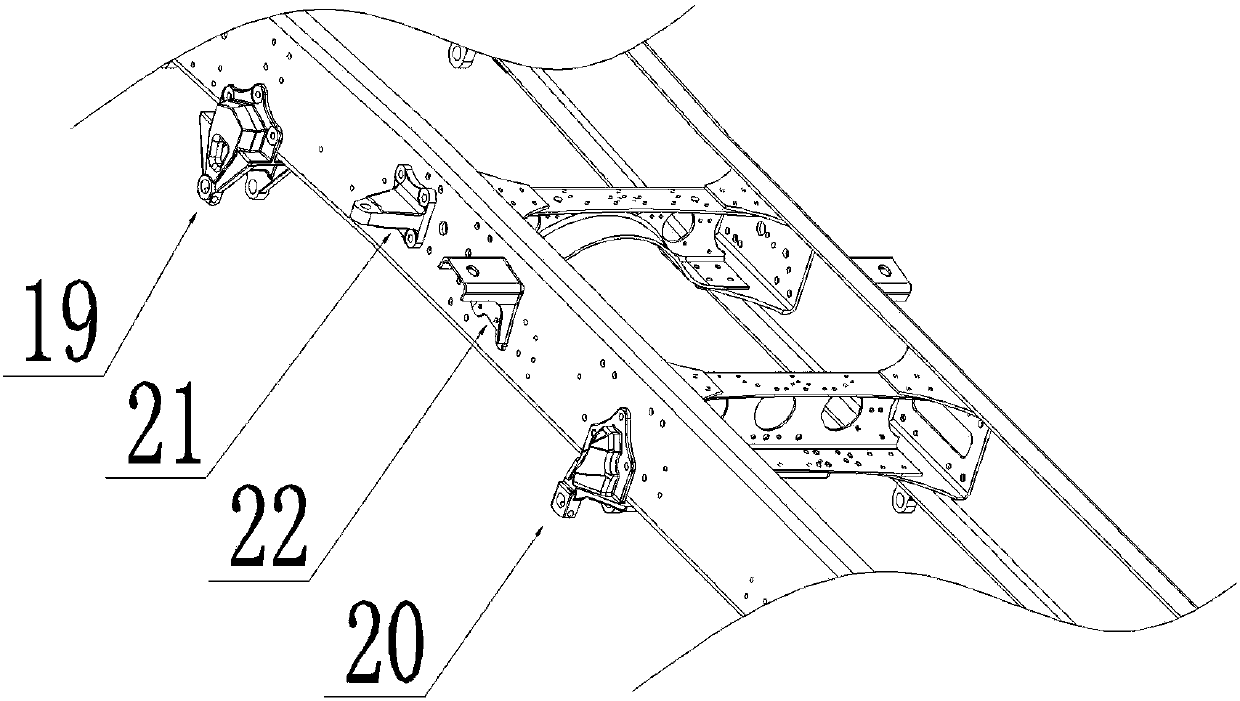

Automobile frame assembly

PendingCN107776671AImprove consistencyImprove aestheticsUnderstructuresNumerical controlVehicle frame

The invention relates to the field of automobile parts, in particular to an automobile frame assembly. The automobile frame assembly comprises left and right vertical beams, cross beam pieces, and hanging pieces installed at the outer sides of the left and right vertical beams, a U-shaped design is adopted to the left and right vertical beams, and to install an engine better, a Z-shaped design isadopted on the front-section parts of the left and right vertical beams and completed through a Huaqi company vertical beam numerical control bending forming production line; assembling of the automobile frame assembly is completed at an automobile frame assembly rivet line, two methods of rivet riveting and bolt fastening are adopted to connect all the parts, the appearance attractiveness of theautomobile frame assembly is improved, a novel flexible production line is adopted, and the cost of frame and vertical beam development is reduced.

Owner:ANHUI HUAQI AUTOMOTIVE COMPONENTS CO LTD

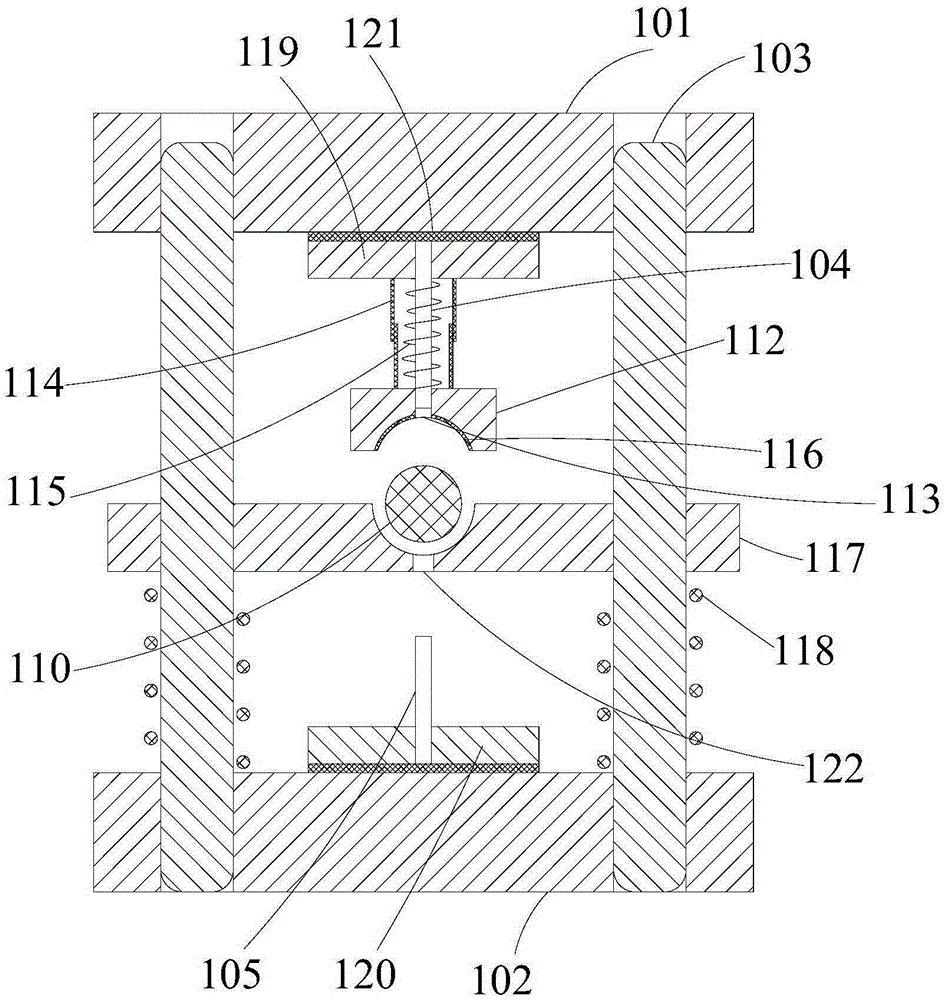

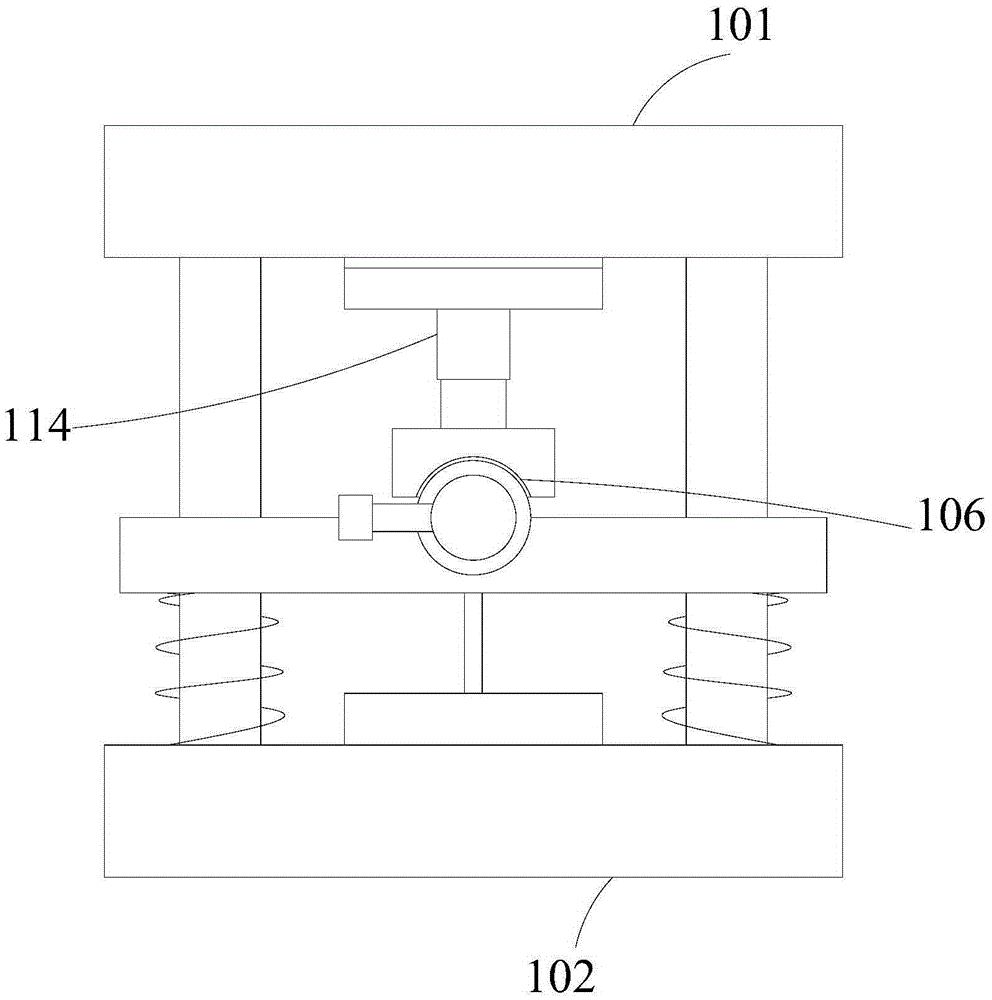

Piercing die for piercing in sidewall of round tube

The invention provides a piercing die for piercing in a sidewall of a round tube and belongs to the field of dies. The piercing die comprises an upper die holder and a lower die holder; the upper die holder is connected with the lower die holder through a guide column; the bottom of the upper die holder is connected with an upper terrace die; a round tube holding portion is longitudinally arranged on the lower die holder; the lower die holder is further connected with a positioning mechanism; the positioning mechanism comprises a driving assembly, a transmission assembly and a positioning assembly, all of which are orderly connected with each other; the positioning assembly comprises a columnar positioning rod that can be driven by the driving assembly to move in a longitudinal direction; when the round tube is placed on the round tube holding portion, the positioning rod can be inserted into the round tube while moving. Such a piercing die is capable of quickly and accurately piercing the sidewall of the round tube; a machined workpiece has the characteristics of high quality and high accuracy and is capable of meeting the requirements of modern production.

Owner:TAIZHOU RUNJIE LOGISTICS SAFETY EQUIP TECH CO LTD

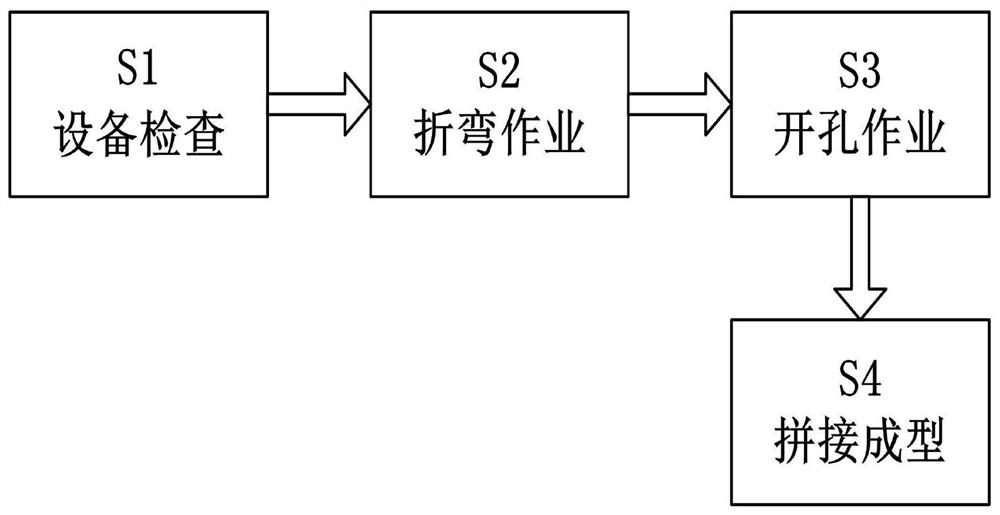

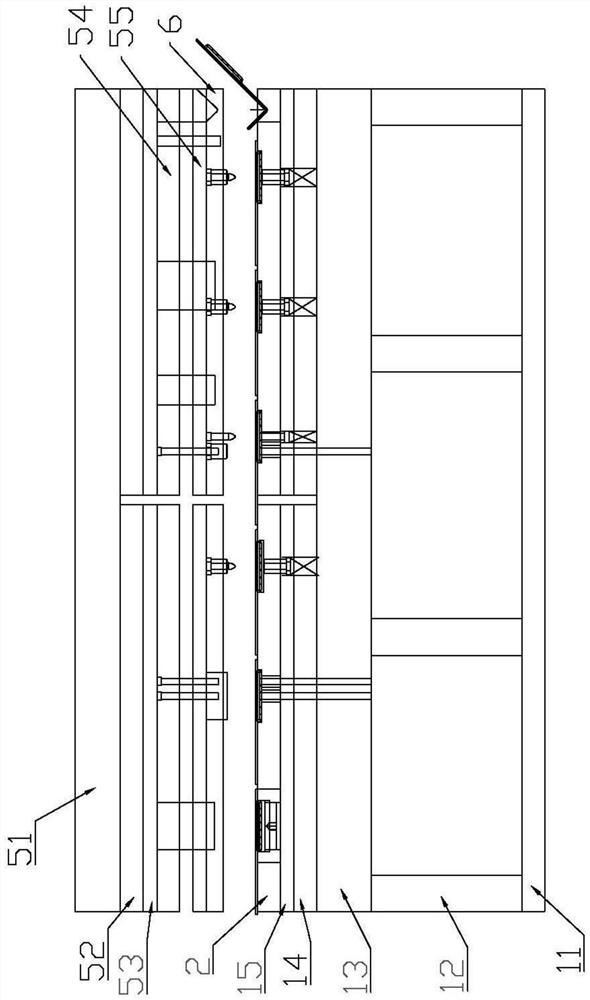

Manufacturing method of power distribution switch cabinet

InactiveCN112719808AShorten production timeSolve low production efficiencySwitchgearMechanical engineeringIndustrial engineering

Owner:张福全

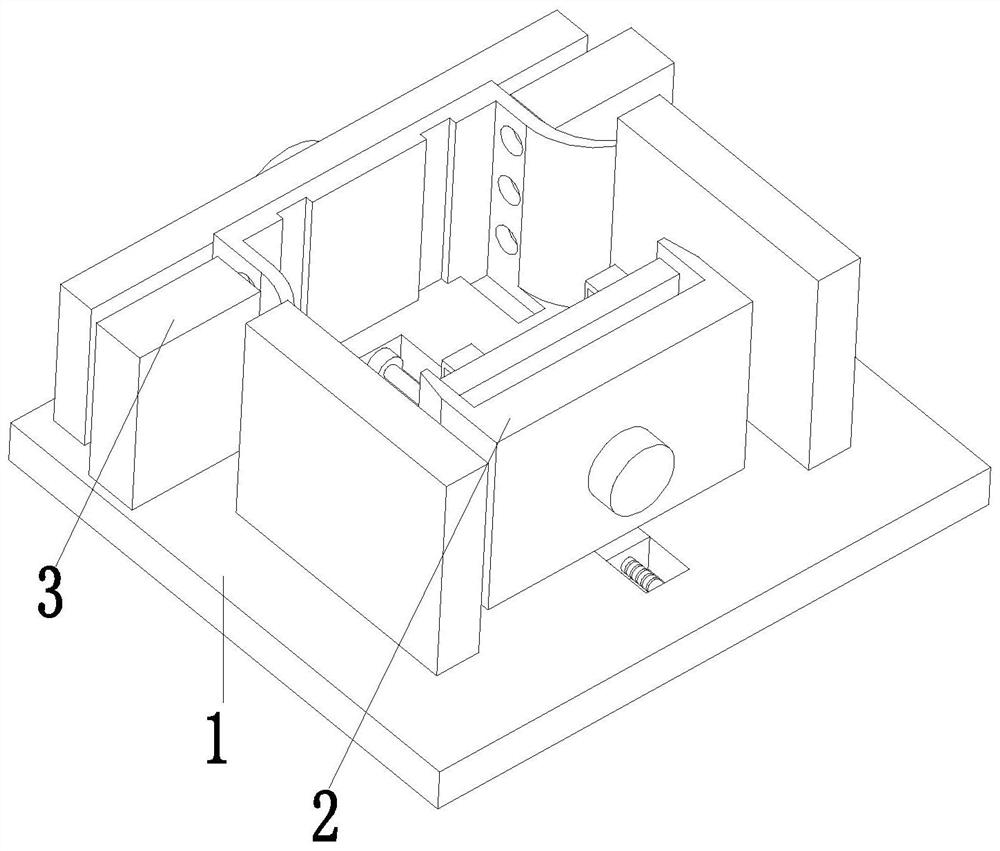

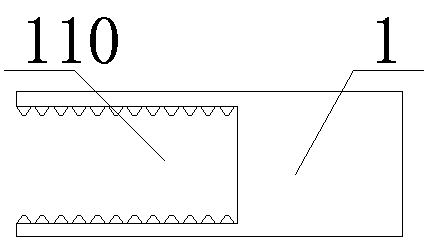

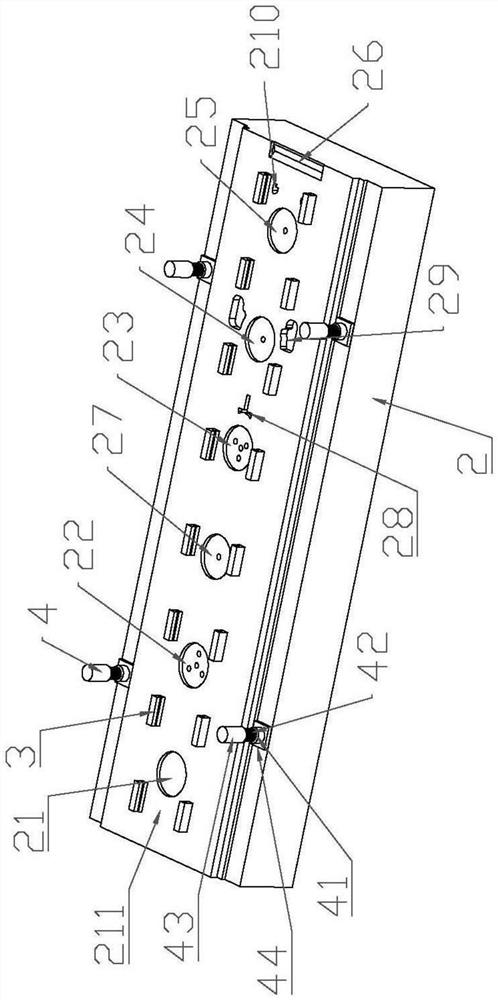

Wiring hidden box machining tool

PendingCN109304621AAccurate shapePrecise hole positionOther manufacturing equipments/toolsPunchingEngineering

The invention discloses a wiring hidden box machining tool, and belongs to the field of wiring hidden box manufacturing. The wiring hidden box machining tool comprises an upper mounting seat and a lower mounting seat which are mounted on a rack. A punching and tapping mold set, a stamping mold set and a forming mold set are sequentially mounted in the upper mounting seat and the lower mounting seat in the feeding direction. The punching and tapping mold set is used for machining mounting holes, lug seats, connecting holes and knock-off holes on plates. The stamping die set is used for machining buckles and clamp grooves on the plates, and gaps used for subsequent forming and splicing are punched on the two sides, in the width direction, of each plate. The forming die set is used for bending the plates after the plates are shorn off to form finished hidden boxes. By means of the wiring hidden box machining tool, one-time machining of wiring hidden boxes can be continuously completed, the machined wiring hidden boxes are precise in shape and accurate in hole position, and the machining efficiency is extremely high.

Owner:安徽省华夏机床制造有限公司

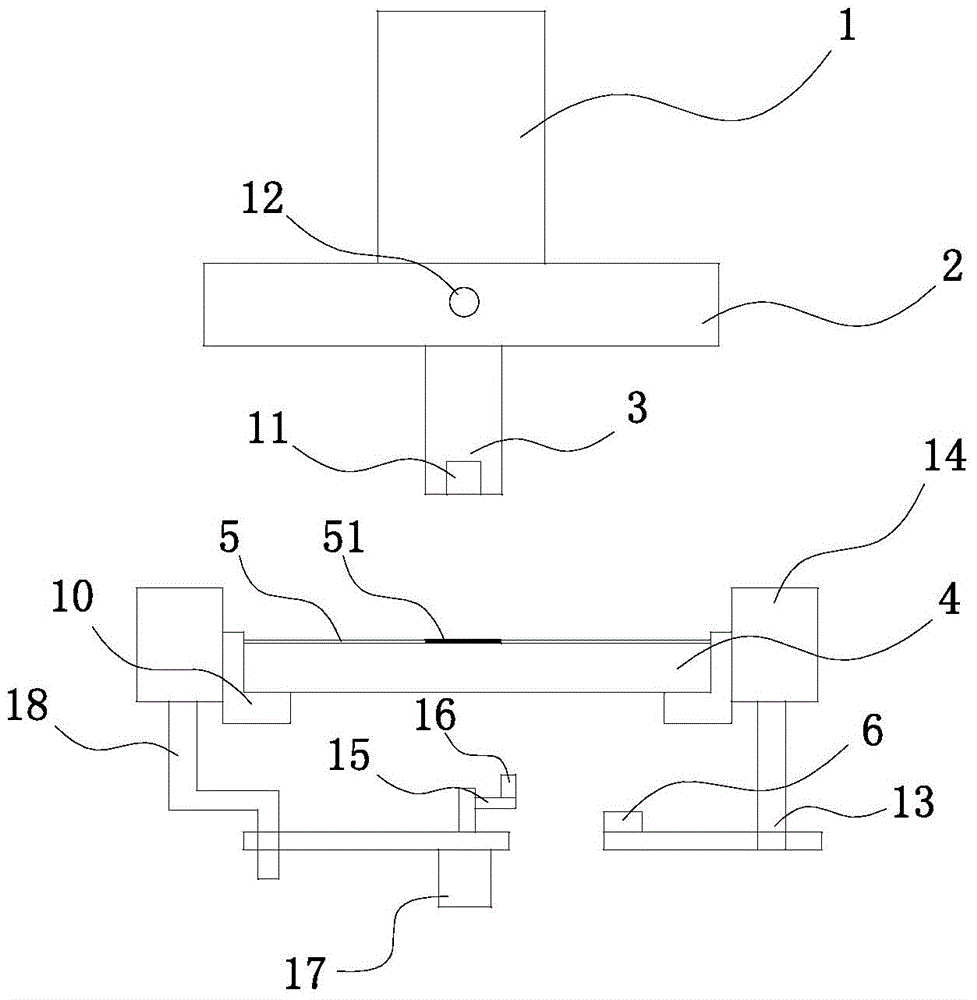

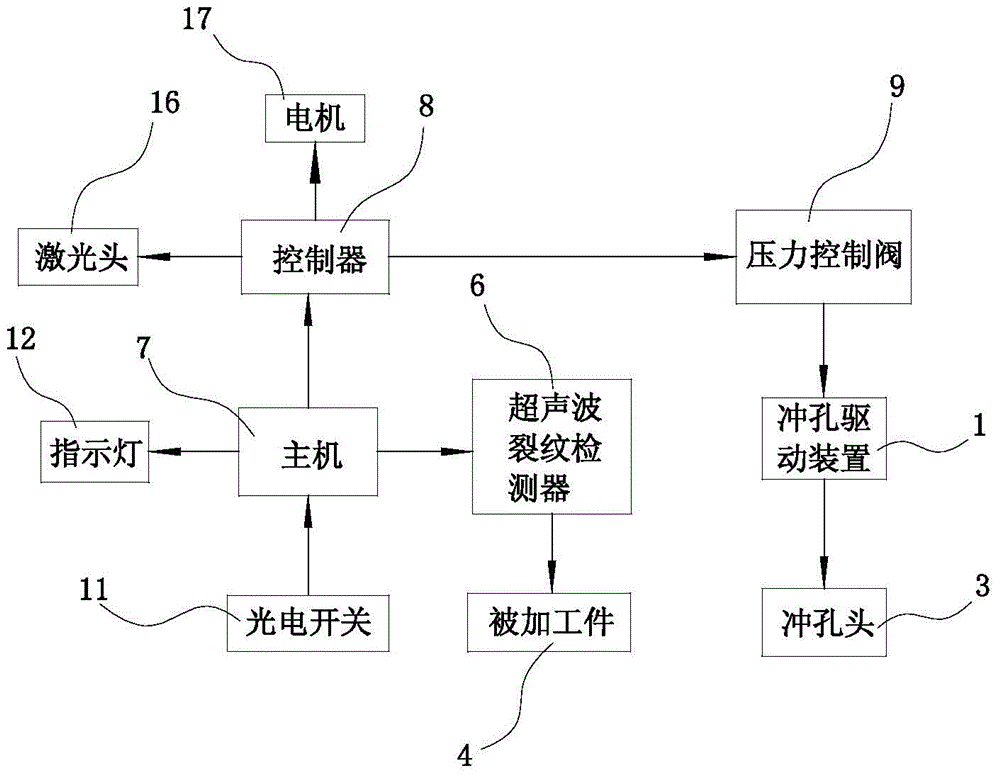

Punching device for positioned processing and opening cutting and trimming of micromotor support plate

InactiveCN105642740AImprove processing efficiencyReduce punching burrsMetal-working feeding devicesPositioning devicesPunchingMicromotor

The invention relates to a punching device for positioned processing and opening cutting and trimming of a micromotor support plate. The punching device comprises a punching driving device, an upper die plate, a punching head and a clamping device positioned at a position below the punching head, wherein the micromotor support plate is arranged in the clamping device; the punching device also comprises a main unit, a controller, a pressure control valve and an ultrasonic crack detector positioned below the micromotor support plate; an optoelectronic switch is arranged in the punching head; the micromotor support plate is coated with a film; a color mark for detection of the optoelectronic switch is arranged on the film; the clamping device is arranged on a support; the ultrasonic crack detector is arranged at one side of the lower surface of the support by means of a connecting rod; a laser opening cutting device is arranged at the other side of the lower surface of the support by means of a bending frame; and an indicating lamp connected with the main unit is arranged on the front side face of the upper die plate. According to the punching device disclosed by the invention, pinching processing of sheet metal is realized by combining laser opening cutting with punching of the punching head; the punching device is high in processing efficiency and fewer in punching burrs; and the punching device has the characteristics of accuracy in positioning, convenience in operation and small deformation.

Owner:WUXI SAINENG MICRO MOTOR

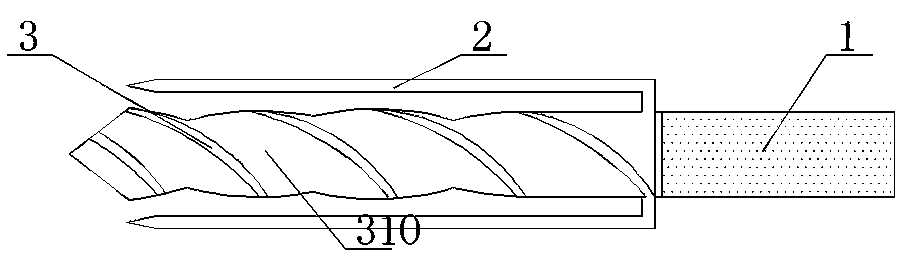

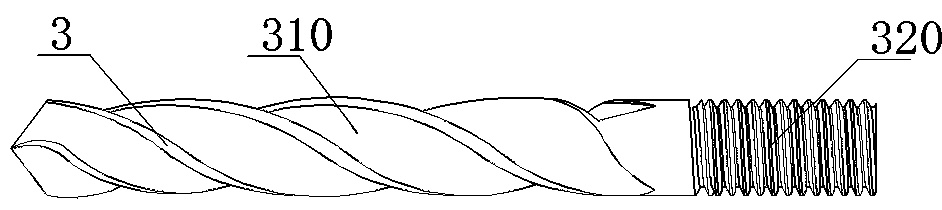

Cemented carbide bit

InactiveCN108788250ASave materialPrecise hole positionTransportation and packagingTwist drillsAlloyCemented carbide

The invention discloses a cemented carbide bit. The cemented carbide bit comprises a bit body and a bit stock. The surface of the bit body is provided with a chip groove. The upper side and the lowerside of the bit body are provided with a drilling assist device. A hollow gap is reserved between the drilling assist device and the bit body. A threaded column is further arranged at the right end ofthe bit body. The bit stock is internally provided with a threaded hole. The size of the space in the threaded hole is roughly the same as that of the threaded column. A hole drilled by the bit smaller the drilling assist device is more accurate. When the cemented carbide bit is used for drilling holes in some fine hole positions, the irreparable adverse influence caused by the inaccurate size ofthe drilled holes is avoided. On the other hand, the bit body is provided with the threaded column, the bit stock is provided with the threaded hole, and the threaded column is in threaded connectionwith the threaded hole. In the using process, only the bit body needs to be replaced. The material for manufacturing the bit stock is saved to some extent, and resources are saved.

Owner:长沙仲瑞新材料有限公司

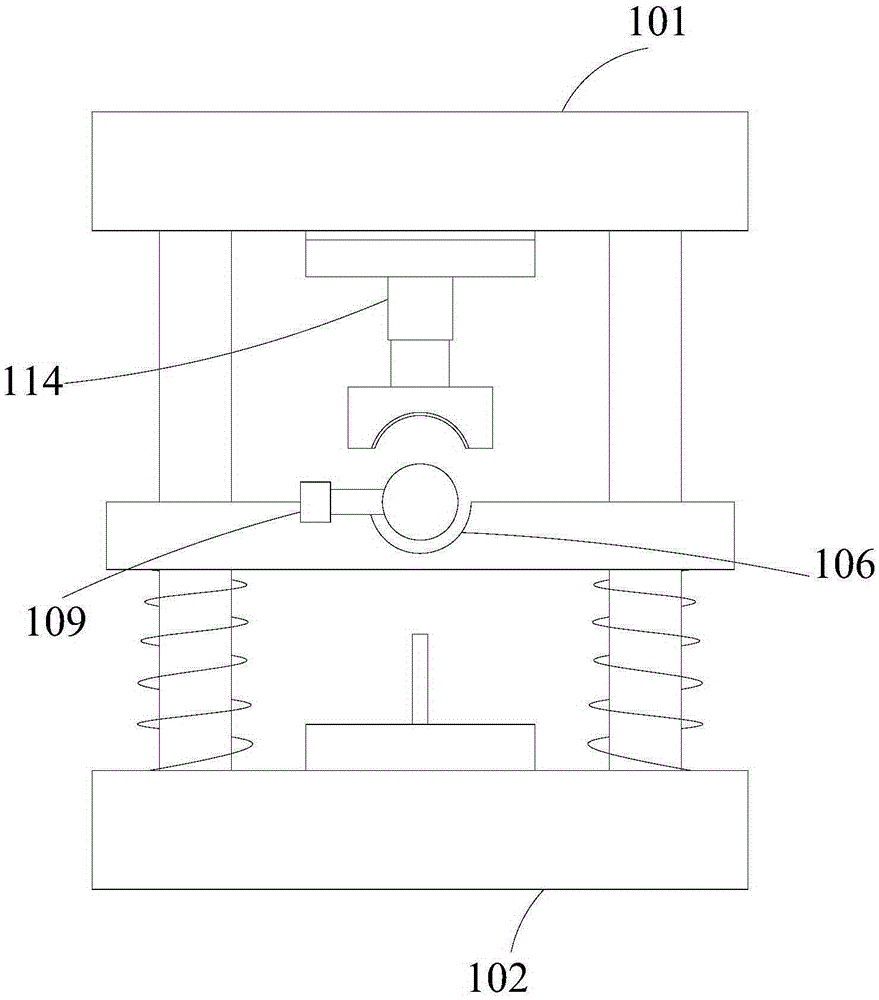

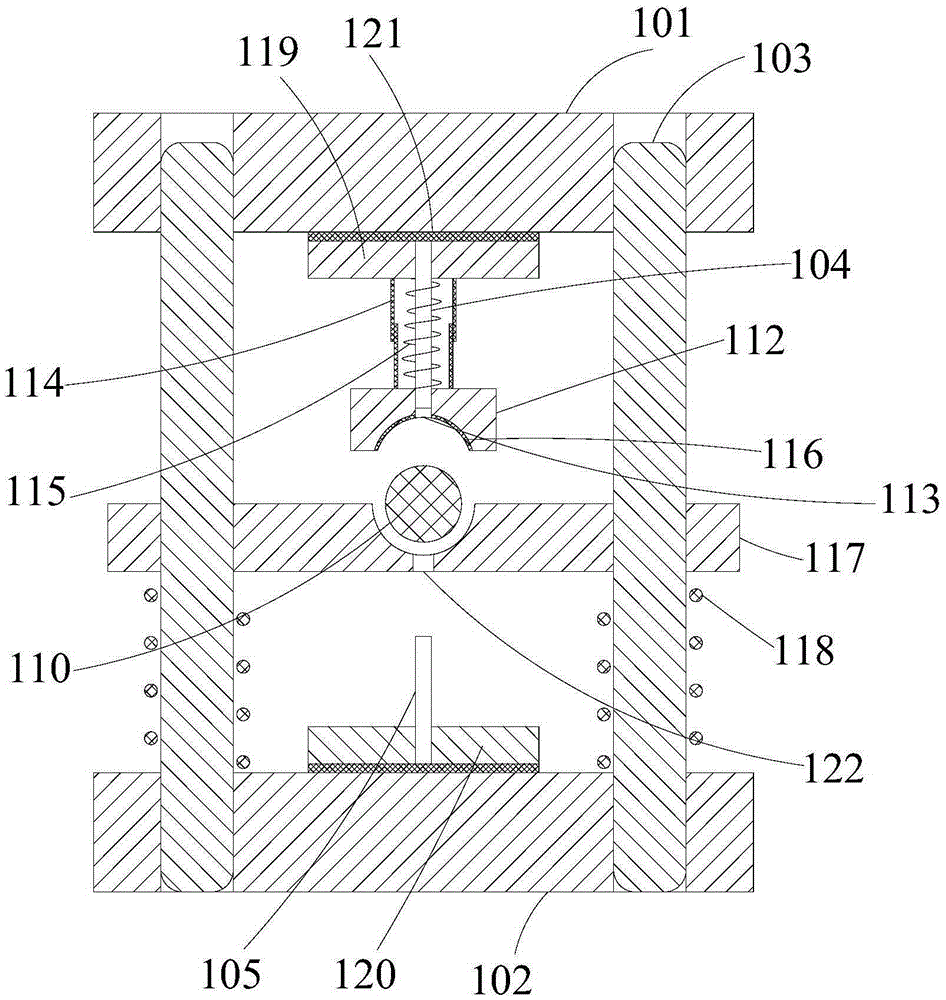

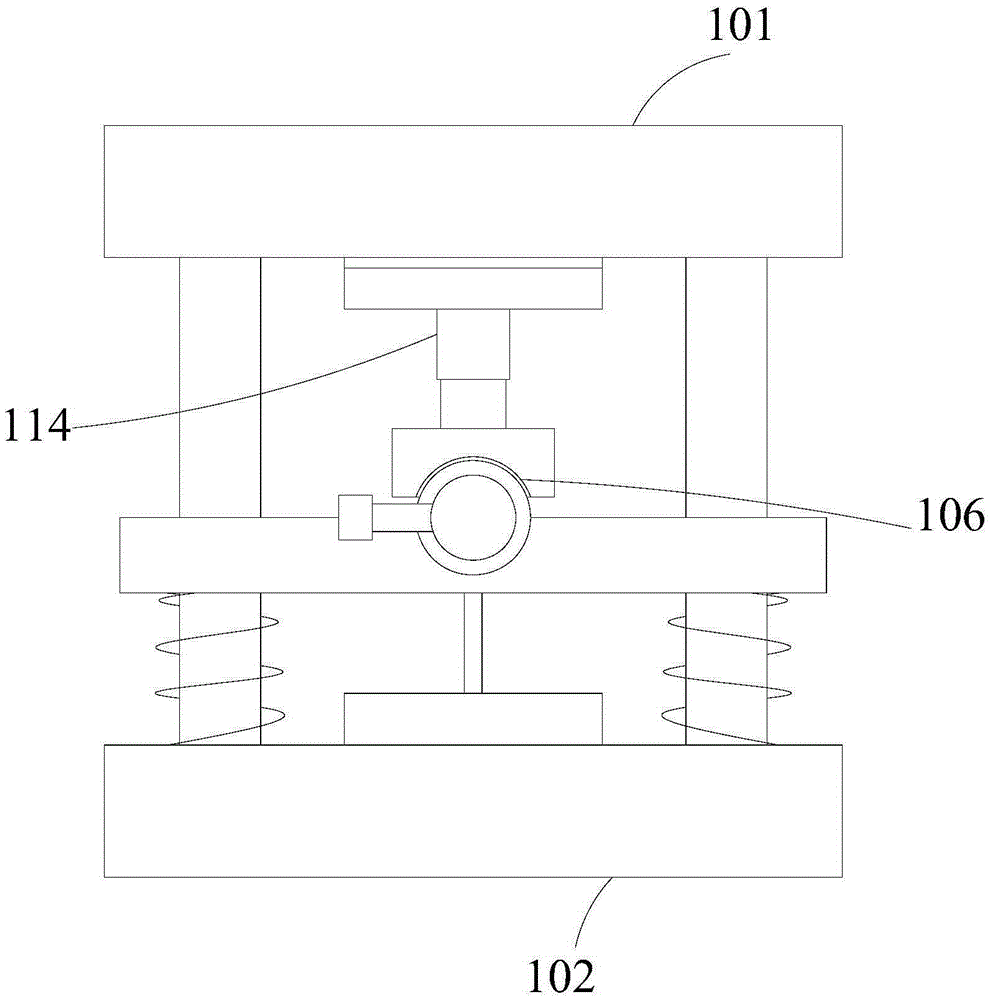

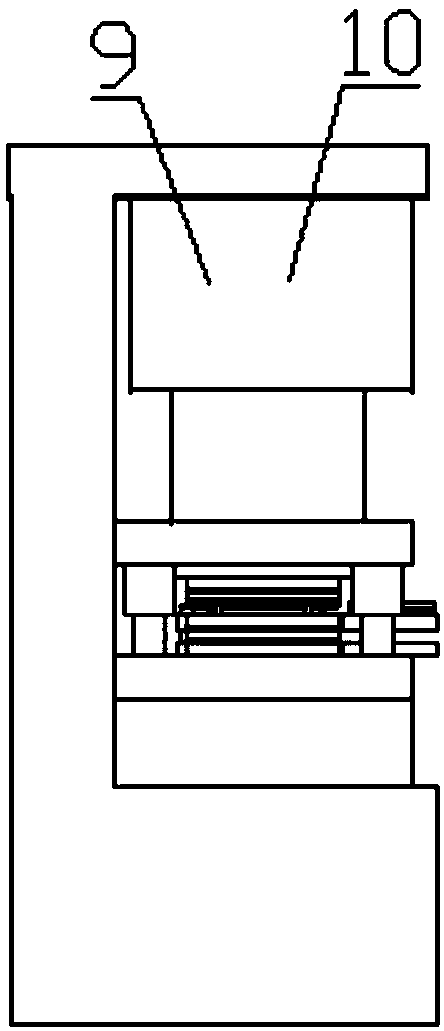

Punching die with opposite-punching mechanism

The invention provides a punching die with an opposite-punching mechanism, and belongs to the field of dies. The punching die with the opposite-punching mechanism comprises an upper die seat and a lower die seat which are connected by a guide column, wherein the bottom of the upper die seat is connected with an upper convex die; the top of the lower die seat is also connected with a lower convex die; a middle die seat is arranged between the upper die seat and the lower die seat and is connected with the lower die seat by a rest spring; the rest spring is arranged on the outer part of the guide column in a sleeving manner; a round pipe placing part is arranged on the middle die seat and is in an arc-shaped sinking groove structure; and the bottom of the arc-shaped sinking grove is provided with a round hole communicated with the bottom of the middle die seat. The punching die can punch a round pipe from two directions of the round pipe so as to finish the punching on two side hole positions of the round pipe, so that the working efficiency is improved, the device input is reduced, the workpiece accuracy is improved, and enterprise benefits can be promoted directly.

Owner:CHONGQING CHIHENG MOLD

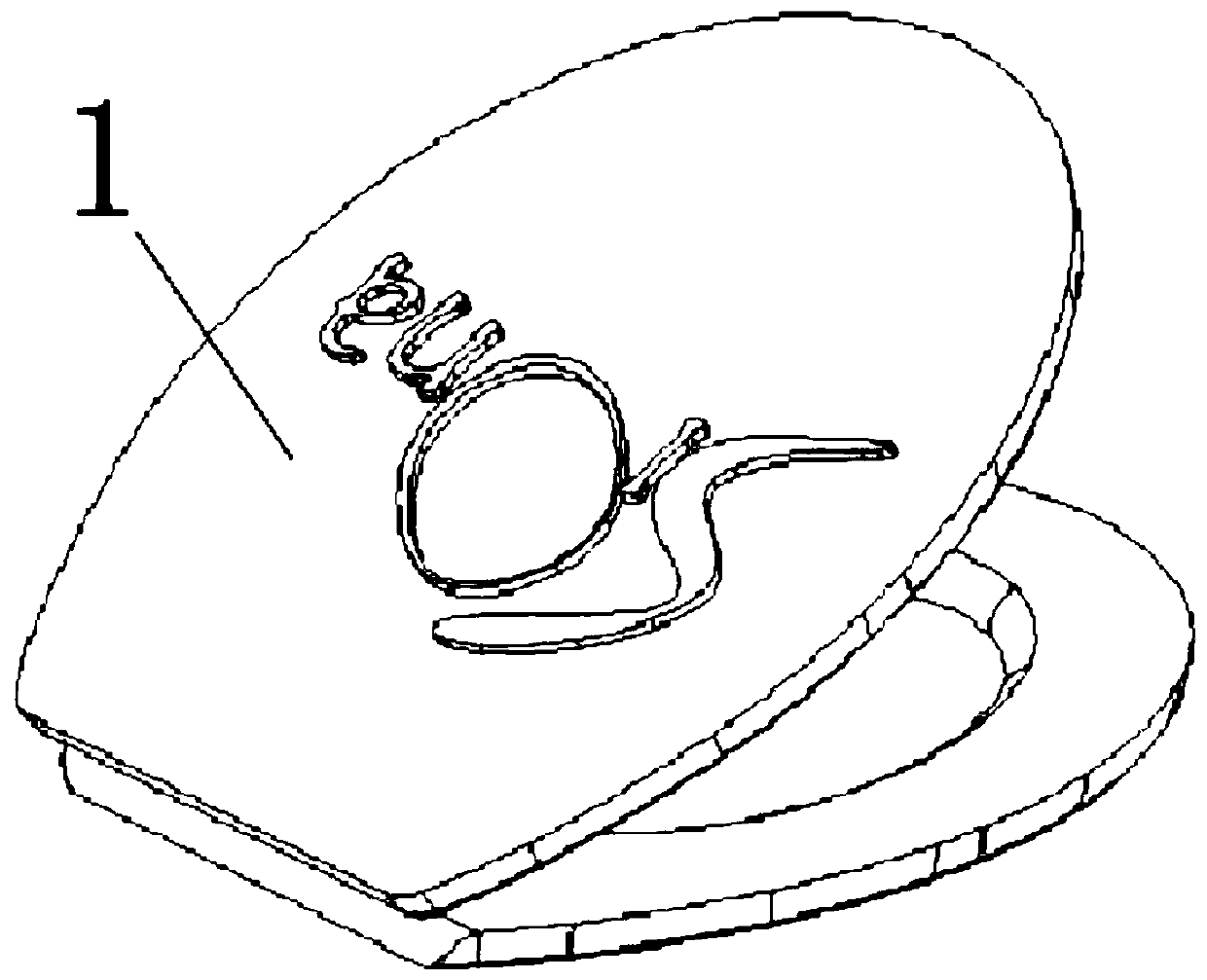

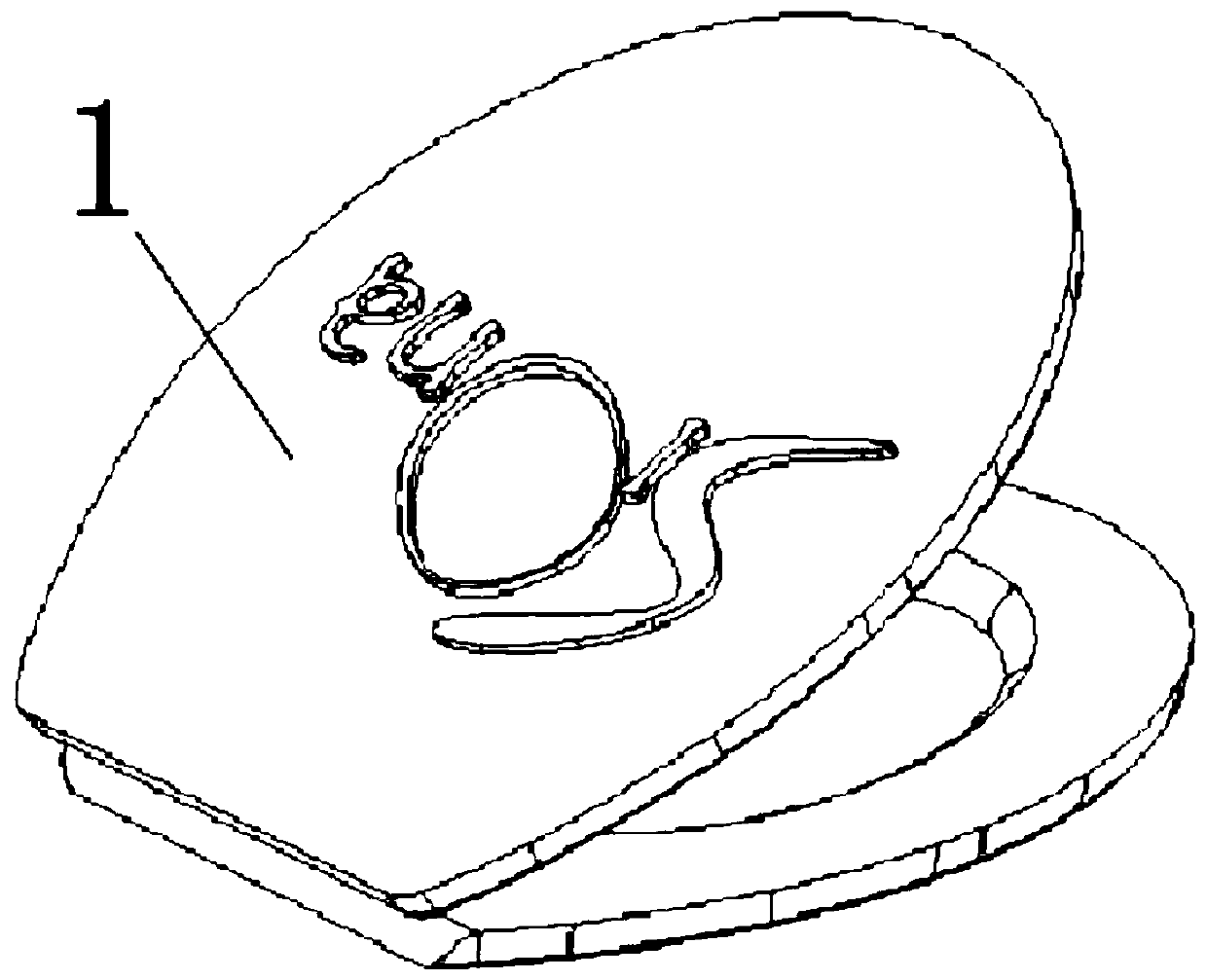

Leather carving closestool cover process

InactiveCN110014777AFlame retardantSound-absorbingDecorative surface effectsBathroom coversMildewEngineering

The invention provides a leather carving closestool cover process, and belongs to the technical field of bathroom products machining. The process comprises the following steps of (1) carving, specifically, placing a density plate on a workbench of a carving machine, carving and molding an inner contour and an outer contour according to an arrangement program; (2), edge trimming, specifically, placing the density plate on a working disc of the automatic edge trimmer in the middle, driving the density plate to rotate to be close to a rotating abrasive belt, starting automatic edge trimming; (3),spraying, specifically, uniformly coating the back surface of the cover, the front surface of the ring and the back surface of the ring; (4),embossing, specifically, carrying out an embossing processon the leather on the surface of the closestool cover by using an embossing machine; (5), finishing, specifically, cutting off redundant leather and edge sealing; and (6), polishing. According to theprocess, an autonomous improved CNC machining technology and a trimming technology are utilized, so that the production efficiency and the processing quality are improved, in addition, the hand feeling of the leather carving is excellent, the pattern is fine and graceful, and leather carving closestool cover has the functions of flame retardancy, sound absorption, sound insulation, moisture prevention, mildew prevention, anti-bacteria, water-proof, oil-proof, dust-proof, anti-fouling, anti-static and anti-collision.

Owner:ZHEJIANG HENGYUAN SANITARY WARE

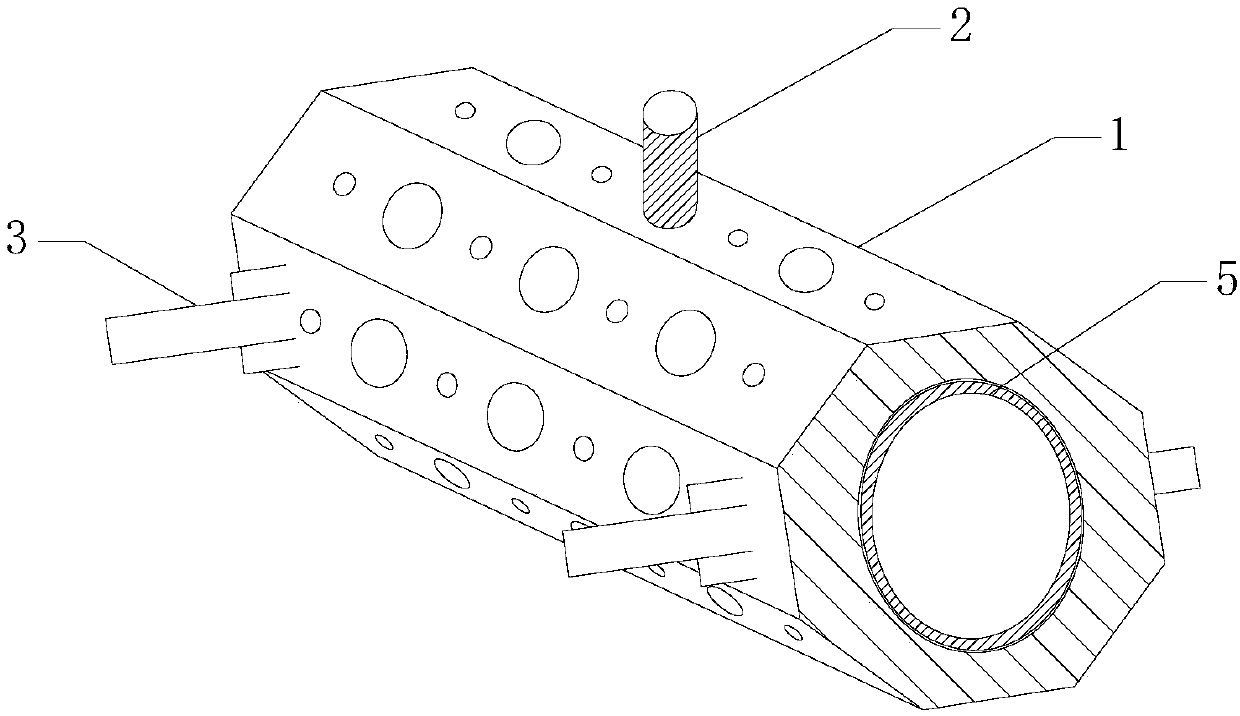

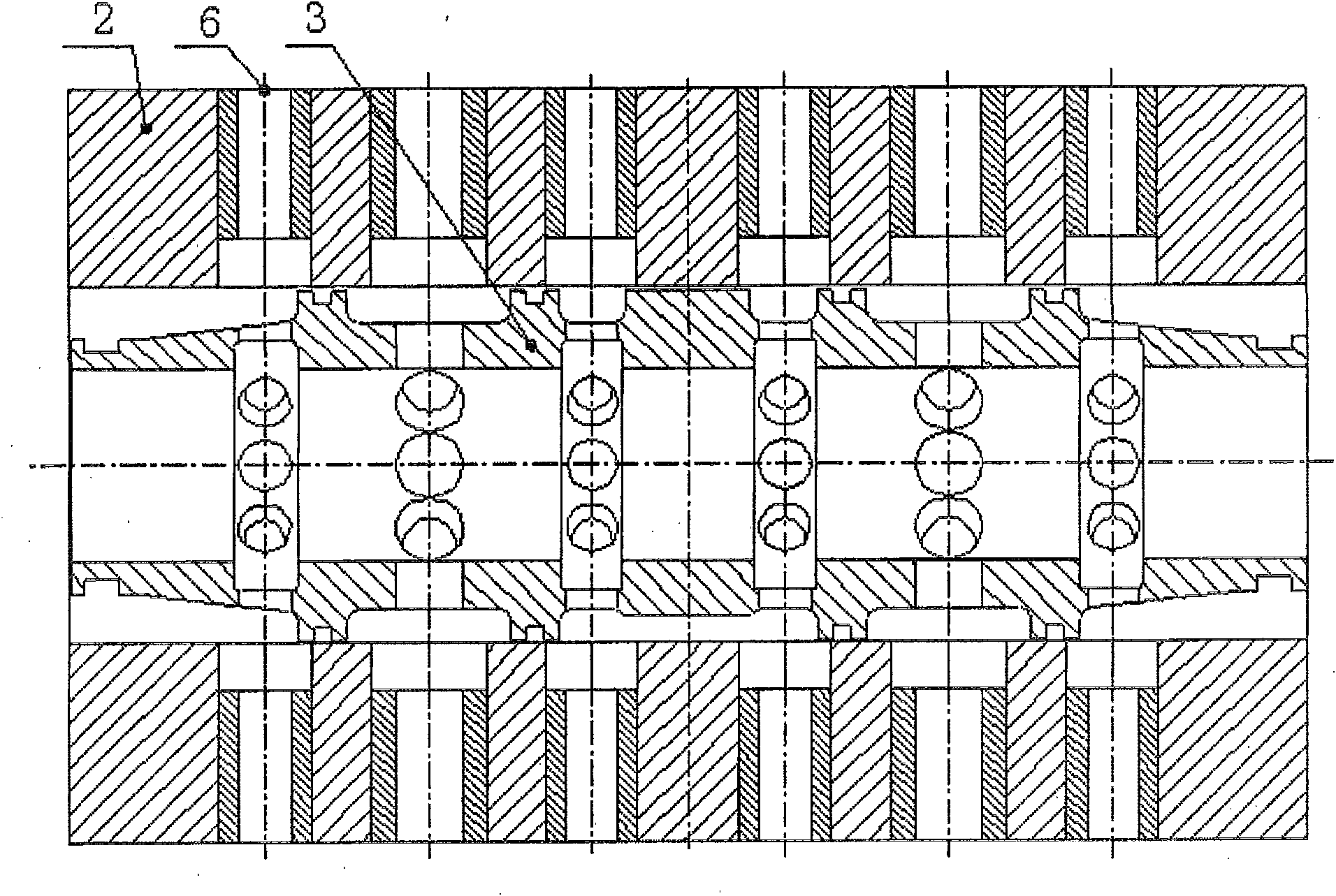

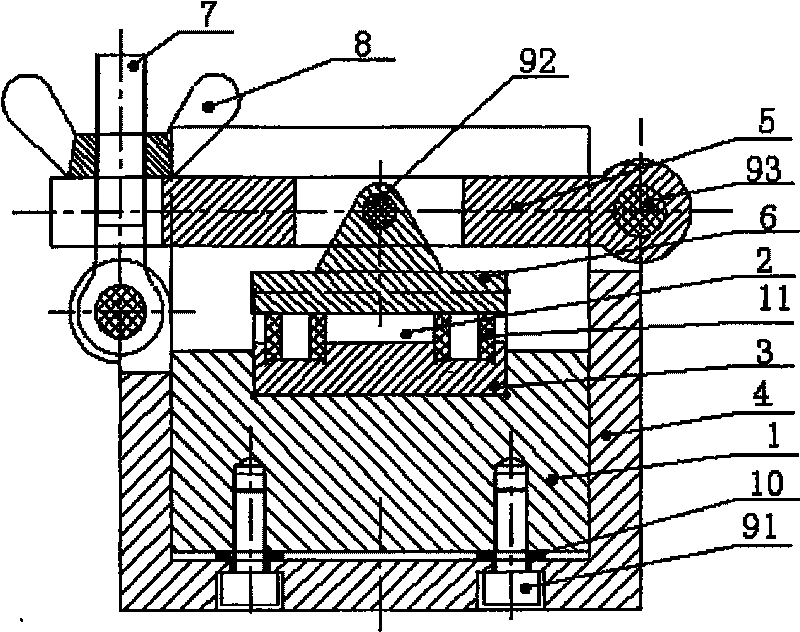

Valve sleeve boring fixture

PendingCN110355582AReduce setup timeAccurateWork clamping meansPositioning apparatusHydraulic machineryPrism

The invention provides a valve sleeve boring fixture and belongs to the technical field of hydraulic mechanical manufacturing. The valve sleeve boring fixture specifically comprises a fixture body, alocating pin and lead screws. The fixture body is a cylindrical hollow eight-edge prism. The eight surfaces of the fixture body are all provided with through holes. The lead screws penetrate through the fixture body and are fixed to the fixture body through nuts. The lead screws are symmetrically arranged on the edges of the fixture body. The valve sleeve boring fixture provided by the invention can enable a valve sleeve and the fixture body to be coaxial and ensure the position correctness and high precision of machining holes. Moreover, a machined valve sleeve is complete in appearance and high in rate of finished products.

Owner:XIANGYANG HANGYU ELECTROMECHANICAL HYDRAULIC APPL TECH CO LTD

Continuous forming die for machining corrugated resistance tube support

PendingCN114309248AImprove bending effectReduce in quantityShaping toolsPerforating toolsPunchingEngineering

The invention relates to the technical field of resistance tube processing equipment, in particular to a continuous forming die for processing a corrugated resistance tube support, which comprises a lower die set and an upper die set arranged right above the lower die set, the lower die set comprises a lower support plate, a lower foot pad, a lower die holder, a lower back plate, a lower base plate and a lower die plate which are sequentially arranged from bottom to top; the lower die plate is provided with a forging and pressing positioning groove, a punching positioning groove, a cutting positioning groove and a bending pressing groove, a lower die insert core is arranged beside the cutting positioning groove, and discharging holes penetrating through the lower die plate, the lower base plate, the lower back plate and the lower die base are formed in the bottoms of the punching positioning groove and the lower die insert core. The upper die set comprises an upper die base, an upper back plate, an upper base plate, an upper clamping plate, a stopping plate and an upper stripping plate which are sequentially arranged from top to bottom. The upper stripping plate is provided with a stretching bow aligned with the forging and pressing positioning groove, a punching needle aligned with the punching positioning groove, a punch aligned with the lower die insert core and a bending cutter aligned with the bending pressing groove. And the production efficiency is high, the product quality is excellent, and the cost is saved.

Owner:GUANGDONG FULLDE ELECTRONICS +2

A device for ensuring the coaxiality of multi-tab holes

ActiveCN112091283BPrecise hole positionPrecise positioningDrill jigsEngineeringMechanical engineering

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

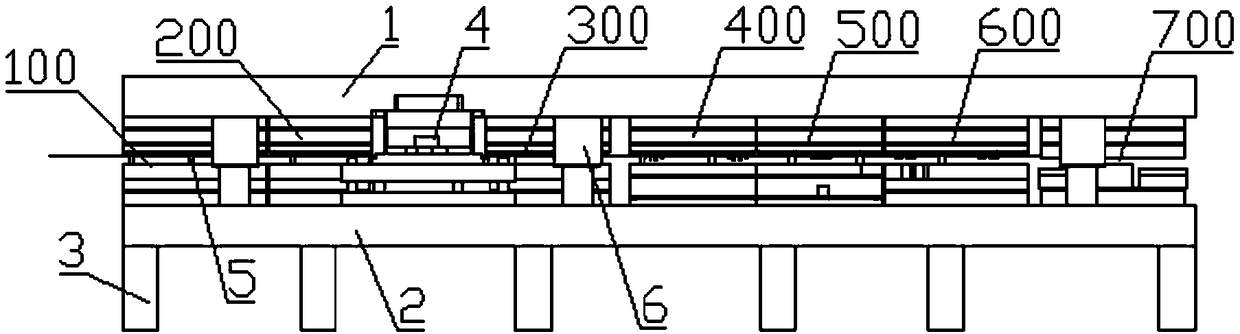

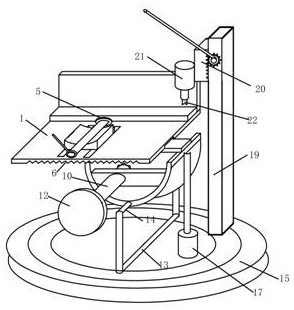

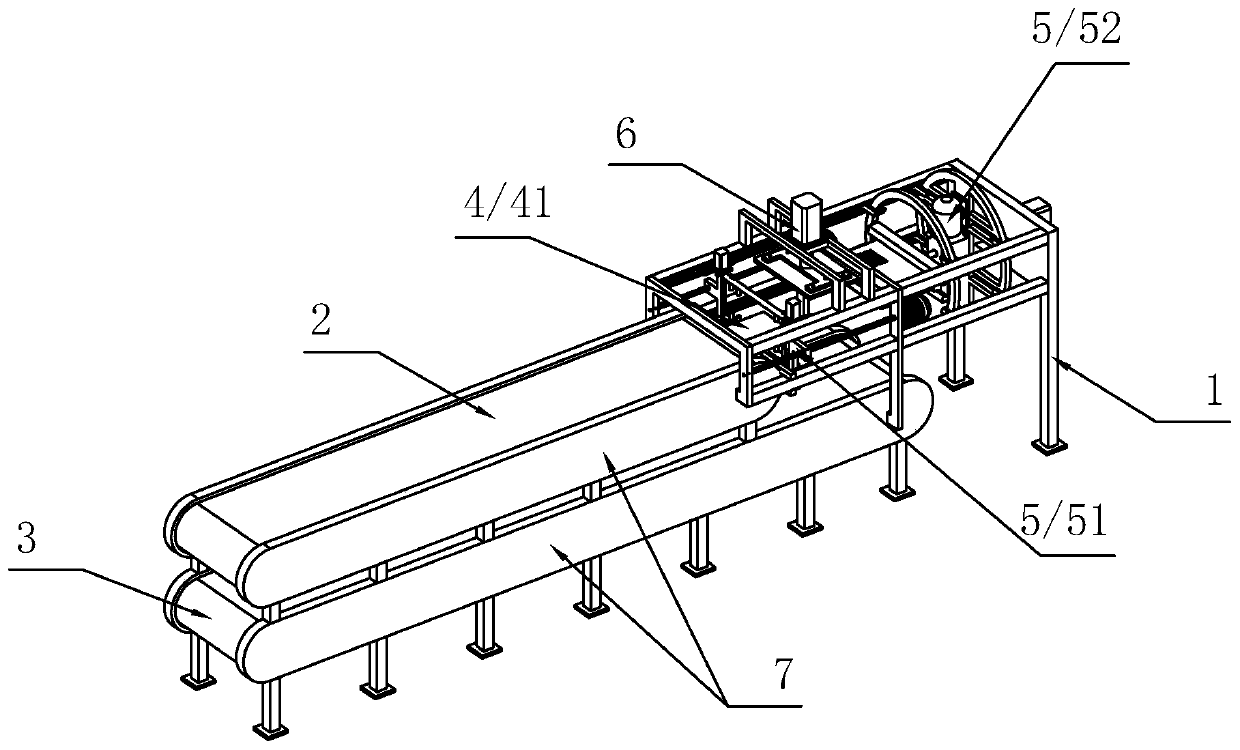

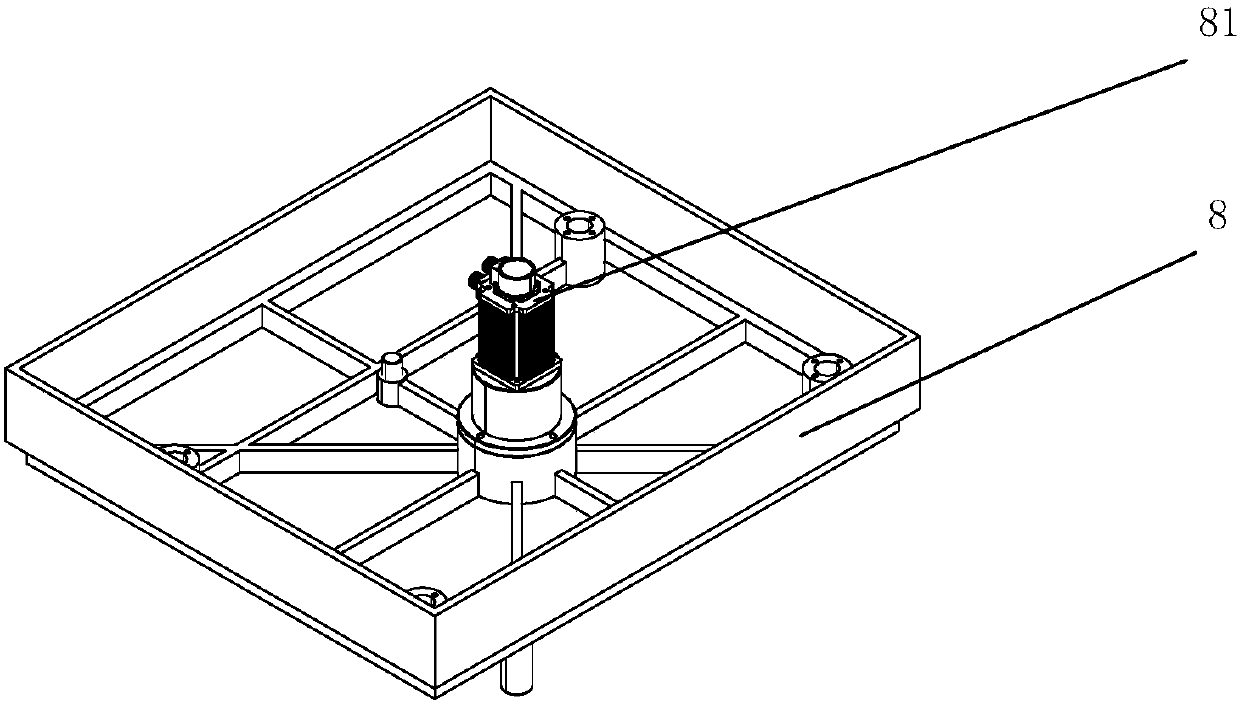

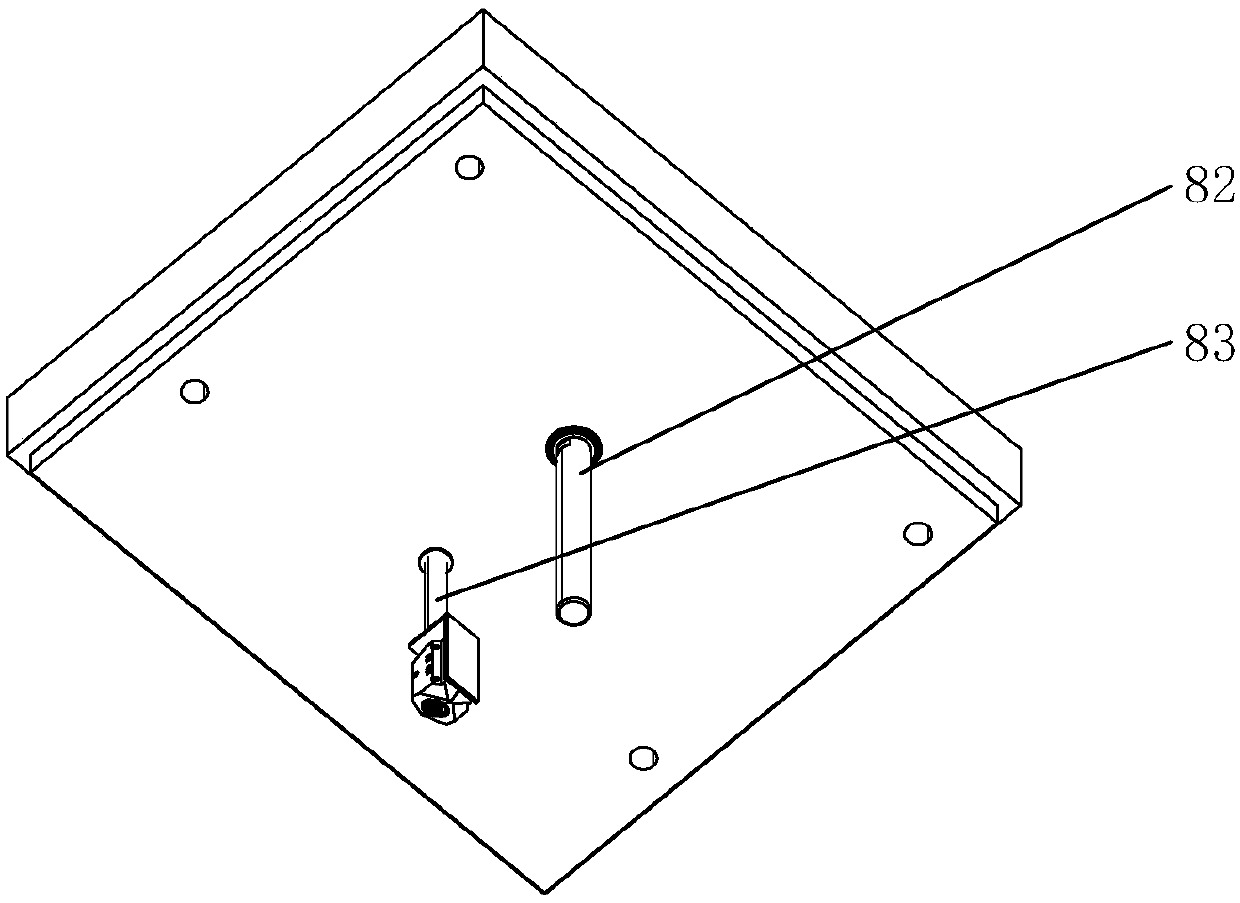

Flexible, simple and convenient plate processing equipment

InactiveCN112536849AAccurate openingPrecise hole positionMetal working apparatusElectric machineryEngineering

The invention belongs to the technical field of home decoration tools, and particularly relates to flexible, simple and convenient plate processing equipment. The invention discloses the flexible, simple and convenient plate processing equipment which comprises a base. A rack is arranged on the base; a driving rack is meshed with a driven rack; a rotary table is arranged at the other end of a rotating shaft; a supporting arm is arranged on the base; a sliding plate is arranged on the upper part of the supporting arm; a motor is arranged on the front face of the sliding plate; and the output end of the motor is connected with a rotating head. The flexible, simple and convenient plate processing equipment provided by the invention has the beneficial effects that continuous punching can be achieved, the hole position is ensured to be more accurate, meanwhile, inclined hole punching can be well and accurately conducted, and hole punching is easier, more convenient and more accurate.

Owner:浙江赛尚装饰材料有限公司

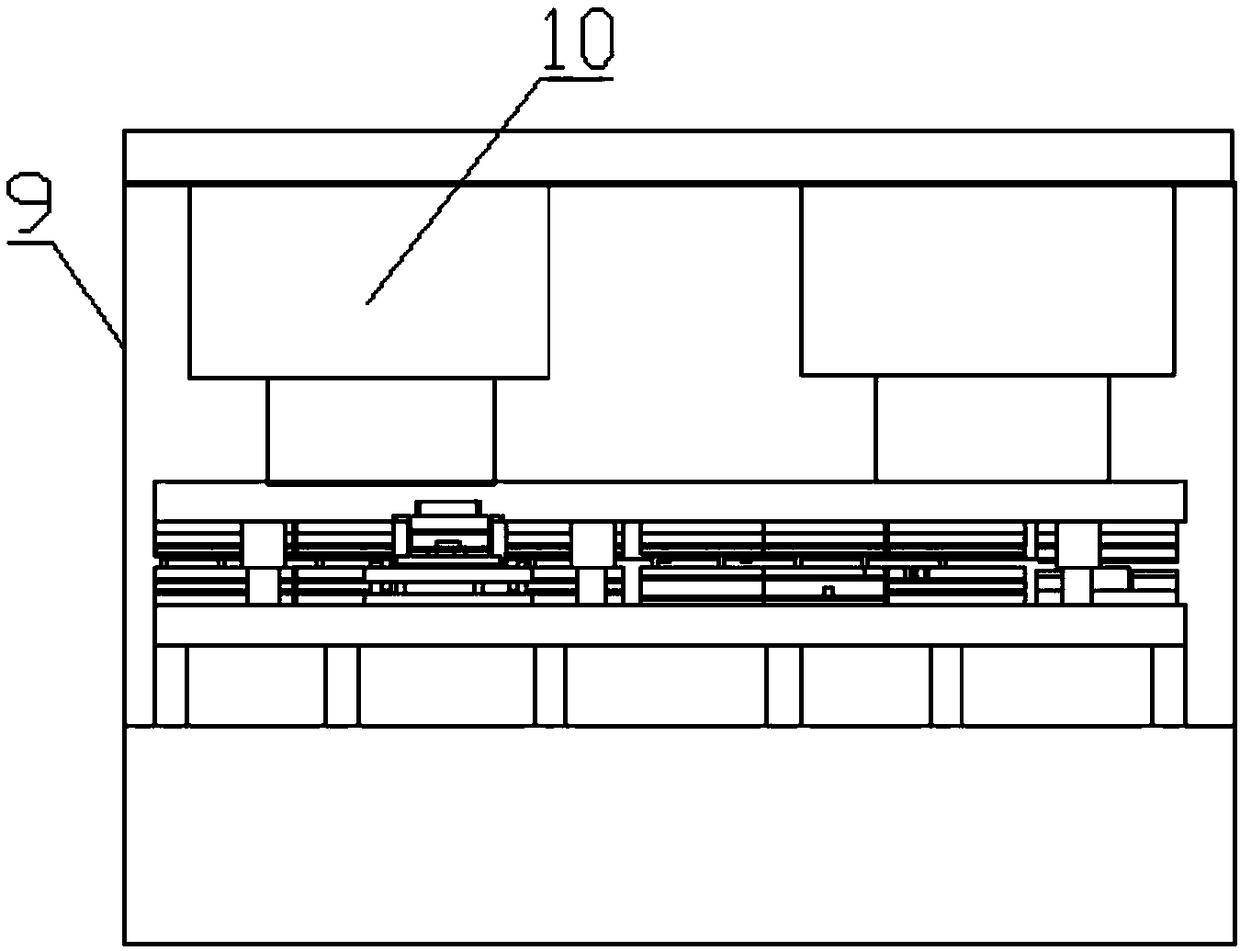

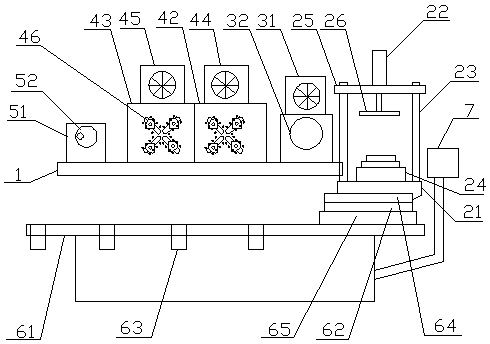

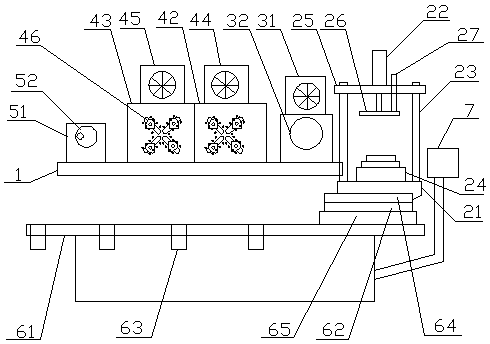

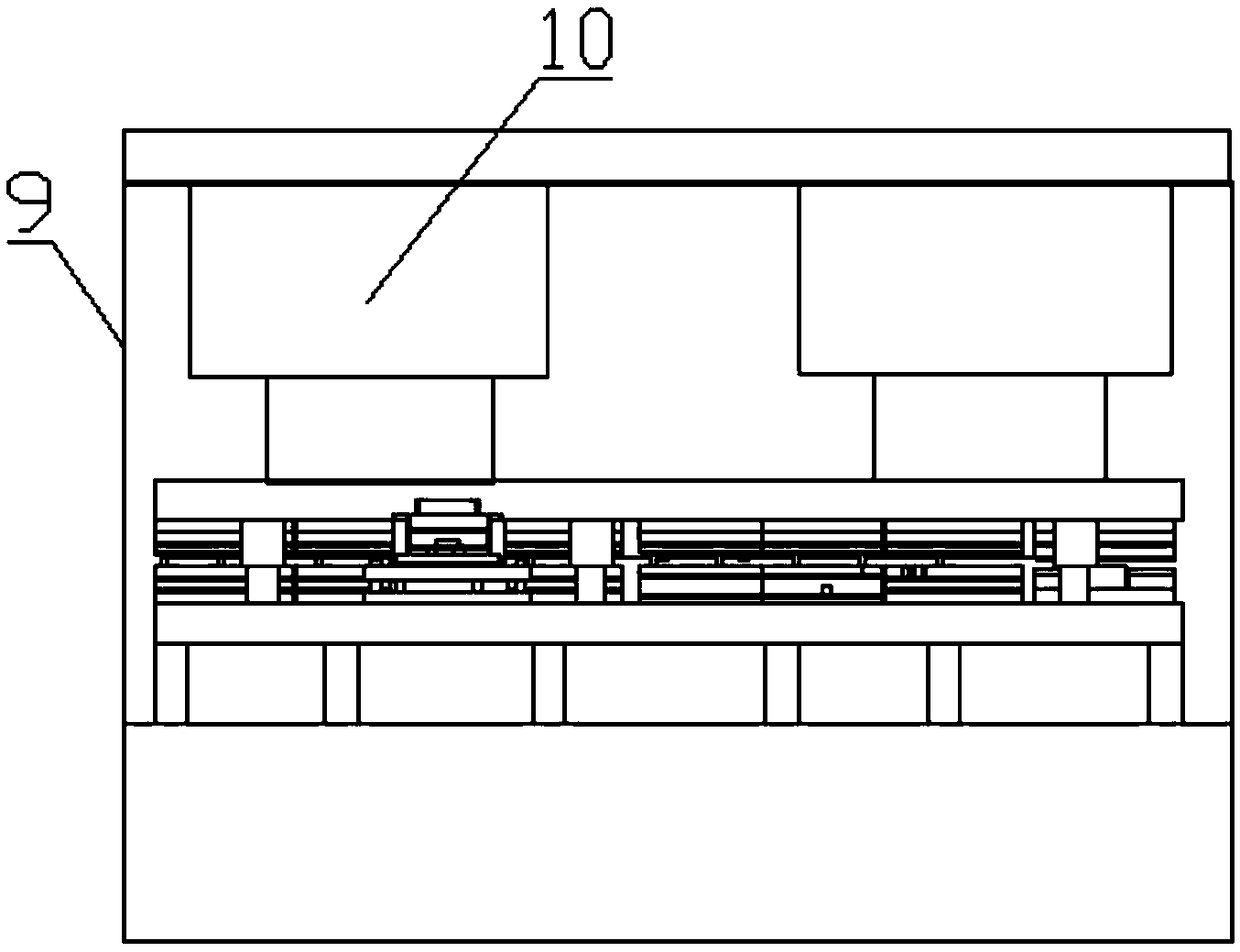

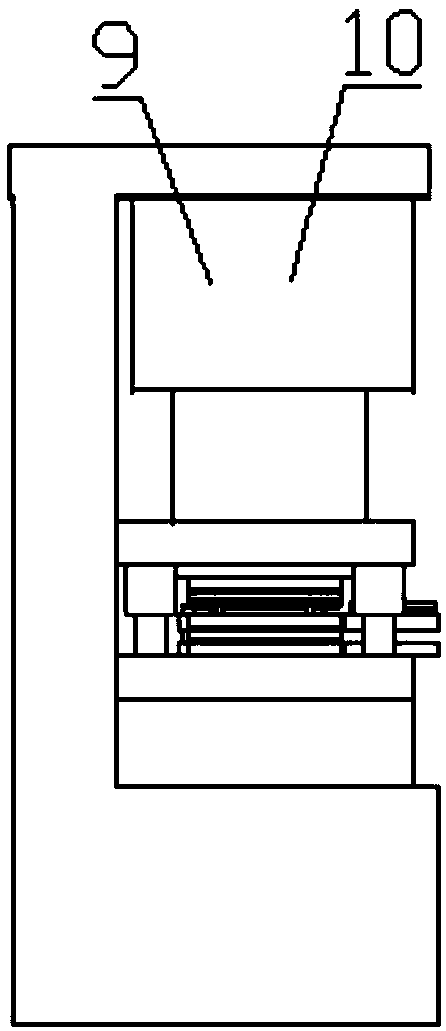

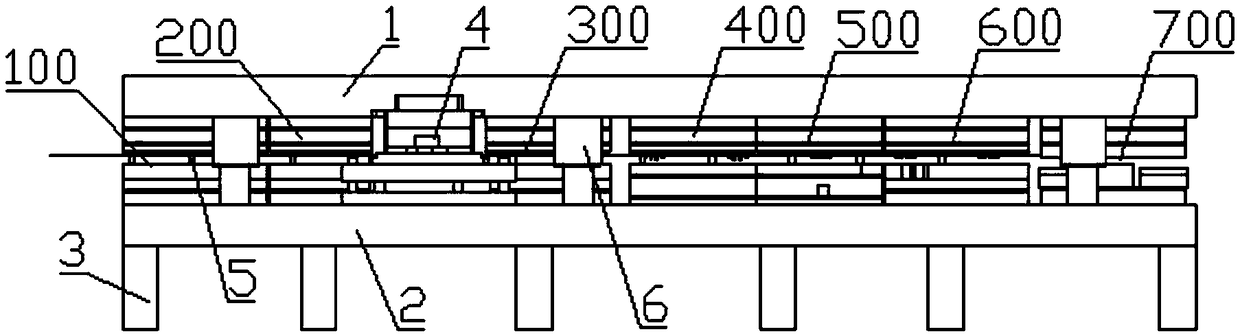

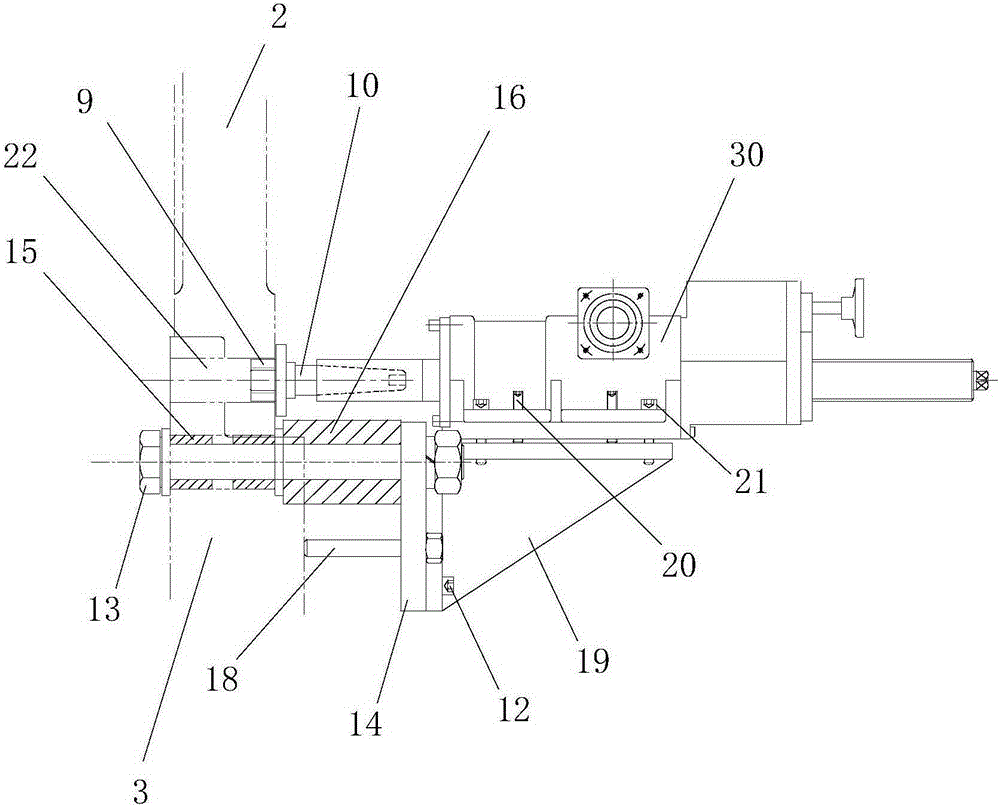

Explosion-proof motor base wiring hole combined machining device and machining method

PendingCN108213962AImprove the efficiency of combination processingSure easyOther manufacturing equipments/toolsPunchingEngineering

The invention discloses an explosion-proof motor base wiring hole combined machining device and a machining method and belongs to the technical field of explosion-proof motor machining. The explosion-proof motor base wiring hole combined machining device comprises a bearing platform. A milling mechanism, a punching mechanism and a turning mechanism are sequentially arranged on the bearing platform. A translation mechanism is arranged on the bearing platform. A pressing and positioning mechanism is arranged on the translation mechanism. The milling mechanism, the punching mechanism, the turningmechanism and the translation mechanism are all connected with a controller. By the adoption of the explosion-proof motor base wiring hole combined machining device and the machining method, during combined machining of an explosion-proof motor base, milling, drilling and tapping of mounting screw holes and drilling of wiring holes can be carried out continuously by means of one-time clamping, sothat the precision of combined drilling is improved, and the machining efficiency is high.

Owner:南阳微特防爆电机有限公司

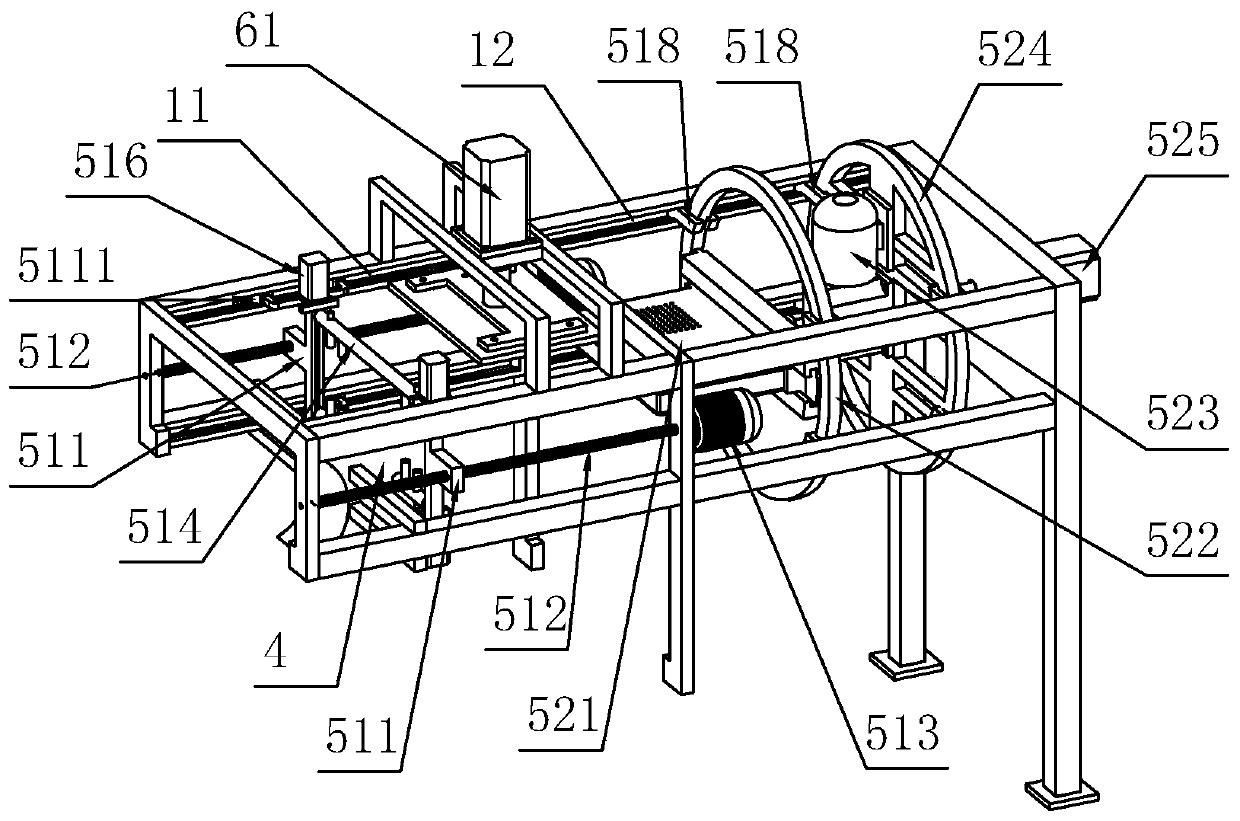

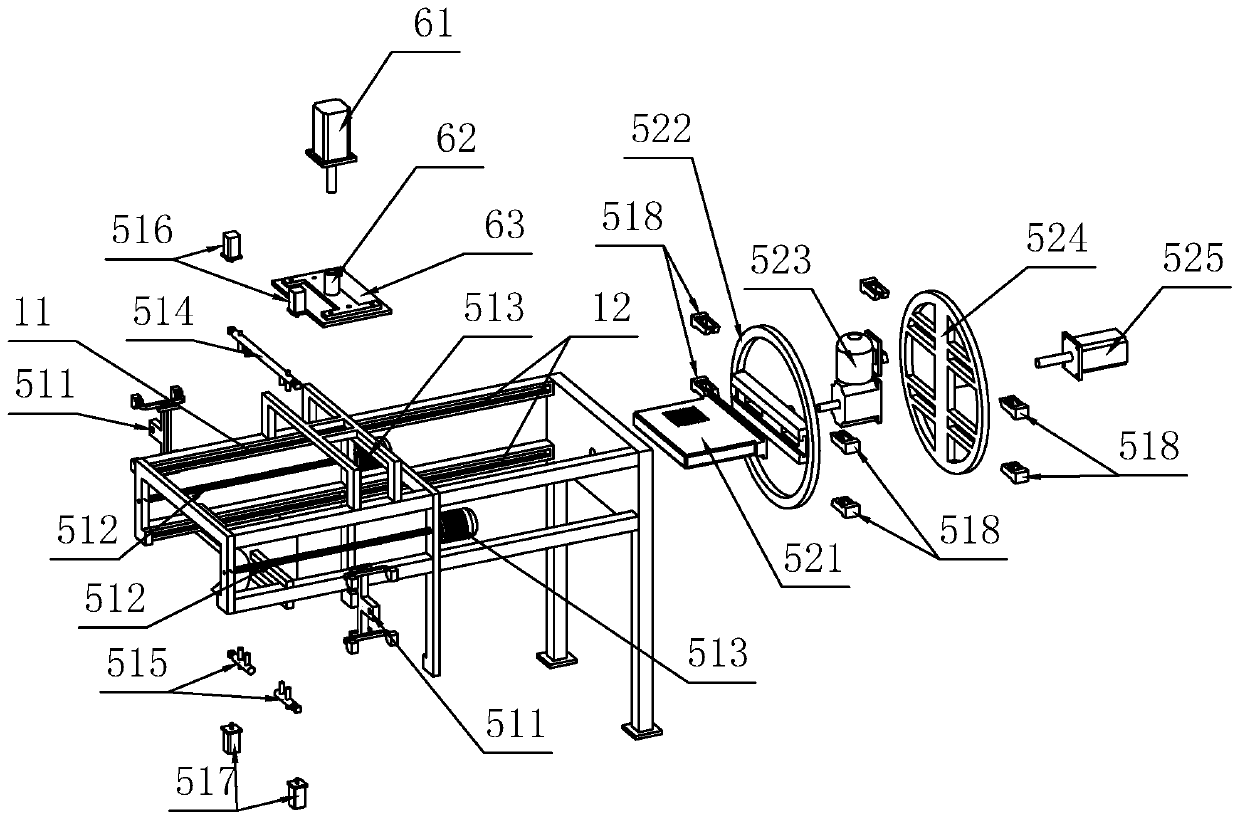

Non-woven fabric bag trepanning machine

ActiveCN111438992APrecise processingPrecise hole positionBag making operationsPaper-makingElectric machineryStructural engineering

The invention relates to a non-woven fabric bag trepanning machine. A rack is included and provided with a feeding platform, a bag body expanding mechanism and a trepanning mechanism. The bag body expanding mechanism comprises a transmission assembly and a tight expanding assembly. The transmission assembly comprises a horizontal sliding frame, a lead screw, a horizontal drive motor, an upper negative pressure suction pipe, a lower negative pressure suction pipe, an upper drive air cylinder and a lower drive air cylinder. The rack is provided with a horizontal track. A vertical track is arranged on the horizontal sliding frame. The lead screw is rotationally arranged on the rack. The horizontal sliding frame is in threaded connection to the lead screw. The vertical downward side of the upper negative pressure suction pipe is provided with an upper adsorption port, and the vertical upward side of the lower negative pressure suction pipe is provided with a lower adsorption port. The tight expanding assembly comprises a tight expanding module, and the tight expanding module is provided with hole-position-corresponding die hole positions. By adoption of the above scheme, the non-wovenfabric bag trepanning machine is provided, sewn non-woven fabric bags can be expanded, the parts needing trepanning are directly punched, and quantitative and high-precision production of non-woven fabric bags is achieved.

Owner:浙江中宇节能科技有限公司

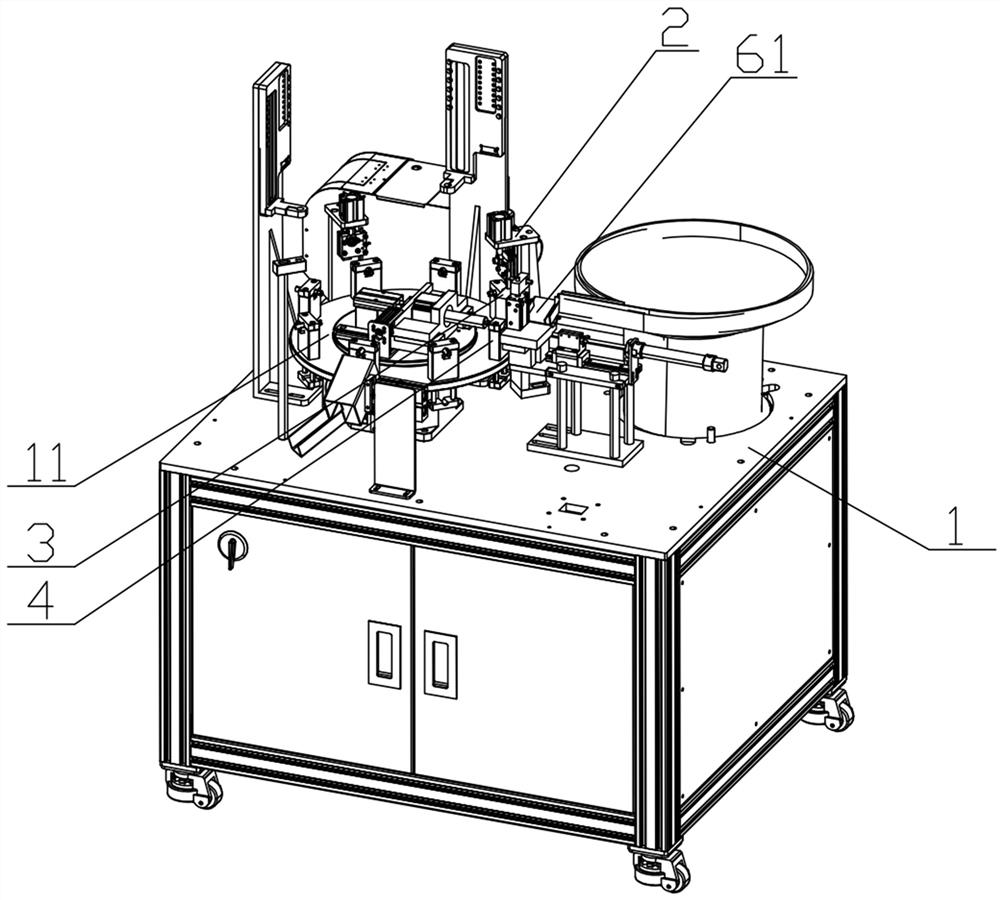

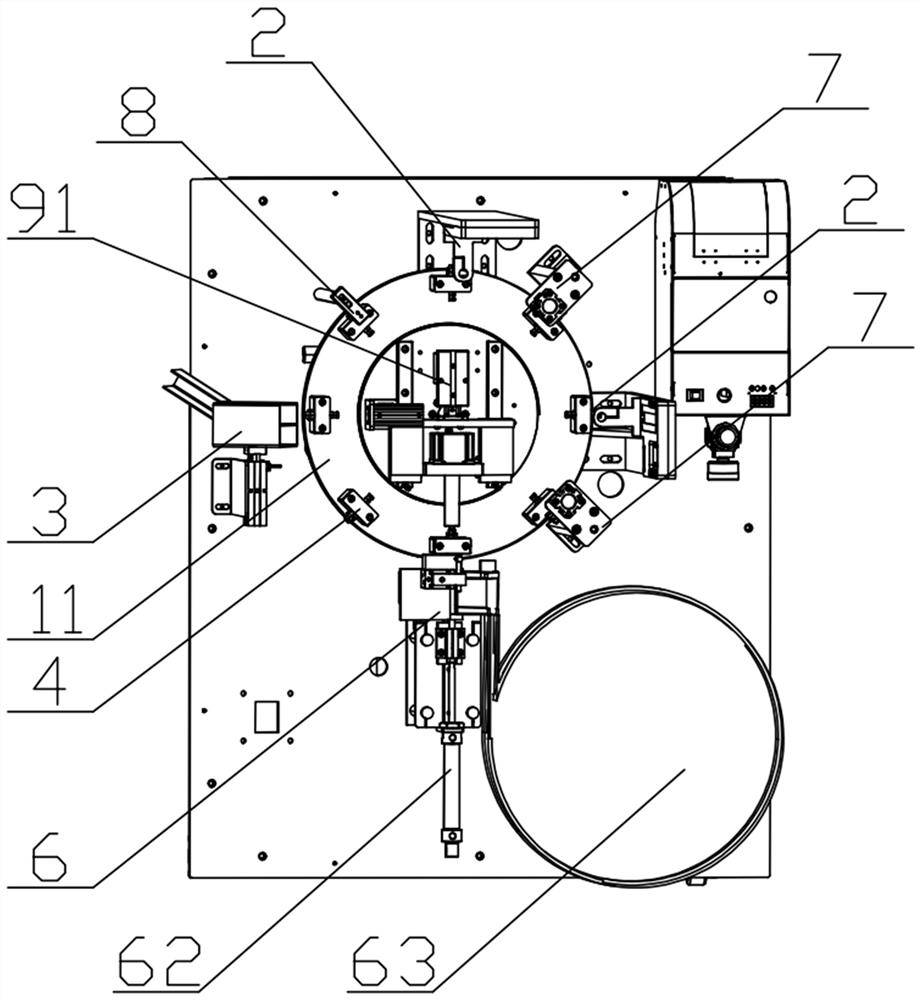

Columnar plug-in screw turning machine

PendingCN114473418APrecise hole positionGood technical effectMetal working apparatusPhysicsEngineering

The invention relates to the field of plug-in machining equipment, and discloses a columnar plug-in screw turning machine which comprises a rack, a conveying platform, a screw turning device and a plug-in direction adjusting device are arranged on the rack, the plug-in direction adjusting device comprises a limiting mechanism, a plug-in fixing mechanism is arranged on the conveying platform, and a limiting hole allowing a plug-in to axially pass through is formed in the plug-in fixing mechanism. The inserting piece can rotate in the limiting hole in the circumferential direction, the inserting piece direction adjusting device is provided with a matching part in transmission connection with the rotating power source, and the matching part is connected with the inserting piece. The limiting mechanism comprises a coordination needle in transmission connection with the positioning power source, and when the matching part is connected with the inserting piece, the center axis of the coordination needle is located in the plane where the center axis of the bolt hole is located; the plug-in is conveyed through the conveying platform, the plug-in direction adjusting device and the limiting mechanism are respectively matched with the plug-in so as to adjust the direction of the plug-in to the correct direction of screwing a screw, and then the plug-in with the adjusted direction is automatically conveyed to the screw screwing device to be automatically screwed into the screw.

Owner:温州盛时利智能装备股份有限公司

An automatic positioning device and method for drilling a drilling rig

ActiveCN105257274BExtended service lifeHigh degree of automationAutomatic control for drillingComputer terminalInteractive displays

The invention discloses a drilling automatic positioning device and method for a tunneling and drilling jumbo. The device comprises a drilling supporter, a distance measuring sensor, an advancing beam positioner, displacement sensors, an angle sensor, a laser alignment part, an interactive display terminal, a controller and a handle. The distance measuring sensor is used for determining a position relation among the tunneling and drilling jumbo, an advancing beam and an operation roadway face; the displacement sensors are respectively arranged on a near-slope oil cylinder, a telescopic oil cylinder, a pitch oil cylinder, a compensating cylinder and a lift cylinder; the angle sensor is arranged on a rotary oil cylinder; the interactive display terminal is used for the display of data and the selection and setting of a hole arrangement mode; the controller is used for receiving an instruction and driving a hydraulic valve, controlling strokes of oil cylinders, calculating the position and pose of the advancing beam by the measured data of the sensors, and finally determining the position of a drill; the handle is used for controlling the operation of the jumbo. According to the device and the method, drilling automatic positioning is realized according to the hole arrangement mode, the automation degree of the drilling jumbo is improved, the technical requirements on operators are reduced, the efficiency of tunnel operation is improved and the service lives of a drill pipe and the drill are prolonged.

Owner:上海绿钻机械有限公司 +1

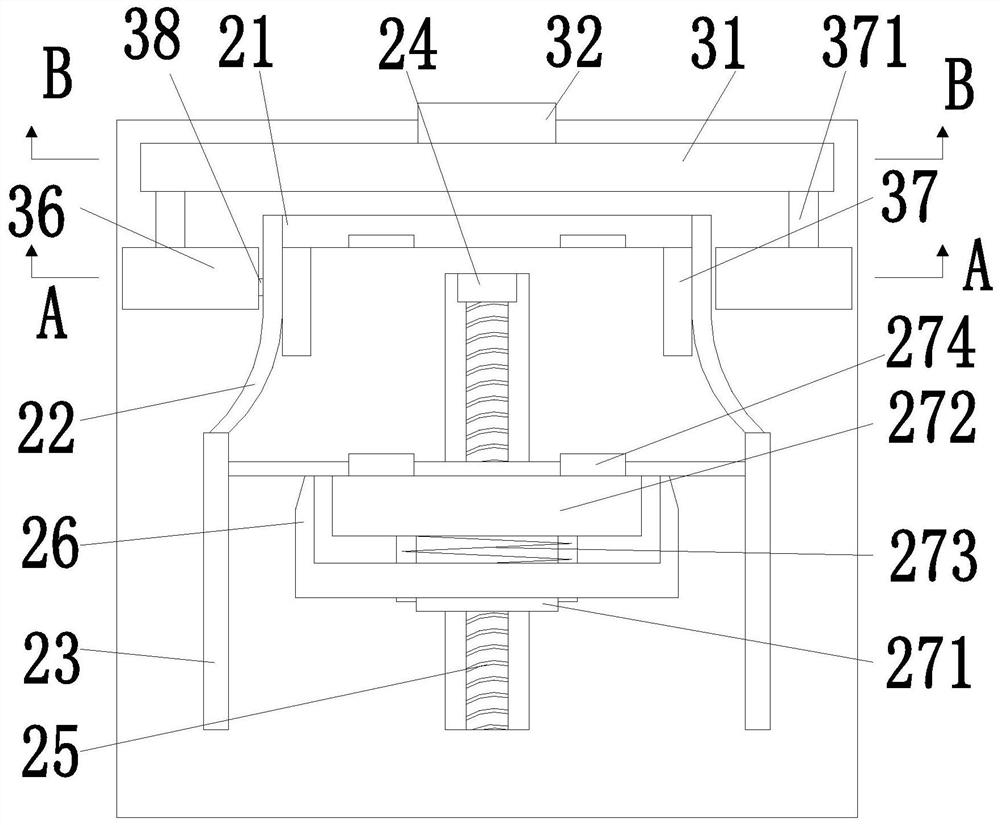

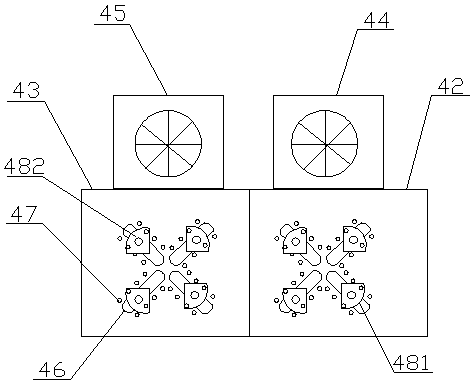

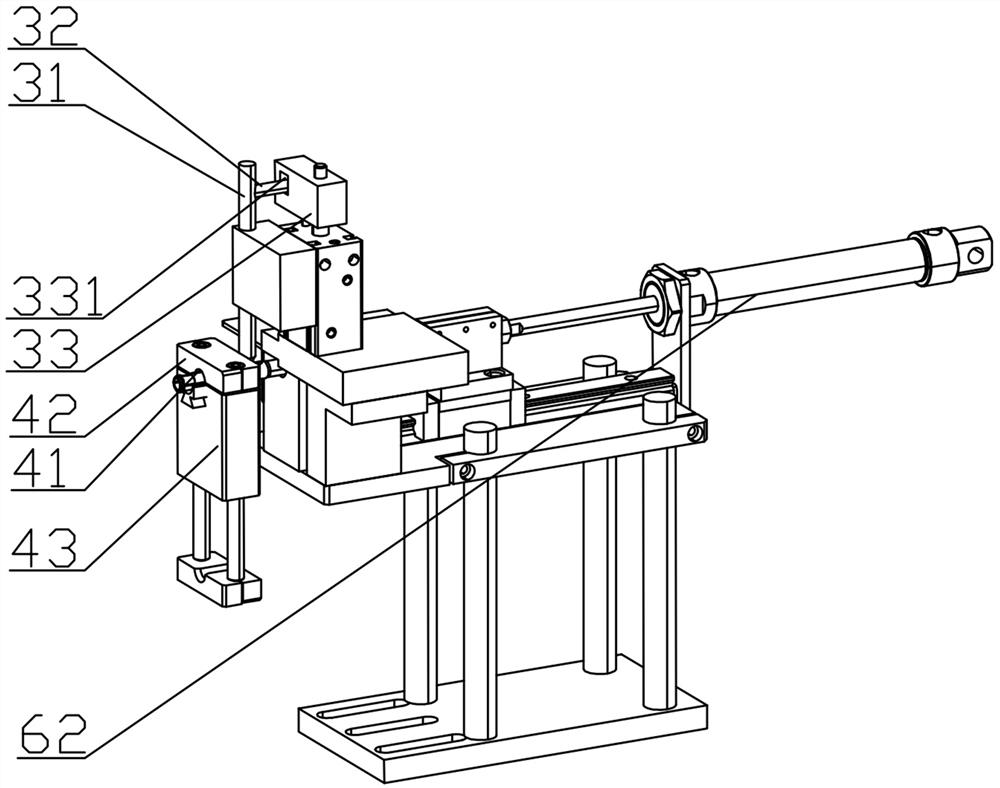

Punching and tapping module for wiring cassette machining machine tool

ActiveCN109202464AAccurate shapePrecise hole positionOther manufacturing equipments/toolsPunchingEngineering

The invention discloses a punching and tapping module for a wiring cassette machining machine tool, and belongs to the field of wiring cassette manufacturing. The punching and tapping module comprisesan upper mounting seat and a lower mounting seat which are mounted on a frame, wherein a first group module, a second group module, a tapping device and a third group module are successively installed in the upper mounting seat and the lower mounting seat in the feeding direction; the first group module is provided with a mounting hole punch, a connecting hole punch and an ear hole punch; the second group module is provided with a first batch of knockout hole punches and a second batch of knockout hole punches; the tapping device is provided with an ear hole screw tap; the third group moduleis provided with a third batch of knockout hole punches, a fourth batch of knockout hole punches and a lug hole punch. Punching and tapping operations can be performed on a plurality of positions on asheet material at the same time, the machining position is accurate, and the machining efficiency of the wiring cassettes by the machining machine tool is improved.

Owner:安徽省华夏机床制造有限公司

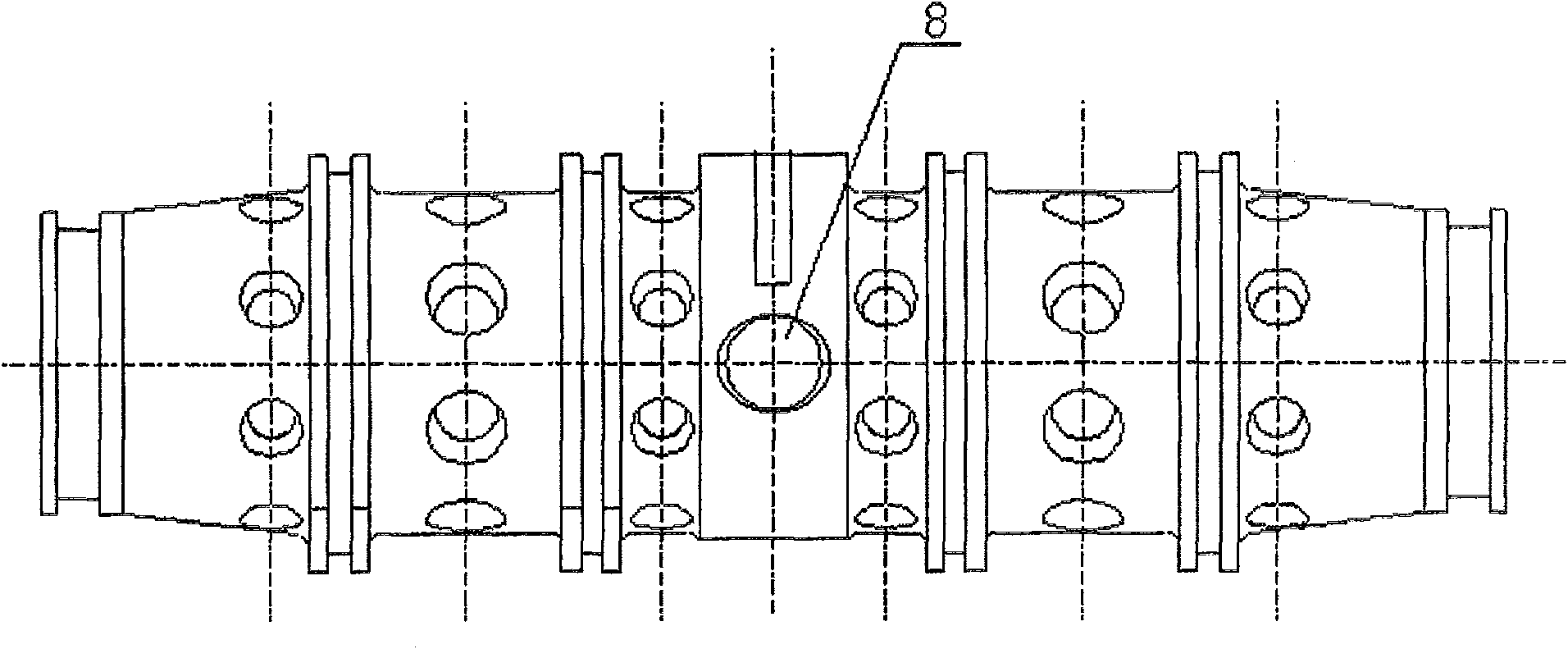

Co-drilling and reaming processing method and equipment for marine low-speed diesel engine crankshaft flywheel

ActiveCN103551855BAvoid fixationReduce volumeCrankshaftsOther manufacturing equipments/toolsLow speedSmall footprint

Owner:CSSC MES DIESEL

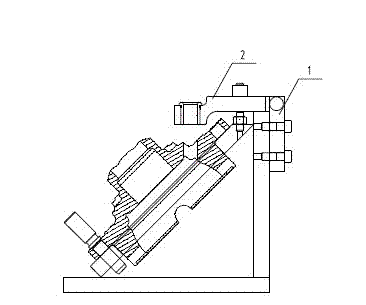

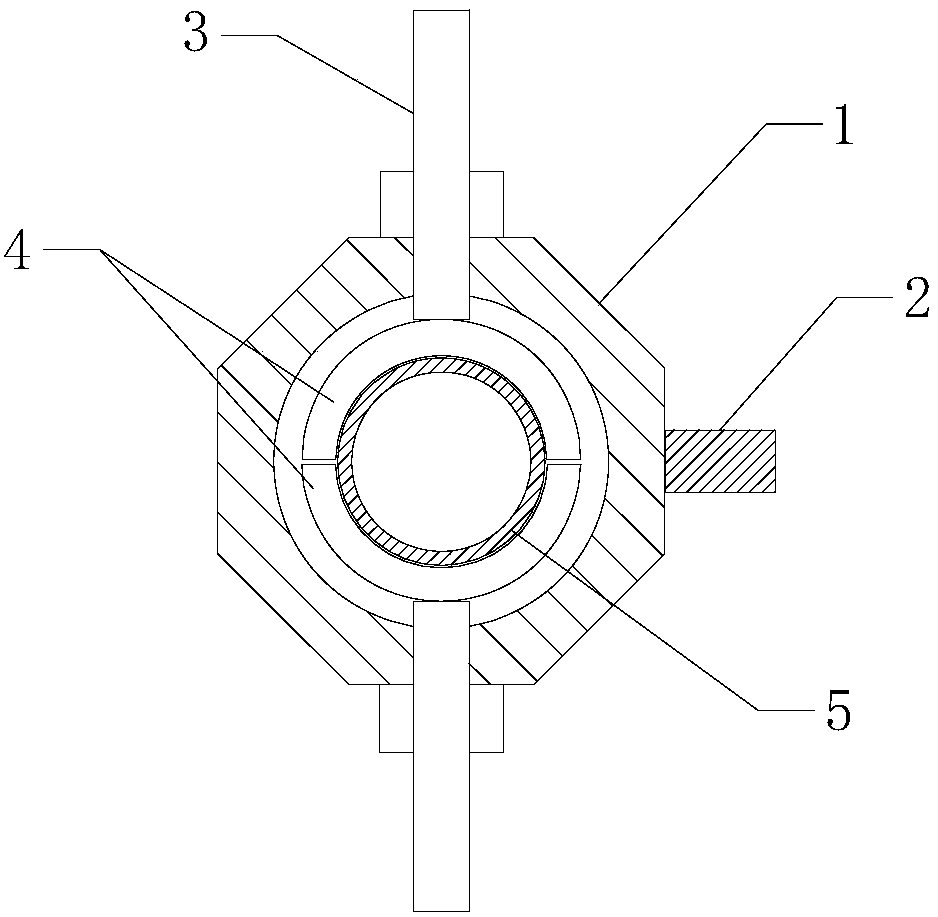

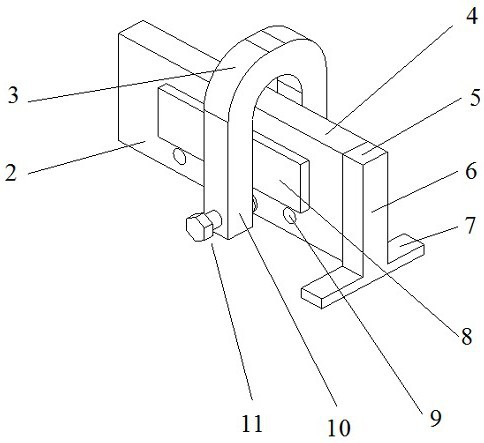

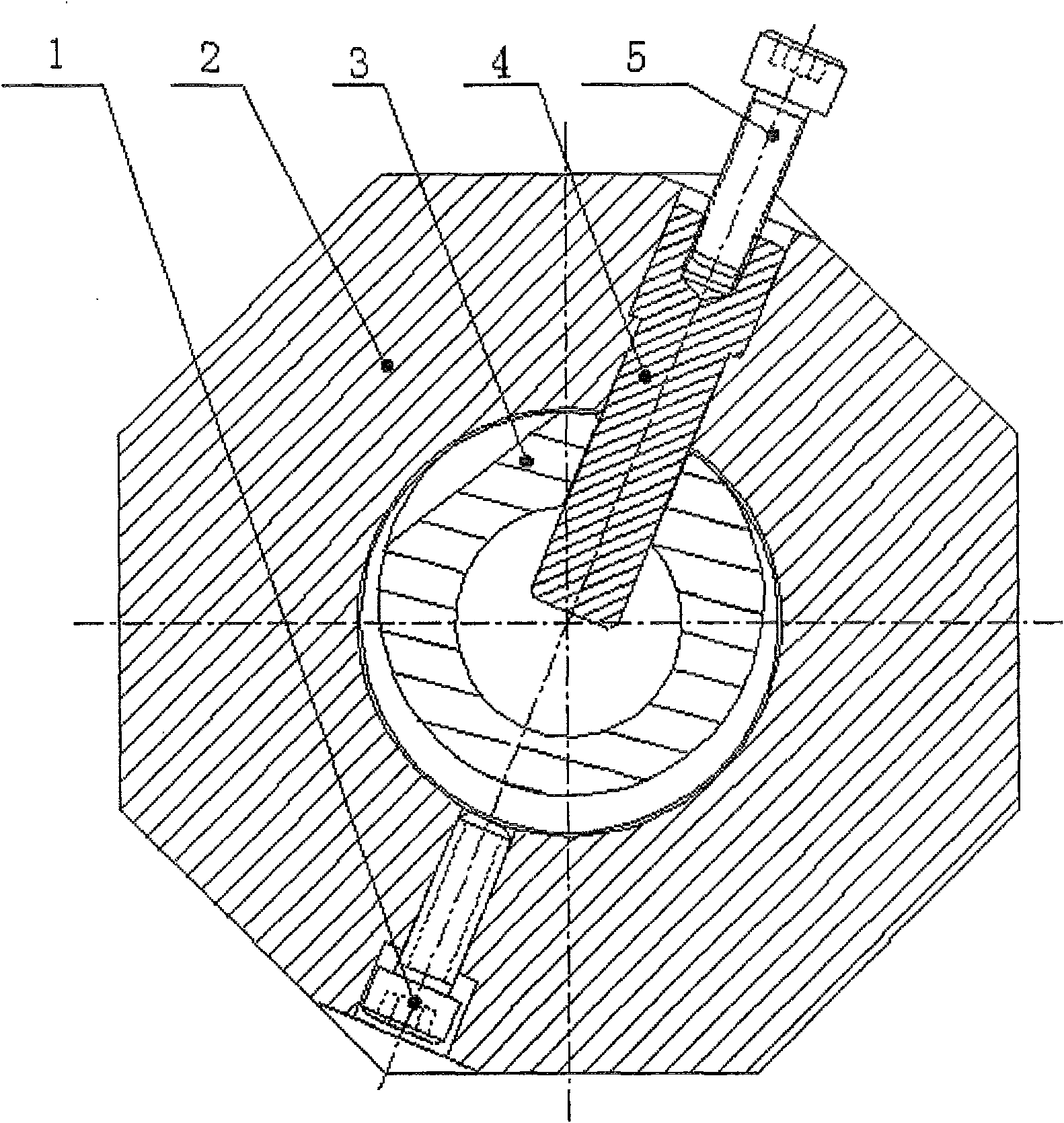

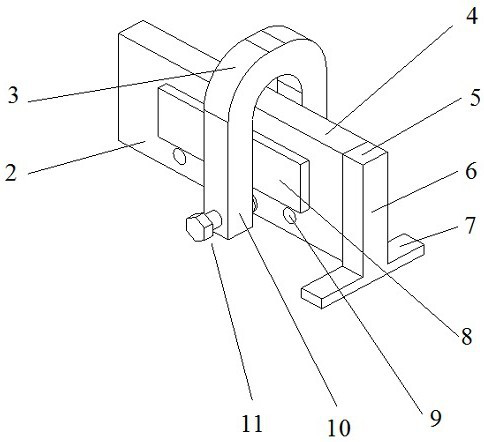

Clamp for machining through hole on valve housing of electro-hydraulic servo valve

InactiveCN100562392CPrecise hole positionLow skill level requiredDrill jigsOctahedronElectro hydraulic

The invention relates to a processing fixture for the through hole on the valve sleeve of an electro-hydraulic servo valve, which comprises a drill body (2) and a drill sleeve (6), and is characterized in that the drill body (2) is a hollow octahedron, There are placement holes for drill sleeves (6) on its eight faces, positioning pin placement holes (4) on one edge, positioning screw placement holes (1) on its symmetrical edges, and the drill sleeve (6) ) is arranged in the placement hole provided on the surface of the drill template body (2); the positioning pin and the positioning screw are arranged in the placement hole. The invention makes the processing and clamping of the through hole on the valve sleeve in the electro-hydraulic servo valve more convenient and simple, has high repeat positioning and rotation precision, high efficiency and low cost. The hole position of the processed valve sleeve is correct and the consistency is good, which greatly improves the processing efficiency and reduces the requirement for the technical level of workers.

Owner:SHANGHAI NUOMA HYDRAULIC SYST

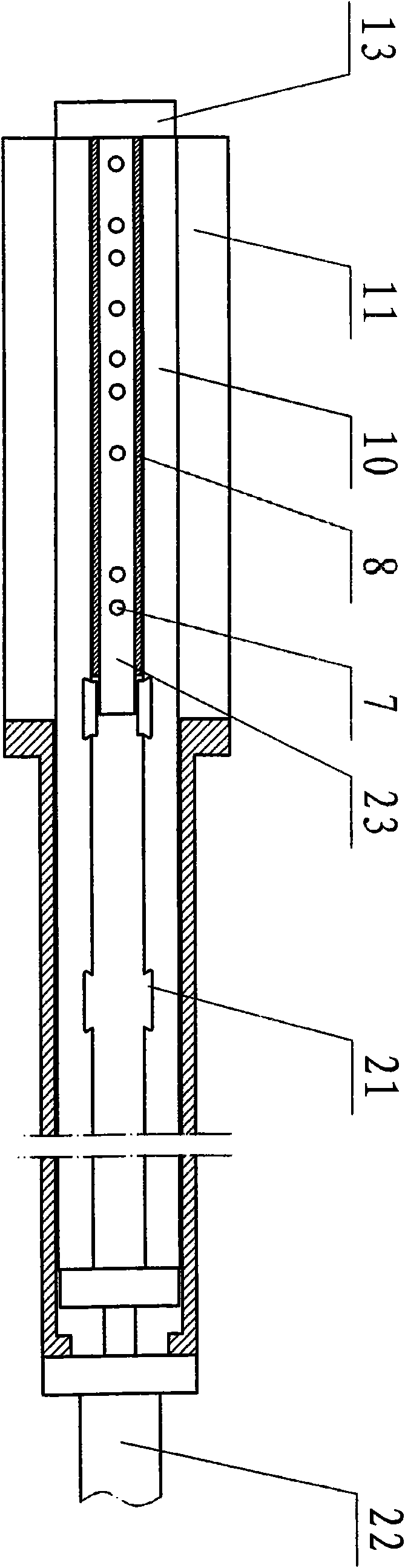

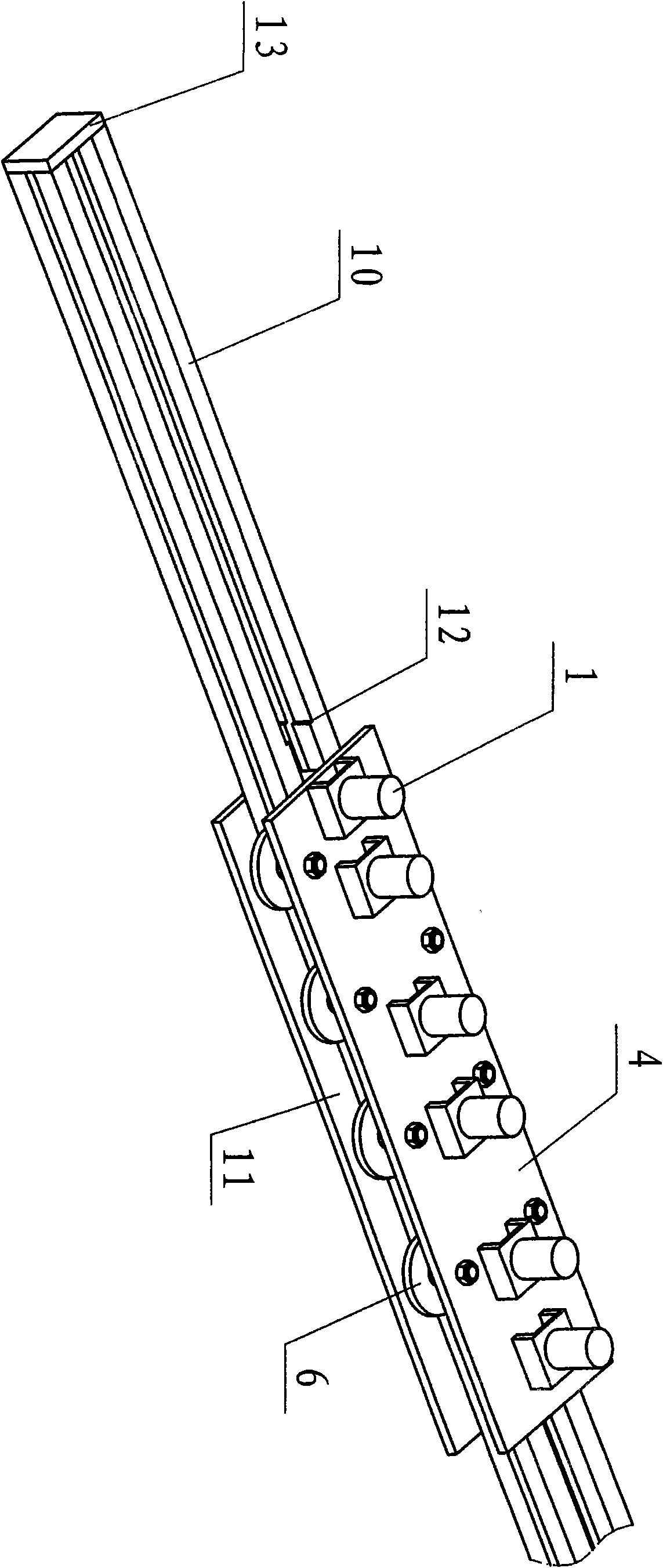

Method and device for punching multiple holes on square tube, and aerator manufactured therefor

ActiveCN101612636BImprove processing efficiencyPrecise hole positionPerforating toolsPisciculture and aquariaEngineeringScrap

Owner:ZHEJIANG FORDY MACHINERY

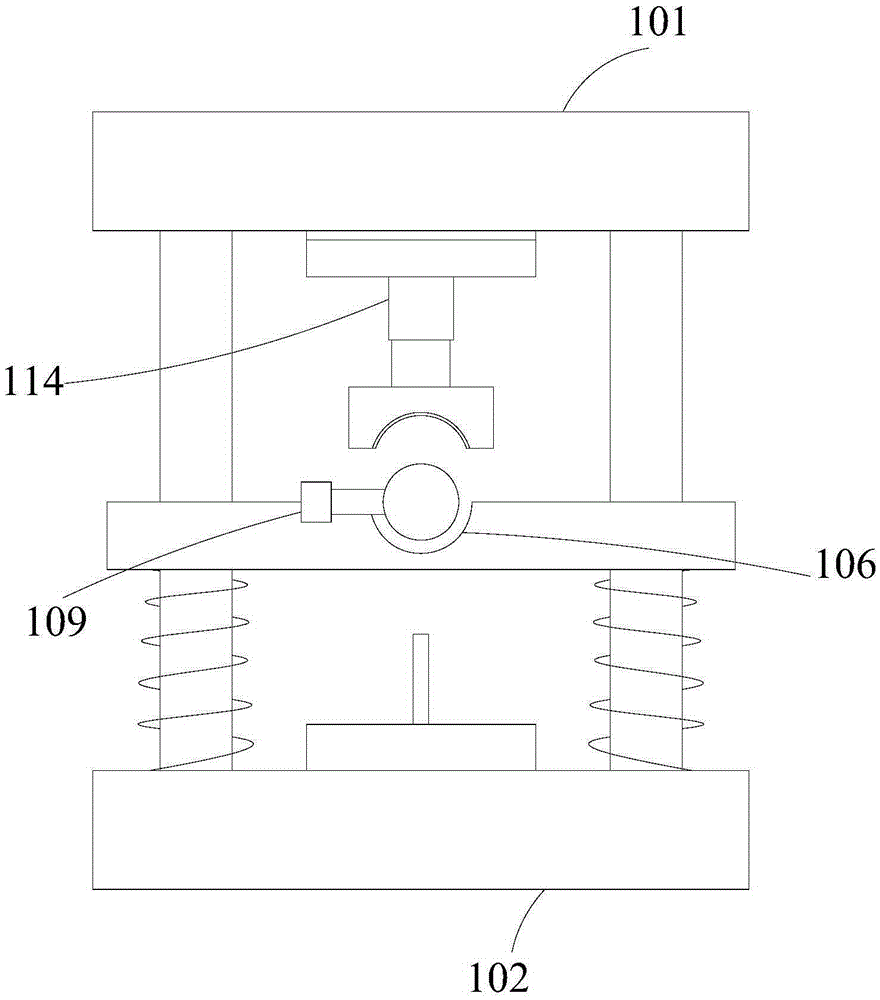

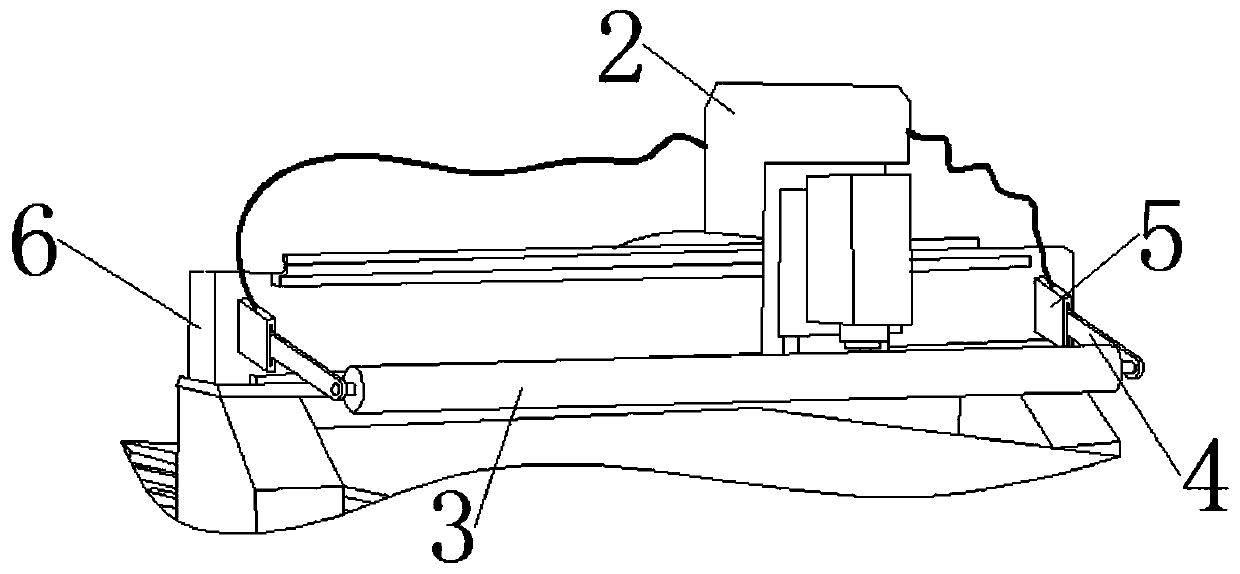

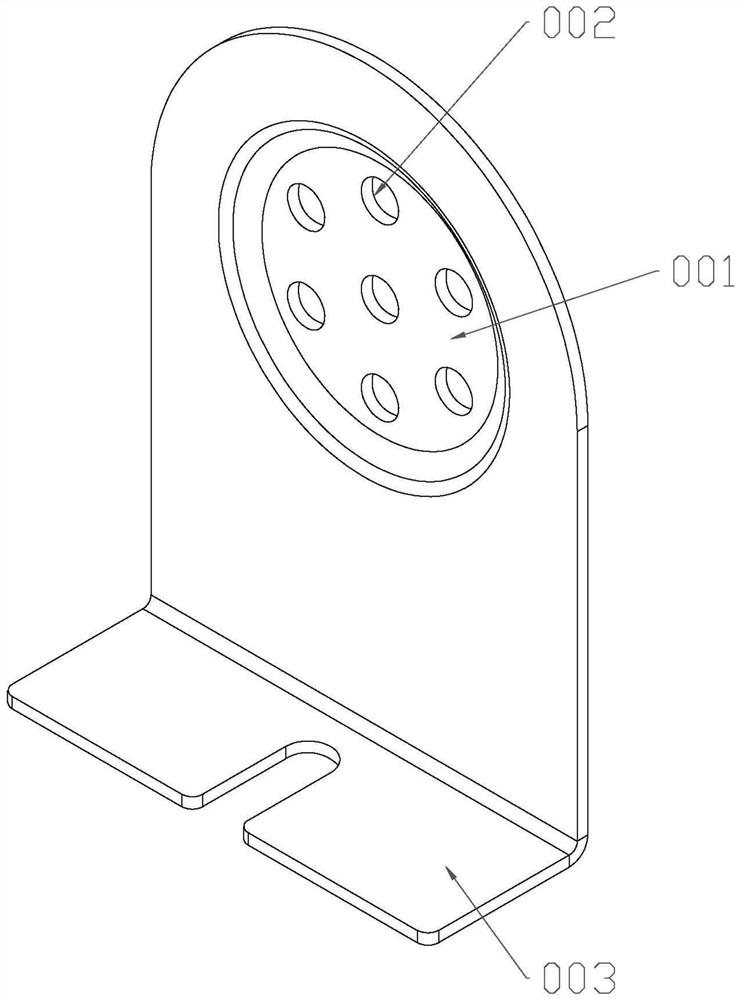

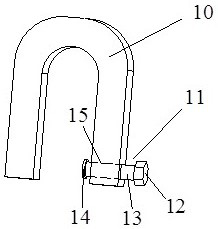

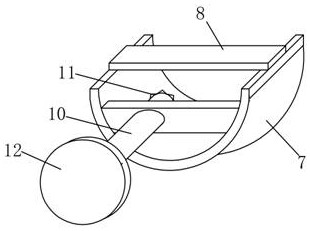

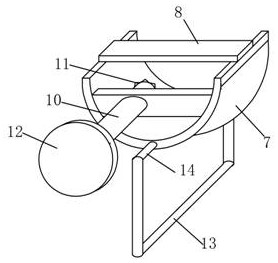

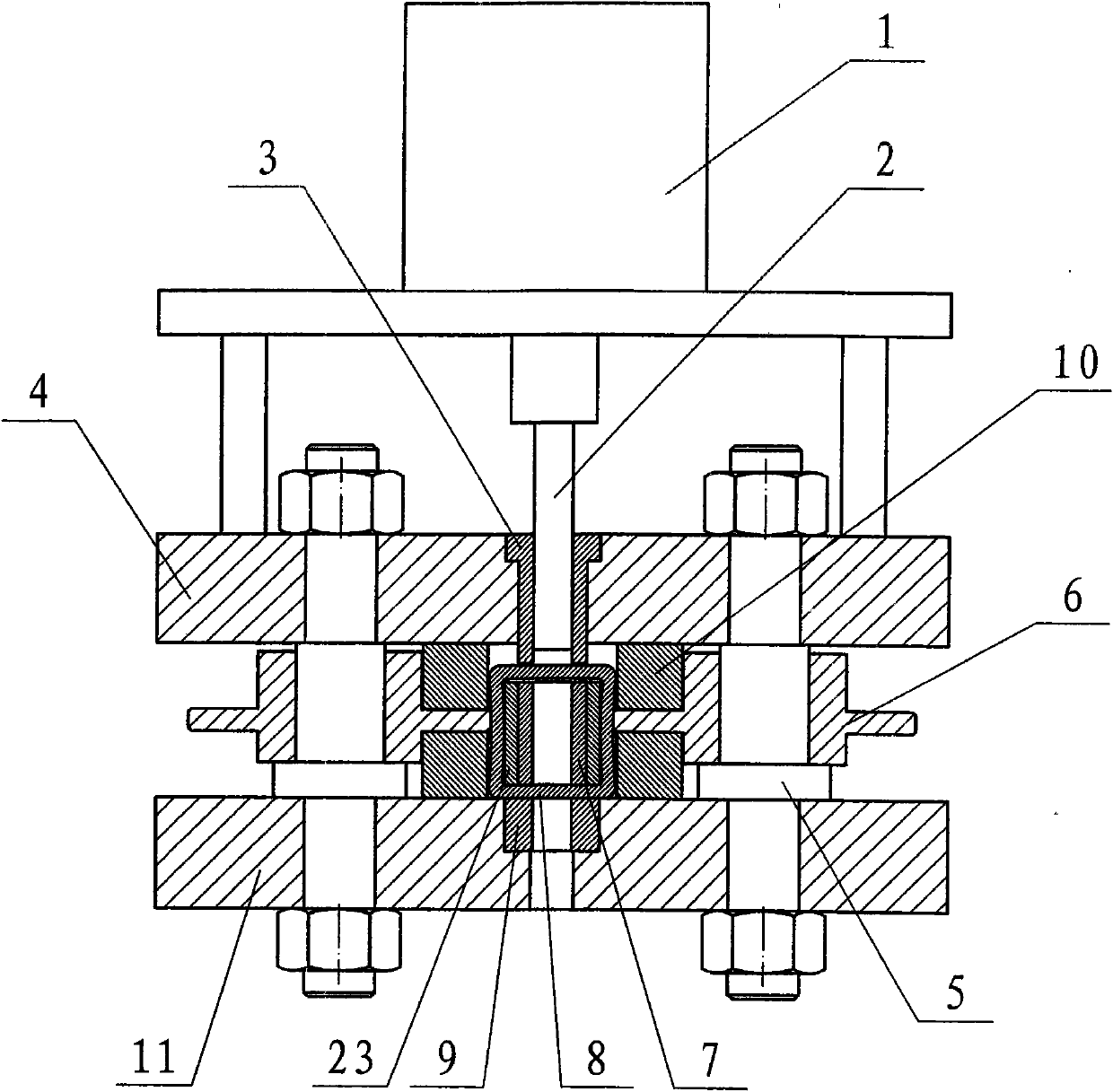

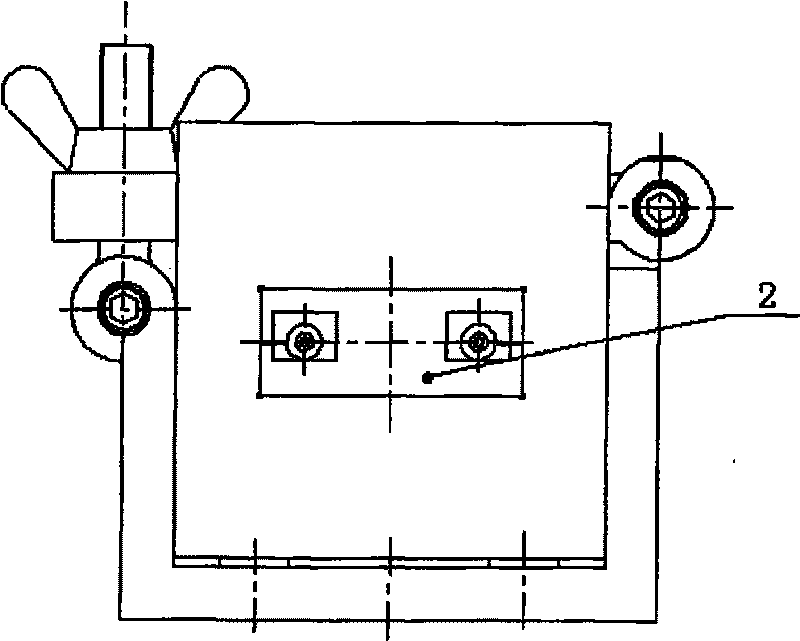

Fixture for electro-hydraulic servo valve keeper positioning center

InactiveCN101200036BEasy clampingPrecise hole positionPositioning apparatusDrill jigsElectro hydraulicEngineering

The invention relates to a clamp for armature centre positioning in electrohydraulic servo valve, comprising a drill jig body (1), two positioning blocks (2), a cushion block (3) and a compaction mechanism; the drill jig body (1) is a concave structure with windows arranged on both sides to coordinate with the positioning blocks(2); the transfixion between the two windows is the installation position of the cushion block (3); the bottom of the drill jig body (1) is equipped with a screwed hole for fixing bracket; the positioning blocks (2) are installed in the window arranged on both sides ofthe drill jig body (1); the cushion block (3) is arranged in installation position of the cushion block (3) arranged between the two windows of the drill jig body (1), and two grooves that contain the armature(11) are arranged above the cushion block (3). The invention has the advantages of convenient and simple clamping, high accuracy in repetitive positioning and rotating, high efficiency and low cost. The processed valve housing has accurate hole position and good consistency; thus the processing efficiency is greatly improved, and the technical level requirement of the workers is reduced.

Owner:SHANGHAI NUOMA HYDRAULIC SYST

Device for guaranteeing coaxiality of multiple lug piece holes

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

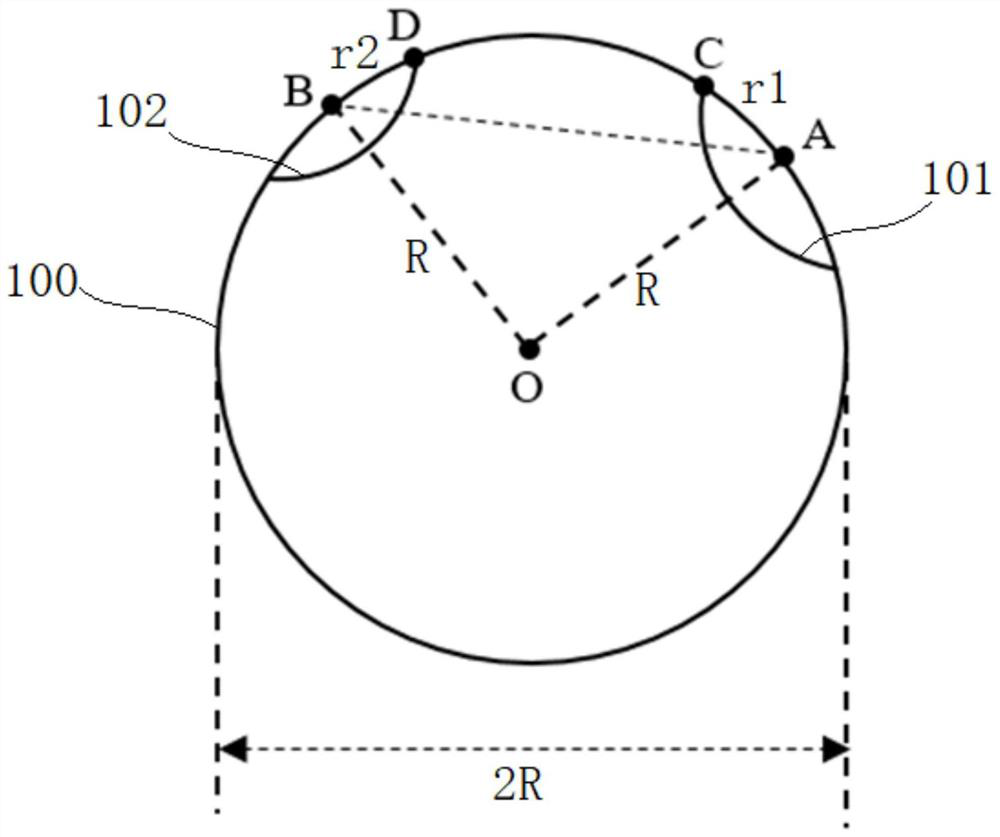

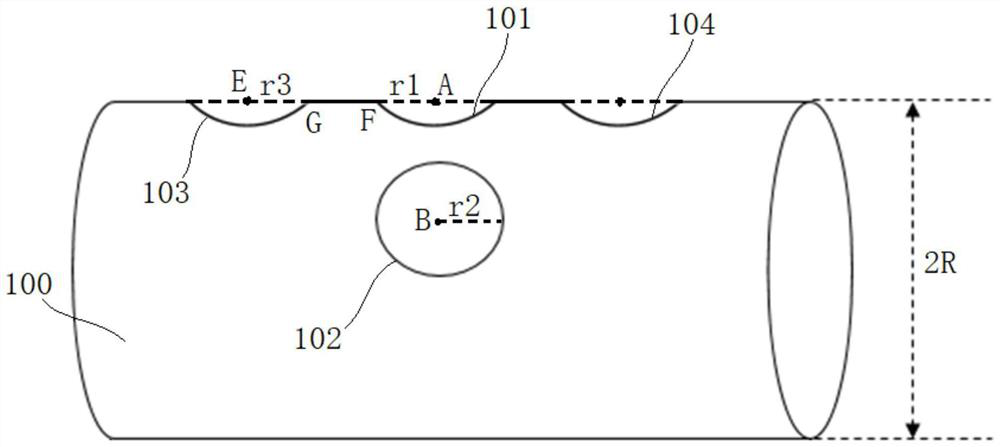

Artificial blood vessel perforating method

ActiveCN113441851AQuality improvementPrecise hole positionMetal working apparatusLaser beam welding apparatusSurgeryVascular prosthesis

The invention relates to an artificial blood vessel perforating method. The artificial blood vessel perforating method comprises the step of positioning and cutting a reference hole and a connecting hole, and the step of positioning and cutting the reference hole and the connecting hole comprises the following steps of positioning the central point of the reference hole on the surface of an artificial blood vessel body, and cutting the surface of the artificial blood vessel body by taking the central point of the reference hole as a circle center and based on the preset radius of the reference hole to form the reference hole; and positioning the central point of the connecting hole on the surface of the artificial blood vessel body in the same circumferential direction and axial direction of the central point of the reference hole, positioning a hole opening starting point of the connecting hole on the surface of the artificial blood vessel body based on the preset radius of the connecting hole with the central point of the connecting hole as the circle center, and cutting to form the connecting hole. The position of the hole formed in an artificial blood vessel is consistent with a preset position, and the hole position is accurate; and the shape of the cut hole is regular, and the overall quality of an artificial blood vessel product is improved.

Owner:ACCUPATH MEDICAL JIAXING CO LTD

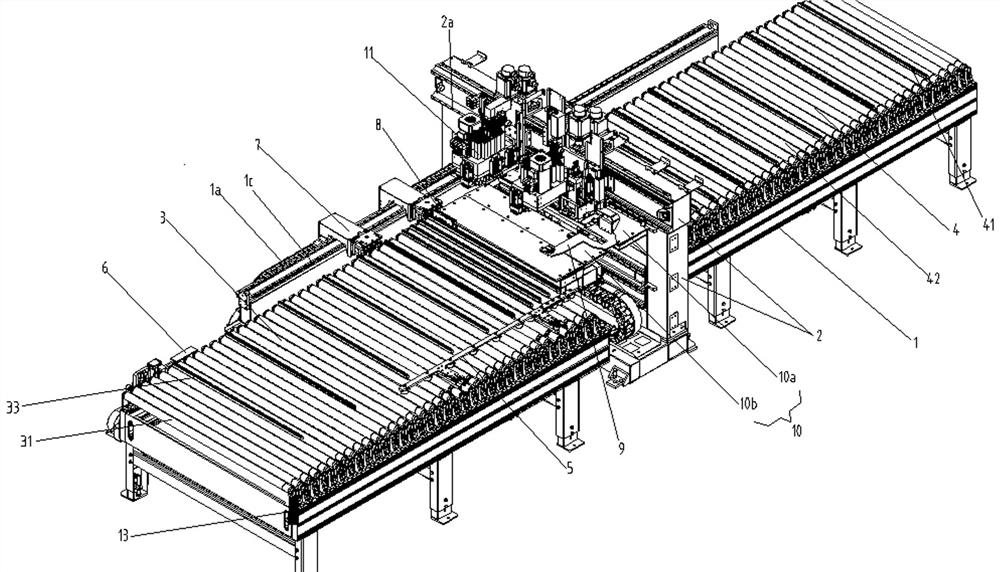

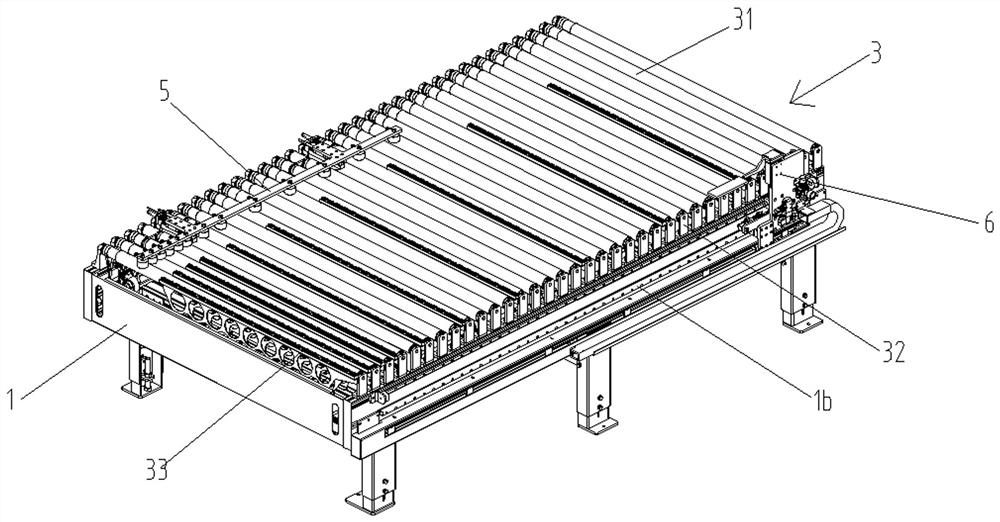

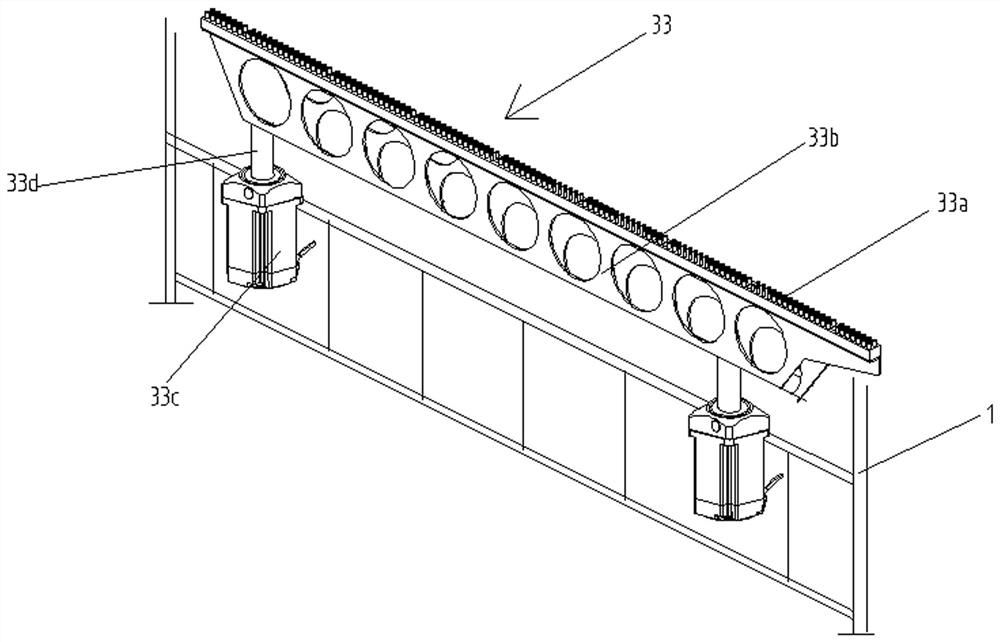

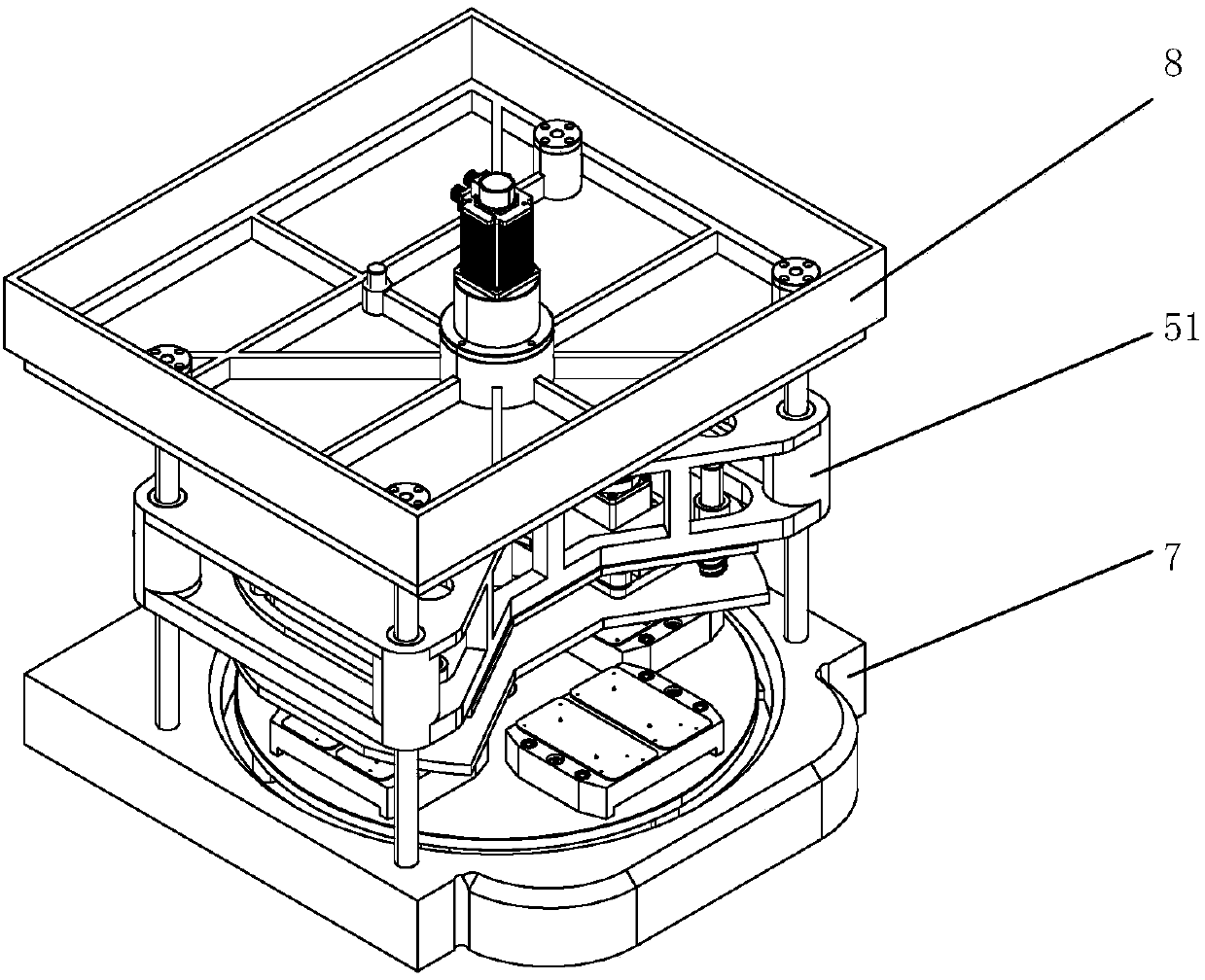

A high-efficiency CNC six-sided drilling machine and its processing method

ActiveCN110355830BRealize automatic feeding processPrecise positioningStationary drilling machinesMulti-purpose machinesPunchingEngineering

Owner:JIANGSU LIWEI LOGISTICS MACHINERY

Tapping device and multi-station drilling and tapping integrated equipment thereof

PendingCN109531154AEasy to change jobsLow costThread cutting toolsThread cutting machinesMachiningDrill

The invention provides a tapping device and multi-station drilling and tapping integrated equipment thereof. Multi-station threaded hole synchronous forming of micro-hole spacing can be realized. Thetapping device adopts a structure form of matching a split disconnected type screw tap with a screw tap spindle transmission member. The multi-station tapping device can effectively utilize multiple tapping device bodies and realize multi-station synchronous drilling by adopting a synchronous belt transmission mode. The multi-station drilling and tapping integrated equipment can perform drilling and tapping on a workpiece simultaneously on one machine to achieve precise drilling and tapping positioning machining. The tapping device is precise in machining position, and the equipment use cost and the manufacturing cost are low. The multi-station drilling and tapping integrated equipment is not affected by the radius of a drill chuck, and the multi-station threaded hole synchronous forming of the micro-hole spacing can be realized.

Owner:杨东佐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com